Patents

Literature

183results about How to "Improve delivery stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

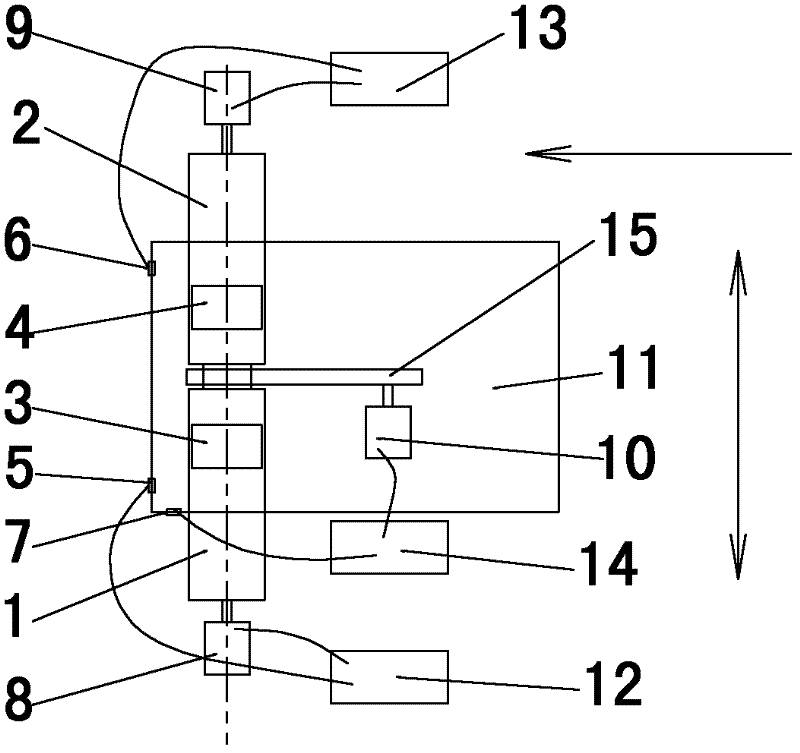

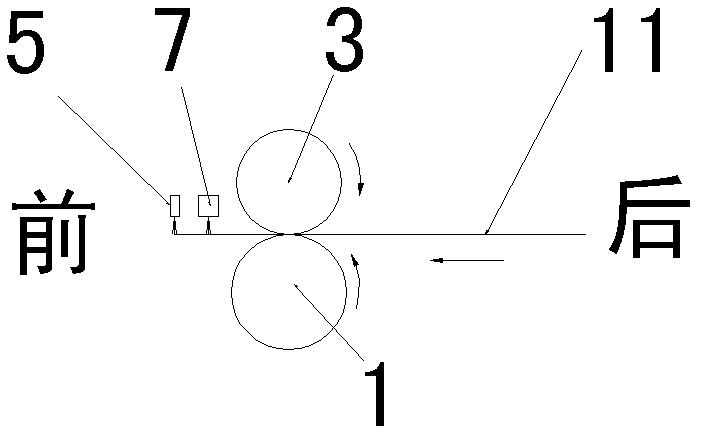

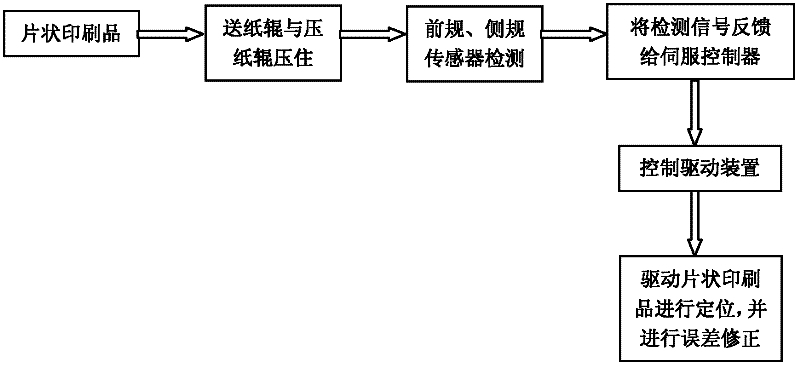

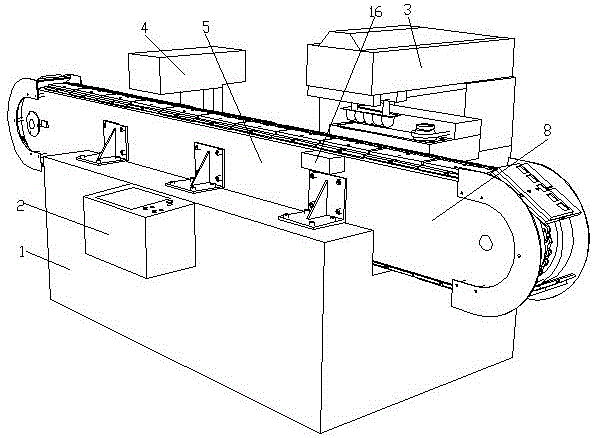

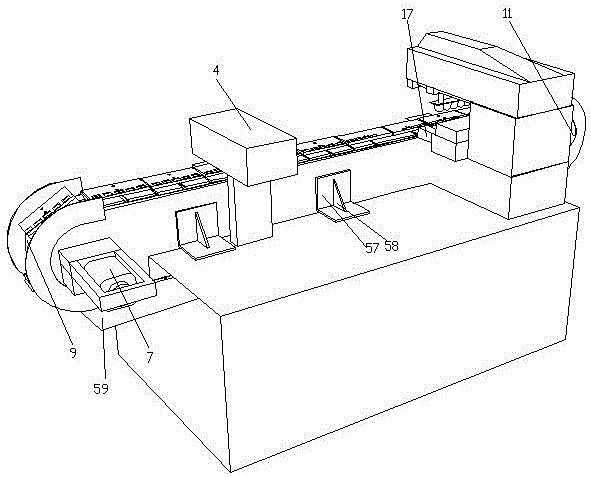

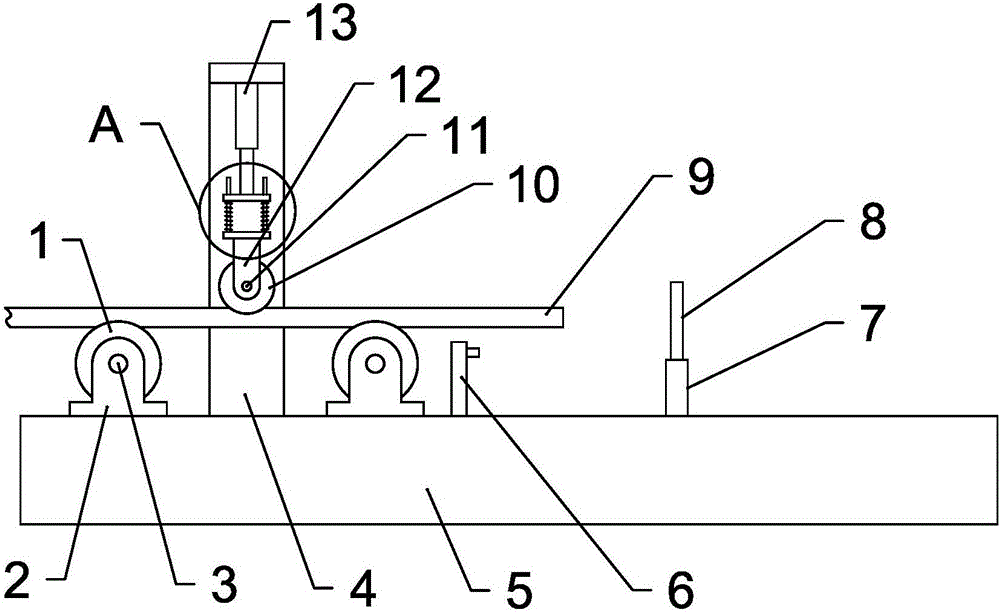

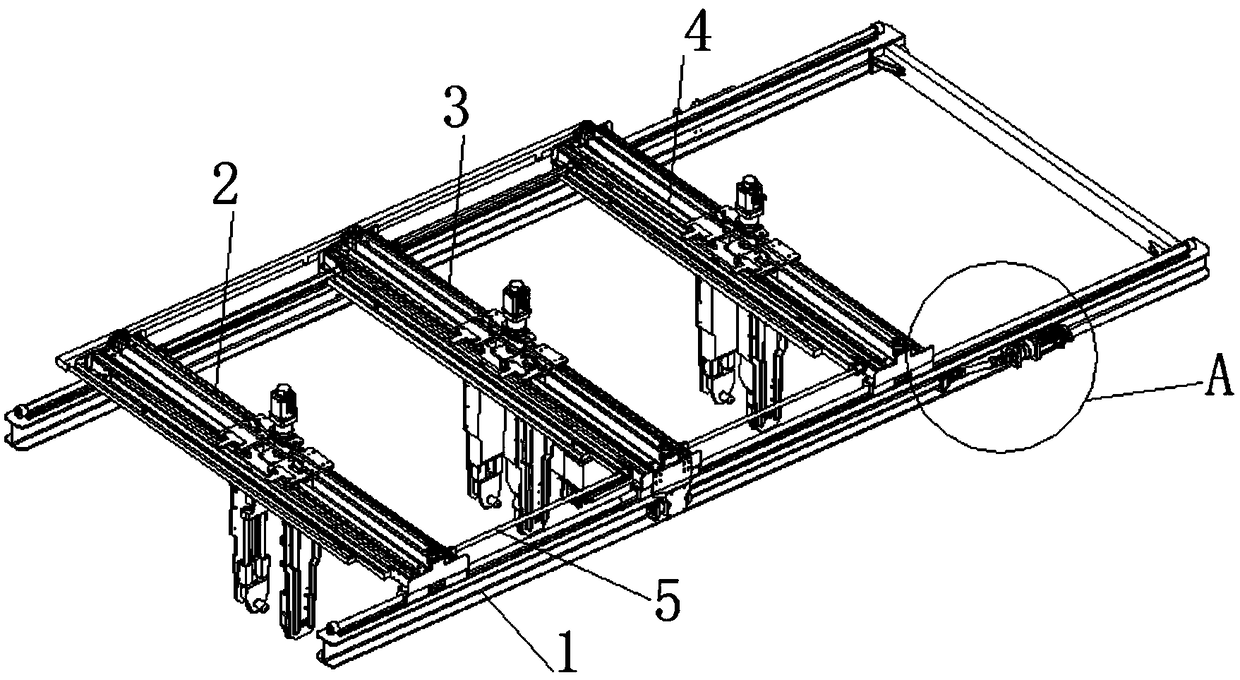

An electronic registration system and its working method

ActiveCN102285216AHigh conveying precisionImprove delivery stabilityPrinting press partsEngineeringFixed position

The invention discloses an electronic alignment system, which comprises a sheet printed matter, and is characterized by also comprising a paper feeding roll, a rubber roll, a front-guide sensor, a side-guide sensor, a paper feeding roll driving device, a side-guide driving device, a front-guide servo controller, a side-guide servo driving controller and a connecting plate. The device directly detects positioning marks or edges printed on the sheet printed matter through the sensors, and feeds the detected signals to the servo controller, and the servo controller controls the servo device to perform fixed-position conveying and error correction on the sheet printed matter to position the single-paper printed matter. The electronic alignment system has the advantages that: the marks on the printed matter are directly detected by the sensors for positioning, and the positioning precision is high; and the paper feeding roll controls the sheet printed matter through an operating side paper feeding roll and a transmission side paper feeding roll so as to overcome errors of the sheet printed matter on the operating side and the transmission side caused by errors of a conveying platform when the conveying platform conveys the sheet printed matter.

Owner:MASTERWORK GROUP CO LTD

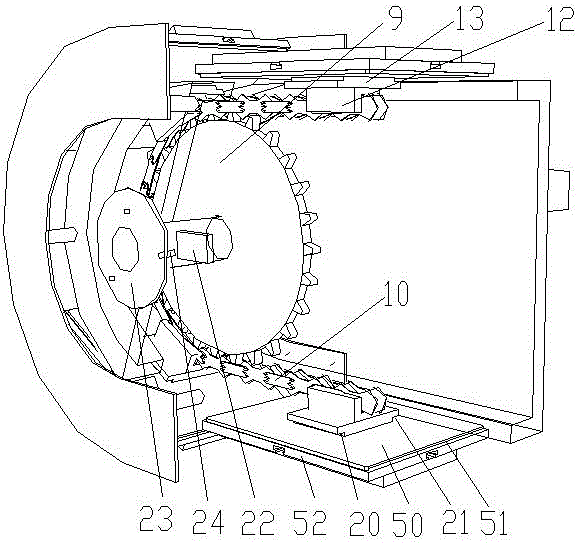

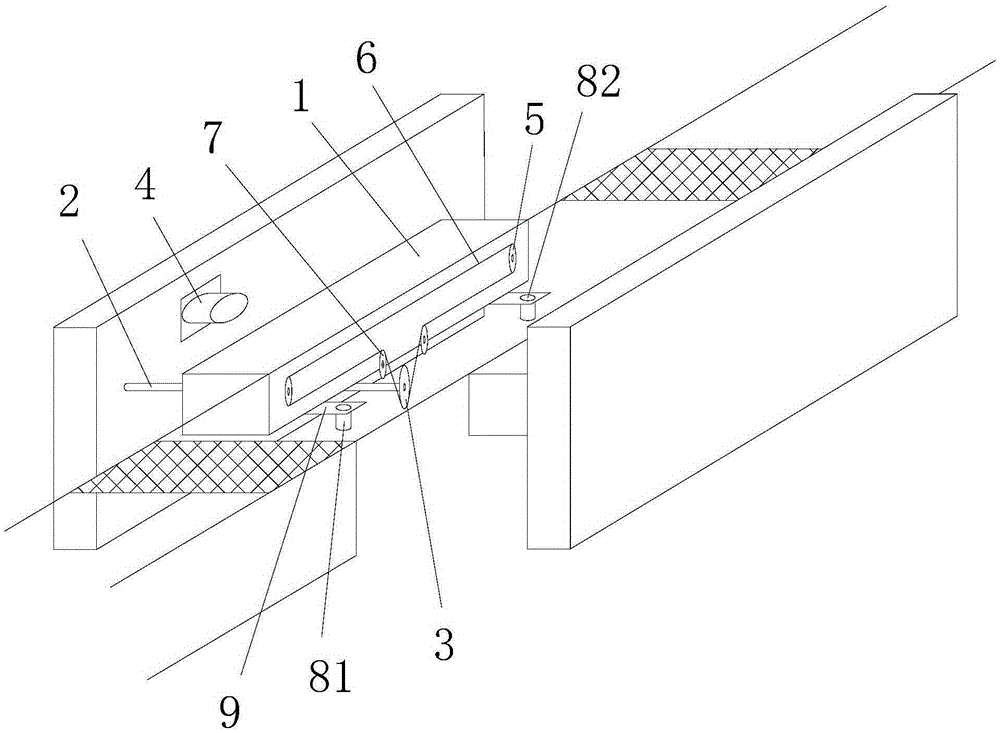

Transfer printing and coding equipment

ActiveCN106364151AEasy to clamp and positionGood pauseRotary pressesPrinting press partsElectricityFinesse

The invention discloses transfer printing and coding equipment which comprises a workbench, a PLC and a transfer printer, and further comprises a laser coding machine and a conveying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. Multiple fixing bases are fixed to the chain and connected with positioning blocks. A bracket is connected to the positioning blocks and provided with die grooves. The side wall of the transmission case is provided with a transfer printing positioning part. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disc. Three sensing columns are distributed on the wheel disc. The infrared sensor, the transfer printer and the laser coding machine are electrically connected with the PLC. By means of organic combination of transfer printing and coding, continuous transfer printing and coding operation of large batches of printed products is achieved, the production efficiency is greatly improved, transfer printing and coding are clearer, and the finesses degree is higher.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

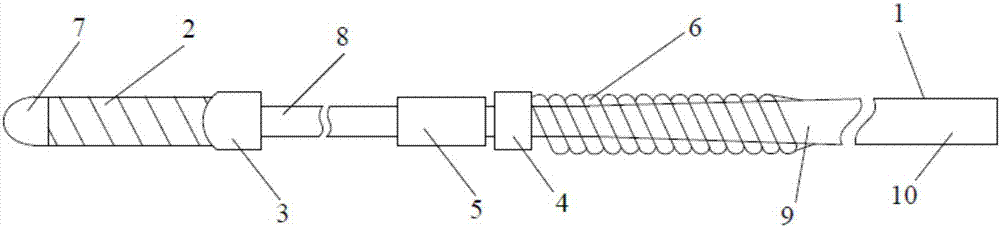

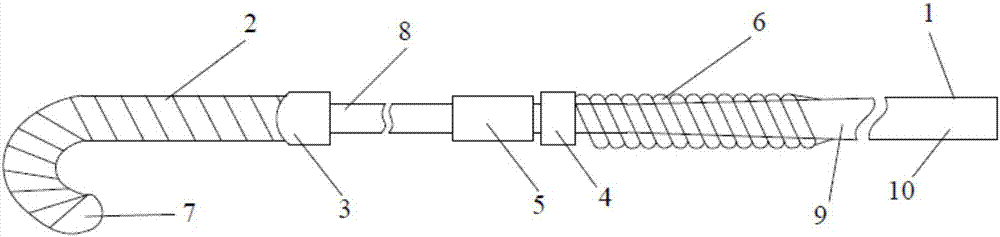

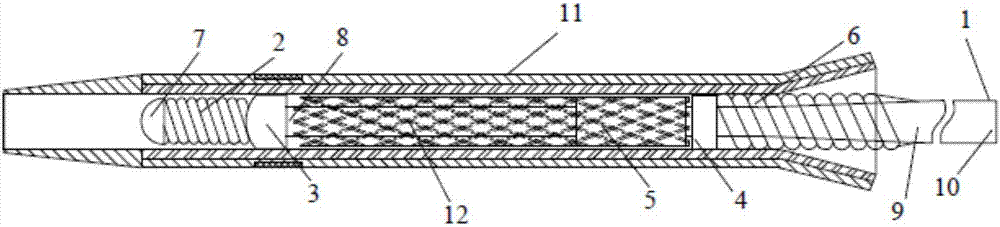

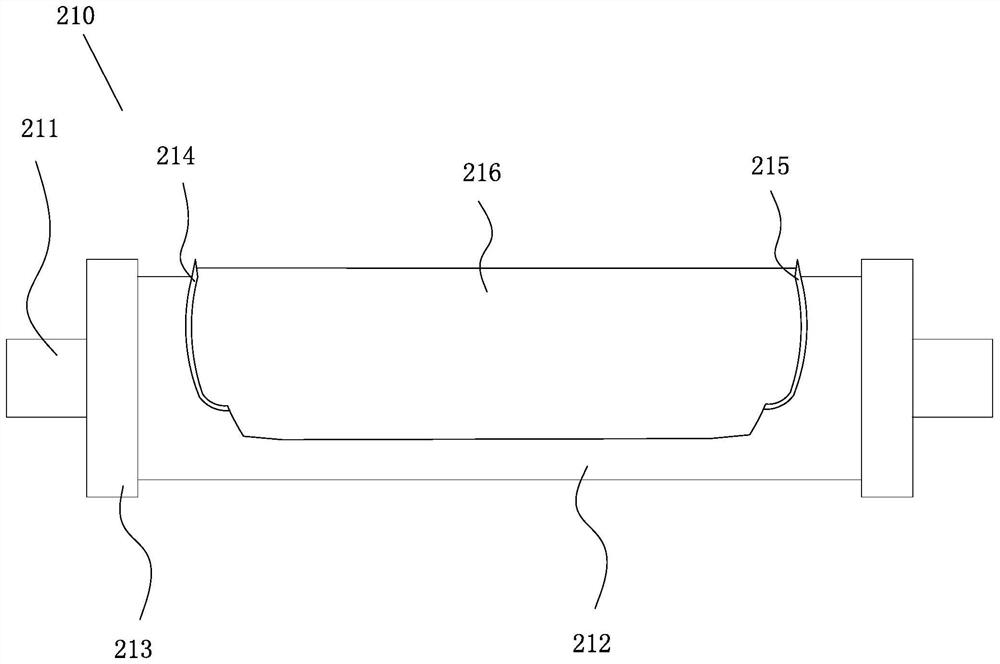

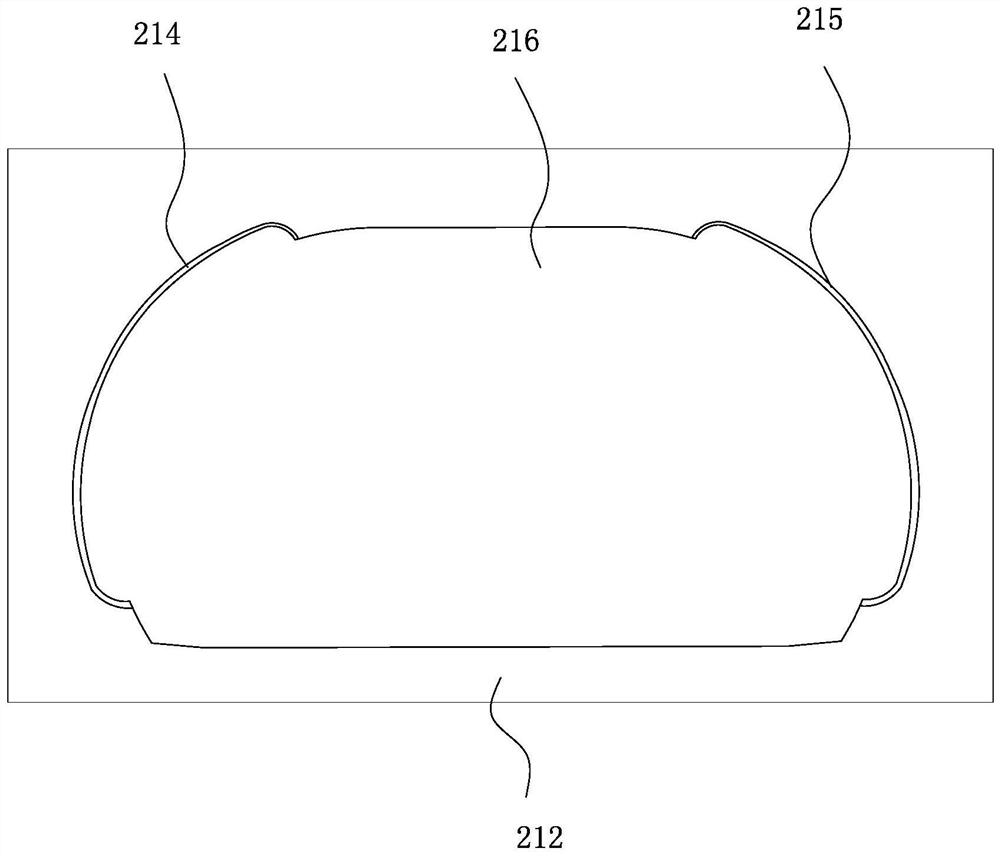

Conveyor of blood flow guiding device and blood flow guiding device

The invention provides a conveyor of a blood flow guiding device. The conveyor comprises a pushing guide wire and a guiding spring of which one end is connected with the left end of the pushing guide wire, the pushing guide wire is further provided with a dual-developing mark, the dual-developing mark comprises a first developing mark which is in contact connection with the guide spring and a second developing mark, the first developing mark and the first developing mark are arranged in a spaced mode, the portion, between the first developing mark and the second developing mark, on the pushing guide wire is further provided with a friction cover, and the friction cover is made from a crylic acid polymer. Through the adoption of the crylic acid polymer to be the material of the friction cover which is a core part of the conveyor of the blood flow guiding device, good adhesive force of the material itself and the pushing guide wire is made use of, loosening, wrinkling or displacement caused by large force of friction generated when the flood flow guiding device is delivered by a microtube are prevented, and the delivery stability and smoothness of the blood flow guiding device in the matched microtube are improved.

