Patents

Literature

172results about How to "High conveying precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic package machine for corrugated cartons with different lengths

InactiveCN105730772AHigh conveying precisionModerate delivery speedWrapper twisting/gatheringCartonEngineering

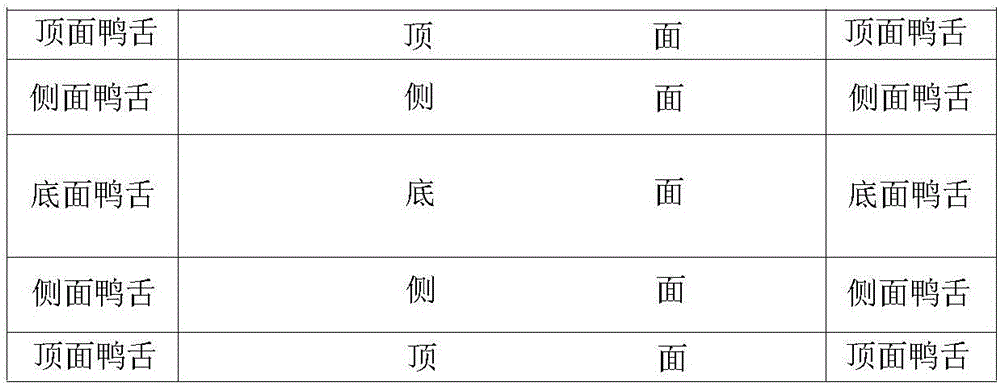

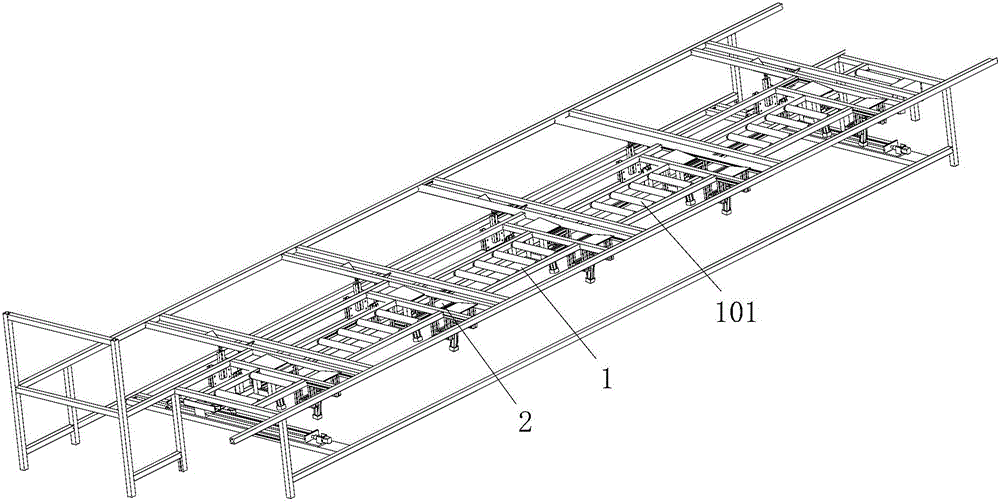

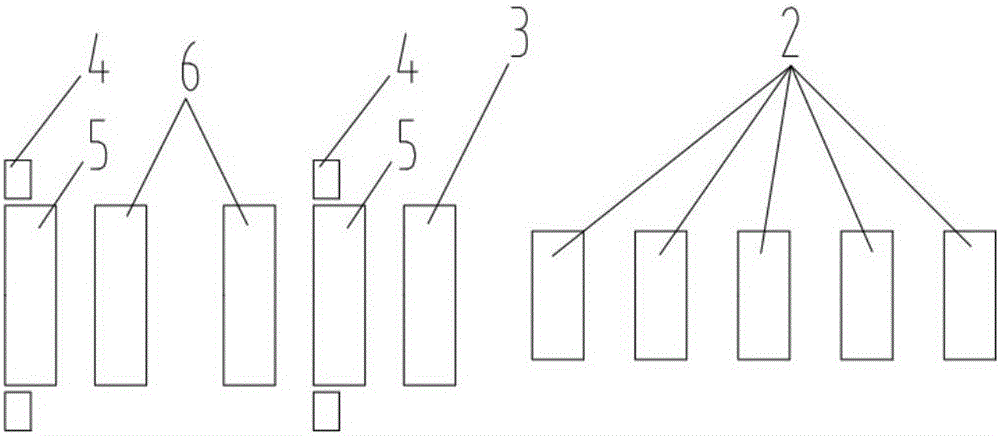

The invention discloses an automatic package machine for corrugated cartons with different lengths. The automatic package machine comprises a rack. An initial material position containing area, a wrapping forming area and a carton sealing area are sequentially arranged on the rack in the carton conveying direction. A material conveying device is arranged below the initial material position containing area. A carton containing area is arranged in the wrapping forming area. A top face folding mechanism, a front end folding system and a tail end folding system are arranged in the carton containing area. A side face folding mechanism is arranged below the carton containing area. Each of the front end folding mechanism and the tail end folding mechanism comprises a side face duck tongue folding mechanism, a top face duck tongue folding mechanism and a bottom face duck tongue folding mechanism. A plurality of powerless transmission rollers are arranged in the carton sealing area in the length direction of the carton sealing area. A two-end carton sealing mechanism, a length direction carton sealing system and a width direction carton sealing system are arranged in the carton sealing area in the carton conveying direction. By means of the automatic package machine, packaging of carton type products of different specifications and different sizes can be achieved, and the application range is wide.

Owner:SHANDONG UNIV OF SCI & TECH

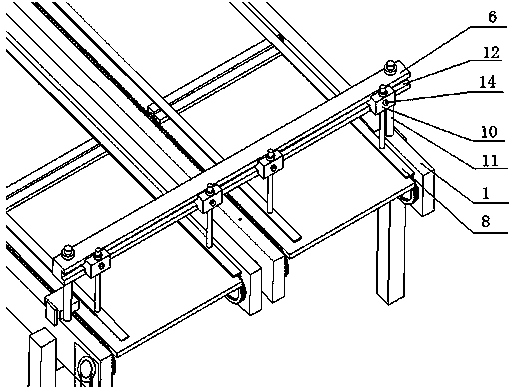

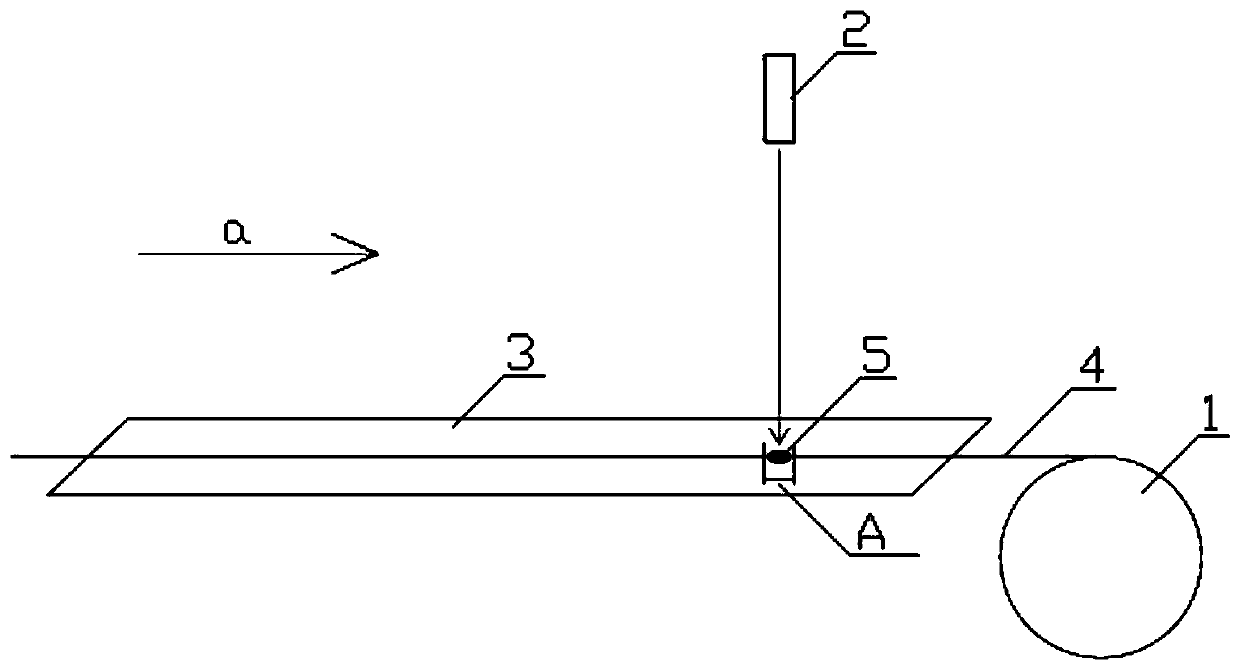

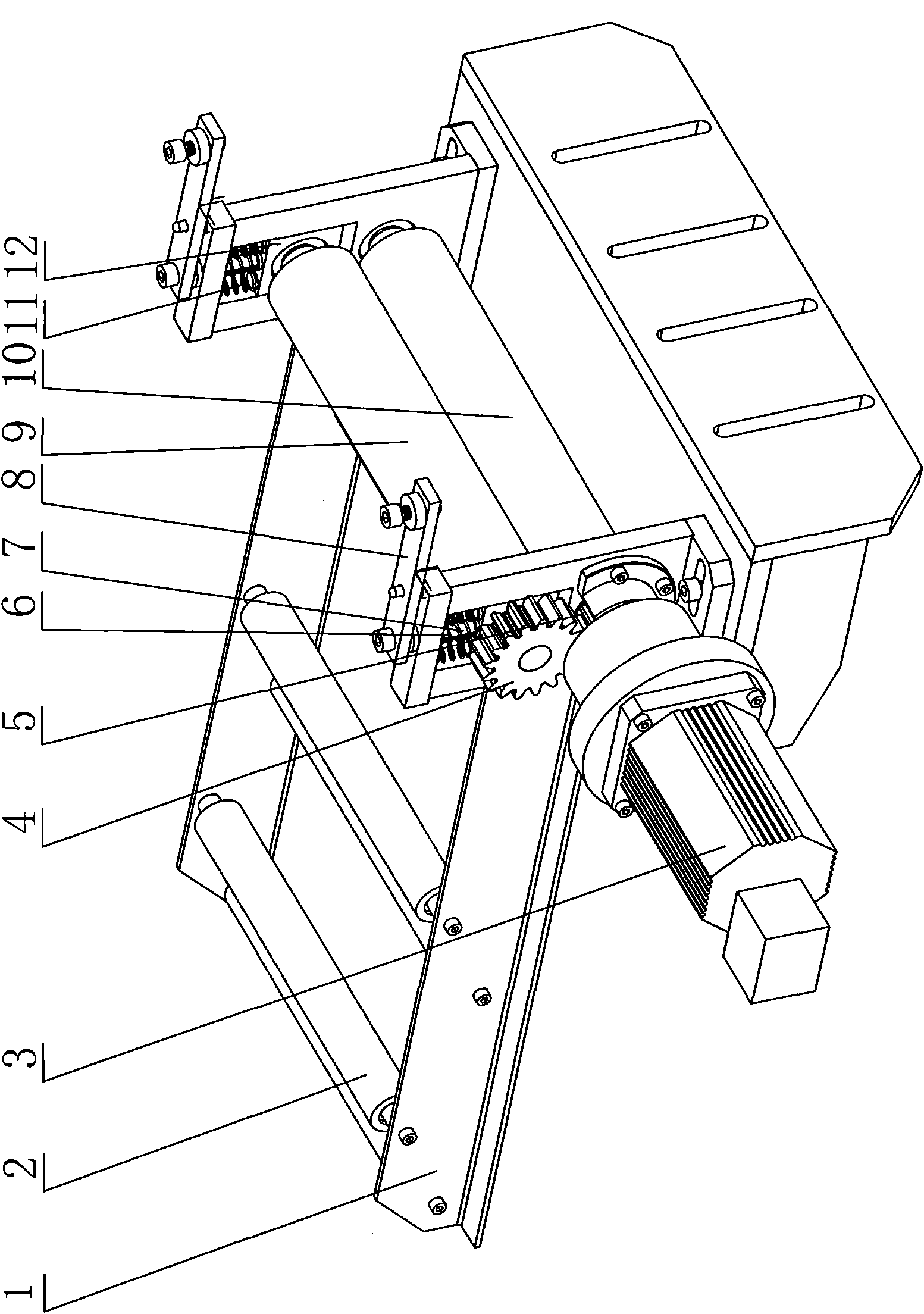

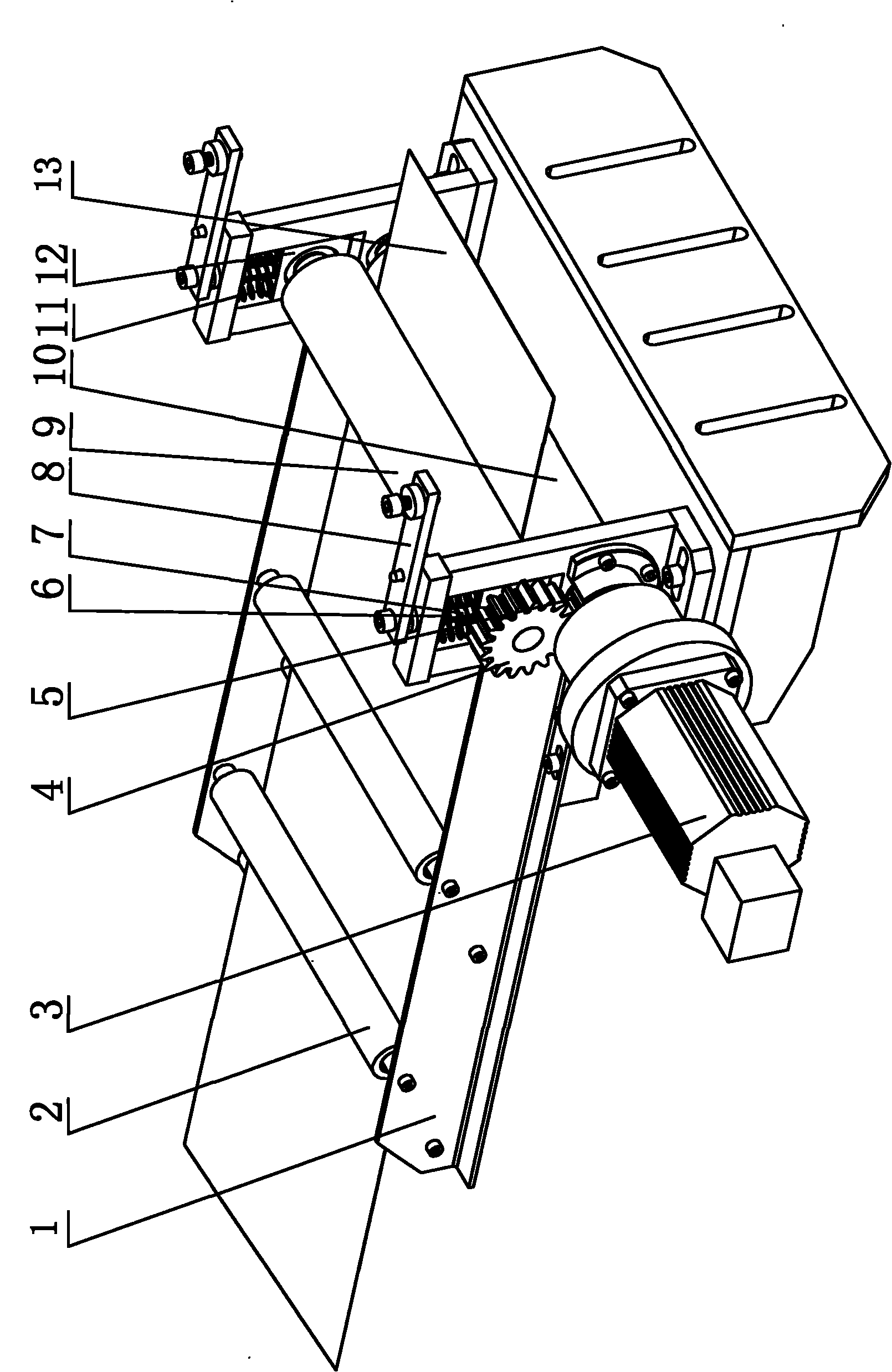

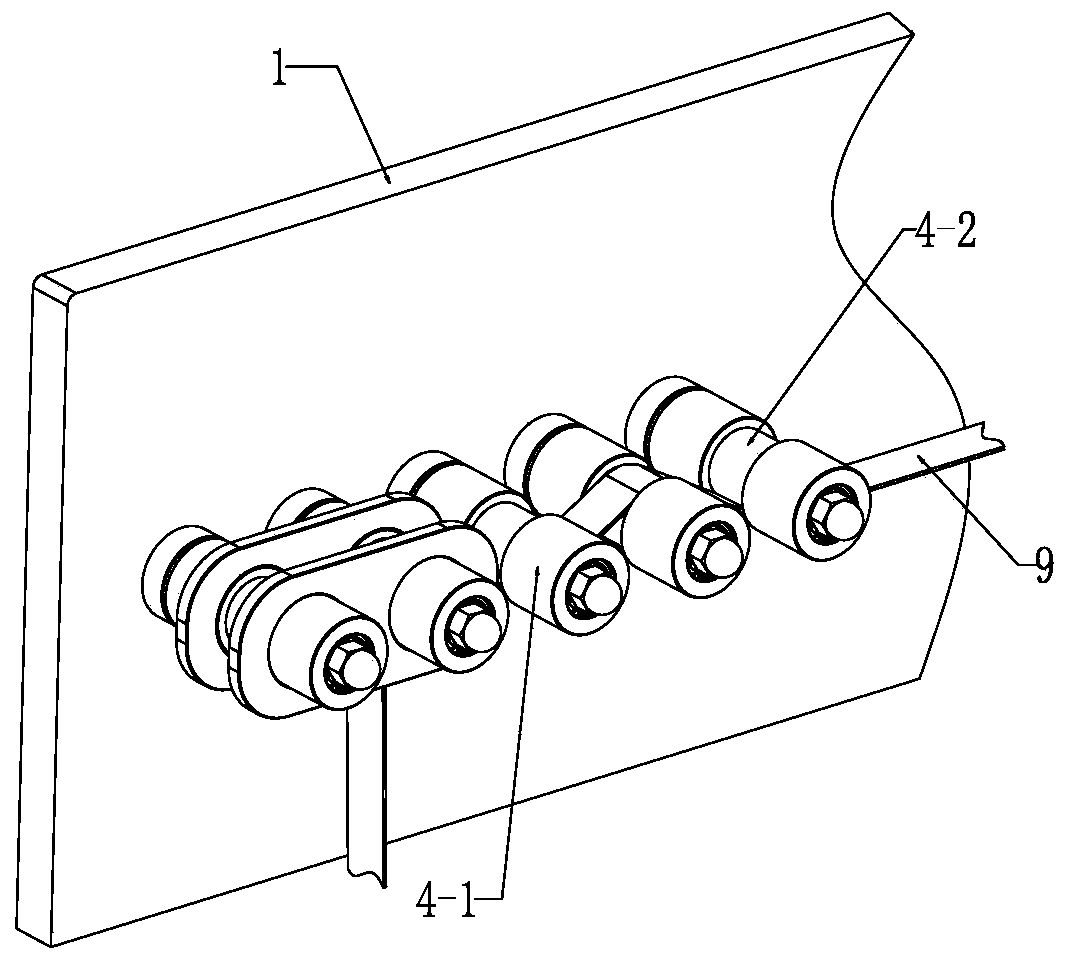

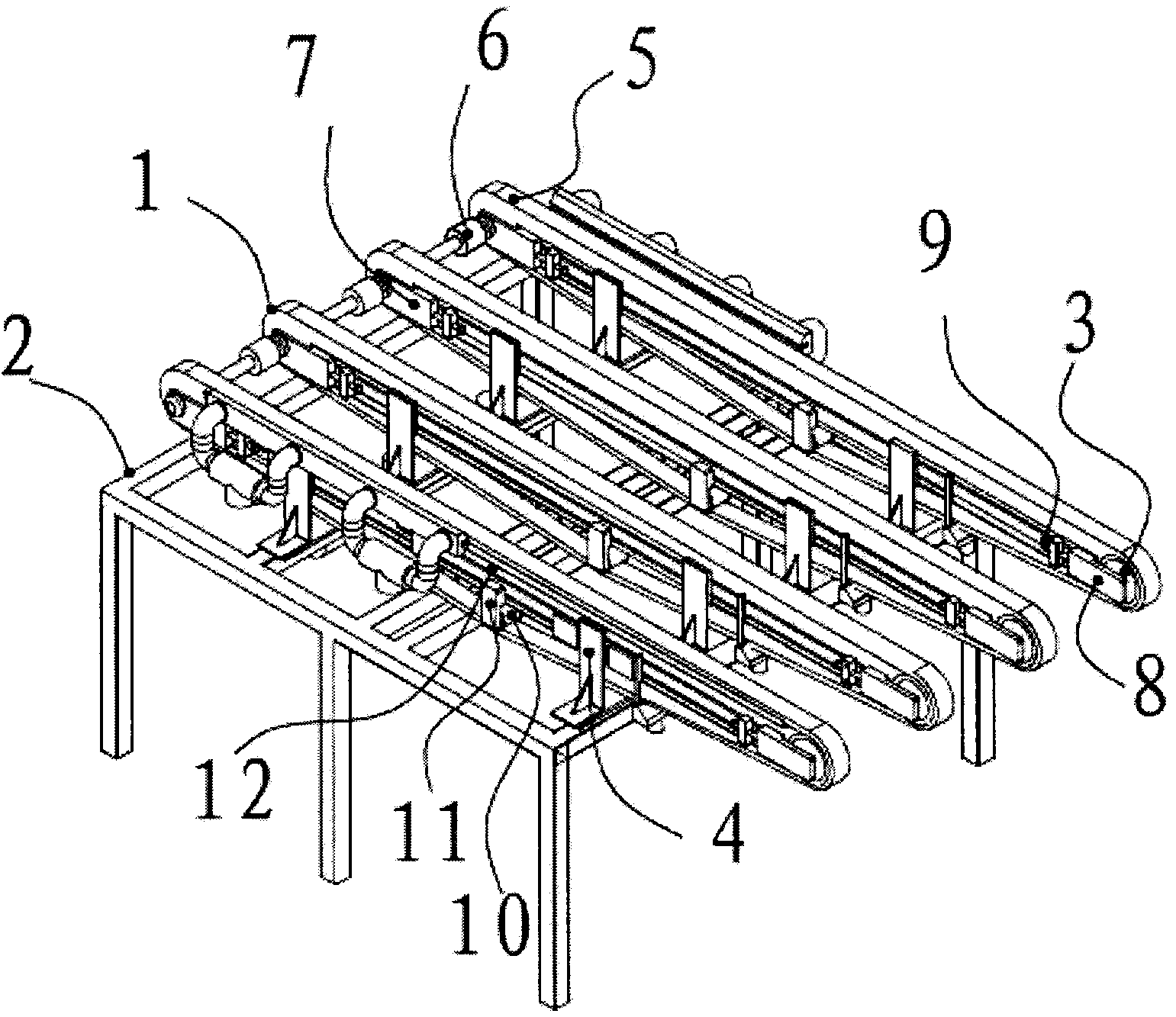

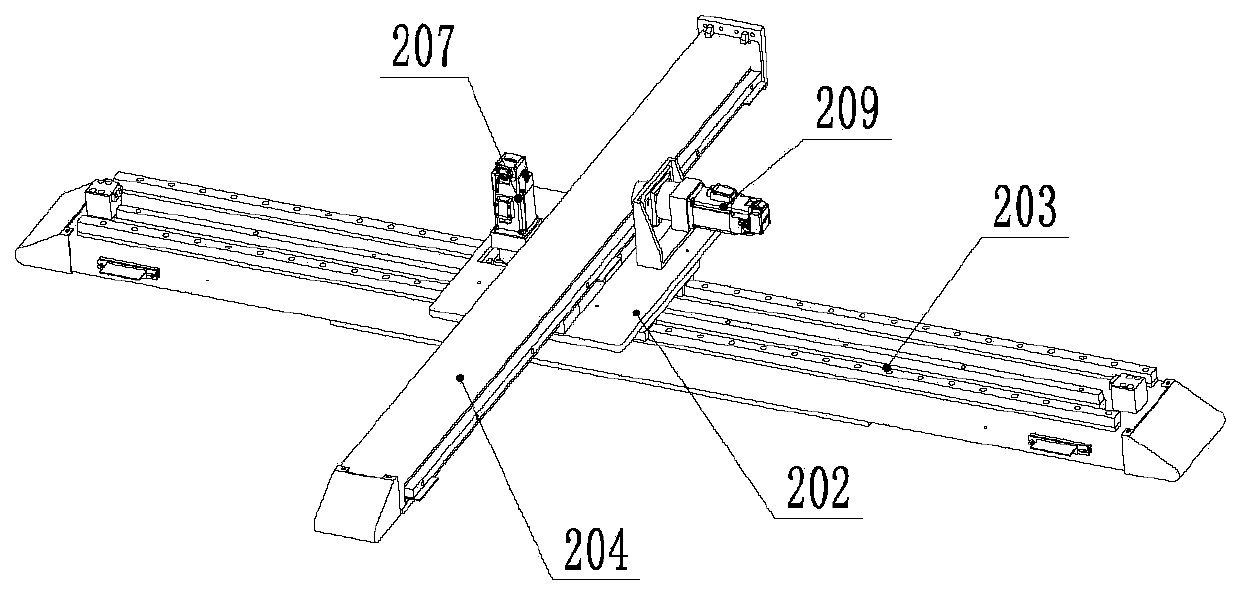

Conveying and positioning device and method used for automatic potted tray seedling transplanter

InactiveCN103787051AAvoid damageAdaptableControl devices for conveyorsTransplantingMotor driveChain device

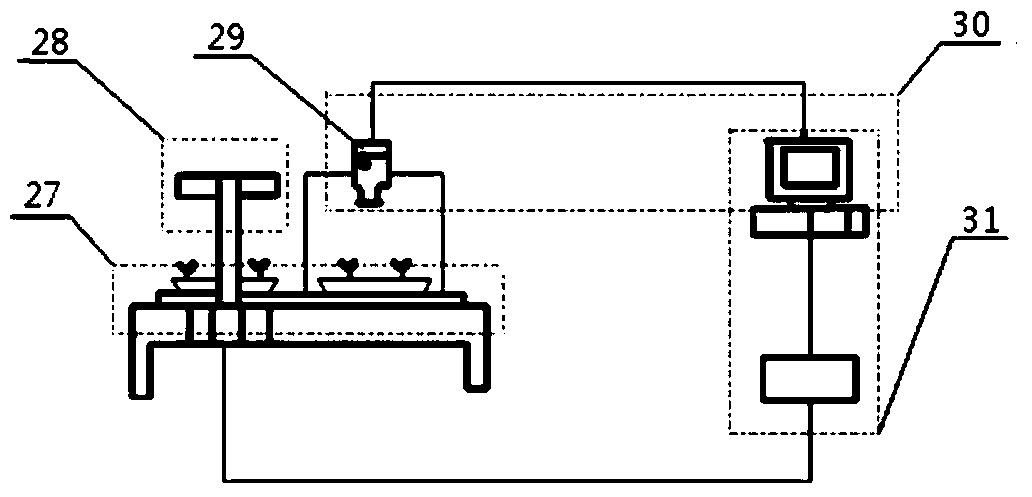

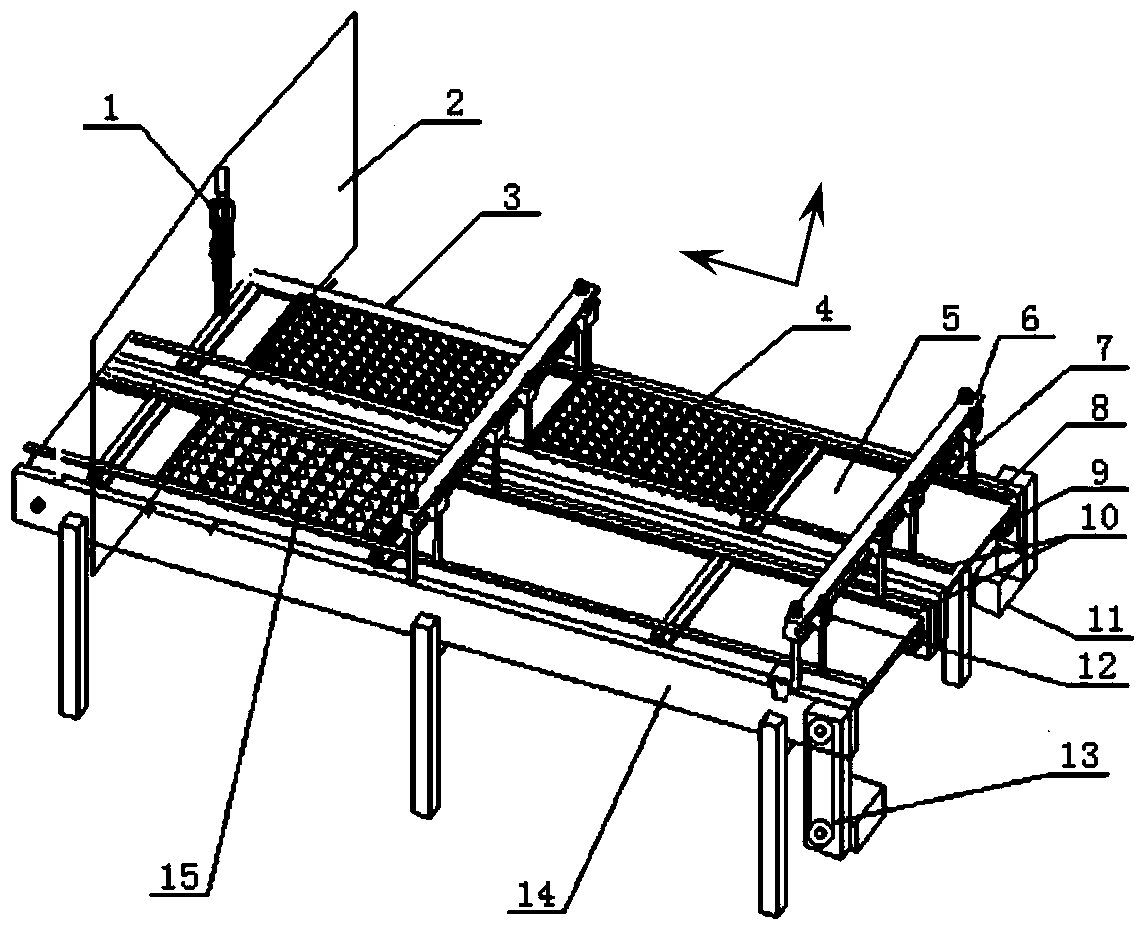

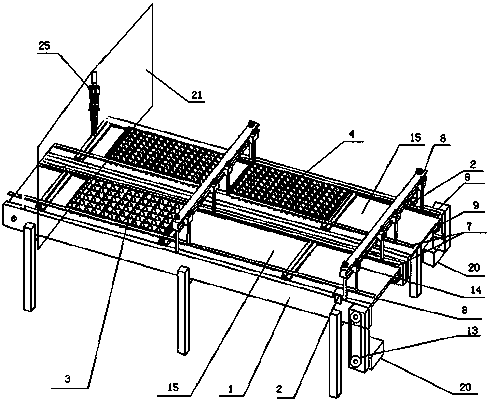

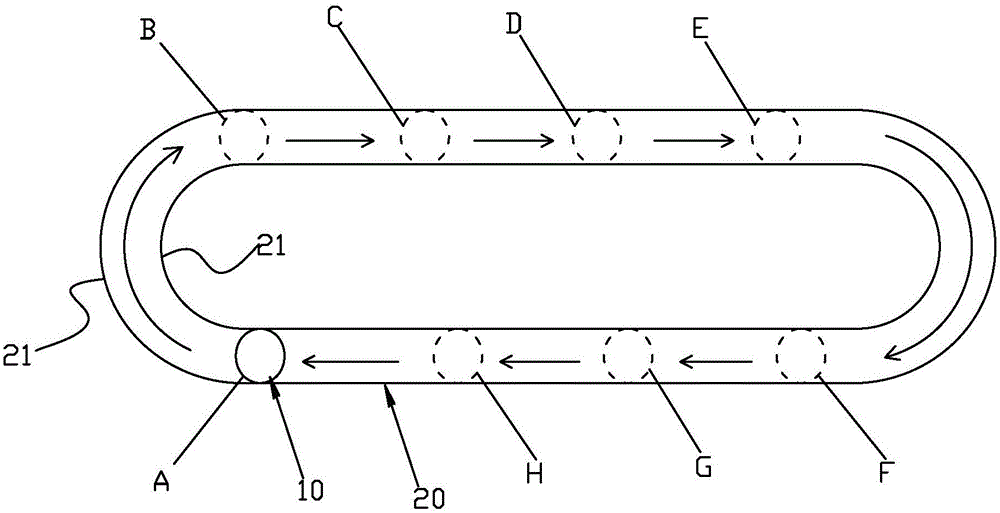

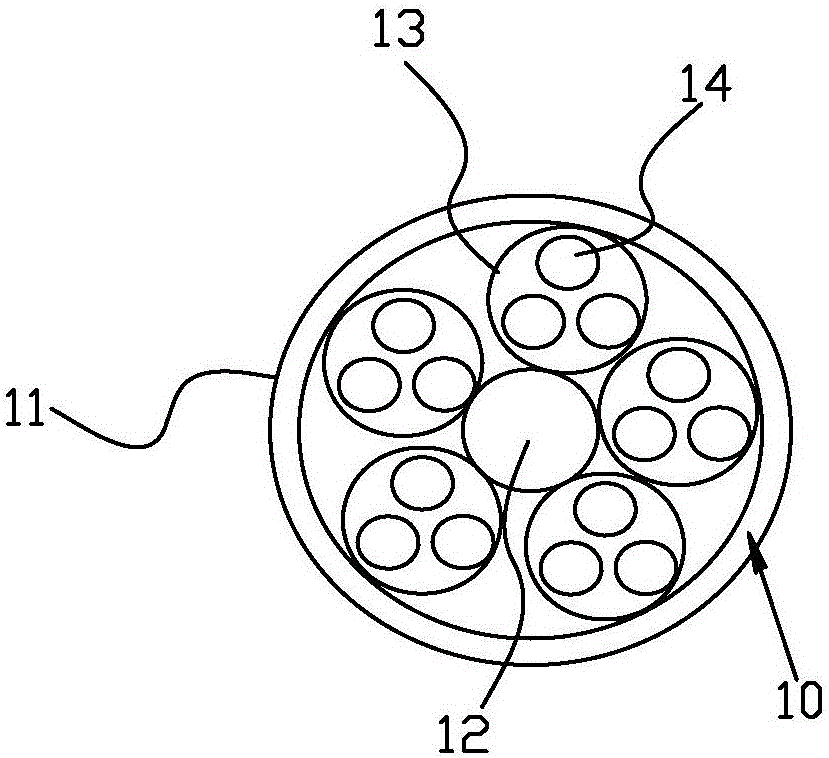

The invention provides a conveying and positioning device and method used for an automatic potted seedling transplanter. A conveying platform is fixedly mounted on a conveying rack, a seedling tray conveying guide device is mounted on the conveying platform, seedling supplying and planting trays are placed among conveying guide rails on the conveying platform, horizontal conveying chain devices are mounted on two sides of the conveying rack, a plurality of potted tray pushing plates are mounted on each horizontal conveying chain, and a transmission chain device is mounted on the outer side of the conveying platform. When a servo motor drives a transmission chain to rotate by one cycle, the potted tray pushing plates on the horizontal conveying chains move for a certain distance along with the transmission chain to realize positioning and conveying of the seedling supplying and planting trays. Adjusting devices used for adjusting transverse positions of the potted trays are mounted on two sides of the conveying rack, and the adjusting devices execute seedling tray transverse position adjusting instructions given by a transplanting control center to realize transverse accurate positioning of the seedling supplying and planting trays. The conveying and positioning device is high in accuracy and good in stability and reliability, damage to potted tray seedling pots can be reduced, and transplanting efficiency of potted tray seedlings can be improved.

