Patents

Literature

591 results about "Slice thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slice Thickness. Slice Thickness is a parameter that can be selected by the technologist. This will change the thickness of our slice in millimeters. By increasing the slice thickness, many more different types of tissues will be collected in our 2D slice.

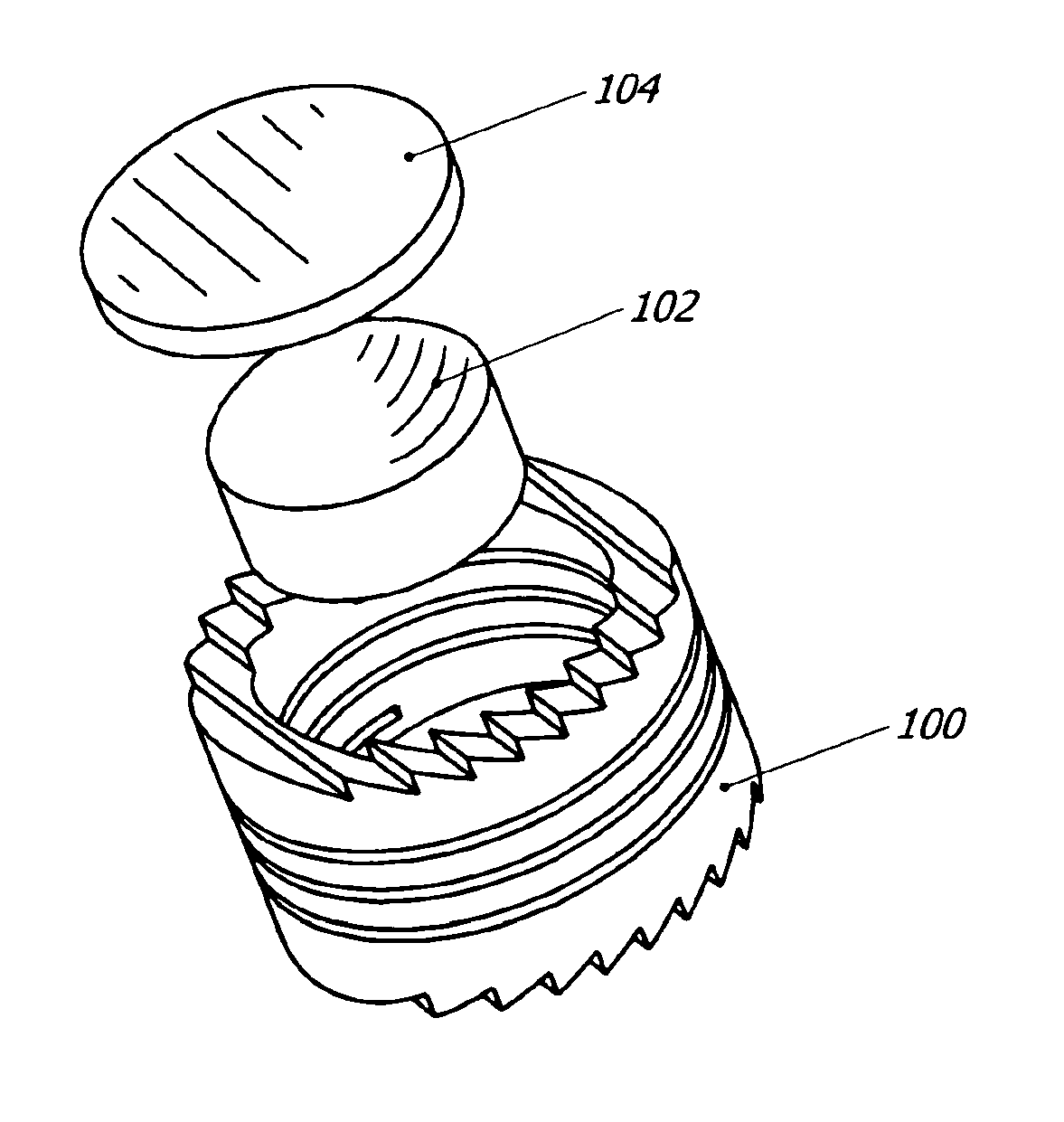

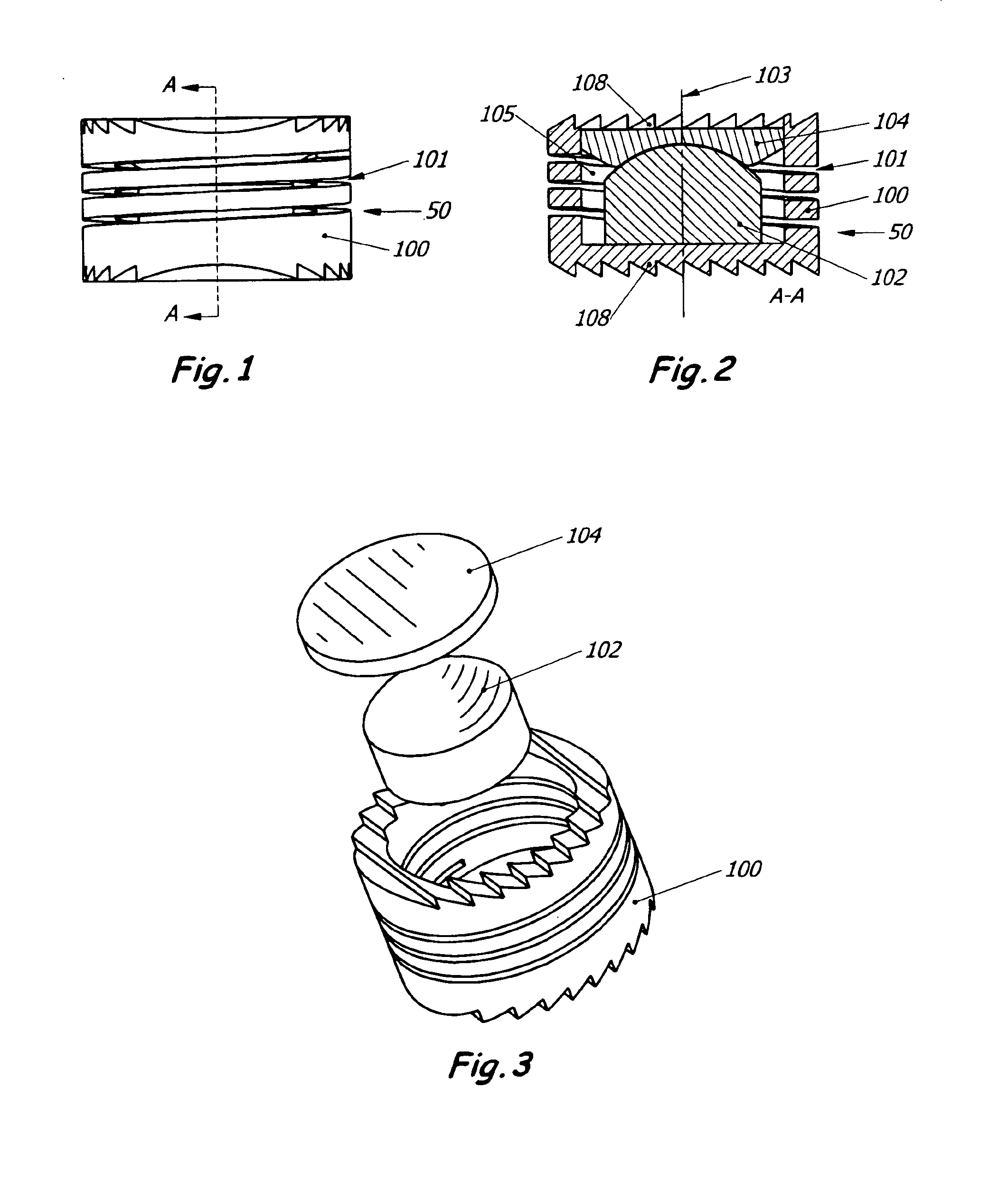

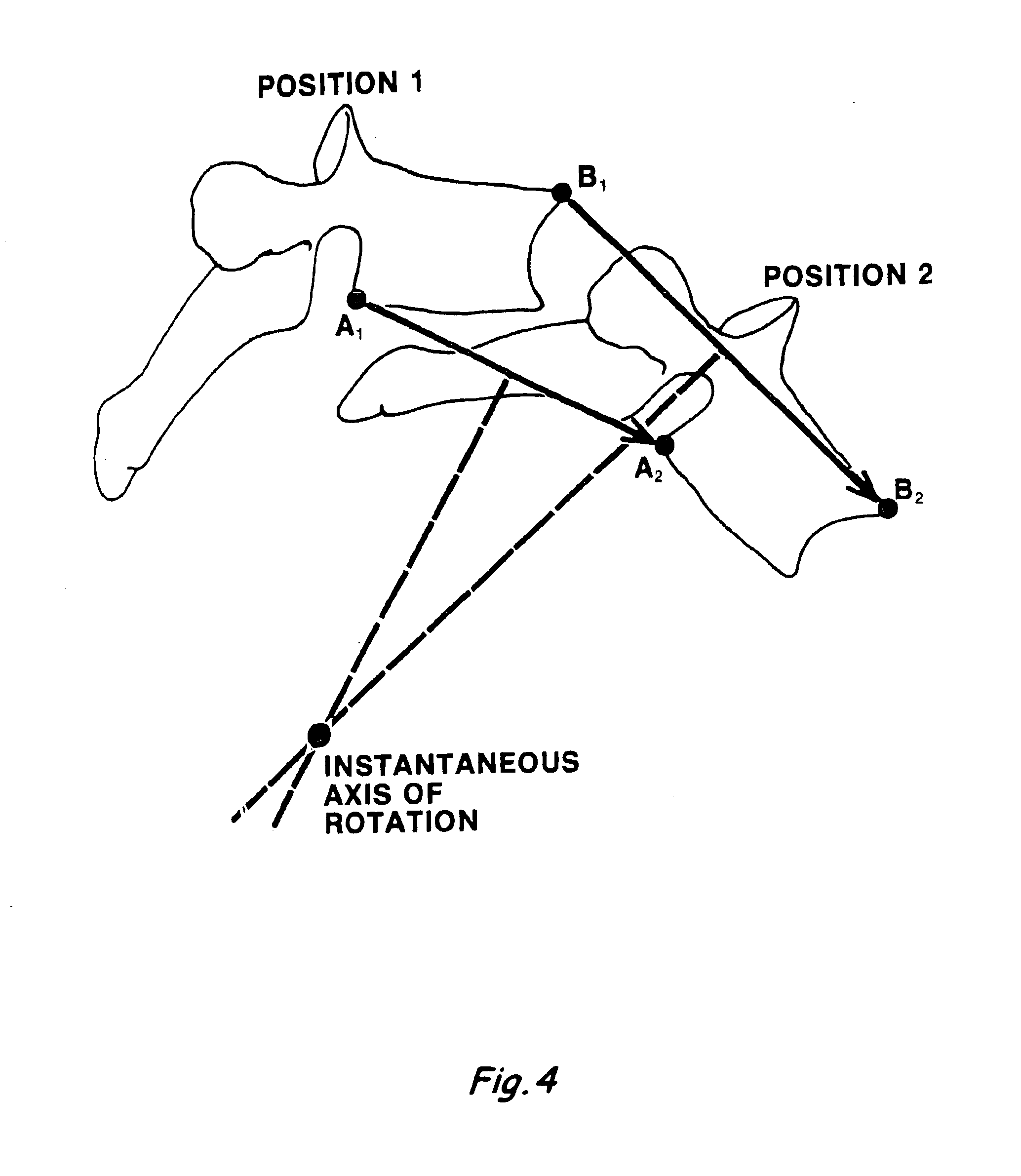

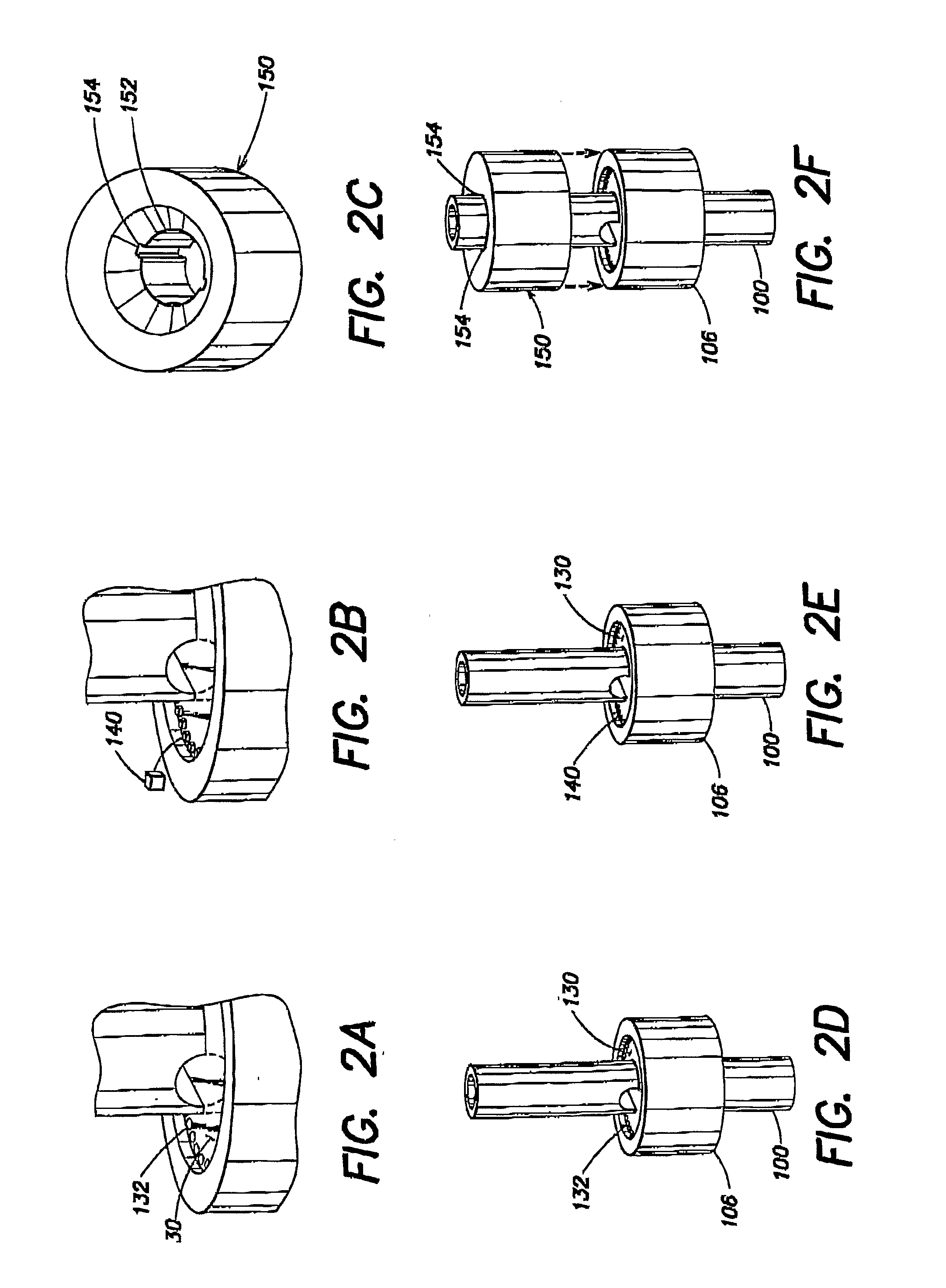

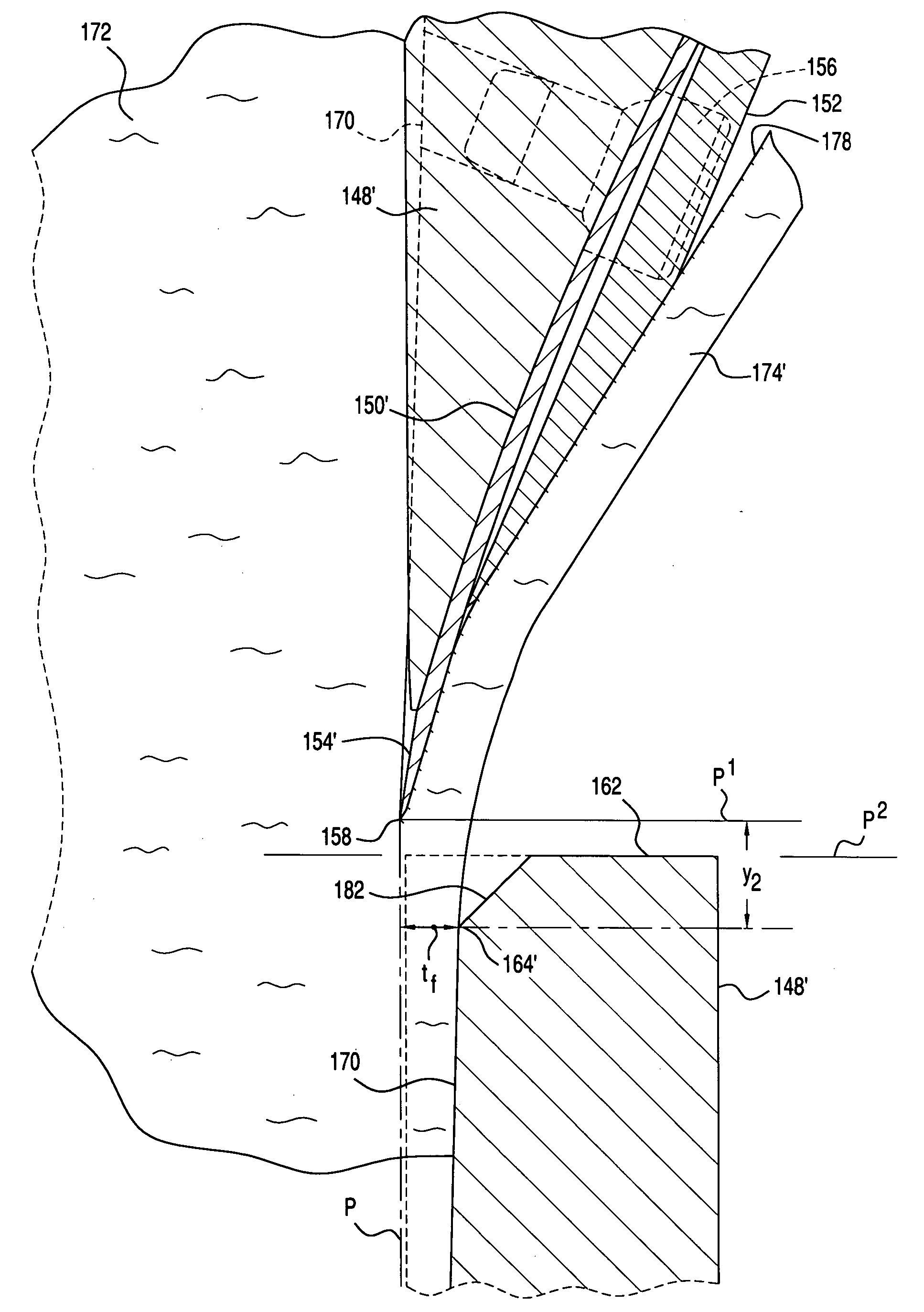

Intervertebral disc replacement prosthesis

InactiveUS6964686B2Relieve symptomsNot compromising healthJoint implantsSpinal implantsSlice thicknessIntervertebral disk

An intervertebral disc prosthesis that comprises a deformable flexure with an axial cavity, the axial cavity extending along the axis of the flexure, and a slit defined in the perimeter surface of the flexure to provide flexibility to the disc member, the slit having a slit thickness. The slit may be in the form of a coil to impart a spring-like appearance and function. The intervertebral disc prosthesis further comprises a lower disc support housed in the axial cavity and an upper disc support housed in the axial cavity; with the lower and upper disc supports communicating with one another to provide support to the disc. The lower or upper disc support may alternatively be incorporated into the flexure.

