Method for laser-induced chemical synthesis of micro-nano-scale MoS2 at atmospheric normal temperature and application

A technology of laser induction and chemical synthesis, applied in nanotechnology, molybdenum sulfide, nanotechnology, etc. for materials and surface science, can solve the problem of rapid direct writing processing of products with micron-level feature sizes, and energy utilization of thermal decomposition methods Low efficiency, difficult to control product morphology and other issues, to achieve high peak power, high energy density, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

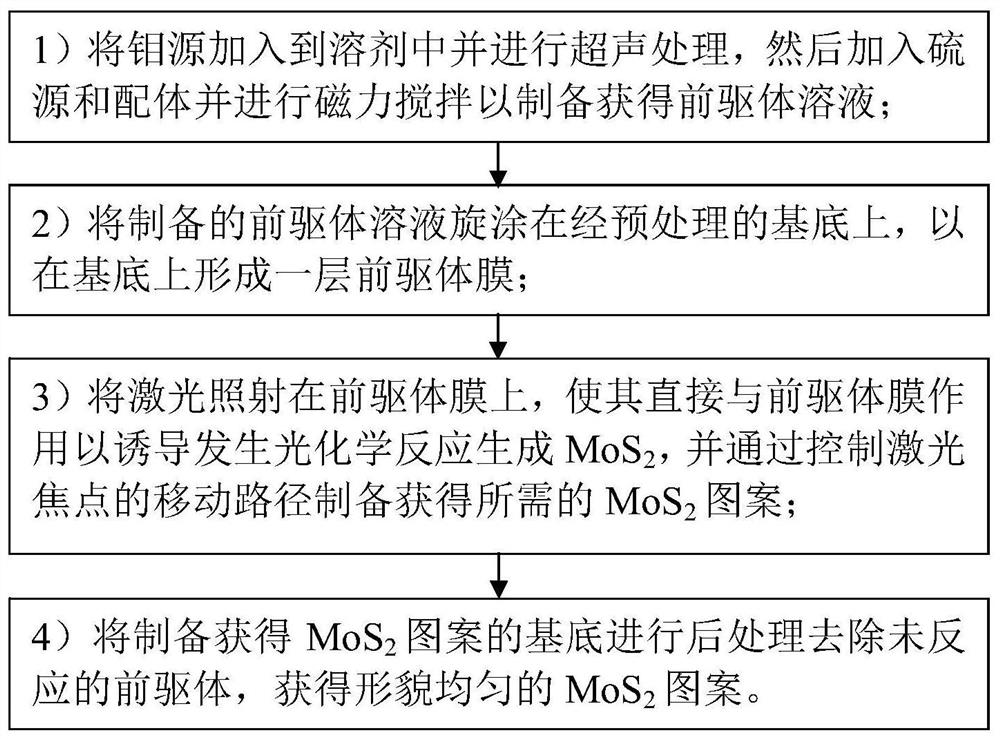

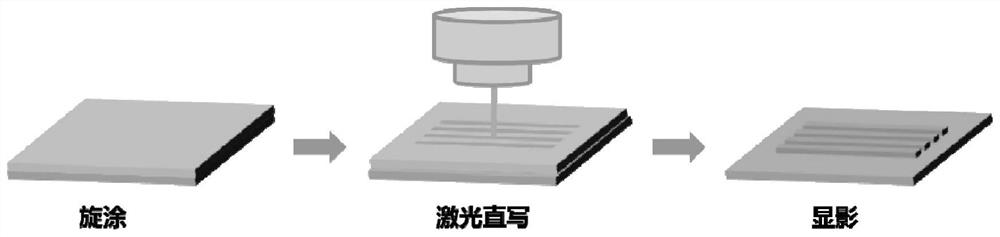

[0057] 2) Preparation of laser direct writing samples

[0058] The prepared precursor solution is spin-coated on the pretreated substrate to form a layer of precursor film on the substrate. More specifically, the substrate is ultrasonically treated in acetone, isopropanol, and deionized water for 15-40 minutes. minutes, and then heated on a hot stage at 100°C to 120°C for 0.5min to 1.5min. After the clean substrate is dried, add the precursor solution obtained in step 1) onto the substrate and spin coat it with a coater to A precursor film with uniform thickness is formed on the surface of the substrate to obtain a laser direct writing sample.

[0059] Among them, the specific process of spin coating is to first uniform the glue at a speed of 200rpm to 600rpm for 5s to 8s, and then to uniform the glue at a speed of 800rpm to 3000rpm for 20s to 30s. Under this spin coating process, the precursor can be spin coated on the substrate to form Uniform liquid film.

