Patents

Literature

1175results about "Basic electric elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

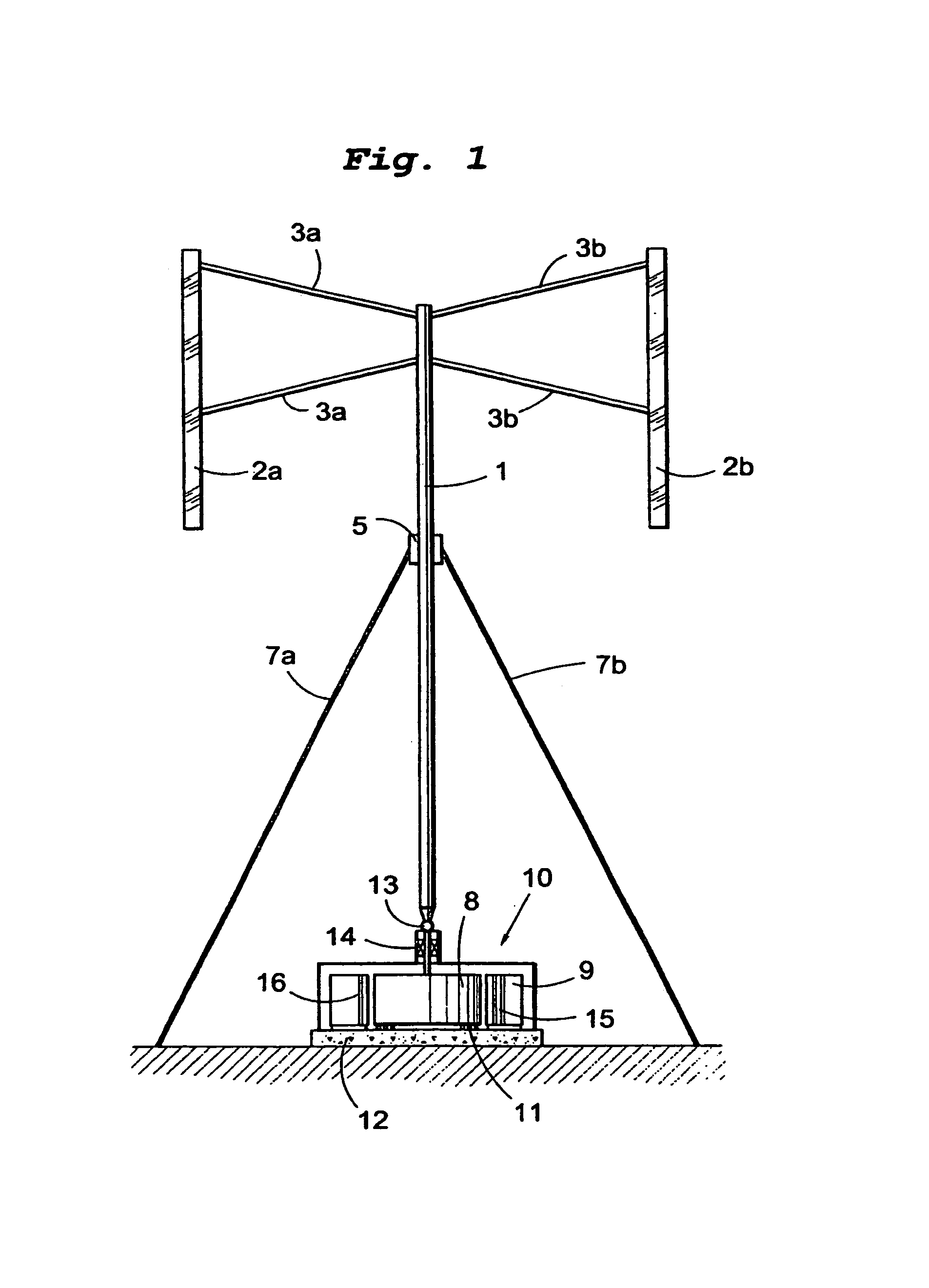

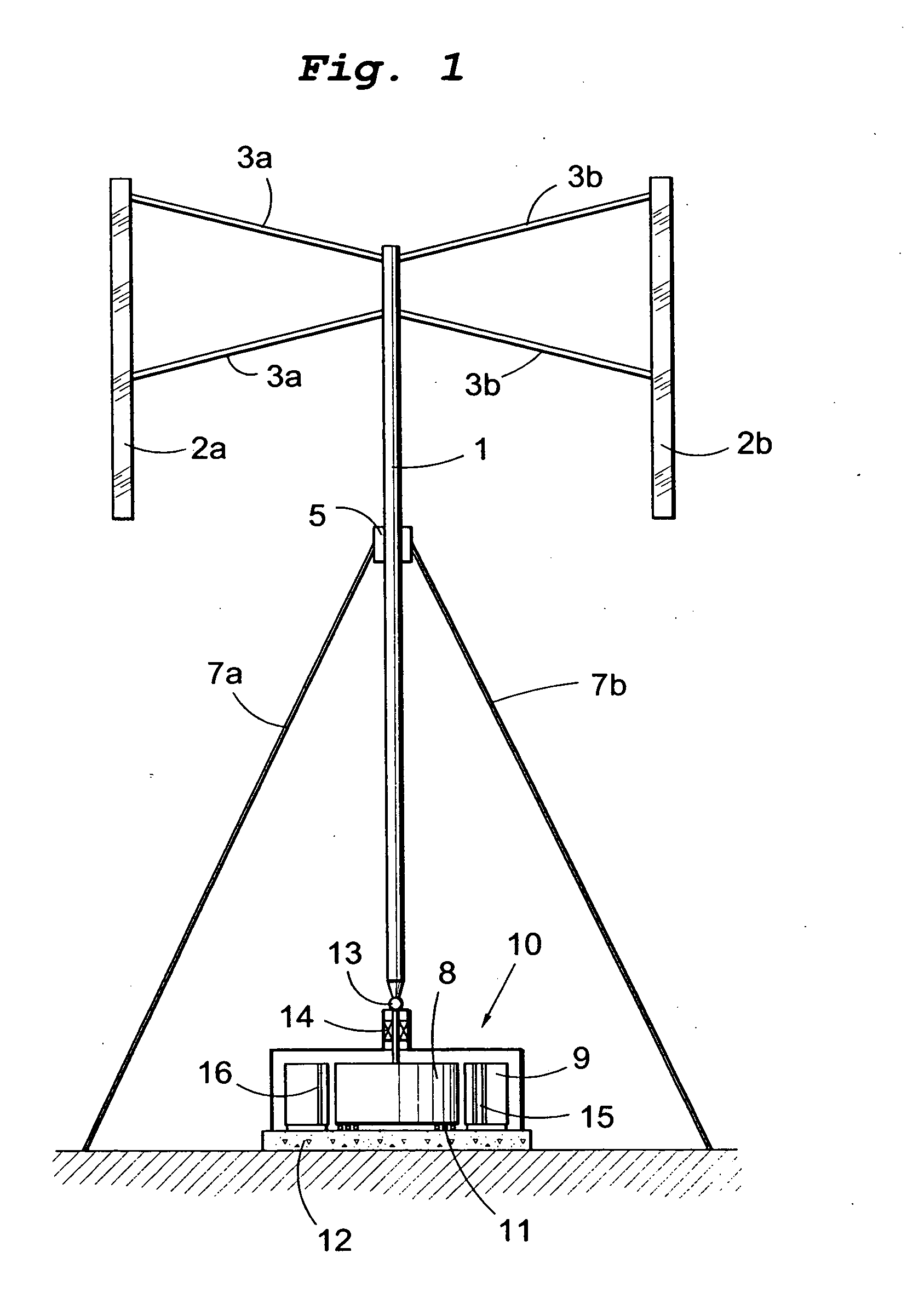

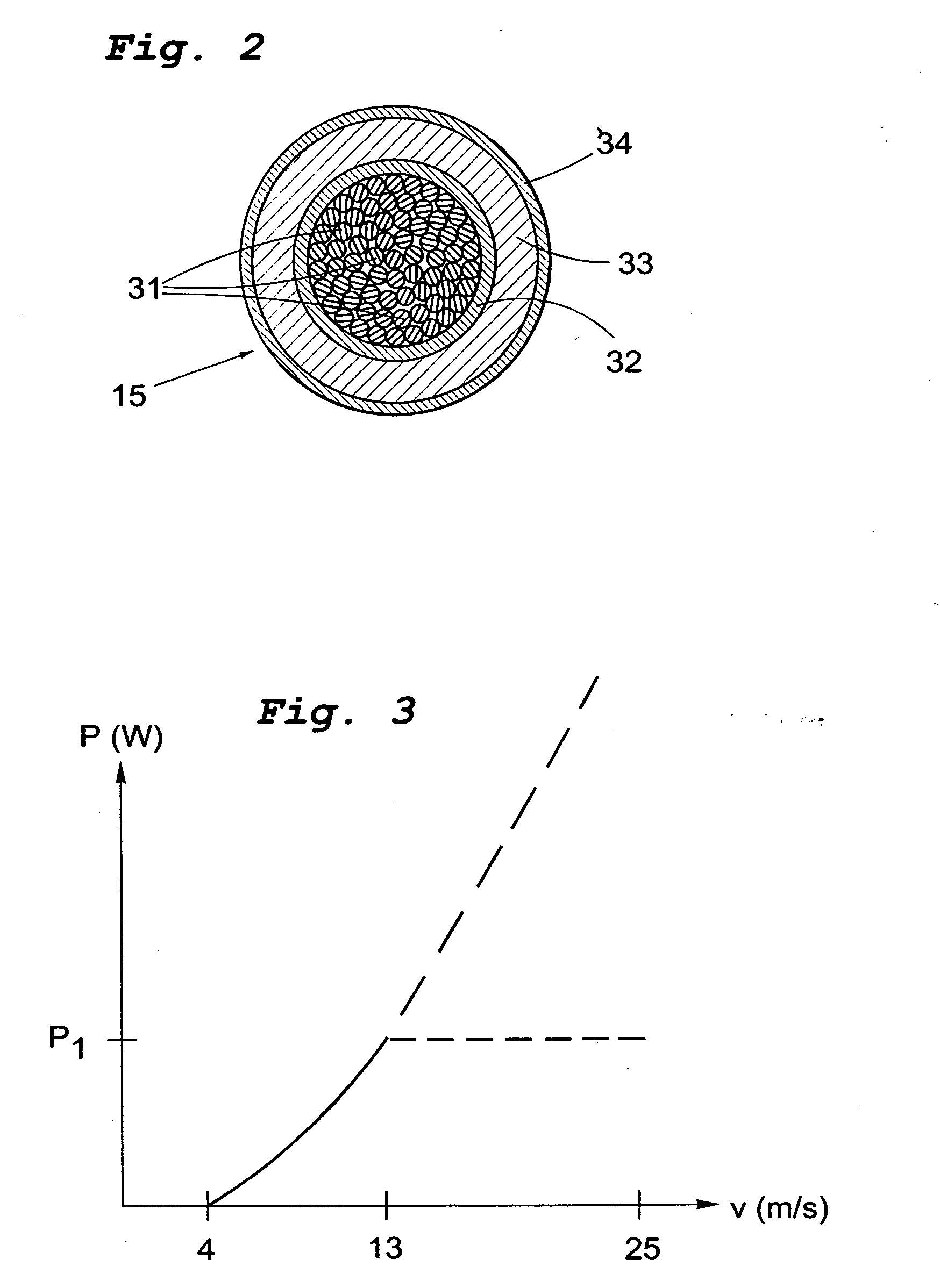

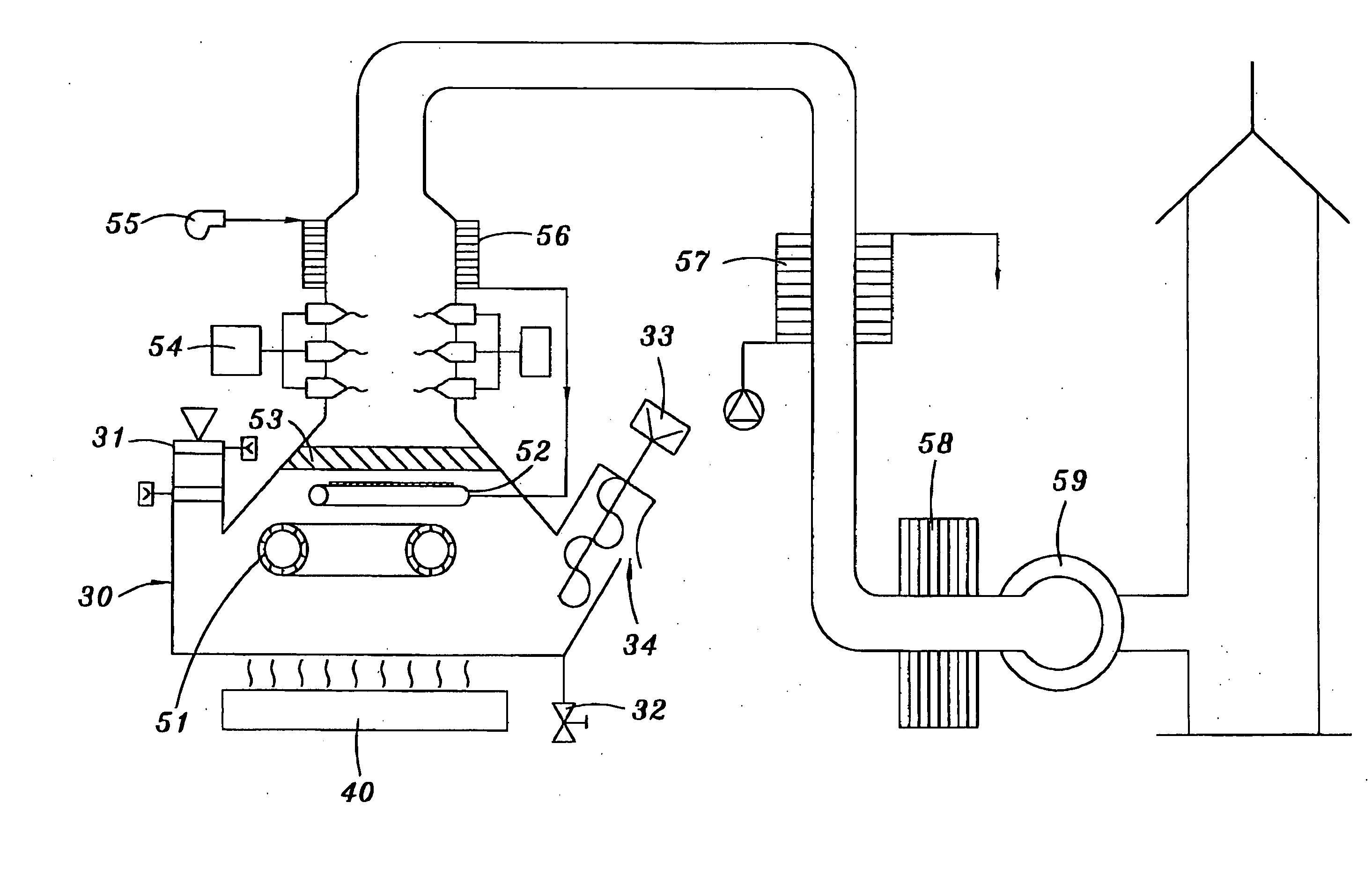

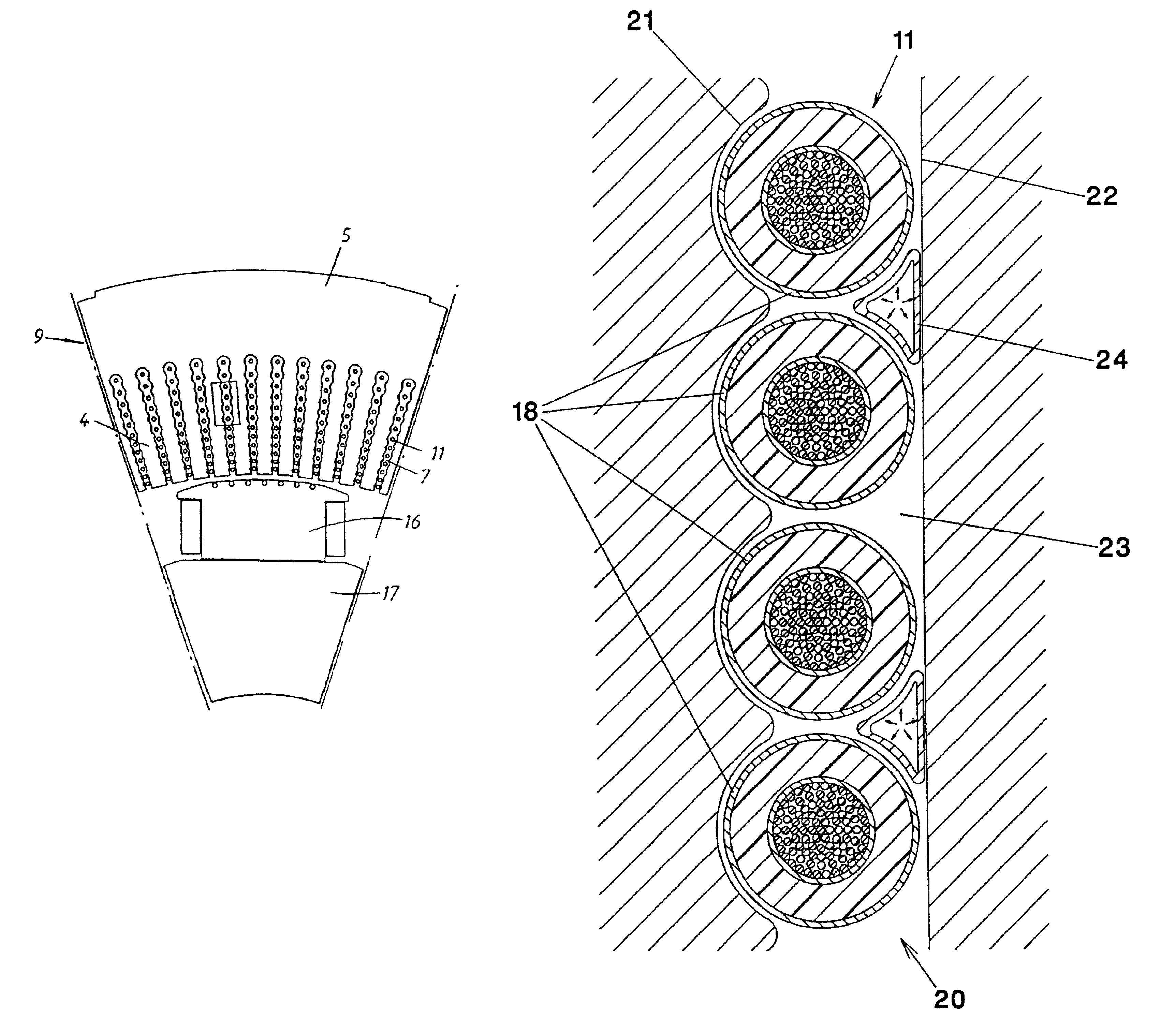

Wind power plant

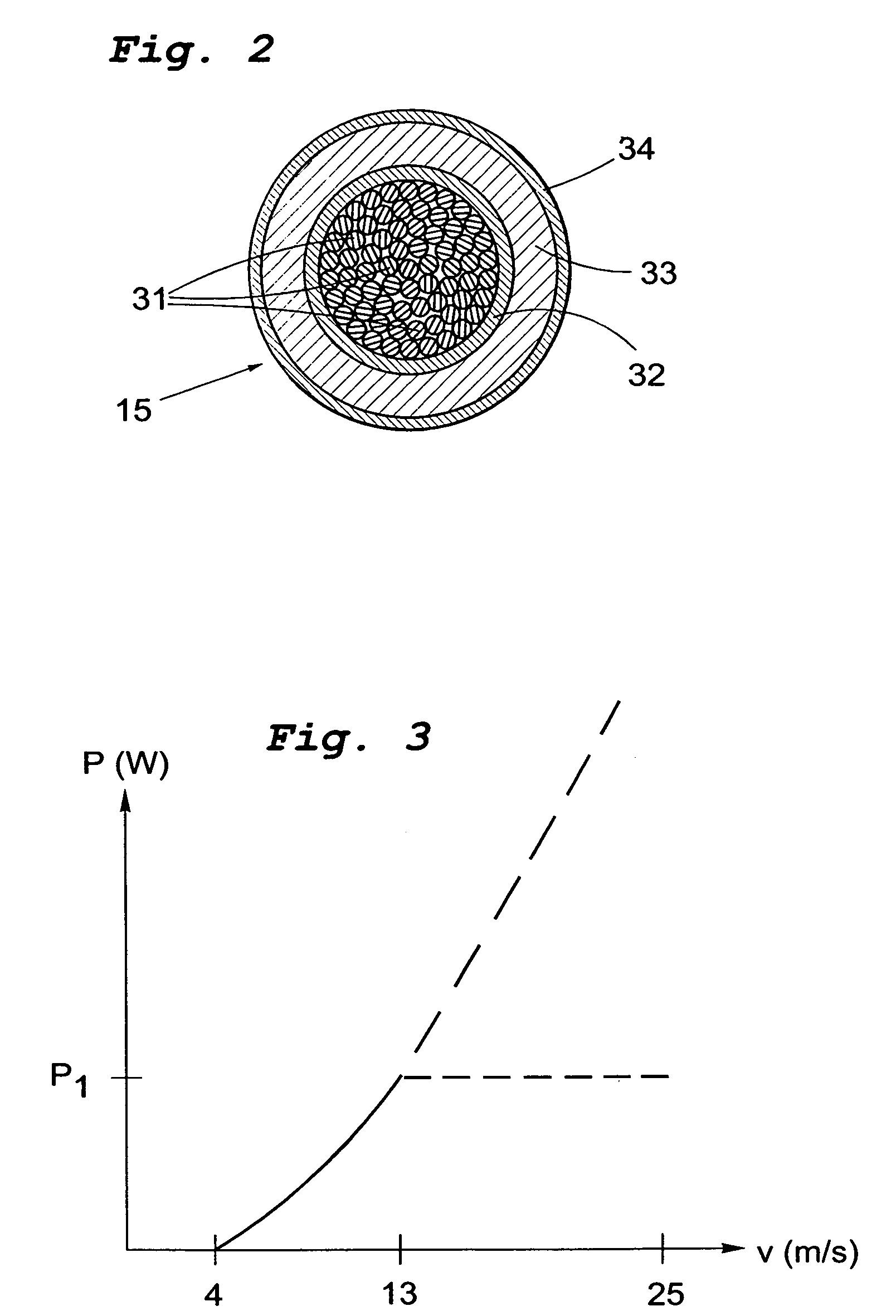

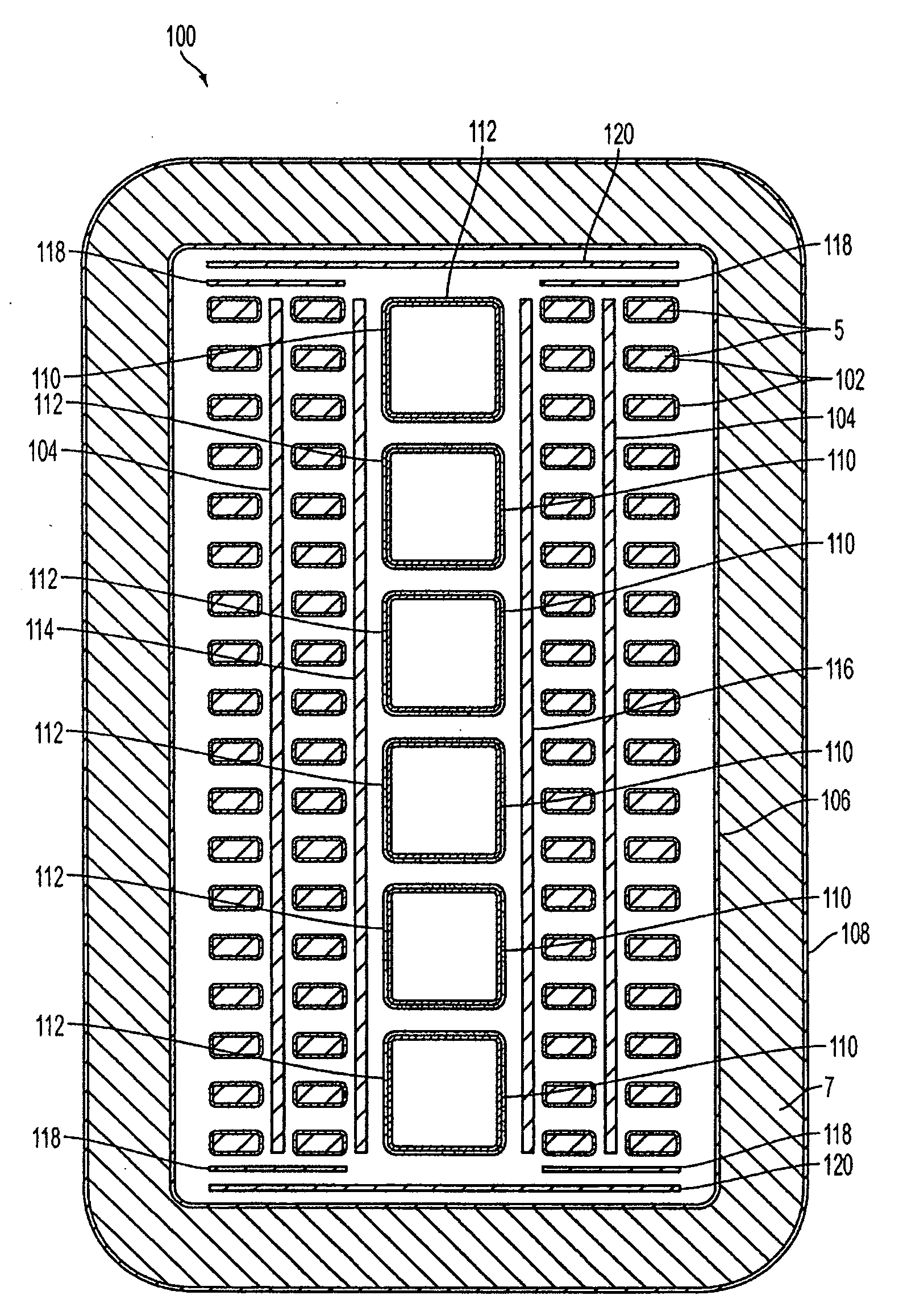

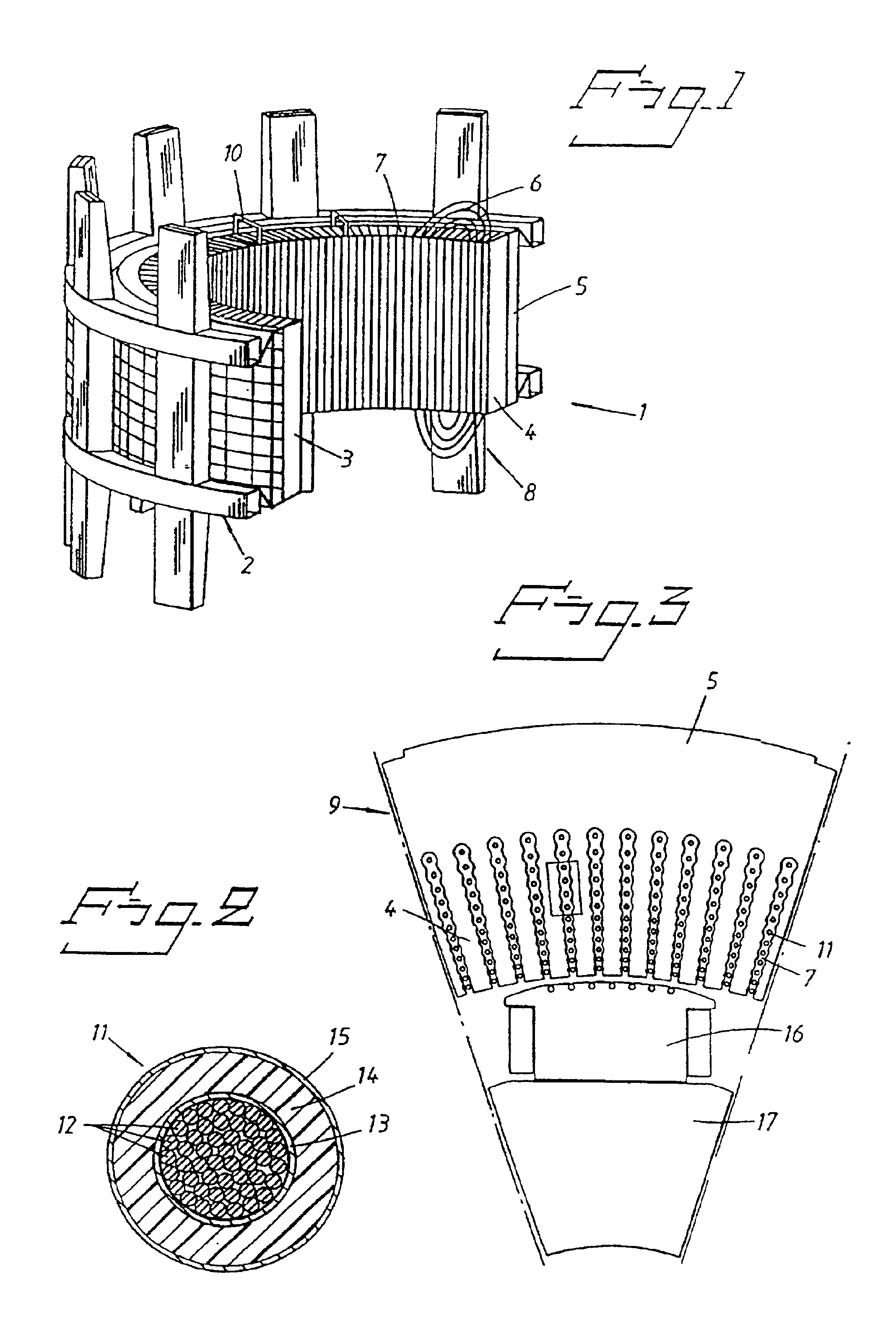

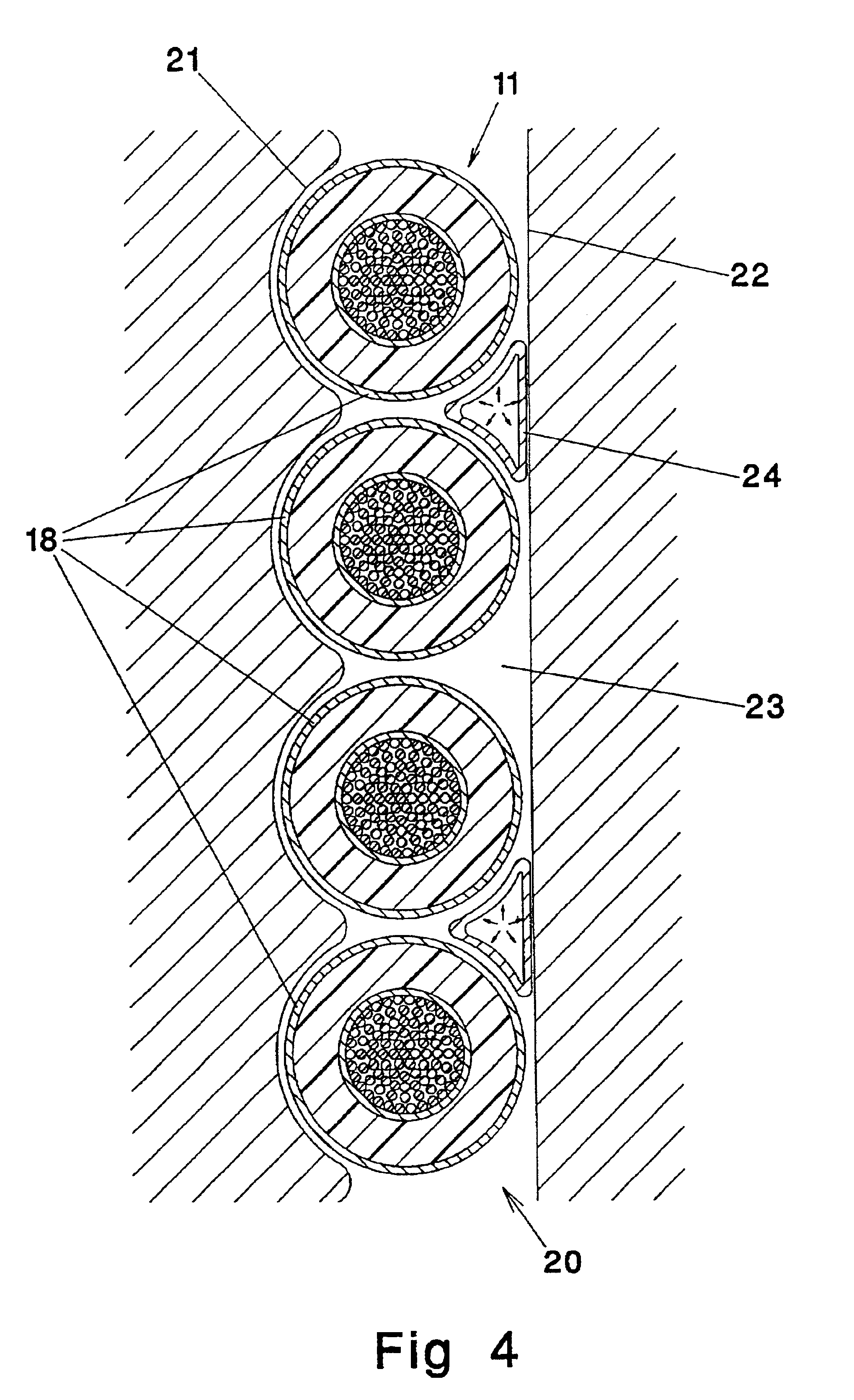

InactiveUS7061133B1Low stray lossEasy to storeWindings insulation shape/form/constructionMagnetic circuitPeaking power plantElectrical conductor