Owner:VANDERBILT UNIV

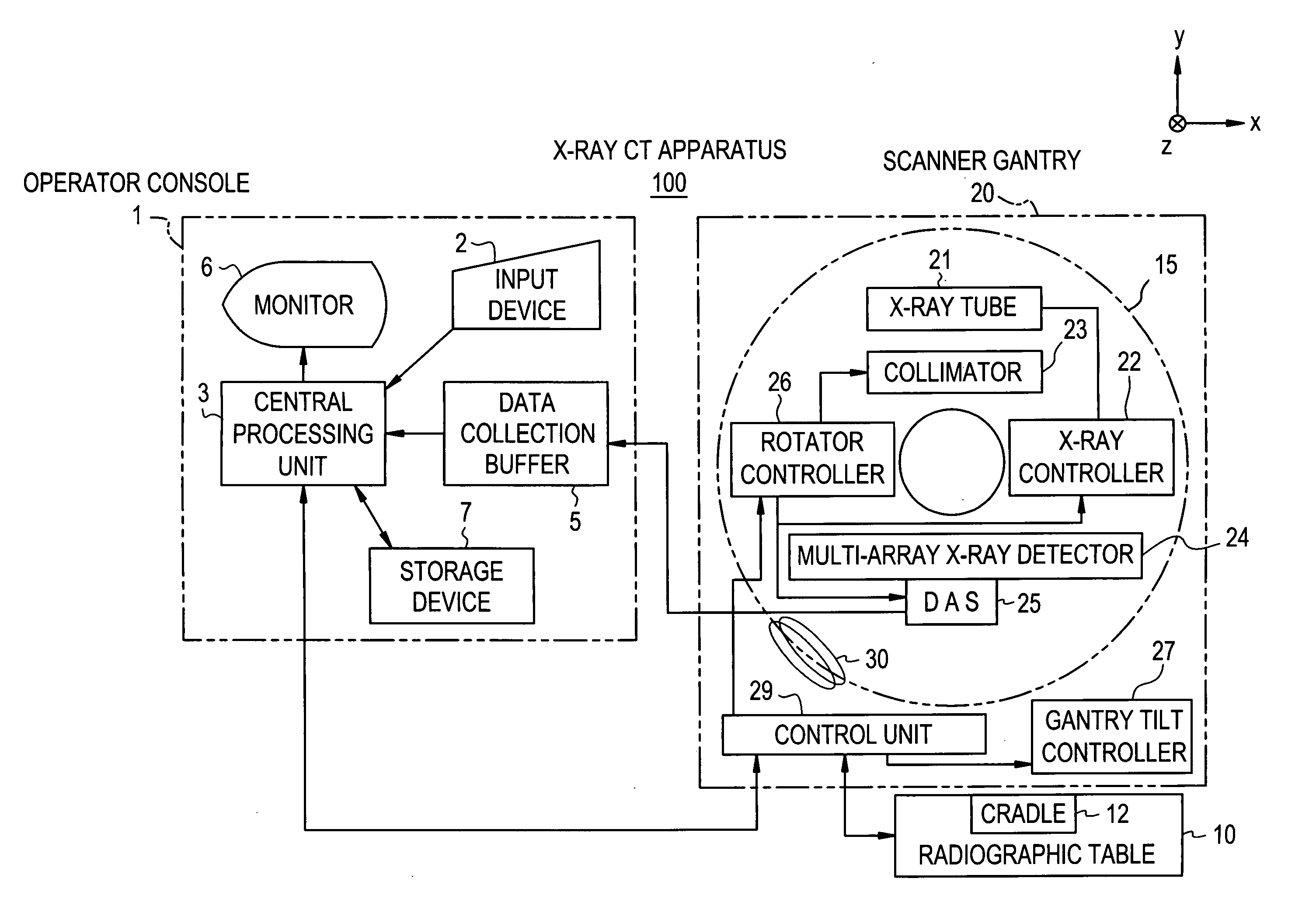

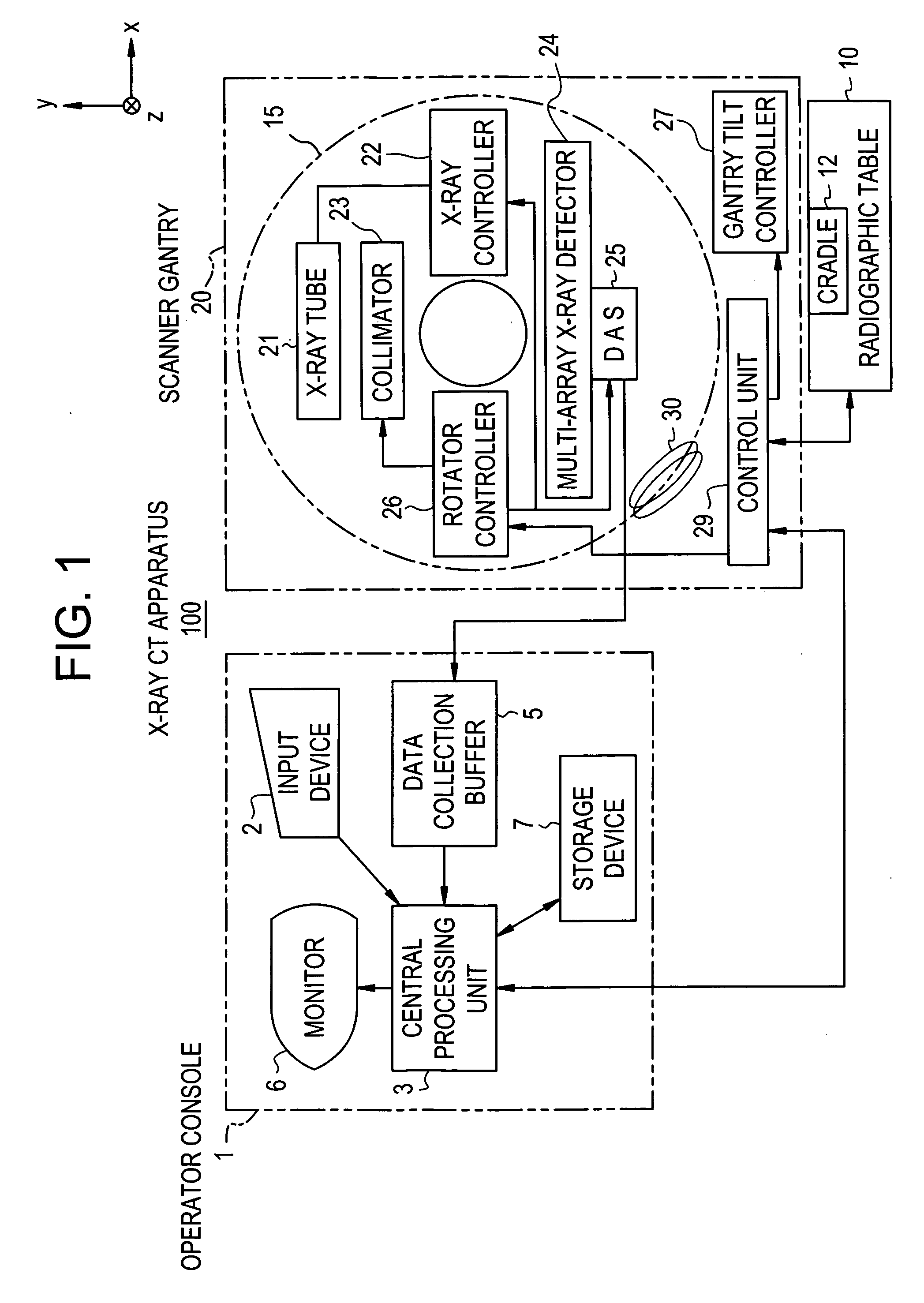

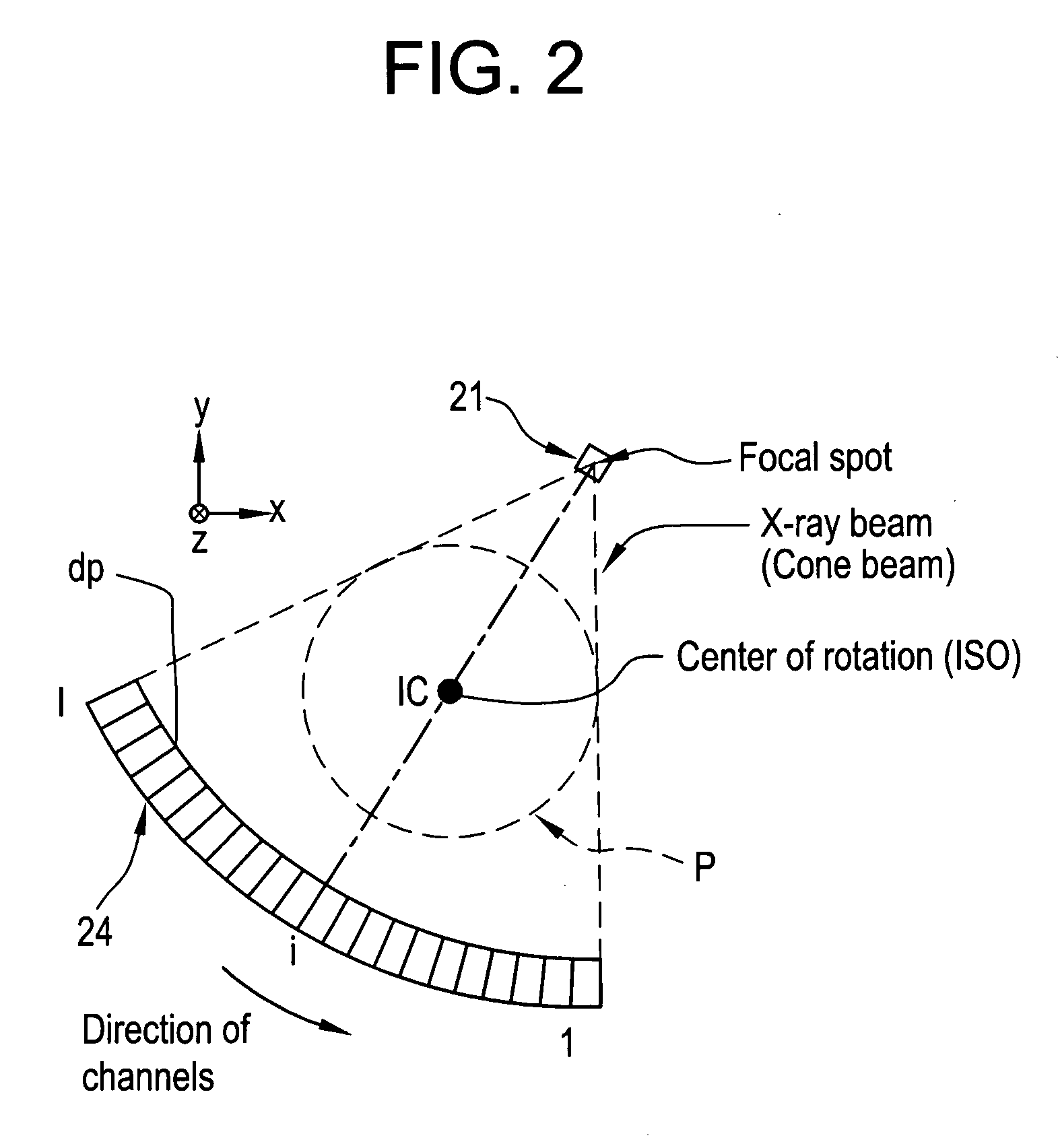

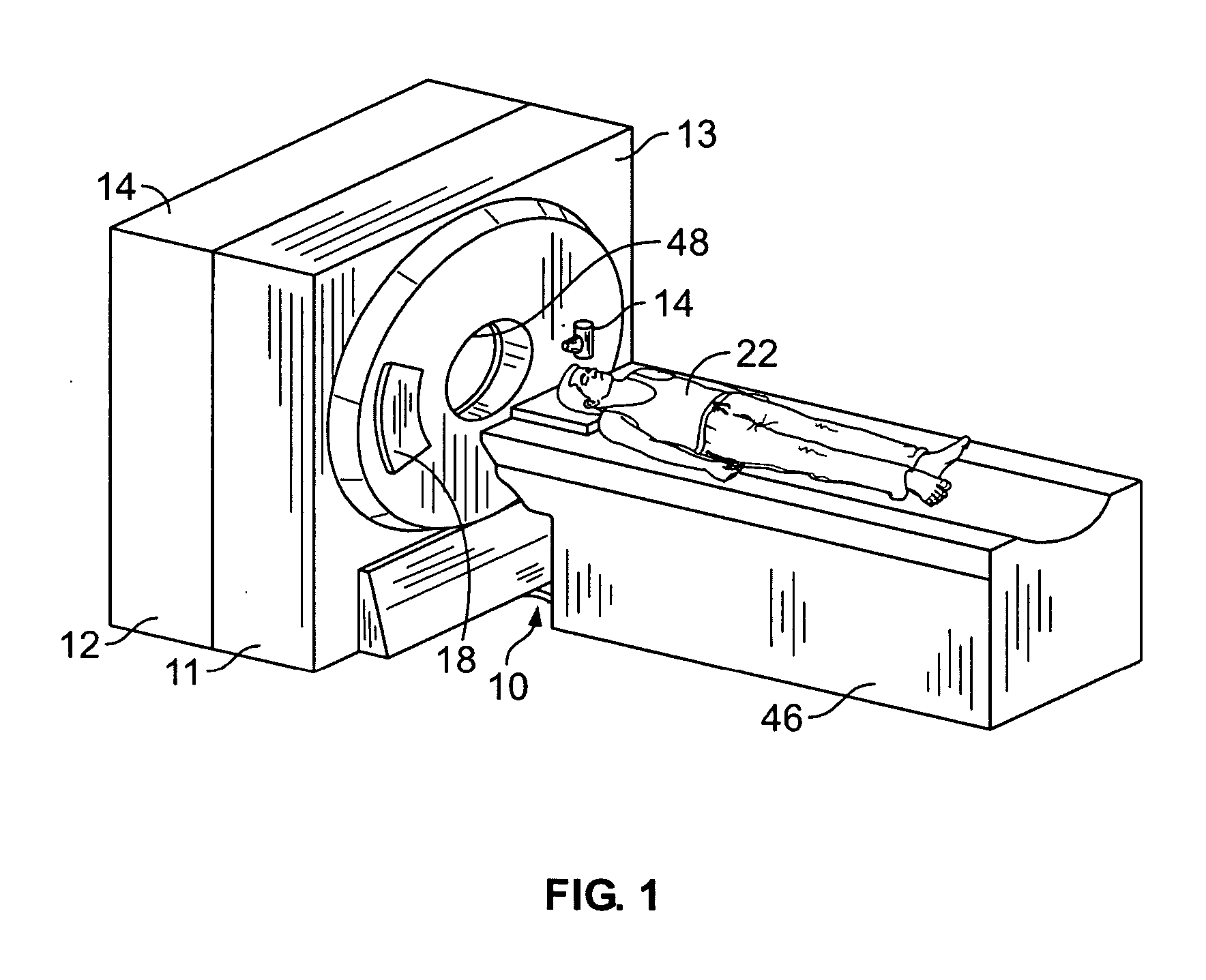

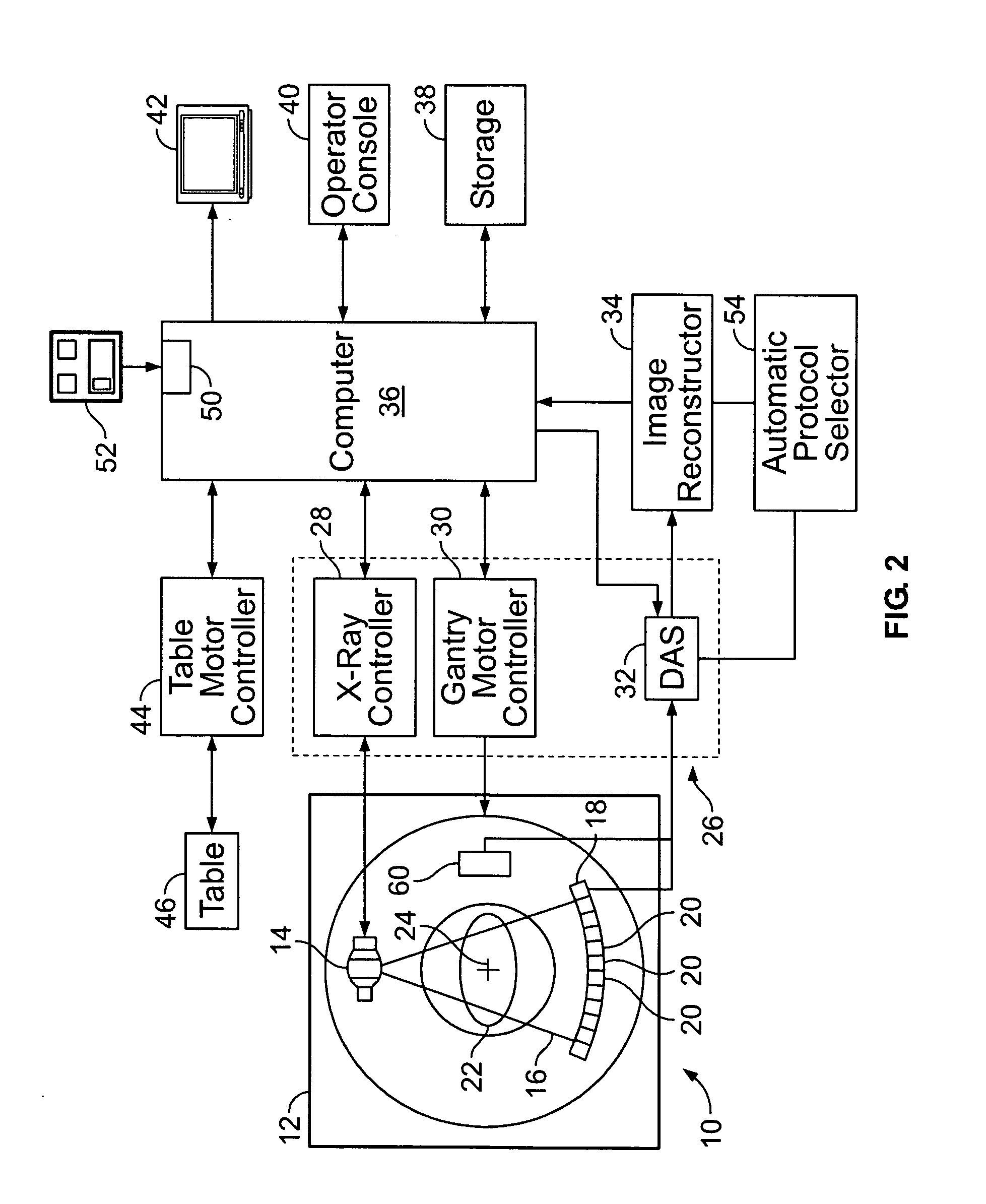

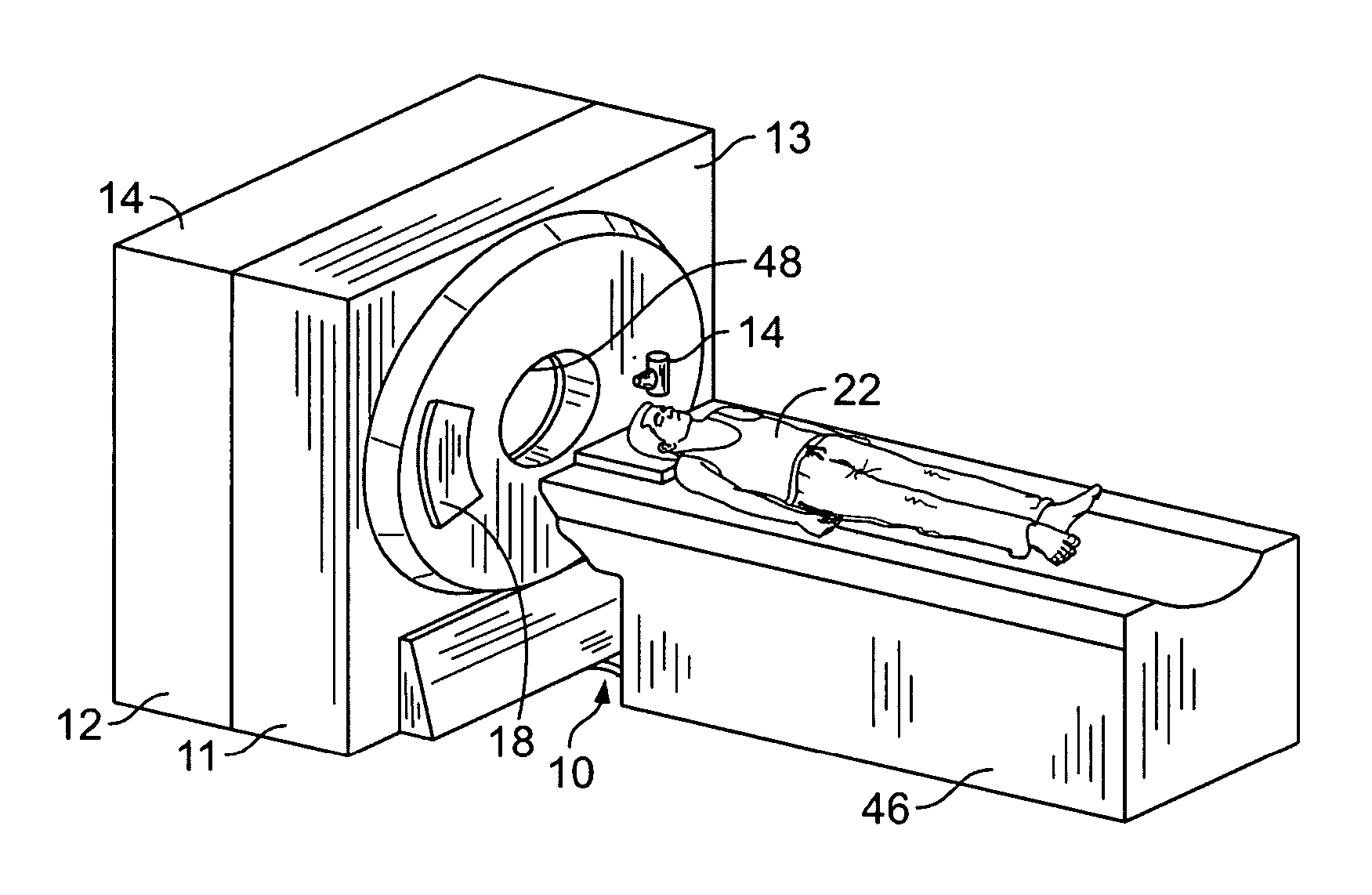

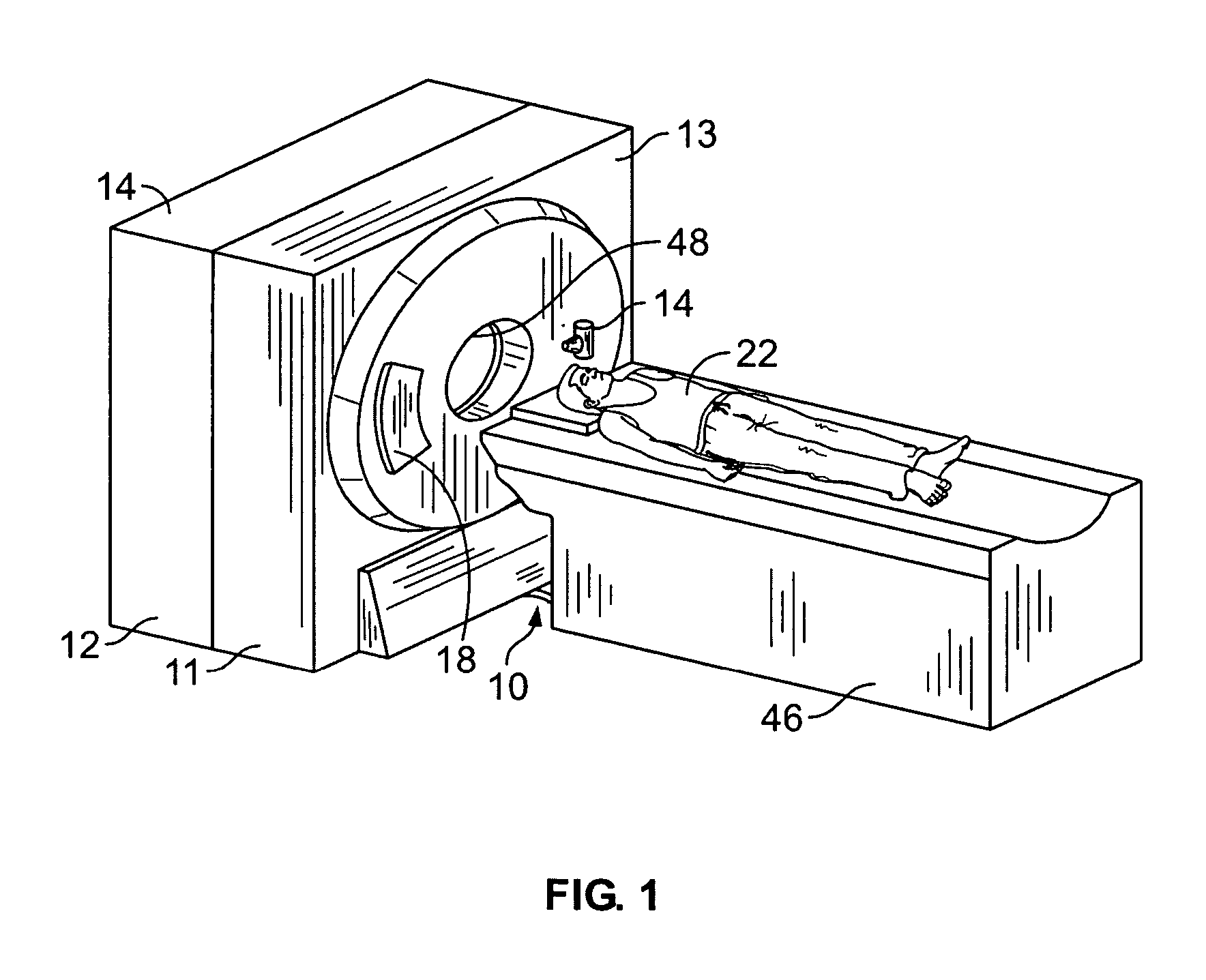

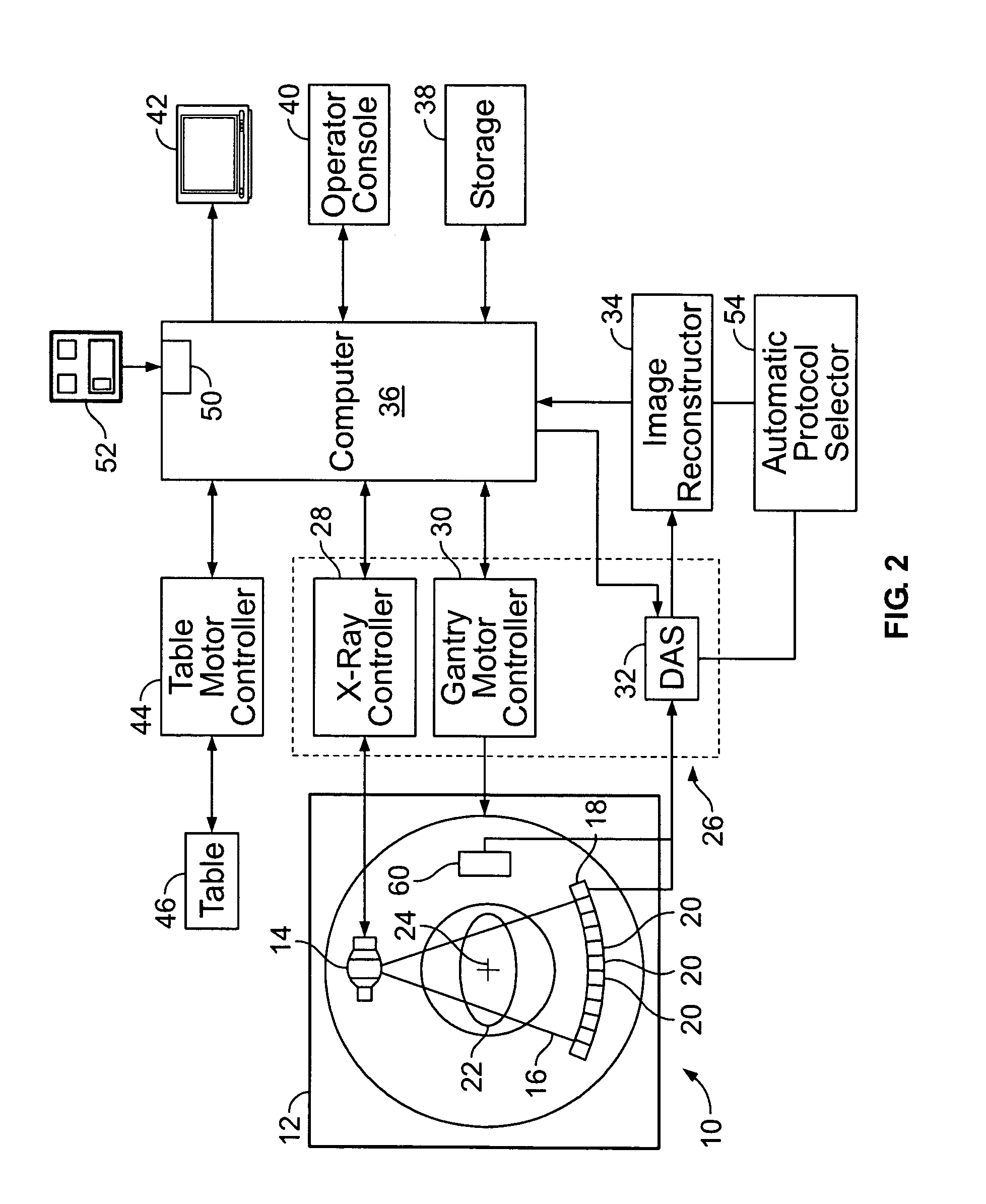

X-ray CT method and X-ray CT apparatus

InactiveUS20060291612A1Optimize radiographic conditionMaterial analysis using wave/particle radiationRadiation/particle handlingX-ray filterSlice thickness

In an X-ray CT apparatus, radiographic conditions (protocols) for imaging of each position represented by a z-coordinate are optimized in relation to an X-ray cone beam that spreads in a z direction. A slice thickness of a tomographic image is freely controlled in the z direction using a z filter during a conventional scan or a cine scan. For each tomographic image, a reconstruction function, an image filter, a scan field, a tomographic-image tilt angle, and a position of a tomographic image are freely adjusted or independently designated for scanning of each position in the z direction. Thus, a tomographic image is reconstructed. Moreover, the position of a beam formation X-ray filter in the z direction is shifted in order to optimize a patient dose that depends on the size of the scan field, and X-ray quality.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

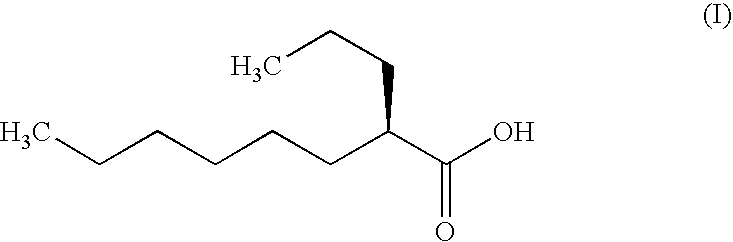

Capsule Stable Against Mastication

InactiveUS20080057115A1Good disintegrationExcellent pharmaceutical preparationAntibacterial agentsNervous disorderSlice thicknessMedicine

The present invention relates to a soft capsule which is easily disintegrated in the stomach, wherein the contents thereof are not easily leaked at the time of mastication, which is obtained by providing a soft capsule comprising (2R)-2-propyloctanoic acid or a salt thereof with at least one property, preferably all properties, selected from (A) wherein it has a strength of 150 to 400 N by a cracking test; (B) wherein it has a disintegration time of 3 to 10 minutes by the disintegration test stipulated in Japanese Pharmacopoeia; (C) wherein the capsule shell has a shell thickness of 0.05 to 0.50 mm; (D) wherein the capsule shell has a first seam thickness of 0.10 to 0.55 mm; (E) wherein the capsule shell has a second seam thickness of 0.05 to 0.50 mm; (F) wherein the capsule shell has a water content of 5.0 to 9.0%.

Owner:ONO PHARMA CO LTD

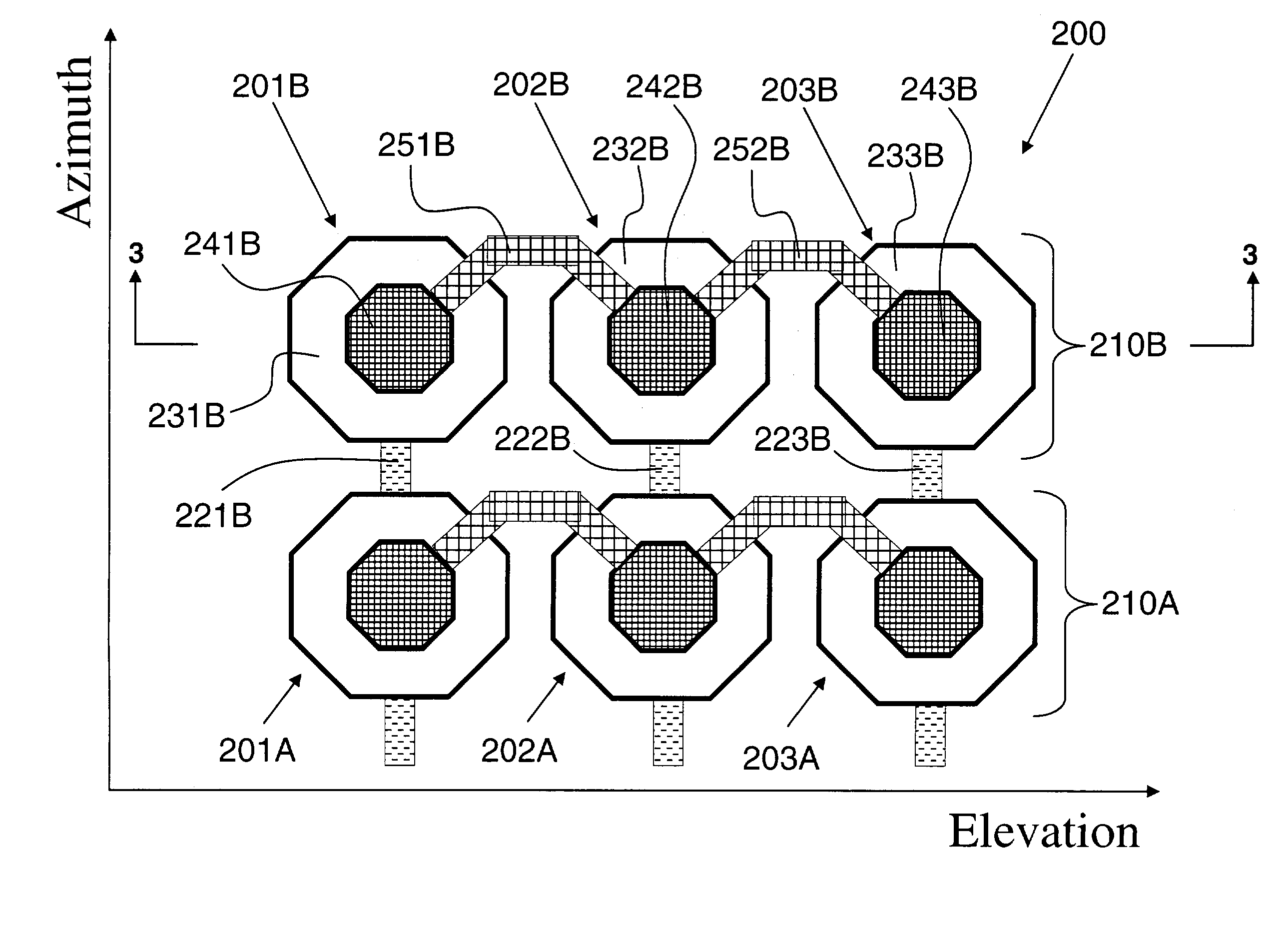

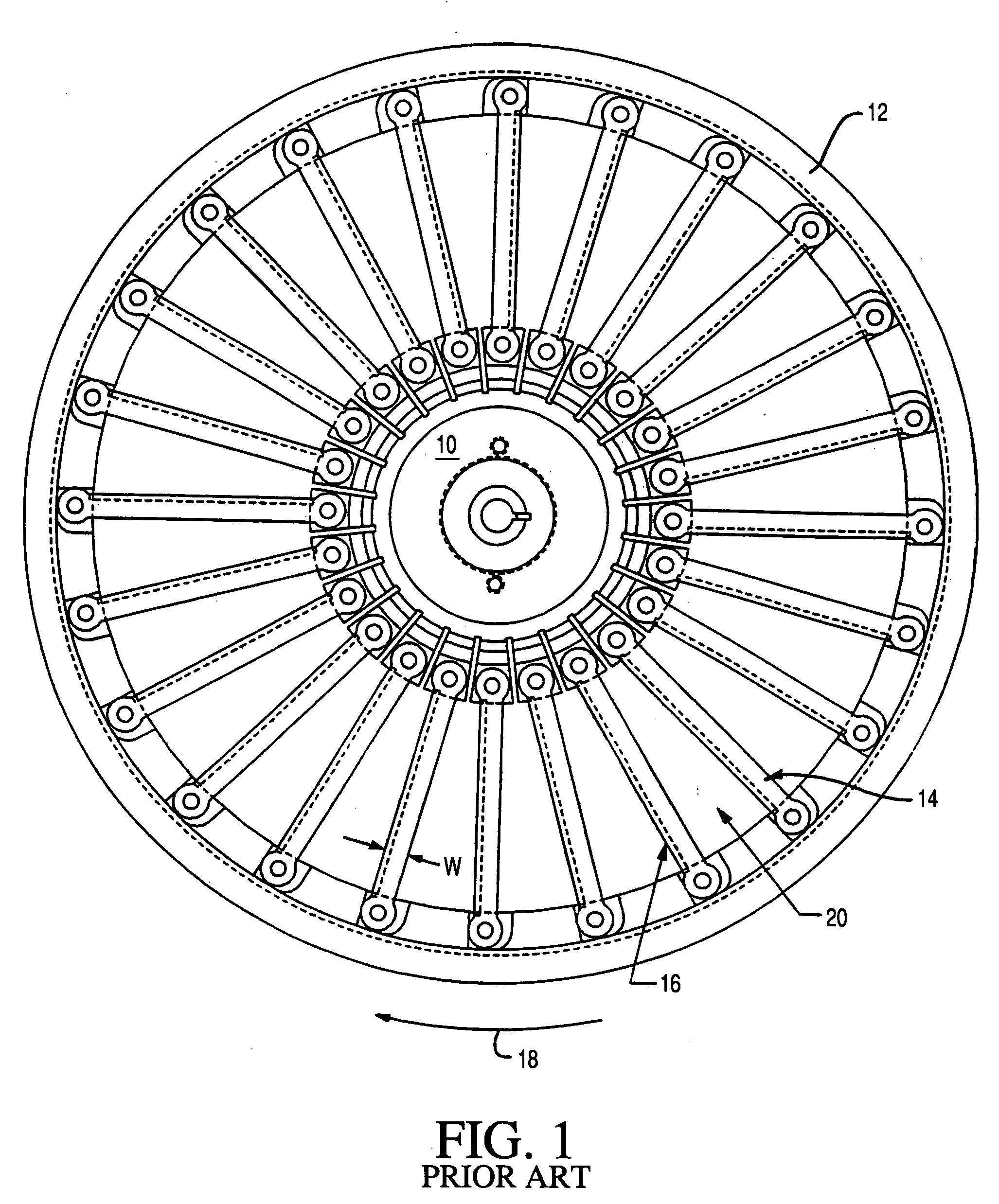

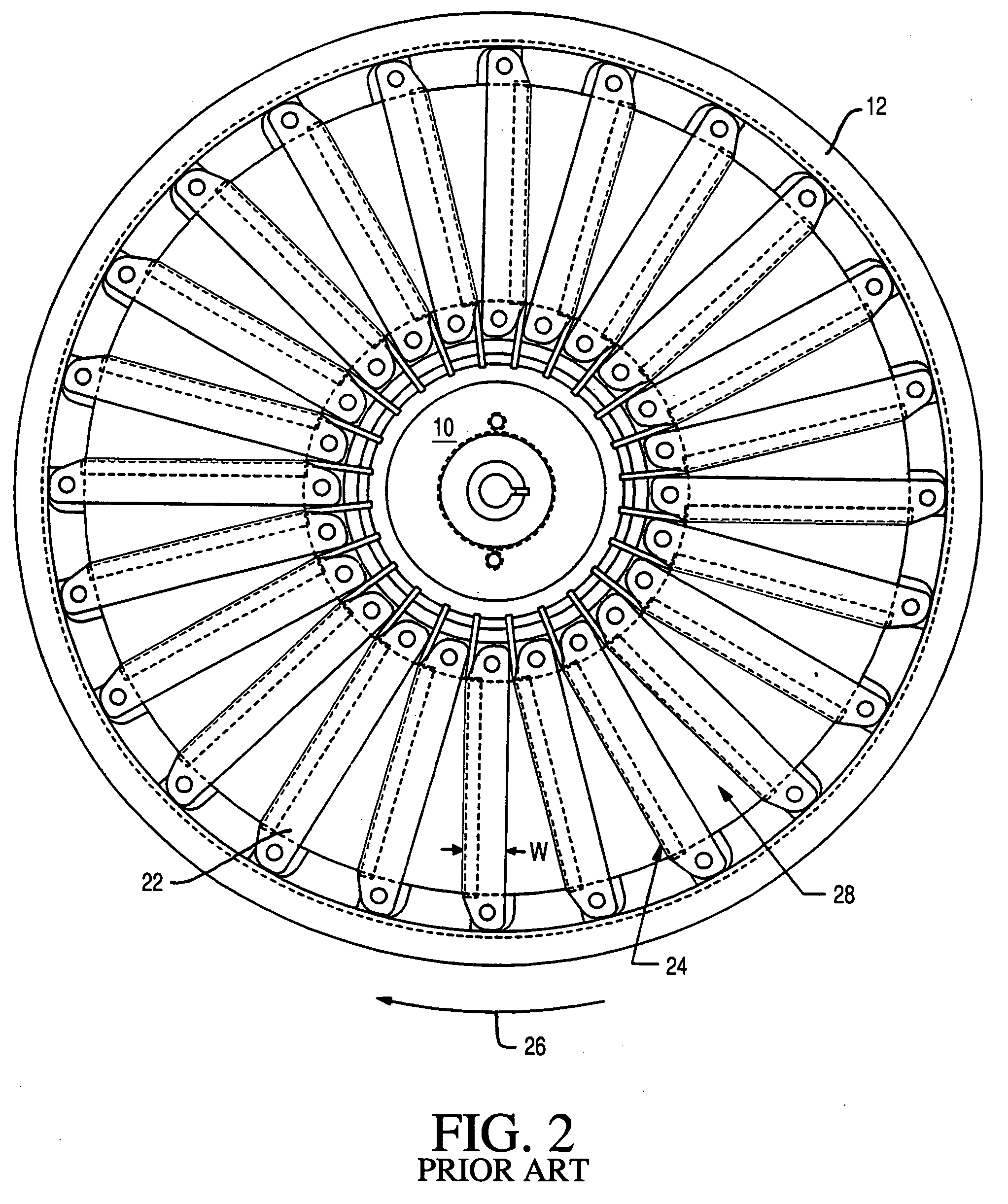

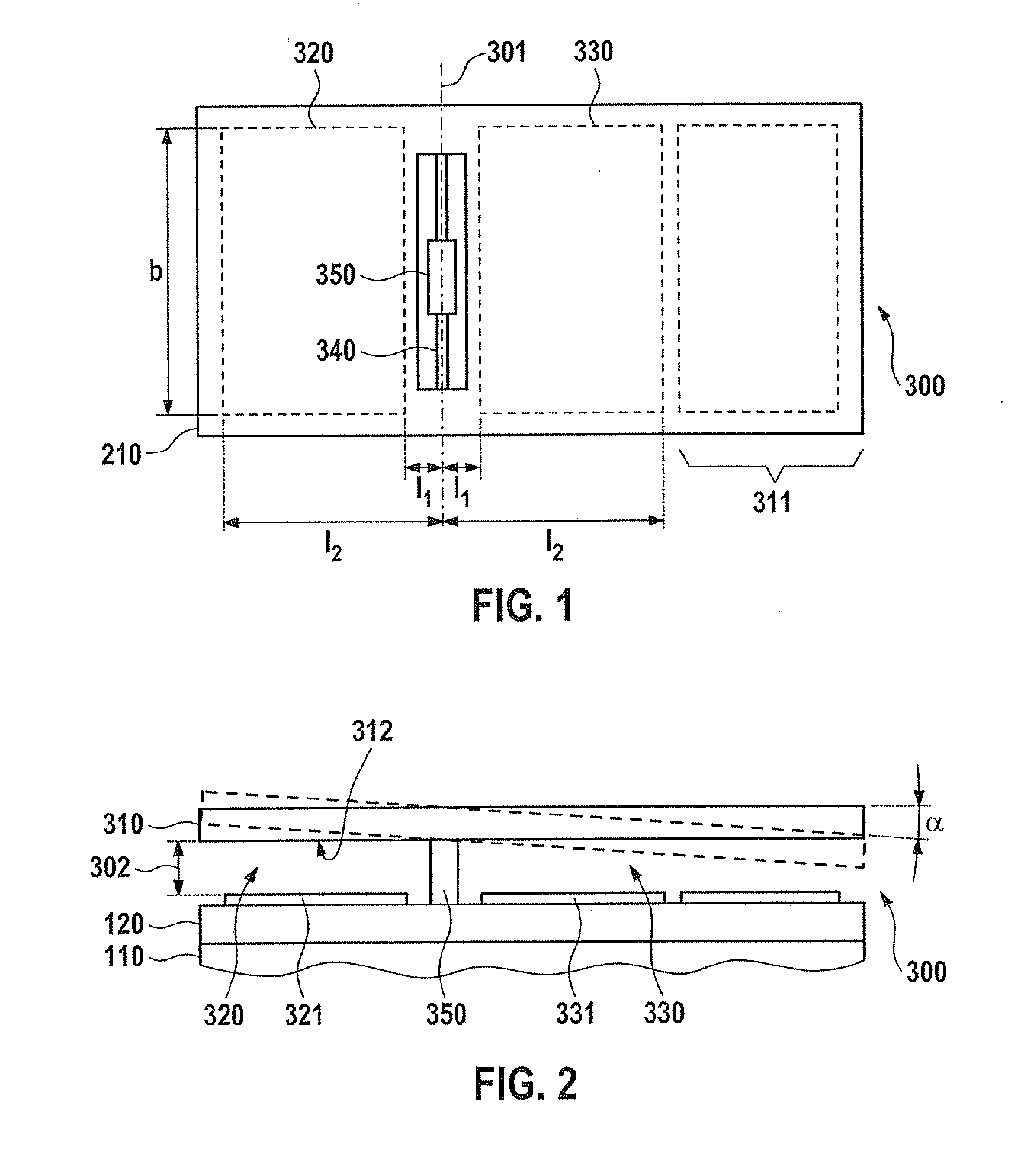

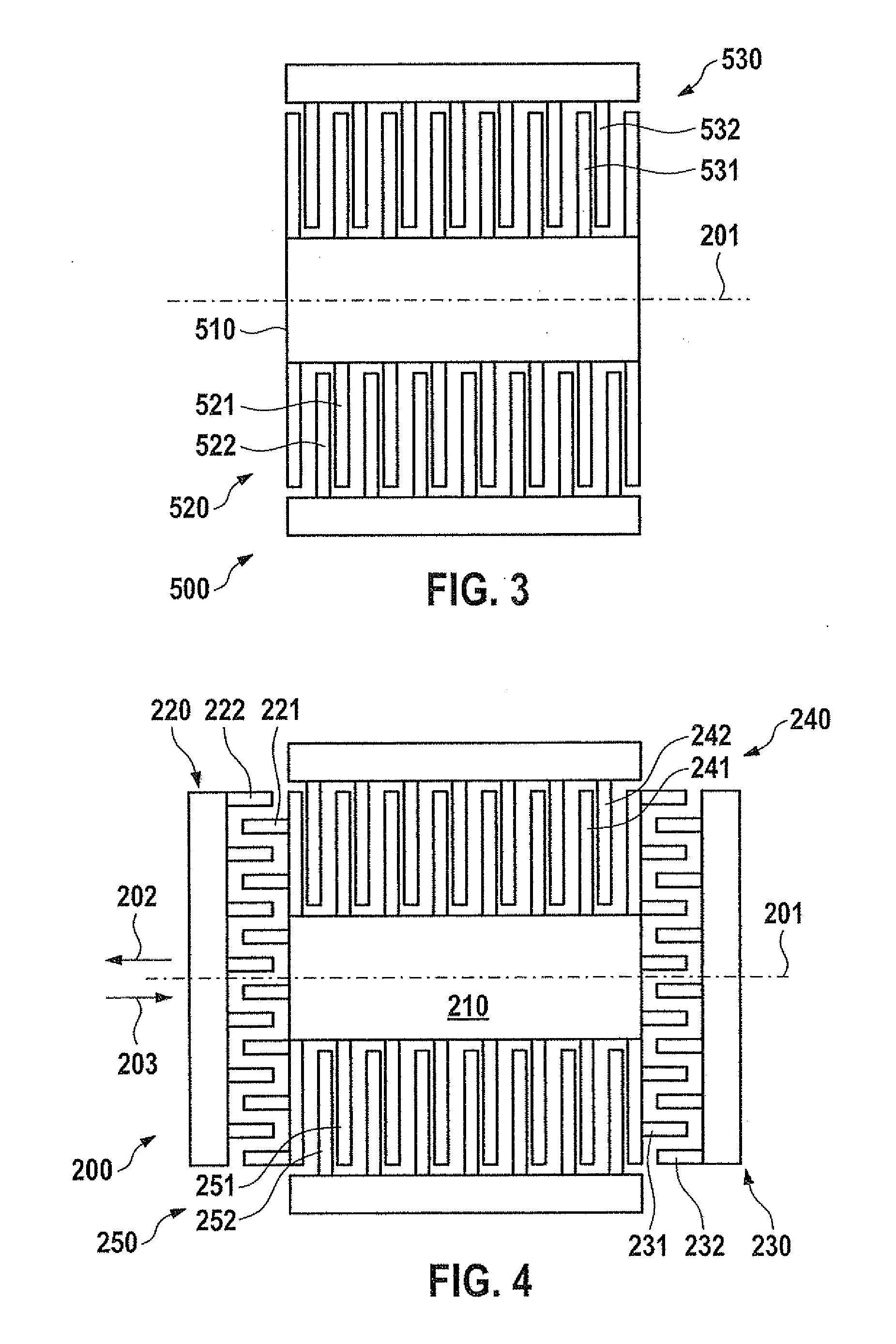

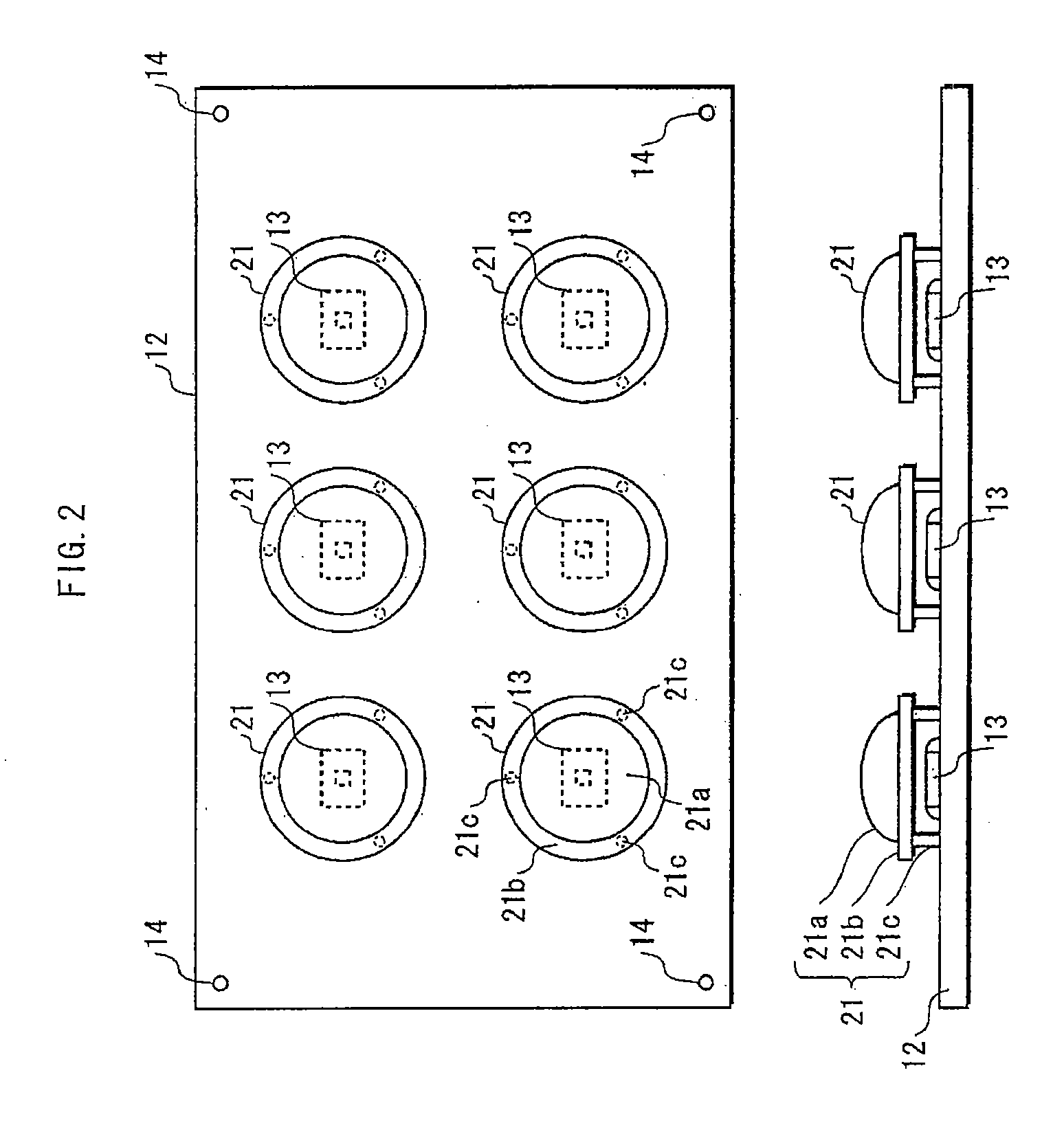

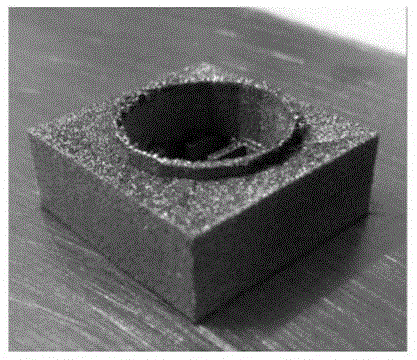

Microfabricated ultrasonic transducers with bias polarity beam profile control and method of operating the same

