Patents

Literature

662 results about "Knife cuts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

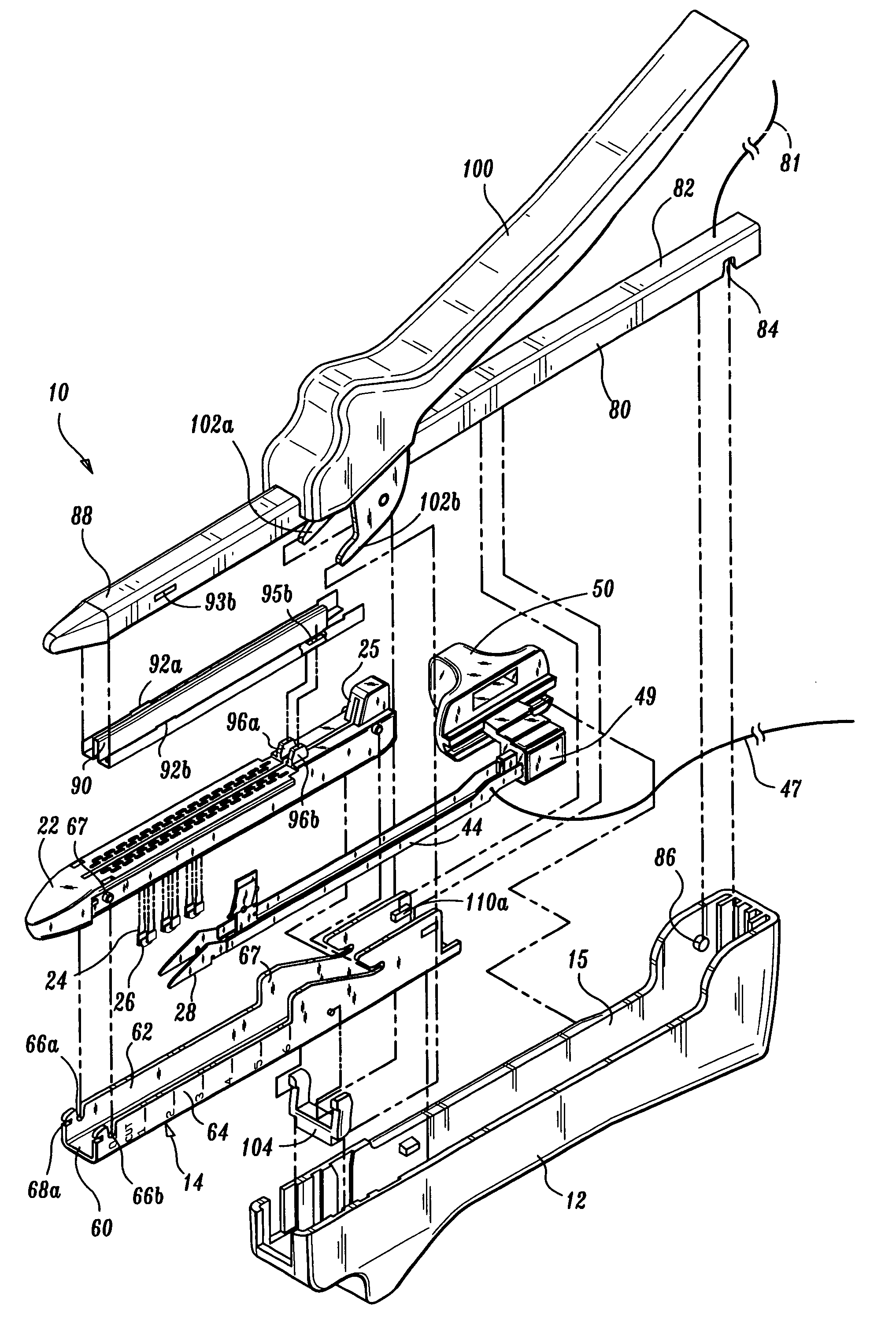

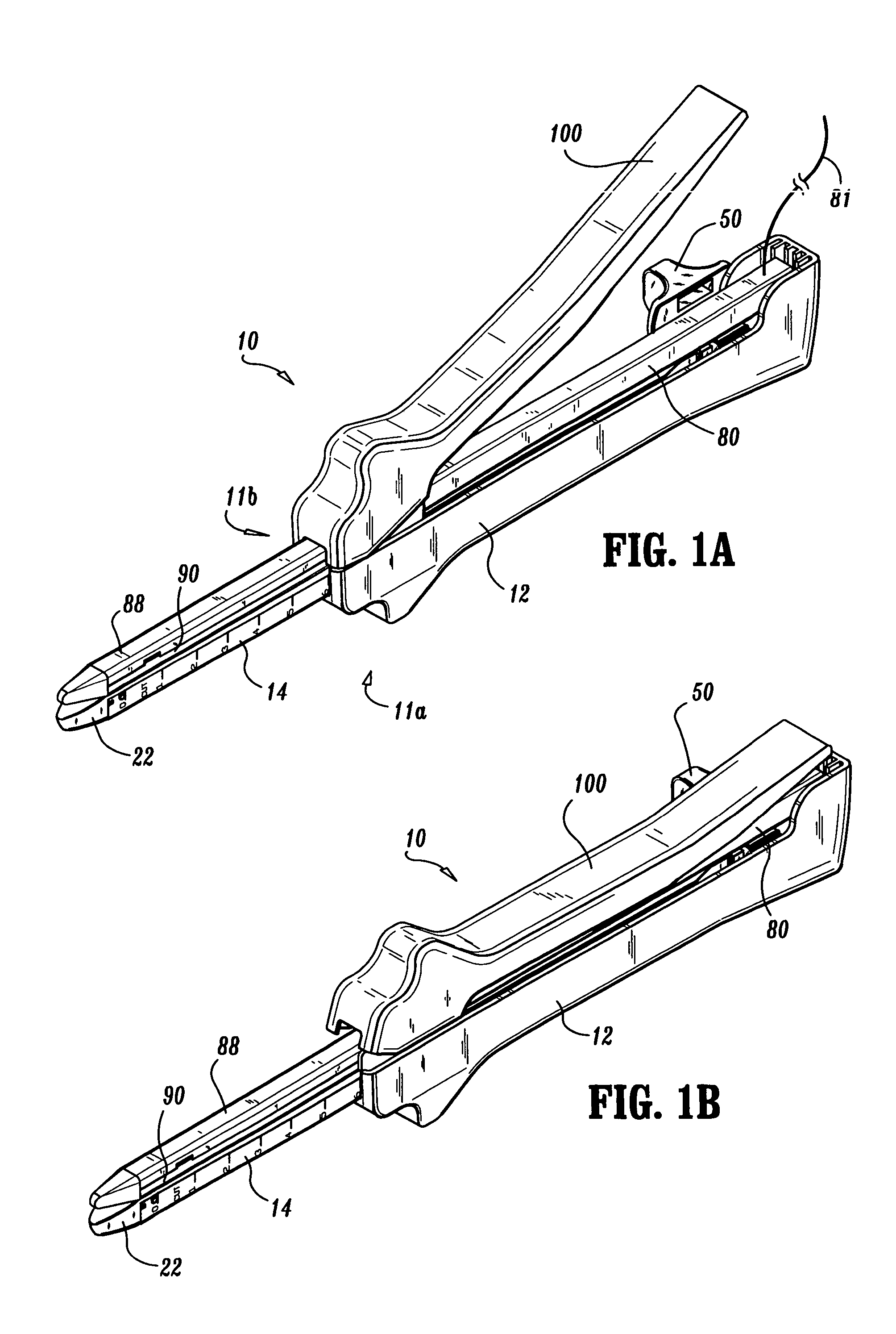

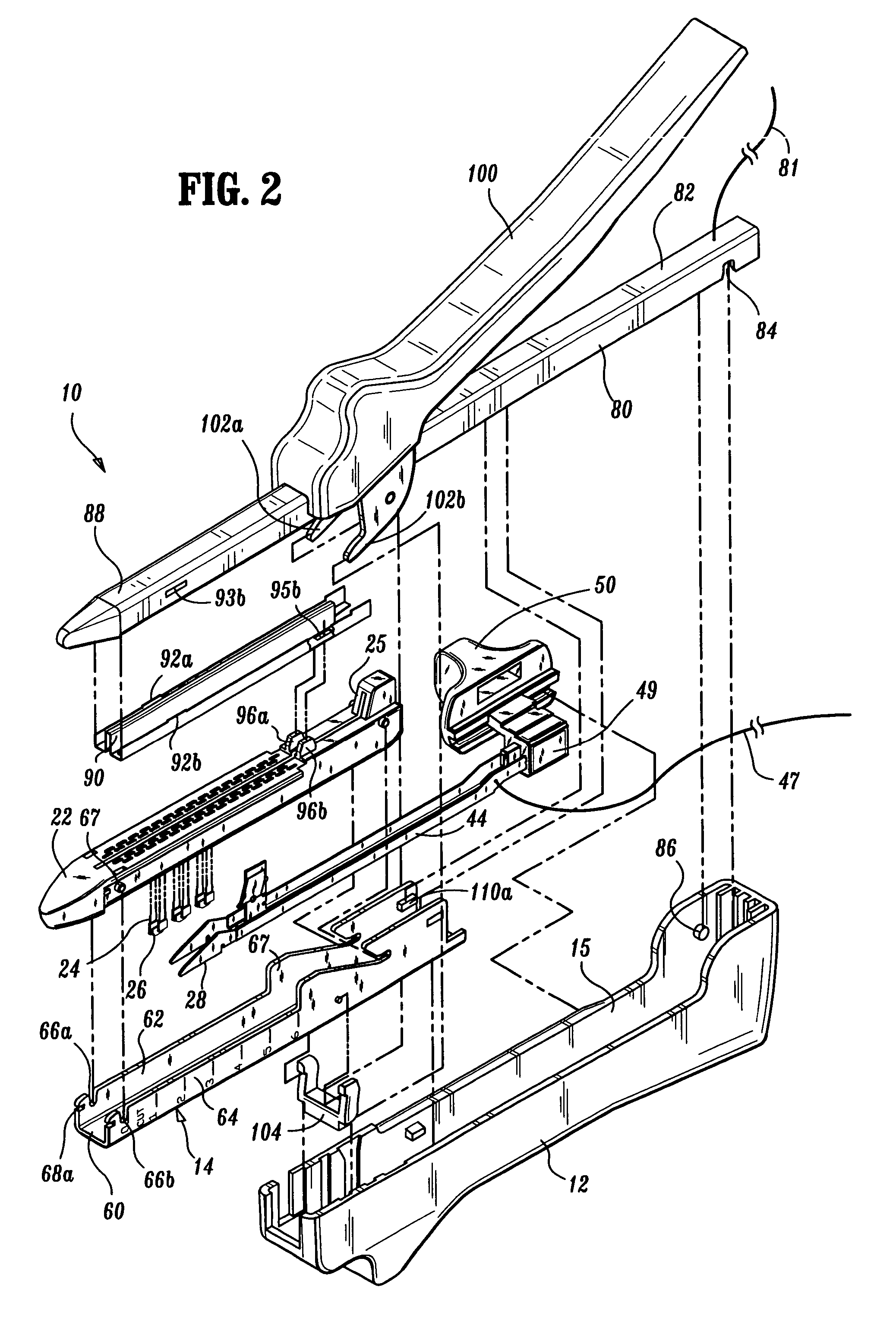

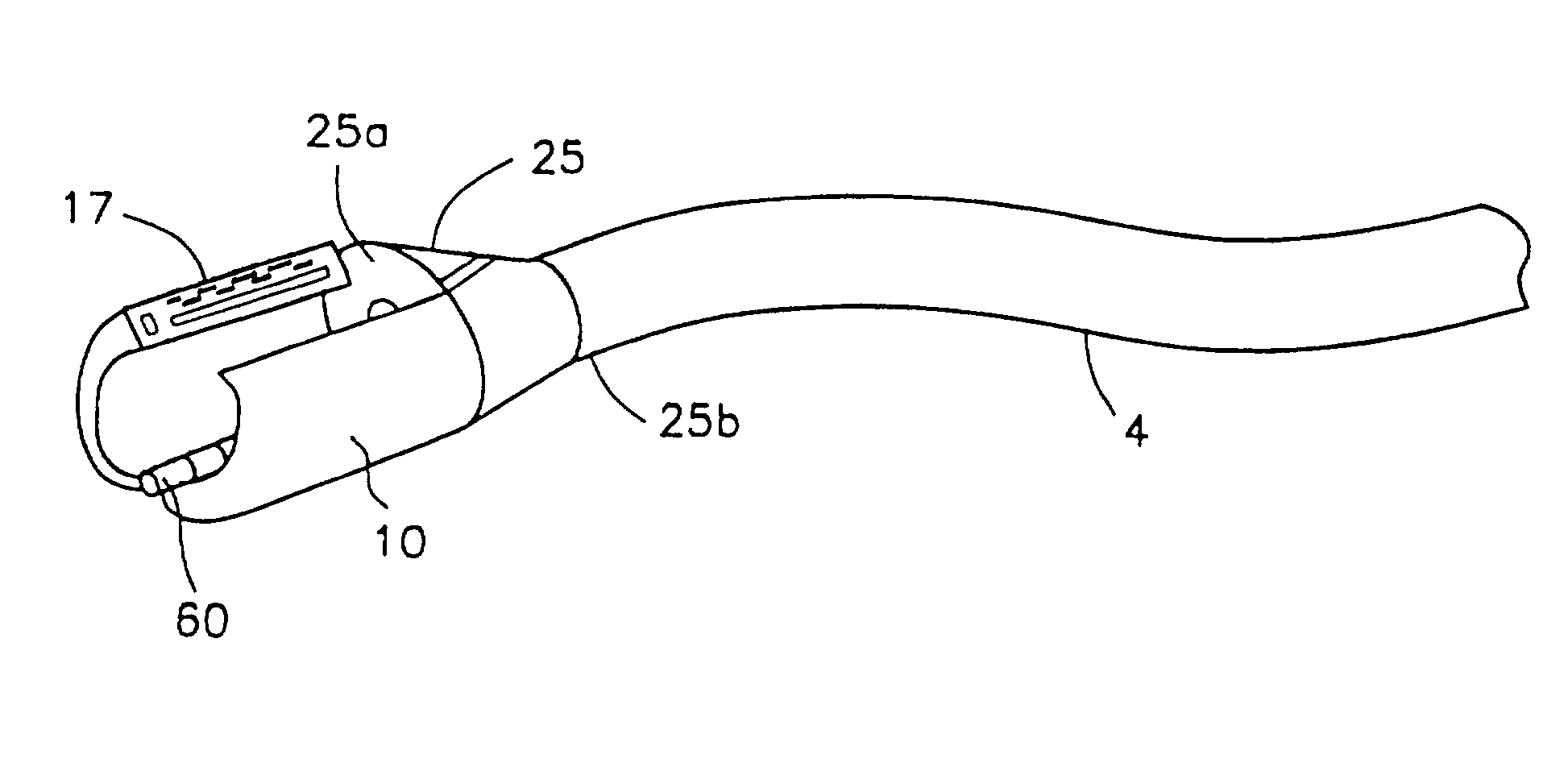

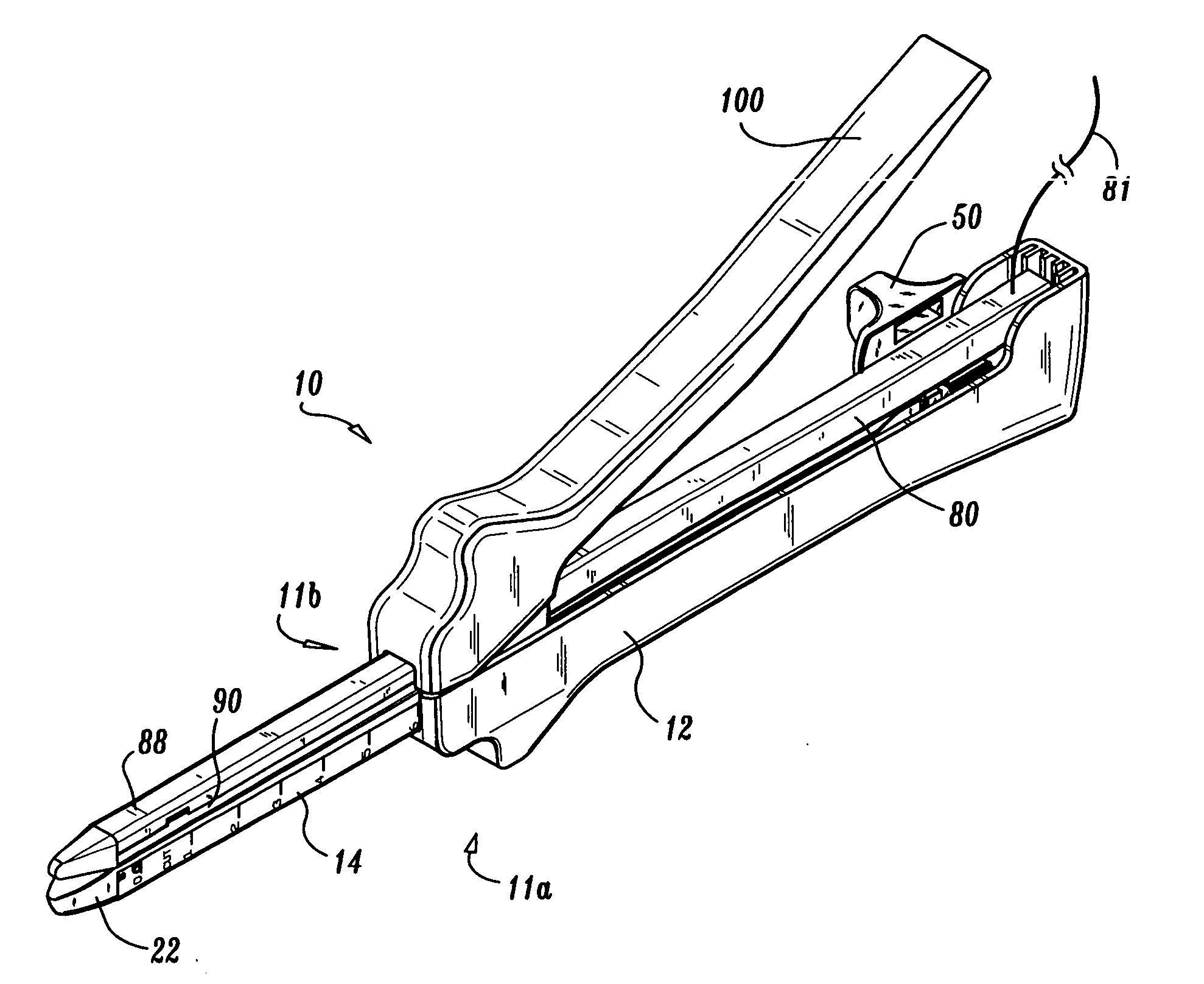

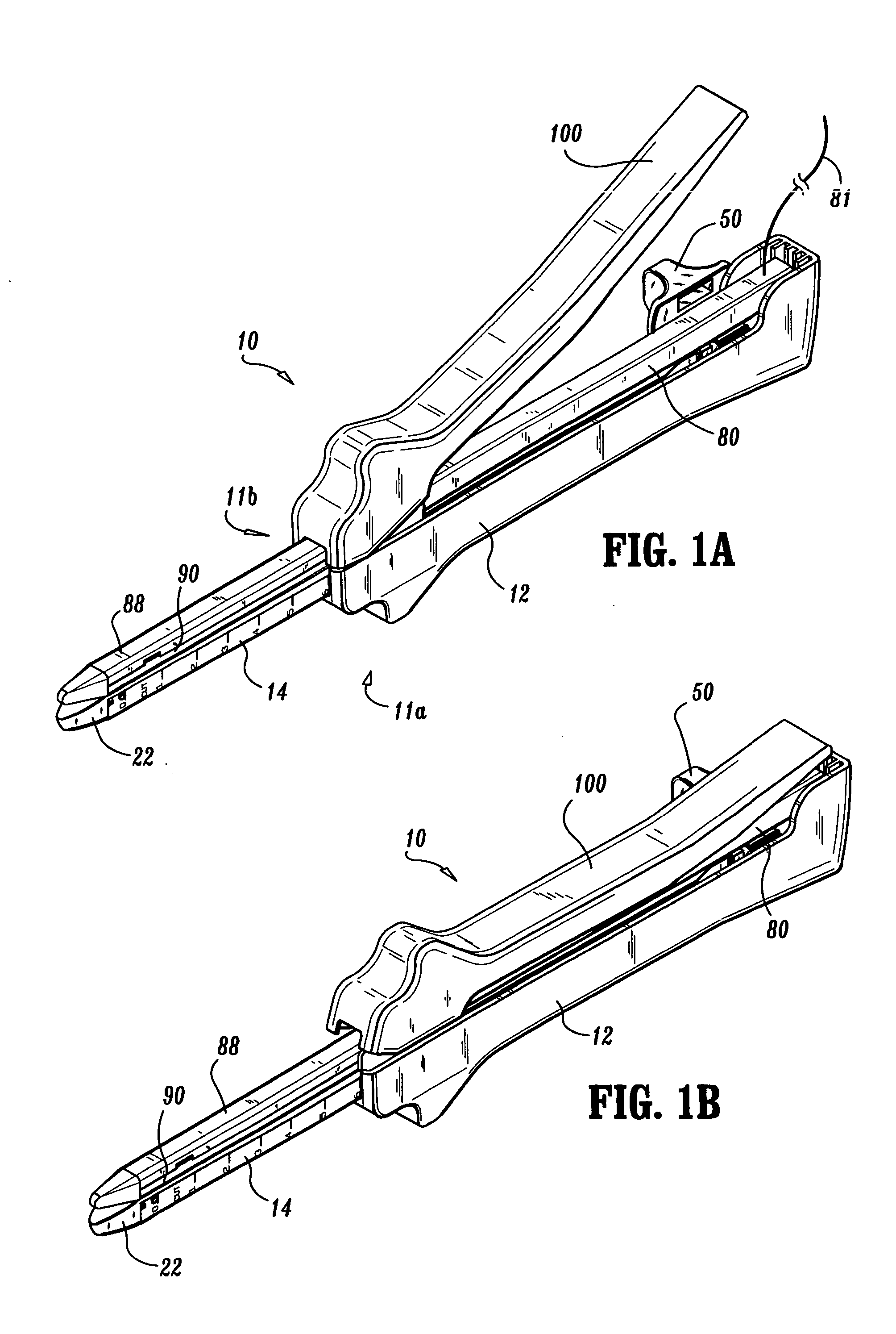

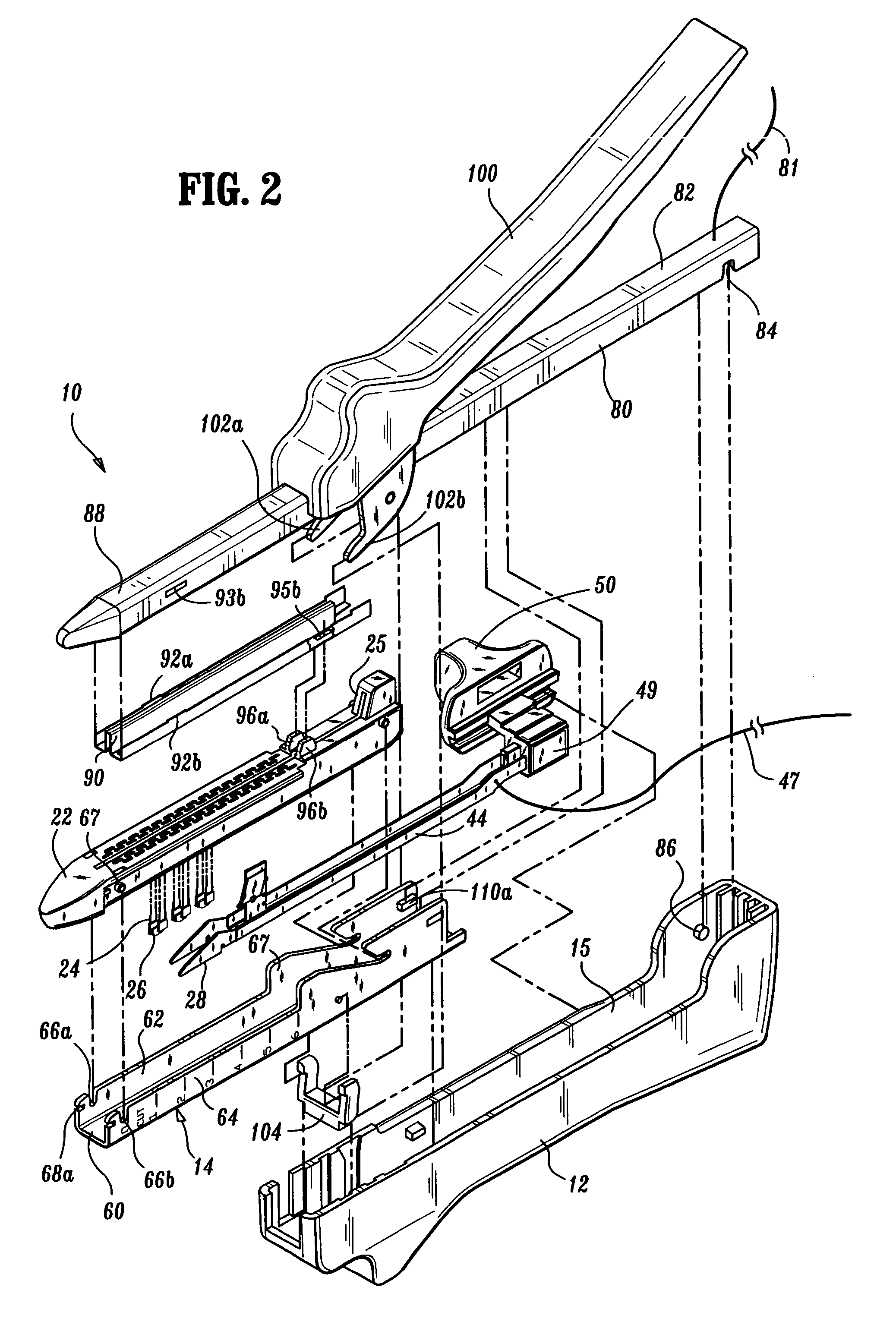

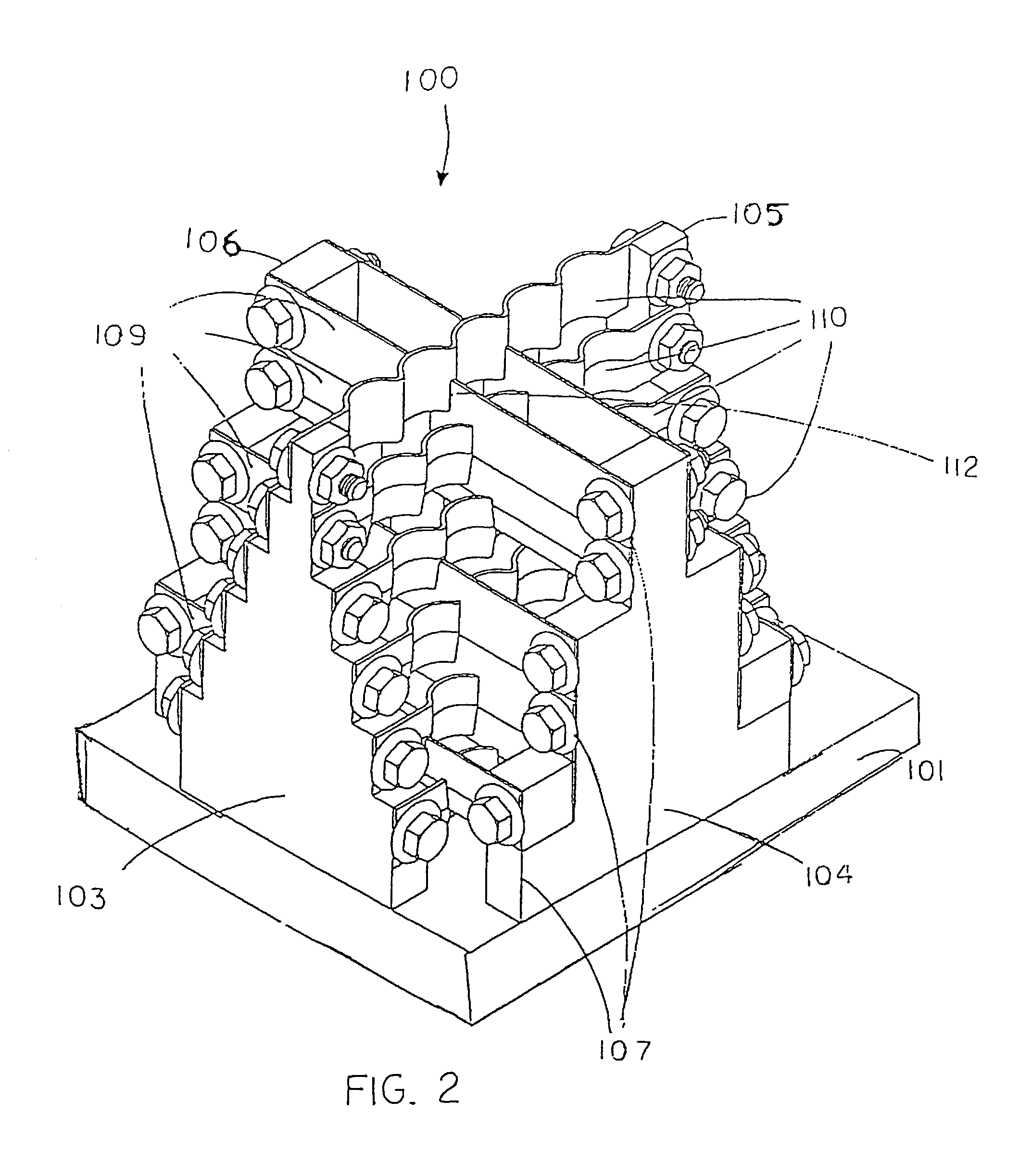

Electrosurgical stapling apparatus

InactiveUS7207471B2Reduces or prevents staple line and cut line bleedingShort and strengthSuture equipmentsStapling toolsStaple lineEngineering

An electrosurgical stapling apparatus is provided which uses thermogenic energy as well as surgical fasteners or staples for strengthening tissue, providing hemostasis, tissue joining or welding. The thermogenic energy also strengthens tissue in proximity to a staple line and knife cut line and provides hemostasis along the staple and cut lines formed by the staples and a knife blade during surgical stapling. The use thermogenic energy provides short-term hemostasis and sealing, and reduces or prevents staple line and cut line bleeding, while the stapling features provide short and long-term tissue strength and hemostasis. The stapling apparatus further substantially reduces or prevents knife cut line bleeding by energizing a knife blade for cauterizing tissue while it is being cut. In one embodiment, energy is applied to the anvil to energize the staples as they make contact with the anvil.

