Adjustable internal curve hydraulic pump or motor

A technology of inner curve and hydraulic pump, applied in the direction of rotary piston type/oscillating piston type pump parts, pumps, pump elements, etc., can solve the problem that the stator and rotor cannot move in the axial direction, the wear of the inner wall of the stator is aggravated, and the structure cannot be adjusted and other problems, to achieve the effect of reducing eccentric wear, simple and compact structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

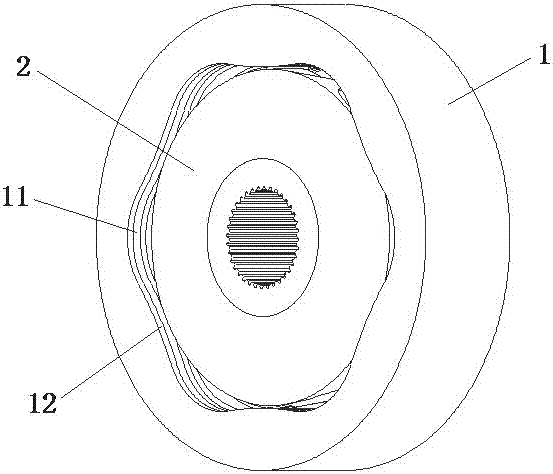

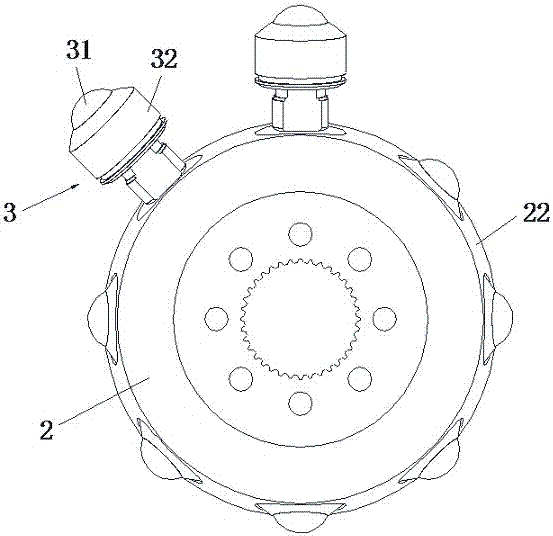

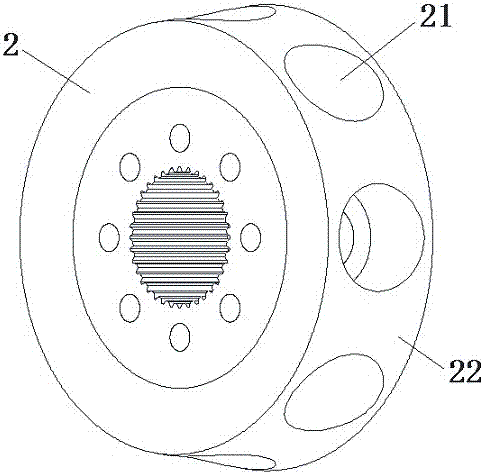

[0032] See attached figure 1 to attach Figure 8 , the adjustable internal curve hydraulic pump or motor in this embodiment, it includes a stator 1 and a rotor 2 that are coaxially connected and relatively rotatable.

[0033] Reference attached figure 2 to attach Figure 4 , the rotor 2 has a piston hole 21, the axis line of the piston hole 21 intersects the axis line of the rotor 2, in the plane where these two axis lines are located, the axis line of the piston hole 21 and the diameter of the rotor 2 to form an angle, that is, attached Figure 4 The α angle shown in , preferably, the included angle is in the range of 0° to 50°. There are a plurality of piston holes 21 , which are evenly distributed along the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com