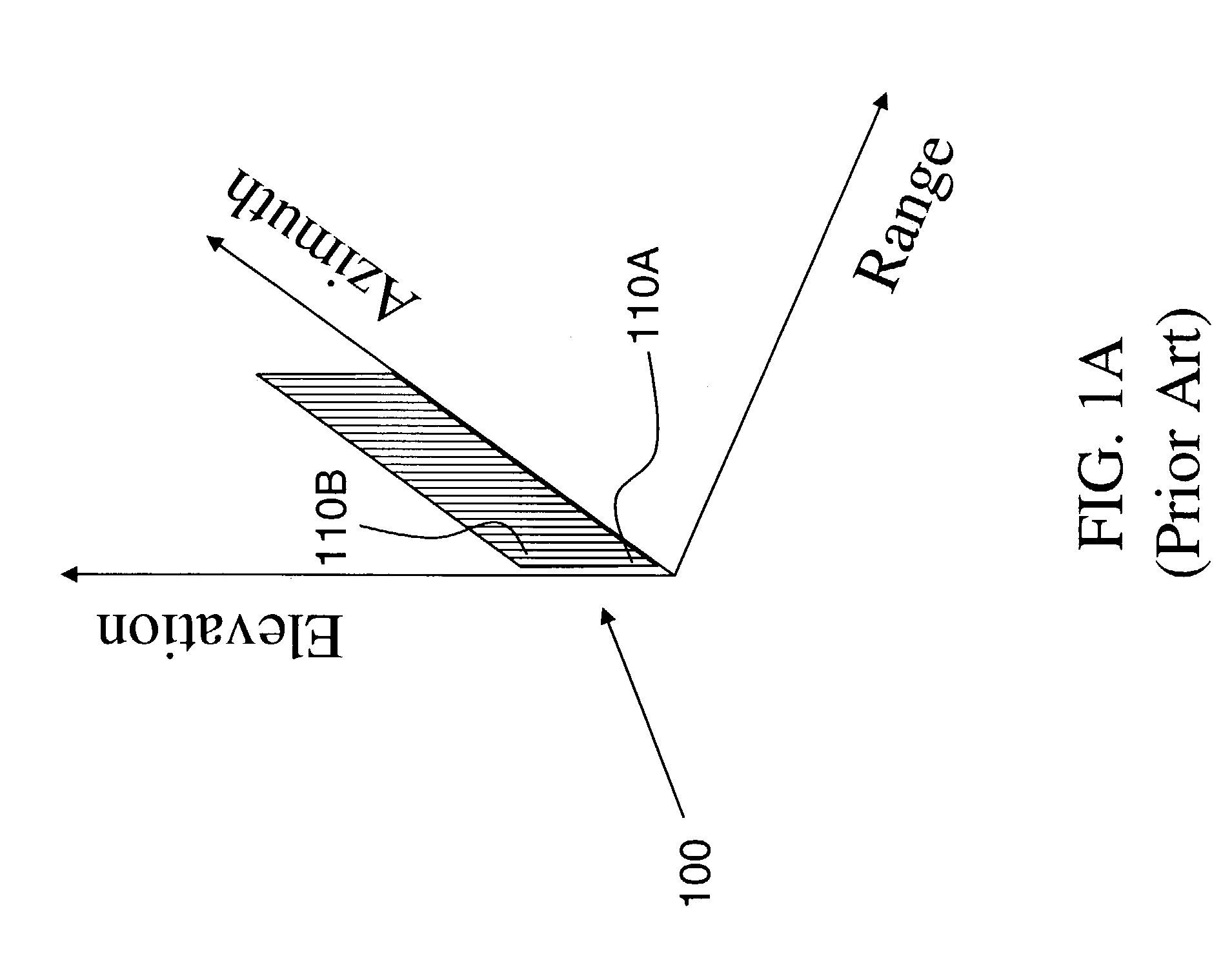

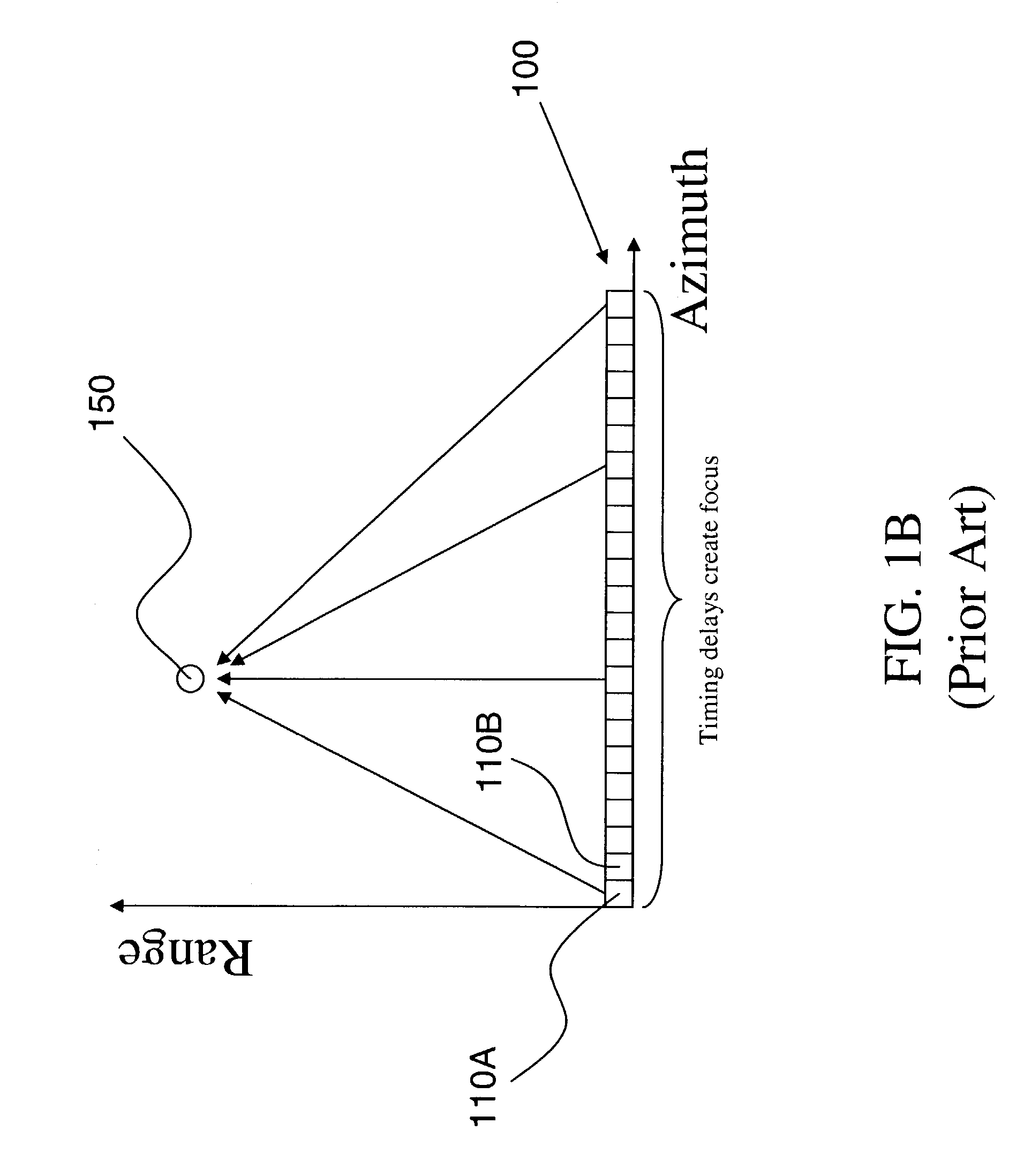

InactiveUS7087023B2Increased complexityIncrease expensesUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesCapacitanceSlice thickness

A capacitive microfabricated ultrasonic transducer with control of elevation phase through alternating bias polarity is disclosed. Such control of elevation phase results in simple ultrasonic probes with excellent slice thickness attributes. Furthermore, tight spatial variation of phase results in an effective way to achieve transmit aperture and apodization control. Further still, such capacitive microfabricated ultrasonic transducers can achieve elevation focus without the need of a lossy mechanical lens.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

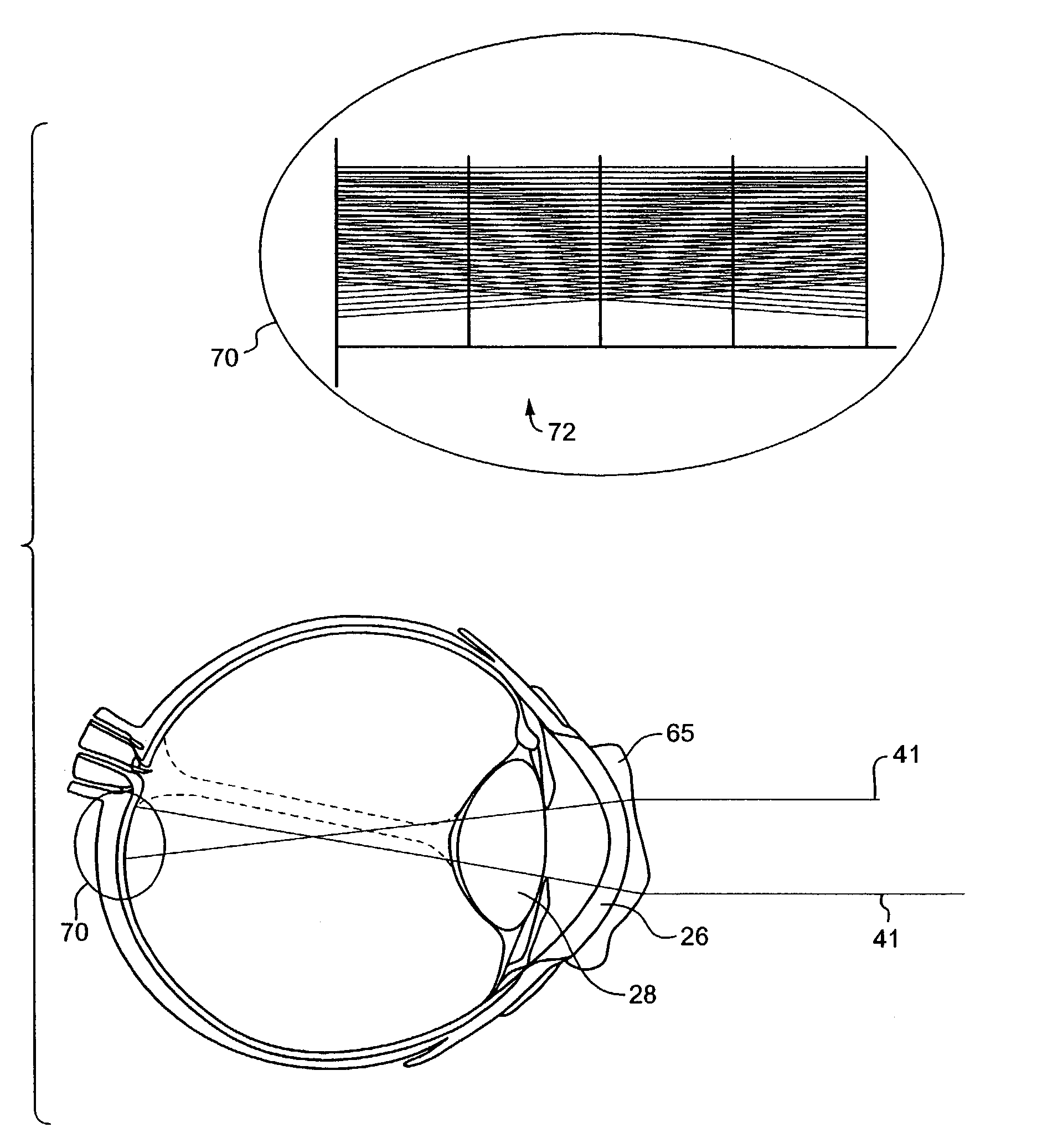

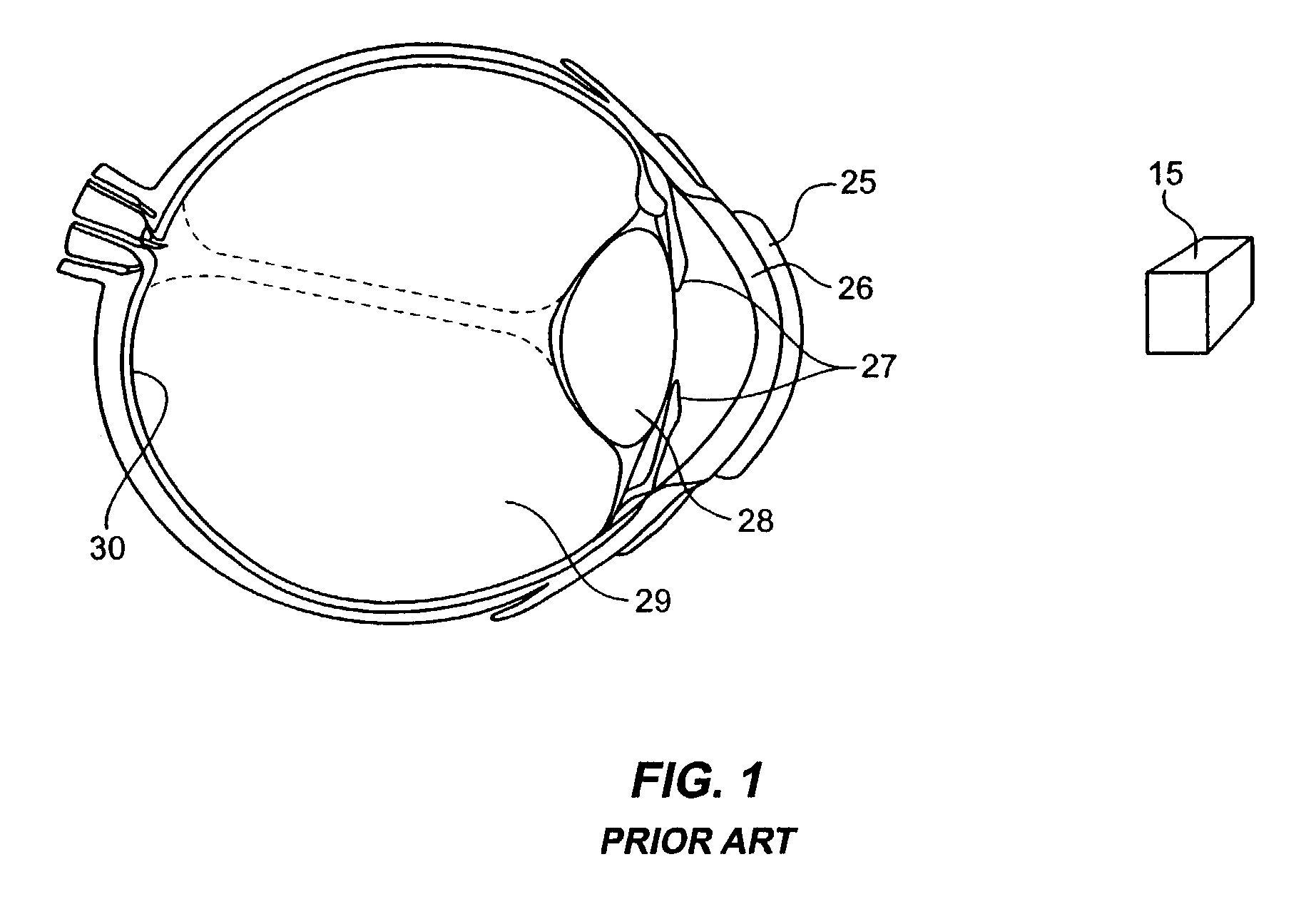

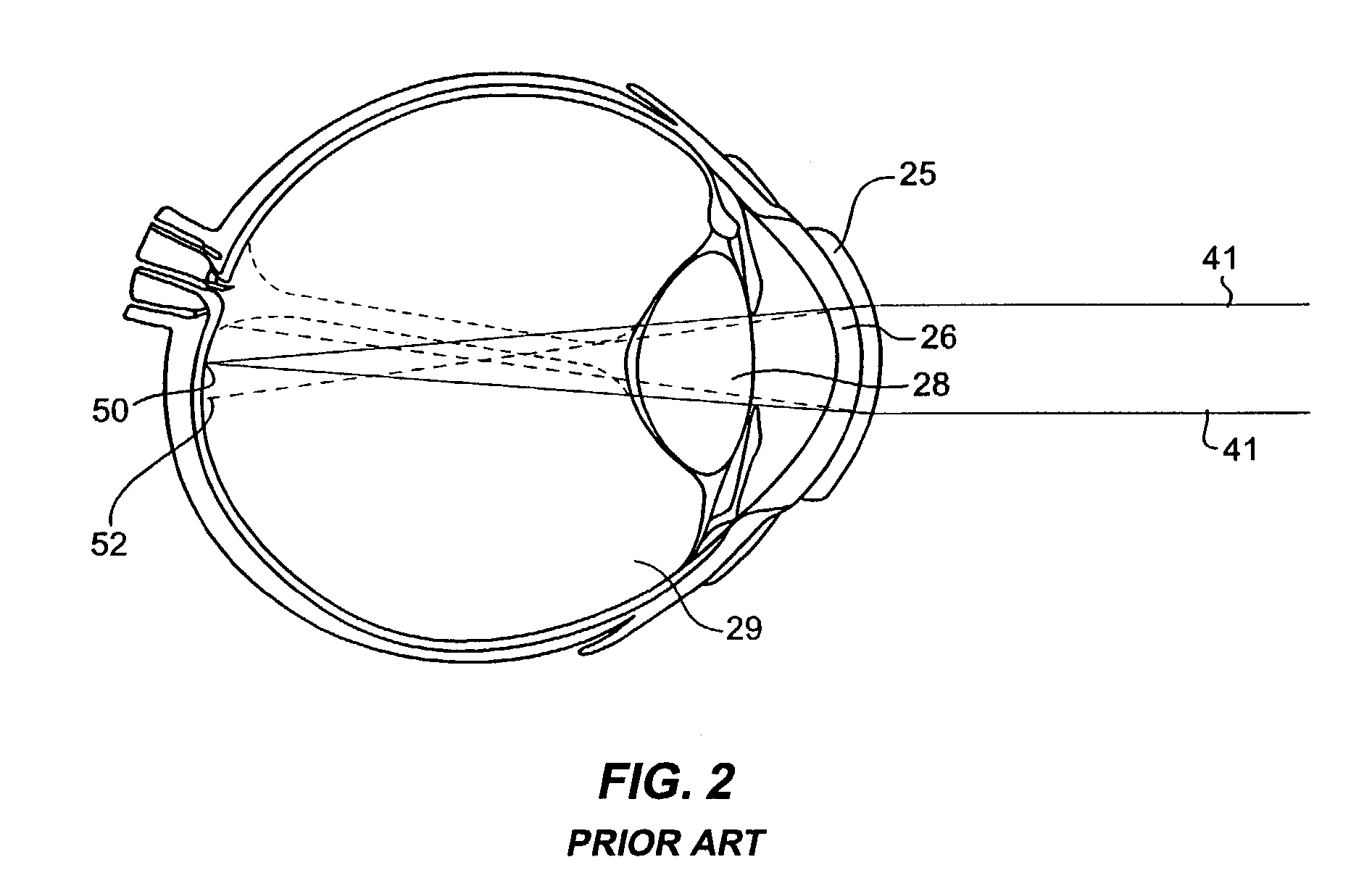

Extended depth of field optics for human vision

The present invention provides extended depth of field to human eyes by modifying contact lenses, intraocular implants, and / or the surface of the eye itself. This may be accomplished by applying selected phase variations to these optical elements (e.g., by varying surface thickness of the cornea of the eye). The phase variations EDF-code the wavefront and cause the optical transfer function to remain essentially constant within a range of distances from the in-focus position. This provides a coded image on the retina. The human brain decodes this coded image, resulting in an in-focus image over an increased depth of field.

Owner:UNIV OF COLORADO THE REGENTS OF

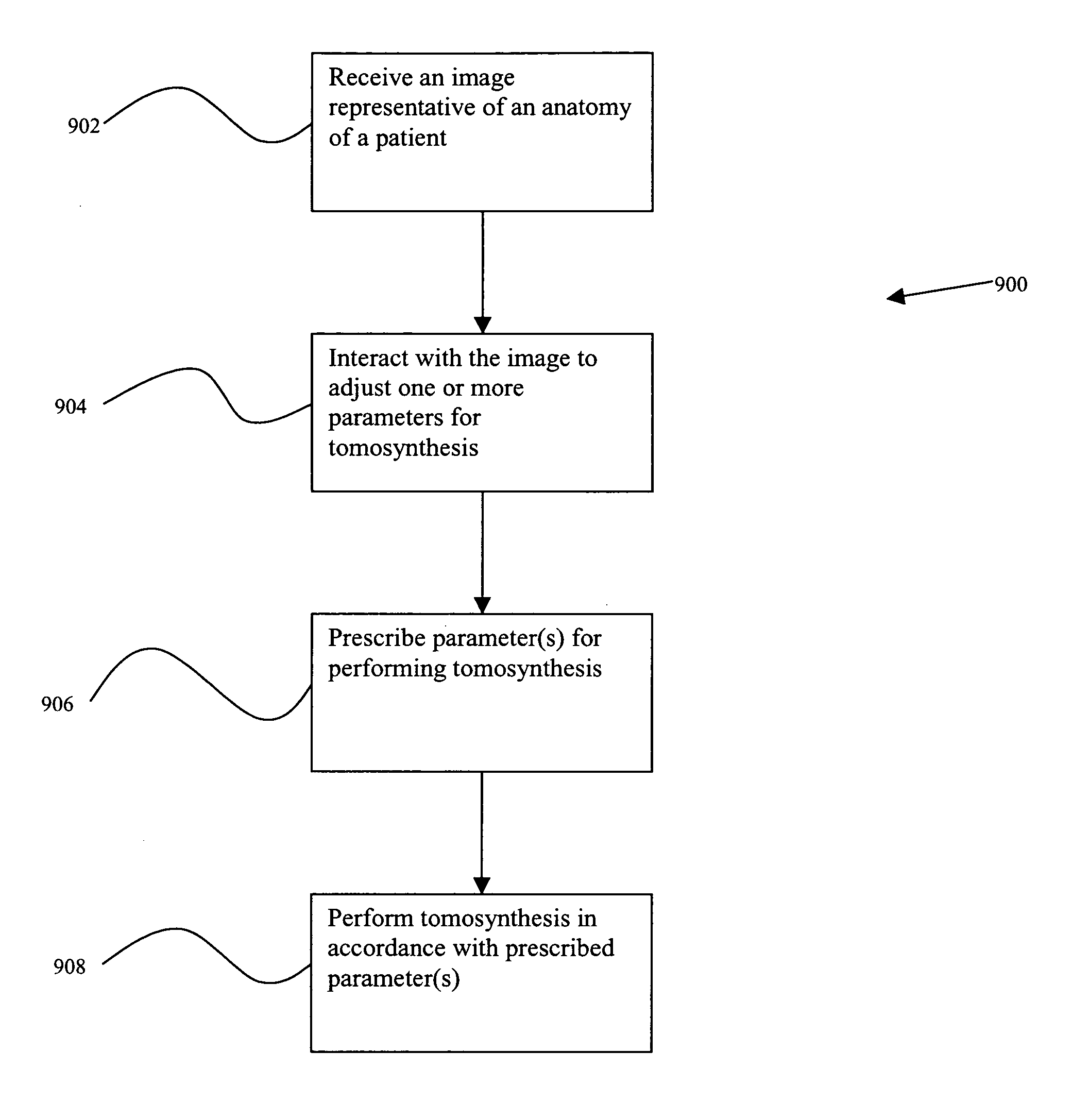

Methods and systems for prescribing parameters for tomosynthesis

Certain embodiments of the present invention provide a method for performing tomosynthesis including: receiving an image representative of an anatomy of a patient; allowing an interaction with the image to arrange at least one element with respect to the image to form an arrangement; and prescribing at least one parameter for obtaining a tomosynthesis image based at least in part on the arrangement. In an embodiment, the method further includes performing tomosynthesis in accordance with the at least one parameter. In an embodiment, the at least one element includes a detector representation. In an embodiment, the at least one element includes at least one thickness guide. In an embodiment, the at least one element includes at least one slice location guide. In an embodiment, the at least one parameter includes at least one of: a detector position, a detector size, a thickness size, a thickness position, a slice size, a slice position, a slice thickness, a slice separation, a field of view, a reconstruction algorithm, a hanging protocol, and an image processing routine. In an embodiment, the at least one parameter includes at least one of: an x-ray source location, an x-ray source angulation, an x-ray beam intensity, an x-ray beam gating, and a detector sensitivity.

Owner:GENERAL ELECTRIC CO

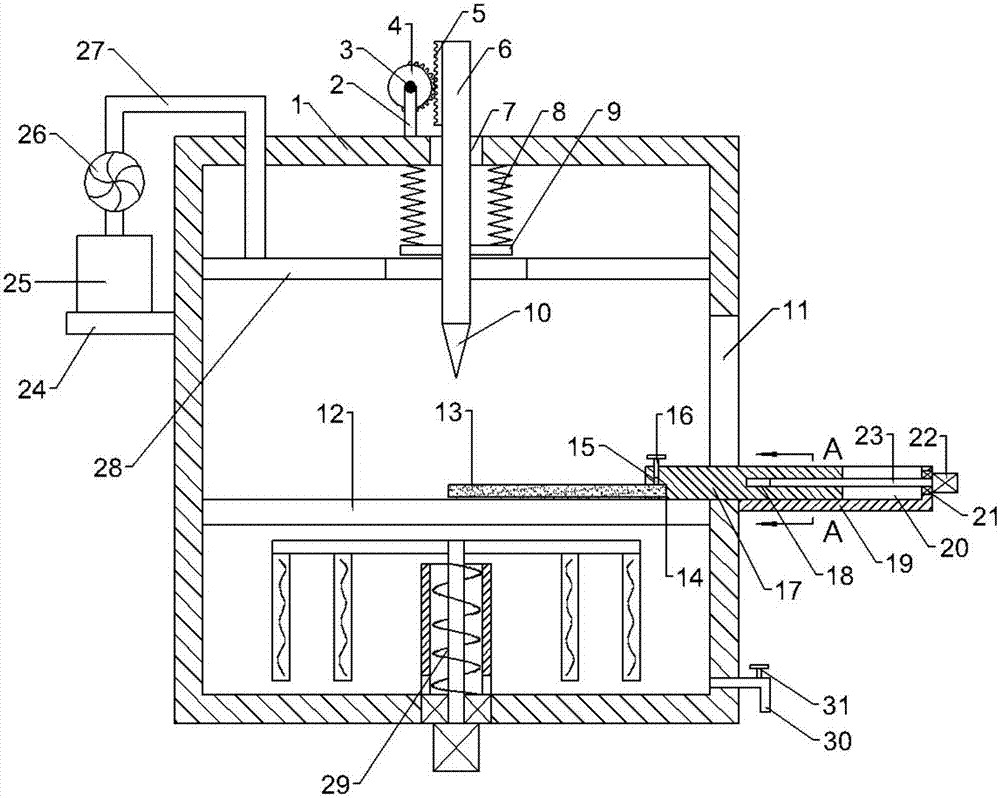

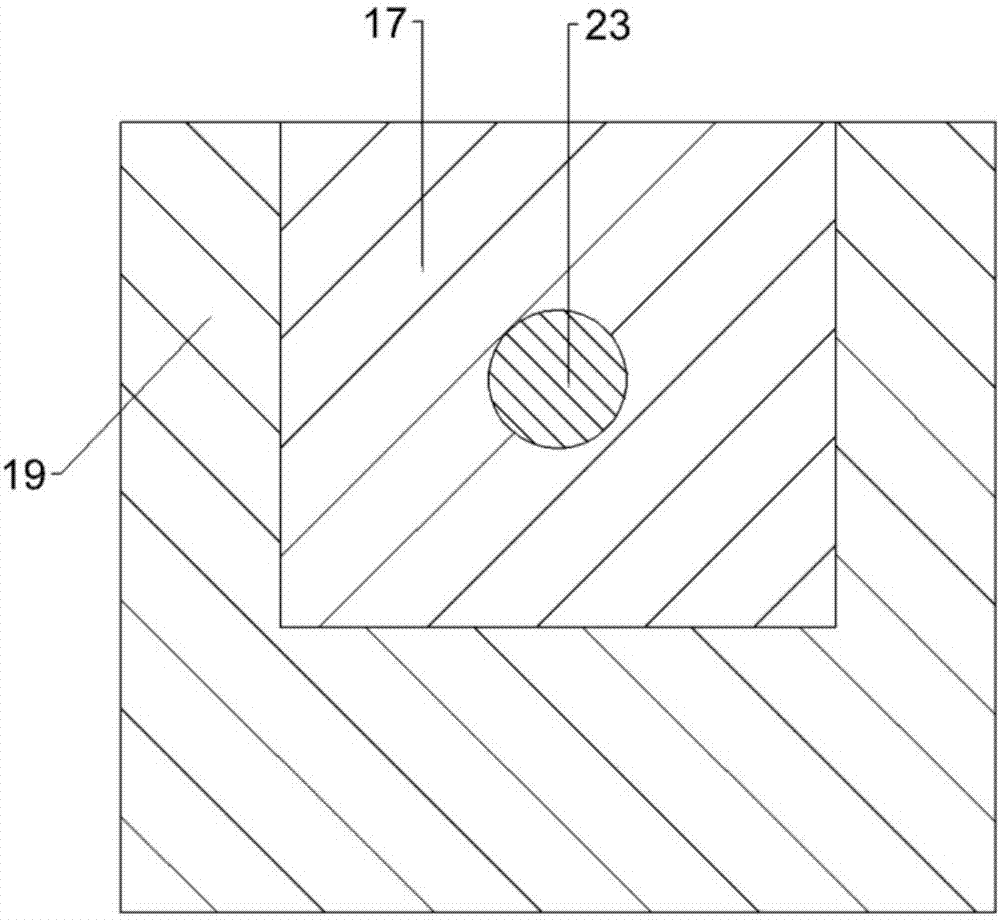

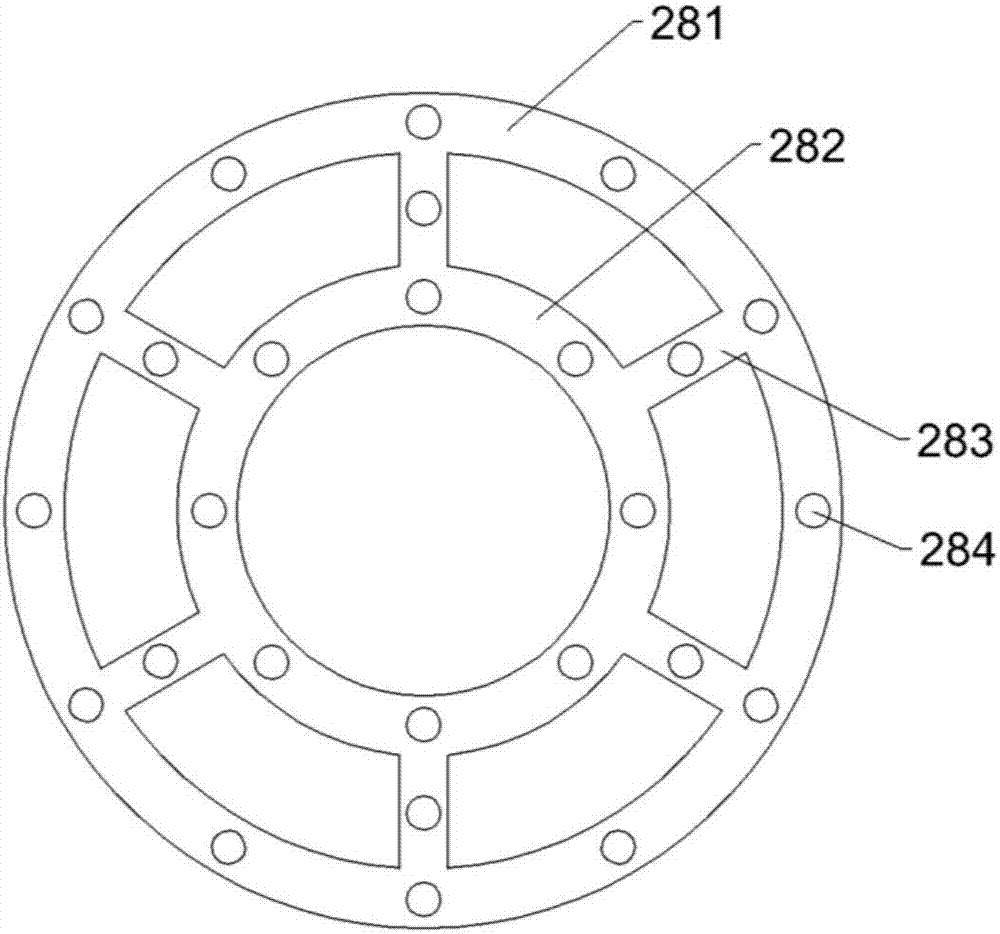

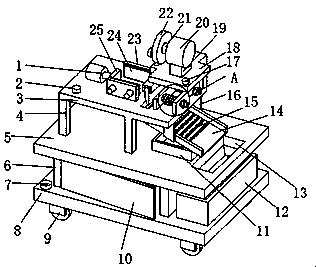

Medicinal material processing device for producing traditional Chinese medicine (TCM) decoction pieces, with dust removal and drying functions

InactiveCN107139234AGuaranteed uniformityImprove processing qualityUsing liquid separation agentDirt cleaningSlice thicknessInstability

A device for processing medicinal materials for the production of decoction pieces of traditional Chinese medicine with the function of dust removal and drying, comprising a shell, a through hole is opened in the middle of the top of the shell, and a lifting plate passes through the through hole, and the upper left side wall of the lifting plate is fixedly connected There is a rack, and the top of the housing on the left side of the lifting plate is fixedly connected with two support frames, and the top of the support frame is rotatably connected with a first rotating shaft, and one end of the first rotating shaft is fixedly connected with the output shaft of the first motor, and the first rotating shaft The upper part is fixedly connected with a half gear, and half of the gear teeth are arranged on the half gear, and the half gear is meshed with the rack. The invention has the beneficial effects of ensuring the uniformity of slice thickness, making the processing quality of medicinal materials better, meeting the requirements of production specifications, reducing the quality instability during manual slicing, and having certain application value; at the same time, it can also be processed The adsorption of dust ensures the life safety of the operators; the drying device is used to fully dry the sliced medicinal materials.

