Device for cutting off flat tube of heat exchanger

A technology for cutting off devices and heat exchangers, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of hindering refrigerant flow, restricting production efficiency, reducing heat exchange efficiency of heat exchangers, etc., to reduce energy consumption, Improve the effect of cutting burrs and extrusion, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

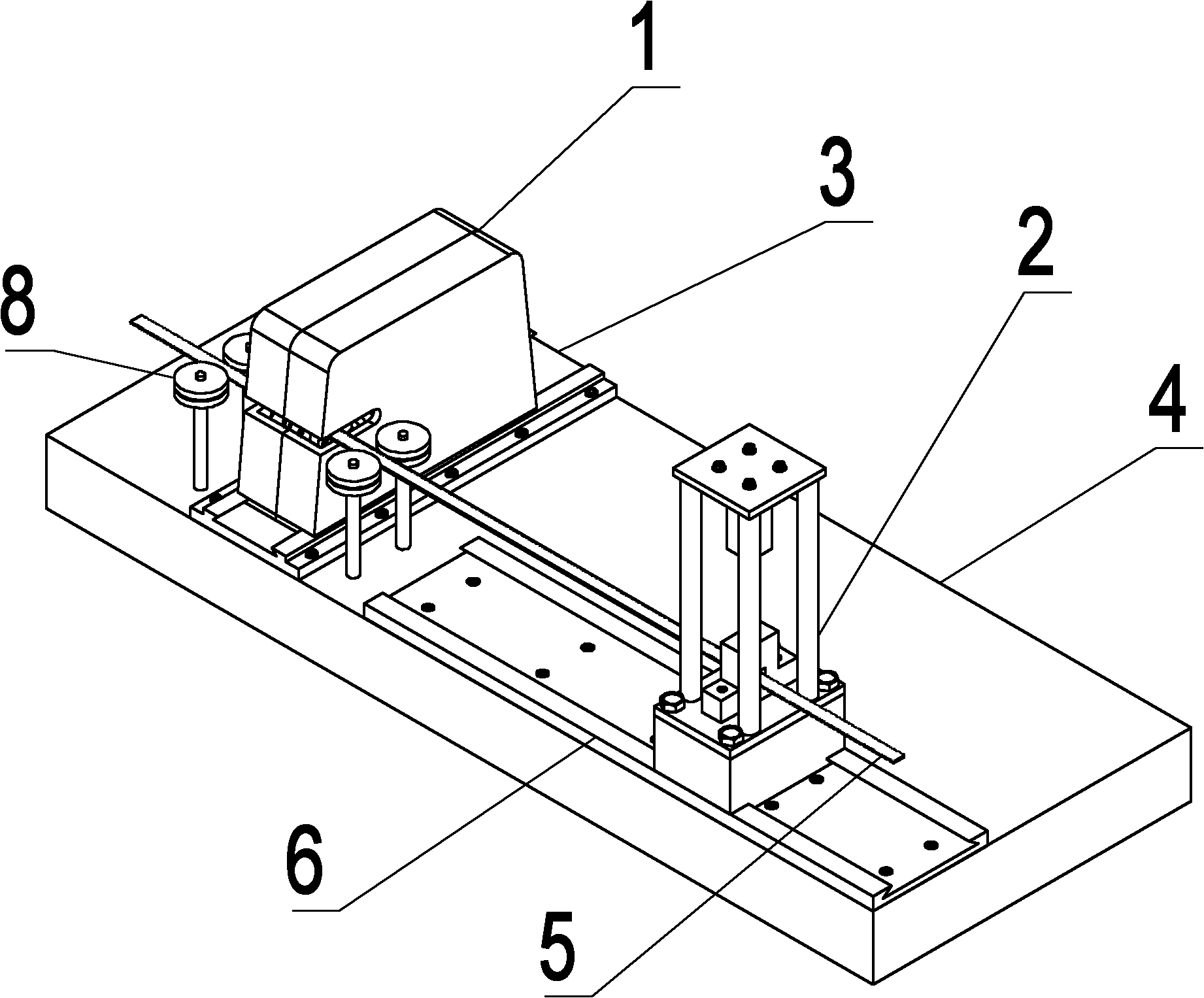

[0022] The present invention will be further described below in conjunction with accompanying drawing.