Owner:TYCO HEALTHCARE GRP LP

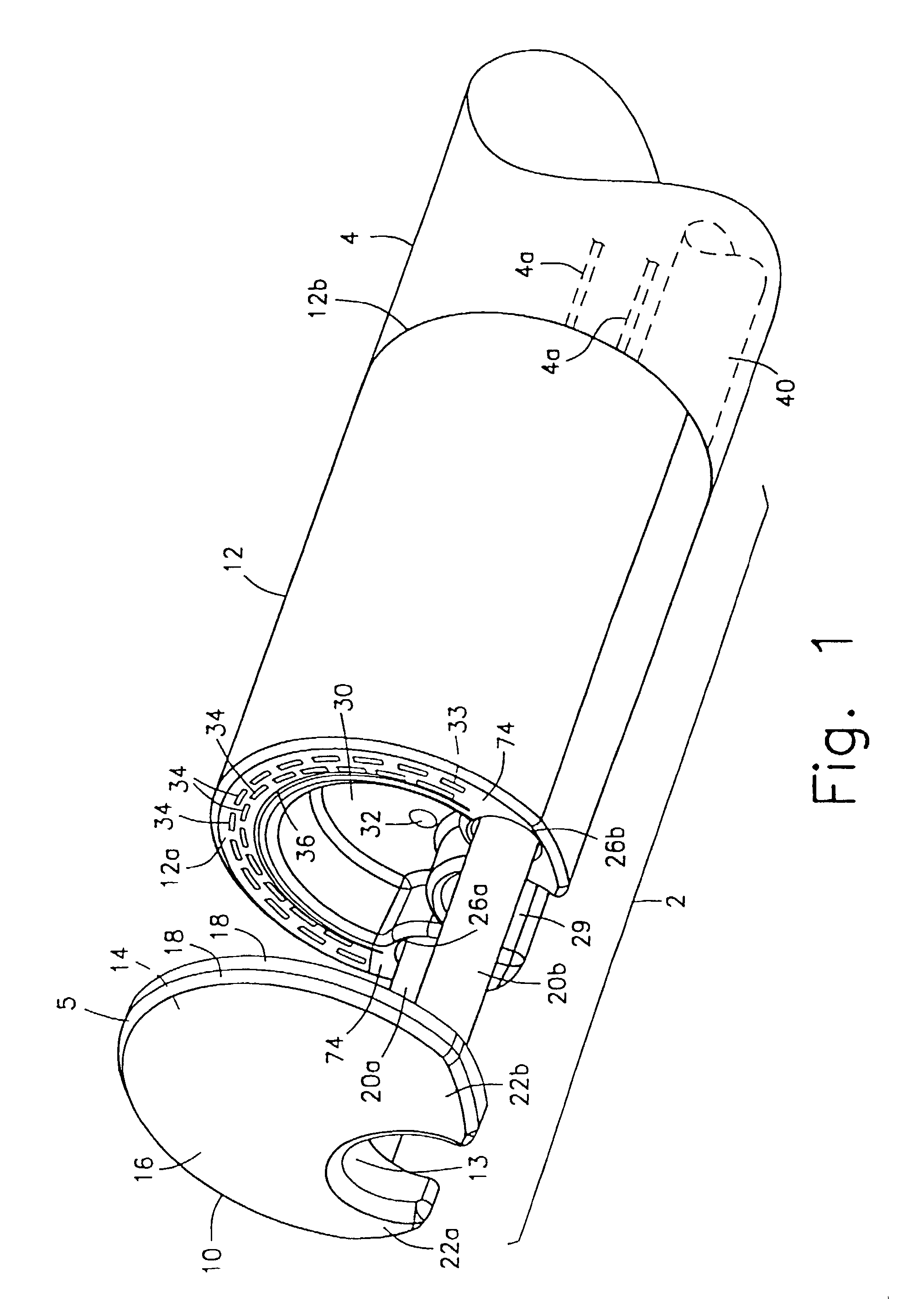

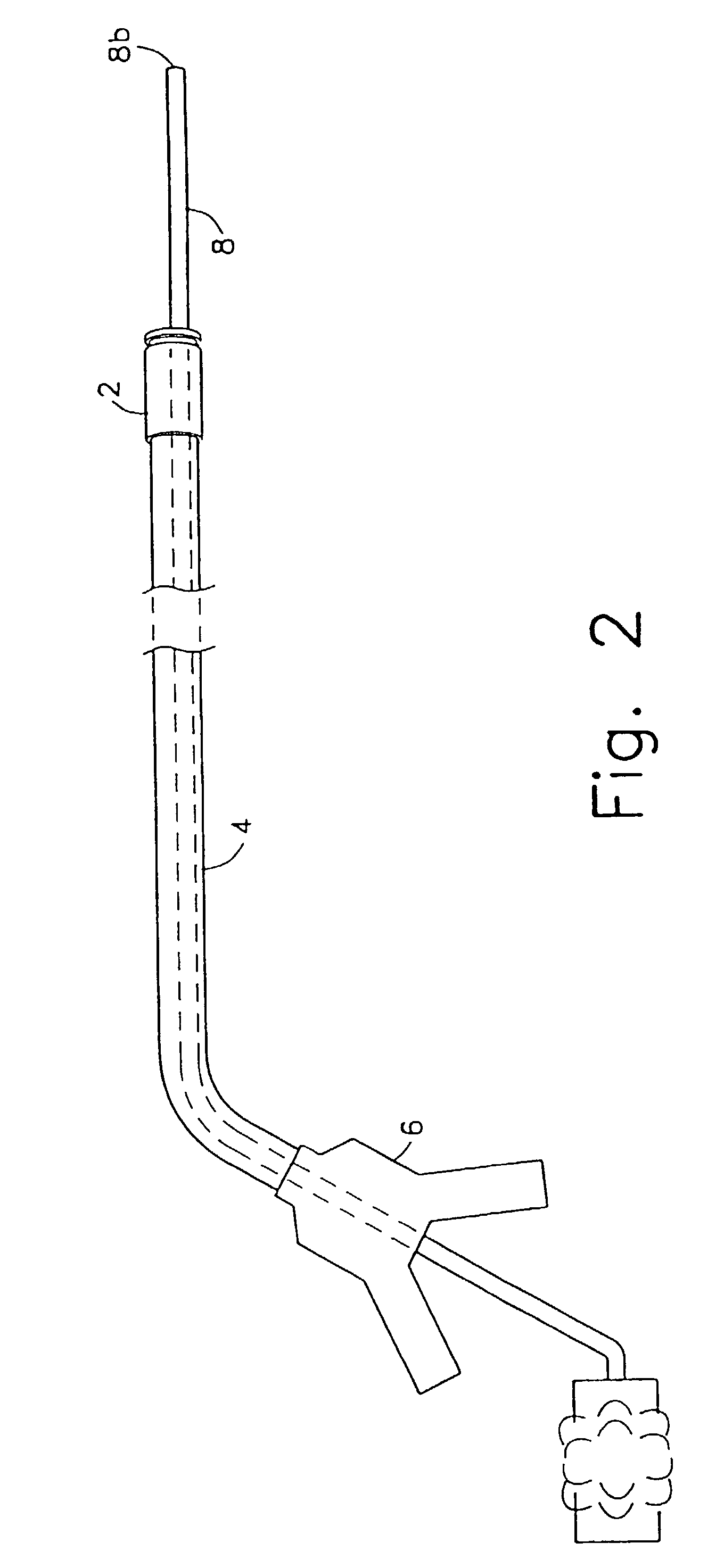

Method and device for full thickness resectioning of an organ

A full-thickness resection system comprises a flexible endoscope and a stapling mechanism, wherein the endoscope is slidably received through at least a portion of the stapling mechanism. The stapling mechanism comprises an anvil and a stapling head mounted to the anvil so that the anvil and the stapling head are moveable with respect to one another between a tissue receiving position and a stapling position and wherein a gap formed between the stapling head and the anvil is larger in the tissue receiving position than it is in the stapling position. A position adjusting mechanism is provided for moving the anvil and the stapling head between the tissue receiving and stapling positions and a staple firing mechanism sequentially fires a plurality of staples from the stapling head across the gap against the anvil and through any tissue received in the gap and a knife cuts a portion of tissue received within the gap. A control unit which remains outside the body is coupled to the stapling mechanism for controlling operation of the position adjusting mechanism and the staple firing mechanism.

Owner:BOSTON SCI SCIMED INC

Electrosurgical stapling apparatus

InactiveUS20050159778A1Reduces or prevents staple line and cut line bleedingShort and strengthSuture equipmentsStapling toolsStaple lineEngineering

An electrosurgical stapling apparatus is provided which uses thermogenic energy as well as surgical fasteners or staples for strengthening tissue, providing hemostasis, tissue joining or welding. The thermogenic energy also strengthens tissue in proximity to a staple line and knife cut line and provides hemostasis along the staple and cut lines formed by the staples and a knife blade during surgical stapling. The use thermogenic energy provides short-term hemostasis and sealing, and reduces or prevents staple line and cut line bleeding, while the stapling features provide short and long-term tissue strength and hemostasis. The stapling apparatus further substantially reduces or prevents knife cut line bleeding by energizing a knife blade for cauterizing tissue while it is being cut. In one embodiment, energy is applied to the anvil to energize the staples as they make contact with the anvil.

Owner:TYCO HEALTHCARE GRP LP

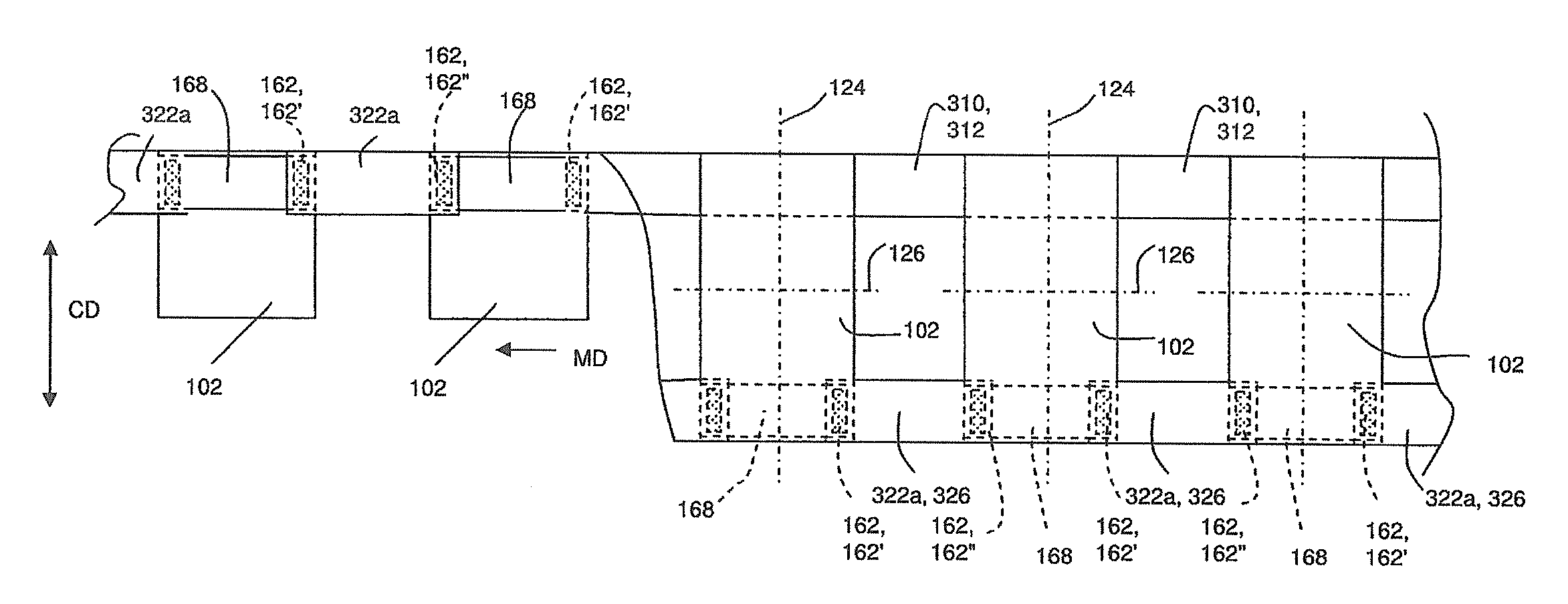

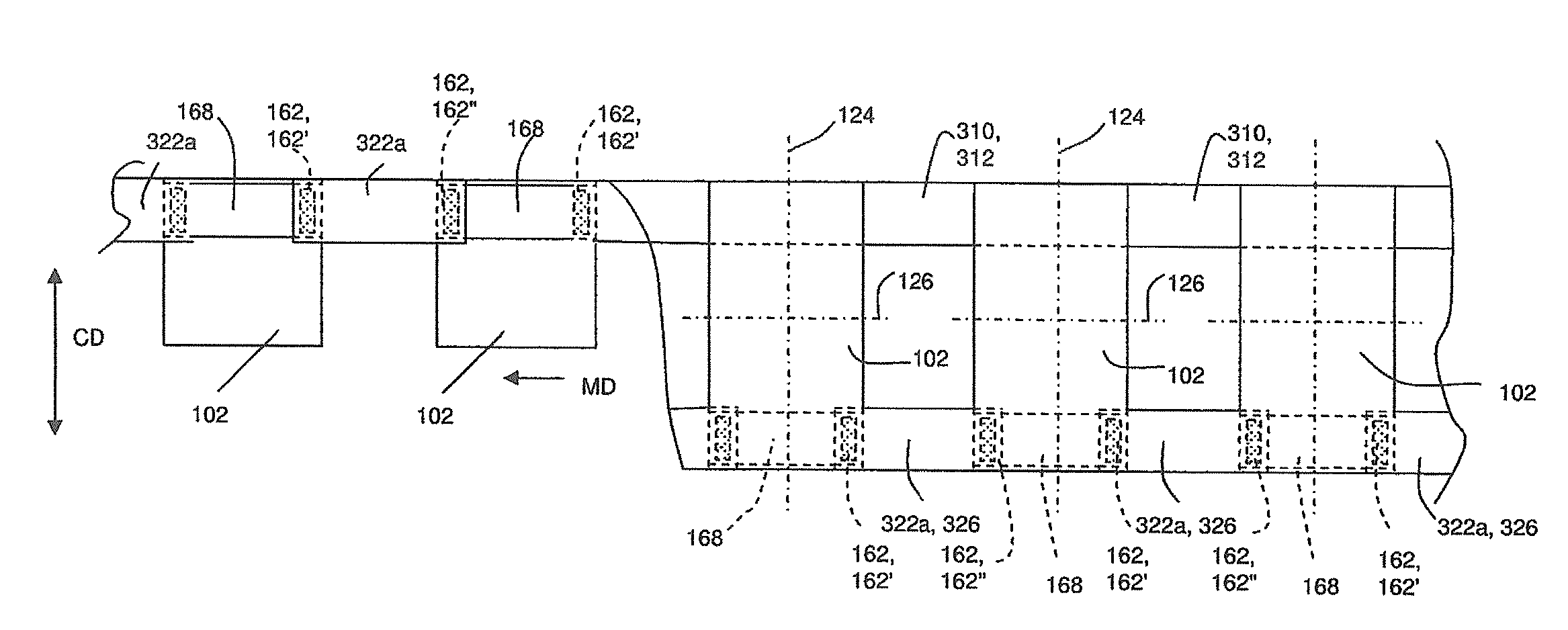

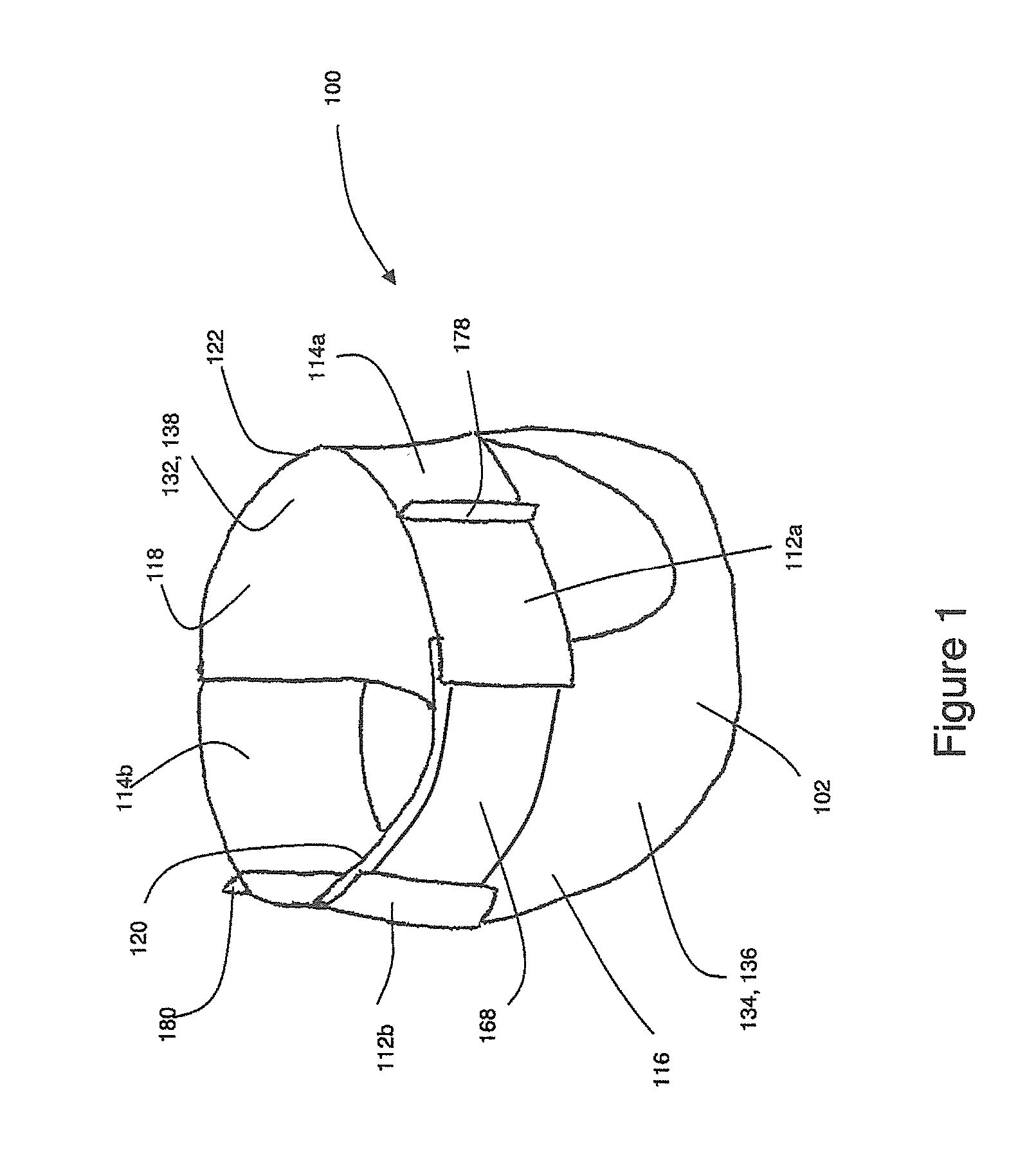

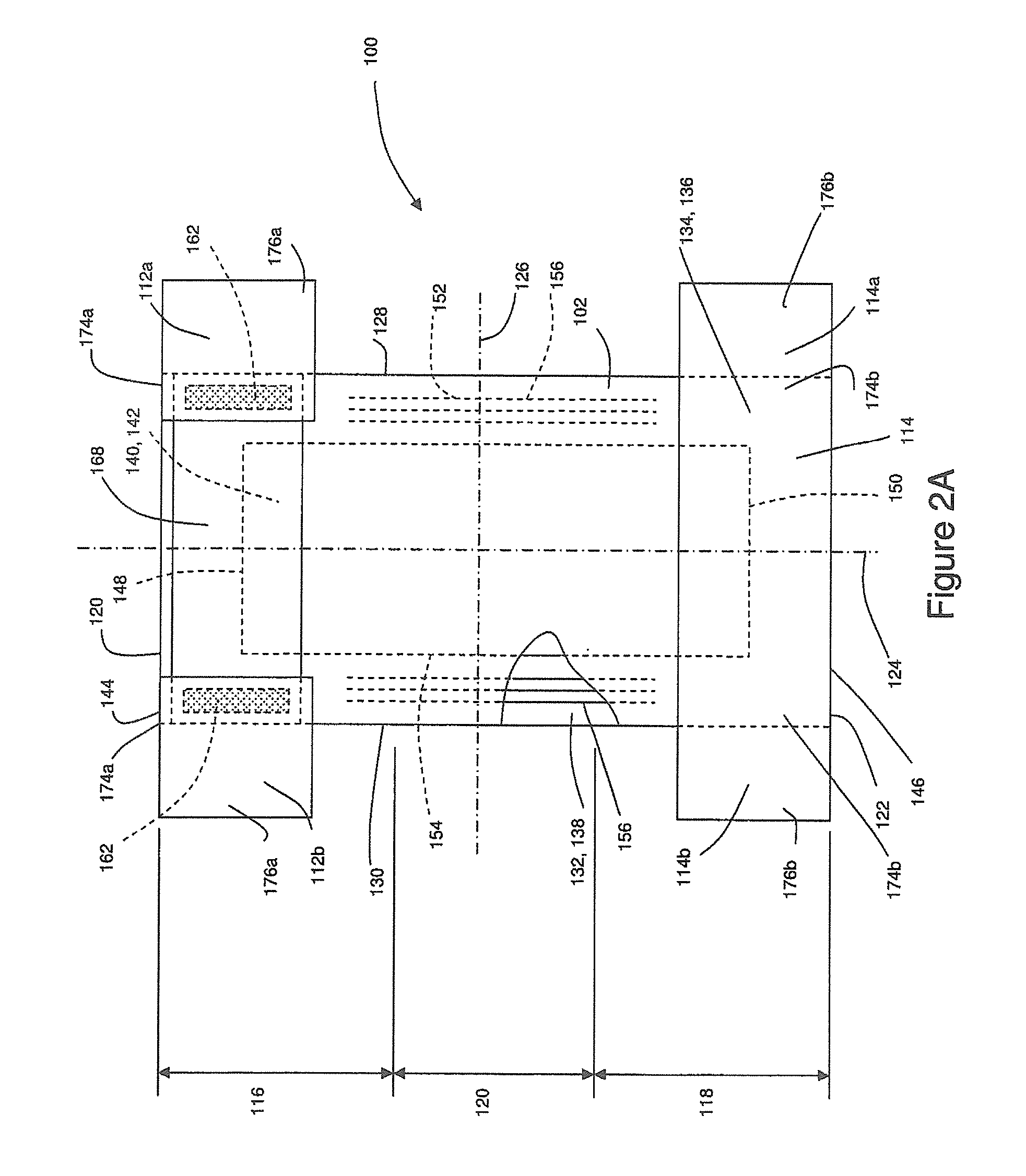

Method of Making Prefastened Refastenable Disposable Absorbent Articles

The present disclosure relates to methods for manufacturing absorbent articles, and in particular, methods for making pre-fastened refastenable pant diapers. Aspects of the methods according to the present disclosure relate to the fabrication of refastenable pant diapers wherein discrete chassis are advanced in a machine direction such that the lateral axis is parallel with the machine direction. First side panels are then refastenably connected with the first waist region, and second side panels are permanently connected the second waist regions of the discrete chassis. The chassis are connected with discrete lengths of side panel material and / or connection zone material. The chassis are then folded, and the first and second side panels are subsequently bonded together. The article is then subjected to knife cut at or adjacent the bonded regions to create discrete, pre-fastened refastenable pant diapers.

Owner:THE PROCTER & GAMBLE COMPANY

Method of Making Prefastened Refastenable Disposable Absorbent Articles

InactiveUS20120061015A1Lamination ancillary operationsLaminationKnife cutsElectrical and Electronics engineering

Aspects of the methods according to the present disclosure relate to the fabrication of refastenable pant diapers wherein discrete chassis are advanced in a machine direction such that the lateral axis is parallel with the machine direction. First side panels are then refastenably connected with the first waist region, and second side panels are permanently connected the second waist regions of the discrete chassis. The methods disclosed herein connect chassis with discrete lengths of side panel material and / or connection zone material, and forms a continuous web of articles formed by intermittently spaced chassis and intermittently spaced side panels bridging the gap between the intermittently spaced chassis. The chassis are then folded in the cross direction parallel to a lateral centerline and the first and second side panels are subsequently bonded together. The article is then subjected to knife cut adjacent the bonded regions to create discrete, pre-fastened refastenable pant diapers.

Owner:THE PROCTER & GAMBLE COMPANY

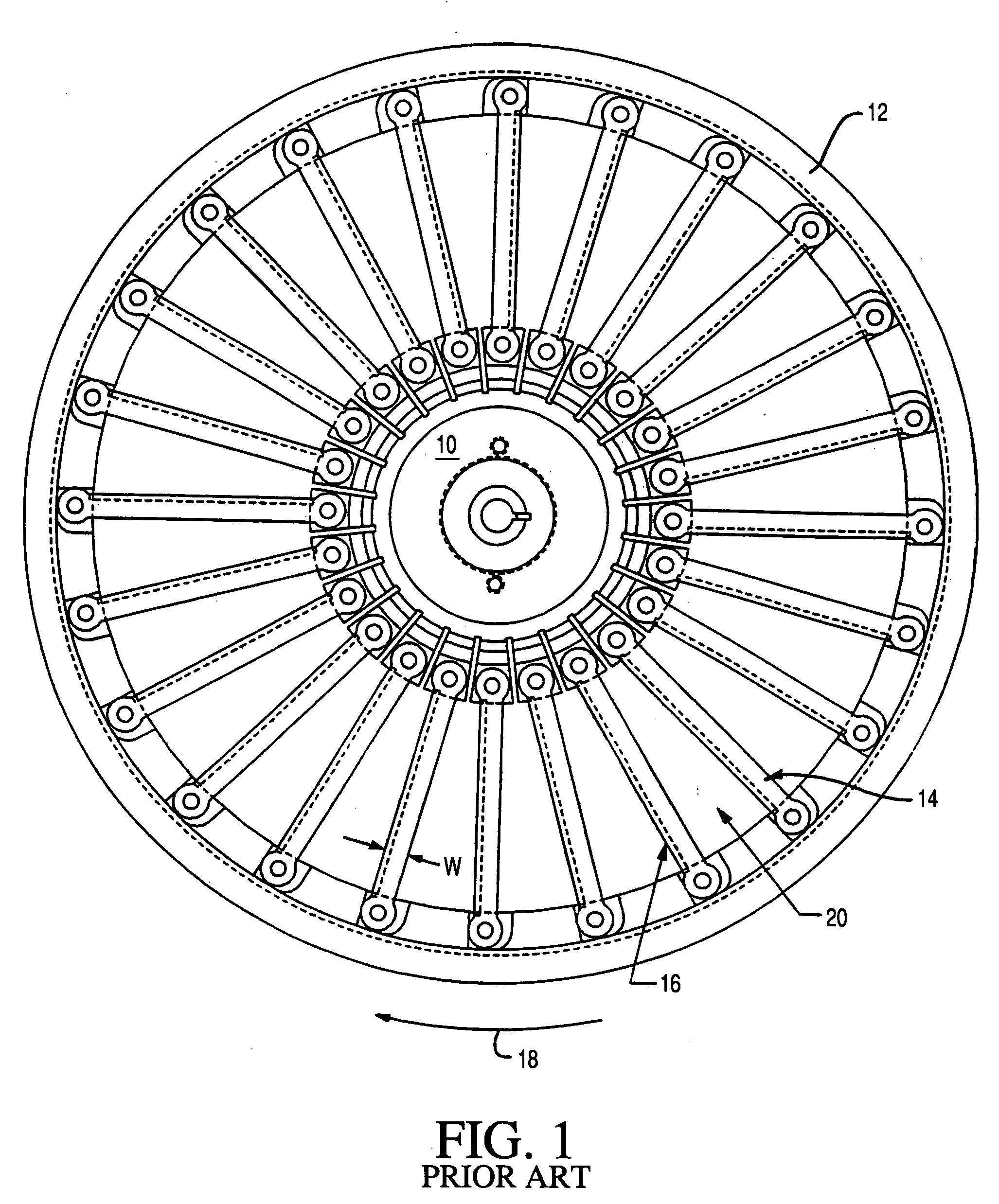

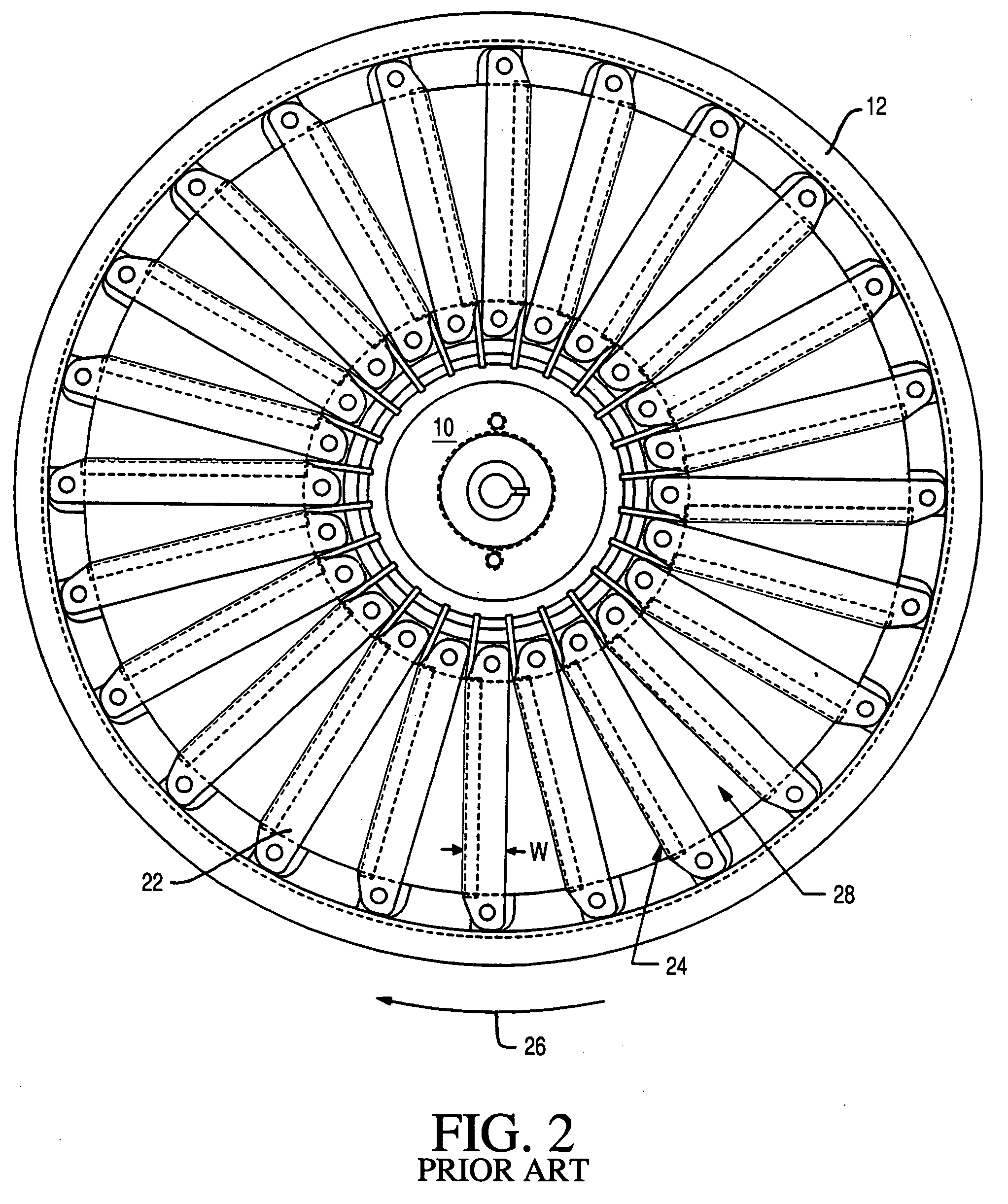

Knife arrangement for minimizing feathering during high speed cutting of food products

InactiveUS20050000344A1Minimize pressure appliedPrecise consistencyMetal working apparatusSlice thicknessKnife cuts

A cutting wheel using knives with slice thickness gauging surfaces defining, with the knife cutting edges, a thickness dimension of sliced food products and a throat dimension measured perpendicular to the wheel cutting plane between each knife cutting edge and the terminal edge of the adjacent gauging surface, wherein the knives each have a single primary bevel extending practically tangent to the cutting plane on the side of the knife facing towards the cutting plane and a smooth transition area on the opposite side of the knife, and the ratio of throat dimension to slice thickness dimension is equal to or more than 1 to 1.7.

Owner:URSCHEL LAB

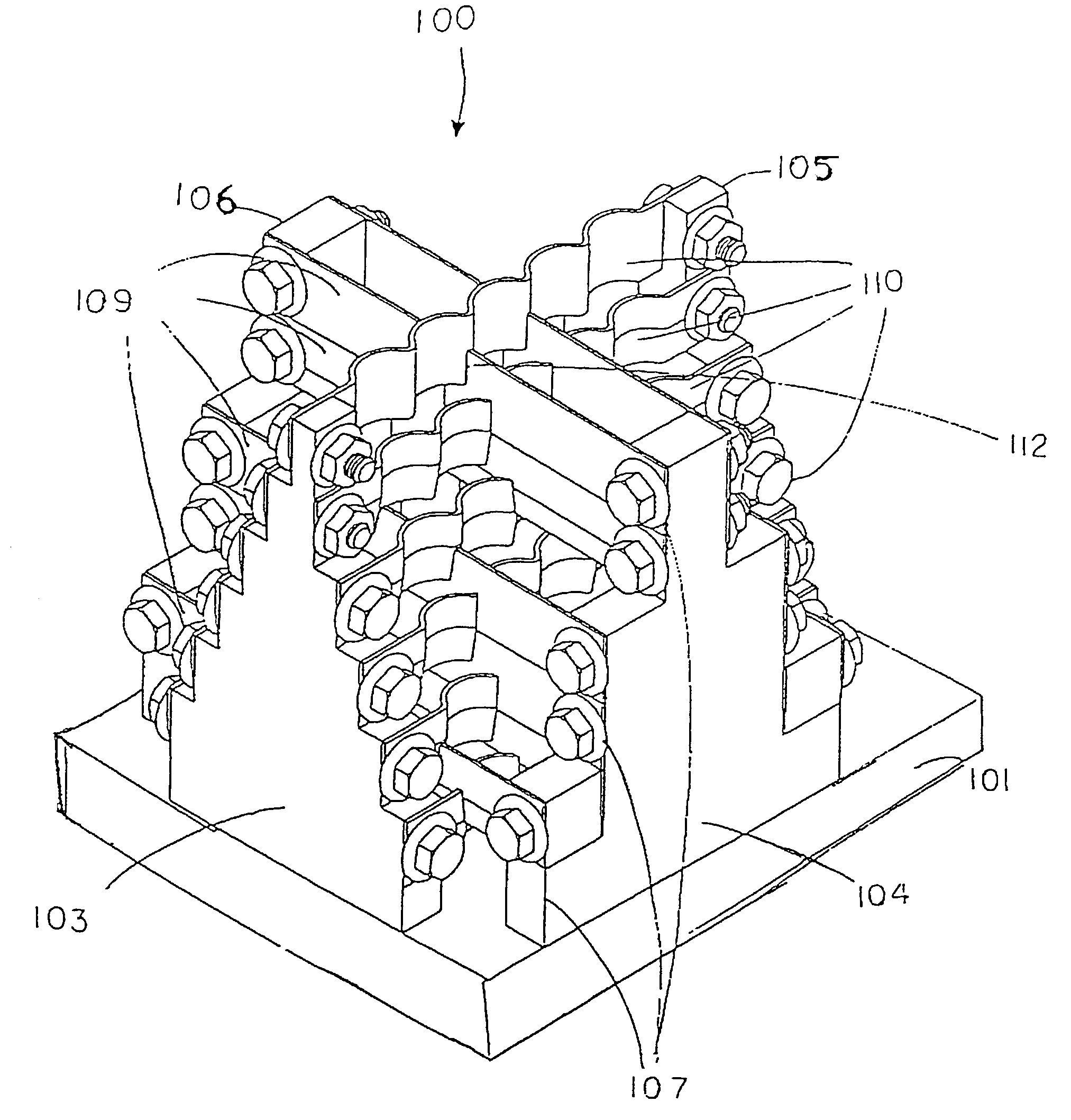

Cutter blade assembly for cutting scoop shaped vegetable products

A cutter blade assembly that presents a sequential series of perpendicularly oriented cutting knife arrays which are attached to a frame. A first set of cutting knives is comprised of knives that are generally scalloped shaped. A second set of cutting knives is comprised of knives that are generally straight and are connected in general perpendicular orientation to the first set of strip knives. When a vegetable product such as a potato is forced through the cutter blade assembly, the first set of knives cuts the potato into a scalloped shaped slab. The second set of knives then cuts the slab into a scoop shaped potato piece emulating a portion of a cut stalk of celery.