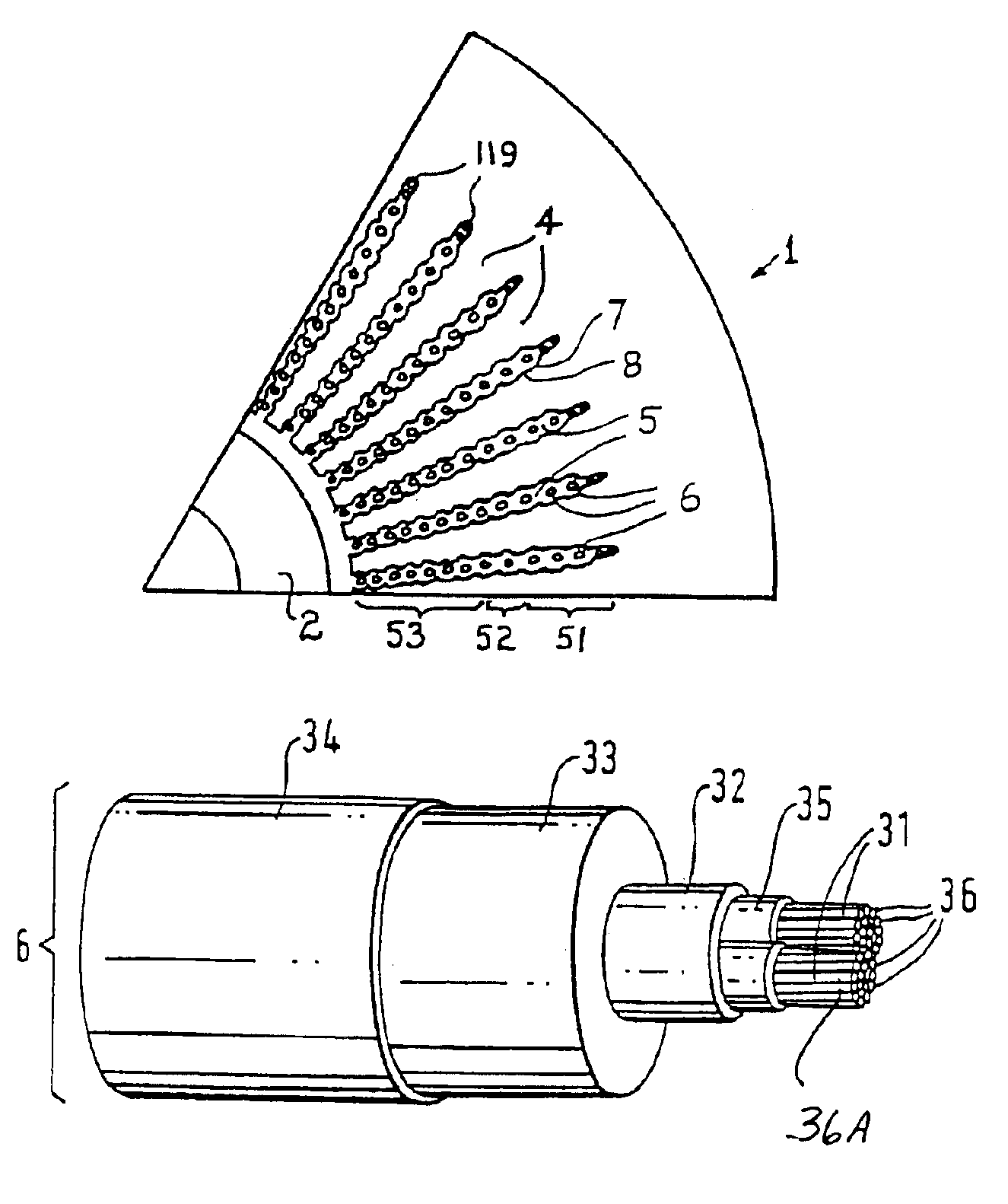

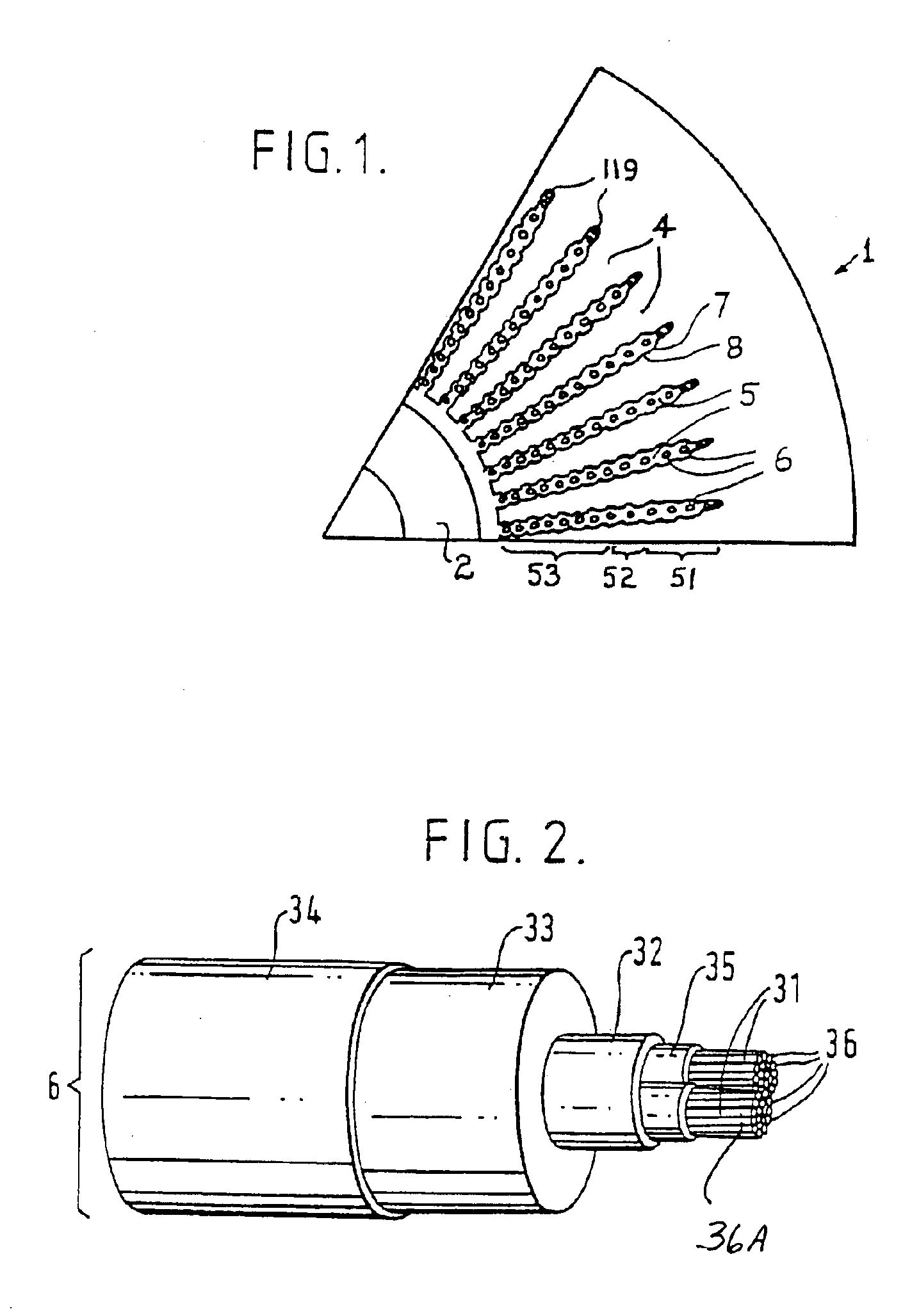

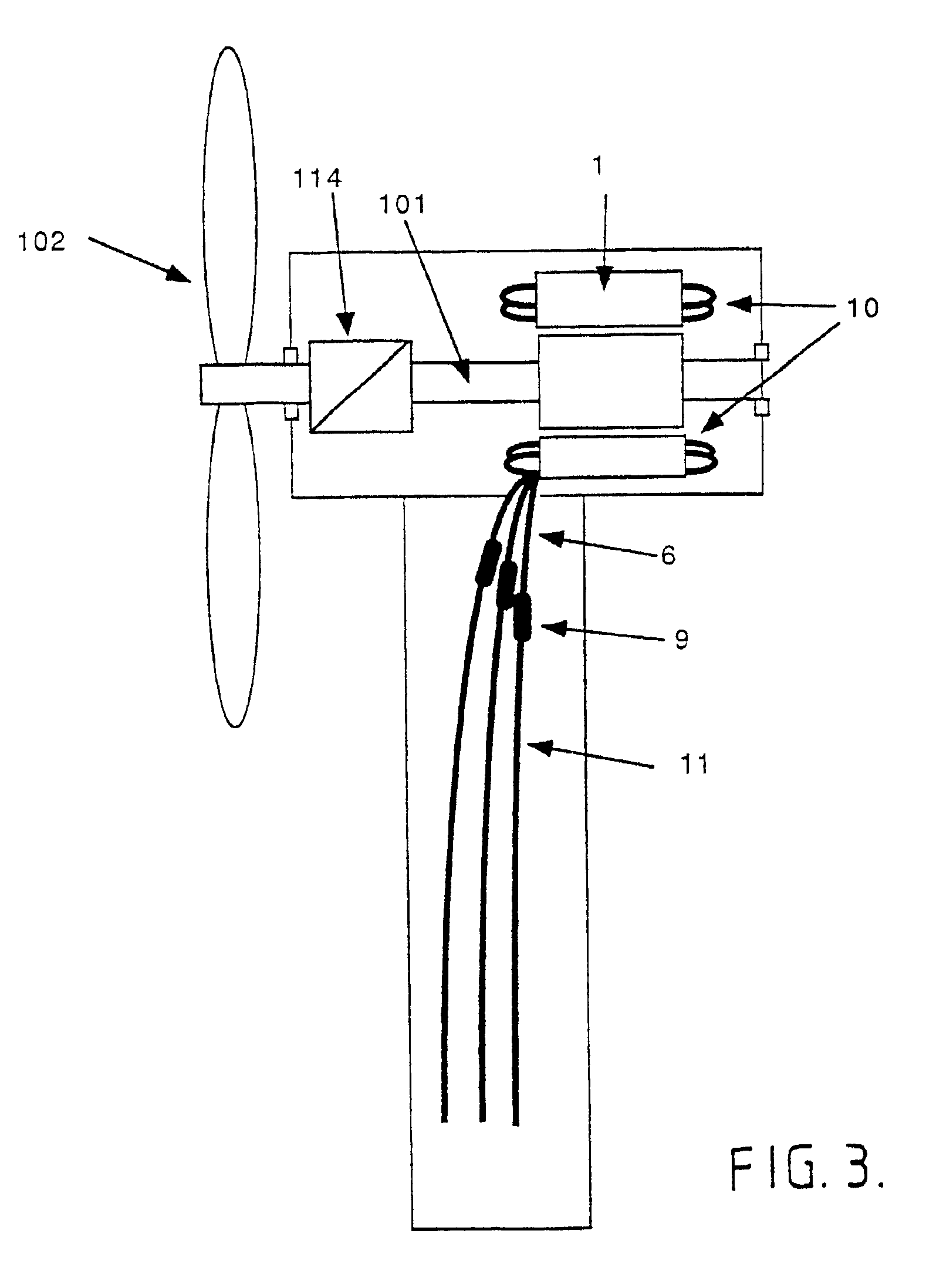

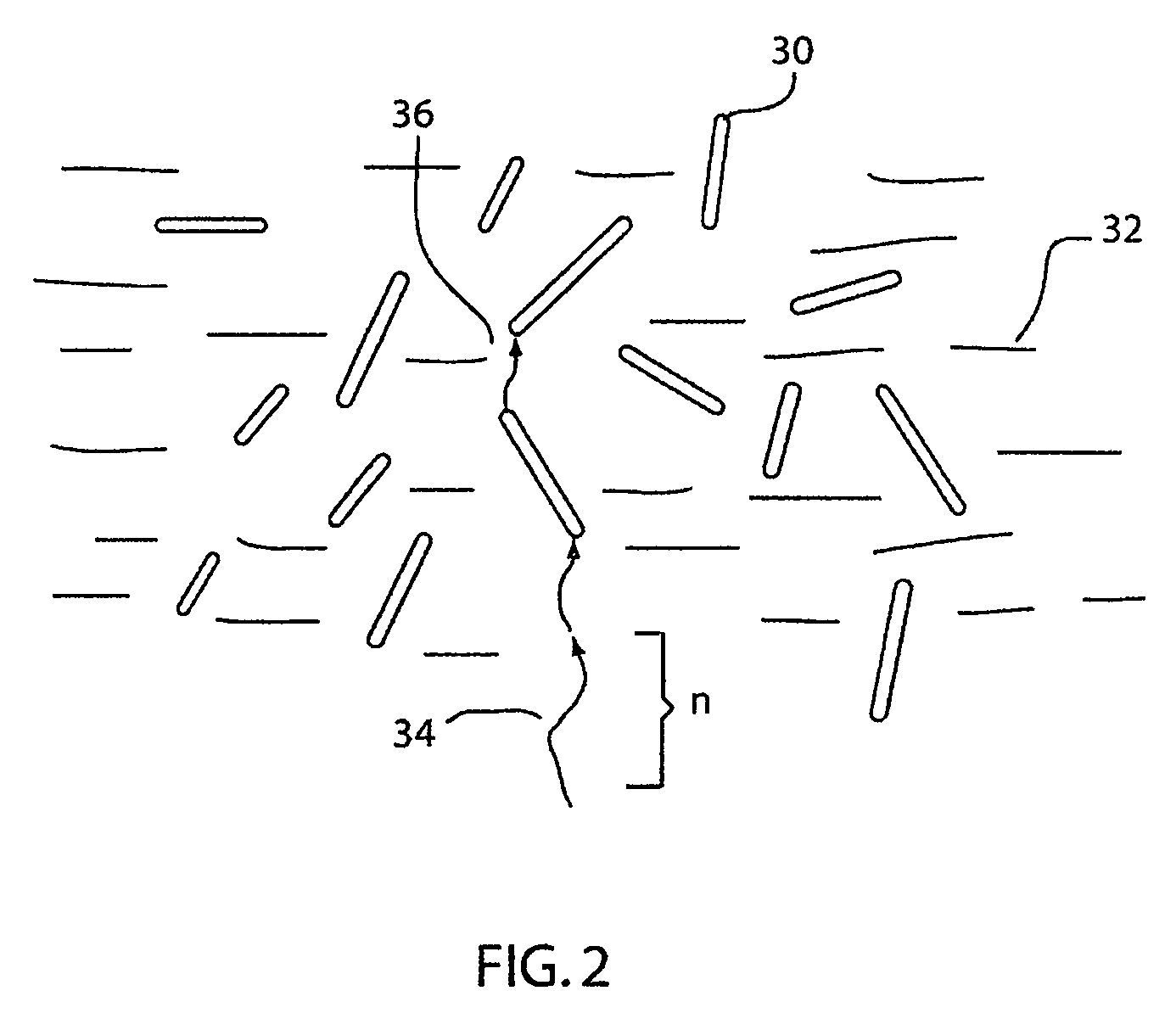

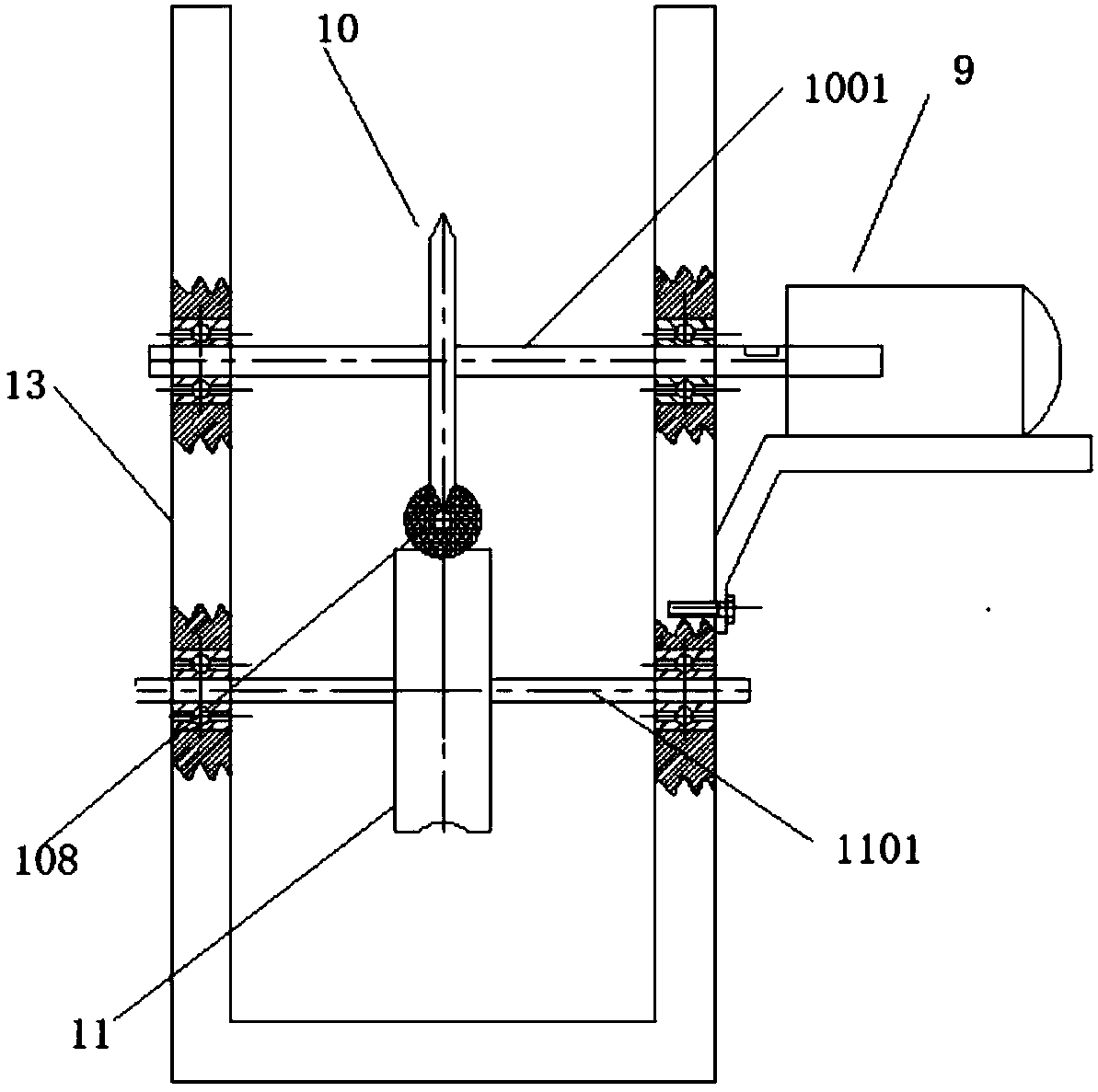

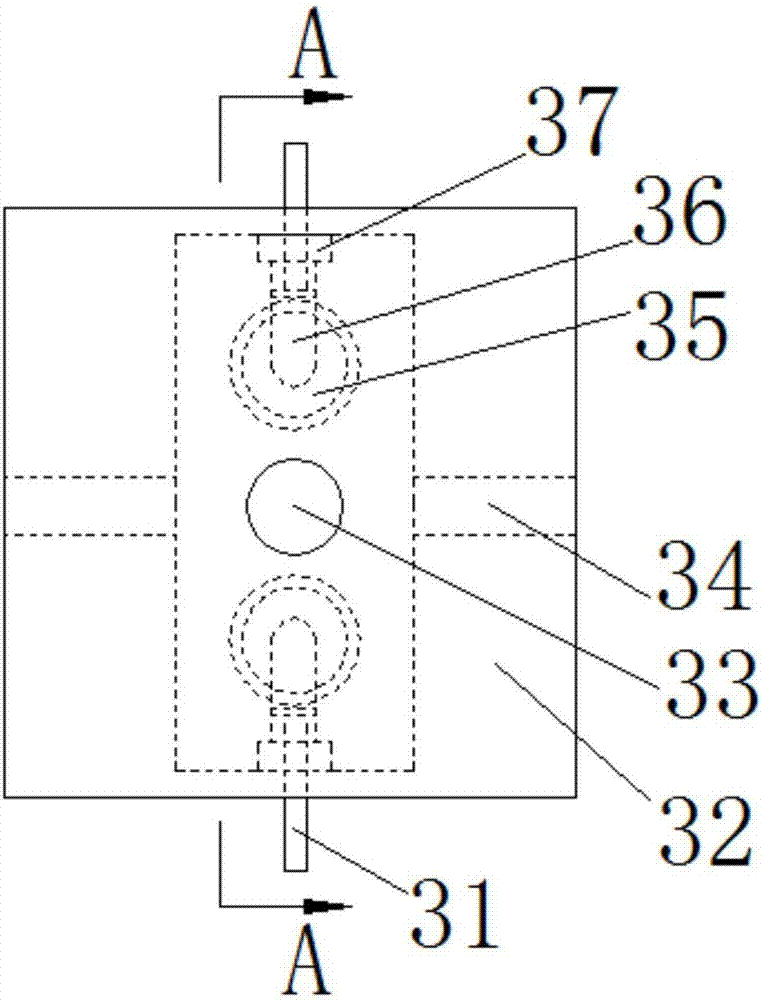

The magnetic circuit of a generator in a wind power plant is arranged to directly supply a high supply voltage of 2-50 kV, preferably higher than 10 kV. The generator is provided with solid insulation and its winding includes a cable (6) comprising one or more current-carrying conductors (31) with a number of strands (36) surrounded by at least one outer and one inner semiconducting layer (34, 32) and intermediate insulating layers (33). The outer semiconducting layer (34) is at earth potential. The stator winding may be produced with full or fractional slot winding, the phases of the winding being Y-connected. The Y-point may be insulated and protected from over-voltage by means of surge arrestors, or else the Y-point may be earthed via a suppression filter. The invention also relates to a wind power plant, a generator included in the plant and a variable speed system for such a plant.

Owner:ABB (SCHWEIZ) AG

Wind power electric device and method

InactiveUS7126235B2High induced voltageEasy windingWindings insulation shape/form/constructionWind motor controlSemiconductor materialsHigh pressure

A wind-power unit has a wind turbine has an electric generator connected to the wind turbine. The stator of the generator has a winding formed of a high-voltage cable having a core of conducting material, a first layer of semiconducting material surrounding the core, an insulating layer of solid material surrounding the first layer, and a second layer of semiconducting material surrounding th solid insulation. The wind turbine has a plurality of turbine blades running vertically and being connected to a turbine shaft. The generator is arranged at the lower end of the turbine shaft. A wind-power plant; the use of a wind-power unit; and a method of generating electric power are described.

Owner:VERTICAL WIND AB

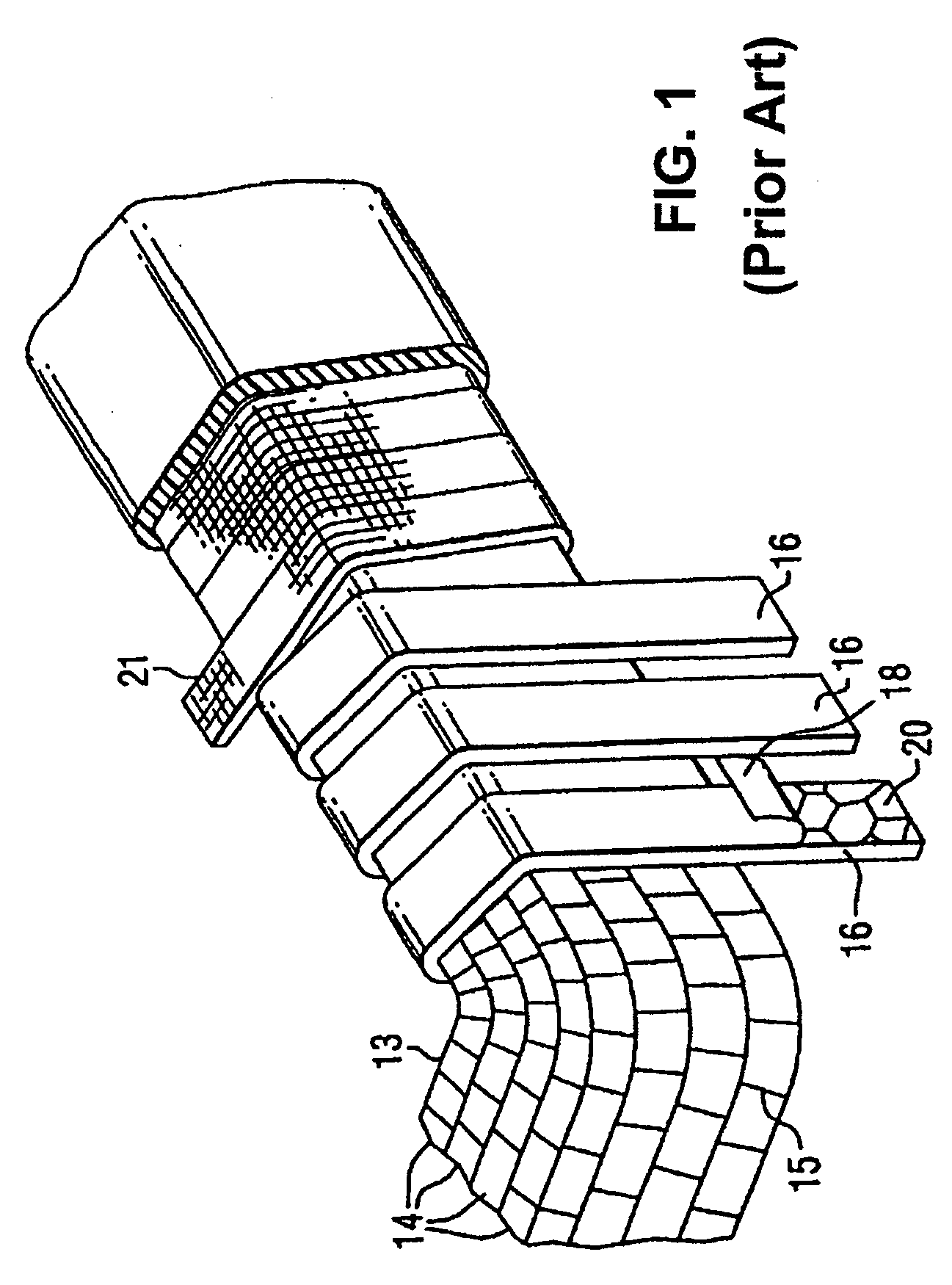

Stator coil with improved heat dissipation

ActiveUS20080284262A1Improve heat transfer performanceImprove thermal conductivityWindings insulation materialMagnetic circuitStator coilCopper

A stator coil includes a plurality of copper strands and a layer of high thermal conductivity polymer disposed adjacent at least one of the copper strands. The high thermal conductivity polymer includes a host polymer and a high thermal conductivity filler. The high thermal conductivity polymer improves heat transfer from the plurality copper strands.

