Cable peeling device

A cable and peeling knife technology, applied in circuits, electrical components, electronic waste recycling, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of low labor intensity and high recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

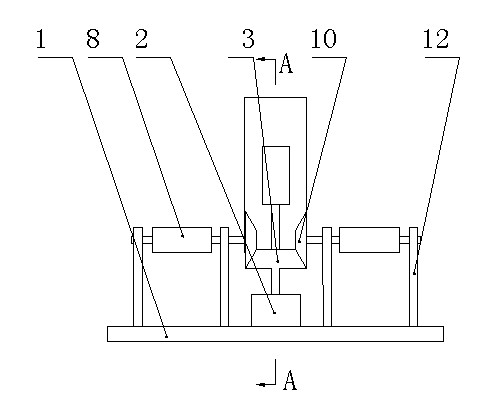

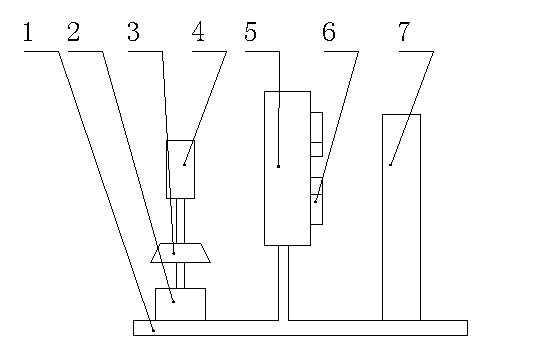

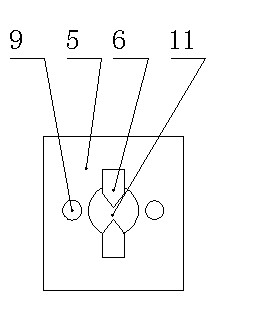

[0012] like figure 1 , figure 2 and image 3 As shown, a cable stripping device includes a support 1, a fixed plate 5 is provided on the support 1, two cable leather holes 9 and a cable core hole 11 are arranged on the fixed plate 5, two A peeling knife 6, a motor 2 is provided on the support 1, and a cable core reel 4 is fixed on the output shaft of the motor 2.

[0013] The output shaft of the main motor 2 is provided with a driving bevel gear 3, the driving bevel gear 3 meshes with two driven bevel gears 10, the output shaft of the driven bevel gear 10 is fixed with a cable sheath reel 8, and the driven bevel gear 10 outputs The shaft is arranged on the bracket 12 .

[0014] The method used in the present invention is as follows: wind the waste and old cables on the fixing column 7, first manually separate the cable sheath at the end of the waste and old cables from the cable core, the cable sheath is divided into two parts, and the two parts are separated from the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com