Owner:许晶

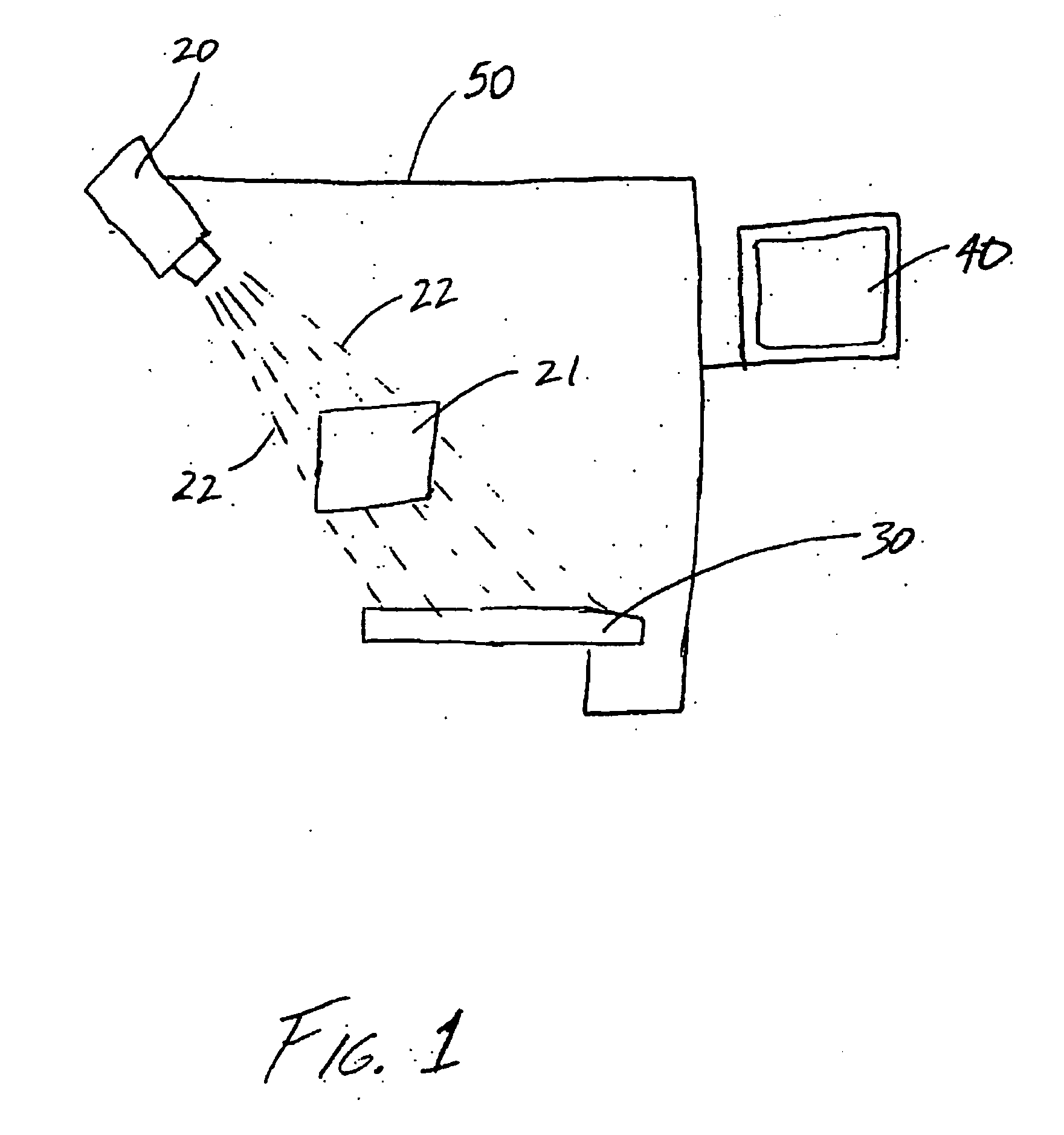

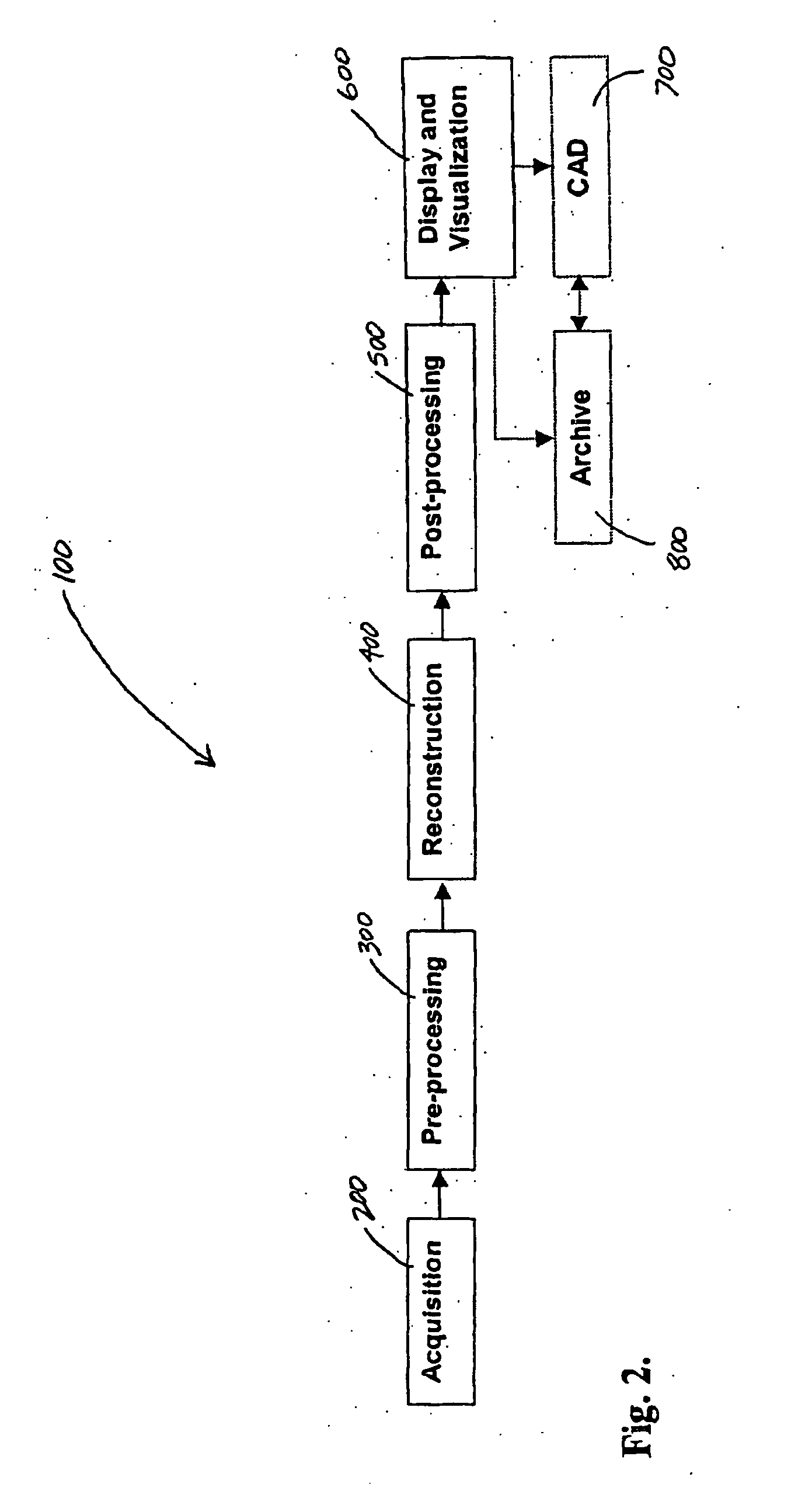

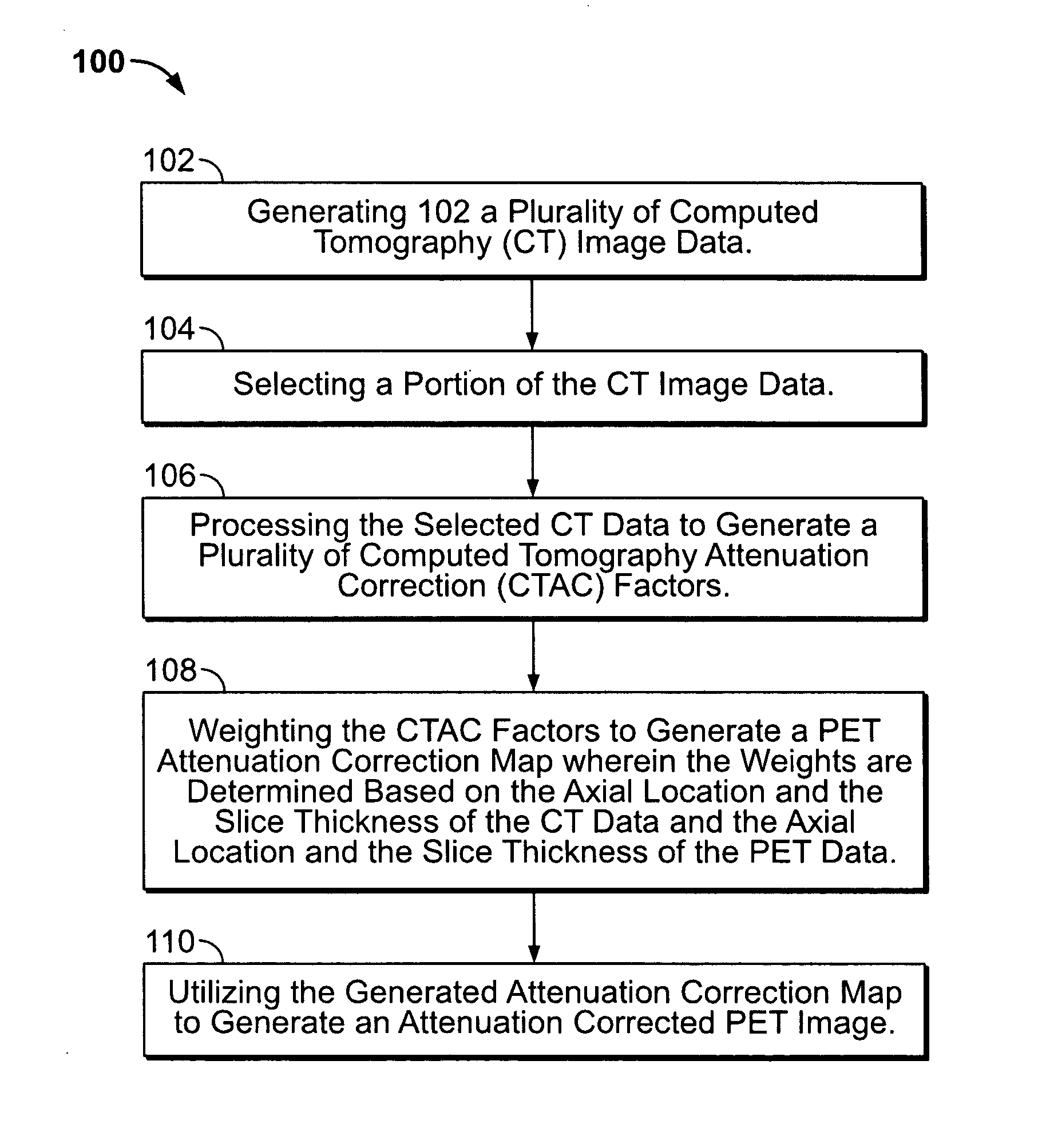

Multi modality imaging methods and apparatus

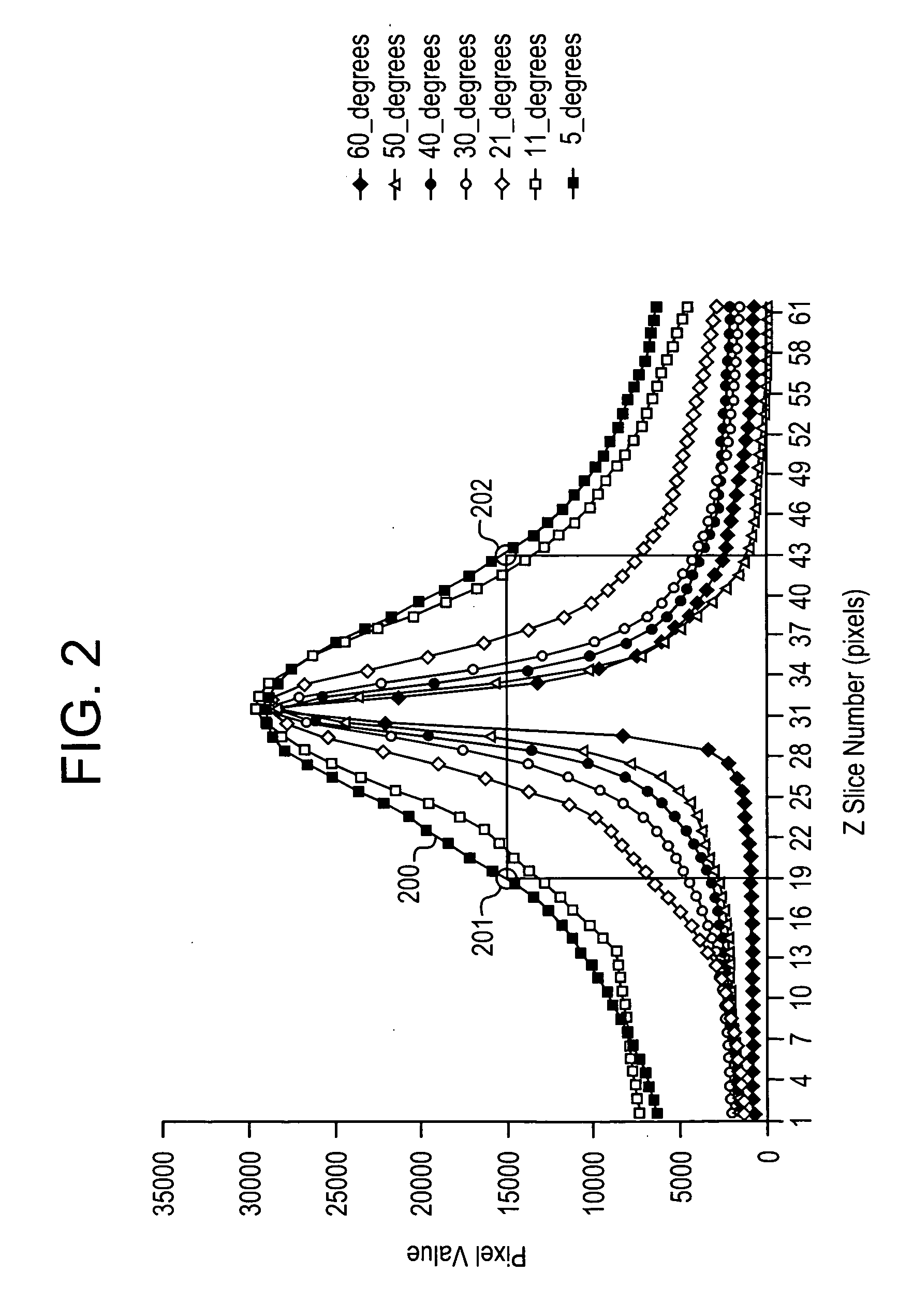

A method for correcting emission data from Positron Emission Tomography (PET) or SPECT includes generating a plurality of computed tomography (CT) image data, selecting a portion of the CT image data, processing the selected CT data to generate a plurality of attenuation correction (CTAC) factors at the appropriate energy of the emission data, weighting the CTAC factors to generate an emission attenuation correction map wherein the weights are determined based on the axial location and the slice thickness of the CT data and the axial location and the slice thickness of the PET or SPECT data, and utilizing the generated attenuation correction map to generate an attenuation corrected PET image.

Owner:GENERAL ELECTRIC CO

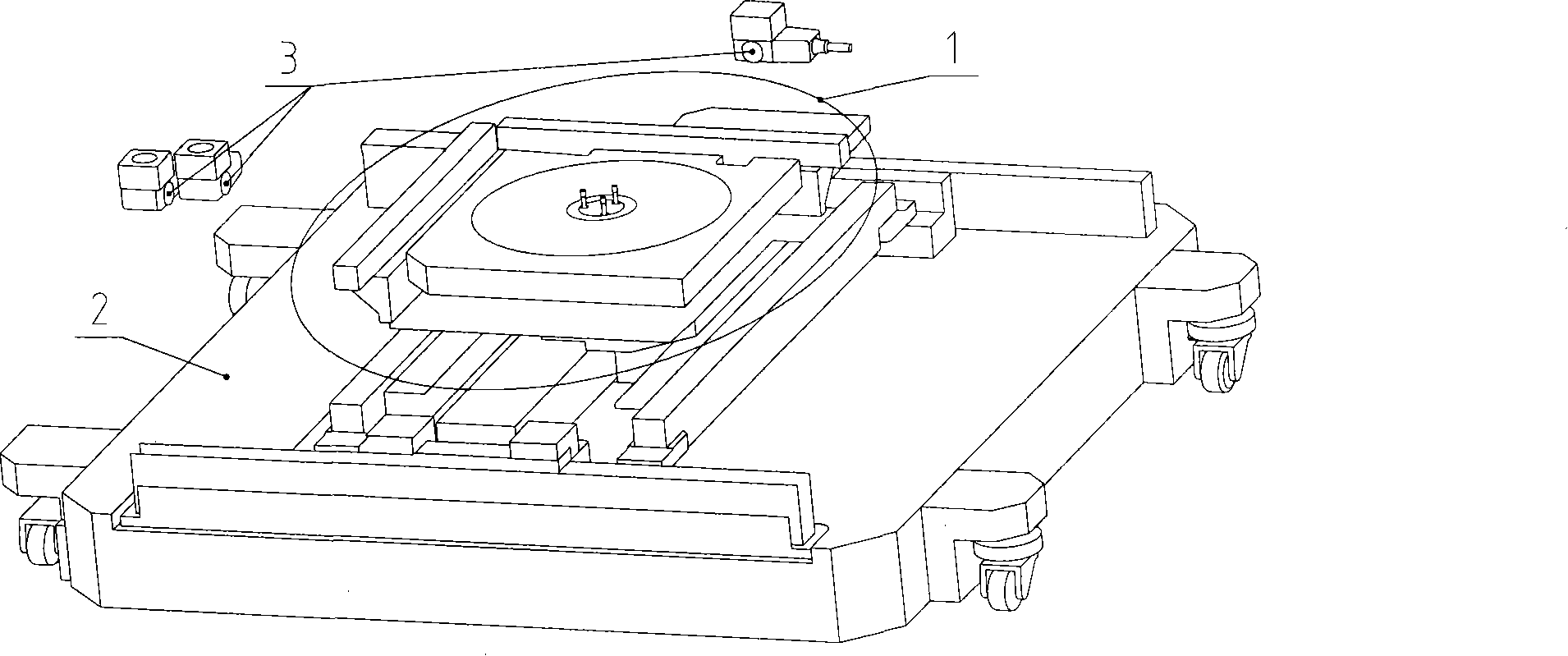

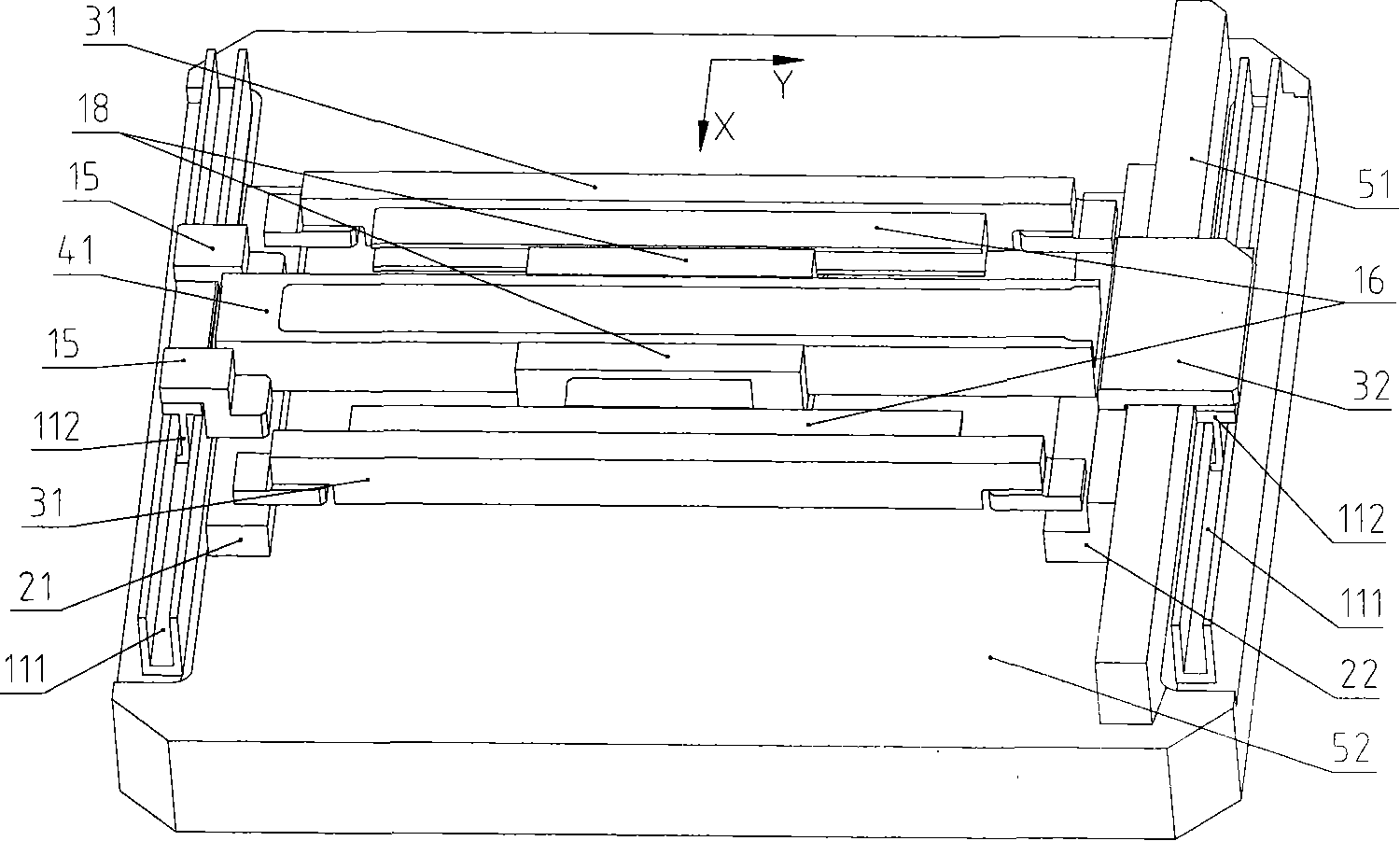

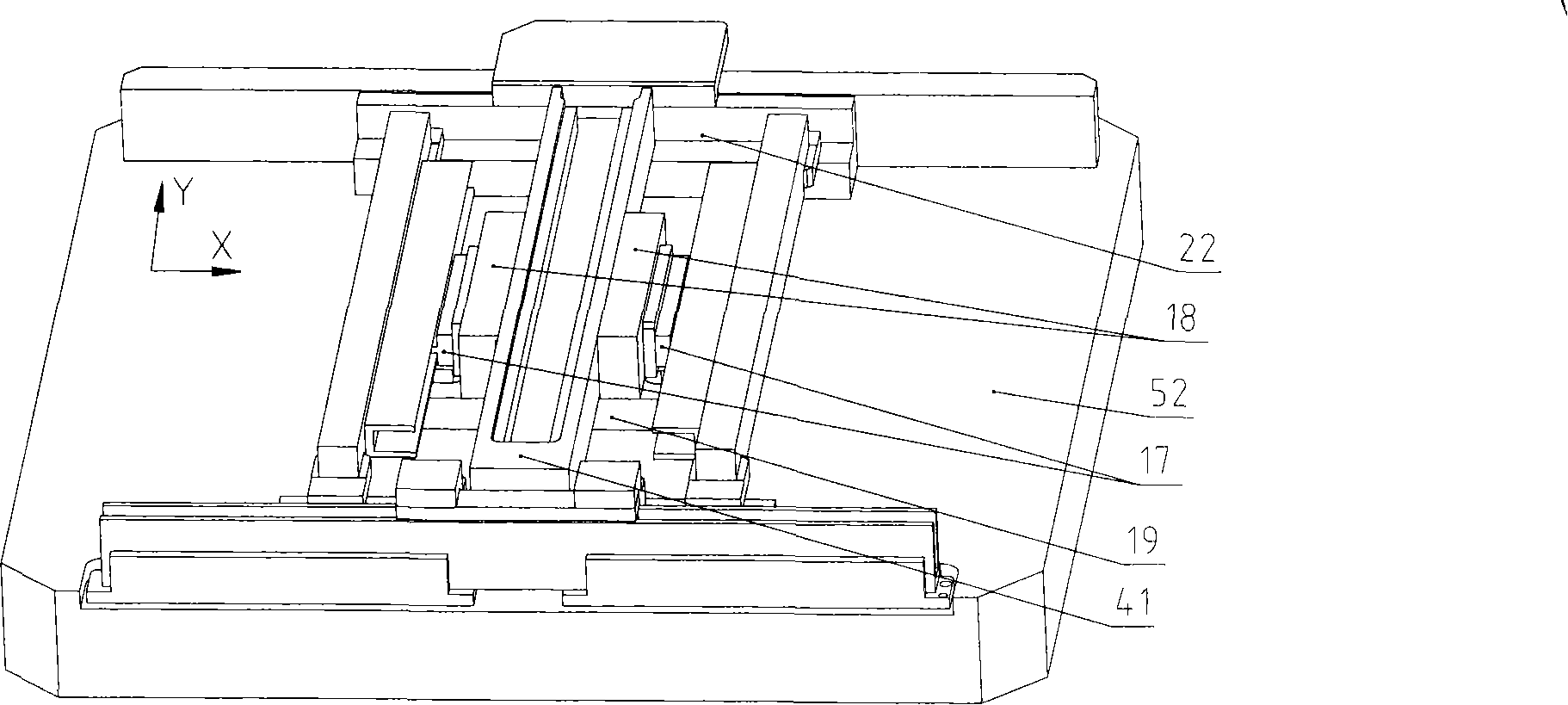

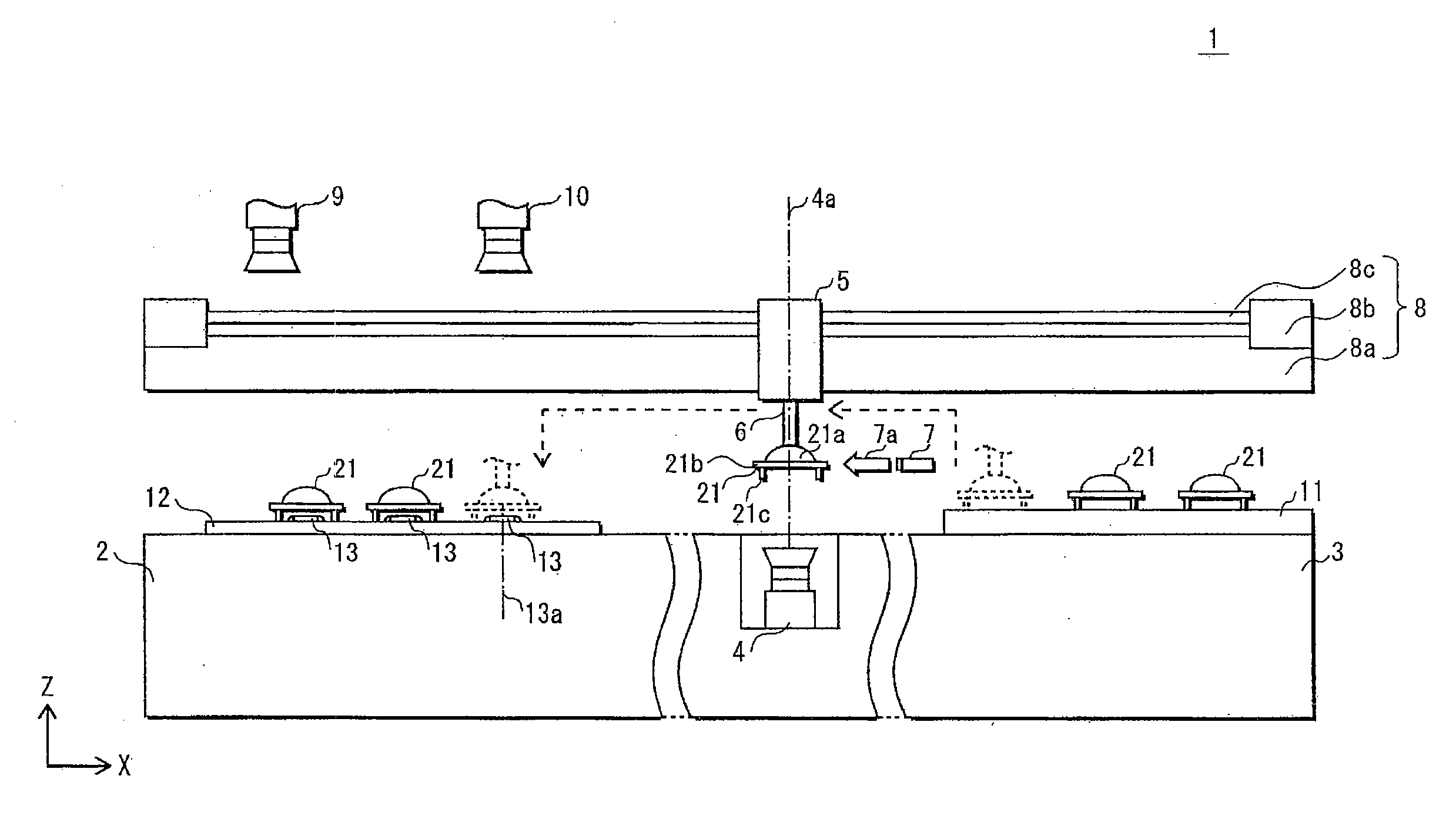

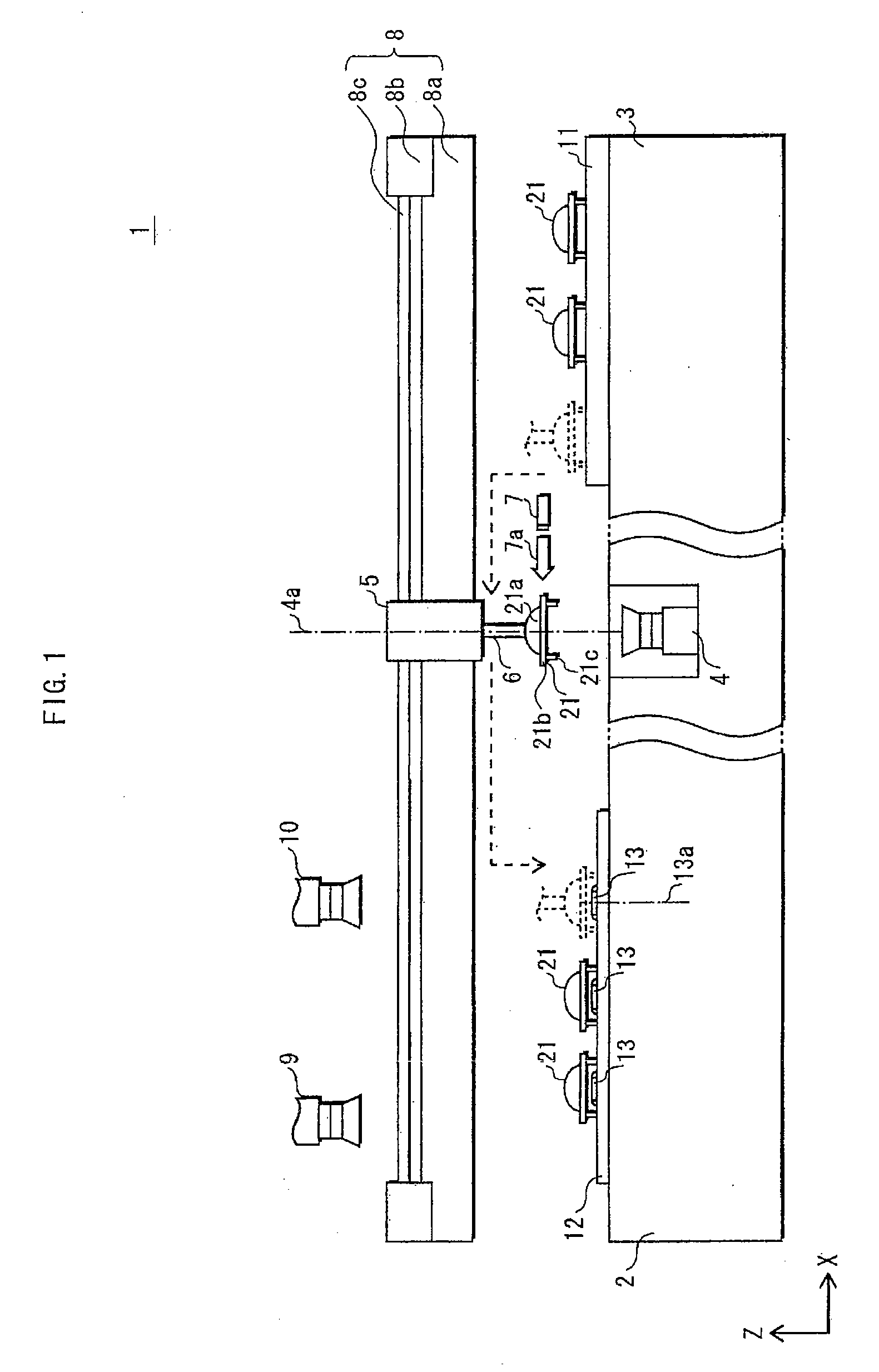

6 freedom degree precision positioning station capable of compensating z-direction position

ActiveCN101241314ACompact structureEasy to implementPhotomechanical exposure apparatusWork benchesRotary stageSlice thickness

The invention provides a six-freedom precision positioning stage capable of compensating Z-direction position, comprising a XY stage and an exposure stage structurally. The XY stage is a horizontal precision positioning stage for implementing horizontal (X, Y directions) precision positioning by a set of horizontal driver, an accurate and effective transmission device and closed-loop control; the exposure stage is divided from the top down into three layers which are a rotating stage, a leveling and focusing mechanism and a silicon slice thickness compensating mechanism. A silicon anastomosis mechanism is disposed between the rotating stage and the silicon slice compensating mechanism. The invented six-freedom precision positioning stage capable of compensating Z-direction position can be used in an occasion with a large stroke, a high speed and a high precision in horizontal direction, and can implement submicron precision adjustment in three freedoms in vertical direction.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD +1

