Power wire recycling device

A technology for recycling devices and wires, applied in cable installation devices, electronic waste recycling, cable installation, etc., can solve the problems of inability to strip, classify and recycle work efficiency, low efficiency, etc., and achieve the effect of stable rotation and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

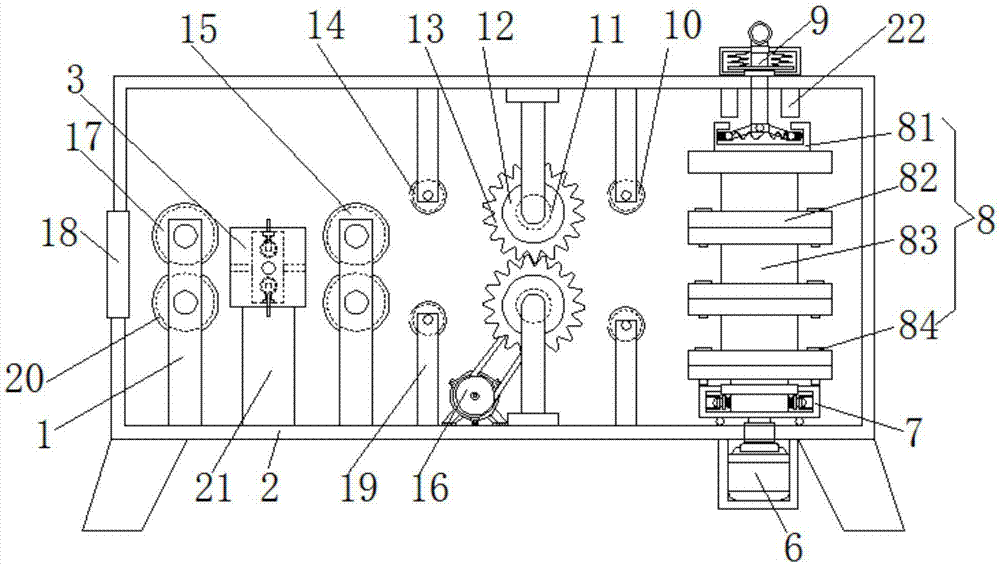

[0036] see Figure 1-7 , the present invention provides a technical solution: a power wire recycling device, comprising a device frame 2 and support legs arranged at the bottom of the device frame 2, a wire inlet 18 is provided on the left side wall of the device frame 2, and the device frame The interior of 2 is installed sequentially from left to right:

[0037] The first guide wheel 17 is used to guide the electric wires to move to the right, and the first guide wheel 17 is fixed on the inner wall of the bottom surface of the device outer frame 2;