Owner:JIANGSU UNIV

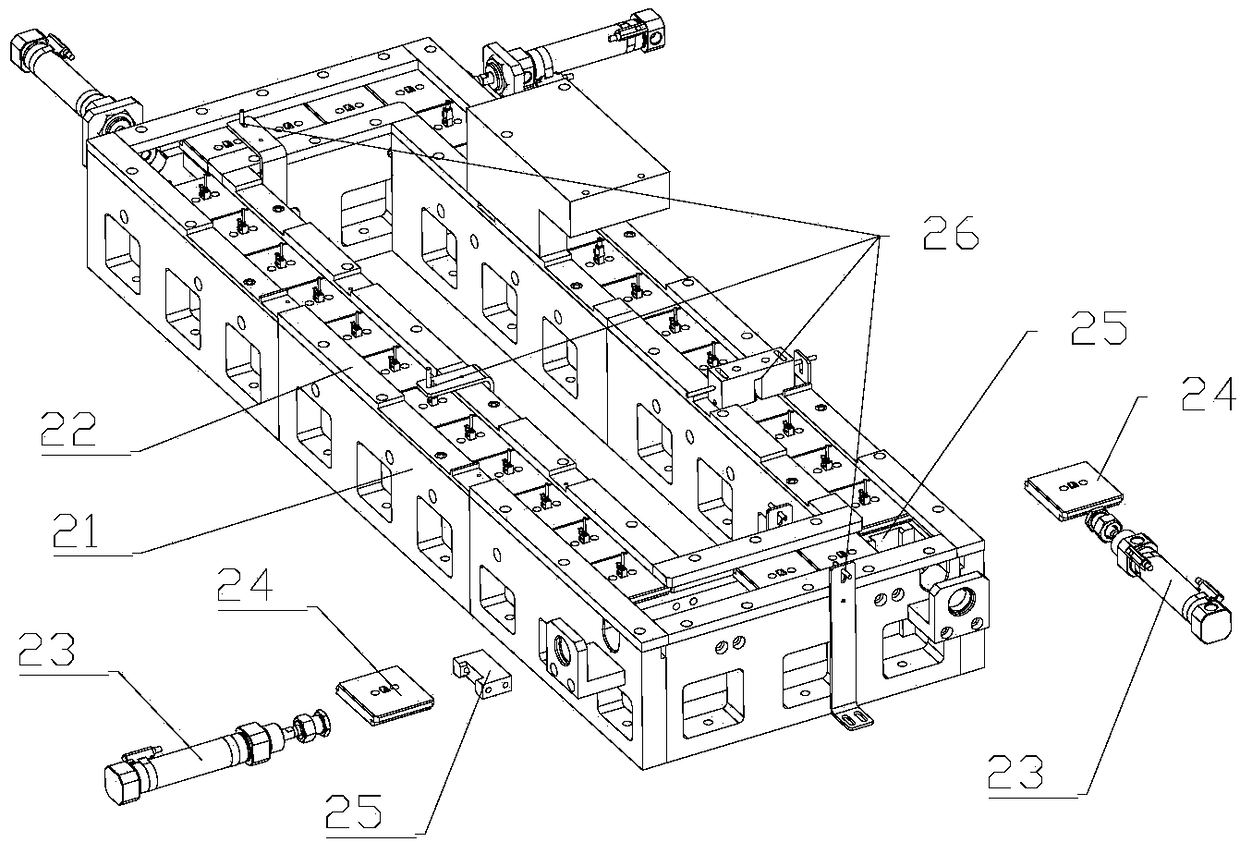

Hole tray conveying locating device for pot seedling transplanter

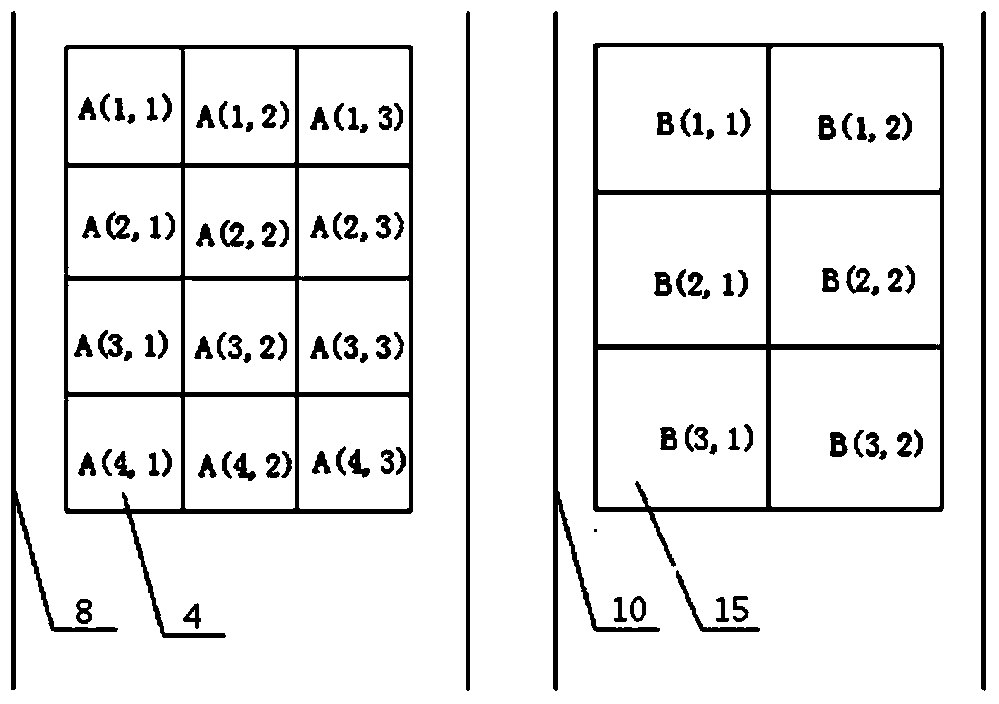

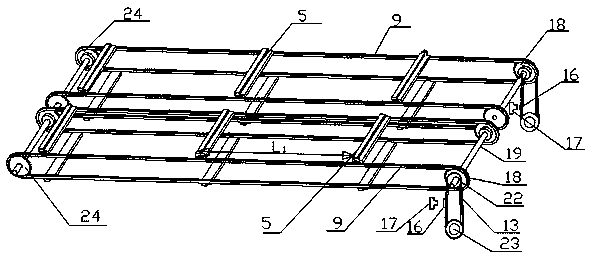

The invention provides a hole tray conveying locating device for a pot seedling transplanter. The pot seedling transplanter is provided with two hole tray conveying locating devices identical in structure, the two hole tray conveying locating devices are parallel to each other, conveying platforms are fixedly installed on a conveying table frame, a hole tray conveying guiding device is installed above the conveying platforms, hole trays are placed on the conveying platforms and between two conveying guide rails, horizontal conveying chain devices are installed on two sides of the conveying table frame, a plurality of hole tray push plates are installed on horizontal conveying chains at intervals of L1, a transmission chain device is installed on the outer side of the conveying table frame, and a Hall sensor is installed on one side of a transmission chain. When a servo motor drives the transmission chain to rotate for a round, the hole tray push plates on the horizontal conveying chains move a distance of L1, simultaneously the Hall sensor on one side of the transmission chain obtains induction signal once, and accordingly hole tray locating conveying is achieved. The hole tray conveying locating device is high in conveying locating precision, stable and reliable and is mainly applied to pot seedling transplantation.