Owner:BEIJING TAIJIE WEIYE TECH

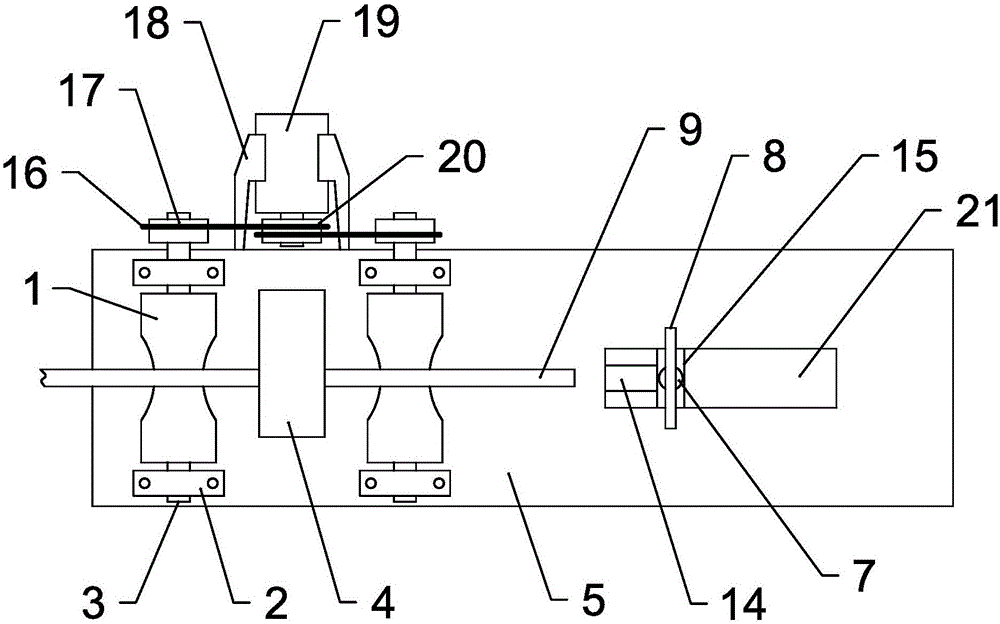

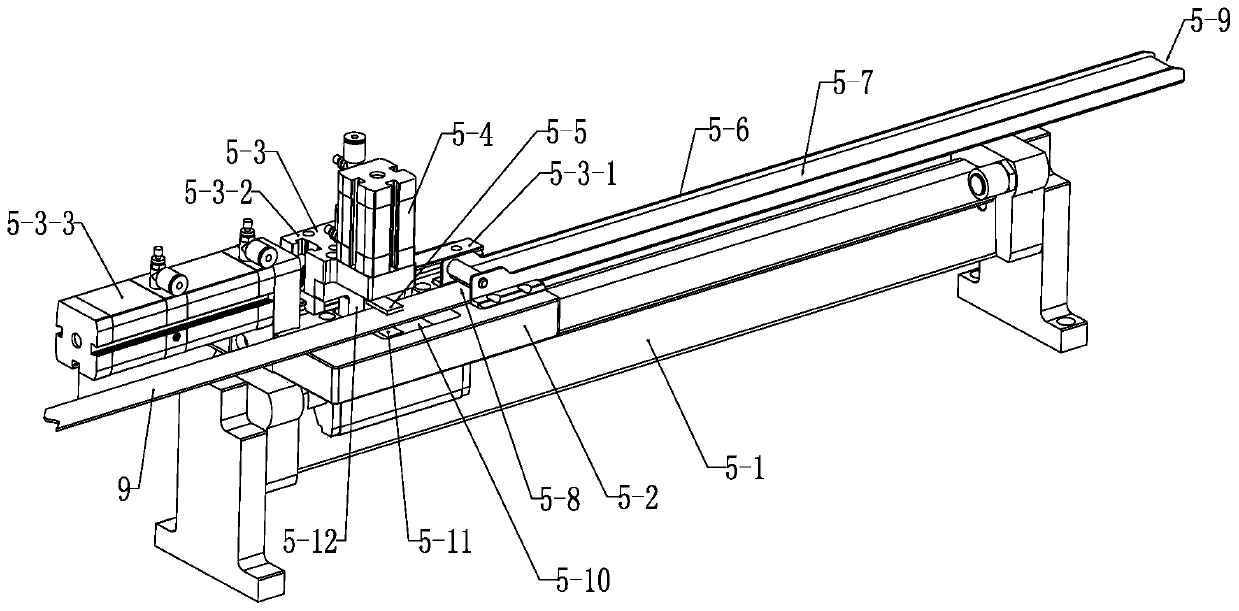

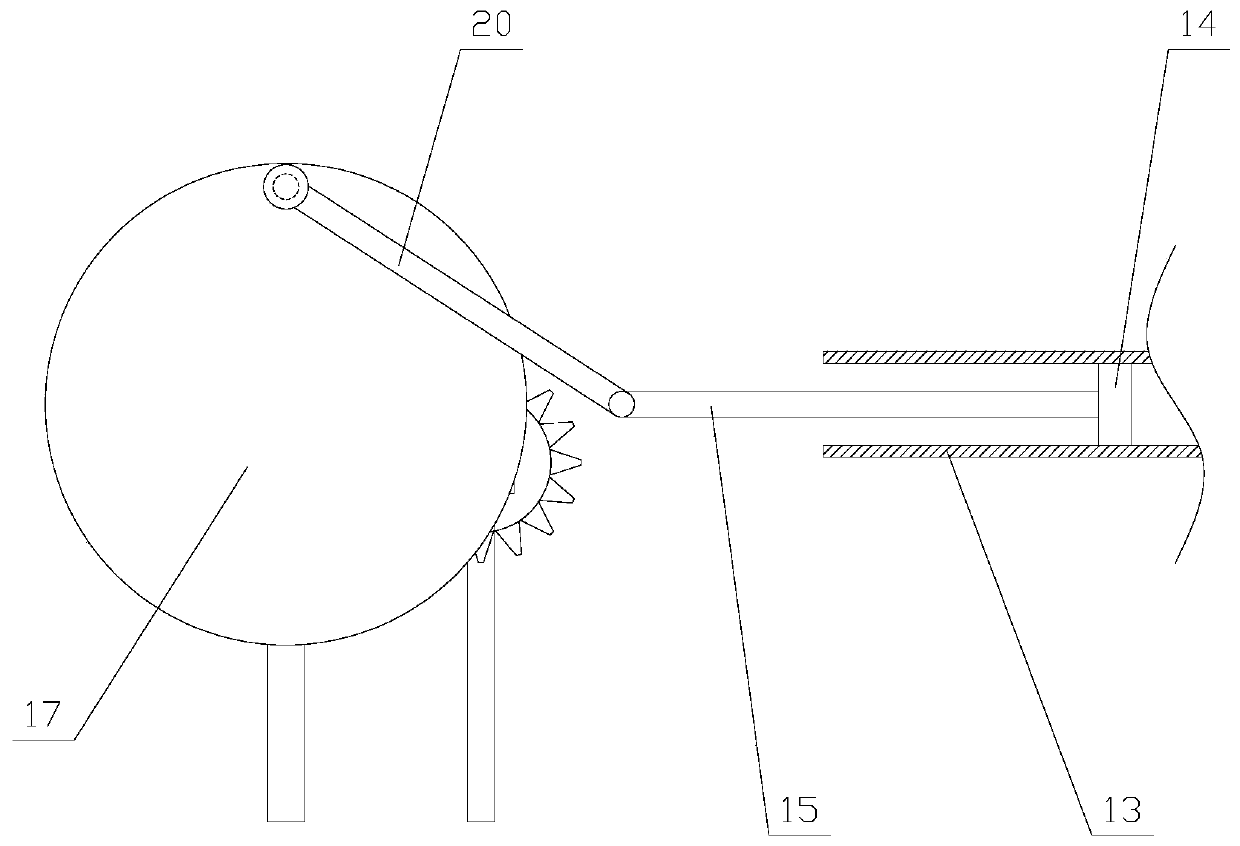

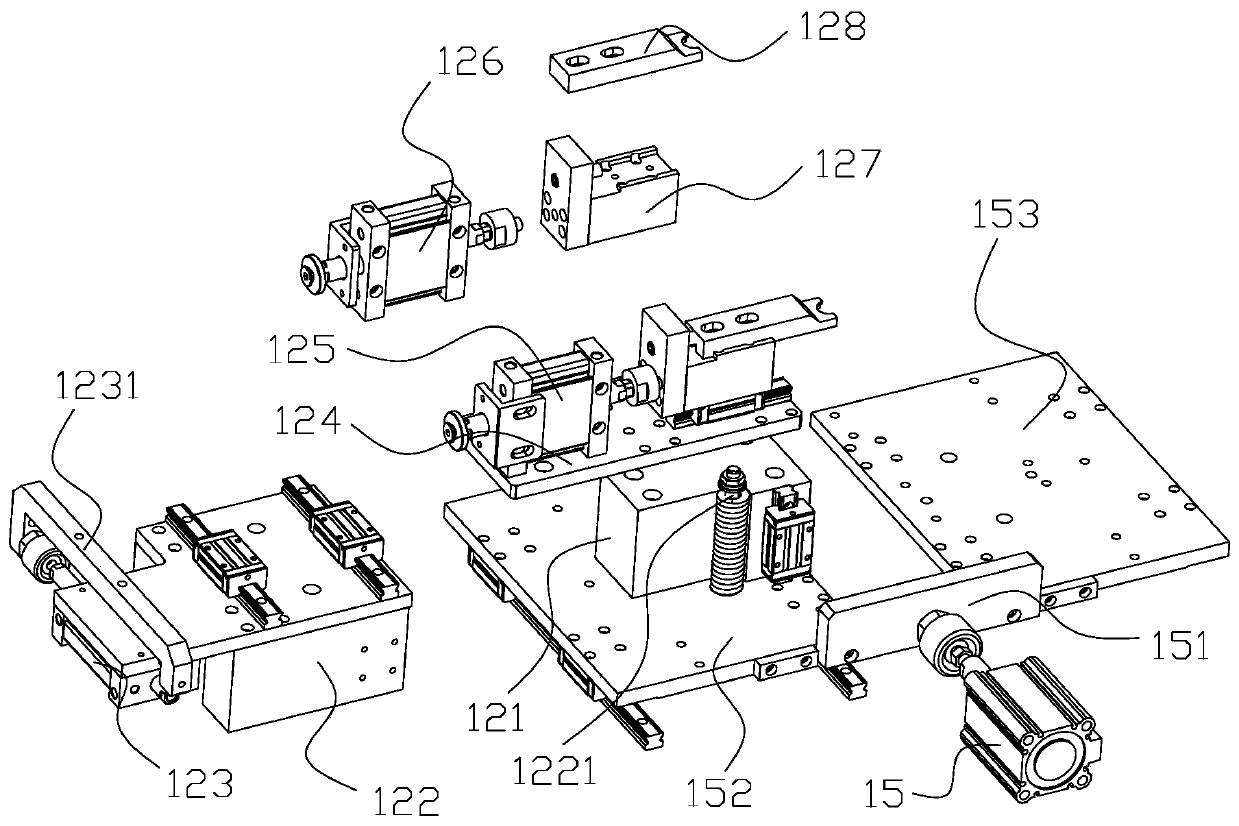

Sizing mechanism of equipment in steel bar shearing process

InactiveCN106825334AImprove delivery stabilityEasy to controlMetal working apparatusArchitectural engineeringRebar

The invention discloses a sizing mechanism of equipment in a steel bar shearing process, comprising a driving roller, an L-shaped bracket, a workbench, a positioning baffle and a pressing roller; the left side of the top part of the workbench is provided with two groups of steel bar gliding rolling mechanisms, and each of the steel bar gliding rolling mechanism comprises the driving roller, the L-shaped bracket is fixedly between the two groups of the steel bar gliding rolling mechanisms and on the workbench; the lower side of a horizontal part of the L-shaped bracket is equipped and fixed with a second telescopic cylinder, and the lower end of a piston rod of the second telescopic cylinder is connected with a roller wheel frame through a buffer supporting mechanism; the lower end of the roller wheel frame is equipped with a pressing roller, and the right side of the top part of the workbench is provided with an installing base holding groove; an installing base is arranged in the installing base holding groove, the left side of the installing base is provided with a third telescopic cylinder, and the top part of the installing base is fixedly provided with a first telescopic base; the upper end of the piston rod of the first telescopic cylinder is fixedly equipped with a positioning baffle. The sizing mechanism can stably convey the steel bar, convenient to carry out the sizing operation, and high in both stability and precision.

Owner:康振智能装备(深圳)股份有限公司

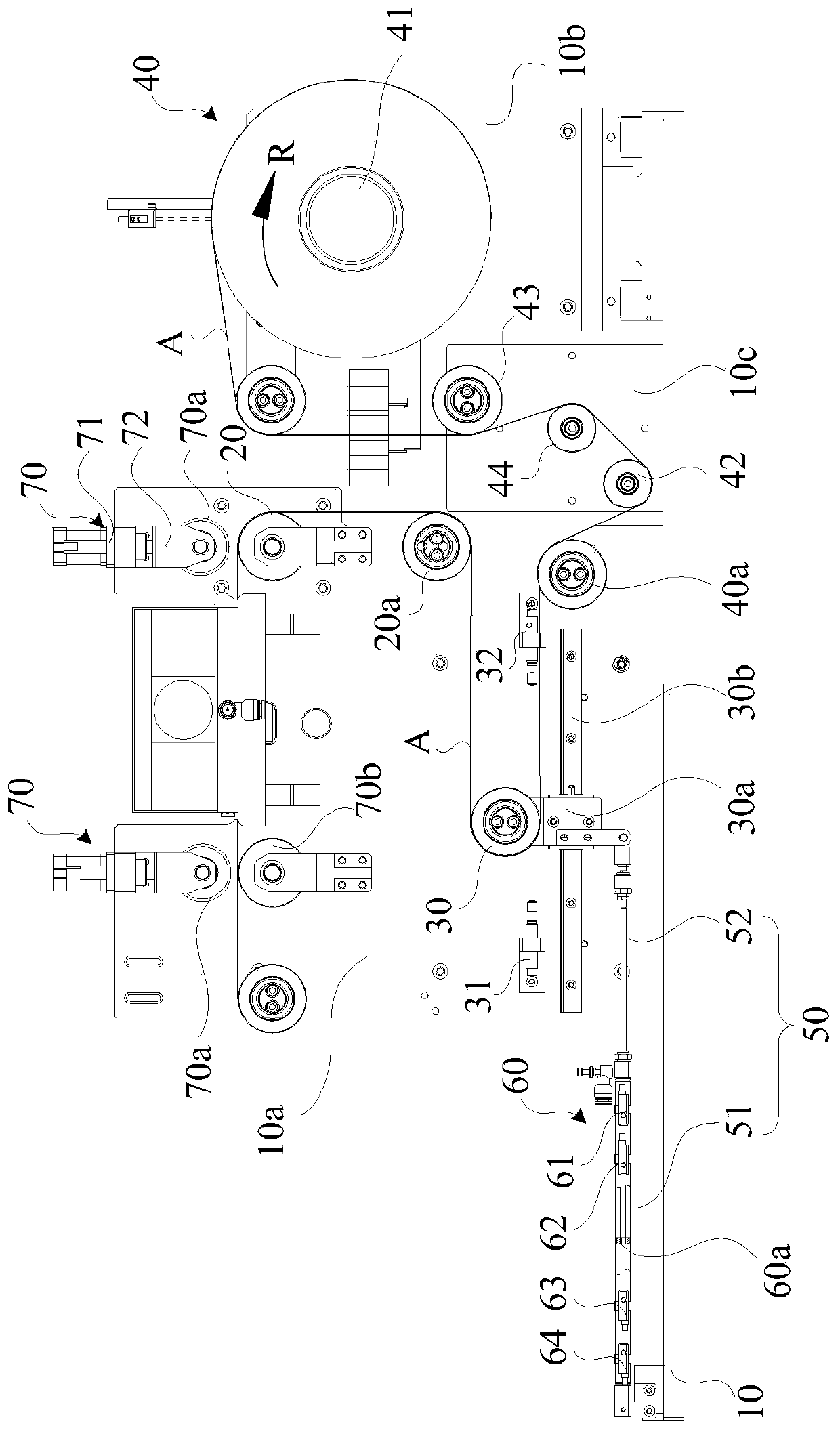

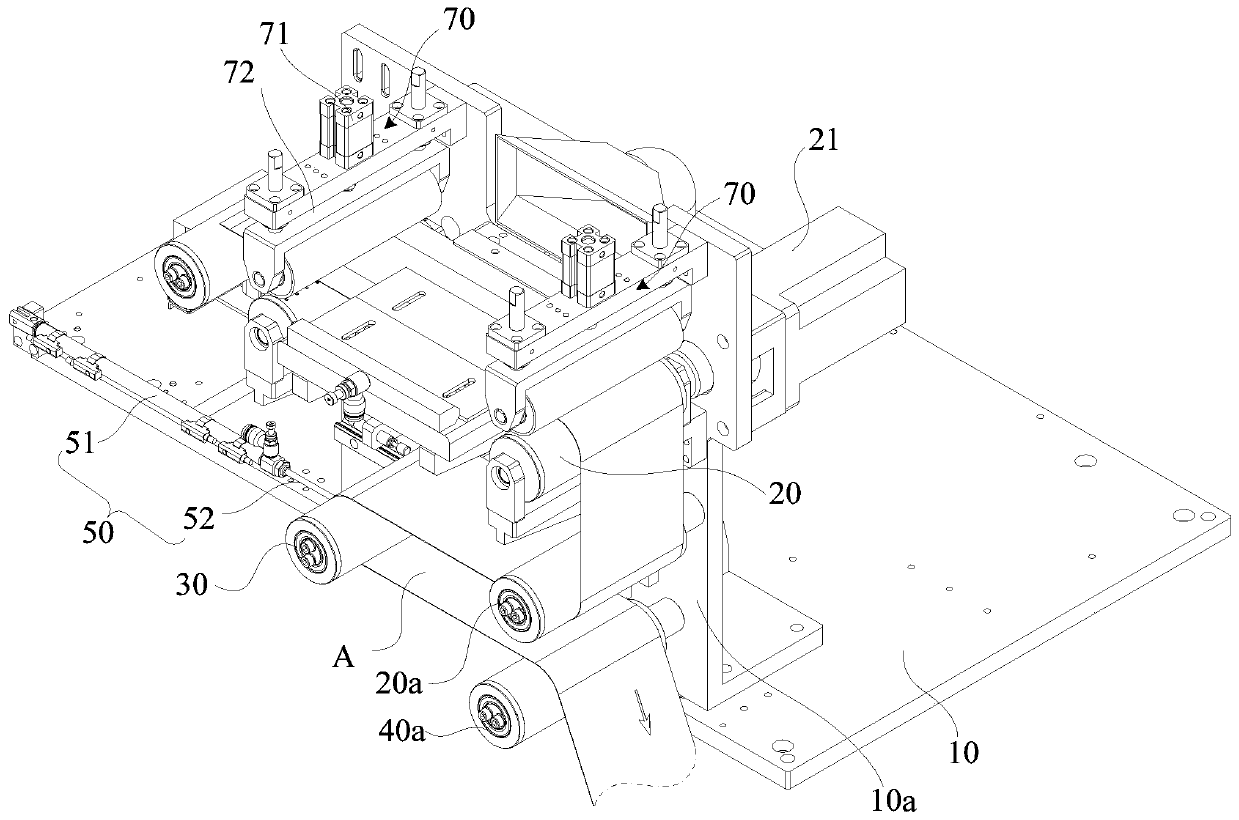

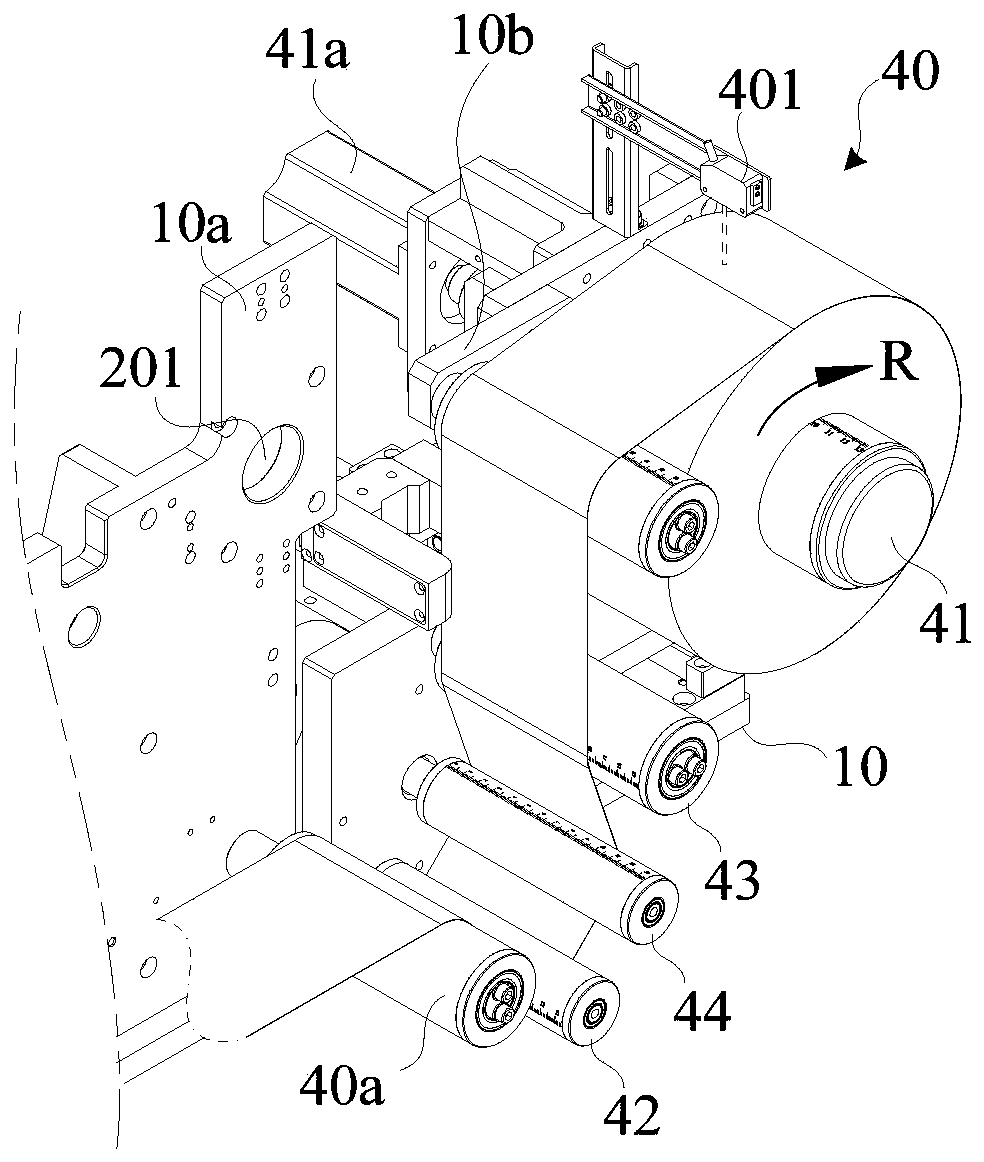

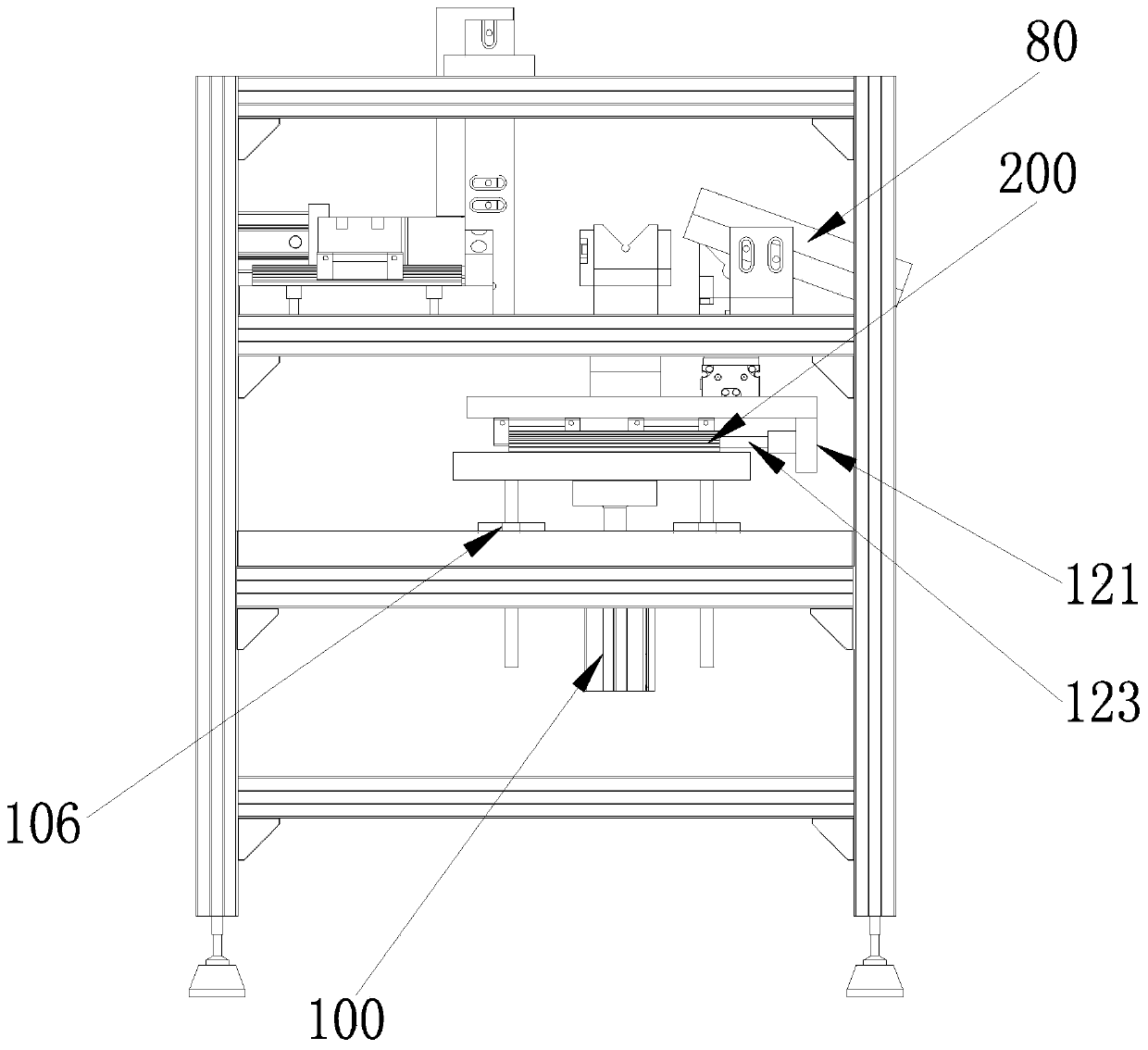

Material conveying method, material conveying device and material receiving mechanism thereof

The invention relates to a material conveying method, a material conveying device and a material receiving mechanism thereof. The material receiving mechanism comprises a winding roller, a driving part, a measuring assembly and a controller, wherein the winding roller is connected with the driving part and can rotate under the driving of the driving part to wind a material belt; the material beltwinds through the measuring assembly; the measuring assembly can measure the tension of the material belt to obtain tension information; the driving part and the measuring assembly are both electrically connected with the controller; the controller can receive the tension information obtained by the measuring assembly and adjust the motion state of the driving part according to the tension information so as to control the rotation speed of the winding roller and maintain the tension of the material belt at a preset range. According to the material conveying method, the material conveying device and the material receiving mechanism thereof, the winding speed of the material belt is feedback adjusted by detecting the tension of the material belt, so that the tension of the material belt is in a preset range, loosening or over-tightening of the material belt is avoided, and the conveying stability of the material belt is improved.

Owner:HANS LASER TECH IND GRP CO LTD

Automatic workpiece feeding mechanism

ActiveCN111532717ASimple structureEasy to operateConveyorsConveyor partsElectric machineryEngineering

Owner:浙江省平湖技师学院

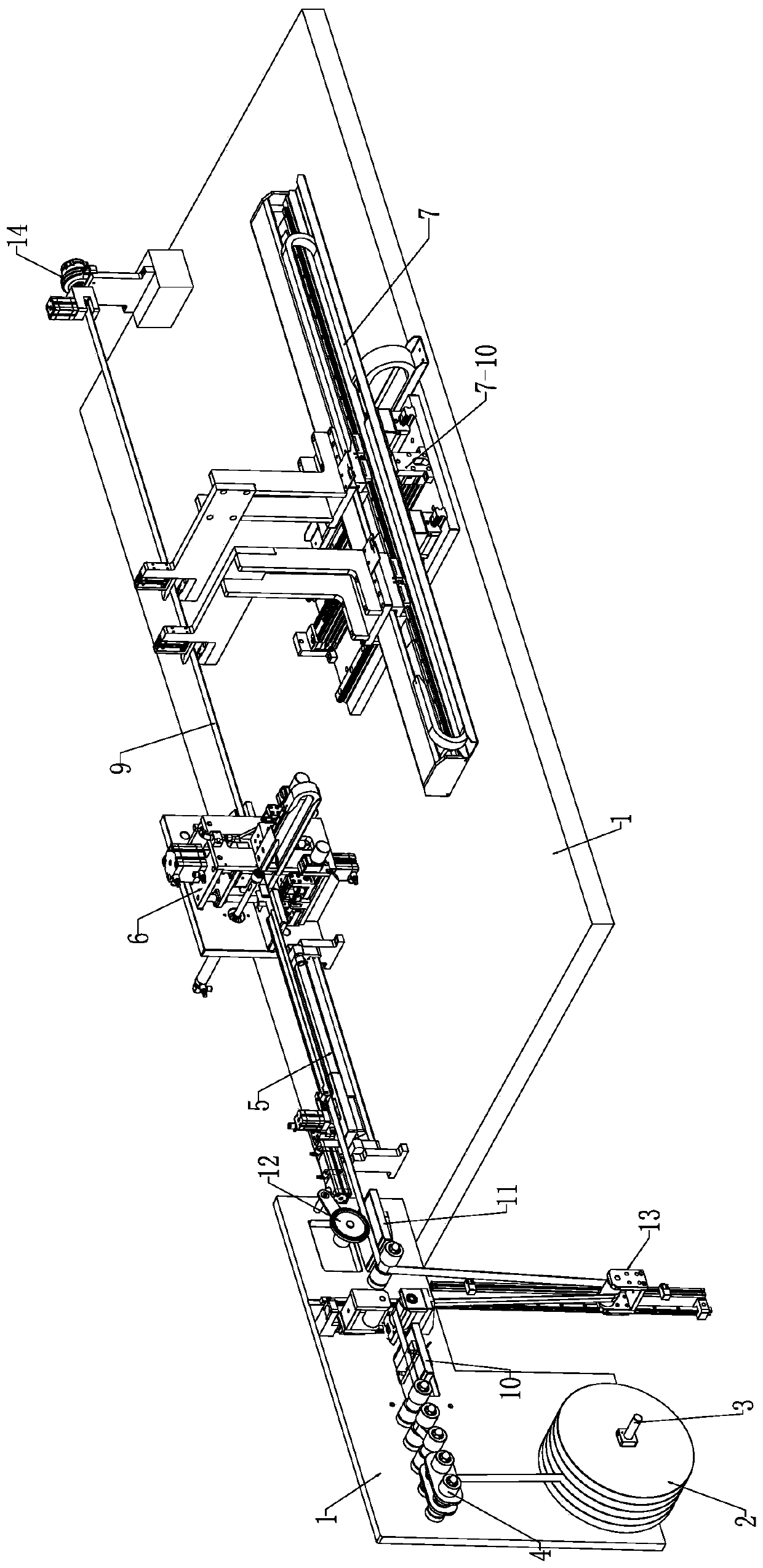

Automatic braid feeding device applied to automatic production of safety belts

PendingCN110480698APrecise deliveryRealize automated productionSevering textilesBeltsEngineeringMechanical engineering

The invention relates to an automatic braid feeding device applied to automatic production of safety belts. The automatic braid feeding device comprises a machine frame, wherein a material reel, a braid guide device, a first traction device, a cutting device, a second traction device, a controller and a power source are arranged on the machine frame, the material reel is used for mounting braid coils, the braid guide device is located above the material reel, the first traction device is located downstream of the braid guide device, the cutting device is located downstream of the first traction device, the second traction device is located on the downstream of the cutting device, and the controller and the power source are used for controlling the coordinate motion of the first traction device, the cutting device and the second traction device. The braid coils are supported by the material reel, the braid guiding device is used for adjusting the running direction of braids, the braidsare accurately conveyed, the first traction device and the second traction device are adopted to traction the braids before and after cutting, the braids are cut by the cutting device, the coordination action of each mechanisms is controlled by the controller, automatic production of automatic braid feeding is realized, and a foundation is laid for automatic production of the whole safety belts.

Owner:无锡平舍智能科技有限公司

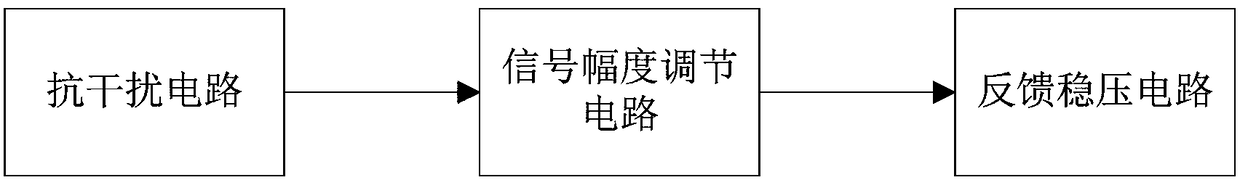

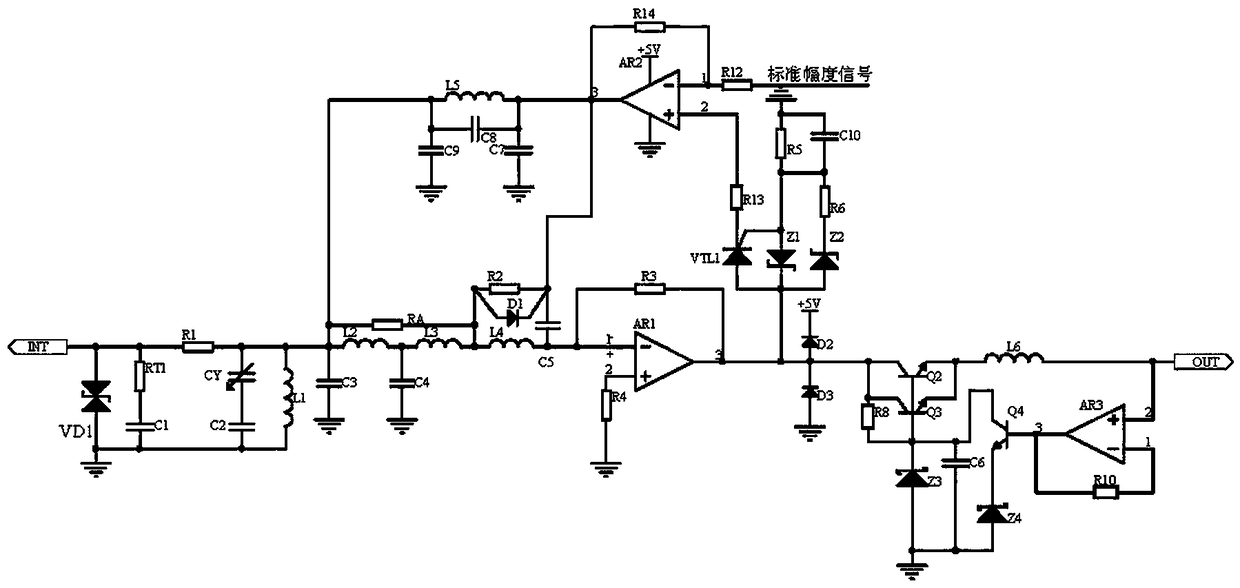

Data security intelligent operation and maintenance monitoring system

ActiveCN109283962AImprove delivery stabilityAvoid disorderElectric variable regulationInternal resistanceZener diode

The invention discloses a data security intelligent operation and maintenance monitoring system. A signal received by an anti-interference circuit is subjected to suppression, electromagnetic interference absorption and frequency selection and then enters a signal amplitude adjustment circuit. A first impedance conversion circuit outputs a resistance value matched with the internal resistance of the signal, and the resistance value is effectively transmitted and used as an input resistance of an operational amplifier AR1 for proportional amplification. When the signal amplitude is abnormal, asecond impedance conversion circuit outputs a resistance value matched with the internal resistance of the difference signal to be in parallel with the output resistance value of the first impedance conversion circuit for changing the amplification factor of the operational amplifier AR1 for amplitude adjustment. When the signal amplitude is normal, the signal enters a feedback voltage regulator circuit, a transistor Q2, a transistor Q3, a Zener diode Z3 and a capacitor C6 form a voltage regulator circuit to stabilize the voltage, and an operational amplifier AR3 and a transistor Q4 are designed to output the voltage after the feedback of voltage stabilization. The system effectively solves the technical problems of signal transmission attenuation, poor anti-interference and stability of the data security intelligent operation and maintenance monitoring system.

