T-shaped three-crawler-belt slipform paver

A sliding-form paver and crawler technology, which is applied to roads, road repair, roads, etc., can solve the problems of complex operation and control, and achieve the effects of low adjustment difficulty, stable adjustment process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

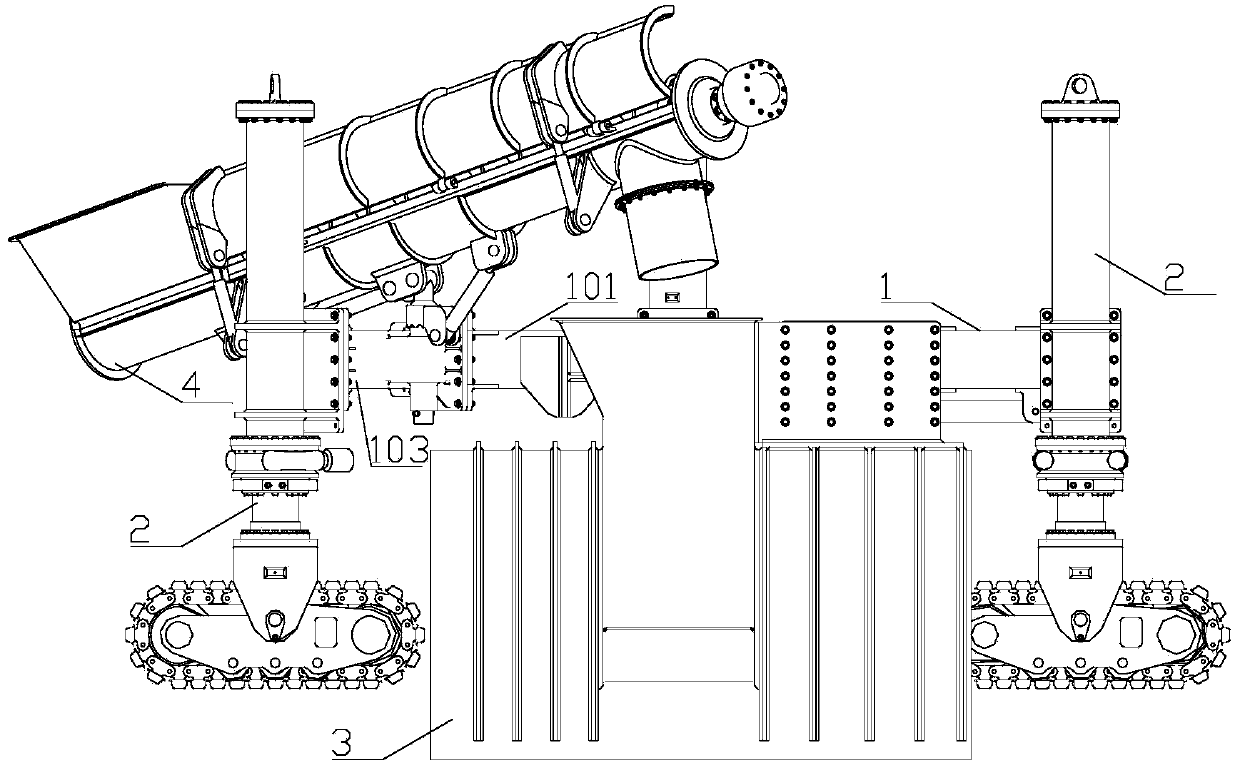

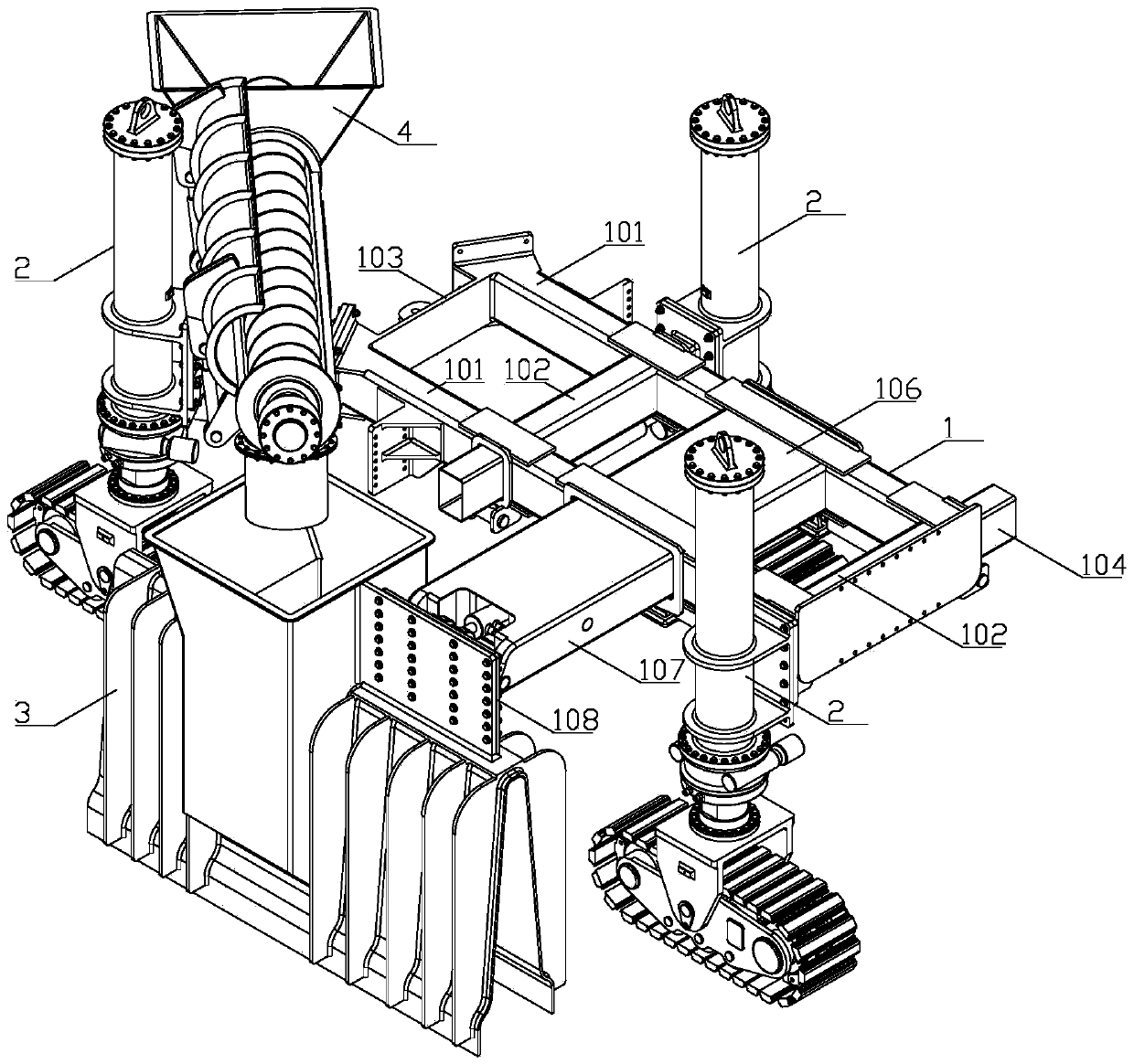

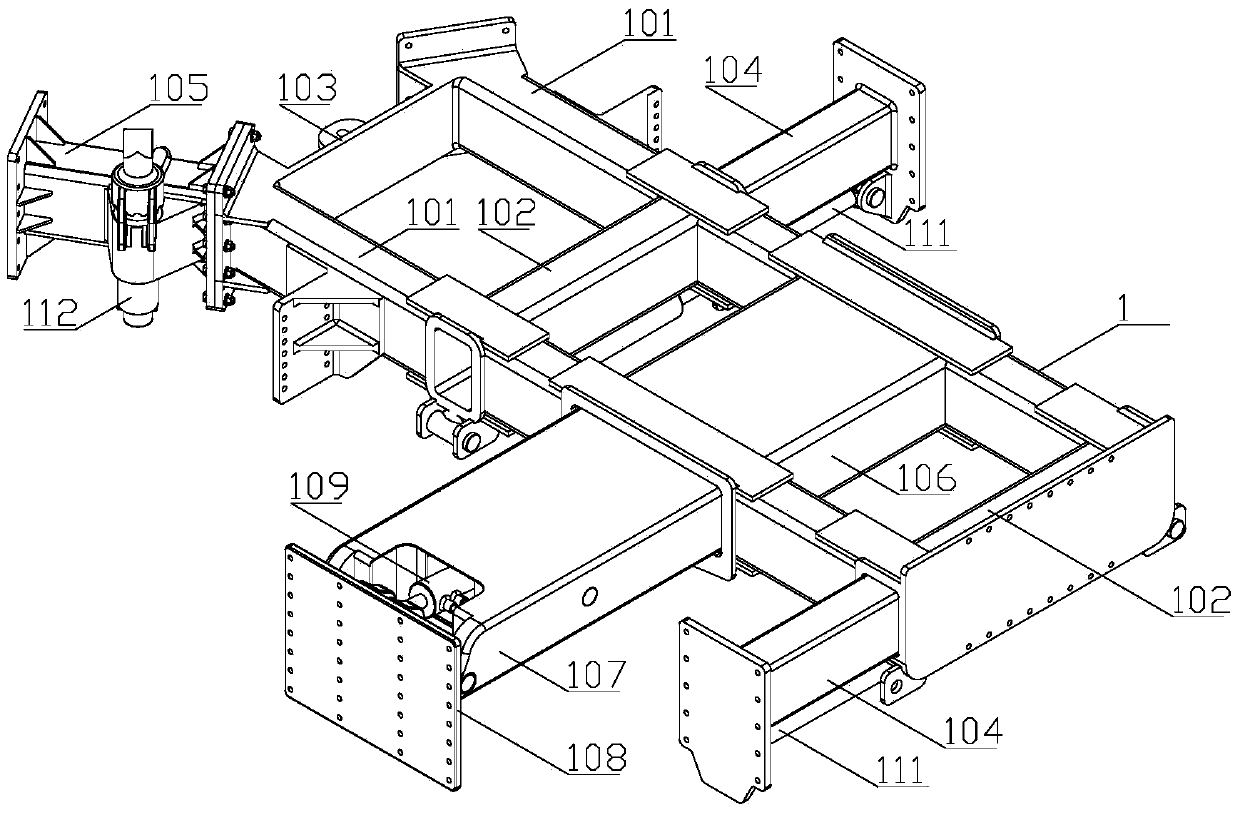

[0044] Embodiment 1: as figure 1 and figure 2 As shown, the T-type three-crawler slipform paver includes a T-type telescopic chassis 1 and a crawler-type lifting and steering device 2, such as image 3 As shown, the T-shaped telescopic chassis 1 includes two longitudinal main beams 101, two hollow transverse main beams 102, a strengthening connecting plate 103, two telescopic beams 104, a connecting beam 105, a hollow telescopic arm cover 106, and a telescopic arm 107. , fixed plate 108, adjustment oil cylinder 109, telescopic arm oil cylinder 110, a horizontal main beam 102 is vertically fixed between the rear ends of two longitudinal main beams 101 arranged in parallel, and a horizontal main beam 102 