Manufacturing process for improving capacity of aluminum gallium indium phosphorus light-emitting diodes

A light-emitting diode, gallium indium phosphide technology, applied in the field of quaternary light-emitting diodes, can solve the problems of reducing single-chip production, and achieve the effects of improving yield, reducing cracking, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] The manufacturing process for increasing the yield of aluminum gallium indium phosphide light-emitting diodes, the process steps are as follows:

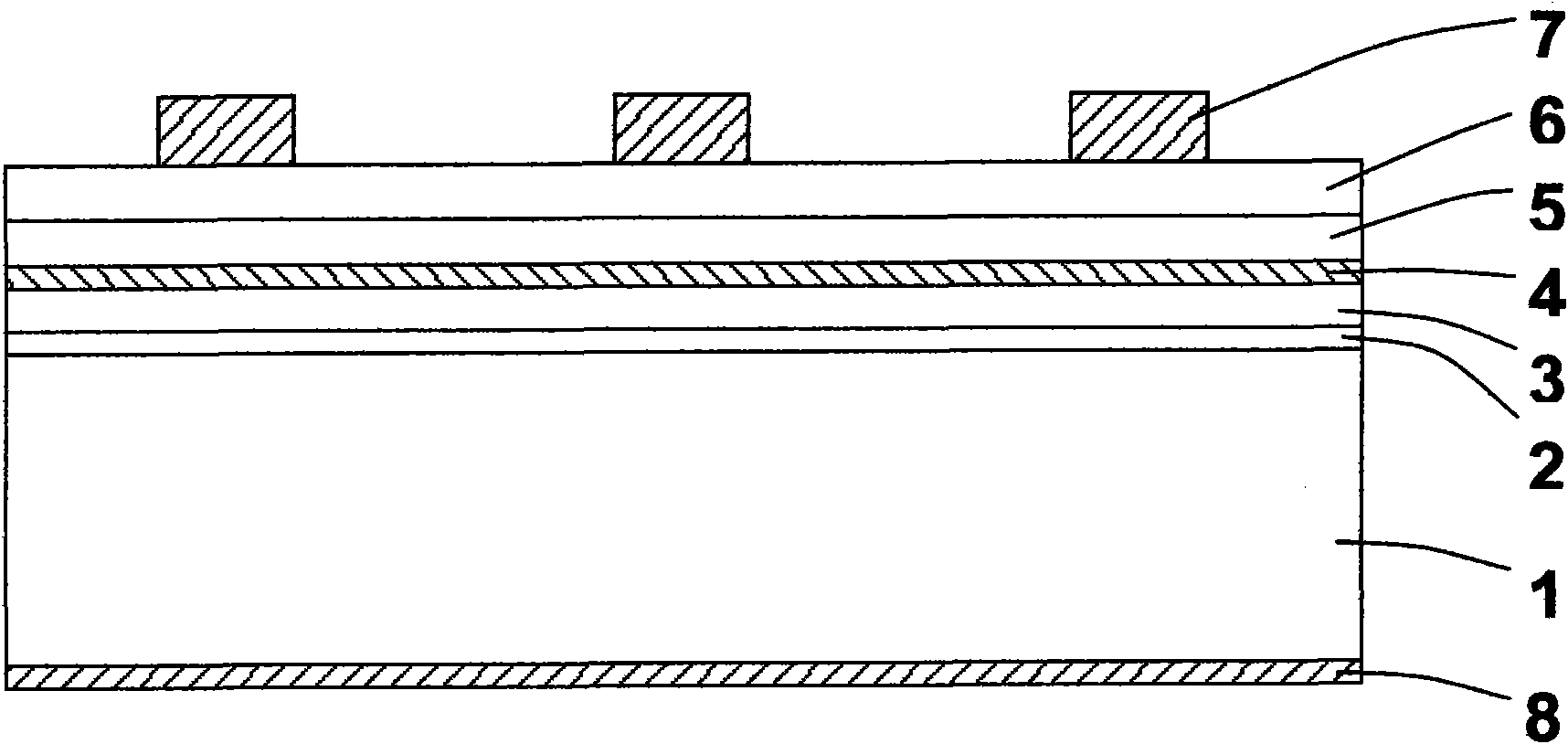

[0025] Such as figure 1 As shown, a distributed Bragg reflection layer 2, a first-type epitaxial layer 3, a light-emitting layer 4, a second-type epitaxial layer 5, and a window layer 6 are sequentially formed on a GaAs substrate 1; a P electrode 7 is formed on the window layer 6 And form an N electrode 8 on the bottom surface of the substrate 1 to form a wafer;

