Patents

Literature

617results about How to "Ingenious and reasonable design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

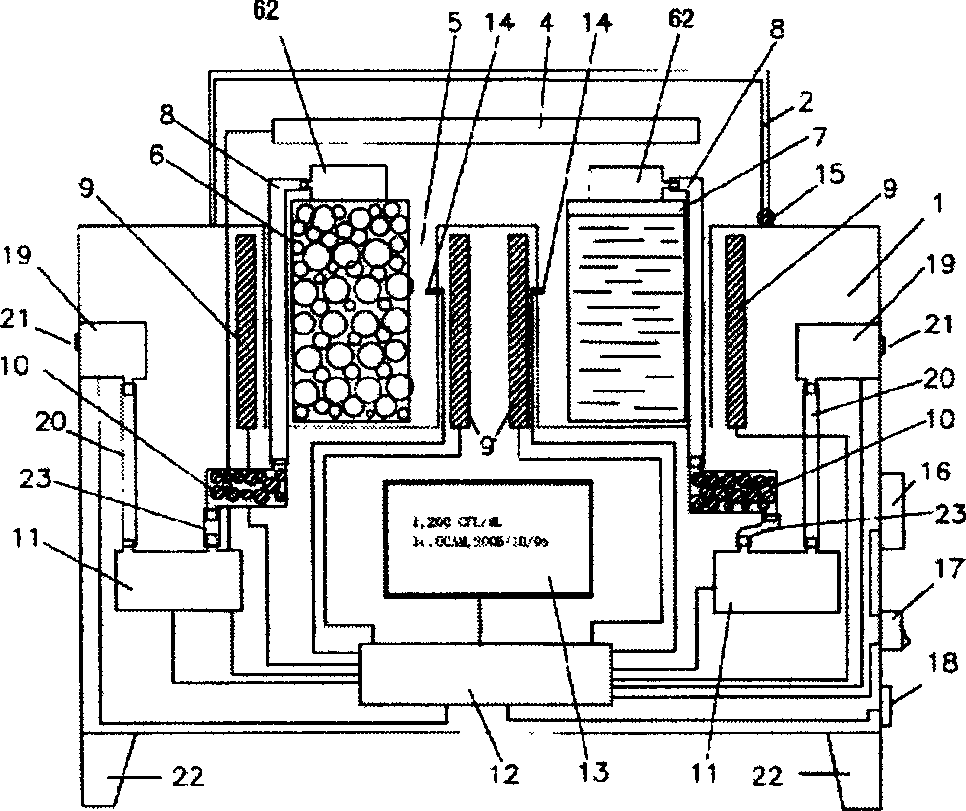

Method for quickly producing water vapor and steamed furnace using same

InactiveCN102777877ASimple structureIngenious and reasonable designSteam generation heating methodsSteam cooking vesselsProduced waterBoiling point

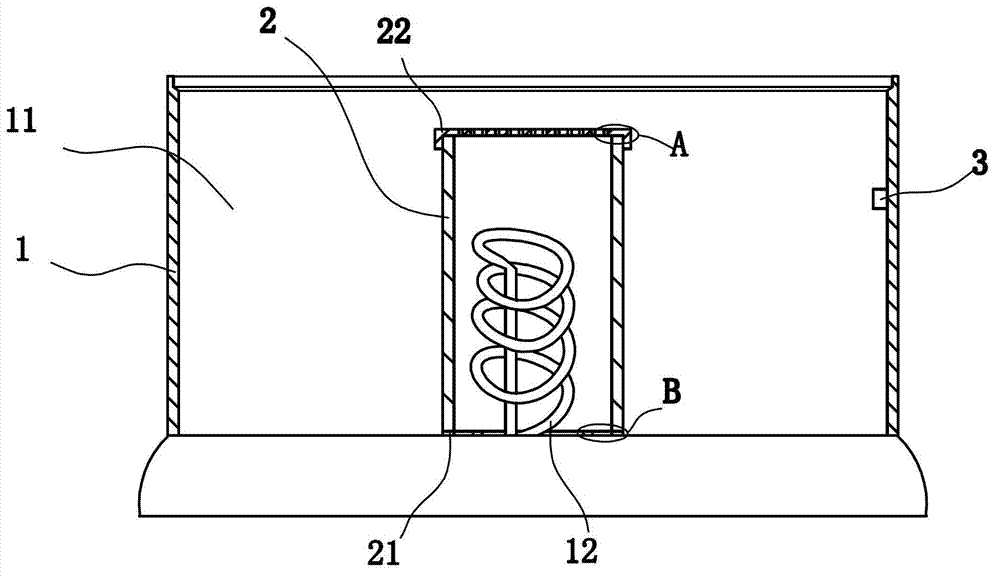

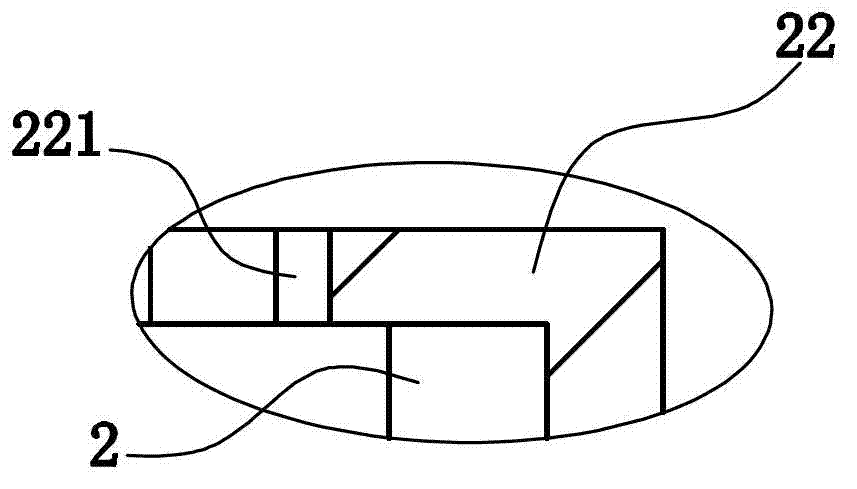

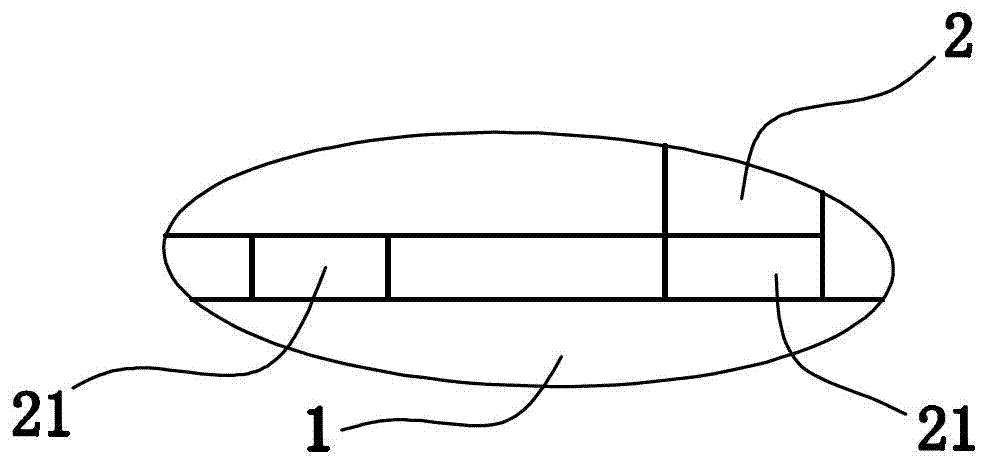

The invention discloses a method for quickly producing water vapor. The method includes the following steps that a furnace body is prepared. A cavity body filled with water is arranged on the furnace body, and a heating body is arranged in the cavity body. A water dividing body prepared by heat insulation materials is covered on the heating body, the top height of the water dividing body is larger than the top height of the heating body, the water is filled in the cavity body of the furnace body, and the heating body works to produce heat. Heat transfer between water in the water dividing body and the outside of the water dividing body is slow due to separation of the water dividing body, so that water in the water dividing body is heated prior to the water outside the water dividing body. Temperature is quickly improved, so that water in the water dividing body can achieve the boiling point prior to the water outside the water dividing body to produce the water vapor. Compared with the traditional steamed furnace not provided with the water dividing body, the steamed furnace is high in water vapor production speed. The steamed furnace using the method is further disclosed.