Owner:SIEMENS ENERGY INC

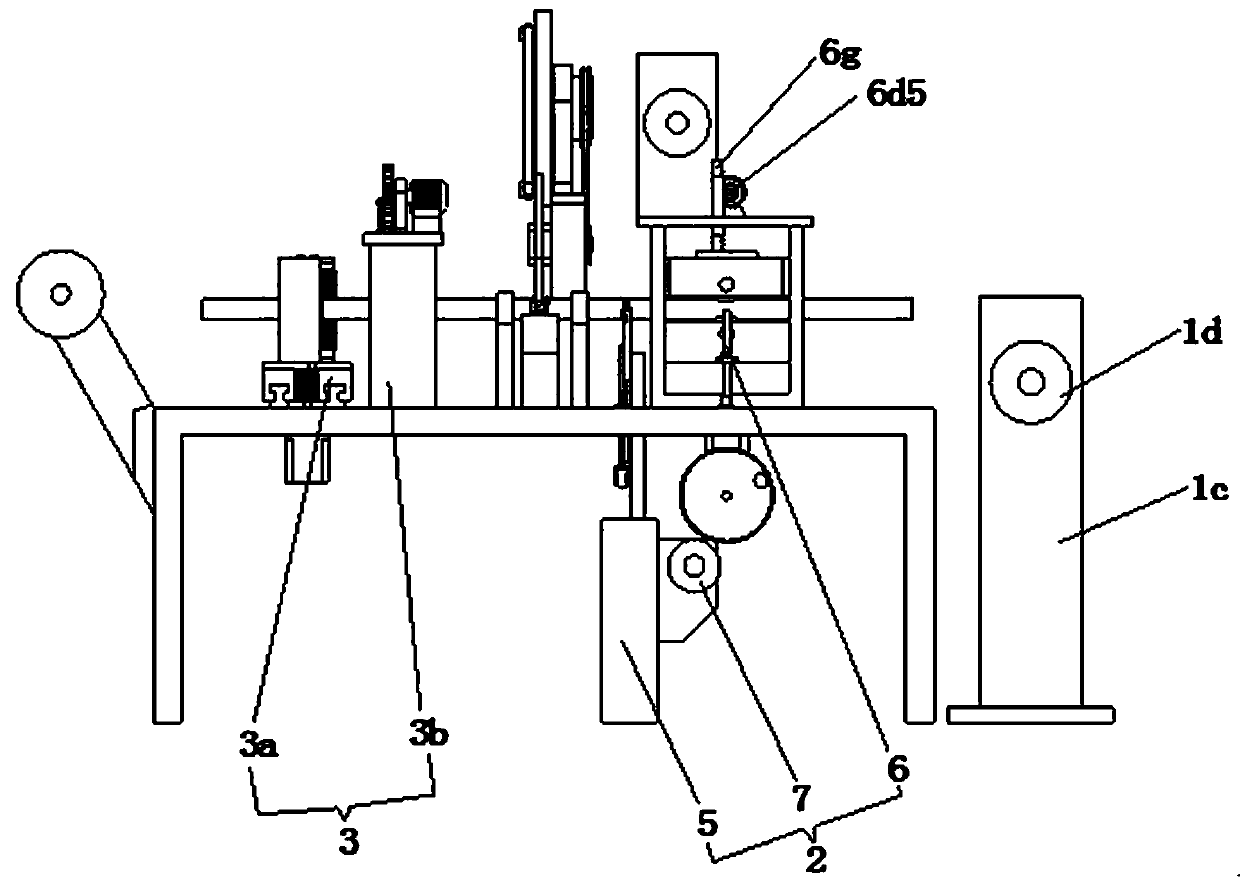

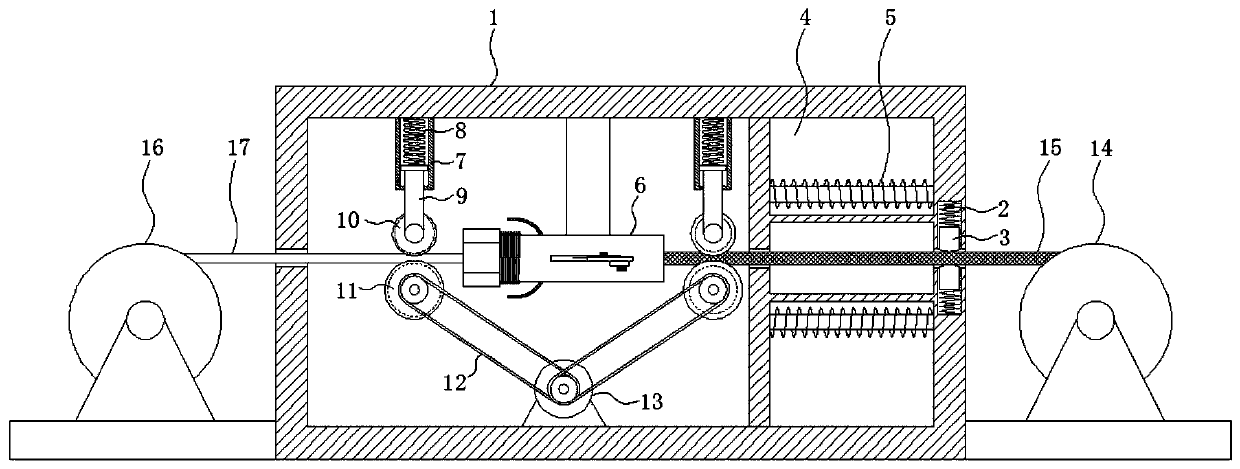

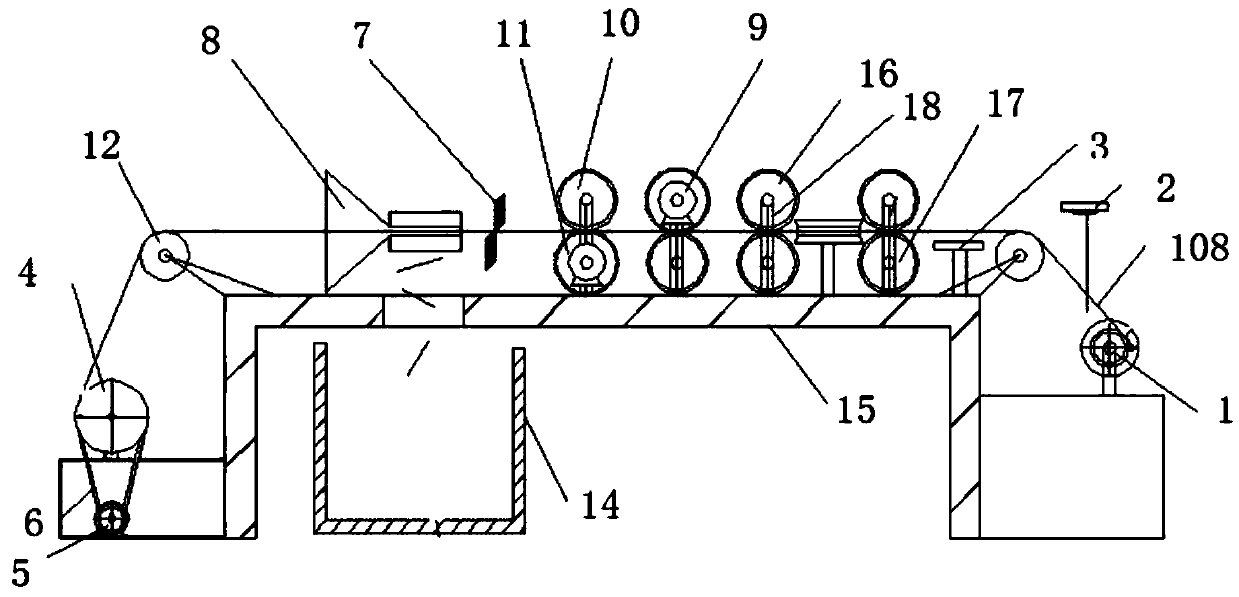

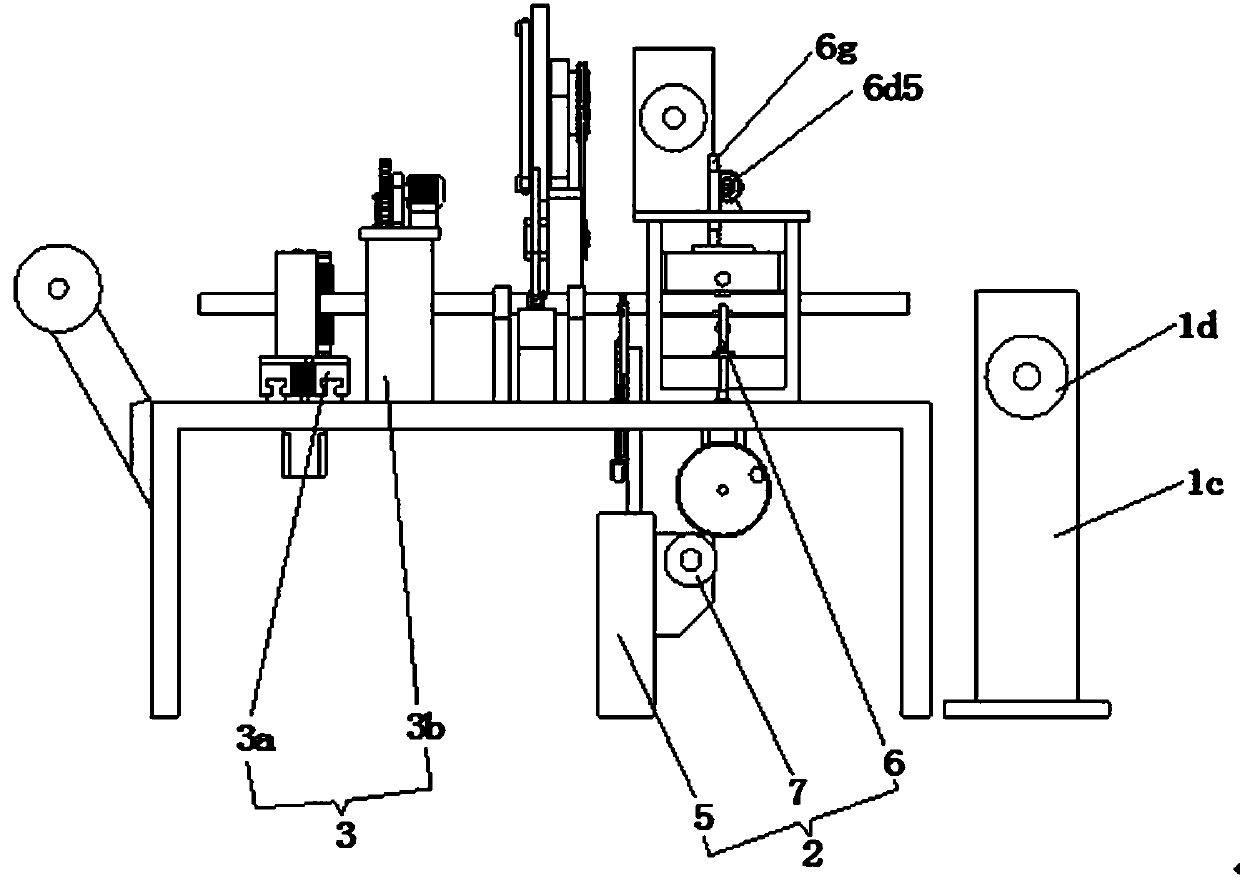

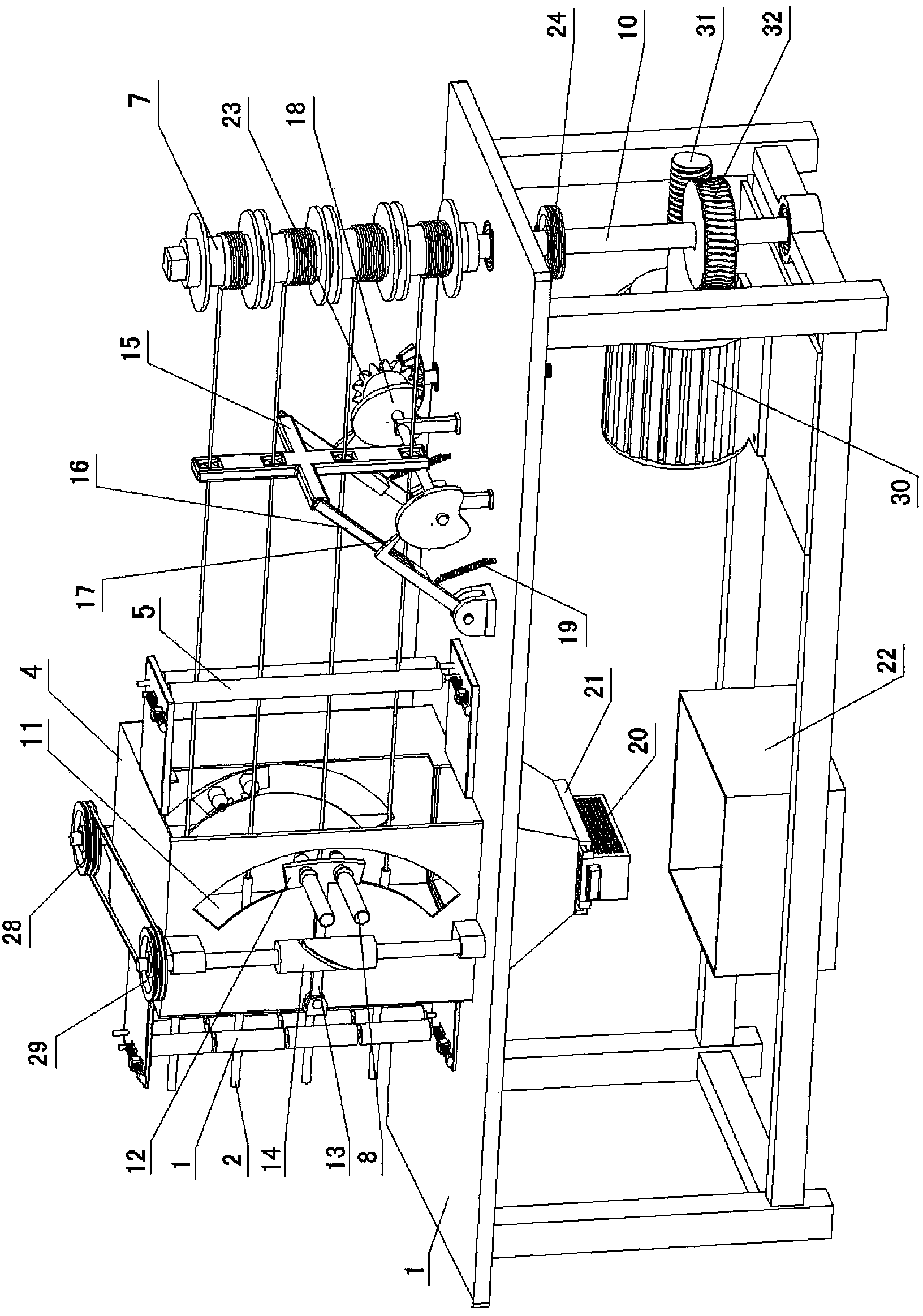

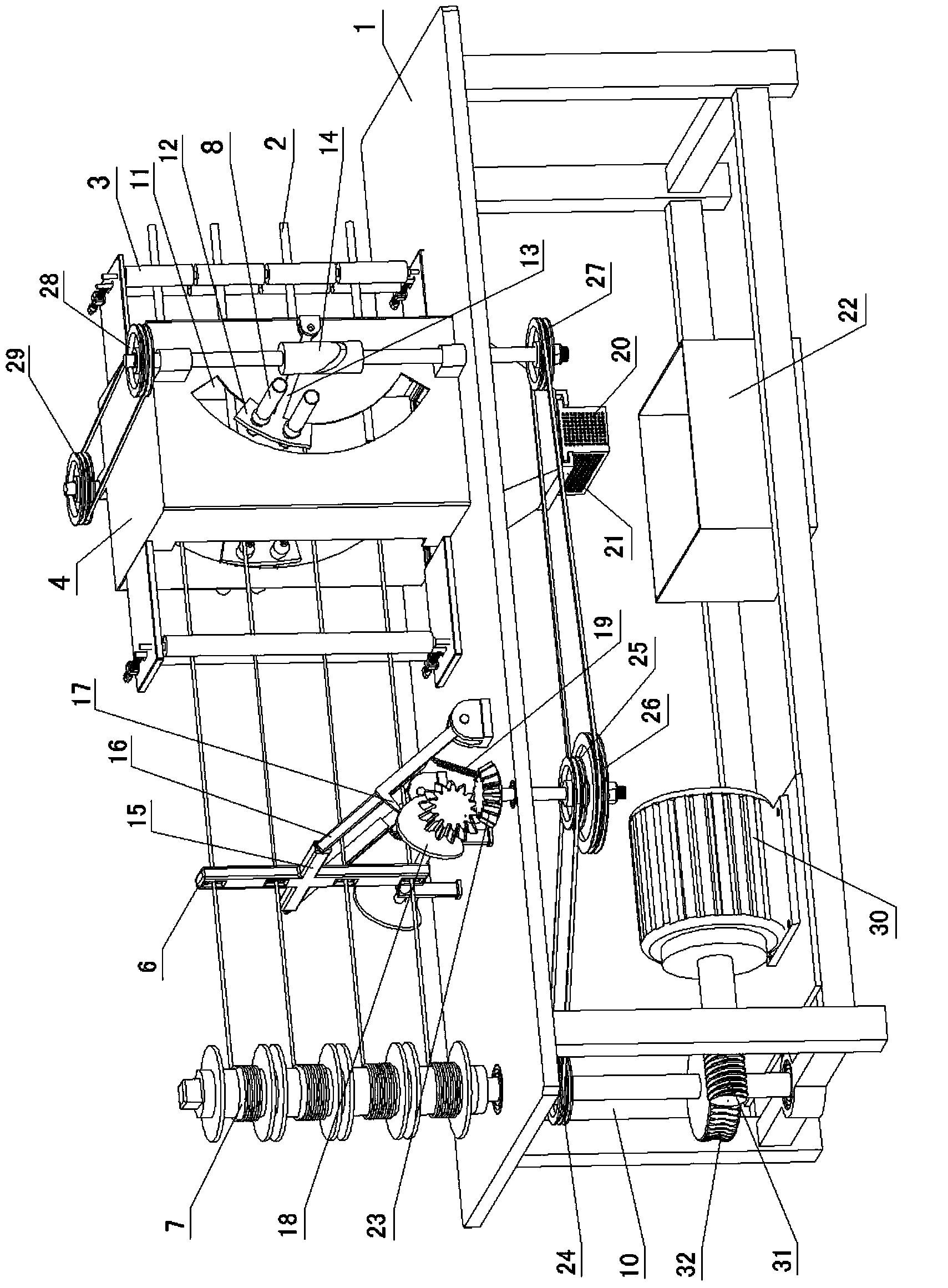

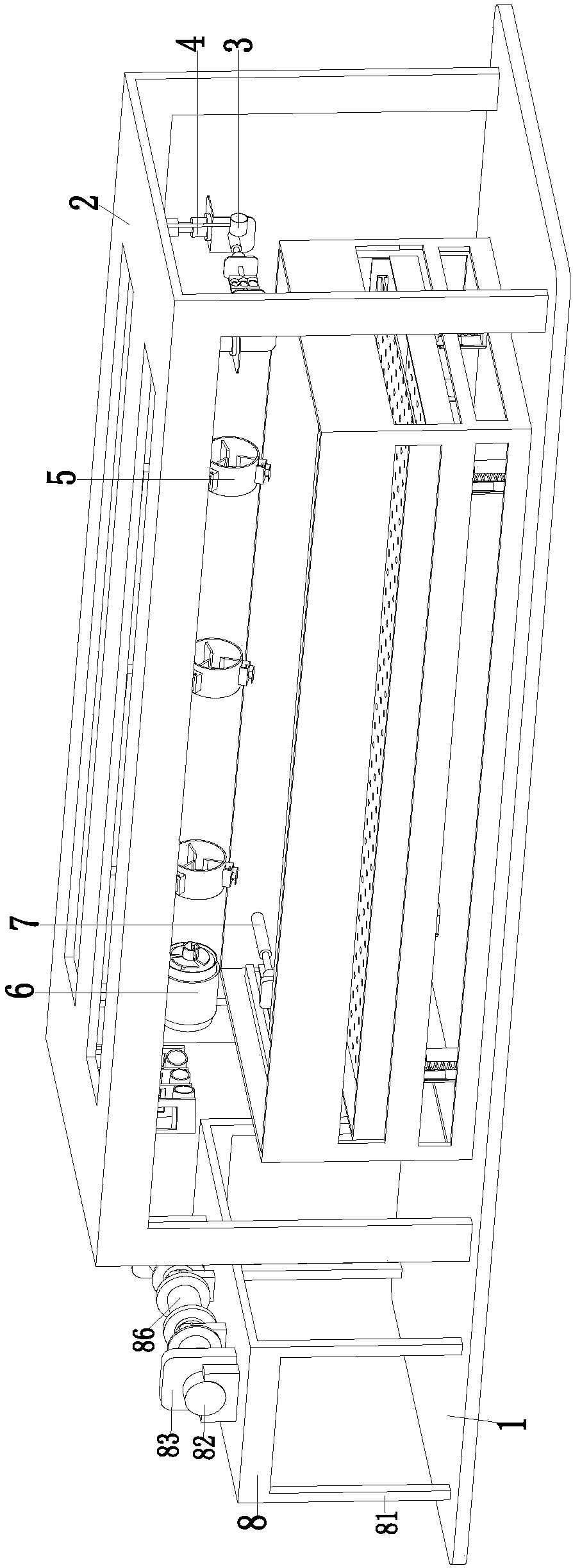

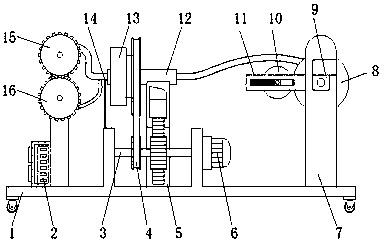

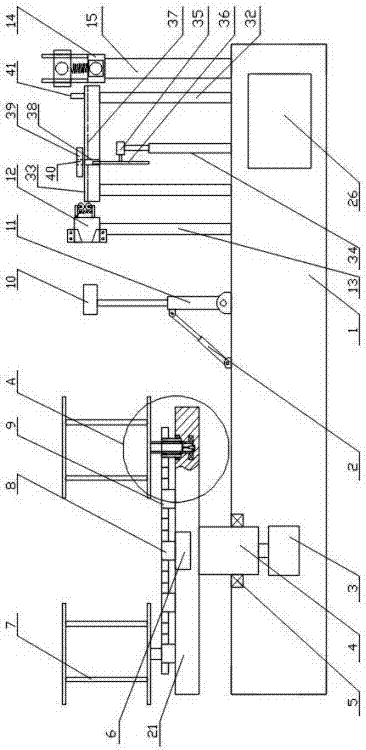

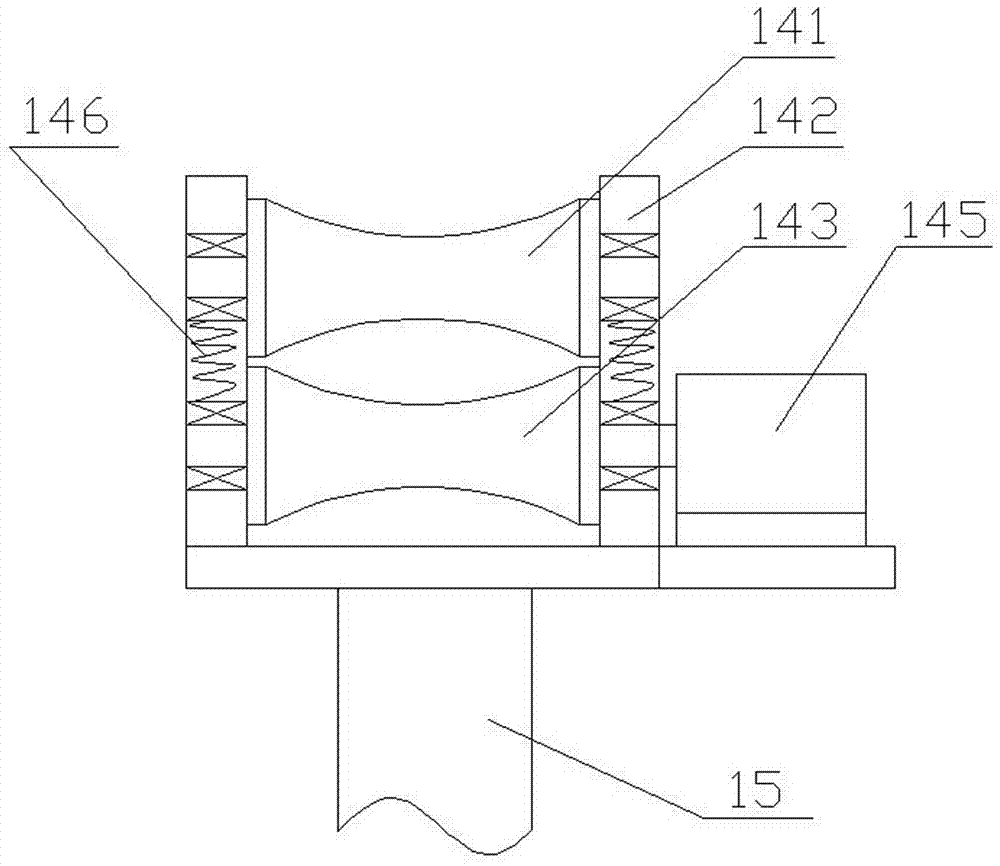

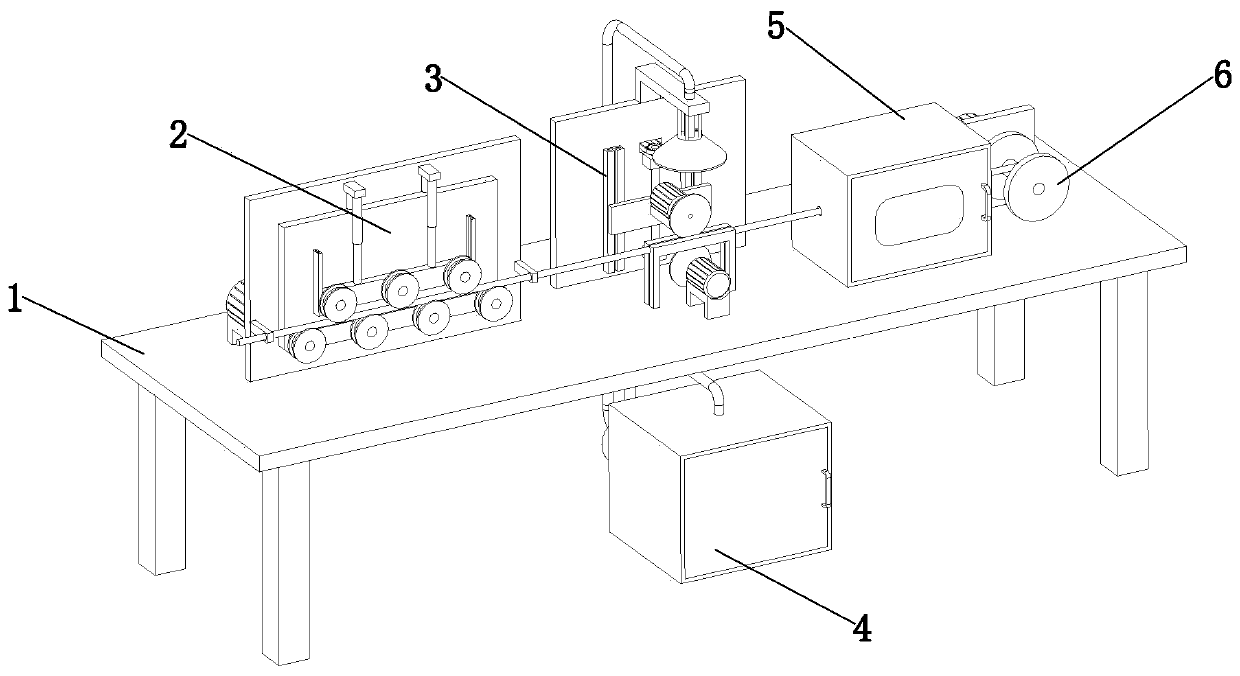

Waste Cable Recovery System

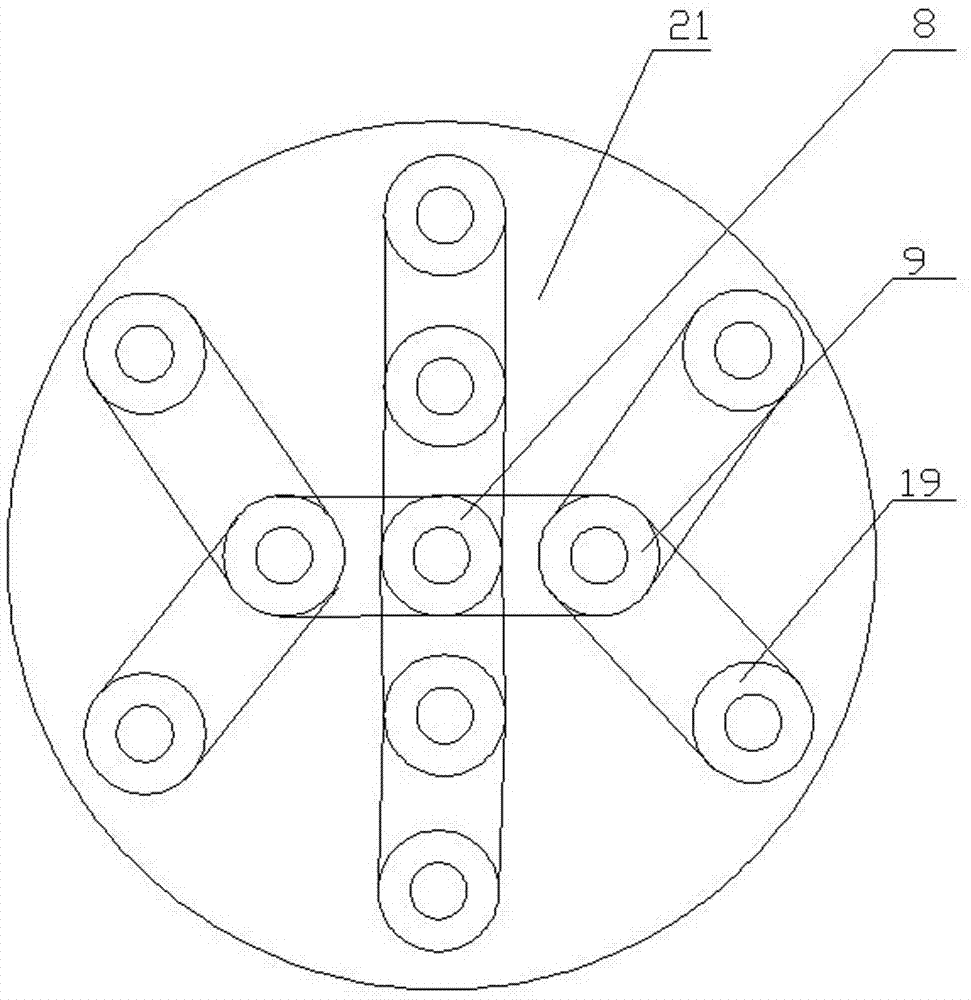

ActiveCN109036736AImprove recycling effectAvoid stickingBasic electric elementsApparatus for removing/armouring cablesEngineeringCopper

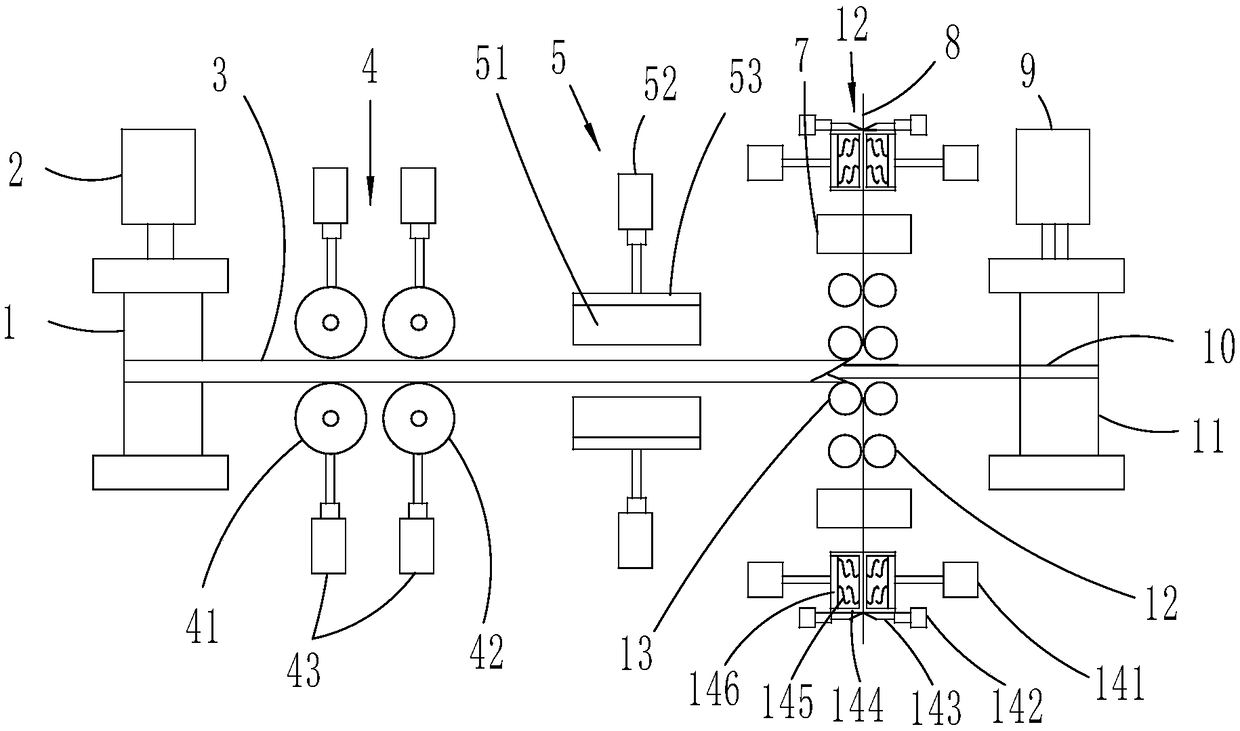

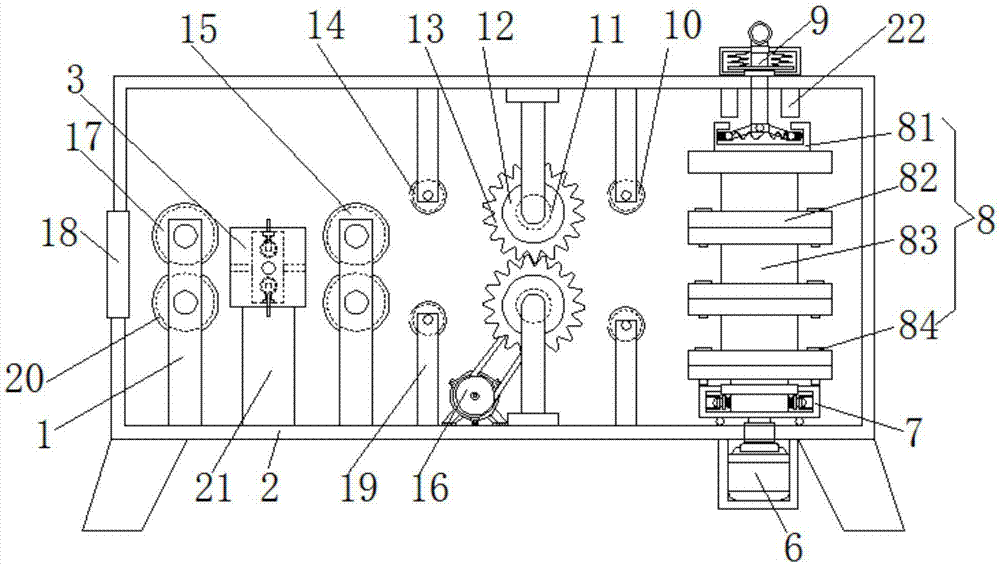

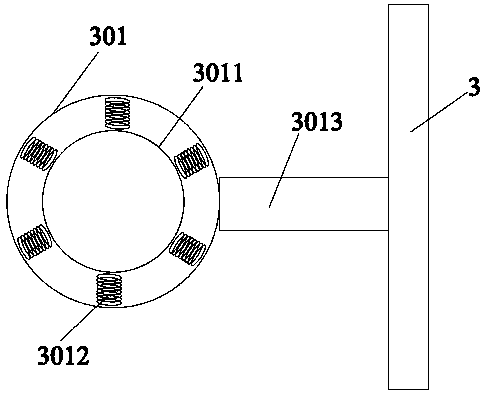

The invention provides a waste cable recovery system and belongs to the technical field of waste cable reuse. The system includes frame, pay-off roll, straightening device, cutting device, cop core winding roller, two cooling devices, two cutting devices and crushing device. A let-out roller, a straightening device, a cutting device and a cop core winding roller are arranged in sequence from one end of that frame, two cooling device and two cutting devices are arranged between the cutting device and the cop core winding roller and are symmetrically arranged on both sides of the frame, the cooling device is close to the frame, and the cutting device is far away from the frame. The invention provides a waste cable recovery system, by carrying out straightening first, and Cutting, Cut off thecable sheath after cooling, the cable sheath after the cutting-off falls into the lower crushing device for crushing, copper core is wound on the copper core winding roller along a straight line, after straightening the cable sheath, adhesion and incessant cutting of the cable sheath can be avoided, thereby avoiding scratching the copper core, the cable sheath is cut off after cooling, and is easy to cut and crushing.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