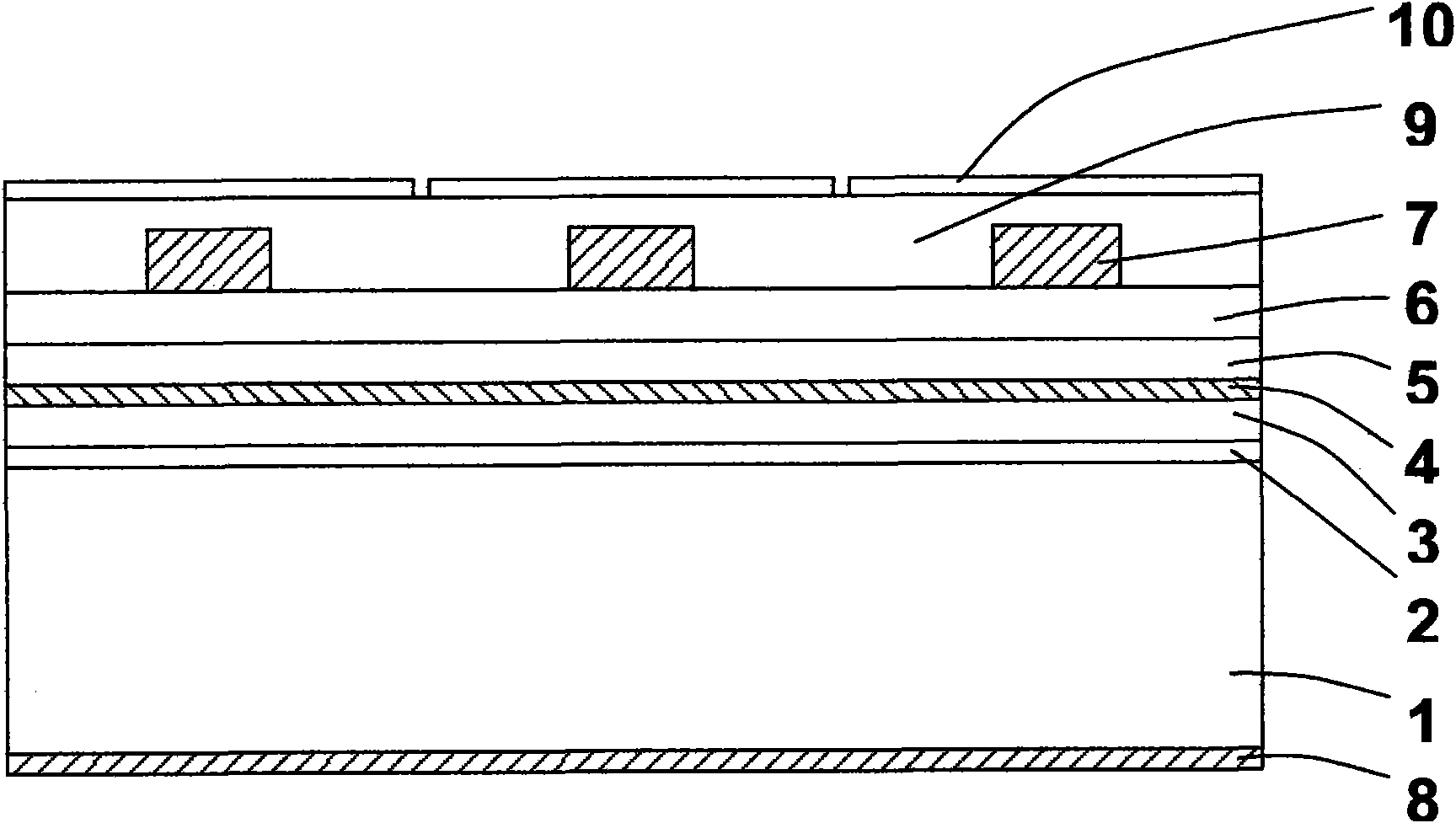

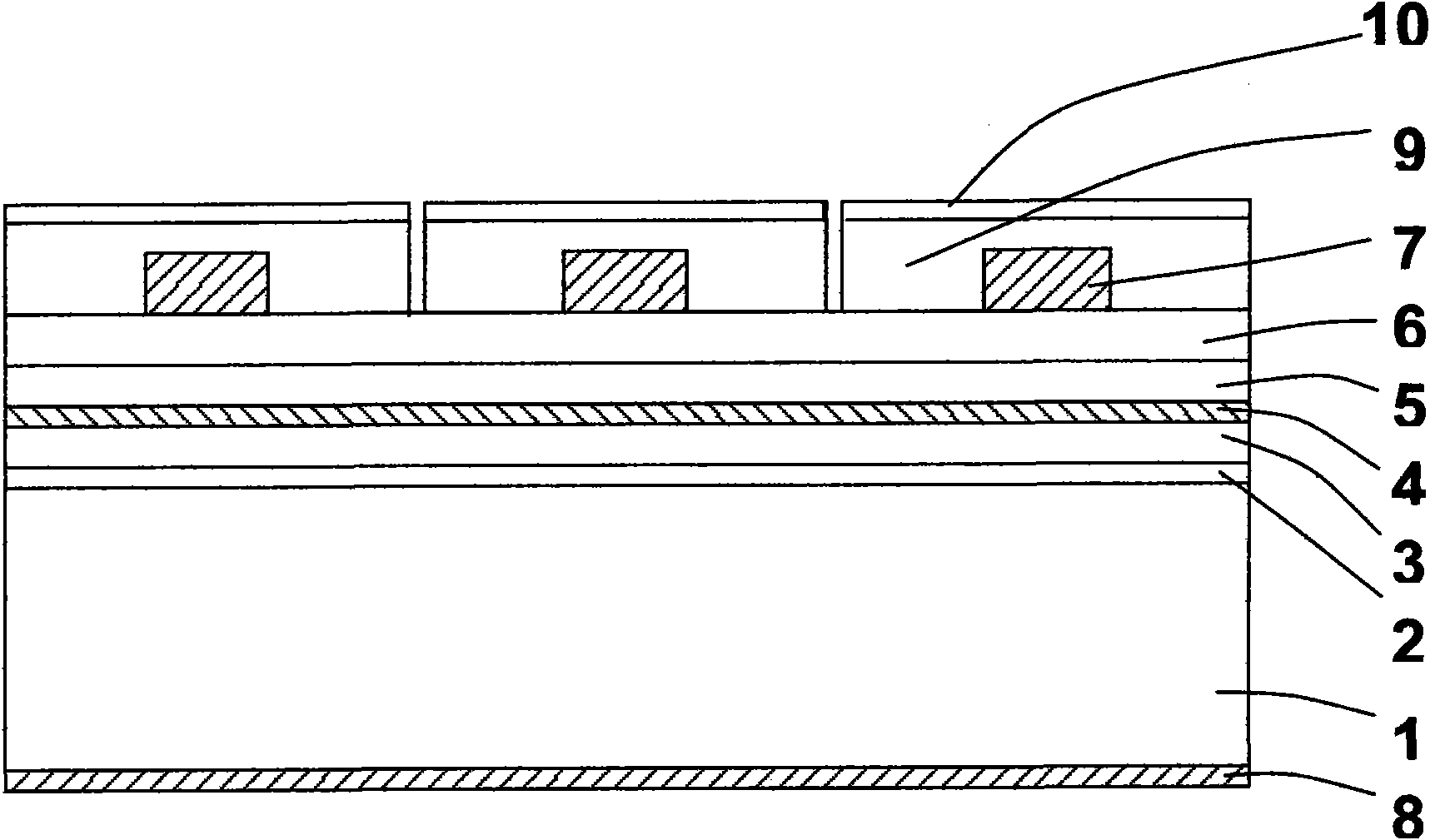

[0026] Such as figure 2 As shown, a protective layer is formed on the top surface of the wafer to cover the P electrode 7, and a 3 μm dicing line is formed on the top surface of the wafer by photolithography technology, and the size of the pre-cut grain is defined, wherein the top protective layer is made of SiO 2 The first protective la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com