Waste cable recovering device

A technology for recycling equipment and waste cables, which is applied in the field of waste cable recycling equipment, can solve the problems of heavy wires and cables, long length, time-consuming and laborious, etc., and achieve the effects of simple structure, wide application range and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

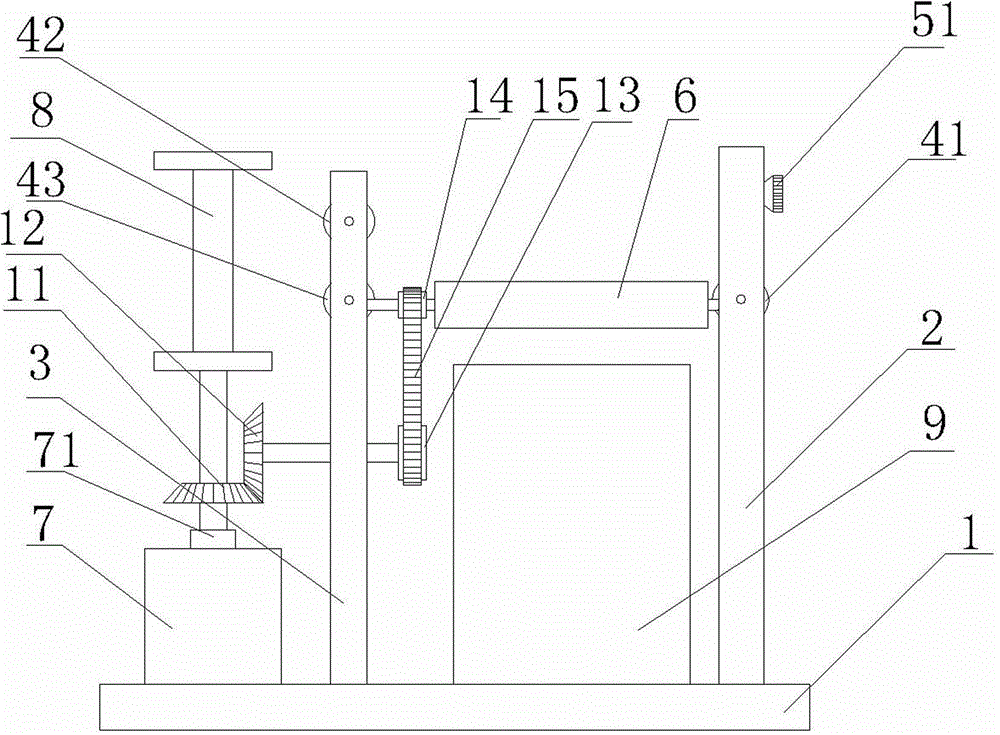

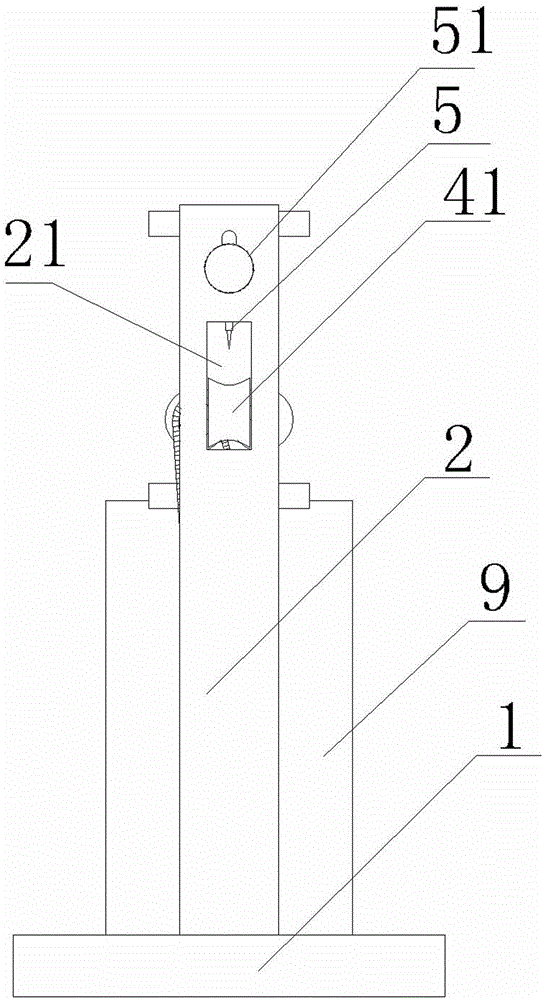

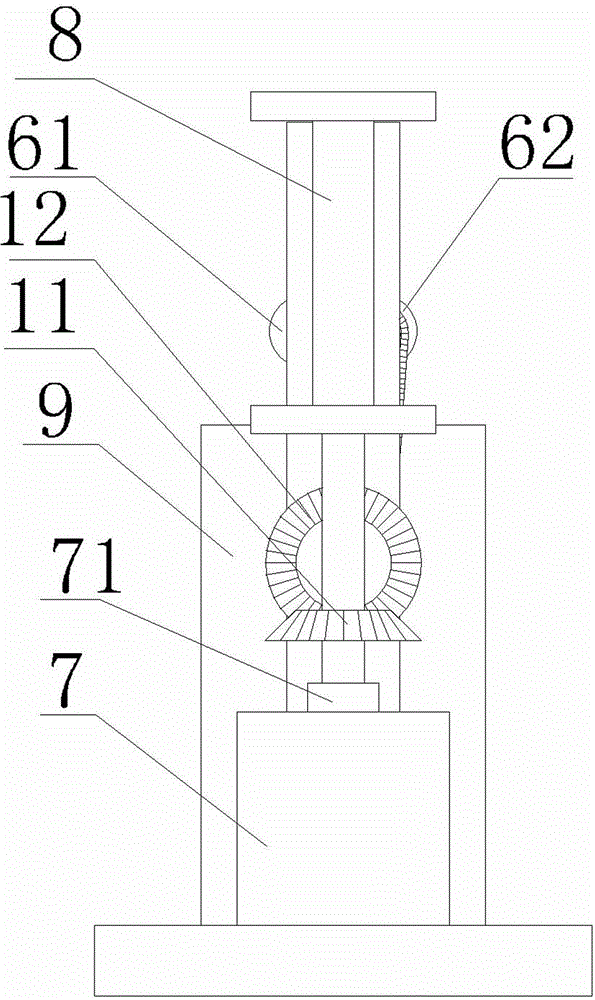

[0021] The following will be combined with Figure 1-5 The present invention will be described in further detail.

[0022] A waste and old cable recovery equipment, which includes a base 1, a front bracket 2, a rear bracket 3 and a motor 7 fixedly arranged on the base 1, a peeling roller group 6 is arranged between the front bracket 2 and the rear bracket 3, the The front bracket 2 is provided with a cable inlet 21, the cable inlet 21 is provided with a stripping knife 5 and a front limit wheel 41, and the rear bracket 3 is provided with a cable core outlet 31, and the cable core outlet 31 is provided with a rear upper limit wheel 42 and a rear lower limit wheel 43, the motor 7 is arranged on the outside of the rear bracket 3, and the output shaft 71 of the motor 7 is connected with the driving bevel gear 11 and the cable core reel 8, so The driving bevel gear 11 is meshed with a driven bevel gear 12, and the driven bevel gear 12 is connected with a second driven wheel 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com