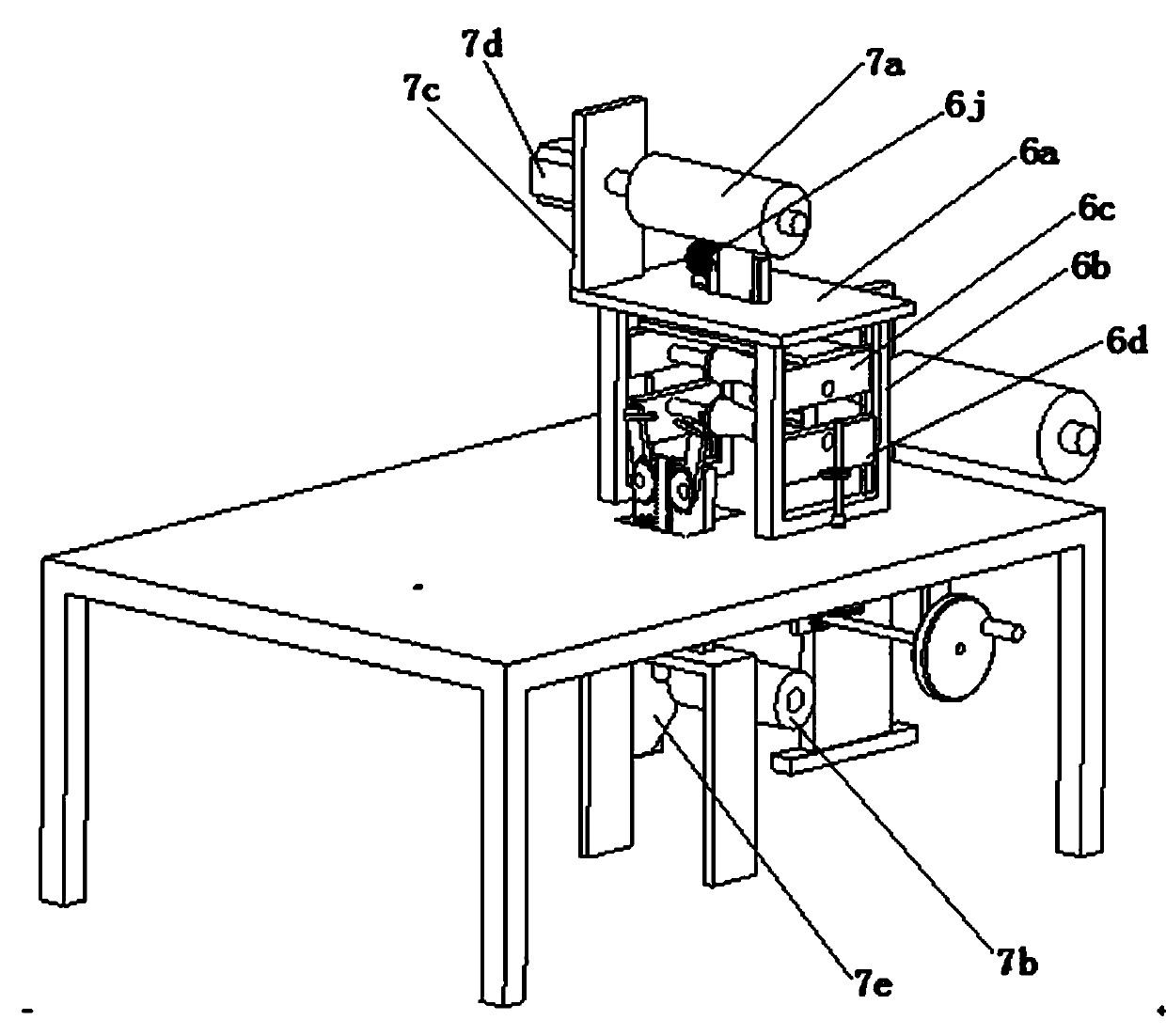

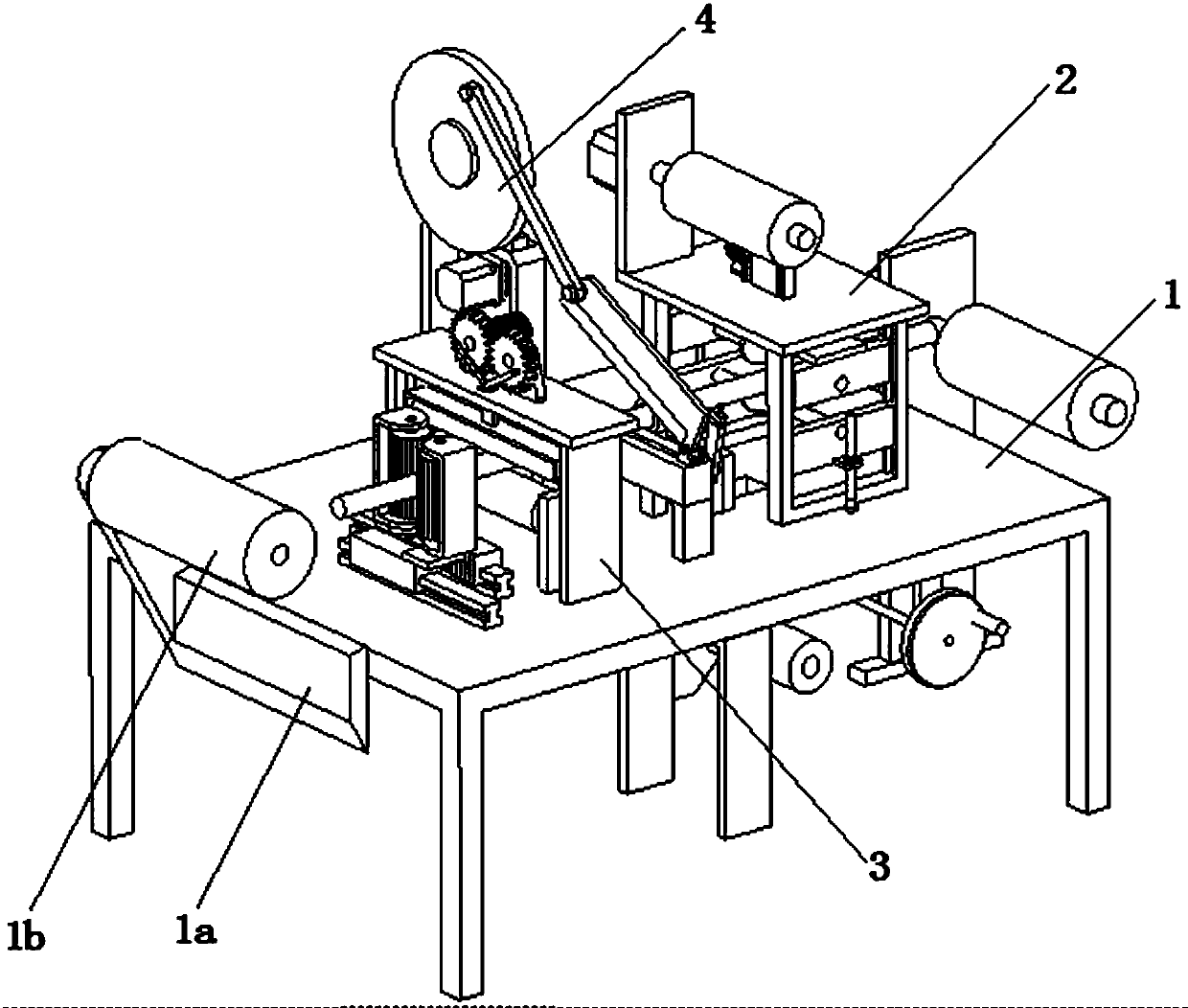

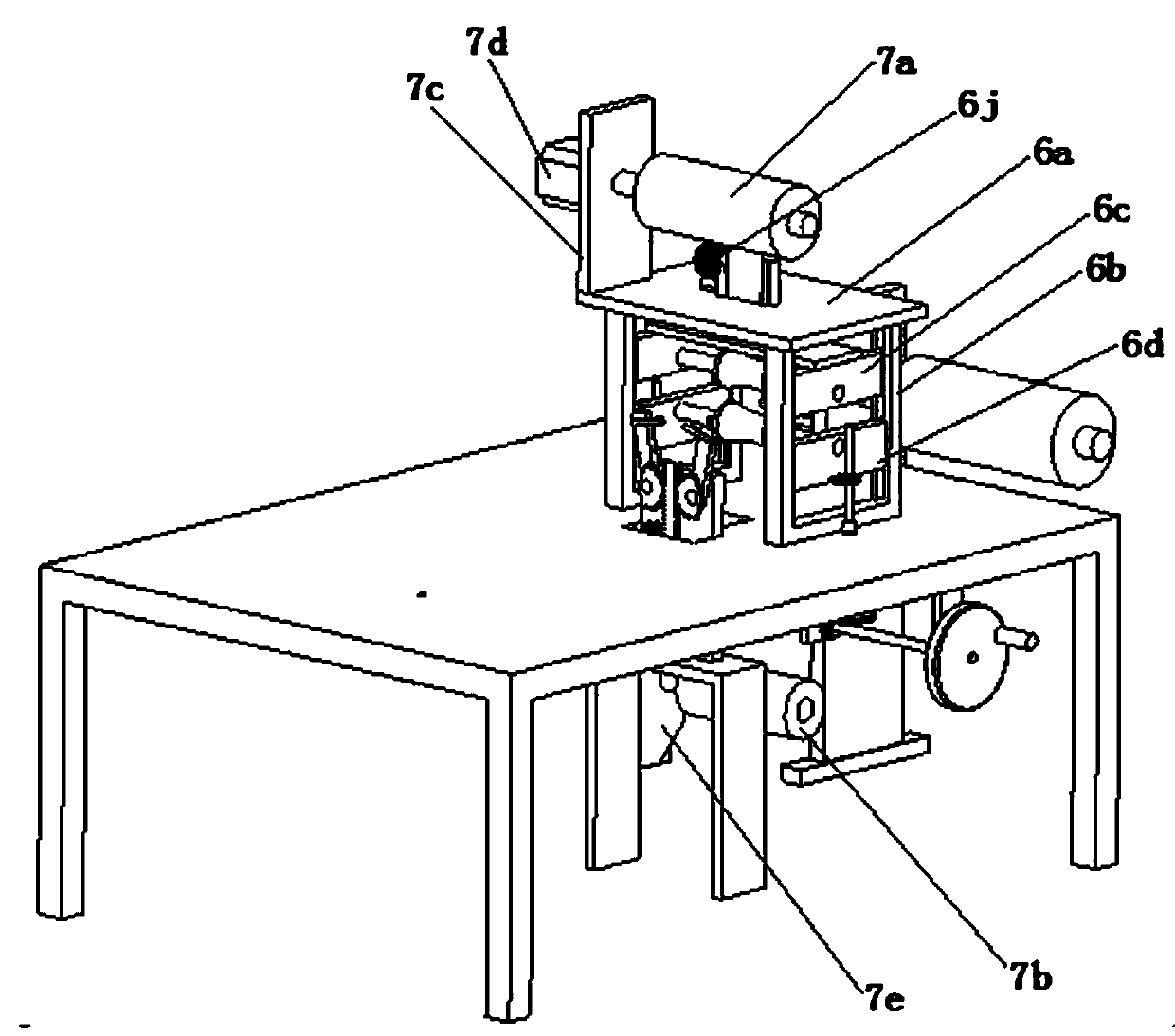

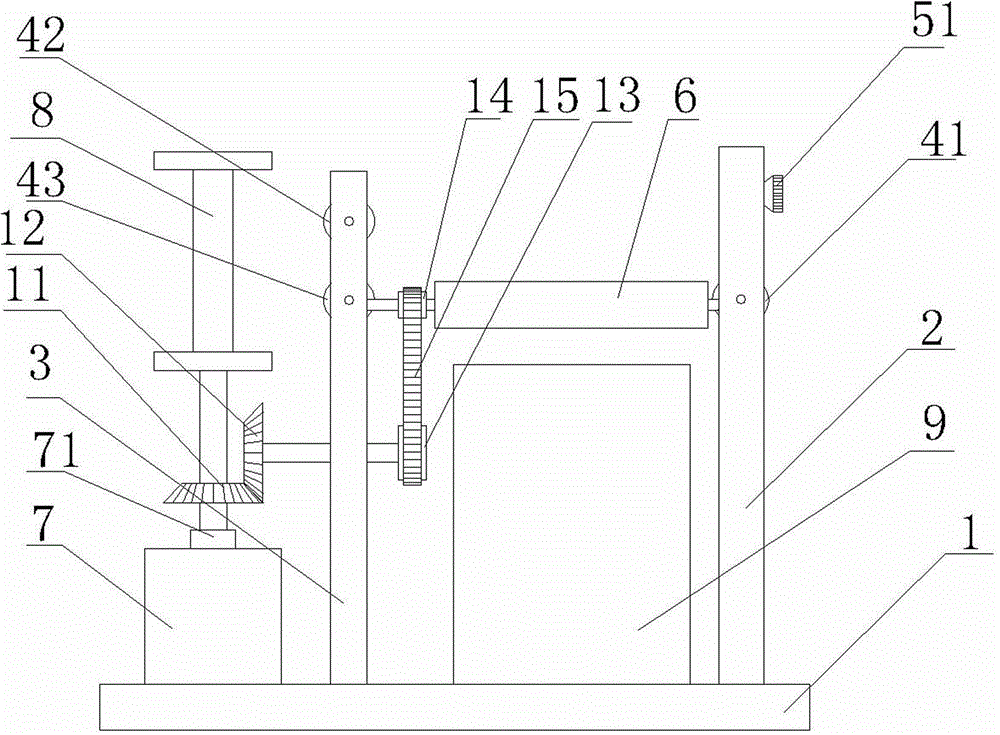

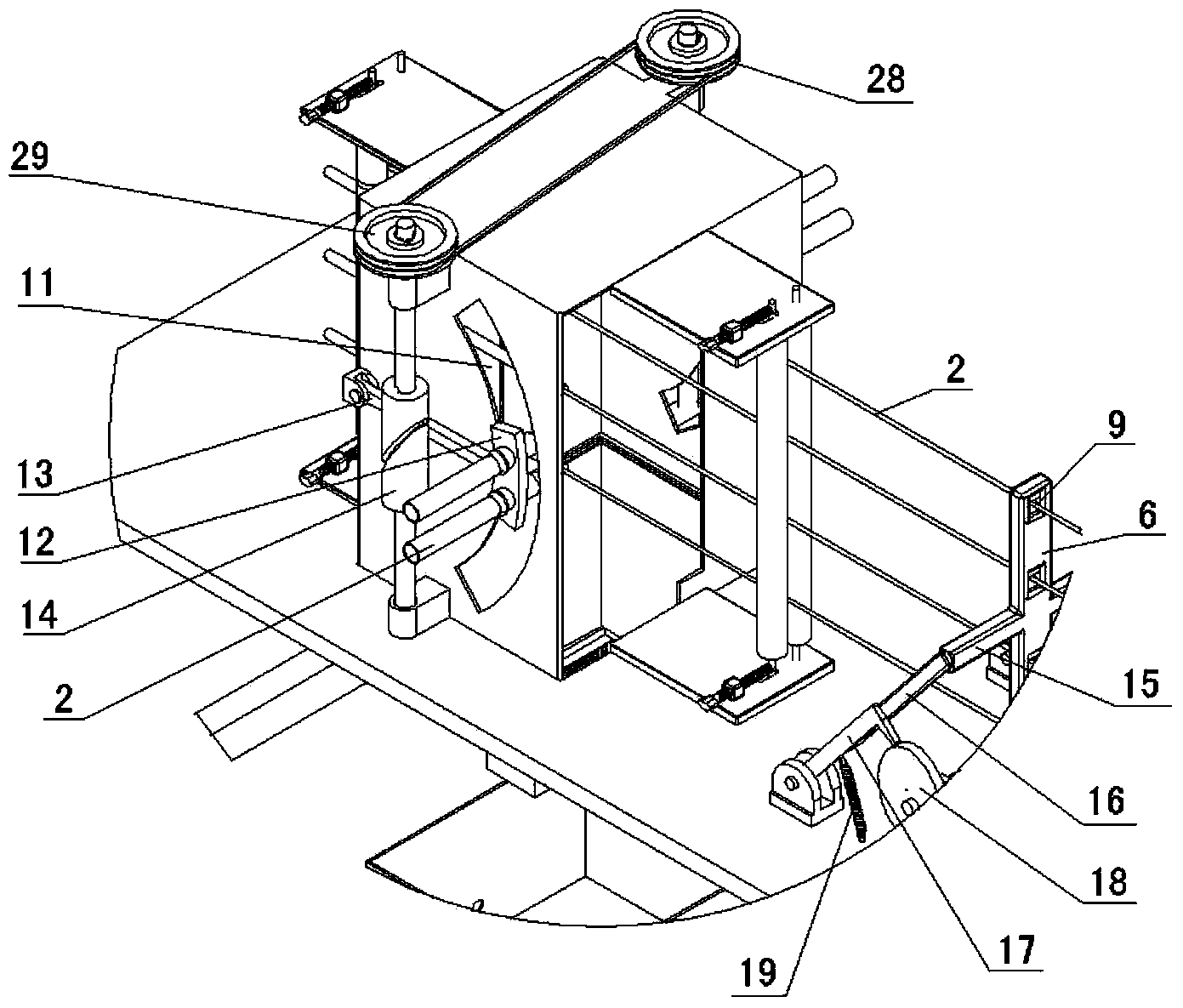

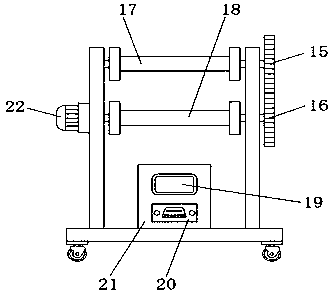

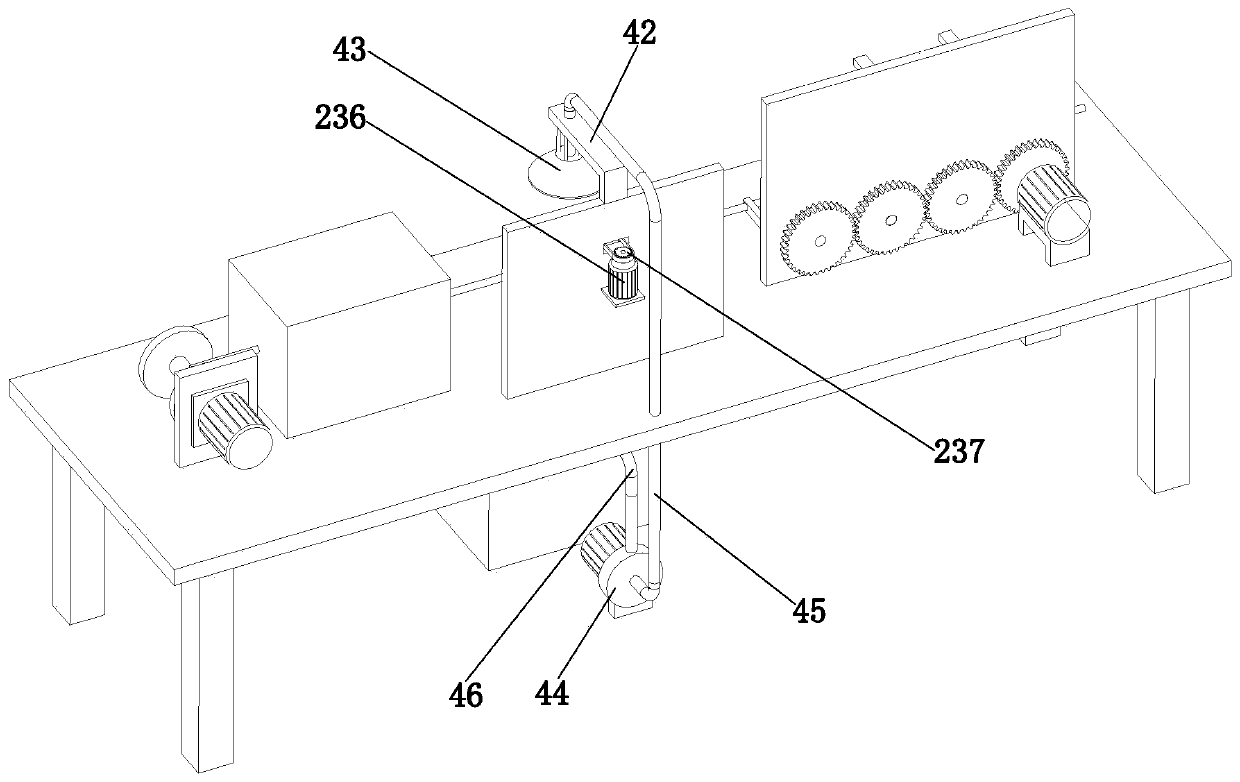

Automatic stripping and recycling device for waste cable

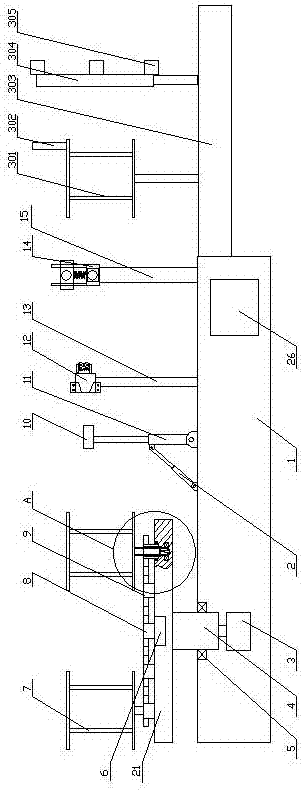

ActiveCN109842061AReduce laborTroubleshoot technical issues with strippingBasic electric elementsApparatus for removing/armouring cablesFixed frameConductor Coil

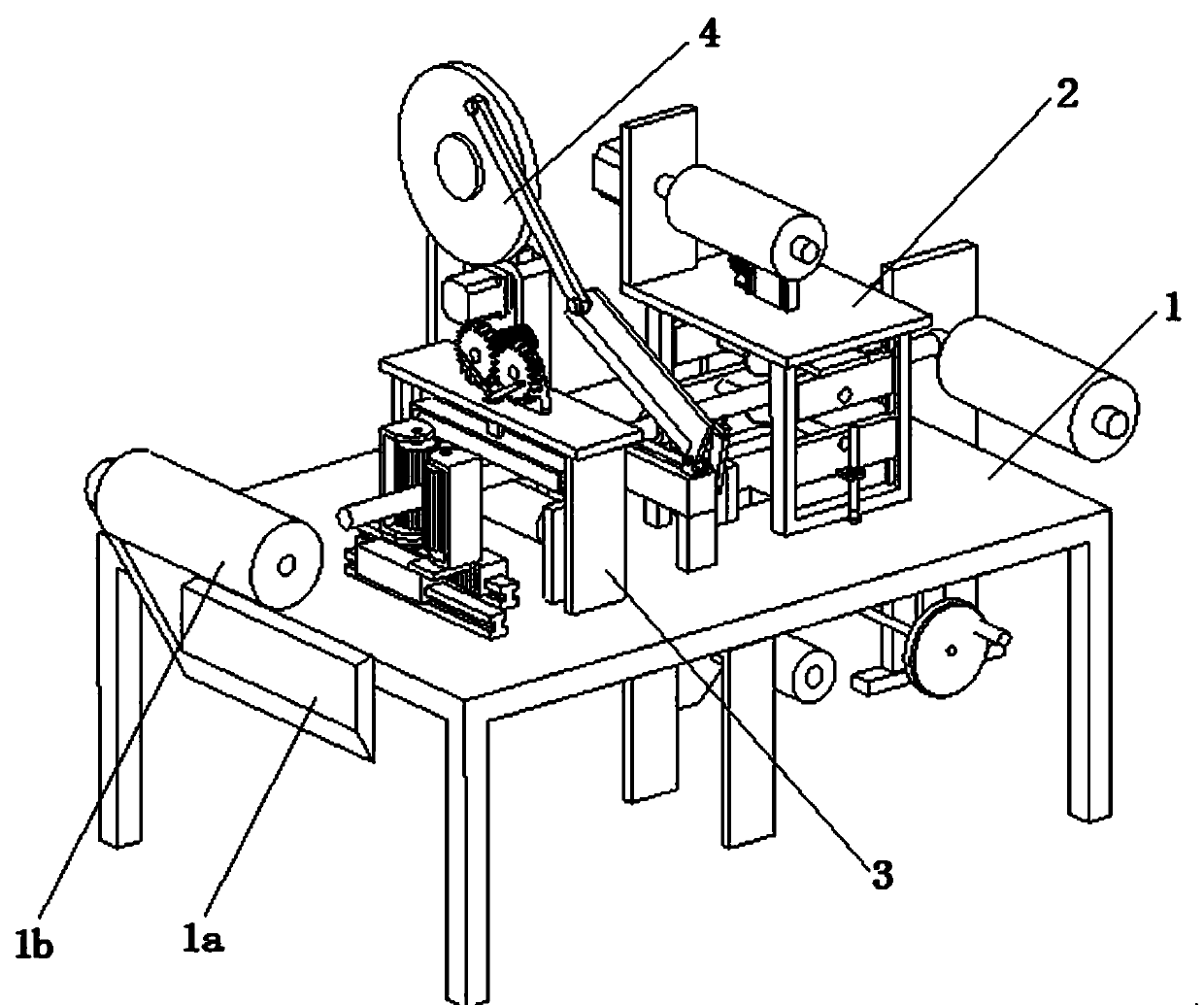

The invention discloses an automatic stripping and recycling device for waste cables. The automatic stripping and recycling device belongs to the technical field of cable stripping equipment, and comprise a workbench, wherein the top part of the workbench is provided with a cable stripping mechanism, a cable straightening mechanism and a cable cutting mechanism, the cable stripping mechanism comprises a cable limiting assembly, a transverse cutting assembly and a waste sheath winding assembly, the cable straightening mechanism comprises a transverse straightening assembly and a longitudinal straight-pressing assembly, the left end of the workbench is provided with a left fixing frame and an unwinding roller, and the right end of the workbench is provided with a right fixing frame and a material collecting roller. The automatic stripping and recycling device can strip cable sheathes of different diameters by means of the cable stripping mechanism, so that the sheathes of the cables aredivided into two sections and the winding operation can be automatically completed by means of the waste sheath winding assembly, and the cable straightening mechanism can automatically straighteningthe passing cables, so as to avoid the transverse cutting assembly from cutting bent cables and damaging the cables.

Owner:ANHUI HUATENG AGRI TECH CO LTD

Wire Stripping Device

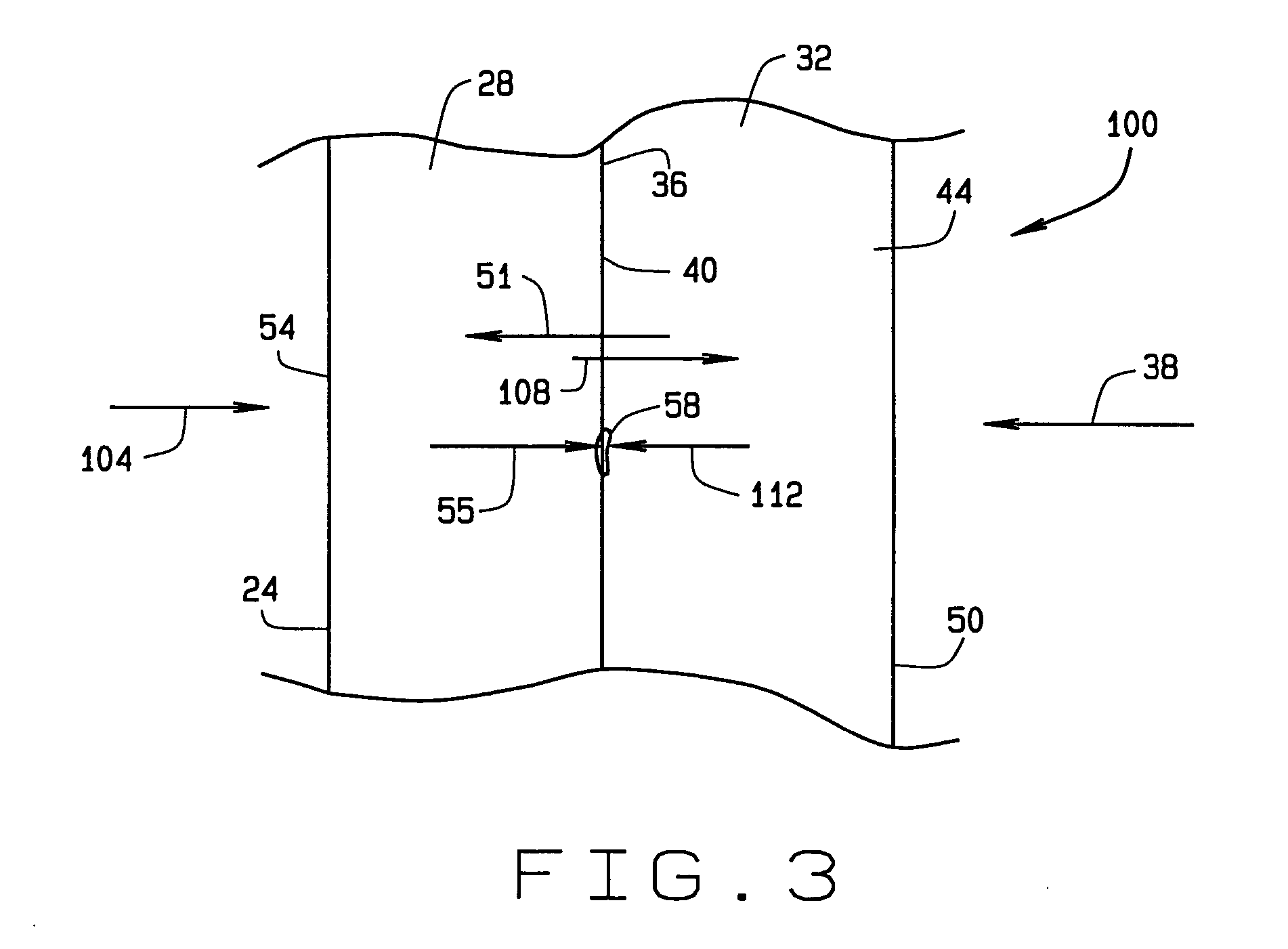

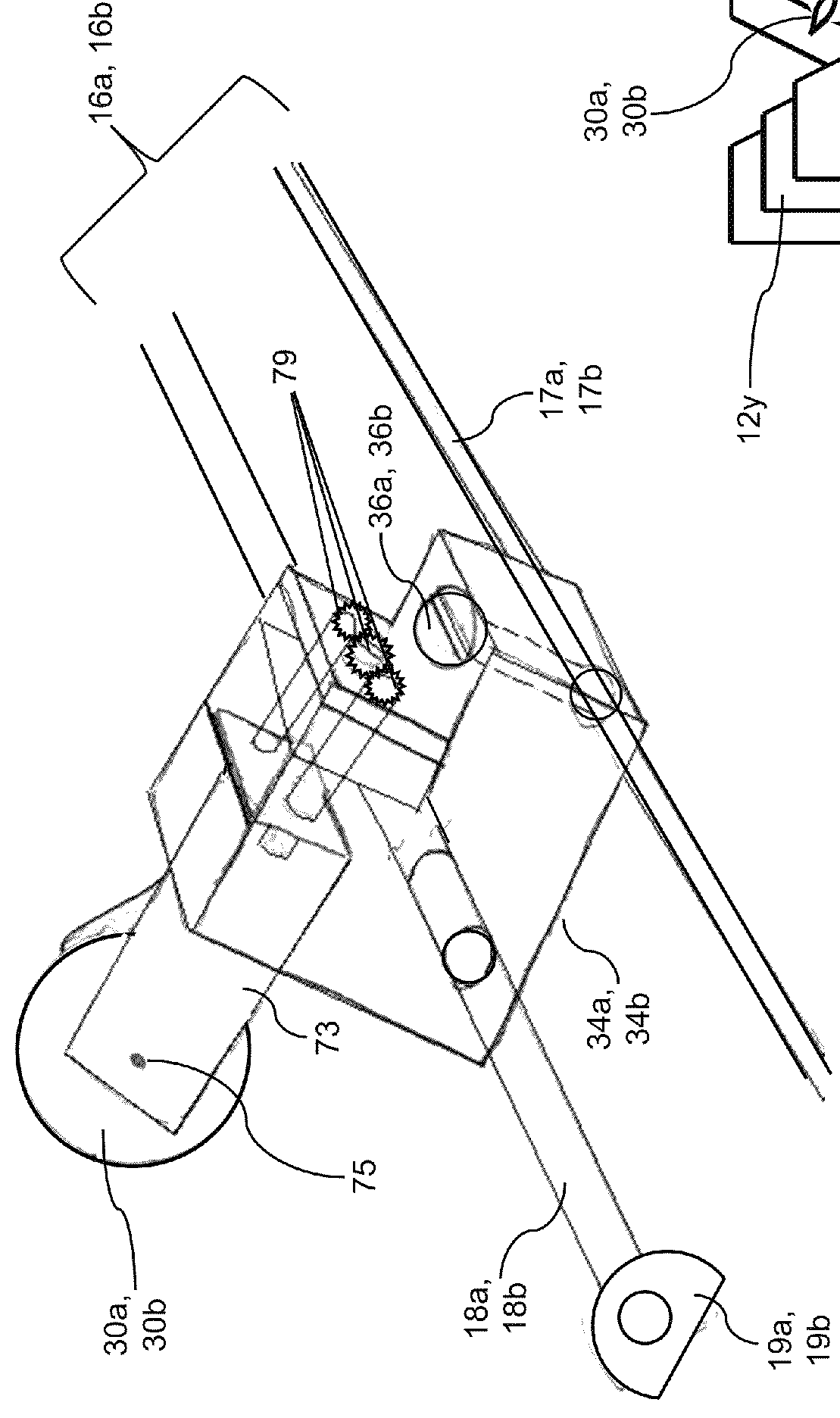

ActiveUS20120167719A1Easy to useEncourages recyclingBasic electric elementsApparatus for removing/armouring cablesEngineeringElectric wire

A device for removing an insulation jacket from a wire core of an insulated wire or cable is provided for encouraging recycling. The device employs cutting blades engaged to a first roller to cut a slice along the length of an inserted insulated wire or cable. A frictional engagement between the distal edge of the blade and an opposing recess surface provides for translation of the length of wire through the device during rotation of one or both of the blade and recess surface. Translational movement of the blades and a biasing force can enhance the frictional engagement and provide a distance of travel to prevent cutting of the insulated wire or cable.

Owner:THE NEWMAN TRADING COMPANY

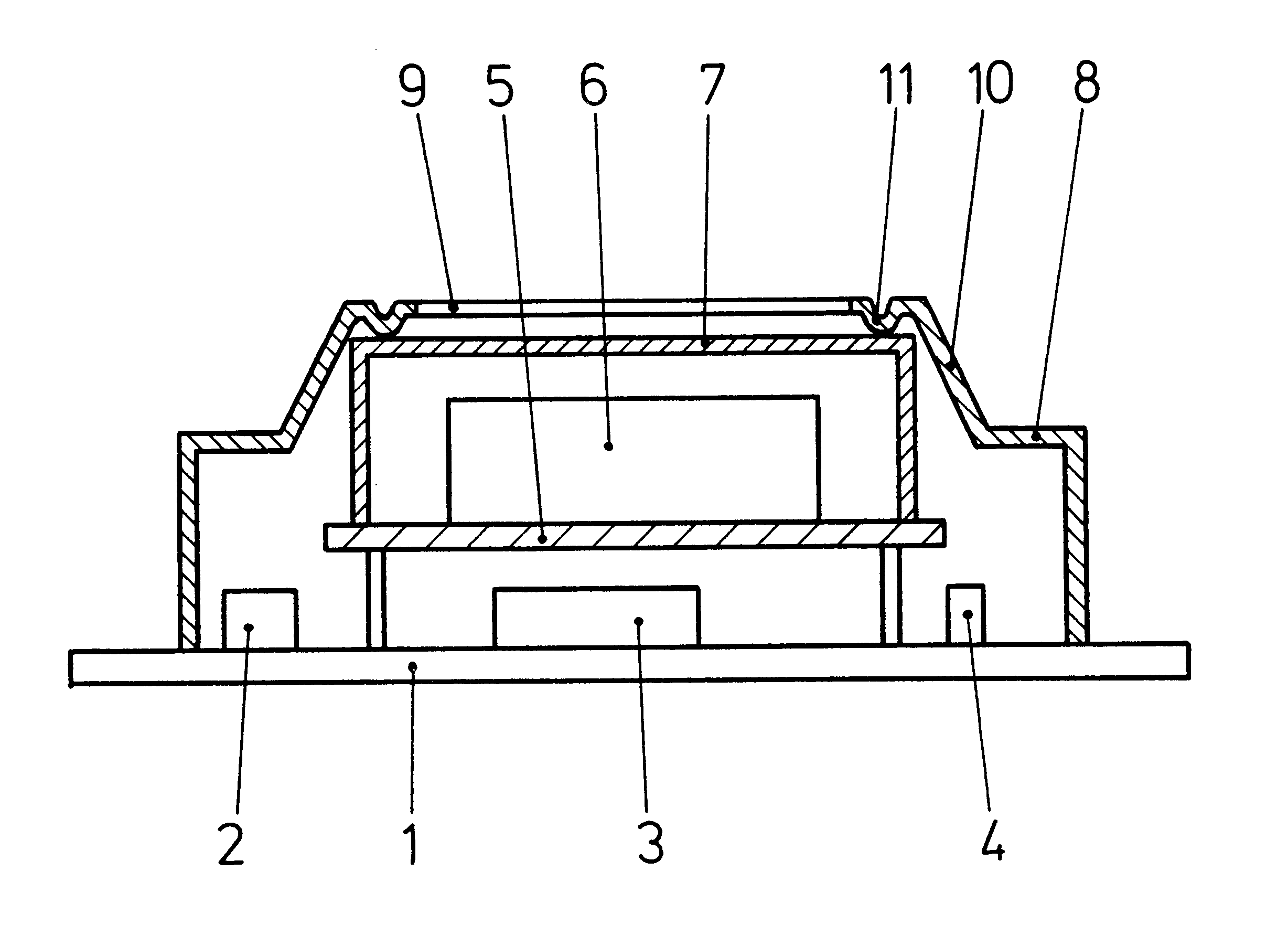

Shielded electronic circuit

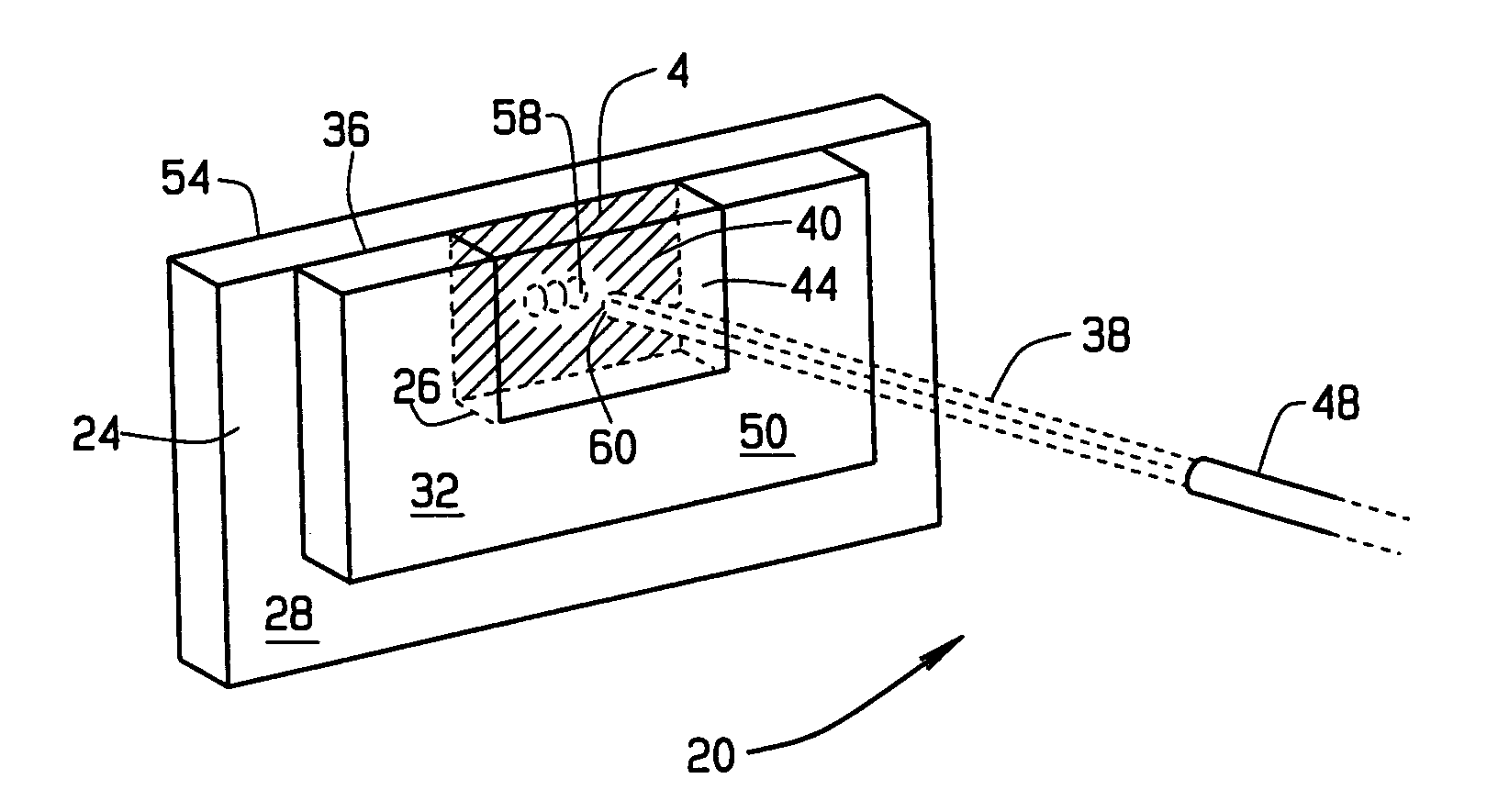

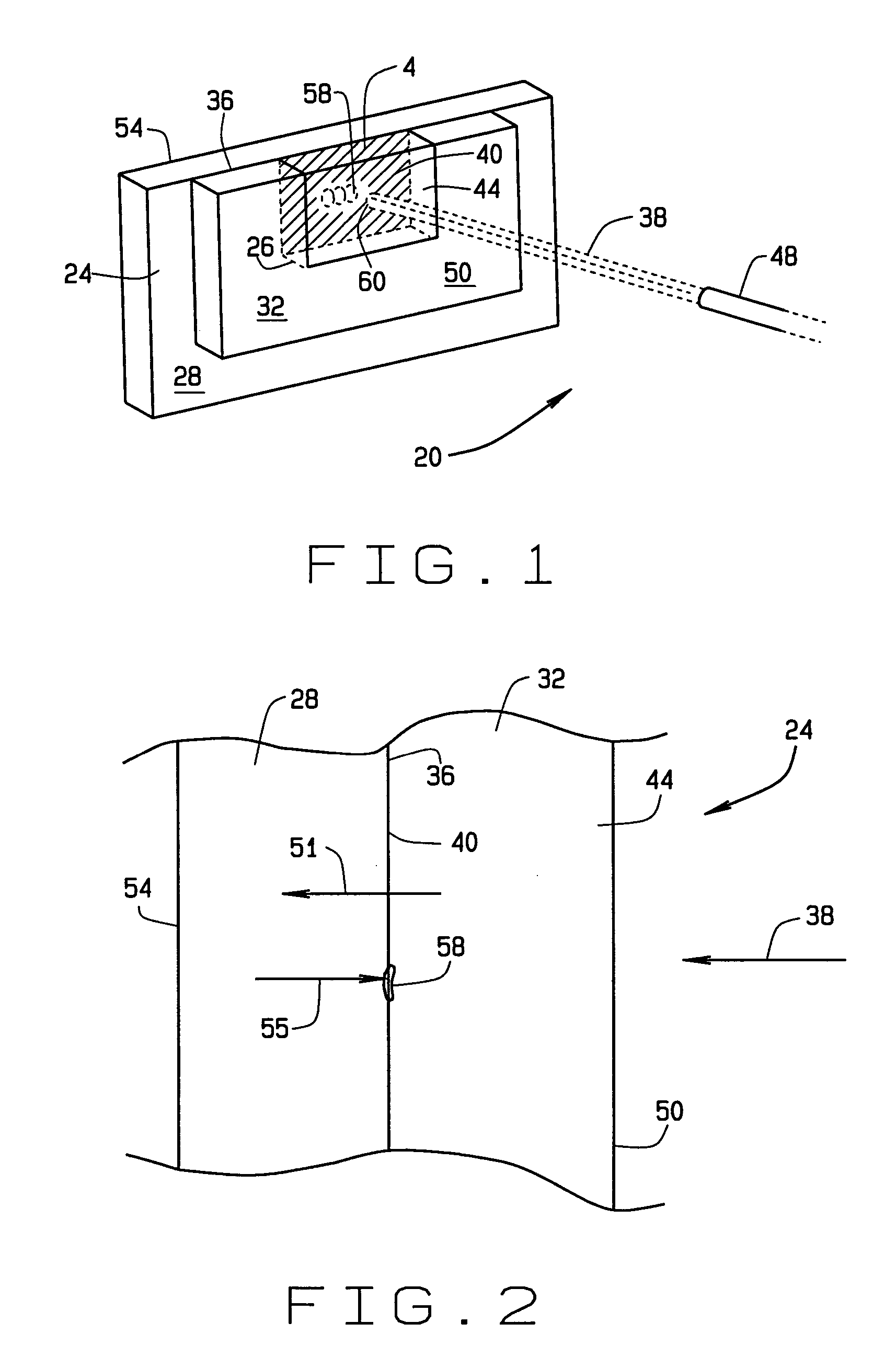

InactiveUS6590783B2Magnetic/electric field screeningBasic electric elementsEngineeringElectronic component

An electronic circuit includes an outer shielding mounted on a main printed circuit board. To prevent electronic components from affecting one another, at least one inner shielding is arranged within the outer shielding. The outer shielding has an opening bounded by spring tongues which rest on the inner shielding.