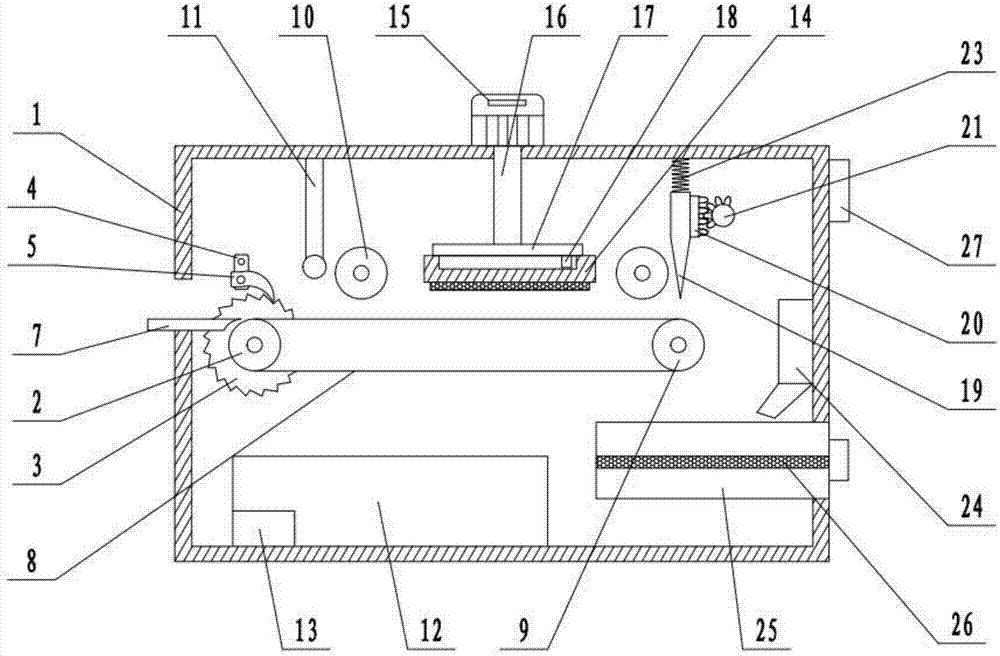

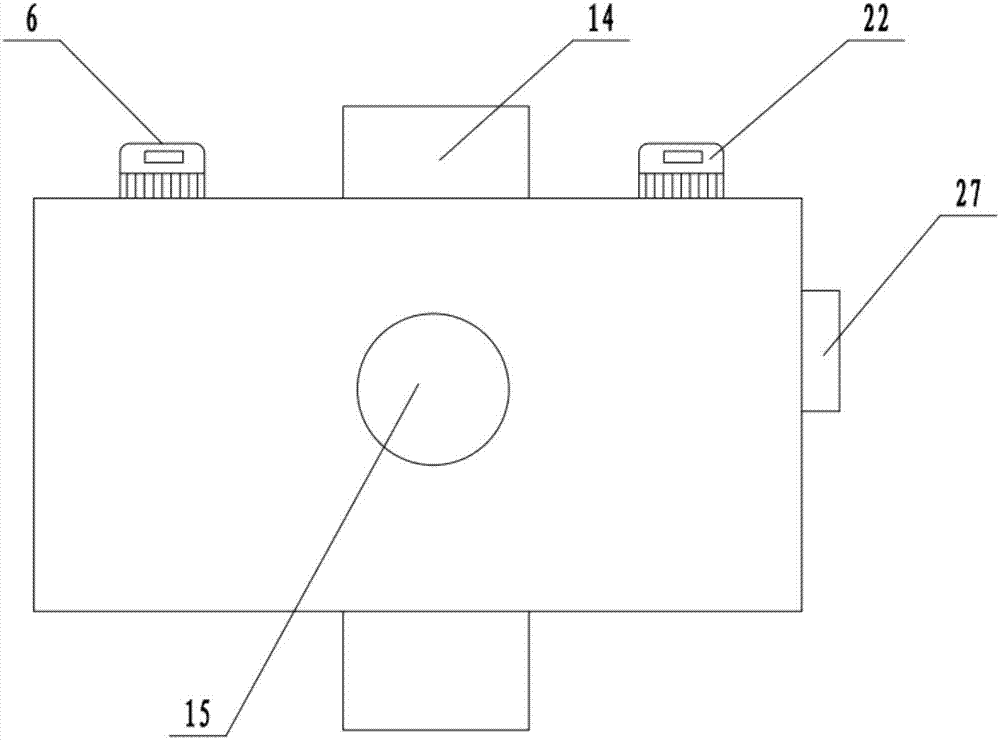

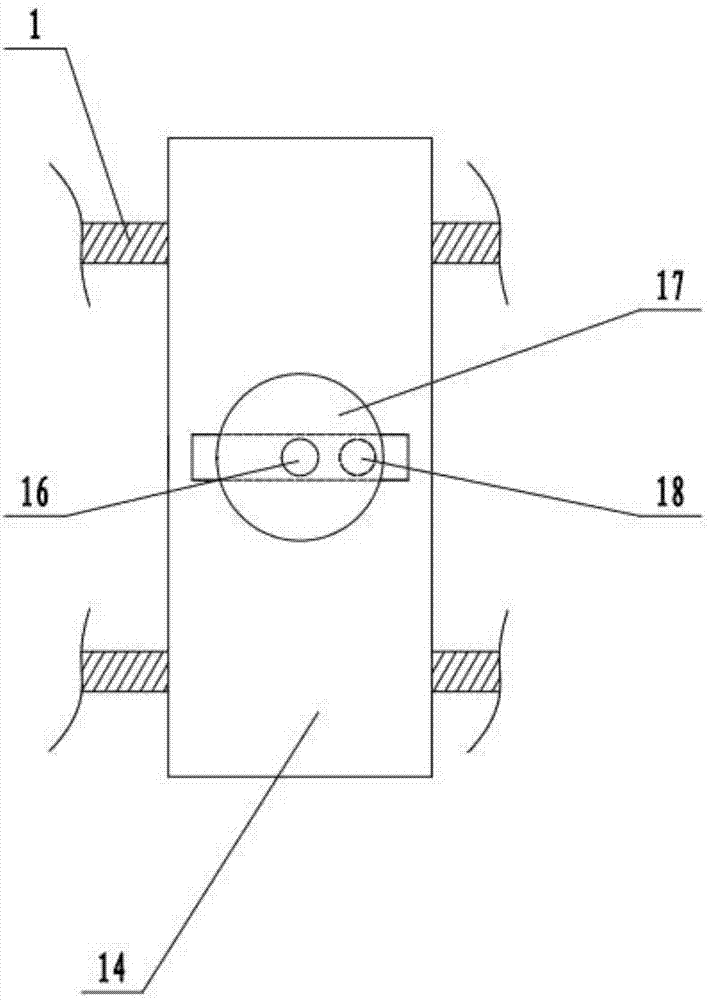

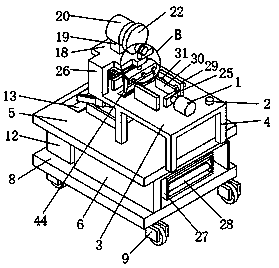

Step type bar-shaped traditional Chinese medicinal material cleaning and slicing integrated machine

InactiveCN107234083AImprove processing efficiencySlicing process is stableCleaning using toolsCleaning using liquidsBristleIntermittent motion

The invention discloses a step type bar-shaped traditional Chinese medicinal material cleaning and slicing integrated machine which comprises a shell, a conveying belt, a water tank, a cutter and a drawer. A driving roller and a driven roller are arranged in the shell. The surfaces of the driving roller and the driven roller are sleeved with the conveying belt. A brush plate is arranged above the conveying belt. A second motor is fixedly connected to the upper surface of the shell. The shaft stretching end of the second motor is fixedly connected with a rotating shaft. The rotating shaft penetrates through the shell to stretch into the shell. The lower end of the rotating shaft is fixedly connected with a rotating disc. A fixing bar is fixedly connected to the position, close to the edge, of the lower surface of the rotating disc. The cutter is arranged above the driven roller. The drawer is arranged below the driven roller. A bar-shaped traditional Chinese medicinal material is placed to the conveying belt through a guide plate, the brush plate moves back and forth in the horizontal plane, brush bristles on the lower surface of the brush plate are utilized for brushing the traditional Chinese medicinal material, the cutter is utilized for slicing the traditional Chinese medicinal material, the slicing process is stable due to the fact that the conveying belt does intermittent motion, the slice thickness is uniform, and the traditional Chinese medicinal material is dried by a drying machine.

Owner:惠安益源信息技术咨询有限公司

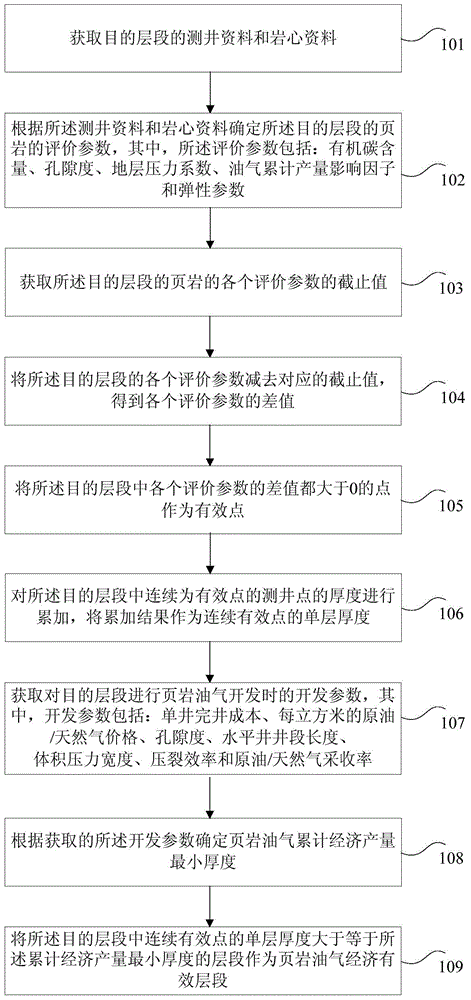

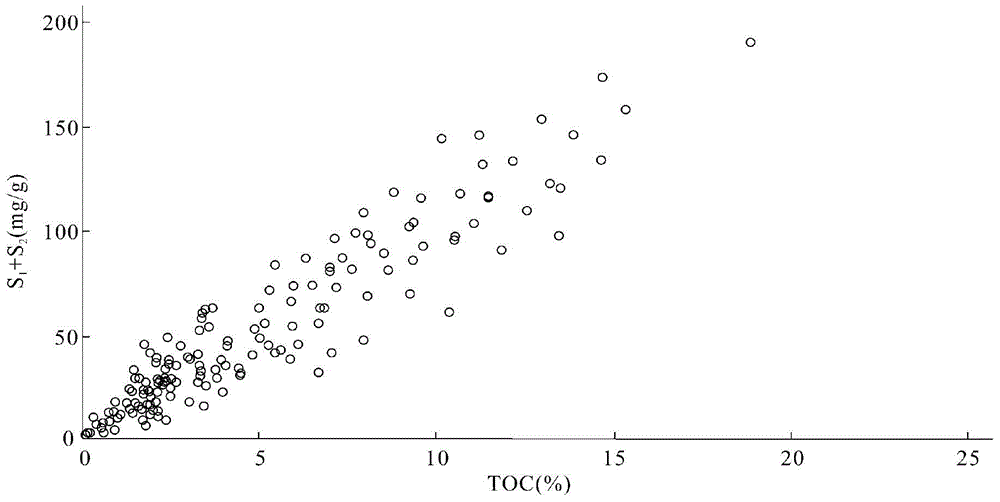

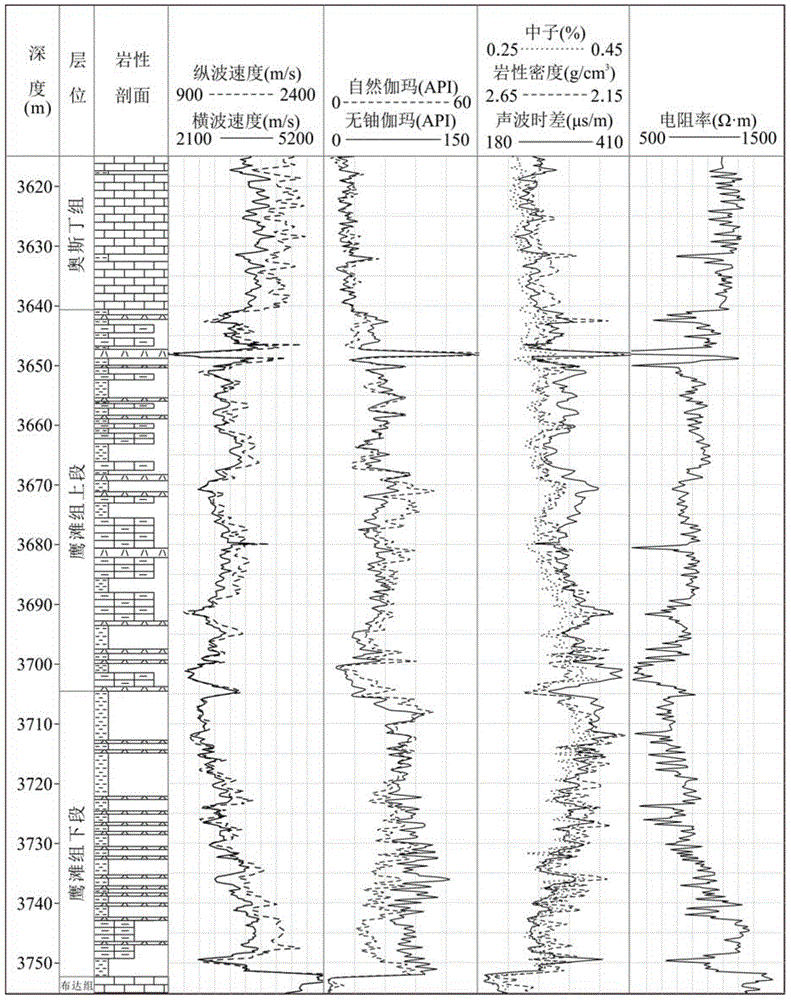

Shale oil-gas economical and effective layer section evaluation method

ActiveCN104453873AImprove development efficiencyEliminate defects with large evaluation errorsBorehole/well accessoriesPorositySlice thickness

The invention provides a shale oil-gas economical and effective layer section evaluation method. The method comprises the steps of determining evaluation parameters of shale of target layer sections according to obtained logging data and core data, wherein the evaluation parameters include the organic carbon content, the porosity, the formation pressure coefficient, the oil-gas accumulative output impact factor and elastic parameters; subtracting a corresponding cut-off value from each evaluation parameter to obtain a difference value of each evaluation parameter; using points with the difference values, larger than 0, of the evaluation parameters as efficient points; adding the thicknesses of logging points which are continuous efficient points in the target layer sections, and using the added result as the single-layer thickness of the continuous efficient points; determining the shale oil-gas accumulated economical yield minimum thickness; using the layer section with the single-layer thickness of the continuous efficient points larger than or equal to the accumulated economical yield minimum thickness in the target layer section as the shale oil-gas economical and effective layer section. According to the shale oil-gas economical and effective layer section evaluation method, the shale oil-gas economical and effective layer section can be accurately and effectively determined, and therefore the shale oil-gas development benefits are improved.

Owner:PETROCHINA CO LTD

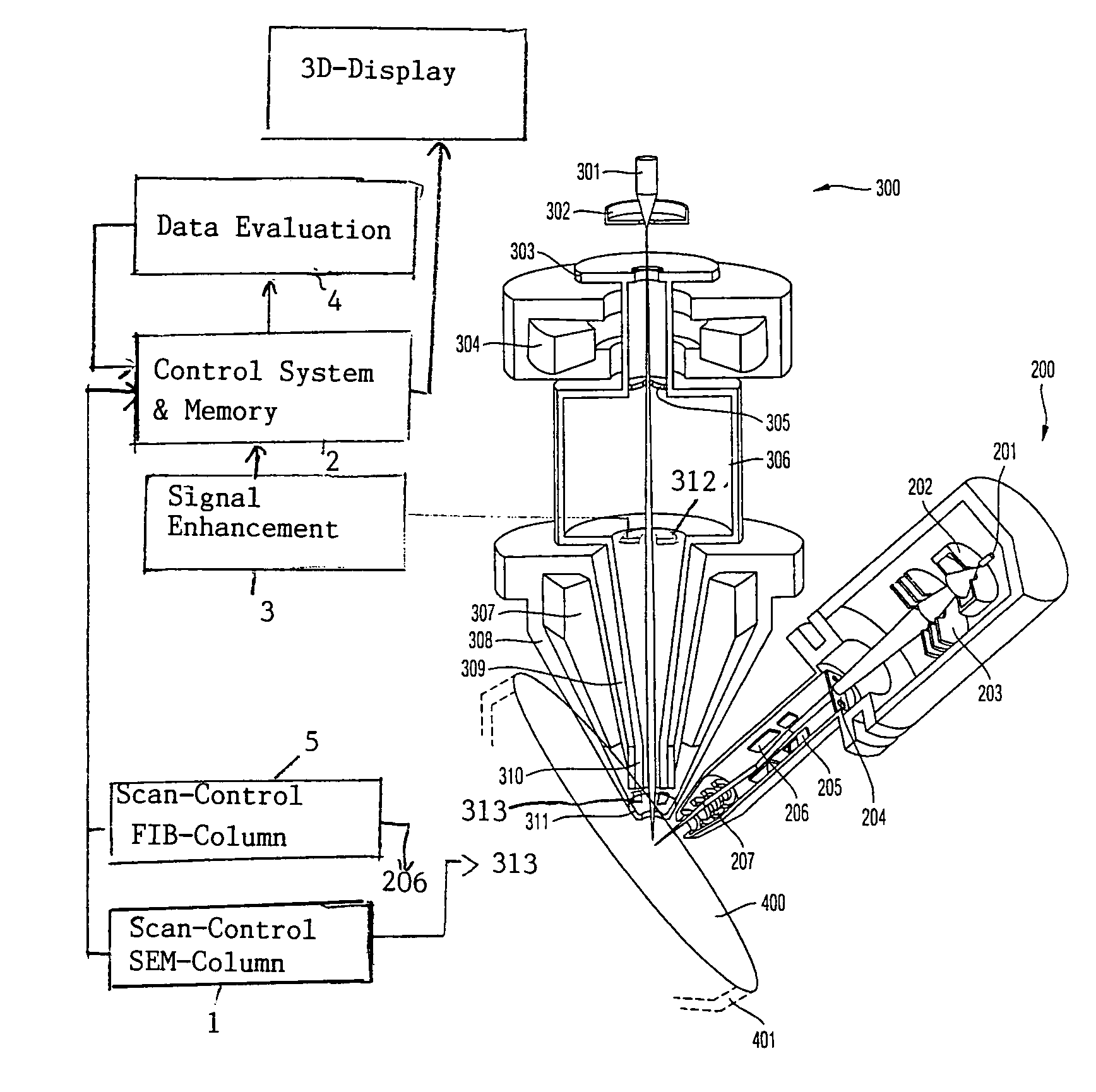

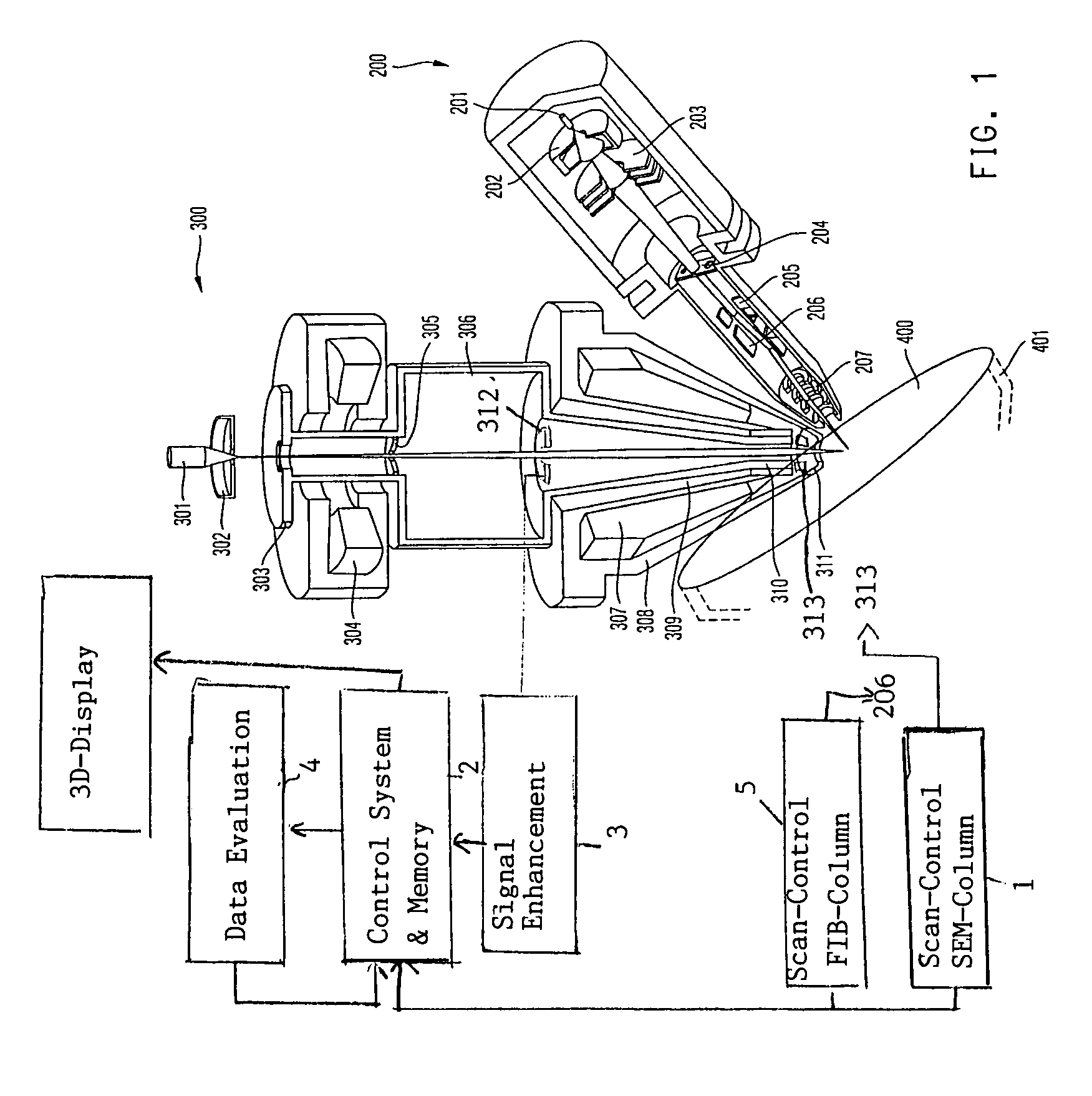

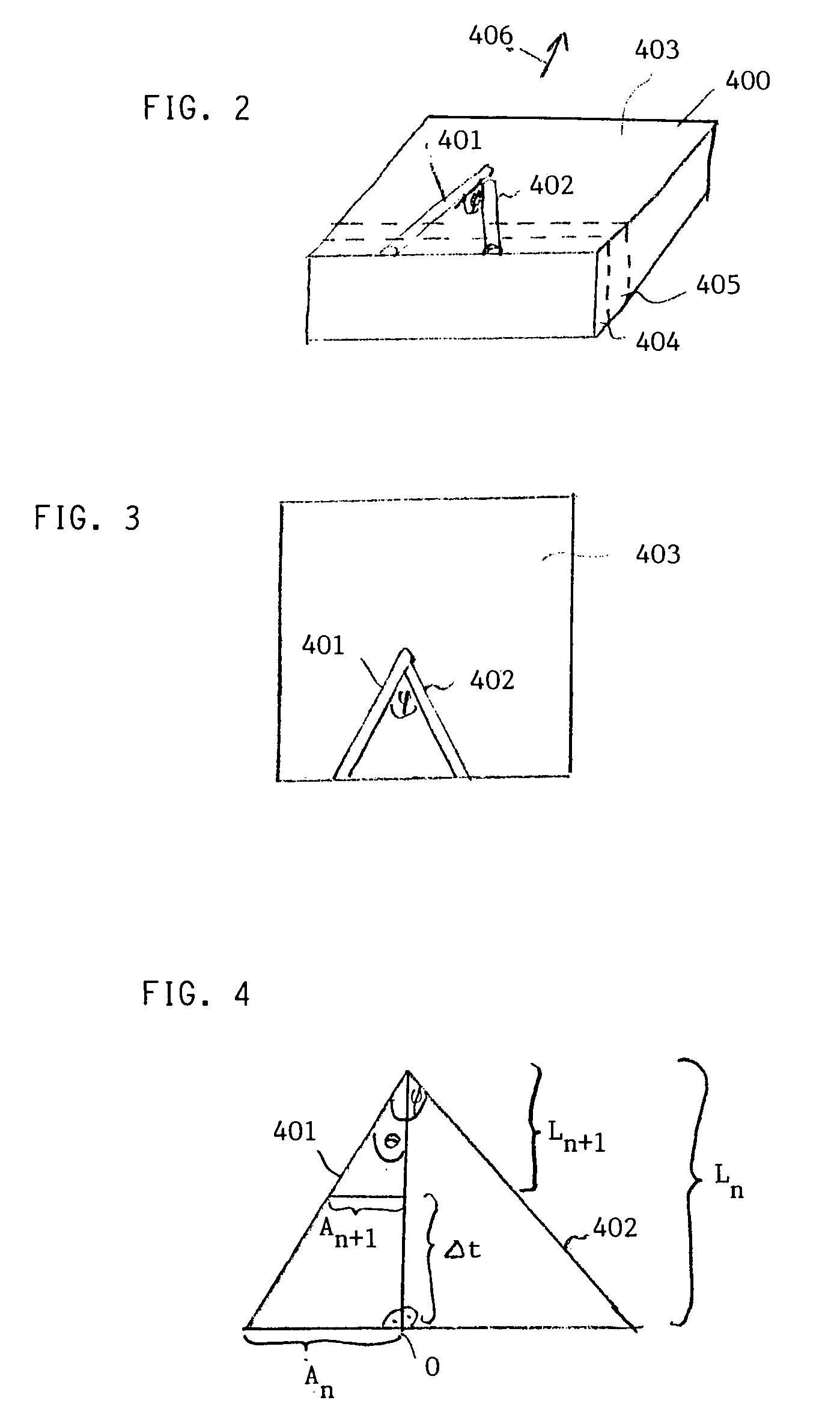

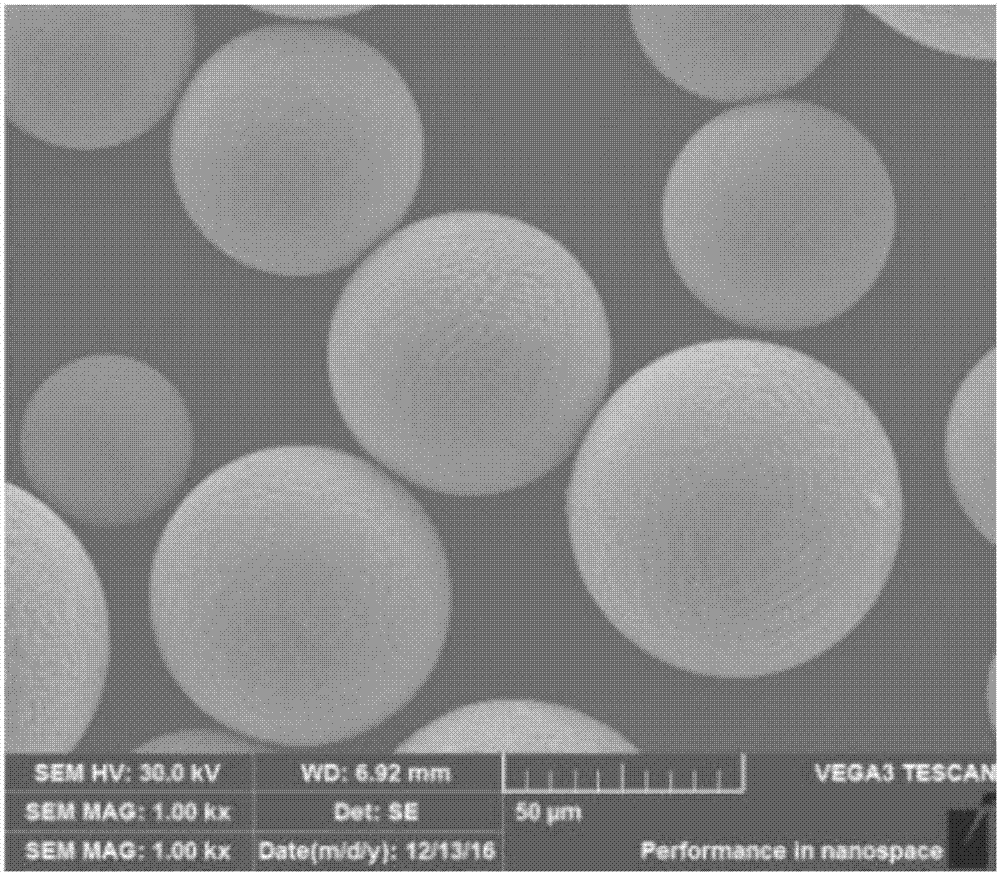

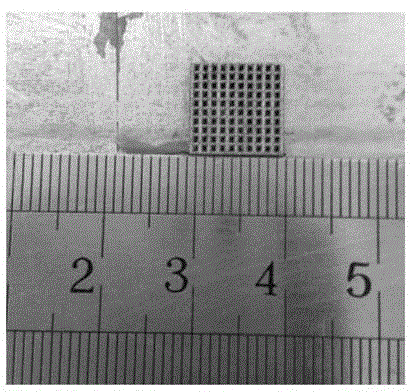

Method and apparatus for quantitative three-dimensional reconstruction in scanning electron microscopy

ActiveUS7312448B2Material analysis using wave/particle radiationElectric discharge tubesSlice thicknessScanning confocal electron microscopy

A method and an apparatus are for three-dimensional tomographic image generation in a scanning electron microscope system. At least two longitudinal marks are provided on the top surface of the sample which include an angle therebetween. In consecutive image recordings, the positions of these marks are determined and are used to quantify the slice thickness removed between consecutive image recordings.

Owner:CARL ZEISS SMT GMBH

Multi-slice X-ray CT apparatus and method of controlling the same

InactiveUS6445764B2Simple partsSimple configurationHandling using diaphragms/collimetersComputerised tomographsSlice thicknessMulti slice

For the purpose of reconstructing a plurality of X-ray tomographic images having a plurality of practical slice thicknesses while reducing the number of X-ray detector arrays and simplifying configuration, X-rays generated by an X-ray tube 4 are emitted via a slit 15 of a collimator 6 toward a detector 8 disposed opposite to the X-ray tube 4; the length (width) of the collimator 6's slit 15 in the D1 direction and the position of the collimator 6 in the D1 direction are adjustable; the detector 8 is comprised of four X-ray detector arrays; and the widths of the two outer X-ray detector arrays in the D1 direction are larger than the widths of the two center X-ray detector arrays.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

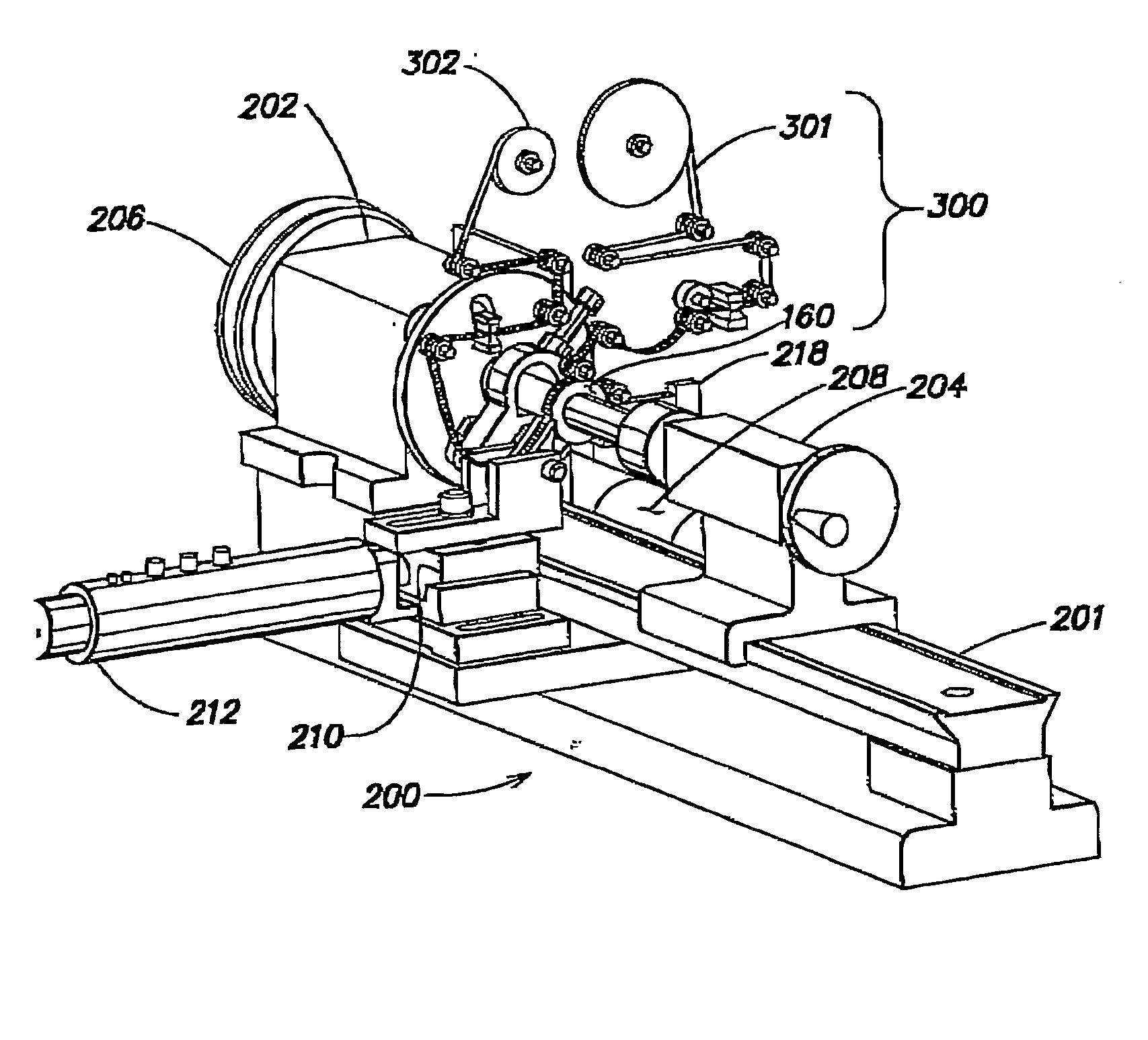

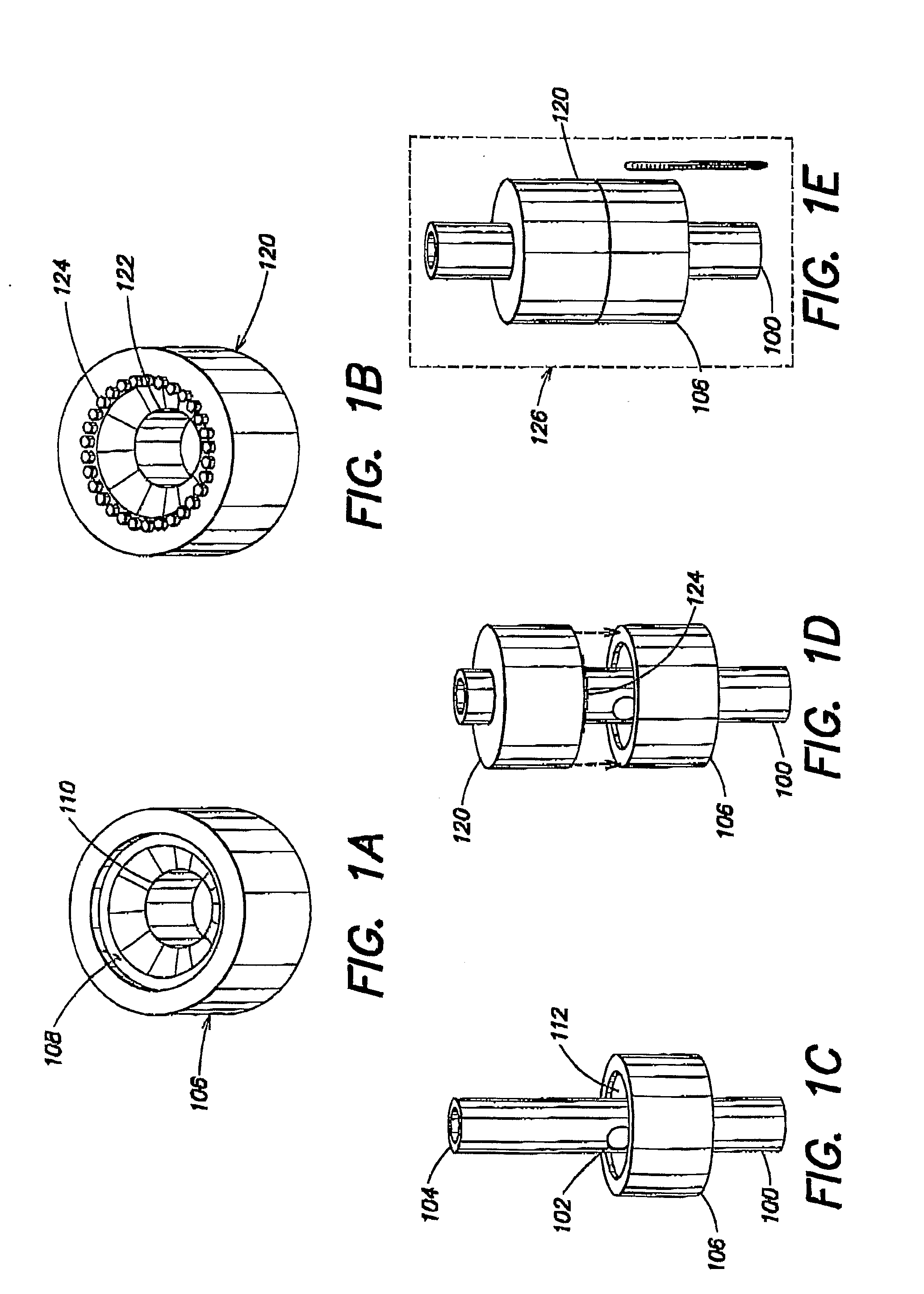

Methods and apparatus for providing and processing sliced thin tissue

InactiveUS20100093022A1Facilitate subsequent imagingPromote the fullTemperatue controlStatic/dynamic balance measurementSlice thicknessTissue sample

Methods and apparatus for providing and processing serial tissue sections. In one example, an “automatic tape collecting lathe ultramicrotome” (ATLUM) slices a block of tissue sample having various geometries into a continuous ribbon of thin tissue, or multiple thin tissue sections, and disposes the sliced thin tissue on an appropriate substrate to facilitate subsequent imaging of the sliced thin tissue. Closed-loop control of section thickness of the sliced thin tissue sections or ribbons is implemented to produce thinner sliced tissue sections or ribbons and tightly regulate thickness. Thin tissue sections or ribbons may be particularly processed / prepared to facilitate imaging with a scanning electron microscope (SEM). Collected thin tissue sections or ribbons may be used to create UltraThin Section Libraries (UTSLs) that allow for fully automated, time-efficient imaging in the SEM to facilitate expansive tissue studies.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Efficient slicing machine special for preparation of traditional Chinese medicine decoction pieces

InactiveCN108789581AAvoid uneven slice thicknessEasy to replaceMetal working apparatusHeating arrangementSlice thicknessEngineering

The invention discloses an efficient slicing machine special for preparation of traditional Chinese medicine decoction pieces. The efficient slicing machine comprises a machine seat. A drying box is arranged on the left side of the upper surface of the machine seat. A collecting box is arranged on the right side of the upper surface of the machine seat. A base is arranged on the upper surface of the drying box. A discharging port is formed in the right side of the upper surface of the base. Supporting columns are arranged on the left side of the upper surface of the base. A workbench is arranged at the upper ends of the four supporting columns. A slice thickness adjusting mechanism is arranged on the right side of the upper surface of the workbench. A pushing mechanism is arranged on the left side of the upper surface of the workbench. A first positioning clamp plate is arranged on one side of the middle of the upper surface of the workbench. A second positioning clamp plate is arranged on the other side of the middle of the upper surface of the workbench. Adjustable bolts are connected with threads of threaded holes in the side surface of the second positioning clamp plate. A clamping plate is arranged at the ends of the adjustable bolts. According to the efficient slicing machine special for preparation of the traditional Chinese medicine decoction pieces, moving is convenient, traditional Chinese medicine is convenient to clamp, it is guaranteed that slice thickness is uniform, the slice thickness can be adjusted, and chippings and slices are collected in a classified mode.