Owner:梁首强

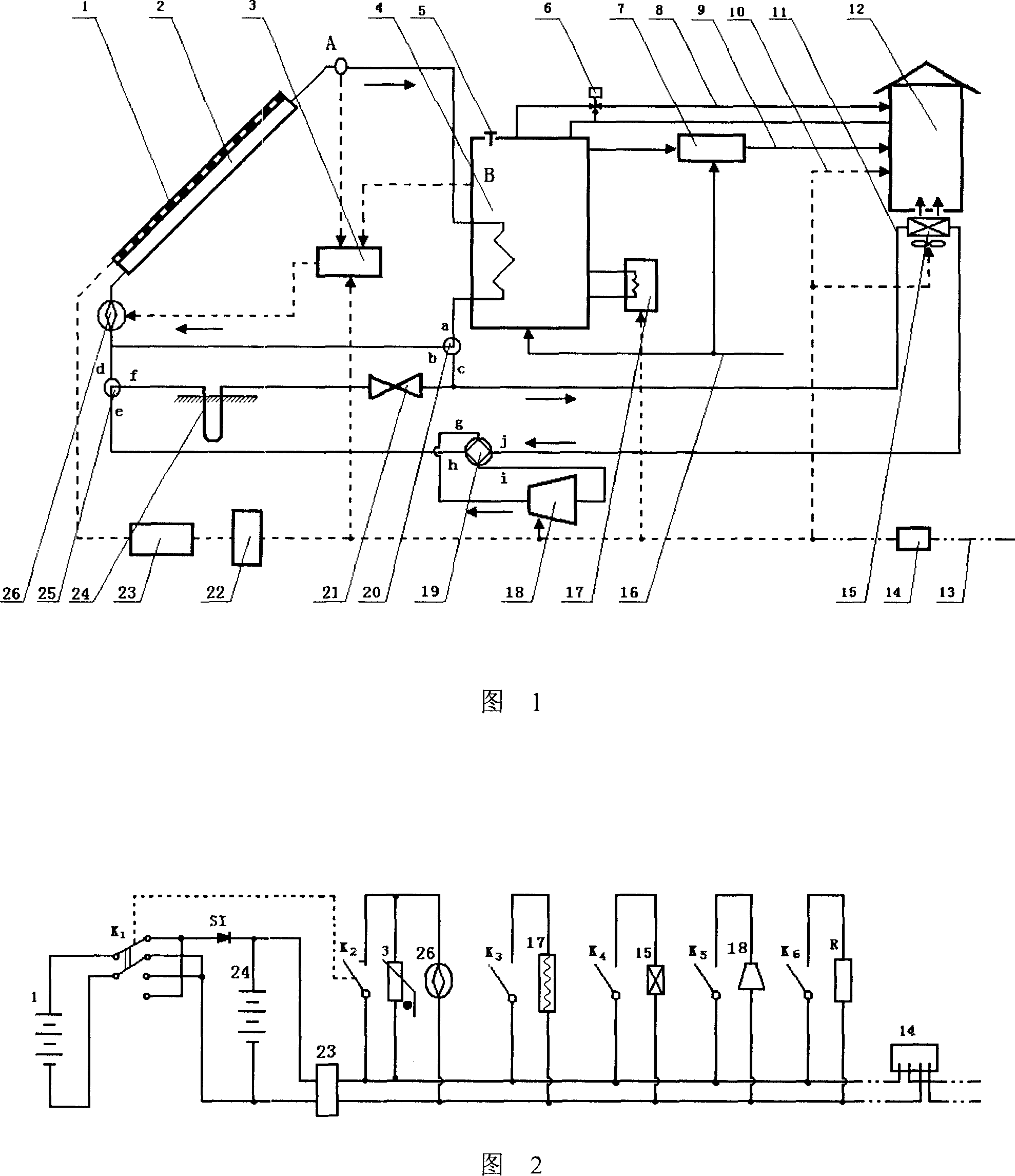

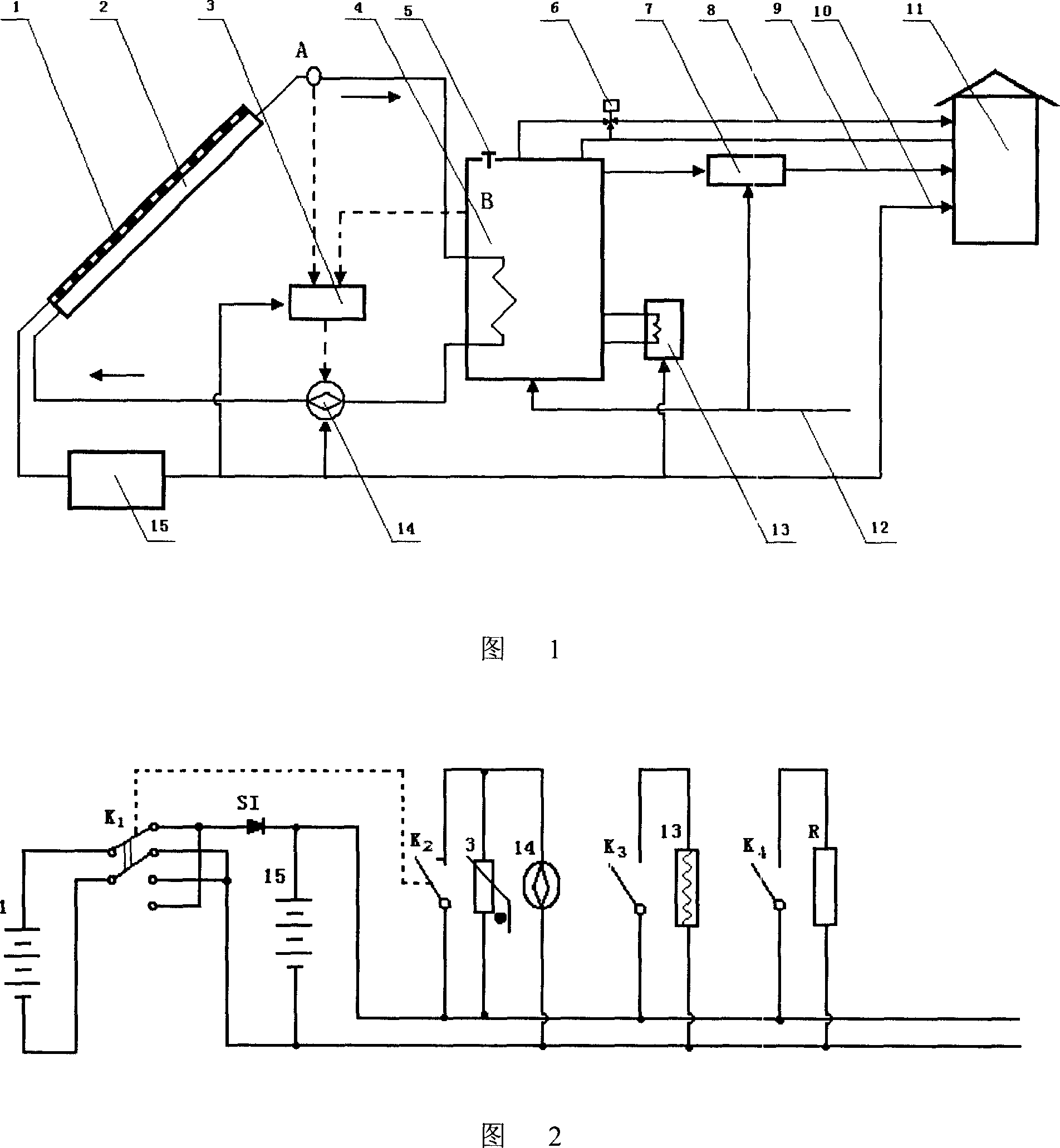

Solar energy-ground source united heat supply, hot water supply, power supply and refrigerating system and its operation method

InactiveCN1987211AImprove utilization efficiencySimple structureSolar heat devicesElectric power transfer ac networkWater sourceEngineering

A solar energy-geothermic-source combining system for supplying heat and hot water, generating electric energy and refrigerating is composed of thermoelectric cells, solar heat collecting tubes, thermoelectric relay, heat accumulator, safety valve, auxiliary heater, mixer, room heating regulator, electric accumulator set, inverter, KW-hour meter, bidirectional pump, compressor, reverse valve, throttle valve, underground heat exchanger and geothermic pump set.

Owner:JIANGSU UNIV

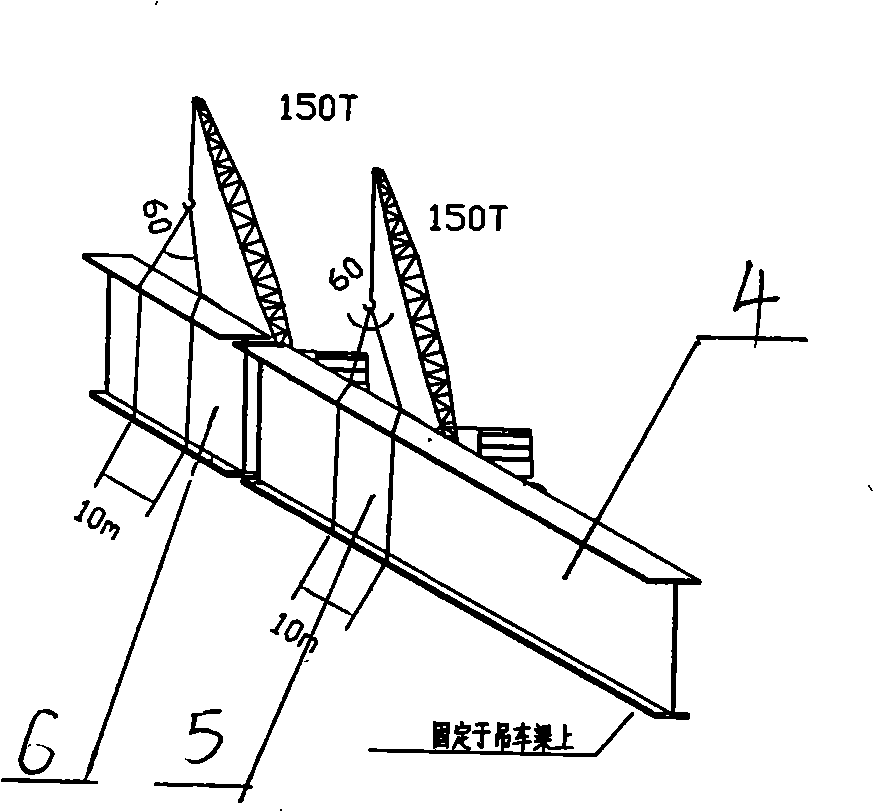

Giant crane beam mounting method

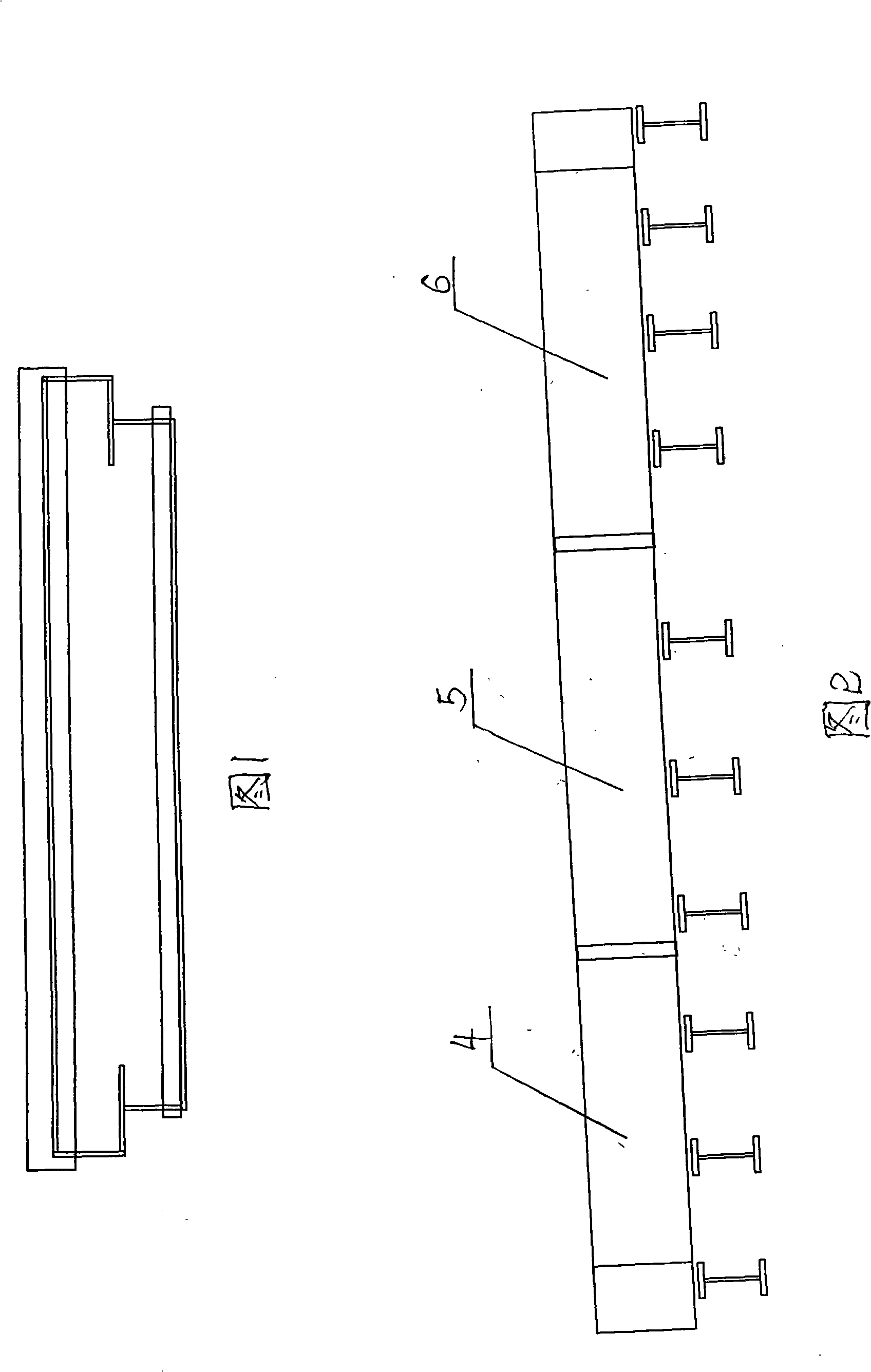

The invention relates to a construction method, in particular to a method for installing super-large crane beams, solving the technical problems of the prior art in the installation of large-span and large-mass crane beams. The method for installing the super-large crane beams comprises the following steps: a temporary bracket is first put up on the ground at one third of the span of a crane beam installation position; a crane beam is assembled on site; a left-segment crane beam component and a middle-segment crane beam component which are welded together are integrally lifted in place by use of two cranes; the left-segment crane beam component is partially fixed with a steel column connecting part; the other end of the middle-segment crane beam component falls on the bracket; a right-segment crane beam component is lifted to the height in accordance with the middle-segment crane beam component by use of another crane; and the right-segment crane beam component and the middle-segment crane beam component are paired and welded in the air. The method is applicable to the installation of the crane beam of which the length is over 60 meters and the mass is over 220 tons. The method has the advantages of high safety performance, short construction period, convenient construction operation and good engineering quality.

