Picking robot end effector

A technology for end effectors and picking robots, which is applied in the direction of picking machines, manipulators, harvesters, etc., can solve the problems of increasing the difficulty of system control and the complexity of the mechanism, the transmission mechanism scheme and the control and sensing system are redundant, and the cost is increased. Achieve the effect of reducing cost and control difficulty, small and compact structure, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail now in conjunction with accompanying drawing.

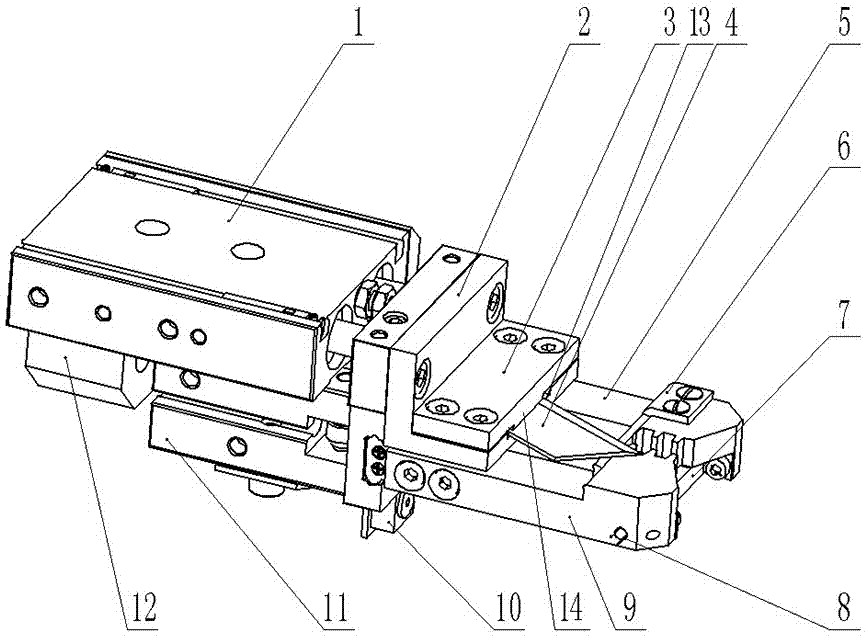

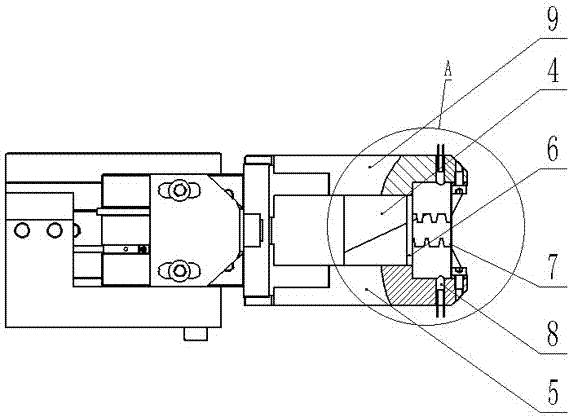

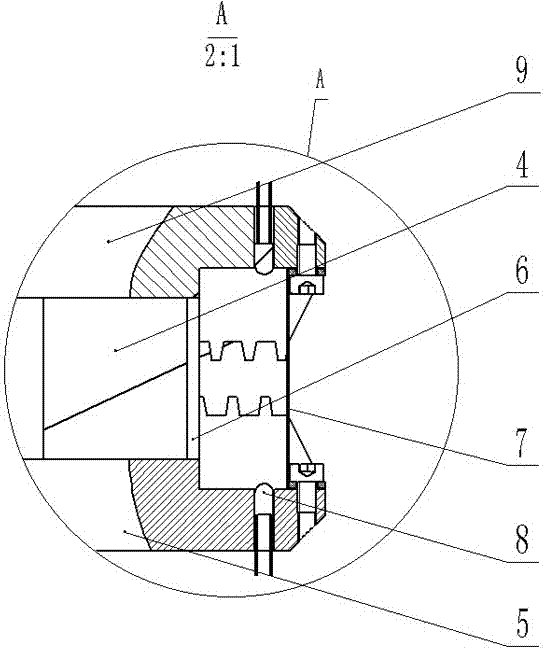

[0020] Such as Figure 1-3 As shown, the end effector of the picking robot includes a translation clamping fruit stem assembly and an oblique knife cutting fruit stem assembly. The translation clamping fruit stem assembly includes a translation finger cylinder 11, a left trapezoidal tooth finger 5, a right trapezoidal tooth finger 9, and a stopper 6 , elastic shading cloth 7, opposite beam photoelectric switch 8, visual sensor 10 and mechanical arm docking part 12, the oblique knife cutting fruit stem assembly includes a double-rod guiding cylinder 1, a cutter mounting plate 2, a cutter pressure plate 3 and a cutter 4 .

[0021] The mechanical arm docking part 12 is fixedly connected with the translation finger cylinder 11 and the double-rod guiding cylinder 1 respectively by screws, and a threaded waist-shaped installation hole connected with the picking mechanical arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com