Owner:浙江宏远智能科技有限公司

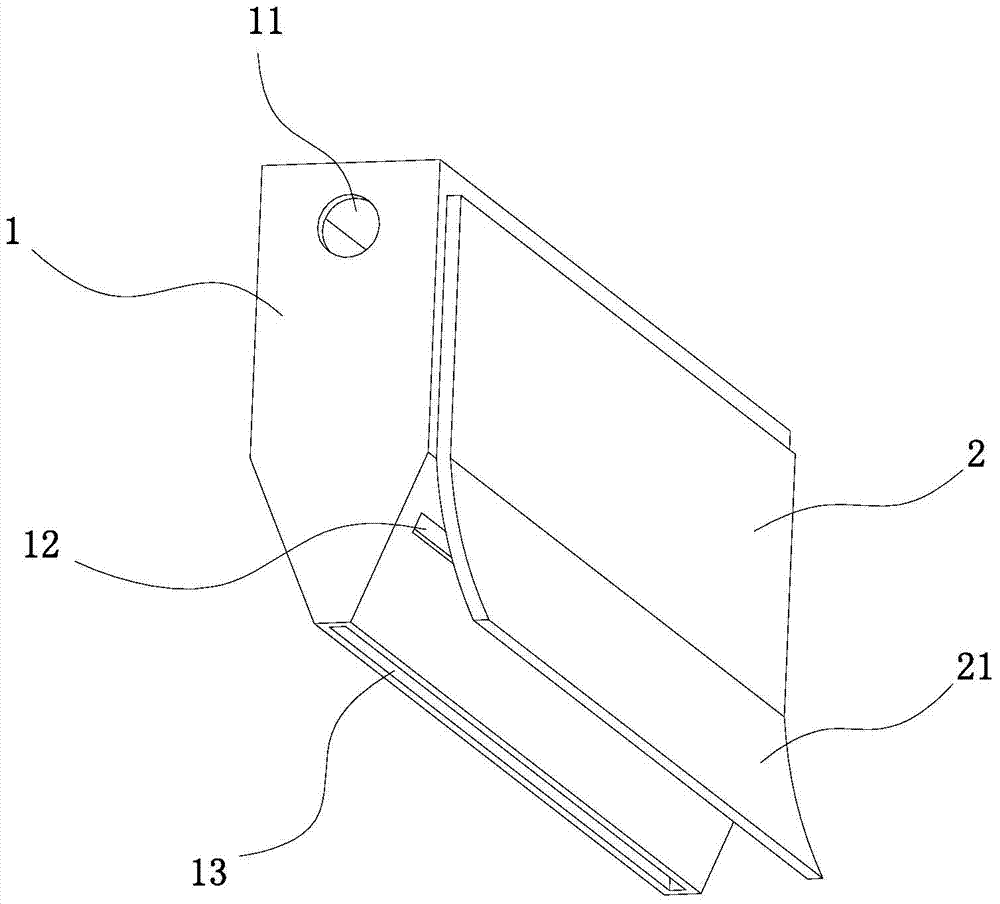

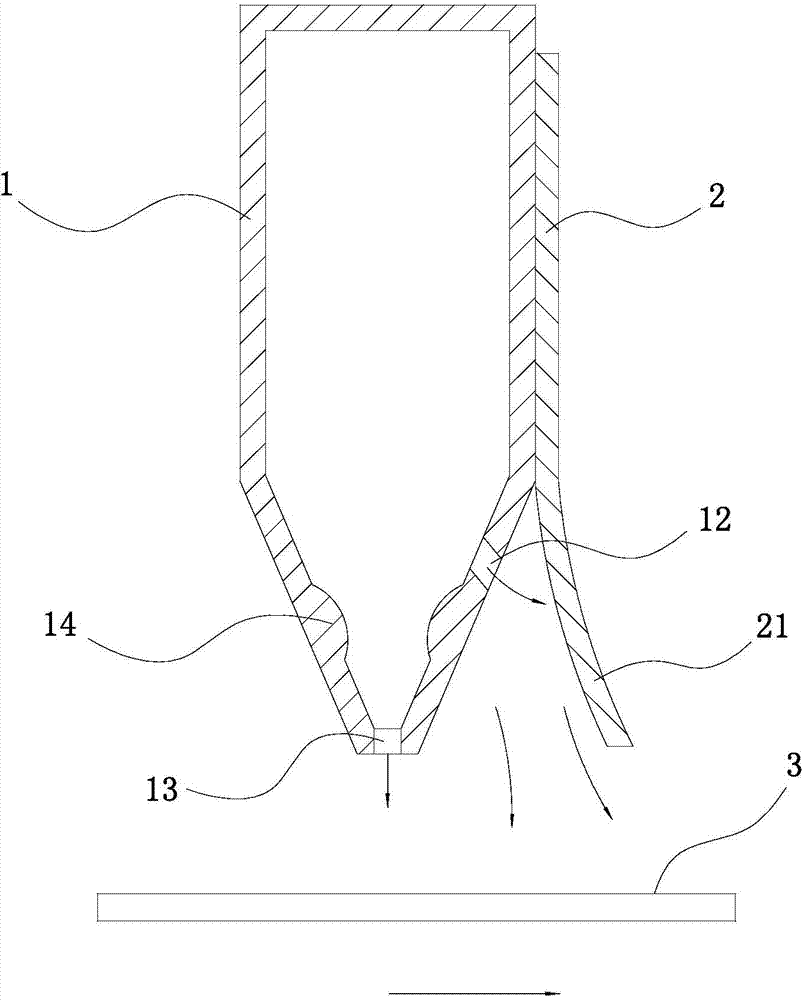

Air knife structure of glass air knife cleaning machine

InactiveCN104121768AImprove delivery stabilitySpeed up water evaporationDrying gas arrangementsFlexible article cleaningAirflowAir knife

The invention relates to an air knife structure of a glass air knife cleaning machine. The air knife structure comprises an air knife body which is of a shell structure, and the air knife body is provided with an air inlet hole and an air outlet groove. The air knife structure further comprises an air guide plate mounted on the side face of the air knife body, and the air guide plate comprises an air guide part which is of an arc-shaped structure. A conical part is arranged at the lower end of the air knife body, arc-shaped protrusions are symmetrically arranged on the inner conical surface of the conical part, and a through groove is formed in the upper portion of the conical part. The through groove faces the air guide part of the air guide plate. According to the air knife structure of the glass air knife cleaning machine, the air outlet groove of the air knife body conducts primary air drying treatment on glass sheets, by the adoption of the arc-shaped protrusions on the inner surface of the conical part, air pressure is increased, air outlet efficiency is improved, and moisture evaporation on the surfaces of the glass sheets is accelerated; by the aid of the air guide plate in the forward motion direction of each glass sheet, airflow can be guided to the front ends of the glass sheets, on one hand, secondary air drying can be conducted on the glass sheets, on the other hand, pressurizing and guiding are carried out on the front ends of the glass sheets, and therefore the conveying stability of the glass sheets is improved.

Owner:SUZHOU YIHE OPTICAL

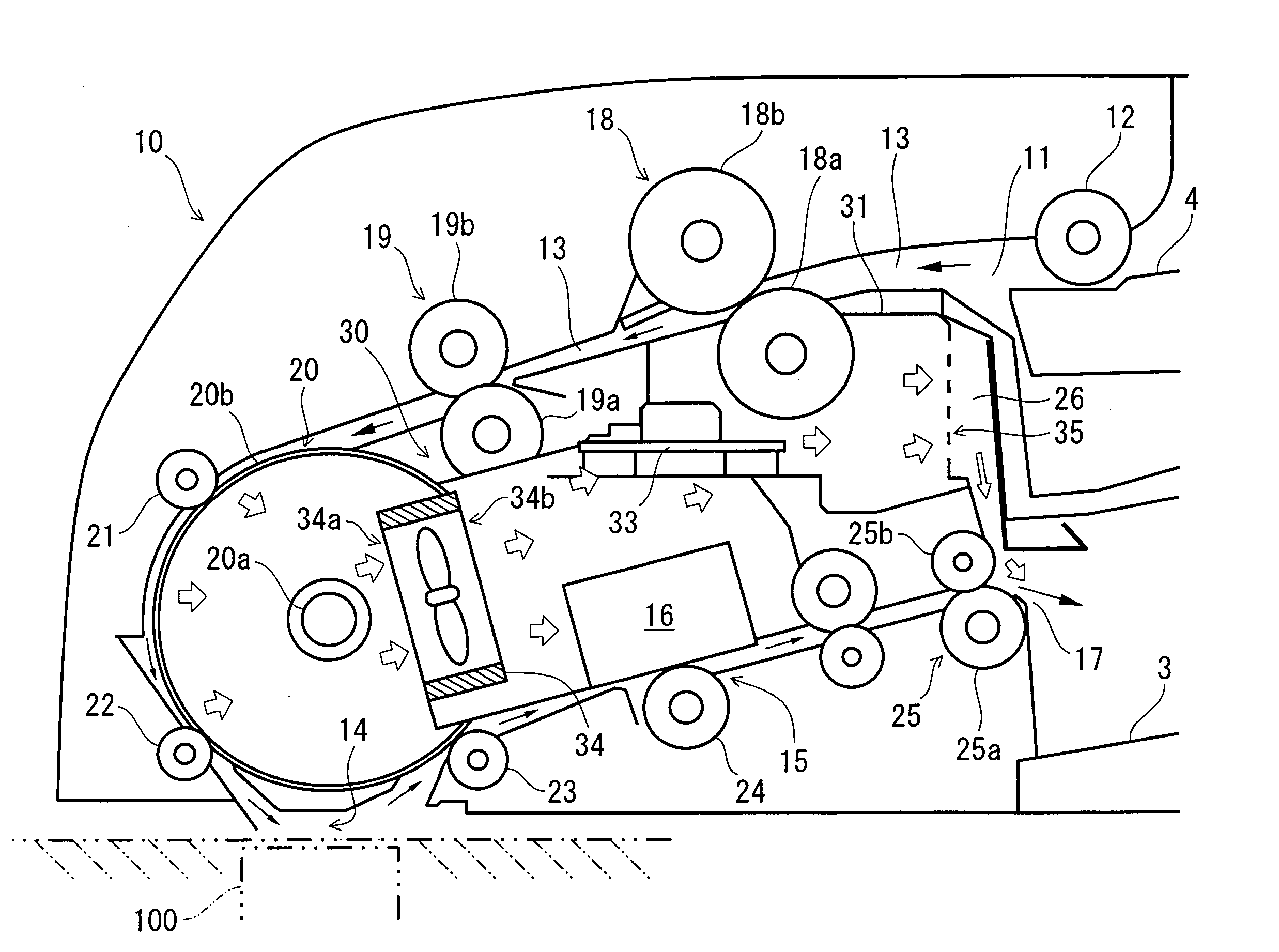

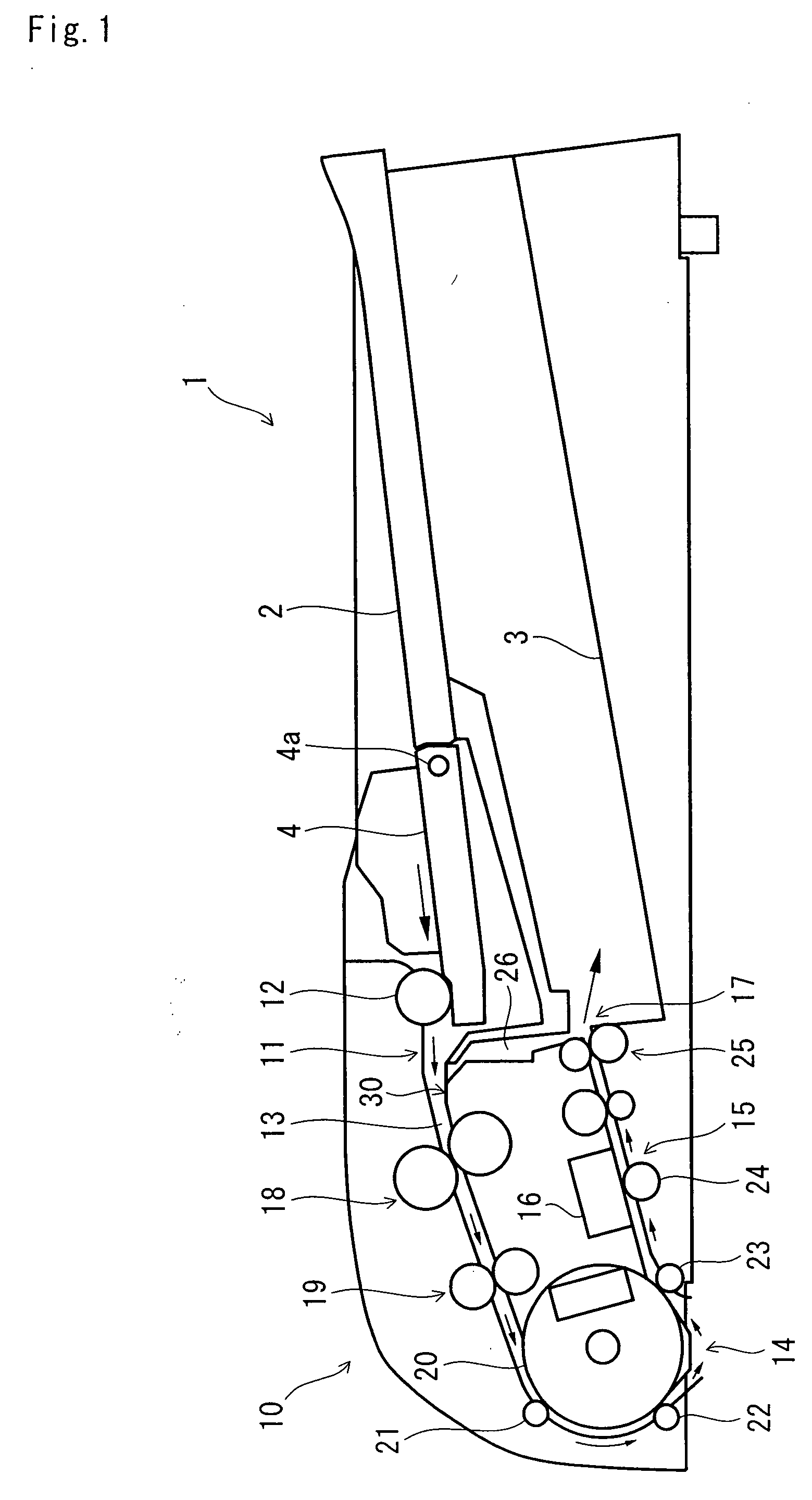

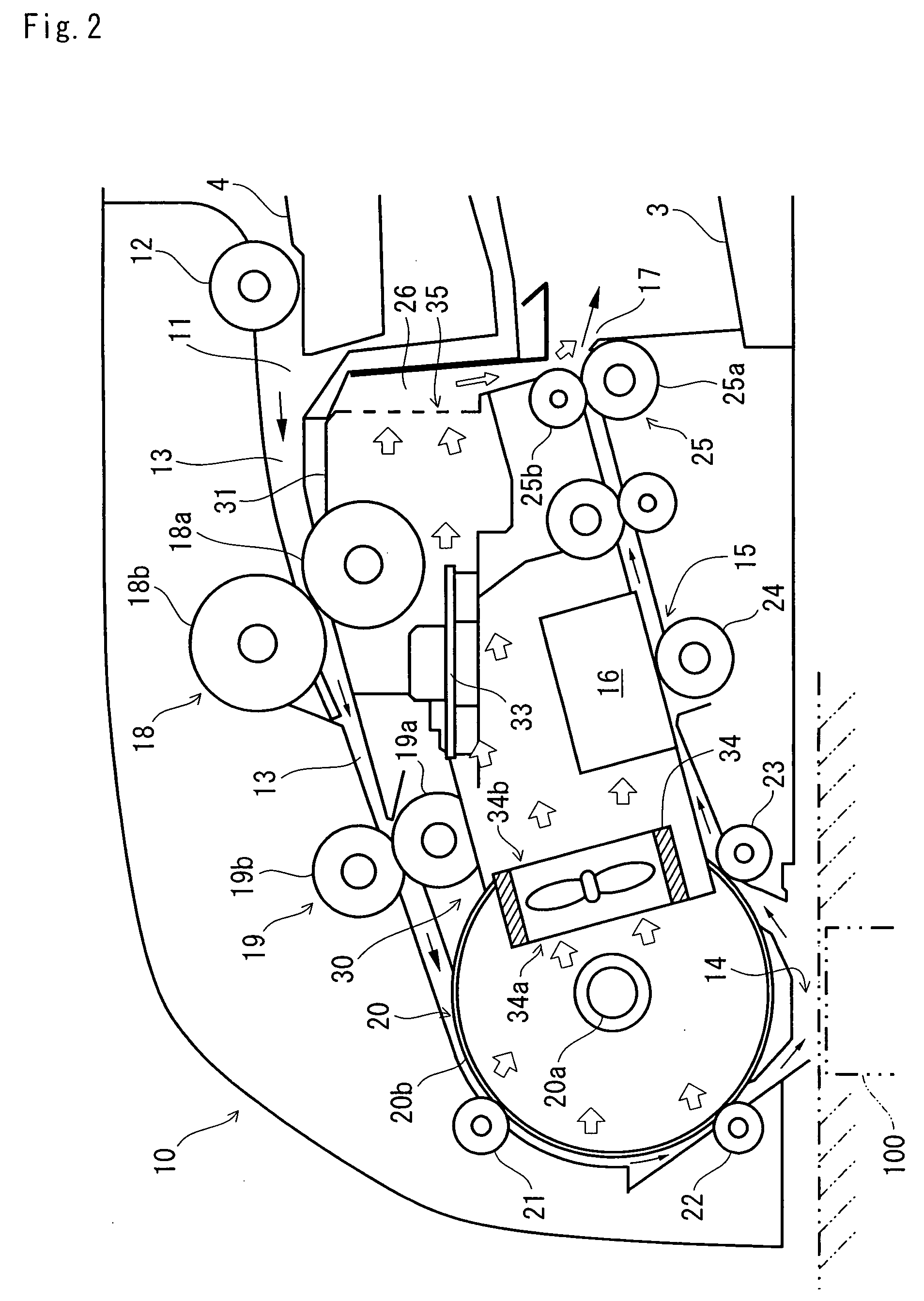

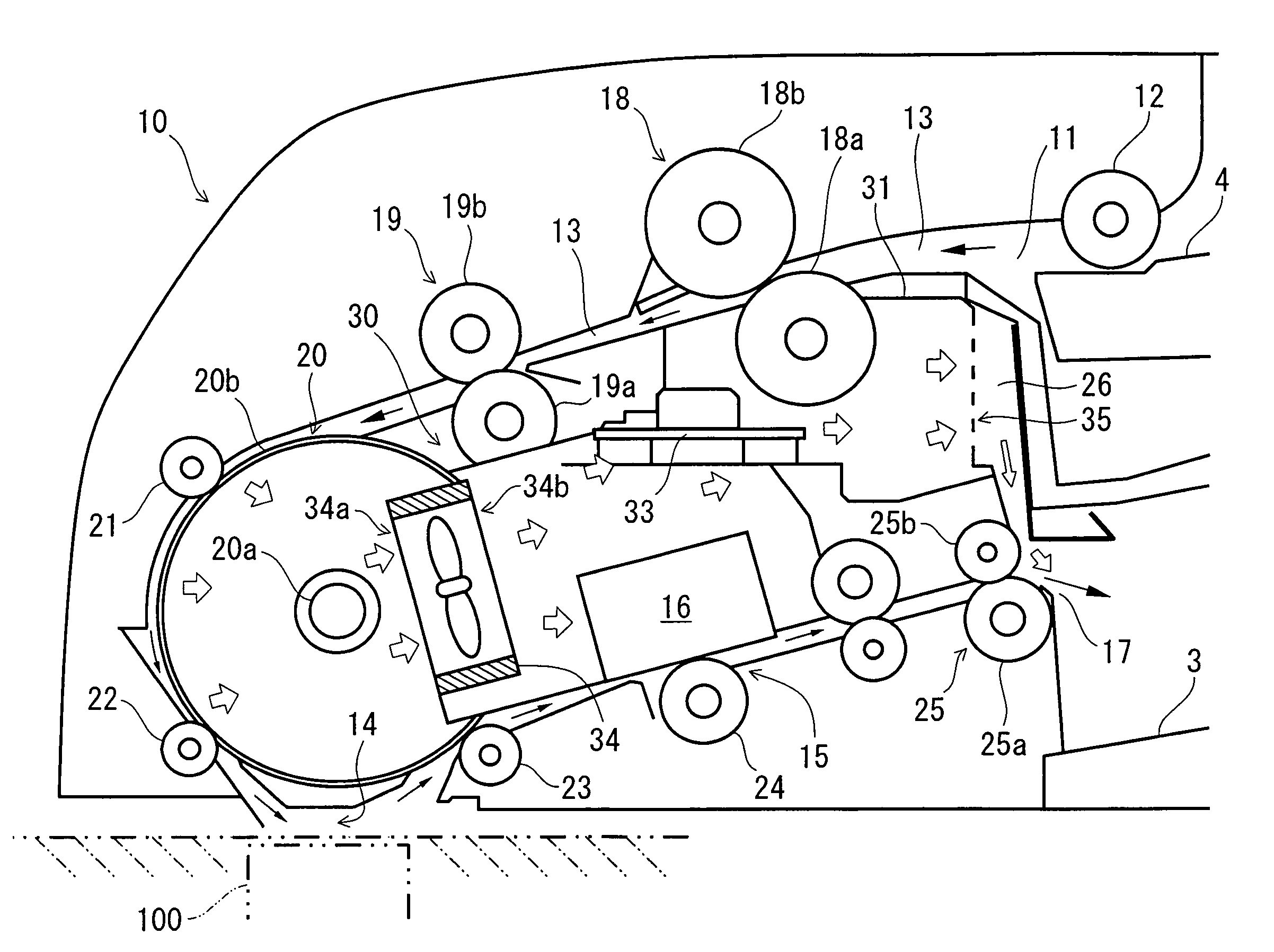

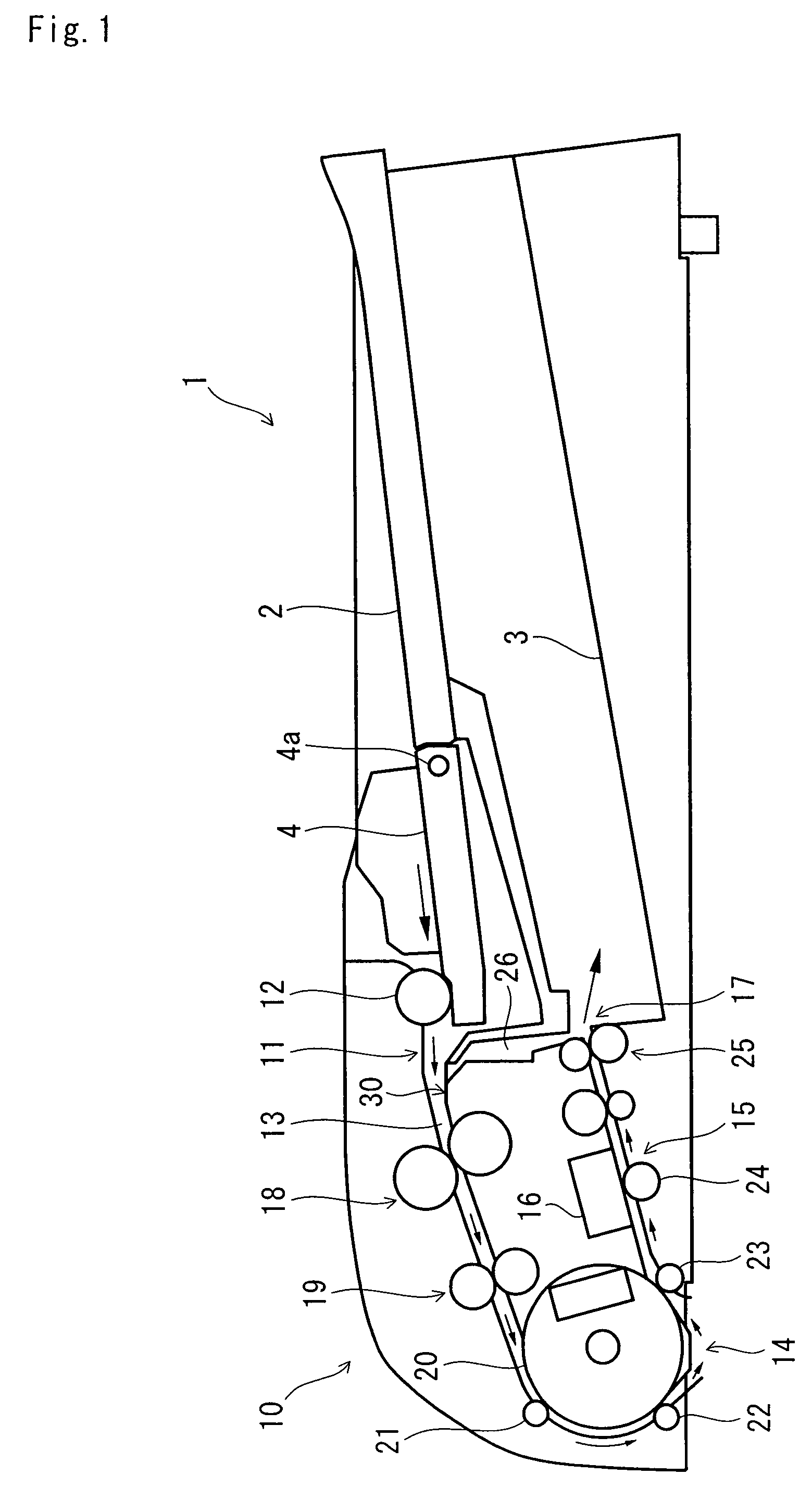

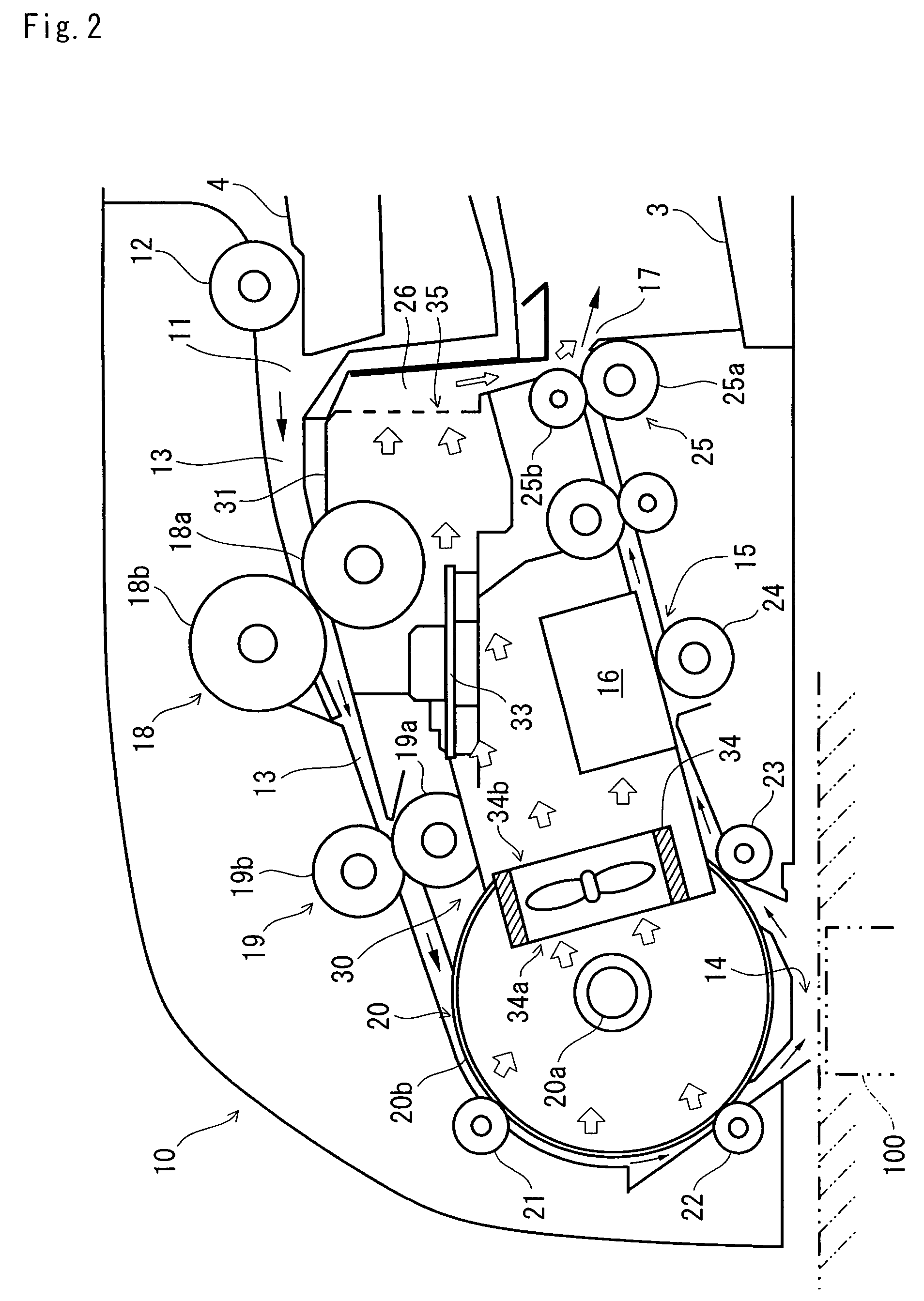

Document conveying apparatus

InactiveUS20070216083A1Improve delivery capacityImprove delivery stabilityOverturning articlesElectrography/magnetographyEngineeringPaper document