Owner:VANMARK EQUIP

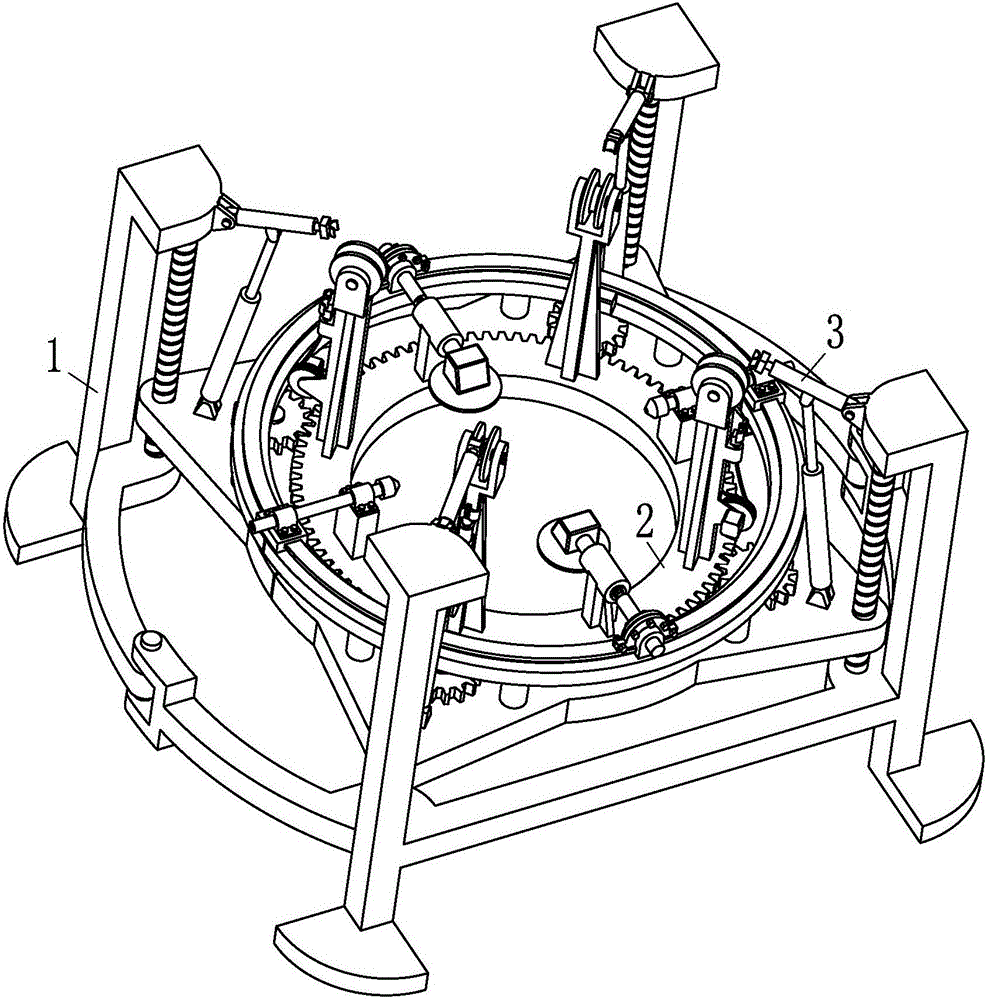

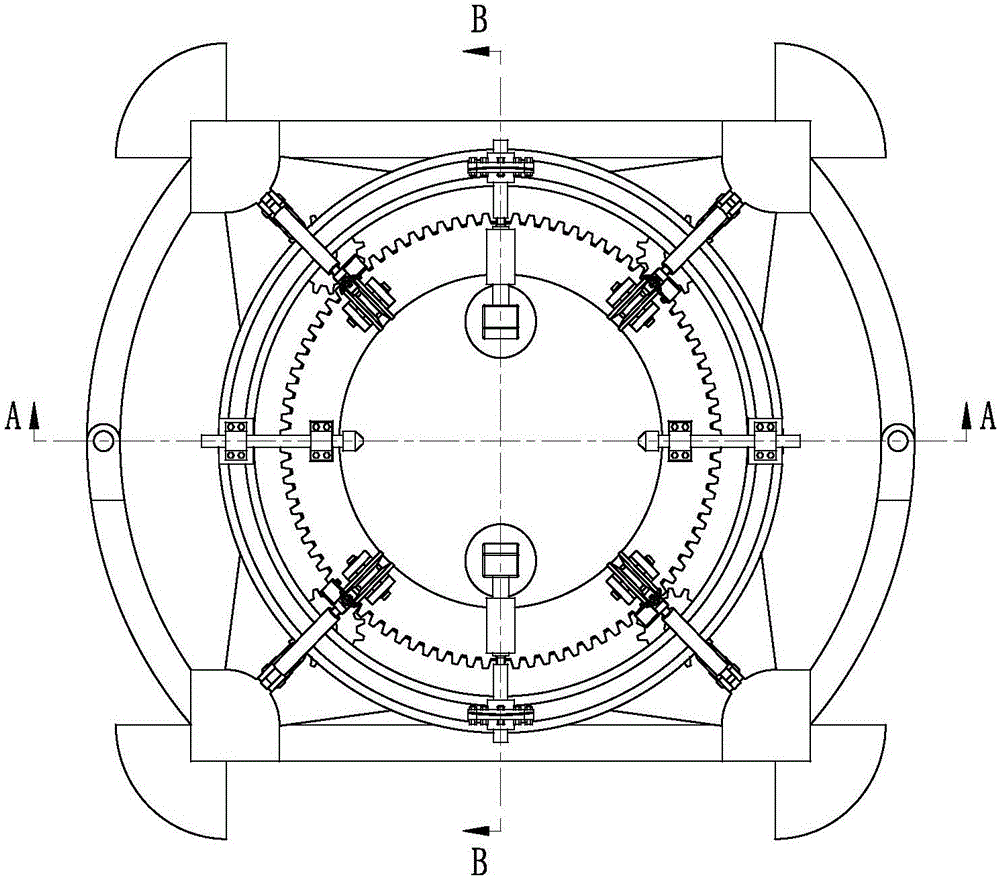

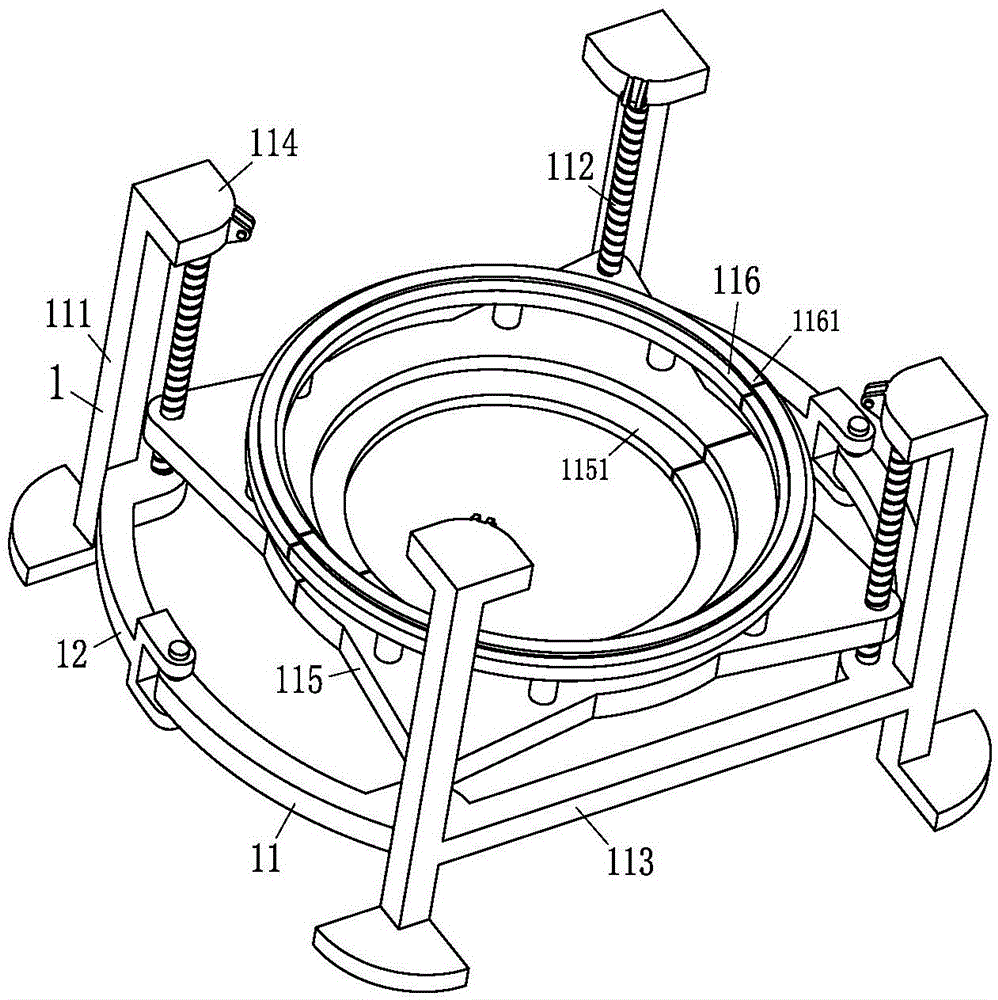

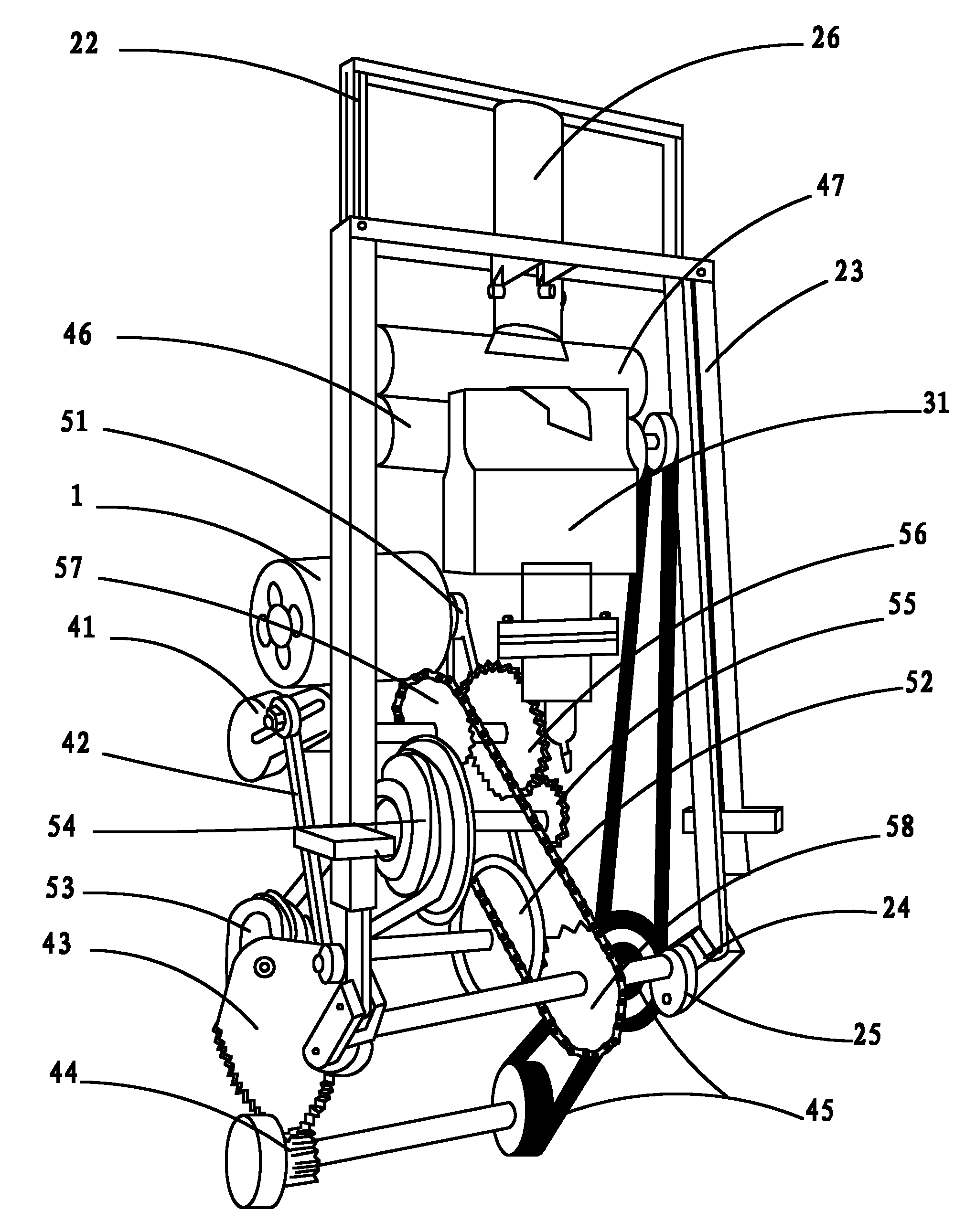

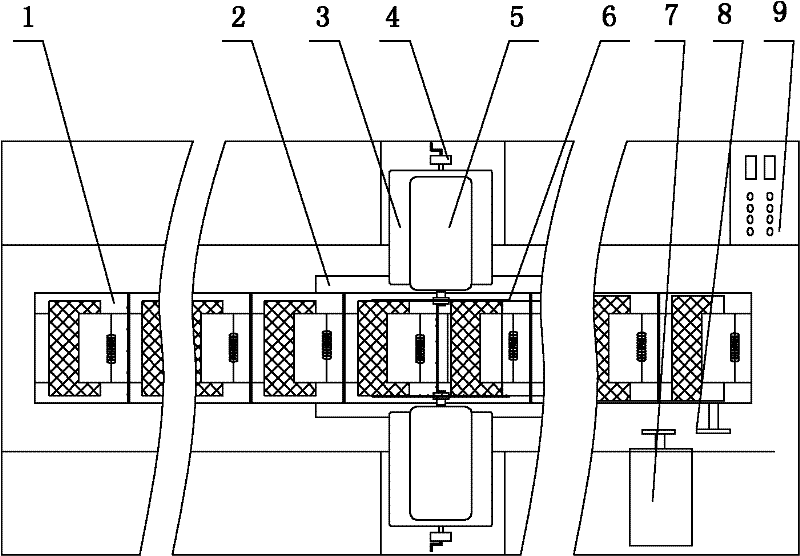

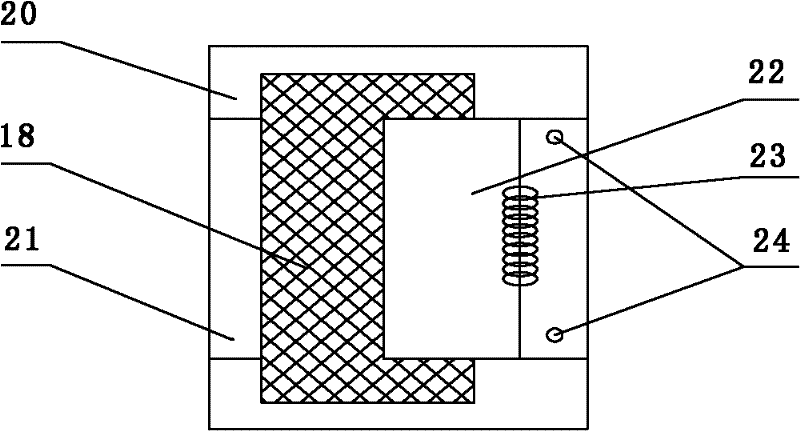

Pile head ring incision machine for high-speed railway bearing platform

The invention relates to the field of high-speed railway pier construction, in particular to a pile head ring incision machine for a high-speed railway bearing platform. The pile head ring incision machine comprises a machine body, a ring incision device and a bent terminal. The machine body comprises a front machine frame and a rear machine frame. The front machine frame and the rear machine frame each comprise a pair of struts, a pair of moving table screws, a bottom connecting plate, a top connecting plate, a moving table and a supporting sliding table. The ring incision device comprises a turntable, a turntable gear, a knife cutting device and a water cutting device. The bent terminal comprises a fixed position supporting rod, a bent guide wheel, a rope winding wheel, a rope winding motor, an embedded head block, a capturing head and a steel wire rope. The machine body can wrap a pile head in a half-and-half rotation mode. The ring incision device can perform rotary motion to use a cutting knife to cut open part of the pile head, and water cutting is utilized to completely cut open the pile head. The bent terminal is used for bending steel bars in the pile head. The pile head ring incision machine automatically treats the pile head, manpower is saved, dust is prevented from being sucked into the body, health is ensured, environmental pollution is alleviated, and the pile head ring incision machine is convenient to operate.

Owner:中交二公局第四工程有限公司

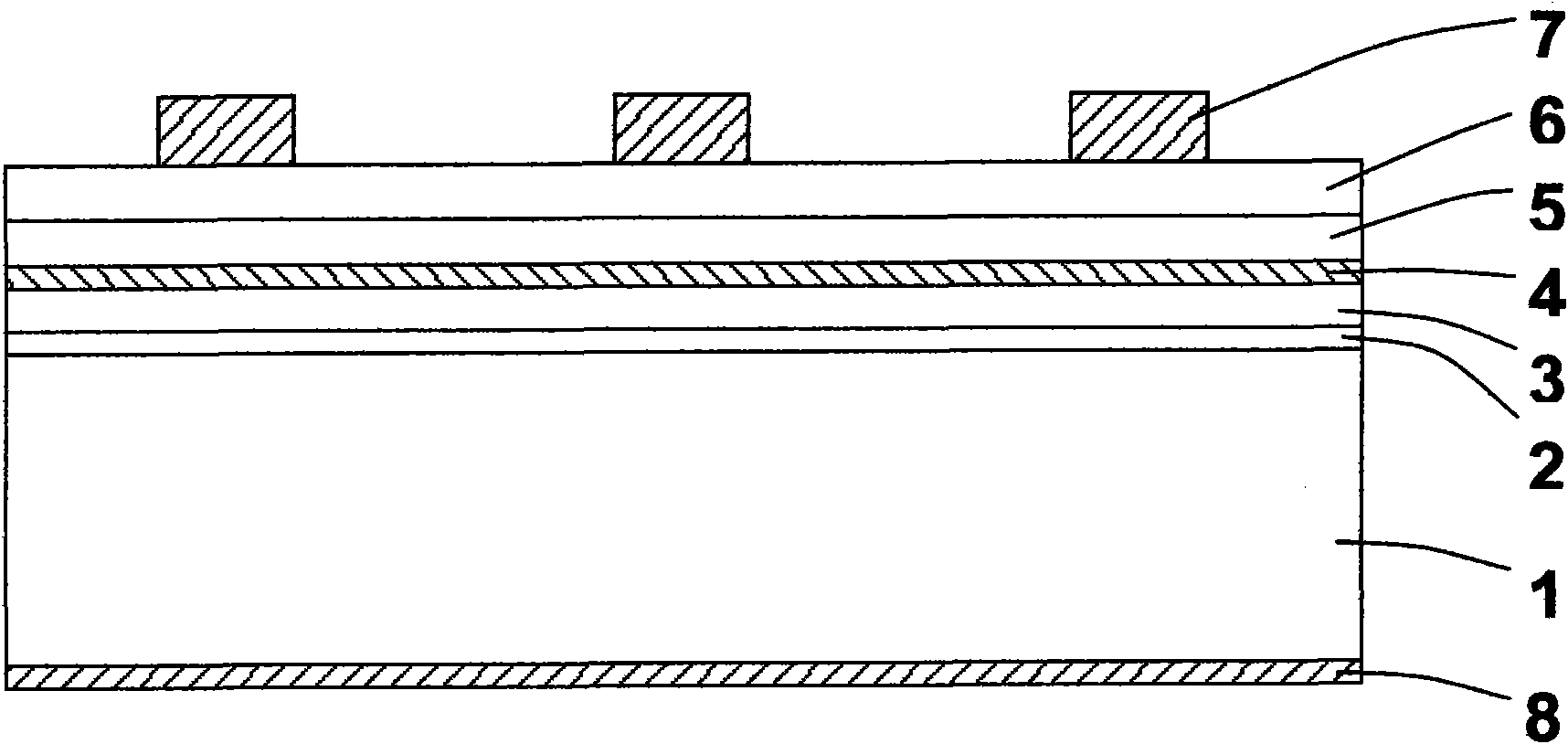

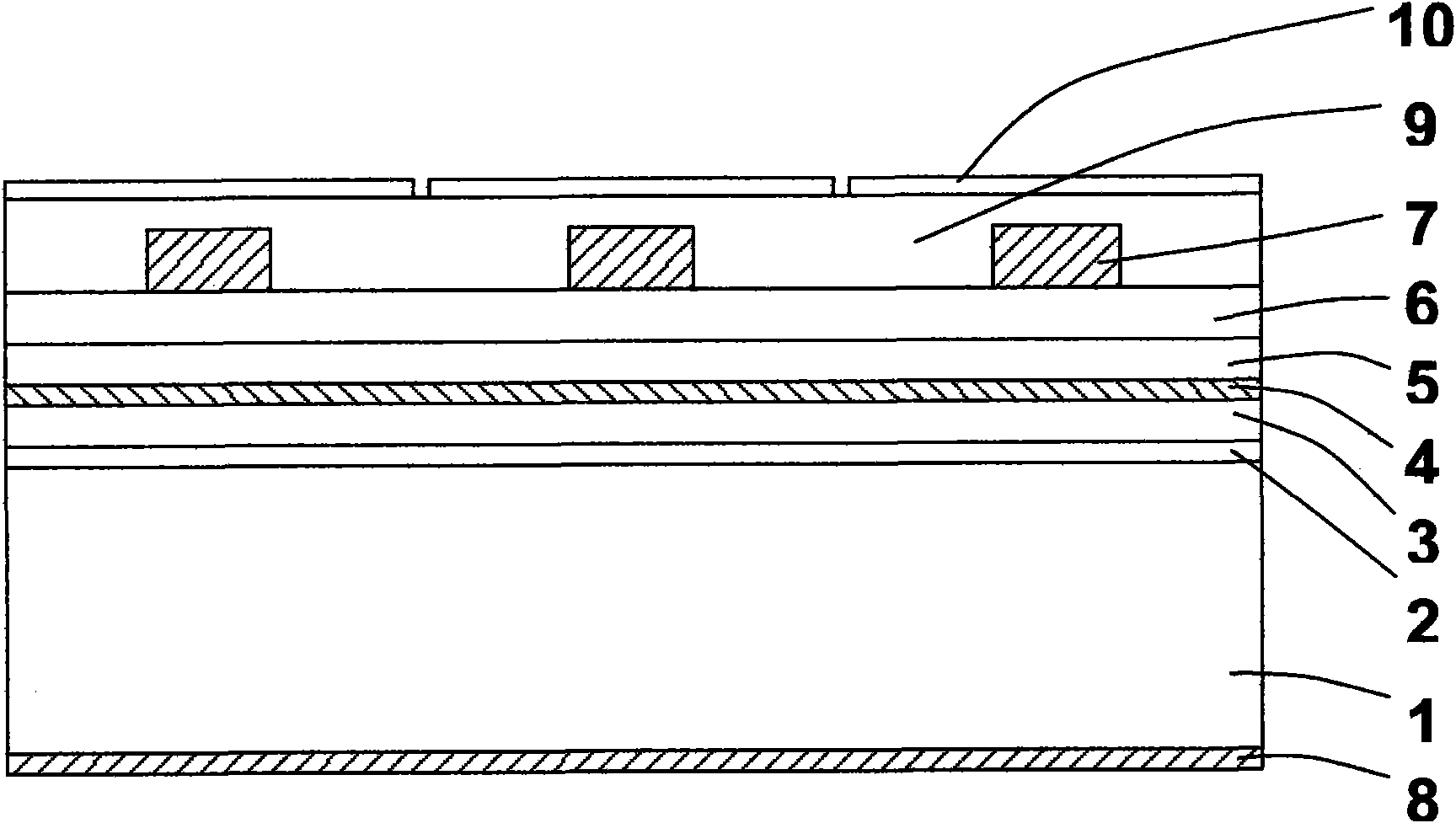

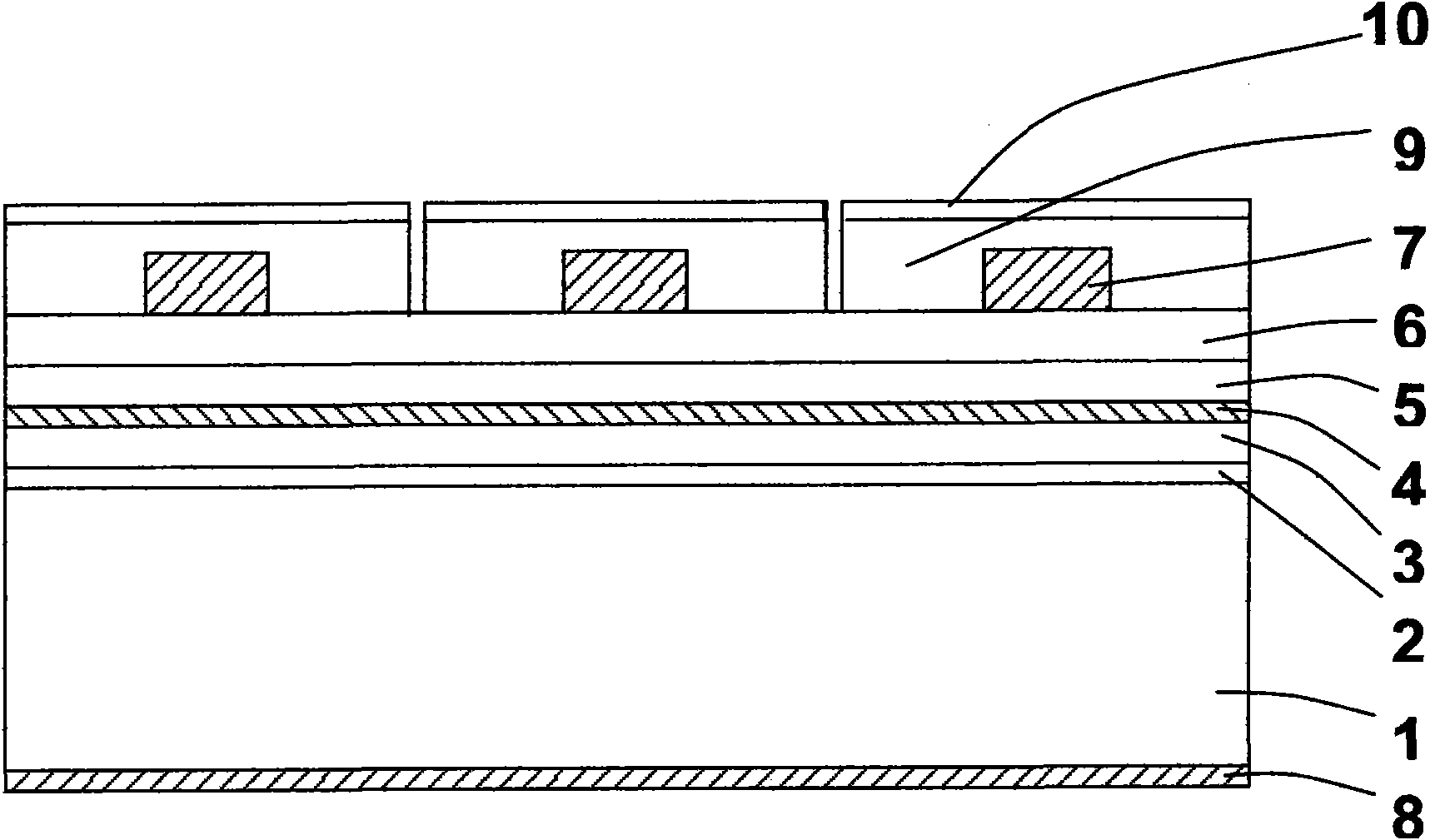

Manufacturing process for improving capacity of aluminum gallium indium phosphorus light-emitting diodes

ActiveCN101859852ALoss area reductionHigh outputSemiconductor/solid-state device manufacturingSemiconductor devicesIndiumAnisotropic etching

The invention discloses a manufacturing process for improving the capacity of aluminum gallium indium phosphorus light-emitting diodes. After finishing conventional processes, the technical combination of dry wet etching and cleavage is adopted to replace a diamond knife cutting technology to separate core particles; the dryly etched anisotropy etching can reduce crack of core particle margin, so as to reduce area loss between core particles, can improve single-chip output amount, effectively avoid electric leakage caused by the fact that the cut residual dust attaches to side face, thus improving yield of products, and effectively reducing production cost.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

