Profile-modeling pineapple peeler based on automatic detection

An automatic detection and peeling machine technology, applied in the peeling of vegetables or fruits, program control in sequence/logic controllers, food science, etc., can solve the problems of pulp waste, low degree of automation, safety and hygiene, etc. , to achieve the effect of reducing fruit waste rate, improving work efficiency and reducing labor level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

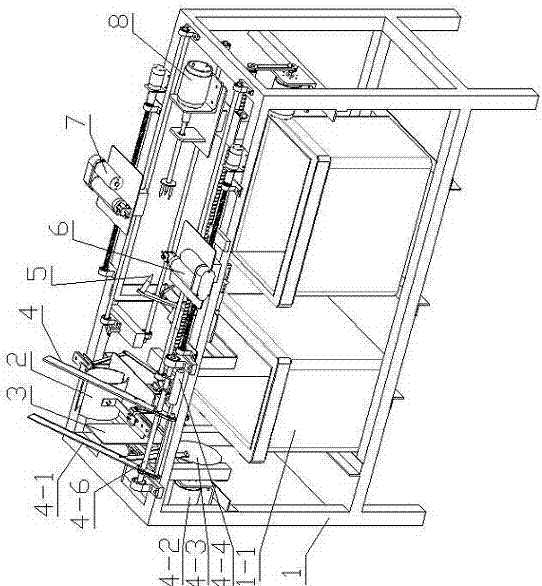

[0023] Accompanying drawing is a kind of specific embodiment of the present invention.

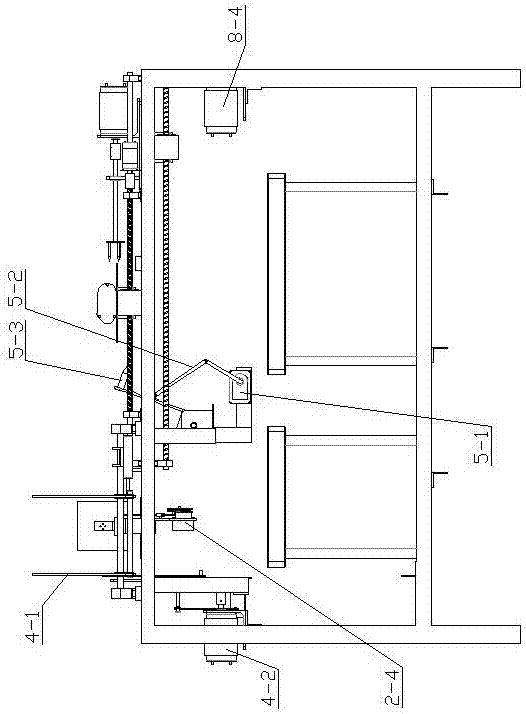

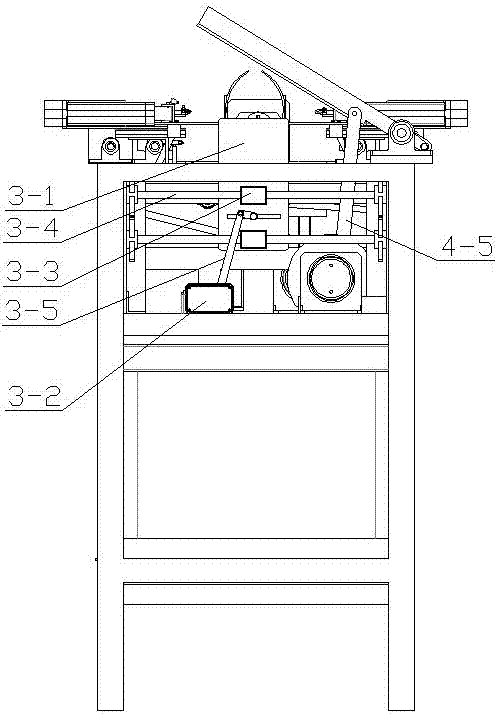

[0024] The profiling pineapple peeling machine based on automatic detection of the present invention is characterized in that: it includes a clamping mechanism 2 installed on the front part of the frame 1 for cutting head and tail, a baffle mechanism 3 and a knife cutting mechanism 4, and the middle part of the frame 1 The centering mechanism 5, the peeling mechanism 6 on both sides and the black eye mechanism 7, the rotating mechanism 8 at the rear of the frame 1, the detection sensors of each mechanism are connected with the controller data, and the controller is connected to control each mechanism motorized parts, of which:

[0025] The clamping mechanism 2 includes a two-piece arc-shaped clamping disc 2-1 and a steering gear A2-4, the clamping disc 2-1 is fixed on the slider A2-2 oppositely, and the slider A2-2 is moved and installed on the slider On the rail 2-3, the output end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com