An electronic registration system and its working method

An electronic and operation-side technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as low precision and large fluctuations in registration precision, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

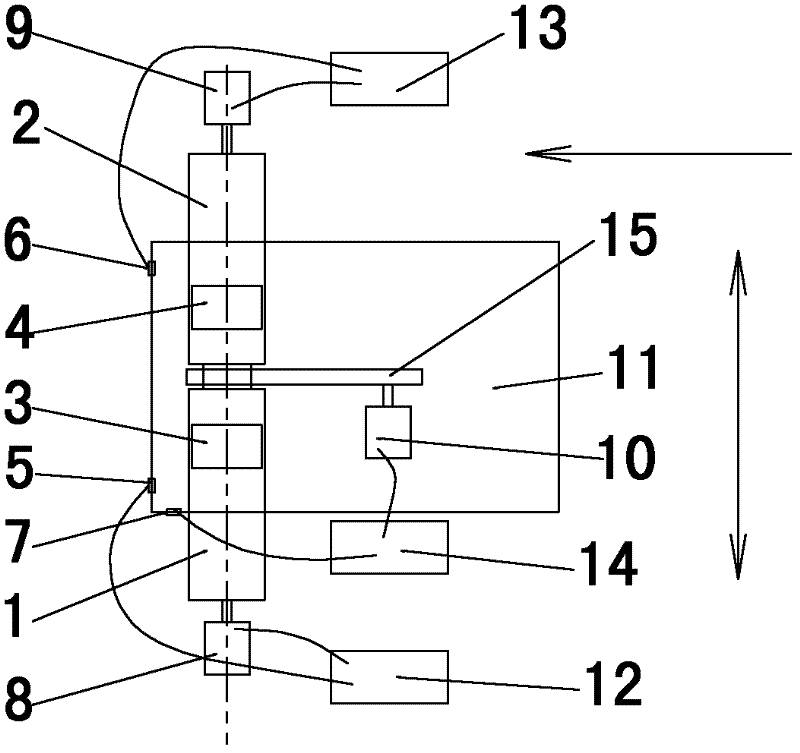

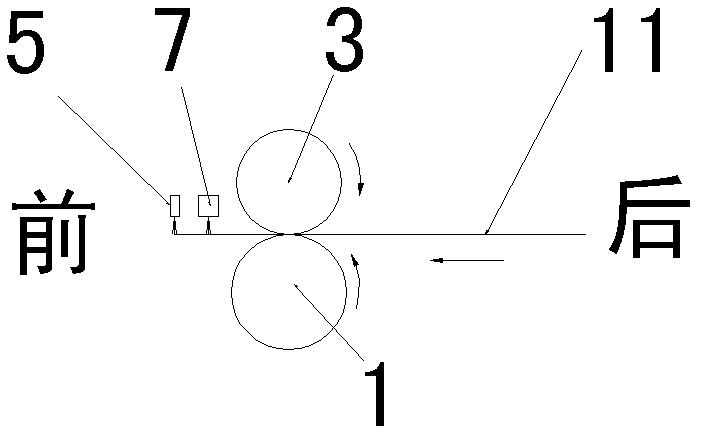

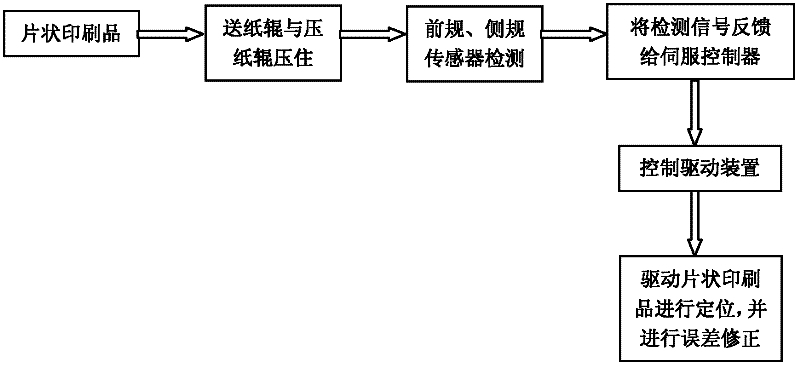

[0020] Embodiment: a kind of electronic registration system (see figure 1 , figure 2 ), including sheet-like printed matter 11, is characterized in that it also includes paper feeding roller, platen rubber roller, front gauge sensor, side gauge sensor 7, paper feeding roller drive unit, side gauge drive unit 10, front gauge servo controller, Side gauge servo drive controller 14 and connecting plate 15; the paper feed roller is connected to the output end axis of the paper feed roller driving device; the paper pressing rubber roller is placed directly above the paper feeding roller, and the The outer circular surface is pressed on the surface of the paper feed roller; the front gauge sensor is placed in front of the paper feed roller; the side gauge sensor 7 is placed on the side in front of the paper feed roller; the front gauge servo controller The input end is connected to the front gauge sensor, and the output end is connected to the paper feed roller driving device; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com