High-efficiency cutting knife structure of grass cutter

A lawnmower, high-efficiency technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of easy damage to the blade, unreasonable structure design of the mowing knife, and low mowing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

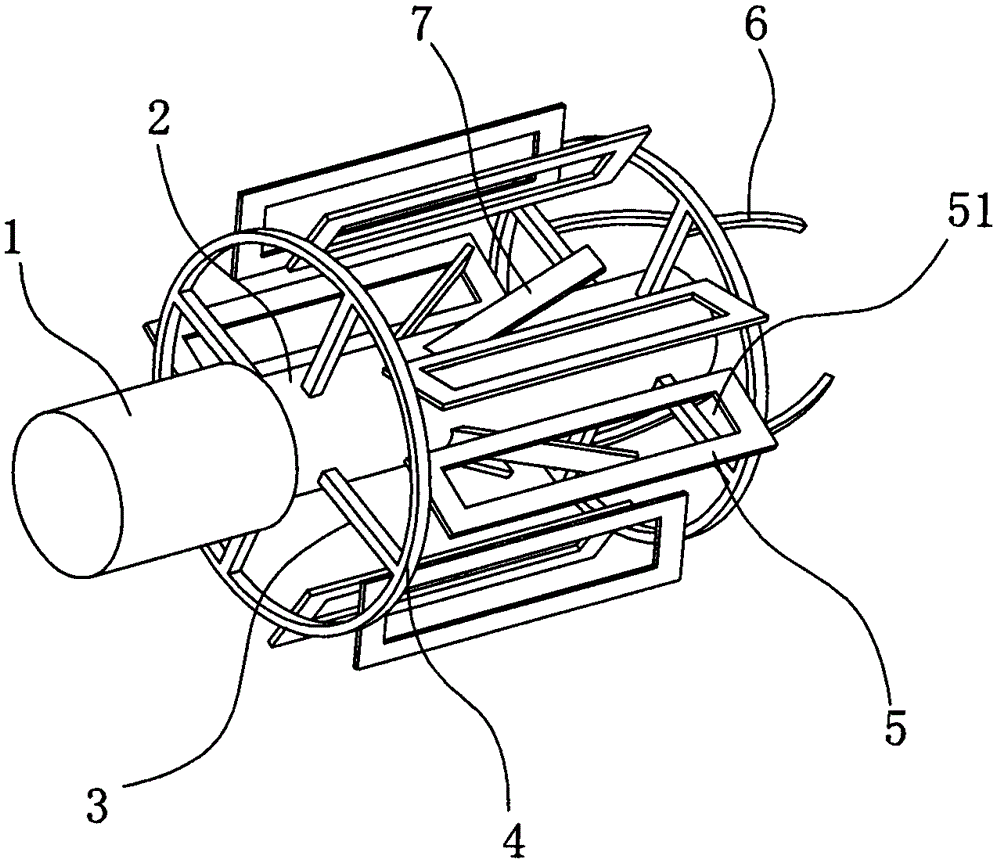

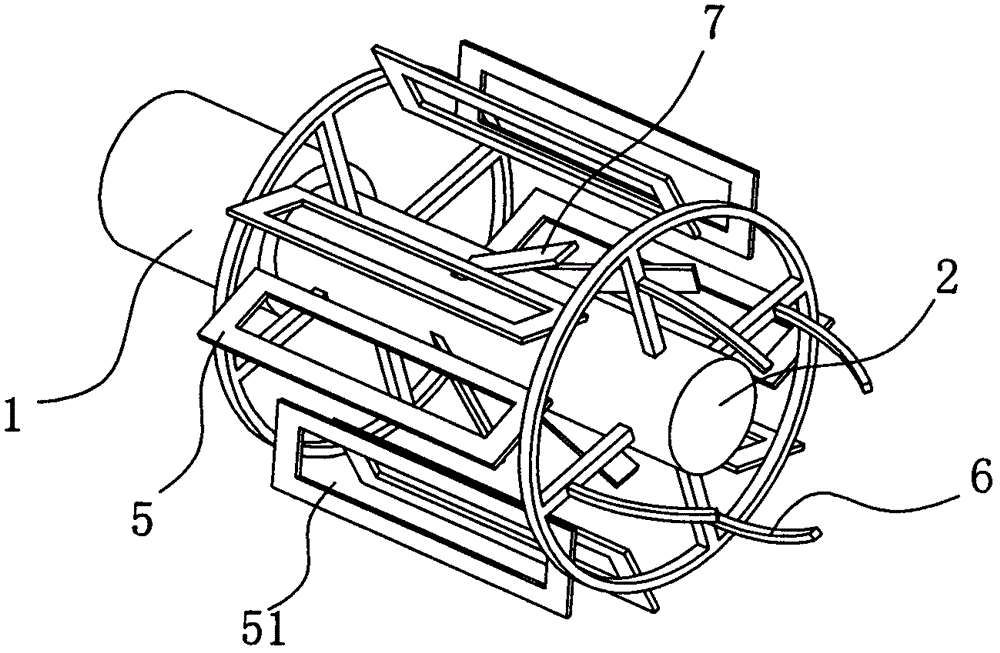

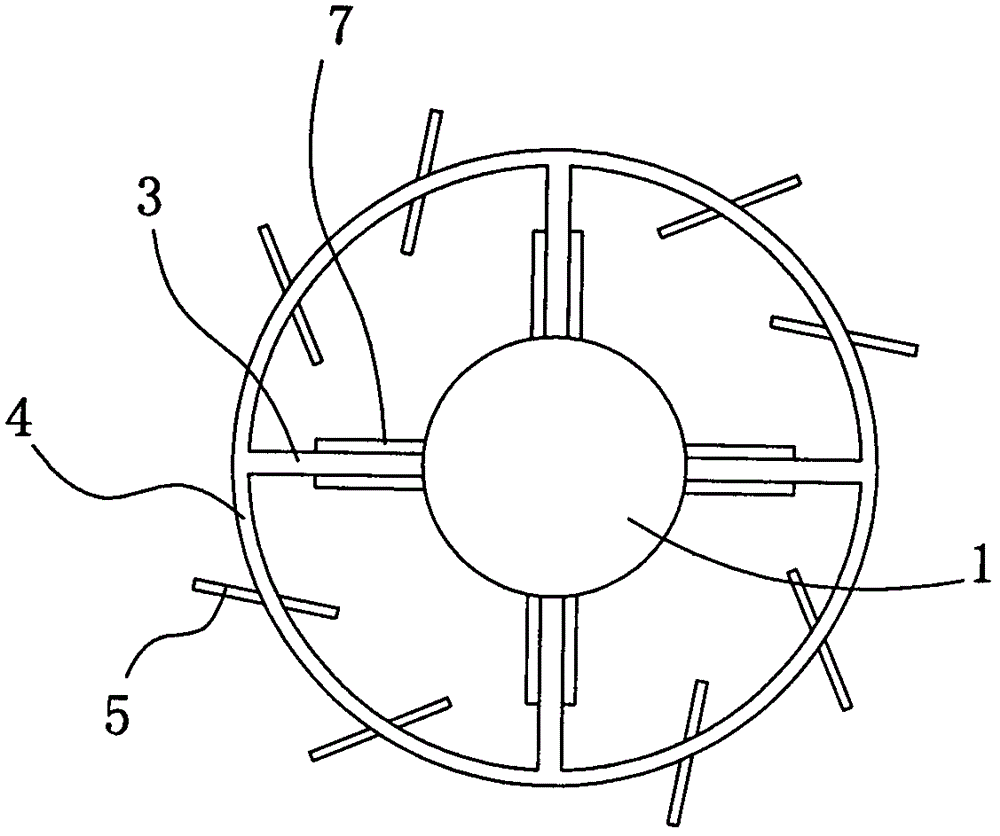

[0020] Such as Figure 1 to Figure 3 As shown, the high-efficiency cutter structure of the lawnmower of the present embodiment includes a drive shaft 1, a cutter shaft 2 is installed on one end of the drive shaft 1, and a cutting blade 5 is installed on the cutter shaft 2, and the outer walls of the two ends of the cutter shaft 2 are respectively supported by Bar 3 is equipped with supporting ring 4, and two supporting rings 4 are fixedly connected cutting blade 5, and cutting blade 5 is inclined to arrange symmetrically around the central axis of cutter shaft 2, and cutting blade 5 has cutting knife groove 51, and cutting knife groove 51 will cut The blade 5 is divided into two parts, so that the weeds falling into the cutter groove 51 can continue to be divided, and the division efficiency is improved.

[0021] The outer walls of both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com