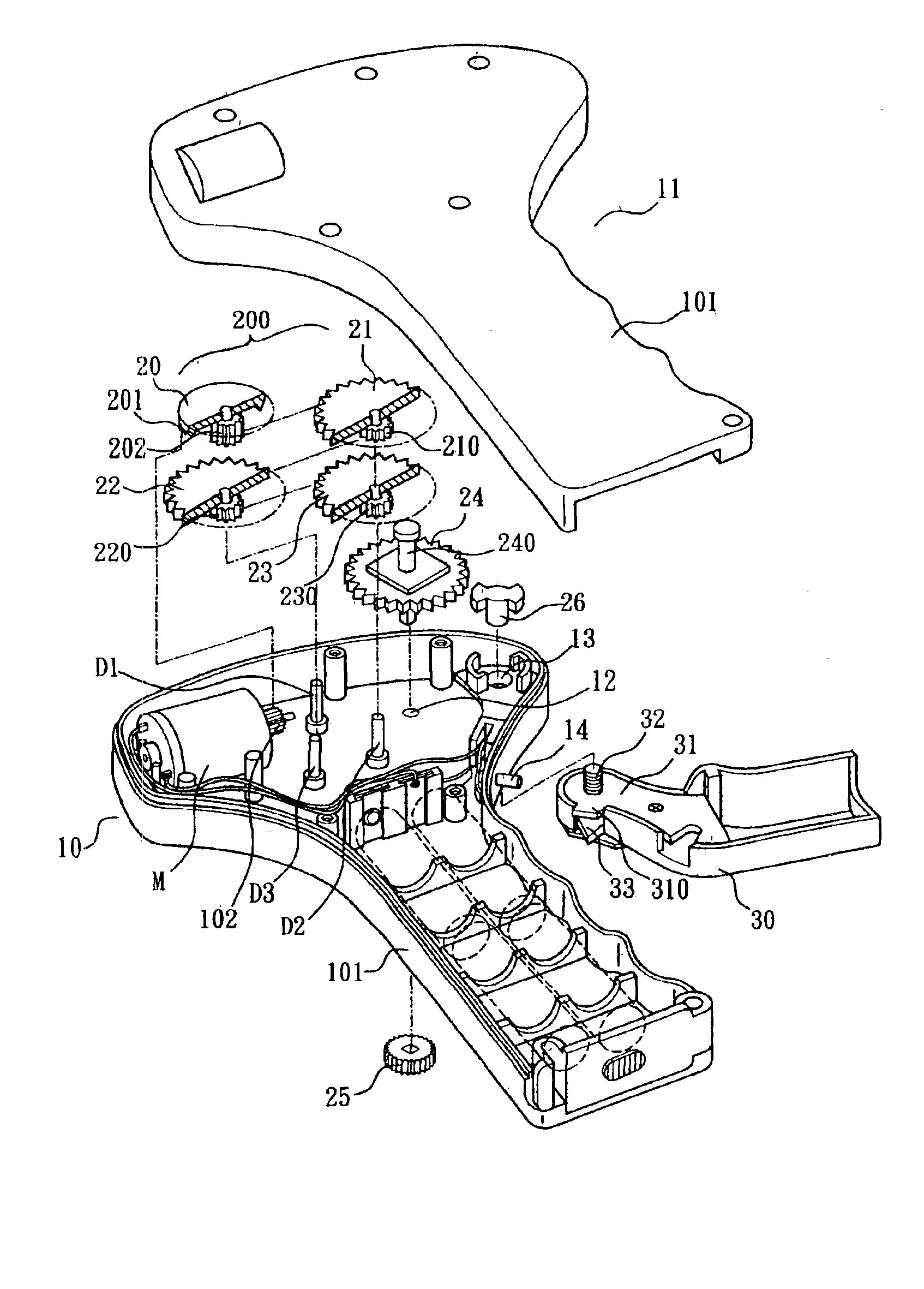

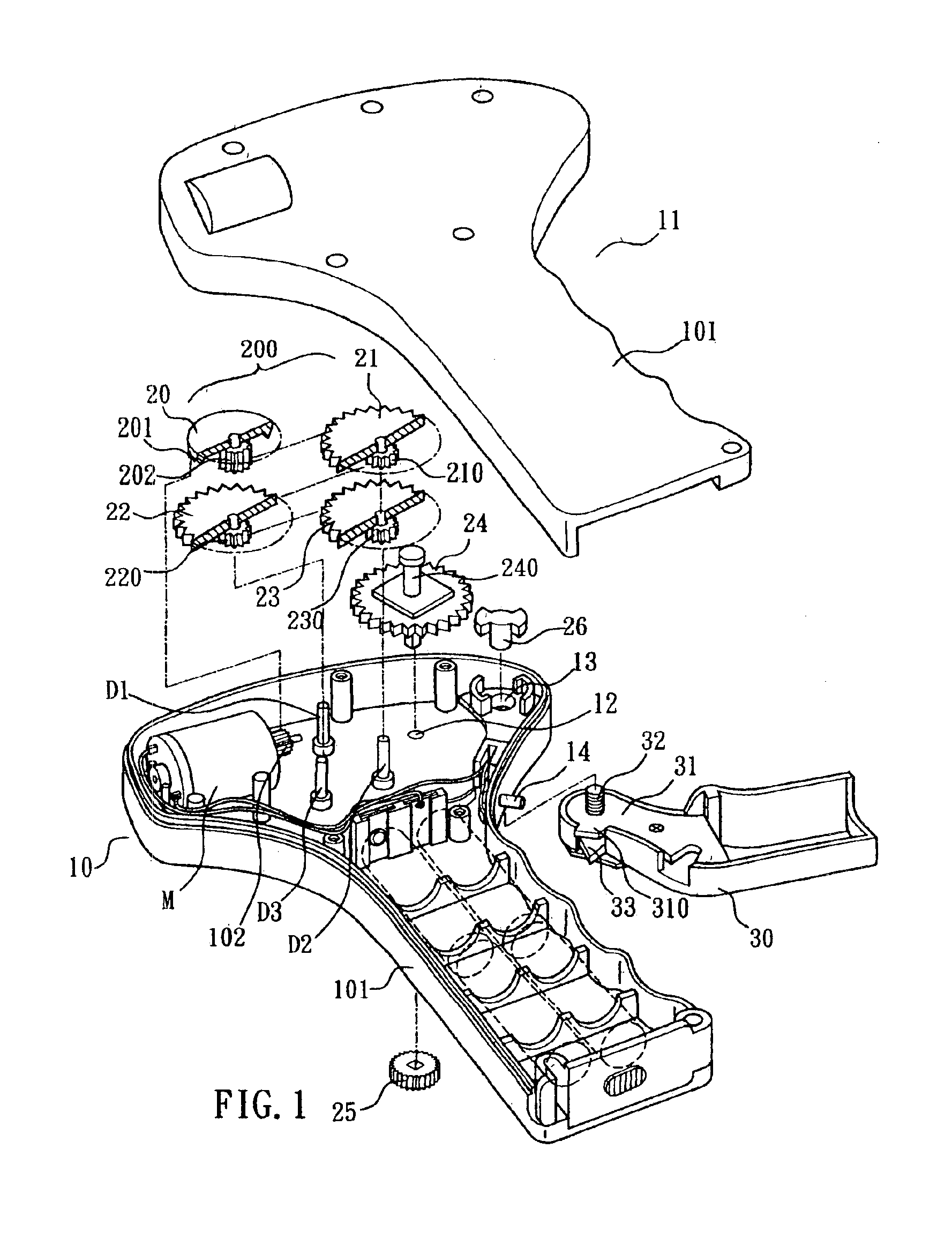

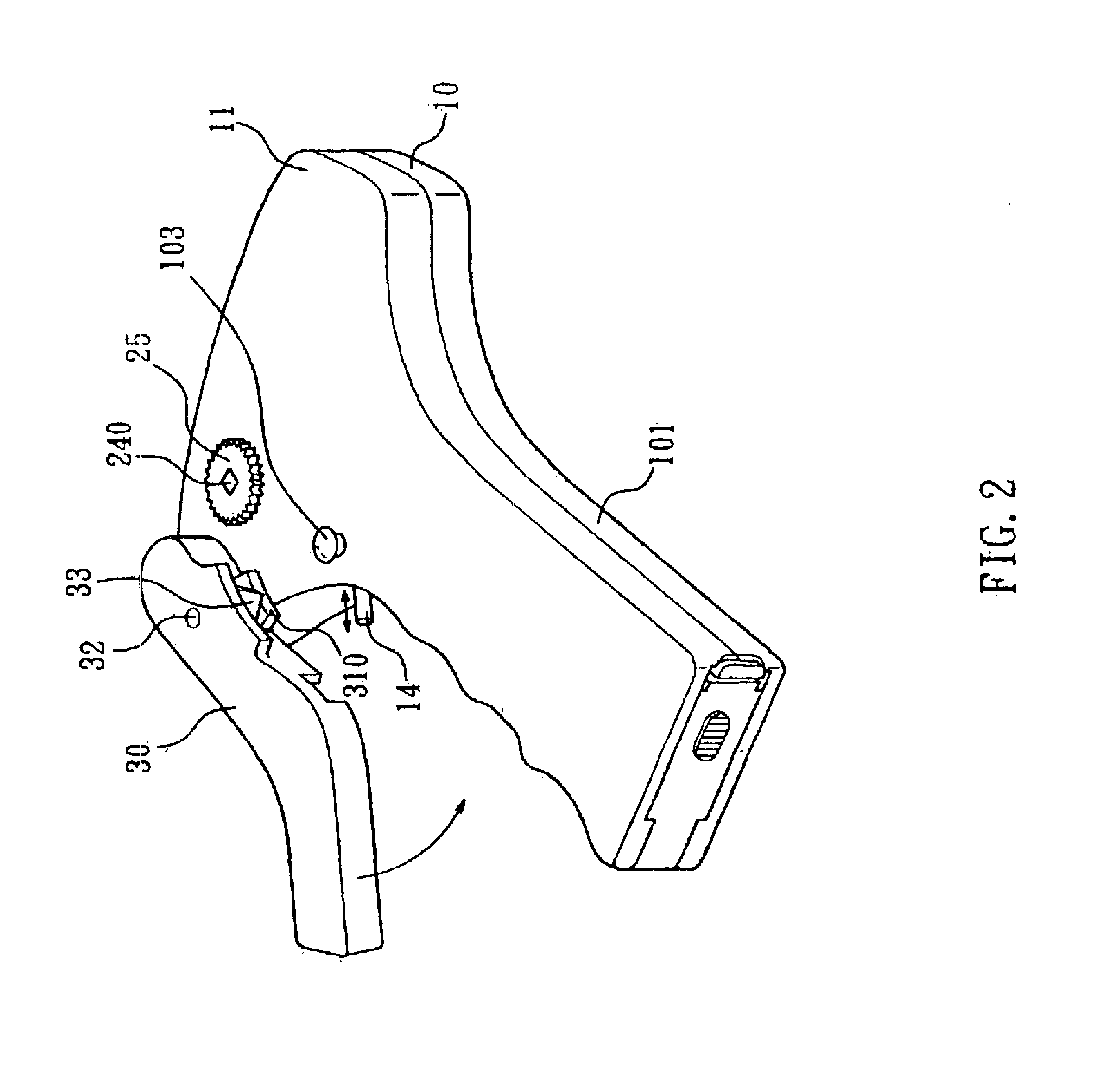

Electromotive can opener

InactiveUS6886260B1Increase torqueBottle/container closurePower operated devicesGear wheelDrive shaft

An electromotive can opener comprises a body. The body is formed by a first half and a second half. A motor, a touch switch for actuating the motor, a high twisting gear set, and a cutter handle are assembled to the body. In the high twisting gear set, a plurality of following gears and driving gear are engaged one by one and then is engaged to a driven shaft. The driven shaft is assembled with a driving gear. A knife protrudes out of a cutter handle. In operation, the knife cuts into the can and the touch switch is pressed by the cutter handle to actuate the motor and the shaft is driven. The can is driven to rotate to be cut along the periphery by the knife; and high twisting gear set formed by the plurality of gears provides a high twisting force for securing the can firmly.

Owner:LEE HUI LING

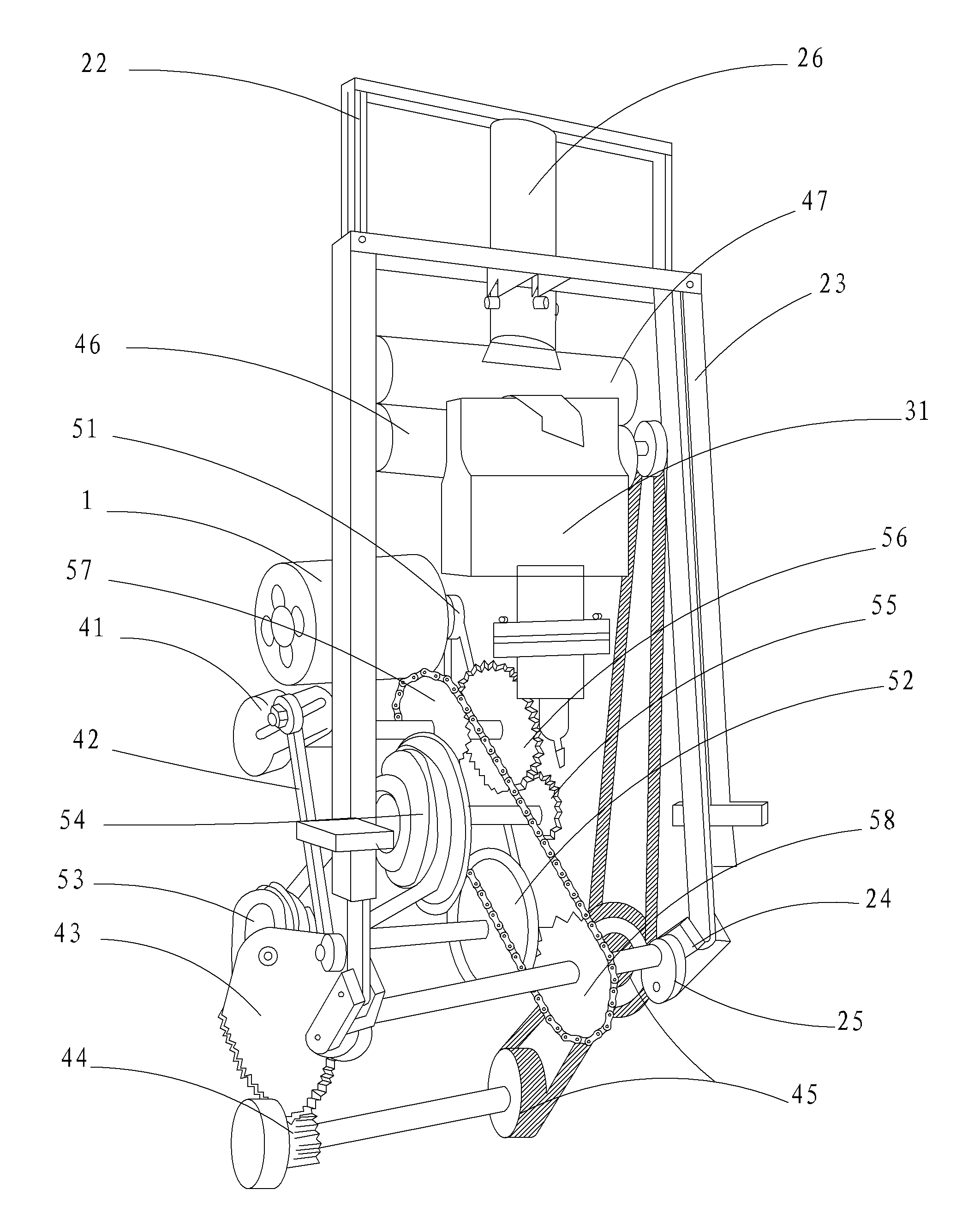

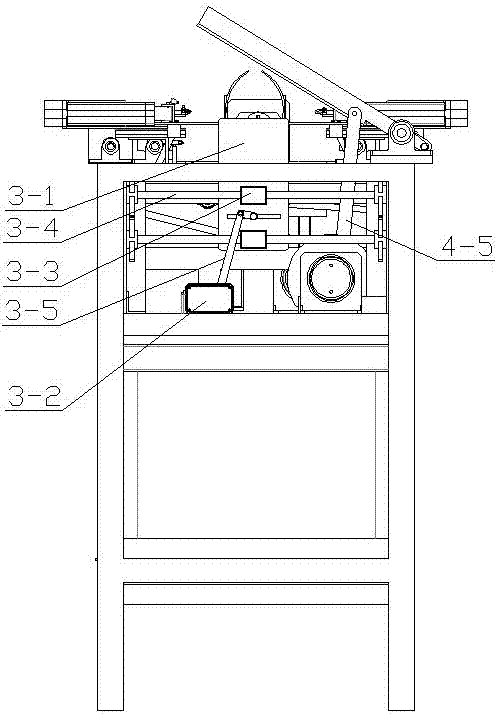

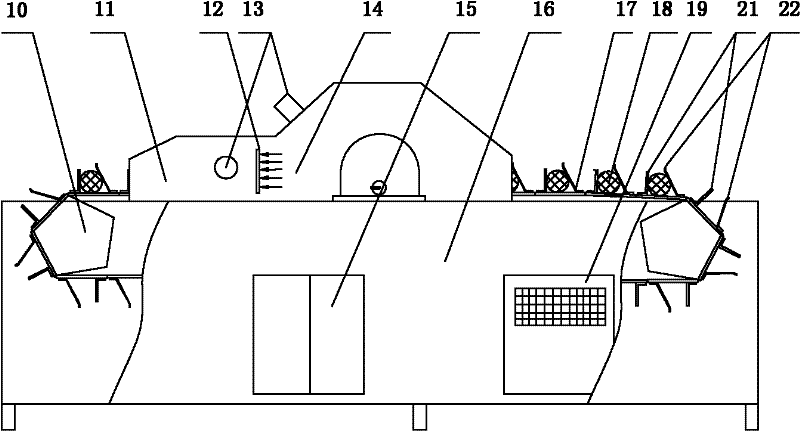

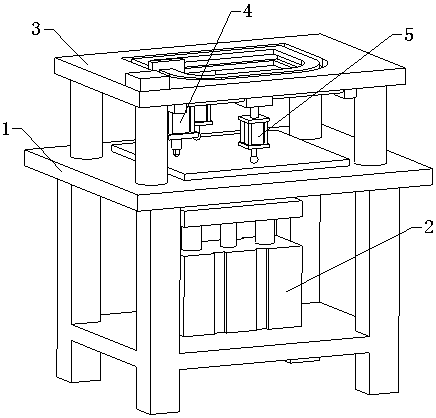

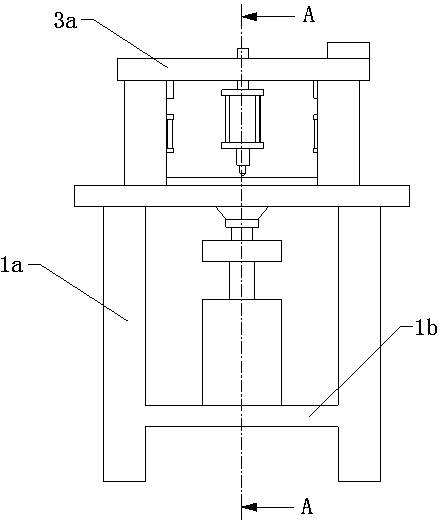

Ultrasonic tape cutting machine

ActiveCN102242496AEfficient and fast production efficiencyLow costSevering textilesArticle deliveryTransducerDrive motor

The invention discloses an ultrasonic tape cutting machine which comprises a machine frame, a driving motor, a transmission mechanism, a cutting knife device, an ultrasonic device and a feeding device; the driving motor and the transmission mechanism are arranged at the lower part of the machine frame; the cutting knife device and the ultrasonic device form a tape cutting platform to be arranged on the upper part of the machine frame; the feeding device is arranged between the knife cutting device and the ultrasonic device; and the driving motor drives the cutting knife device and the feedingdevice to work through the transmission mechanism. In the invention, as the cutting knife device and the ultrasonic device form a tape cutting platform, when an ultrasonic generator works, ultrasonicenergy can be transferred to a welding head through an ultrasonic energy transducer to produce severe vibration friction with a knife mold and produce high temperature instantaneously, thereby achieving a cutting effect, and ensuring that the cutting product have advantages of more attractiveness, more firmness and higher production efficiency; an independently innovated angle converter is adopted to solve the difficulty of changing angles, therefore, cost of manufacturing tools is saved, and an automatic multi-angle tape cutting function is realized.

Owner:海南坚强机械制造有限公司

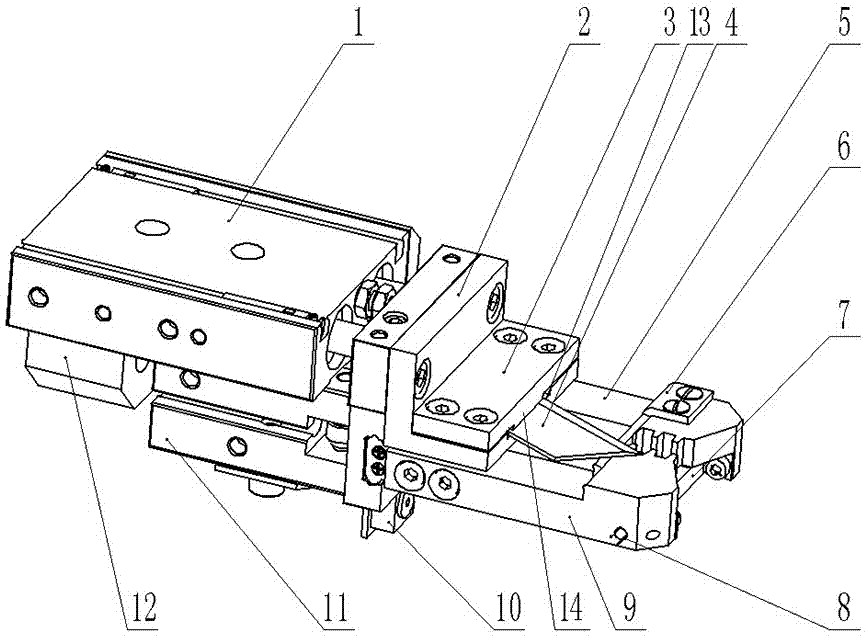

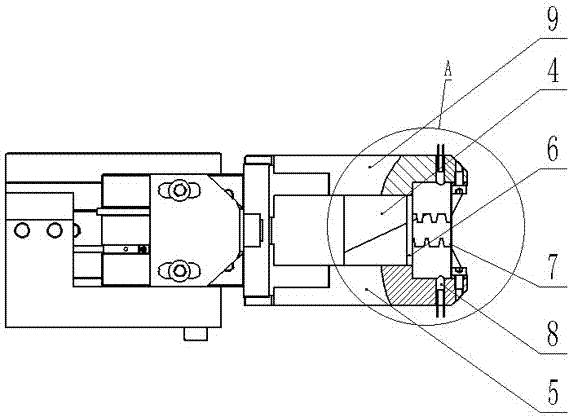

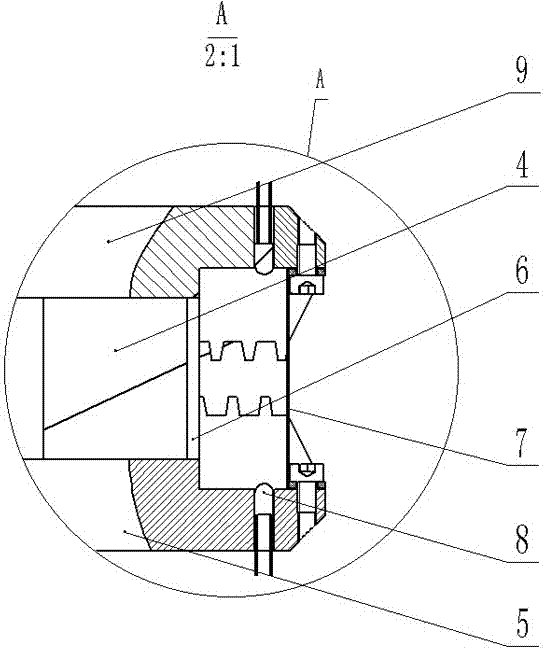

Picking robot end effector

PendingCN106863342AReduce weightReliable clampingGripping headsPicking devicesCamera imageSwitching signal

Provided is a picking robot end effector. The picking robot end effector comprises a fruit stem translation clamping assembly and a fruit stem oblique knife cutting assembly. The fruit stem translation clamping assembly comprises a translation finger cylinder, a left trapezoidal tooth finger, a right trapezoidal tooth finger, a stopping piece, an elastic black-out cloth, a biinjection optoelectronic switch, a visual sensor and a mechanical arm butt joint piece. The fruit stem oblique knife cutting assembly comprises a double-pole guide cylinder, a cutter mounting plate, a cutter pressing plate and a cutter. According to the picking robot end effector, the picking movement mode that pneumatic trapezoidal teeth clamp fruit stems and a pneumatic oblique knife extends out to cut off the fruit stems is mainly adopted; and meanwhile, camera image recognition and optoelectronic switch signals are combined to automatically match a robot to complete fruit picking operation, and the picking robot end effector has the advantages of being simple in structure, high in universality, low in component weight and free of pollution.

Owner:NANJING INST OF TECH

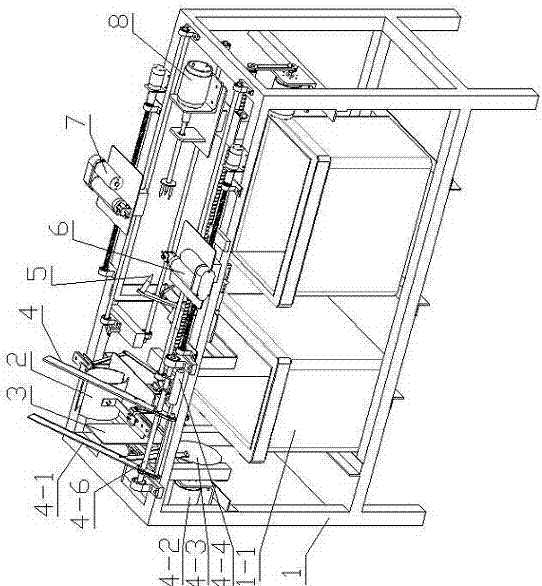

Profile-modeling pineapple peeler based on automatic detection

InactiveCN107495407AReduce fruit waste rateExquisite appearanceVegetable peelingProgramme control in sequence/logic controllersData connectionEngineering

The invention belongs to the technical field of fruit processing, in particular to a profile-modeling pineapple peeler based on automatic detection. The profile-modeling pineapple peeler is characterized in that the profile-modeling pineapple peeler comprises a clamping mechanism, a baffle mechanism and a knife-cutting mechanism; the clamping mechanism, the baffle mechanism and the knife-cutting mechanism are installed on the front part of a frame and used for cutting heads and tails; the profile-modeling pineapple peeler further comprises a centering mechanism in the middle of the frame, a peeling mechanism, a black-eye removing mechanism and a rotary mechanism at the tail of the frame; the peeling mechanism and the black-eye removing mechanism are arranged on two side edges of the frame; all mechanisms are in data connection with a controller; and the controller is connected with all motorized parts of all the mechanisms in a controllable manner. The profile-modeling pineapple peeler based on automatic detection has the following beneficial effects: heads and tails as well as black eyes of pineapples can be automatically removed and the pineapples are automatically peeled; the profile-modeling pineapple peeler is fully-automatic and peels pineapples instead of manual work; therefore, it is no longer difficult to grip and hold pineapples; labor intensity is reduced to obtain the greatest benefit; the peeler shows great safety performance and working efficiency is greatly increased; additionally, the cutting process is set according to the manner that peels and eyes are manually removed along spiral curved surfaces; overall finished pineapples are attractive in appearances; and the waste rate of fruit pulps is greatly decreased.

Owner:BINZHOU UNIV

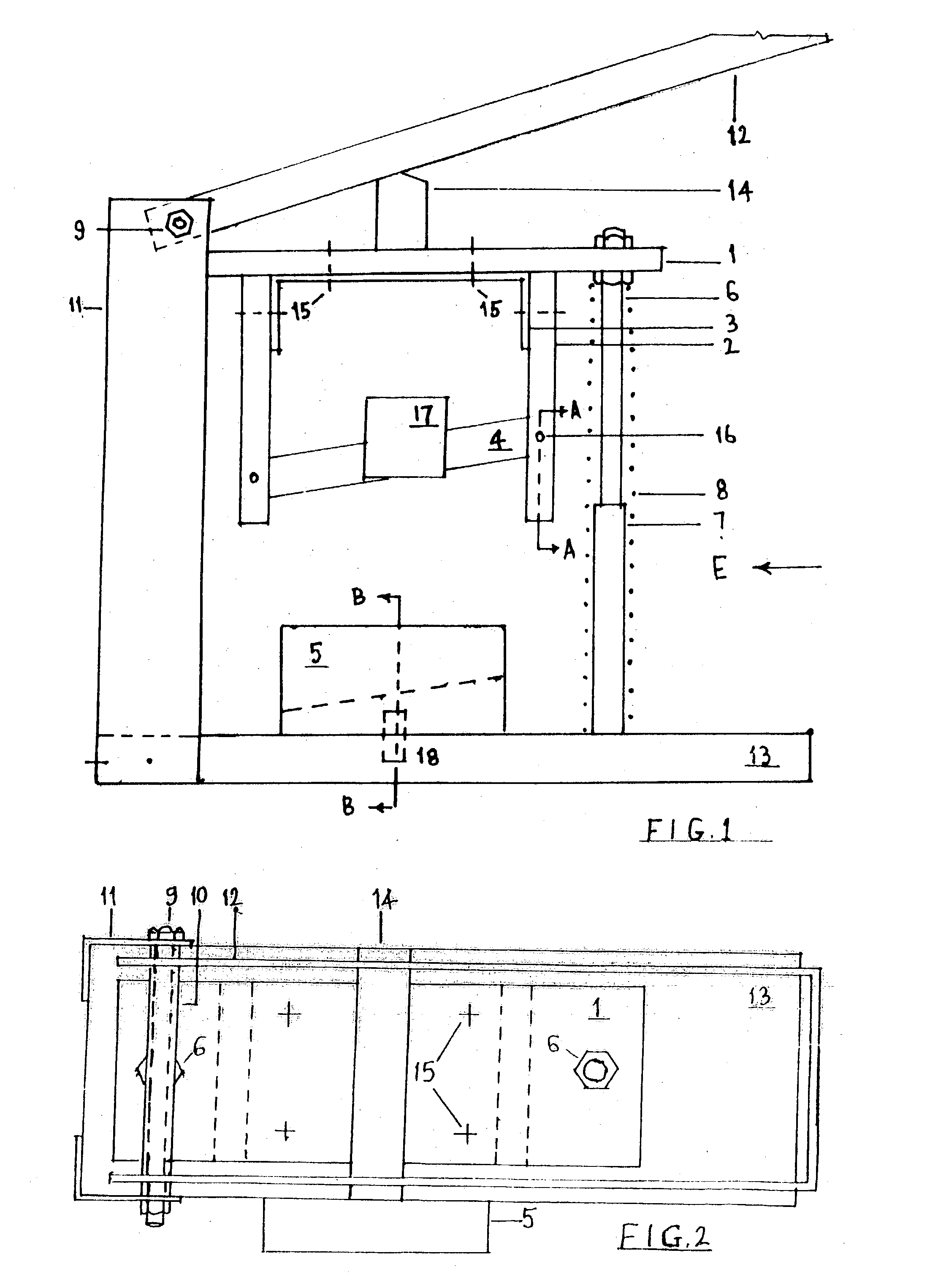

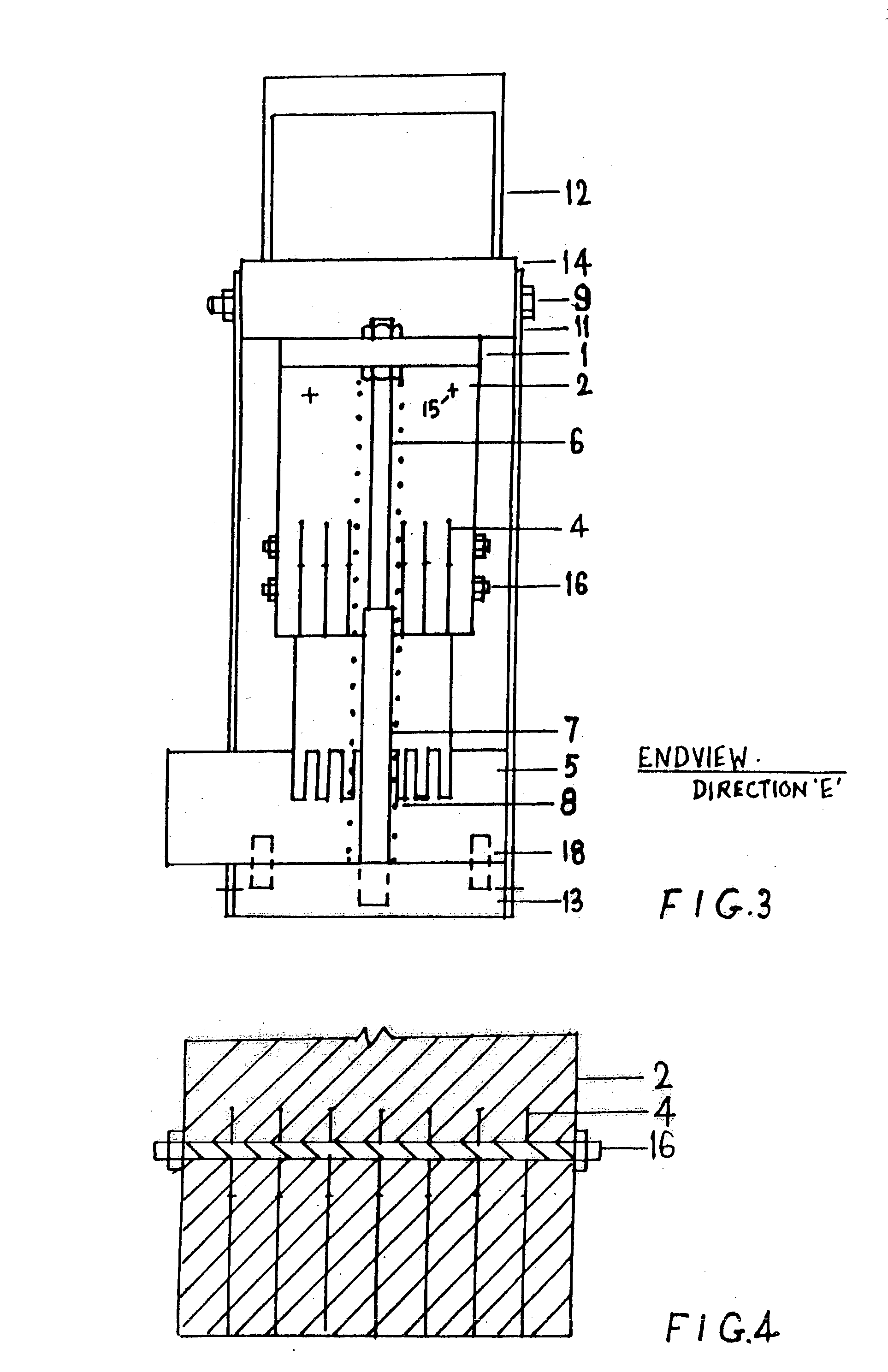

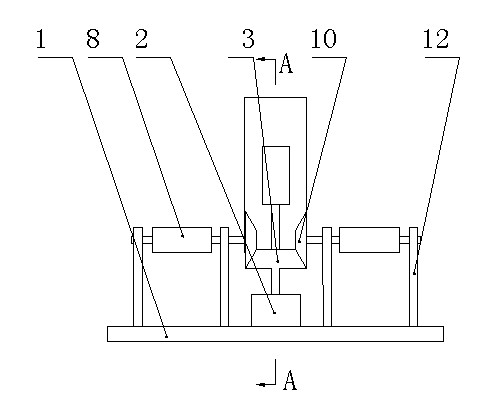

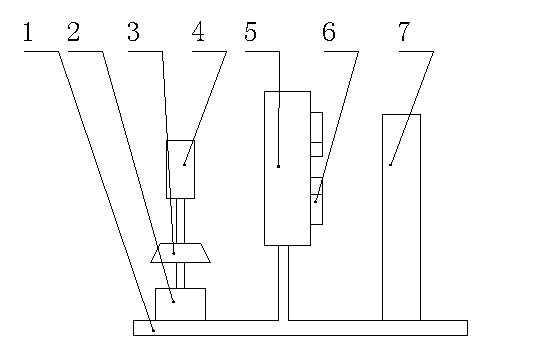

Multi knife cutting device

The invention relates basically to cutting vegetables efficiently either at home or in commercial establishments. It can also be used for other fibrous materials where practical. The aim is a low cost solution for an efficient device. The new element is that of using several knives simultaneously without holding them in the hand except in Device C. Also the vegetables are not held by hand during cutting. These are excellent safety features. Such a device is not seen in the market. The important and novel feature of this invention is the use of slotted platform to eject the cut pieces from between the knives during the cutting process. Without this feature the device becomes clumsy and unusable. One more new element is the knives do not touch the board in Devices A and B. They are maintained at a distance of 2 mm above the slot bottom. This saves the board from knife marks and reduces the damage to the knife-edge. Also the deice reduces the on hand through using several knives, because of the use of lever action in devices A and B.