Owner:亳州市合七医药科技有限公司

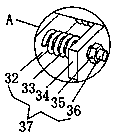

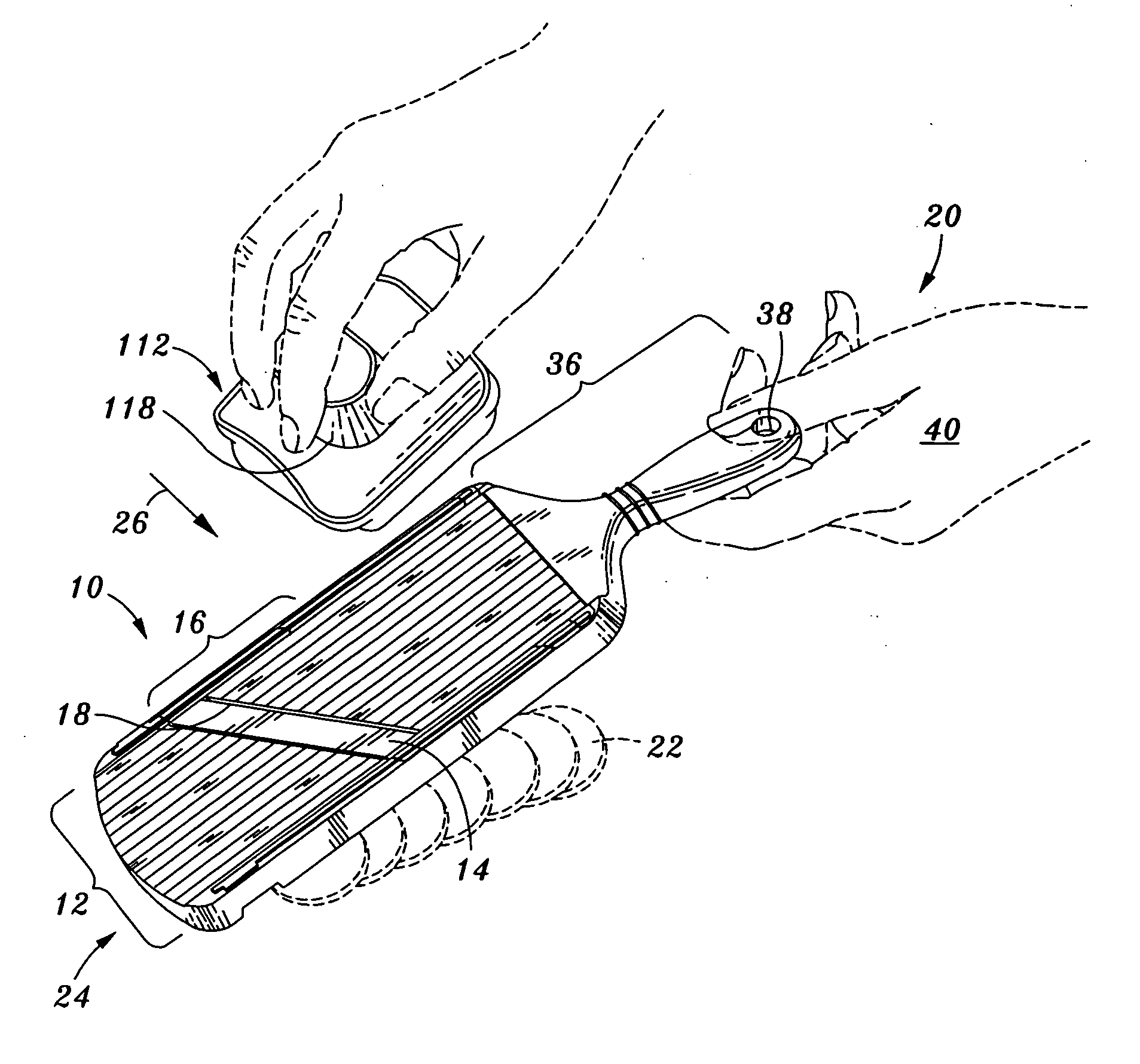

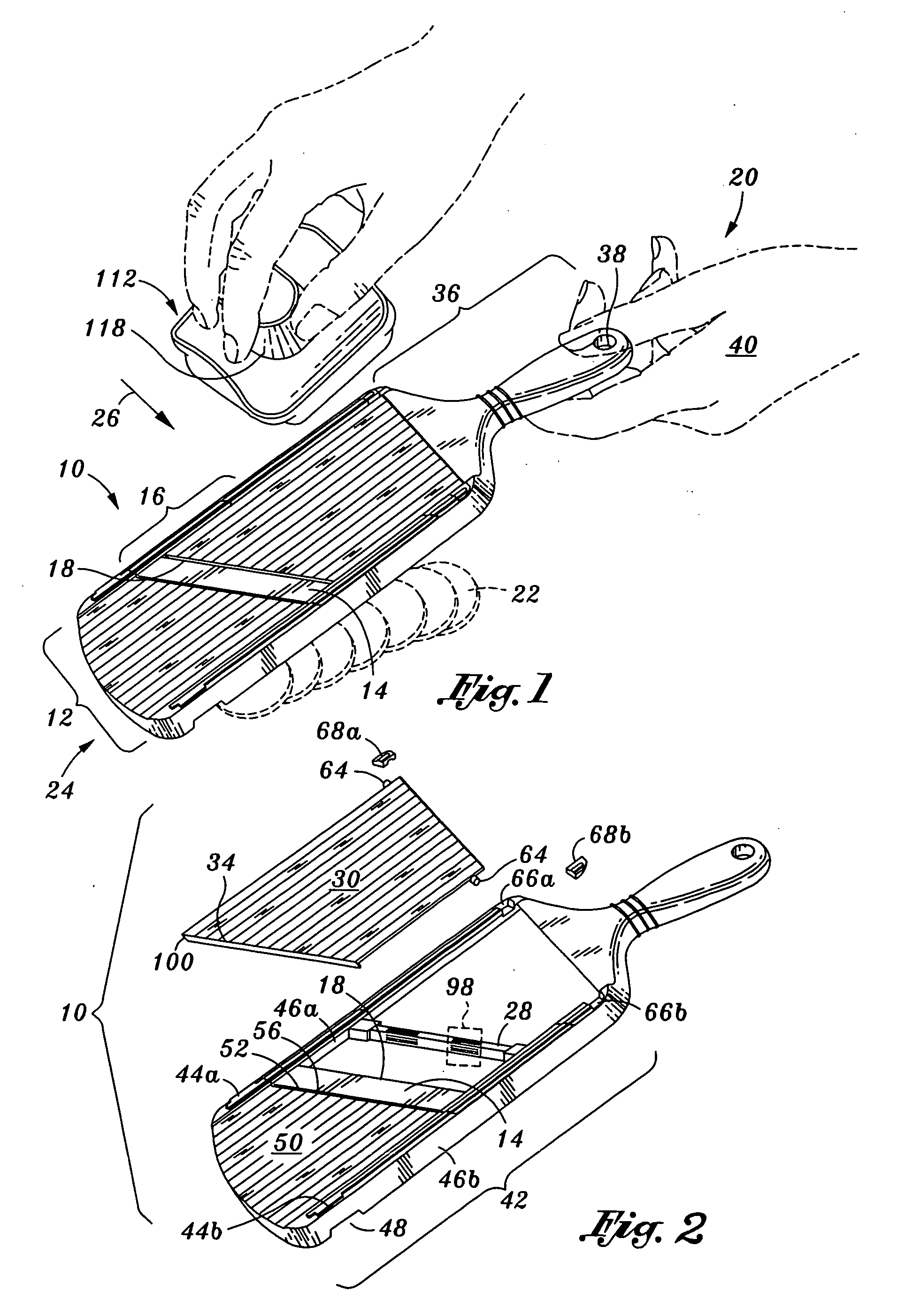

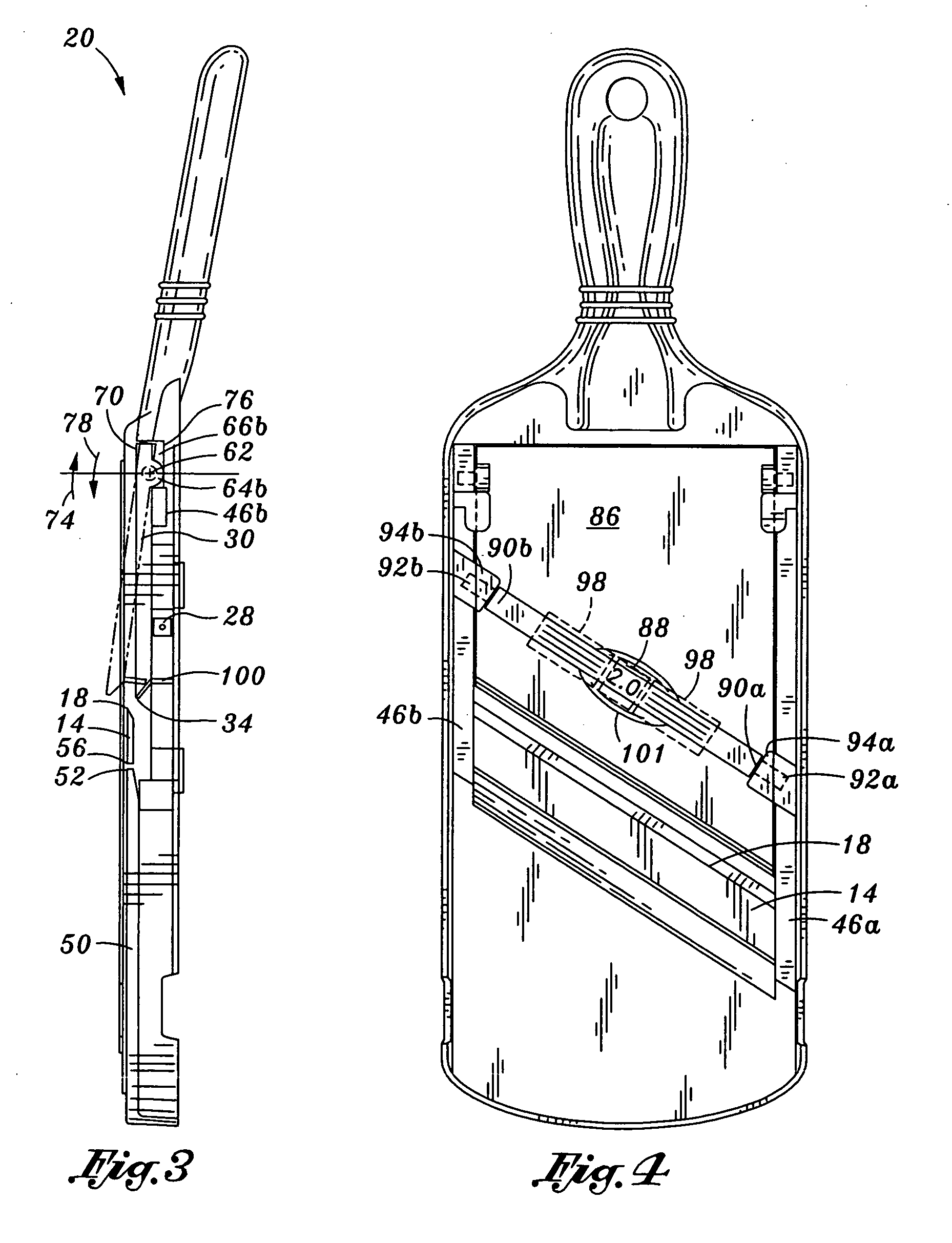

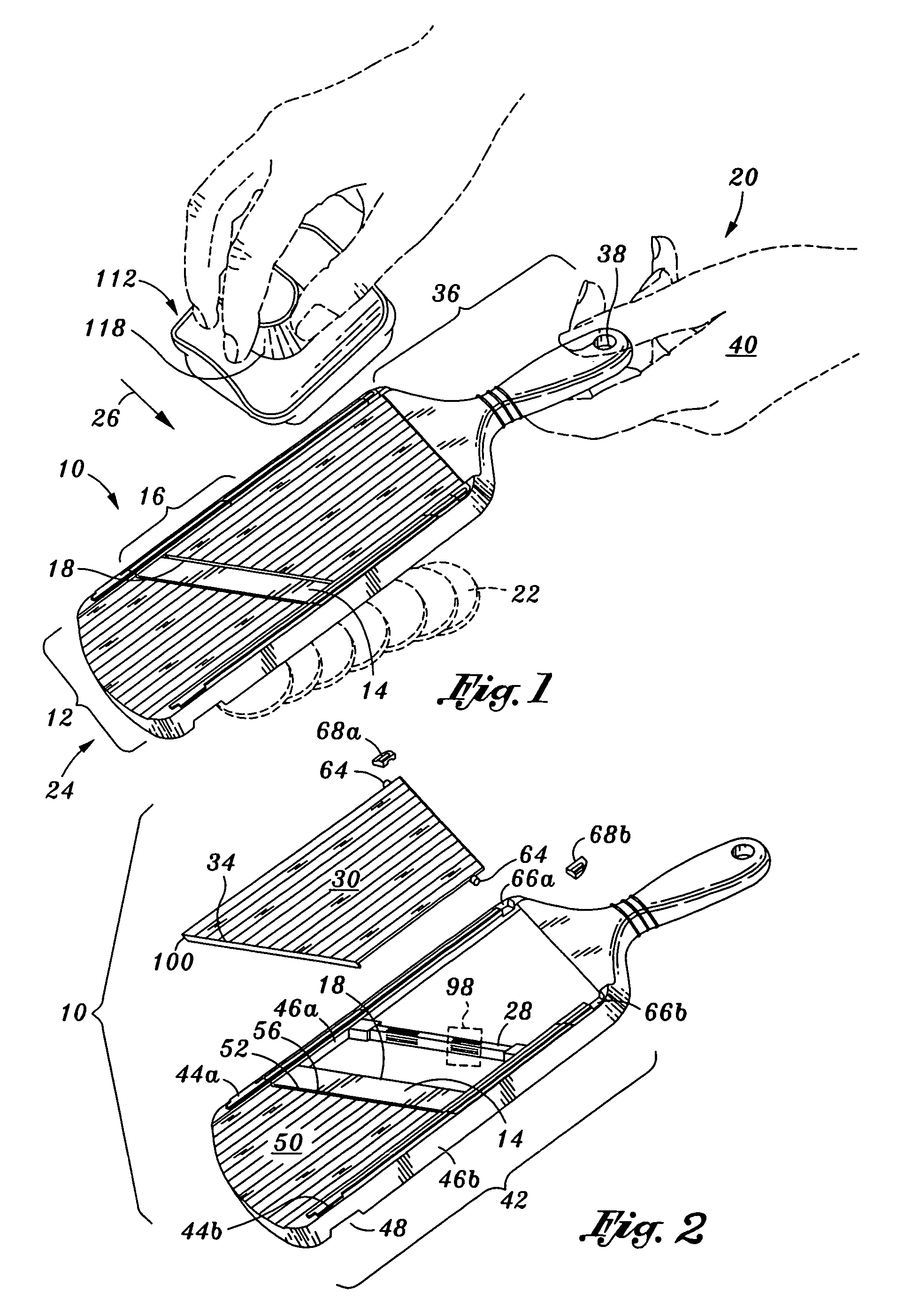

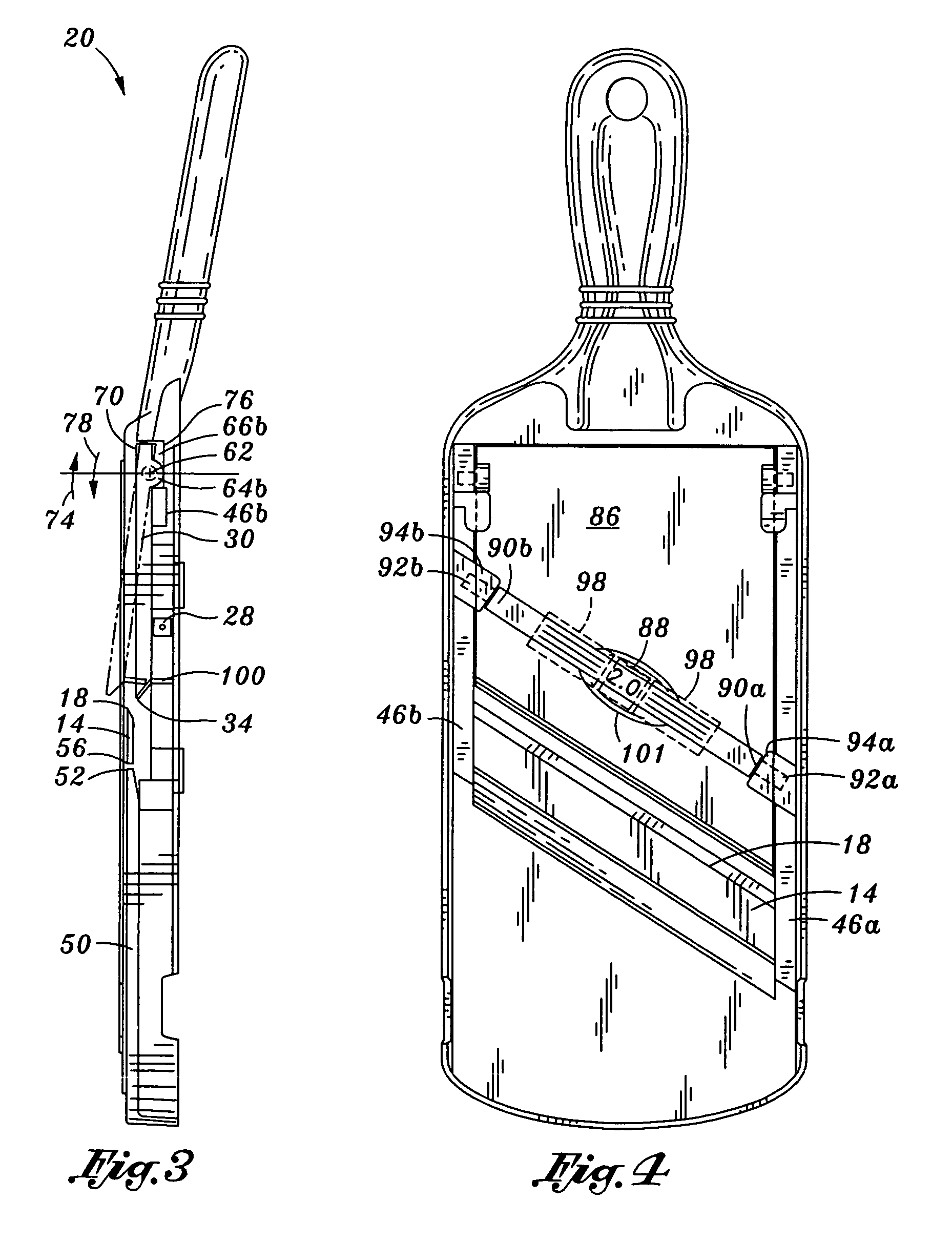

Adjustable slicer

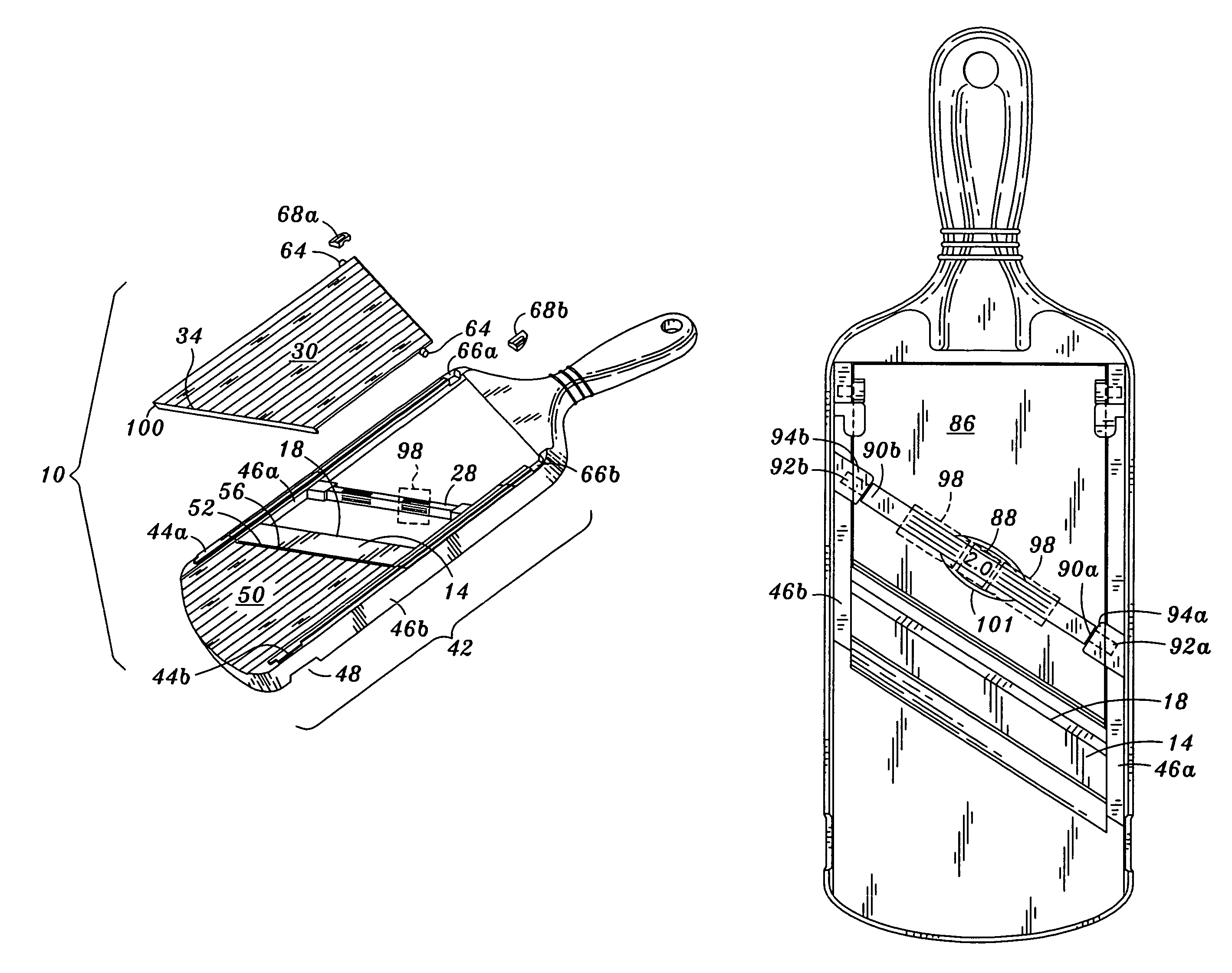

ActiveUS20070062349A1Easy to changeSmooth rotationGang saw millsStock shearing machinesSlice thicknessEngineering

A food slicer for slicing a food product is provided. The slicer may have an adjustable surface and a stationary surface with a blade interposed therebetween. The food product may be sliced with a specific thickness via the blade by traversing the food product from the adjustable surface to the stationary surface. A trailing edge of the adjustable surface and an edge of the blade may define a gap distance which determines a slicing thickness of the food product. A cam may contact an underside of the adjustable surface to set the gap distance. The gap distance may be reset by rotating the cam. More particularly, the cam may have a plurality of cam surfaces. Each of the cam surfaces may have a different distance to a rotating axis of the cam. The gap distance may be changed by rotating the cam such that a different cam surface contacts the adjustable surface's underside.

Owner:KYOCERA CORP

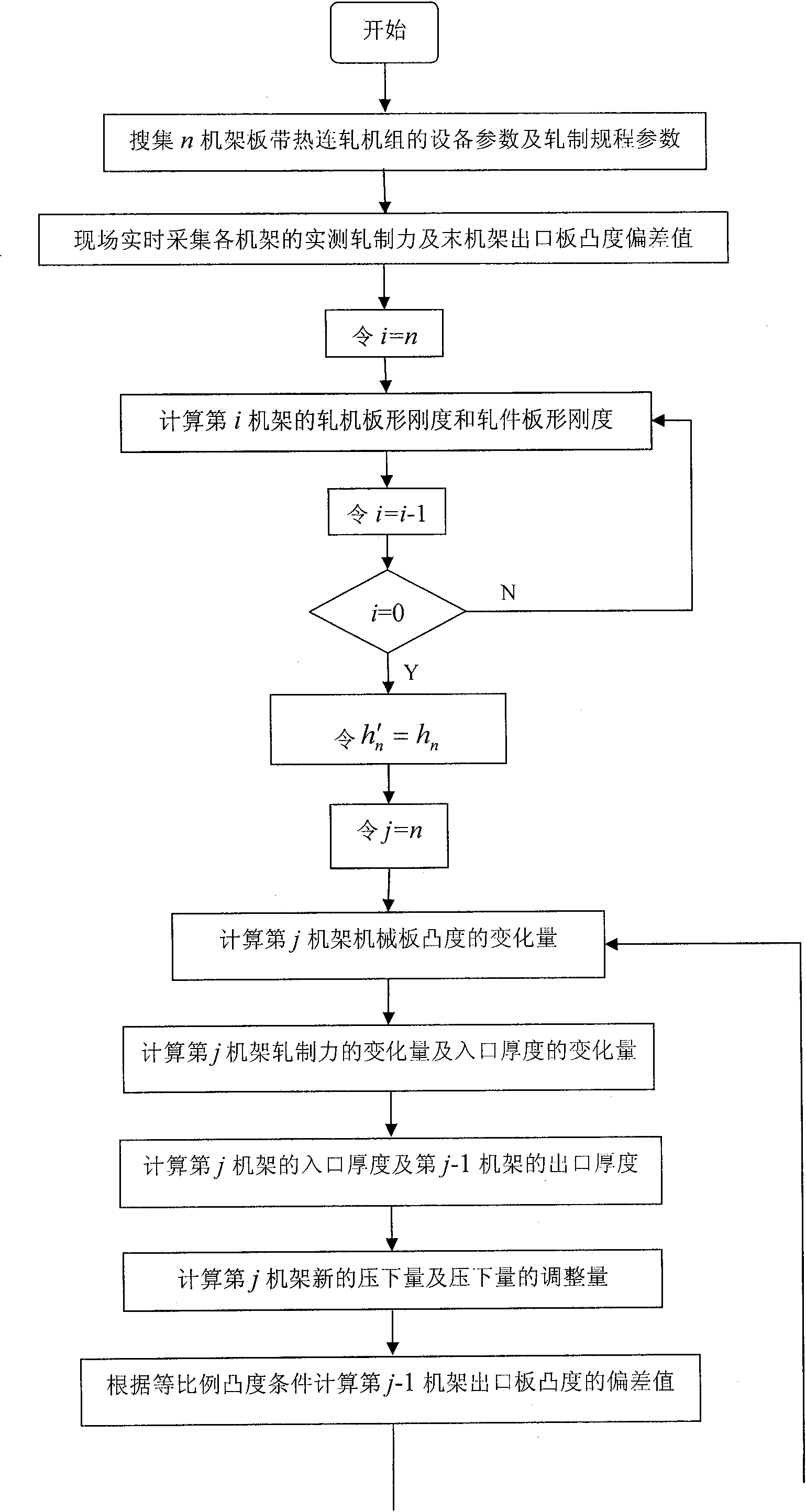

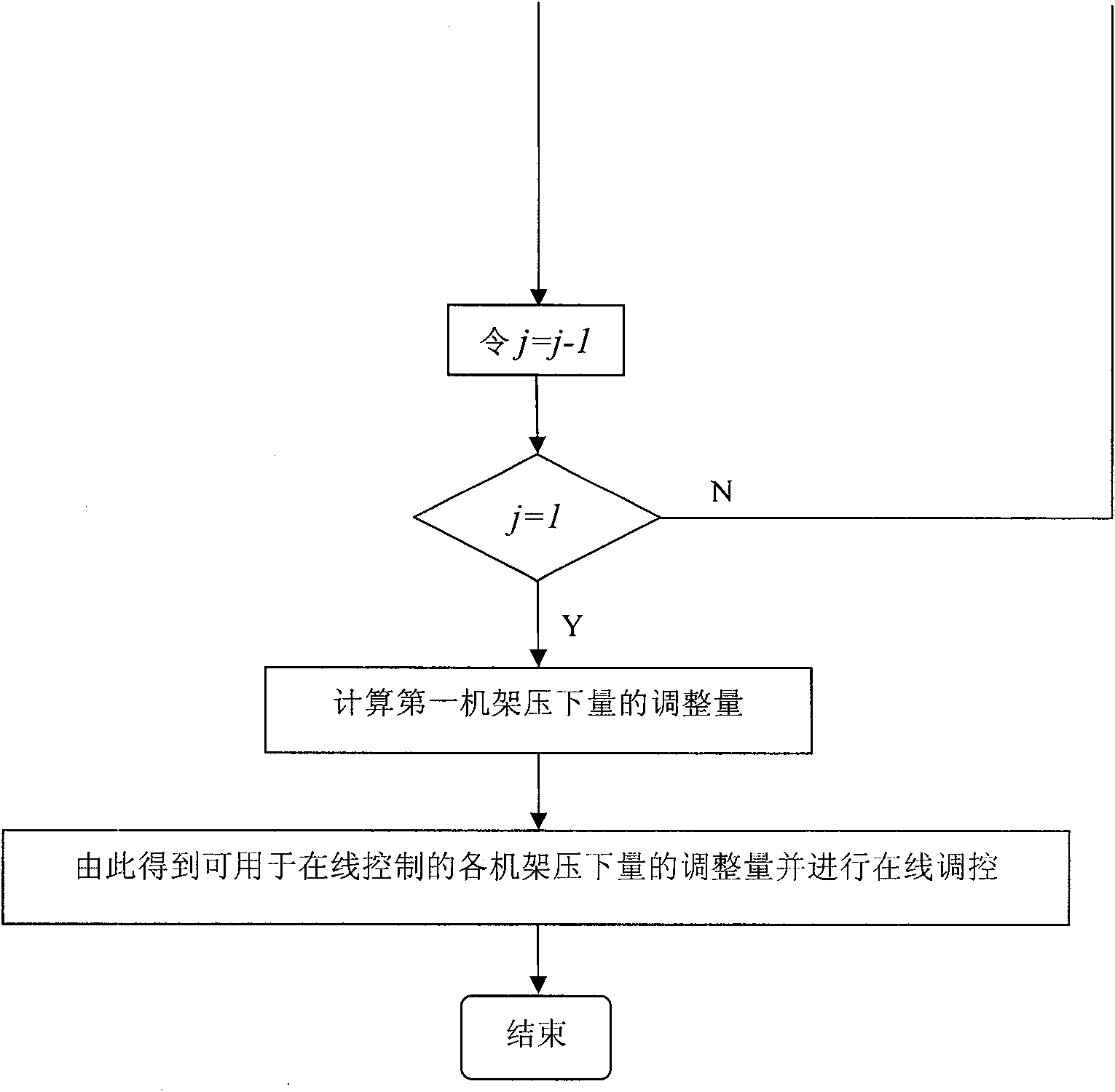

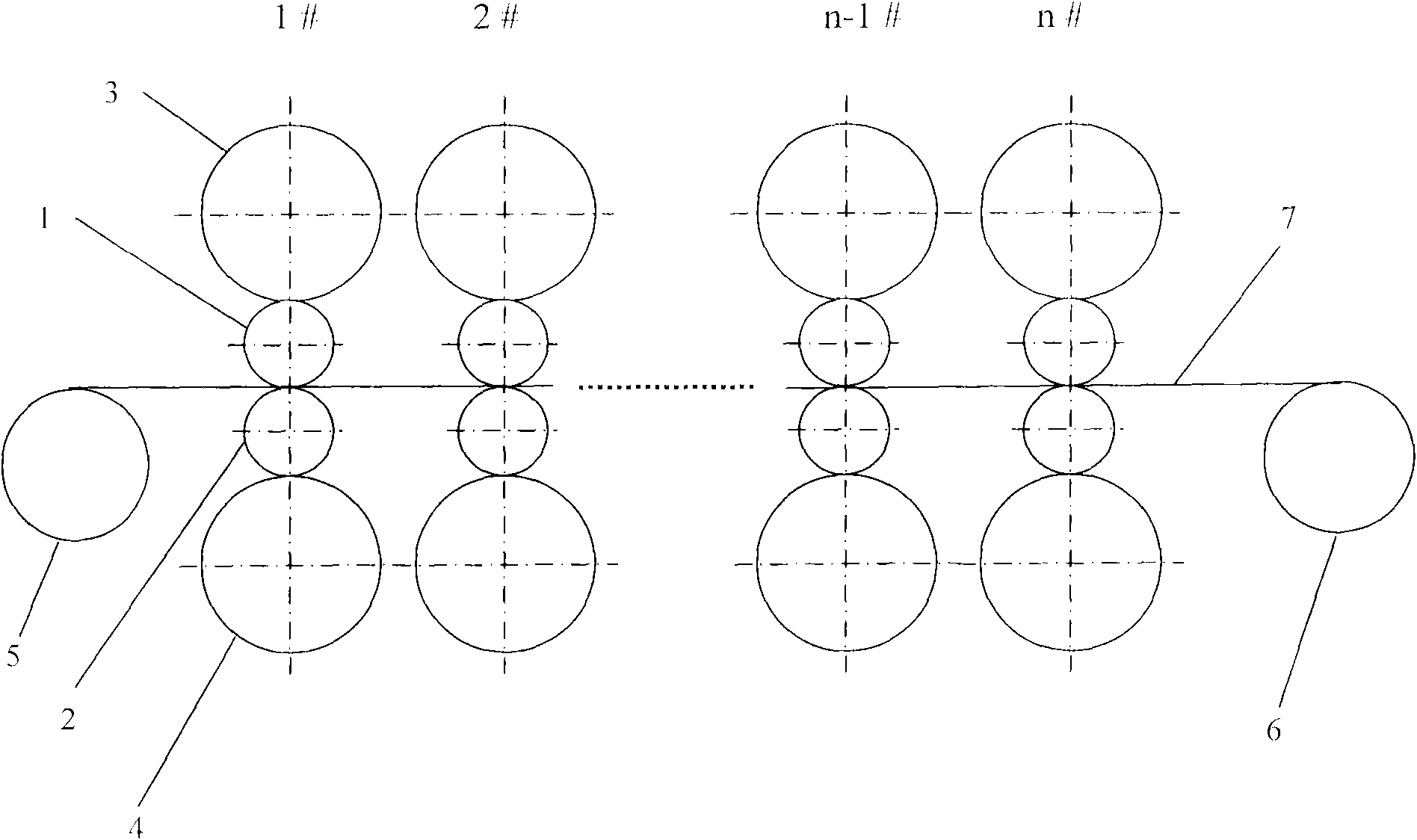

On-line coordination control method for plate shape and plate thickness of strip tandem hot continuous rolling mill

InactiveCN101890433ALower control costsSimple control methodRoll force/gap control deviceProfile control deviceSlice thicknessEngineering

The invention discloses an on-line coordination control method for the plate shape and plate thickness of a strip tandem hot continuous rolling mill, belonging to the technical filed of hot continuous rolling of sheets and strips. The method is characterized by comprising the following steps: (1) collecting n rack hot continuous rolling mill equipment and rolling schedule parameters; (2) collecting the roll force and the convexity offset value of a last rack plate in situ; (3) calculating the plate shape stiffness of each rack; (4) keeping the thickness of the outlet of the tail rack to be constant; (5) inversely calculating the convexity variable quantity of the mechanical plate of the i rack from the tail rack; (6) calculating the roll force and the variable quality of the thickness of the inlet of the i rack; (7) calculating the thickness of the new inlet and outlet of the i rack; (8) calculating the rolling reduction and adjusted quantity of the i rack; (9) calculating the convexity variable quantity of the outlet plate of the (i-1) rack according to the equi-proportional convexity condition; (10) repeating steps from (5) to (9) to obtain the rolling reduction and adjusted quantities of 2nd to n racks; (11) calculating the rolling reduction and adjusted quantity of the first rack; and (12) carrying out on-line coordination control according to the rolling reduction and adjusted quantities, thereby achieving the purpose of coordination control on the plate shape and plate thickness.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Knife arrangement for minimizing feathering during high speed cutting of food products

InactiveUS20050000344A1Minimize pressure appliedPrecise consistencyMetal working apparatusSlice thicknessKnife cuts

A cutting wheel using knives with slice thickness gauging surfaces defining, with the knife cutting edges, a thickness dimension of sliced food products and a throat dimension measured perpendicular to the wheel cutting plane between each knife cutting edge and the terminal edge of the adjacent gauging surface, wherein the knives each have a single primary bevel extending practically tangent to the cutting plane on the side of the knife facing towards the cutting plane and a smooth transition area on the opposite side of the knife, and the ratio of throat dimension to slice thickness dimension is equal to or more than 1 to 1.7.