Owner:MCC TIANGONG GROUP

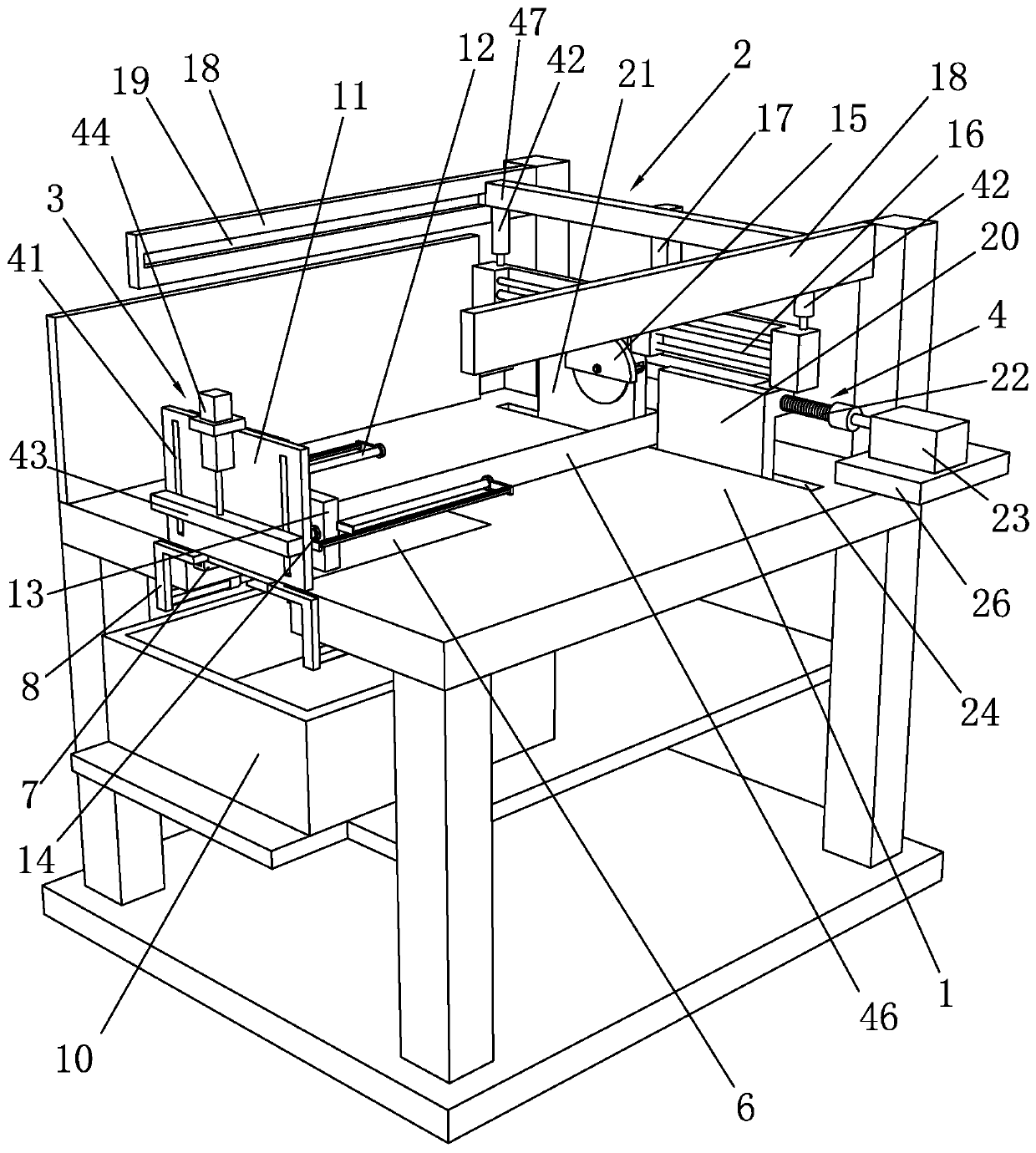

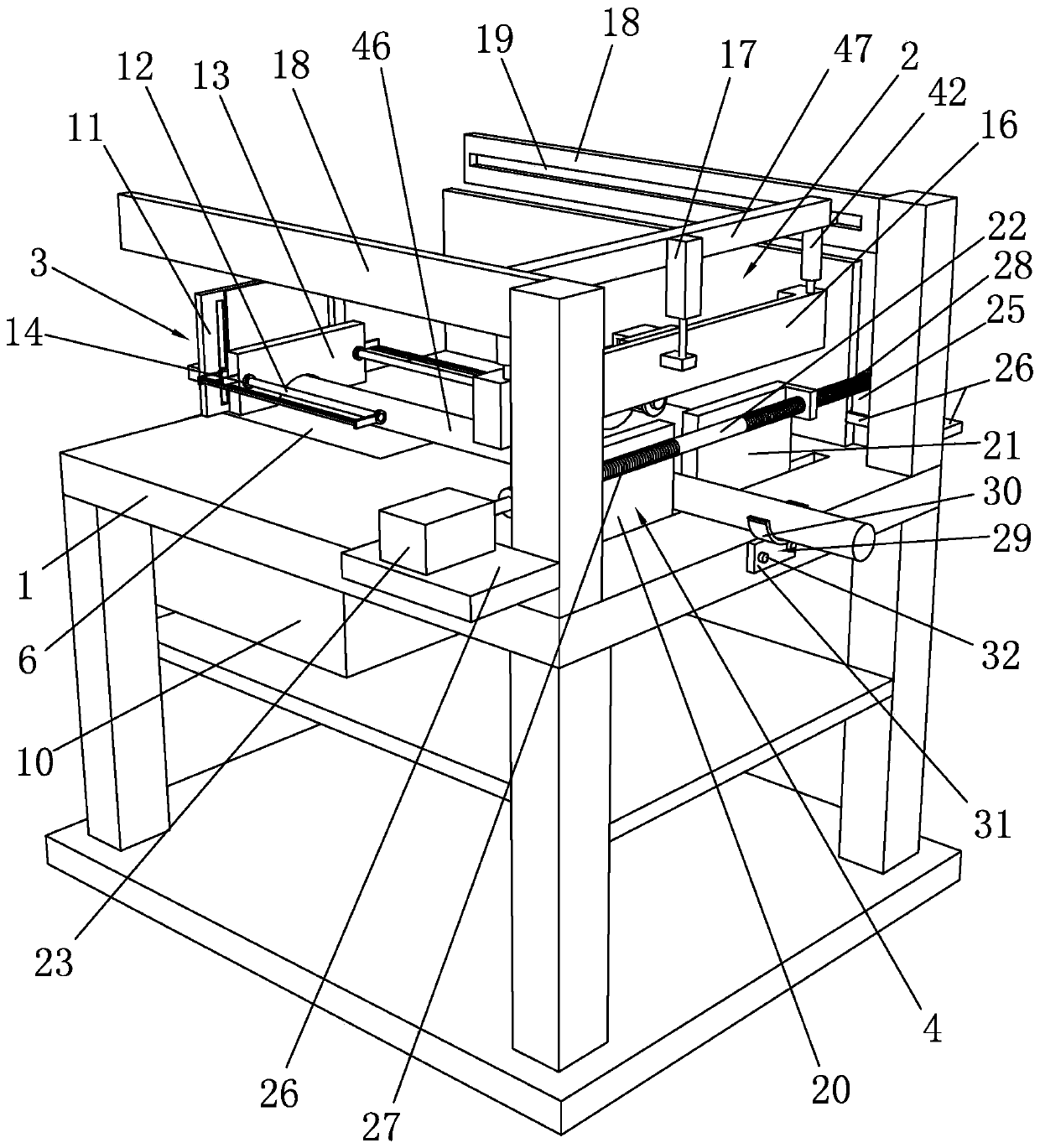

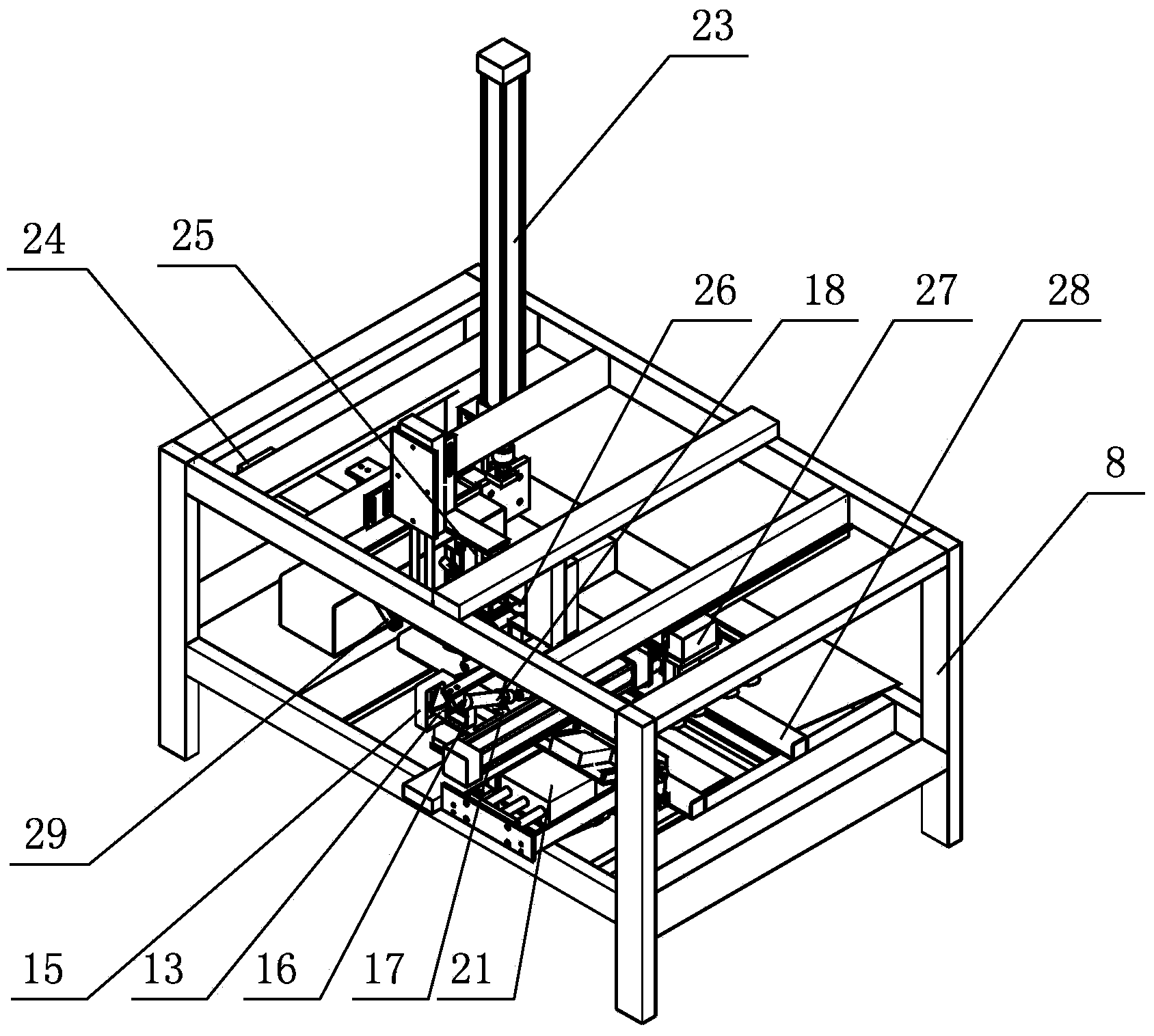

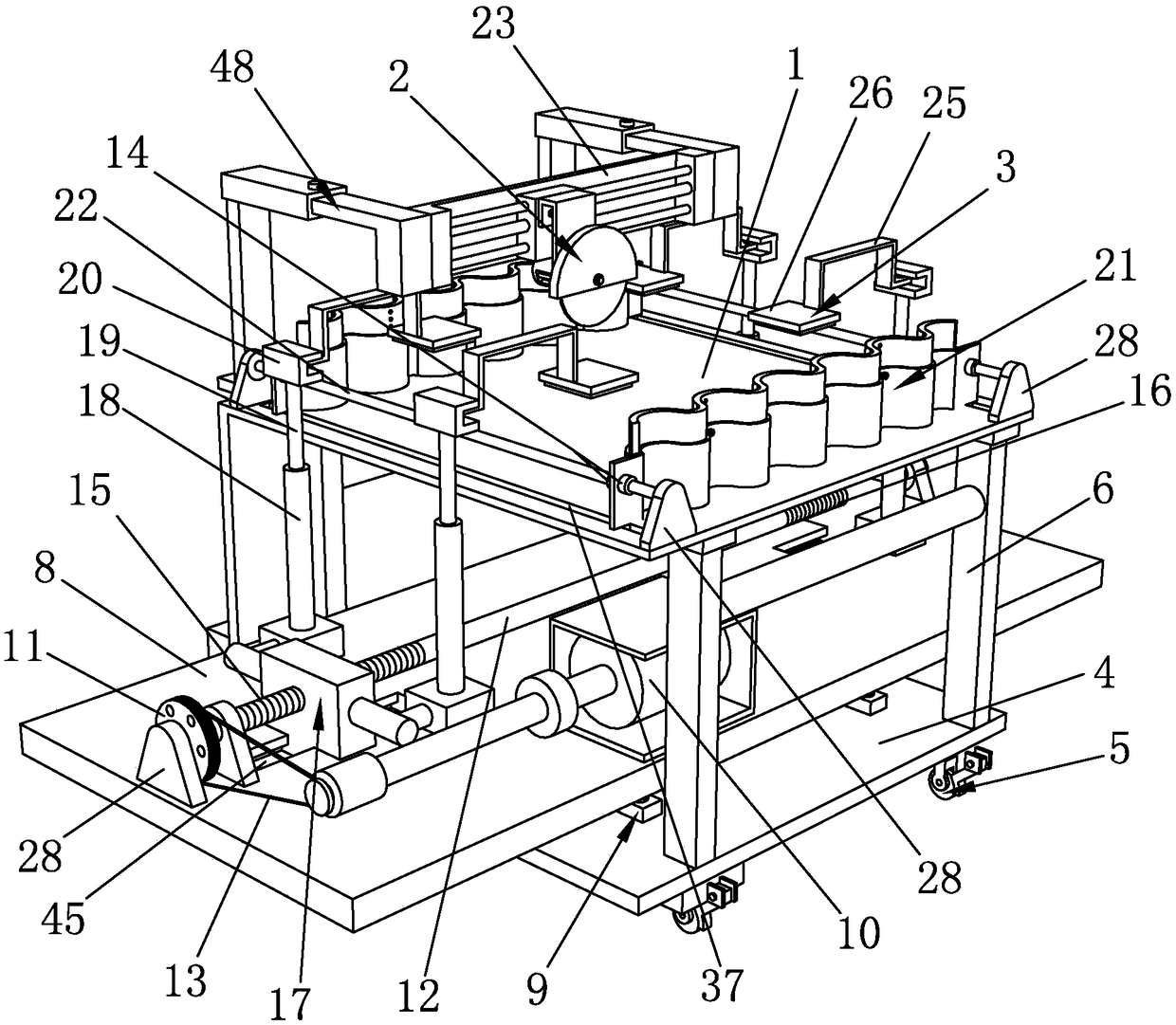

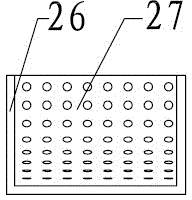

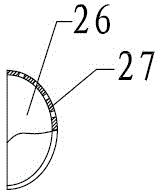

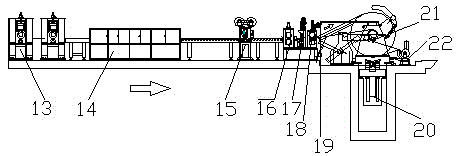

Cutting device for mechanical automatic production of spare and accessory parts

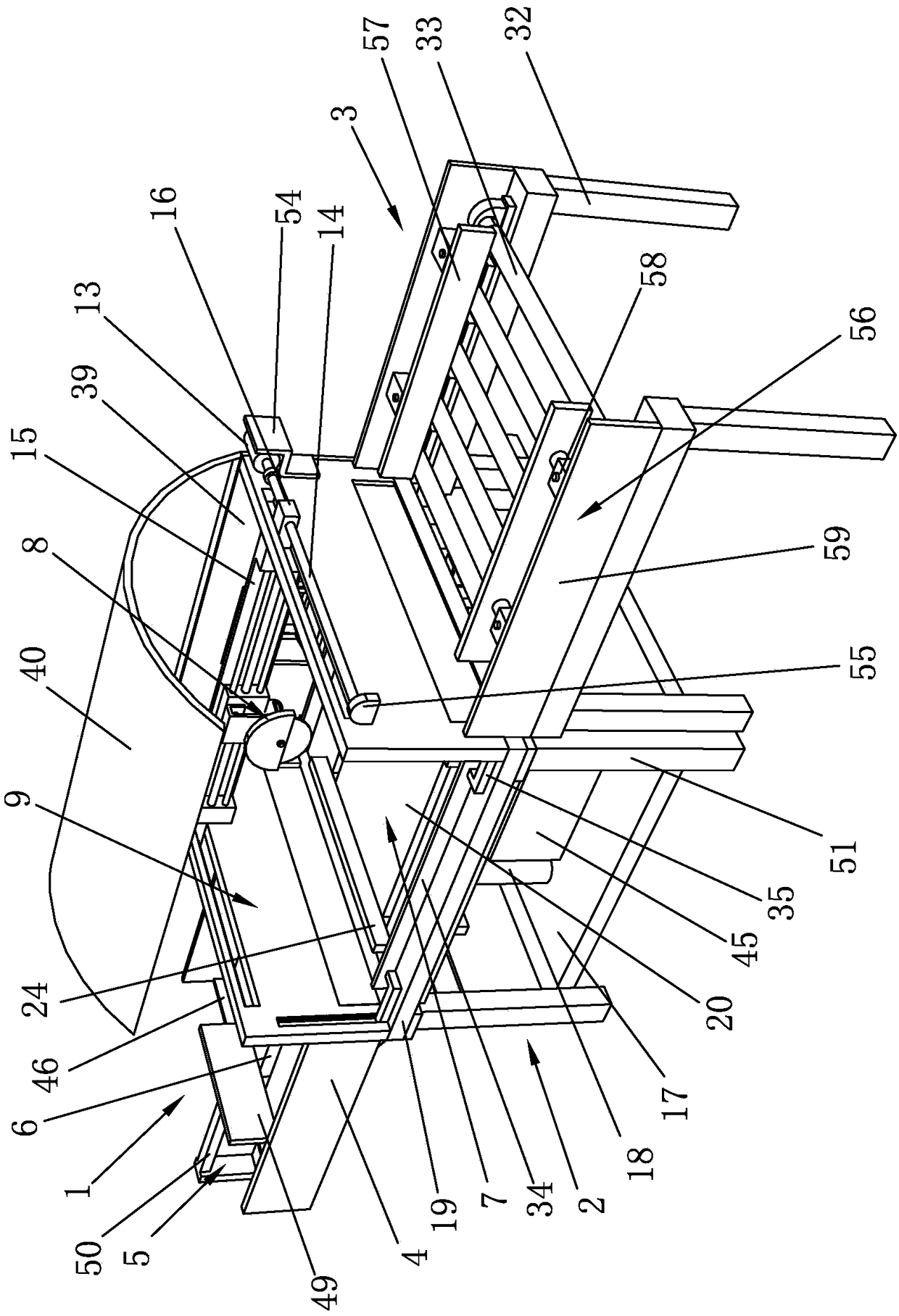

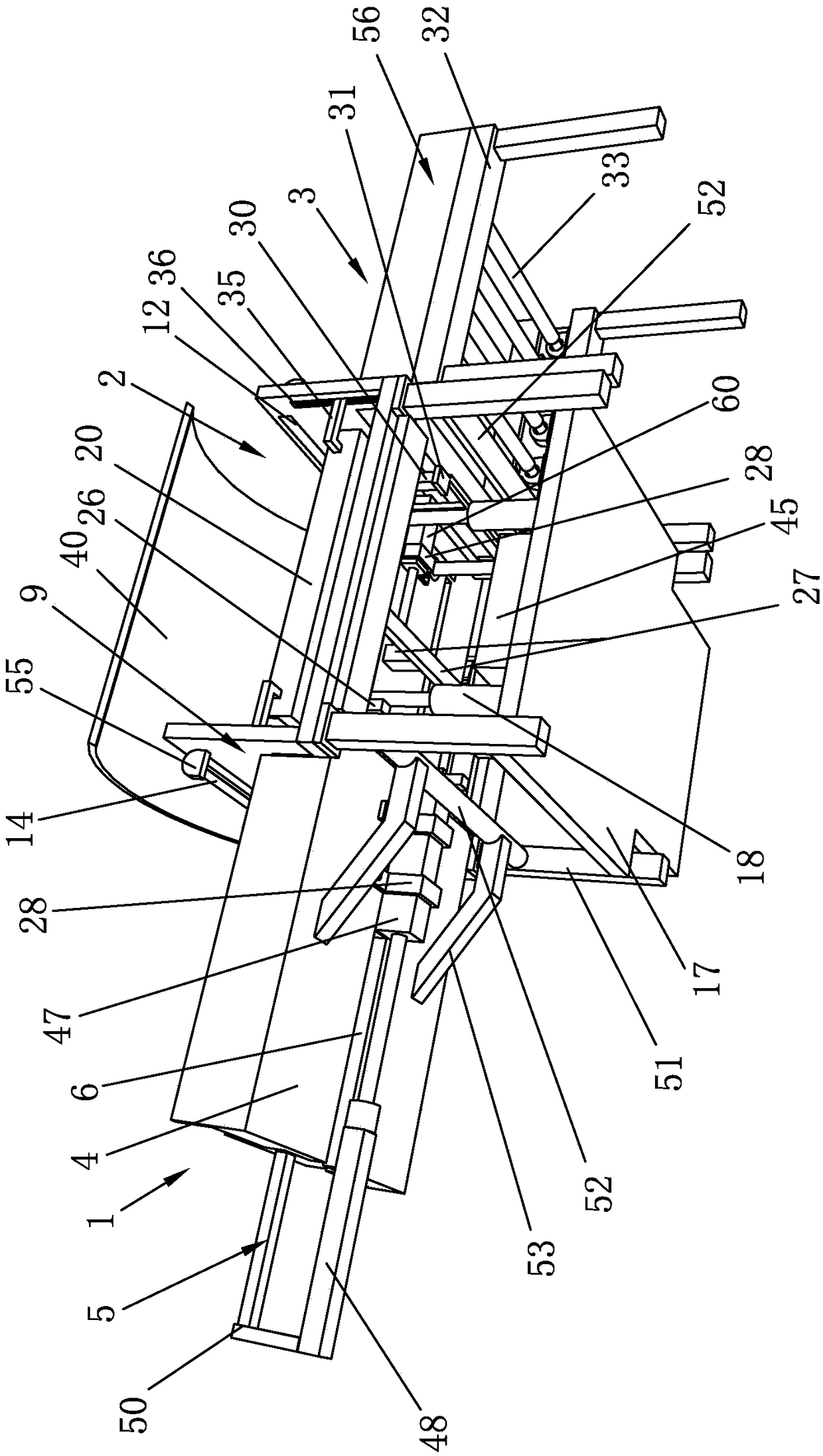

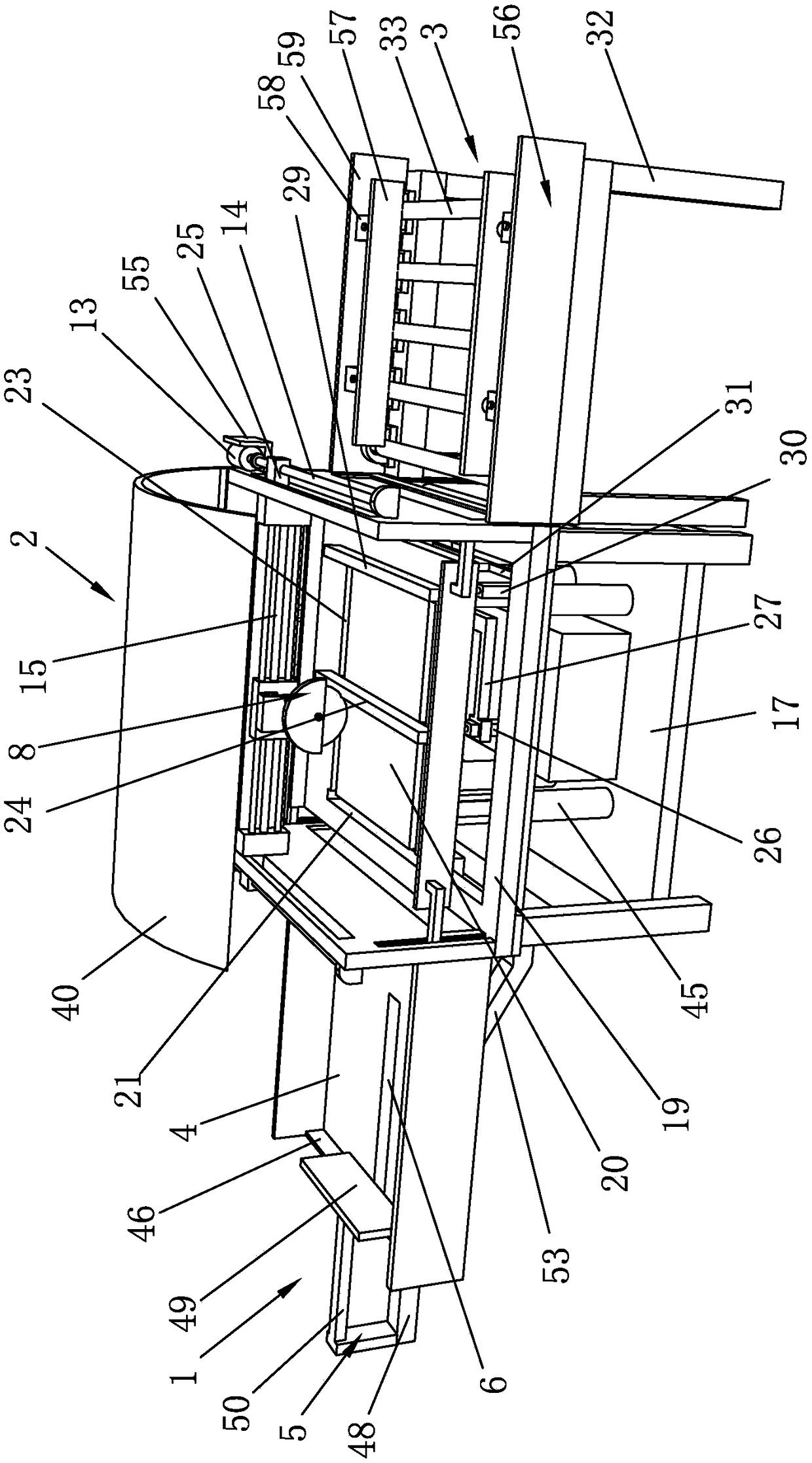

ActiveCN109227663APlay a limiting roleSwipe up and down smoothlyMetal working apparatusEngineeringOperation safety

The invention discloses a cutting device for mechanical automatic production of spare and accessory parts, which includes a feeding mechanism, a cutting mechanism and an unloading mechanism, wherein the feeding mechanism includes a feeding table and a pushing mechanism and the cutting mechanism includes a cutting table and a cutting head group. Gate components are arranged on both sides of the cutting table, a supporting plate is arranged under the cutting table, and lifter columns are evenly arranged between the supporting plate and the cutting table. The cutting table comprises a supportingbracket and a lifting table. A longitudinal chute and a transverse chute are arranged on the top face of lifting table. The longitudinal chute includes a left longitudinal chute and a right longitudinal chute, wherein a left spacing splint is arranged in the longitudinal chute and a right spacing splint is arranged in the right longitudinal chute, and the transverse chute is communicated with theleft longitudinal chute. The overall structure of the cutting device for mechanical automatic production of spare and accessory parts is ingenious and reasonable. The automatic operation is achieved by the design of the feeding mechanism and the unloading mechanism which can feed and unload workpieces automatically, thereby reducing the labor intensity and hidden safety hazard, improving the operation safety performance and the cutting speed.