Owner:BADDEPUDI GOPINATH

Cable peeling device

InactiveCN102486953AImprove recycling efficiencyReduce labor intensityBasic electric elementsElectronic waste recyclingMotor driveUltimate tensile strength

The invention discloses a cable peeling device which comprises a support, wherein a fixed plate is arranged on the support; the fixed plate is provided with two cable sheath holes and one cable core hole; the fixed plate is provided with two peeling knives; the support is provided with a motor; and a cable core drum is fixed on the output shaft of the motor. In the cable peeling device, the two peeling knives cut the cable sheath into two parts; two parts of cable sheath penetrate through the cable sheath holes; the cable core passes through the cable core hole; the motor drives the cable core drum to rotate to roll up the cable core; and meanwhile, a waste cable is dragged to move forward. The cable peeling device has the advantages of high cable core recovery rate and low labor intensity.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER

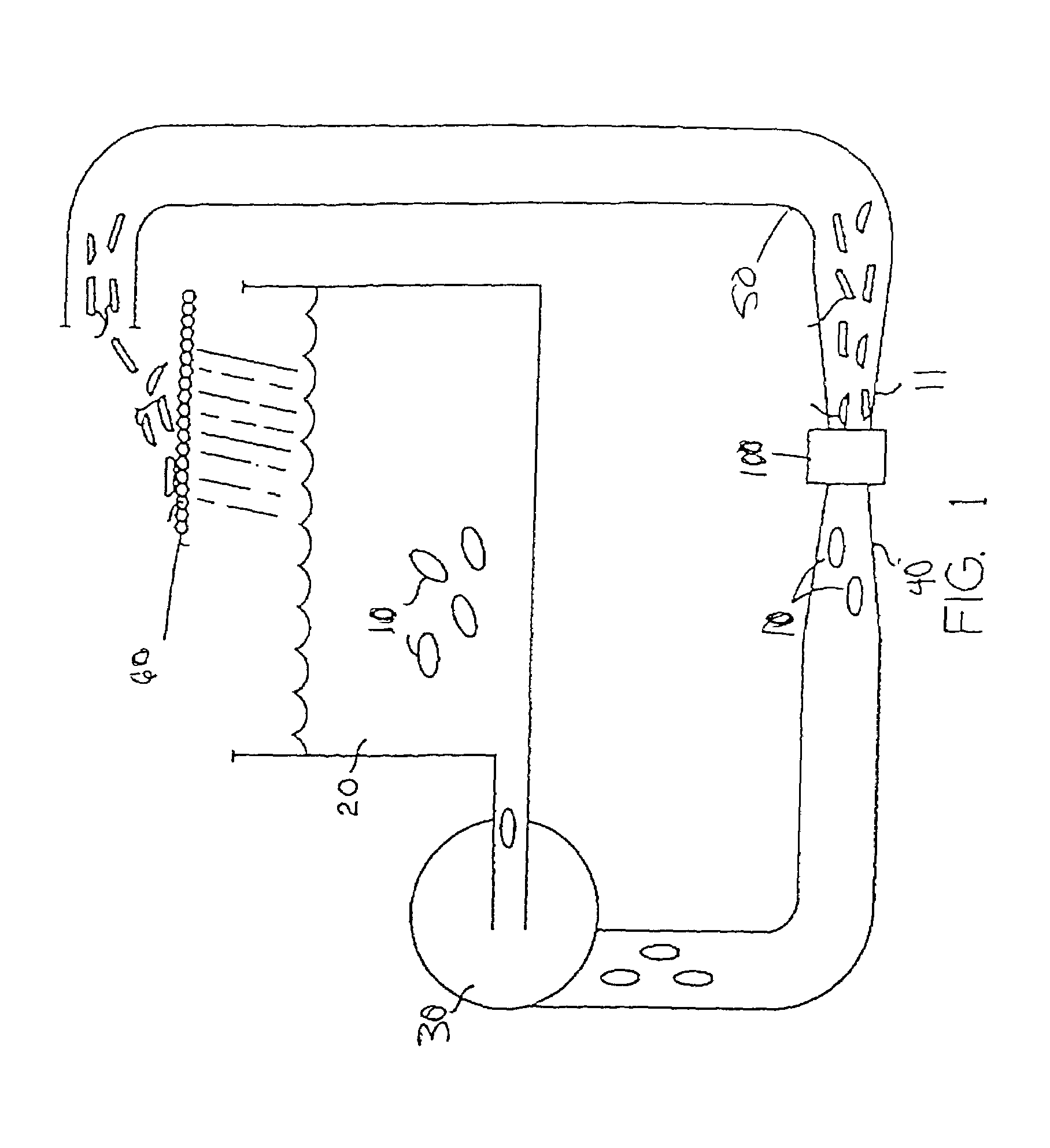

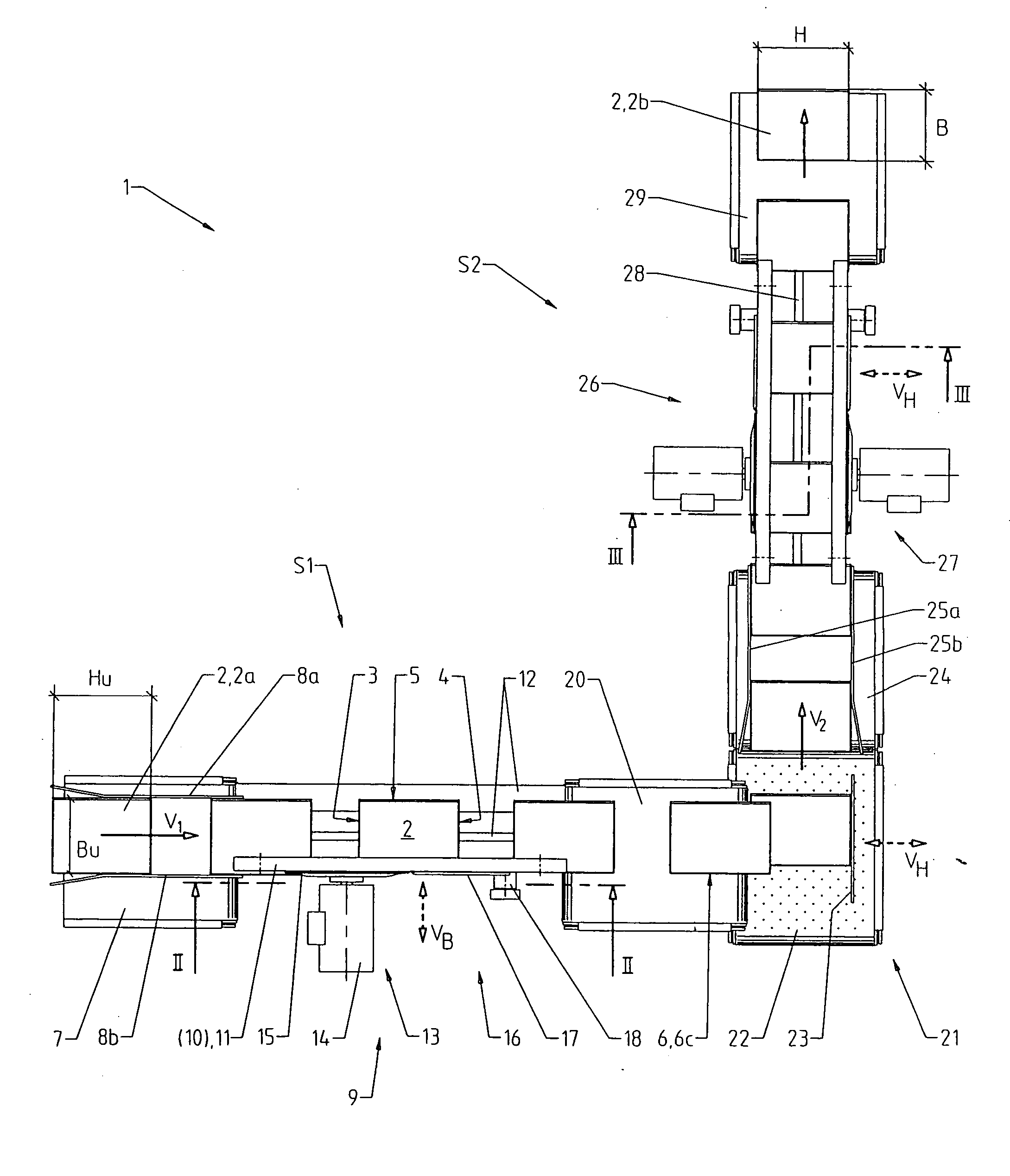

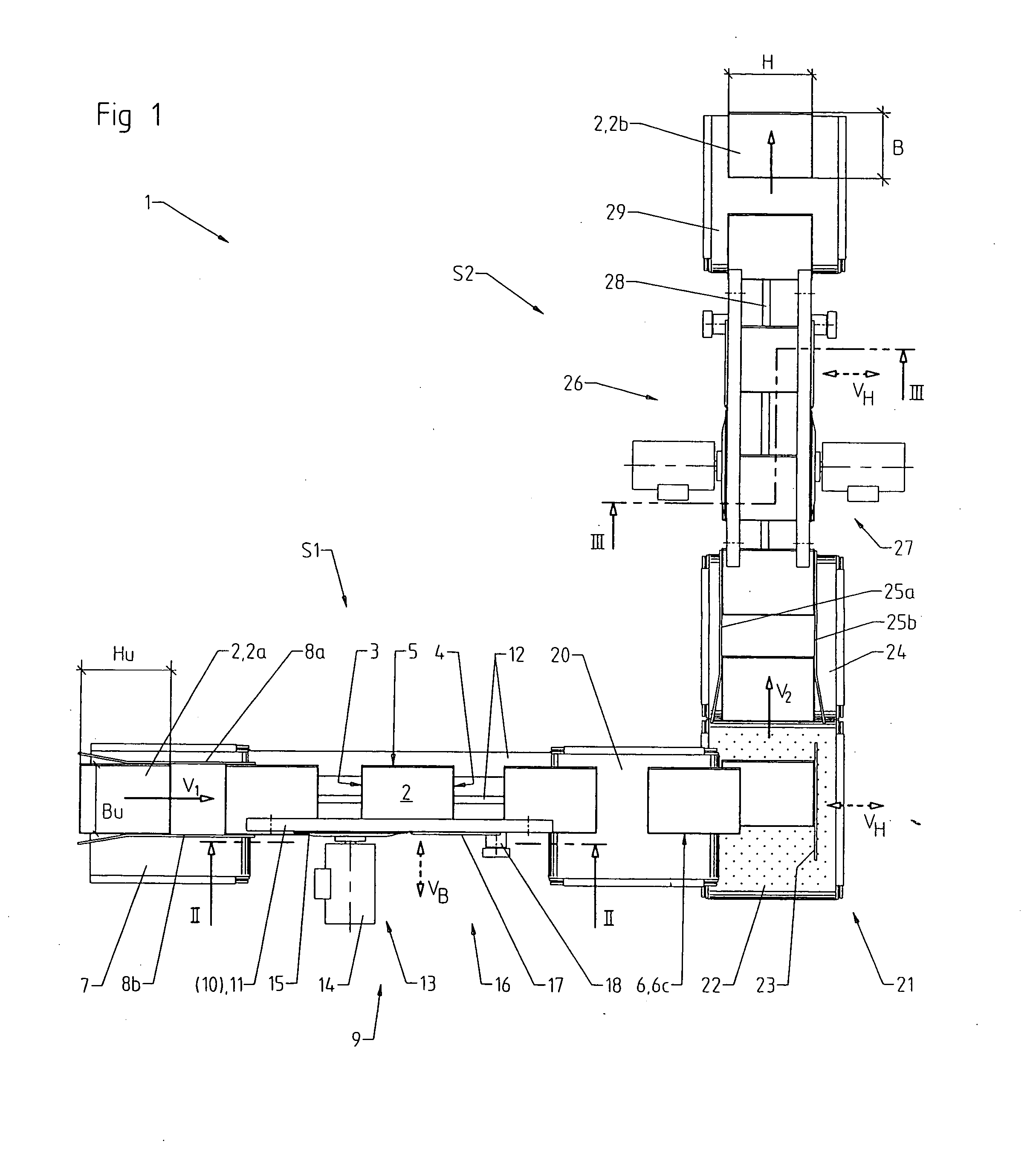

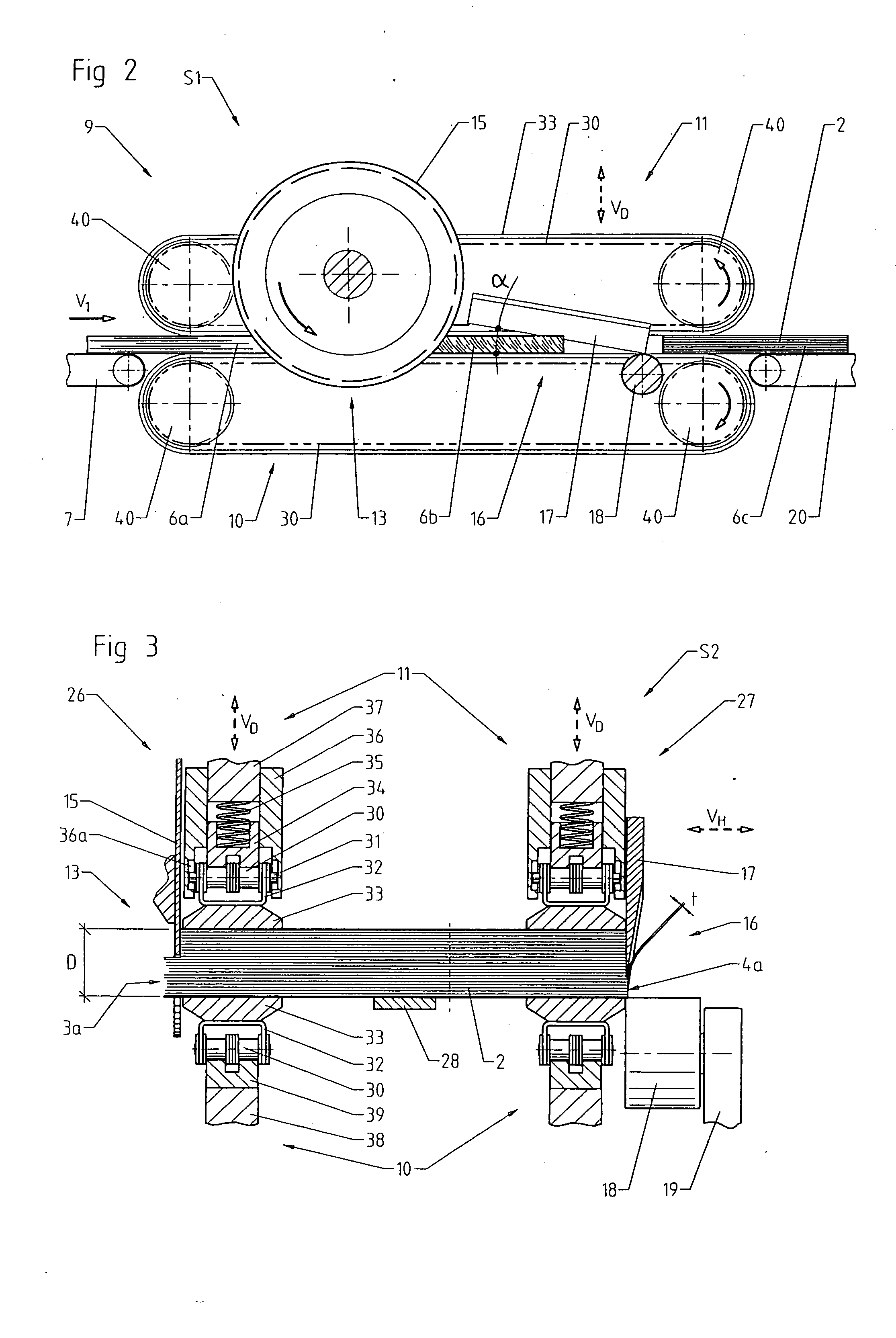

Method and apparatus for trimming printed products

InactiveUS20050066781A1Quality improvementHigh cutting rateCircular sawsMetal working apparatusKnife cutsEngineering

For a method for trimming printed products 2, such as book blocks, brochures and the like with the aid of a tractive knife cut, in which the printed products 2 are moved against a stationary knife 17, it is proposed that the cutting process takes place in two successive operations, the edge of the printed product 2 to be trimmed being cut off in a first operation by a precut 13 extending close to the final trimming dimension and being finally trimmed in a second operation by a smoothing or final trimming cut 16 by means of the tractive knife cut. The apparatus for implementing the method includes a conveying system 10, 11 for retaining and guiding the printed products 2 in a clamped state at least during the cutting process, and a first cutting station 13 with a rotationally driven cutting tool 15 for precutting and a second cutting station 16 with a stationary knife 17 for smooth final trimming. The two cutting stations 13, 16 and the conveying system 10, 11 are combined in a compact cutting module 9, 26, 27.

Owner:KOLBUS

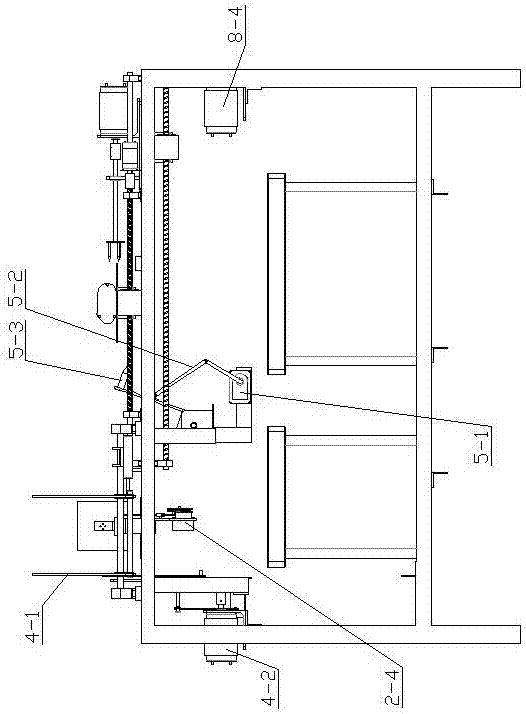

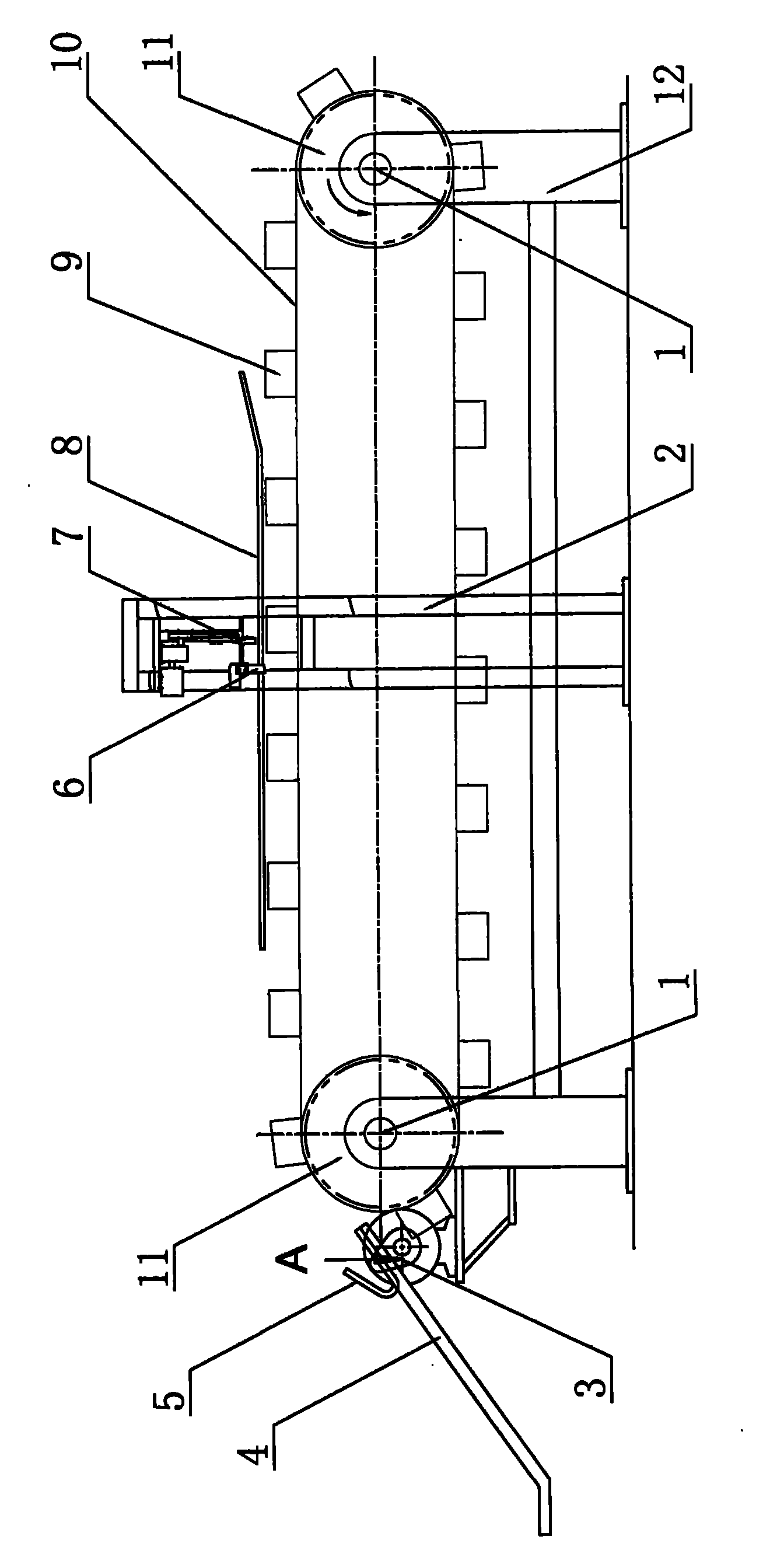

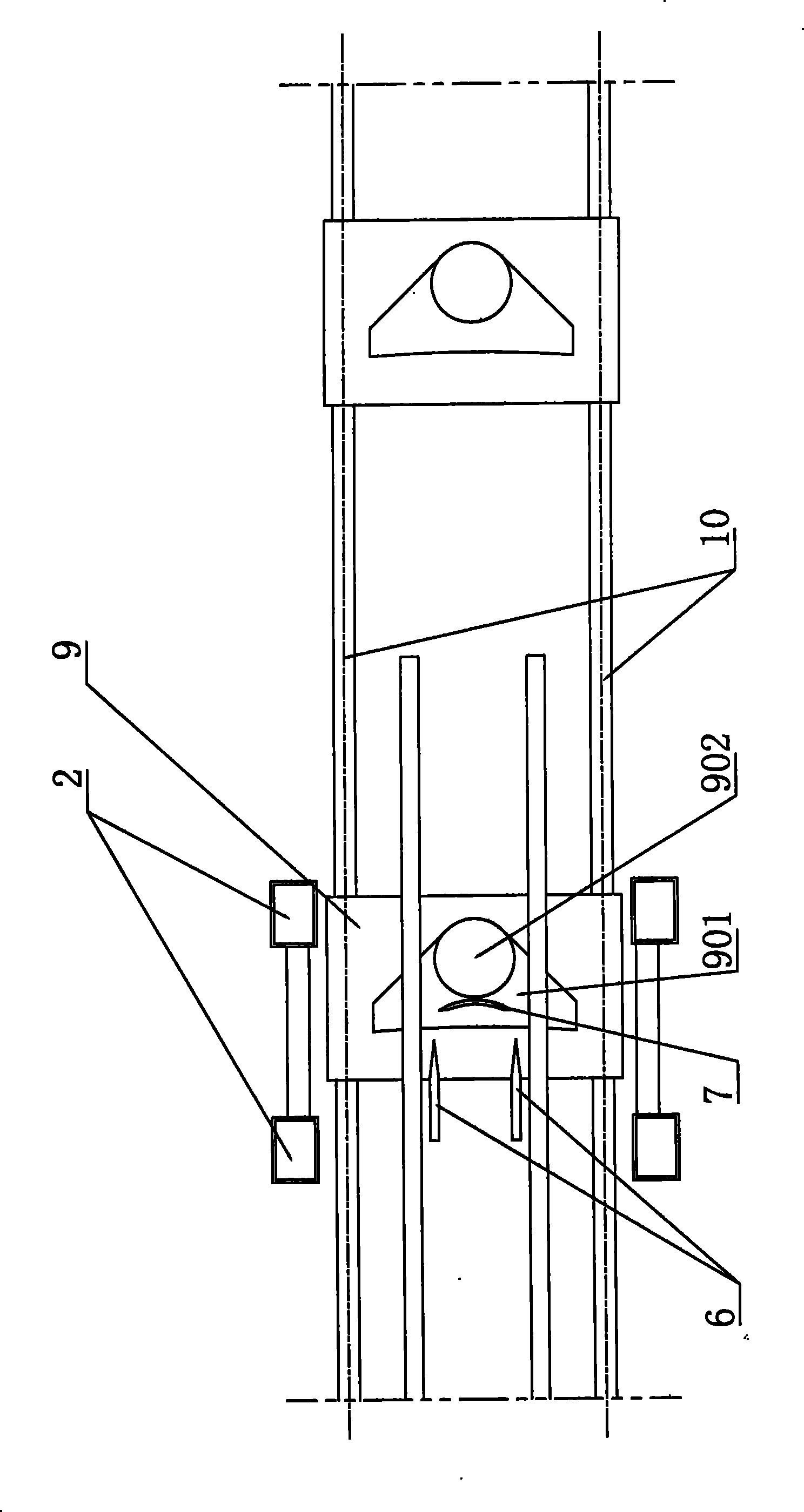

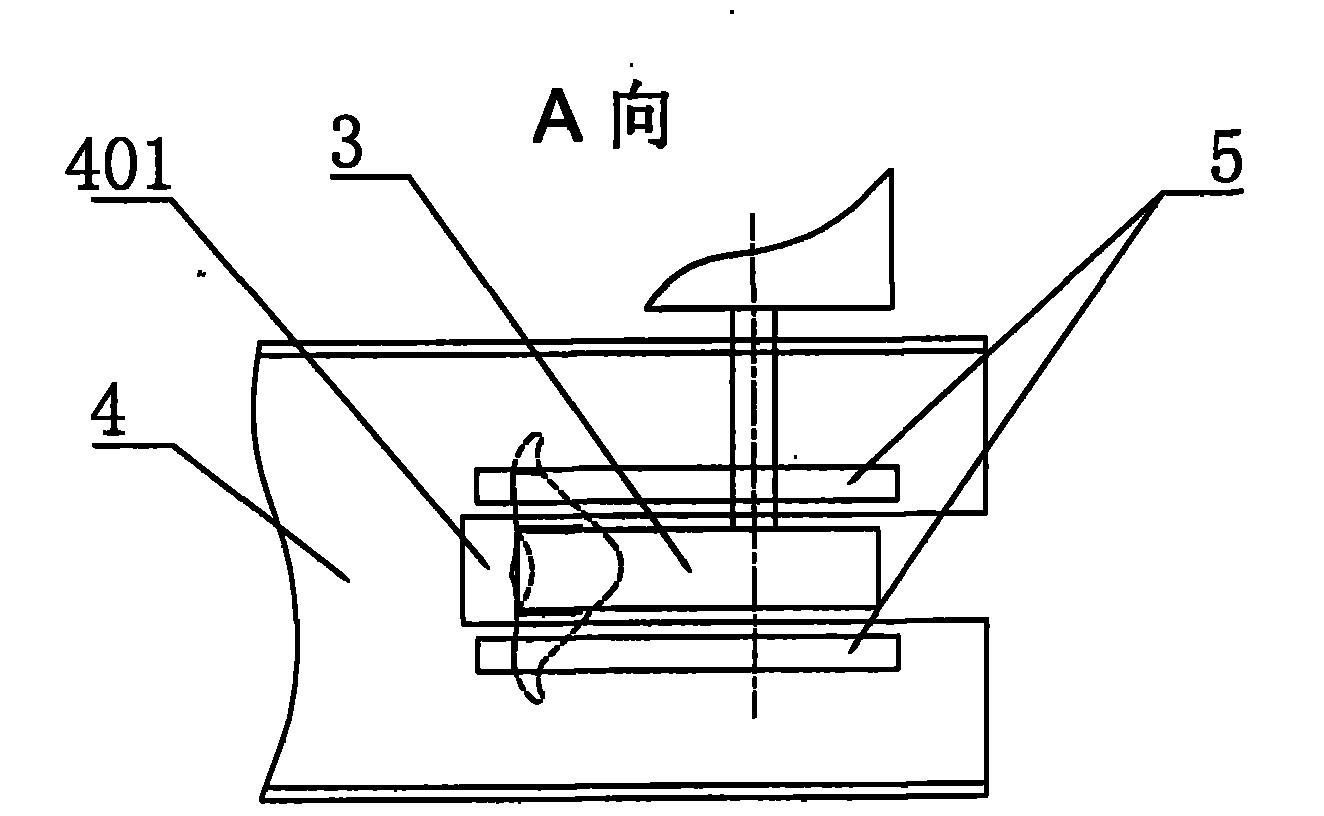

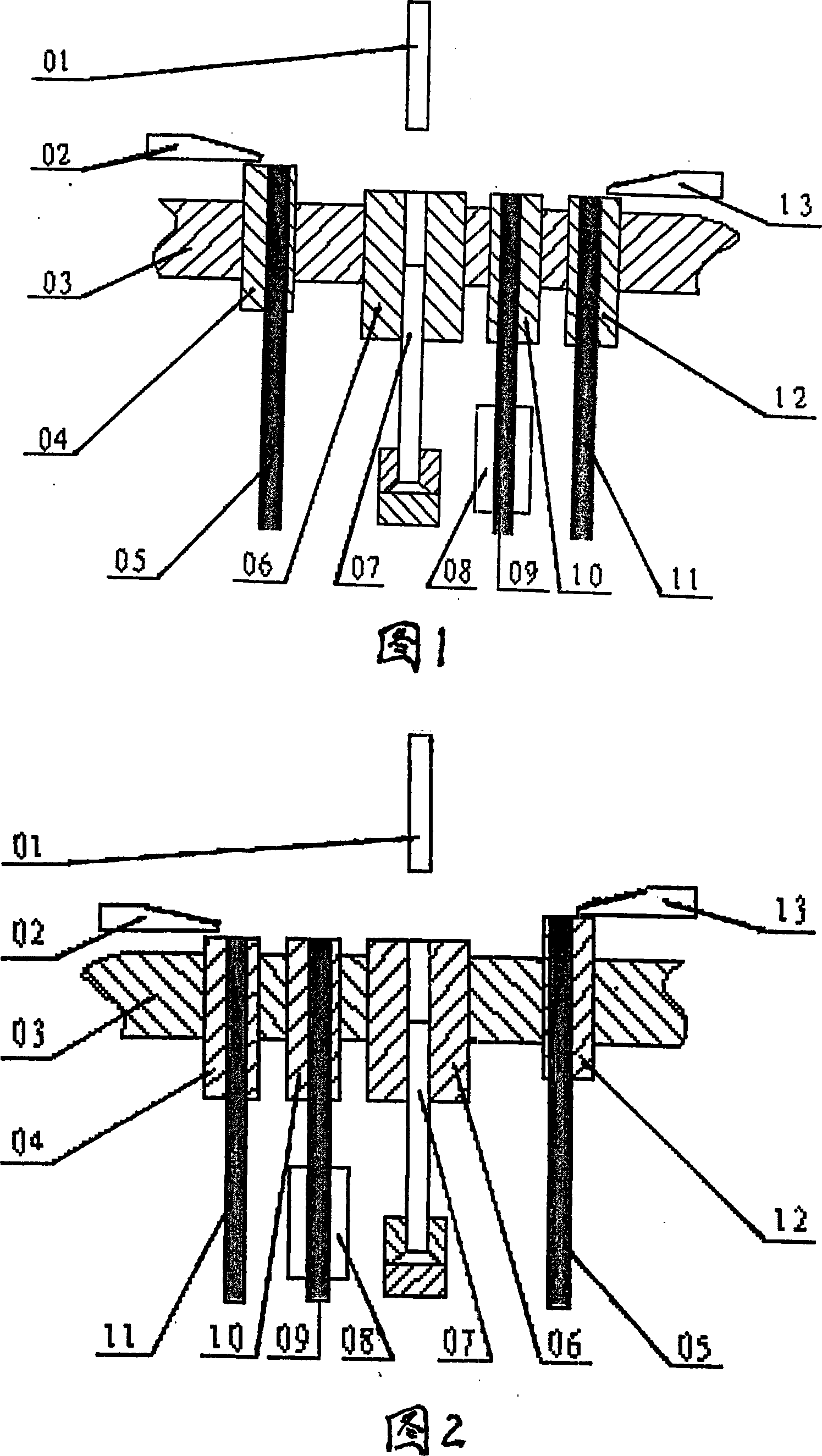

Double-knife continuous cutting machine for honeycomb ceramic dry green body

ActiveCN102241060AImprove dust removal efficiencyHigh precisionCeramic shaping apparatusWorking accessoriesControl systemKnife cuts

The invention relates to a double-knife continuous cutting device for a honeycomb ceramic dry green body, which comprises a green body spring clamping plate, elastic clamps, a conveying track, a positioning slideway and an automatic dedusting device, wherein the spring clamping plate is fixed on the elastic clamps, and 10-32 elastic clamps are connected into the closed conveying track through dowel pins; the closed track can move under the drive action of a pentagonal rolling body and a speed-regulating motor, and the positioning slideway is positioned in the double-knife cutting position of the green body; the automatic dedusting device is arranged behind the cutting position, and the automatic dedusting device comprises a dedusting cover, an air inlet hole, an air blowing pipe, a dust suction port and an external deduster; and compressed air is connected with the air inlet hole and the air blowing pipe through a pipeline to blow off dust, and the dust suction port is further connected with the external deduster. The double-knife cutting device adopts a double-knife structure to enable two ends of the green body to be synchronously cut, and the precision is high; the automatic dedusting device comprises the dedusting cover, the dust suction port, the air inlet hole and the external deduster, thereby removing the dust generated in the cutting process and simultaneously completing dust suction and blowing off of the dust; and the control system is mainly used for controlling cutting and the transmission speed of the track, and the operation is simple and convenient.