Owner:MANNESMANN VDO AG

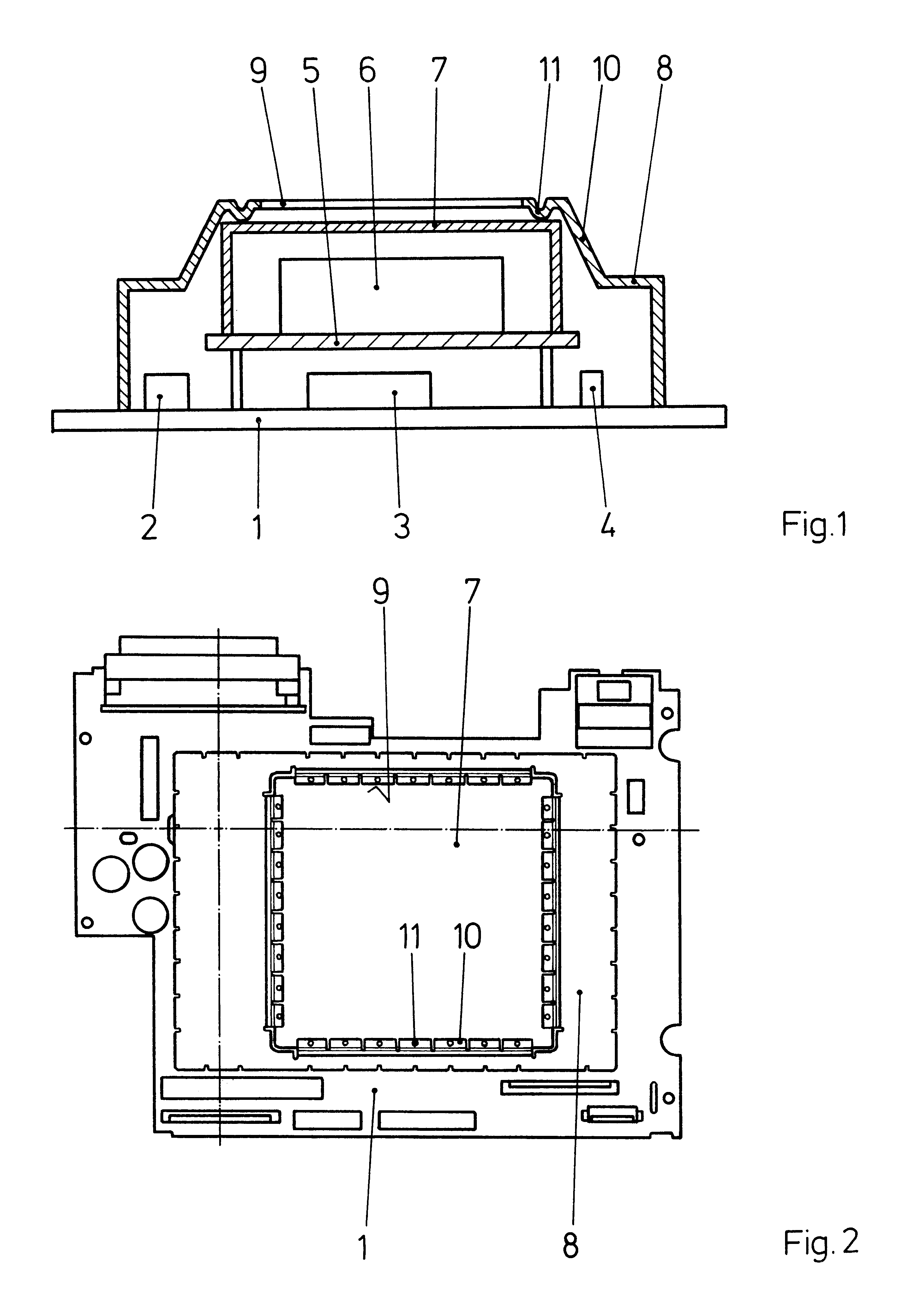

Automatic stripping device for power communication cable recycling

InactiveCN110265932AImprove practicalityEasy to cutBasic electric elementsApparatus for removing/armouring cablesResistance wireEngineering

The invention provides an automatic stripping device for power communication cable recycling, which relates to the technical field of communication cable recycling. The automatic stripping device for power communication cable recovery includes a frame. An extruding block is fixedly connected inside the right inner wall of the frame through a first spring. A heating box is arranged on the right side inside the frame. A heating resistance wire is fixedly connected inside the heating box. A stripping device is fixedly installed inside the frame. A cylinder is fixedly installed at the top end of the inside of the frame. A pressure bar is fixedly connected inside the cylinder through a second spring. The bottom end of the pressure bar is rotationally connected with a driven wheel. The automatic peeling device for power communication cable recycling facilitates the cutting and removing of the sheath. The blade can be easily adjusted and replaced, which makes the device highly practical. Because a push plate is added, there is no need for the blade to cut off the sheath completely, the scratch of the surface of the copper core is avoided, and the wear of the blade is reduced.

Owner:朱兴兴

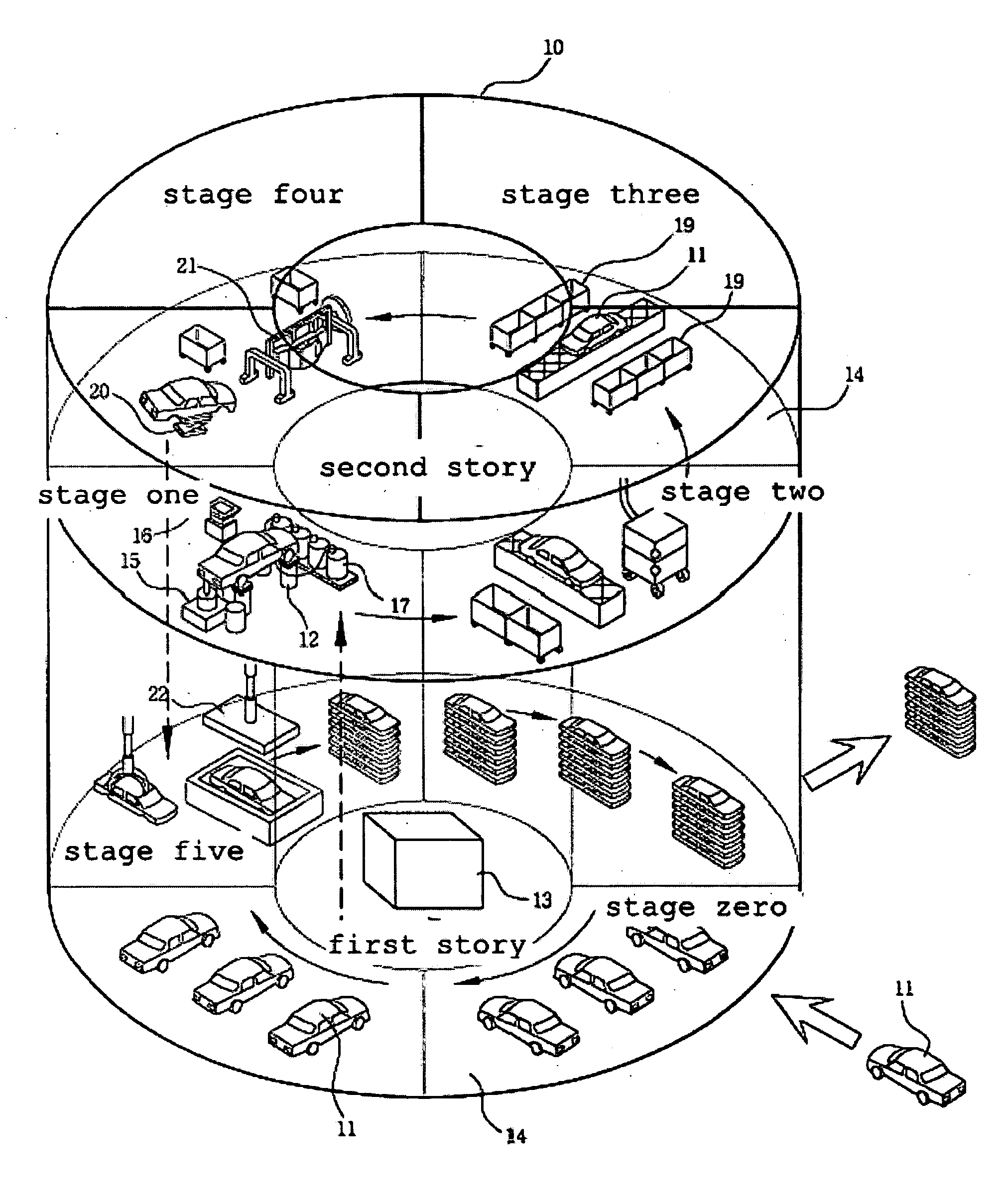

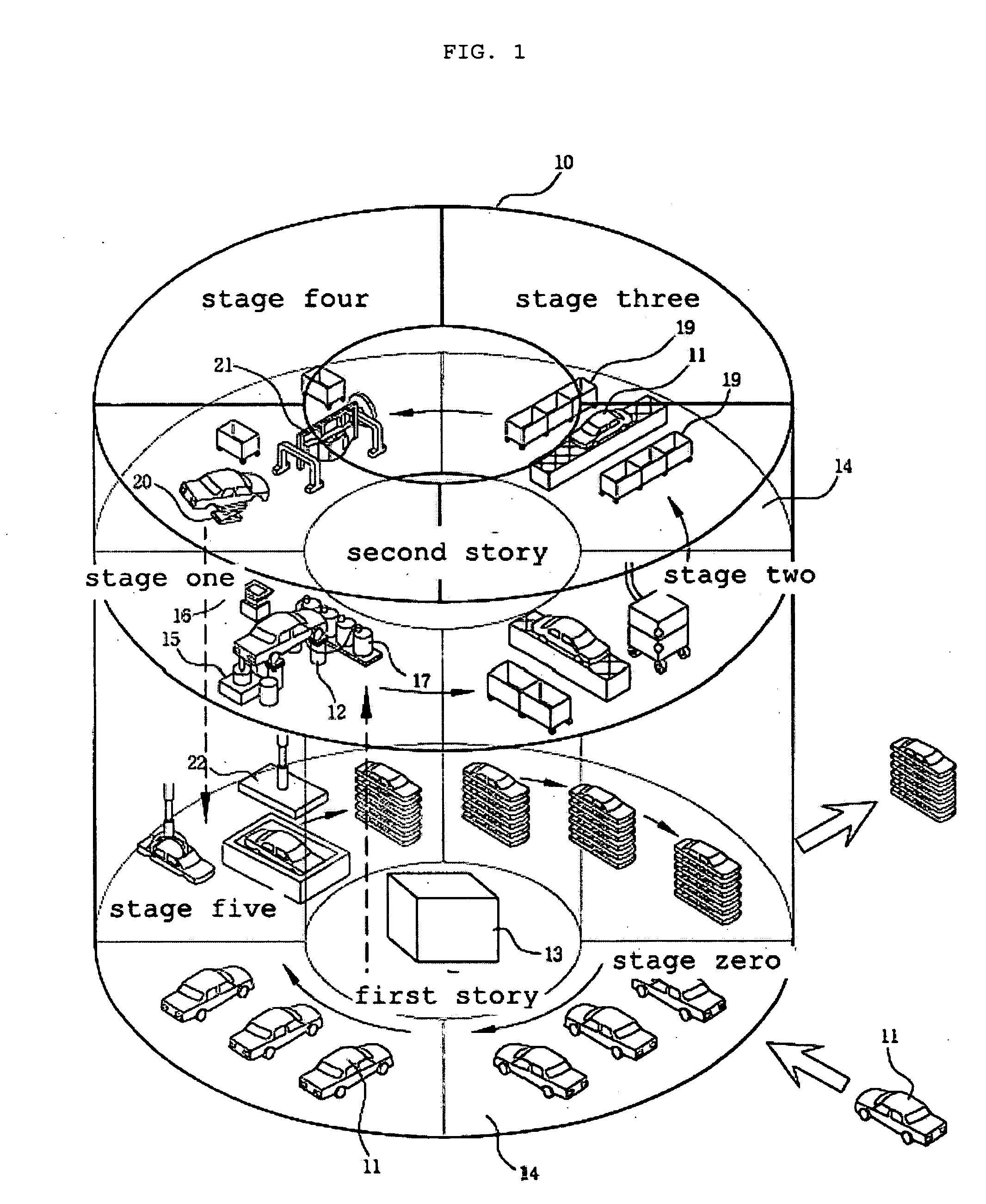

System for method of disassembling end-of-life vehicles

InactiveUS20070124906A1Shortening time spent disassembling component partLow costVehicle dissasembly recoveryBasic electric elementsMobile vehicleFloor level

A disassembling process of end-of-life vehicles (ELVS) takes place in a circular two-story structure. An elevator moves a vehicle between stories of the structure, and a conveyor system moves the vehicle between facilities in each story. The first and last steps in the disassembling process take place on the first story and the other steps take place in facilities arranged sequentially around the perimeter of the second story.

Owner:HYUNDAI MOTOR CO LTD

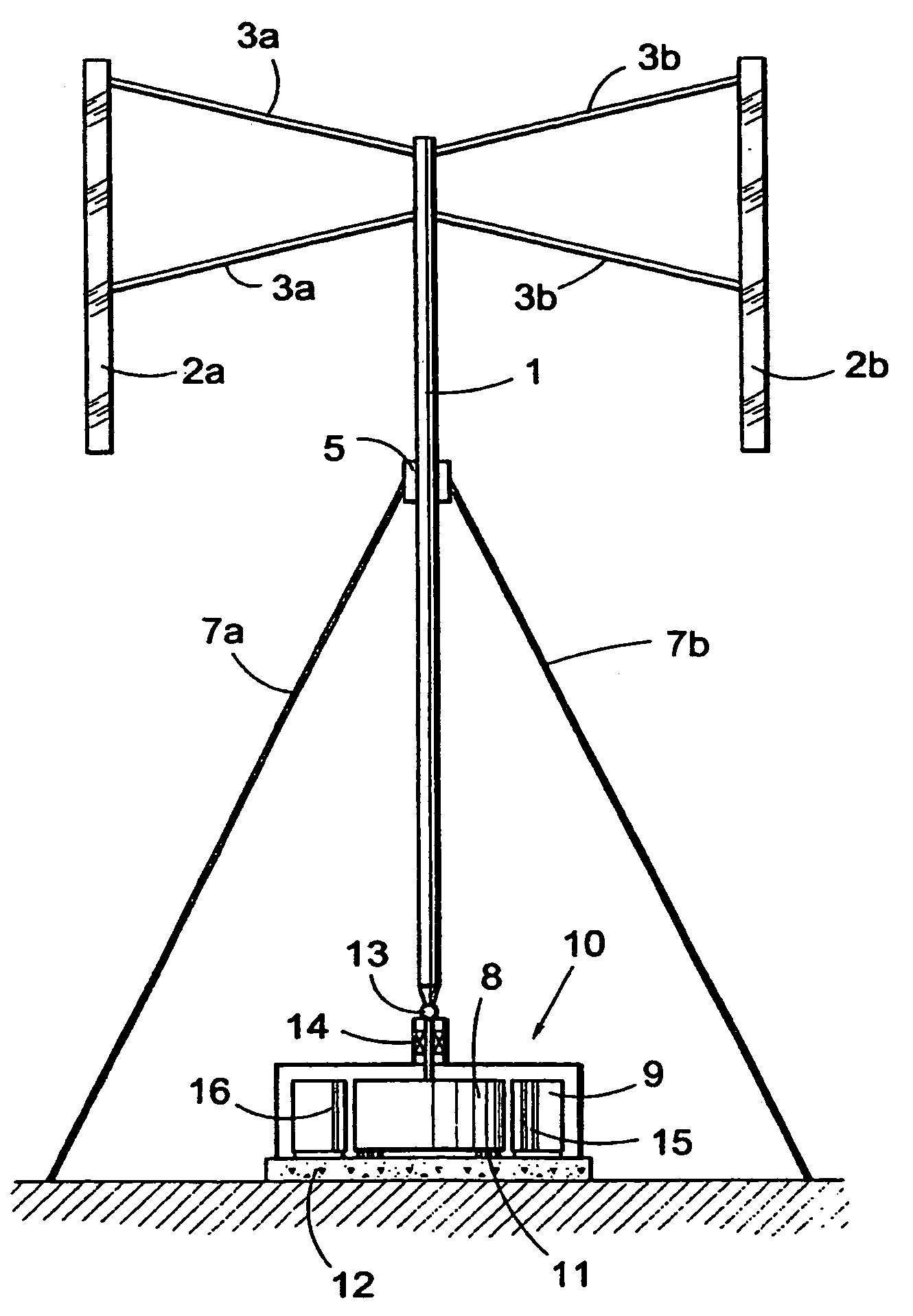

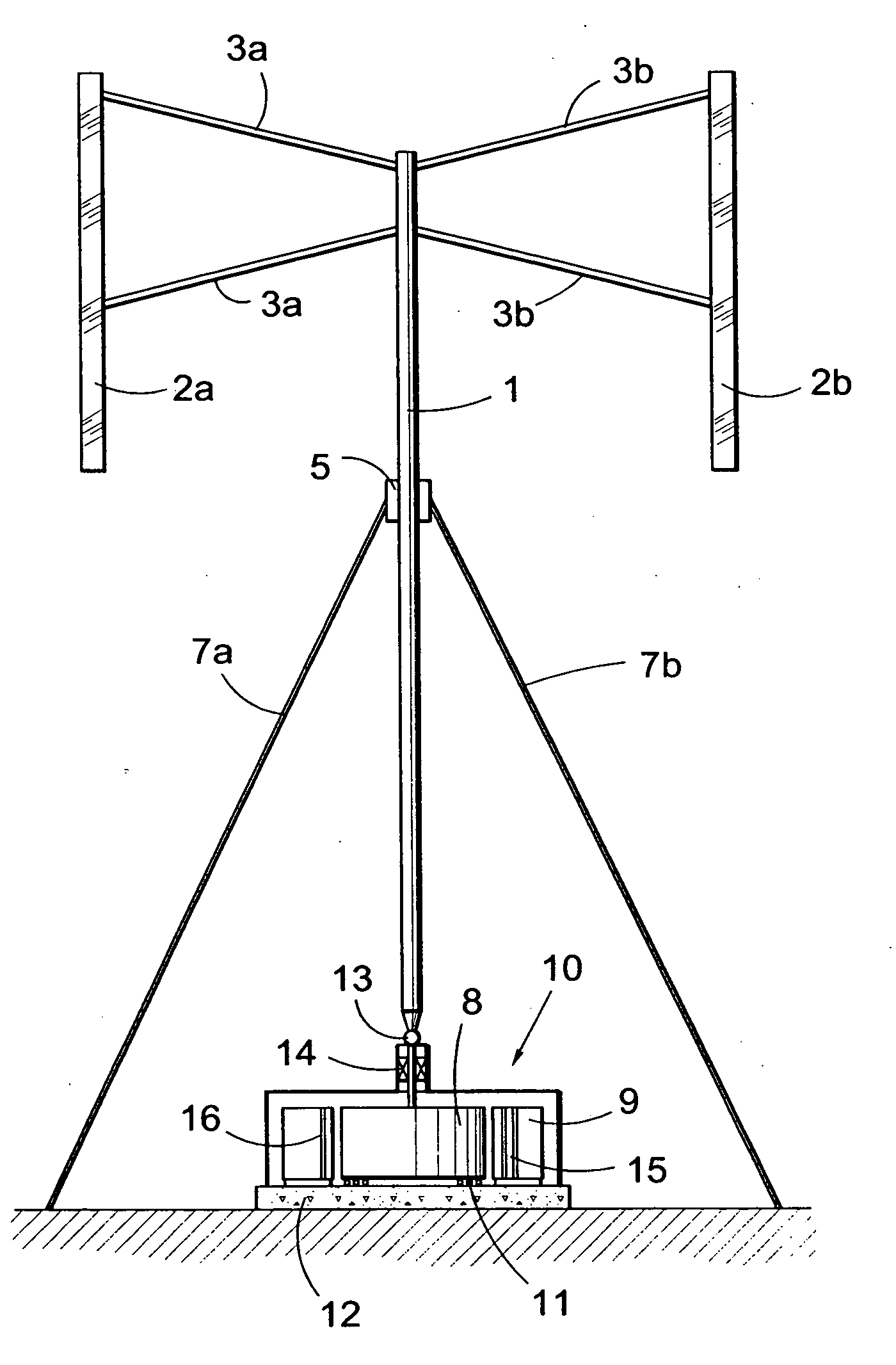

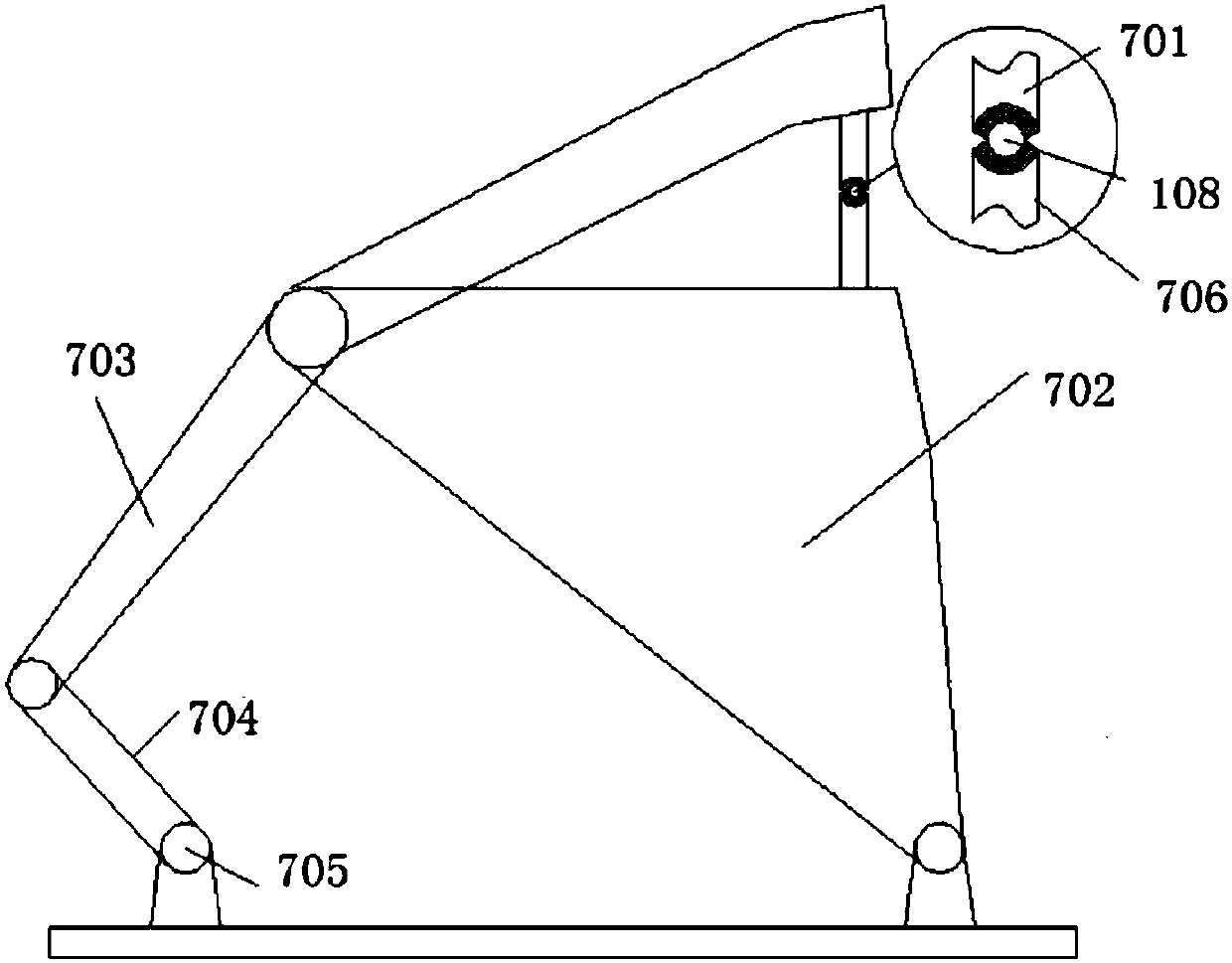

Wind power plant with vertical axix turbine

InactiveUS20050151376A1Easy to useEliminate needWindings insulation shape/form/constructionMagnetic circuitSemiconductor materialsHigh pressure

A wind-power unit has a wind turbine has an electric generator connected to the wind turbine. The stator of the generator has a winding formed of a high-voltage cable having a core of conducting material, a first layer of semiconducting material surrounding the core, an insulating layer of solid material surrounding the first layer, and a second layer of semiconducting material surrounding th solid insulation. The wind turbine has a plurality of turbine blades running vertically and being connected to a turbine shaft. The generator is arranged at the lower end of the turbine shaft. A wind-power plant; the use of a wind-power unit; and a method of generating electric power are described.

Owner:VERTICAL WIND AB

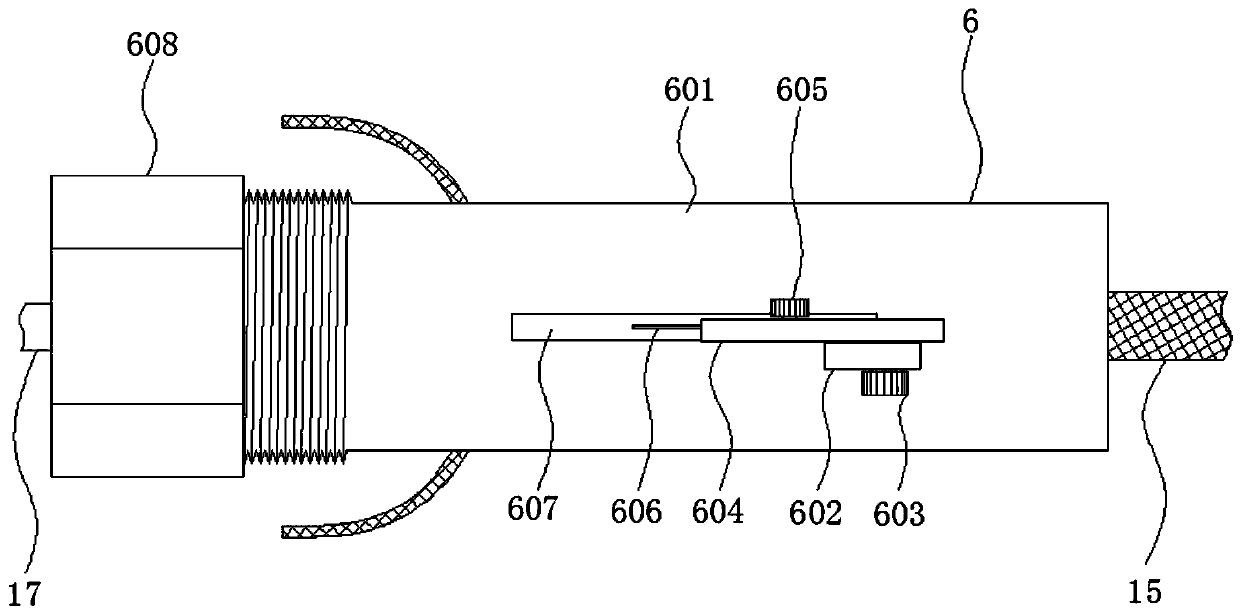

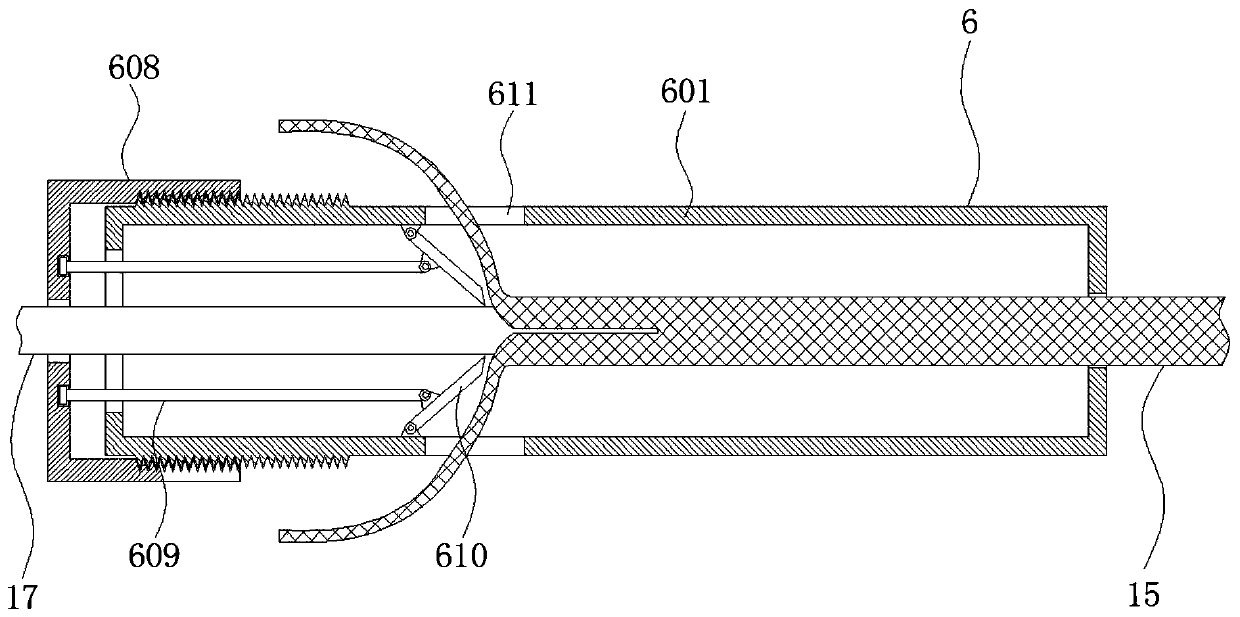

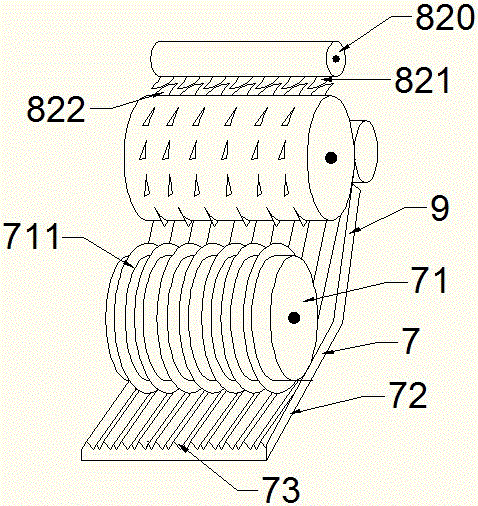

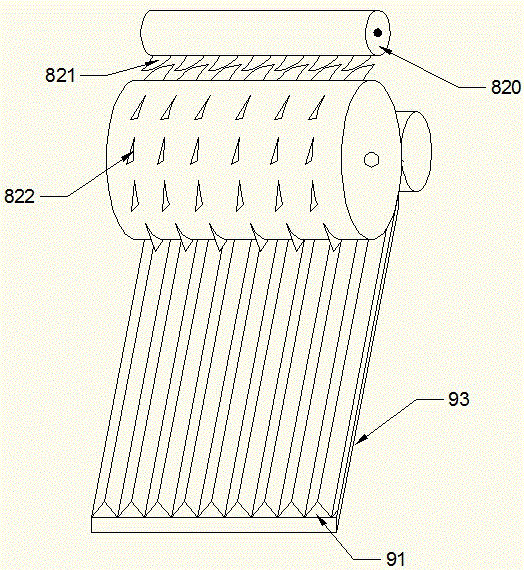

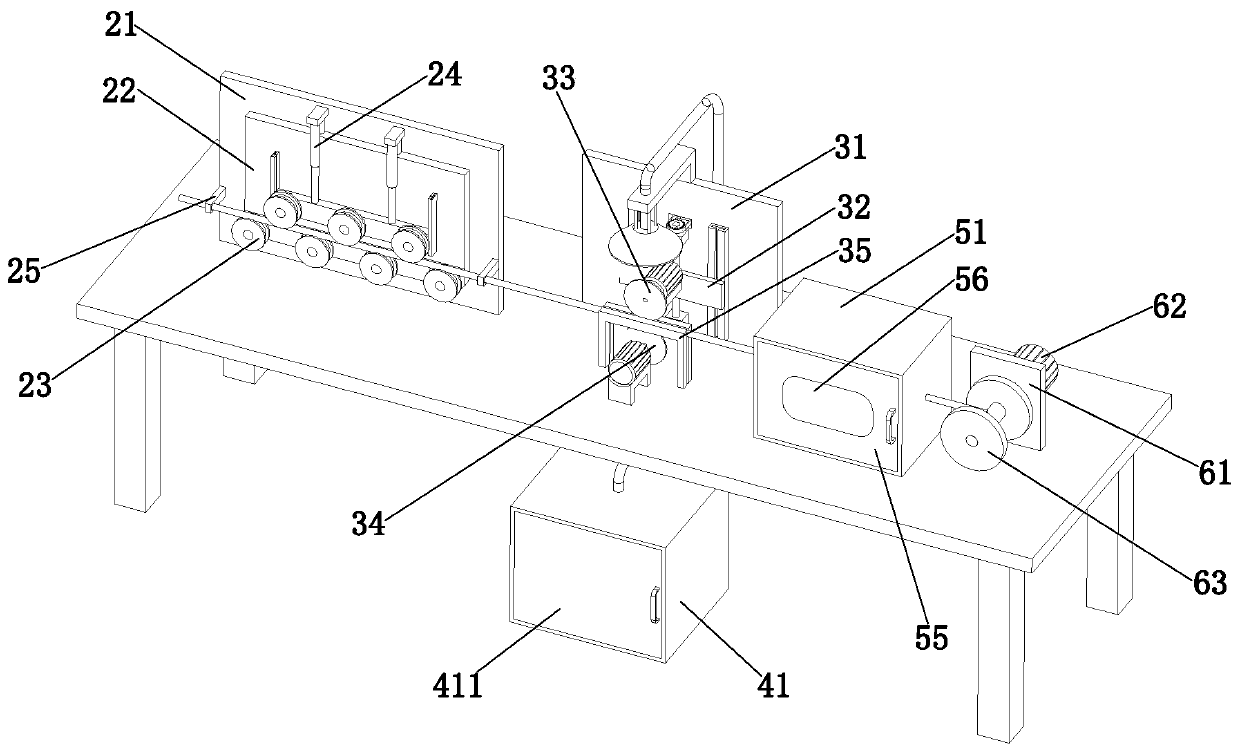

Waste electric wire stripping and core-taking apparatus

ActiveCN107658077AEasy to manufactureLow costBasic electric elementsApparatus for removing/armouring cablesCopperElectric wire

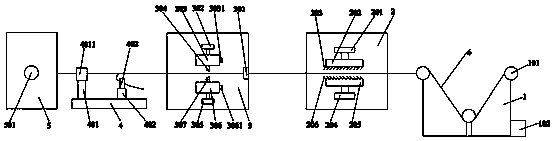

The invention discloses a waste electric wire stripping and core-taking apparatus. The waste electric wire stripping and core-taking apparatus comprises a paying-off mechanism, a straightening and guiding mechanism, a cutting mechanism, a flying shear mechanism, a stripping mechanism and a wire-collecting mechanism arranged on a working table in sequence. By virtue of the waste electric wire stripping and core-taking apparatus, the problems of difficulty in stripping and not high stripping efficiency caused by the fact that the conventional electric wire cutting apparatus only cuts one surfaceof an electric wire, and the problem of not high recycling rate caused by easy breaking of a copper core can be solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Power wire recycling device

InactiveCN107516853AImprove work efficiencySuitable for peeling and recyclingBasic electric elementsApparatus for removing/armouring cablesElectric powerElectric wire

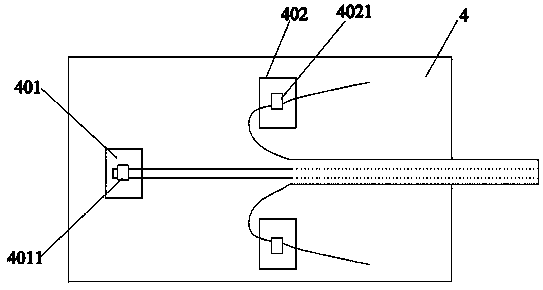

The invention discloses a power wire recycling device. The power wire recycling device comprises a device frame and supporting legs arranged at the bottom of the device frame. A wire inlet is formed in the left side wall of the device frame. First guide wheels, a cutter device, second guide wheels, third guide wheels, two wire skin recycling wheels, fourth guide wheels and a winding rod are sequentially installed in the device frame from left to right, wherein the first guide wheels are used for guiding a wire in moving rightwards, the cutter device is used for cutting the wire skin into halves, the second guide wheels are used for guiding the wire discharged out of the cutter device in moving rightwards, the third guide wheels are used for guiding the wire skin in moving rightwards, the wire skin recycling wheels are used for recycling the cut wire skin, the fourth guide wheels are used for guiding the wire core in moving rightwards, and the winding rod is used for recycling the wire core. The power wire recycling device solves the problems that an existing wire recycling device can not conduct peeling or classified recycling on wires and is low in working efficiency.

