Stabilizer Bars and Stabilization Methods

A stabilizer bar and bearing technology, which is applied in the directions of transportation and packaging, interconnection system, elastic suspension, etc., can solve the problems of undesired axial movement, large size, and interference with the normal operation of the stabilizer bar. Ground clearance and/or packaging issues, effects of overall size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

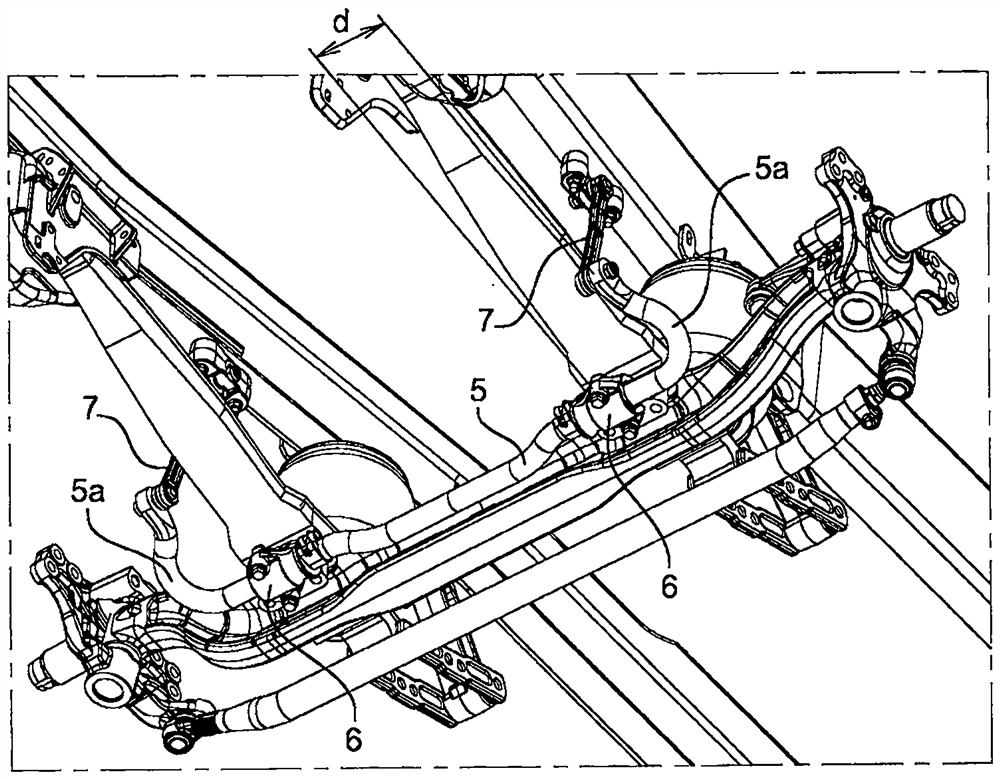

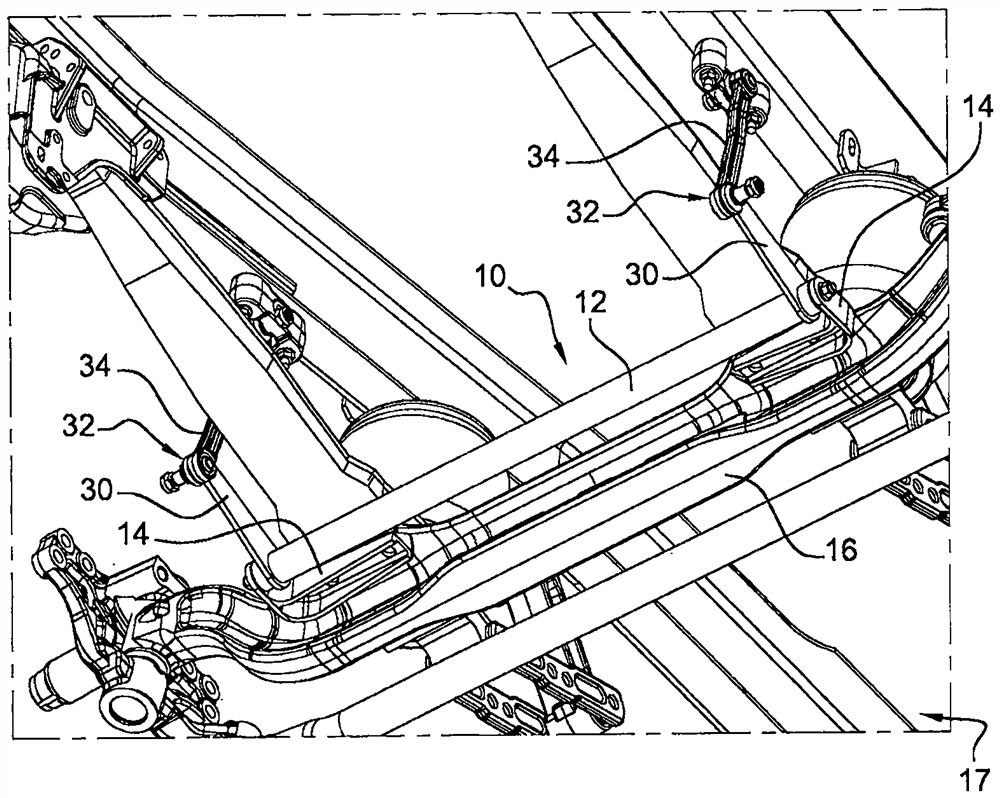

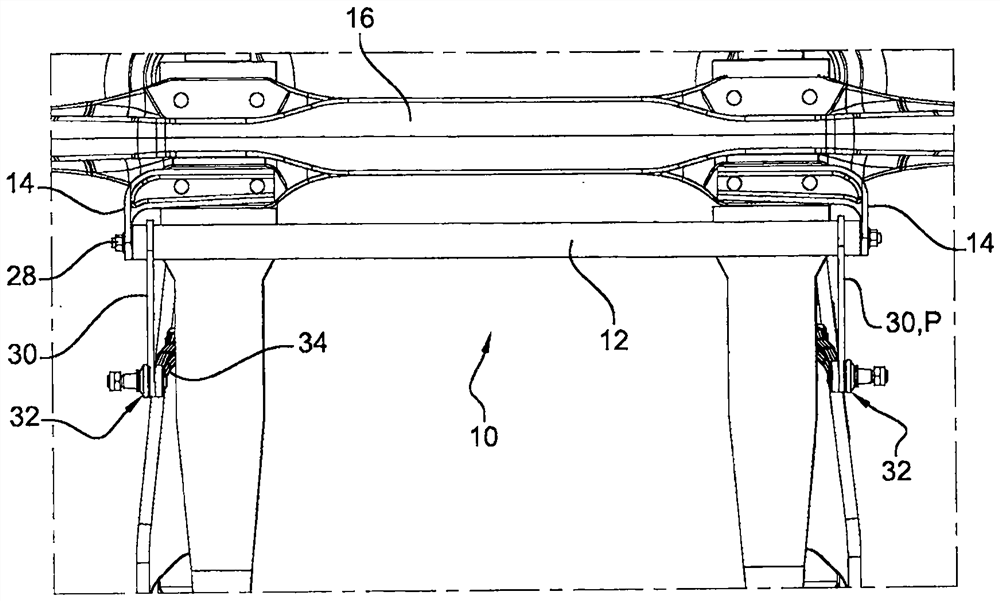

[0032] Refer to the attached Figure 2 to Figure 4 , shows a stabilizer bar 10 comprising an elongated shaft 12 mounted via a bracket 14 to an axle 16 of a truck 17 (only a small portion of the truck 17 is visible in the figure). In the arrangement shown, the shaft 12 is hollow along its entire length and is preferably in the form of a composite material. It will be appreciated that considerable weight savings can be achieved compared to arrangements comprising solid steel shafts or the like. Although in the arrangement shown, the shaft 12 is hollow throughout its length, it will be appreciated that this need not be the case, but instead, the shaft 12 may be of solid form or only near its ends. Hollow arrangements are also possible and such arrangements do not depart from the scope of the present invention.

[0033] Such as Figure 4 As best seen in FIG. 1 , within each end of the shaft 12 is a bearing assembly 18 secured to the associated bracket 14 in a manner that permit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com