Device for recycling waste electric wires based on water jet

A technology of waste wire and cable device, applied in the field of wire and cable, can solve the problems of easy wear and tear of the cutter head of the crushed cable, easy to be oxidized, many processes, etc., and achieve the effects of low cost, efficient recovery and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

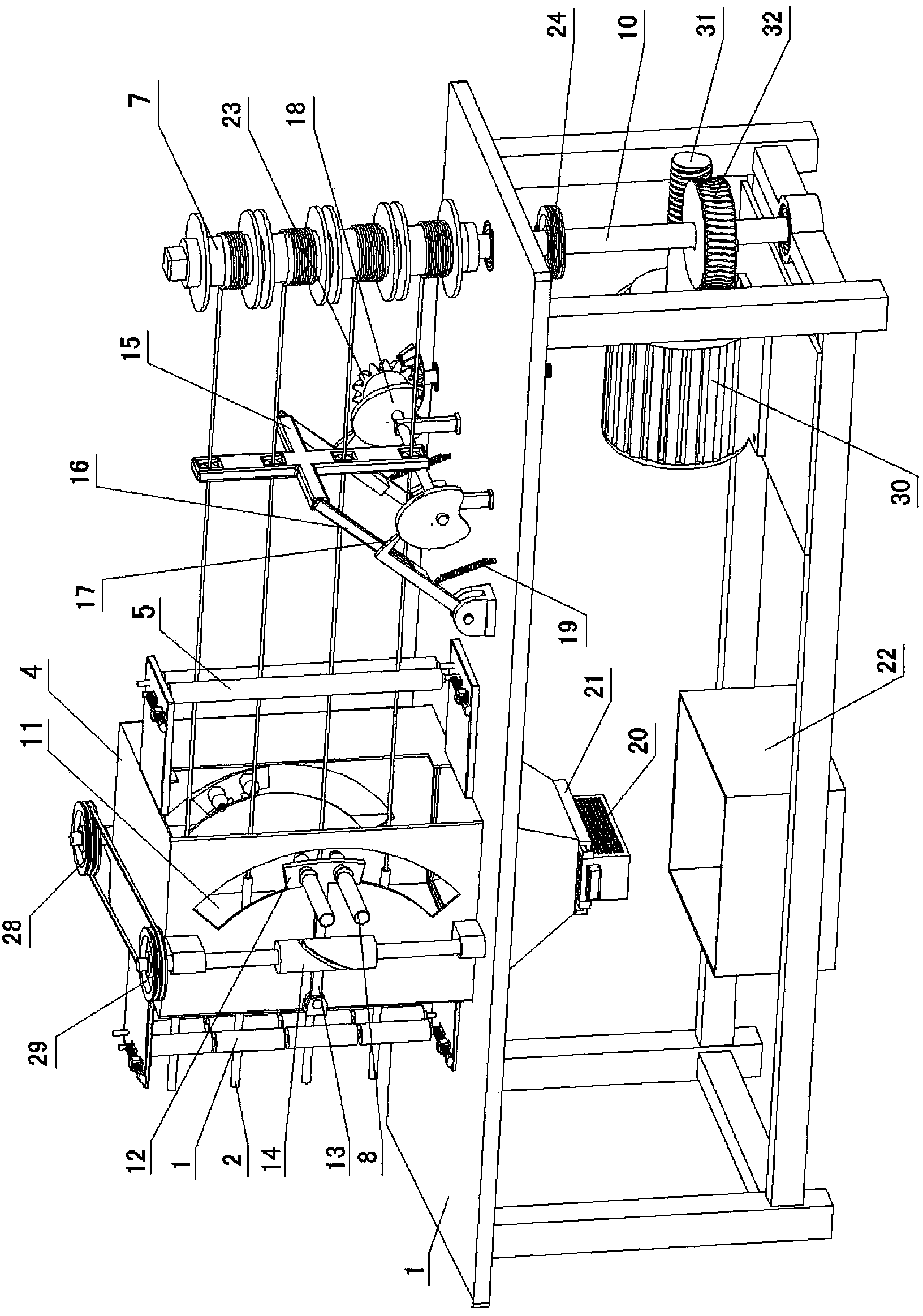

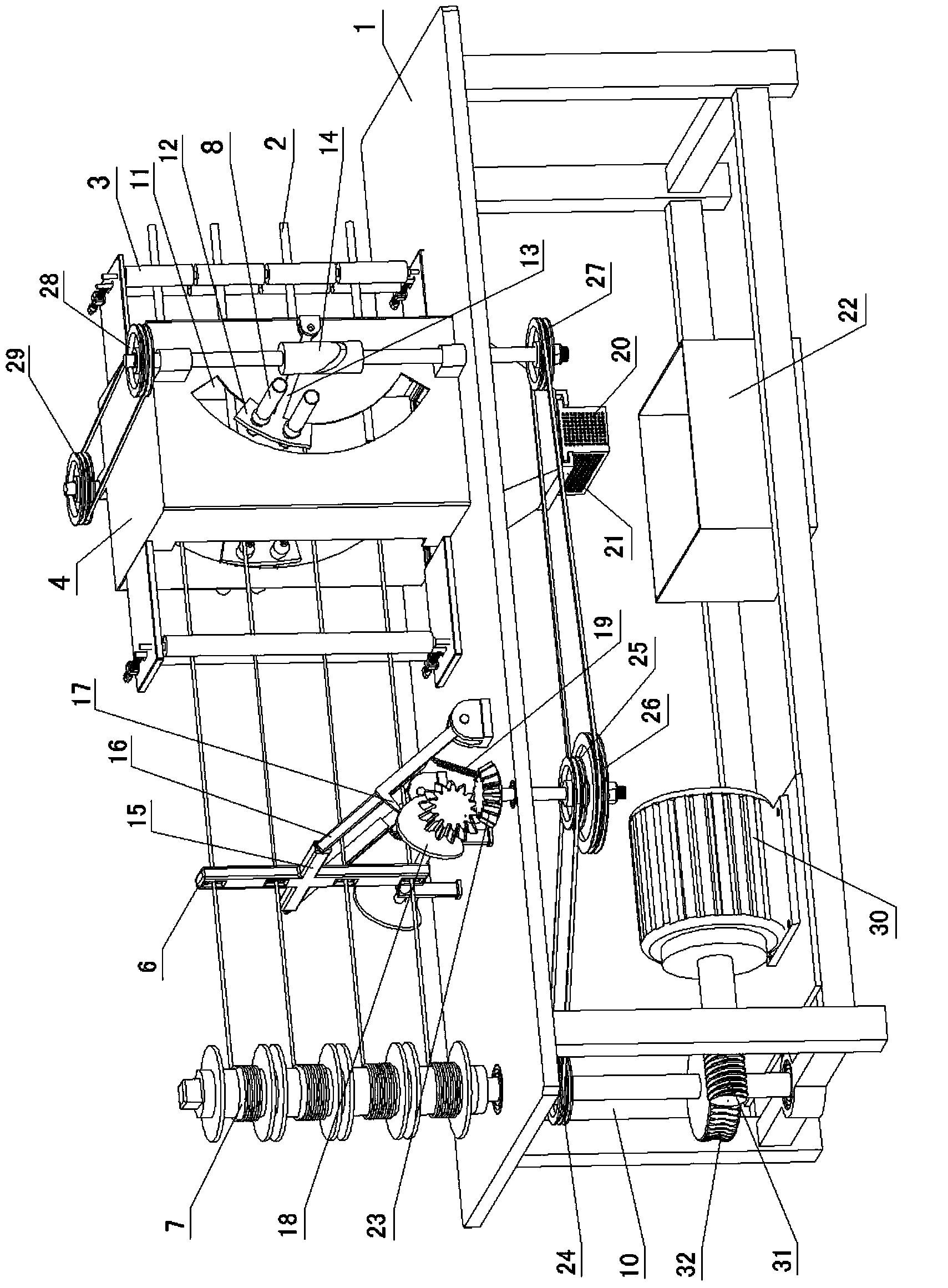

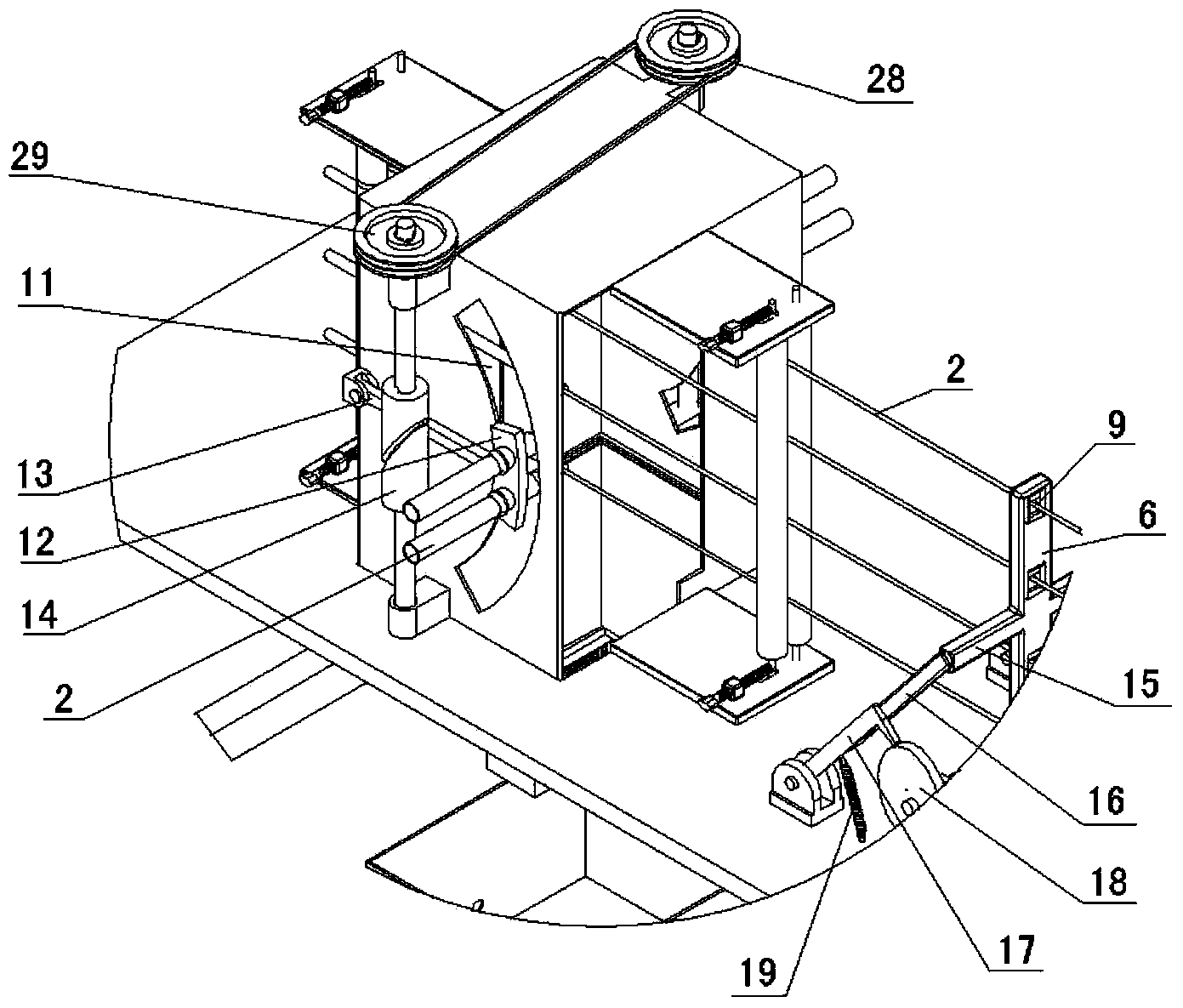

[0032] In this embodiment, the structure of the waste wire and cable device based on water jet recycling is set as follows:

[0033] Such as figure 1 and figure 2 As shown, the front friction wheel 3, the crushing chamber 4, the rear friction wheel 5, the winding plate 6 and the bobbin 7 are sequentially arranged on the workbench 1 along the feeding direction of the wire and cable 2; the front friction wheel 3 and the rear friction wheel The wheels 5 are composed of a pair of rollers perpendicular to the worktable surface with adjustable spacing, which are used to clamp the wires and cables 2 respectively; the grinding chamber 4 is arranged between the front friction wheel 3 and the rear friction wheel 5, and is equipped with multiple The high-pressure jet nozzle 8 with the nozzle facing the wire and cable is distributed on both sides of the wire and cable; Pair of rollers 33 (such as Figure 4 shown); there are multiple bobbins 7, connected in series from top to bottom on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com