A document conveying apparatus (1) includes a conveying unit (30) inside a document feeding section (10), and the conveying unit (30) includes two fans (34) for cooling the inside of the document conveying apparatus (1). The fans (34) are arranged to pass air from upstream to downstream with respect to the document conveying direction. Thus, the stream of air produced by the fan (34) flows along the document conveying direction so that a document sheet is conveyed without being affected by a braking effect. Moreover, the air stream produced by the fan (34) flows along the document conveying passage (13) both on the air intake side and the air exhaust side of the fan (34). This facilitates the conveying of a document sheet by pulling it on the air intake side of the fan (34) and pushing it on the air exhaust side of the fan (34).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

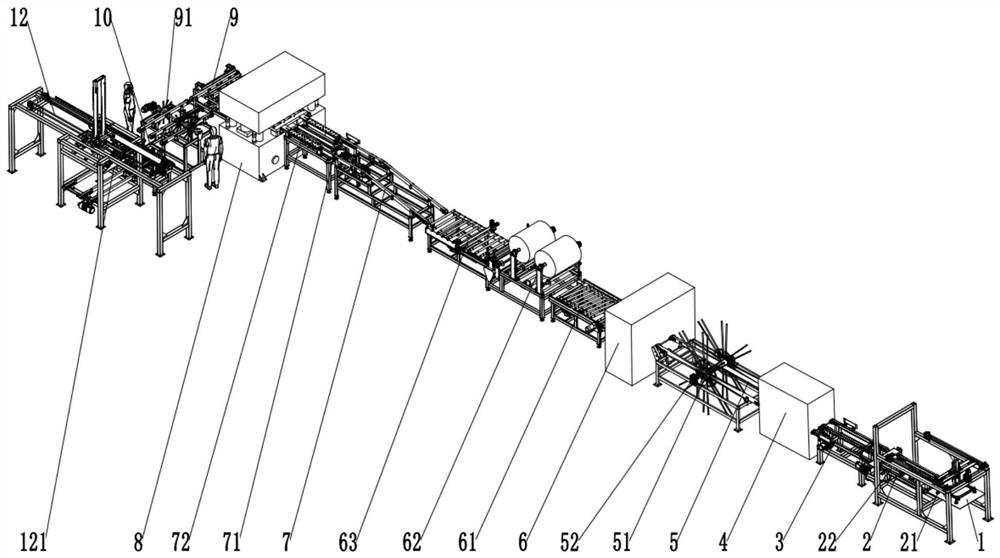

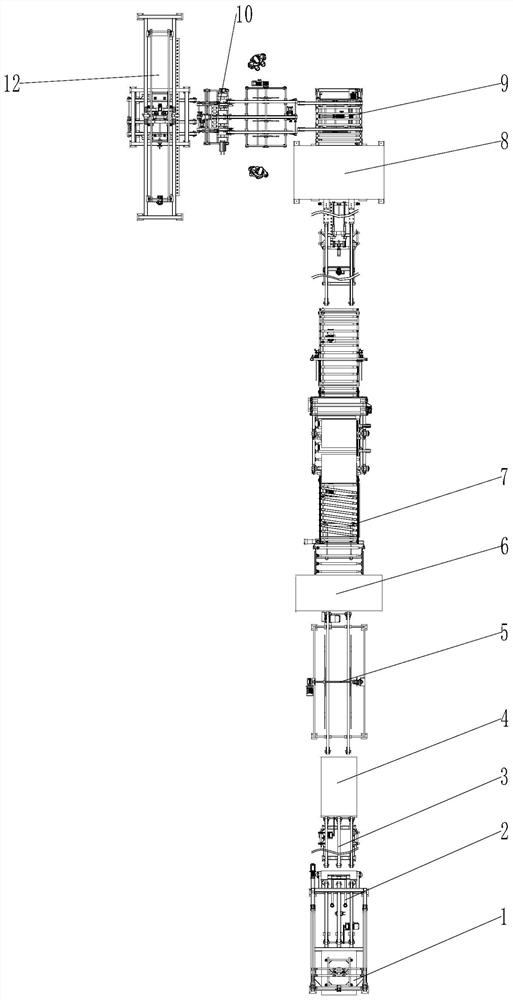

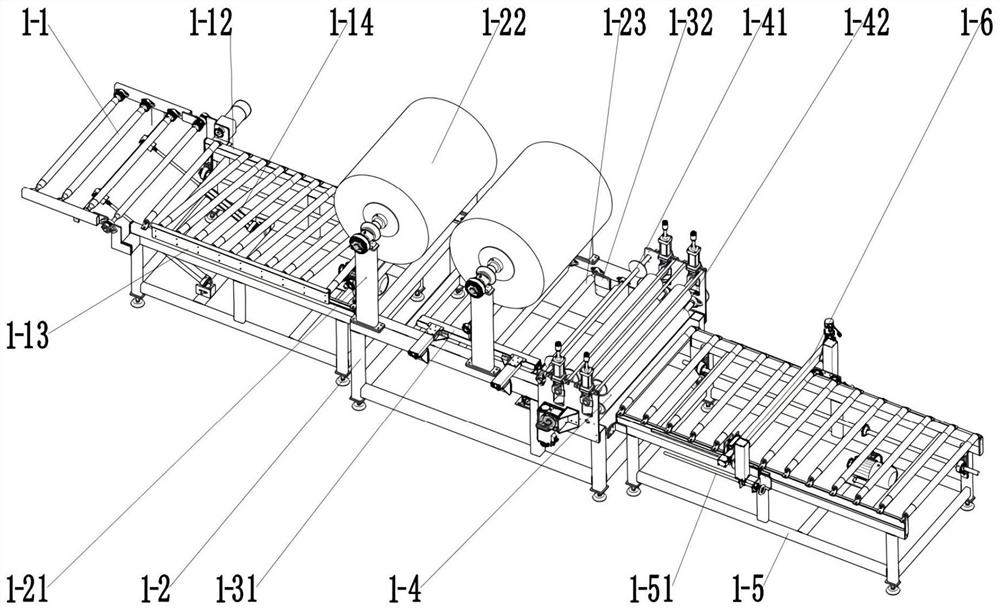

Automatic film laminating production line and method for PVC composite floor mute pad

PendingCN111791572AIncrease productivityIngenious and reasonable designLamination ancillary operationsLaminationUV curingManufacturing engineering

The invention discloses an automatic film laminating production line and method for a PVC composite floor mute pad, and belongs to automatic plate production equipment. The production line comprises an automatic feeding device, a UV curing machine, a continuous plate overturning machine, a gluing machine, a conveying device, an automatic large plate mute pad laminating machine, an automatic cutting machine, a punching feeding device, a punching device, a reversing conveying device, a small plate overturning machine, an automatic plate stacking machine and a double-station stacking machine which are connected in sequence. The automatic feeding device is used for feeding positively and negatively stacked base plates into the UV curing machine one by one in a manner that the front surfaces face upwards; the continuous plate overturning device overturns a base plate till the reverse side is upward and sends the base plate into the gluing machine, the gluing machine glues the surface of thebase plate, the base plate is conveyed into the automatic large plate mute pad laminating machine through the conveying device to be laminated, and then the base plate is cut off by the automatic cutting machine and sent to the punching device through the punching feeding device. The automatic film laminating production line is high in automation degree, capable of saving the cost of at least tenworkers, high in film laminating precision, environment-friendly, energy-saving, high in production efficiency, labor-saving and material-saving.

Owner:CHINA UNIV OF MINING & TECH

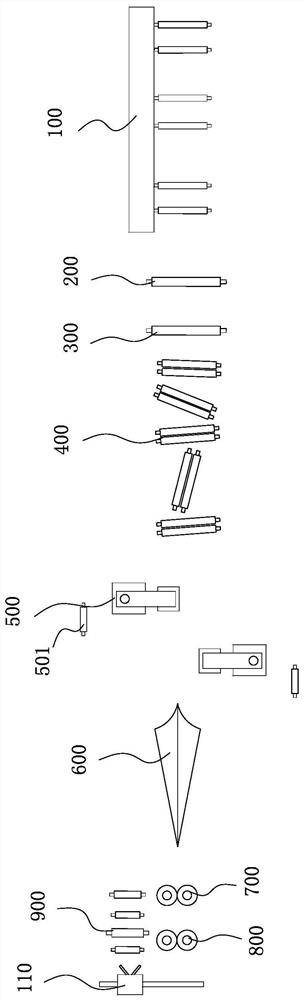

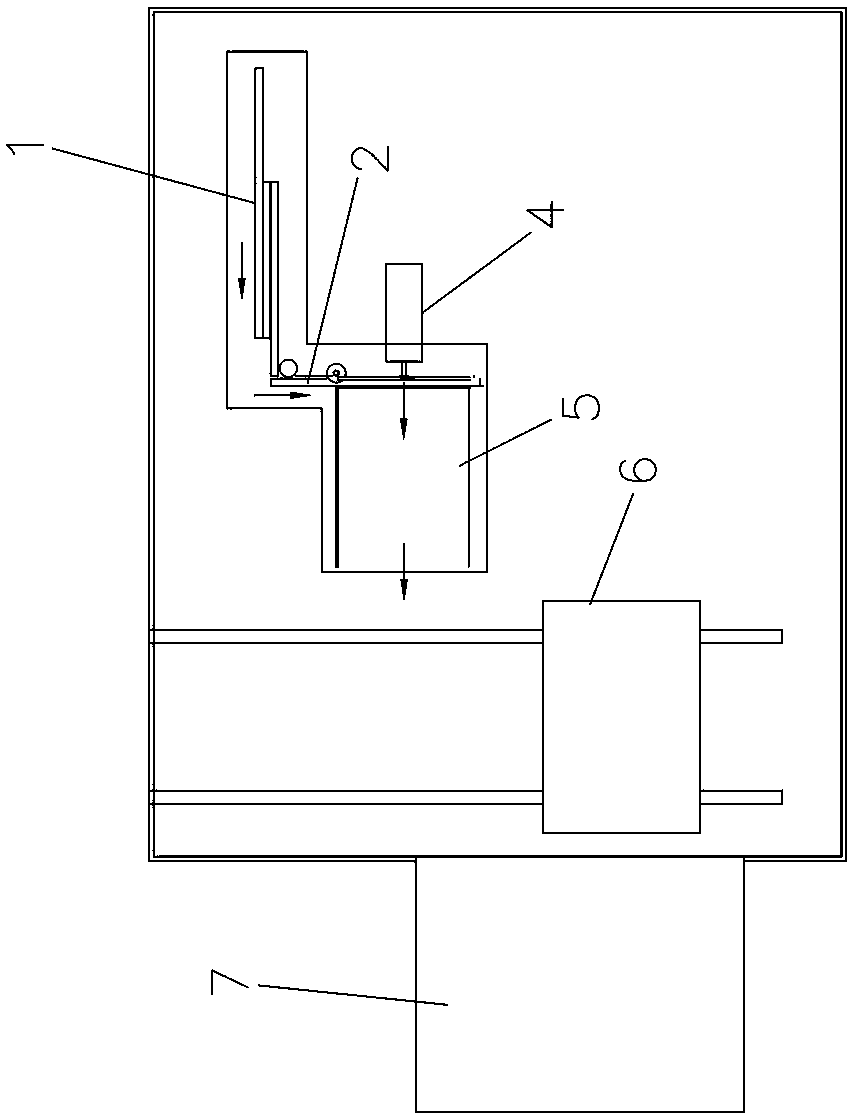

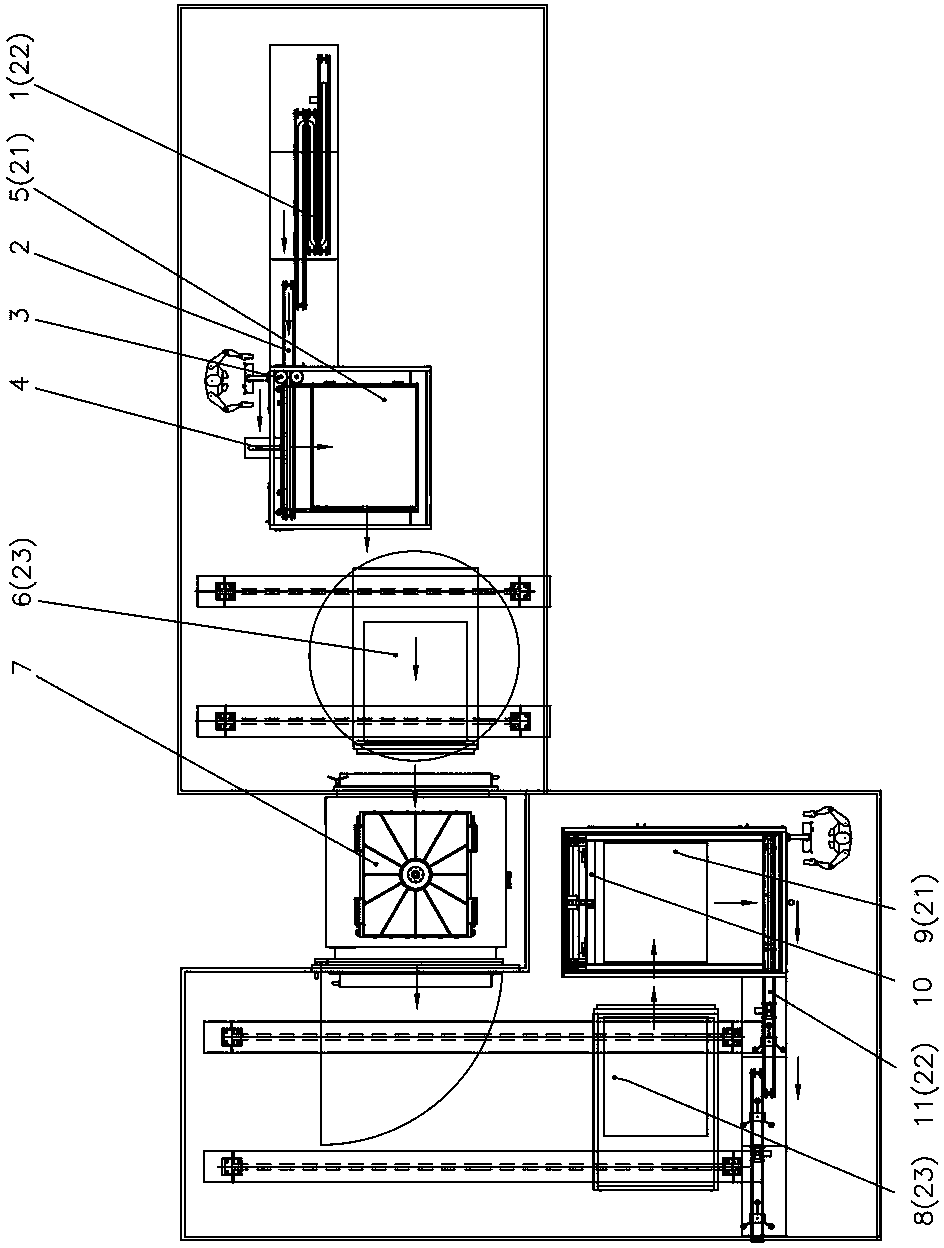

Mask machine production line

ActiveCN111616456AImprove operational efficiencyAchieve reductionProtective garmentClothes making applicancesProduction lineEngineering

The invention relates to the field of mask production equipment, particularly to a mask production line which can produce masks applicable to most people and well fitting with the face of a user whenbeing worn and is high in production efficiency. The mask production line comprises a rack, a control device arranged on the rack, an unwinding device, a pre-pressing edge-cutting device, a cushion forming device, a turnover device, an ear belt discharging and spot welding device, a folding device, an inclined sealing device, a slitting device, a nose bridge strip discharging and slitting device and a nose bridge strip welding and discharging device, wherein the cushion forming device comprises an edge sealing mechanism used for sealing the edge of a cover body and bending and warping cushionparts, and further comprises a welding mechanism used for enabling the cushion part to be distributed in a stacked mode and connecting the free edges of the cushion parts with the cover body.

Owner:FUJIAN HENGAN HLDG CO LTD +1

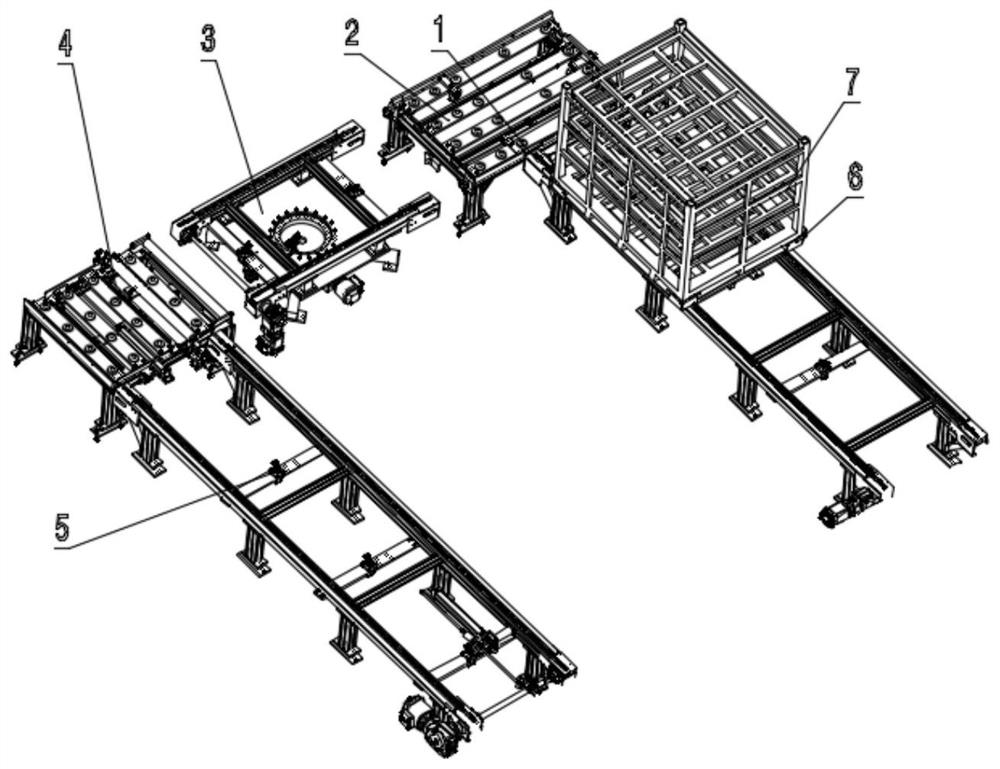

Feeding platform and freeze-drying-line mobile feeding and discharging system

ActiveCN103662709ASimple structureCompact layoutConveyor partsMechanical conveyorsFreeze-dryingSmall footprint

The invention discloses a feeding platform and a freeze-drying-line mobile feeding and discharging system with the same. In a material conveying sequence, the feeding platform is located between a feeding mesh belt and a mobile feeding cart of a freeze-drying line, a feeding direction of the feeding platform is perpendicular to a discharging direction, and the direction that materials are fed from the feeding platform to the feeding mesh belt or fed from the feeding mesh belt to the feeding platform is perpendicular to the conveying direction of the feeding mesh belt. The feeding and discharging system comprises a feeding component, a freeze dryer and a discharging component disposed sequentially according to the material conveying sequence, and at least one of the feeding component and the discharging component comprises the feeding mesh belt, the mobile feeding cart and the feeding platform. The feeding platform and the mobile freeze-drying line feeding and discharging system have the advantages of simple structure, compact layout, small occupied area, low cost, smooth and steady conveying, high conveying efficiency and the like.

