Optimized design method for nozzle number of nozzle sets considering turbine actual operation binding

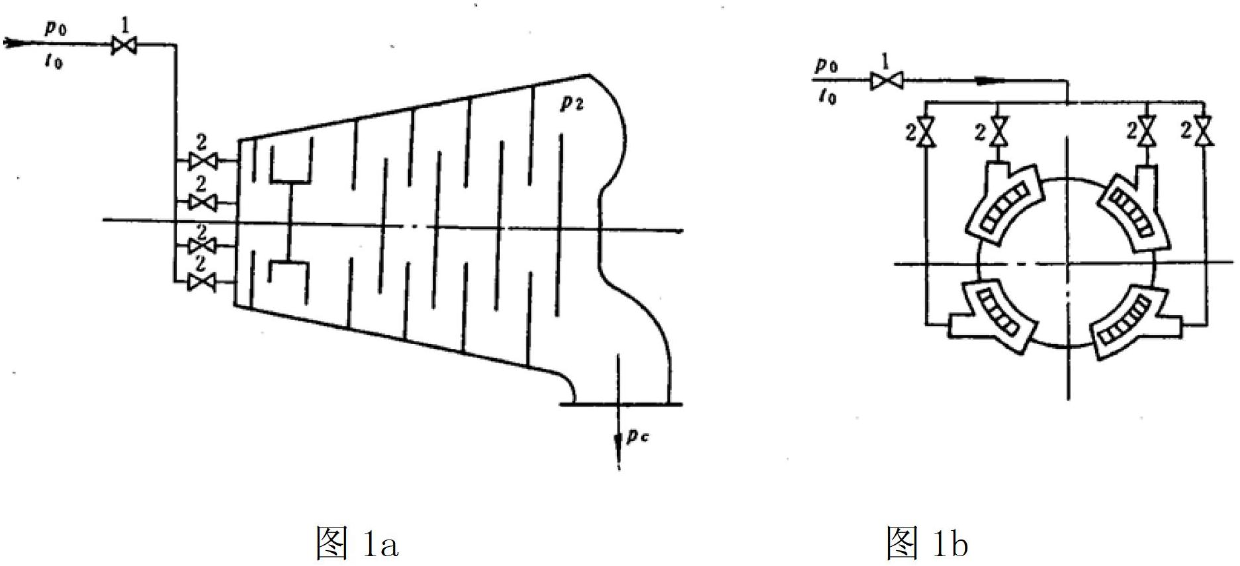

A technology of practical operation and optimized design, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as reduced internal efficiency, small valve opening, throttling loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

