Slitting cutting disc and preparation method thereof

A manufacturing method and disc cutter technology, applied in the field of tool processing, can solve the problems of short service life, poor toughness, low stability, etc., and achieve the effects of long service life, stable performance, high compactness and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

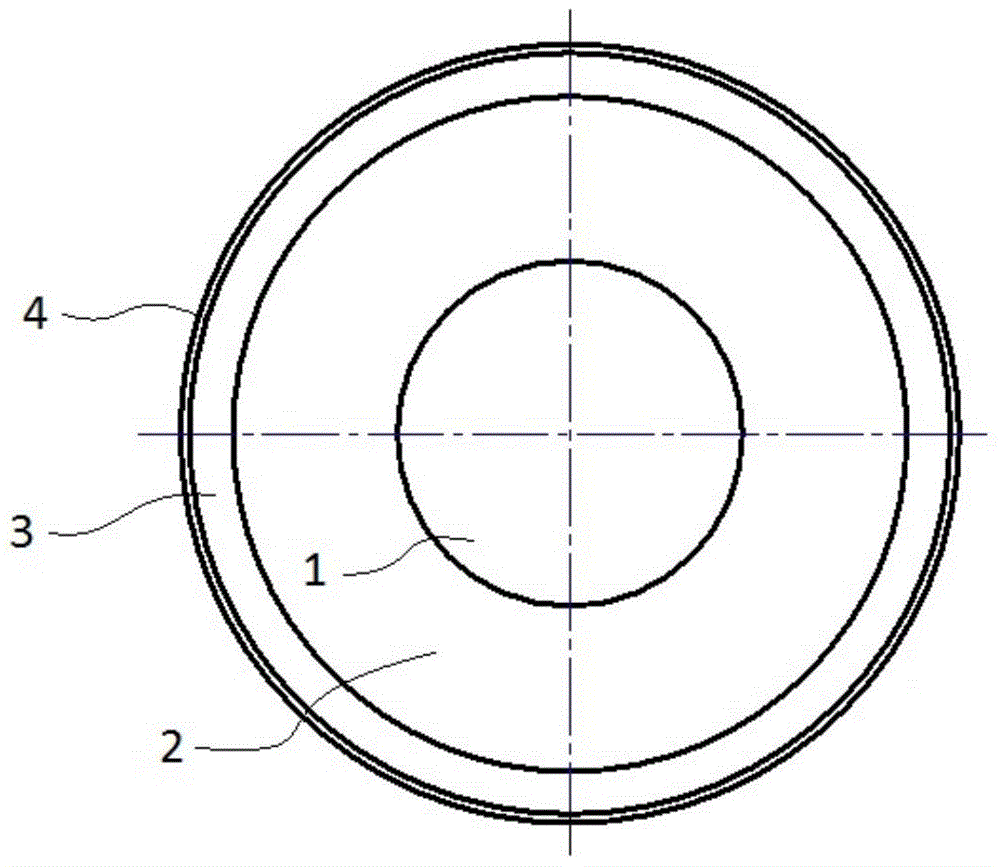

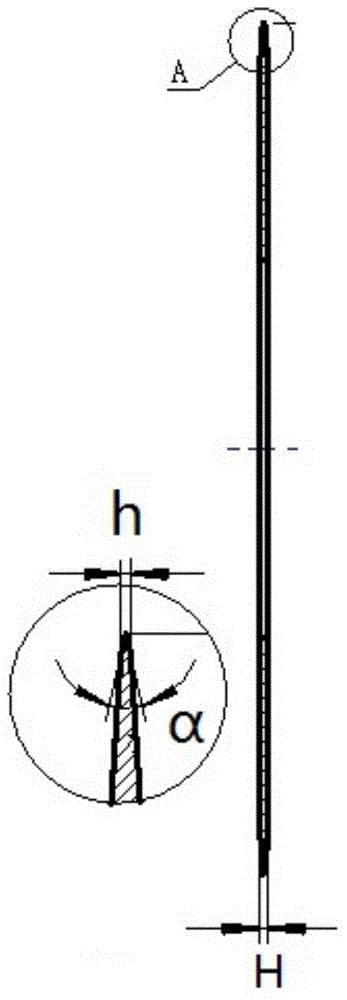

[0046] Such as figure 1 and figure 2 Shown, a kind of slitting disk knife, its shape is the annular blade, and the outer circle diameter of whole disk knife is 100mm, comprises center hole 1, cutter head 2 and blade 3, and the diameter of center hole 1 is 25mm, Center hole 1 is positioned at the center of cutter head 2, and blade 3 is positioned on the outer ring of cutter head 2, and the outer ring of blade 3 is provided with blade edge 4, and the edge angle δ of blade edge 4 is 25 °; The thickness h of the mouth is 0.25mm, and the thickness H of the blade 3 is 1.2±0.02mm; the parallelism of one surface of the blade 3 with respect to the other plane is ≤0.03.

[0047] The method of making above-mentioned slitting disc cutter is:

[0048] (1) Preparation of rough raw materials:

[0049] It is made by using a forging blank for forging. The mass percentage of the components of the forging blank is: C: 1.25%, N: 0.32%, Mn: 0.34%, Si: 0.76%, Cr: 9.00%, W: 2.10%, V: 0.42%, Mo:...

Embodiment 2

[0069] Such as figure 1 and figure 2 Shown, a kind of slitting disk knife, its shape is the annular blade, and the outer circle diameter of whole disk knife is 100mm, comprises center hole 1, cutter head 2 and blade 3, and the diameter of center hole 1 is 25mm, Center hole 1 is positioned at the center of cutter head 2, and blade 3 is positioned on the outer ring of cutter head 2, and the outer ring of blade 3 is provided with blade edge 4, and the edge angle δ of blade edge 4 is 25 °; The thickness h of the mouth is 0.24mm, and the thickness H of the blade 3 is 1.2±0.02mm; the parallelism of one surface of the blade 3 with respect to the other plane is ≤0.02.

[0070] The method of making above-mentioned slitting disc cutter is:

[0071] (1) Preparation of rough raw materials:

[0072] It is made by using forging blanks for forging. The mass percentages of the components of the forging blanks are: C: 1.15%, N: 0.20%, Mn: 0.30%, Si: 1.20%, Cr: 8.50%, W: 1.50%, V: 0.35%, M...

Embodiment 3

[0092] Such as figure 1 and figure 2 Shown, a kind of slitting disk knife, its shape is the annular blade, and the outer circle diameter of whole disk knife is 100mm, comprises center hole 1, cutter head 2 and blade 3, and the diameter of center hole 1 is 25mm, Center hole 1 is positioned at the center of cutter head 2, and blade 3 is positioned on the outer ring of cutter head 2, and the outer ring of blade 3 is provided with blade edge 4, and the edge angle δ of blade edge 4 is 25 °; The thickness h of the mouth is 0.26mm, and the thickness H of the blade 3 is 1.2±0.02mm; the parallelism of one surface of the blade 3 with respect to the other plane is ≤0.01.

[0093] The method of making above-mentioned slitting disc cutter is:

[0094] (1) Preparation of rough raw materials:

[0095]It is made by using forging blanks for forging. The mass percentages of the components of the forging blanks are: C: 1.33%, N: 0.40%, Mn: 0.40%, Si: 0.52%, Cr: 10.50%, W: 2.50%, V: 0.50%, M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com