Owner:NANJING KERUI SPECIAL CERAMICS +1

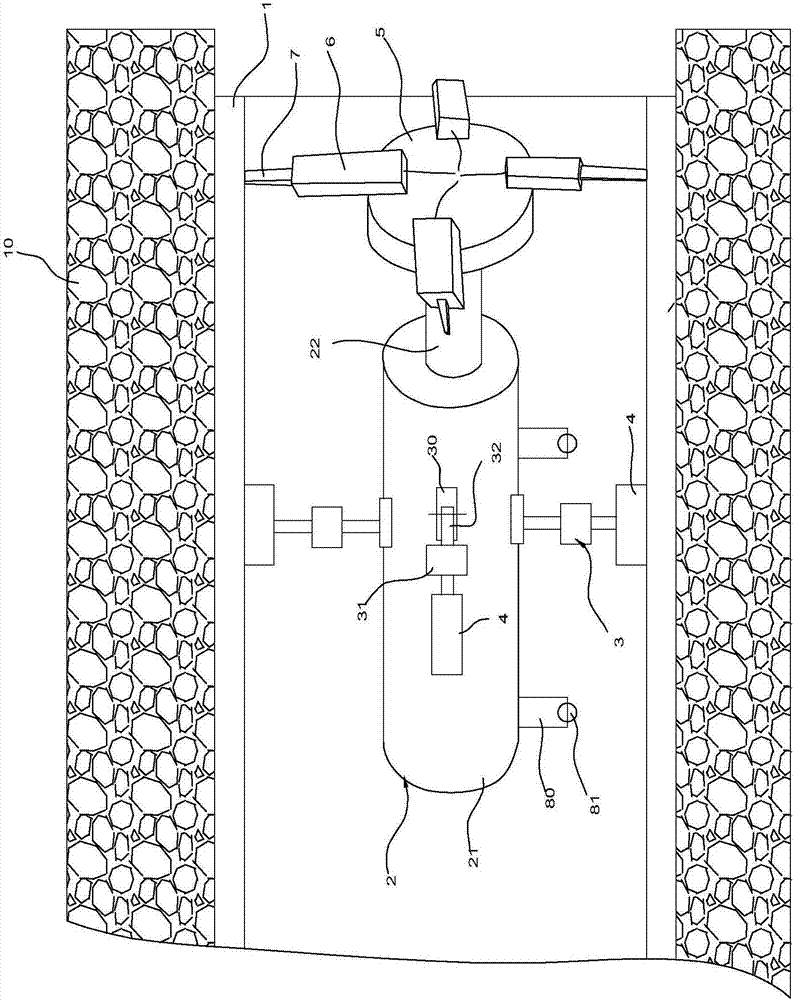

Buried pipe cutting device and cutting method thereof

The invention discloses a buried pipe cutting device and a cutting method thereof. The buried pipe cutting device comprises a driving motor. The outer wall of the driving motor is provided with supporting cylinders, rolling wheels and air injection assemblies. An output shaft of the driving motor is provided with a mounting plate, and the mounting plate is provided with a plurality of cutting cylinders. The ends of piston rods of the cutting cylinders are provided with cutting knives. The cutting method includes the following steps that a controller controls the air injection assemblies to move along a buried pipe; after the buried pipe arrives at a position, the buried pipe cutting device is stopped, the controller controls piston rods of the supporting cylinders to be stretched out, supporting blocks on the piston rods act on the inner wall of the buried pipe, the driving motor is strutted up, and the buried pipe cutting device is fixedly supported at the center of the buried pipe; the controller controls the piston rods of the cutting cylinders to be stretched out, and the cutting knives extend to be tightly pressed onto the inner side wall of the buried pipe; and the driving motor rotates, and the cutting knives cut the buried pipe from the inner wall of the buried pipe.

Owner:覃小倩

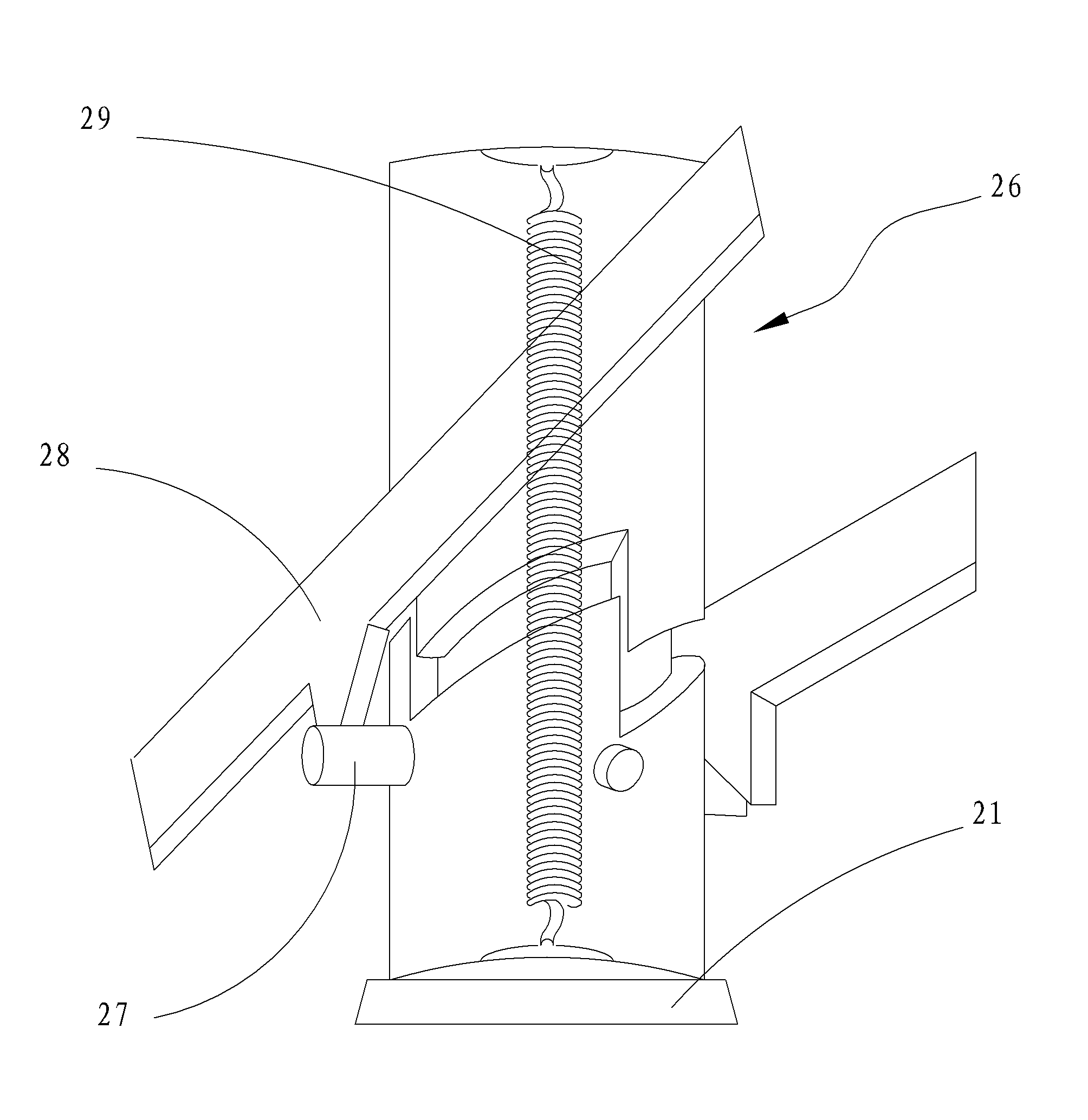

Water chestnut de-hulling device

InactiveCN101803789AReduce the difficulty of shellingIncrease productivityHuskingHullingWater ChestnutsGear wheel

The invention relates to a water chestnut de-hulling device, which comprises a rack. Two rotating shafts are arranged on the rack in parallel, two gears are fixed on each rotating shaft, two paralleled chains are wound on the corresponding gear between the two rotating shafts, a plurality of feeding moulds are fixed between the two chains at intervals, a groove to accommodate the water chestnut is arranged on the feeding moulds, and two hold-down strips used to hold down two sides of the water chestnut are respectively arranged on two sides above the groove; an upright column is arranged on the outer side of the chain on the rack, and a hylum cutting knife which can move up and down is arranged on the upright column, the position of the hylum cutting knife is opposite to the position of the groove, and at least a hull breaking knife is arranged at the rear side of the hylum cutting knife on the upright column. When the device is put into operation, firstly the hylum cutting knife cuts the hylum of the water chestnut to rift cut the hylum; secondly the hull breaking knife cuts an opening on the water chestnut to break the wrapping structure of the tough closed hull of the water chestnut; and the nut can be quickly taken out, thereby reducing the de-hulling difficulty and improving the production efficiency.

Owner:李会扬

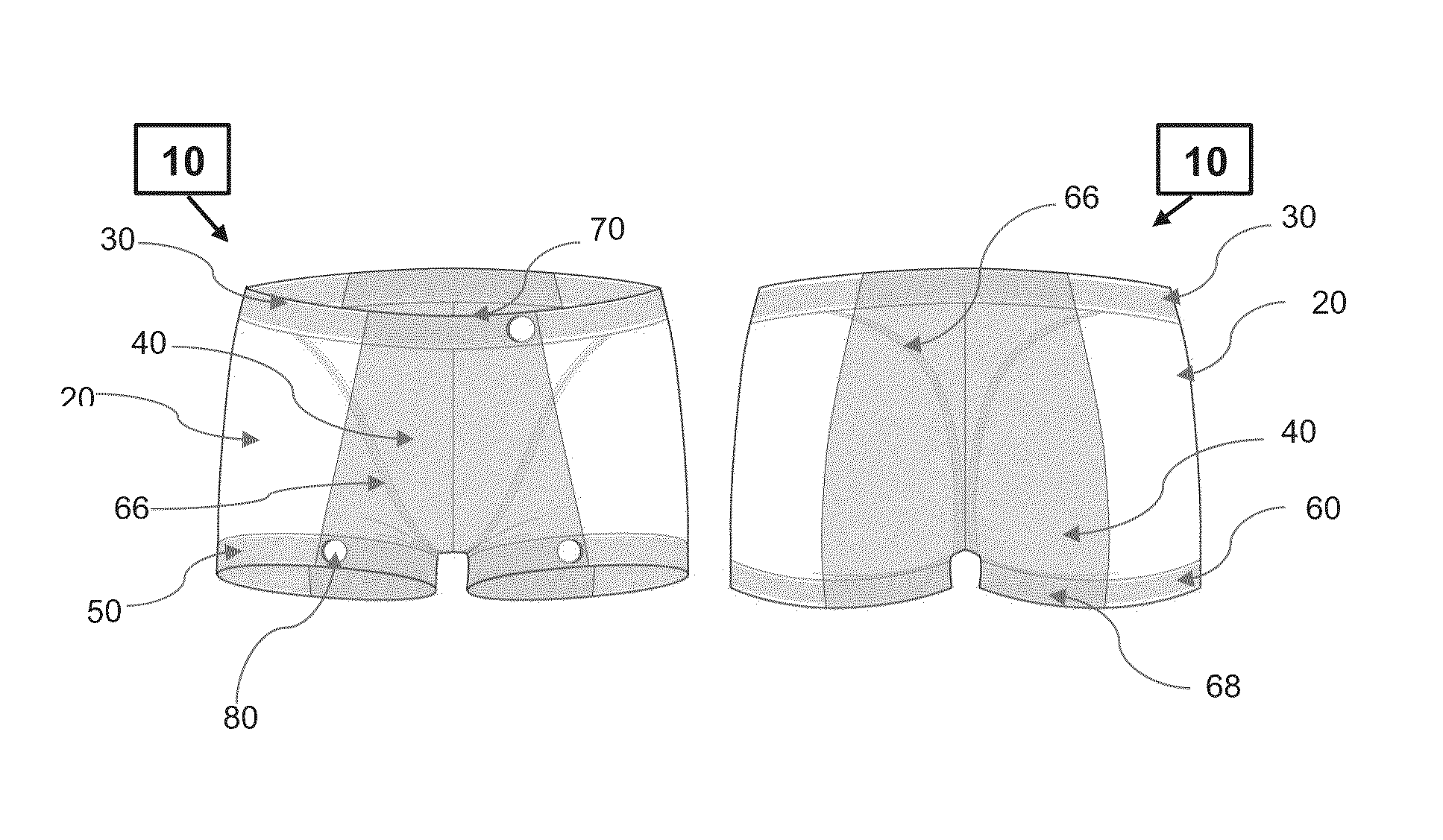

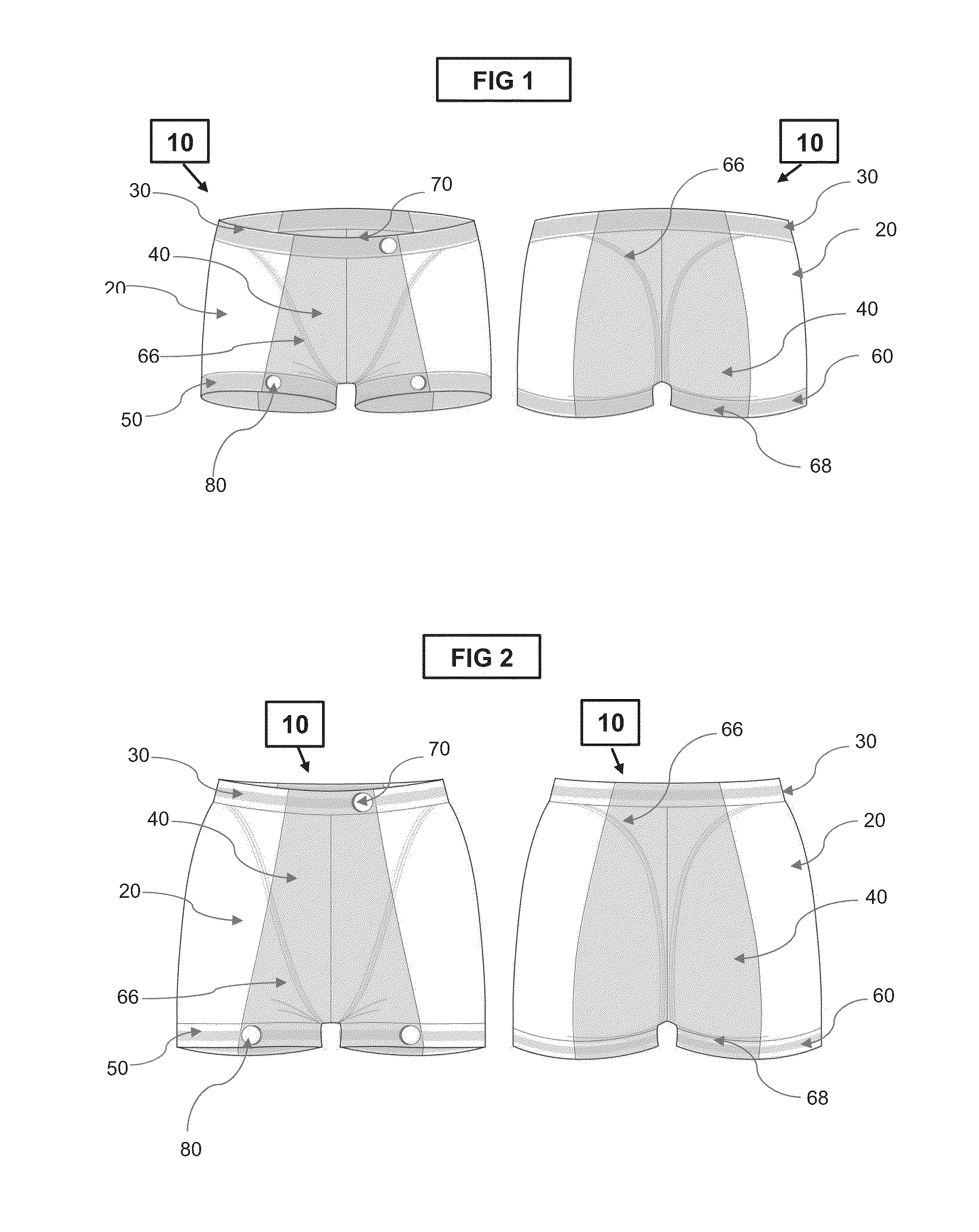

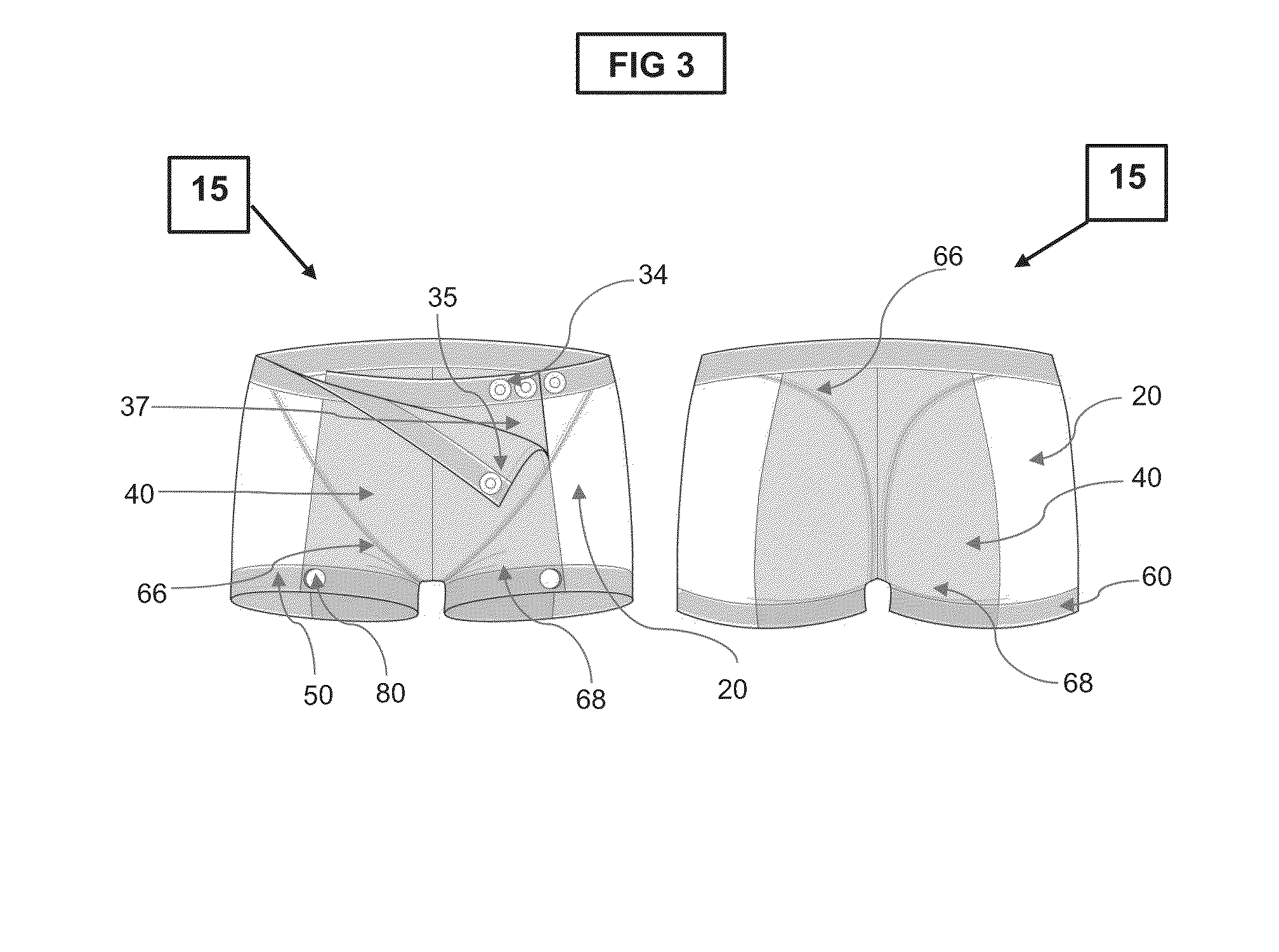

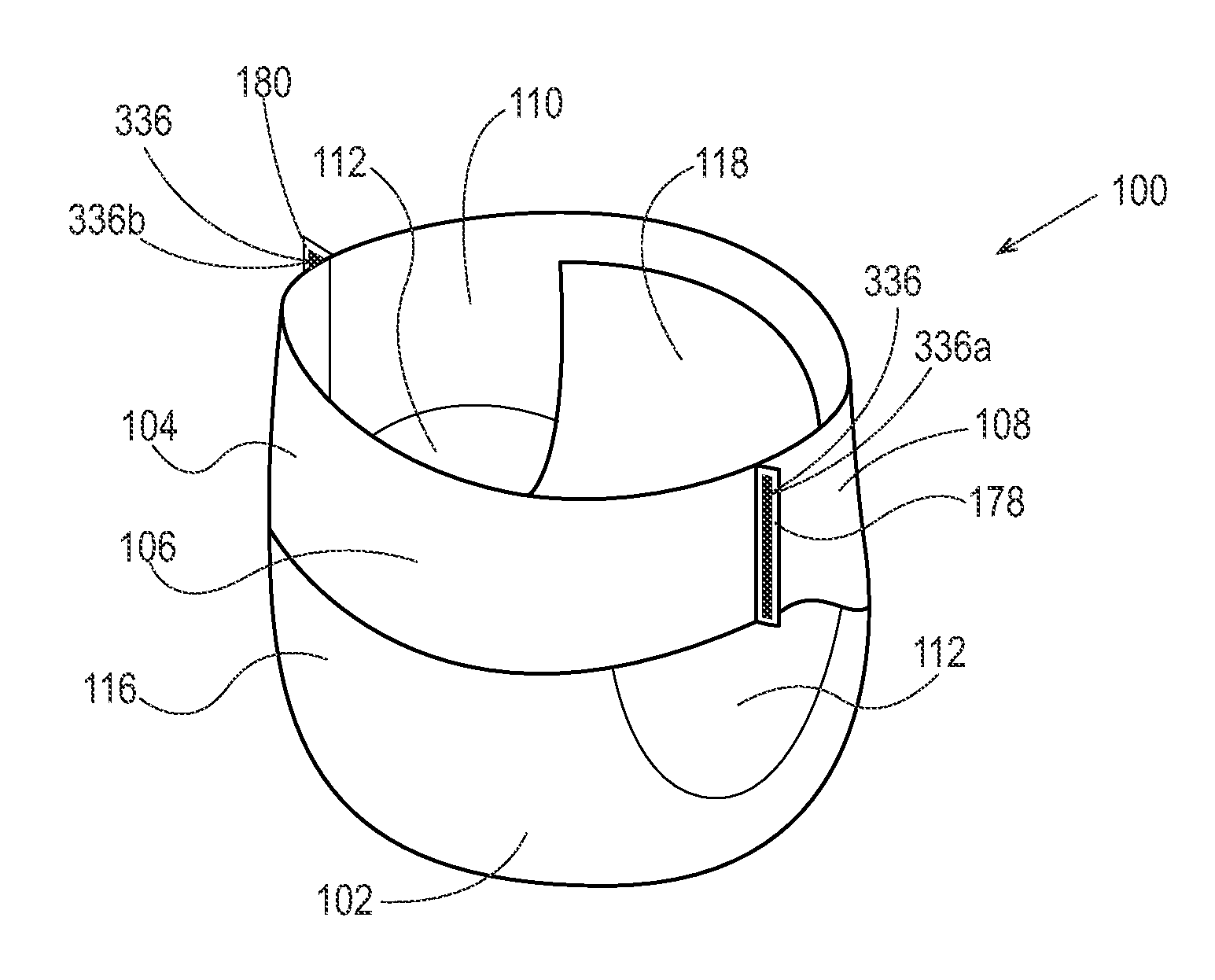

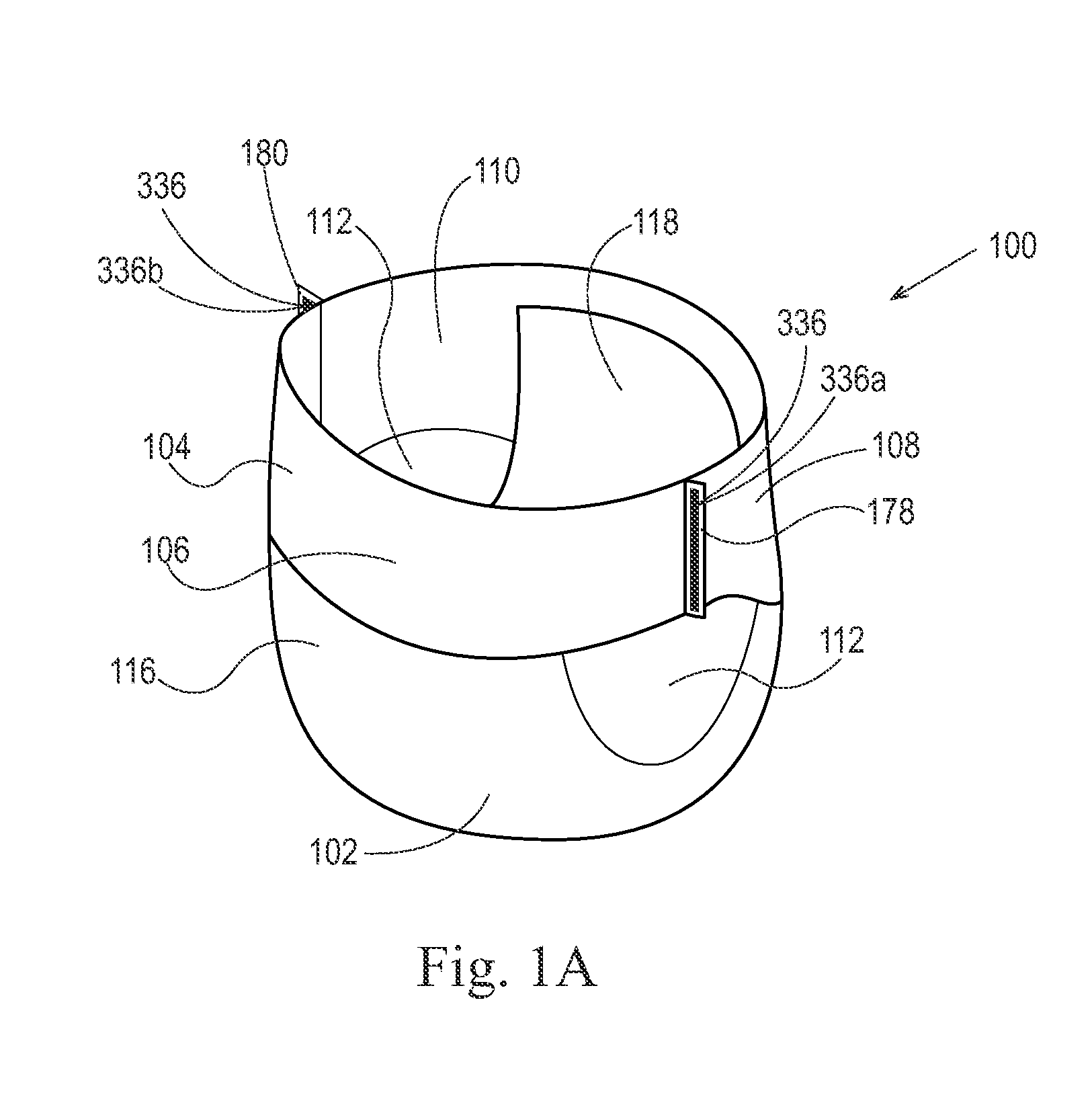

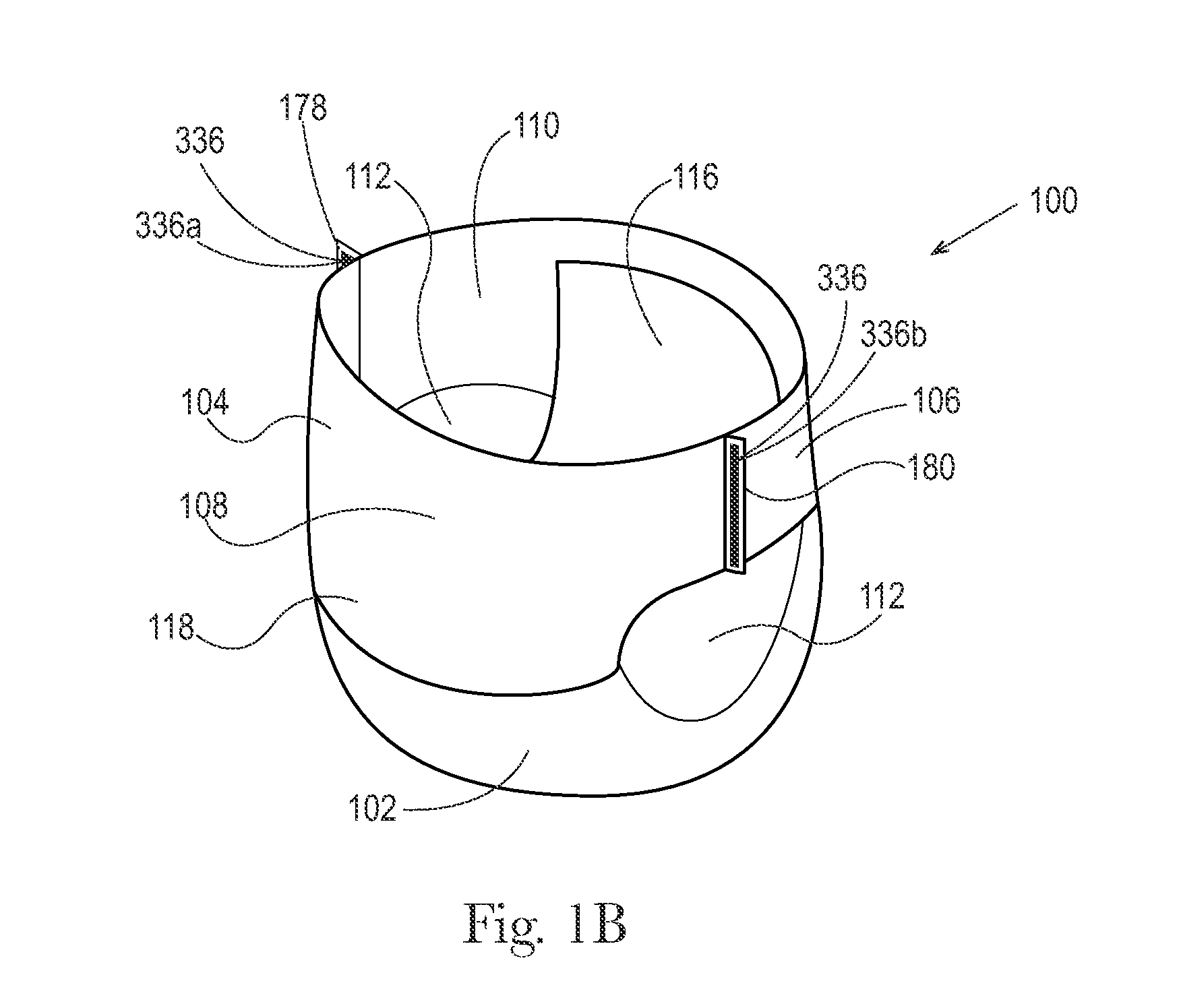

Ergonomic Garment with Cut and Shearing Resistant Strapping and an Adjustable Girth and Lock

InactiveUS20140182038A1Prevent unwanted removalAnti-rape devicesPersonal protection gearStrappingEngineering

A protective garment of elastic ergonomic material covering a wearer from his or her waist to their thighs comprises waist and thighs straps, and a central panel of cut resistant fabrics and comprise knife cut resistant and scissors shearing obstacles in various patterns and combinations in order to delay, impede and deflect such tools' blades. Both waist and thigh structures enable adjustable girth via a lock and as such create a flexible and a non-elastic rigid and connected overall protective structure resistant to forcible attempts of undressing by pulling and or by cutting or shearing the garment.

Owner:HIRSCH YUVAL

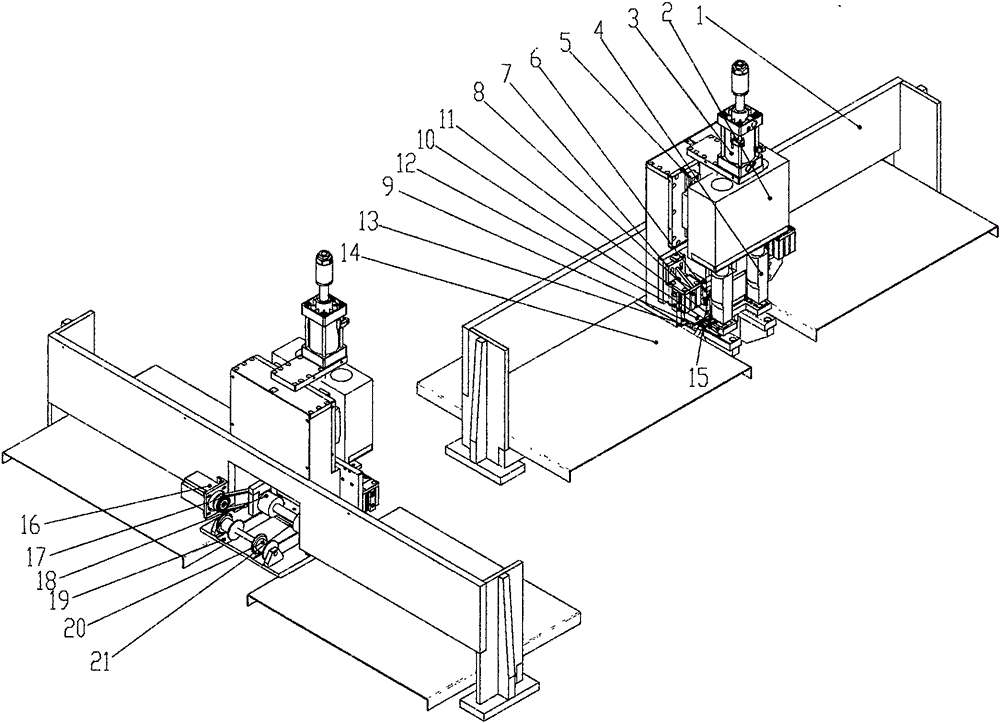

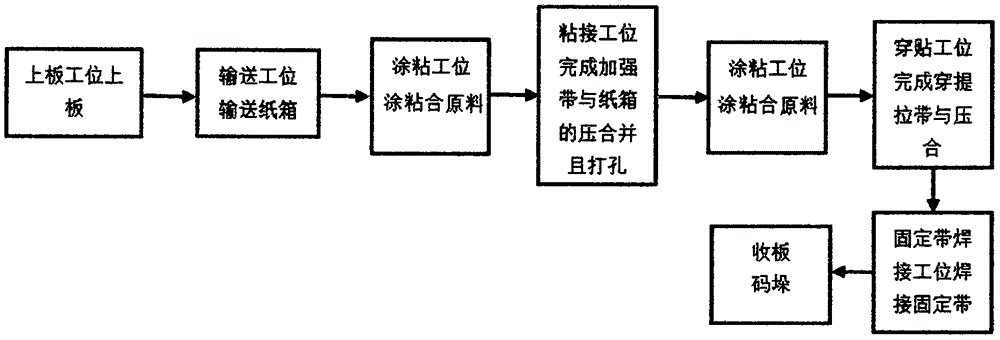

Ultrasonic lifting strip welding device

The invention discloses an ultrasonic lifting strip welding device. The device comprises a frame, an ultrasonic welding device, a strip conveying device, a strip cutting device and a pneumatic device; the strip cutting device comprises a cutter resetting tension spring, a strip cutting cylinder fixing seat, a strip cutting cylinder, a strip cutting guide rail, a strip cutting bottom cutter, a strip cutter and a cutter mounting plate; the strip conveying device comprises a strip conveying motor, a strip conveying transmission wheel, a strip conveying rubber covered roller, a strip passing guide groove, a strip conveying guide wheel and a strip conveying driven roller; rotation between the strip conveying rubber covered roller and the strip conveying driven roller is powered by the strip conveying motor; a fixed strip passes through the strip passing guide groove by virtue of the strip conveying guide wheel and is then conveyed to a fixedly-welded strip limiting block by engagement of the strip conveying rubber covered roller and the strip conveying driven roller in order to wait for a strip cutting mechanism to cut the strip and wait for a downward-pressing welding device to press the strip downwards and weld the strip. According to the ultrasonic lifting strip welding device disclosed by the invention, a welding process is applied to installation of a paper box lifting strip by using ultrasonic wave and is applied to automatic mounting equipment for the lifting strip; continuous stable production can be realized; the pass percent of products is increased by 100%.