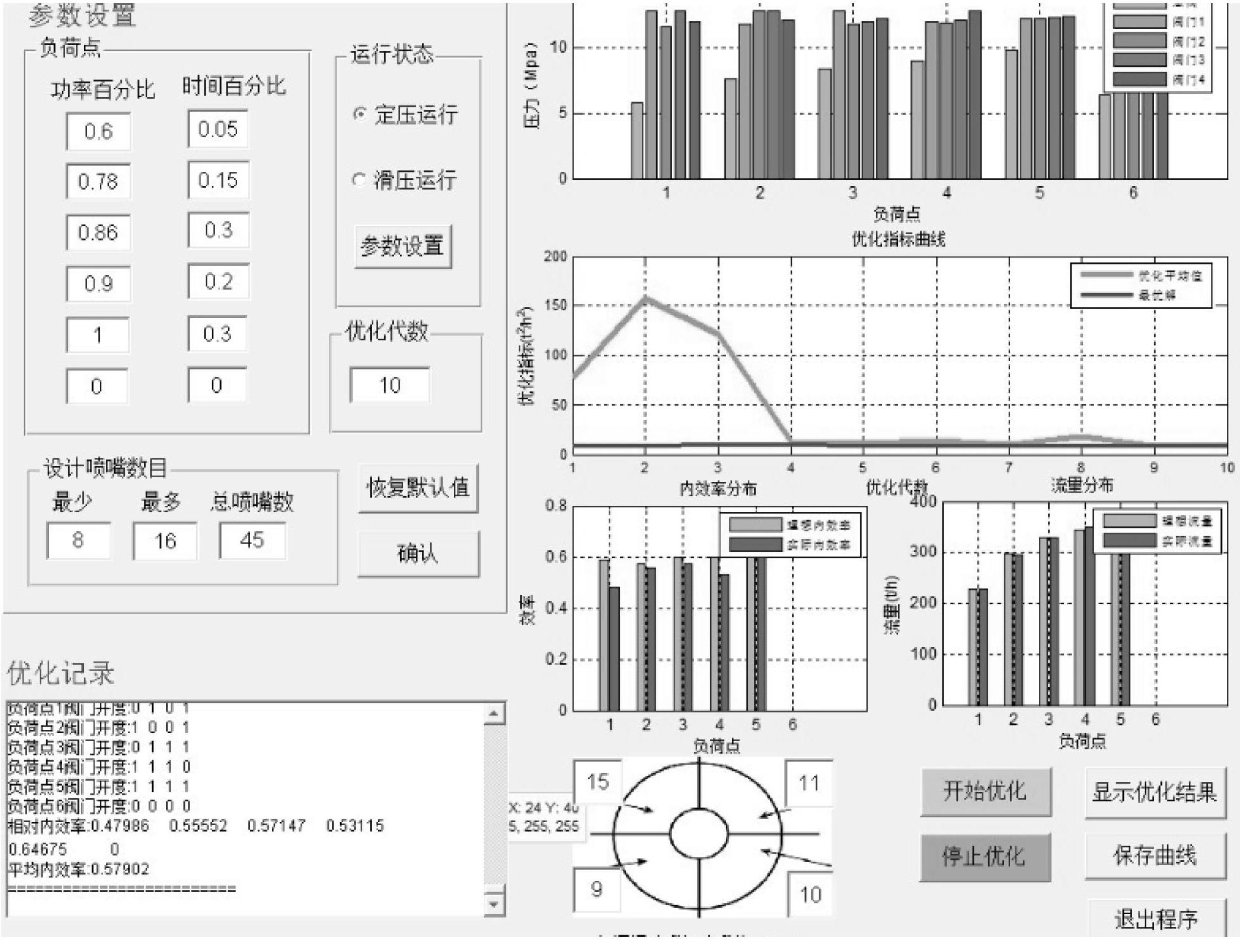

Examples

specific Embodiment approach 1

[0102] Embodiment 1: The optimal design method for the number of nozzles of each nozzle group considering the actual operation constraints of the steam turbine described in this embodiment is implemented according to the following steps:

[0103] Step 1. Build an optimization model for the number of nozzles:

[0104] Y=W 1 (xgz 1 -Ge 1 ) 2 +W 2 (xgz 2 -Ge 2 ) 2 +...+W l (xgz l -Ge l ) 2 (2-10)

[0105] W 1 , W 2 ......W l Indicates the percentage of operating time at each load point;

[0106] xgz 1 , xgz 2 ......xgz l Indicates the actual flow of each given load point;

[0107] Ge 1 , Ge 2 ......Ge l Indicates the theoretical flow at each given load point;

[0108] The comprehensive deviation degree between the actual flow and the theoretical flow is represented by Y;

[0109] Step 2: Calculate the actual flow of each given load point:

[0110] Calculate the actual flow of 1...l given load points from the number of nozzles of each valve and their c...

specific Embodiment approach 2

[0220] Specific embodiment 2: In this embodiment, in step 2, the dichotomy method is used to calculate p 2 During the process, the pressure after the nozzle is p 1k The calculation process is as follows: the sliding pressure operation law curve obtained by the steam turbine unit in the actual operation: power - main steam pressure, and then according to the actual operating load, check the main steam pressure, and then calculate p 1k . Other steps are the same as in the first embodiment.

