Method and device for separating and recovering metallic copper and tin in tinplating copper rice

A technology of separation recovery and separation device, which is applied in the field of direct recovery of metal copper and tin from tinned copper rice. It can solve the problems of poor wettability, small particle size of tinned copper rice, and difficult separation of tinned copper rice from copper and tin. Fast, high tin removal rate and recovery rate, simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

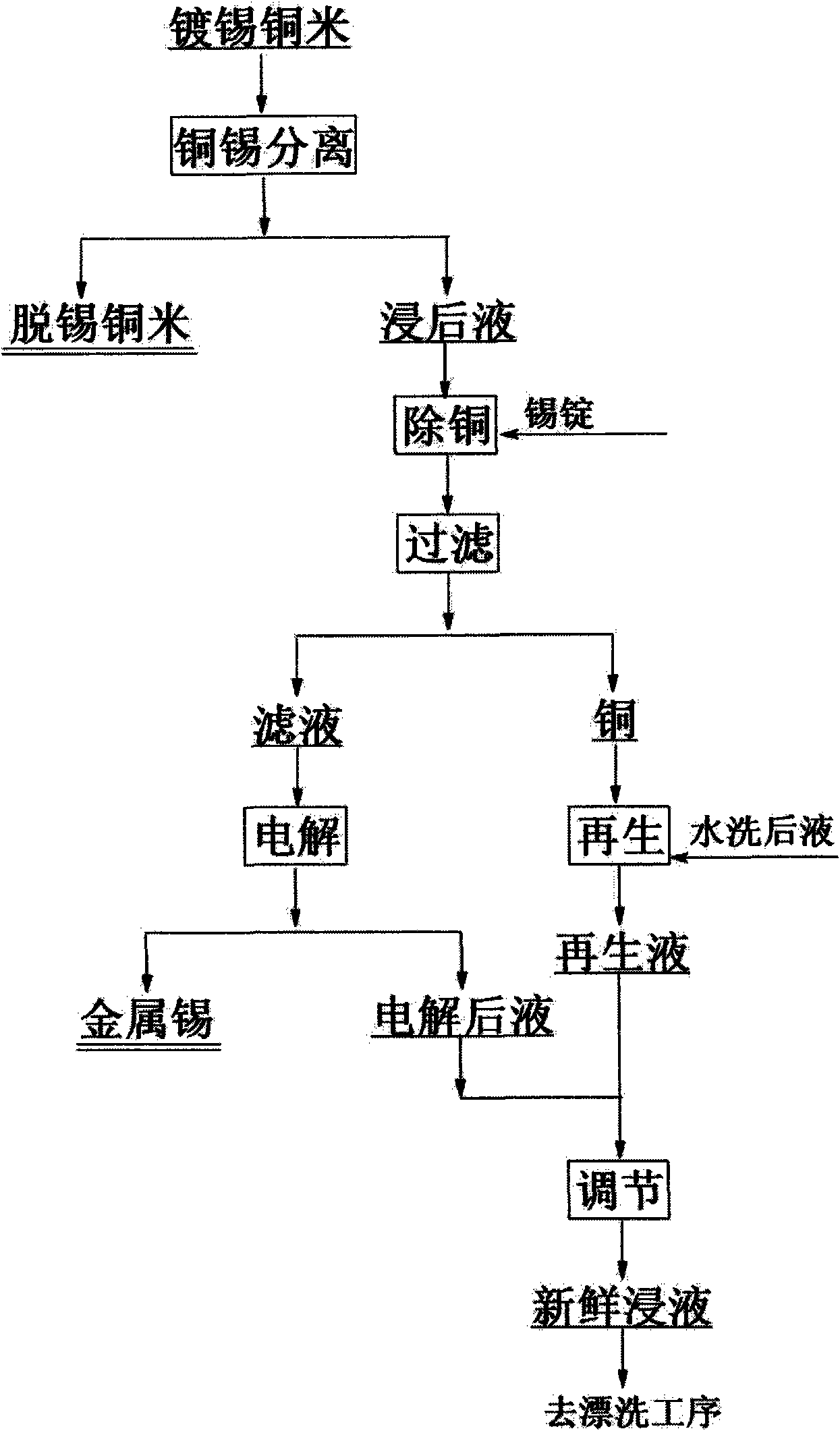

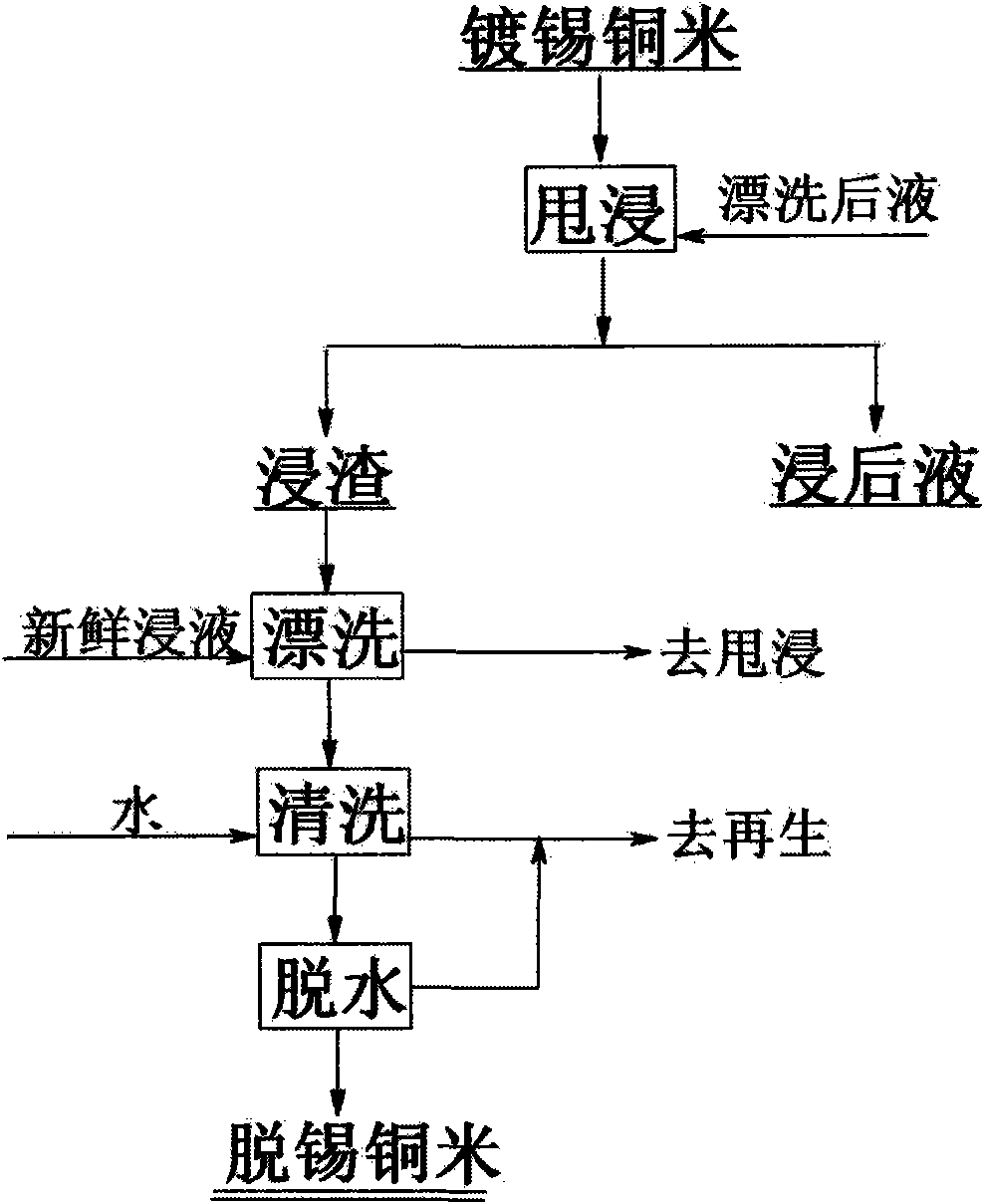

Method used

Image

Examples

Embodiment 1

[0038] Put 100 kilograms into the special leaching equipment for copper and tin separation treatment. The temperature is 40°C, the time is 15 minutes, and the rotation speed is 50rpm. 80mL / L, the time is 10 minutes, the rotation speed is 50rpm, the washing time is 10 minutes, the rotation speed is 50rpm, the dehydration time is 3 minutes, and the rotation speed is 3000rpm; the immersion liquid is added to excess tin ingots for copper removal treatment, and the treatment temperature is 40°C, until the blue color of the immersion solution is completely eliminated, filter to obtain the filtrate and copper powder; electrolyze the filtrate in the electrolytic cell, and the cathode current density is 0.5A / dm 2 , temperature 20°C, until the concentration of stannous ions in the solution is 14g / L, the electrolysis is stopped to obtain metal tin and the liquid after electrolysis; an appropriate amount of copper powder is added to the liquid after washing and air is blown in, and the amo...

Embodiment 2

