Equipment for recycling waste electric communication cables

A communication cable and cable technology, which is applied in the field of cable recycling, can solve the problems of function failure, imminent imminence, and inability to meet the interests of enterprise labor costs and rising materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiment of the present invention will be described in detail in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation and specific operation process, but the scope of protection of the present invention is not limited to the following embodiments.

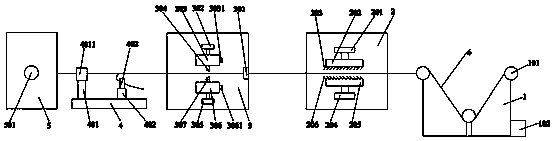

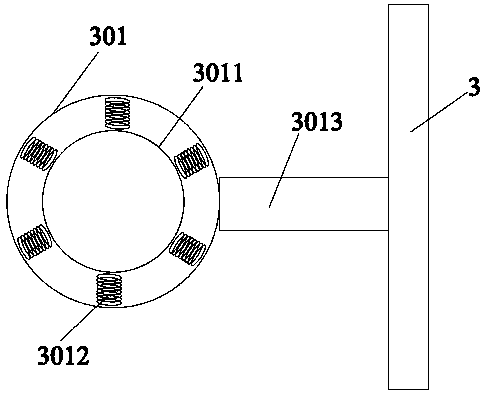

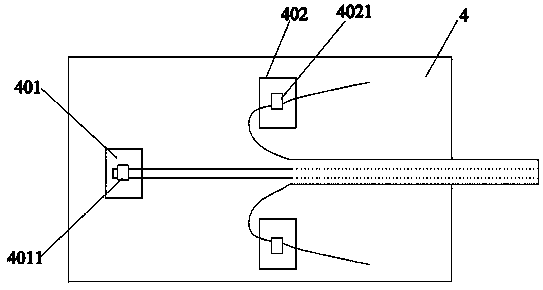

[0021] As shown in the accompanying drawings, a kind of equipment for recycling waste electric power communication cables, the device is used to recycle the insulation protection layer and conductor of the cable wire 6, the device includes a cleaning device, a drying device, a cutting device, a stripping device and a collecting device device, the cleaning device, the drying device, the cutting device, the stripping device and the collecting device are arranged in sequence in the horizontal direction, and the cleaning device includes a cleaning tank 1 and several lead wheels 101, and the lead wire There are three whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com