Owner:陈功鸿

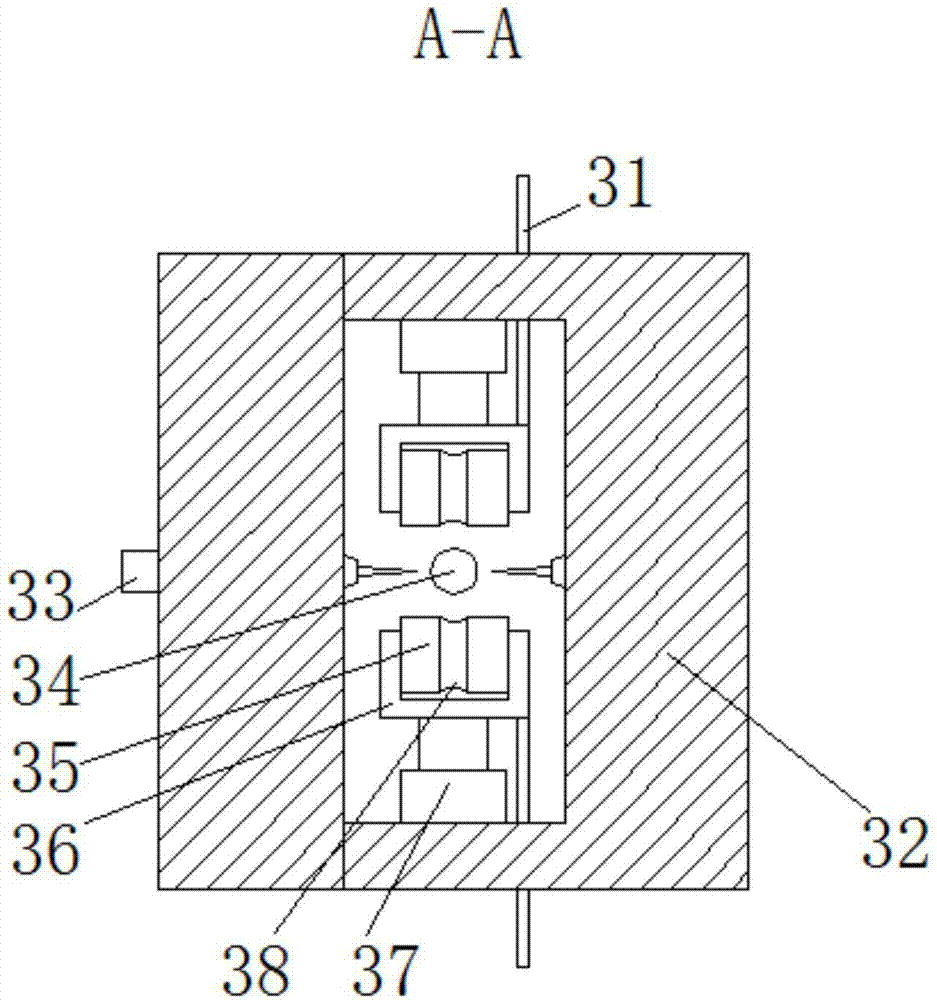

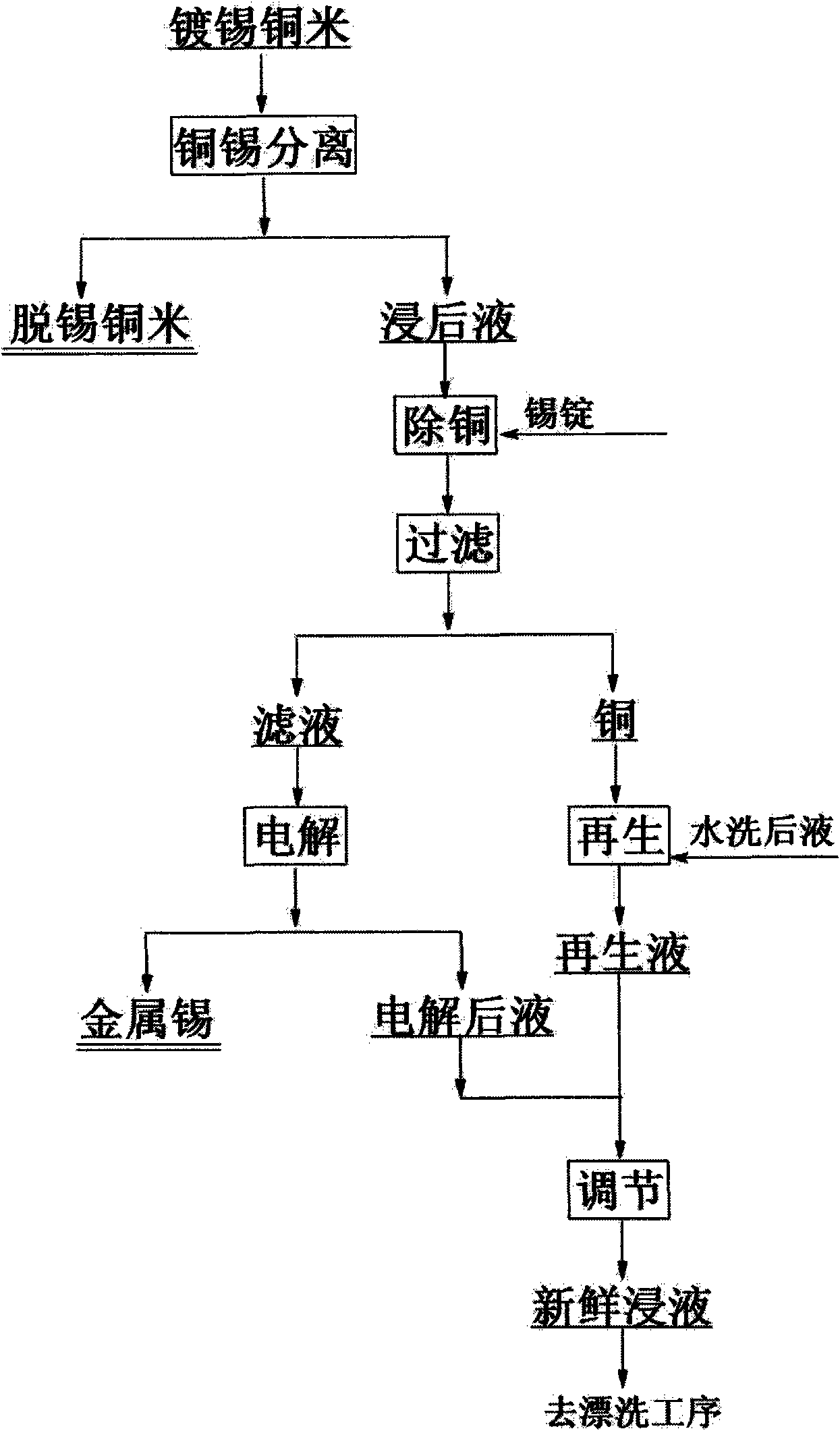

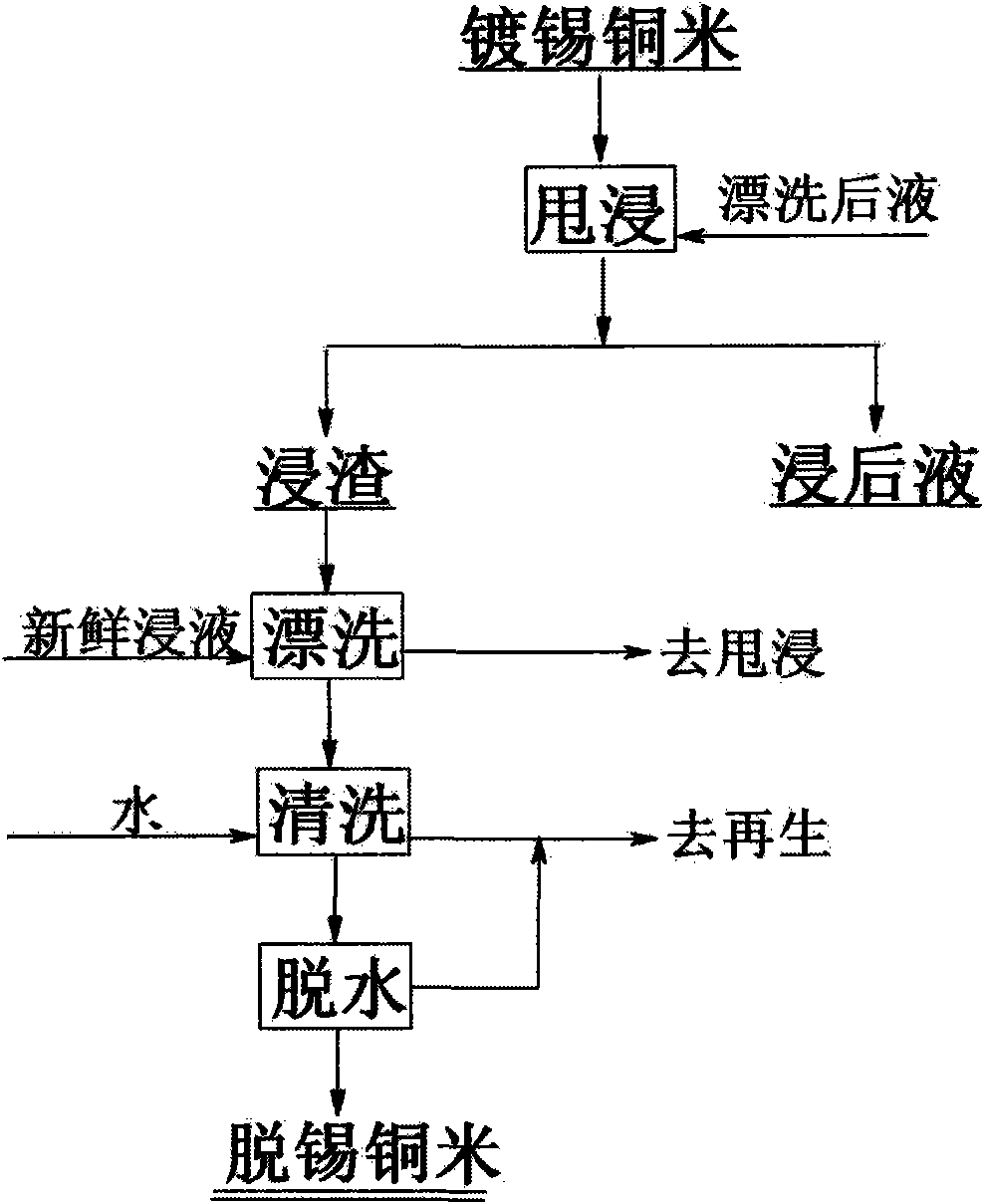

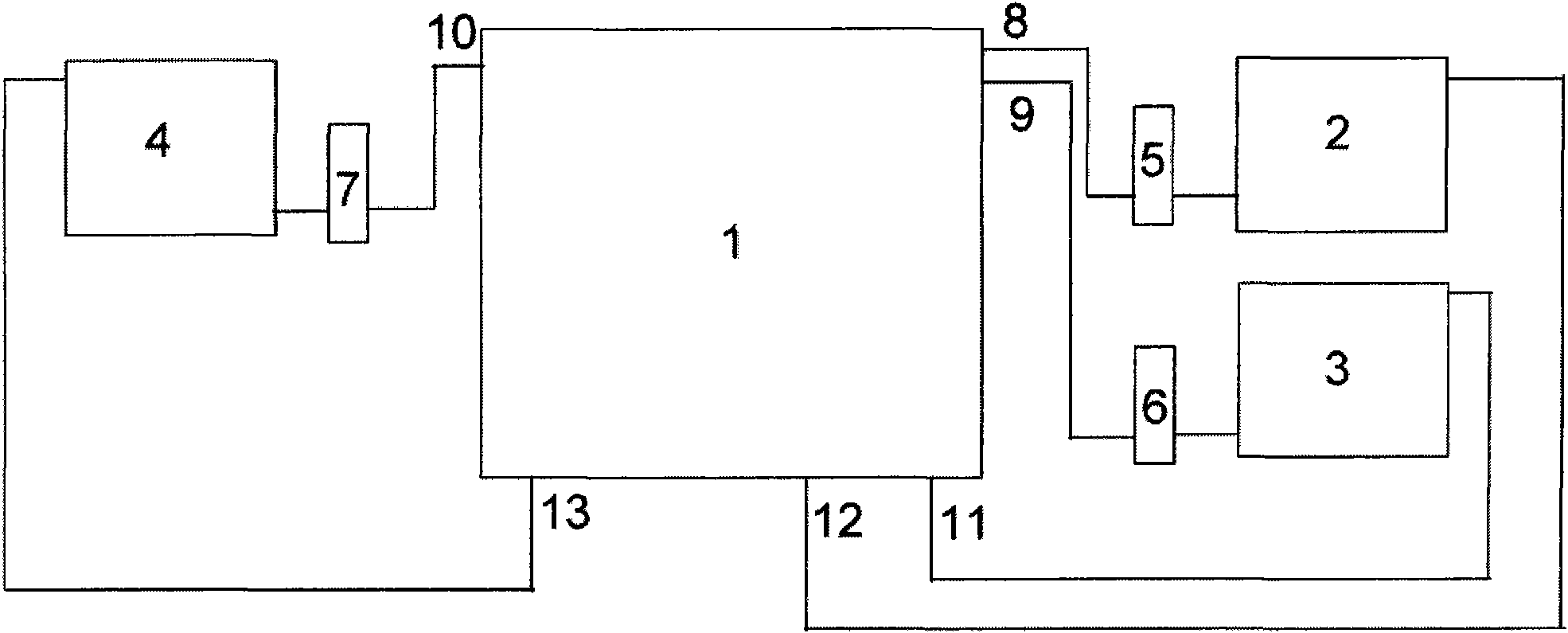

Method and device for separating and recovering metallic copper and tin in tinplating copper rice

InactiveCN101937742AHigh removal rateHigh recovery rateBasic electric elementsElectronic waste recyclingTinningIngot

The invention relates to a method and a device for separating and recovering metallic copper and tin in the tinplating copper rice by a wet method. The method comprises the following steps: placing the tinplating copper rice into a dedicated leaching plant for copper and tin separation according to the design requirement; adding excessive tin ingot to the immersion liquid to remove the copper until the blue of the immersion liquid is completely eliminated; filtering to obtain filter liquor and copper powder; electrolyzing the filter liquor in an electrolytic cell to obtain the metallic tin and liquid after electrolyte; adding a proper amount of copper powder and blowing air into the liquid for regeneration after being washed with water; mixing the regenerated liquid and the liquid after the electrolyte; regulating the concentration of copper sulfate and sulfuric acid in the solution by utilizing water, copper sulfate and 98% of sulfuric acid to obtain fresh immersion liquid to be used in the next tinplating copper process. The copper and tin separation processing device is composed of the dedicated leaching plant, an immersion liquid trough, a fresh immersion liquid trough and a rinsing bath. The method and the device have simple and feasible process; and all the raw materials and equipment are more common and have low price.

Owner:UNIV OF SCI & TECH BEIJING

Using laser shock loads to debond structures

Owner:THE BOEING CO

Equipment for recycling waste electric communication cables

InactiveCN108565075AEasy to reuseEasy to cutBasic electric elementsElectronic waste recyclingMechanical engineeringElectric power

The invention provides equipment for recycling waste electric communication cables. The equipment comprises a cleaning device, a drying device, a cutting device, a striping device and a collection device, wherein the cleaning device comprises a cleaning slot and a plurality of lead wheels; the drying device comprises a support plate, an upper drying mechanism and a lower drying mechanism; the cutting device comprises a cutting board, a lead mechanism and a cutting mechanism; the cutting mechanism comprises an upper cutting assembly and a lower cutting assembly; the upper cutting assembly comprises an upper cutting air cylinder, an upper cutter and an upper fixing block; the lower cutting assembly comprises a lower cutting air cylinder, a lower cutter and a lower fixing block; the stripingdevice comprises a base, a telescopic rod, two wire separating rods, a positioning ring and a wire separating ring, the positioning ring is arranged at the top end of the telescopic rod, and the wireseparating ring is arranged at the top end of the wire separating rod; and the collection device comprises two parallel fixing plates and rotating shafts mounted on the two fixing plates. According tothe equipment, the striped leads and insulation protecting sleeves are collected, so that the labor is greatly saved, and the striping efficiency is improved.

Owner:XUCHANG YONGXIN ELECTRIC

Using laser shock loads to debond structures

A method of disassembling at least a portion of a structure that includes parts which are bonded together. The method includes selecting a subsurface depth within the structure at which it is desired to cause debonding of the structure. A laser beam diameter, pulse width and power level predetermined to produce a peak tensile stress within the structure at the selected depth are selected. A laser having the selected beam diameter is used to apply a shock load at the selected pulse width and power level to the structure. Using this method, damaged or unwanted aircraft skin, patches or overlays on structure can be removed more cleanly and simply than milling, grinding or other mechanical methods.

Owner:THE BOEING CO

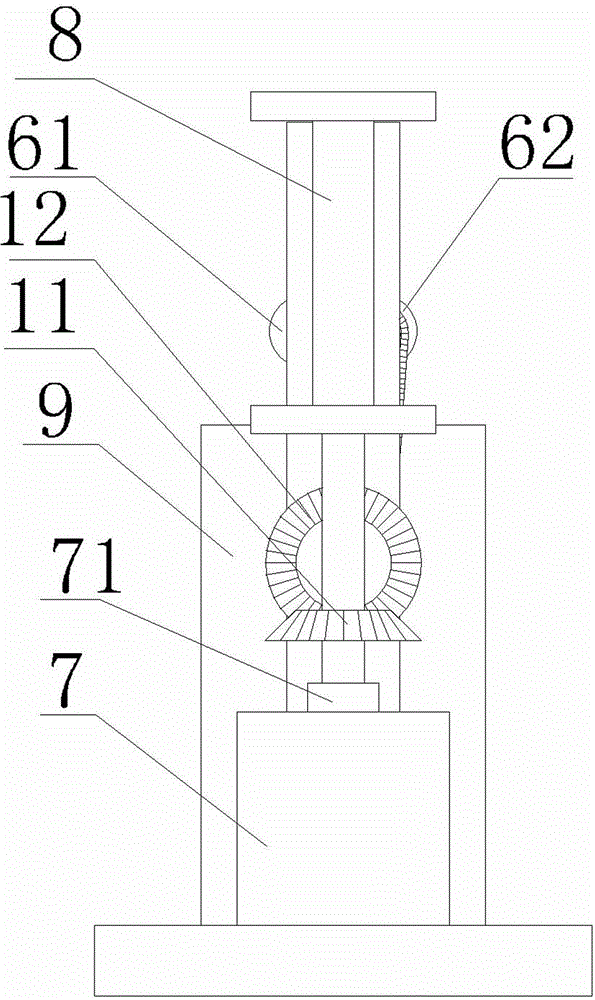

Waste cable disassembling device

ActiveCN105931762AAvoid pollutionSimple structureBasic electric elementsElectronic waste recyclingWire cuttingEnvironmentally friendly

The invention provides a waste cable disassembling device, which comprises a rack, a machine body, a motor and a speed regulation machine. The motor is connected with the speed regulation machine, and the motor and the speed regulation machine are arranged on the rack; the upper portion of the machine body is provided with a feed port, and the lower portion of the machine body is provided with a discharge port; and the machine body is internally provided with a wire cutting and stripping mechanism. The waste cable disassembling device also comprises a wire tidying mechanism and a wiring feeding mechanism. The automation degree of the device is improved, thereby improving work efficiency, improving work environment, saving labor cost and preventing dust pollution caused by waste cable disassembling. The waste cable disassembling device is environmentally-friendly and energy saving, simple in structure, easy to produce and capable of processing waste cables efficiently and quickly. The device fills the blank of the waste cable disassembling machinery field at home and abroad.

Owner:川木智能设备江苏有限公司

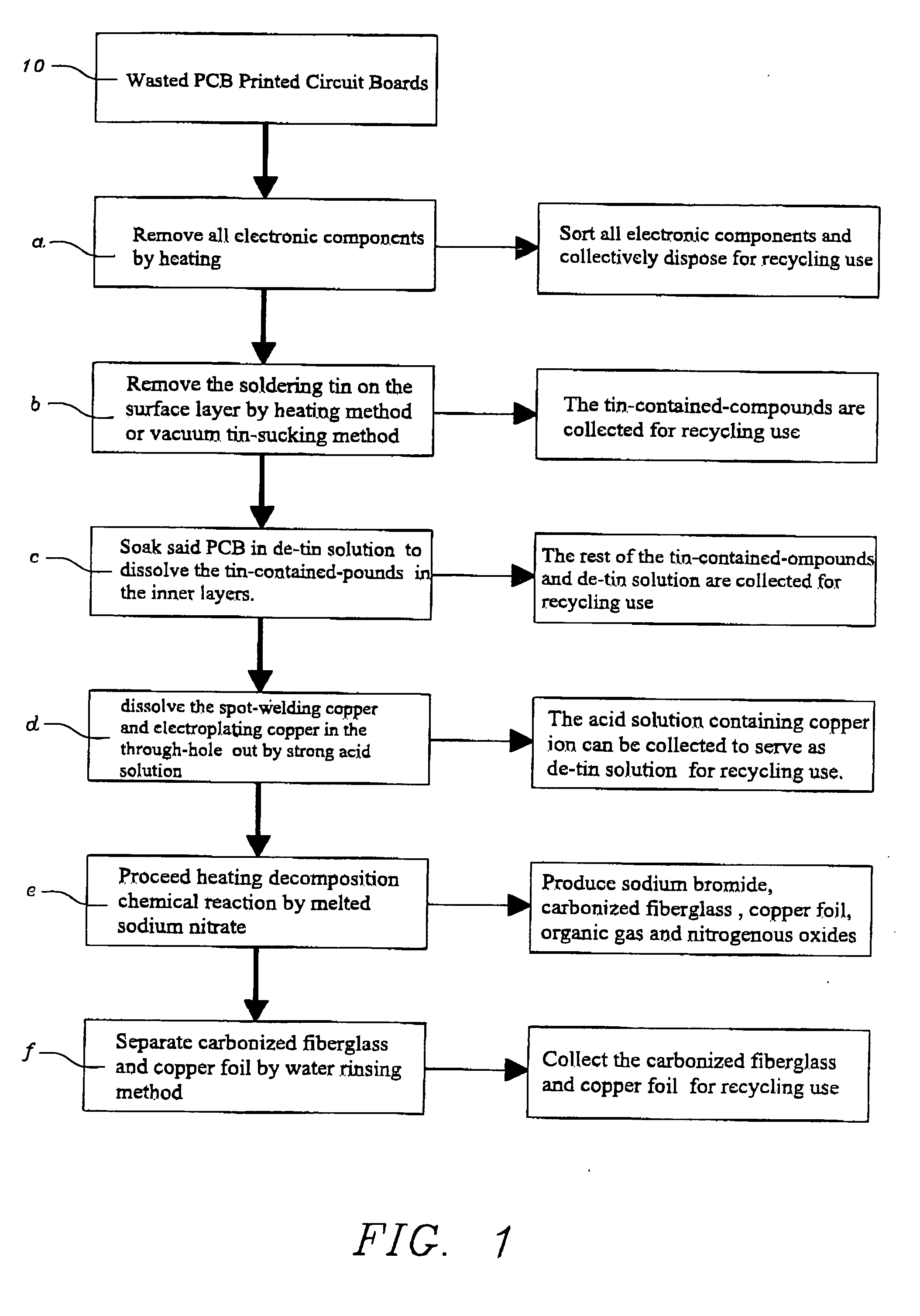

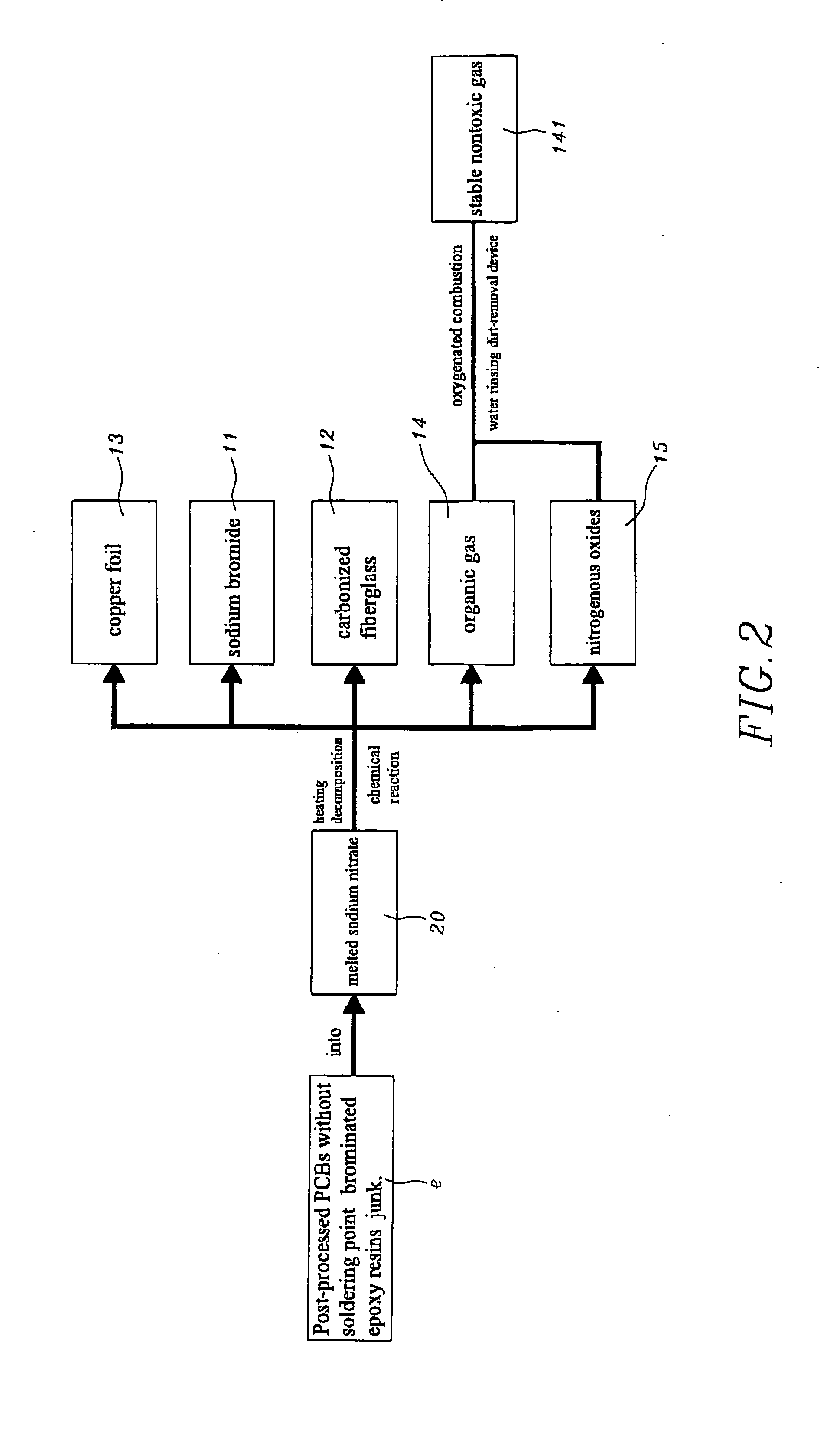

Method of recycling wasted printed-circuit-board

InactiveUS20070169330A1Final product manufactureTransportation and packagingRecovery methodGlass fiber

The present invention relates to a “method of recycling wasted printed-circuit-board”, which takes advantage of the characteristics of the PCB so as to dispose different recycling material in stage manner, so that different metals remaining on said PCB are sorted out step by step; Thereby, the bromide and the fiberglass of importance in the resins are collected and converted into variety of industrial materials as resource for recycling use in order to prevent said wasted PCB from spoiling the natural environment after recycling use.

Owner:WU HSIEH SEN

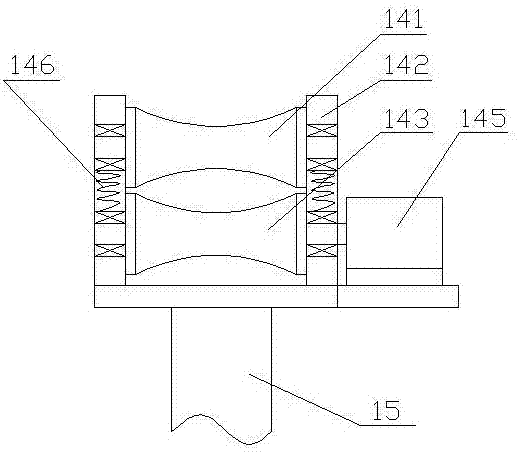

Automatic stripping control method for waste cable

ActiveCN109755900AAvoid damageNo offsetBasic electric elementsApparatus for removing/armouring cablesFixed frameEngineering

The present invention discloses an automatic stripping control method for waste cable, and belongs to the technical field of a cable stripping device. The control method is realized based on a cable stripping device. The device comprises a workbench; the top of the workbench is provided with a cable stripping mechanism, a cable straightening mechanism and a cable cutting mechanism. The cable stripping mechanism comprises a cable limiting component, a transverse cutting component and a waste sheath winding component; the cable straightening mechanism includes a transverse straightening component and a longitudinal straightening component; and the left end of the workbench is provided with a left fixing frame and a unwinding roller. According to the invention, the sheath of the cable with different diameters can be automatically stripped by the cable stripping mechanism so that the cable sheath is divided into two sections and the winding operation can be automatically completed by the waste sheath winding component; the passing cable can be automatically straightened by the cable straightening mechanism; and the cases where the bent cable is cut by the transverse cutting component and then damaged are avoided.