[0221] The method of the present invention is further elaborated as follows:

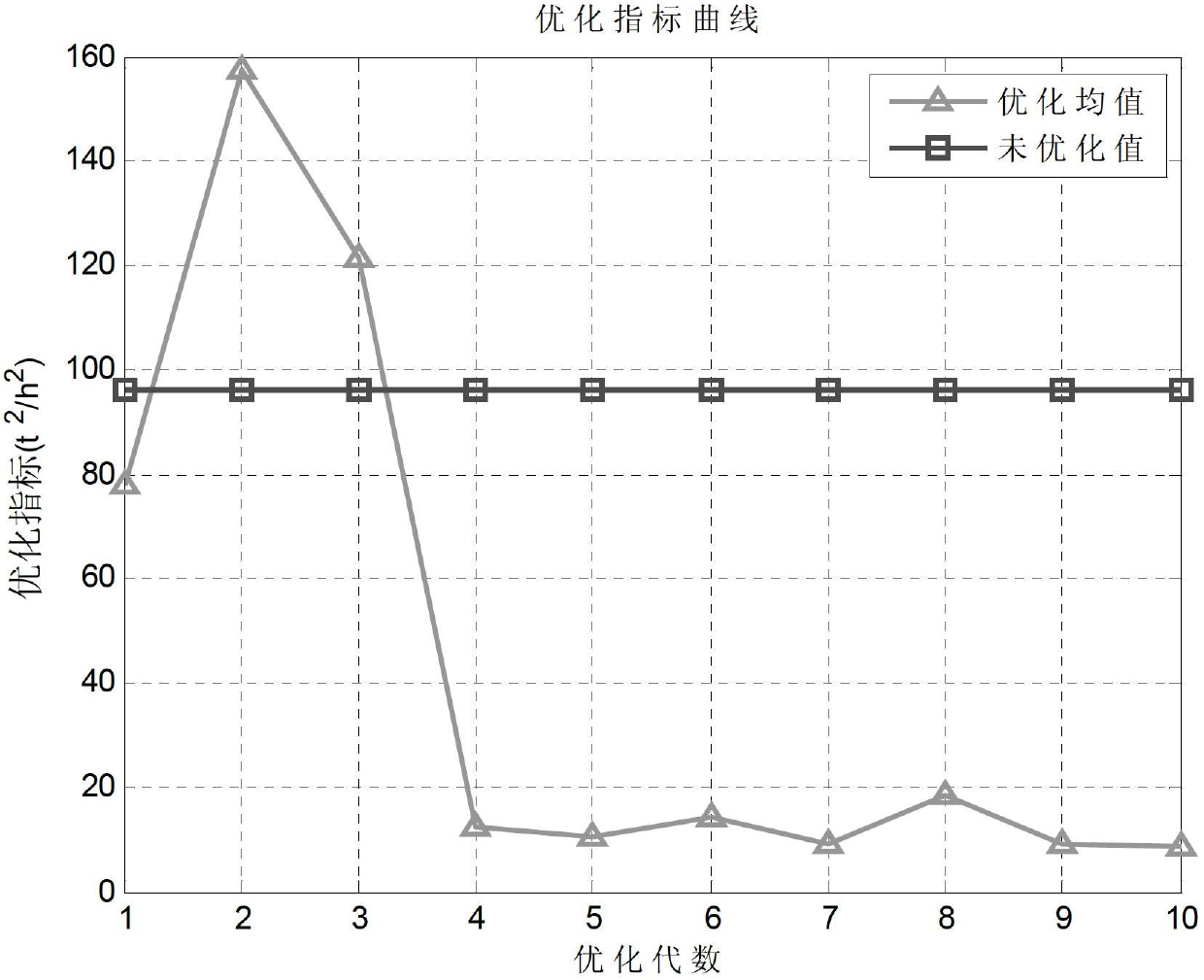

[0222] 1. Genetic algorithm and its improved optimization method

[0223] Genetic algorithm is an efficient global search algorithm based on natural selection and genetic theory, which combines the survival rule of the fittest in the process of biological evolution with the random information exchange mechanism of chromosomes within the population. The genetic algorithm abandons the traditional search method, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com