Owner:TRUKING TECH LTD

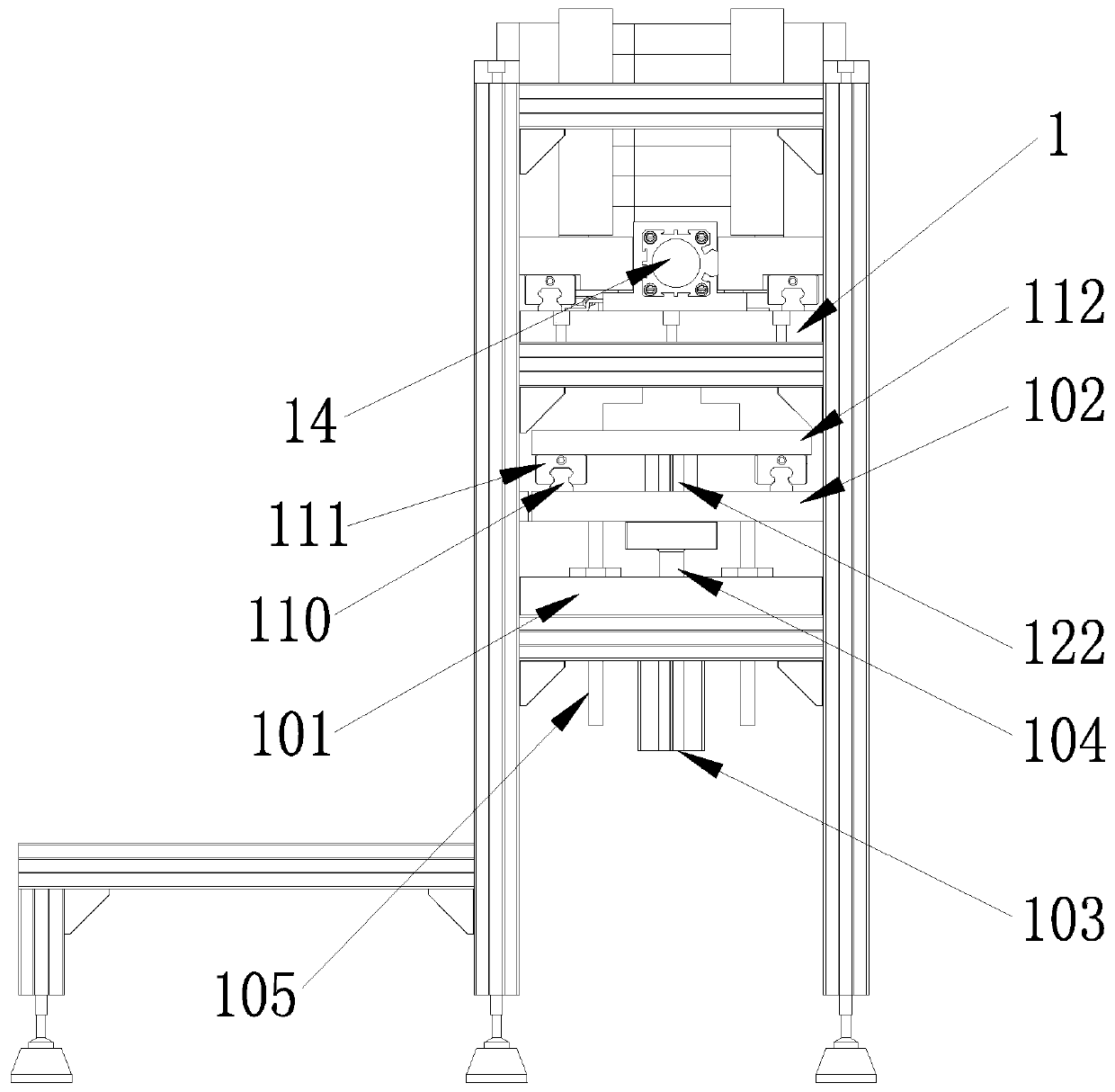

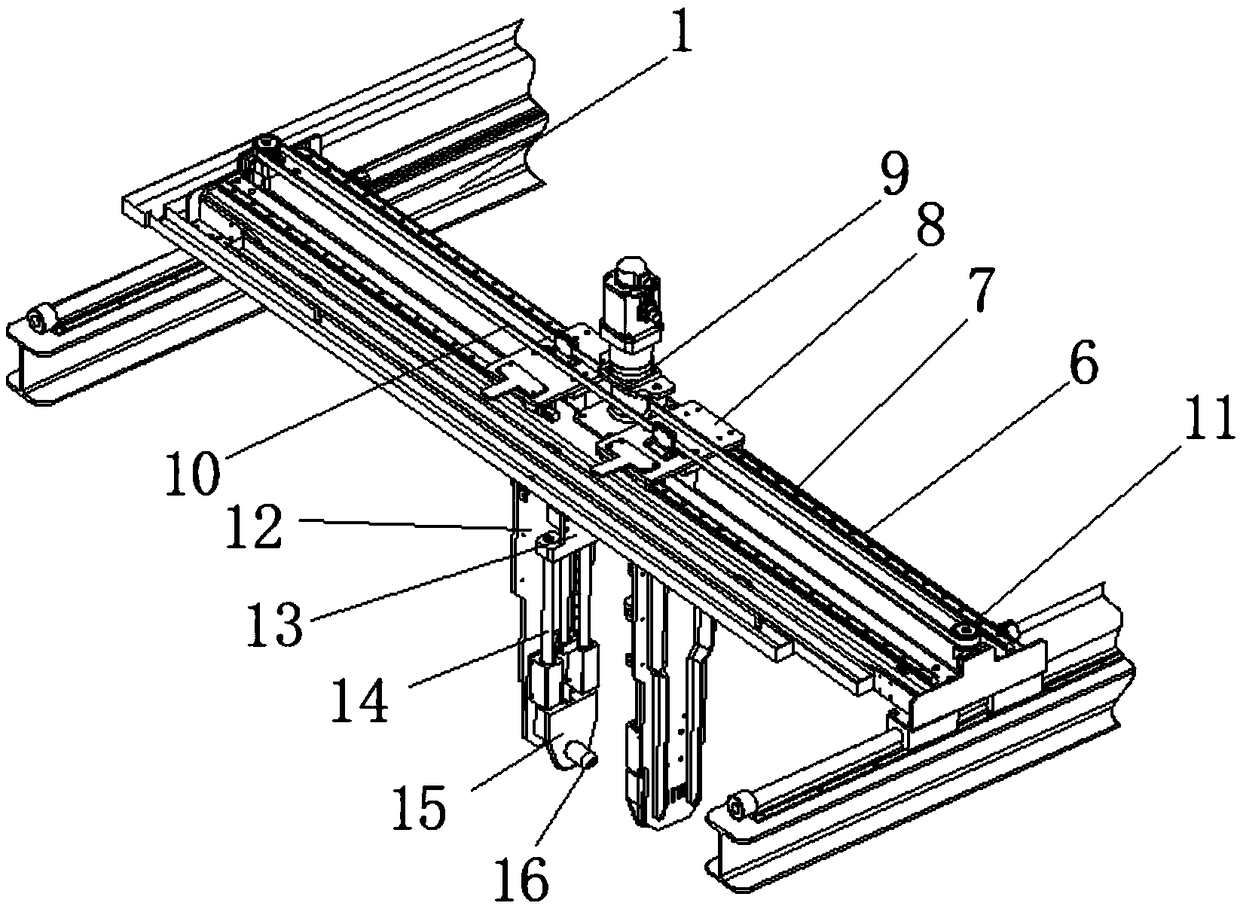

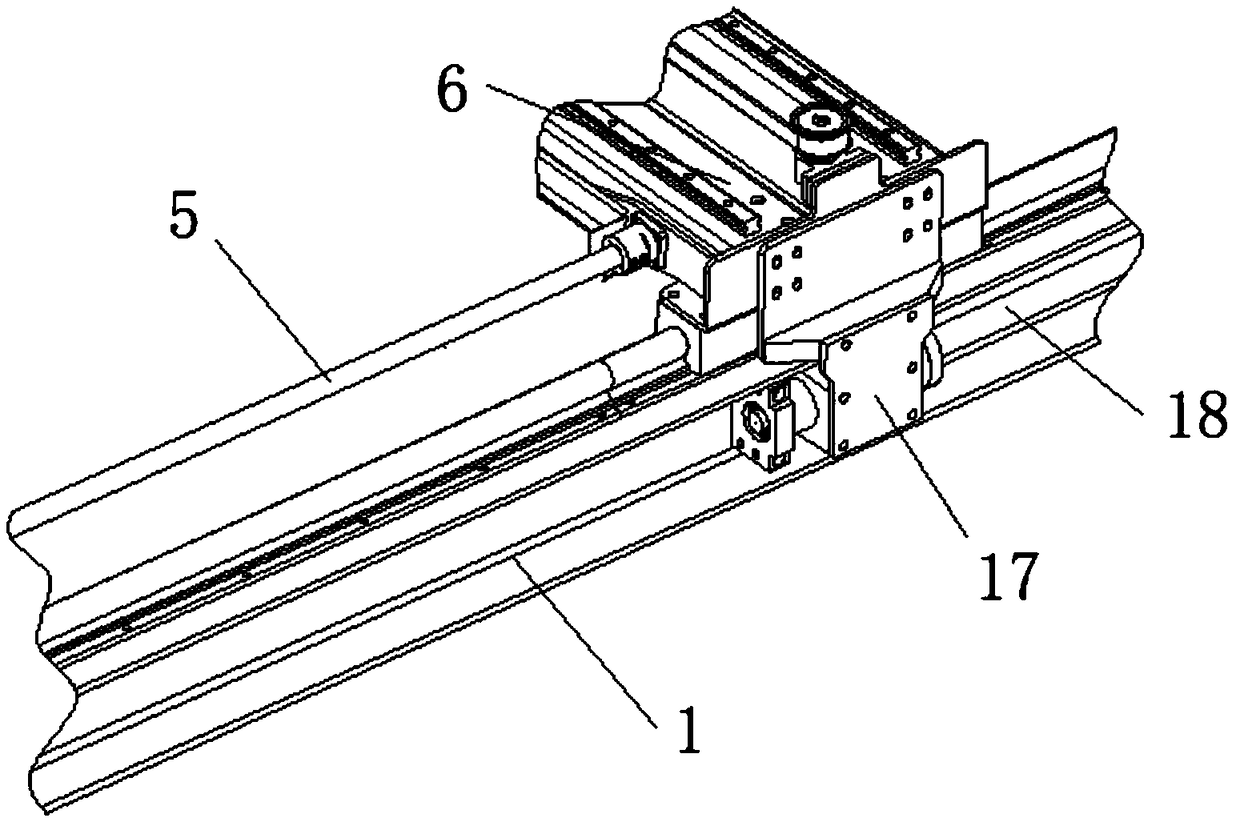

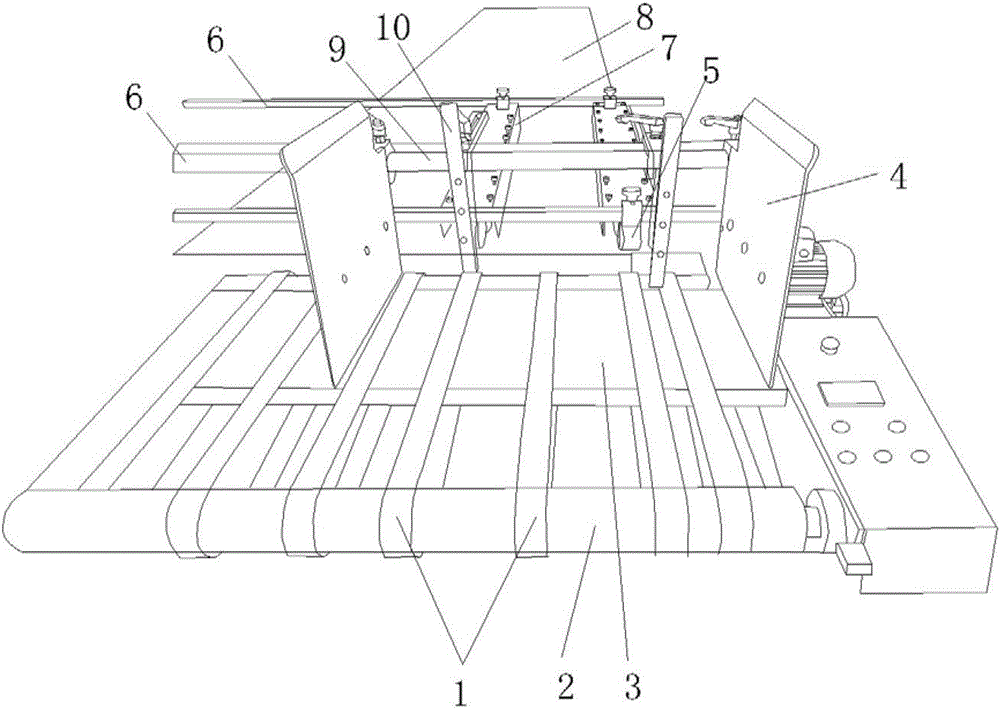

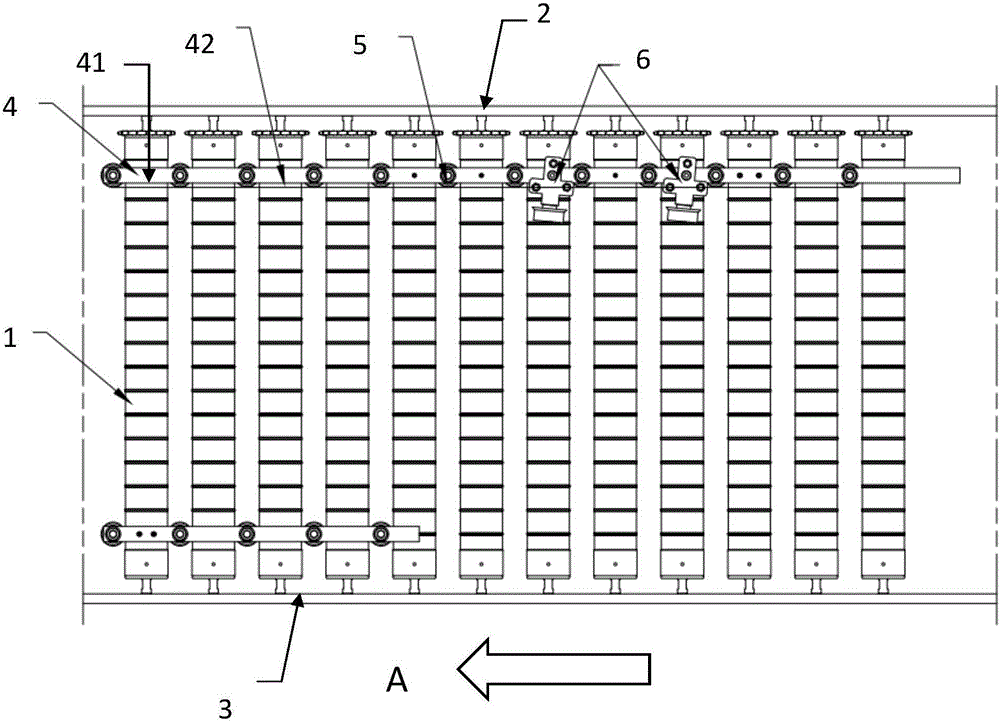

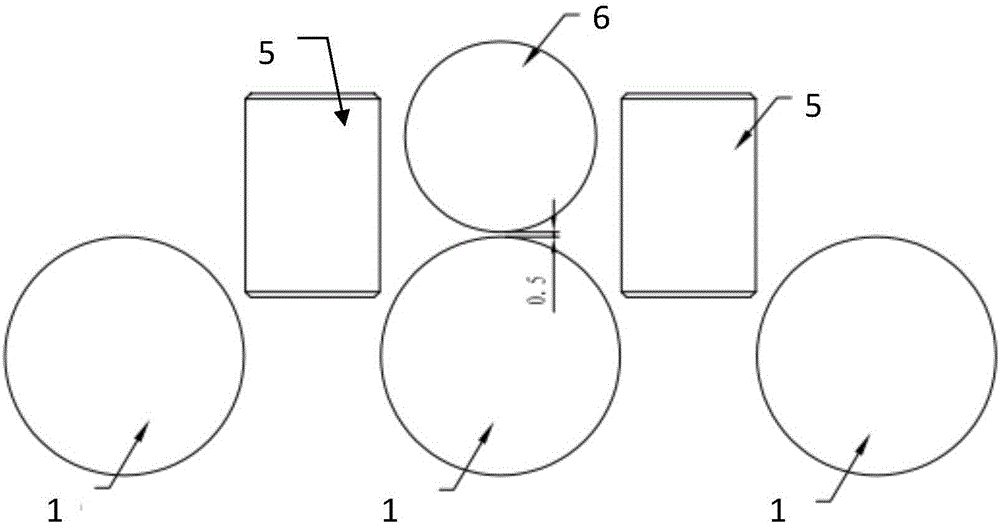

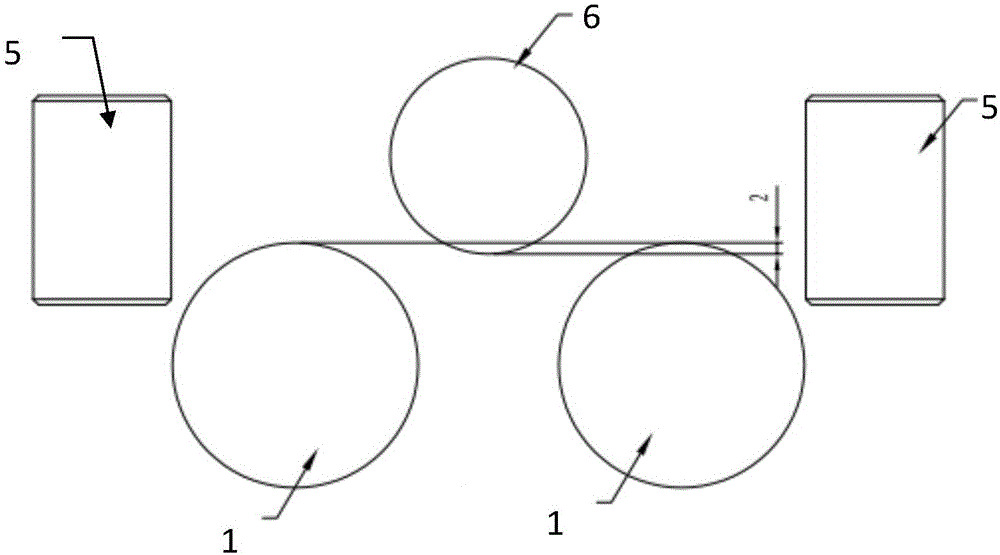

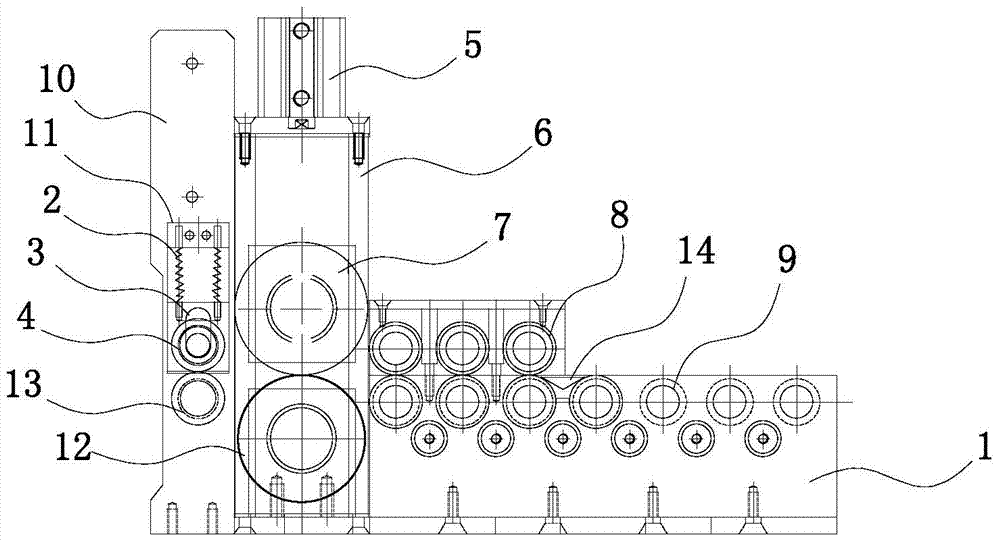

Printed circuit board (PCB) conveying mechanism

InactiveCN105416997AAvoid skewImprove delivery stabilityConveyorsConveyor partsWork in processPrinted circuit board

The invention discloses a printed circuit board (PCB) conveying mechanism. The PCB conveying mechanism is arranged between a chip mounter and a curing furnace, so that PCBs subjected to chip mounting treatment through the chip mounter are conveyed into the curing furnace to be subjected to chip curing treatment. The PCB conveying mechanism comprises two conveying rails (1) arranged symmetrically, two conveying belts and a driving device. The conveying rails (1) are arranged in the conveying direction of the PCBs, and the conveying belts are arranged on the opposite inner side walls of the two conveying rails (1). The top end of the conveying face formed by the conveying belts is located below the PCBs and is wider than each PCB. The driving device is connected with the conveying belts so as to drive the conveying belts to conduct conveying operation. By means of the PCB conveying mechanism, the semi-finished PCBs can be conveyed between the chip mounter and the curing furnace conveniently and rapidly, the production time is shortened, and the working efficiency is improved.

Owner:芜湖雅葆轩电子科技股份有限公司

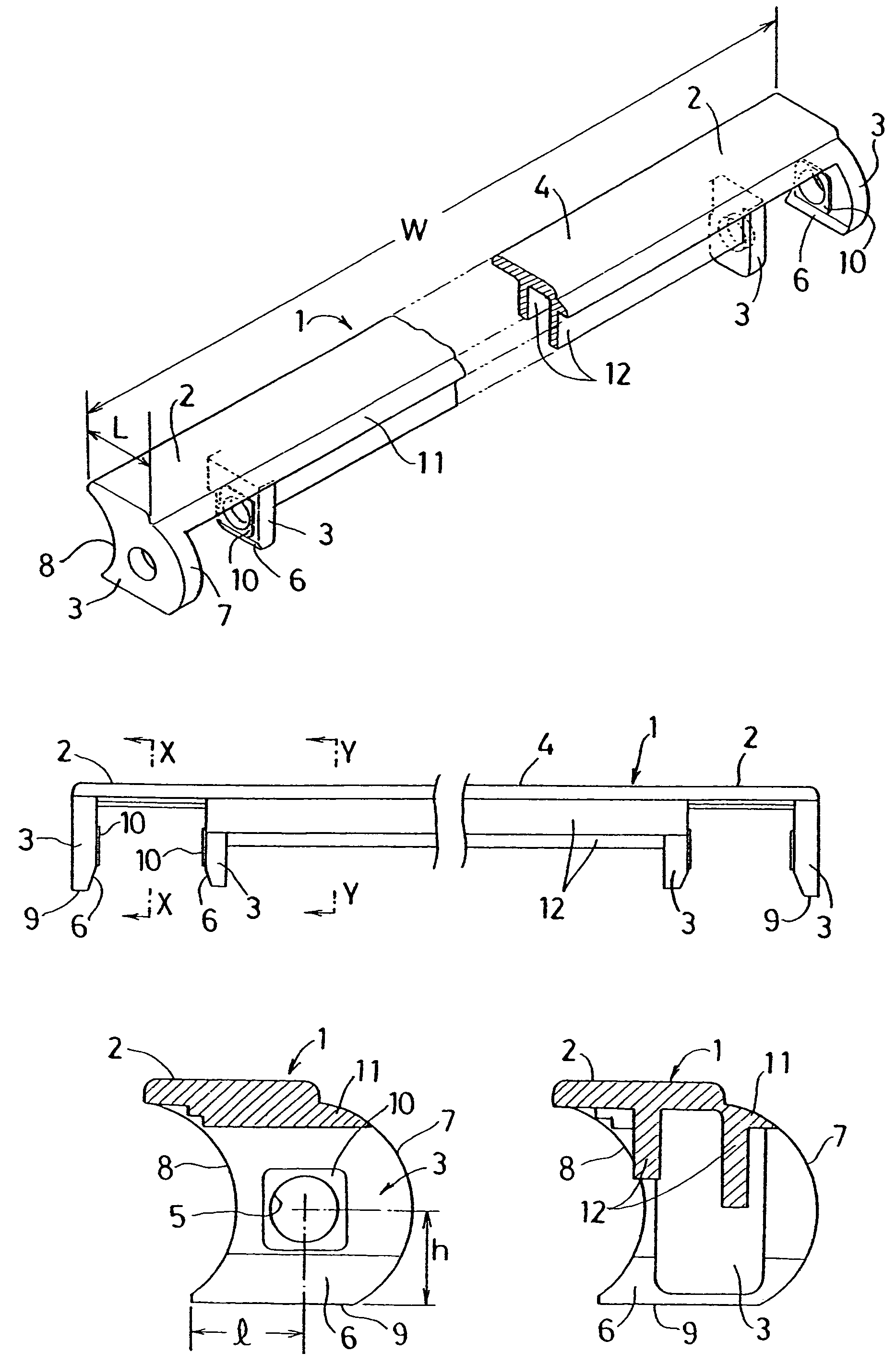

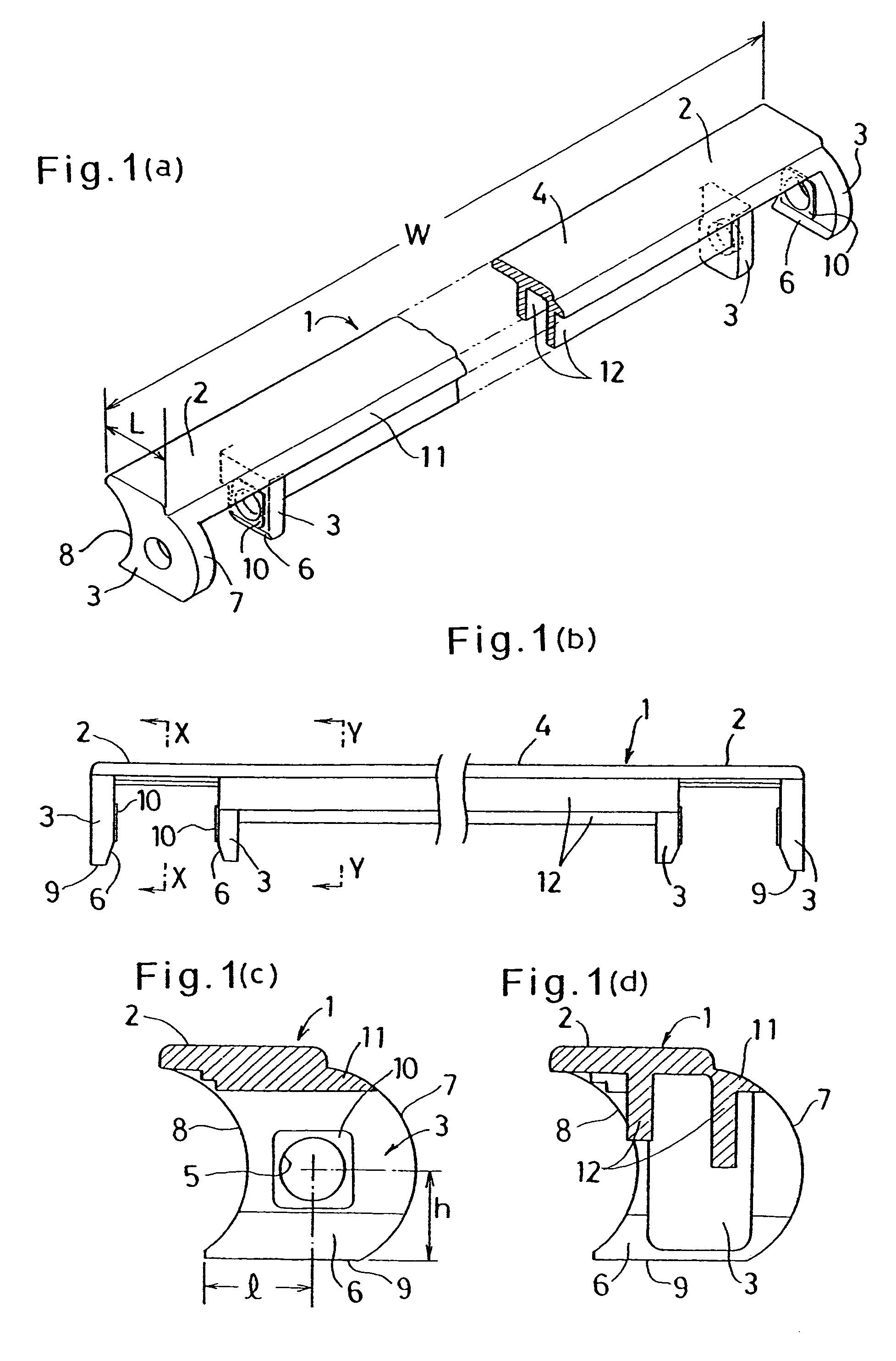

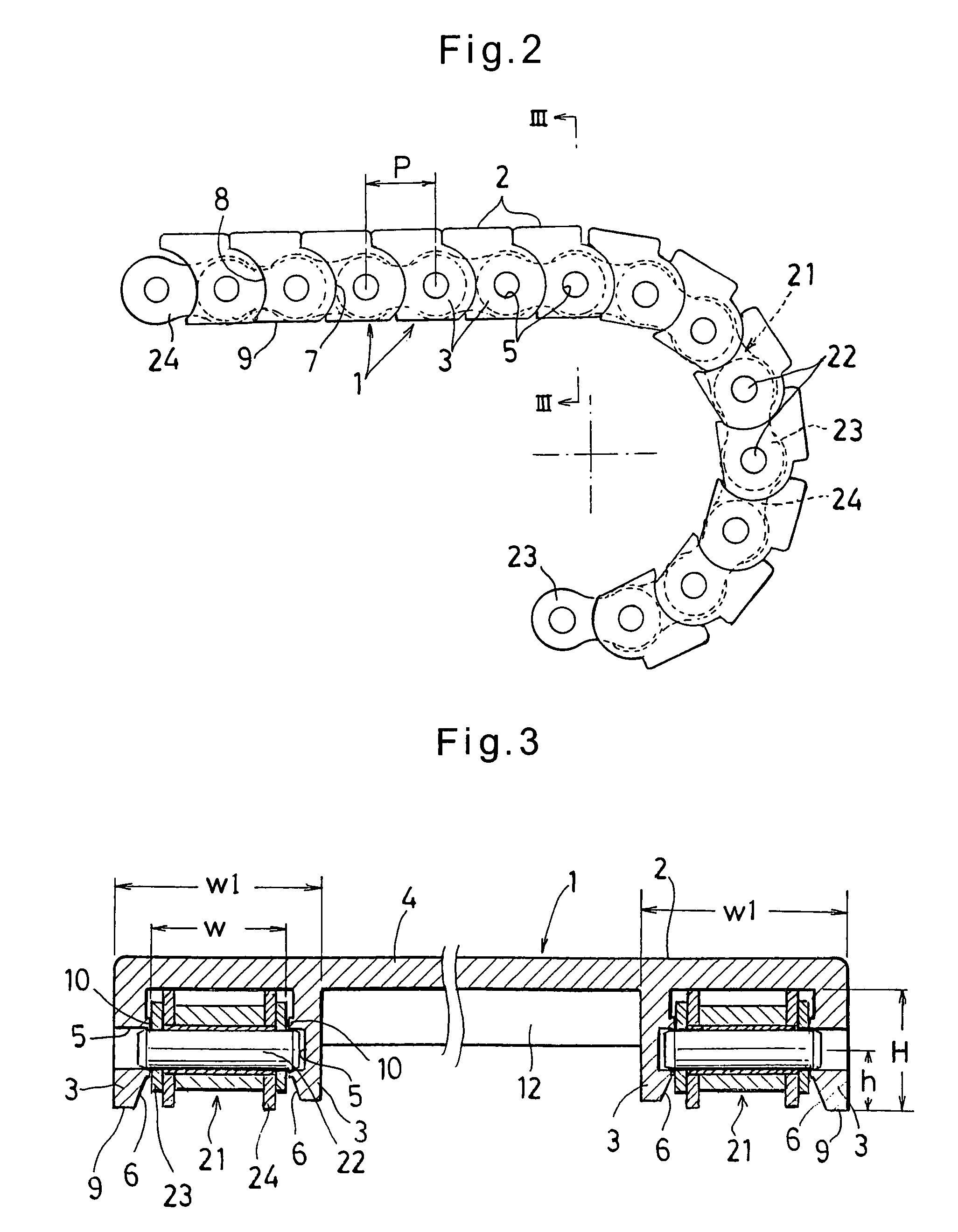

Chain cover and slat conveyor using the same

A chain cover includes side covers each formed with a shaft hole for receiving a coupling pin of a roller chain, two top covers each having a length substantially equal to a chain pitch of the roller chain, and a coupling plate coupling the top covers adjacent to each other. The side cover at each end of the chain cover has a convexly arcuate front edge concentric with the shaft hole and a concavely arcuate rear edge similar to the front edge, and the coupling plate and two top covers cooperate to form a slat. A plurality of these chain covers can be mounted on a plurality of parallel roller chains to cover the top and sides of each roller chain and form a flat goods conveying surface between the roller chains, thereby forming a slat conveyor which is less expensive than a roller conveyor and provides excellent conveying stability.

Owner:YAMAMOTO MASAKAZU

Document conveying apparatus

InactiveUS7677551B2Improve delivery capacityImprove delivery stabilityOverturning articlesElectrography/magnetographyEngineeringPaper document

Owner:KYOCERA DOCUMENT SOLUTIONS INC

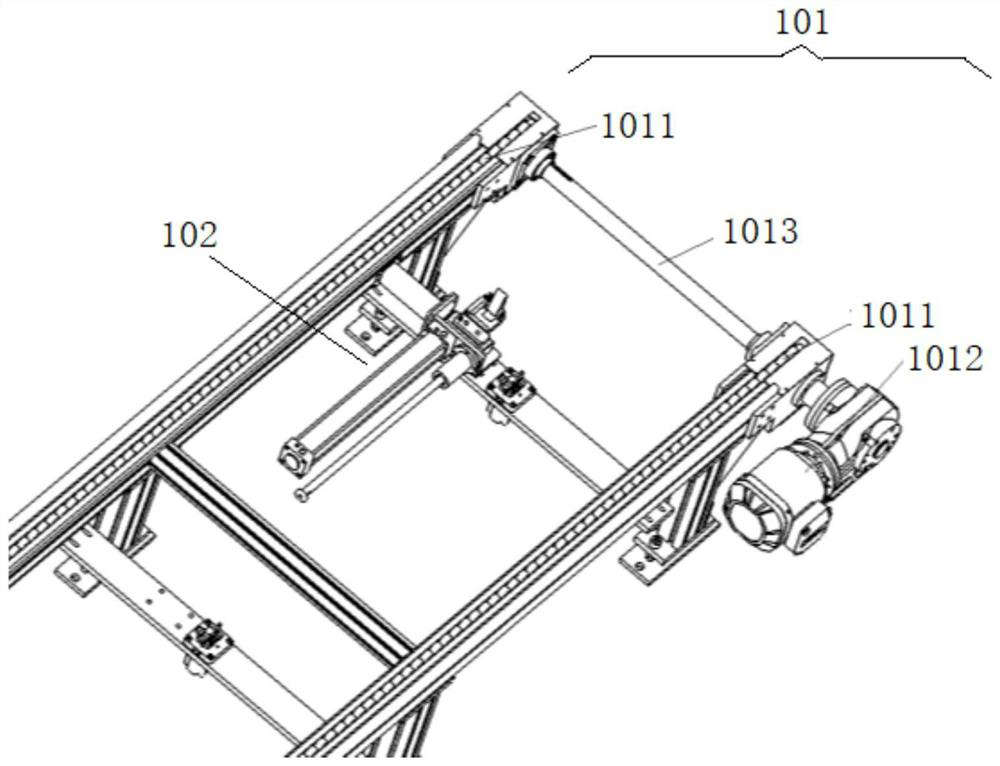

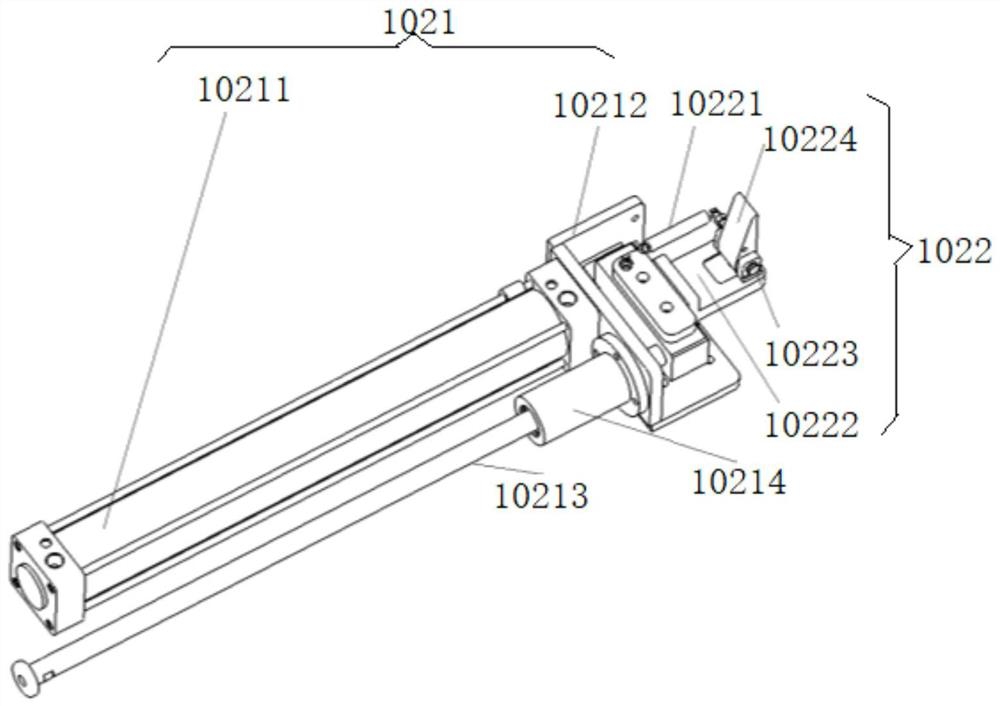

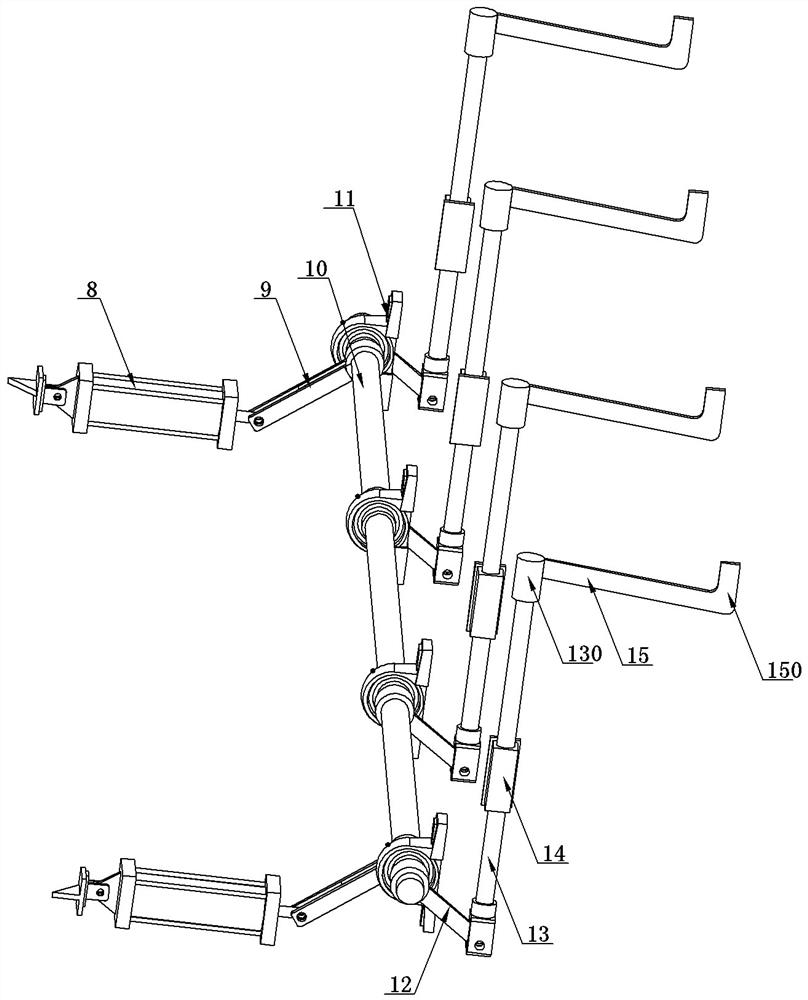

Device for lifting and moving coiled material through synchronous clamping and fixing in three-coordinate mode

ActiveCN108639739AMove quicklyImprove delivery stabilityProgramme-controlled manipulatorGripping headsTransverse axisLubrication

The invention discloses a device for lifting and moving a coiled material through synchronous clamping and fixing in a three-coordinate mode, and belongs to the technical field of multi-directional movement of automatic manipulators. According to the device for lifting and moving the coiled material through synchronous clamping and fixing in the three-coordinate mode, transverse beam moving rods are fixedly connected with the upper ends of a paper cover processing grabbing mechanical arm body, a contract processing grabbing mechanical arm body and a hot melt processing mechanical arm body; clamping and fixing clamp pieces are arranged at upper ends of transverse shaft horizontal moving sliding blocks and are attached to synchronous conveying belts; the synchronous conveying belts are attached to the rotary ends of center drivers; vertical moving rods are fixedly connected with the lower ends of vertical drivers; a gel layer is attached to the inner side of each synchronous conveying belt; antiskid grooves are formed in the inner sides of the gel layers and filled with magnesium carbonate powder; positioning dividing rules are carved on longitudinal moving slide rods; lubrication oil is hydrogenated base oil; and three-dimensional accurate lifting of coiled material tube cores can be achieved, and then the coiled material tube cores are rapidly moved.