Owner:JIANGSU UNIV

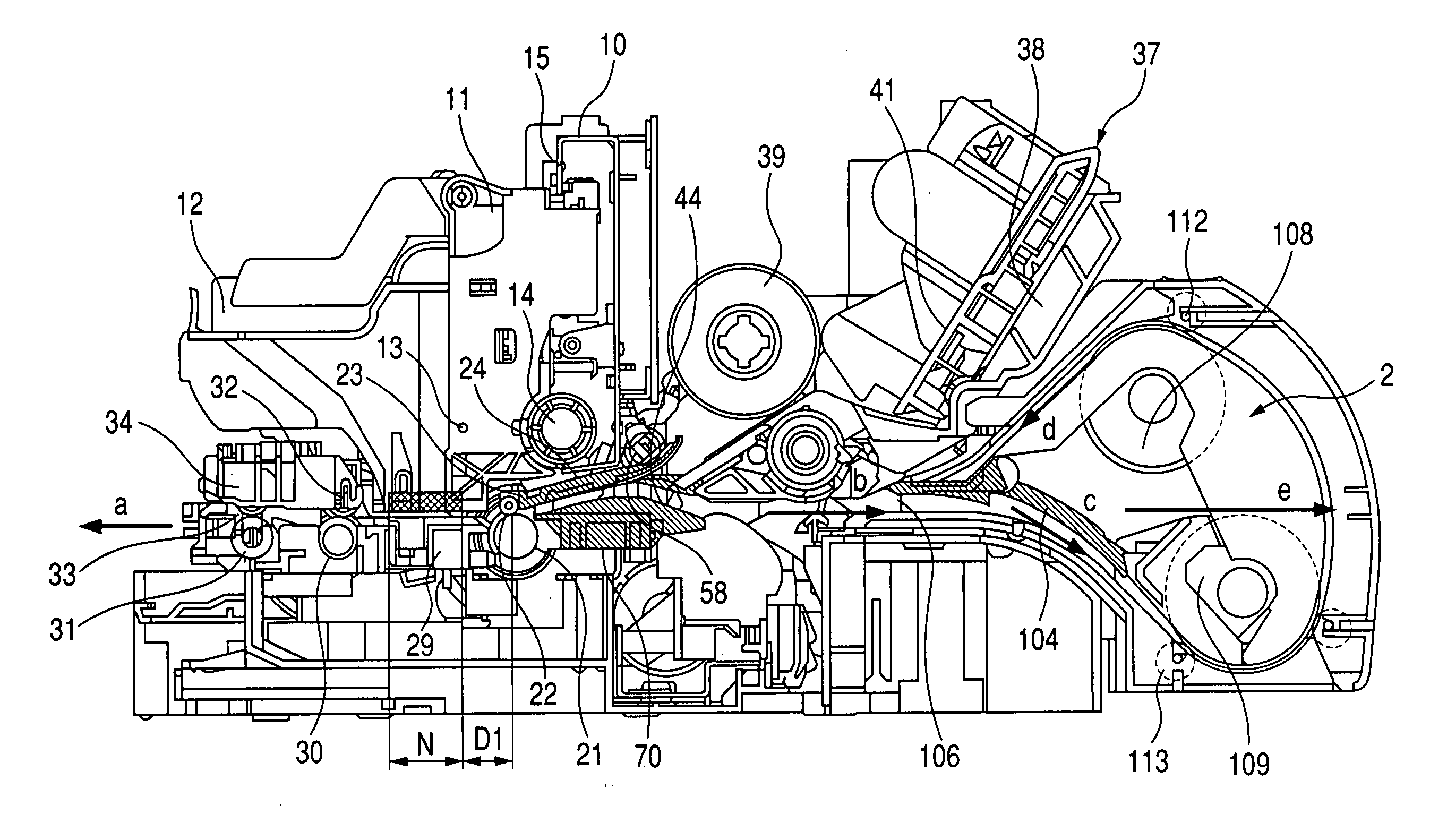

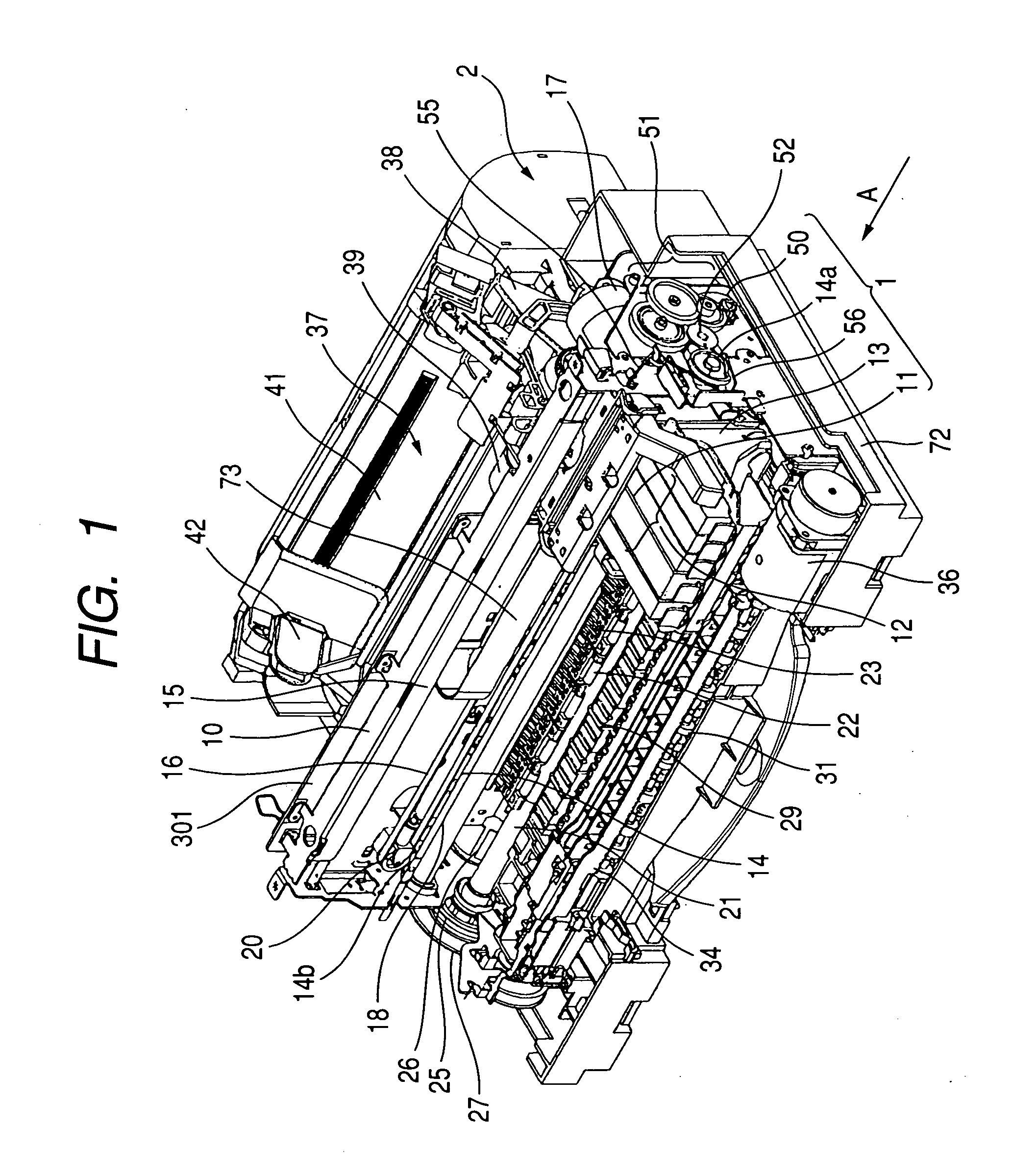

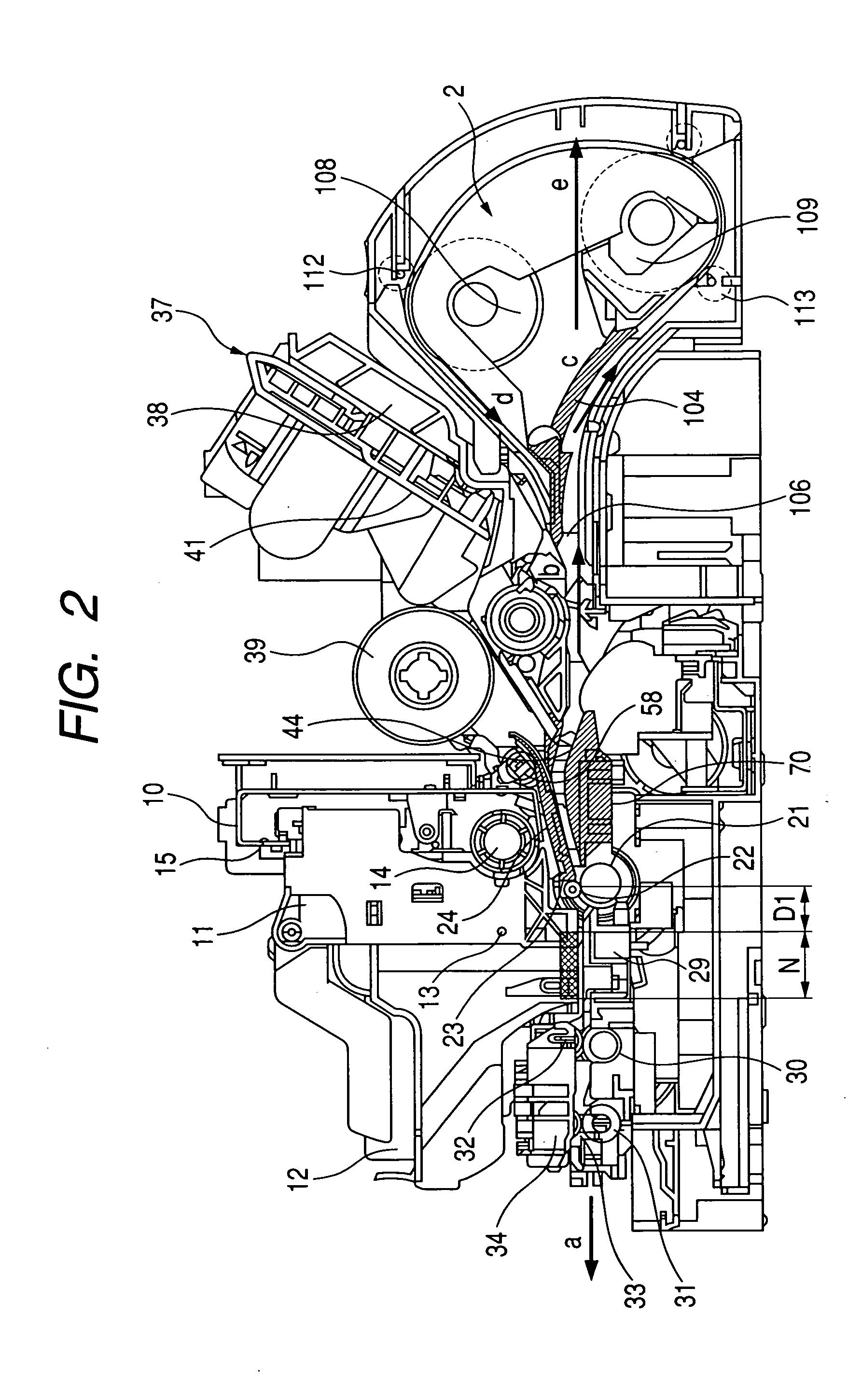

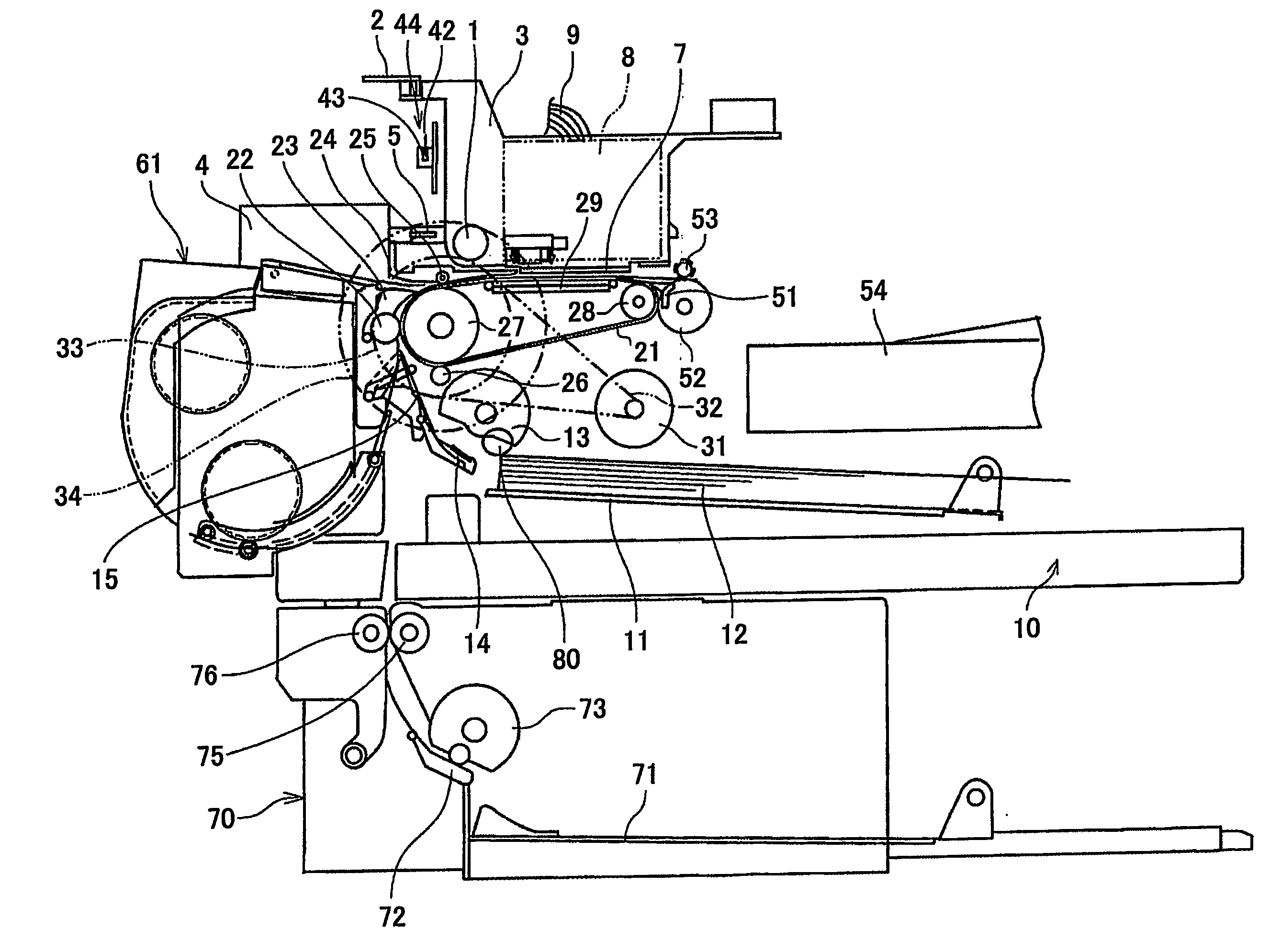

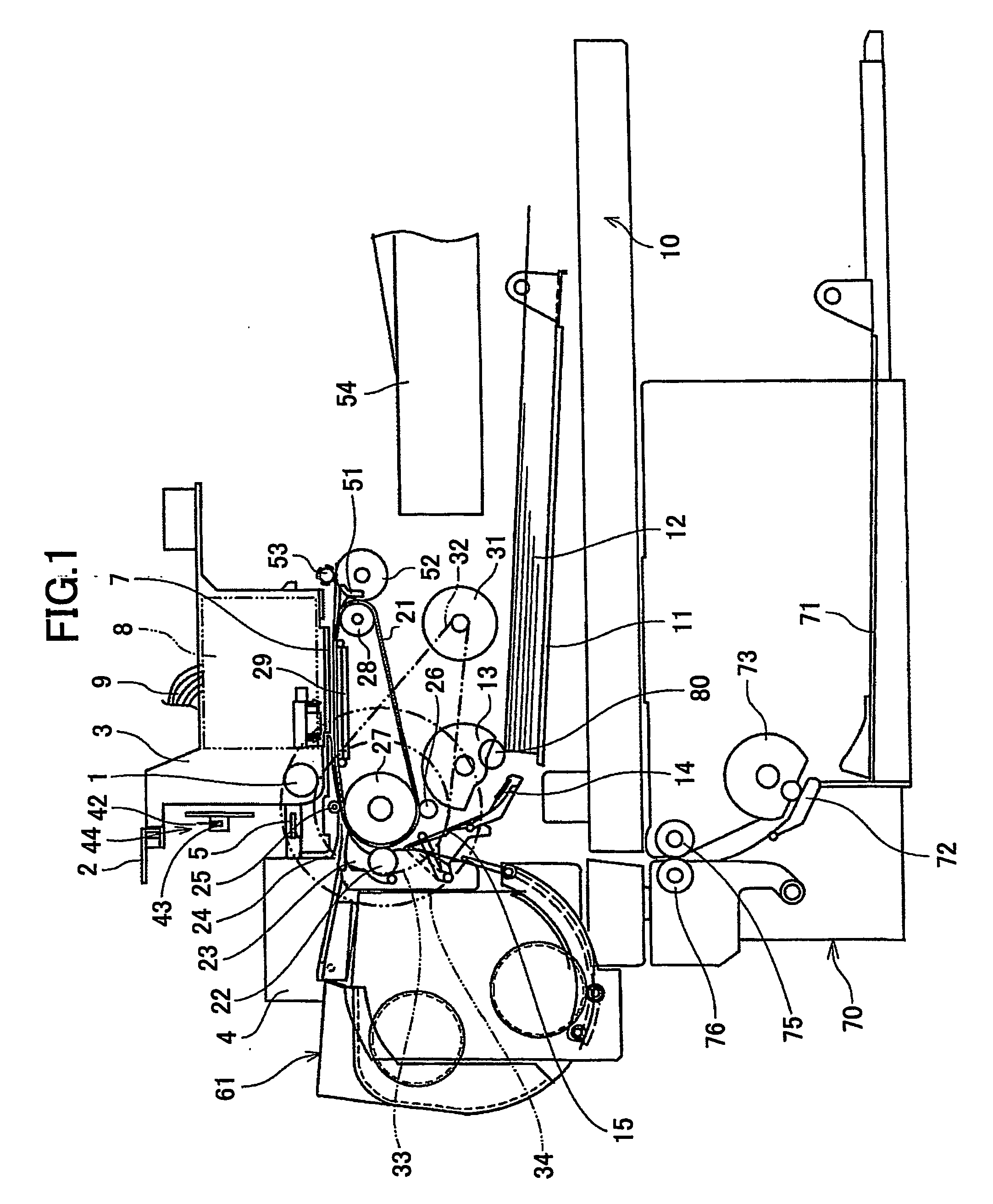

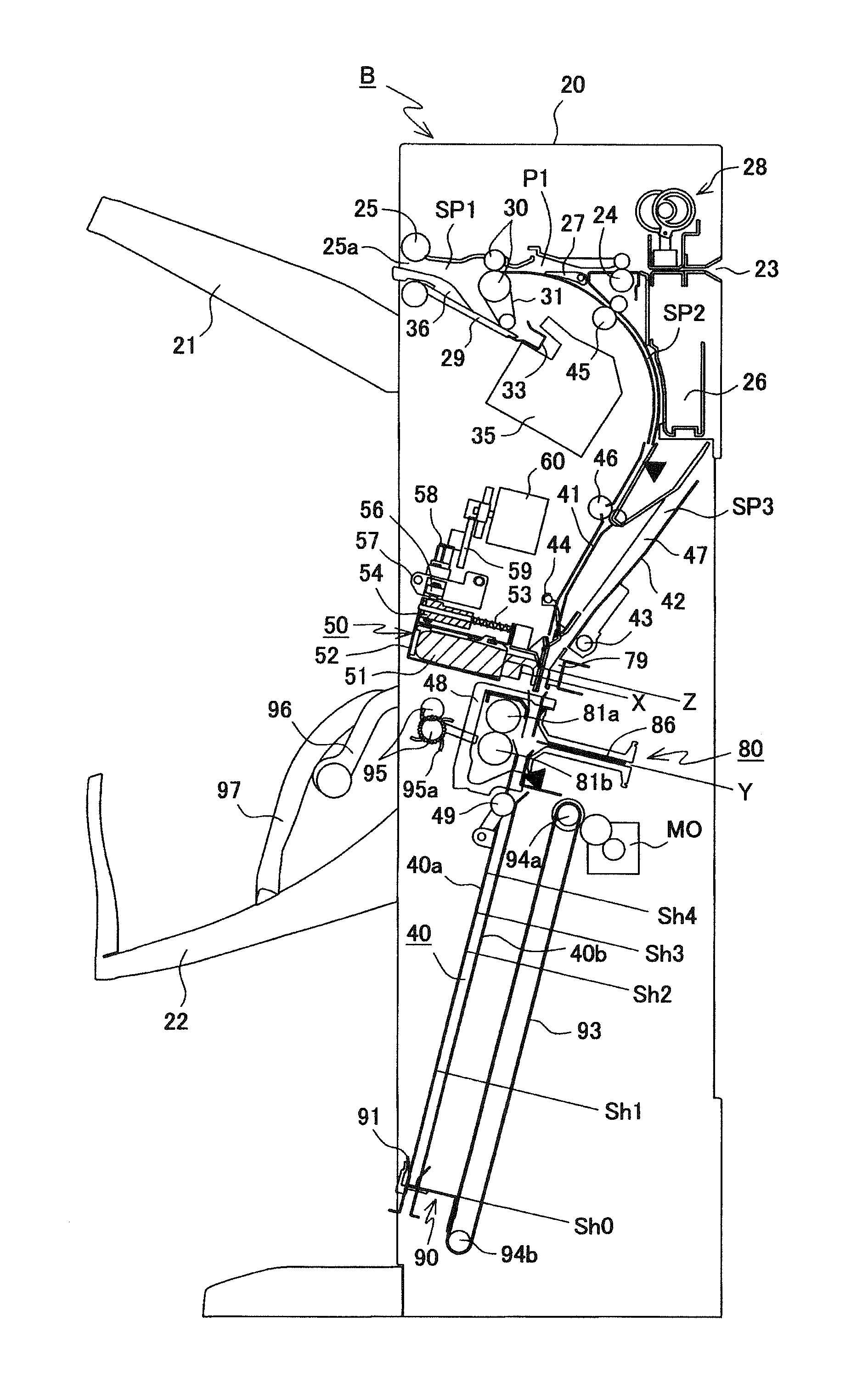

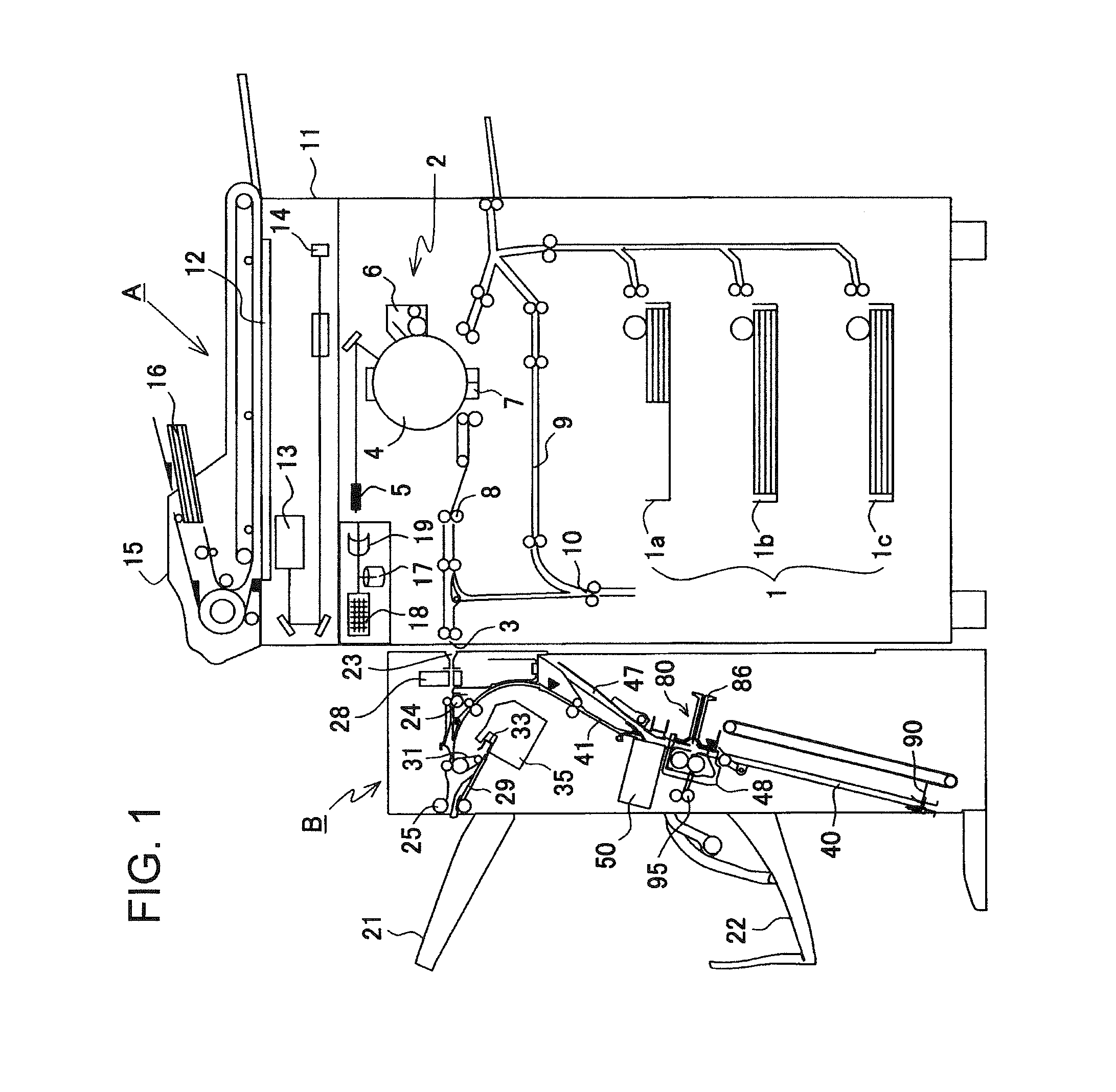

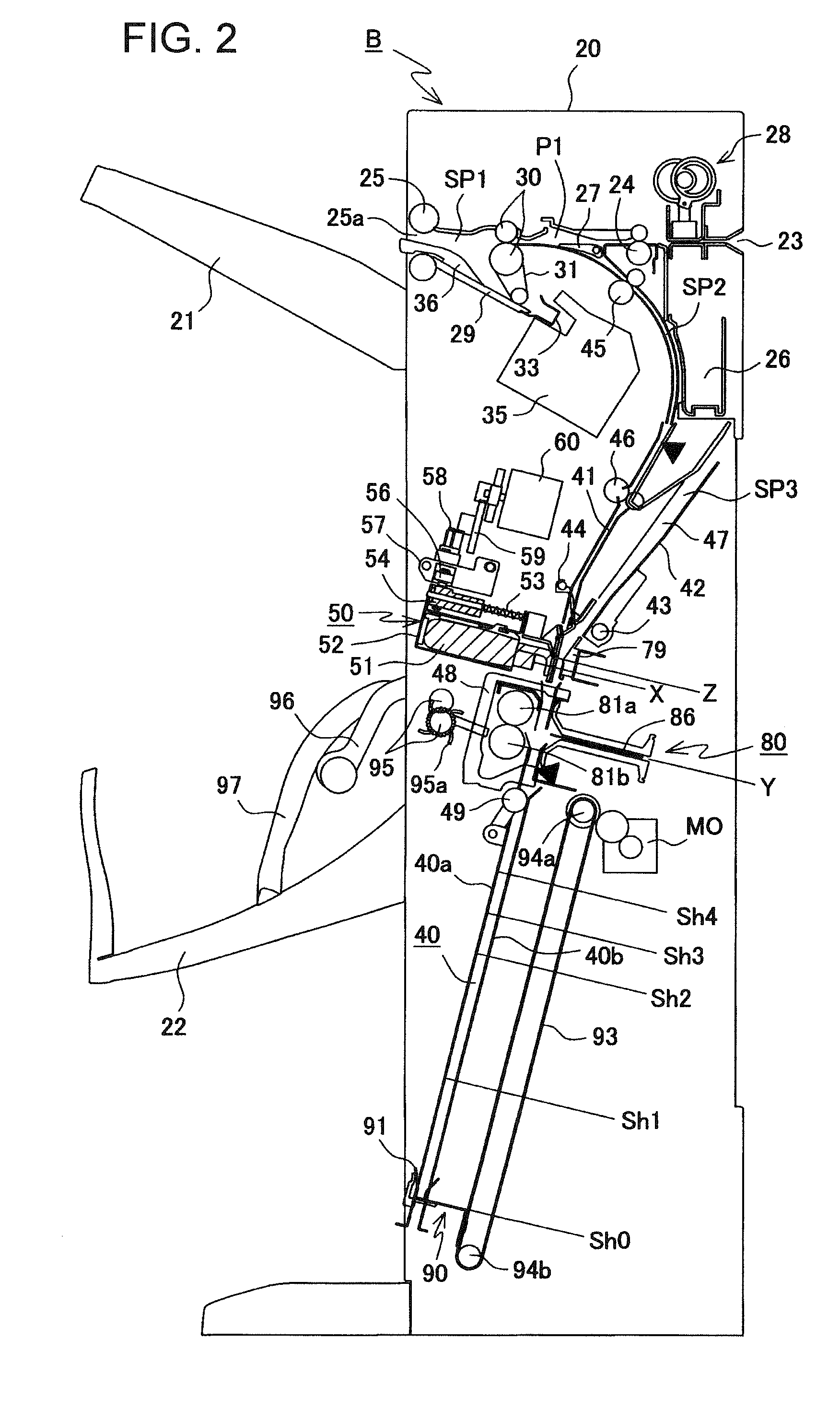

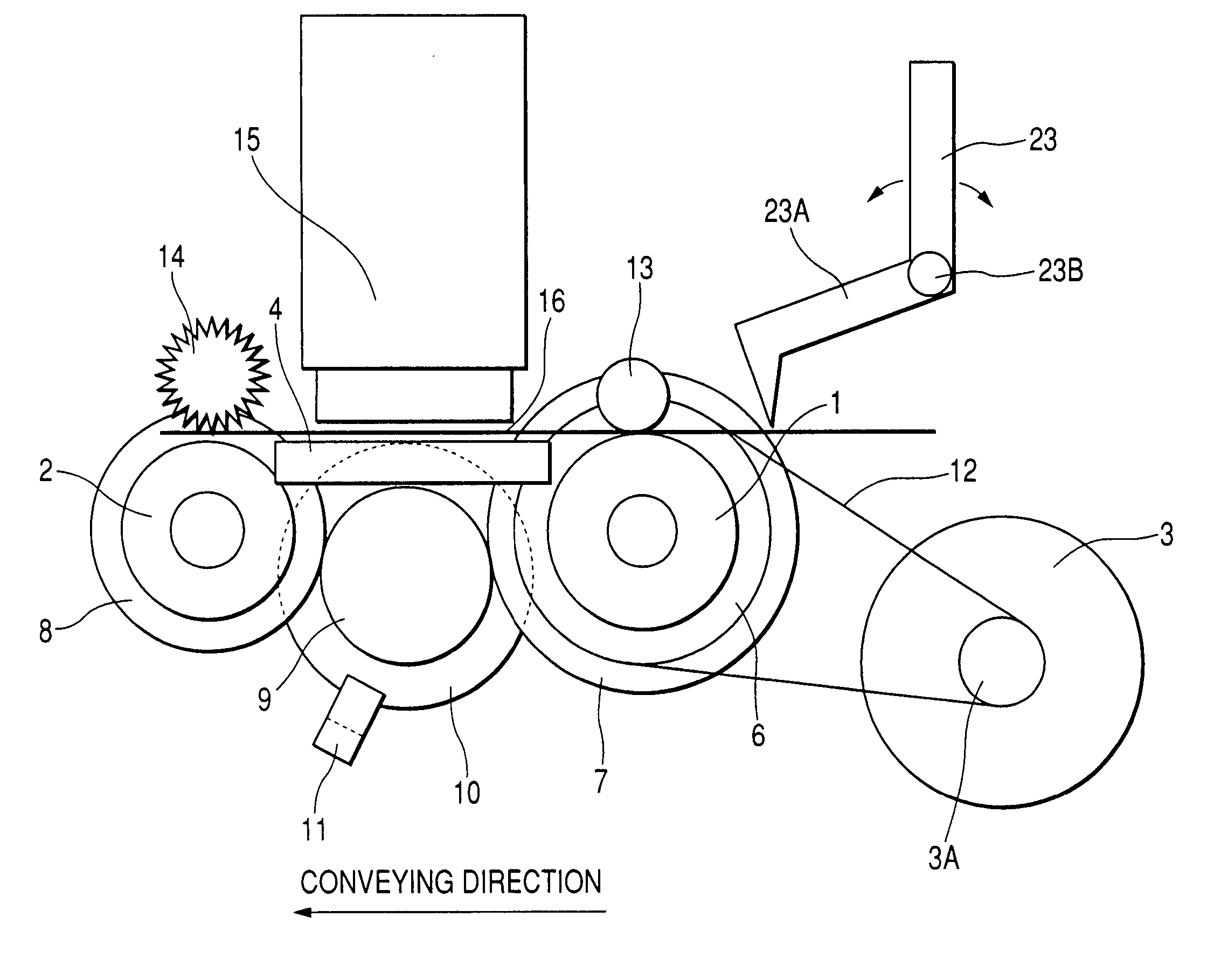

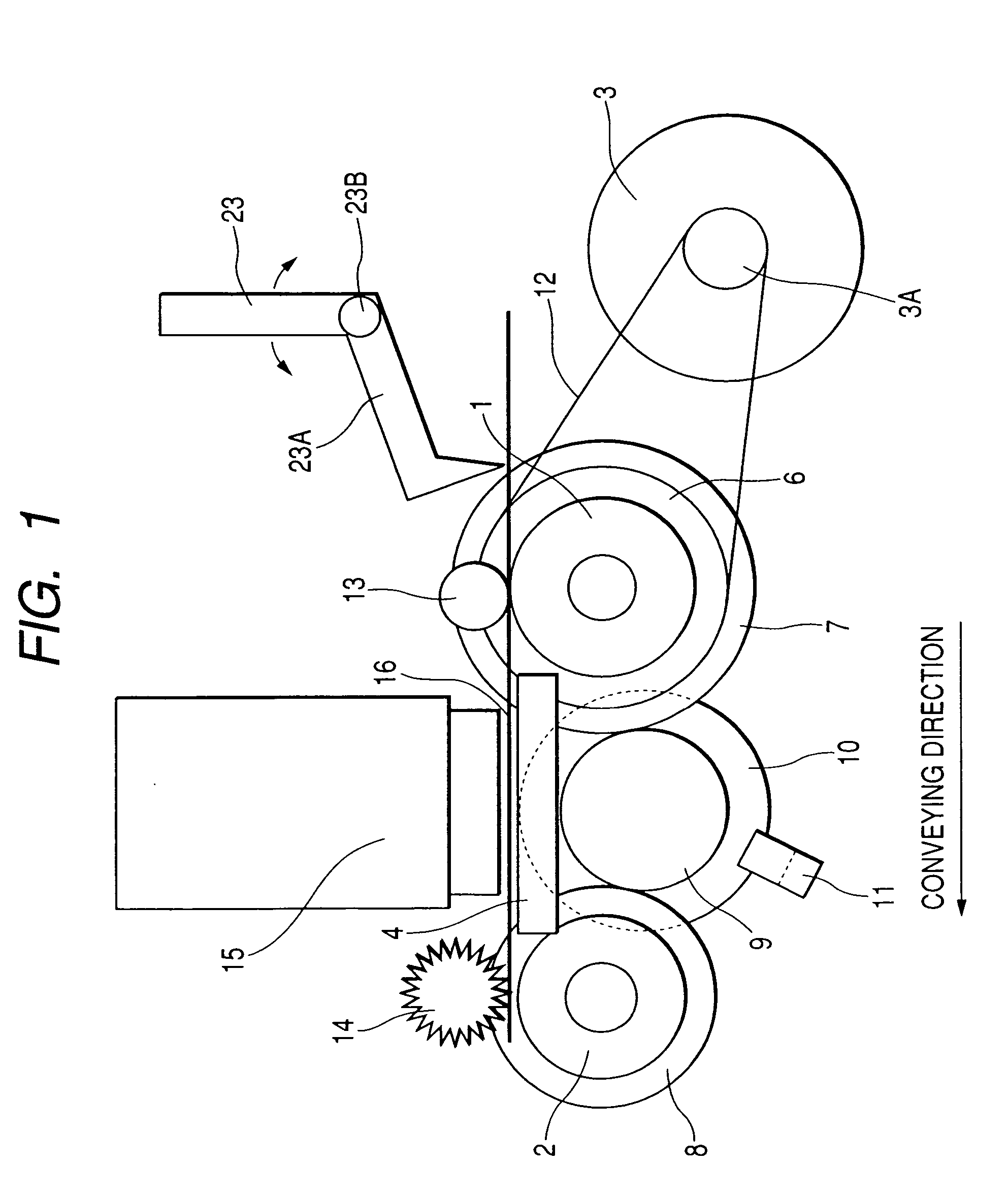

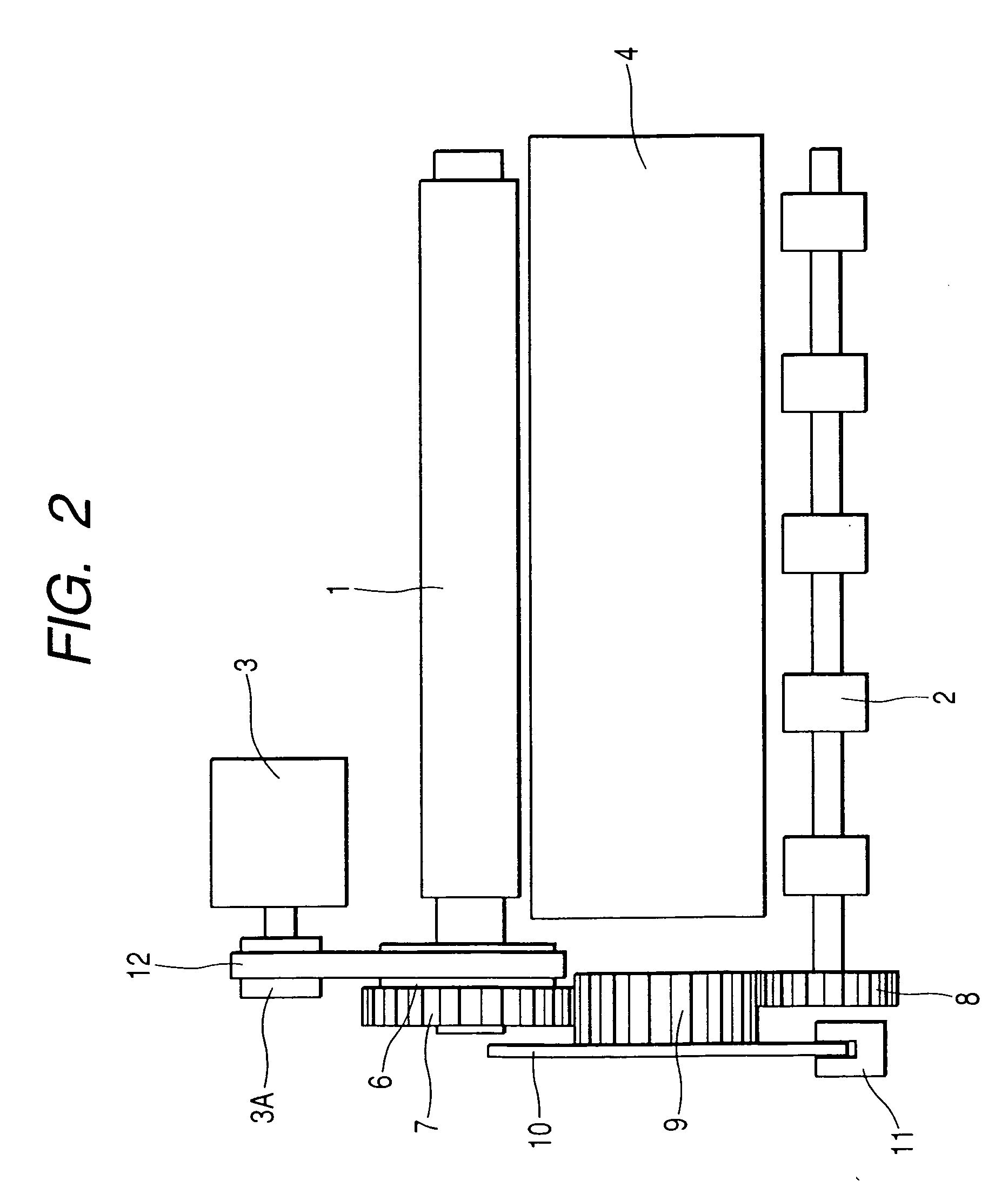

Both-side recording apparatus

InactiveUS20050012800A1Restricted degrees of freedomReduction in apparatus sizeTypewritersOther printing apparatusEngineeringPaper sheet

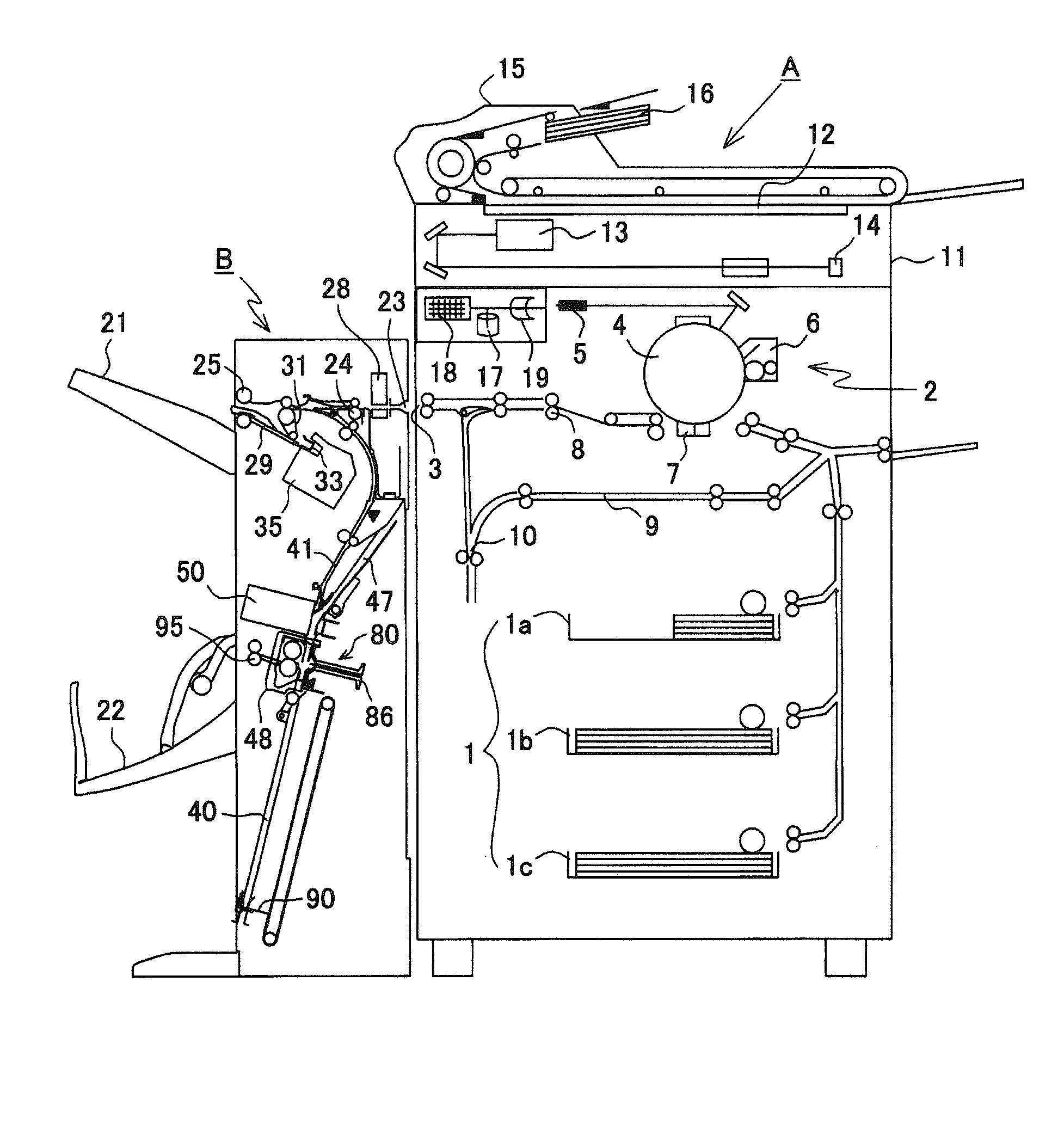

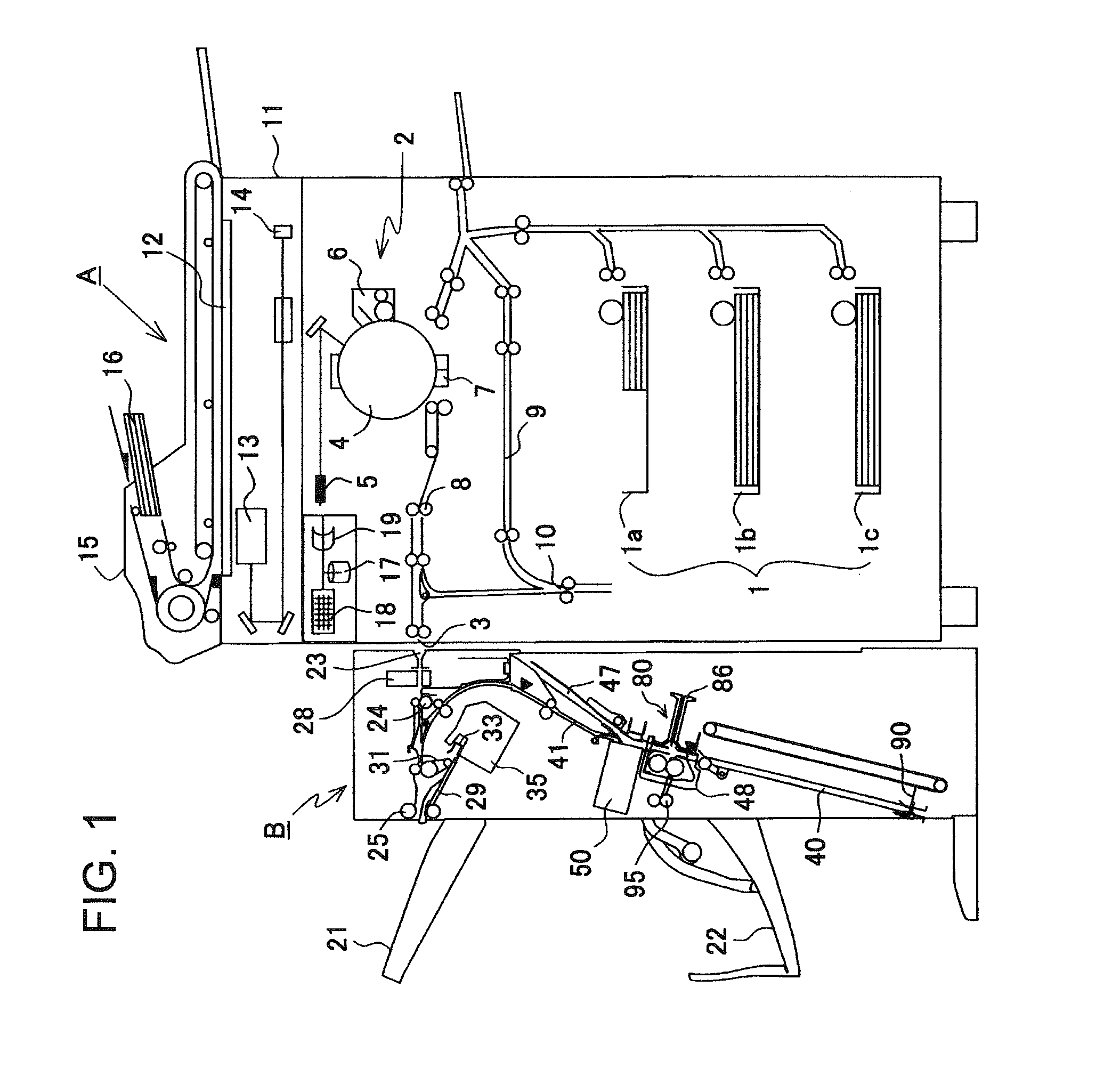

Driving sources of a reversing section roller and a sheet feeding roller are made common, a drive transmission mechanism to the reversing section roller is provided with clutch means for starting and stopping synchronous rotation after a predetermined rotation, and a degree of freedom in control is enhanced by properly bringing the reversing section roller into a halted state as necessary, thereby realizing reduction in load on the driving source, reduction in noises, and reduction in the size of the apparatus and cost. The apparatus is provided with clutch means, which starts synchronous rotation of the reversing section roller with the sheet feeding roller is started in a period of time from a start of a drive of the sheet feeding roller until nipping of a recording medium by the reversing section roller, after recording is performed onto a front surface, and stops the synchronous rotation of the reversing section roller with the sheet feeding roller in a period of time from release from the reversing section roller until finishing of a sheet discharge operation, after the recording medium from a sheet reversing section is nipped by the sheet feeding roller again.