Owner:柳州蒸达机械配件有限公司

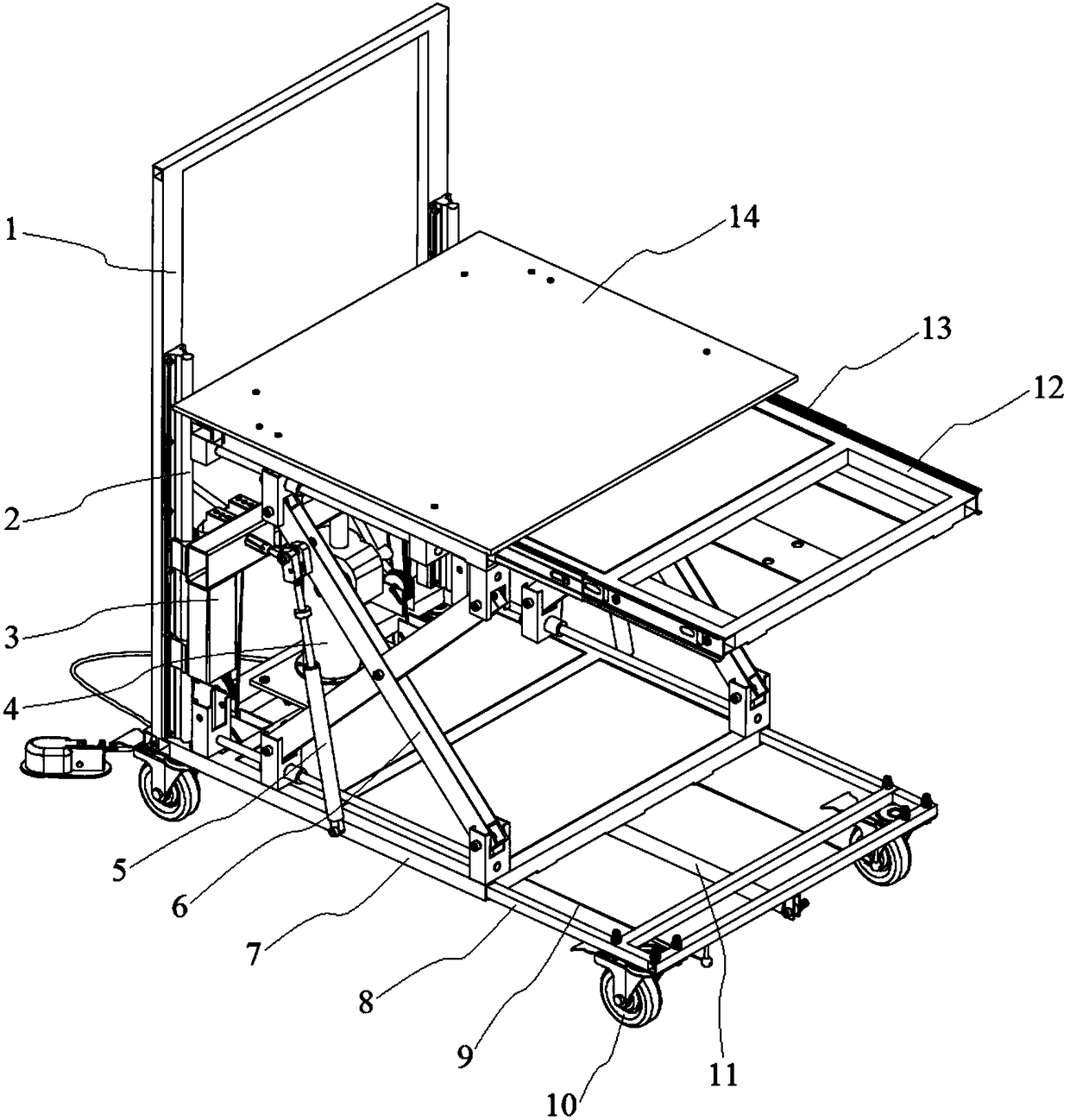

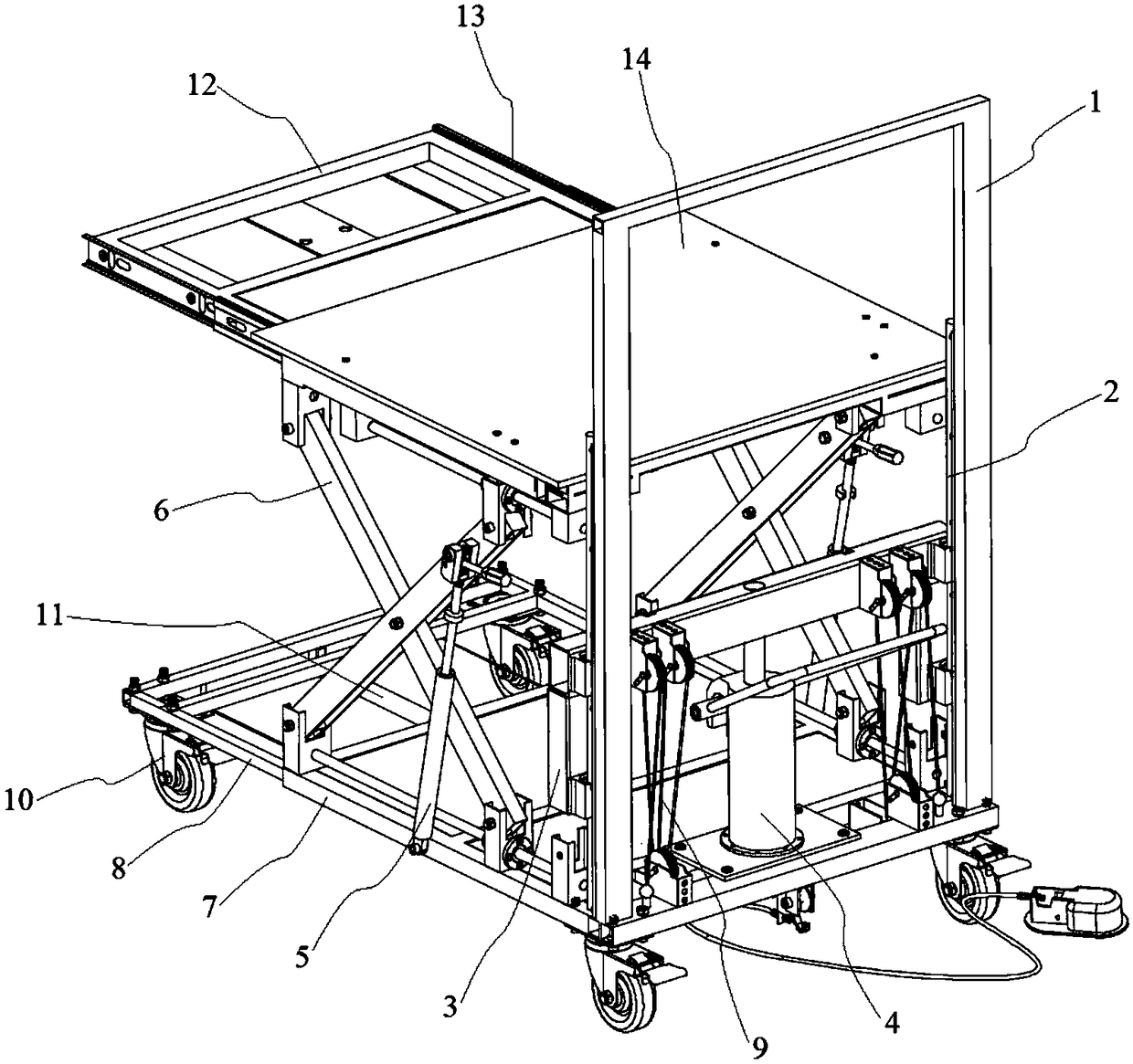

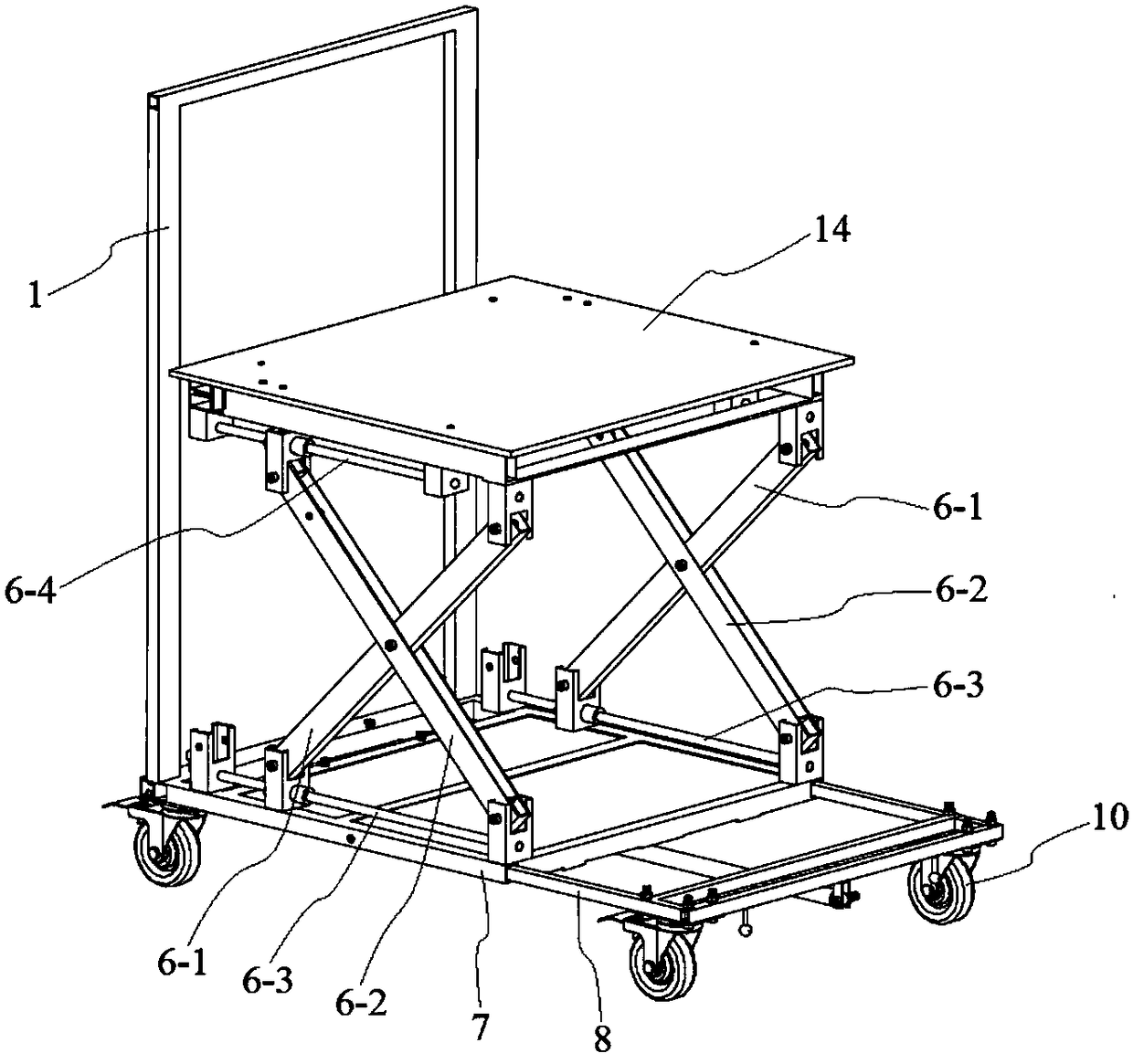

Multifunctional trolley with double-layer platform

ActiveCN108099980AIncrease loading capacityHarmonization of functionsLifting framesHand carts with multiple axesAir springEngineering

The invention discloses a multifunctional trolley with a double-layer platform, and belongs to the field of carrying tools. The trolley comprises an upper-layer platform body, a bottom-layer platformbody and a pushing hand, the pushing hand is fixed at the rear portion of the bottom-layer platform body, the upper-layer platform body is installed over the bottom-layer platform body through a scissor-type lifting mechanism, and the scissor-type lifting mechanism is further internally provided with an upper-layer locking air spring; the bottom-layer platform body comprises a bottom-layer platform fixing frame and a bottom-layer platform retractable frame which are retractably matched, the rear portion of the bottom-layer platform fixing frame and the front portion of the bottom-layer platform retractable frame are provided with rolling wheels, a bottom-layer retractable air spring for keeping the bottom-layer platform retractable frame elastically extending out is arranged between the bottom-layer platform fixing frame and the bottom-layer platform retractable frame, and the rear portion of the bottom-layer platform fixing frame is provided with a linkage mechanism for driving the bottom-layer platform retractable frame to retract back. By means of the trolley, the flexible use of the double-layer platform can be achieved; the loading capacity of the double-layer trolley is improved, and the trolley is flexible and convenient to use and easier to operate.