Owner:GUANGDONG SHICHENG PLASTIC MACHINERY

Bamboo board conveyer provided with baffles and dual hold-down mechanisms

InactiveCN106241217APrevent slippingThe problem of blocking deviationMechanical conveyorsEngineeringBack support

The invention relates to a bamboo board conveyer provided with baffles and dual hold-down mechanisms. An existing bamboo board conveying mechanism is a one-level conveying mechanism and conducts conveyance through multiple rollers arranged side by side generally, the friction coefficient between bamboo boards and the rollers is small, slipping is prone to happen, and the conveying efficiency is influenced. The bamboo board conveyer provided with the baffles and the dual hold-down mechanisms comprises a machine frame, a first conveying mechanism and a second conveying mechanism, wherein the first conveying mechanism and the second conveying mechanism are arranged on the machine frame. The bamboo board conveyer provided with the baffles and the dual hold-down mechanisms is characterized in that the first conveying mechanism is provided with cross rods, at least two vertical hold-down blocks are arranged on the cross rods, and each vertical hold-down block can be adjusted leftwards and rightwards; the upper portion of the second conveying mechanism is provided with a front supporting rod and a back supporting rod, and at least two hold-down wheel mechanisms are arranged between the two supporting rods from front to back; and the first conveying mechanism is provided with a supporting platform, and the vertical baffles are arranged on the supporting platform and can be moved and adjusted leftwards and rightwards. The bamboo board conveyer is provided with the two levels of conveying mechanisms, a conveyer belt is in direct contact with the bamboo boards to be conveyed in the manner that the rollers and the conveyer belt are combined, and the situation that because the bamboo boards are in direct contact with the rollers, slipping is caused is avoided.

Owner:安吉县孝丰天友竹木机械制造厂

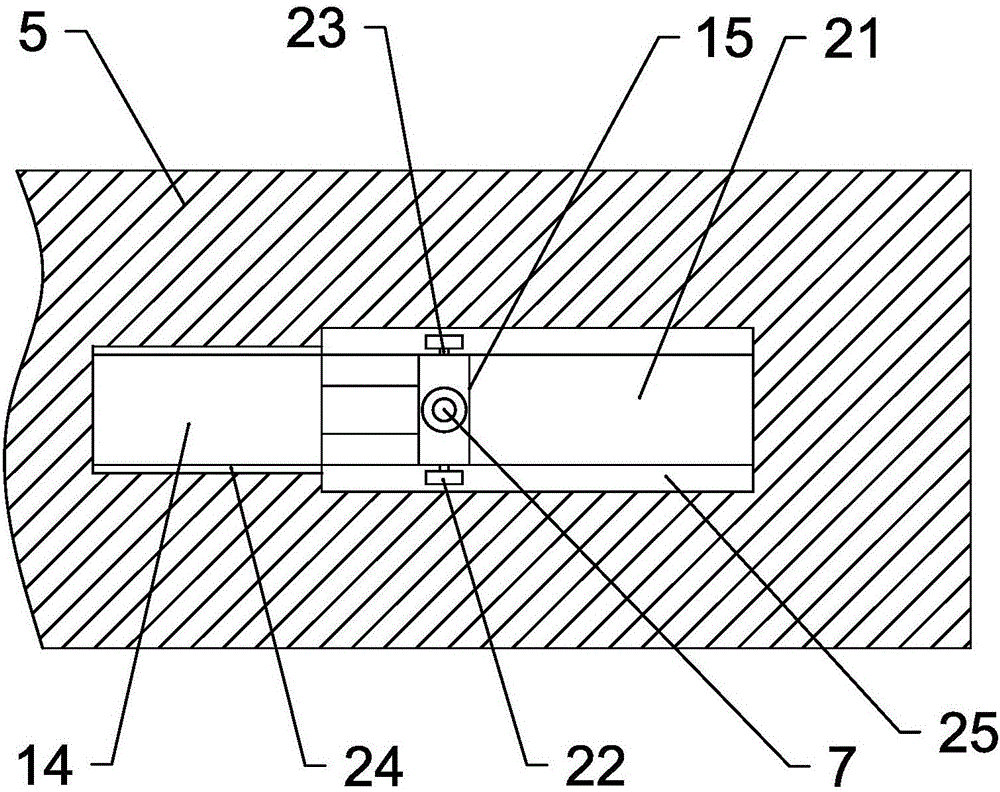

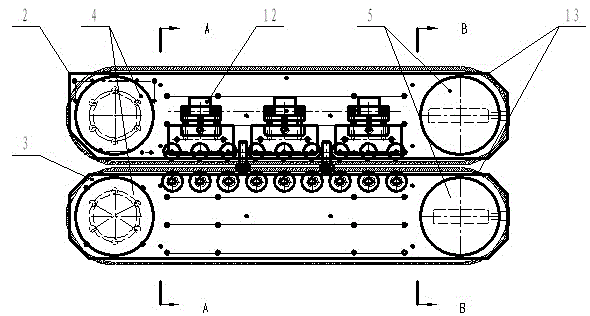

Drip irrigation pipe traction system

InactiveCN104909205APrevent slippingSynchronous operationConveyorsFilament handlingTraction systemDrive wheel

The invention discloses a drip irrigation pipe traction system. The system is characterized by comprising a driving motor, transmission wheels, a transmission belt, driving wheels, driven wheels, conveying belts, an upper pressing wheel set, a lower support wheel and a pressing cylinder, wherein two transmission wheels are provided; the driving motor is connected with one of the transmission wheels; the two transmission wheels are connected through the transmission belt, and oppositely rotate; upper and lower two sets of the driving wheels, the driven wheels and the conveying belts are provided; the upper and lower two sets of the conveying belts are distributed and wound on the upper and lower two sets of the driving wheels and driven wheels; the upper and lower two sets of the driving wheels are respectively connected with the two transmission wheels; the upper pressing wheel set is connected with the pressing cylinder, and is mounted in the upper set of the conveying belts; the lower support wheel is mounted in the lower set of the conveying belts; and a drip irrigation pipe is positioned between the upper and lower two sets of the conveying belts. The drip irrigation pipe traction system has the following advantages: a downward pressing traction belt and a support traction belt realize synchronous operation to improve the conveying stability; and a belt pressing mechanism in the downward pressing traction belt is connected with a belt pressing cylinder to adjust the pressure.

Owner:TIANJIN HUAXU SHENGTAI TECH

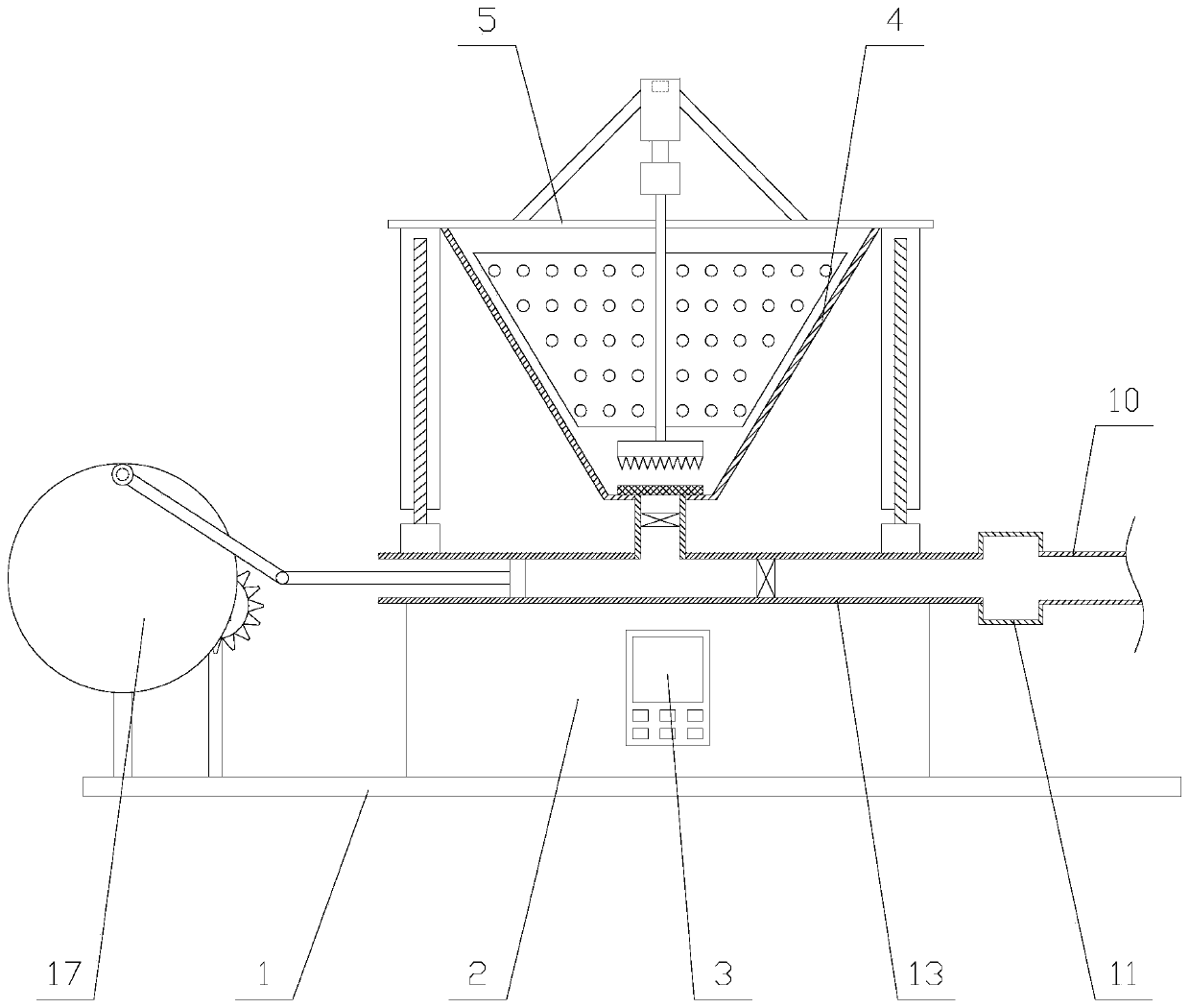

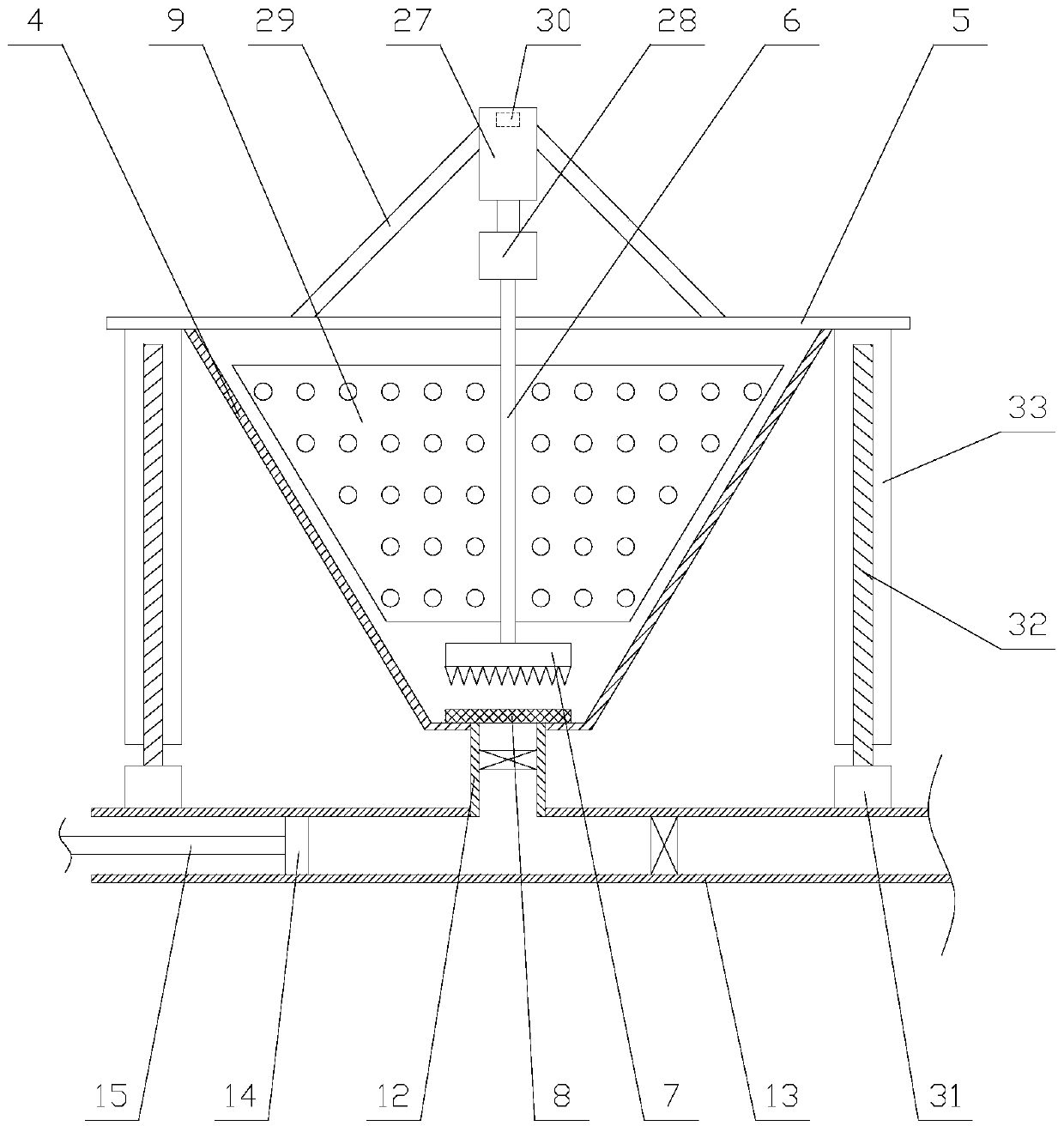

Concrete conveying pump

InactiveCN110259130AImprove delivery efficiencyImprove delivery stabilityBuilding material handlingEngineeringMechanical engineering

The invention relates to a concrete conveying pump. The concrete conveying pump comprises a base, a support block, a controller, a conveying mechanism and a feeding mechanism, the feeding mechanism comprises a hopper, a cover plate, a power assembly, a rotating shaft, a serrated block, a screening net and two stirring plates, the conveying mechanism comprises a driving assembly, a conveying pipe, a connecting pipe and two conveying assemblies, and the conveying assemblies comprise discharging pipes, feeding pipes, sealing plugs and driving rods. According to the concrete conveying pump, large pieces of aggregate and clumps in concrete can be ground into fine and small particles through the feeding mechanism, plugging occurring in the conveying process is avoided, smooth circulation is ensured, not only that, the two feeding pipes provide the concrete for the connecting pipe through the connecting pipe by utilizing the conveying mechanism, so that the concrete is continuously conveyed out from the conveying pipe, the concrete conveying efficiency and the conveying stability are improved, and thus the practicality of the concrete conveying pump is improved.

Owner:内蒙古巨华集团大华建筑安装有限公司

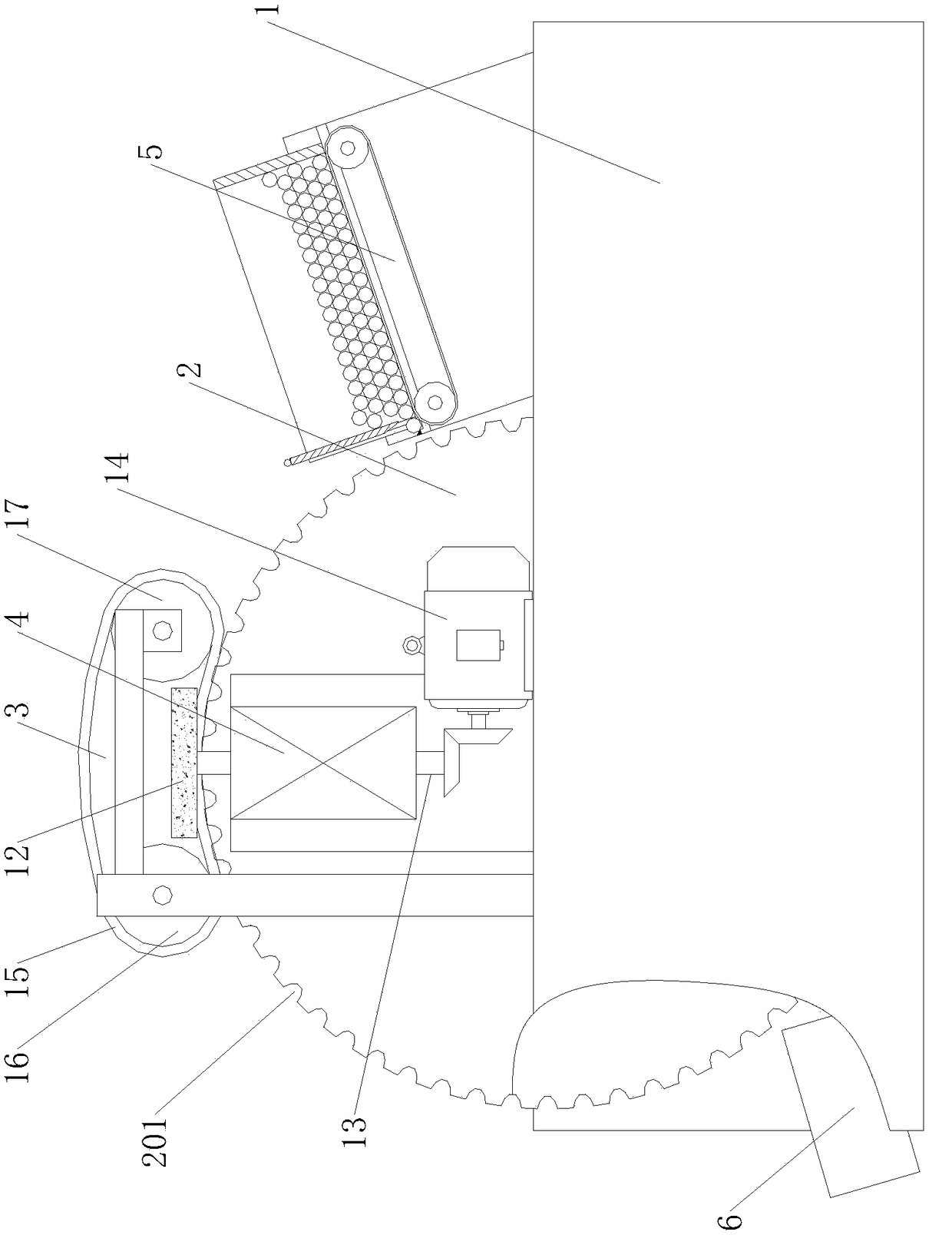

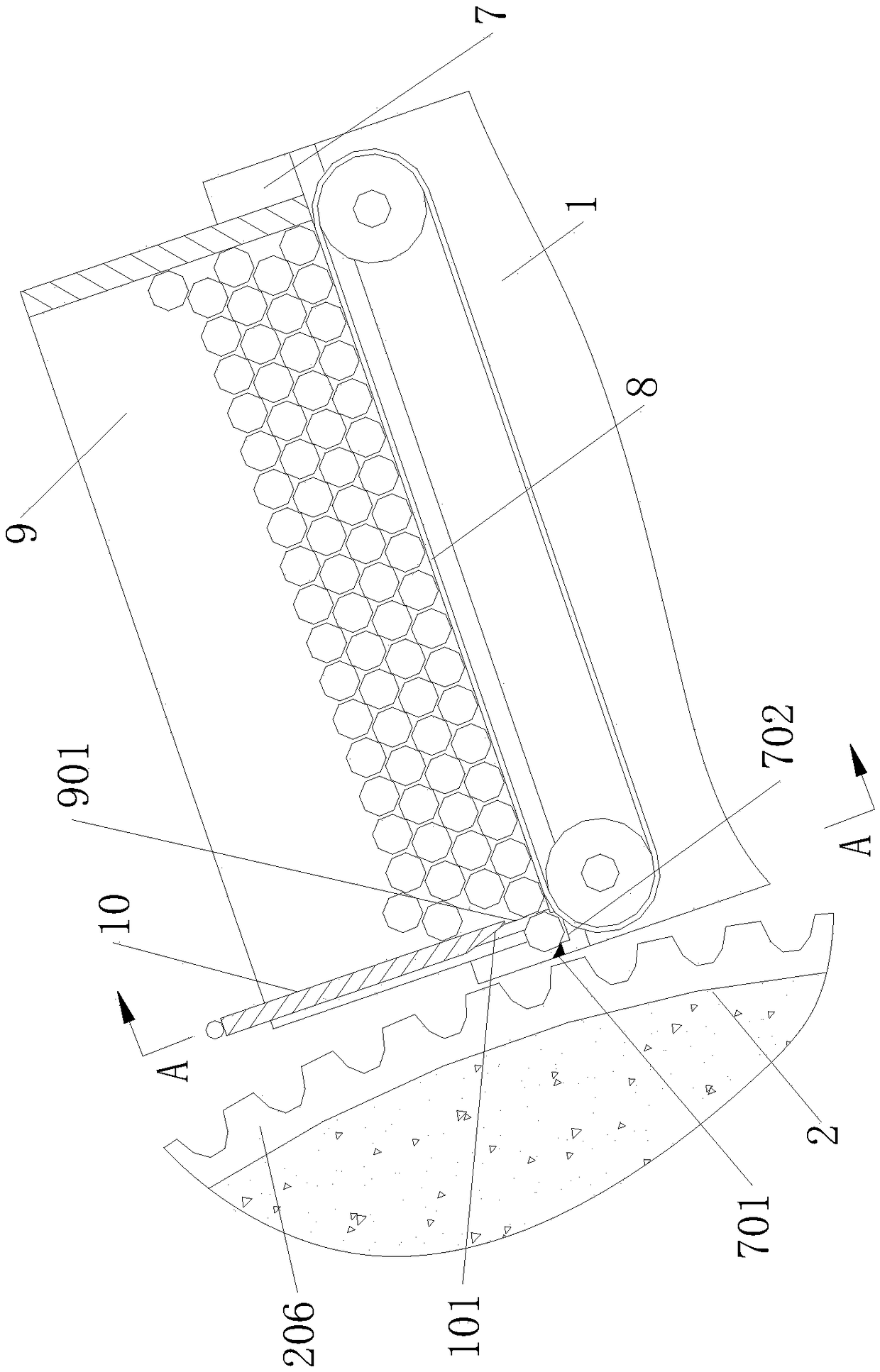

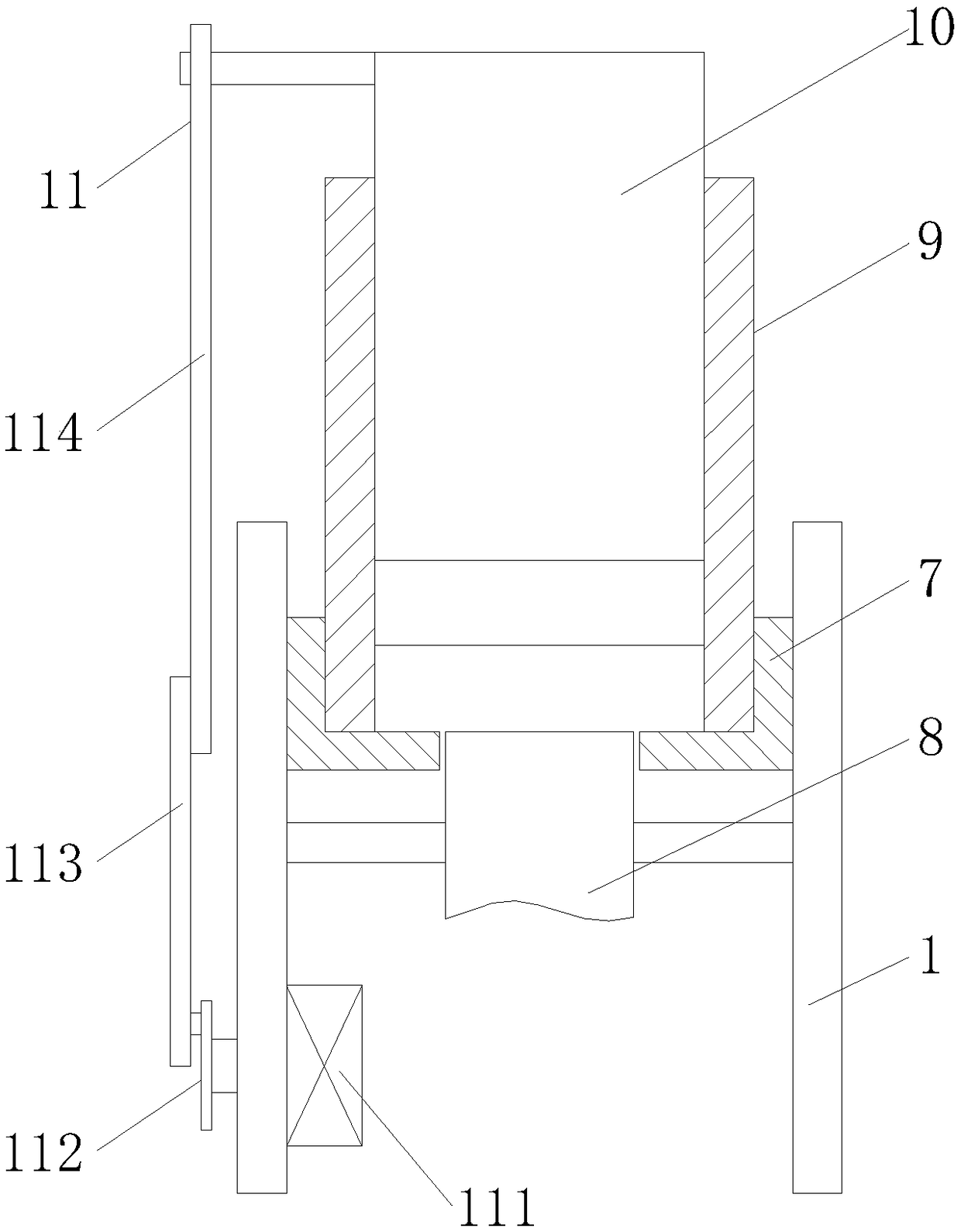

High-stability bamboo stick sharpening machine

InactiveCN109015243AHigh conveying precisionImprove delivery stabilityEdge grinding machinesGrinding drivesEngineeringConveyor belt

The invention discloses a high-stability bamboo stick sharpening machine which comprises a machine base. A rotating wheel is rotationally connected to the middle of the machine base, and a plurality of feeding grooves are evenly distributed on the rotating wheel. A conveyor belt set is arranged at the top of the rotating wheel, and grinding devices are arranged on the two sides of the conveyor belt set. A push rod device and a collecting groove are formed in the two sides of the rotating wheel correspondingly. The feeding grooves comprise arc-shaped grooves, oblique faces are arranged on the positions, between the arc-shaped grooves and the outer wall of the rotating wheel, of one sides of the arc-shaped grooves in the rotating direction of the rotating wheel, and protruding corners are arranged at the junctions of the oblique faces and the arc-shaped grooves. Arc-shaped faces are arranged on the positions, between the arc-shaped grooves and the outer wall of the rotating wheel, of theother sides of the arc-shaped faces in the rotating direction of the rotating wheel. The high-stability bamboo stick sharpening machine has the characteristics of being high in working efficiency andgood in conveying and sharpening stability.