Owner:CANON KK

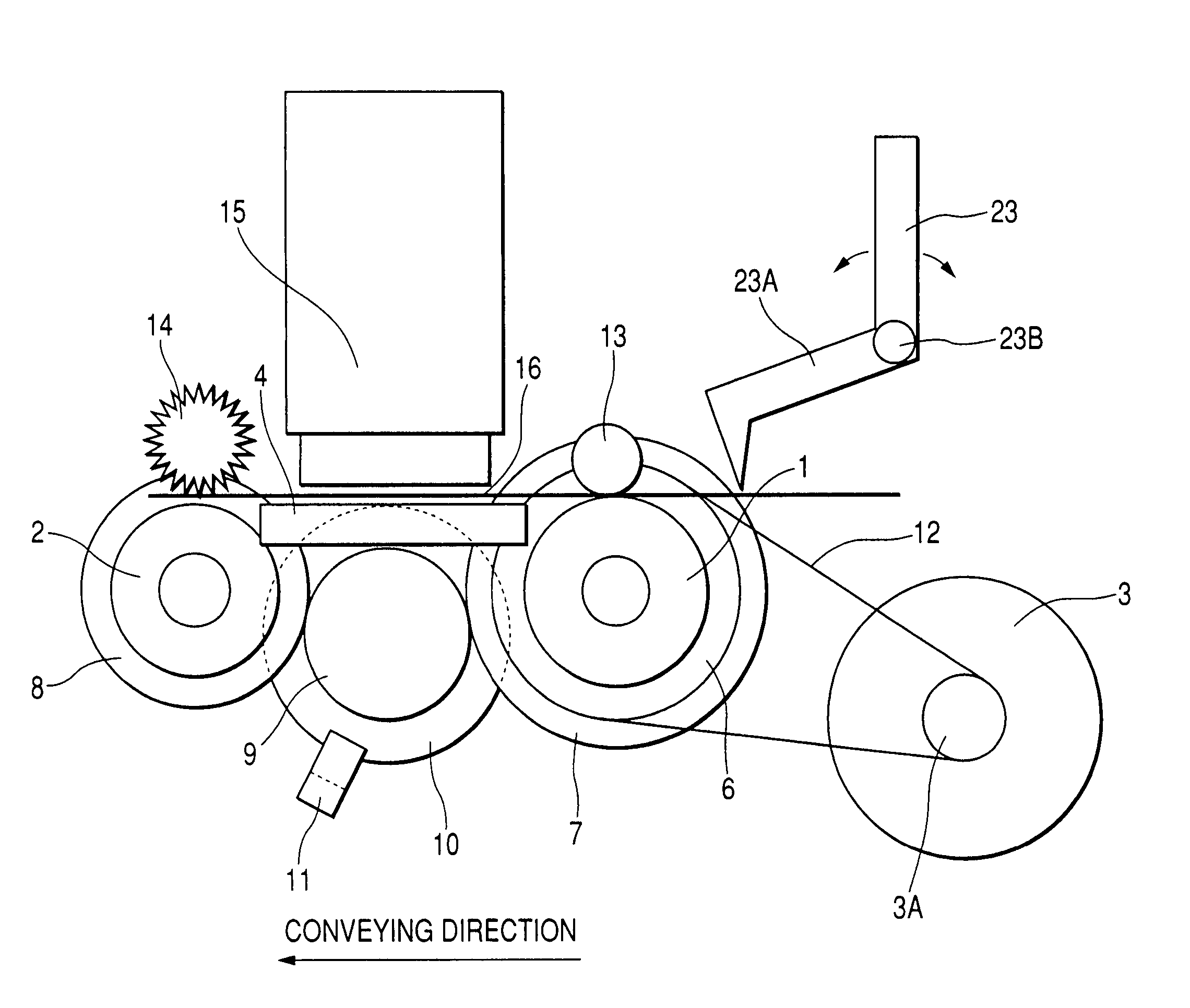

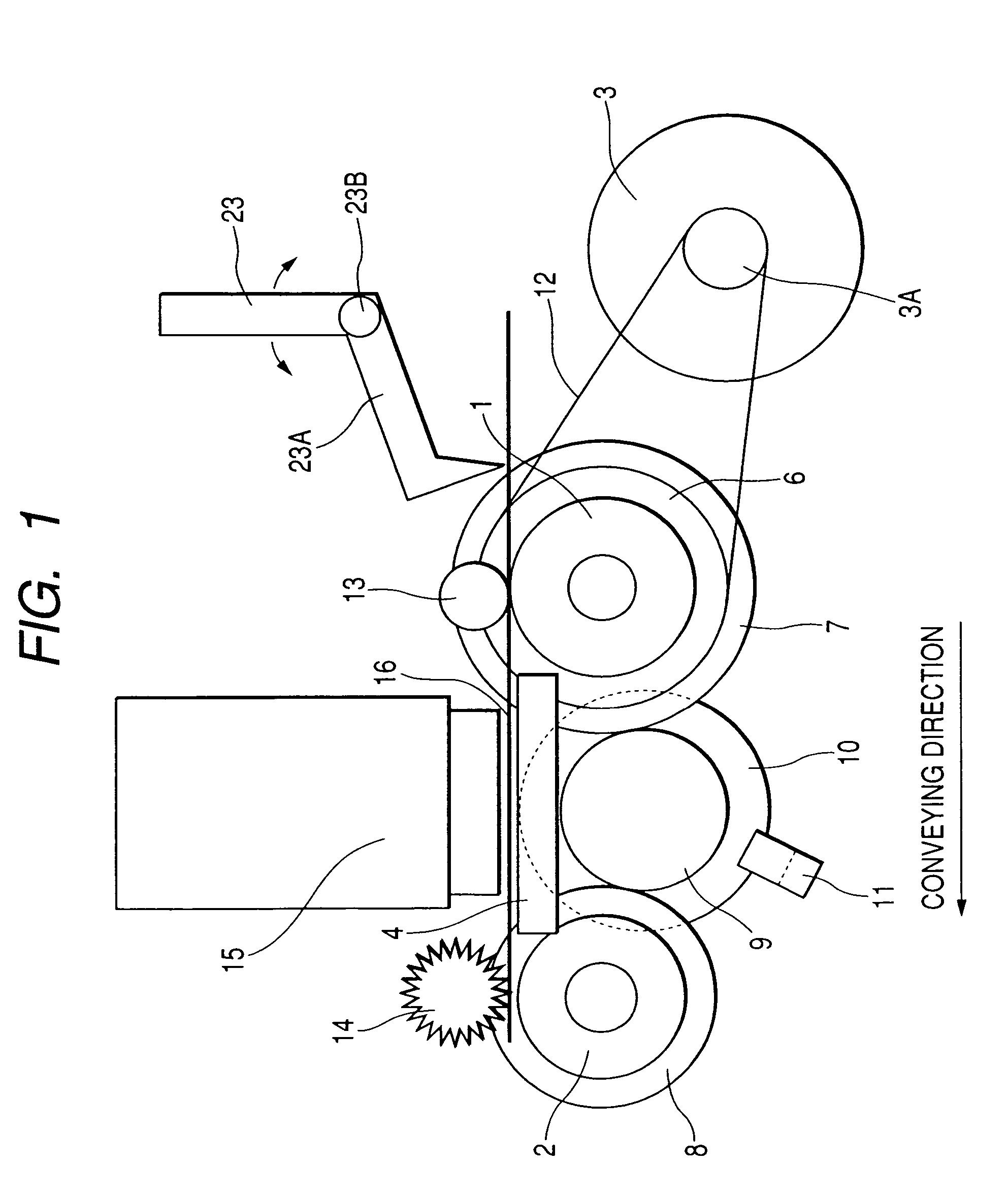

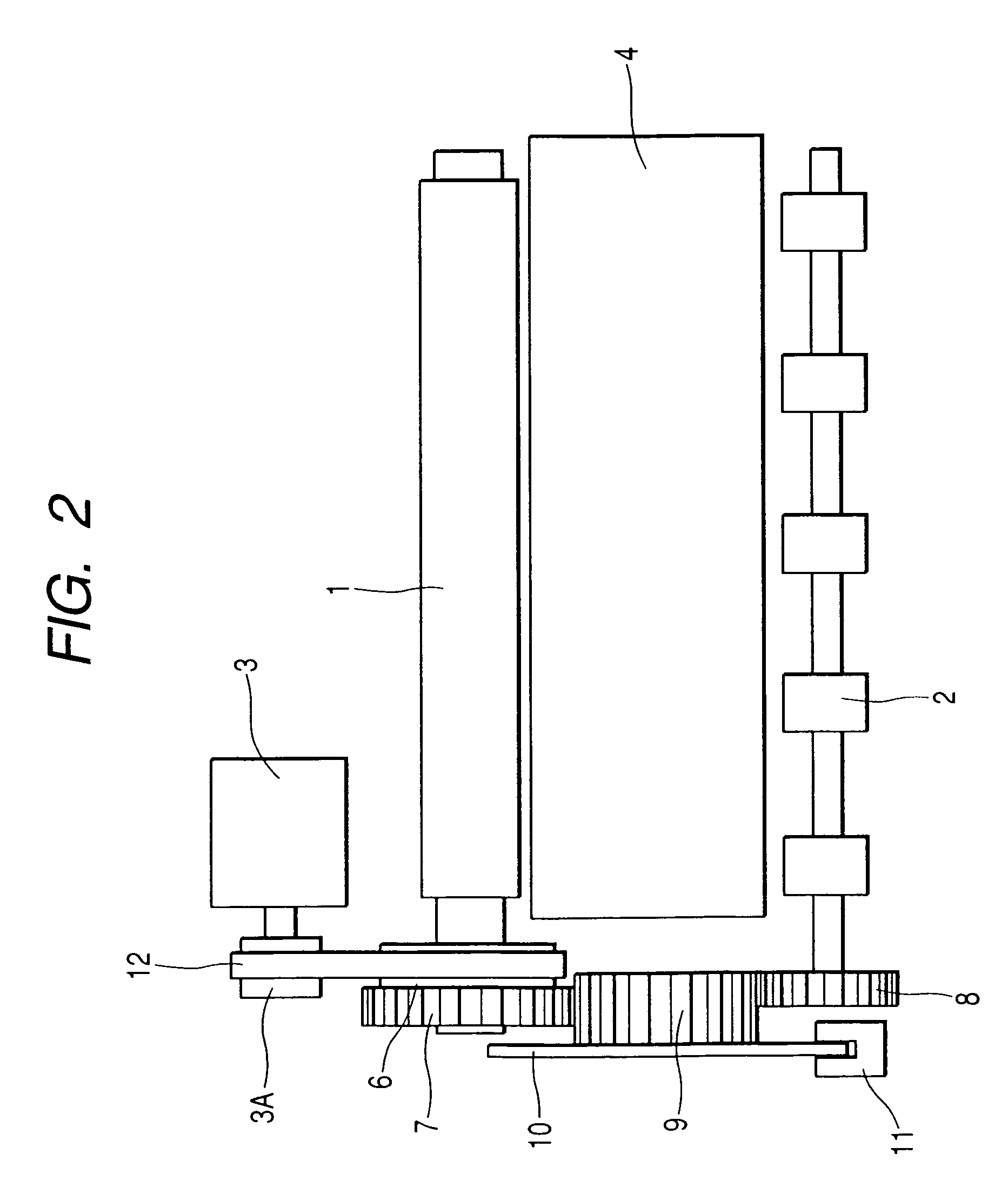

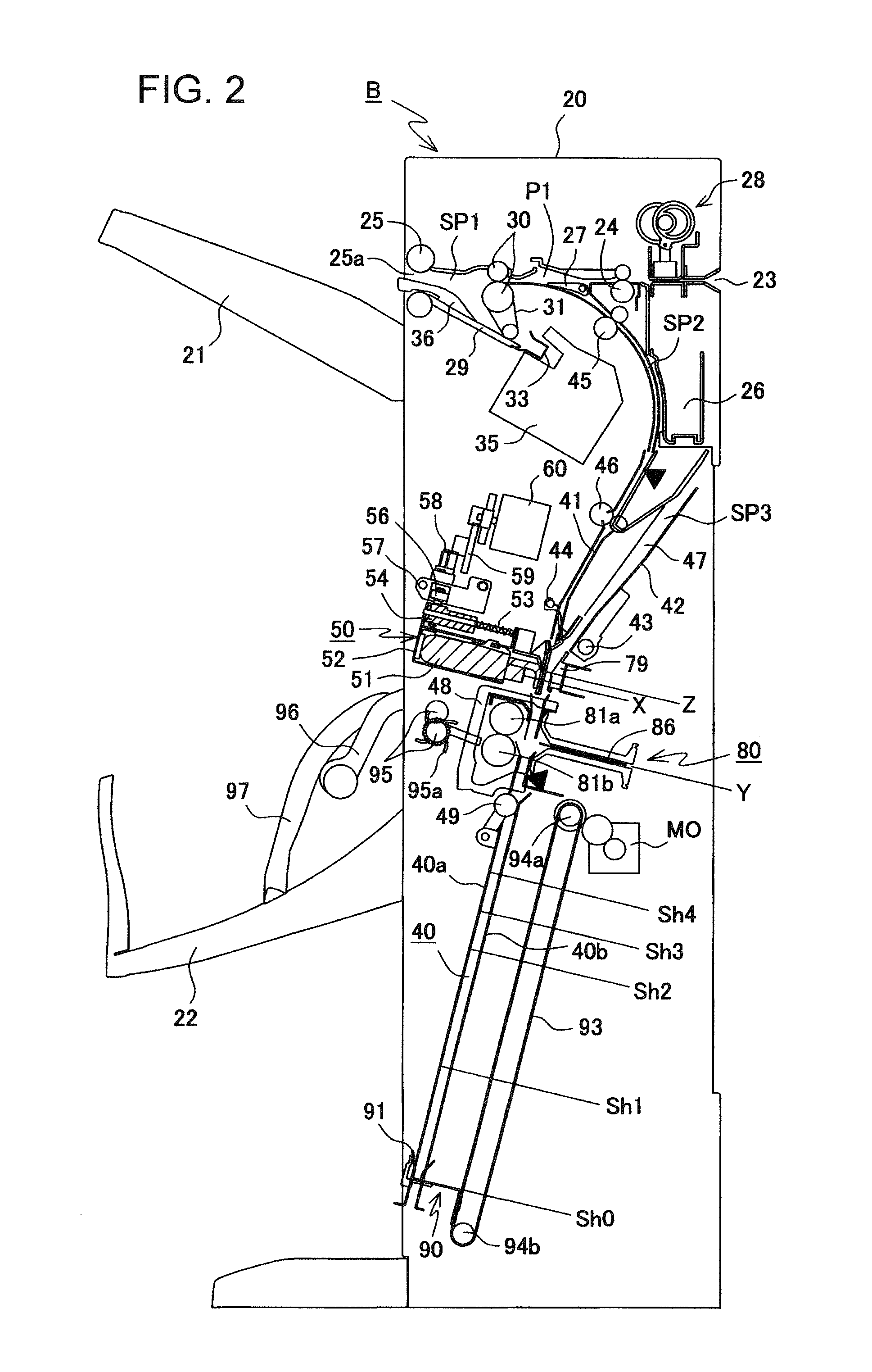

Image forming apparatus

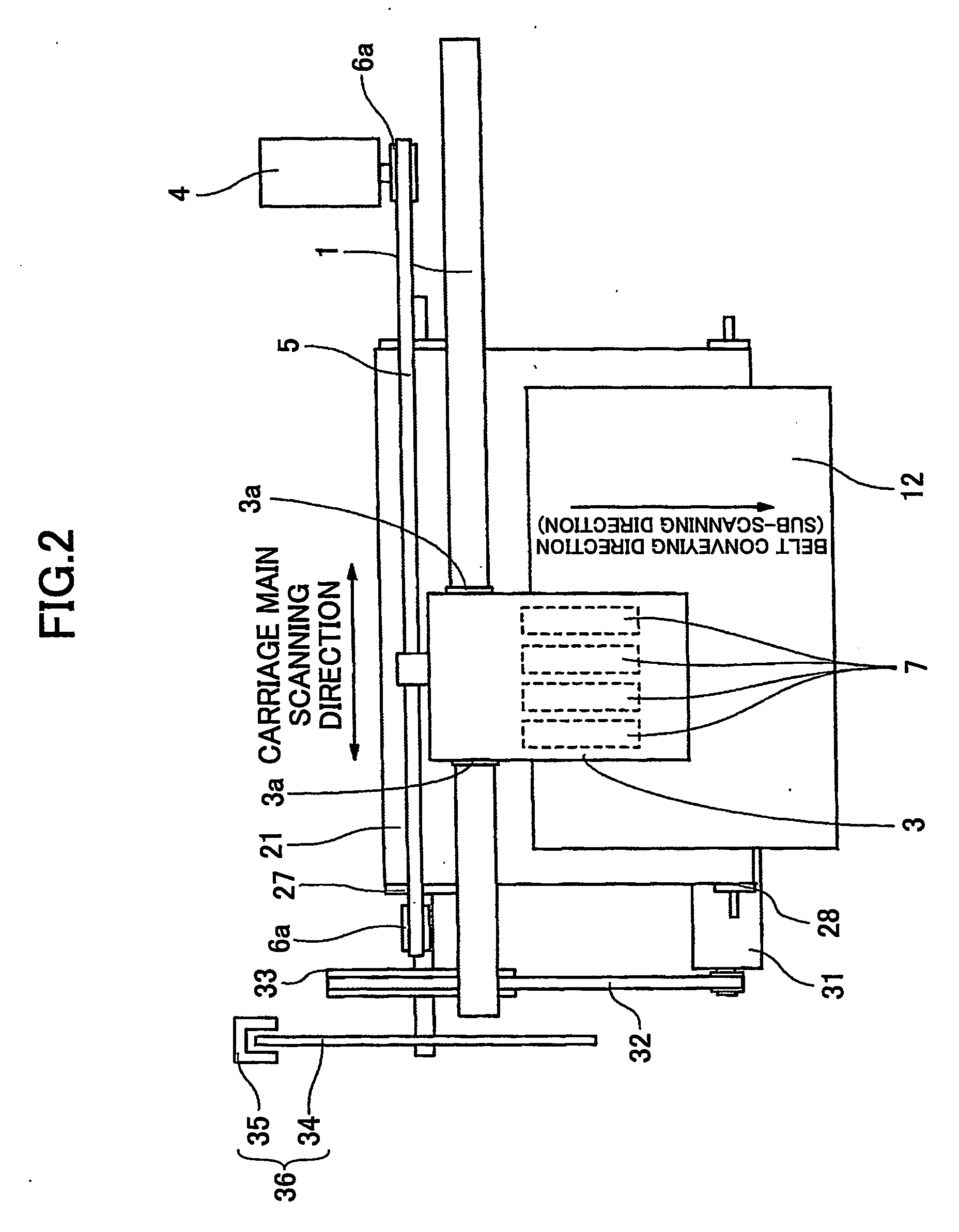

ActiveUS20070103532A1Eliminate the problemHigh conveying precisionFunction indicatorsElectrographic process apparatusImage formationEngineering

An image forming apparatus can improve an accuracy of conveyance of a recording medium with a simple structure and prevent a reverse flow of mist so as to stably form a high-quality image. A conveyance belt (21) conveys a recording medium (12) by attracting the recording medium by an electrostatic force generated by electric charges applied thereto. A recording head (7) discharges droplets of a recording liquid toward the recording medium (12). An amount of electric charges induced on a surface of the recording medium (12), which has been conveyed to a recording position where the droplets of the recording liquid are discharged from the recording head (7) toward the recording medium (12), is adjusted in accordance with a resistance value of the recording medium (12).

Owner:RICOH KK

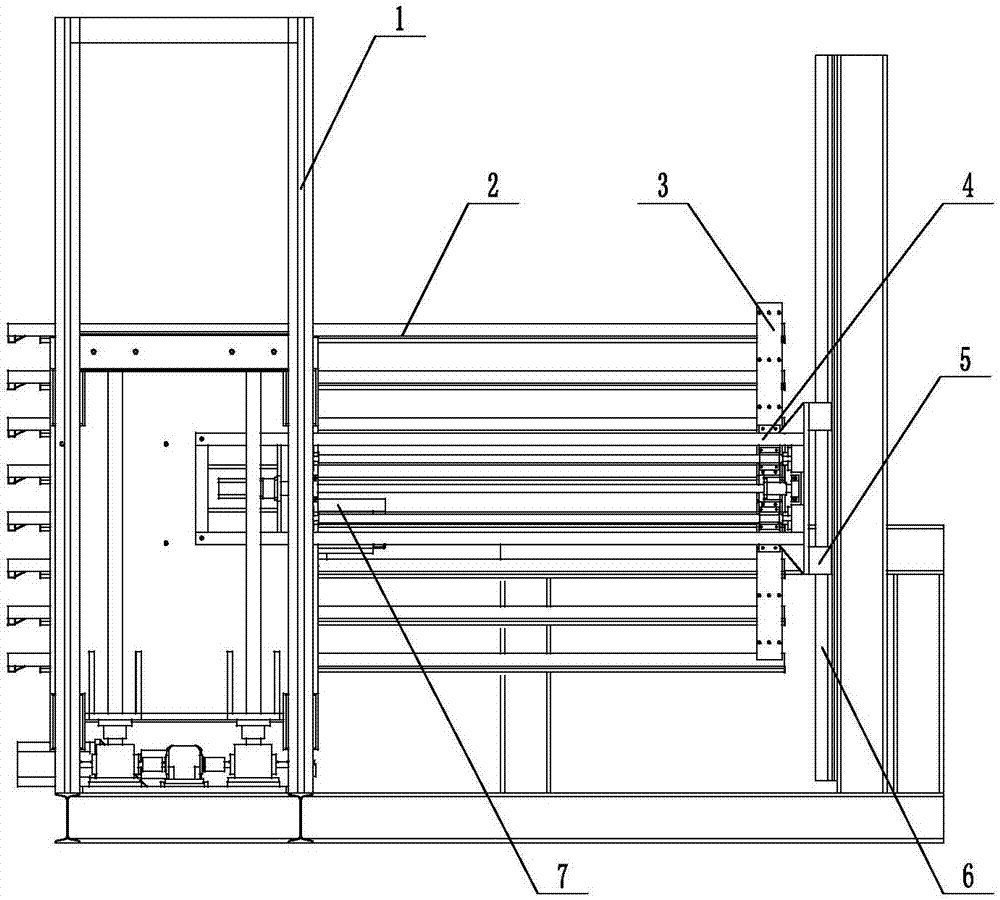

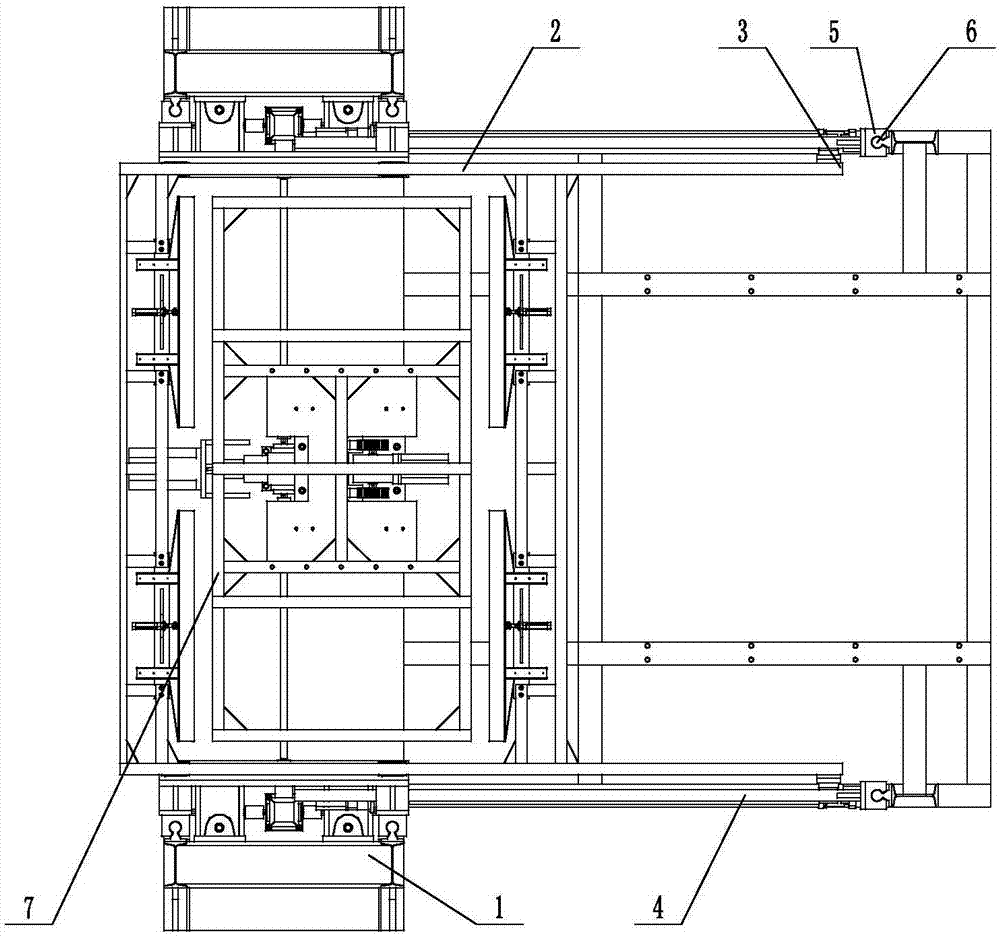

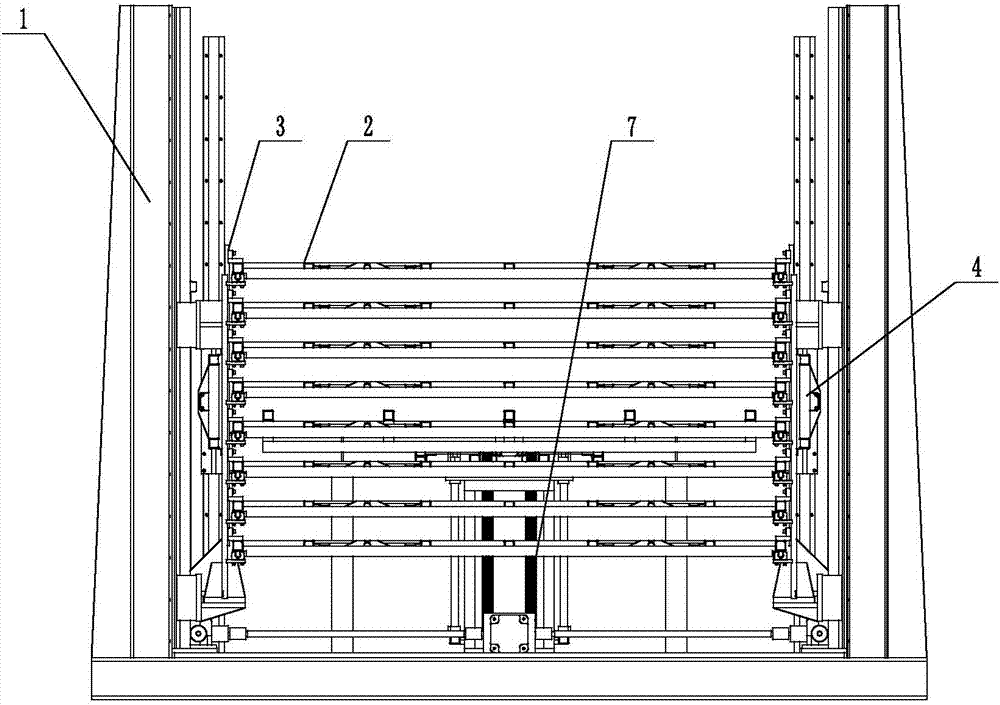

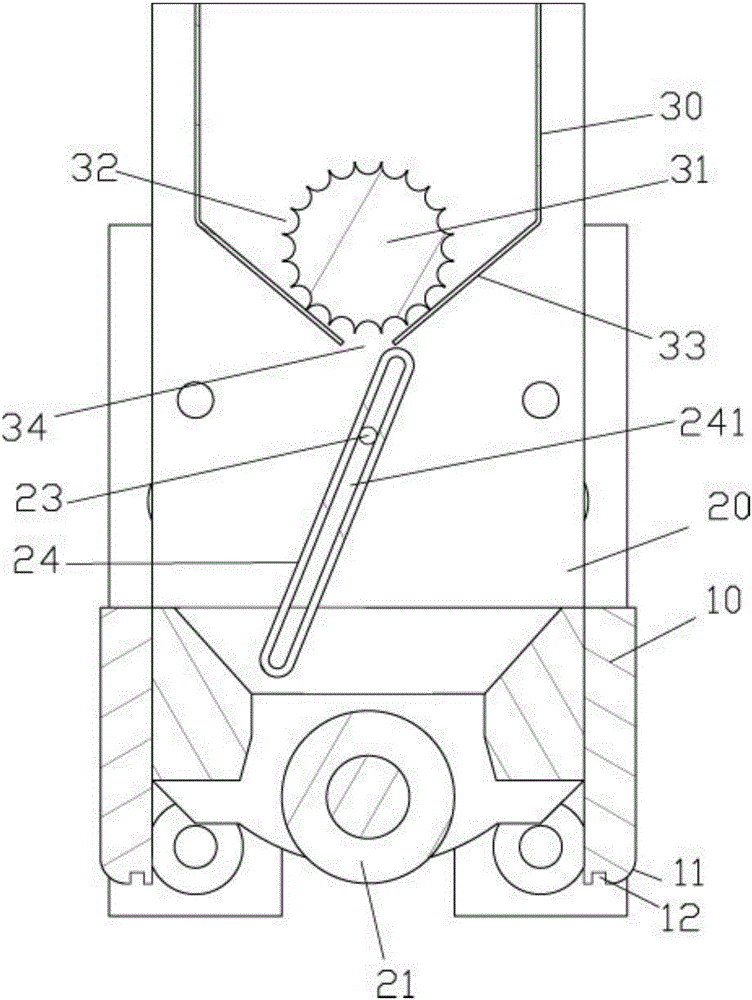

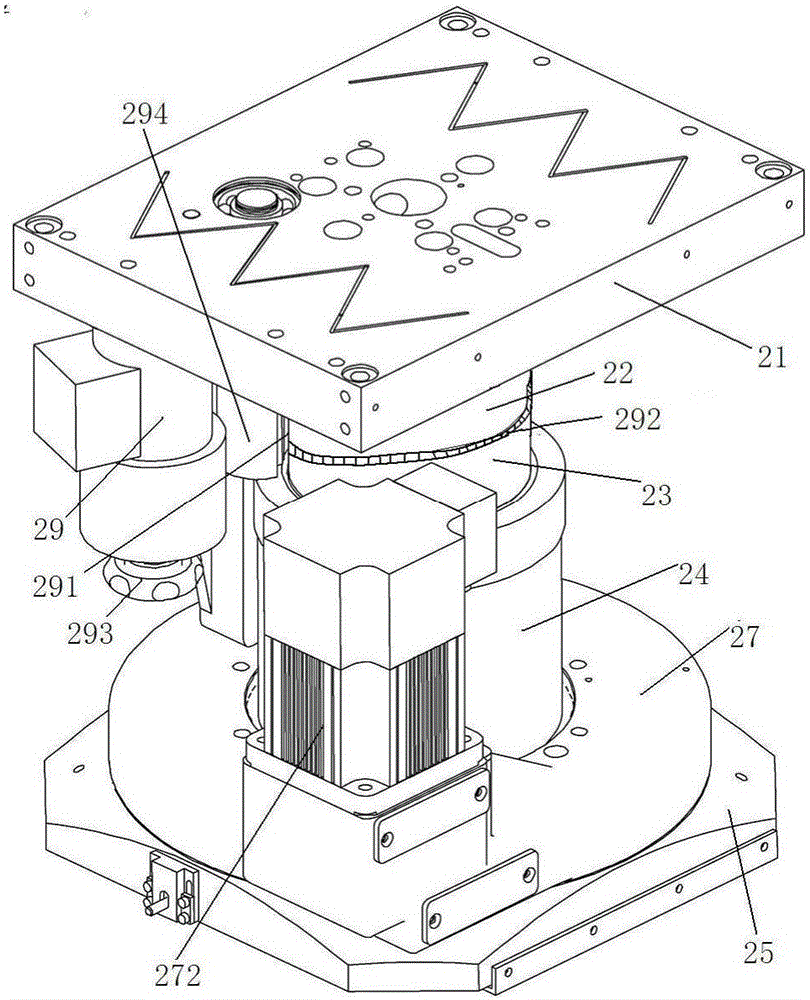

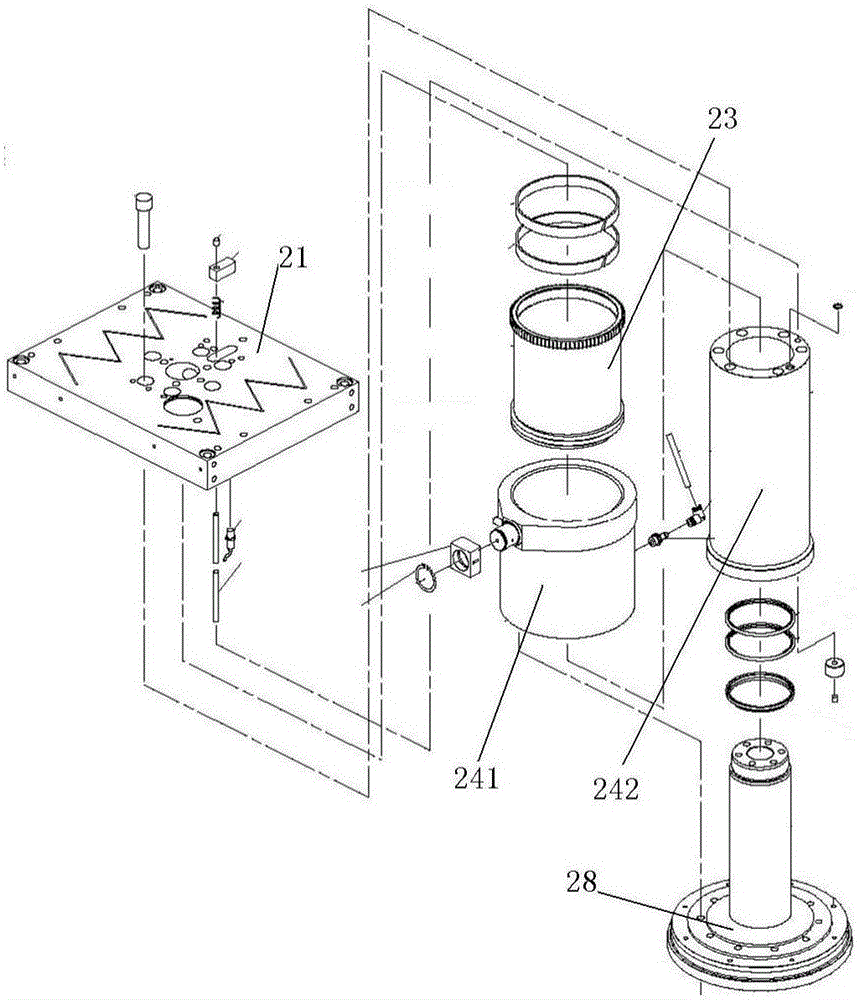

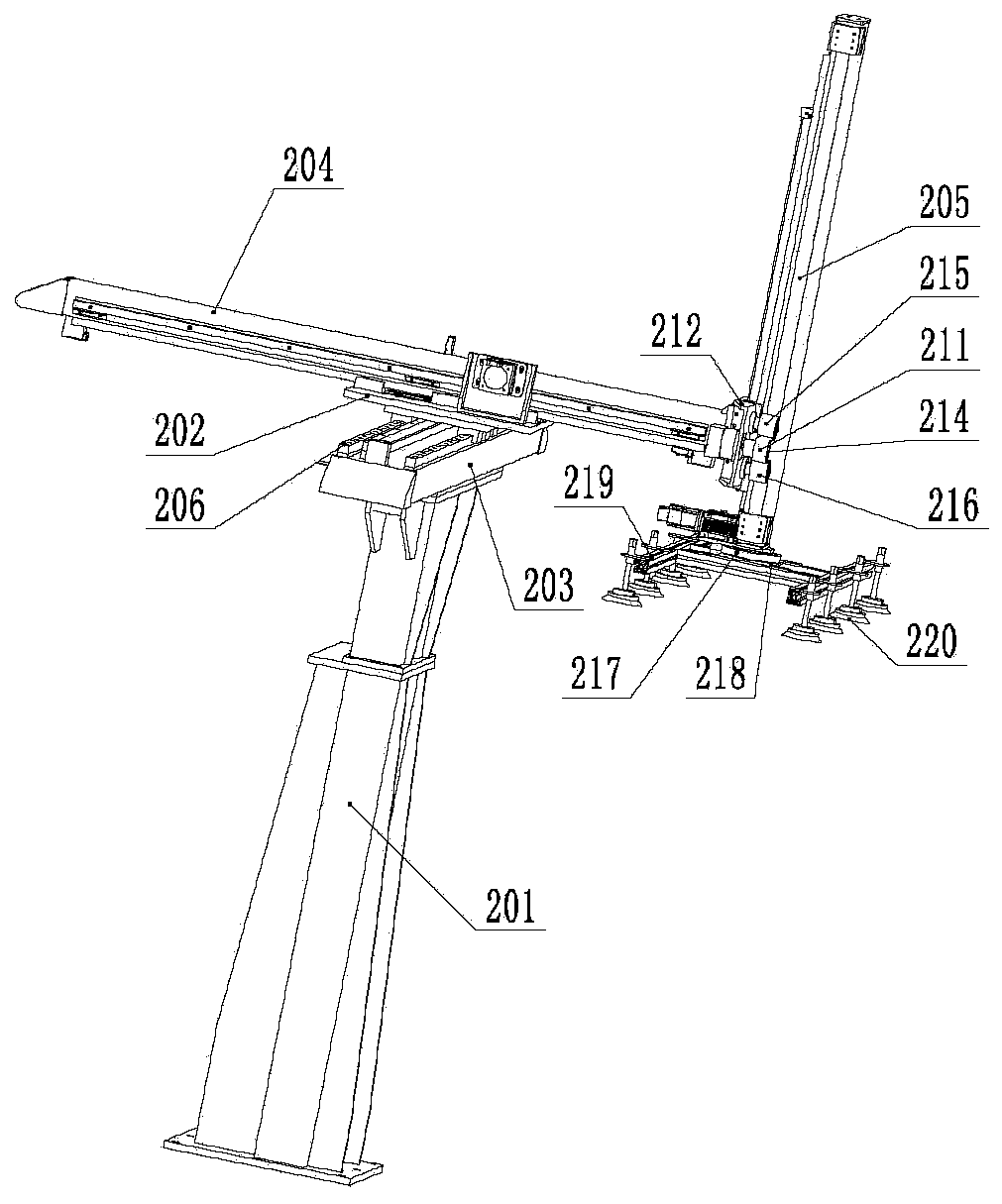

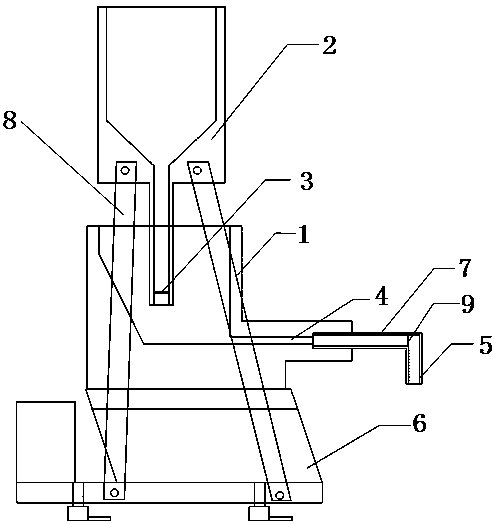

Wood board loading and unloading lifting assembly

ActiveCN107139280AHigh degree of automationReduce manpower consumptionPlywood pressesLaminationEngineeringMechanical engineering

The invention discloses a wood board loading and unloading lifting assembly which comprises a lifting mechanism (1), a jacking mechanism (7), a push mechanism (4) and a plurality of bearing and connecting mechanisms (2). The wood board loading and unloading lifting assembly has the advantages that working efficiency is high, energy consumption is reduced, manpower is saved, conveying precision is high, and a hot press can conduct hot pressing on the two faces simultaneously.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

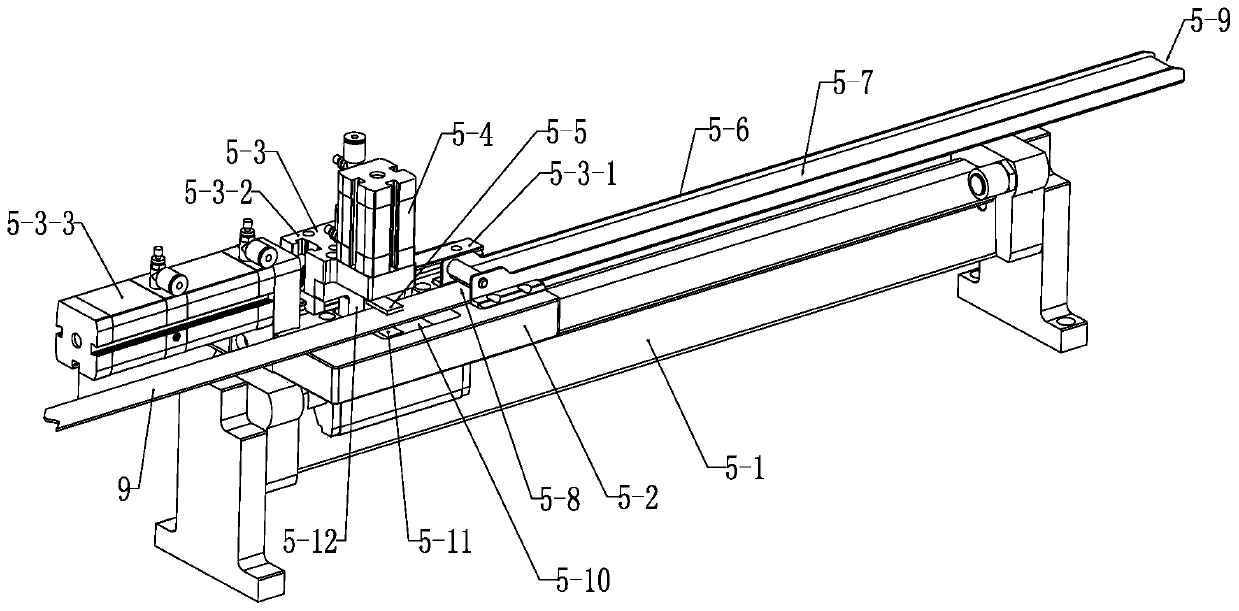

Programmable high speed automatic pipe cutting machine

InactiveCN102642215AHigh conveying precisionEnsure health and safetyMetal working apparatusControl functionEngineering

The invention belongs to the technical field of pipe processing equipment, in particular to a programmable high speed automatic pipe cutting machine. A controller and a belt pulley mounting frame are arranged on a rack, two groups of belt pulleys are horizontally arranged on a same side of the belt pulley mounting frame and driven by a stepping motor respectively, the two groups of belt pulleys are arranged up and down and respectively provided with synchronous belts with adjustable center distances, guide cylinders capable of passing through braided pipes are arranged at the two ends of the two synchronous belts respectively, a color code sensor for detecting shear color code is arranged on the inner side of a first guide cylinder, a braided pipe cutting mechanism is arranged on the outer side of the first guide cylinder, a photoelectric sensor for detecting storage allowance of the braided pipes is arranged on the outer side of a second guide cylinder, signals detected by the color code sensor and the photoelectric sensor are sent to the controller, and the controller controls the rotating degree of the stepping motor and movement of cutting mechanism cutting the braided pipes according to procedures. The programmable high speed automatic pipe cutting machine has the advantages of being high in automation degree and control function, low in cost, high in accuracy and the like.