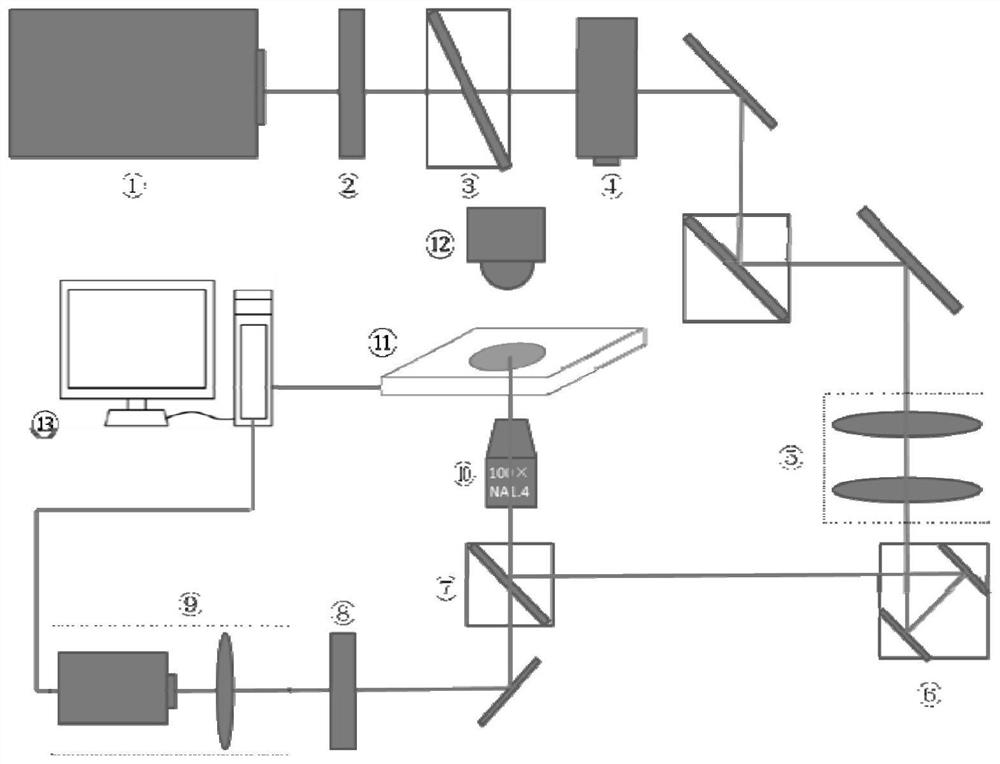

[0060] 3) Lase...

Embodiment 1

[0076] In this example, femtosecond laser-induced synthesis of micro-nano-scale patterned MoS 2 The product, the pattern is the English abbreviation pattern of Huazhong University of Science and Technology, the specific steps are as follows:

[0077] (1) Precursor configuration

[0078] In the glove box, 30 mg (about 0.1 mmol) of organic molybdenum source molybdenum acetylacetonate was added to a reagent bottle containing 2 ml of isopropanol solvent, and the reagent bottle was placed in an ultrasonic cleaner for 30 min of ultrasonic treatment. The ultrasonic frequency is 40kHz, and the power is 840W, so that the solute molybdenum acetylacetonate is fully dissolved in the solvent isopropanol; then add 30mg of sulfur powder (about 0.001mol) to the reagent bottle in the glove box, 2ml of oleylamine, and 2ml of carbon disulfide ( 0.033mol), and the reagent bottle is taken out after sealing treatment; the mixed solution is placed on a magnetic stirrer and stirred for 12h so that e...

Embodiment 2

[0083] This example uses femtosecond laser induction to synthesize micro-nano scale MoS 2 The product line array, the specific steps are as follows:

[0084] (1) Precursor configuration

[0085] In the glove box, 144 mg (about 1 mmol) of molybdenum oxide was first added to a reagent bottle containing 2 ml of methanol and 3 ml of isopropanol solvent, and the reagent bottle was placed in an ultrasonic cleaning machine for 40 minutes of ultrasonic treatment. It is 40kHz, and the power is 840W, so that the solute molybdenum oxide is fully dissolved in the solvent methanol; then add 5ml of carbon disulfide (about 0.083mmol), 2.5ml of oleic acid, and 2.5ml of oleylamine to the reagent bottle in the glove box, and put the reagent The bottle is sealed and taken out; the mixed solution is placed on a magnetic stirrer and stirred for 10 hours, so that each component is fully dissolved in the solvent, and the reaction precursor solution is obtained. The stirring speed is 1000rpm / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com