[0040] Put 100 kilograms into the special leaching equipment and carry out the copper-tin separation treatment. During spin leaching, the temperature is 60° C., the time is 5 minutes, and the rotating speed is 3000 rpm. The fresh immersion solution used for rinsing is the fresh immersion solution prepared in Example 1, and the time is 5 minutes, the rotation speed is 3000rpm, the washing time is 5 minutes, the rotation speed is 3000rpm, the dehydration time is 5 minutes, the rotation speed is 1500rpm; the immersion solution is added to excess tin ingots for copper removal treatment, and the treatment temperature is 60°C until the immersion solution turns blue Until the color is completely eliminated, the filtrate and copper powder are obtained by filtration; the filtrate is electrolyzed in an electrolytic cell, and the cathode current density is 3A / dm 2, temperature 40°C, until the concentration of stannous ions in the solution is 15g / L, the electrolysis is stopped to obtain me...

Embodiment 3

[0042] 100 kilograms are packed into special-purpose leaching equipment and carry out copper-tin separation treatment, and temperature is 50 ℃ during spin leaching, and time is 12 minutes, and rotating speed is 1500rpm, and the fresh immersion liquid used for rinsing is the fresh immersion liquid prepared in embodiment 2, and the time is 7 minutes, the rotation speed is 1200rpm, the washing time is 8 minutes, the rotation speed is 1500rpm, the dehydration time is 4 minutes, the rotation speed is 2500rpm; the immersion solution is added to excess tin ingots for copper removal treatment, and the treatment temperature is 50°C until the immersion solution turns blue Until the color is completely eliminated, the filtrate and copper powder are obtained by filtration; the filtrate is electrolyzed in an electrolytic cell, and the cathode current density is 2A / dm 2 , temperature 30°C, until the concentration of stannous ions in the solution is 13g / L, the electrolysis is stopped to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com