Owner:WATTS VALVE NINGBO

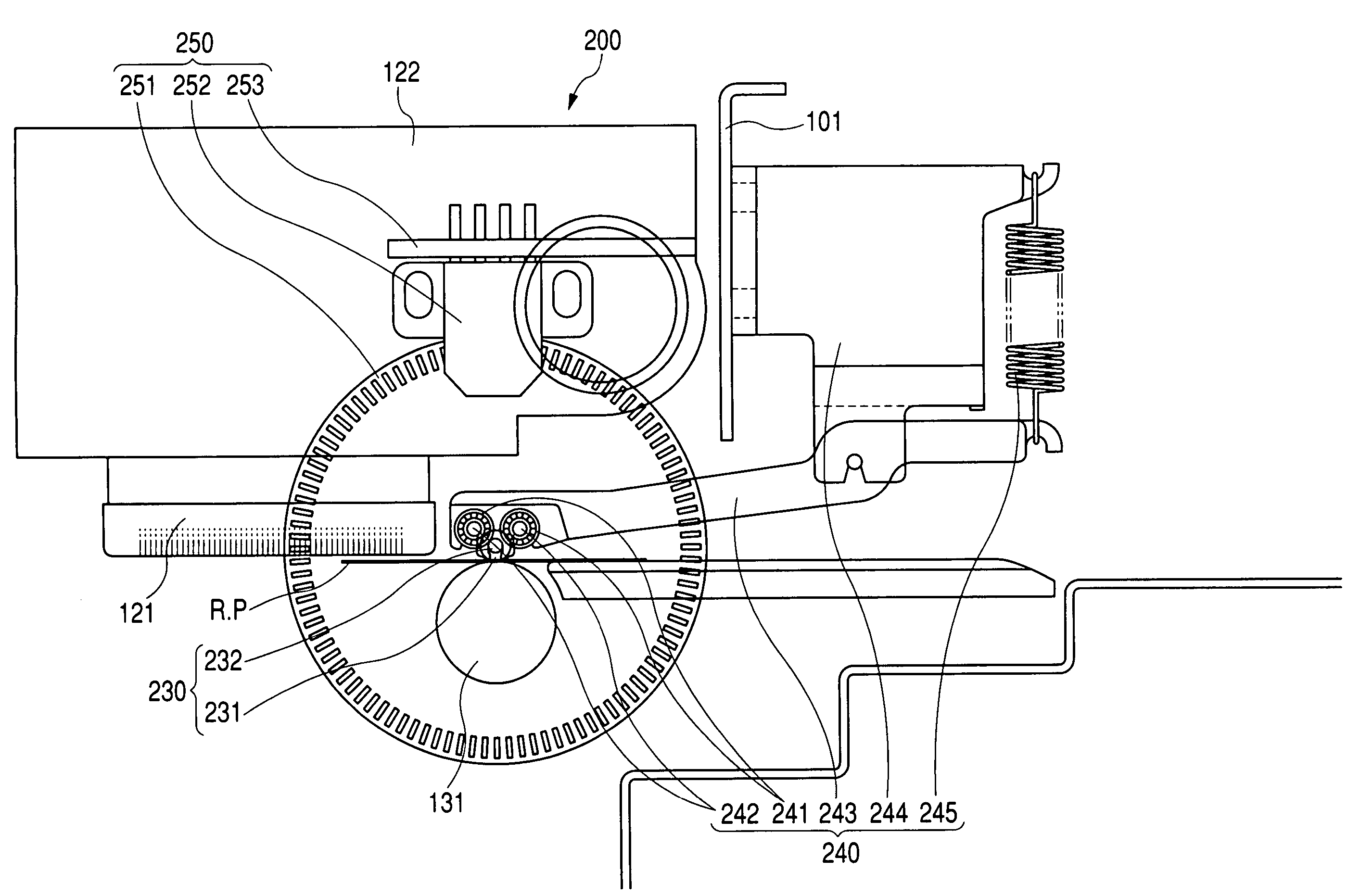

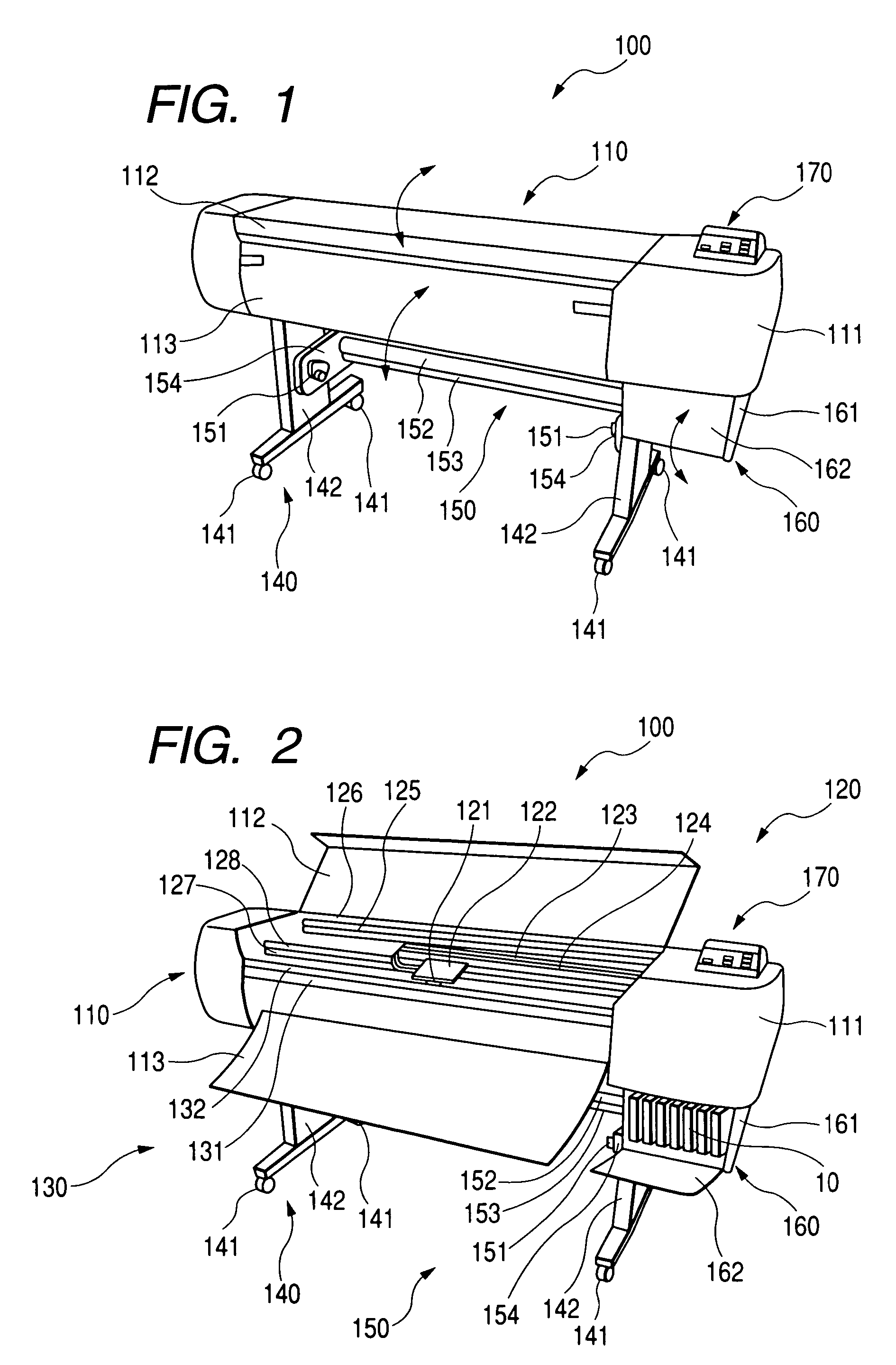

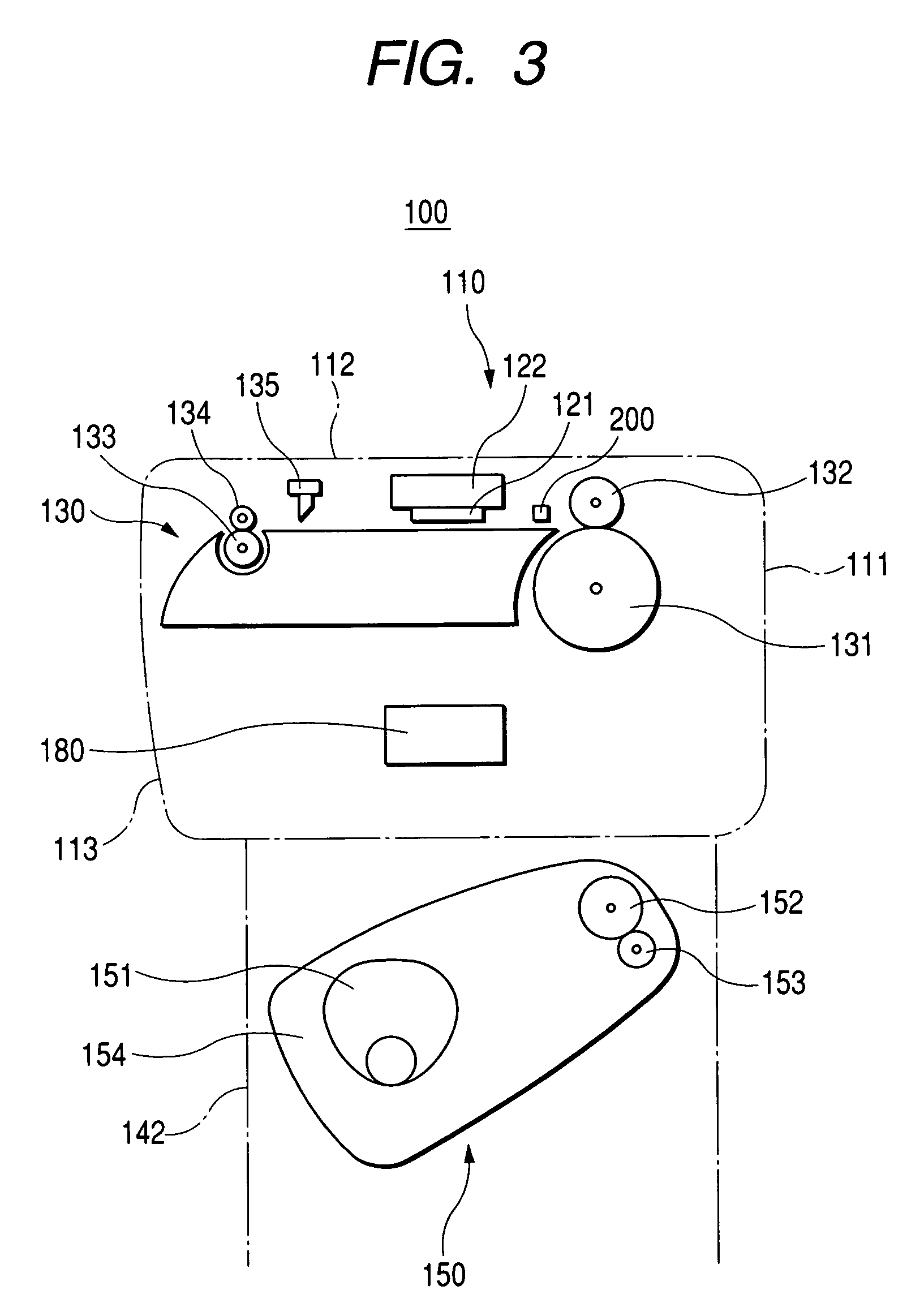

Recording apparatus

InactiveUS7401913B2High conveying precisionCompact and inexpensiveSpacing mechanismsElectrographic process apparatusGear wheelEngineering

Owner:CANON KK

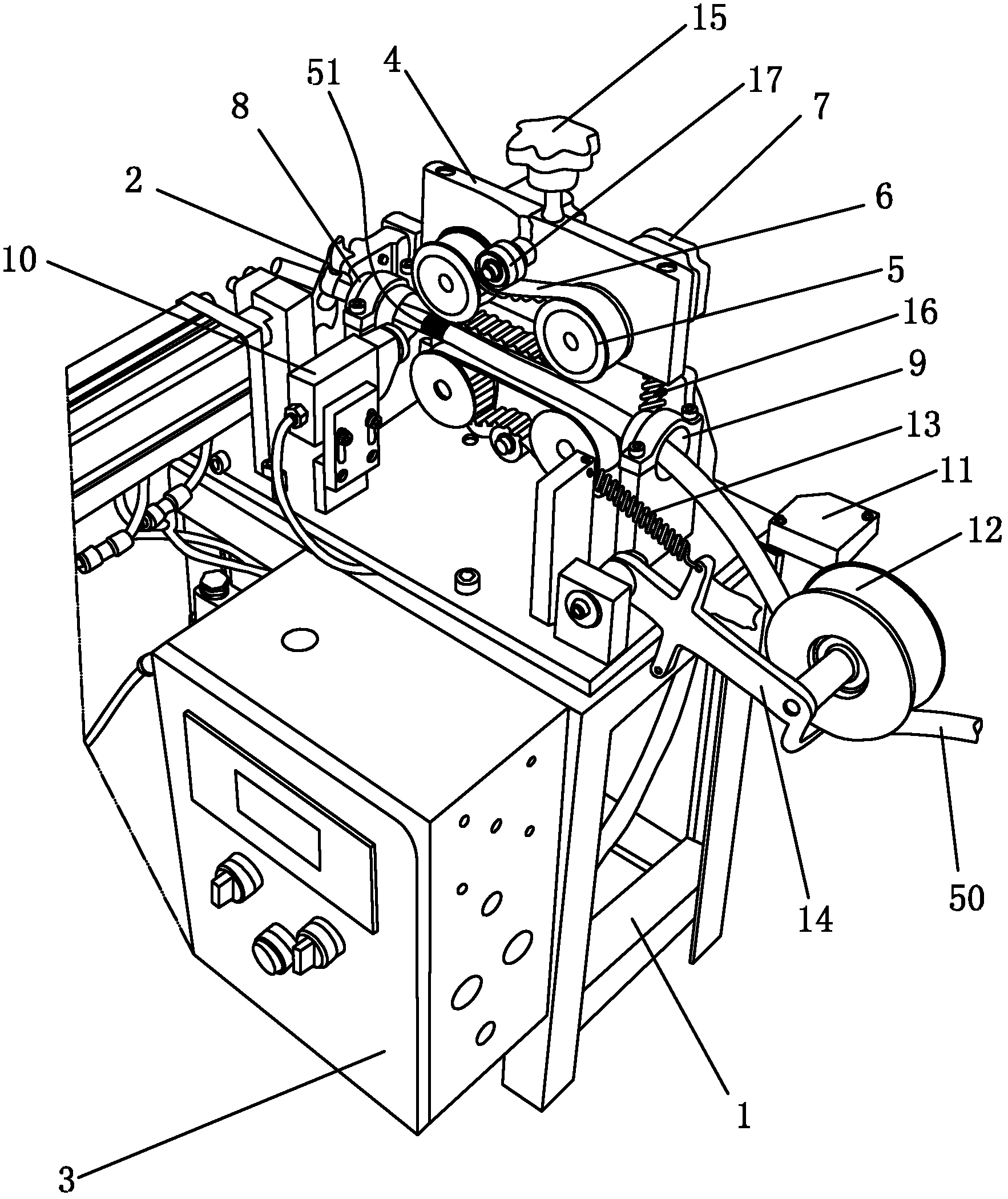

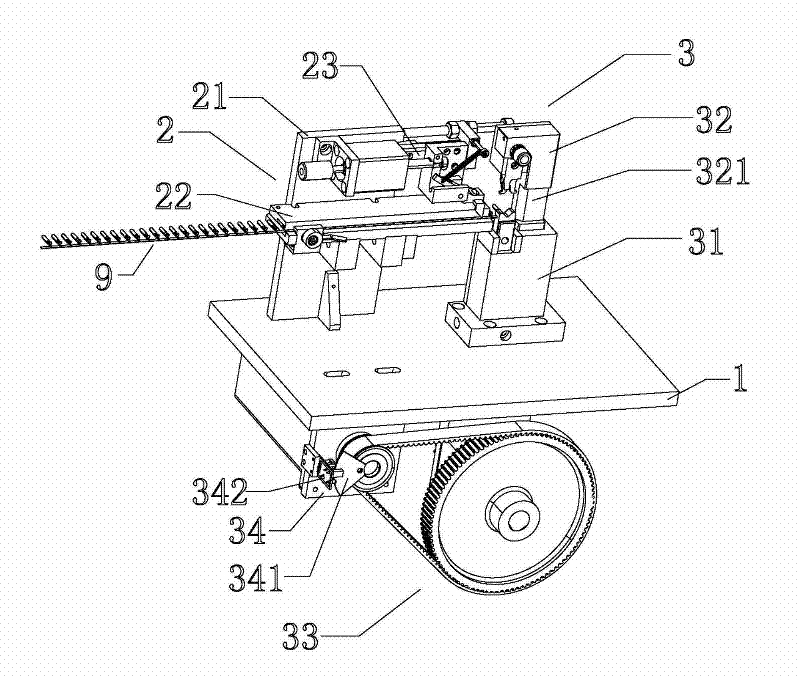

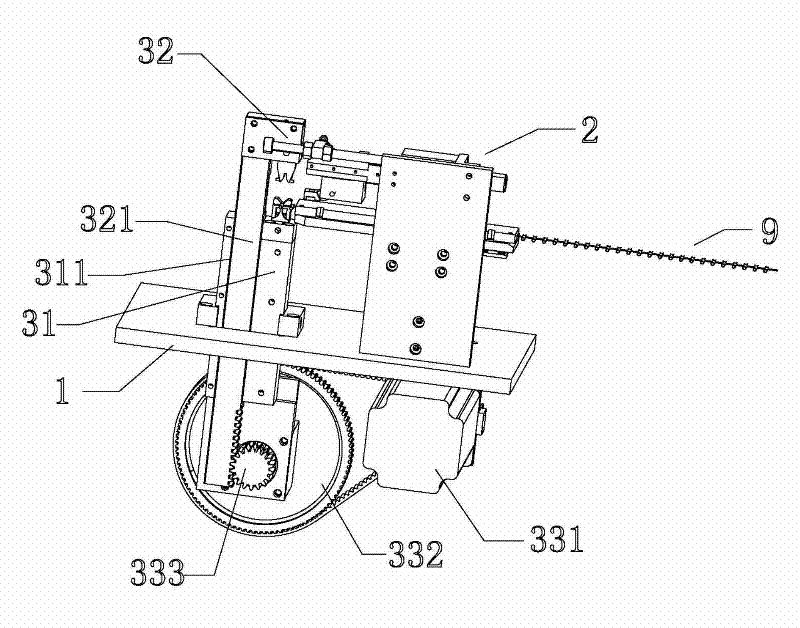

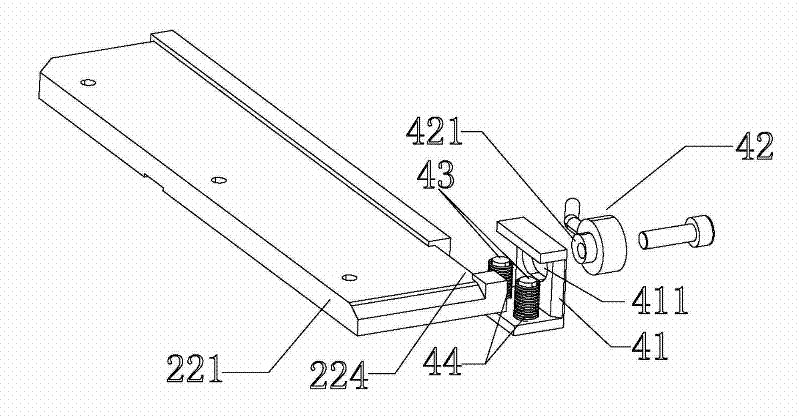

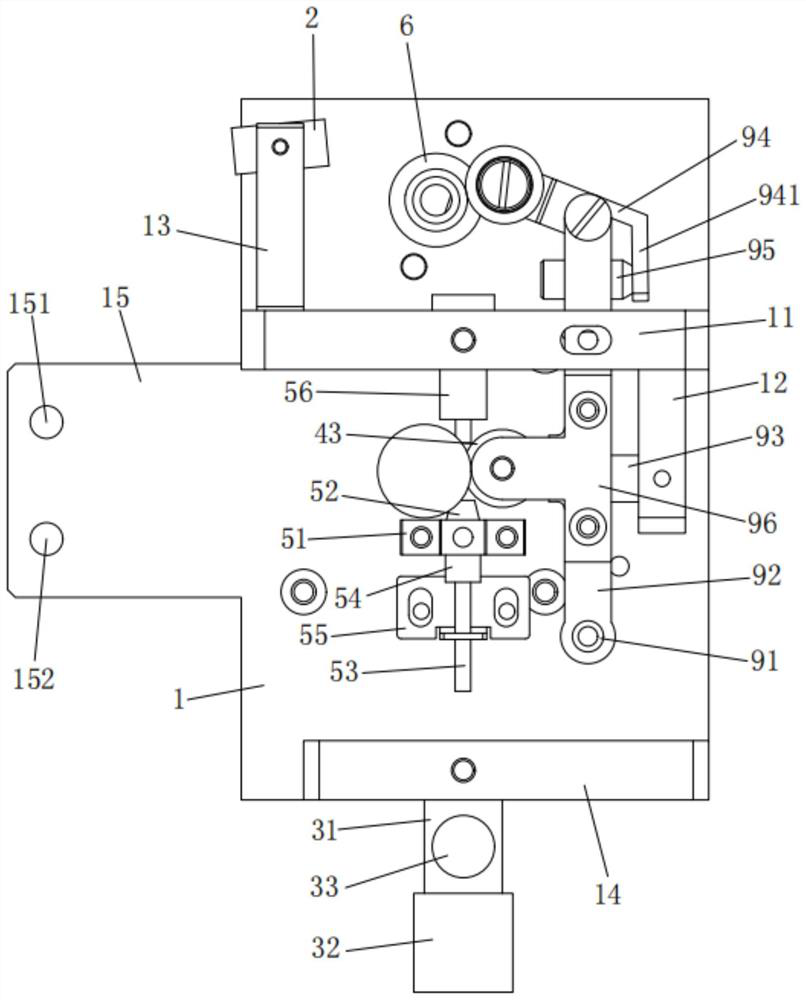

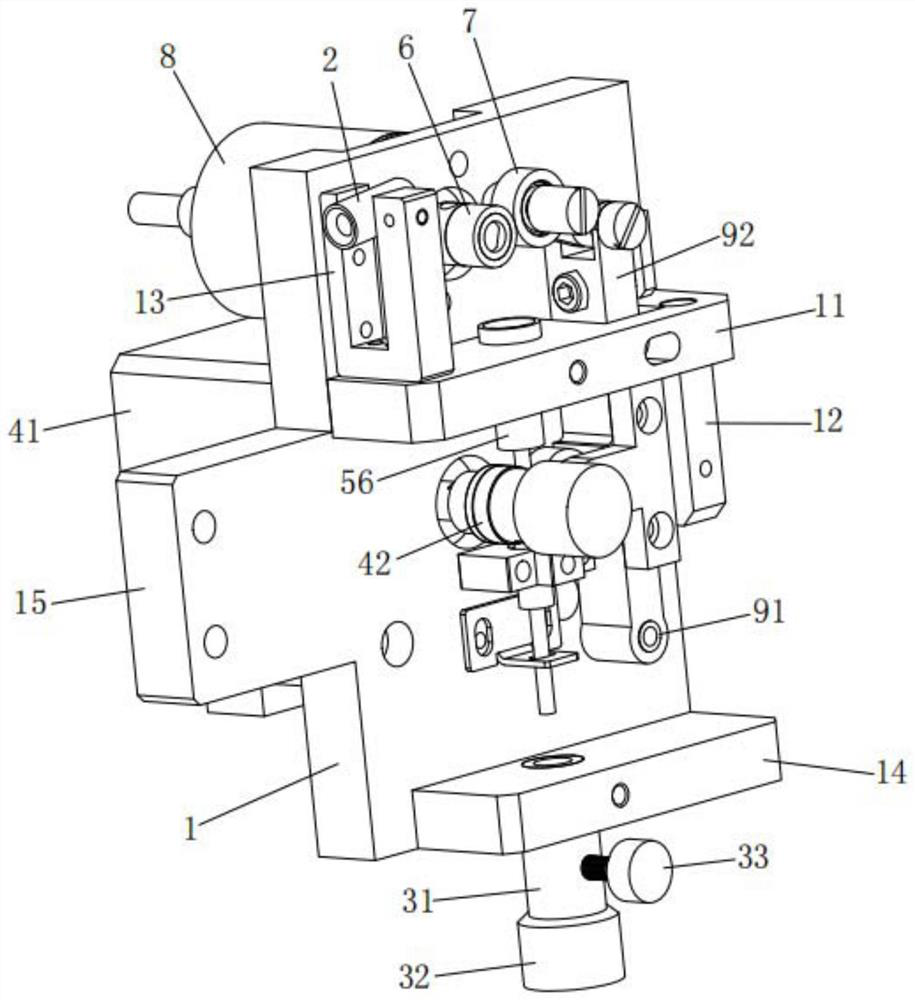

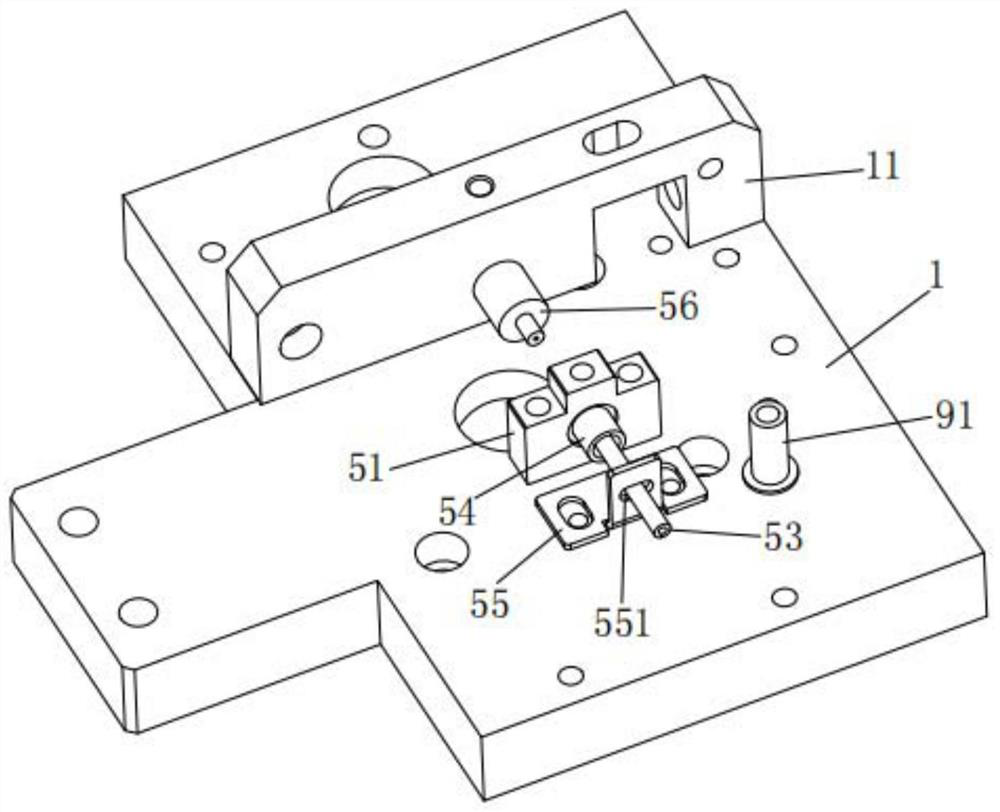

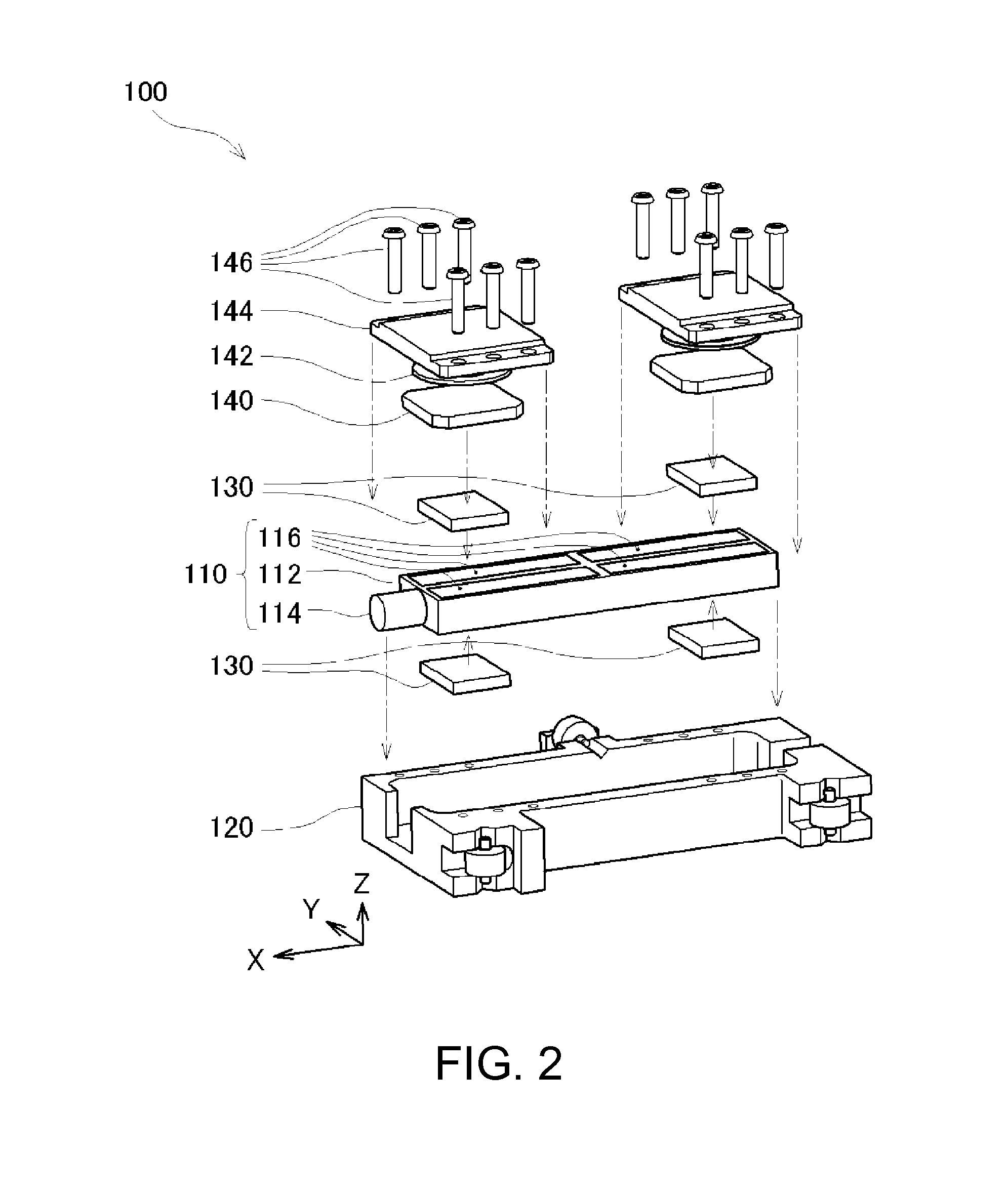

Automatic terminal riveting mechanism

ActiveCN102420384AHigh conveying precisionHigh precisionLine/current collector detailsGravity centerAutomatic testing

The invention discloses an automatic terminal riveting mechanism, which comprises a pedestal, and a terminal conveying mechanism and a terminal pressing mechanism which are respectively arranged on the pedestal, wherein the terminal pressing mechanism is positioned in the output direction of the terminal conveying mechanism; a pressing die driving assembly is arranged on the lower side of the pedestal; the terminal conveying mechanism can convey terminals to the terminal pressing mechanism according to certain frequency; and the pressing die driving assembly controls the terminal pressing mechanism to press the terminals through a connecting mechanism, and the terminals can be continuously pressed by continuous circulation. Because the terminal conveying mechanism and the terminal pressing mechanism are arranged on the same pedestal and collocated correspondingly, the conveying precision of the terminals is improved; the pressing die driving assembly is arranged on the lower side of the pedestal, so the automatic terminal riveting mechanism is simple and scientific in structure, low in cost and very convenient to maintain and eliminate faults; and because the gravity center of the whole automatic terminal riveting mechanism is on the lower part, the stability, the safety and the terminal pressing precision of the terminal riveting mechanism are improved.

