Full-arc admission generator set and water supply bypass regulation method thereof

A full-cycle steam inlet and generator set technology, applied in the control of water supply, steam generation, engine components, etc., can solve the problems of increasing the heat consumption of the unit, increasing the vibration of the steam turbine, and the disturbance of the steam flow, so as to increase the overload power generation capacity and reduce the The effect of throttling losses and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

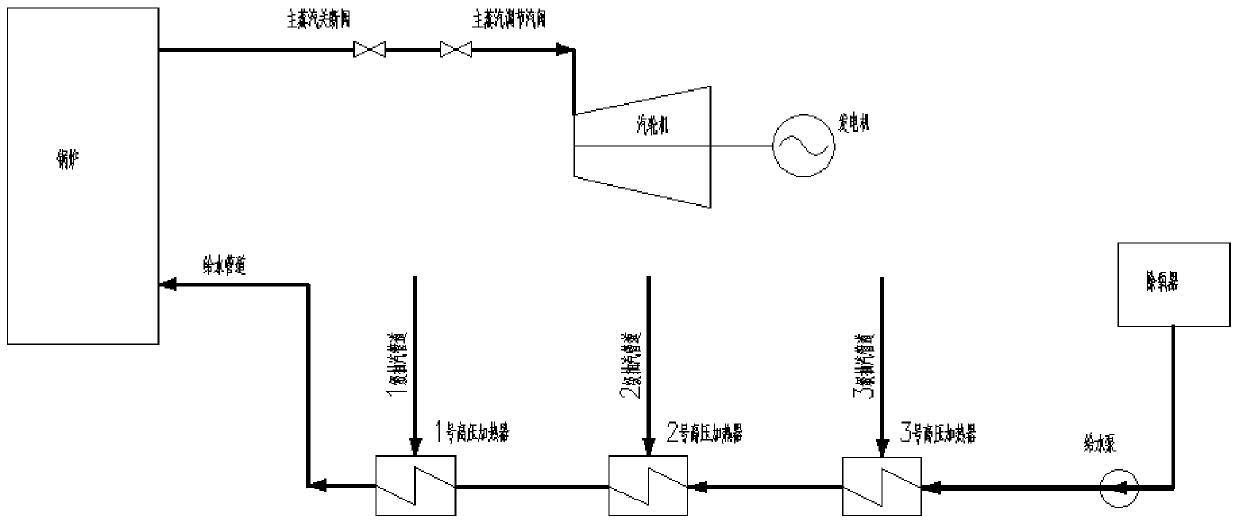

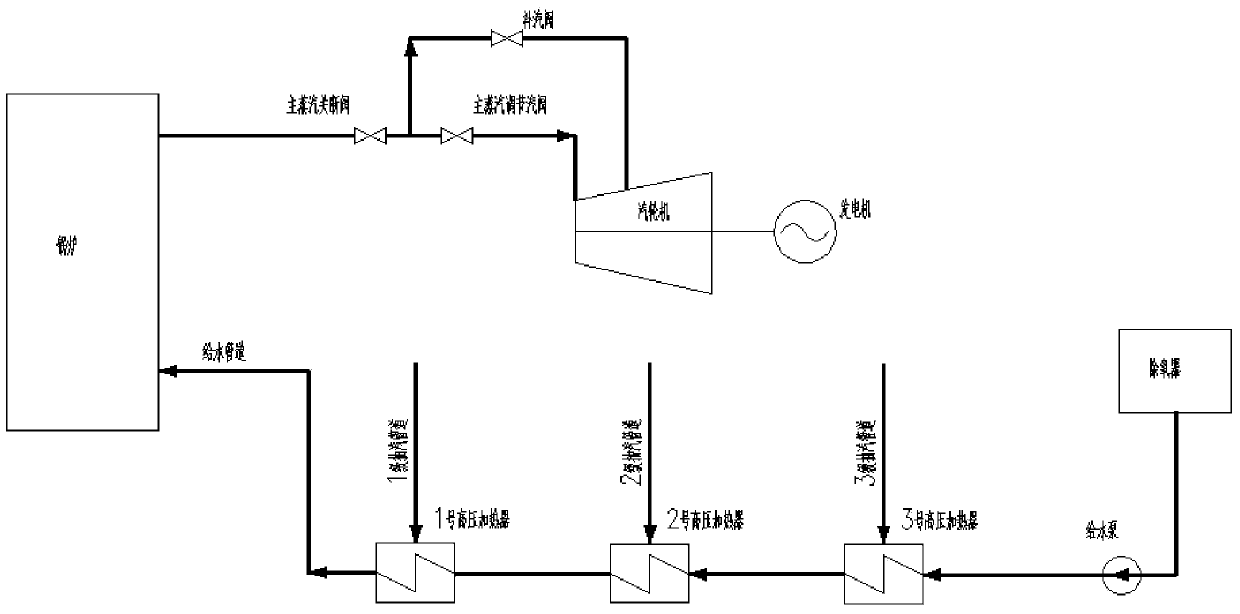

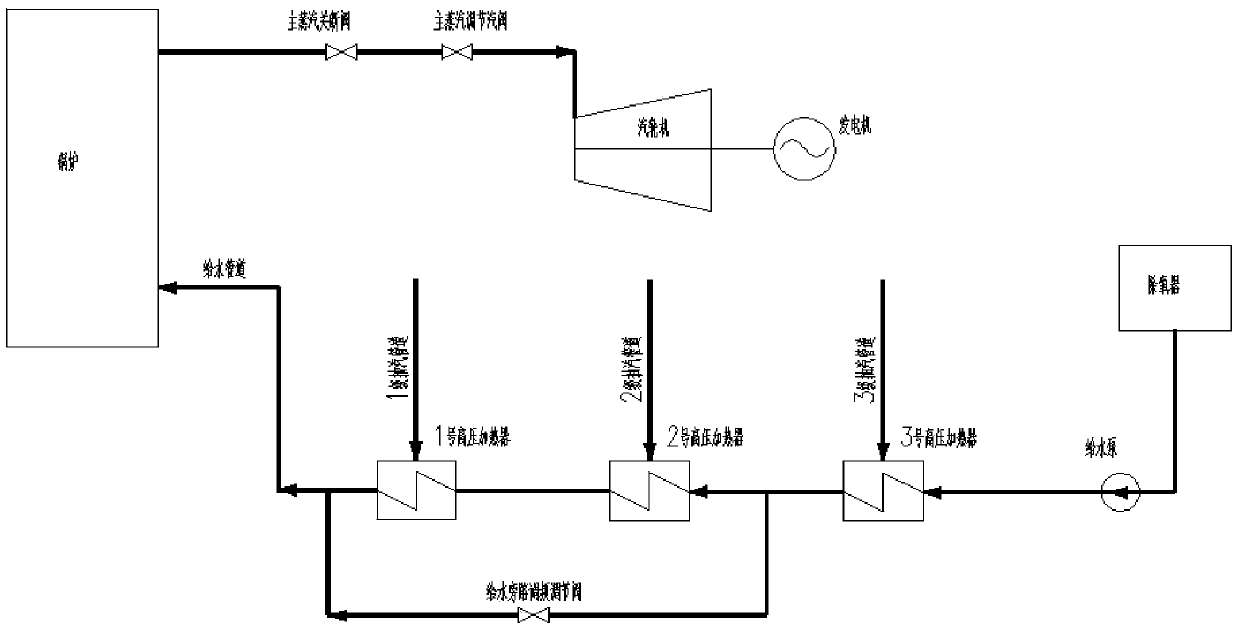

[0023] image 3 An application example of the present invention on a current typical recuperation system with 3-stage high-pressure heaters is shown in . Apparently, the number of high pressure heaters is not limited to 3 in the figure, and may be more than 3. like image 3 As shown, the full-circle steam inlet generator set includes: deaerator, 3 high-pressure heaters connected to the deaerator through the feed water pump, boiler connected to the 3 high-pressure heaters through the feed water pipeline, steam turbine, generator, feed water bypass Frequency modulation regulating valve, main steam shut-off valve, main steam regulating steam valve. Each high-pressure heater is connected with an extraction pipeline. In order to meet the primary frequency regulation requirements of the unit, the feedwater bypass is configured as follows: a feedwater is drawn from the main pipe of the feedwater outlet of the No. 3 high-pressure heater, and then connected to the outlet of the No. ...

Embodiment 2