Owner:江苏力奥智能装备有限公司

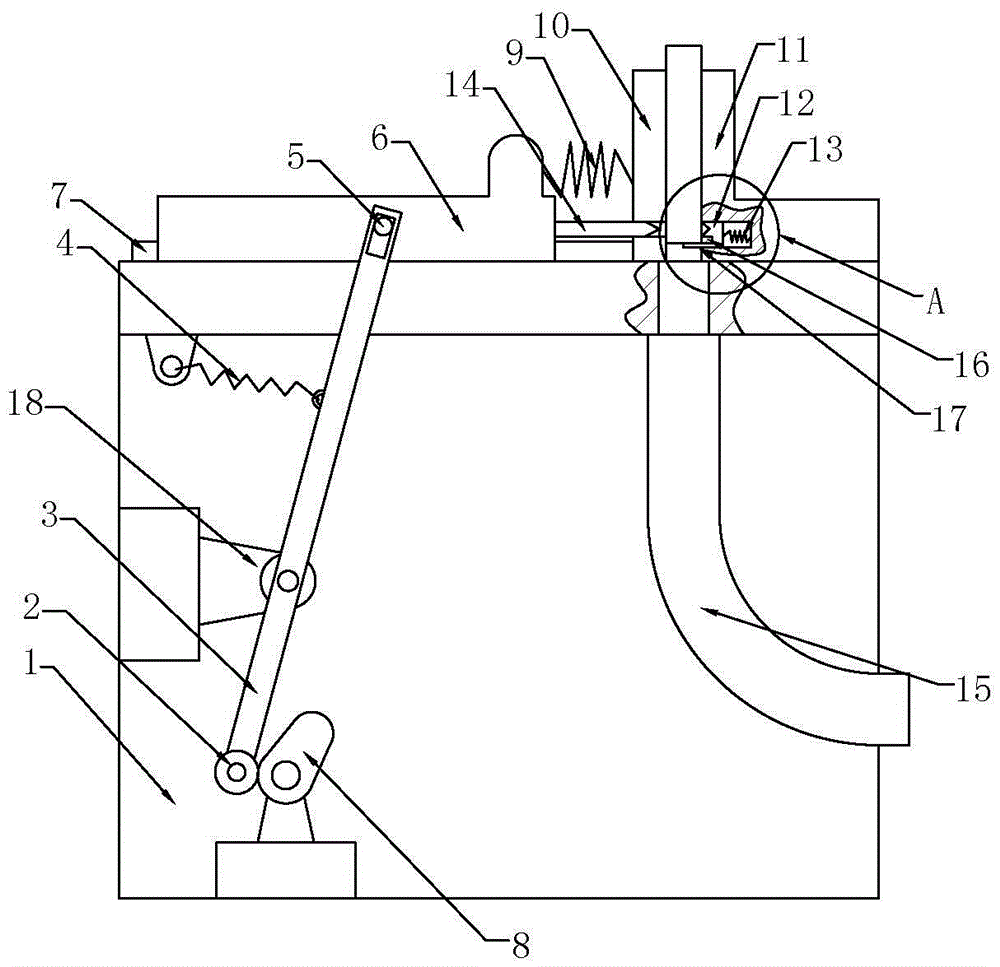

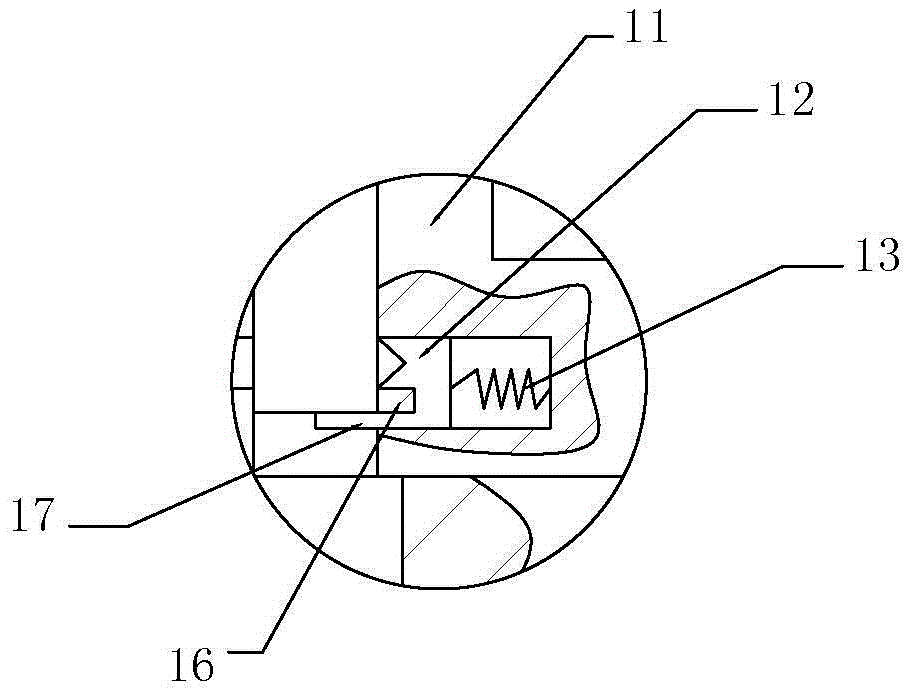

Device for cutting gasket of compressor of refrigerator

The invention discloses a device for cutting a gasket of a compressor of a refrigerator. The device comprises a rack, a cutting knife and a cutting base and further comprises a power device, wherein the cutting base is positioned at one side of the cutting knife; the power device comprises a lever, a lever base and a cam; the lever is hinged on the lever base; a strip-shaped hole is formed in the upper end part of the lever; the cutting knife is rotatably connected with a rolling shaft; a third spring is connected between the lever and the rack; the lower end part of the lever abuts against the cam; a knife head of the cutting knife is in sliding connection into a pressure plate; a through hole is formed in the pressure plate; a first spring is connected between the pressure plate and the cutting knife; a groove is formed in the cutting base; a buffer base is connected in the groove; a second spring is connected between the buffer base and the bottom wall of the groove; the bottom of the buffer base is connected with a limiting block; the limiting block is positioned between the pressure plate and the buffer base; a fixed plate is arranged between the limiting block and the buffer base in an abutting-against manner; and the fixed plate is fixedly arranged in the groove. The cutting knife cuts back and forth, so that the number of operation steps is decreased; and the pressure plate and the limiting block are arranged, so that labor intensity is reduced, and the manufacturing cost is also reduced.

Owner:遵义市乐辉塑业有限公司

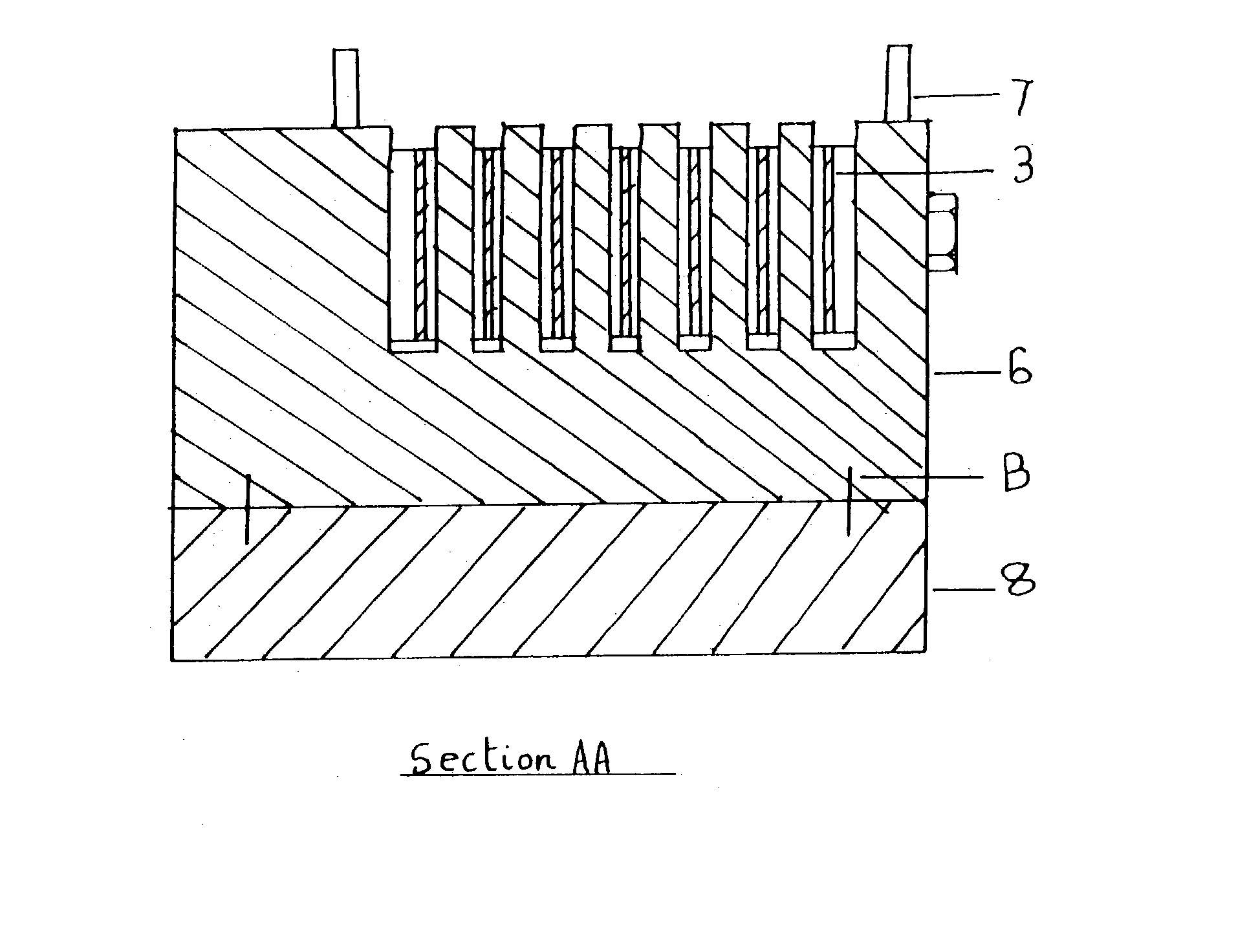

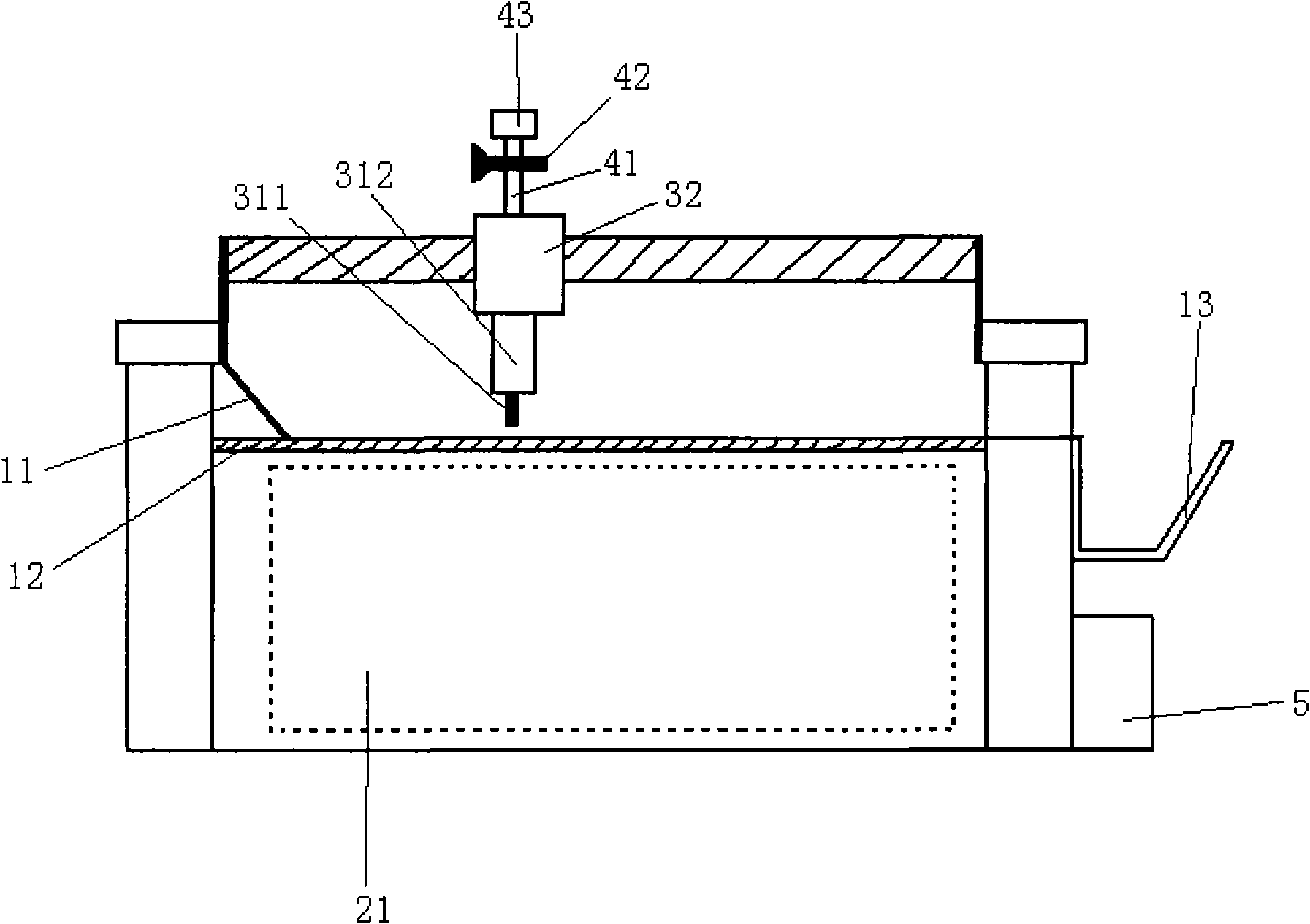

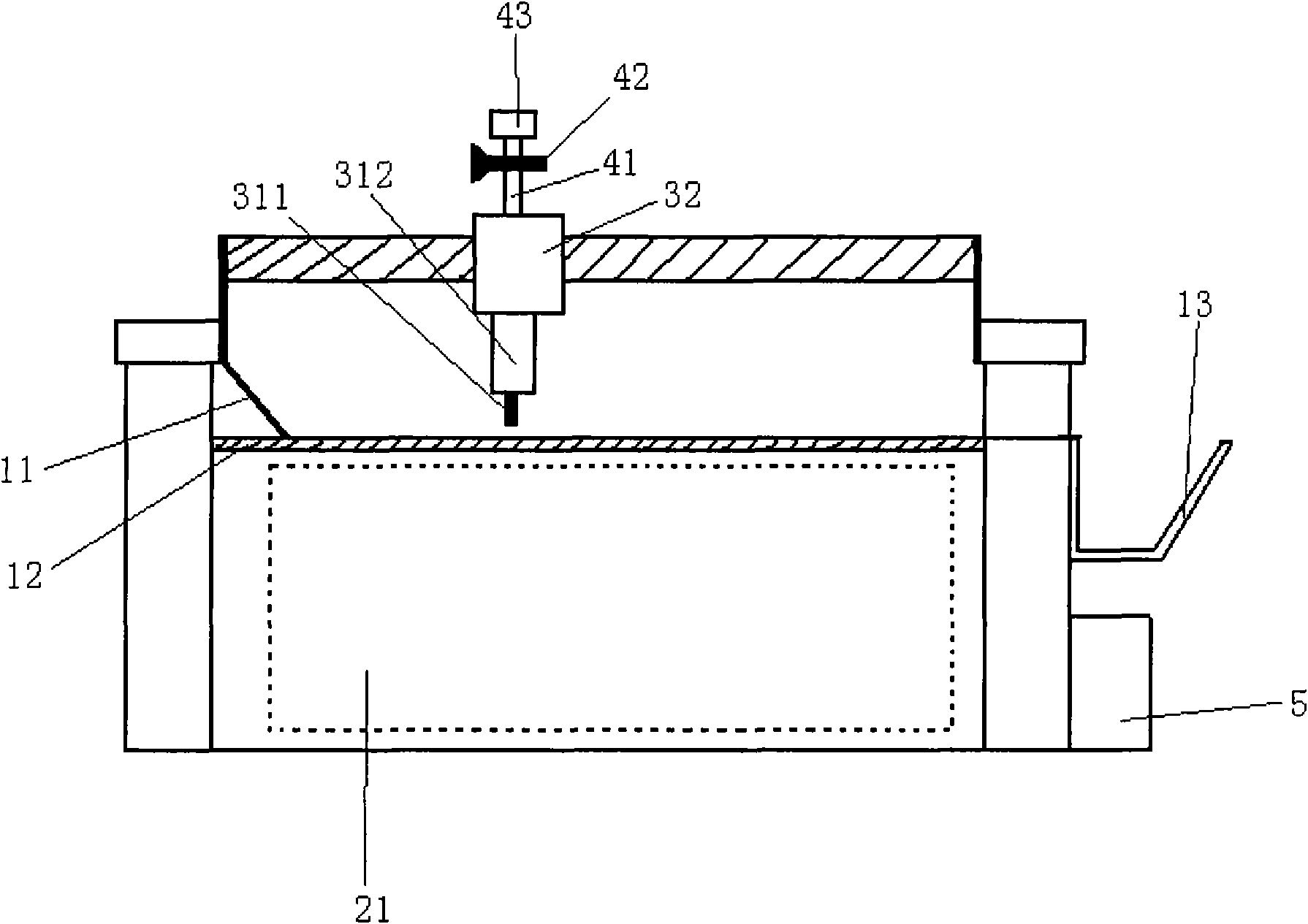

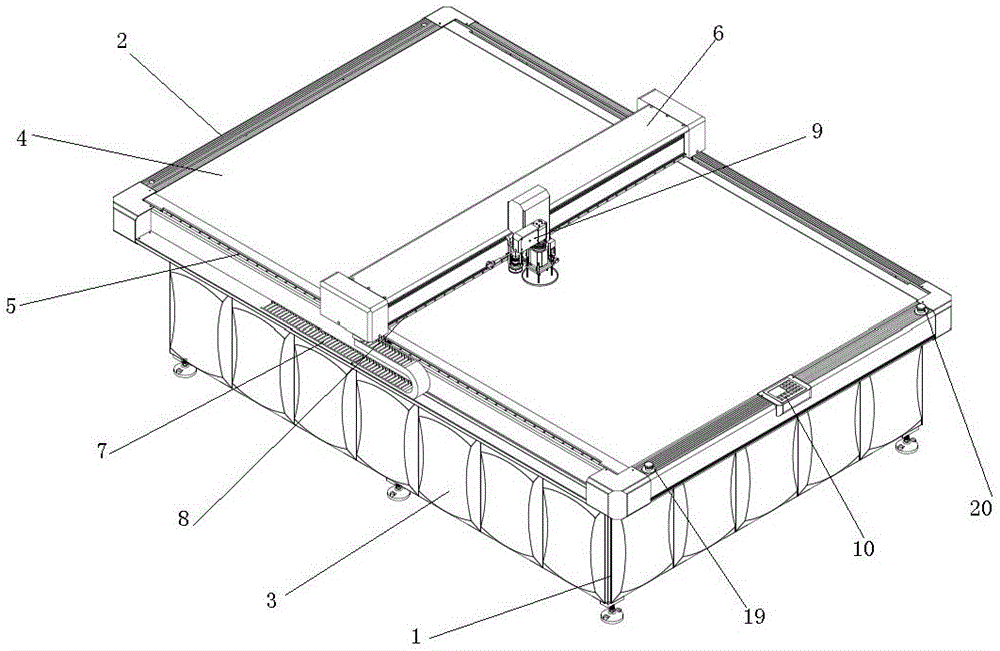

Water knife cutting control system

InactiveCN101837599AHigh precisionFast cutting speedAutomatic control devicesFeeding apparatusControl systemHigh acceleration

The invention relates to a water knife cutting control system for cutting finished products. The system comprises a feed system, a recovery system, a water knife movement control system, a water flow control system and a work station, wherein the work station simultaneously controls the feed system, the recovery system, the water knife movement control system and the water flow control system. The water knife cutting control system has the advantages in the conventional high pressure water knife cutting system; and compared with the conventional high pressure water cutting system using a cantilever type drive structure, the invention also has the advantages of small size, high rigidity and the like, and can bear high speed and provide high acceleration. In addition, the high pressure water knife cutting system of the invention can greatly enhance the cutting accuracy for finished products, prevent the finished products from damage during cutting, increase the finished product cutting speed and yield, and save the manufacturing cost at the same time.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

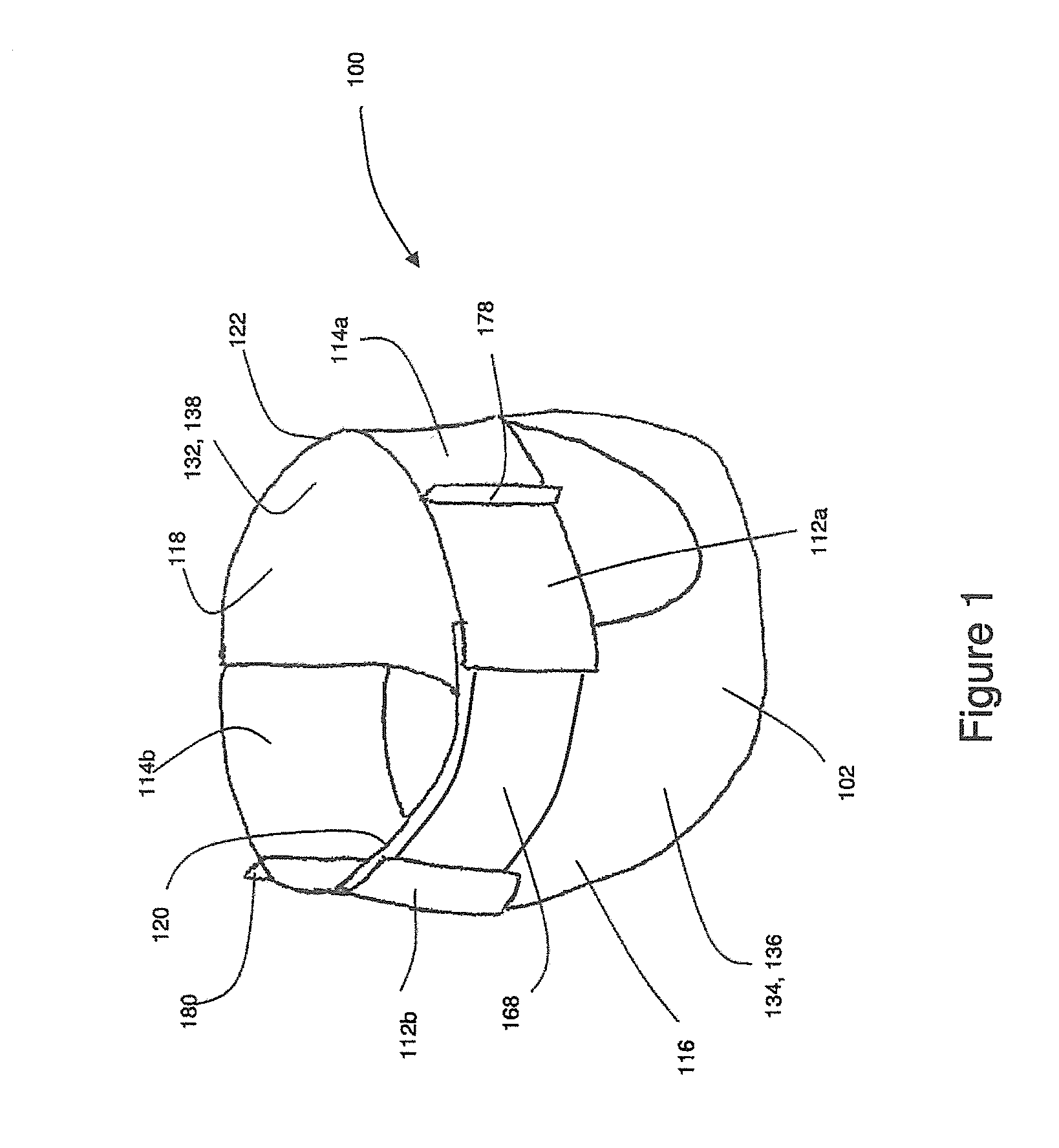

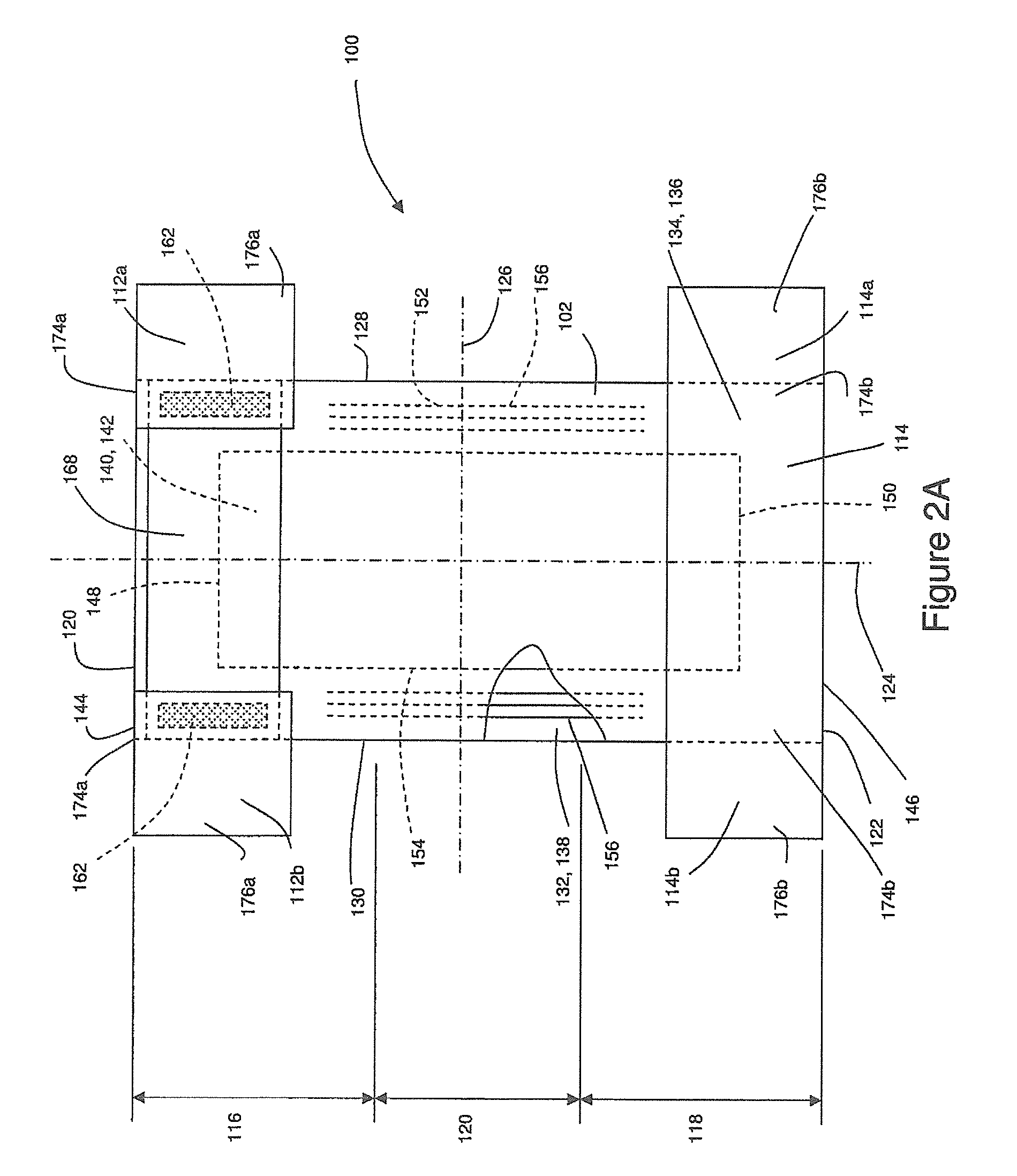

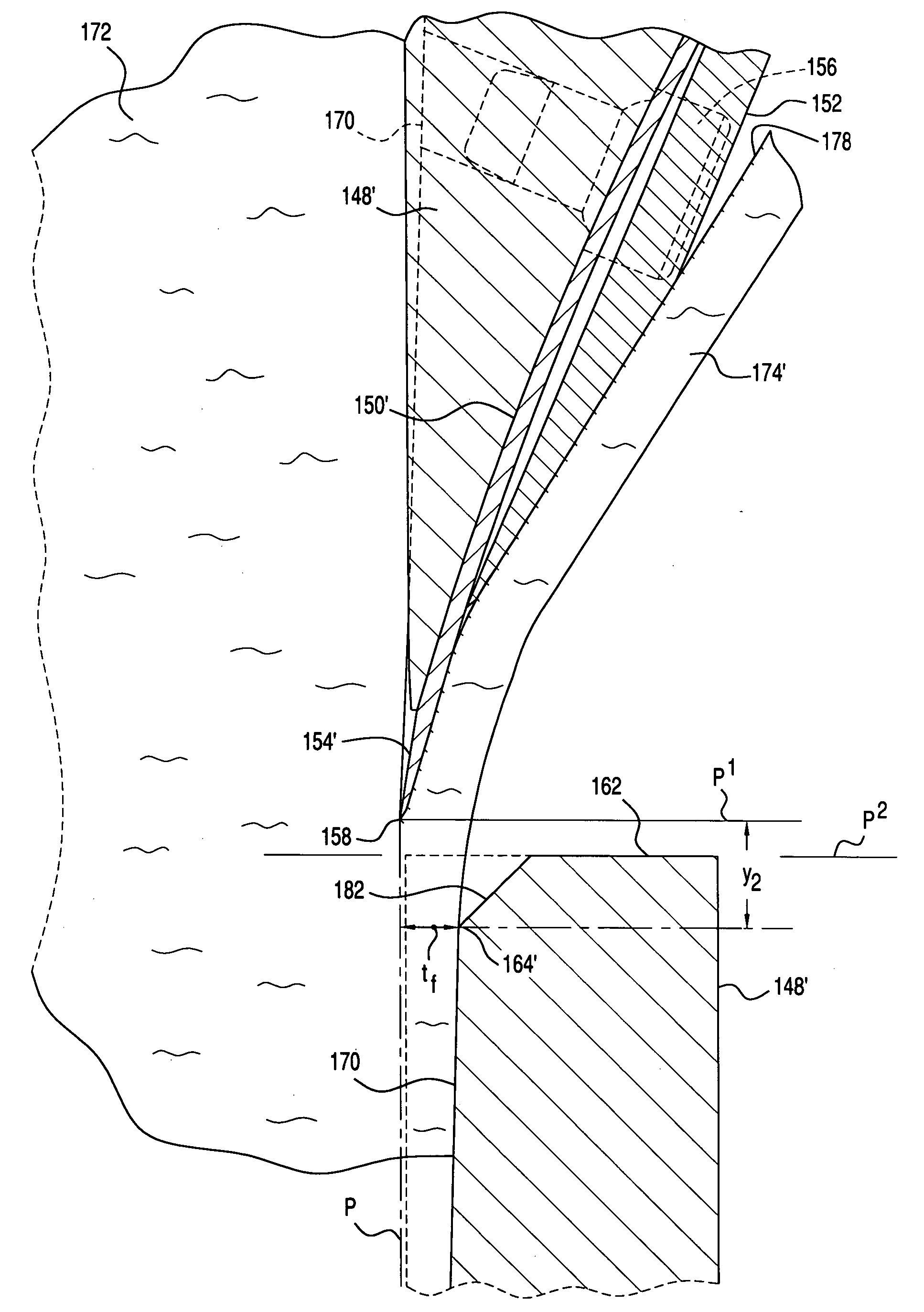

Methods and Apparatuses for Making Absorbent Articles Having Contoured Belts

The present disclosure relates to methods and apparatuses for assembling disposable pant diapers having contoured elastic belts. During the assembly process, opposing end regions of chassis are connected with the elastic belts in the form of first and second continuous elastic laminates. The chassis are then folded to place the elastic laminates into a facing relationship. The inner longitudinal edges of one or both the elastic laminates are then cut to define a contoured shape. Discrete pieces of trim material may be removed from one or both the elastic laminates, and the first and second continuous elastic laminates are cut in the cross direction to form discrete pant diapers. In some configurations, a single knife both removes the trim material and cuts the elastic laminates in cross direction. And in some configurations, a first knife removes the trim material and a second knife cuts the elastic laminates in cross direction.