Owner:山东隽宇电子科技有限公司

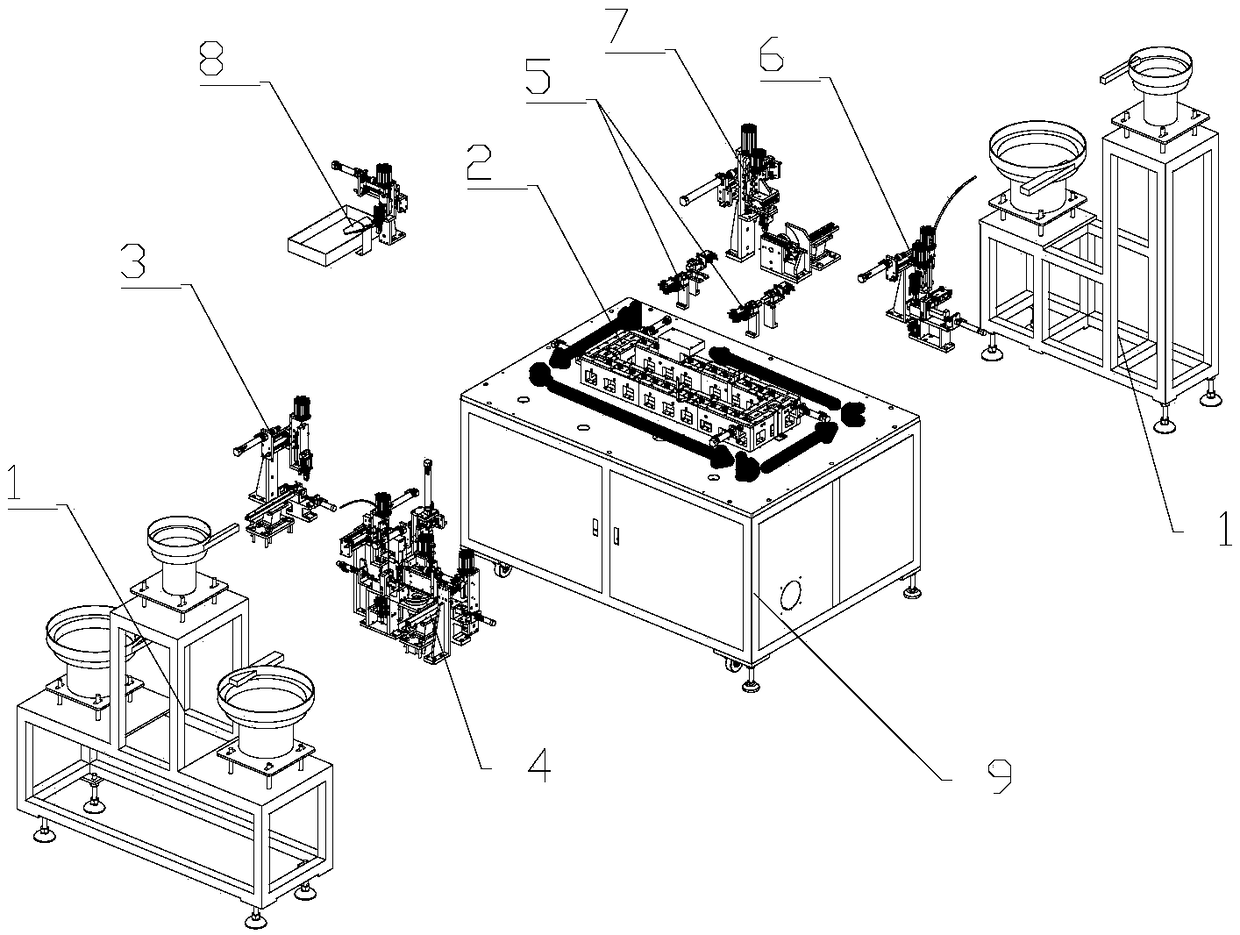

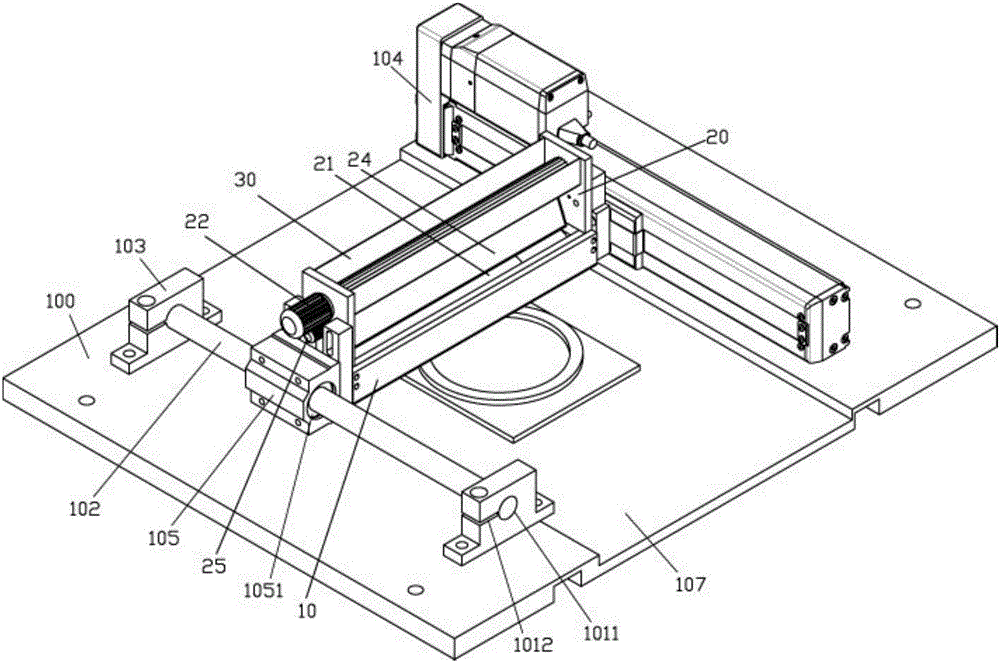

Optical fiber connector assembly machine

InactiveCN109079496AEasy to processLow failure rateAssembly machinesMetal working apparatusOptical fiber connectorOptical fiber cable

The invention relates to the technical field of production of optical fiber connectors. An optical fiber connector assembly machine comprises a rack and further comprises a vibration feeding assembly,a carrier rectangular circulation device, a front shell feeding device, a rubber pipe, an optical fiber core assembly feeding device, a guiding mechanism, a spring installing device, a shell feedingdevice and a finished product carrying device which are arranged on the rack. The optical fiber connector assembly machine has the advantages of fully automatically completing assembly of a front shell, an optical fiber core, a rubber pipe, a spring and a back shell, and the processing efficiency and the yield are high.

Owner:吴美珍

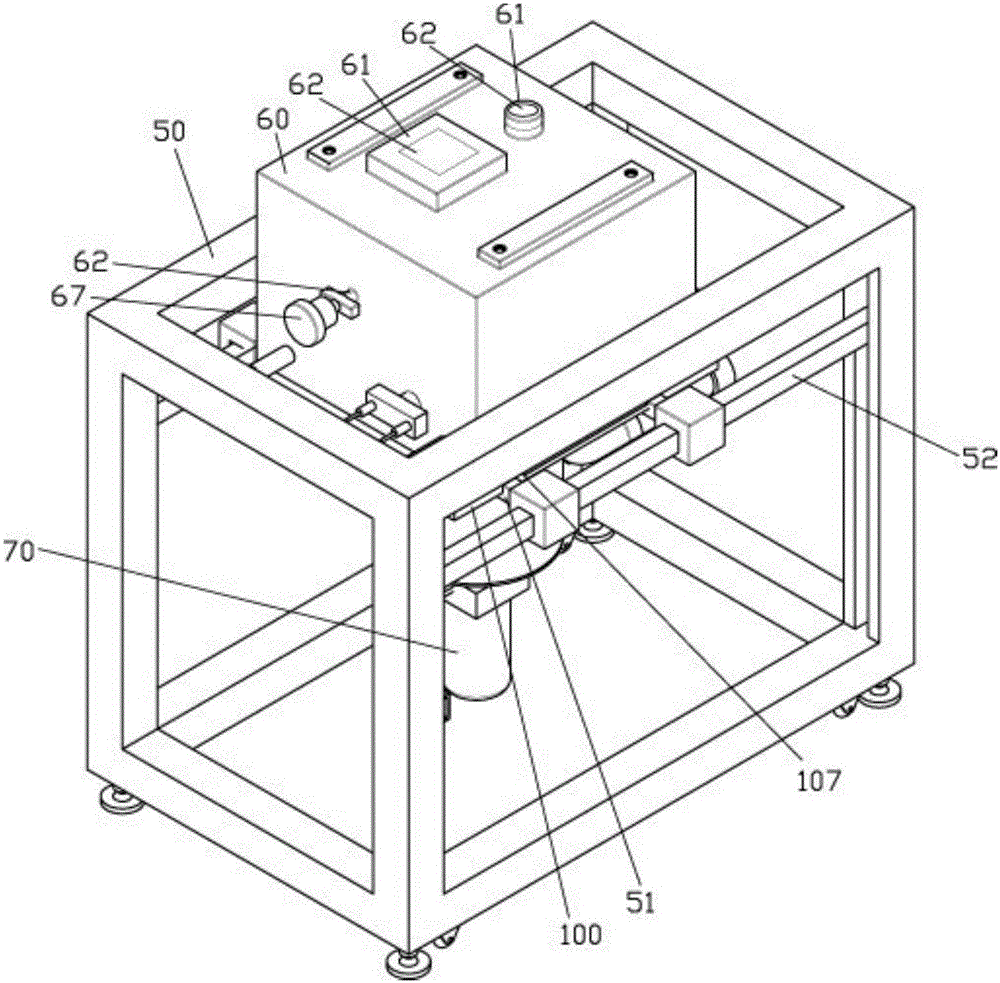

Vacuum sealed type 3D printing device

The invention discloses a vacuum sealed type 3D printing device. The device comprises a frame-form rack and a flat-laying powder conveying device, a transverse beam is fixed to the middle of the frame-form rack, a powder laying base plate is fixed to the transverse beam, a box body is fixed to the powder laying base plate, observation holes are formed in the top face of the box body, quartz glass blocks are fixed to the top face of the box body, the quartz glass blocks cover the observation holes, an air inlet pipe is connected with the side wall of the box body in a communicated mode, the air inlet pipe is communicated with a side wall through hole formed in the side wall of the box body, a vent pipe is connected with the bottom face of the side portion of the powder laying base plate in a communicated mode, and a bottom through hole is formed in the side portion of the powder laying base plate; the flat-laying powder conveying device is arranged inside the box body; the flat-laying powder conveying device comprises a flat-laying rack and a powder storage groove, the flat-laying rack is a rectangular frame, and scraper plates are fixedly connected with the outer walls of a left side plate and a right side plate of the flat-laying rack through bolts. By means of the vacuum sealed type 3D printing device, it can be guaranteed that air cannot enter a vacuum box, thereby it is guaranteed that the quality of products obtained through 3D printing conducted in the vacuum box is good, in addition, a tooth-form groove of a conveying roller is adopted for conveying, and the conveying precision of the device is high.

Owner:SHAOXING UNIVERSITY

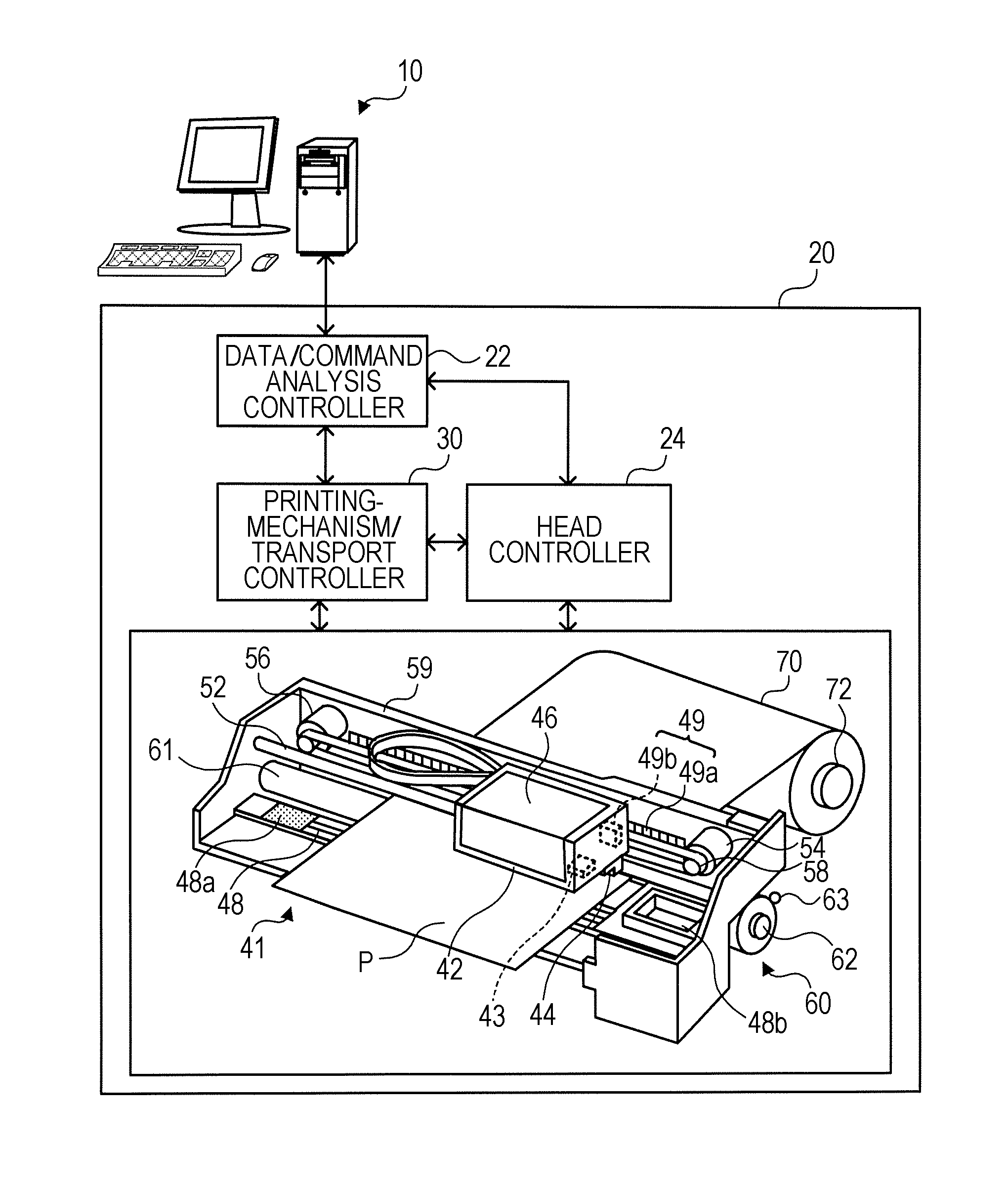

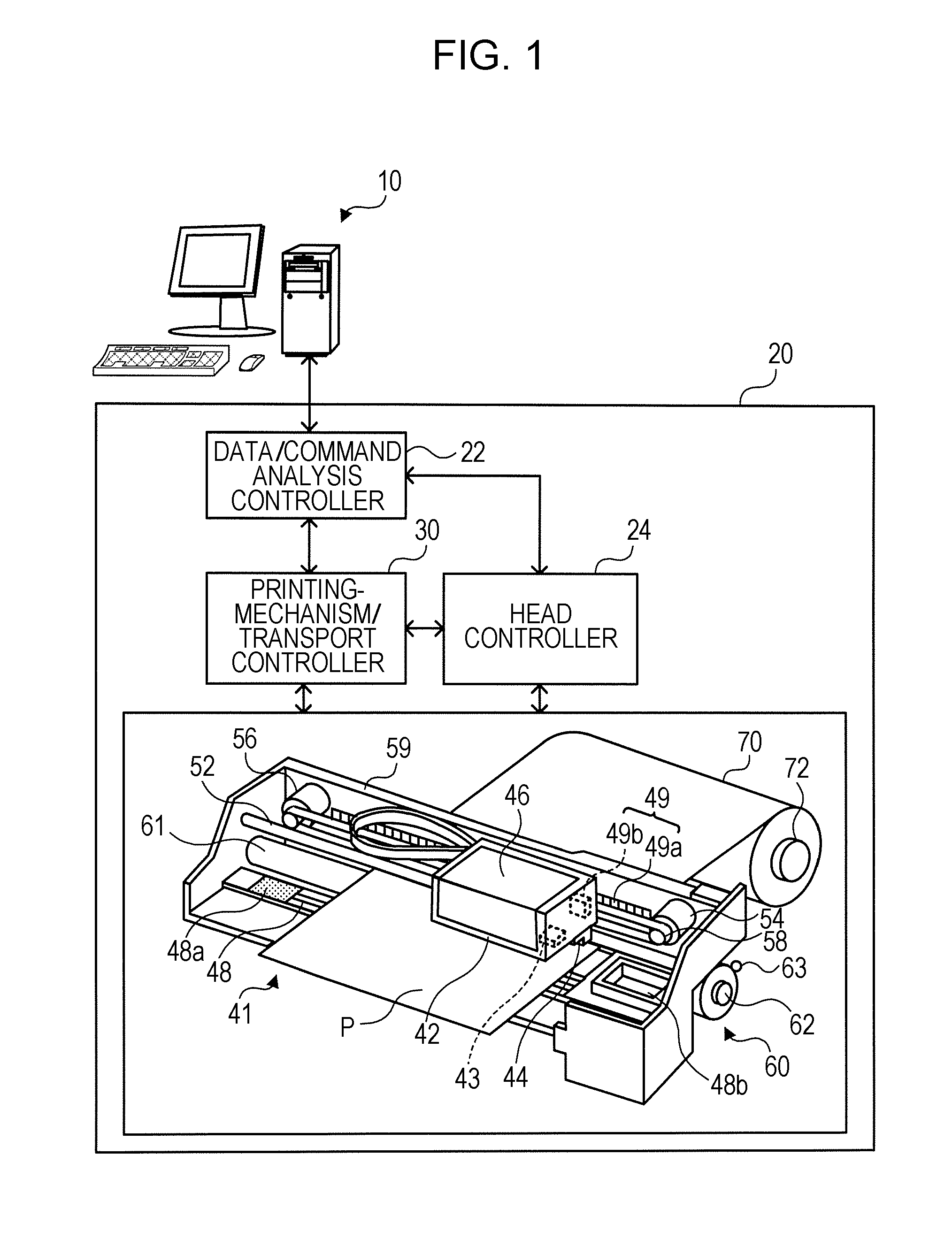

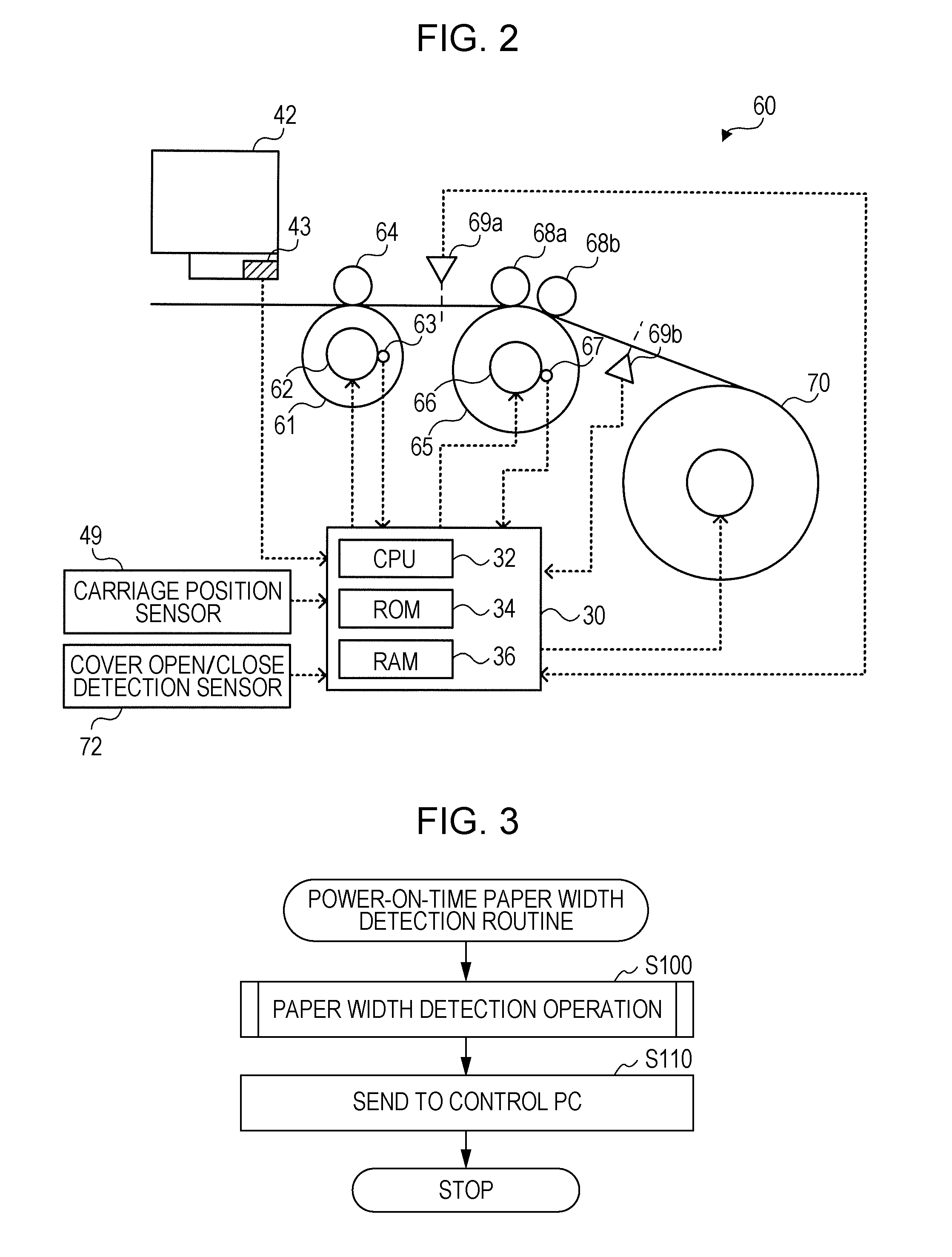

Transport device and image formation apparatus

ActiveUS20120267468A1High paper transport precisionImprove image qualityFilament handlingOther printing apparatusRolling paperImage formation

Owner:SEIKO EPSON CORP

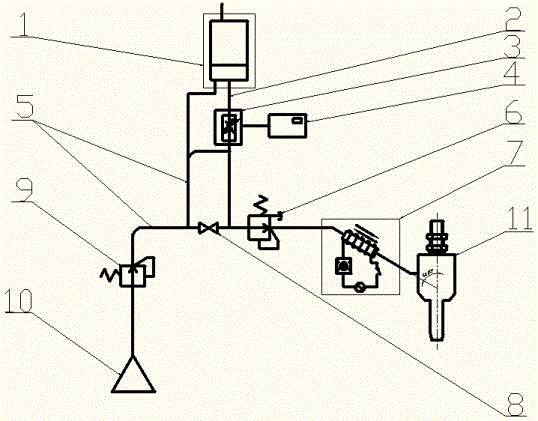

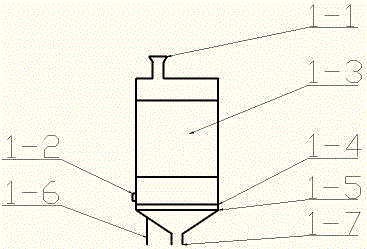

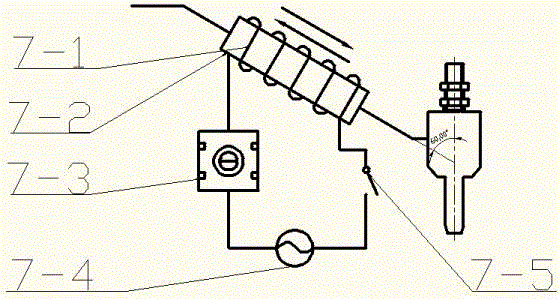

Water jet pulse type magnetic abrasive material feeding device for micro abrasive materials and control method of water jet pulse type magnetic abrasive material feeding device

The invention belongs to special machining techniques, and particularly relates to a water jet pulse type magnetic abrasive material feeding device for micro abrasive materials, and the water jet pulse type magnetic abrasive material feeding device for the micro abrasive materials is applied to precision magnetic abrasive material water jet machining equipment. The water jet pulse type magnetic abrasive material feeding device for the micro abrasive materials is composed of a stock bin, an air source, a pressure regulating valve, a stop valve, a pulse emitter, an electromagnetic control circuit, an air supply pipe and a feeding pipe. An air inlet of the pressure regulating valve is connected with the air source through a pipeline. An air outlet of the pressure regulating valve is connected with an air inlet of the stop valve through a pipeline. An outlet of the stock bin is connected with a throttling valve through a pipeline. The pulse emitter controls the throttling valve. An outlet of a pressure stabilizing valve is connected with the electromagnetic control circuit through a pipeline. According to the water jet pulse type magnetic abrasive material feeding device for the micro abrasive materials, intermittent feeding is achieved through the pulse emitter, and the pulse emitter is matched with the electromagnetic control circuit, so that the problem of feeding interruption is effectively solved, automatic feeding is effectively achieved, and the machining precision is improved.

Owner:SHANDONG UNIV OF TECH

Adhesive bonding sheet processing device and image forming device provided with the same

ActiveUS9346648B2Suppressing adhesion of the adhesive to a device componentHigh conveying precisionFolding thin materialsBookbinding adhesiveAdhesiveEngineering

Owner:NISCA KK

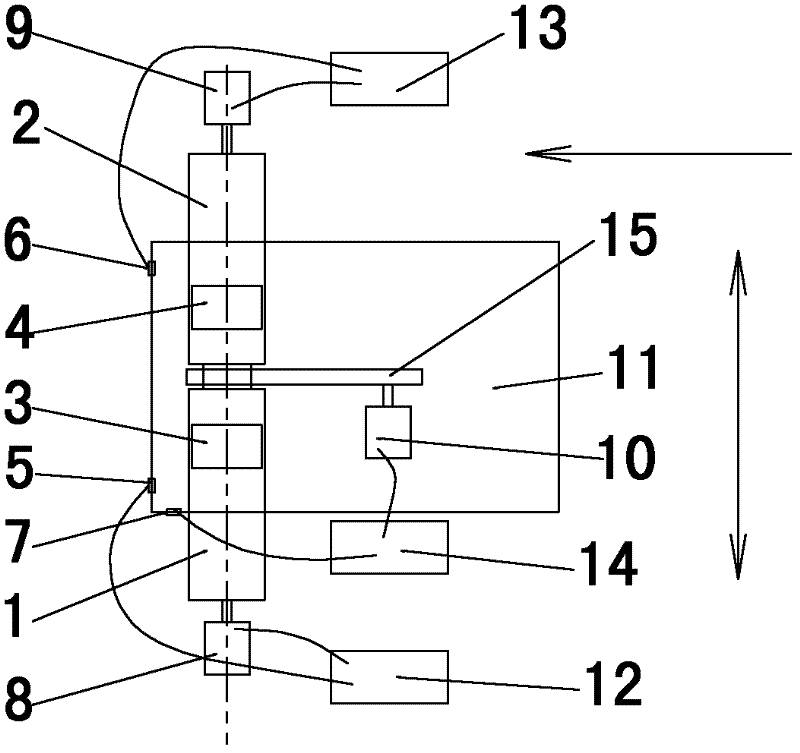

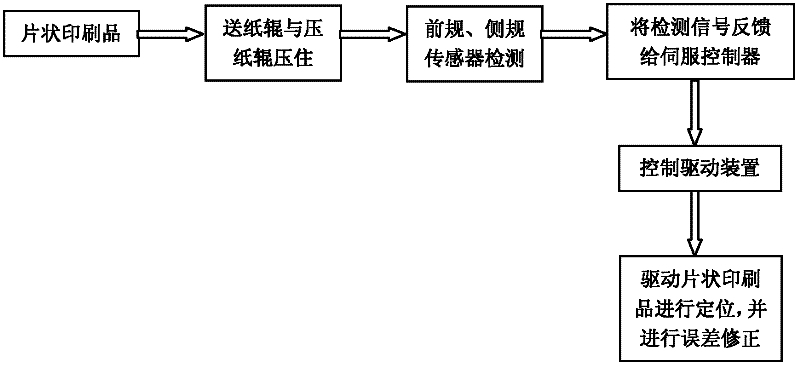

An electronic registration system and its working method

ActiveCN102285216AHigh conveying precisionImprove delivery stabilityPrinting press partsEngineeringFixed position

The invention discloses an electronic alignment system, which comprises a sheet printed matter, and is characterized by also comprising a paper feeding roll, a rubber roll, a front-guide sensor, a side-guide sensor, a paper feeding roll driving device, a side-guide driving device, a front-guide servo controller, a side-guide servo driving controller and a connecting plate. The device directly detects positioning marks or edges printed on the sheet printed matter through the sensors, and feeds the detected signals to the servo controller, and the servo controller controls the servo device to perform fixed-position conveying and error correction on the sheet printed matter to position the single-paper printed matter. The electronic alignment system has the advantages that: the marks on the printed matter are directly detected by the sensors for positioning, and the positioning precision is high; and the paper feeding roll controls the sheet printed matter through an operating side paper feeding roll and a transmission side paper feeding roll so as to overcome errors of the sheet printed matter on the operating side and the transmission side caused by errors of a conveying platform when the conveying platform conveys the sheet printed matter.

Owner:MASTERWORK GROUP CO LTD

Medium transporting device and recording apparatus incorporating with the same

InactiveUS7517077B2High conveying precisionFunction indicatorsOther printing apparatusLiquid jetEngineering

A liquid ejection head is operable to eject a liquid droplet toward a medium at a liquid ejection point A first roller transports the medium toward the liquid ejection point. A second roller ejects the medium transported from the liquid ejection point to the outside of the apparatus. At least one detection roller is directly brought into contact with the medium and is rotated in accordance with the transportation of the medium, the at least one detection roller being disposed in the vicinity of at least one of the first roller and the second roller. A detector detects a rotation amount of the detection roller. A controller controls the transportation of the medium in accordance with the rotation amount.