Owner:URSCHEL LAB

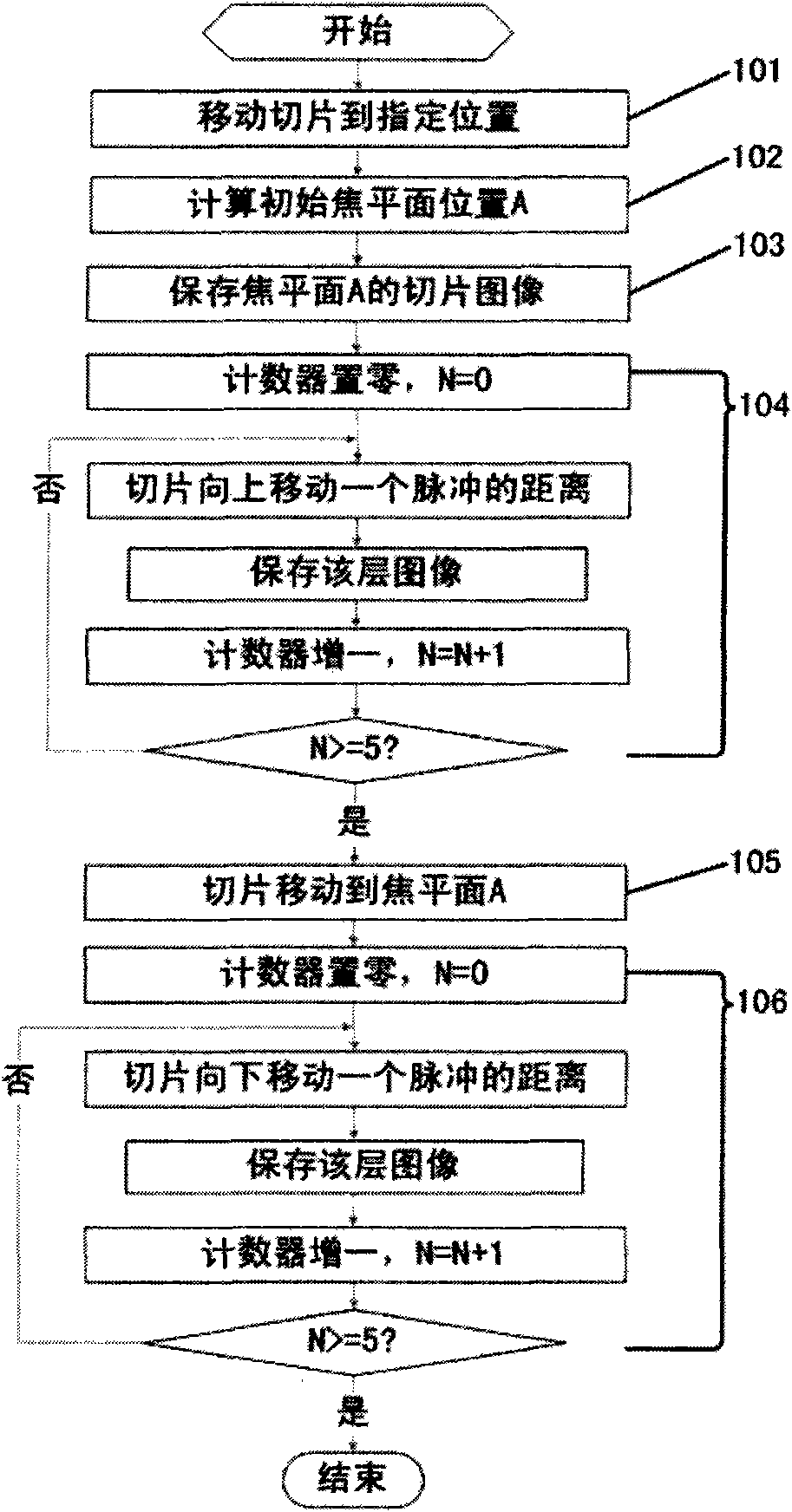

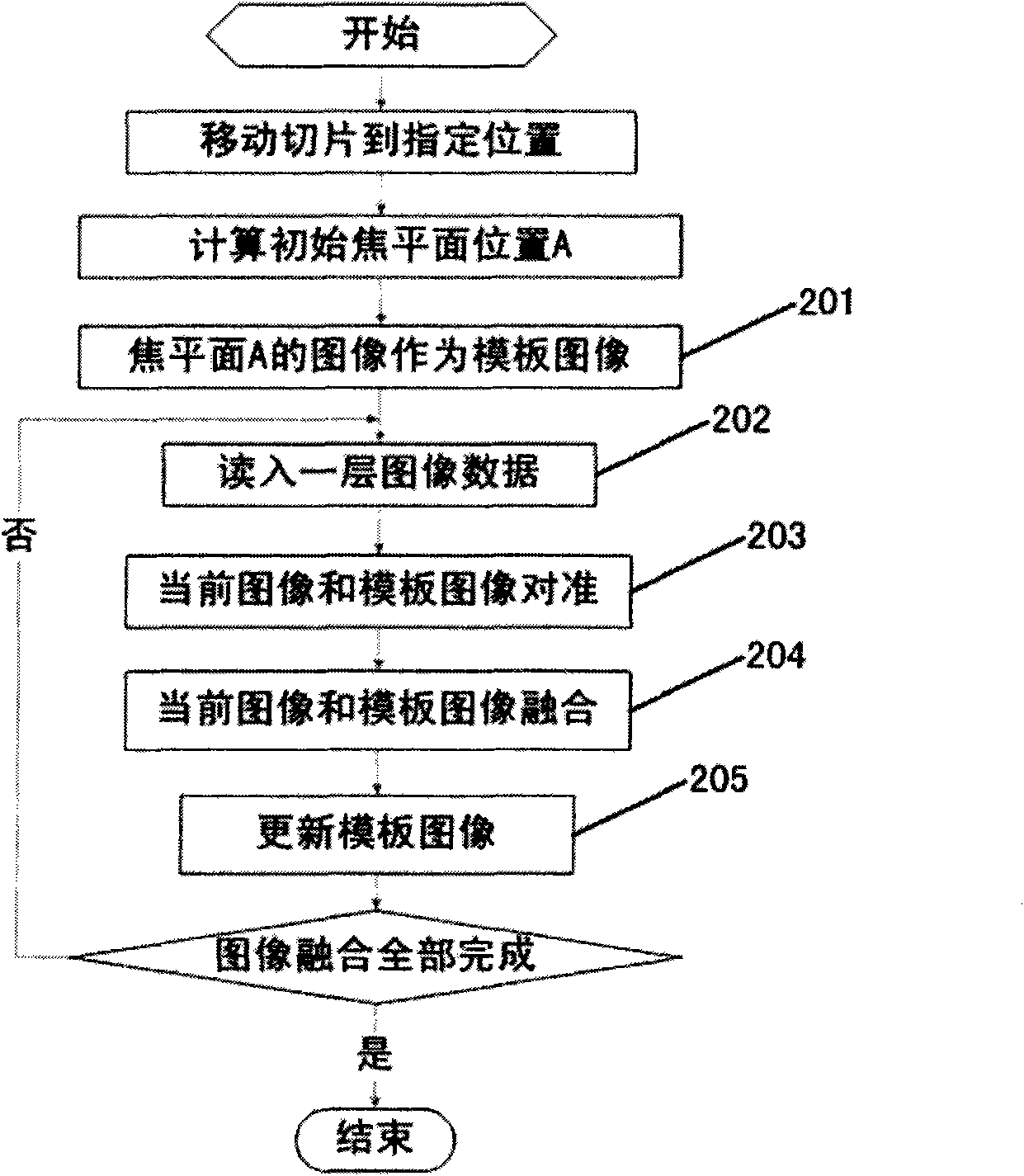

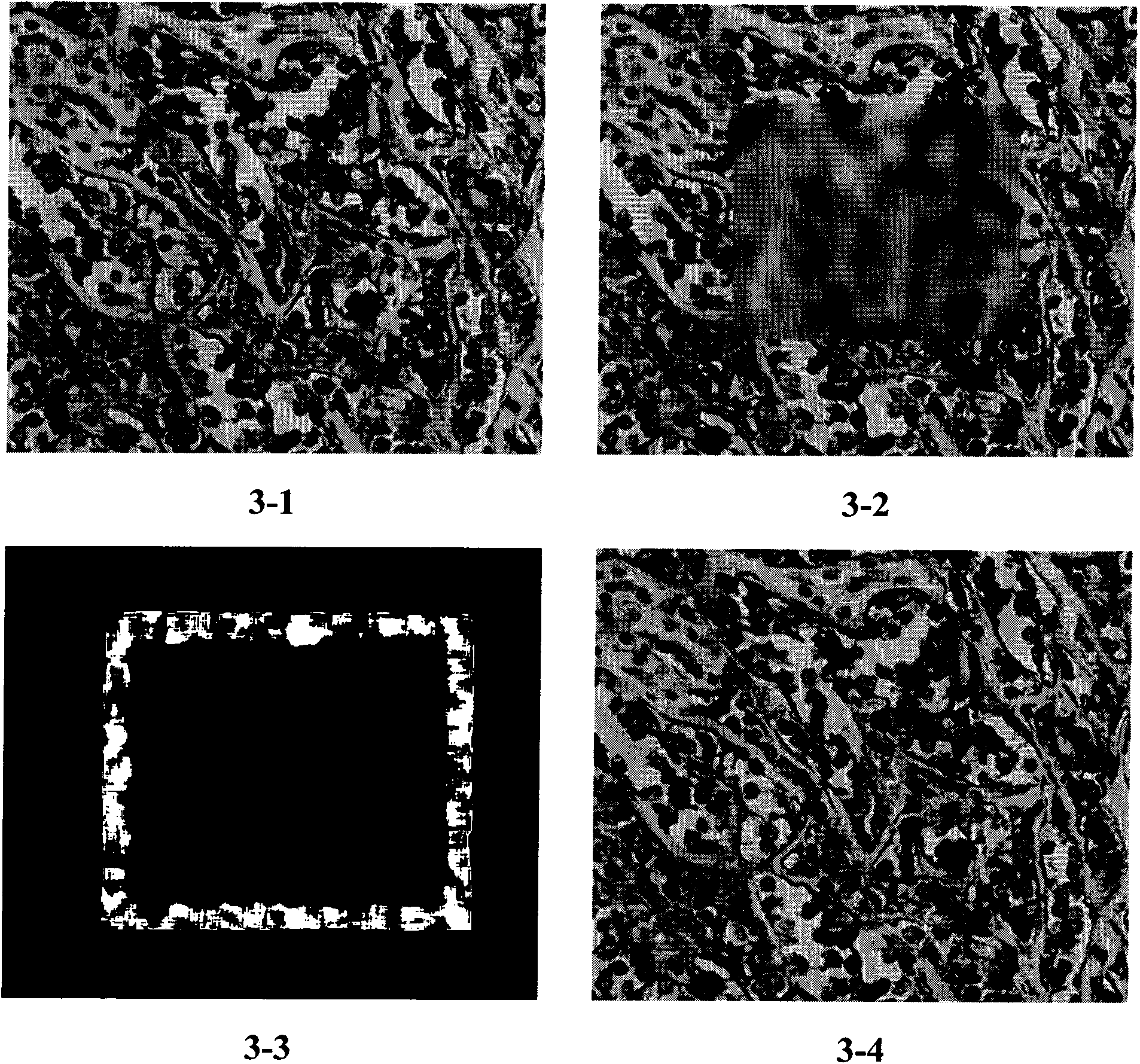

Three-dimensional acquisition of biopsy tissues and fusion method of multilayer images

ActiveCN101615289AHigh precision requirementsReduce omissionsImage enhancementSurface/boundary effectSlice thicknessTissue characterization

The invention discloses three-dimensional acquisition of biopsy tissues and a fusion method of multilayer images after acquisition. During three-dimensional acquisition of the biopsy tissues, the position of the initial focalplane is taken as the center, multilayer image acquisition is carried out on the update positions within the range of biopsy thickness and simultaneously the biopsy image on each layer is stored. The multilayer images of the invention adopt a partitioned area fusion method; based on the definition of the pixels in the images, the areas with relatively high definition in the images to be fused are selected and the template images are updated to finally achieve the purpose of optimizing the definition of the image of the whole biopsy. At the same time, a method of assignment weight is adopted to smoothen the pixel points in the boundary areas, thereby effectively inhibiting false edges. Being adopted, the method of the invention improves the reproduction accuracy of the digital images towards the characteristics of the biopsy tissues. The invention effectively alleviates the workload of the doctors and provides a basis for remote diagnosis.

Owner:苏州优纳医疗器械有限公司

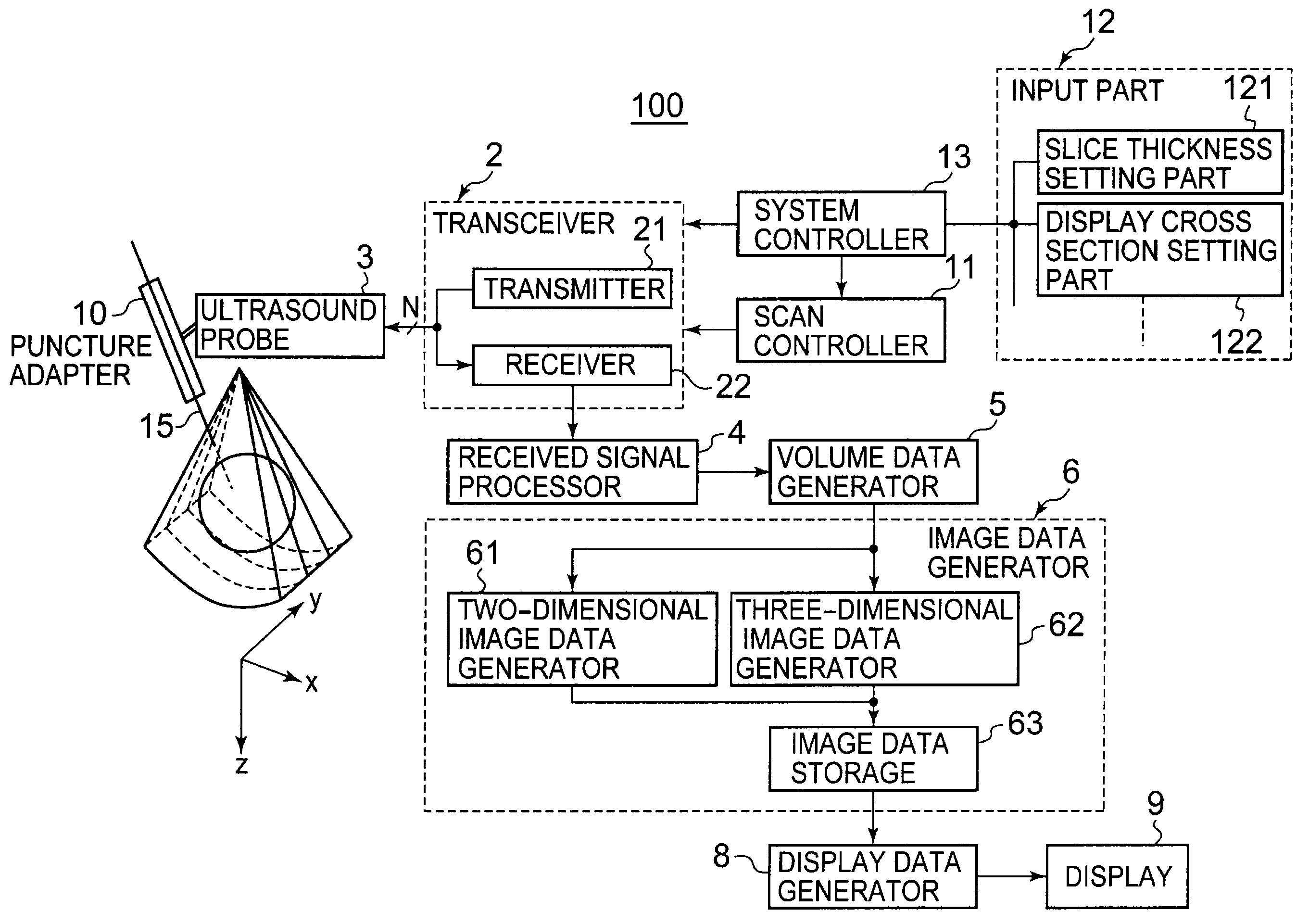

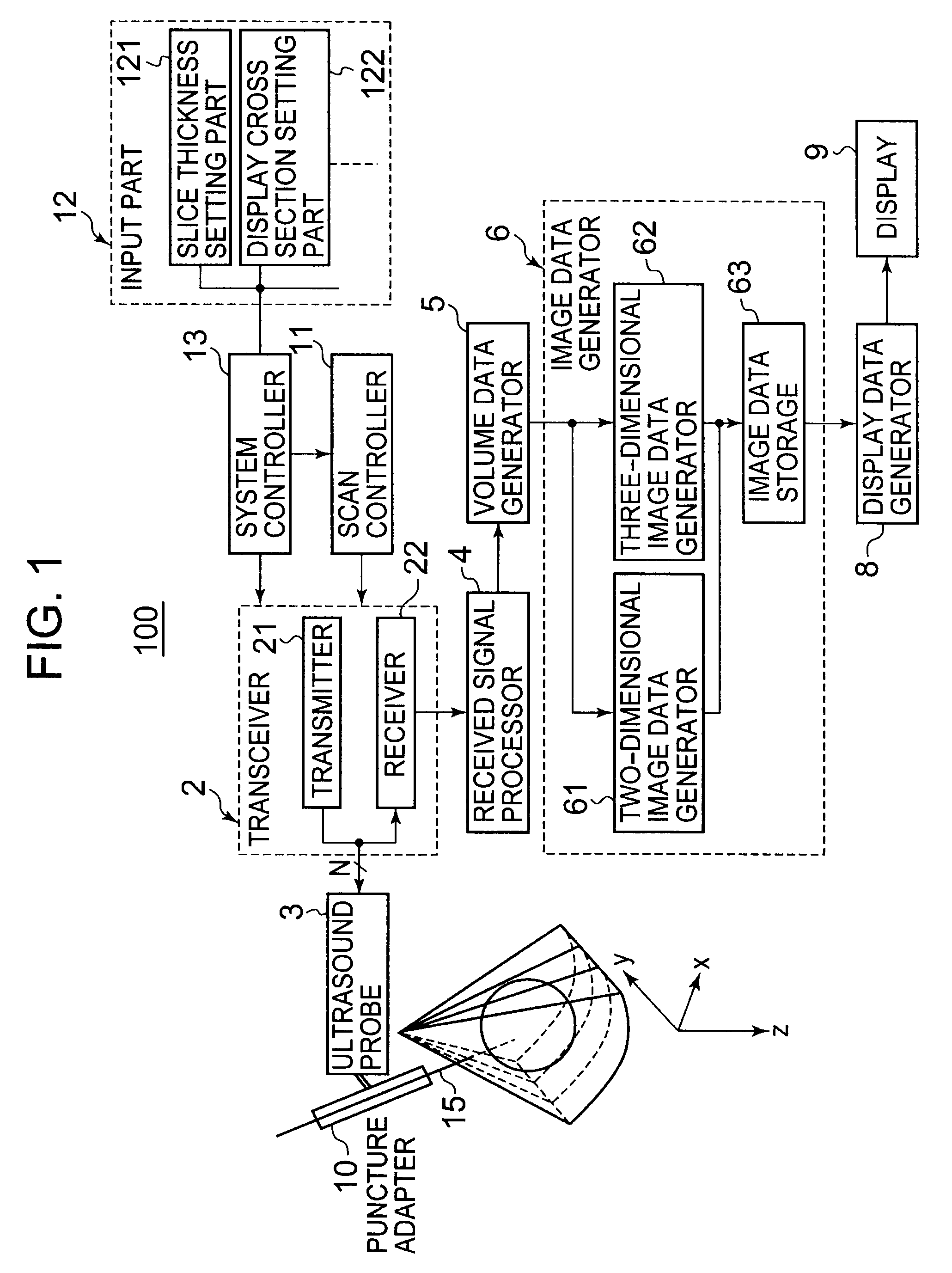

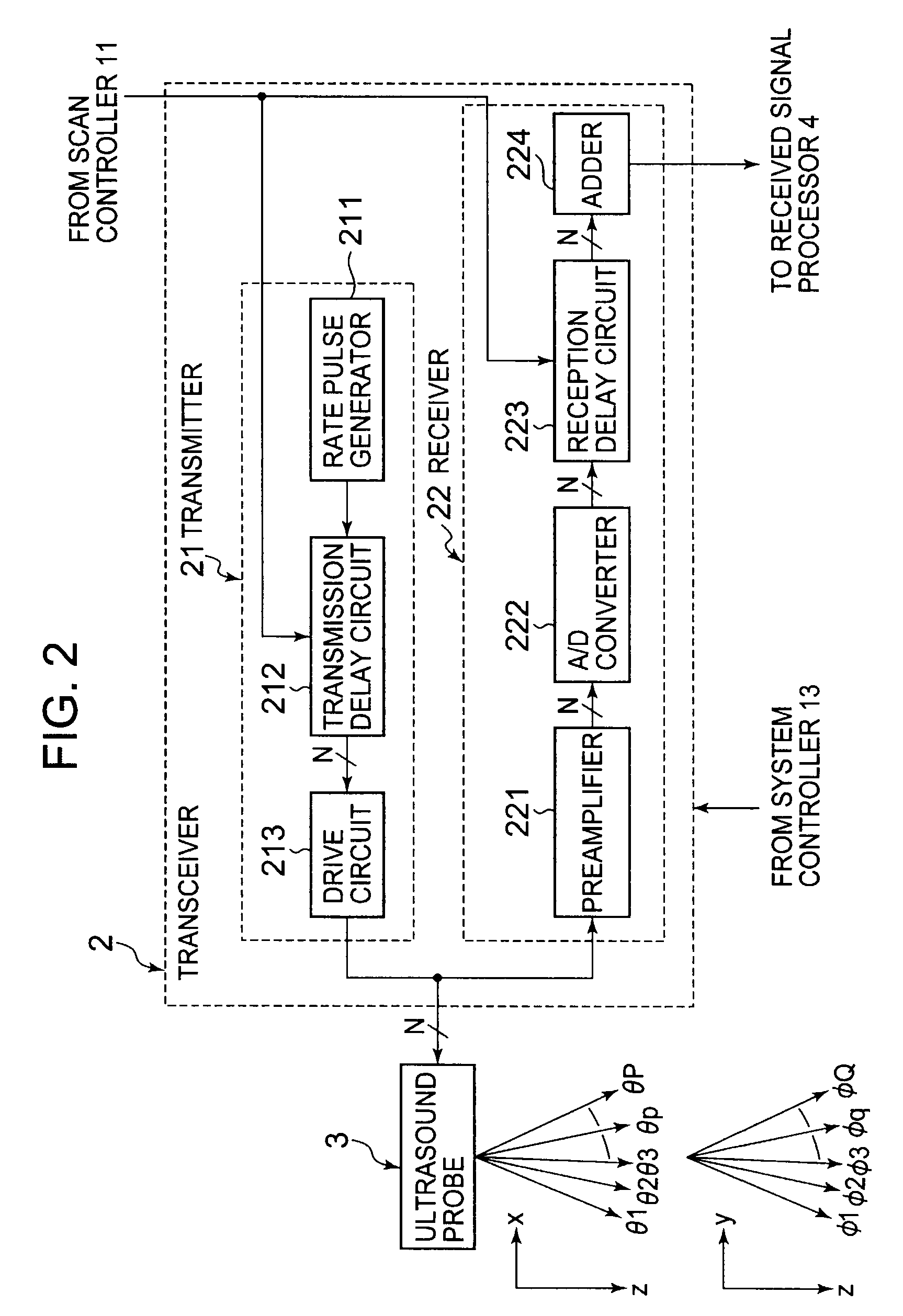

Ultrasound imaging apparatus and method for generating ultrasound image

InactiveUS20090306511A1Improve time resolutionAccurate insertionBlood flow measurement devicesSurgical needlesUltrasound imagingSlice thickness

For a three-dimensional region including a treatment target site of a patient, a puncture needle scanning region R1 having a slice thickness d1 is set with reference to a cross section (a puncture cross section) including an insertion direction of a puncture needle. Subsequently, in the y-direction substantially perpendicular to the puncture cross section, two treatment target scanning regions R2 (R21 and R22) each being adjacent to the puncture needle scanning region R1 and having a slice thickness d2 are set. Then, based on volume data in the puncture needle scanning region R1 acquired by first three-dimensional scan with ultrasound waves and volume data in the treatment target scanning regions R2 acquired by second three-dimensional scan performed at a lower volume rate than the first three-dimensional scan, image data is generated for the purpose of supporting puncture.

Owner:TOSHIBA MEDICAL SYST CORP

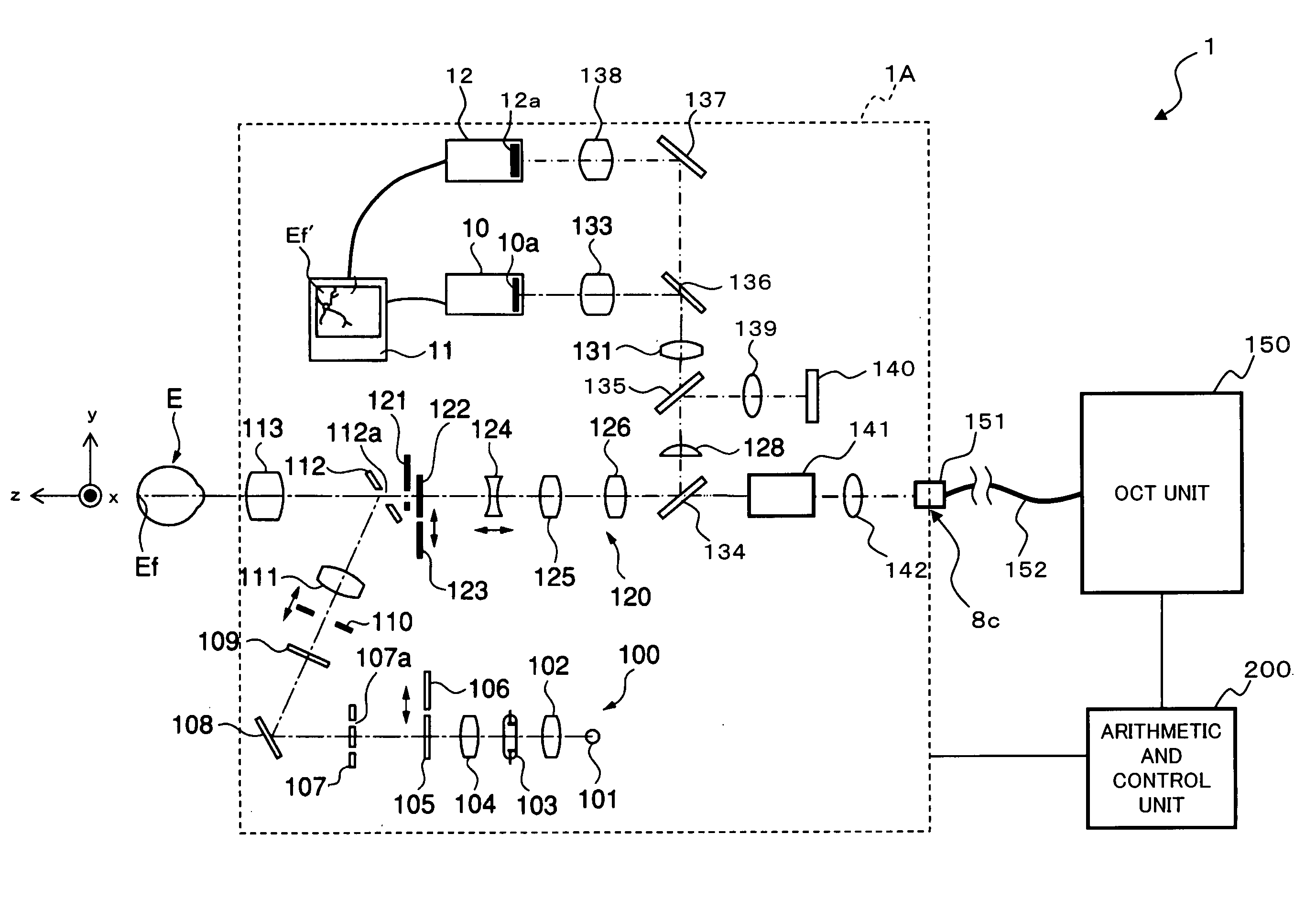

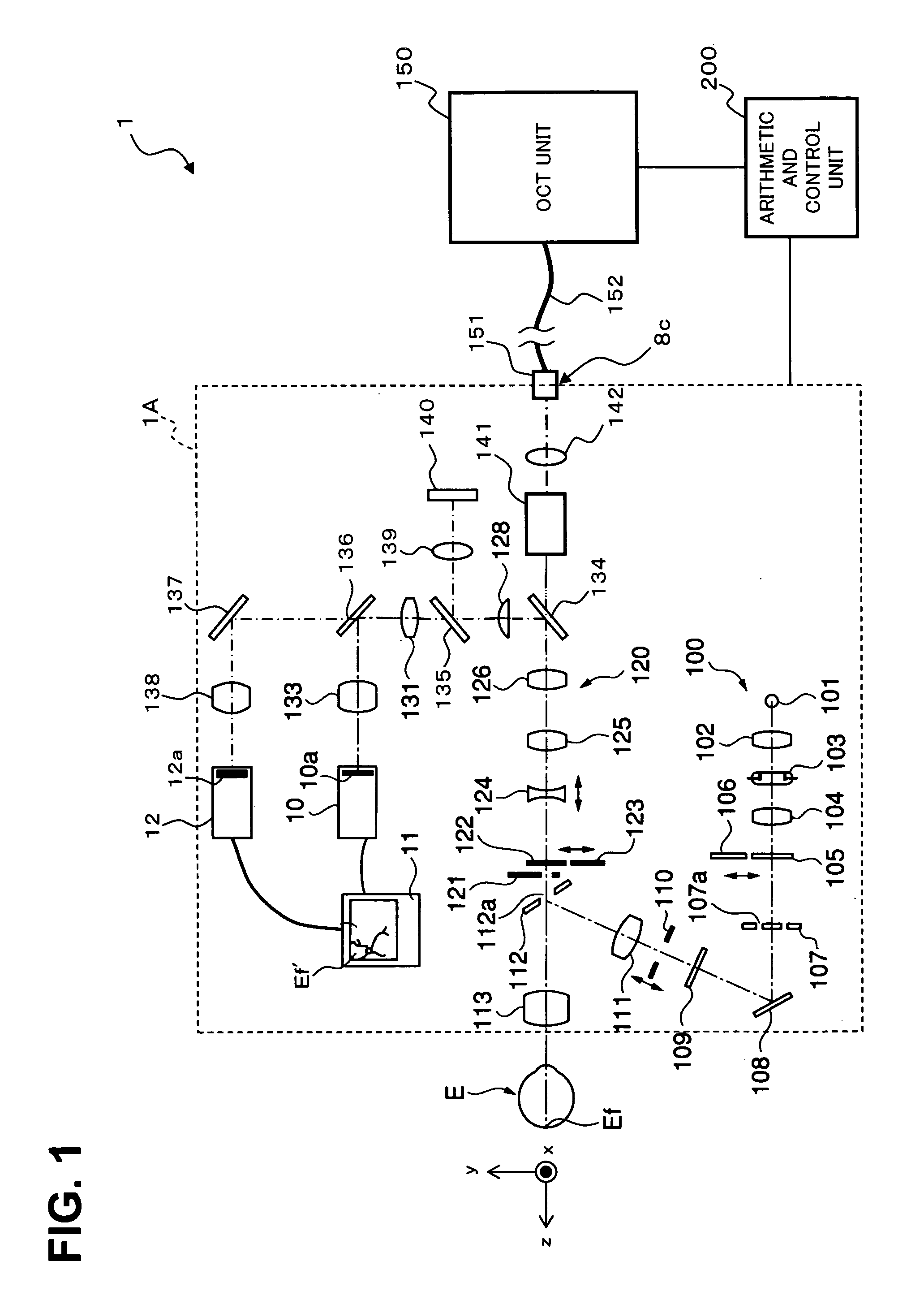

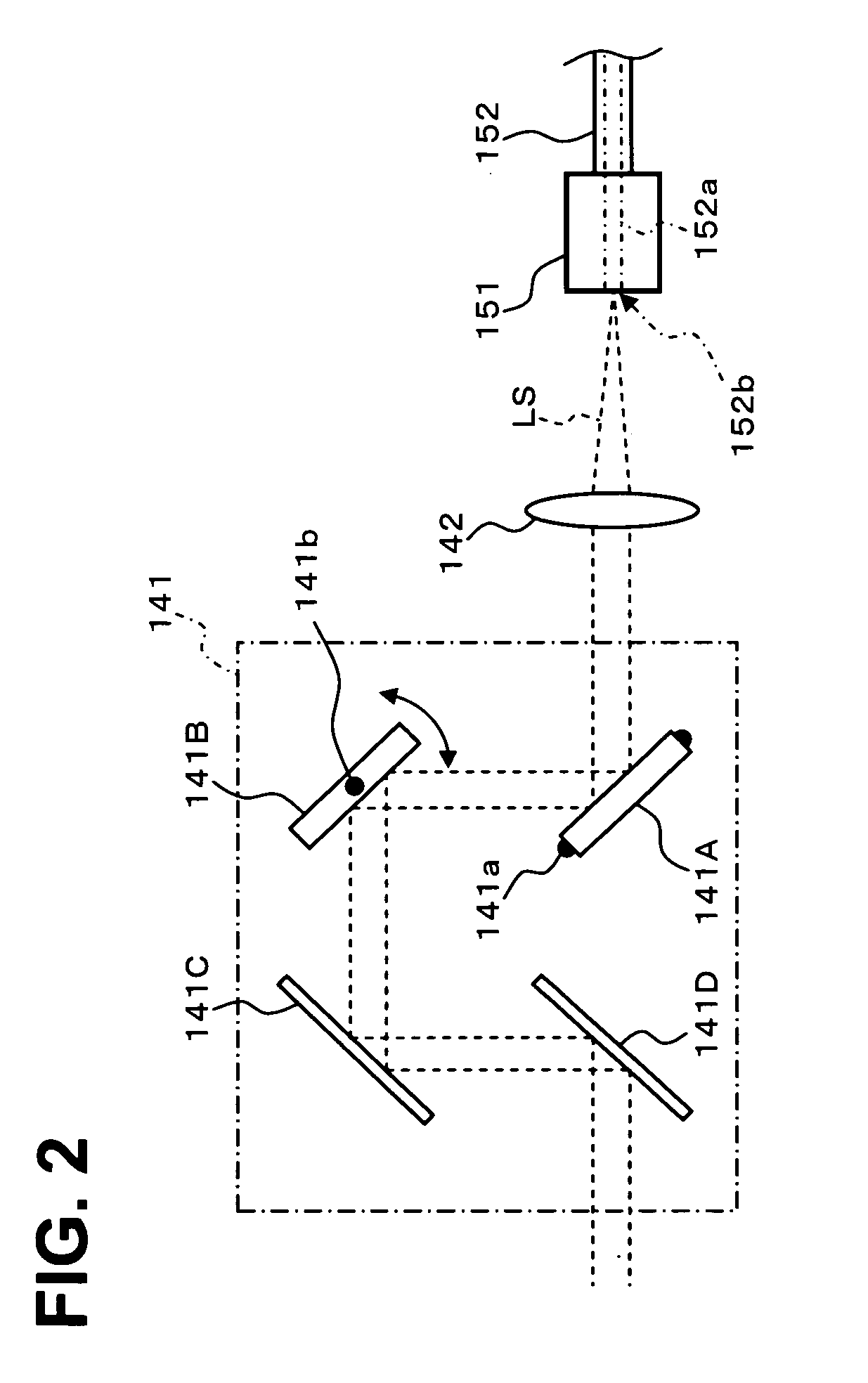

Ophthalmologic information processing apparatus and ophthalmologic examination apparatus

An ophthalmologic examination apparatus 1 projects a light onto a fundus oculi, detects the reflected light thereof, and forms a 3-dimensional image that represents the morphology of a retina based on the detected results. A stimulation-position specifying part 233 specifies, in the 3-dimensional image, a plurality of stimulation positions that correspond to a plurality of stimulation points Pi in a visual-field examination. A layer-thickness measuring part 235 analyzes the 3-dimensional image to find the layer thickness of the retina at each stimulation position. In addition, a displacement calculation part 234 specifies a related position of the stimulation position. A layer-thickness measuring part 235 finds the layer thickness of the retina at the related position.