Owner:ANHUI HUATENG AGRI TECH CO LTD

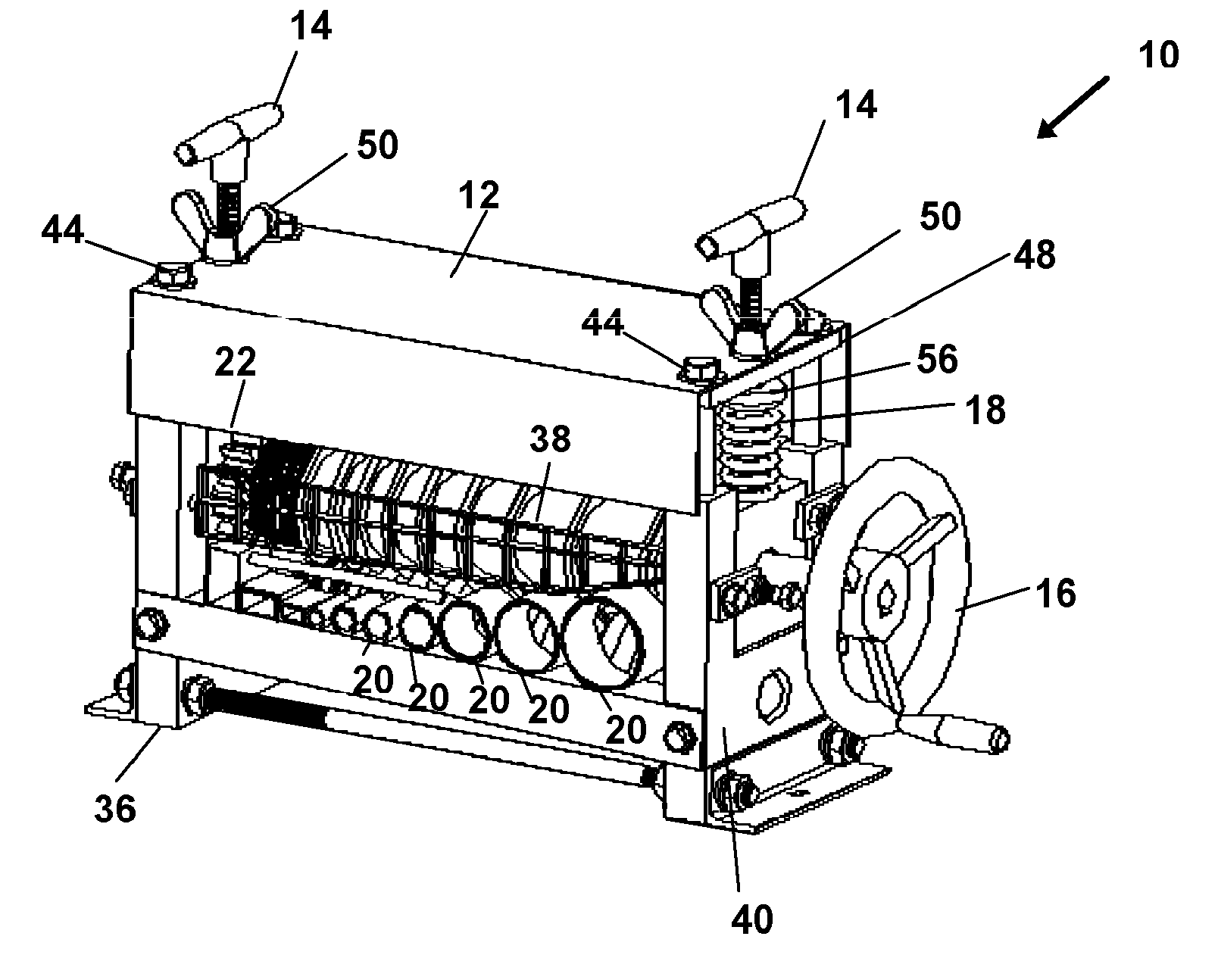

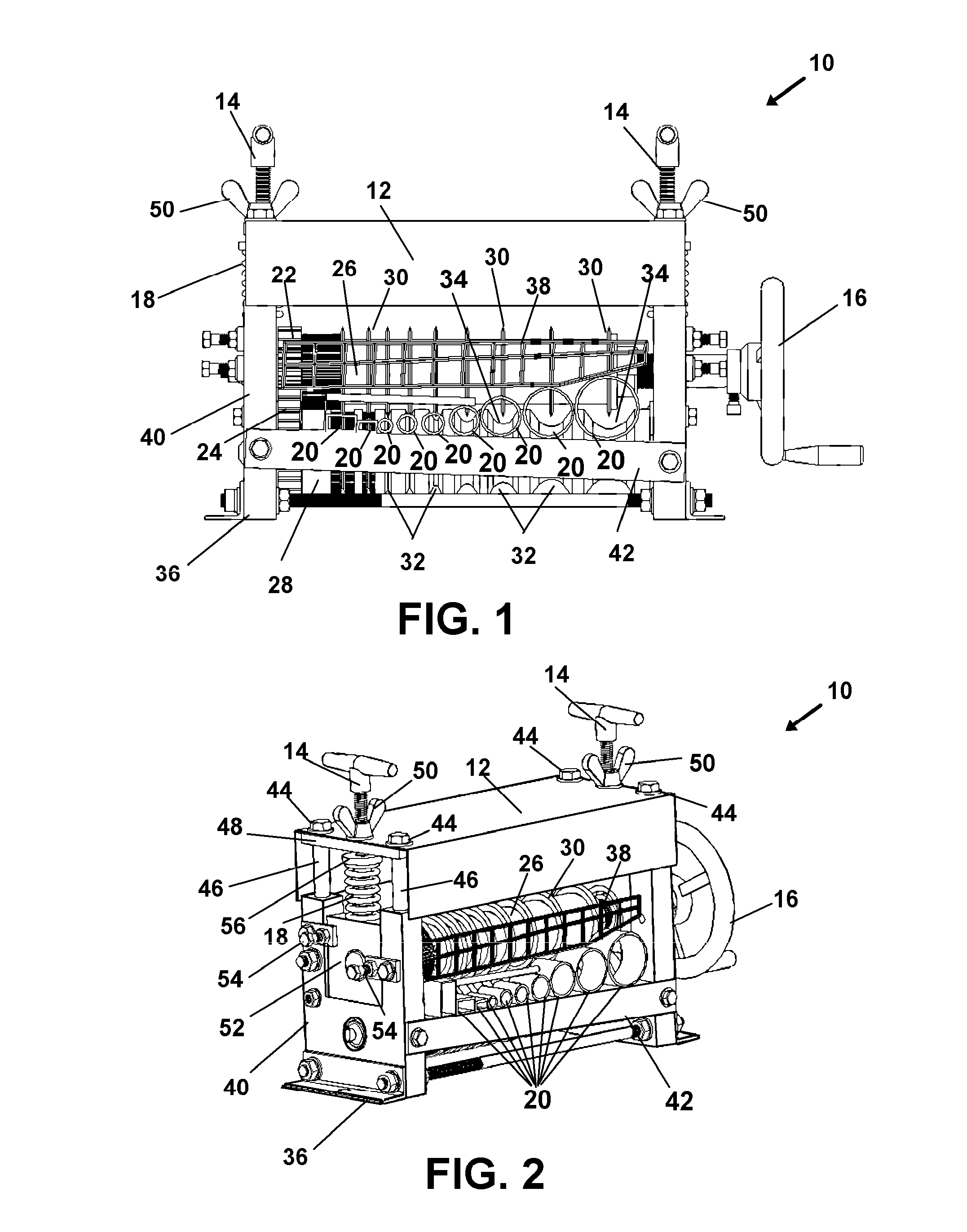

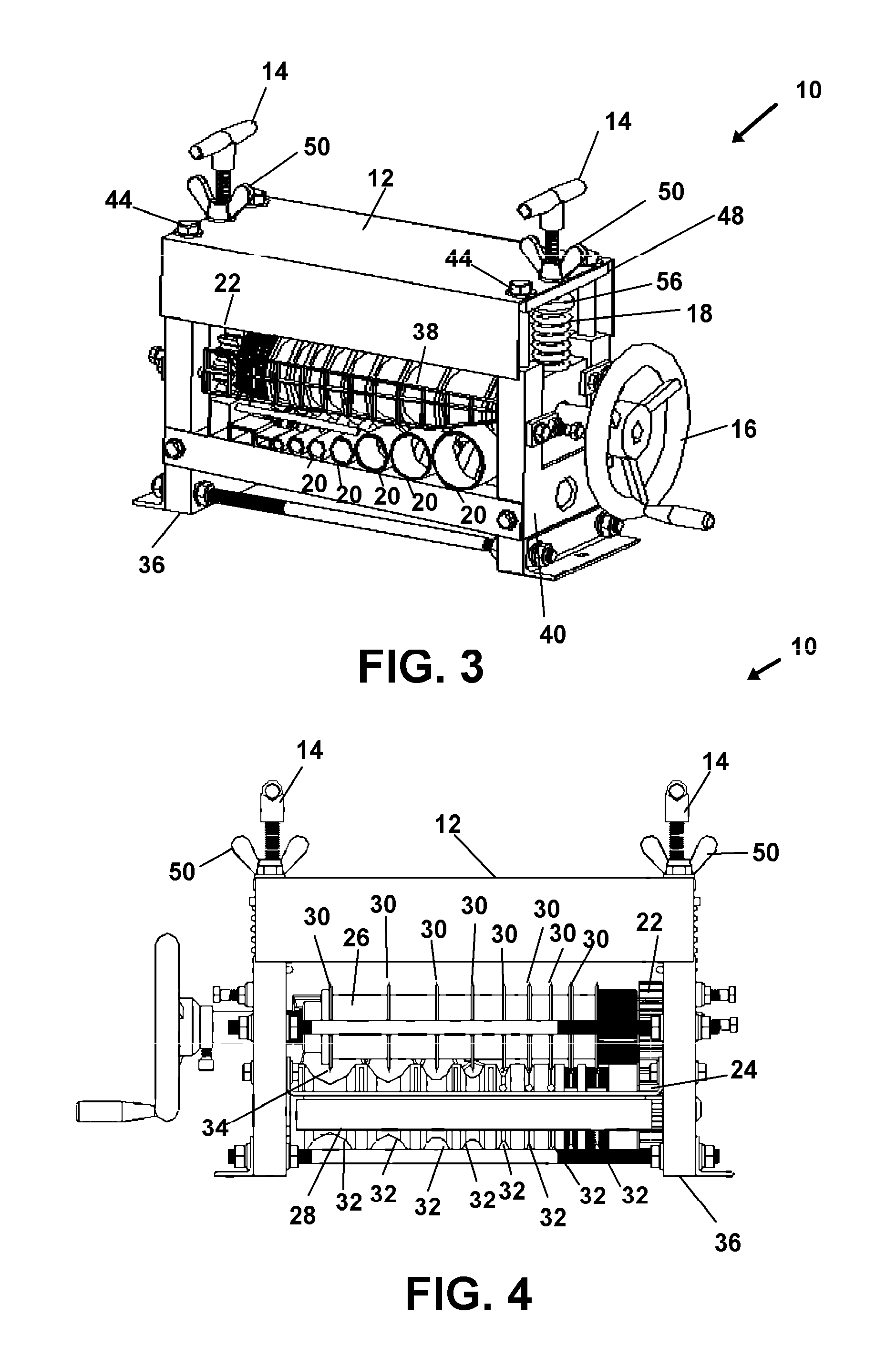

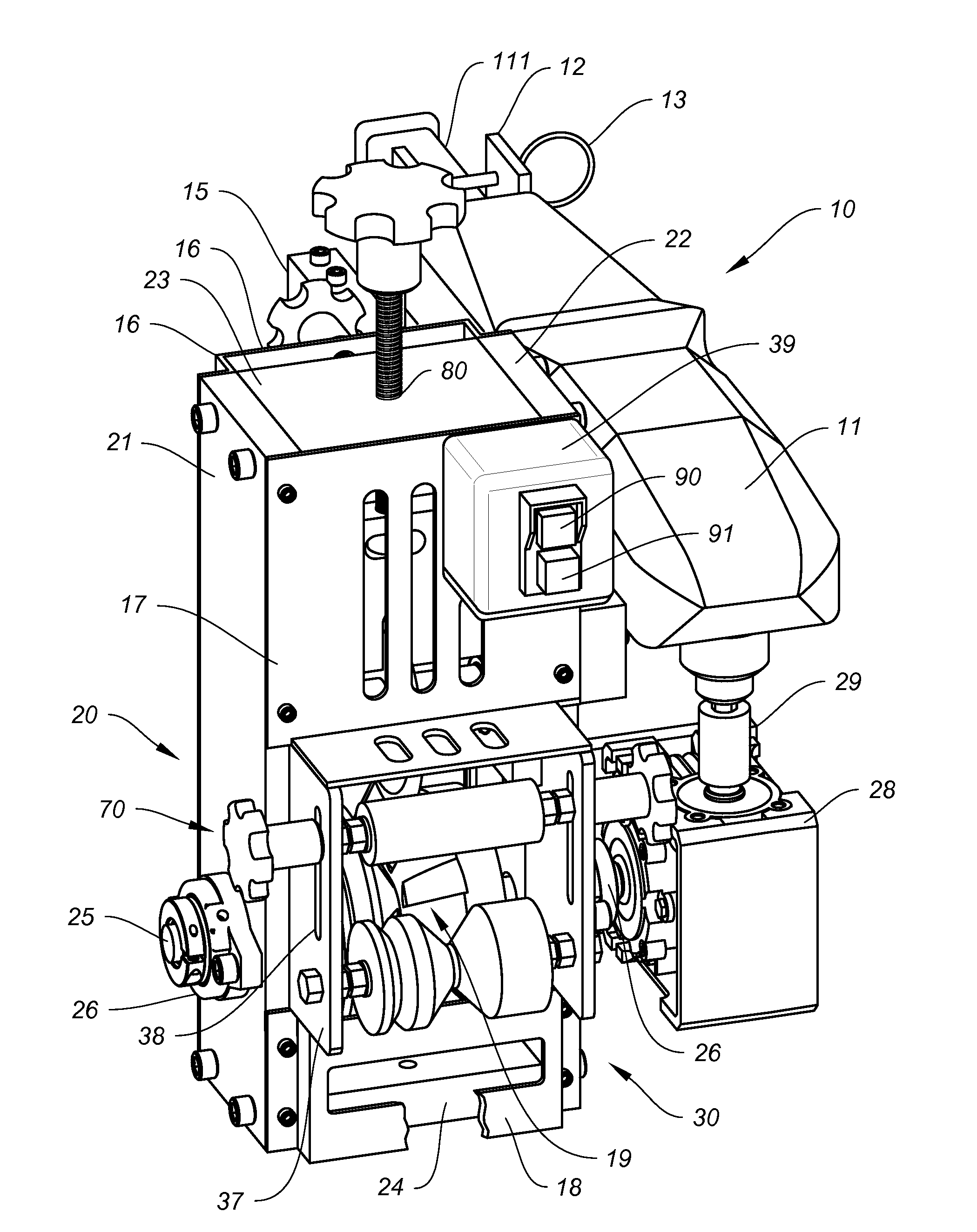

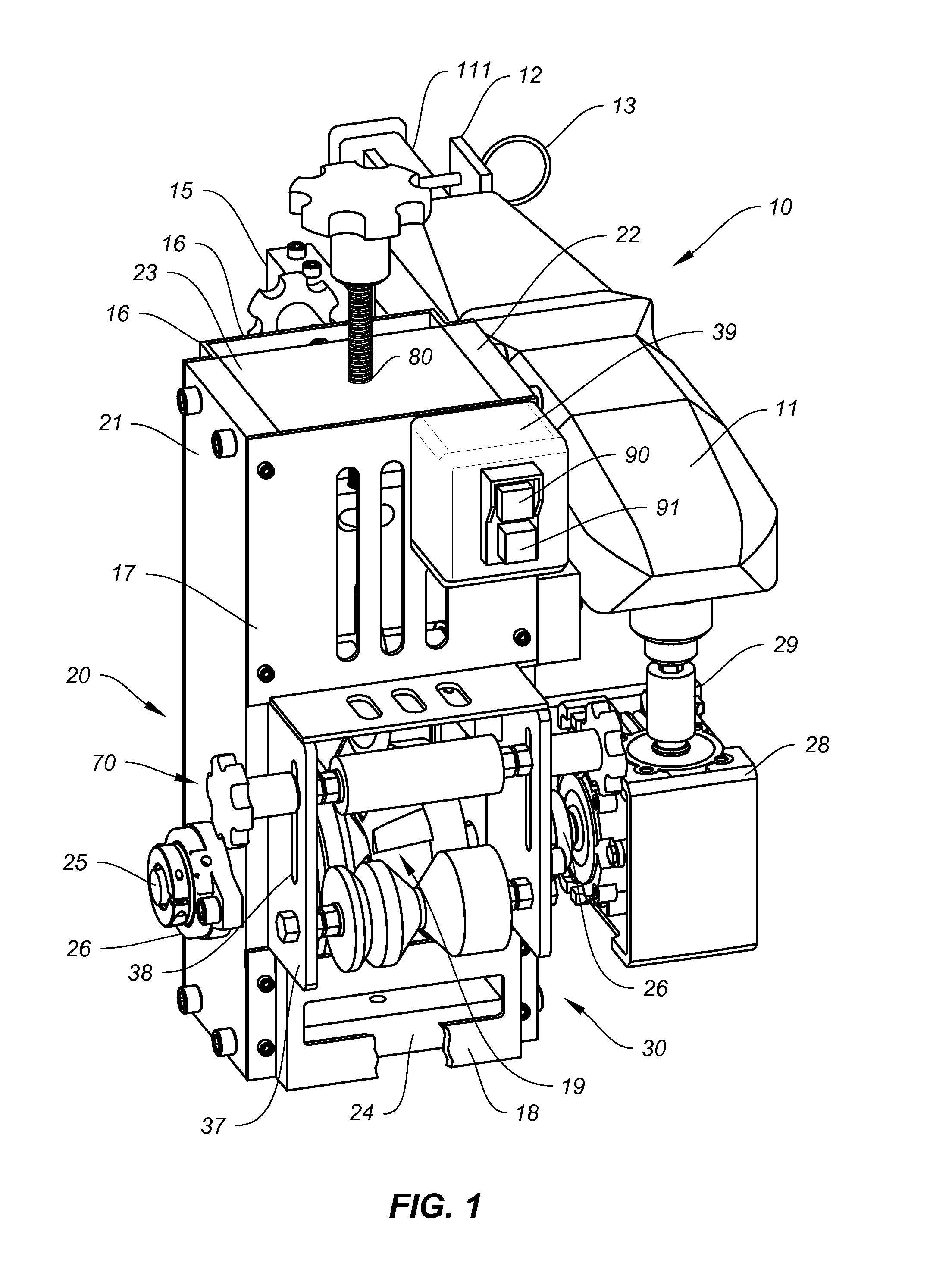

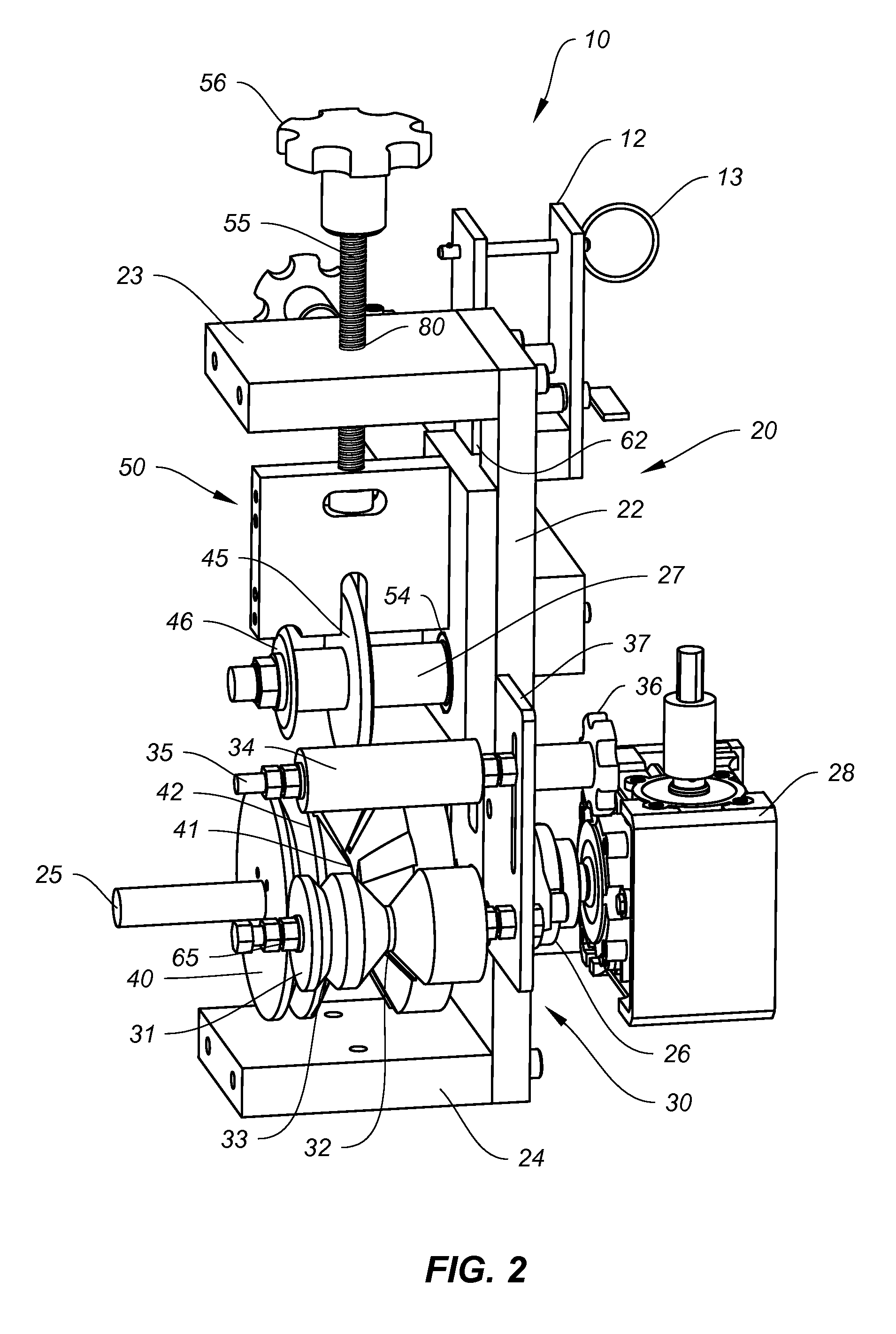

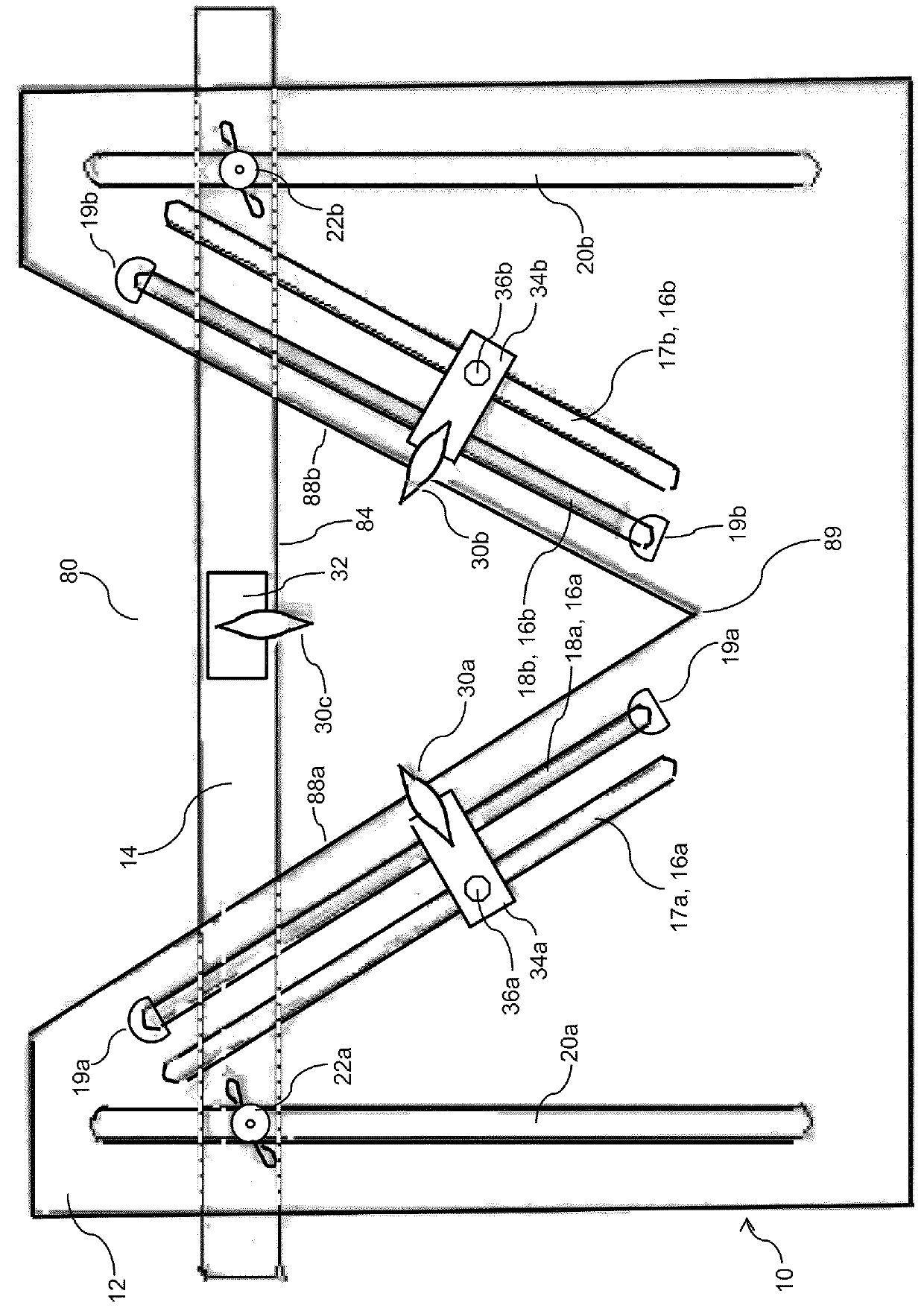

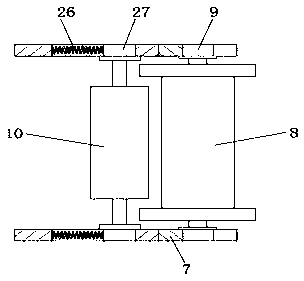

Apparatus and Method for Stripping Insulation Lengthwise fom Electrical Wires and Cables

ActiveUS20130104720A1Reduce coefficient of frictionEasy to cleanBasic electric elementsMetal working apparatusElectric cablesElectric wire

An apparatus for the stripping of insulation lengthwise from an insulated wire or cable on a continuous basis for the recovery of the metal core of the wire or cable. The apparatus has a framework supporting a rotatable feeder wheel having one or more generally “V”-shaped grooves or cable guide paths that are preferably of unlike circumferences so that varying diameters of insulated cable may be stripped quickly. The feeder wheel works in cooperation with a movable carriage assembly supporting rotatable circular cutting tools. The grooves can be formed with shoulders and relieved slots for grabbing the cable. The apparatus further has a transmission mounted to the framework and connected to the feeder wheel by a shaft. The transmission is driven by either a removable electric motor or fixed electric motor.

Owner:PARKER KENT E

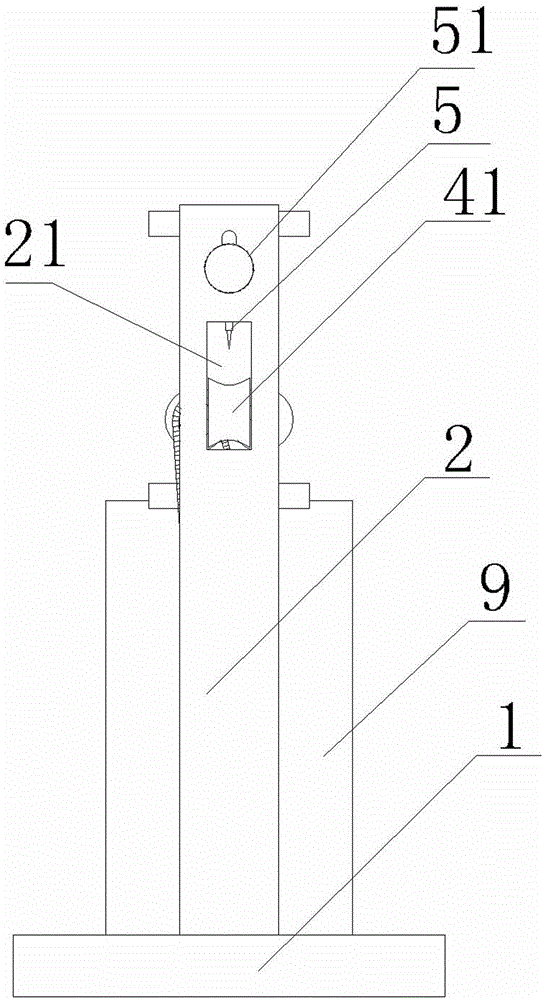

Waste cable recovering device

ActiveCN104091657ASimple structureImprove work efficiencyBasic electric elementsElectronic waste recyclingDrive wheelGear wheel

The invention relates to a waste cable recovering device which comprises a base, and a front support, a rear support and an electric motor which are fixedly arranged on the base. A peeling roller set is arranged between the front support and the rear support. A cable inlet is formed in the front support. A peeling cutter and a front limiting wheel are arranged in the cable inlet. A cable core outlet is formed in the rear support. An upper rear limiting wheel and a lower rear limiting wheel are arranged in the cable core outlet. The electric motor is arranged outside the rear support. An output shaft of the electric motor is connected with a driving bevel gear and a cable core reel. The driving bevel gear is meshed with a driven bevel gear. The driven bevel gear is connected with a second driven wheel. The second driven wheel is connected with a third driven wheel through a belt. The third driven wheel drives the roller set to rotate. A skin chip barrel is arranged below the roller set. The waste cable recovering device is reasonable in structure, capable of rapidly separating the cable skin of a waste cable from the cable core of the waste cable, and high in work efficiency.

Owner:STATE GRID CORP OF CHINA +2

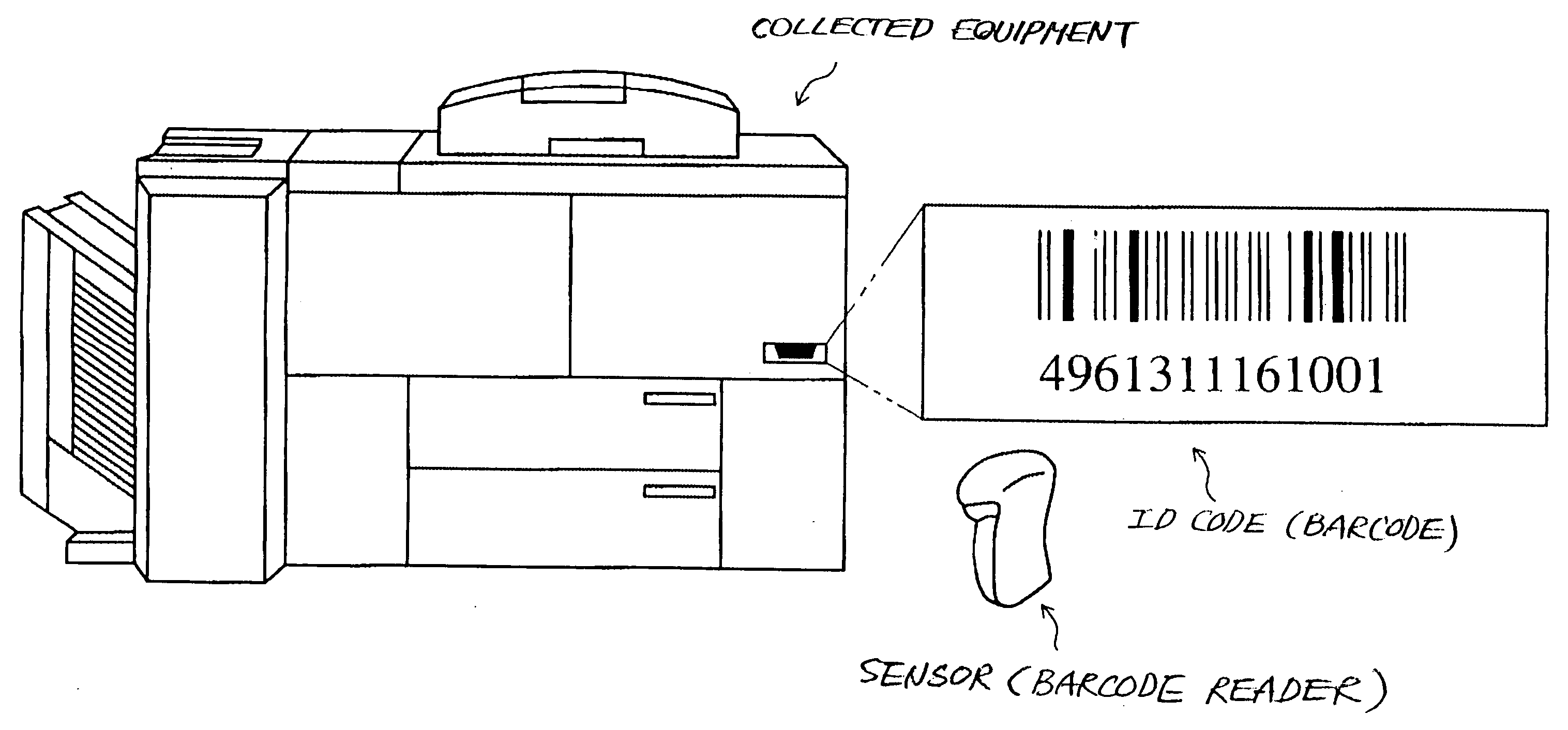

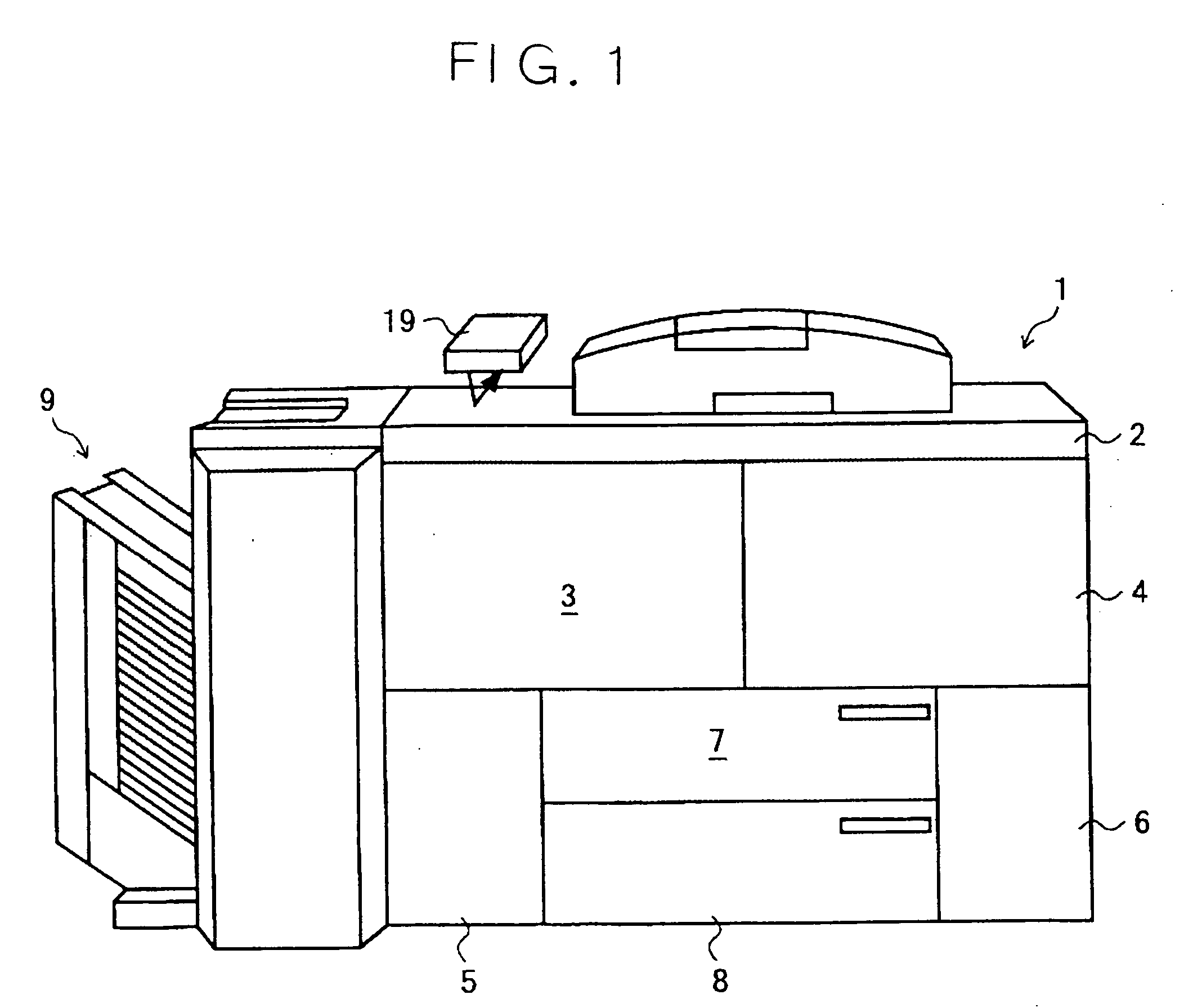

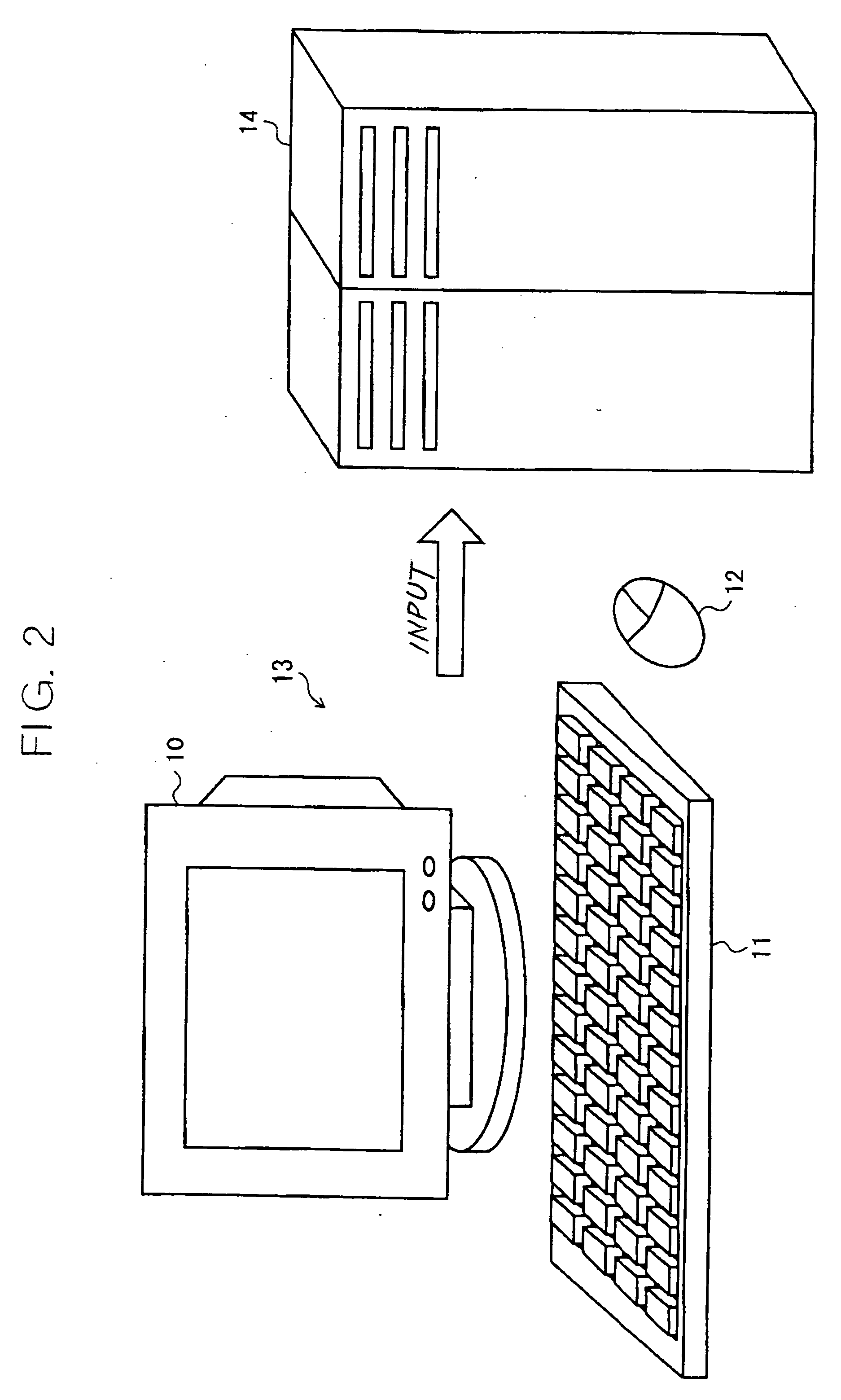

Recycling system and disassembling and classifying method

InactiveUS20060180518A1Accurately identifying informationImprove efficiencyData processing applicationsDigital data processing detailsUltravioletClassification methods

In a recycling system of the present invention for collecting a subject of recycling, which contains plastics, from the market and reprocessing the plastics to thereby produce a recycled product, the plastics contains a line spectrum radiation that radiates light when receiving ultraviolet rays or an electromagnetic wave. Recycle information particular to the subject of recycling is identified on the basis of the wavelengths of light radiated from the line spectrum radiation.