Owner:SEIKO EPSON CORP

Inner frame paper fixed length conveying system and method

PendingCN109808961ARealize deliveryPrecise control of conveying speedWrapping material feeding apparatusPackaging automatic controlControl theoryDelivery system

The invention relates to the technical field of cigarette packaging, in particular to an inner frame paper fixed length conveying system. The inner frame paper fixed length conveying system is arranged on a cigarette packaging machine, and comprises a servo driving mechanism, a detector, an encoder and a controller; the servo driving mechanism is connected with a conveying roller for conveying inner frame paper and drives the conveying roller to rotate; the detector is used for detecting color codes on the inner frame paper, and the encoder is used for acquiring a main engine phase position ofthe cigarette packaging machine; and the servo driving mechanism, the detector and the encoder are all connected with the controller. The invention further relates to an inner frame paper fixed length conveying method adopting the inner frame paper fixed length conveying system. Mainly the controller determines a reference position according to an action signal of the encoder and a first color code position signal detected by the detector, and zero searching operation is completed; and the controller controls the rotating speed at which the servo driving mechanism drives the conveying rollerto rotate according to a deviation value between the color code position signal detected by the detector and a reference position, so that the conveying speed of the inner frame paper meets the fixedlength conveying requirement. High-precision fixed length conveying can be achieved.

Owner:SHANGHAI TOBACCO MACHINERY

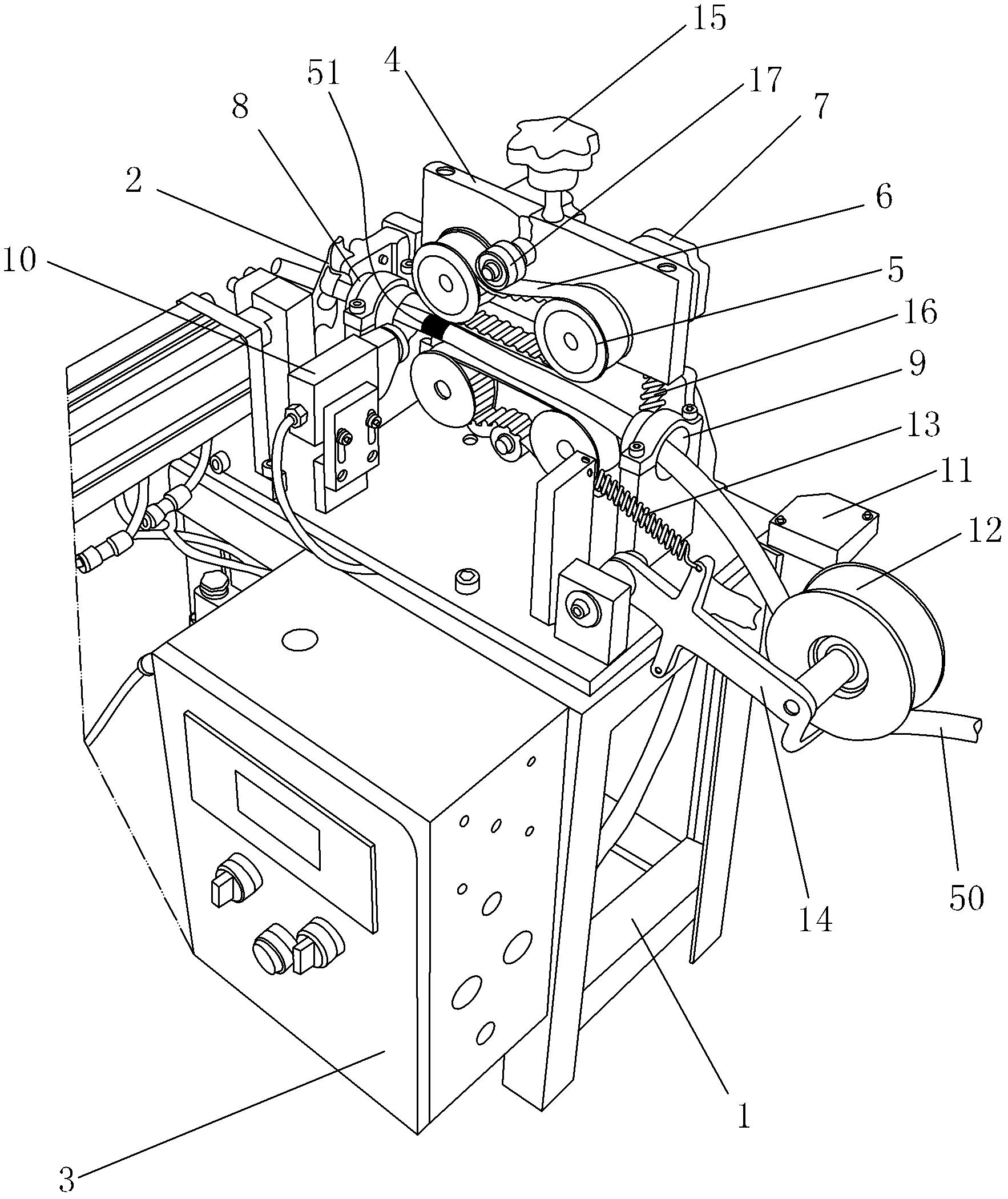

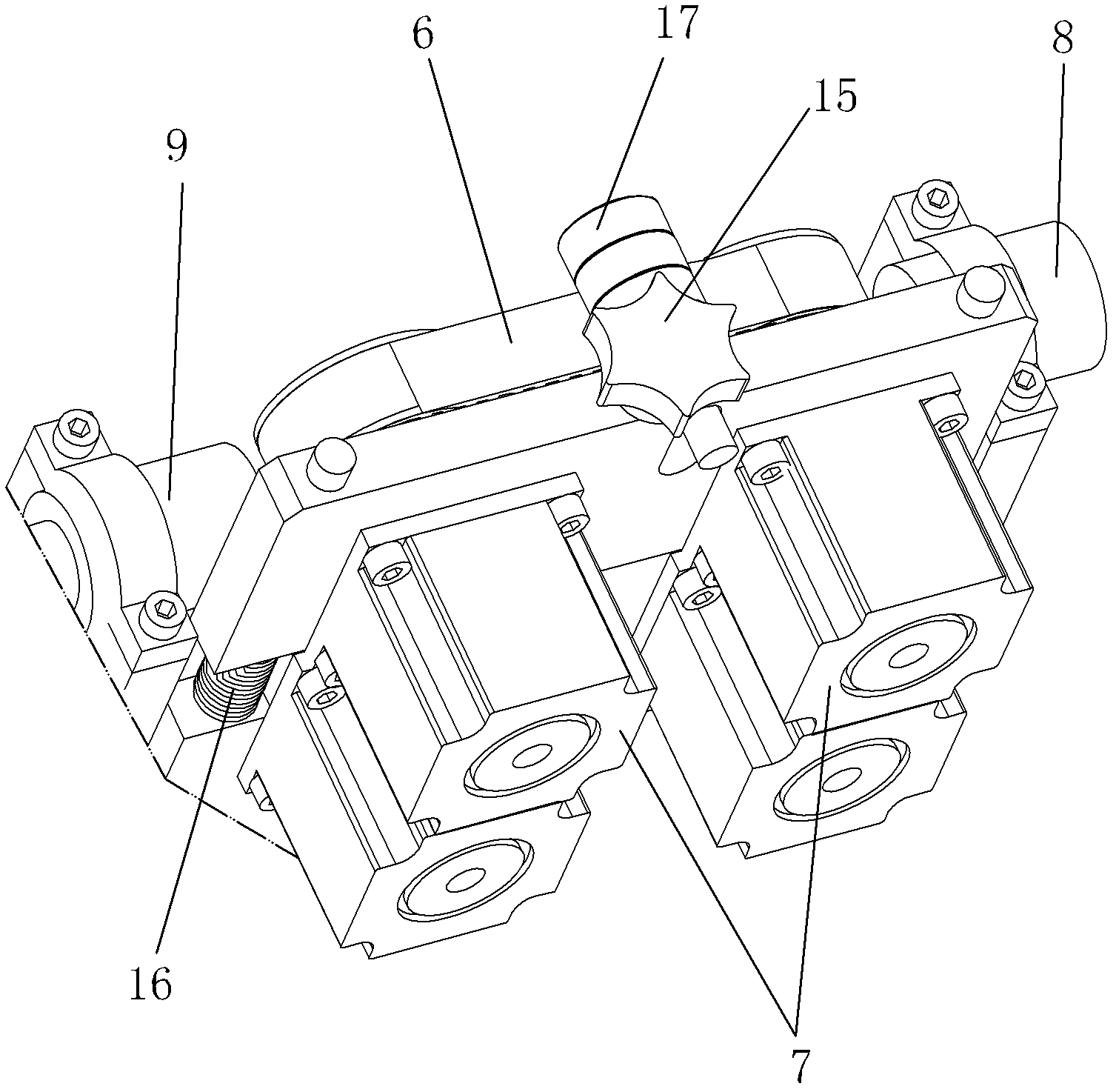

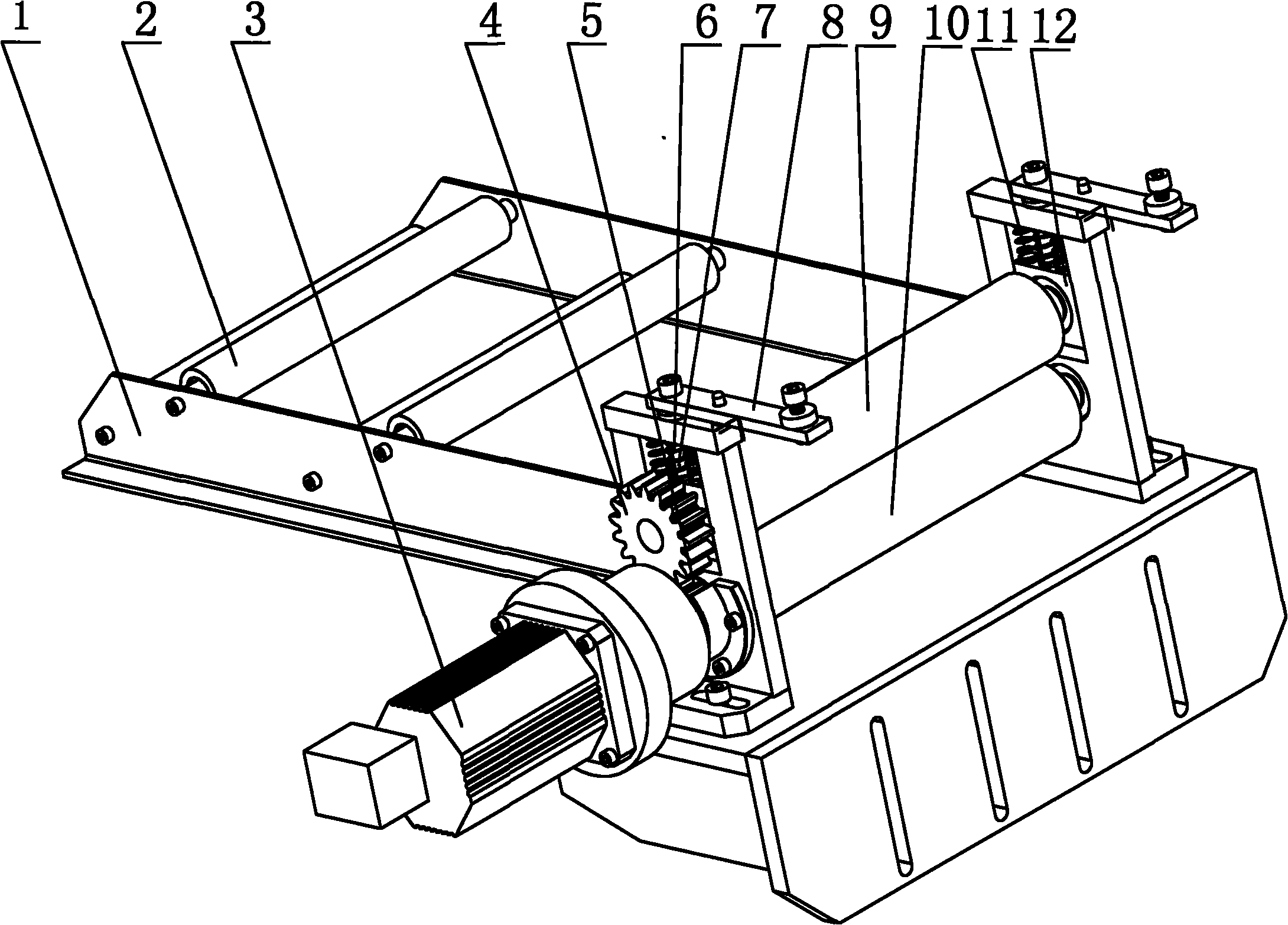

Belting feed mechanism capable of automatically eliminating cumulative errors

InactiveCN101817047ASimple structureAutomatic elimination of accumulated errorsMetal-working feeding devicesPositioning devicesGear wheelEngineering

The invention relates to a belting feed mechanism capable of automatically eliminating cumulative errors. The mechanism comprises a frame, wherein a delivery roller and a driving grinding roller are arranged on the frame; the driving grinding roller is driven by a motor; and a driving gear passes through the driving grinding roller. The belting feed mechanism is characterized in that: the frame is provided with a slide block; a driven grinding roller is arranged on the slide block; a driven gear is arranged on the driven grinding roller; a clearance-eliminating spring is arranged on the slide block; the slide block is connected with a pull rod; a reset spring passes through the pull rod; and a pressure lever is connected with the pull rod. The belting feed mechanism capable of automatically eliminating the cumulative errors of the invention has the advantages of simple structure and high delivering precision and is characterized by automatically eliminating the cumulative errors in the process of belting feeding.

Owner:ZHEJIANG LAISIAO ELECTRIC

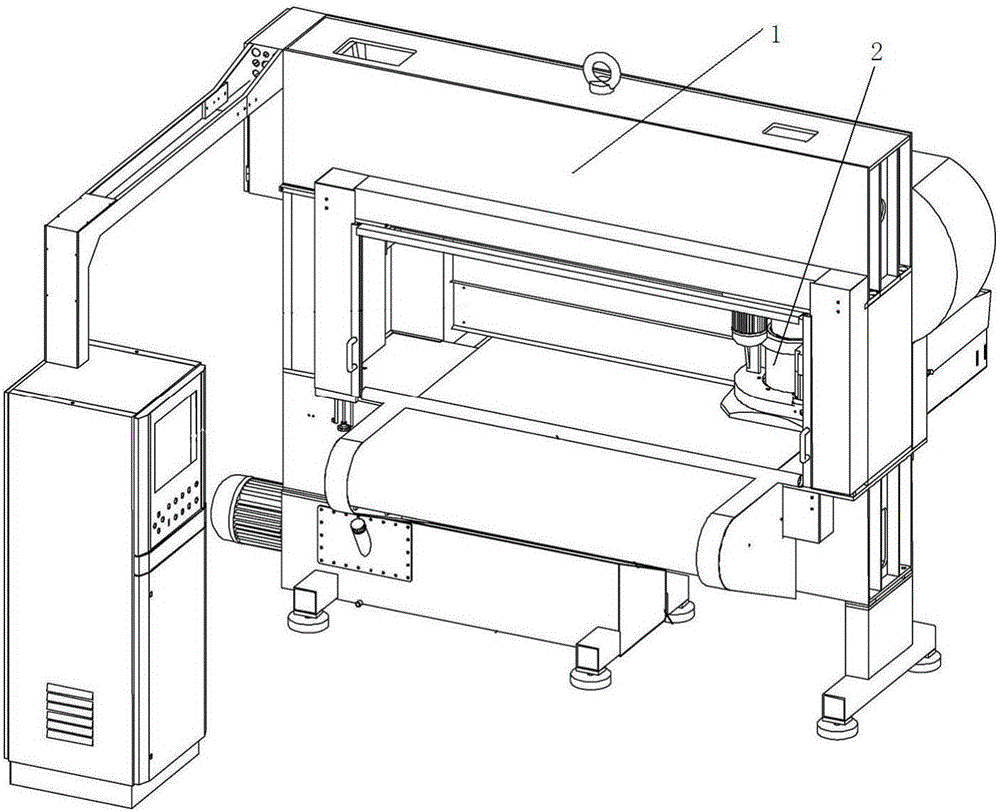

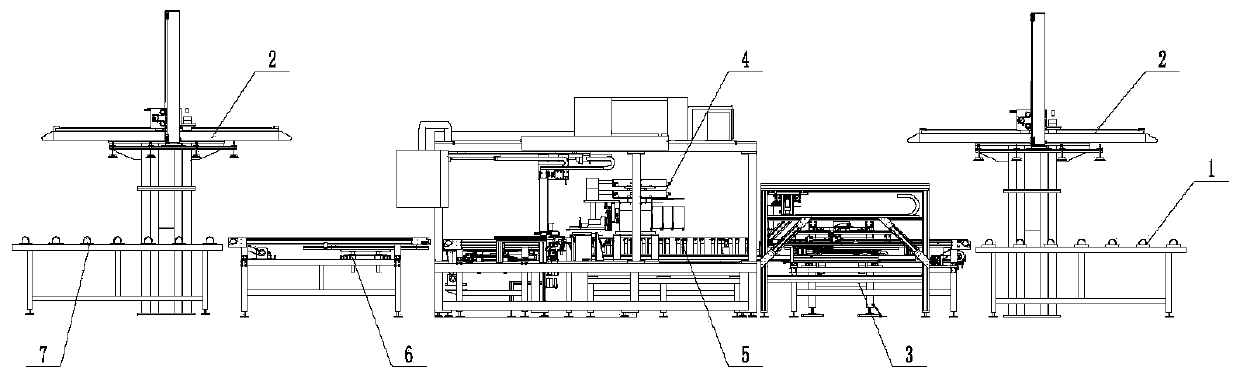

Double-sided polishing processing automatic production line for flaky parts

ActiveCN105798742AIncrease productivityIncrease profitGrinding feed controlGrinding machinesProduction lineRelative motion

The invention discloses a double-sided polishing processing automatic production line for flaky parts. The production line comprises a rack, a conveying mechanism, a loading disk, a slave driver and a main driven, wherein a polishing mechanism and a cleaning mechanism are arranged on the rack. The loading disk comprises an outer ring, a sun gear and a planet wheel, wherein the planet wheel has a workpiece mounting hole, and the outer ring is provided with outer gear teeth. The conveying mechanism comprises two conveyor lines, the outer gear teeth of the outer ring are meshed with the two conveyor lines, the slave driver drives the conveyor lines to move, and the conveyor lines drive the outer ring to circularly roll and walk at least along a feeding position, a first polishing position, a first cleaning position, a second polishing position, a second cleaning position, a blanking position and the feeding position. The polishing mechanism and the cleaning mechanism are respectively corresponding to the polishing position and the cleaning position; the main driver drives the sun gear to rotate and drives the planet wheel to move, and polishing processing is achieved by the opposite movement of the workpiece and the polishing mechanism. The production line has the following advantages: the processing procedure is completed on one production equipment, and in the whole processing, only one time of feeding and blanking is required, thus improving the production efficiency.

Owner:HUAQIAO UNIVERSITY

Sheet processing device and image forming device provided with the same

ActiveUS20150210503A1Suppressing adhesion of the adhesive to a device componentHigh conveying precisionFolding thin materialsRotary pressesAdhesiveImage formation

Provided is a sheet processing device that conveys a paper sheet onto which an adhesive is applied, the device including: a bonding member that applies adhesives onto the conveyed paper sheet at intervals in a sheet width direction; and a protruding guide that is positioned on a conveying path, downstream of the boding member in a sheet conveying direction and guides the paper sheet, facing an adhesive-applied surface of the paper sheet, the protruding guide being positioned between sheet width direction lines of the adhesive-applied position and including a protruding portion protruding into the conveying path. With this configuration, it is possible to suppress the adhesive from being adhered to a device component even in a configuration in which an adhesive-applied paper sheet is moved inside the device to make a sheet jam due to the adhesion less likely to occur.

Owner:NISCA KK

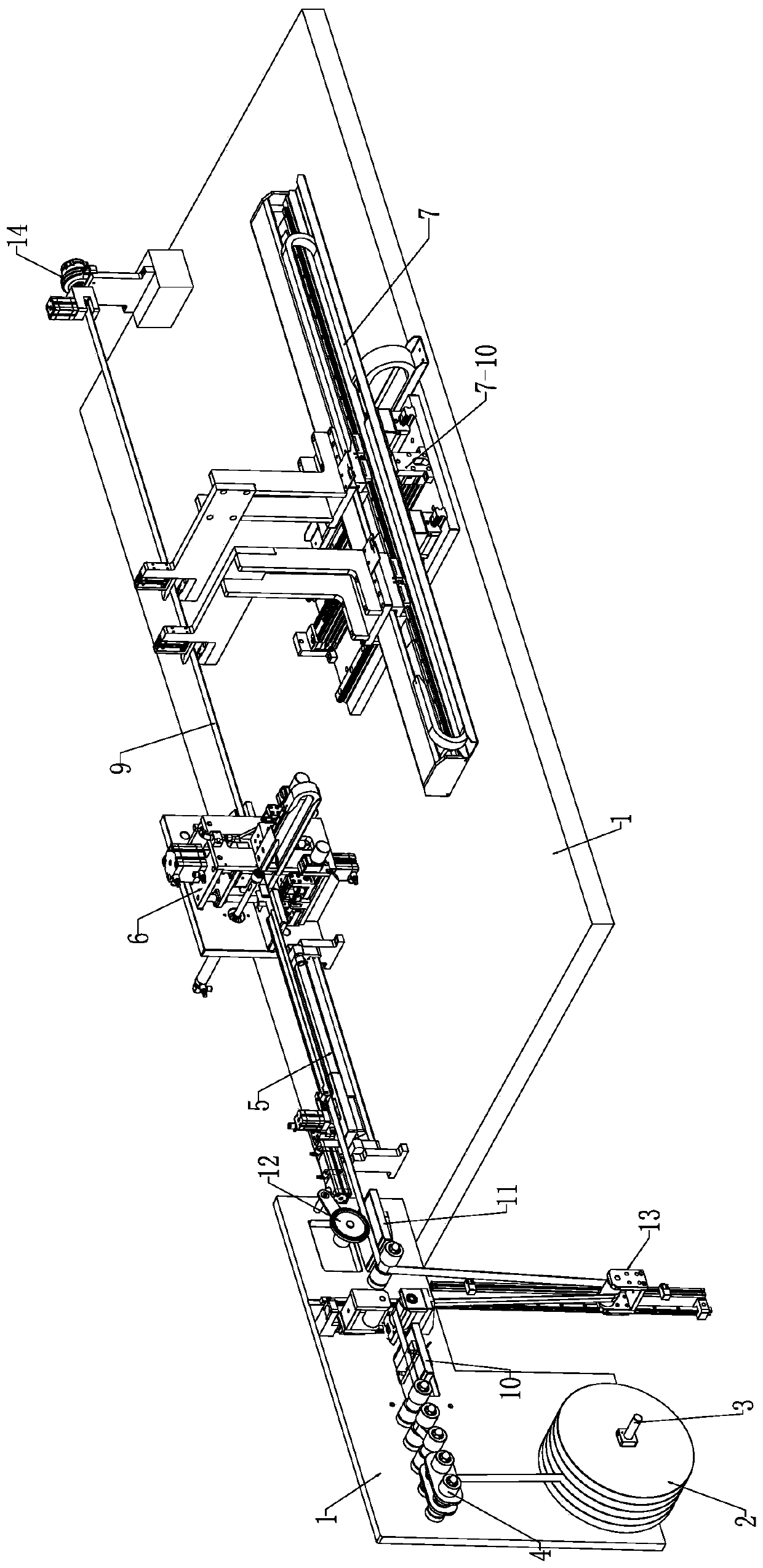

Automatic braid feeding device applied to automatic production of safety belts

PendingCN110480698APrecise deliveryRealize automated productionSevering textilesBeltsEngineeringMechanical engineering

The invention relates to an automatic braid feeding device applied to automatic production of safety belts. The automatic braid feeding device comprises a machine frame, wherein a material reel, a braid guide device, a first traction device, a cutting device, a second traction device, a controller and a power source are arranged on the machine frame, the material reel is used for mounting braid coils, the braid guide device is located above the material reel, the first traction device is located downstream of the braid guide device, the cutting device is located downstream of the first traction device, the second traction device is located on the downstream of the cutting device, and the controller and the power source are used for controlling the coordinate motion of the first traction device, the cutting device and the second traction device. The braid coils are supported by the material reel, the braid guiding device is used for adjusting the running direction of braids, the braidsare accurately conveyed, the first traction device and the second traction device are adopted to traction the braids before and after cutting, the braids are cut by the cutting device, the coordination action of each mechanisms is controlled by the controller, automatic production of automatic braid feeding is realized, and a foundation is laid for automatic production of the whole safety belts.

Owner:无锡平舍智能科技有限公司

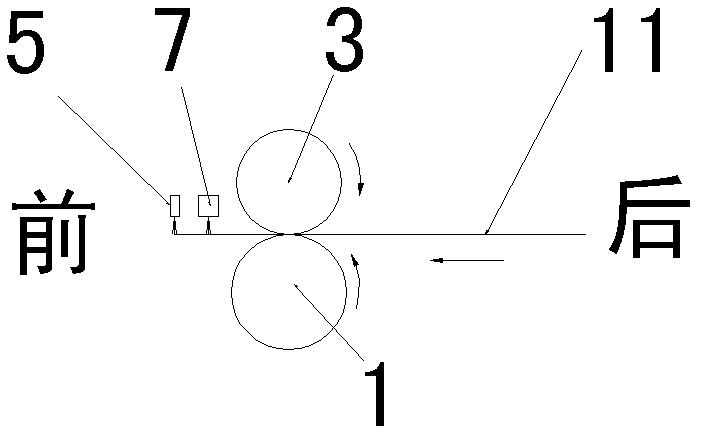

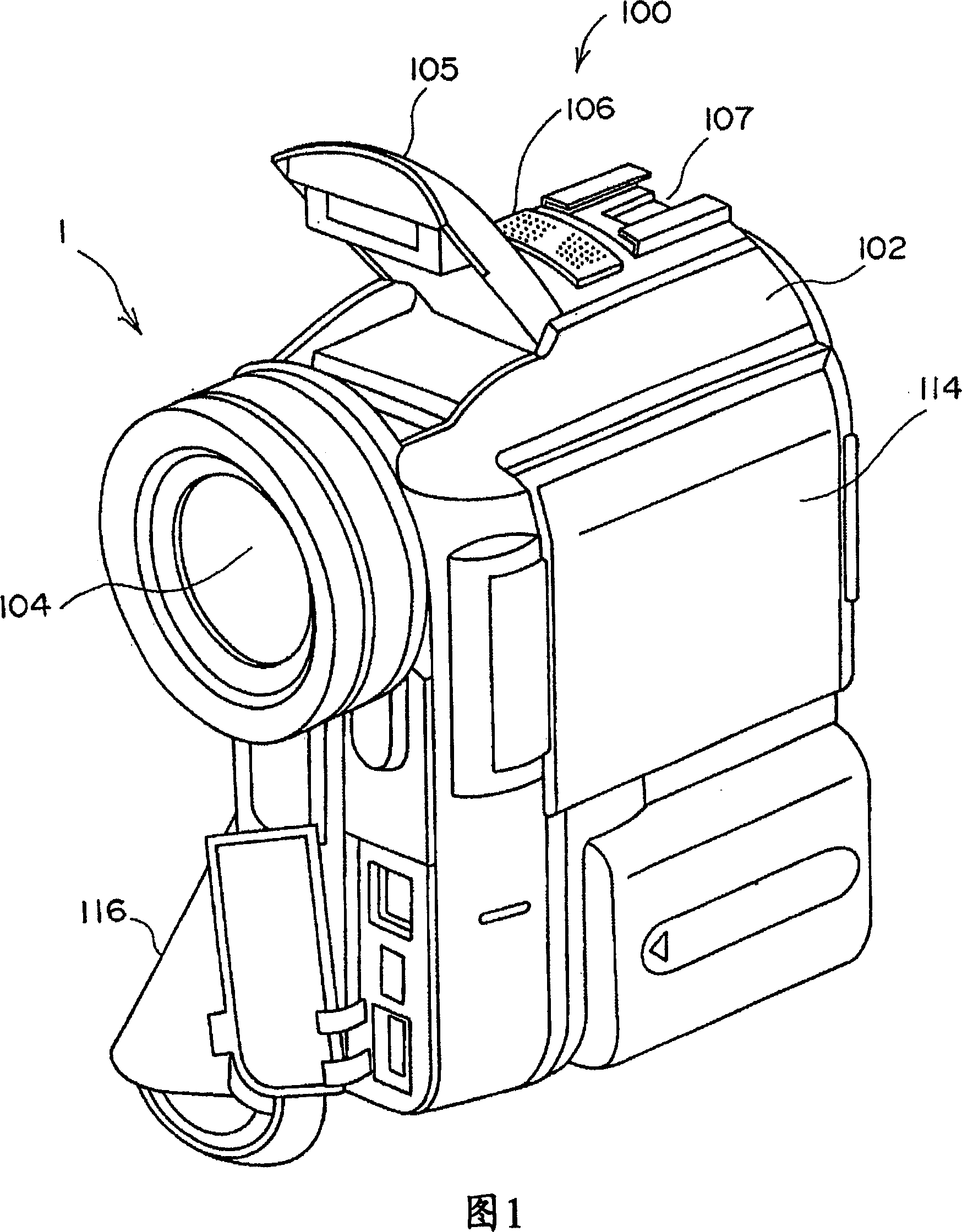

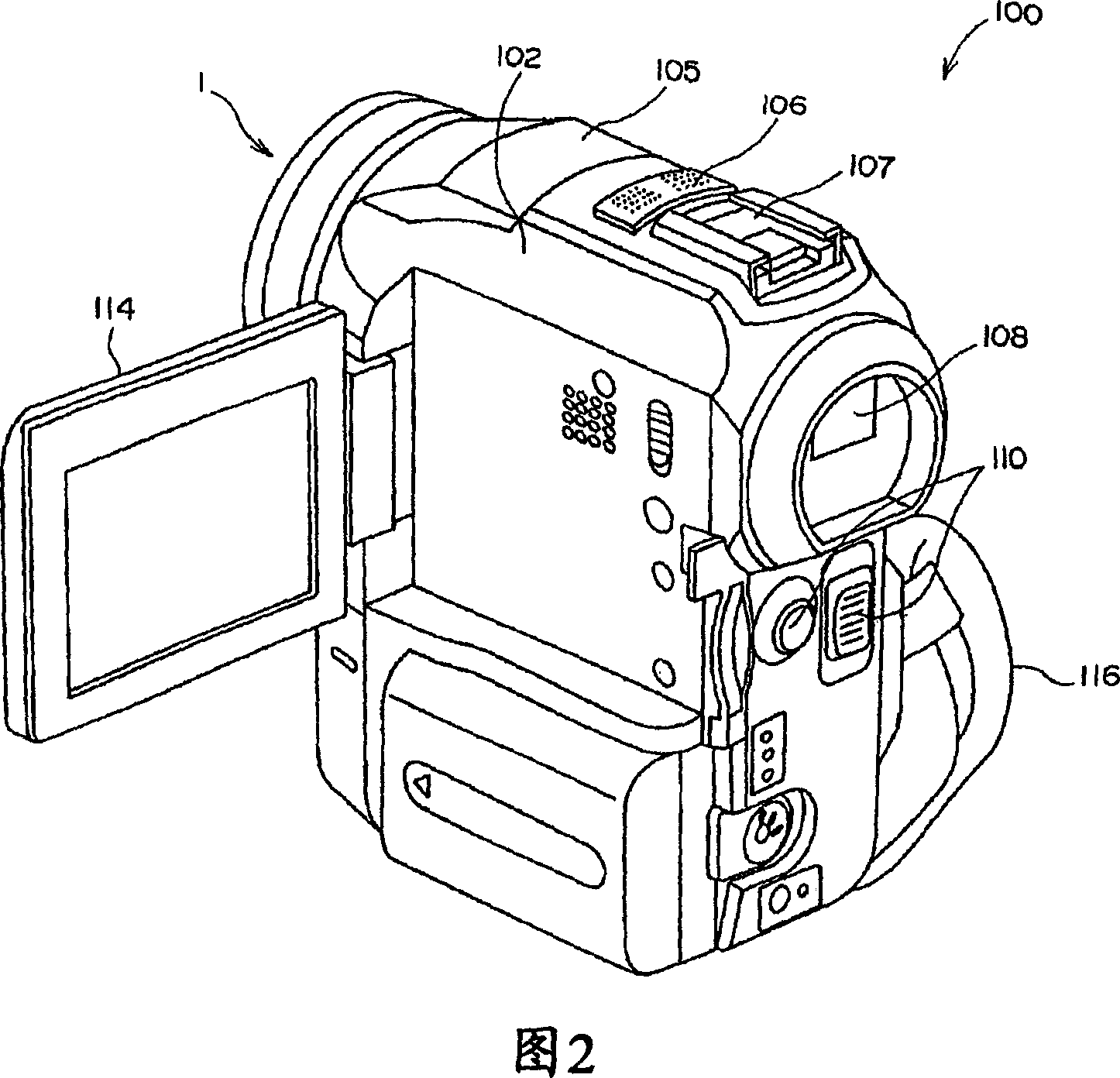

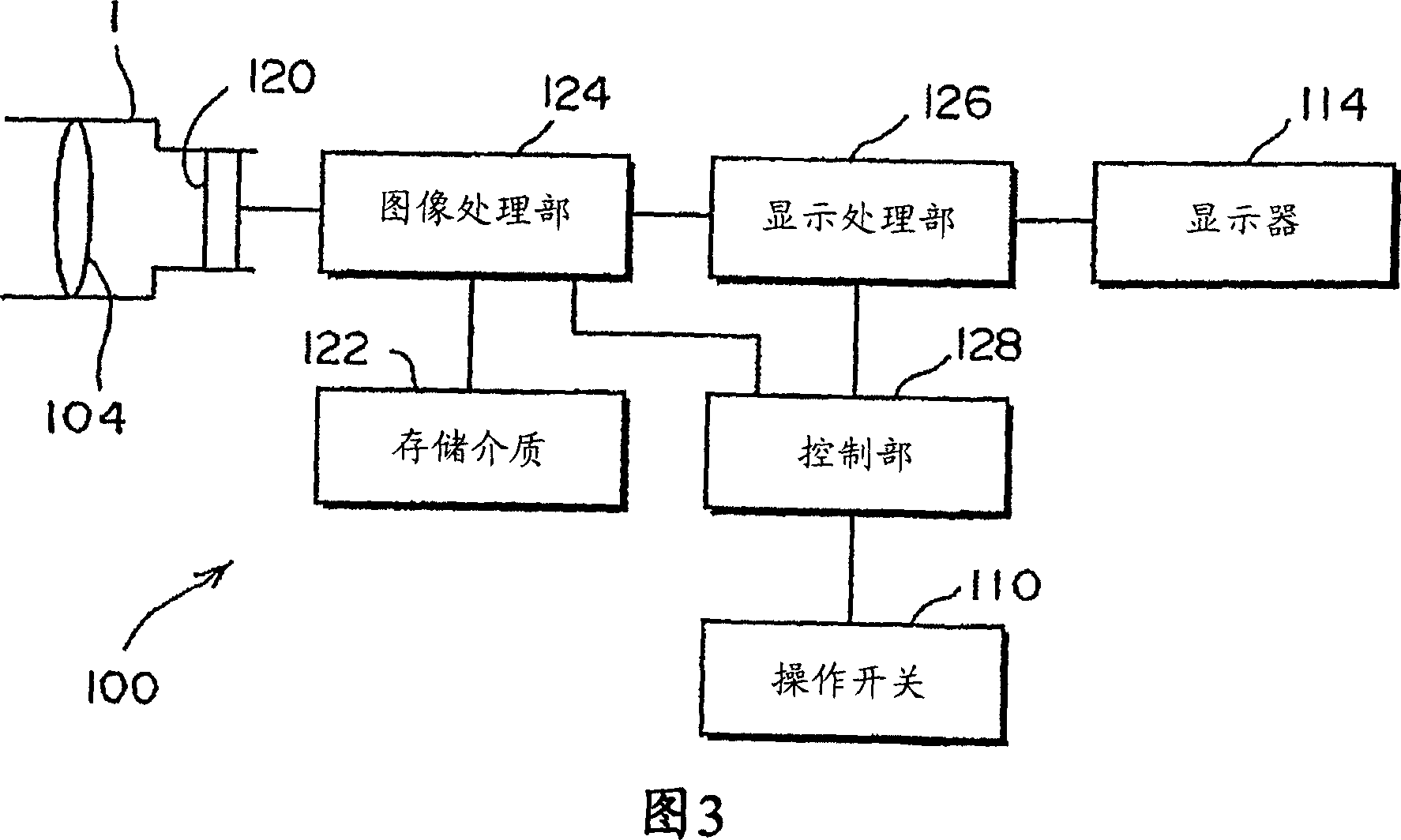

Lens barrel and image capturing apparatus

InactiveCN1922527AHigh conveying precisionTelevision system detailsColor television detailsLocation detectionOptical axis

A lens barrel and an imaging apparatus advantageous in enhancing the feeding accuracy of a movable lens and in reducing the size of the barrel. A position detecting means (34) for two groups generating positional data corresponding to the position of a two-group lens (12) along the optical axis is provided. The amount of rotation of a motor (2804) for two groups is controlled according to the positional data fed from the position detecting means (34) such that the position of the two group lens (12) along the optical axis agrees with a target position. If the positional data is invariant for a specified time during the rotation of the motor (2804), it is judged that movement of the two-group lens (12) is stopped forcedly and the rotation of the motor (2804) is stopped immediately.