[0025] Figure 4 Another example of a full-circle intake steam generator set is shown. Apparently, the number of high-pressure heaters is not limited to 4 in the figure, and may be more than 4 or 3. like Figure 4 As shown, the feedwater bypass is configured as follows: In order to meet the primary frequency regulation requirements of the unit, a feedwater is drawn from the main feedwater pipeline between a two-stage high-pressure heater, and connected to the nearest boiler through the feedwater bypass frequency regulation valve On the main feedwater outlet pipe of the high-pressure heater on the side, it is mixed with the main feedwater and then sent to the boiler. When the unit is in normal operation, both the main steam shut-off valve and the main steam regulating valve are fully open to minimize throttling loss; the feedwater bypass frequency modulation regulating valve is fully closed, and all the feedwater flows through the main feedwater main road. High pressure heat...

Embodiment 3

[0027] Figure 5 Another example of a full-circle intake steam generator set is shown. Apparently, the number of high pressure heaters is not limited to 3 in the figure, and may be more than 3. like Figure 5 shown, and image 3 Compared to the example shown in the Figure 5 The full-circle intake steam generator set in the engine also includes an external steam cooler. Figure 5The feedwater bypass is configured as follows: In order to meet the primary frequency regulation requirements of the unit, a feedwater is drawn from the main feedwater pipeline between a two-stage high-pressure heater, and connected to the nearest boiler side through the feedwater bypass frequency regulation valve. On the main feed water outlet pipe of the external steam cooler, it is mixed with the main feed water and sent to the boiler. When the unit is in normal operation, both the main steam shut-off valve and the main steam regulating valve are fully open to minimize throttling loss; the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com