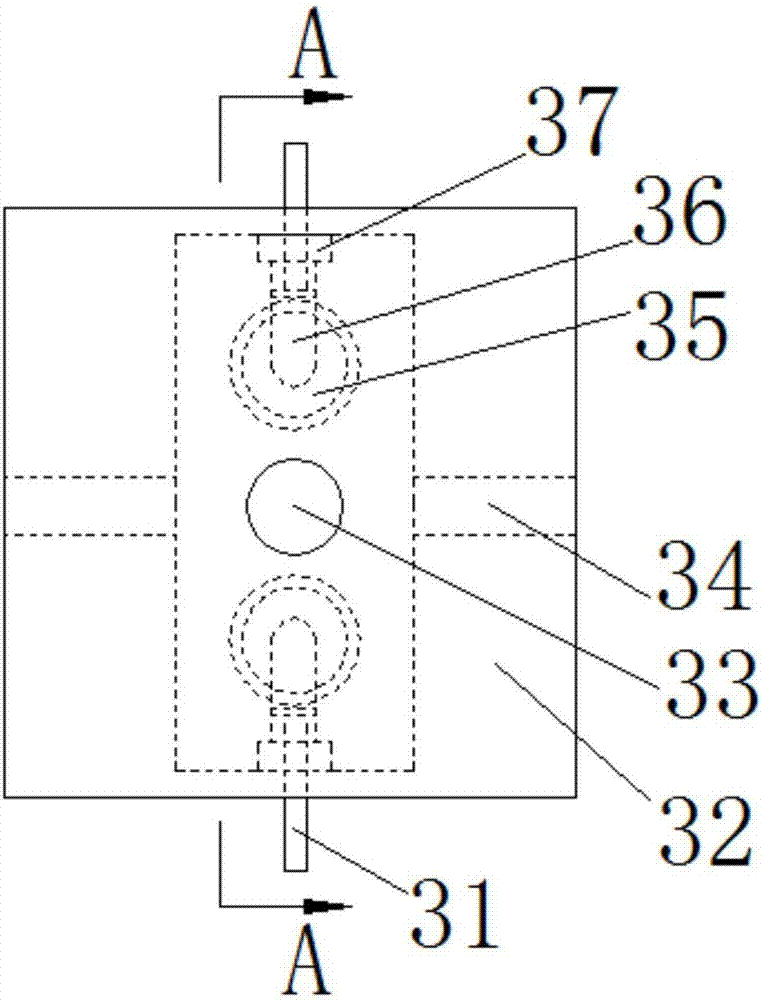

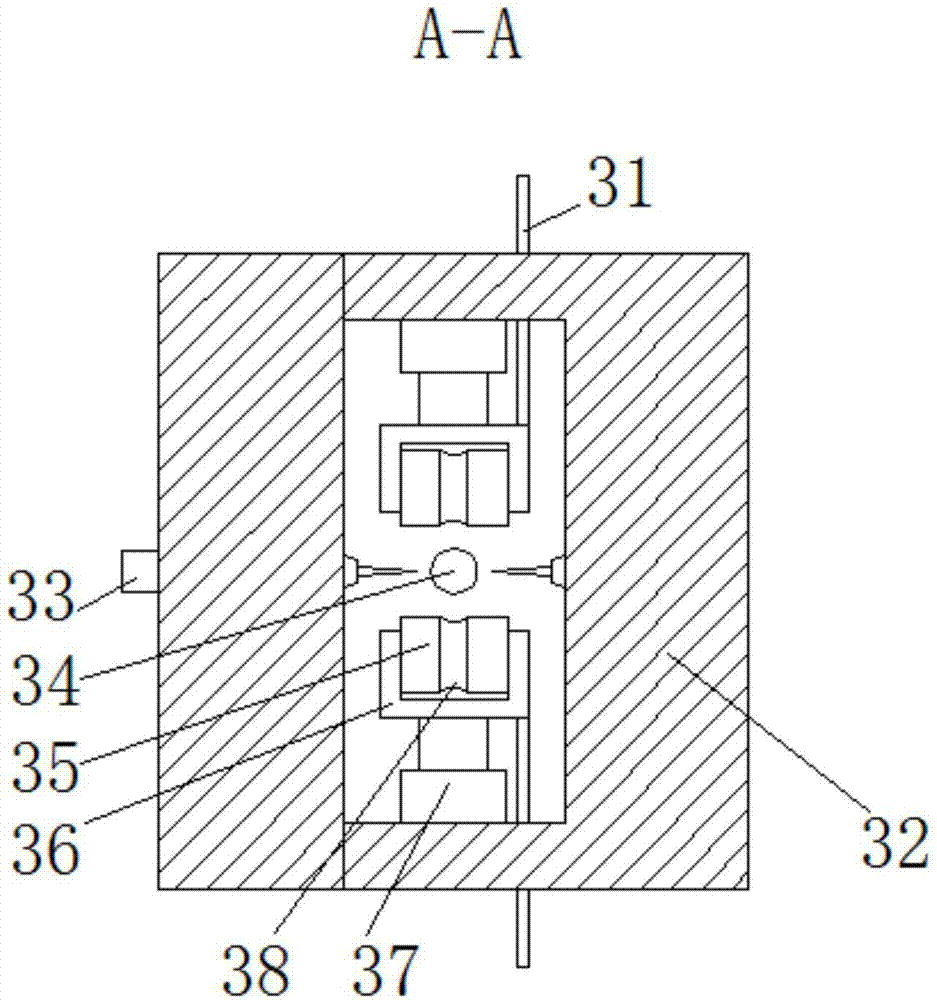

[0038] The cutter device 3 is used to cut the wire skin into two halves, and the cutter device 3 is fixed on the inner wall of the bottom surface of the device outer frame 2 through the cutter base 21;

[0039] The second guide wheel 15 is used to guide the electric wire coming out from the cutter device 9 to move to the right, and the second guide wheel 15 is fixed on the inner wall of the bottom surface of the device outer fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com