Owner:CHANGZHOU INST OF TECH

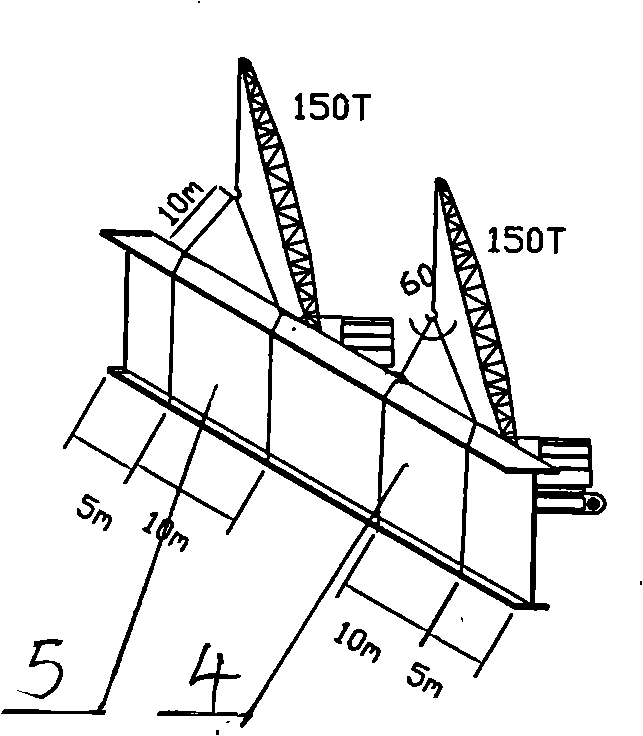

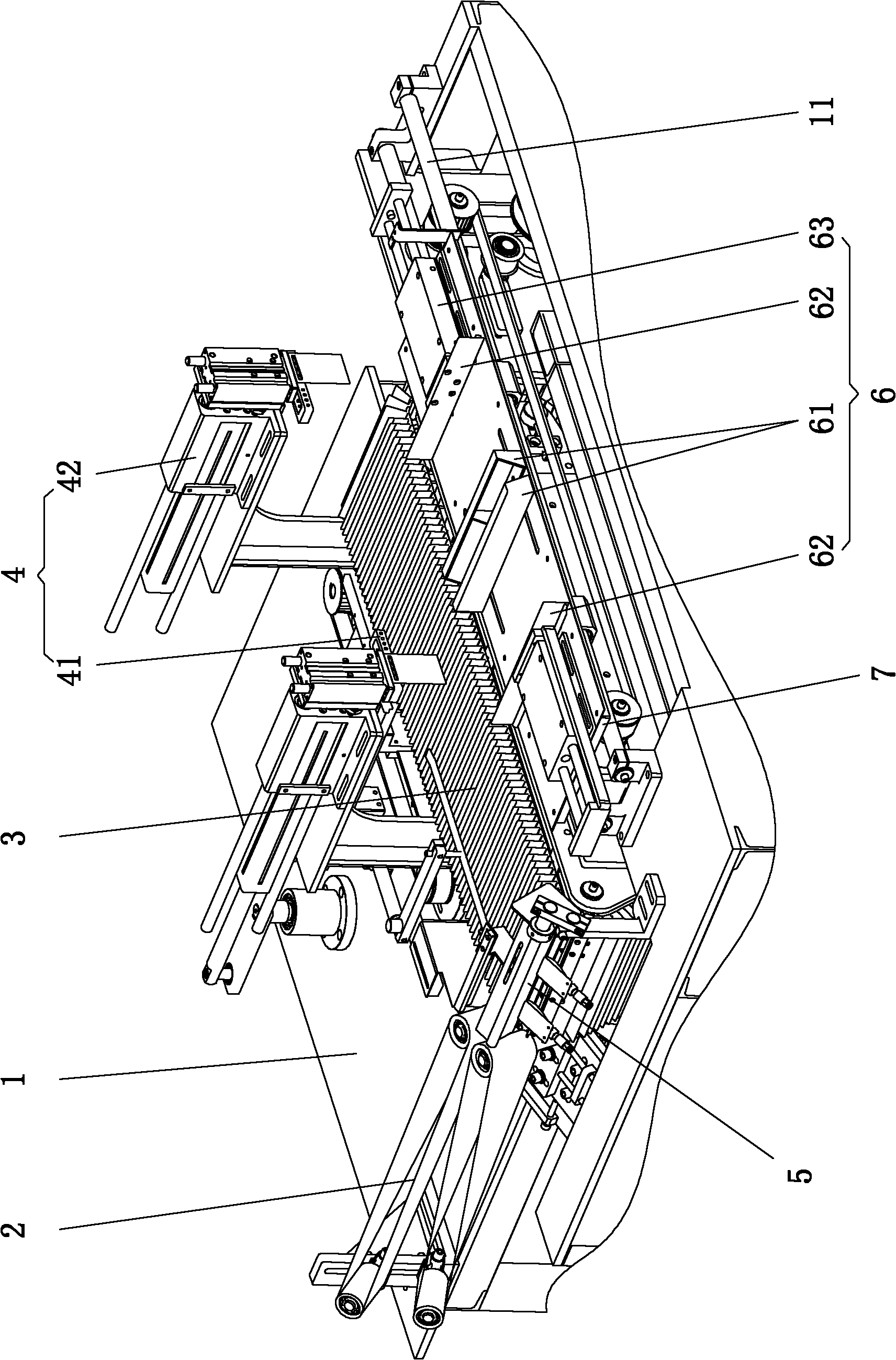

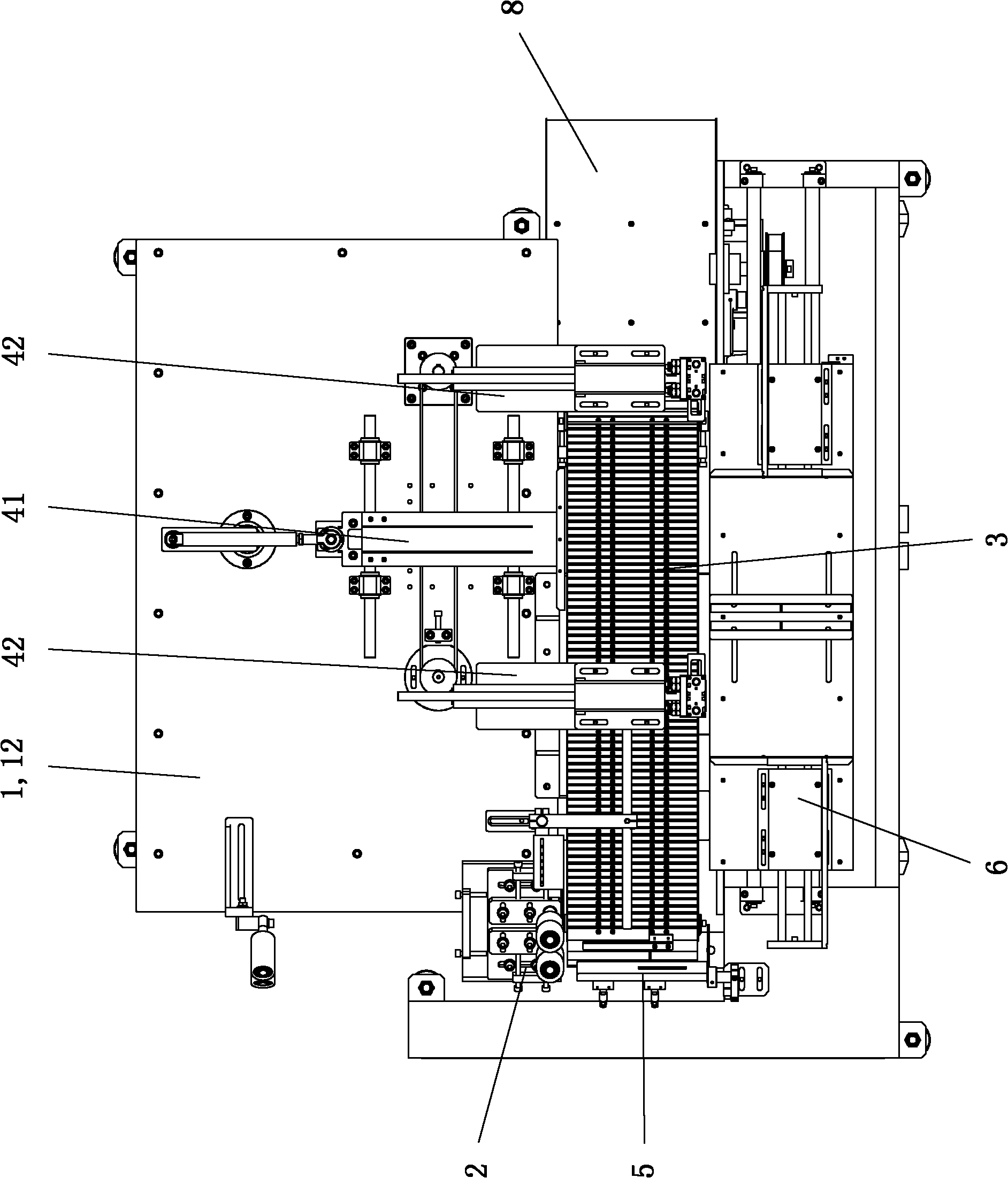

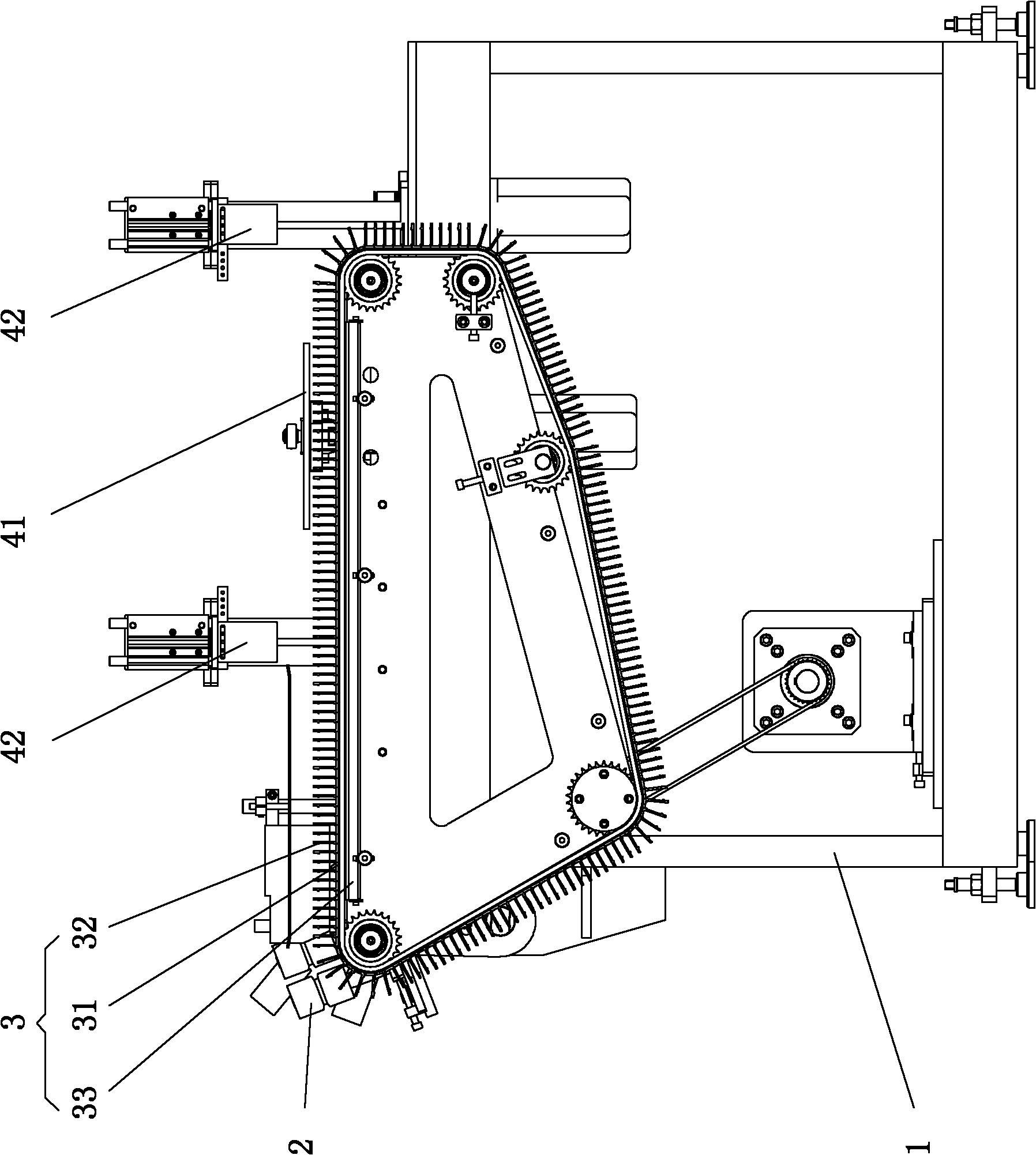

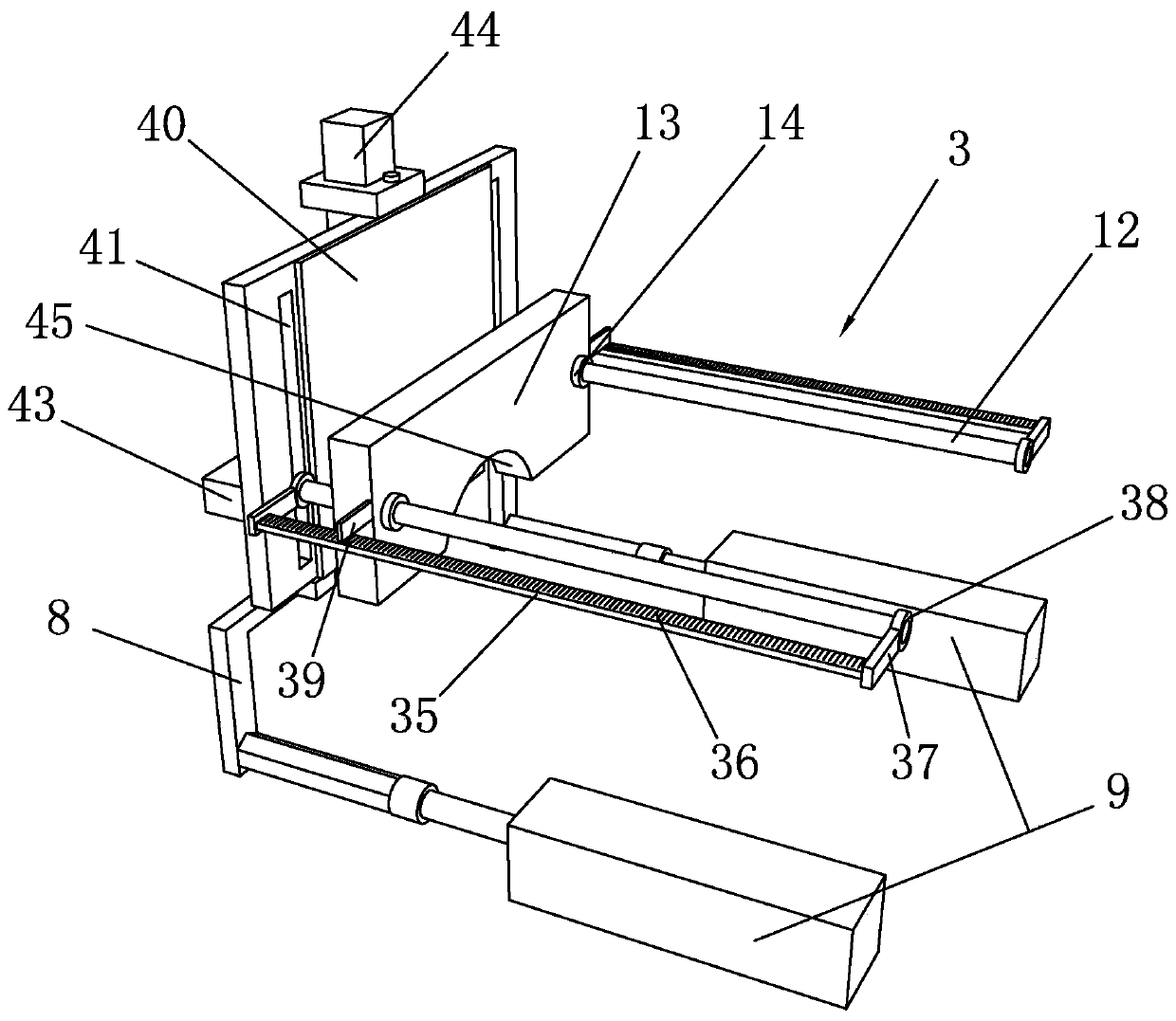

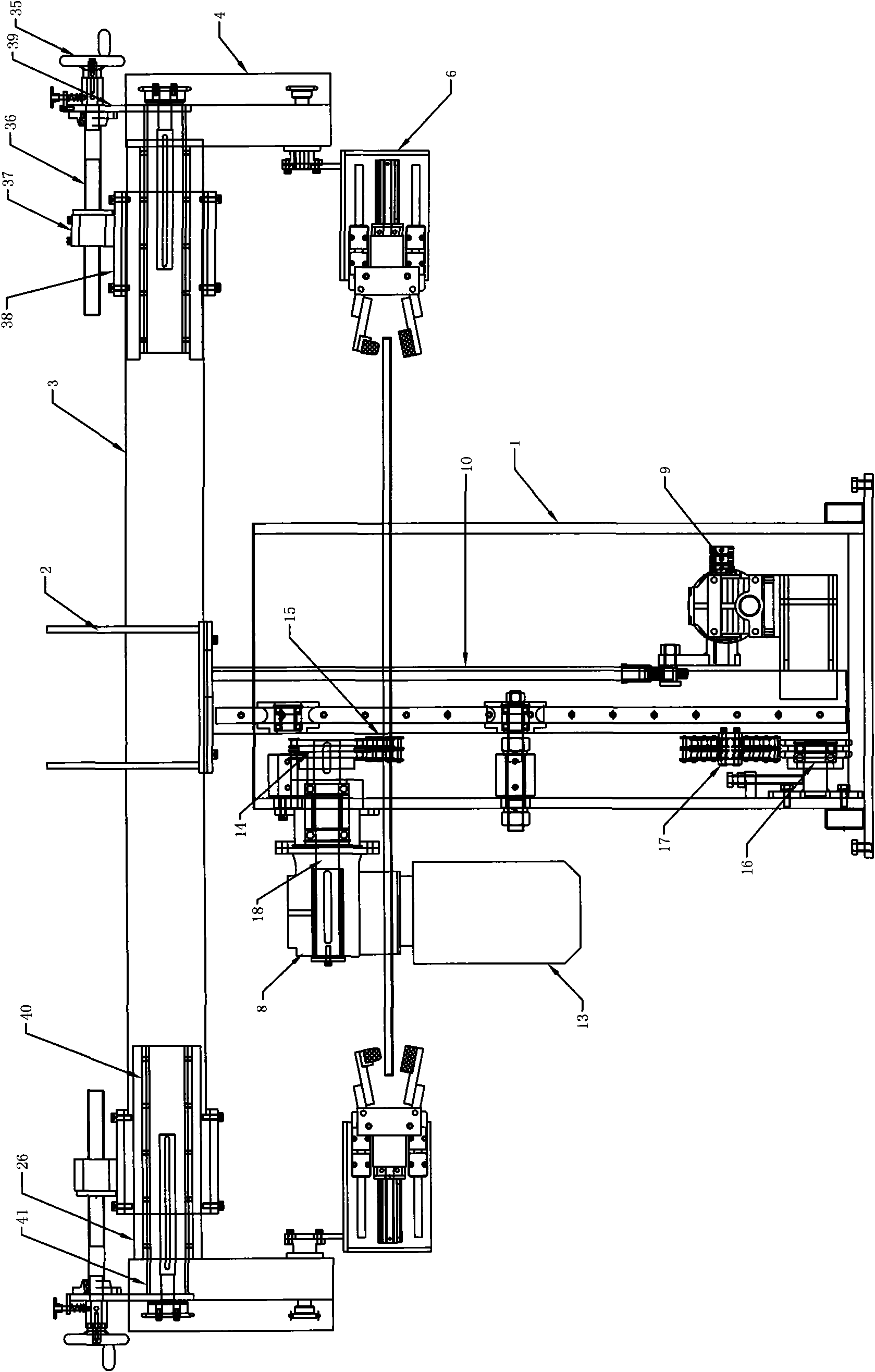

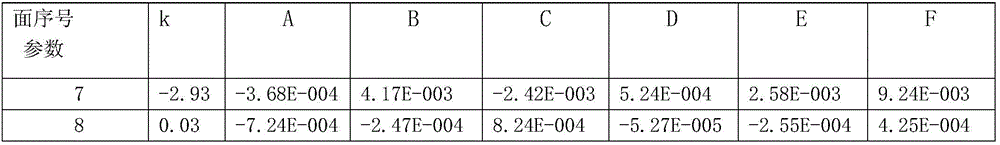

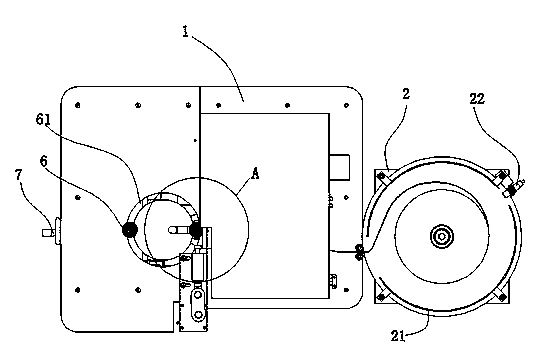

Thin straight-piece product stacking machine

ActiveCN103043253APrevent from causingPrevent upward movementPackagingStack machineIndustrial engineering

The invention relates to a thin straight-piece product stacking machine. The thin straight-piece product stacking machine is provided with a machine frame, a feeding mechanism arranged on the machine frame, a piece arranging mechanism and a pushing hand mechanism. A limiting mechanism is arranged at the position of the piece arranging mechanism corresponding to the feeding mechanism, and the pushing hand mechanism is arranged on one side of the piece arranging mechanism and is provided with a small package pushing hand and two bagging pushing hands symmetrically arranged on the left side and the right side of the small package pushing hand. Two compaction mechanisms are controllably slidably arranged at the position of the other side of the piece arranging mechanism corresponding to the pushing hand mechanism, the sliding direction of the two compaction mechanisms and the moving direction of the piece arranging mechanism are consistent, each compaction mechanism is provided with an adjustable fixed compaction plate and a slidable compaction plate, and the center distance between the small package pushing hand and each bagging pushing hand is matched with the distance between the two compaction mechanisms. The thin straight-piece product stacking machine can adapt to accurate piece arrangement and high-speed stacking of thin straight-piece products, works stably and is high in working efficiency and reasonable in design.

