Spring clutch with coil spring with hook

A spring clutch, coil spring technology, applied in clutches, friction clutches, springs/shock absorbers, etc., to achieve the effect of low cost, simple structure, and small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

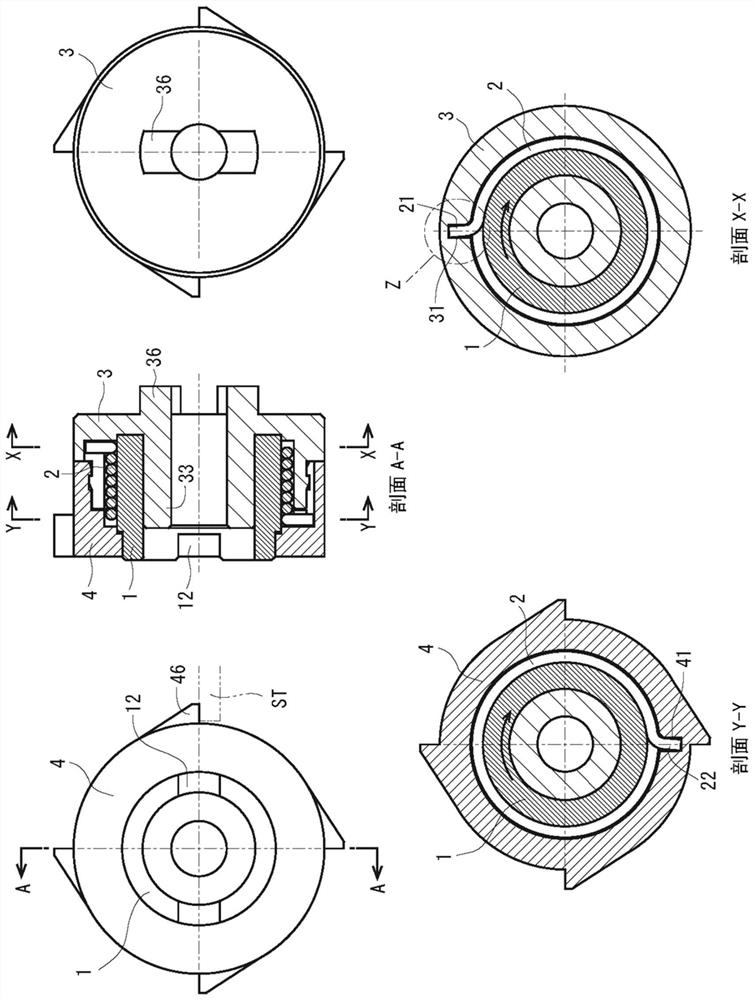

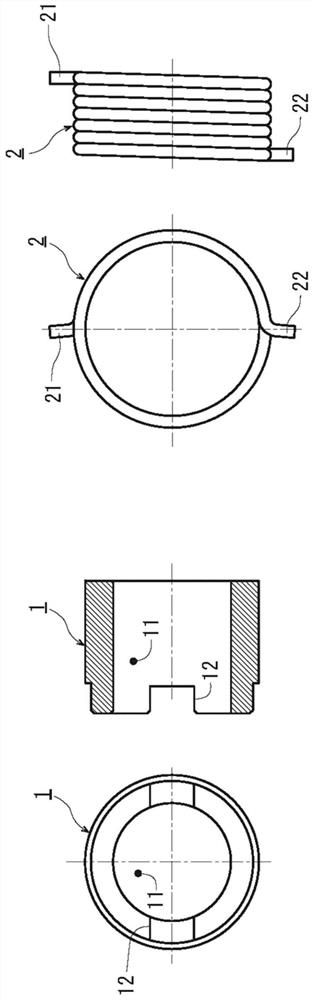

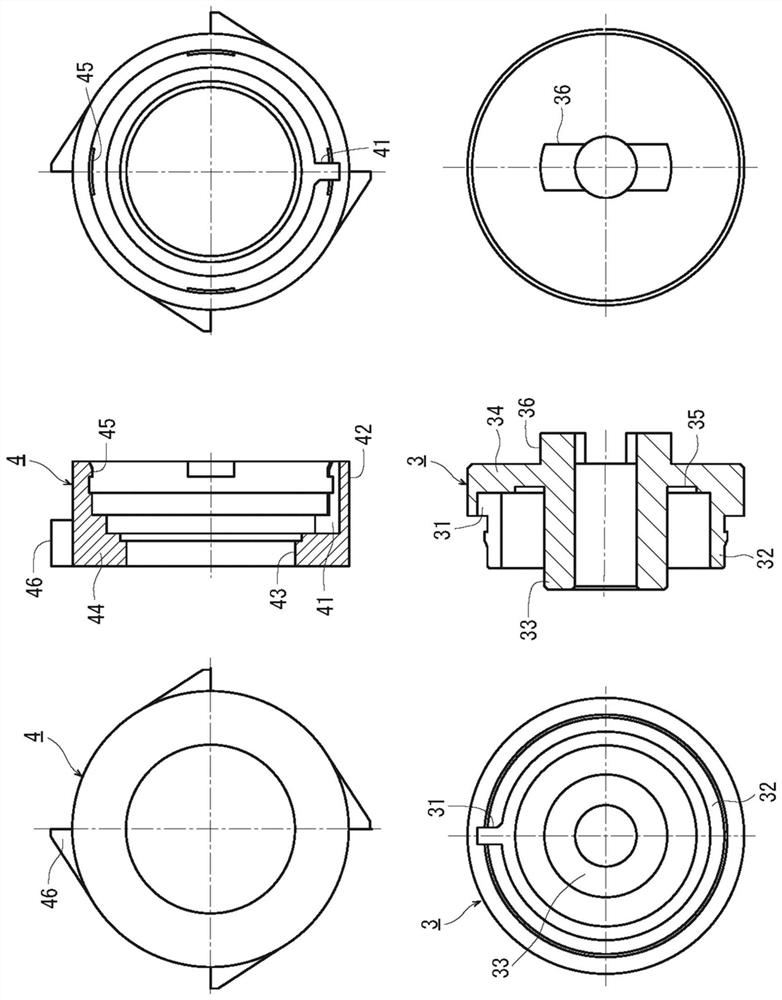

[0056] Hereinafter, the spring clutch of the present invention will be described based on the drawings. figure 1 The overall structure (assembly drawing) of the embodiment of the spring clutch of the present invention is shown, figure 2 The components of the spring clutch, namely the rotating body and the coil spring, are shown in a single-piece diagram. image 3 The output and control components are represented as single-piece diagrams. also, Figure 4 The state in which the rotary body to which the coil spring is attached and the output member are combined is shown, and the hook portion inserted into the slit is shown in an enlarged view.

[0057] like figure 1 As shown, the spring clutch of this embodiment is composed of four parts: a rotating body 1 , an output member 3 , a control member 4 , and a coil spring 2 wound around the outer circumference of the rotating body 1 . The rotating body 1 is formed in a cylindrical shape (see also figure 2 The single-piece dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com