Automatic pallet delivering device for palletizing system

A palletizing system and automatic technology, applied in the field of automatic pallet supply devices, can solve the problems of high energy consumption of electric devices, inconvenient installation and maintenance, and high investment costs, and achieve the effects of flexible and reliable action, easy installation and maintenance, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The structural features and working process of the present invention are further described below through the embodiments.

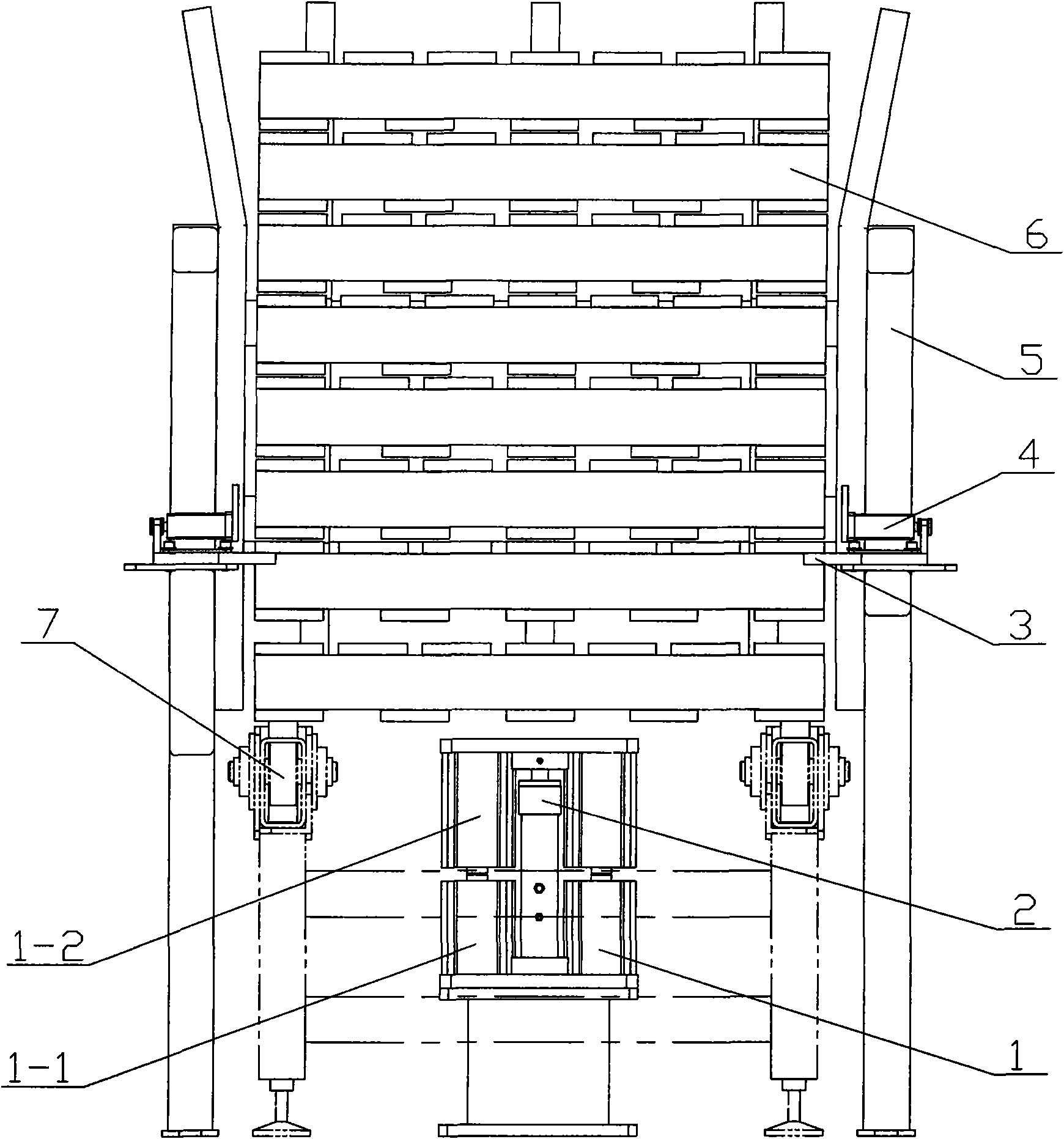

[0009] Referring to the accompanying drawings, the pallet warehouse 5 is a rectangular frame with a built-in pallet group 6. The pallets are loaded from above the rectangular frame, and the pallet groups are stacked neatly through oblique guides. The pallets in the pallet group are designated as P1, P1, P2, P3.... There are two symmetrically distributed double-stroke cylinders 1 at the bottom of the pallet warehouse. Each double-stroke cylinder 1 is a combined cylinder formed by connecting two single-stroke cylinders 1-1 and 1-2 in series. There is a lifting guide mechanism 2 on the side of the cylinder. Two horizontal bolts 3 and matching driving cylinders 4 are arranged on a group of symmetrical sides of the pallet warehouse. The centerlines of each bolt are located in the same horizontal plane. Program control is carried out by the control part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com