Owner:THE PROCTER & GAMBLE COMPANY

Method for manufacturing cuprum-cover-silver as well as silver alloy three composite rivet contact

Disclosed is a process for preparing copper three composite rivet contacts of bonding sliver and silver alloy, an additional eccentric tube and a set of additional wire-feeders are disposed at one side of a bed die of a 30 type dual composite cold holder, an S lead rail of the 30 type dual composite cold holder is changed to a three-step lead rail to realize the process that one of cutting knives cuts two-section materials. One of cutting knives cuts two-section materials, a first draw stick sends the three composite materials to the bed die, and the three composite materials are continuously upset and deformed in the bed die, thereby completing bonding sliver on the foot portions of the three composite rivet contacts. The method is simple and feasible, and can complete the preparation of copper bonding sliver and three composite rivet contacts of sliver alloy, further, the invention is high in productivity effect and in material utilization.

Owner:FUDA ALLOY MATERIALS

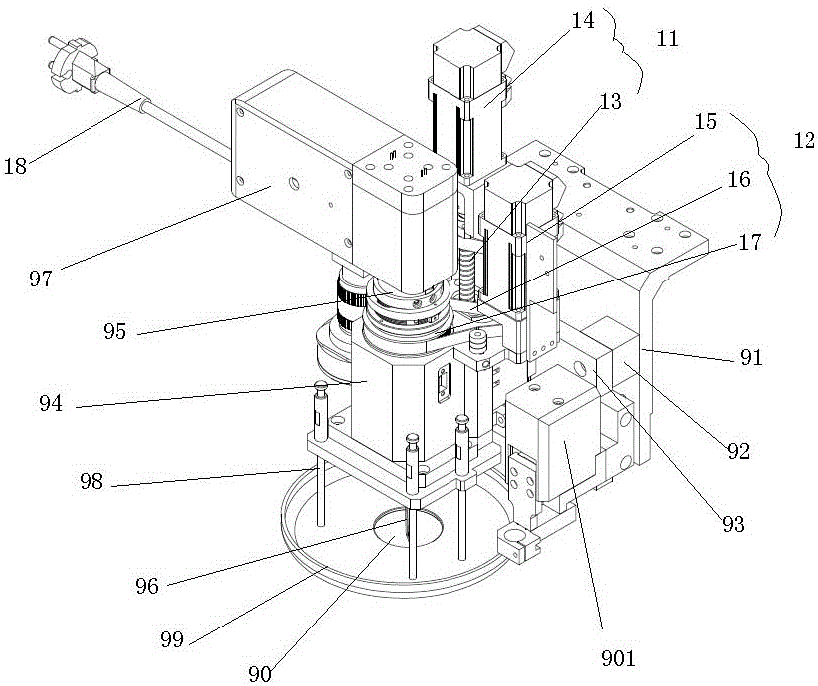

Intelligent hot-knife cutting device

InactiveCN105082241ASmall cutting resistanceImprove automationMetal working apparatusIntelligent lightingEngineering

The invention discloses an intelligent hot-knife cutting device which comprises a lower rack and an upper rack, wherein the upper is mounted on the lower rack; a plurality of lower rack baffles are arranged at intervals on four edges of the lower rack; a cutting table is arranged on the upper plane surface of the upper rack; an X-axis guide rail is arranged on the left side and the right side of the cutting table respectively; a sliding block I is mounted on each of the two X-axis guide rails; a support is mounted on each of the sliding blocks I; the two supports are connected via a Y-axis cross beam; one end of the Y-axis cross beam is connected with an X-axis drag chain; two mutually parallel Y-axis guide rails are arranged on one side of the Y-axis cross beam; sliding blocks II are arranged on both of the Y-axis guide rails; a thermal cutting machine head is mounted on the sliding blocks II; and a main control panel for controlling the thermal cutting machine head to perform X-axis, Y-axis, Z-axis and W-axis motion to cut a product is arranged on the front side of the upper rack. The intelligent hot-knife cutting device is simple in structure, high in cutting efficiency and convenient to control, and can be used for batch production of low-melting-point materials such as pearl wool, sponge and foam.

Owner:GUANGDONG HUAYI TECH CO LTD

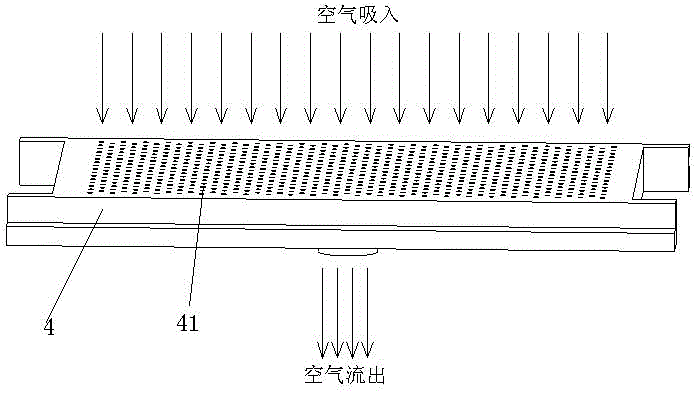

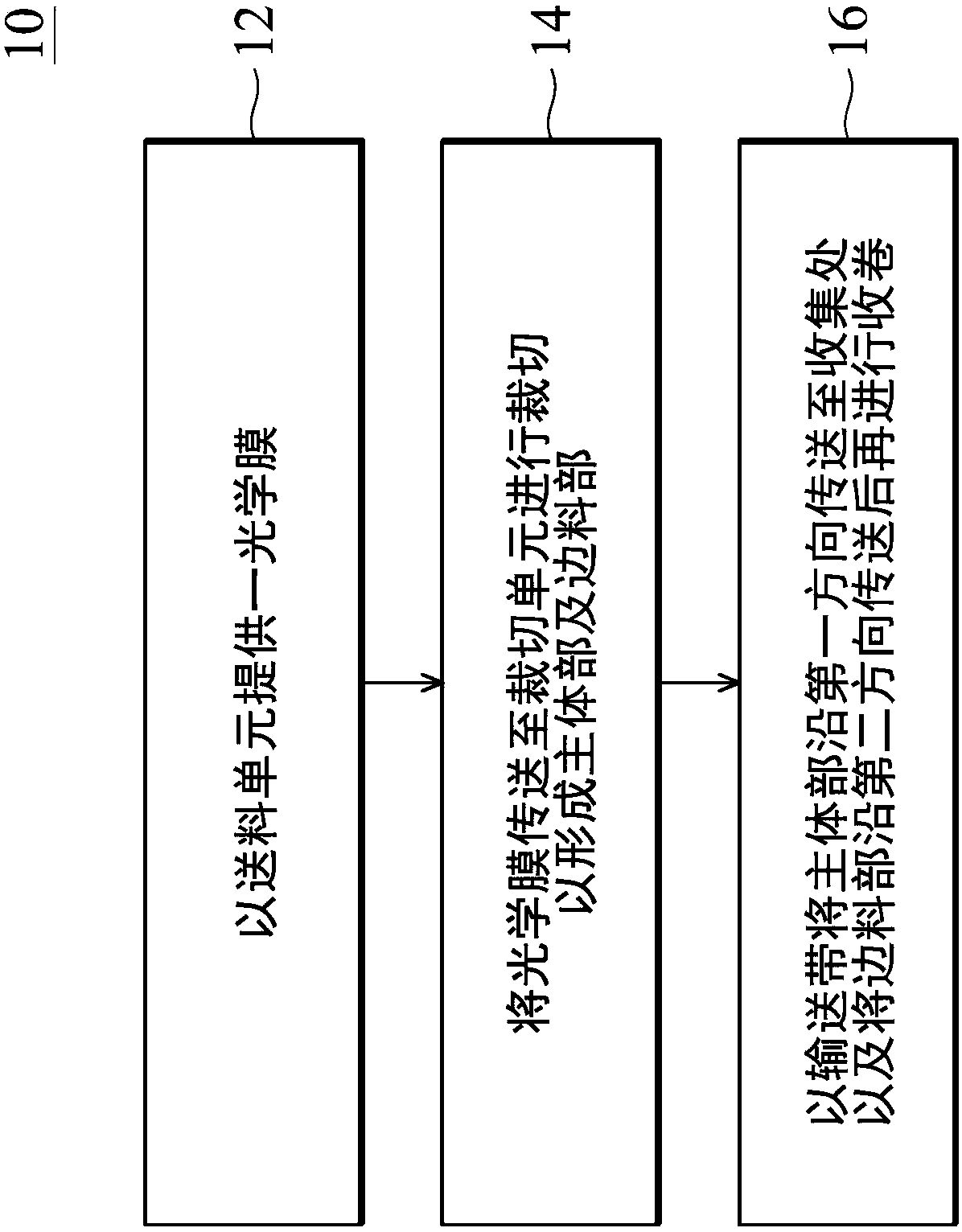

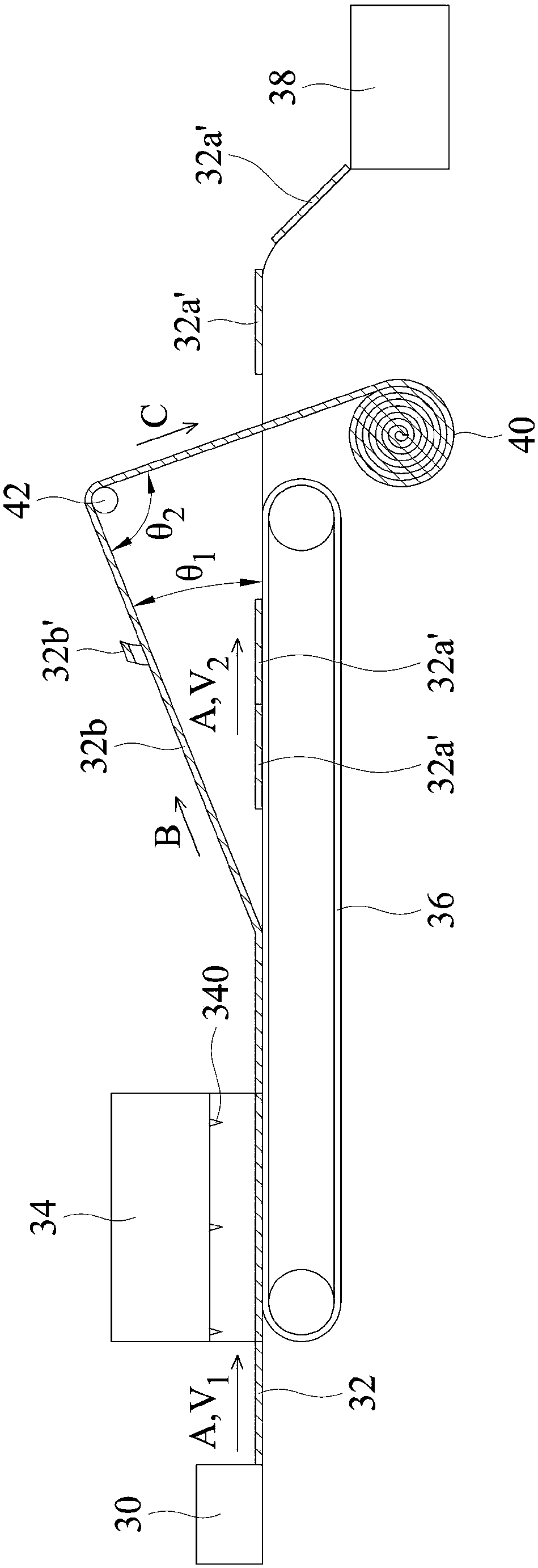

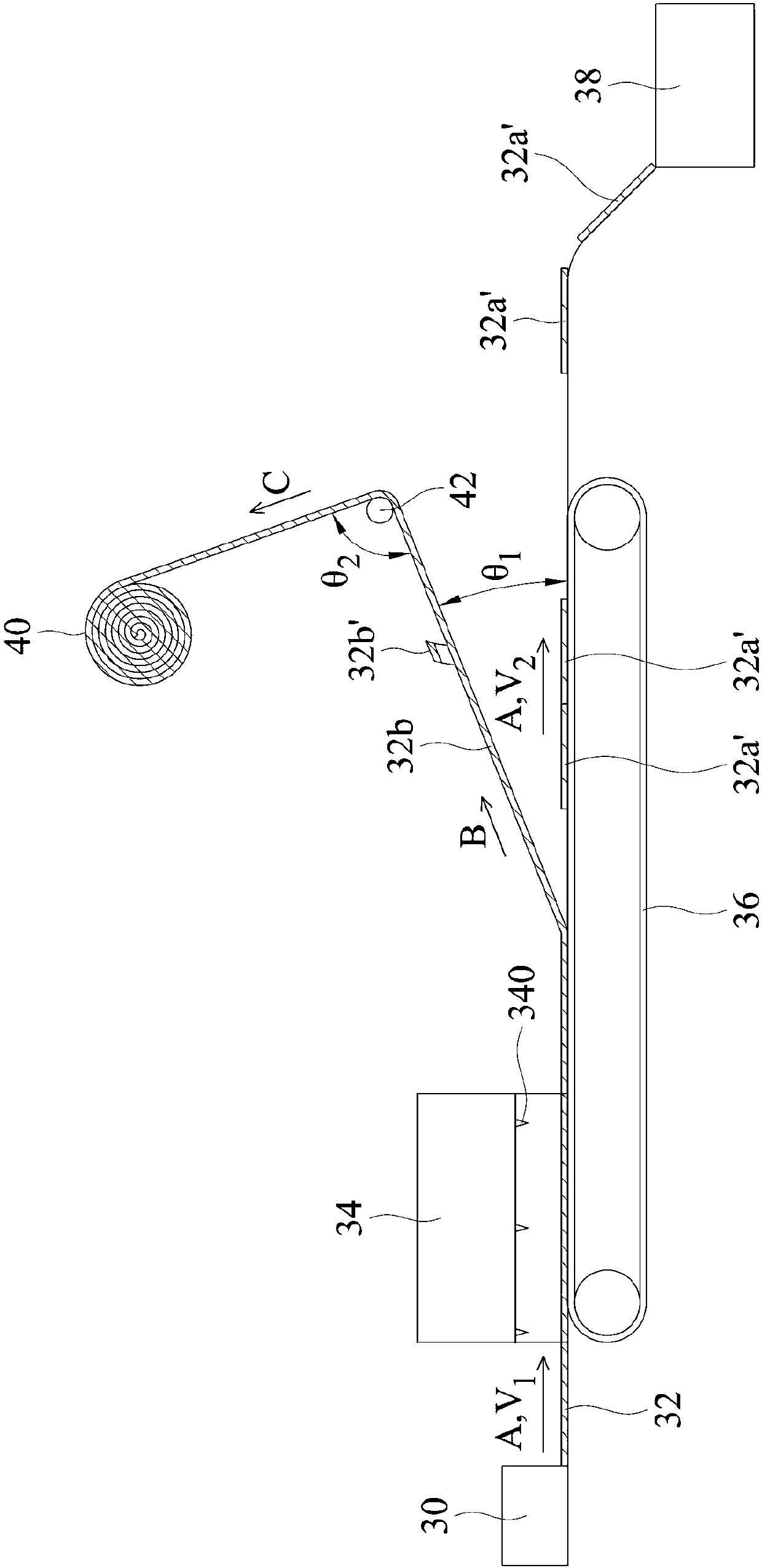

Cutting and winding method for optical film, and cutting knife adopted by method

The invention provides a cutting and winding method for an optical film, and a cutting knife adopted by the method. The cutting and winding method for the optical film comprises the following steps: (A) and a feeding unit is used for providing an optical film; (B) the optical film is conveyed to a cutting unit, and the cutting unit comprises a cutting knife, wherein the cutting knife cuts the optical film into a main body part and an edge material part, wherein the main body part comprises an optical membrane, and the rim charge part is separated from each other; (C) after the step (b), the optical diaphragm is conveyed to a finished product collecting position along a first direction through a conveying belt, and enabling the rim charge parts to be transmitted to a winding unit in a second direction, the included angle between the first direction and the second direction ranges from 0 degrees to 100 degrees, the process efficiency is effectively improved, and the needed labor cost isreduced.

Owner:SUMIKA TECH

Automobile glass cutting machine

InactiveCN108529865ASolve cutting problemsSolve the knock-off problemGlass severing apparatusCutting glassEngineering

The invention relates to the field of automotive glass processing, in particular to an automobile glass cutting machine. The machine comprises a worktable, a glass fixing assembly disposed at the bottom of the worktable, a support assembly disposed on the top of the worktable, a cutting assembly disposed on the support assembly and slidably connected with the support assembly and a tapping assembly disposed at the bottom of the supporting assembly and slidably connected with the supporting assembly; the machine places automobile glass to be processed on the worktable, and adsorbs and fixes theglass through a pneumatic suction cup, a sliding block slides on the support assembly and drives a second cylinder and a cutting knife to move, the cutting knife cuts the glass, due to the fact thatthe cut glass does not immediately fall from the original glass, the cut glass is slidably tapped by a tapping device until the cut part is detached, the whole process is a mechanical operation, and the machine not only solves the problem of glass cutting, but also solves the problem of the falling of the cut glass tapped, achieves two things at one stroke, and is high in work efficiency.

Owner:张小云

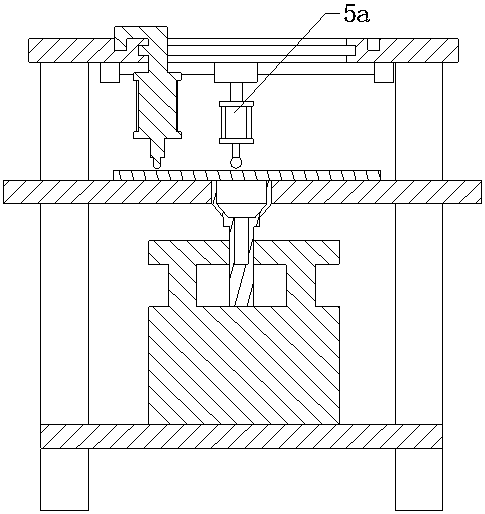

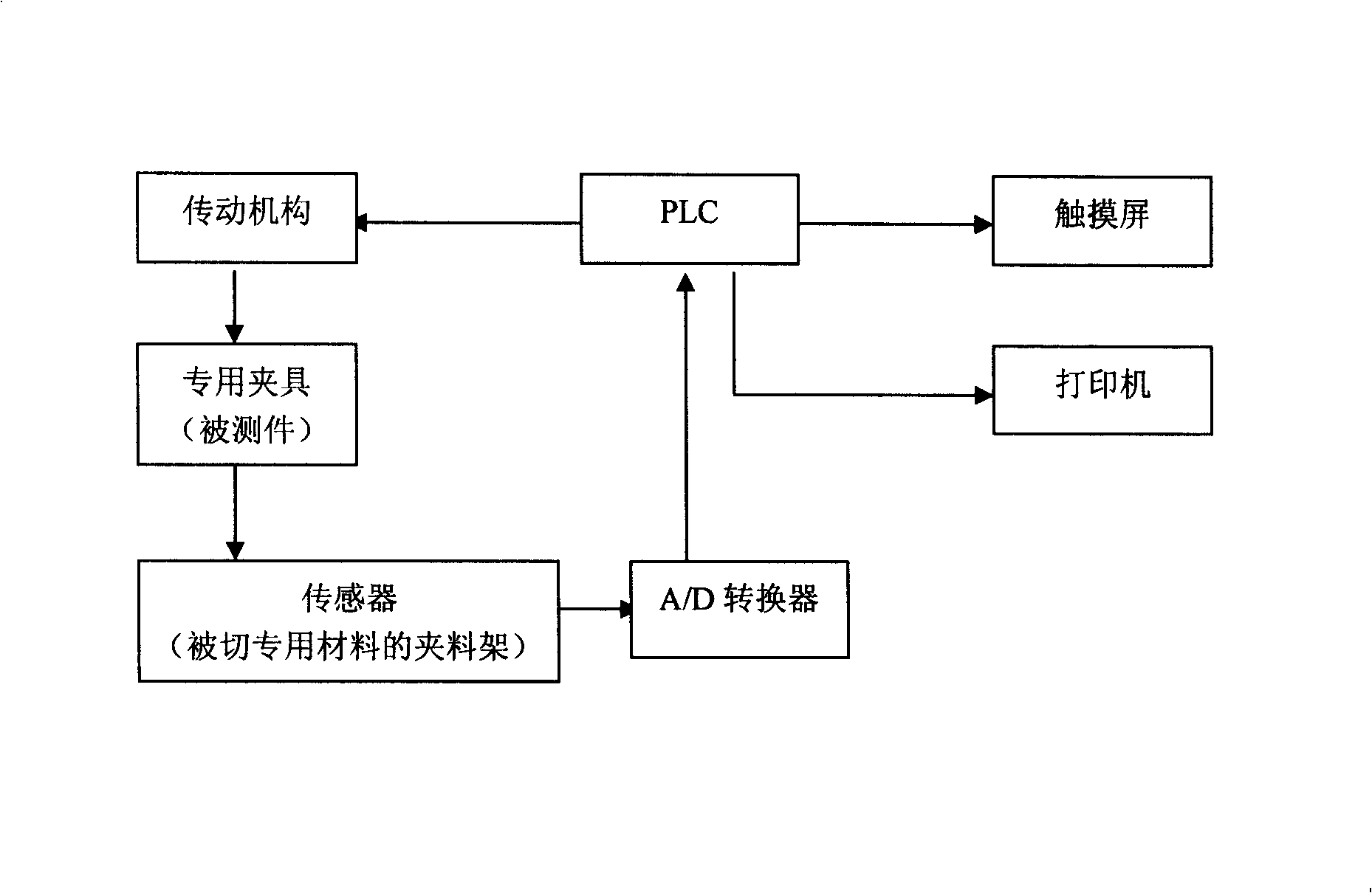

Tester for tartness degree of tool cutting edge

InactiveCN101256129AEasy to useImprove reliabilityInvestigating machinabilityMeasuring instrumentTester device

The invention relates to a knife quality detection device, particularly relates to a knife edge sharpness tester. It includes a PLC, an input device, an output device, a transmission mechanism, a special fixture, a kind ofspecial-purpose material equipped with a sensor for being cut, an A / D converter, wherein: the PLC is the kernel component, which is used for receiving command inputted from the input device to control the transmission mechanism and the special fixture for carrying out the cutting movement, then for receiving the signal converted by the A / D from the sensor, then outputs the tested value from the output device. The device can display the needed value and the cutting-off force curve when the knife cuts off special-purpose material, the measure equipment is a reliable, has accurate data, can make magnitude evaluation of the knife edge sharpness, and is convenient to use. The special fixture is mounted for testing and evaluating the shearing force of scissor. Compared with original artificial subjective test and judgment, the obtained test result is more objective and accurate.

Owner:SHANGHAI HENGYI PHARMA EQUIP

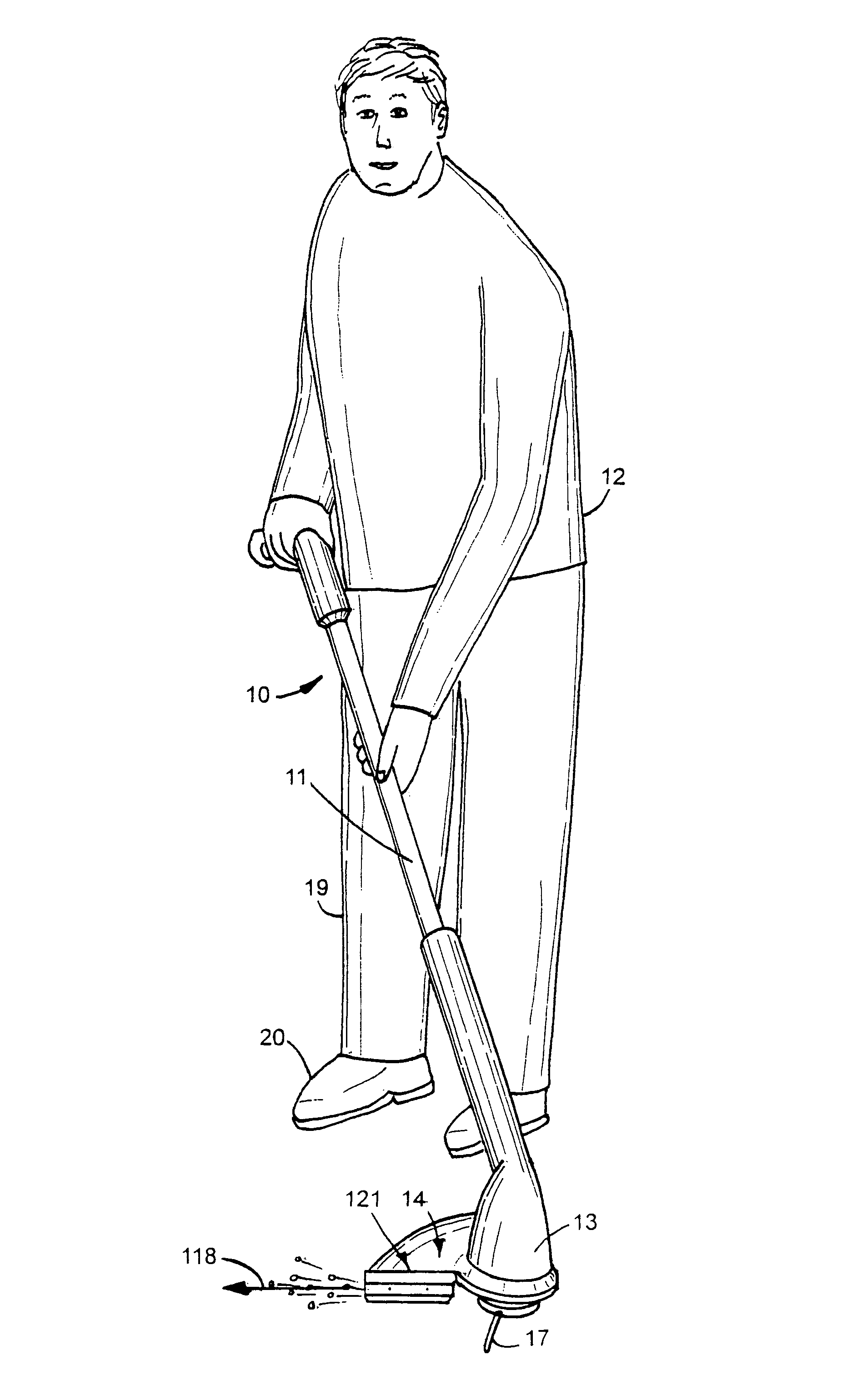

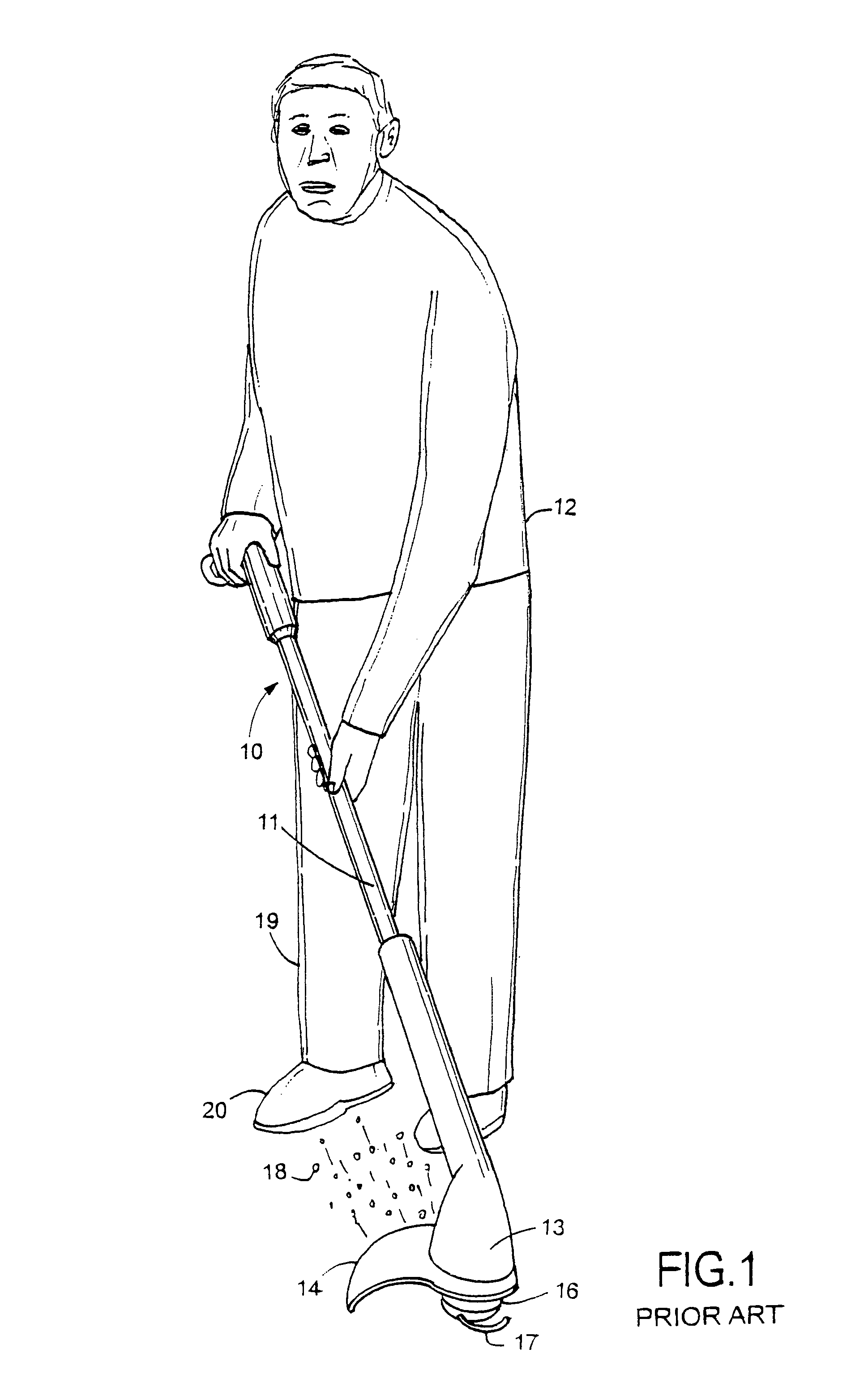

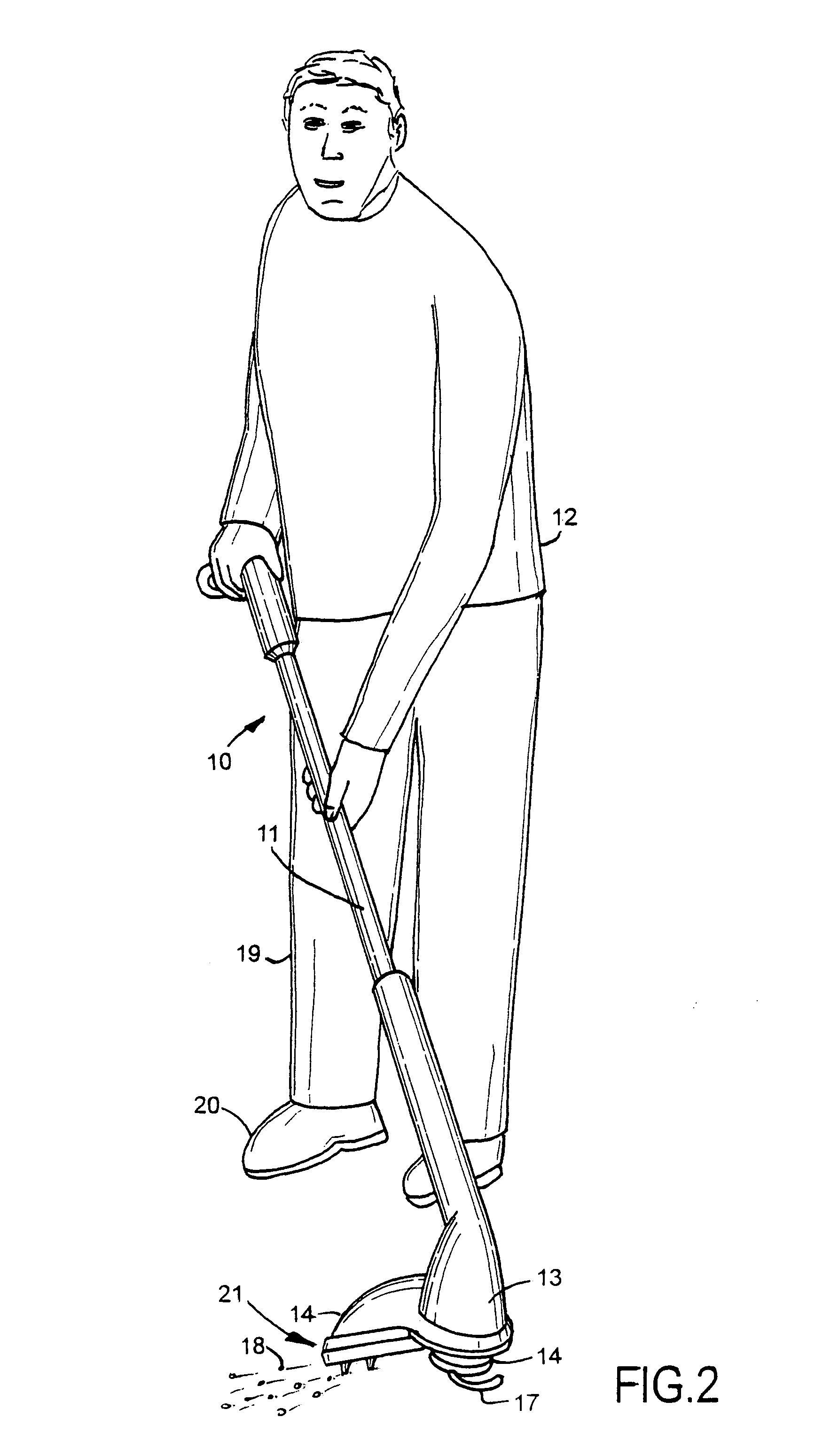

Debris deflector and knife for string trimmer

A string trimmer equipped with a knife and deflector apparatus mounted on the shroud directs cut debris laterally away from a workperson operating the string trimmer. A knife cutting edge located below the shroud cuts vegetation moved by the revolving string into cut debris. An upwardly extended radial deflector mounted on the shroud directs the cut debris laterally away from the shroud and workperson.

Owner:ALBERTSON ROBERT V +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com