Owner:RICOH KK

Device for recycling waste electric wires based on water jet

ActiveCN103854811AImprove qualityEfficient recyclingBasic electric elementsElectronic waste recyclingSprayerEngineering

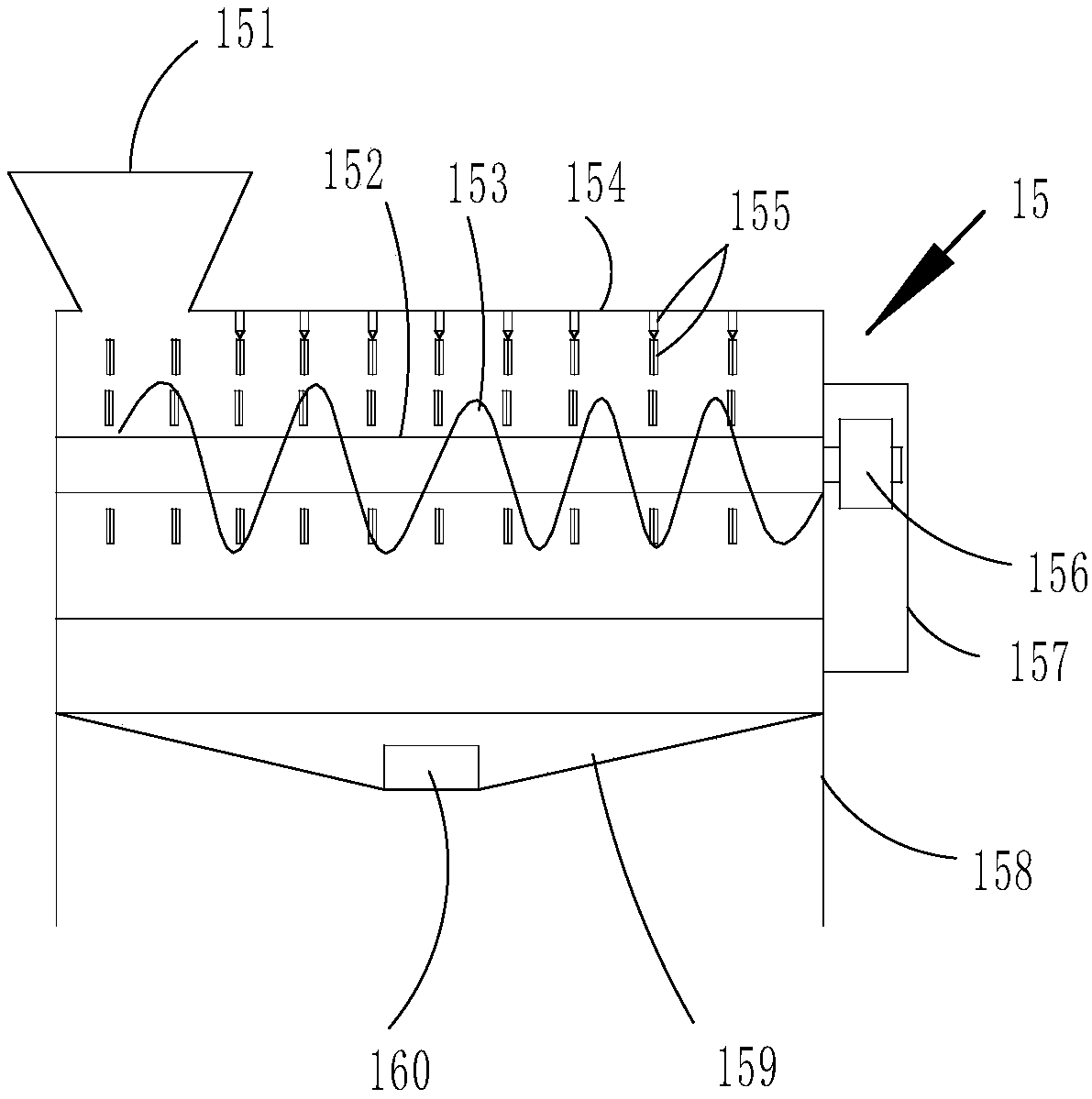

The invention discloses a device for recycling waste electric wires based on water jet. The device is characterized in that front friction wheels, a smashing chamber, a rear friction wheel, a wire winding plate and wire winding barrels are sequentially arranged on a worktable along the feeding direction of electric wires; each of the rear friction wheel and the front friction wheel consists of a pair of rollers which have an adjustable distance and are perpendicular to the worktable, and the front friction wheels and the rear friction wheel are respectively used for clamping the electric wires; the smashing chamber is arranged between the front friction wheels and the rear friction wheel and is provided with a plurality of high-pressure jet sprayers; the jet sprayers are distributed on two sides of the electric wires; a plurality of through holes for enabling the electric wires to penetrate through are formed in the wire winding plate from top to bottom; the multiple wire winding barrels are connected in series to a wire winding shaft from top to bottom; the wire winding shaft is driven by a worm wheel and a worm. The device disclosed by the invention recycles the waste electric wires through high-pressure pure water jet, is clean, environment-friendly, easy to operate and low in cost and can realize high-efficiency recycling of metals and wrapping materials in the electric wires.

Owner:靖江市金舟船舶器材有限公司

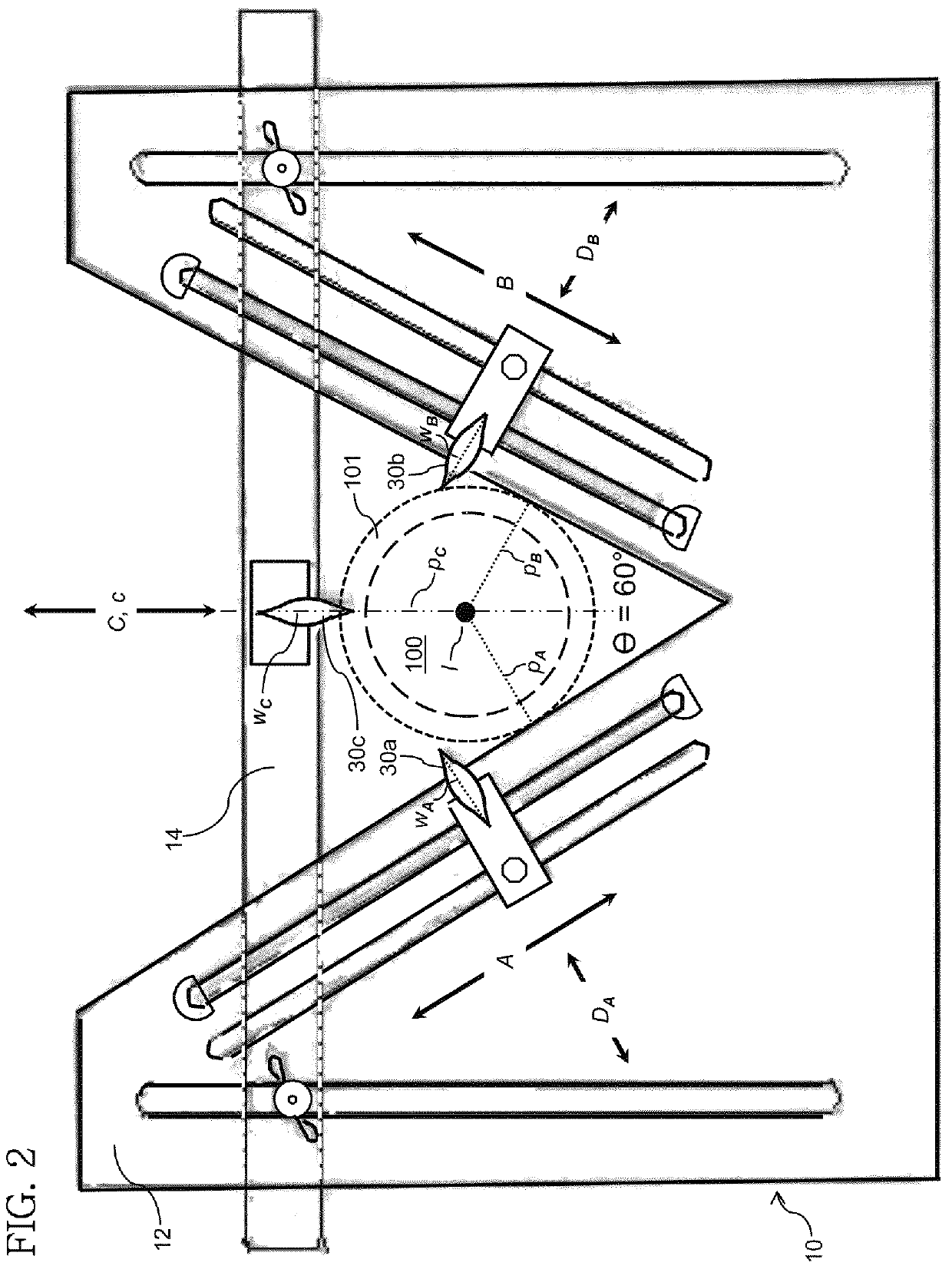

Universal cable jacket removal tool

ActiveUS9230717B1Fast and precise and easily operatedLittle strengthBasic electric elementsApparatus for removing/armouring cablesEngineeringInverted triangle

According to typical inventive practice, a cable is grasped by a Kellum grip and is positioned through the topside “V”-notch of an “M”-structure. Two wires engage pulleys and a ratchet distanced from the pulleys. The pulleys are joined with a grip plate, attached at an axial end of the Kellum grip. The ratchet is joined with a ratchet plate, proximate and / or attached to the “M”-structure. The “M”-structure has joined therewith three blade wheels having cutting orientations in the same linear direction. The blade wheels are situated interiorly and perpendicularly in correspondence to the geometric sides of the inverted triangle defined by the “V”-notch. Each blade wheel is adjustable to suit the diameter of the cable positioned through the “V”-notch. Ratcheting of the wires moves the ratchet plate and hence the “M”-structure, resulting in creation via the blade wheels of three parallel slices in the cable along its axis.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

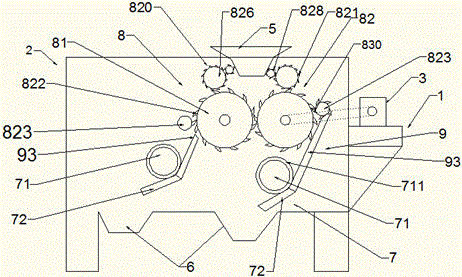

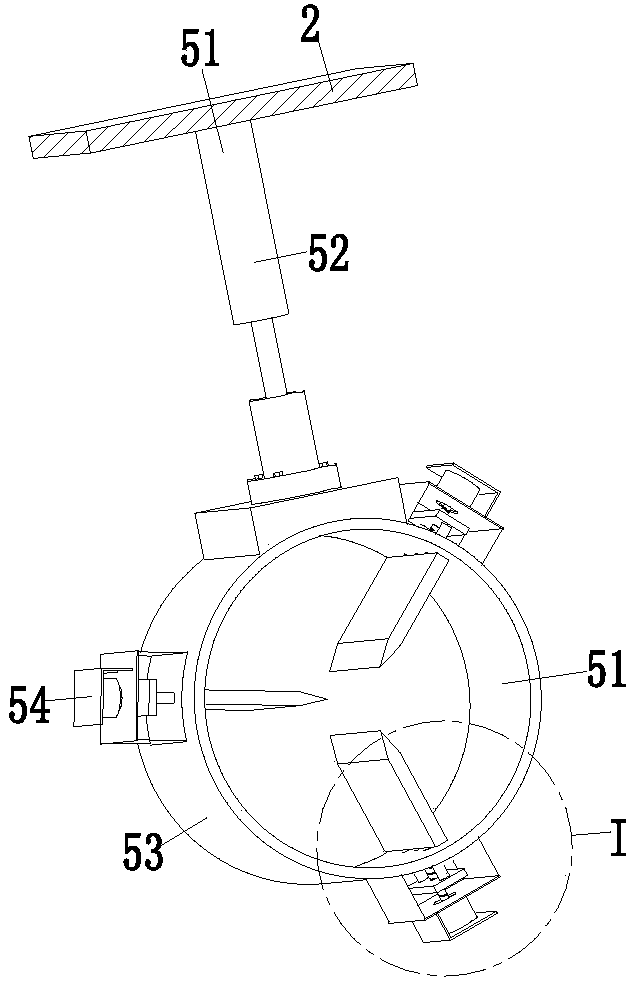

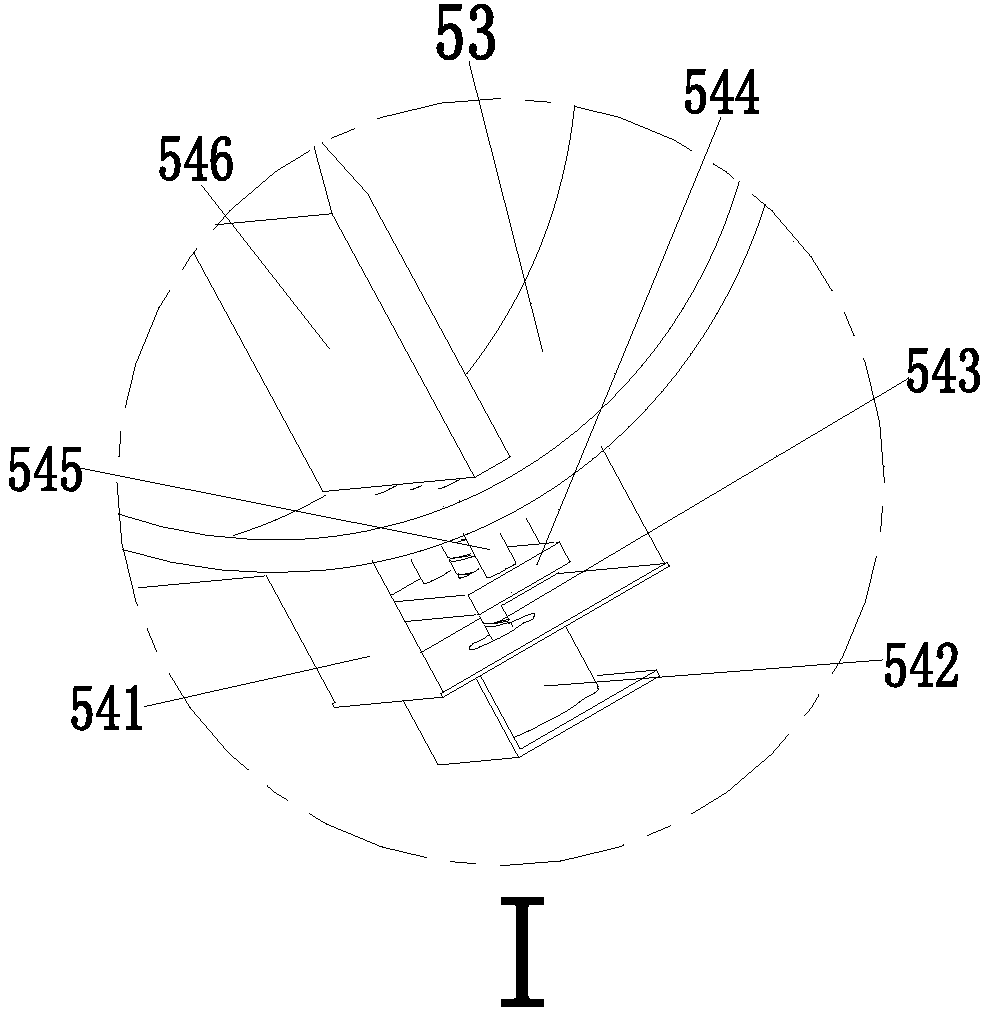

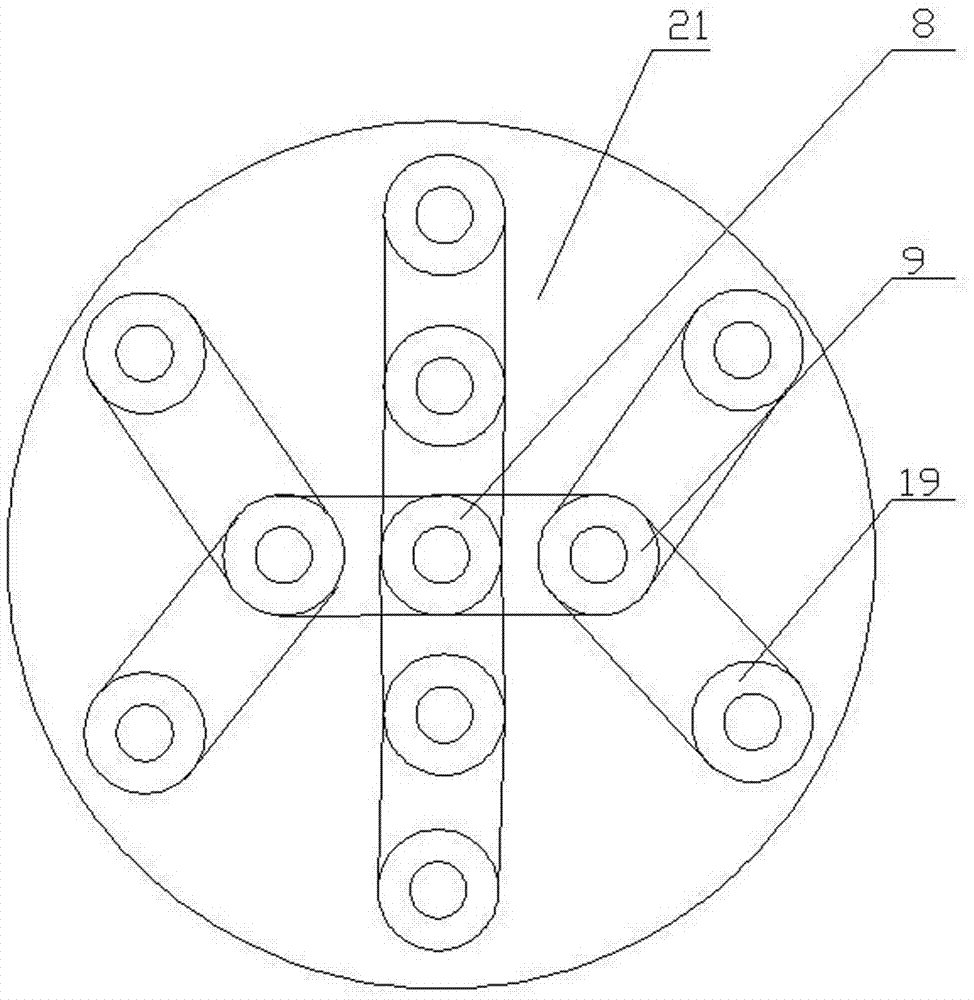

Segmented recycling device of electric power cables

ActiveCN107666136AReduce labor intensityFacilitate strippingBasic electric elementsApparatus for removing/armouring cablesEngineeringPower cable

The invention relates to a segmented recycling device of electric power cables. The device comprises a base plate. A cutting support rack is installed on the base plate. A guidance cylinder, two opposite adjusting skin cutting devices, a segmentation device and a stripping separation guiding device are successively installed on the lower end of the cutting support rack from front to back. A cablerecycling and smashing device is installed on the base plate. A rolling device is installed on the base plate. According to the invention, difficulties in cable recycling method can be solved that workers need to strip insulation bodies from cables in a manual stripping method, different tools are used for stripping electric cables with different diameters, manual cleaning of the stripped electriccable insulation bodies is required, the manually cleaned electric cable insulation bodies should be transmitted to a designated position for smashing, inner organizations of the electric cable insulation bodies will be directly damaged by use of the burning method and the chemical method, gas generated in the burning process pollutes the environment, and long time is consumed, labor intensity ishigh and working efficiency is low in manual rolling of coils since the electric cable consists of various coils.

Owner:TIANJIN SAIXIANG TECH

Waste power cable recycling device convenient for peeling

InactiveCN109473915AQuick changeReduce frictionBasic electric elementsApparatus for removing/armouring cablesPower cableDrive shaft

The invention belongs to the technical field of electric power tools, in particular to a waste power cable recycling device convenient for peeling. For the problem that a cable is inconvenient for being clamped and fixed when the existing cable recycling device is used, and the splicing knife is easy to slip, the following solution is proposed that the waste power cable recycling device comprisesa base, wherein the top and bottom of the outer wall at one side of the base are respectively provided with a driven shaft mounting hole and a driving shaft mounting hole, the inner wall of the drivenshaft mounting hole and the inner wall of the driving shaft mounting hole are respectively connected with a driven shaft and a driving shaft through the bearings, and a push rod screw on the outer wall at one side of the base is fixed with a recovery motor. The device facilitates quick replacement of the pay-off roller, helps to improve the separation speed of the wire and the jacket, helps to improve the working efficiency, can effectively improve the phenomenon that the cable roller is loosened by the rotation of the pay-off roller, can clamp and fix cables of different sizes, and helps toreduce the probability that the cutting is not complete as the splicing knife slides, resulting in rework.

Owner:六安市匠心信息科技有限公司

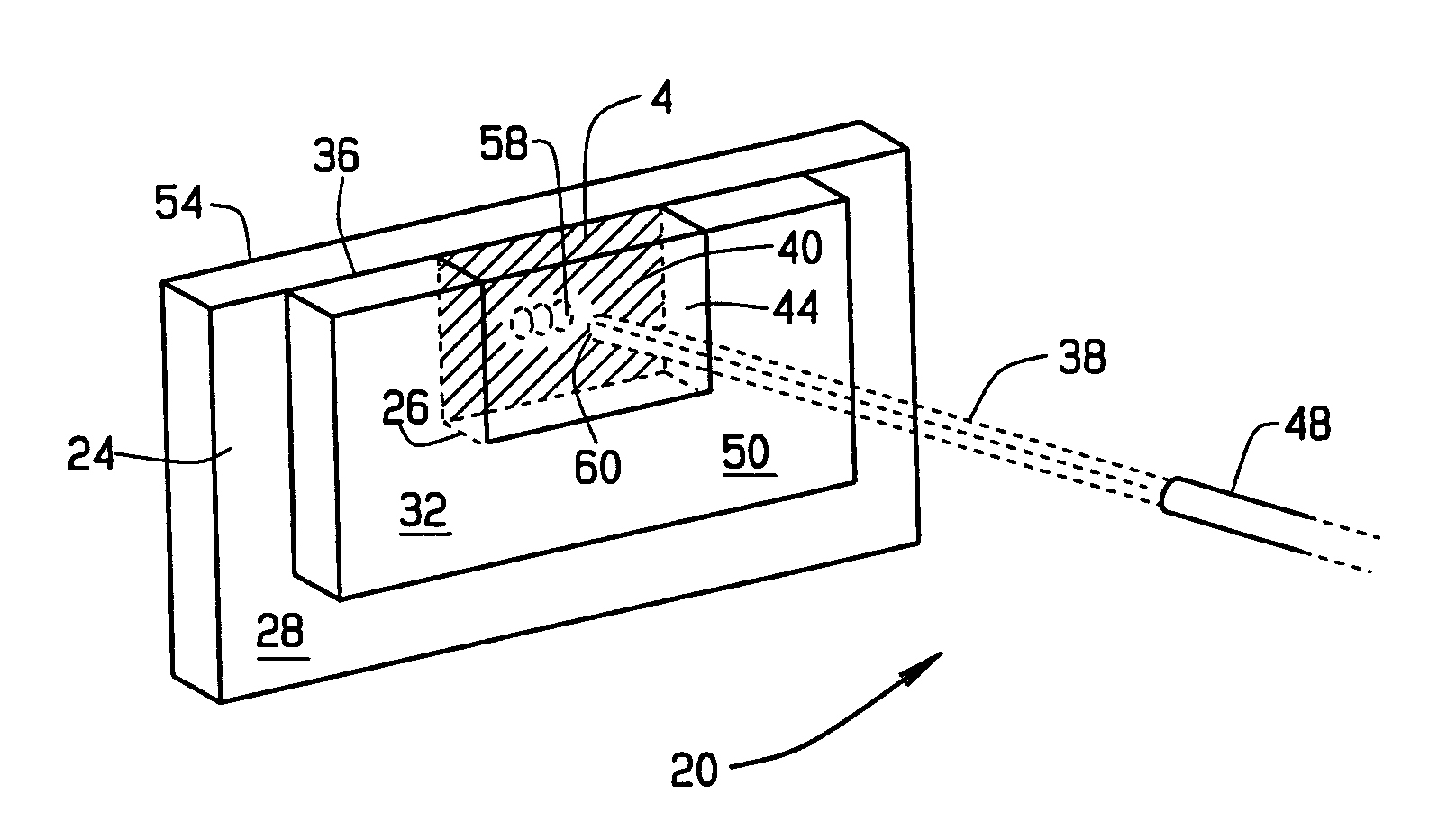

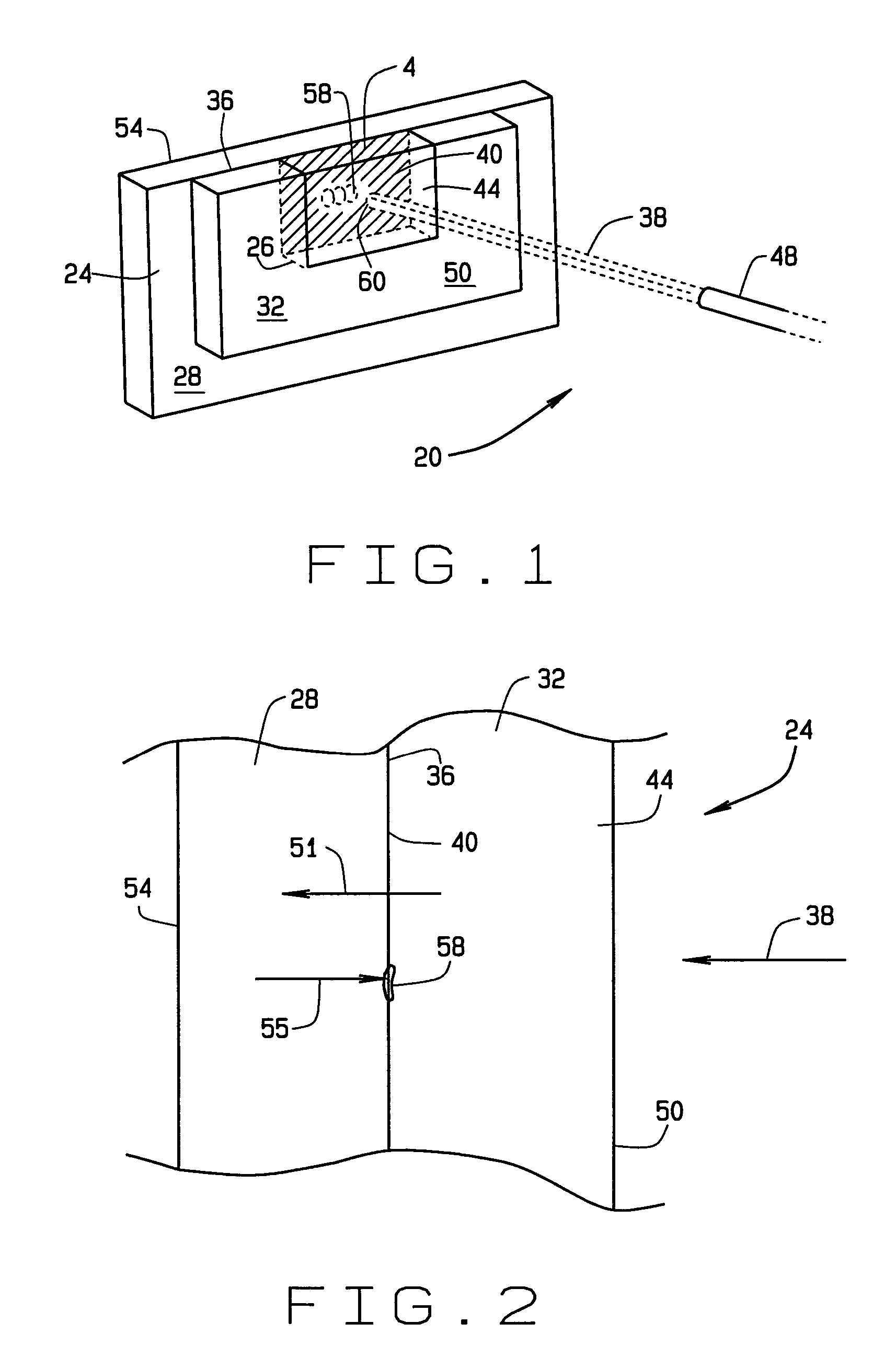

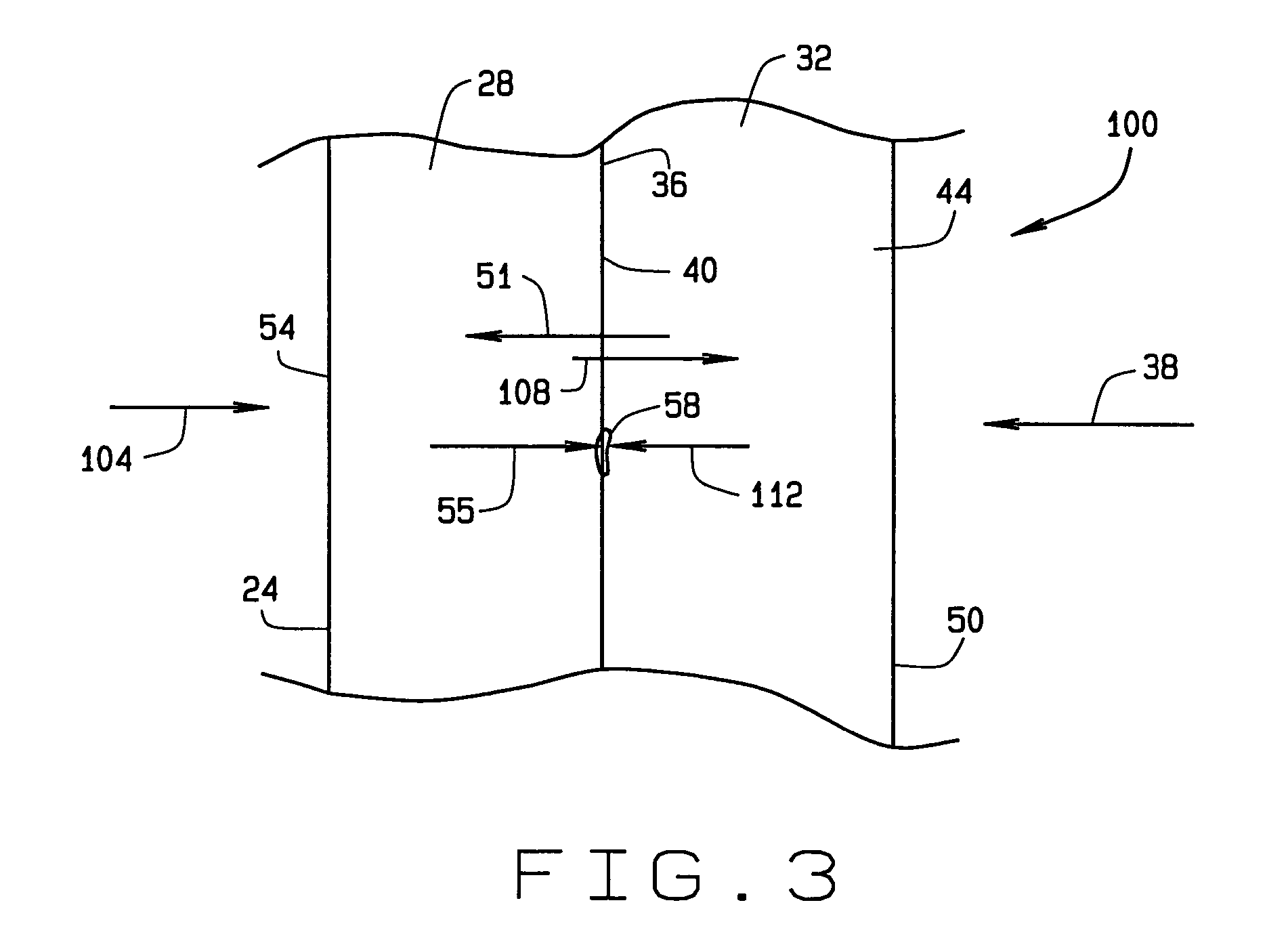

Method of applying a tube member in a stator slot in a rotating electrical machine

InactiveUS7019429B1Eliminate riskHigh densityWindings insulation shape/form/constructionMagnetic circuitElectric machineEngineering

A method for mounting a tube in a space having a shape corresponding to the shape of the tube. The tube is inserted into the space, pressurized with a hot pressure medium causing the tube to expand until the space is filled, then a cold pressure medium is substituted for the hot pressure medium while maintaining constant pressure causing the tube to solidify in its expanded shape. Also, a rotating electric machine having such a tube between windings of a high-voltage cable in a stator slot.

Owner:ABB (SCHWEIZ) AG

Waste cable material separating and recycling device

ActiveCN107472992ADoes not affect the cutting effectAvoid synergiesFilament handlingBasic electric elementsEngineeringCooperative work

The invention provides a waste cable material separating and recycling device comprising a base, a winding mechanism arranged on the base, a plurality of leading mechanisms arranged on the base and matched with the winding mechanism, a peeling mechanism arranged on the base and matched with the leading mechanisms, a guide mechanism arranged on the base and matched with the peeling mechanism, a cutting mechanism arranged on the base and located between the peeling mechanism and the guiding mechanism and a controlling mechanism arranged on one side of the base and used for coordinating and controlling the winding mechanism, the leading mechanism, the peeling mechanism, the guide mechanism and the cutting mechanism. The winding mechanism, the leading mechanisms and the cutting mechanism are arranged on the base. In order to avoid the phenomenon that during peeling, cable materials are instable, the guide mechanism is arranged in front of the peeling mechanism, mutually cooperative work of all the components is achieved through coordination of the control mechanism, rapid separation and cutting can be better conducted, metal and peels are separately stored, and therefore recycling of waste is achieved.

Owner:南通市东风特种电线有限公司

Old cable intelligent recovery device

InactiveCN107316722AAvoid synergiesAvoid wastingBasic electric elementsApparatus for removing/armouring cablesEngineeringCooperative work

The invention provides an old cable intelligent recovery device which comprises a base, a rolling mechanism arranged on the base, a plurality of lead mechanisms arranged on the base, a peeling mechanism arranged on the base, a guiding mechanism arranged on the base, and a control mechanism arranged at one side of the base and used for cooperatively controlling the rolling mechanism, the lead mechanisms, the peeling mechanism and the guiding mechanism. A discriminating mechanism connected with the control mechanism by a signal is arranged at the lateral surface of the base. According to the old cable intelligent recovery device provided by the invention, by cooperation of the control mechanism, mutual cooperative working among each component is implemented, better rapid separation is implemented, and metal and skin are separately stored, so that recycling of waste is implemented; and the discriminating mechanism can carry out shooting on the surface of an old cable to identify a scar, and a cable with perfect skin is recycled, so that cost of power operation is saved.

Owner:南通上汇新材料有限公司

Winding recovery device of power cable

ActiveCN109920610AReach winding recoveryAchieve the purpose of separationBasic electric elementsElectronic waste recyclingPower cableEngineering

The invention relates to a winding recovery device of a power cable, and belongs to the technical field of electric power cable recovery. The winding recovery device comprises a workbench, a conveyingassembly, a sheath-cutting assembly, a cleaning assembly, a peeling assembly and a recovery assembly, wherein the conveying assembly, the sheath-cutting assembly, the peeling assembly and the recovery assembly are sequentially arranged on the workbench from left to right; the cleaning assembly is arranged below the workbench, and one end of the cleaning assembly extends to the sheath-cutting assembly; the conveying assembly comprises a first mounting plate, a bearing plate, a driving part, a pressing part and two limiting plates, wherein the first mounting plate is vertically arranged on theworkbench; the bearing plate is fixedly connected with the front end face of the first mounting plate; and the driving part and the pressing part are arranged on the first mounting plate and the bearing plate. According to the cable, the sheath-cutting assembly is used for cutting an insulating sheath of the cable; and the peeling assembly separates the insulating sheath and metal wires of the cable; and the recovery assembly is used for winding and recovering the metal wires.

Owner:ANQING NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com