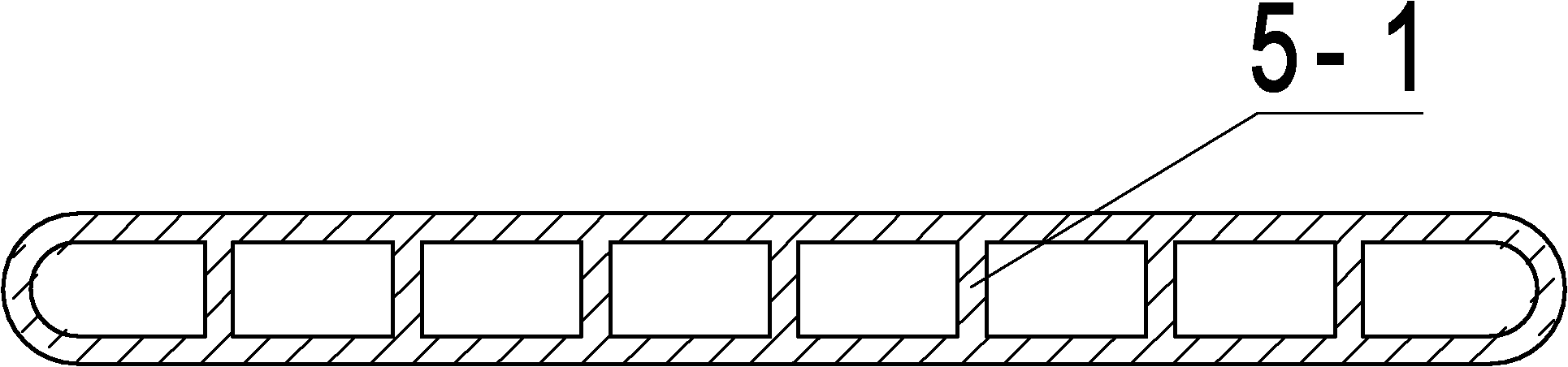

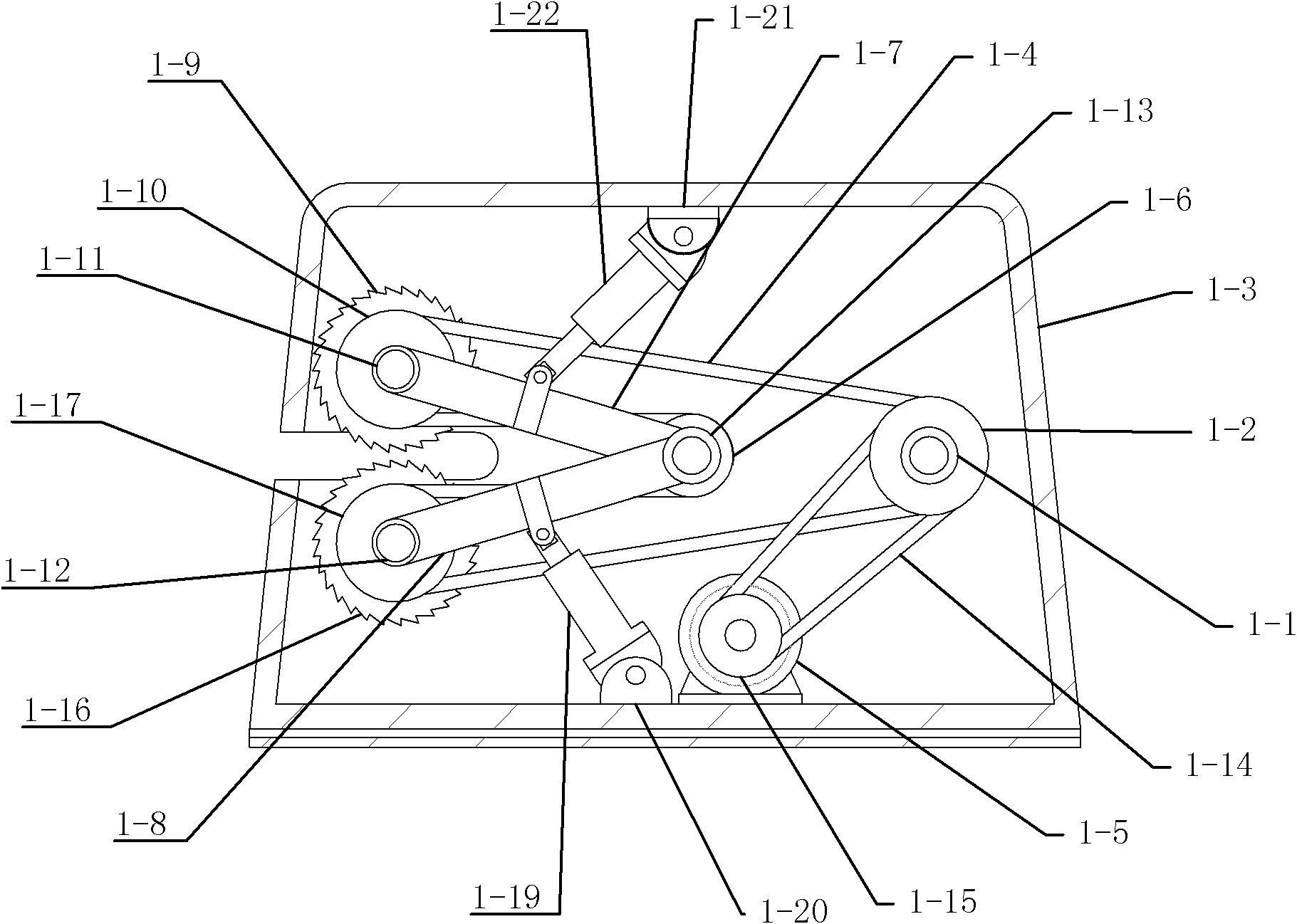

[0023] refer to Figure 1-6 : heat exchanger flat tube cutting device, comprising a base 4, a milling mechanism 1 that can slide along the transverse guide rail 3 of the base 4, a punching mechanism 2 that can slide along the longitudinal guide rail 6 of the base 4, the milling mechanism The mechanism 1 and the punching mechanism 2 are pierced with a flat tube 5 conveyed longitudinally along the machine base 4, and the milling mechanism 1 is provided with a milling cutter for milling the flat tube 5 and forming a milling cut. The mechanism 2 is provided with a punching knife 2-8 that can detect the position of the milling cut and perform punching.

[0024] Described milling mechanism 1 comprises box body 1-3, and drive motor 1-5 is arranged in described box body 1-3, and the transmission mechanism that is connected with drive motor 1-5 is driven by the transmission mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com