Owner:SONY CORP

Numerically-controlled cutting machine capable of realizing rotating punching and punching method thereof

ActiveCN106142216AFast punching responseHigh punching pressureConveyorsMetal working apparatusPunchingEngineering

The invention discloses a numerically-controlled cutting machine capable of realizing rotating punching. The machine comprises a rotating punching device, an automatic belt deviation correcting device, a feeding device, a hydraulic device, a synchronous speed reduction device, a horizontal moving table, a punching mechanism, a rotating mechanism and a travel adjusting mechanism, wherein the punching mechanism comprises a cylinder barrel, a rotating cylinder sleeve, an oil cylinder and a piston assembly; the rotating mechanism comprises a suspending plate with a tool arranged at the bottom; a protecting cover is rotationally connected; and the travel adjusting mechanism comprises a double-end motor, a gear shaft and a fine-adjustment handle. According to the machine, a combined oil cylinder assembly and the combined piston assembly are arranged, the punching reaction speed is high, the punching pressure is high, and the punching effect is good; the travel adjusting mechanism is arranged, the punching travel can be adjusted rapidly by the aid of the double-end motor, the double-end motor can be rotated manually while change, and ultra-high-precision fine travel adjustment is realized; and the rotatable rotating mechanism is arranged, the tool is convenient to replace, and meanwhile, the utilization rate of materials can be greatly increased.

Owner:QUZHOU TAIWEI PRECISE MASCH CO LTD

Recording apparatus

InactiveUS20050270353A1Improve recording accuracyImprove image qualitySpacing mechanismsElectrographic process apparatusElectric machineryRecording media

Owner:CANON KK

Synchronous wheel conveying mechanism

InactiveCN103449180AHigh conveying precisionHigh precisionConveyorsCharge manipulationLiquid-crystal displayEngineering

The invention discloses a synchronous wheel conveying mechanism, which is provided with a synchronous wheel mechanism and a hair brush belt, and conveying of LCD (Liquid Crystal Display) glass substrates is realized by driving the hair brush belt with the synchronous wheel mechanism. Moreover, a tension device is further arranged to control the tightness of the hair brush belt so as to ensure safe and stable conveying. The synchronous wheel conveying mechanism has the advantages of increase in equipment accuracy, increase in product yield and reduction in the production cost.

Owner:SUZHOU HUIQIAO AUTOMATION EQUIP CO LTD

Glass laser cutting equipment

PendingCN111116031ARealize the four-way reformAchieve lengthGlass severing apparatusGlass productionLaser cuttingMechanical engineering

The invention discloses glass laser cutting equipment, and relates to the technical field of glass processing; the glass laser cutting equipment is additionally provided with linear module conveying on the basis of original belt conveying, the linear module conveying precision is high, and the hole site processing precision is effectively improved. And meanwhile, the glass laser cutting equipmentis provided with a transverse alignment measuring assembly and a longitudinal alignment measuring assembly, so that four-direction alignment and length and width measurement of glass are realized, theglass positioning accuracy is improved, and the hole site machining precision is further improved.

Owner:ZHEJIANG HUA GONG GLORY INTELLIGENT EQUIP TECH CO LTD

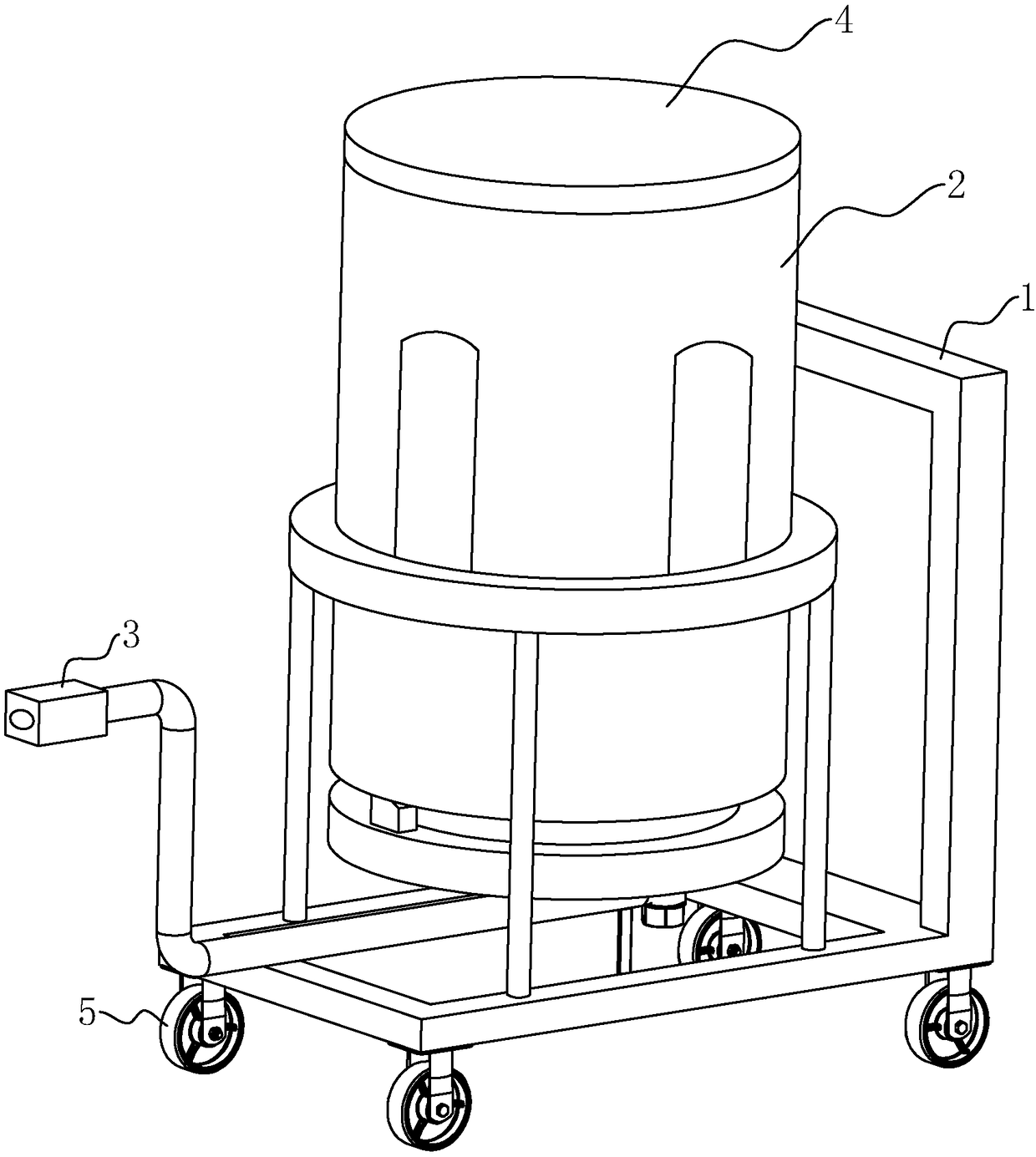

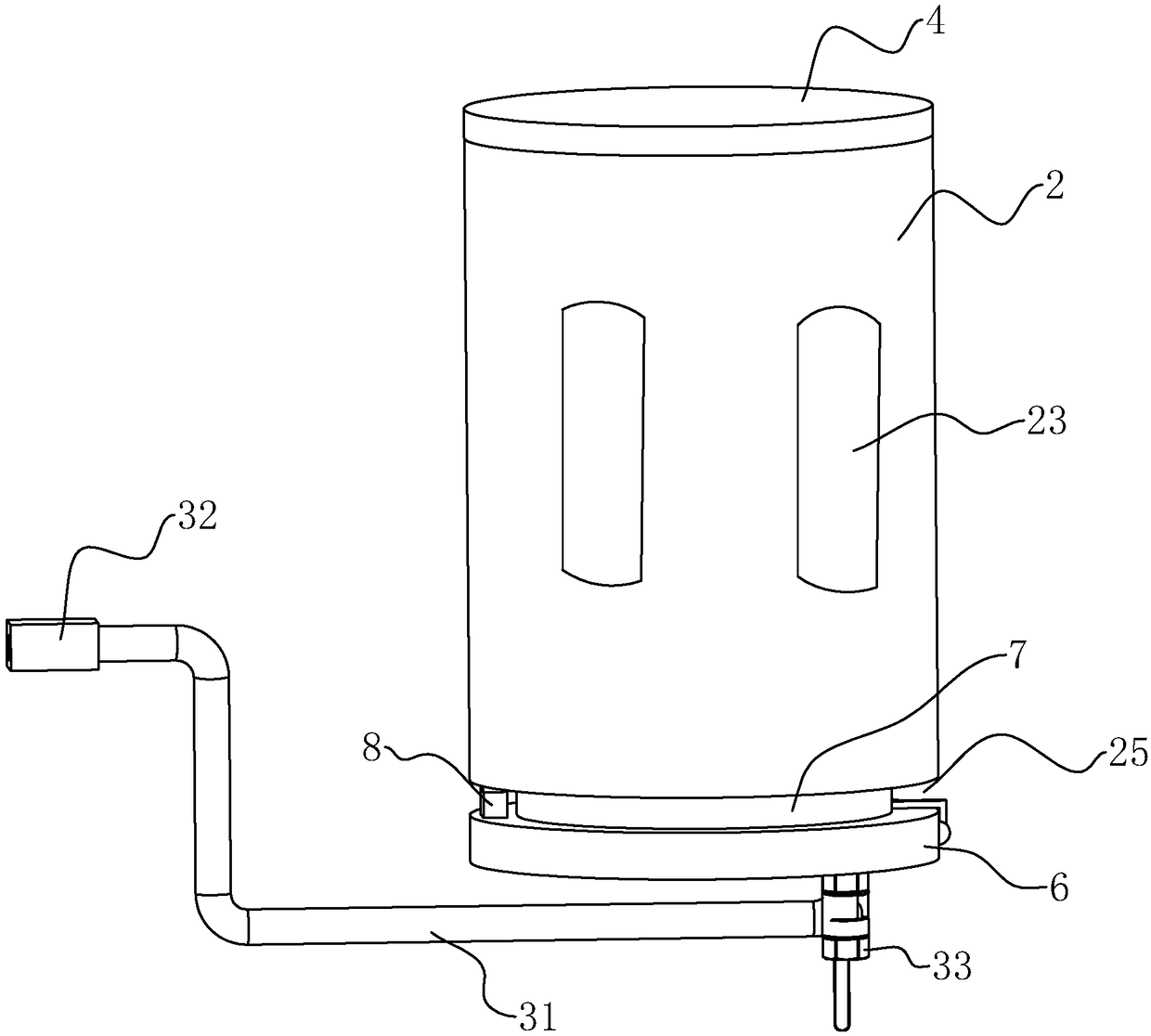

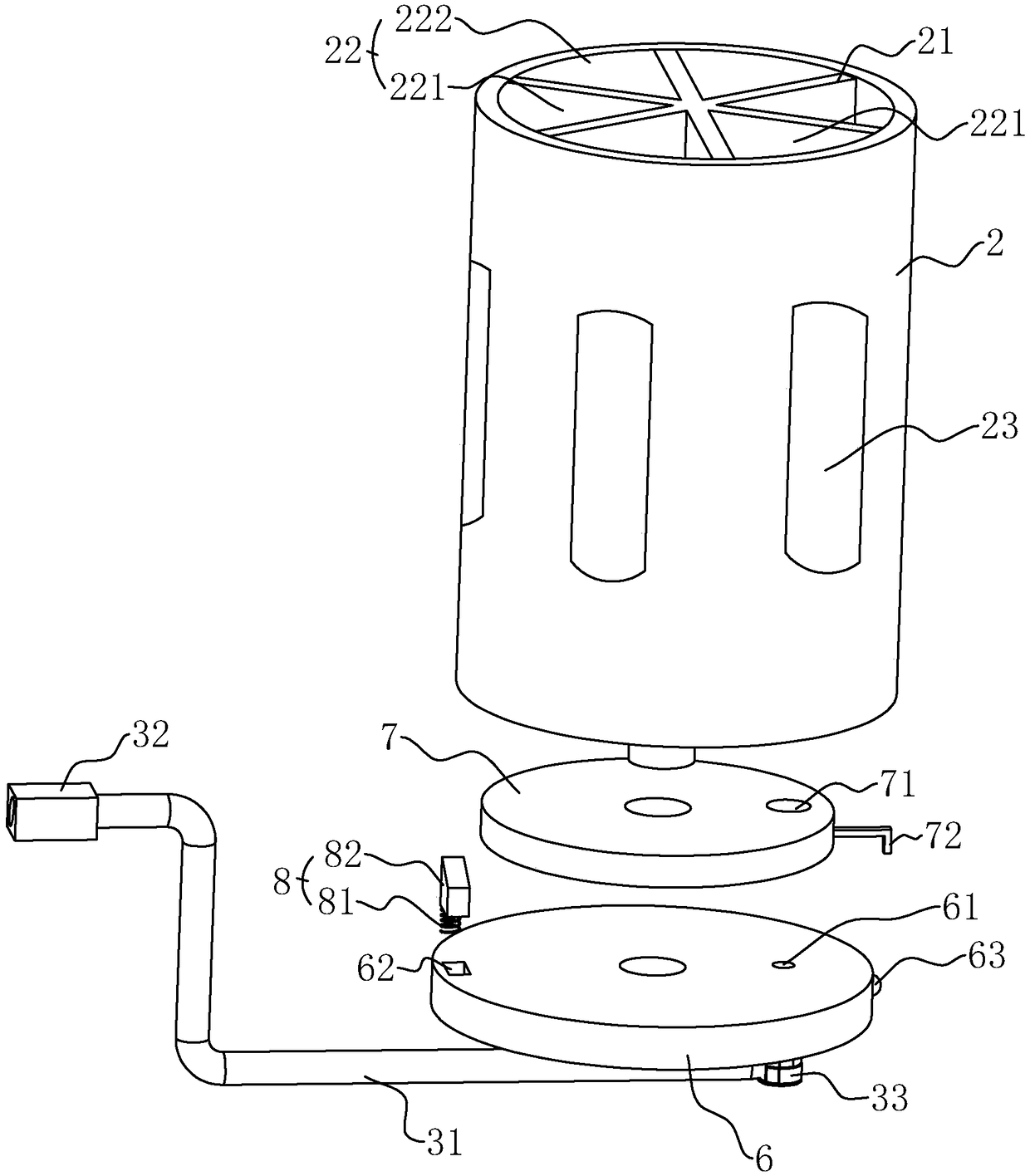

Spraying device for buildings

ActiveCN109013094AAchieve a relatively fixedImprove stabilityLiquid spraying apparatusElectrical and Electronics engineeringEngineering

The invention discloses a spraying device for buildings, and relates to the technical field of spraying equipment. The spraying device comprises a charging barrel used for containing materials and aninjection assembly which is connected with the charging barrel and used for spraying paint. The spraying device for the buildings is characterized in that a plurality of longitudinal partition platesare arranged inside the charging barrel, and the partition plates divide the charging barrel into a plurality of independent charging units used for containing the materials; the bottoms of the charging units are all provided with discharging openings; a rotary disk is arranged at the outer bottom of the charging barrel in a rotating mode, and a through hole is formed in the rotary disk; one end of the through hole is connected with the injection assembly, and the other end of the through hole communicates with one of the discharging openings in the spraying process; and a limiting assembly used for limiting rotation of the rotary disk is arranged between the rotary disk and the charging barrel. The effect of switching injection of different sorts of paint is achieved by rotating the rotary disk and a striker plate together with the limiting assembly, and the usability and working efficiency of the device are improved.

Owner:浙江林鸥工程管理有限公司

Tin wire feeding mechanism

ActiveCN113501379AStable deliveryAvoid breakingFilament handlingSolder feeding devicesDrive wheelEngineering

The invention discloses a tin wire feeding mechanism. The mechanism comprises a base and a tin wire inlet module, a tin wire discharging module, a tin wire feeding driving assembly and a guiding assembly which are arranged on the base, and the tin wire feeding driving assembly comprises a driving wheel driven by a driving mechanism to rotate and a driven wheel in transmission fit with the driving wheel; a first gap for a tin wire to pass through is formed between the driving wheel and the driven wheel; and the guiding assembly is arranged on a tin wire conveying rail in front of and behind the tin wire feeding driving assembly and is provided with a guiding channel extending in the same direction as the common tangent line of the driving wheel and the driven wheel. The guiding channel plays a role in guiding the conveying direction of the tin wire, and the tin wire passes through the guiding channel in the guiding assembly before and after passing through the tin wire feeding driving assembly and does linear motion in the common tangential direction of the driving wheel and the driven wheel, so that the problem that the tin wire is bent in the conveying direction to cause breakage of the tin wire is solved; stable conveying of the small-diameter tin wire can be achieved, the structure is simple, and wire blocking is not prone to occurring.

Owner:SUZHOU RS TECH

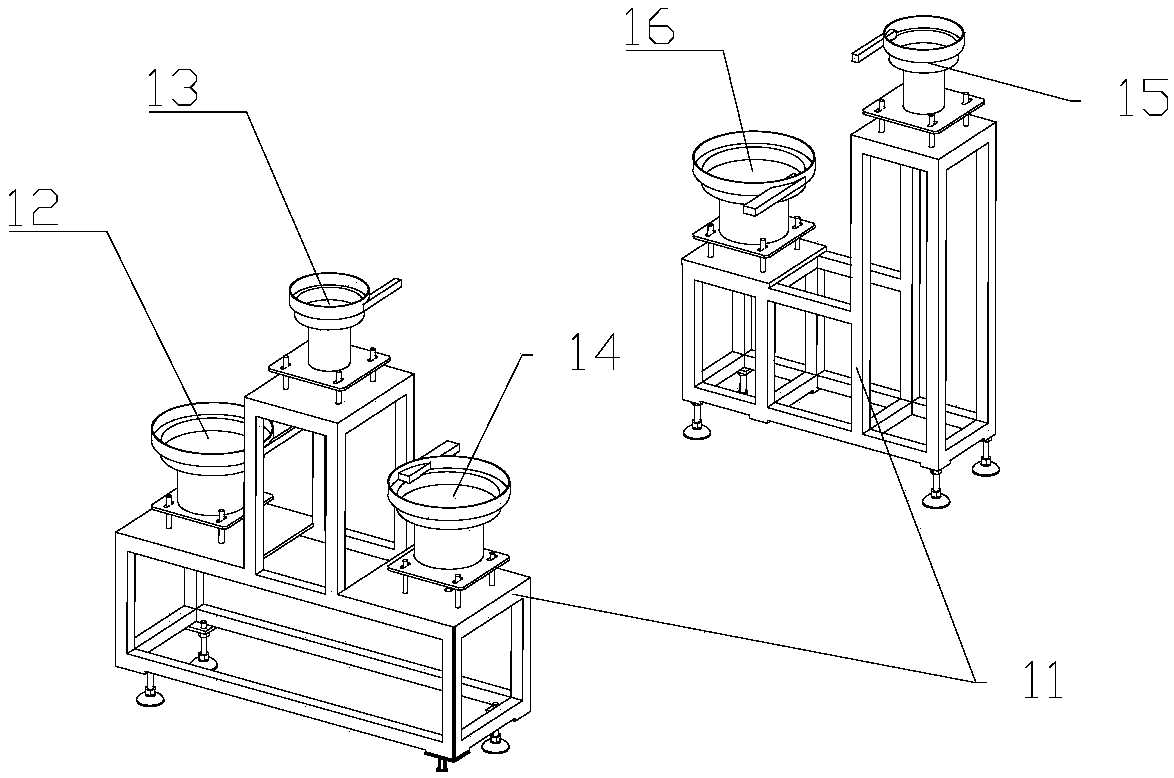

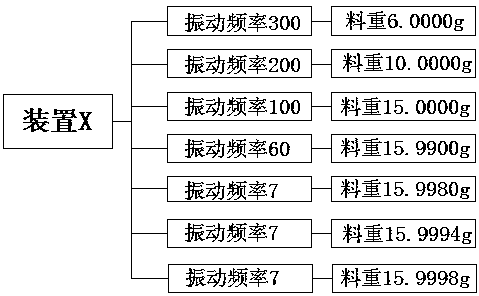

Trace-amount and balanced light-emitting diode (LED) fluorescent powder feeding device and operation method thereof

ActiveCN103407597AAchieve balanceNo human intervention requiredSolid materialEngineeringTrace Amounts

The invention discloses a trace-amount and balanced light-emitting diode (LED) fluorescent powder feeding device and an operation method thereof. The trace-amount and balanced LED fluorescent powder feeding device can evenly feed fluorescent powder into a container through vibration of a vibrator fixed on a platform and comprises a material feeding funnel, a hopper, the vibrator and funnel supports. The vibrator is fixed on the platform, the hopper is integrally formed, a material carrying cavity is formed in one end of the hopper, a material feeding part is arranged at the other end of the hopper, the hopper is fixed on the vibrator, a small material feeding pipe is arranged in the hopper and communicated with the material carrying cavity, the other end of the small material feeding pipe is communicated with a large material feeding pipe, the other end of the large material feeding pipe is connected with a material discharging bend, a fine screen is arranged on the connection portion of the large material feeding pipe and the material discharging bend, the four funnel supports are arranged on two sides of the vibrator and horizontally fixed, and the other ends of the funnel supports are fixed on the material feeding funnel which is fixed right above the material carrying cavity of the hopper through the funnel supports.

Owner:深圳市靶心配比科技有限公司

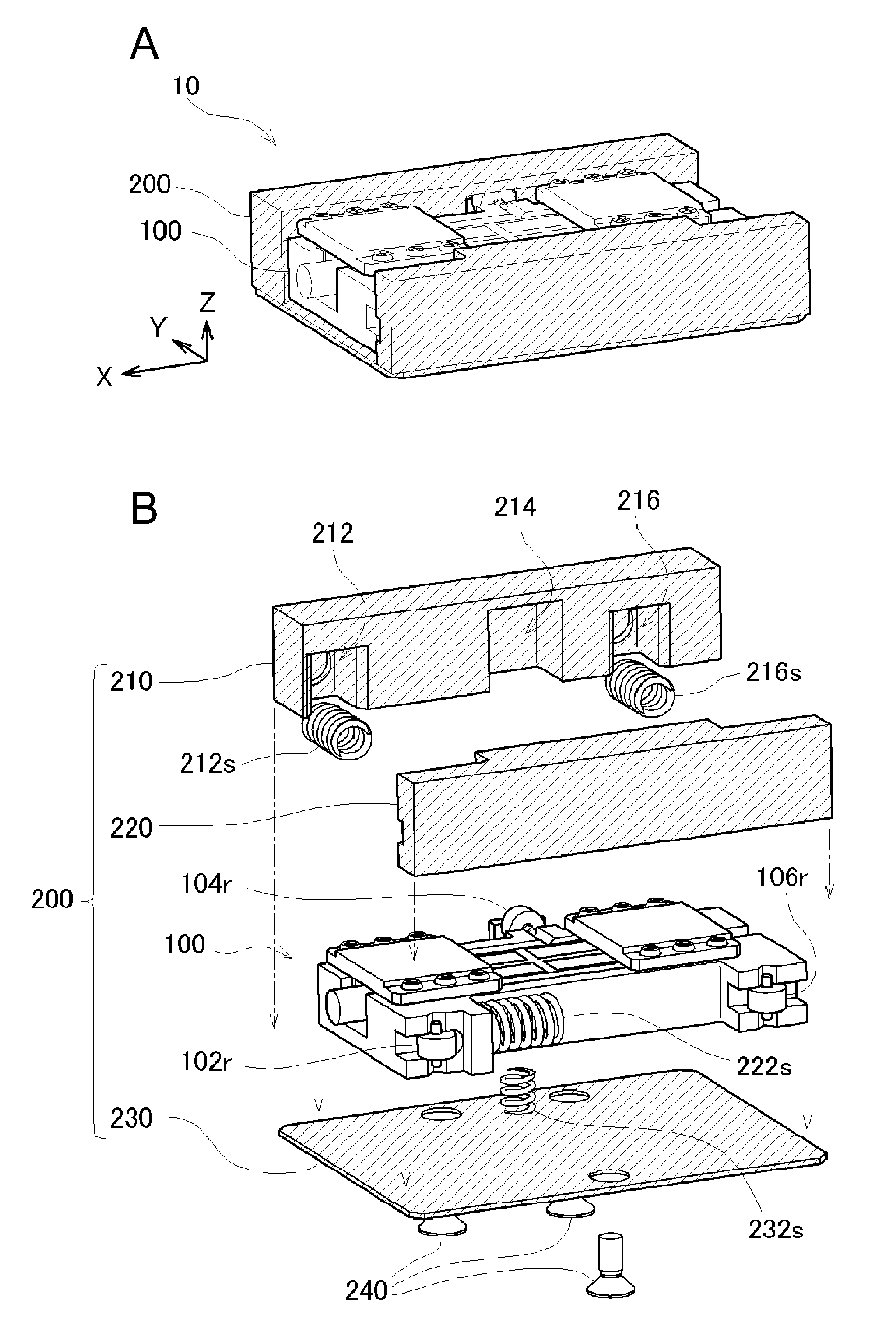

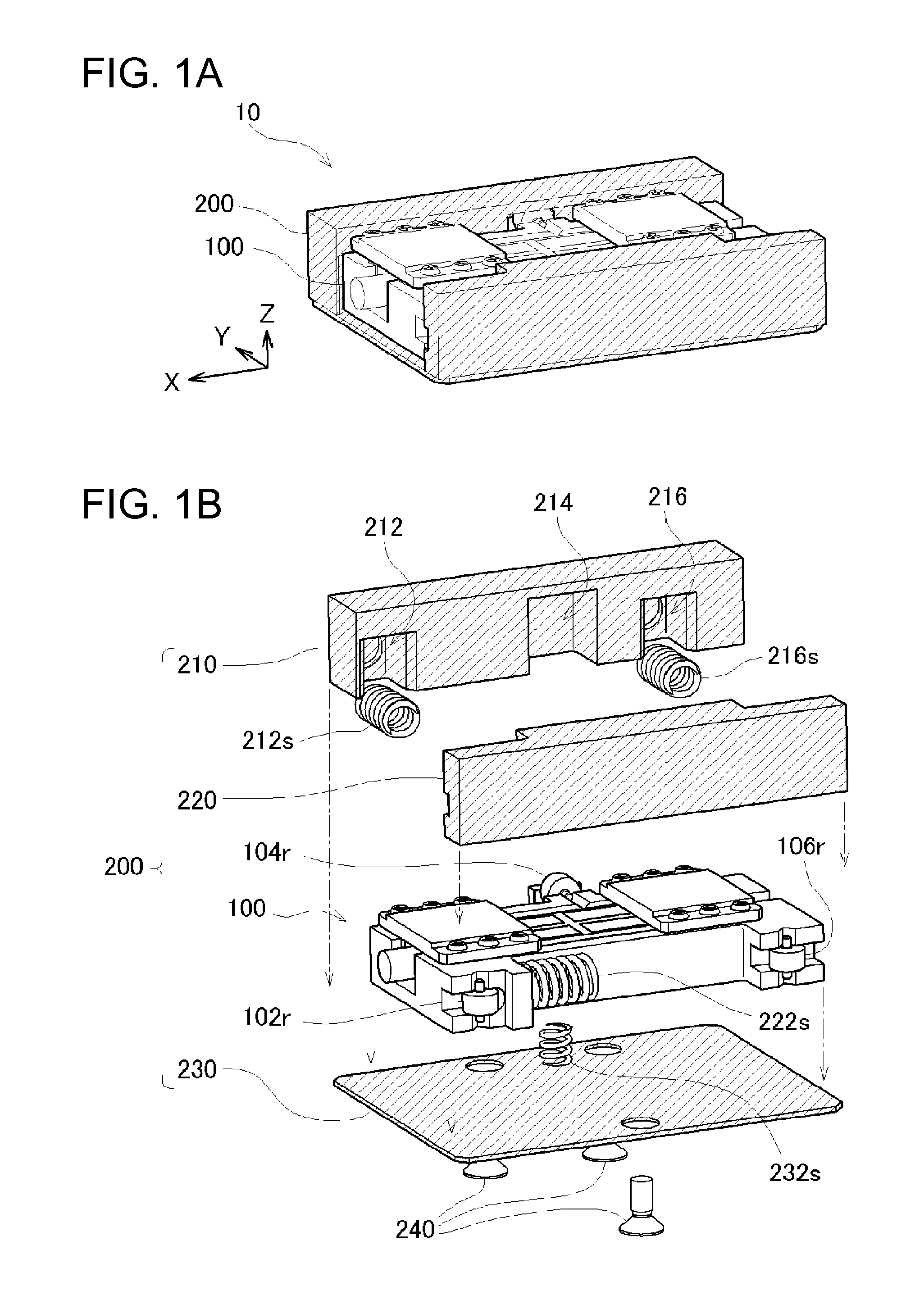

Piezoelectric motor, robot hand, robot, electronic component transporting apparatus, electronic component inspecting apparatus, liquid feeding pump, printing apparatus, electronic timepiece, projecting apparatus, and transporting apparatus

InactiveUS20140078219A1High driving accuracyHigh conveying precisionProgramme-controlled manipulatorPiezoelectric/electrostriction/magnetostriction machinesElectricityHigh stiffness

A vibration case includes a first side portion and a second side portion provided on the both sides of a vibrator in a bending direction and a coupling portion configured to couple the first side portion and the second side portion. In this configuration, stiffness of the vibrator in the bending direction is increased, and the deformation of the vibration case may be suppressed. This structure contributes to reduction in size of the vibration case as long as the same stiffness is secured, and hence the size of the vibration case may be reduced while securing high stiffness. Therefore, a piezoelectric motor having a driving accuracy secured sufficiently may be realized while suppressing increase in size of the piezoelectric motor.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com