Gas-liquid pressurization cylinder

A technology of gas-liquid pressurized cylinder and pneumatic cylinder, which is applied in fluid pressure converters, mechanical equipment, etc., can solve the problems of too much compressed air, low output area efficiency, and too many cylinder blocks, and achieve precise positioning and adjustment, and gas The effect of high source utilization and compact air pressure cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

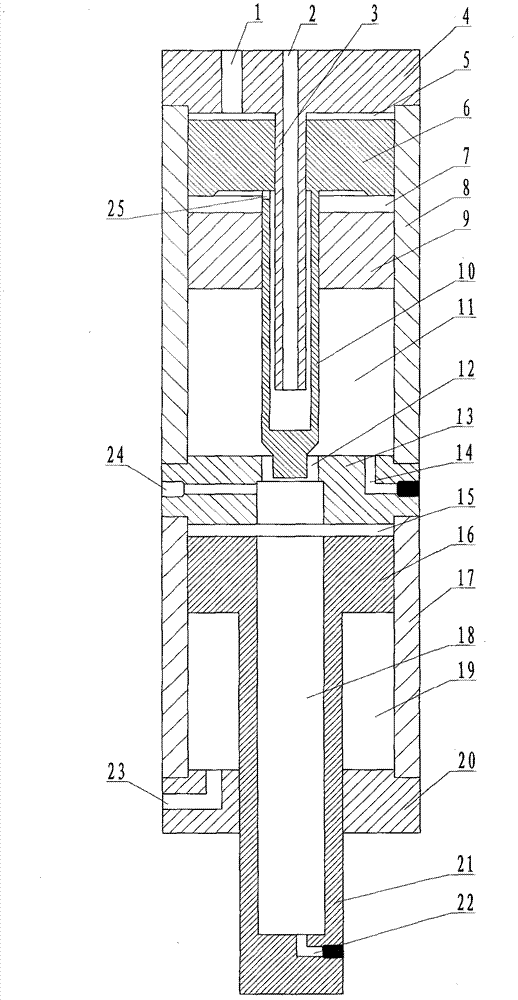

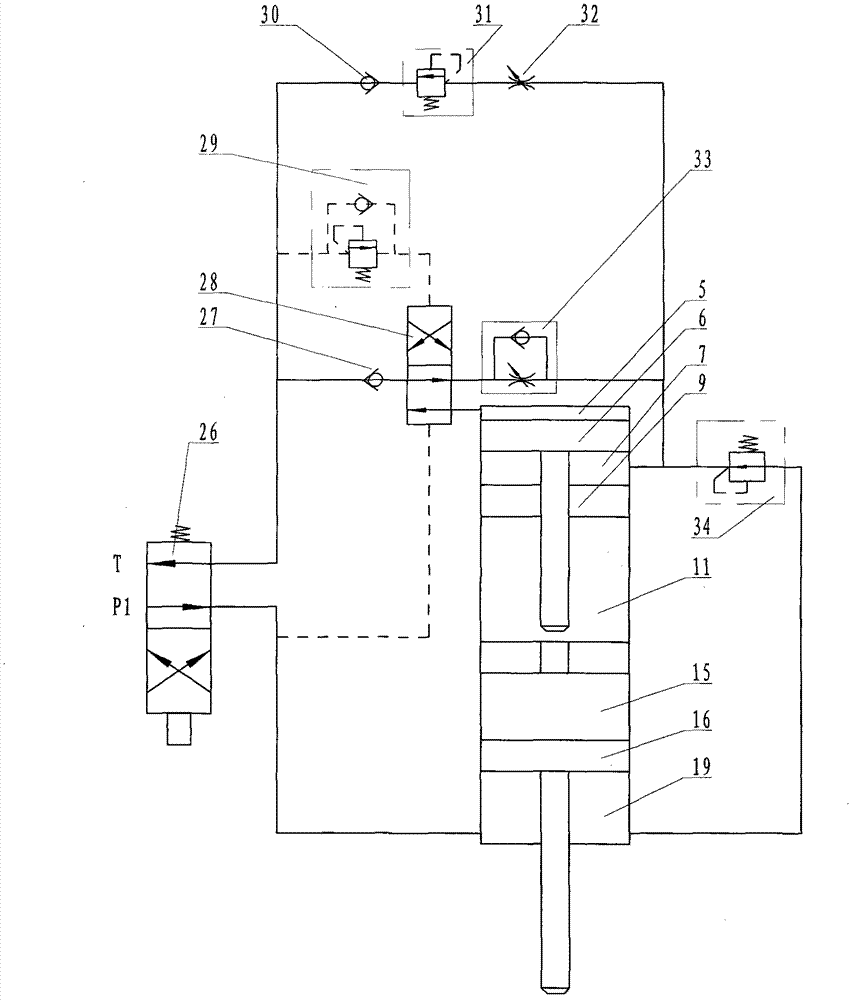

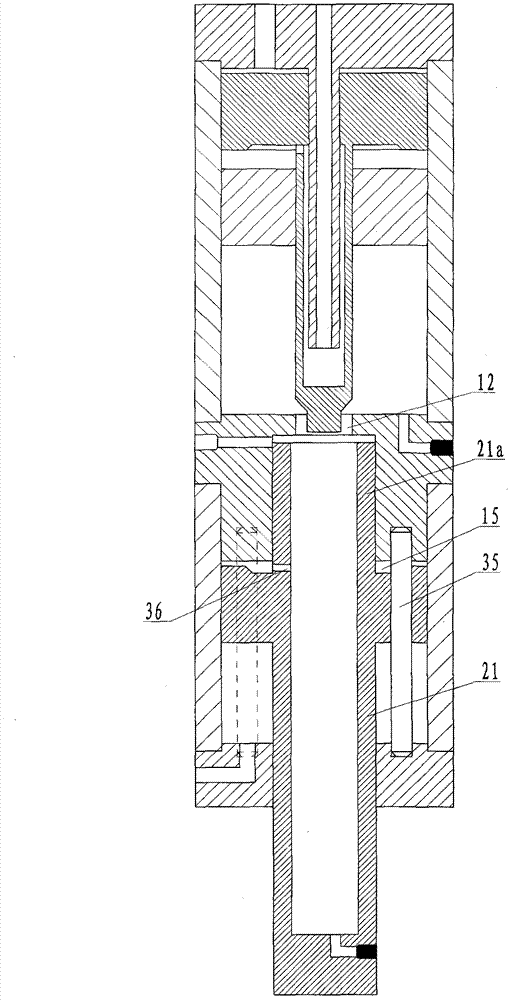

[0020] Attached below Figure 1 ~ Figure 4 Further illustration is made to the principle and structure of the present invention

[0021] Such as figure 1 As shown, the gas-hydraulic booster cylinder composed of pneumatic cylinder 8 and hydraulic cylinder 17 in series is connected and separated by a middle cover 13 between the two cylinders. The other end of the pneumatic cylinder 8 has an upper end cover 4, and the other end of the hydraulic cylinder 17 There is a lower end cover 20. There is a booster piston 6 between the upper end cover 4 and the middle cover 13. A booster air cavity 5 is formed between the upper end cover 4 and the booster piston 6. Between the booster piston 6 and the middle cover 13 There is an air-separating piston 9 with a hole in the middle, and a hollow booster piston rod 10 is arranged on the booster piston 6, and the booster piston rod 10 stretches out from one end of the booster piston 6, and the top of the booster piston rod 10 protruding end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com