Owner:KK TOPCON

Method and system to generate object image slices

InactiveUS20070183564A1Material analysis using wave/particle radiationRadiation/particle handlingProjection imageSlice thickness

A method for creating a variable slice thickness for displaying an imaged object is disclosed. The method includes acquiring a plurality of projection images from a plurality of different projection angles within a defined sweep angle, reconstructing a plurality of object images from the plurality of projection images, each object image having a first slice thickness, and applying a function rule to combine images, whole images or portions thereof or attributes thereof, of the plurality of projection images, of the plurality of object images, or of both, thereby providing for the display of the object utilizing a second slice thickness that varies from the first slice thickness.

Owner:GENERAL ELECTRIC CO

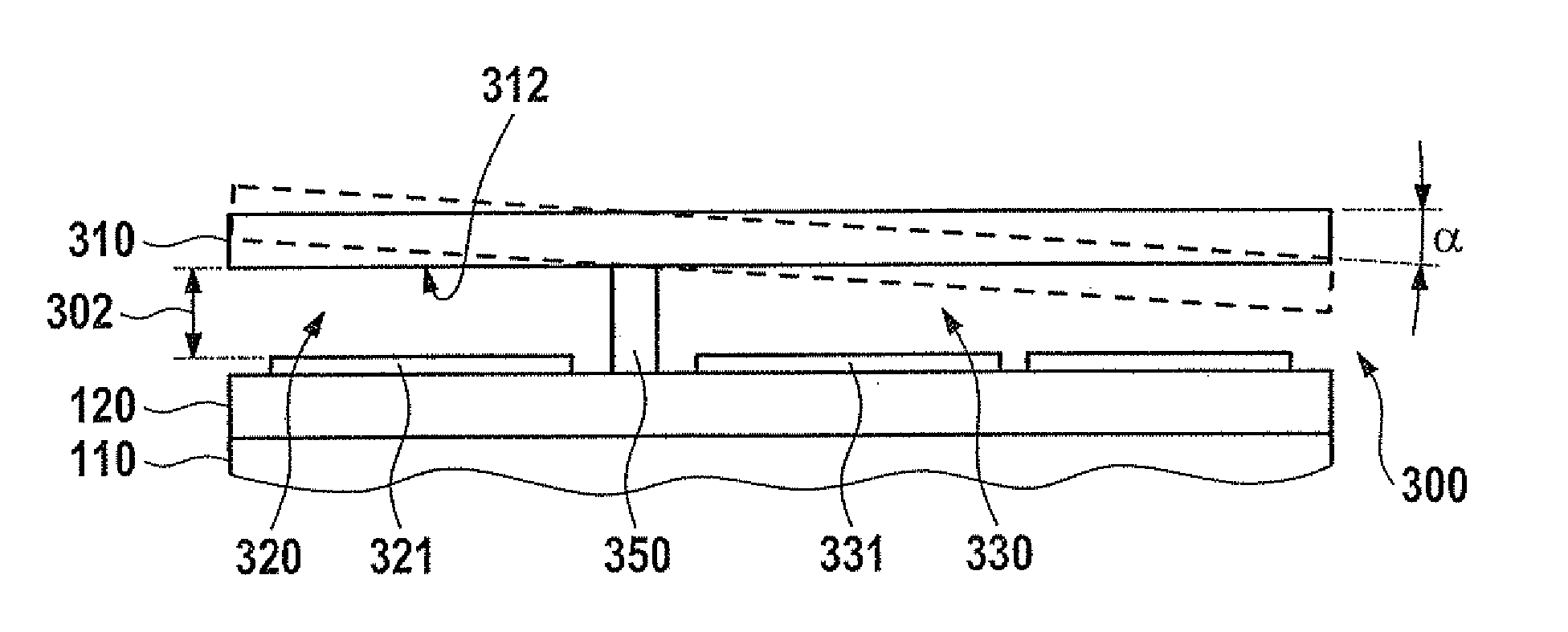

Micromechanical component having a test structure for determining the layer thickness of a spacer layer and method for manufacturing such a test structure

ActiveUS20110296917A1Reduce manufacturing costSimplified determinationResistance/reactance/impedenceAcceleration measurementSeismic massSlice thickness

A micromechanical component is described including a substrate having a spacer layer and a test structure for ascertaining the thickness of the spacer layer. The test structure includes a seismic mass, which is elastically deflectable along a measuring axis parallel to the substrate, a first electrode system and a second electrode system for deflecting the seismic mass along the measuring axis, having a mass electrode, which is produced by a part of the seismic mass, and a substrate electrode, which is situated on the substrate in each case, the first electrode system being designed to be thicker than the second electrode system by the layer thickness of the spacer layer.

Owner:ROBERT BOSCH GMBH

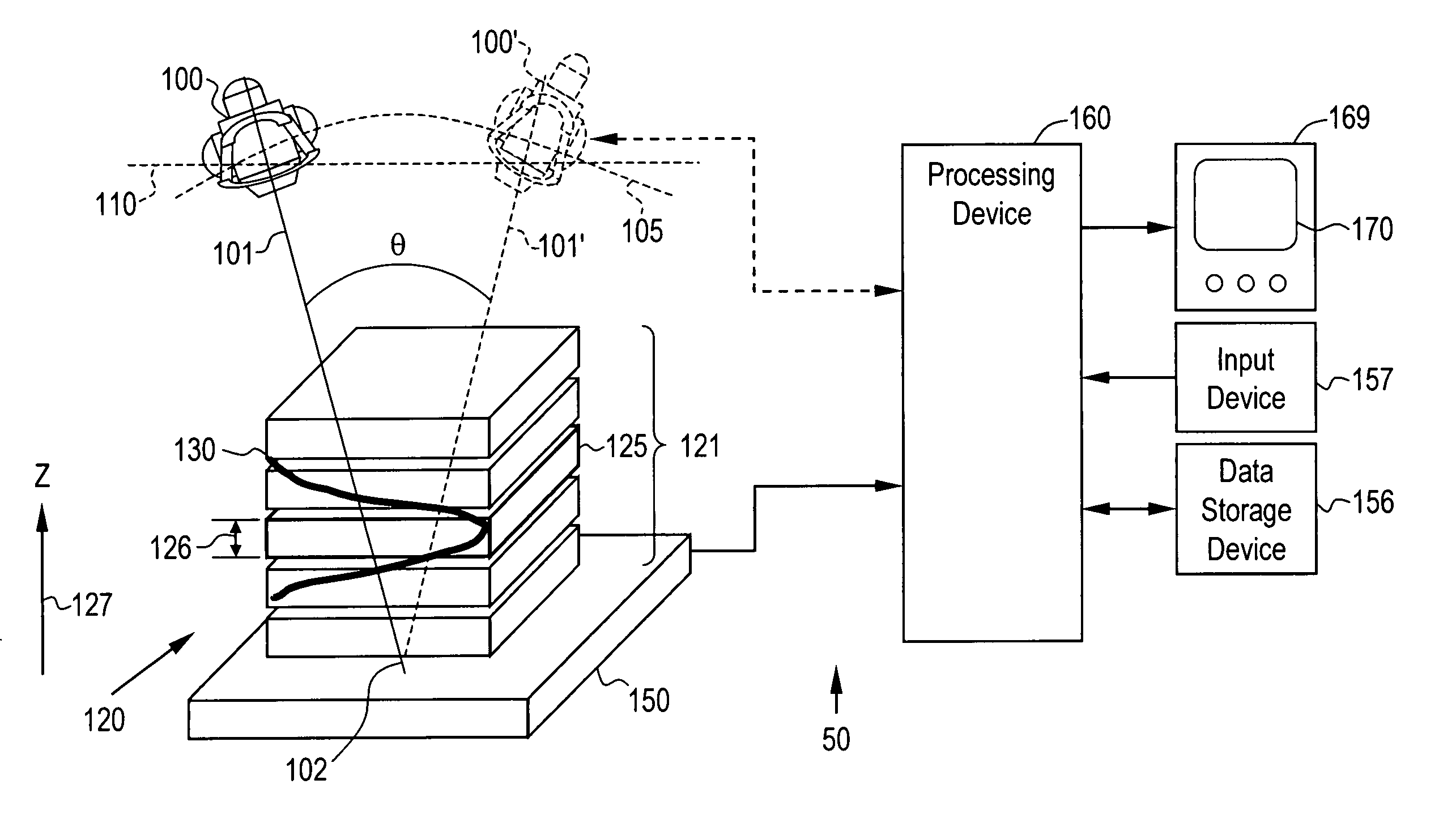

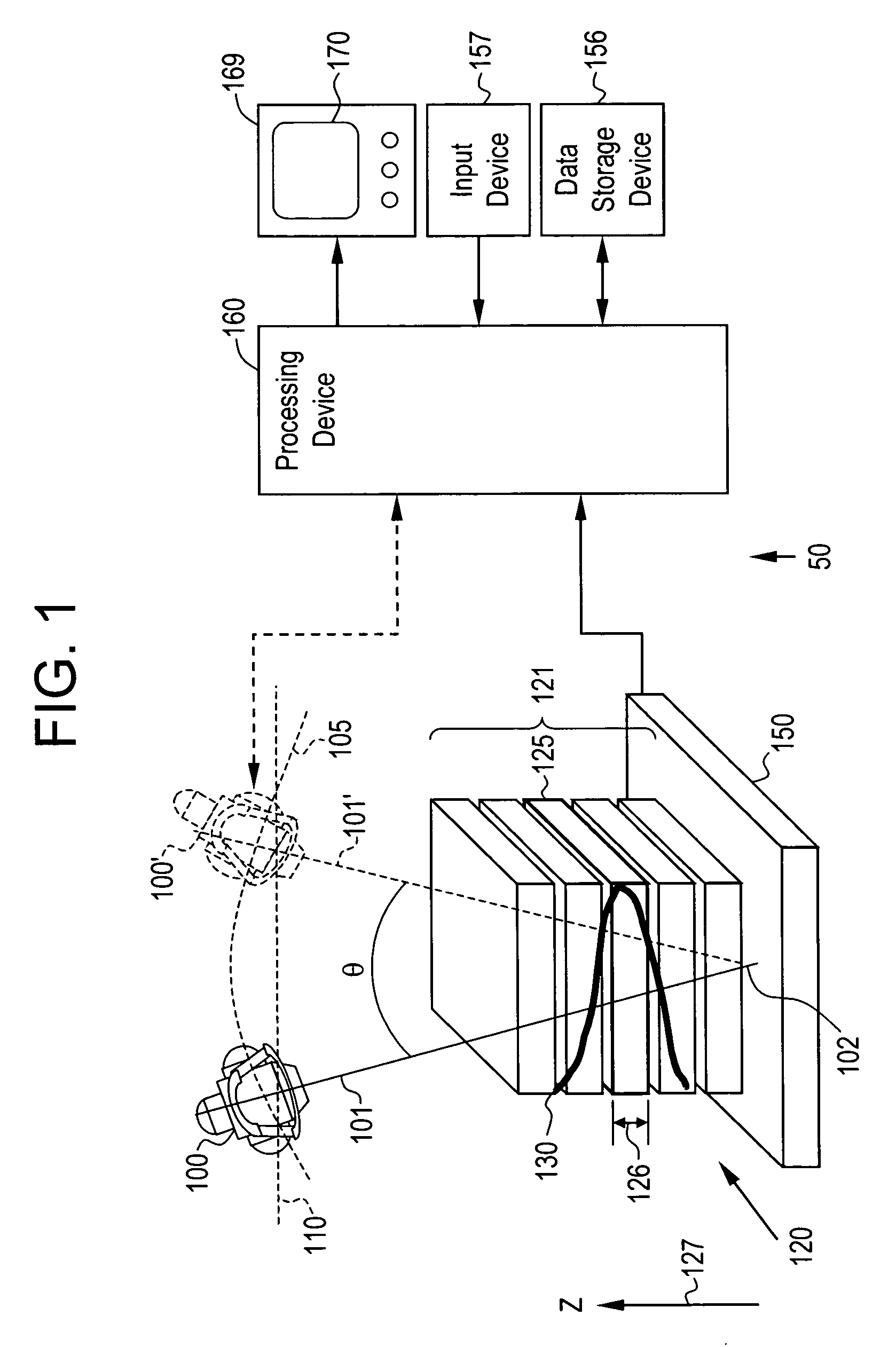

Multi modality imaging methods and apparatus

ActiveUS7348564B2Material analysis by optical meansCalibration apparatusUltrasound attenuationComputed tomography

Owner:GENERAL ELECTRIC CO

Additive manufacturing method

InactiveCN107470623AGuaranteed forming accuracyGuarantee forming qualityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSlice thickness

The invention discloses an additive manufacturing method. The additive manufacturing method comprises the following steps of slicing, specifically, a three-dimensional model of a component is sliced with the slicing thickness of 10-30 [mu]m; path planning, specifically, a scanning path is planned according to two-dimensional information obtained through slicing; powder laying and printing, specifically, in a shielding gas atmosphere, powder is laid on a substrate, a laser beam is controlled to melt the powder along the planned path, and the powder is laid layer by layer and molten so as to accumulate into the component; and cooling and annealing heat treatment of the printed component. The additive manufacturing method is suitable for a selective laser melting additive manufacturing technique adopting rough granular powder under the condition that the forming quality and performance index of the component are not reduced.

Owner:ADVANCED FOR MATERIALS & EQUIP

Slicer

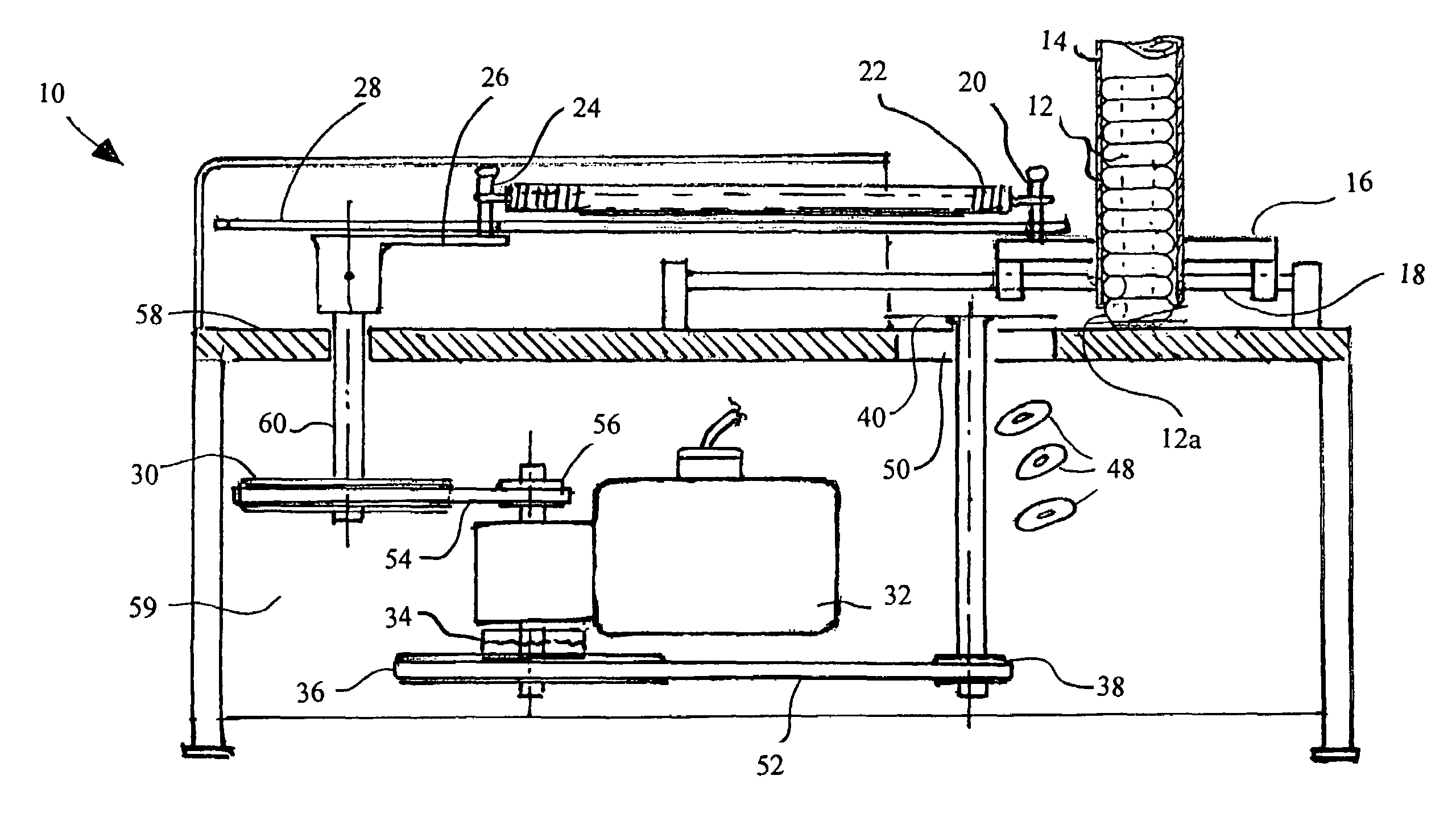

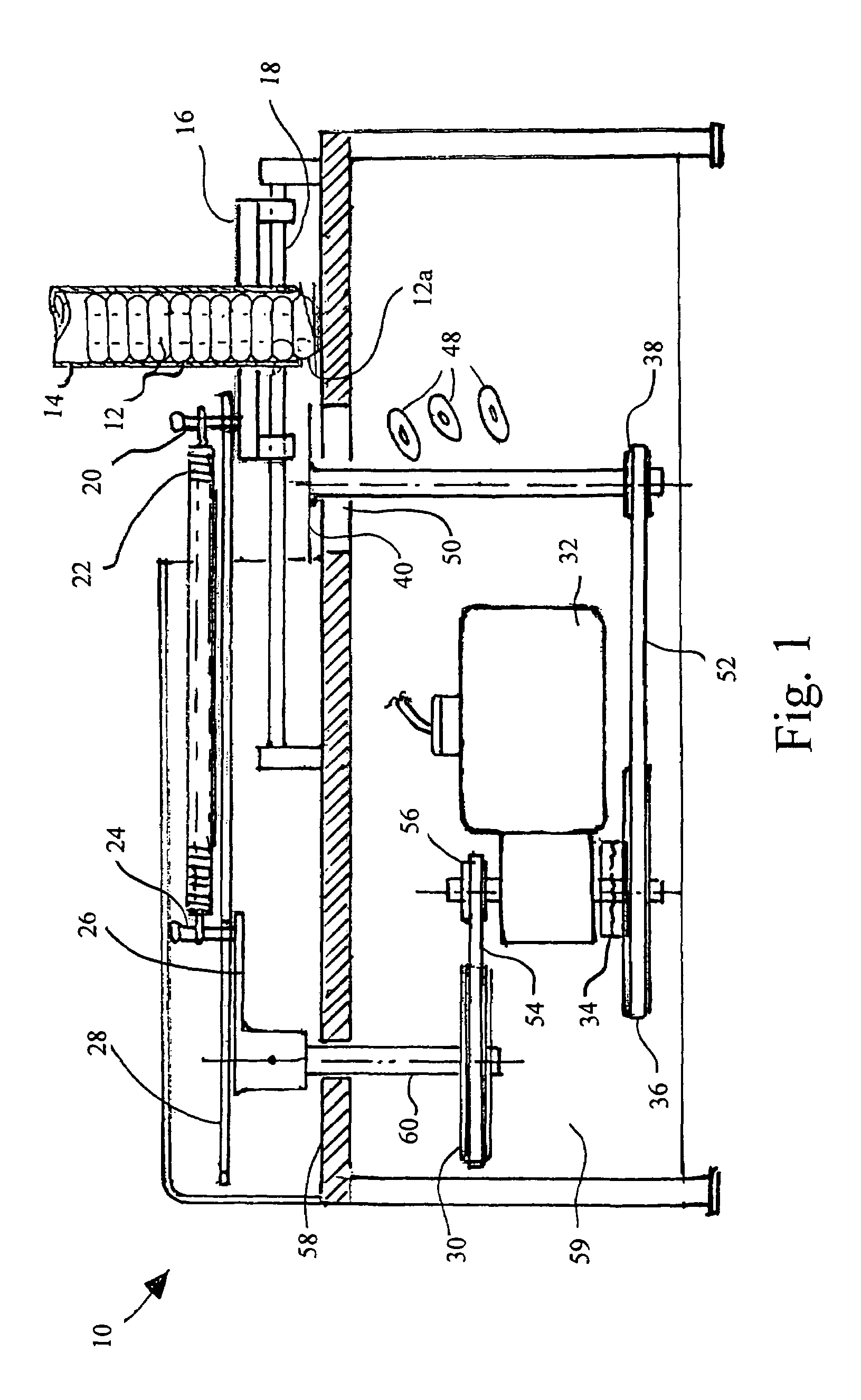

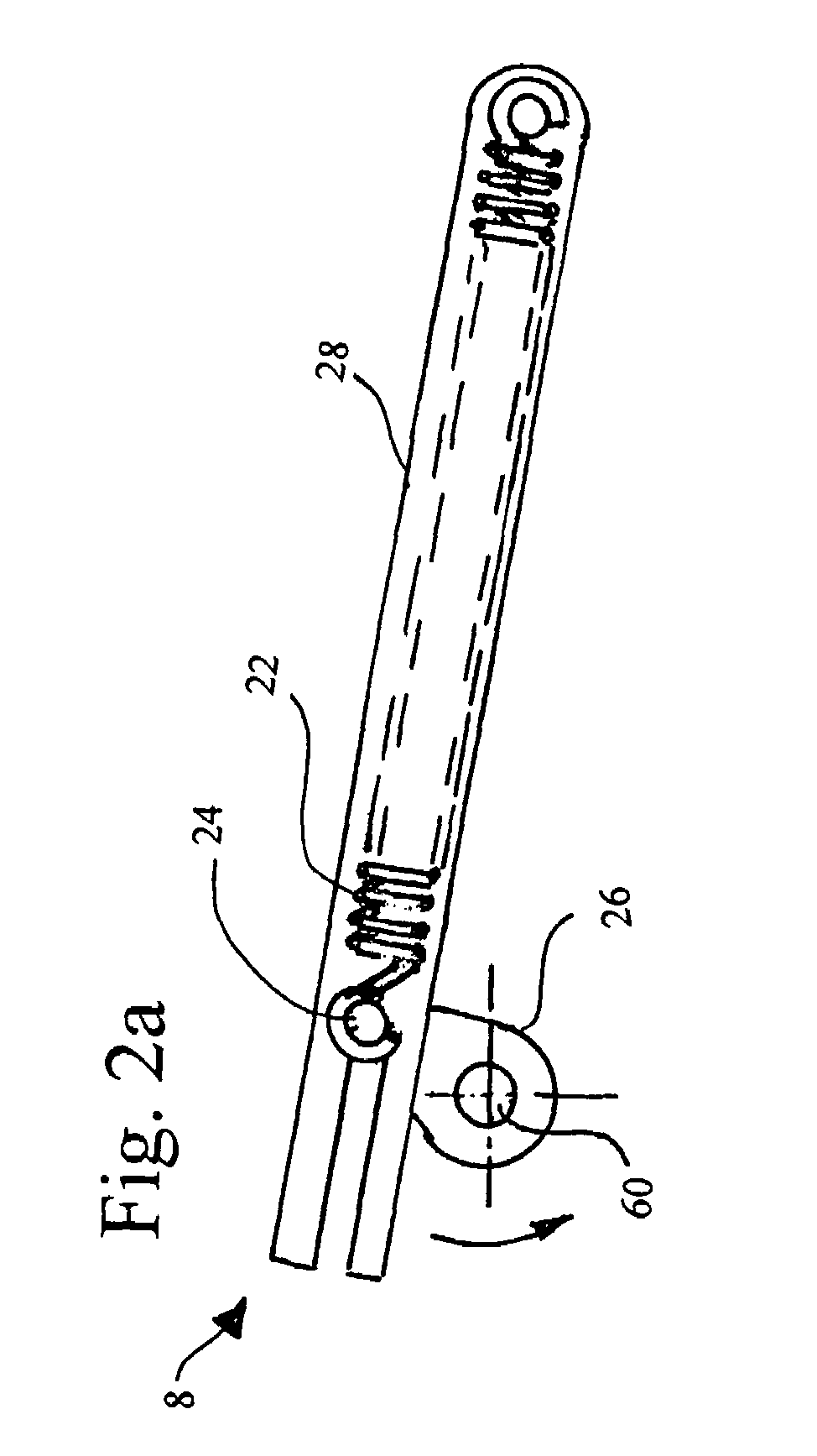

A machine for slicing food products, including a supported table surface with aperture for the passage therethrough of product slices; a power-driven cutting device having a horizontal blade extending above the table surface at a distance substantially corresponding to the slice thickness required; a guided horizontally sliding platform spaced above the cutting device; a power-driven reciprocating lateral thruster attached to the horizontal sliding platform for the purpose of moving the platform both to produce slices of food product and to clear the cutting device in the case it is jammed; and a vertical tube-shaped open-ended hopper rigidly supported by the horizontally sliding platform for containing a stack of food product items, the lowest item in the stack resting on the table surface and being pushed by the hopper into contact with the cutting device to produce a slice.

Owner:KAPLAN ROBERT E

Adjustable slicer

ActiveUS7712402B2Easy to changeSmooth rotationGang saw millsStock shearing machinesSlice thicknessEngineering

A food slicer for slicing a food product is provided. The slicer may have an adjustable surface and a stationary surface with a blade interposed therebetween. The food product may be sliced with a specific thickness via the blade by traversing the food product from the adjustable surface to the stationary surface. A trailing edge of the adjustable surface and an edge of the blade may define a gap distance which determines a slicing thickness of the food product. A cam may contact an underside of the adjustable surface to set the gap distance. The gap distance may be reset by rotating the cam. More particularly, the cam may have a plurality of cam surfaces. Each of the cam surfaces may have a different distance to a rotating axis of the cam. The gap distance may be changed by rotating the cam such that a different cam surface contacts the adjustable surface's underside.

Owner:KYOCERA CORP

Method for mounting transparent component

InactiveUS20110293168A1Easy to installLow costCharacter and pattern recognitionElectrical componentsSlice thicknessEngineering

A transparent component locally includes one or both of a plurality of thick parts that have a large thickness in the vertical direction, and a plurality of thin parts that have a small thickness in the vertical direction. A component recognition camera captures an image of the transparent component held by a mount head, from above or below the transparent component, while a single spotlight or a plurality of spotlights are being irradiated onto the transparent component.

Owner:MATSUSHIMA YOSHIHIKO +3

Material increasing manufacturing method of pure tungsten metal

ActiveCN104889392AHigh densityImprove performanceAdditive manufacturing apparatusSlice thicknessShielding gas

The invention relates to a material increasing manufacturing method of pure tungsten metal. The manufacturing method comprises steps of taking ball-shaped pure tungsten powder particles; screening out and mixing tungsten powder small particles and tungsten powder big particles to obtain mixed powder bodies; installing a metal substrate on an optical fiber laser work bench; filling a powder body stock bin with the mixed powder bodies and sealing a shaping cavity body; using a vacuum pump to pump the interior of the shaping cavity body to be in vacuum degree of -90Kpa; inputting protection gas into the shaping cavity body; repeating vacuumization and protection gas inputting so as to allow the oxygen content in the shaping cavity body to be reduced to less than 300ppm; scanning the sacrificing area of the metal substrate with laser until the oxygen content is reduced to less than 50ppm; sending the mixed powder bodies in the powder body stock bin to the metal substrate by a powder laying machine; using a powder laying scraper to lay the powder bodies so as to obtain a mixed powder body thin layer; fusing the mixed powder bodies in a shaping slicing area via high-energy laser beams; refusing the mixed powder bodies after each layer is shaped; after the refusing is finished, reducing the work bench by one slice thickness; and repeating the laser shaping and refusing until the whole part is finally shaped.

Owner:TSINGHUA UNIV

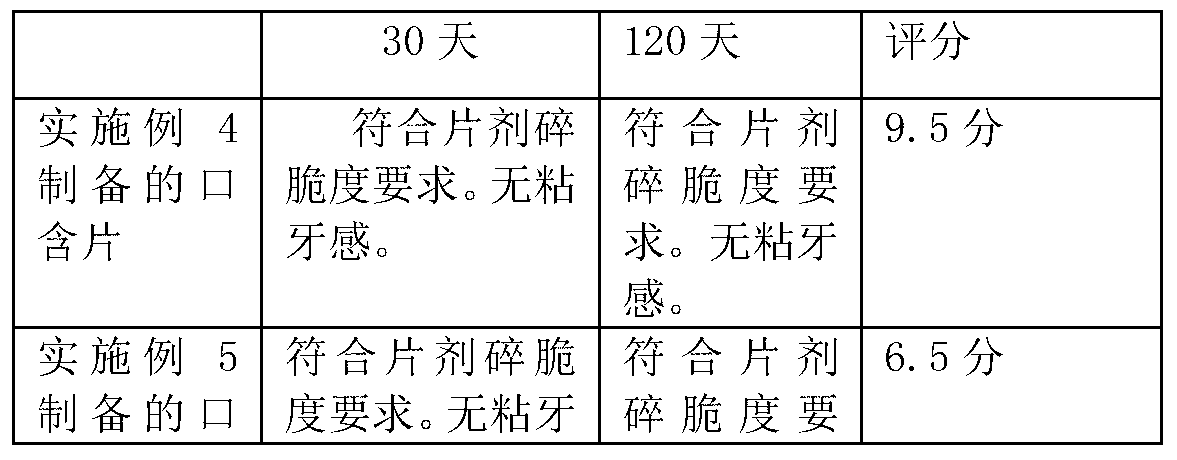

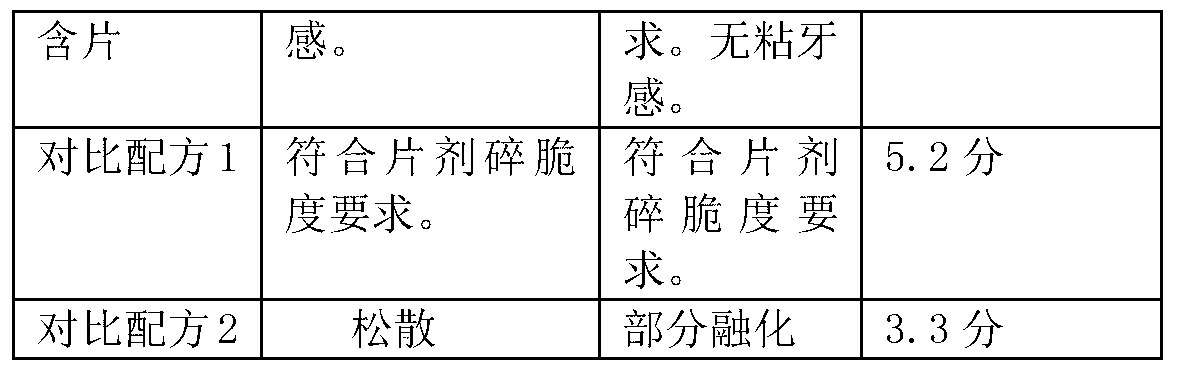

Dendrobium buccal tablets and preparation method for same

ActiveCN103285242ASimple processEasy to operatePill deliveryRespiratory disorderLoss rateSlice thickness

The invention belongs to the field of traditional Chinese medicines or healthcare foods, relates to a dendrobium preparation, and in particular relates to dendrobium buccal tablets. The formula of the dendrobium buccal tablets is composed of dendrobium ultra-fine powder, mannitol, white granulated sugar powder, magnesium stearate, aerosol, citric acid, borneol / menthol, mint oil and mint essence, wherein under the formula aforementioned, wet granulation is performed, and then tabletting is performed to prepare the buccal tablets; and the dendrobium buccal tablets prepared by the formula are high in bioavailability and good in taste. Additionally, the invention further discloses a preparation process for dendrobium ultra-fine powder. The preparation process specifically comprises the following steps of: peeling the cleaned fresh dendrobium bars; drying and slicing to achieve a thickness of not greater than 1 mm; and performing drying treatment at 50-60 DEG C to cause the water content to be 2-3%, and crushing for 10-30 minutes by an ultra-fine crusher, so as to obtain the dendrobium ultra-fine powder. According to the process, the loss rate of the precious medicine of dendrobium is further reduced by optimizing the slice thickness and omitting the step of processing crude powder.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com