is vertically fixed between the front ends of two longitudinal main beams 101. Strengthen the connecting plate 103, and vertically fix another transverse main beam 102 in the middle of the two longitudinal main beams 101 between the transverse main beam 102 and the reinforcing...

Embodiment 2

[0045] Embodiment 2: as Figure 10 and Figure 11 As shown, the T-type three-crawler slipform paver includes a T-type telescopic chassis 1 and a crawler-type lifting and steering device 2, such as image 3 As shown, the T-shaped telescopic chassis 1 includes two longitudinal main beams 101, two hollow transverse main beams 102, a strengthening connecting plate 103, two telescopic beams 104, a connecting beam 105, a hollow telescopic arm cover 106, and a telescopic arm 107. , fixed plate 108, adjustment oil cylinder 109, telescopic arm oil cylinder 110, a horizontal main beam 102 is vertically fixed between the rear ends of two longitudinal main beams 101 arranged in parallel, and a horizontal main beam 102 is vertically fixed between the front ends of two longitudinal main beams 101. Strengthen the connecting plate 103, and vertically fix another transverse main beam 102 in the middle of the two longitudinal main beams 101 between the transverse main beam 102 and the reinforc...

Embodiment 3

[0046] Embodiment 3: as Figure 14 and Figure 15 As shown, the T-type three-crawler slipform paver includes a T-type telescopic chassis 1 and a crawler-type lifting and steering device 2, such as image 3 As shown, the T-shaped telescopic chassis 1 includes two longitudinal main beams 101, two hollow transverse main beams 102, a strengthening connecting plate 103, two telescopic beams 104, a connecting beam 105, a hollow telescopic arm cover 106, and a telescopic arm 107. , fixed plate 108, adjustment oil cylinder 109, telescopic arm oil cylinder 110, a horizontal main beam 102 is vertically fixed between the rear ends of two longitudinal main beams 101 arranged in parallel, and a horizontal main beam 102 is vertically fixed between the front ends of two longitudinal main beams 101. Strengthen the connecting plate 103, and vertically fix another transverse main beam 102 in the middle of the two longitudinal main beams 101 between the transverse main beam 102 and the reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com