Owner:安吉前程竹木机械有限公司

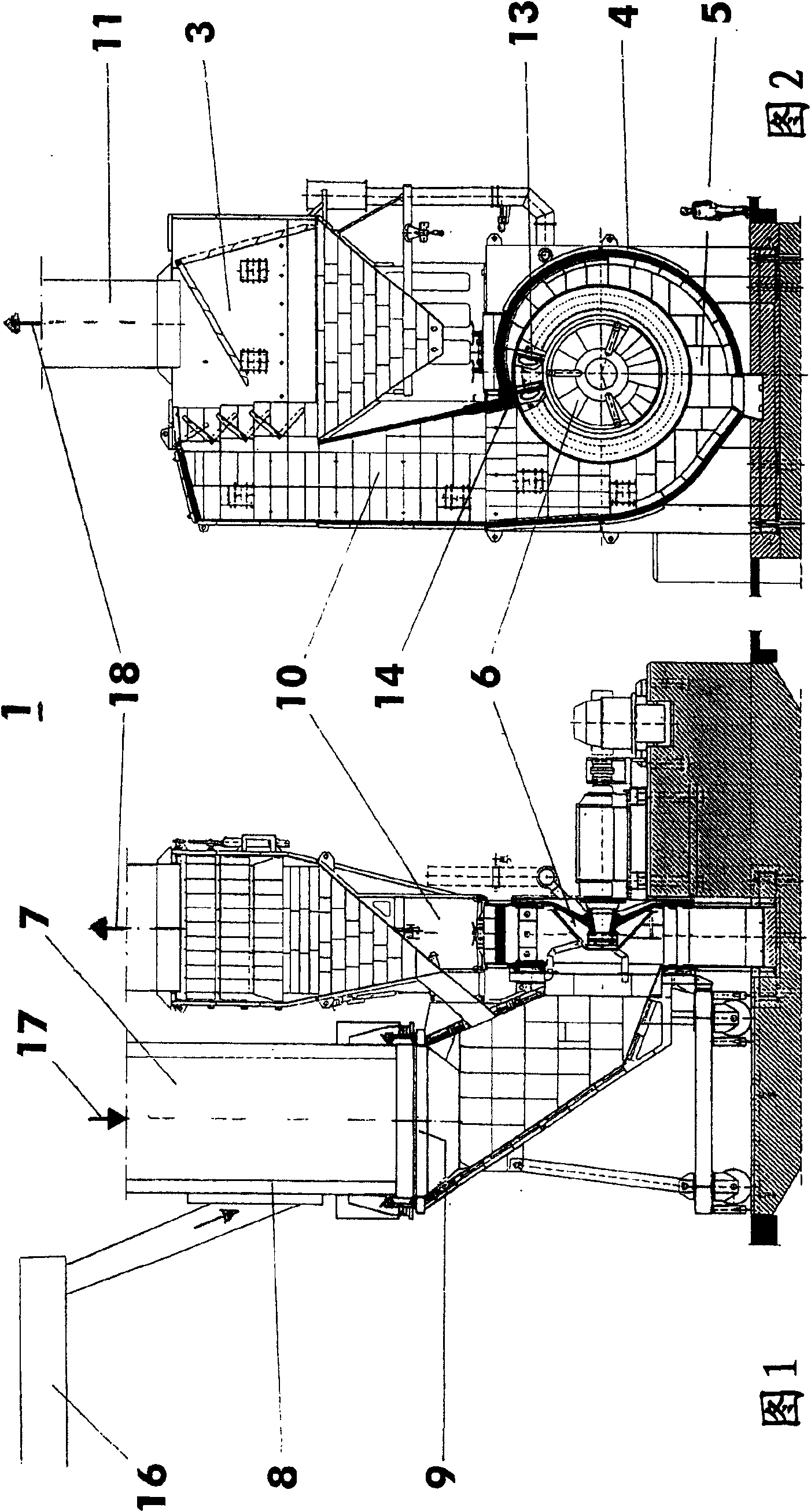

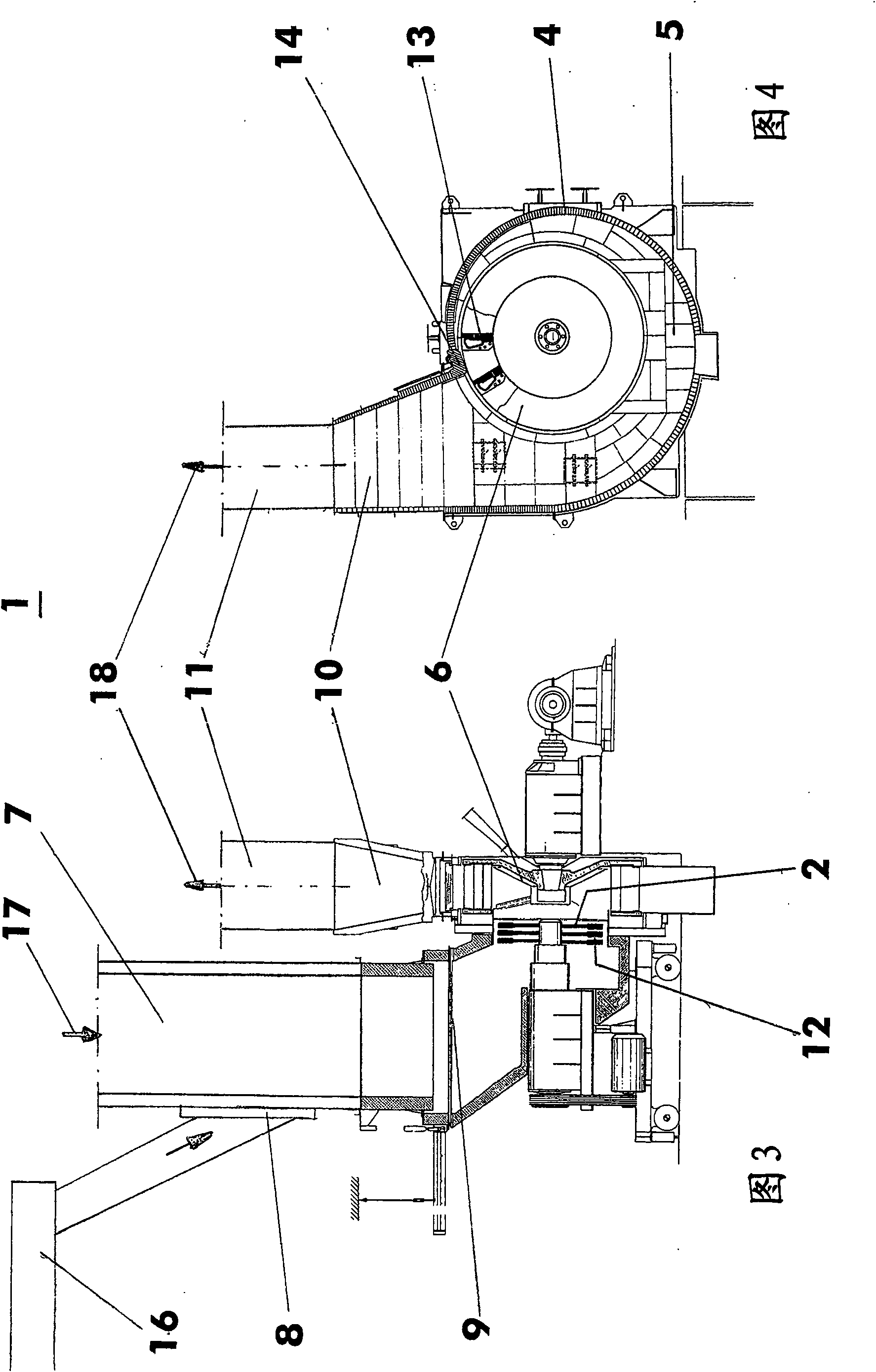

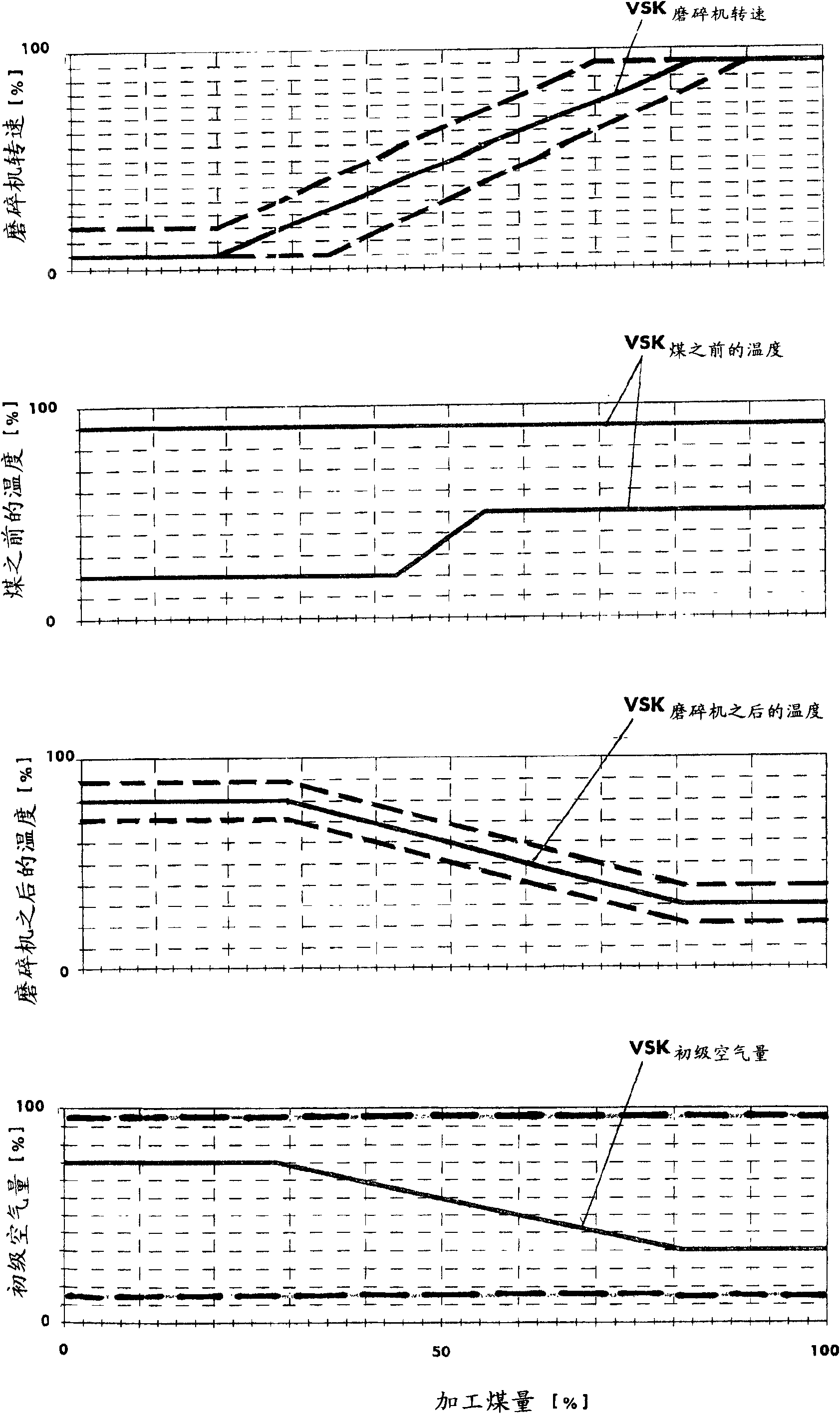

Method and assembly for regulating the grind drying procedure of a coal dust ventilator mill

The present invention provides a method for controlling grind drying procedure of a coal dust ventilator mill, in particular a method for controlling grind drying procedure for brown coal, wherein the method controls at least parameters such as milling speed, temperature after milling and primary air quantity, which involves pre-control curves (VSK[grind rotation speed]) for controlling the milling speed, pre-control curves (VSK[temperature after milling]) for controlling the temperature after milling and pre-control curves (VSK[primary air quantity]) for controlling the primary air quantity, where the pre-control curves (VSK[grind rotation speed], VSK[temperature after milling], VSK[primary air quantity]) are determined depending on coal throughput. The pre-control curve (VSK[grind rotation speed]) of the milling speed is corrected depending on a state of wear (V[IST]) of a mill-tool of a coal dust fan mill. An independent claim is also included for an arrangement for controlling a pulverized drying process of raw lignite, wherein the corresponding curves have minimum curves and maximum curves.

Owner:GENERAL ELECTRIC TECH GMBH

Conveying device

ActiveCN112320244ASmall footprintImprove applicabilityConveyor partsMechanical conveyorsButt jointEngineering

The invention discloses a conveying device. Automatic rotation of a tray can be completed through a first 90-degree turning conveying mechanism and a second 90-degree turning conveying mechanism, in-situ horizontal rotation of a workpiece on the tray can be achieved through a 180-degree rotating conveying mechanism, and the workpiece can be conveniently grabbed by a grabbing tool. Therefore, the conveying device requires no manual operation, the conveying efficiency is improved, the distance between a first linear conveying mechanism and a second linear conveying mechanism is small, that is, the butt joint space between the conveying mechanisms is small, the occupied space of the conveying device is reduced, and the applicability and the conveying stability of the conveying device are improved.

Owner:北京可锐特科技有限公司

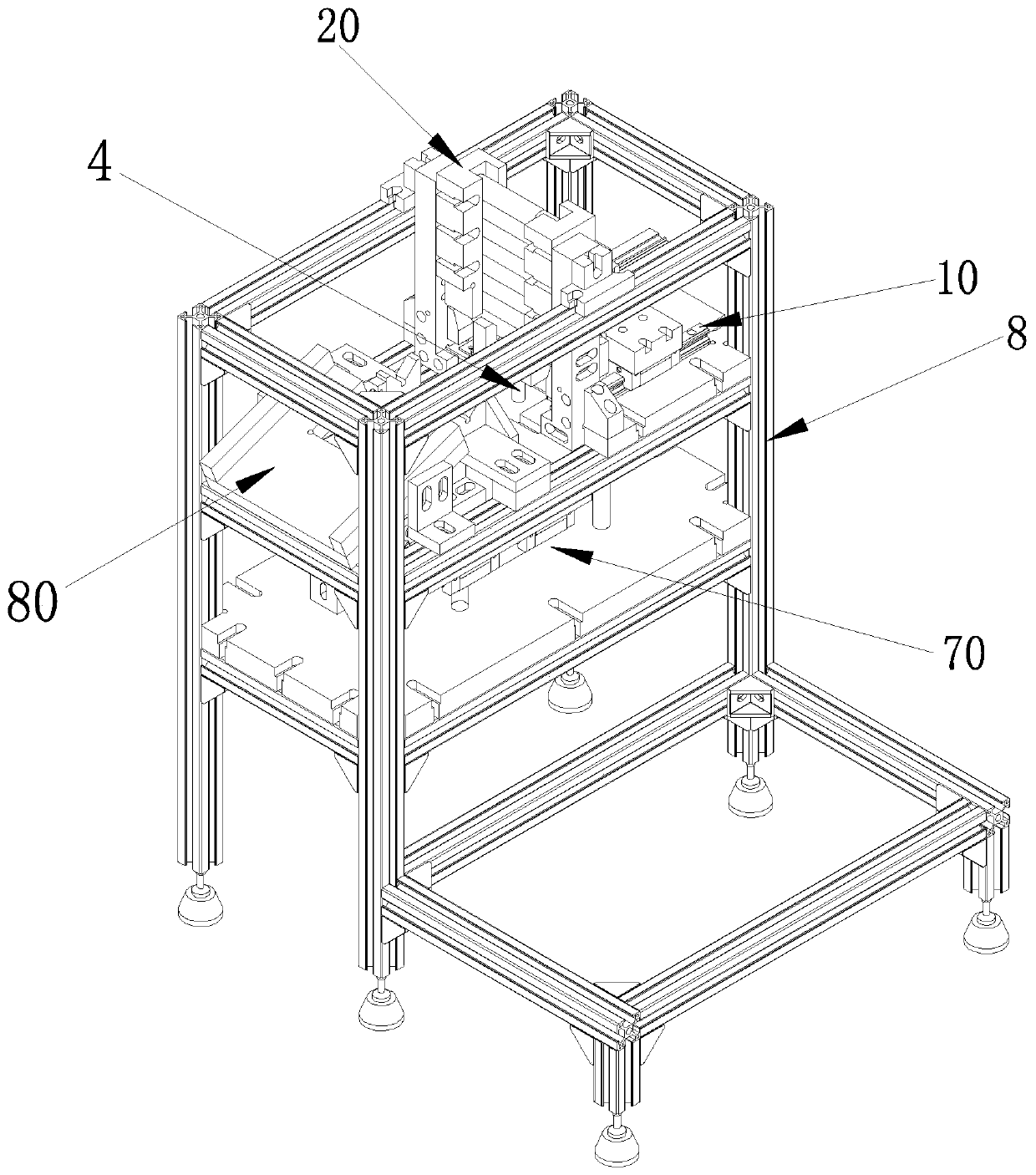

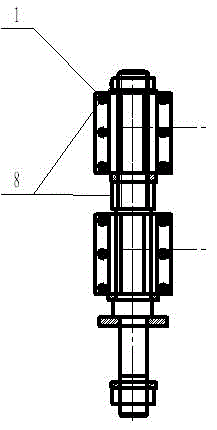

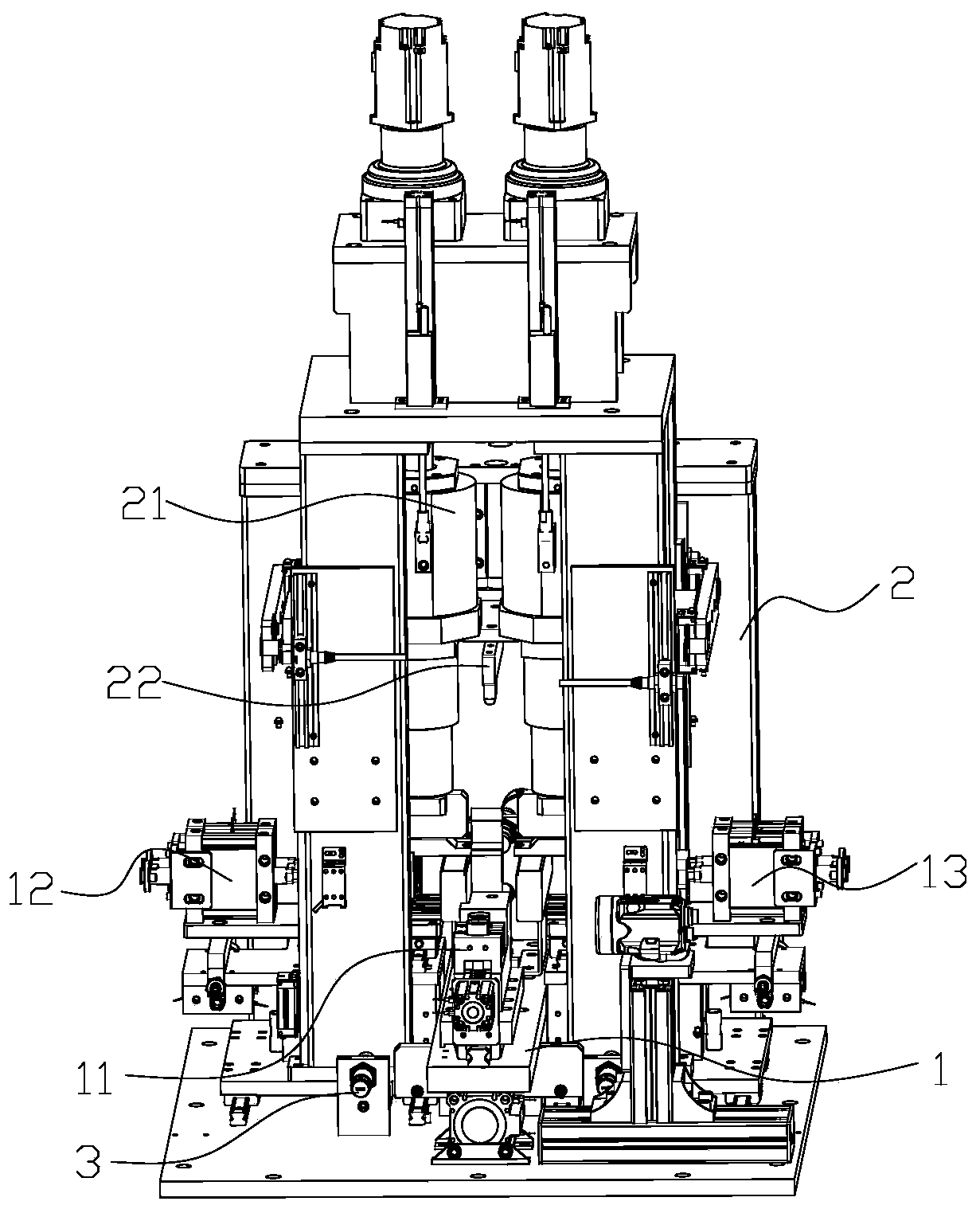

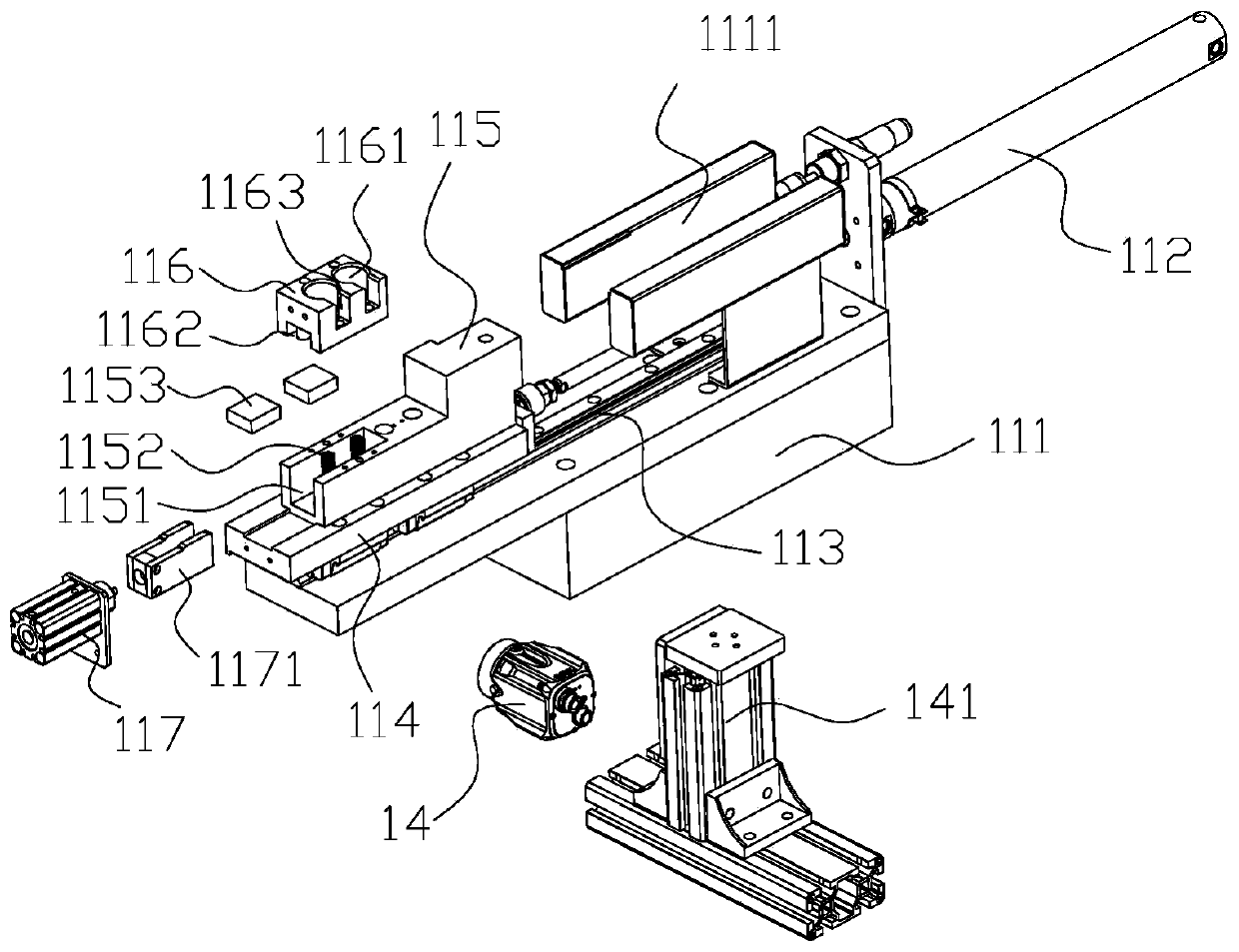

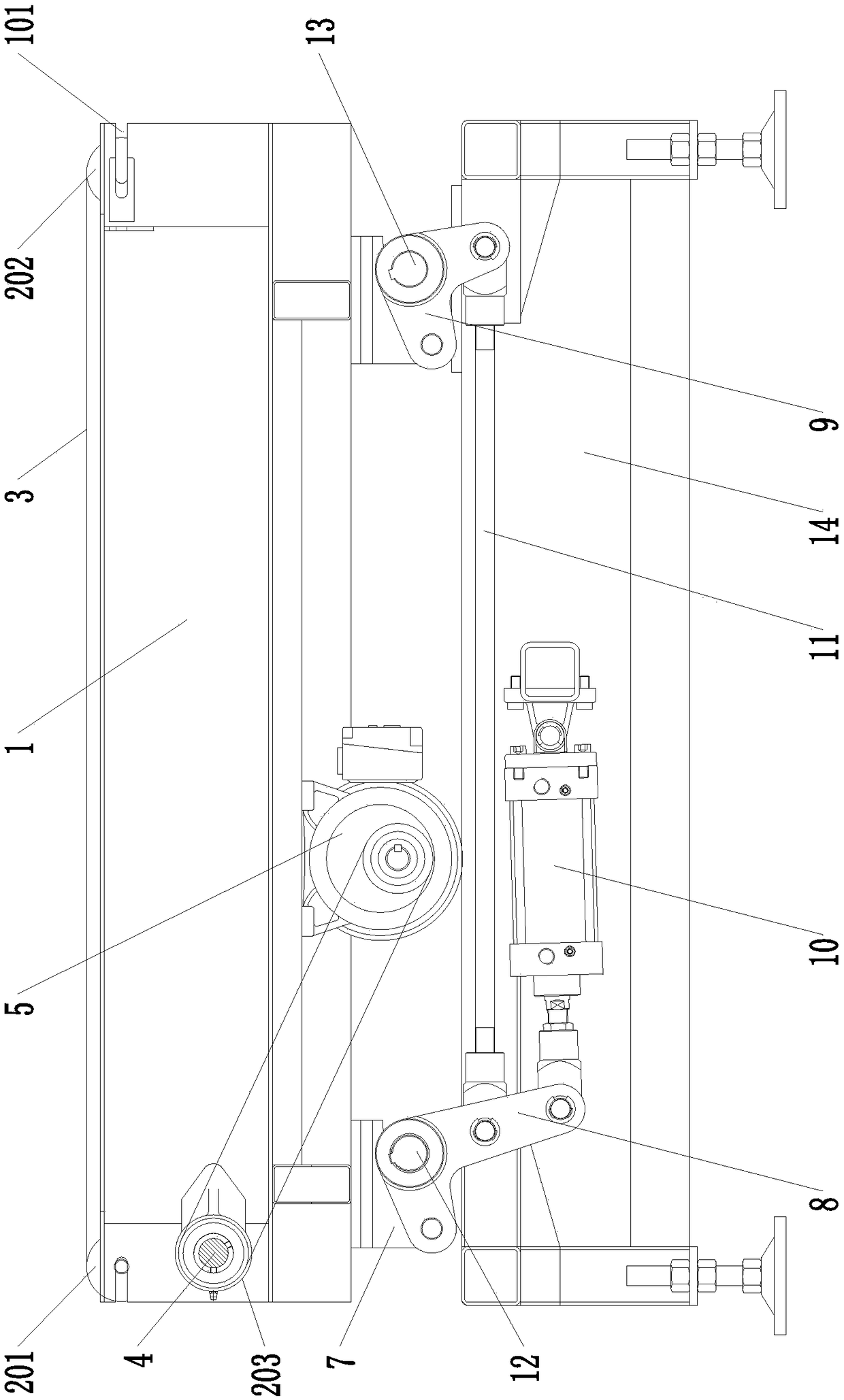

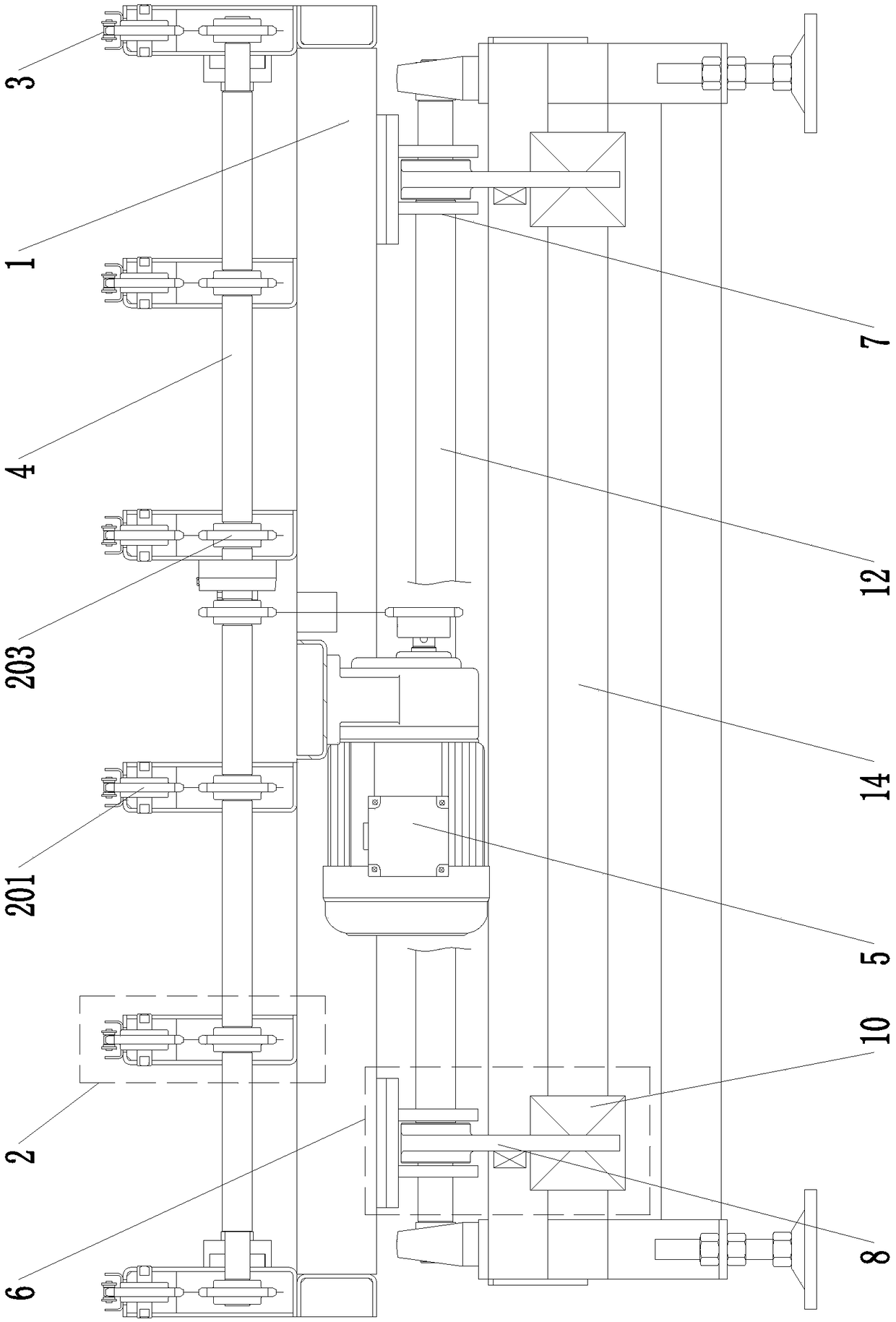

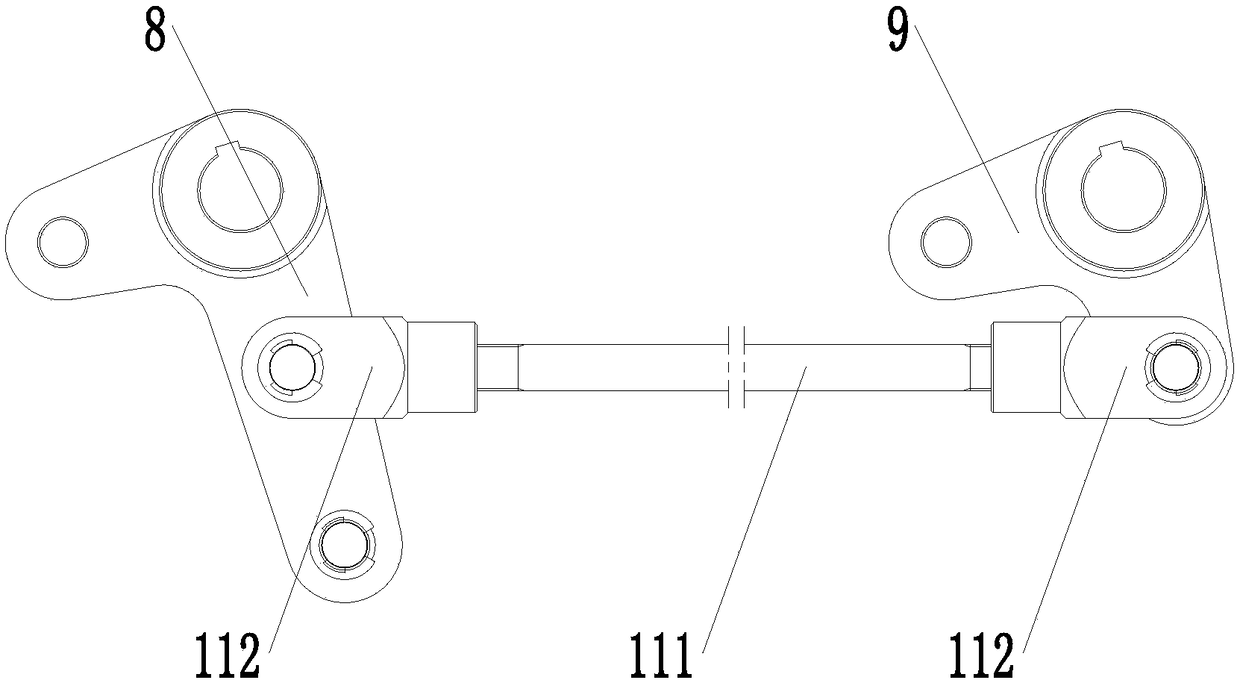

Wiring terminal, automatic press fitting device of wiring terminal, and method

InactiveCN111416258AAvoid damageImprove delivery stabilityContact member manufacturingCoupling contact membersEngineeringMechanical engineering

