Intelligent hot-knife cutting device

A cutting device and intelligent hot knife technology, applied in metal processing and other directions, can solve the problems of not suitable for mass production and processing, the production efficiency of enterprises depends on people, and the production efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below just according to accompanying drawing to the structural representation of the present invention.

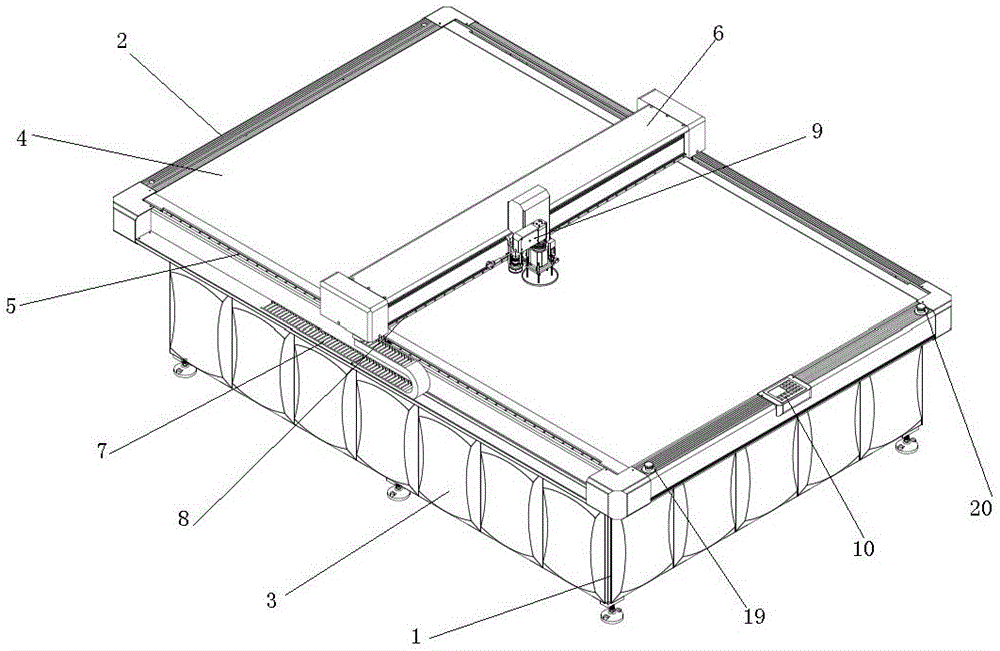

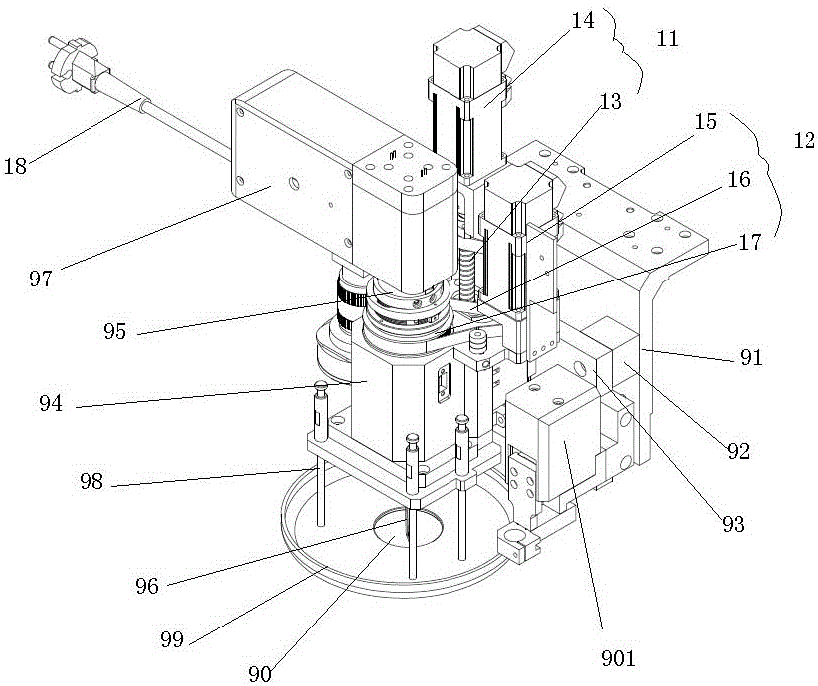

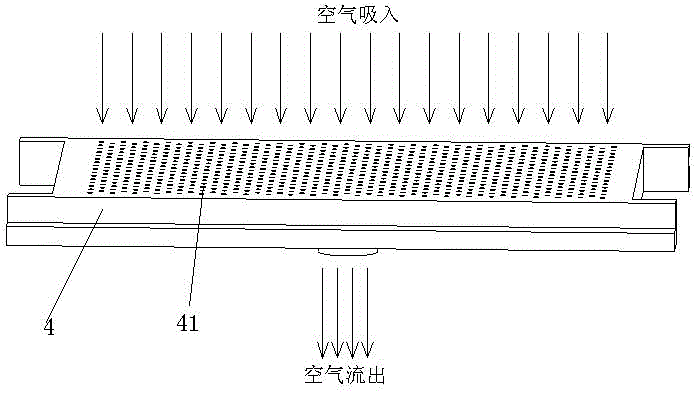

[0018] Such as figure 1 , figure 2 with image 3 As shown, an intelligent hot knife cutting device includes a lower frame 1 and an upper frame 2, the upper frame 2 is installed on the lower frame 1, and the four sides of the lower frame 1 are evenly provided with a plurality of lower frame baffles 3 , the upper plane of the upper frame 2 is provided with a cutting table 4, the left and right sides of the cutting table 4 are respectively provided with an X-axis guide rail 5, a slider is installed on the two X-axis guide rails 5, and a slider is installed on the two sliders. The two brackets are connected by a Y-axis beam 6, one end of the Y-axis beam 6 is connected with an X-axis drag chain 7, and two parallel Y-axis guide rails 8 are arranged on one side of the Y-axis beam 6, and two Y-axis At least one slide block is provided on the guide rail 8, and a heat cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com