The invention belongs to the technical field of wiring terminal production and provides an automatic press fitting device of a wiring terminal. The device comprises a rack, a conveying and clamping device and a press fitting device, wherein the conveying and clamping device and the press fitting device are arranged on the rack; the conveying and clamping device comprises a terminal conveying assembly, a first horizontal clamping assembly and a second horizontal clamping assembly; the terminal conveying assembly is used for conveying a terminal to the position between the first horizontal clamping assembly and the second horizontal clamping assembly; and the first horizontal clamping assembly and the second horizontal clamping assembly are used for horizontally clamping the terminal. With the press-fitting device adopted, conveying stability is improved, stability in a press-fitting process is improved, the wiring terminal is e prevented from being damaged, and press-fitting quality andpress-fitting efficiency are improved.

Owner:温州源利智能科技有限公司

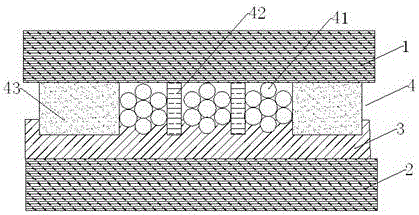

High-strength flame-retarding conveying rubber belt

InactiveCN106005880AImprove delivery stabilityImprove stabilityConveyorsUltimate tensile strengthStructural stability

The invention discloses a high-strength flame-retarding conveying rubber belt. The high-strength flame-retarding conveying rubber belt comprises upper covering rubber, lower covering rubber, core rubber and a reinforcing layer, wherein the reinforcing layer is partially embedded into the core rubber, the upper surface of the reinforcing layer is covered with the upper covering rubber, and the lower surface of the core rubber is covered with the lower covering rubber; the reinforcing layer is composed of steel wire rope sets, filling rubber, side rubber and braided rope belts, wherein the steel wire rope sets are distributed at intervals, the gaps of the steel wire rope sets are filled with the filling rubber, the side rubber is attached to the outer sides of the steel wire rope sets at the two ends of the reinforcing layer, and the braided rope belts are arranged on the side rubber, the steel wire rope sets and the filling rubber in a winding and sleeving mode. The high-strength flame-retarding conveying rubber belt is simple in structure and reasonable in design; through the reinforcing layer and the steel wire rope sets, the structural strength and the structural stability of the reinforcing layer are effectively improved. The high-strength flame-retarding conveying rubber belt is high in overall structural strength, good in stability and high in conveying stability, has incomparable excellent effects compared with conveying rubber belts in the past and has wide market prospects.

Owner:CHANGSHU CHANGJIANG TAPE

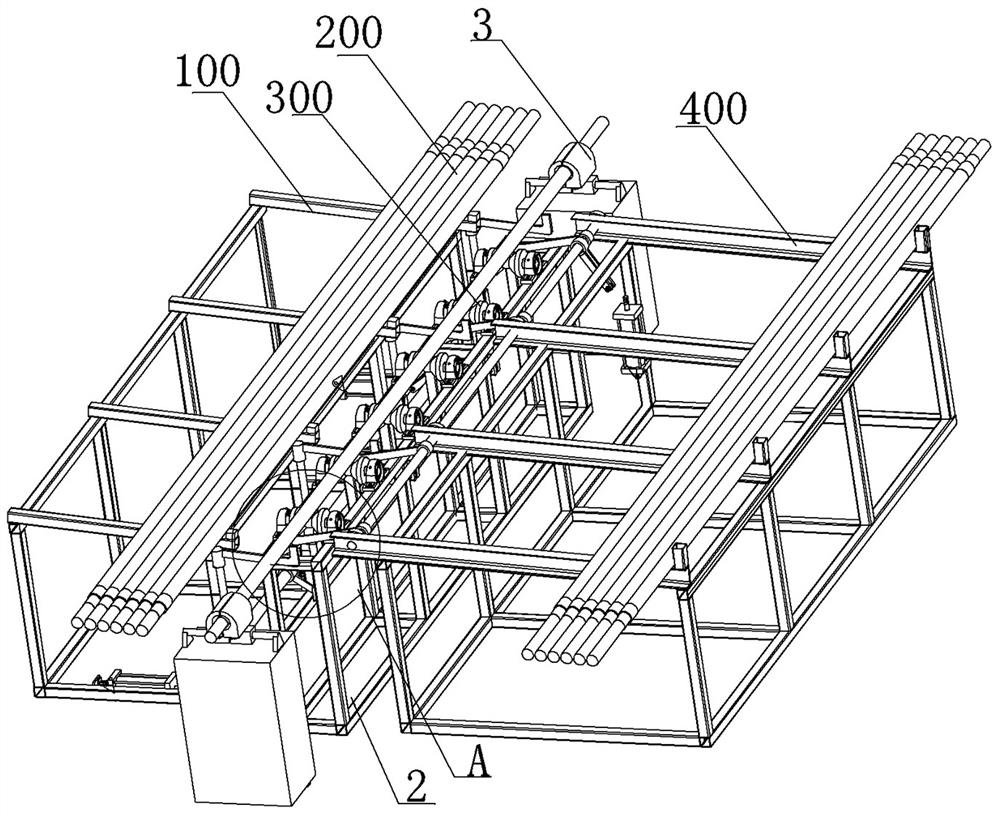

Automatic anchor bolt thermal shrinkage production line

PendingCN113320739AConvenient automatic heat shrink processingReduce labor intensityWrappers shrinkageRod-shaped articlesAnchor boltThermal shrinkage

The invention relates to an automatic anchor bolt thermal shrinkage production line. The automatic anchor bolt thermal shrinkage production line comprises a feeding unit, a thermal shrinkage unit and a material receiving unit; the feeding unit is used for storing anchor bolts to be subjected to thermal shrinkage processing; the thermal shrinkage unit comprises a thermal shrinkage rack and a heating device; the thermal shrinkage rack is provided with a single anchor bolt processing position; the single anchor bolt processing position is used for supporting and placing a single anchor bolt; the heating device is used for heating thermal shrinkage pipes at the two ends of the single anchor bolt to achieve thermal shrinkage processing; the material receiving unit is used for collecting anchor bolts subjected to thermal shrinkage processing; a feeding mechanism is arranged at the rear end of the feeding unit and is used for conveying the anchor bolts to the single anchor bolt processing position one by one; and a discharging mechanism is arranged at the front end of the material receiving unit and is used for transferring the anchor bolts subjected to thermal shrinkage processing to the material receiving unit from the single anchor bolt processing position. The single anchor bolt is conveyed to the single anchor bolt processing position of the thermal shrinkage unit through a feeding structure, the thermal shrinkage pipes on the two sides of the anchor bolt are correspondingly heated through the heating device, and after heating is completed, the anchor bolt is transferred to the receiving unit through the discharging mechanism, so automatic thermal shrinkage processing of the anchor bolt is conveniently achieved.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD +1

Auxiliary orienting device for conveying belted layer

The invention provides an auxiliary orienting device for conveying a belted layer. The auxiliary orienting device comprises a plurality of conveying rollers used for conveying the belted layer, a pressing plate arranged on the multiple conveying rollers in a pressing manner at the same time, a plurality of flange rollers fixed to the pressing plate and located between the adjacent conveying rollers, and roller mechanisms fixed to the pressing plate. Each roller mechanism comprises an installing base, a lock screw fixedly connecting the installing base with the pressing plate, a spring, a plurality of limiting screws and fastening screws, wherein the spring is arranged on the lock screw in a sleeving manner and abuts against the installing base, the multiple limiting screws are fixed to the installing base, and the fastening screws are fixed to the installing base. The auxiliary orienting device for conveying the belted layer is simple in structure, the structure is simplified, the running direction of the belted layer is accurately controlled, and the fixed length accuracy and the material conveying stability are improved.

Owner:VMI HOLLAND BV

Film laminating conveying device of glass panel film laminating machine

InactiveCN104118729AImprove delivery stabilityPrevent deviationCharge manipulationConveyor partsEngineeringExtrusion

The invention relates to a film laminating conveying device of a glass panel film laminating machine. The film laminating conveying device comprises a support. The support is provided with a guide roller conveying device and a compression roller device, the guide roller conveying device is composed of upper guide rollers and lower guide rollers, and the compression roller device is composed of an upper compression roller and a lower compression roller. An auxiliary compression roller device is mounted at the front end of the support, and the auxiliary compression roller device comprises a mounting plate which is fixedly connected to the front end of the support. The mounting plate is provided with an upper clamping roller and a lower clamping roller, the lower clamping roller is connected with the mounting plate in a rotating mode, and the upper clamping roller is connected into a sliding chute of the mounting plate in a sliding mode by the aid of a spring and an adjusting block. The upper compression roller is connected with a cylinder rod of an air cylinder with the help of a supporting plate, and the air cylinder is fixedly connected to the support. A triangular structure guide plate is arranged between the upper guide rollers and the lower guide rollers at the output ends of the lower guide rollers. According to the film laminating conveying device of the glass panel film laminating machine, elastic extrusion force to a glass panel can be adjusted through the auxiliary compression roller device, conveying stability is improved, the glass panel can be prevented from deflecting, and film laminating quality is improved; the compression roller spacing can be adjusted through the air cylinder, operation is simple and convenient, and real-time adjustment can further be achieved.

Owner:SUZHOU YIHE OPTICAL

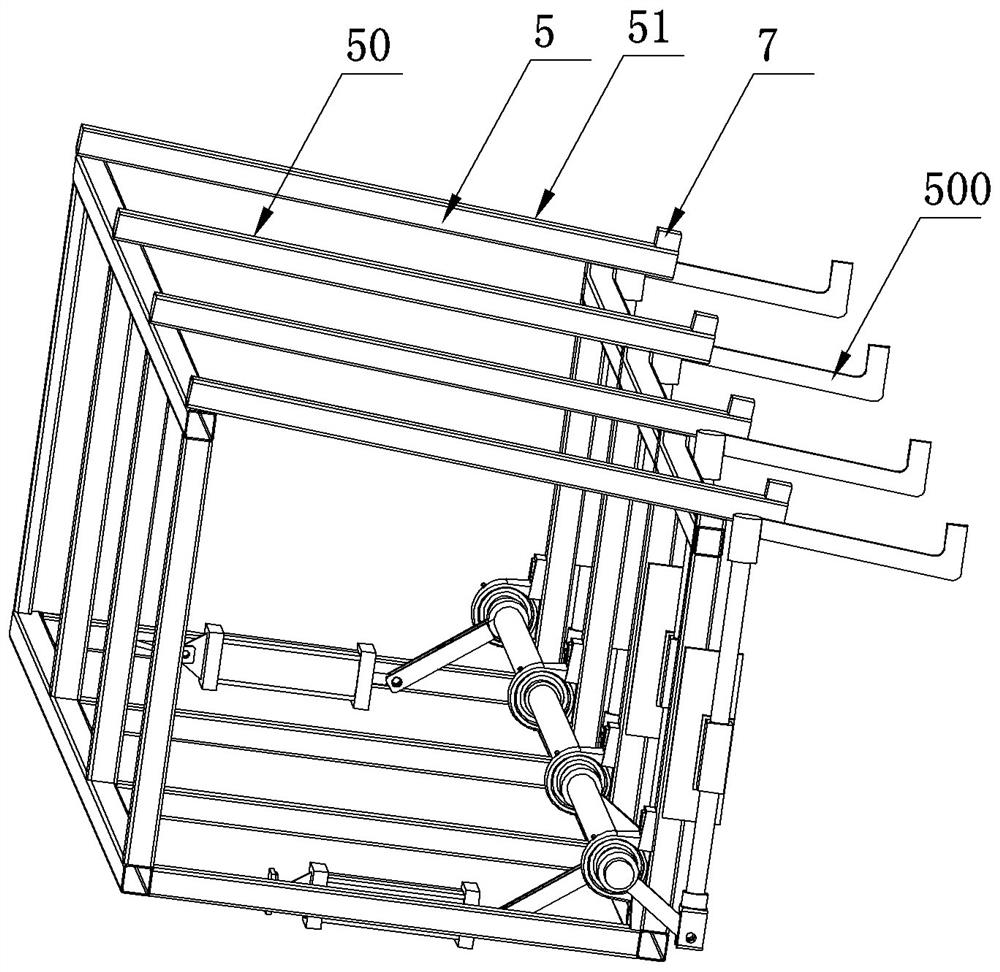

Multi-row rubber chain pneumatic jacking transfer machine

The invention discloses a multi-row rubber chain pneumatic jacking transfer machine. The multi-row rubber chain pneumatic jacking transfer machine comprises a lifting bracket; a plurality of drive chain wheel sets are arranged on the lifting bracket side by side; each drive chain wheel set is provided with a rubber-covered chain; the multiple drive chain wheel sets are mutually connected through adrive shaft; a drive motor is connected to one side of a drive wheel; lifting devices are arranged on the two sides of the bottom of the lifting bracket; each lifting device comprises lifting seats fixed to the two ends of the bottom of the lifting bracket, and the lifting seats on the two sides are connected with a driving lifting arm and a driven lifting arm separately; a jacking-pushing cylinder is connected to the lower end of each driving lifting arm; and each driven lifting arm and the corresponding driving lifting arm are mutually connected through a connection shaft device. The multi-row rubber chain pneumatic jacking transfer machine has the characteristics of high conveying stability and small occupied space.

Owner:湖州龙辉物流机械设备有限公司

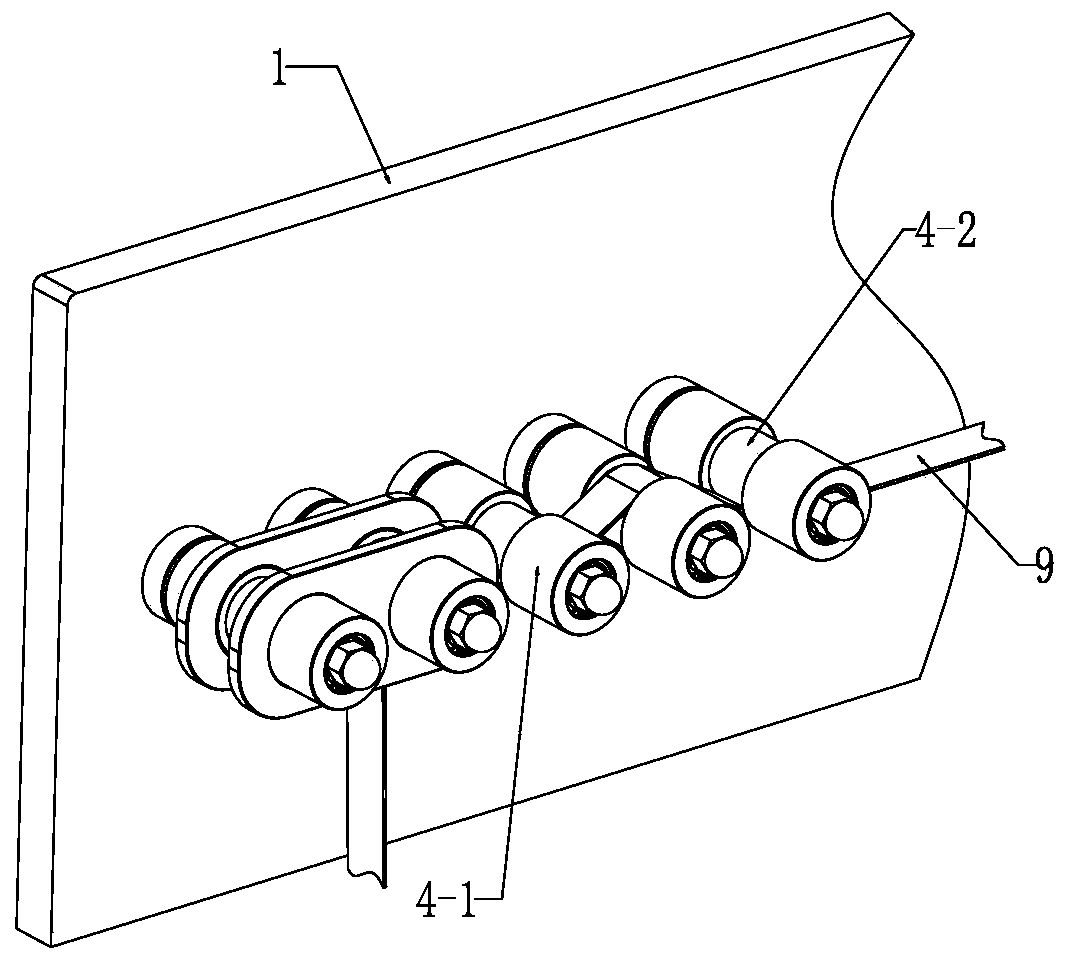

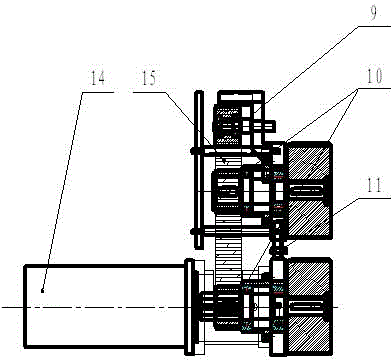

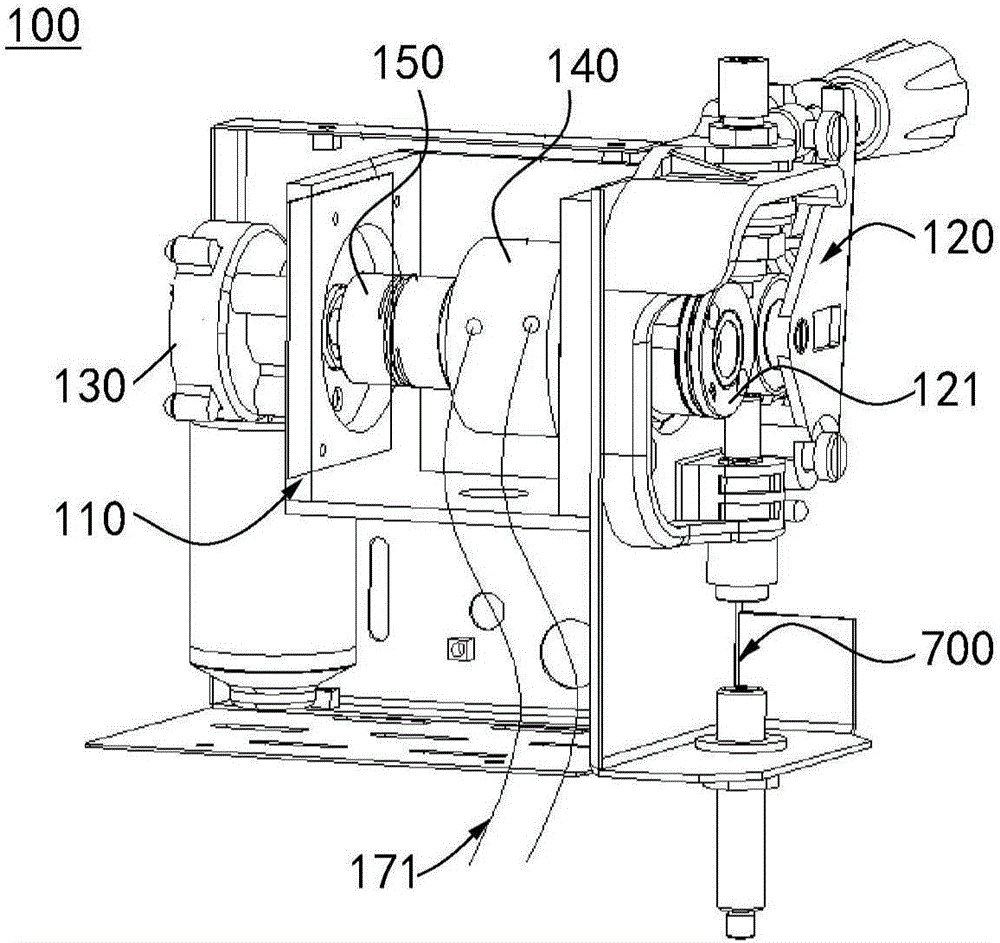

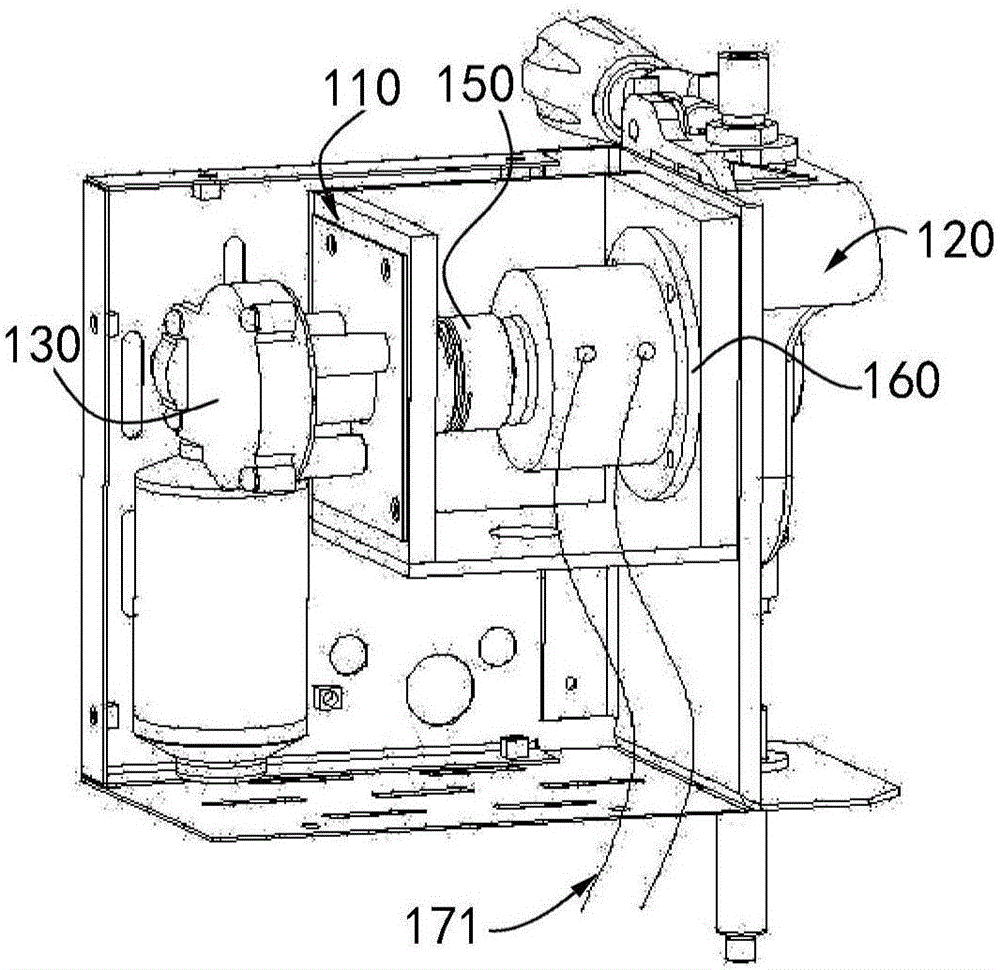

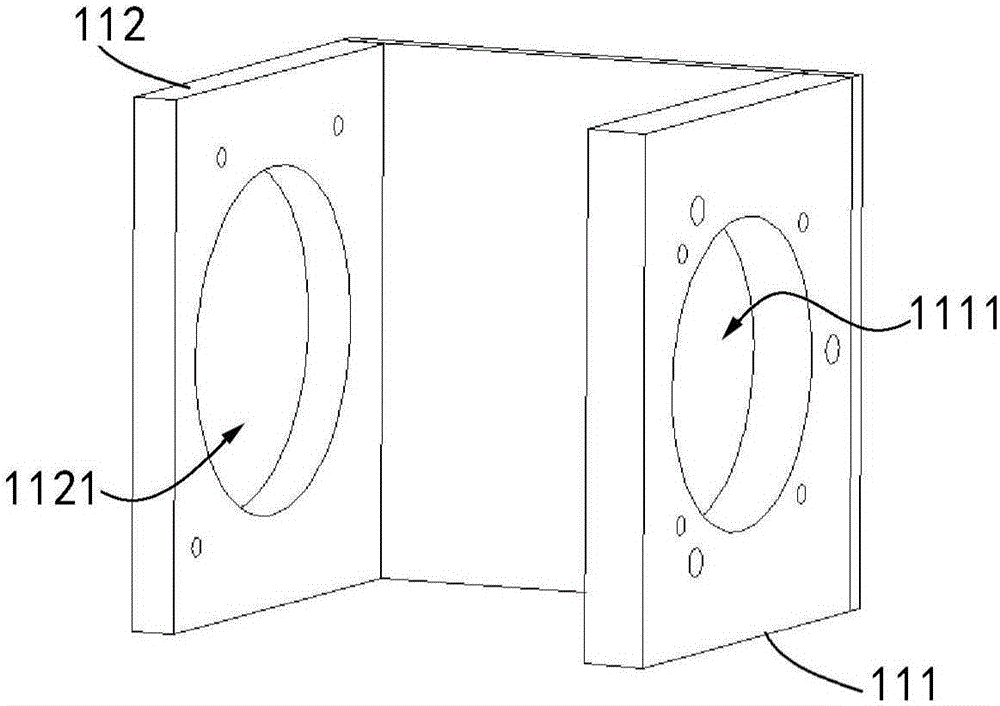

Wire-feeding power assisting device and welding equipment employing same

The invention discloses a wire-feeding power assisting device. The wire-feeding power assisting device comprises a bracket, a wire feeding actuation device and a driving device, wherein the bracket is mounted in welding equipment and corresponds to a wire feeding pipeline; the wire feeding actuation device is arranged on the bracket to provide an auxiliary torque for welding wires in the wire feeding pipeline; and the driving device is arranged on the bracket and is in transmission connection with the wire feeding actuation device to drive the wire feeding actuation device. As the wire-feeding power assisting device is added to the conventional welding equipment, the auxiliary torque is provided for the welding wires, accordingly, the wire feeding torque of a main wire feeding device of the welding equipment is assisted in a cooperating manner to provide an output torque in the welding wire conveying process, resistance of the welding wires is overcome, and an effect of improving the conveying stability is achieved. In addition, the wire-feeding power assisting device provided by the invention is simple in structure, convenient to arrange, and wide in applicability, and coordinated and cooperated use can be performed through adjusting the output torque with respect to different main wire feeding devices and different resistances.

Owner:PANASONIC WELDING SYST TANGSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com