Owner:ANQING HENG CHANG MACHINERY

Suspension bridge steel wire rope damage patrolling robot

ActiveCN107175665AJudging the degree of damageEasy for daily maintenanceProgramme-controlled manipulatorMaterial magnetic variablesRemote controlEngineering

The invention discloses a suspension bridge steel wire rope damage patrolling robot. The suspension bridge steel wire rope damage patrolling robot comprises a base, a patrolling device arranged on the base and conducting patrolling on suspension bridge steel wire rope damage, and a control device controlling the patrolling device. The process for patrolling a steel wire rope includes the steps that firstly, the patrolling device is installed; secondly, the patrolling robot conducts patrolling on the suspension bridge steel wire rope; thirdly, after the robot finish patrolling, the robot returns to the initial end of the suspension bridge steel wire rope; fourthly, the first step, the second step and the third step are repeatedly conducted many times; and fifthly, damage state data are obtained. The suspension bridge steel wire rope damage patrolling robot is novel and reasonable in design, low in using cost, easy to operate, good in safety and capable of conveniently and rapidly finishing the suspension bridge steel wire rope damage patrolling operation; through the arrangement of the control device, a user remotely controls the patrolling robot to conduct high-altitude detection through a wireless remote control transmitter, and safety hidden danger of workers during high-altitude operation is avoided; and design is ingenious and reasonable, reliability and stability are achieved, the size is small, and practicability is high.

Owner:XIAN UNIV OF SCI & TECH

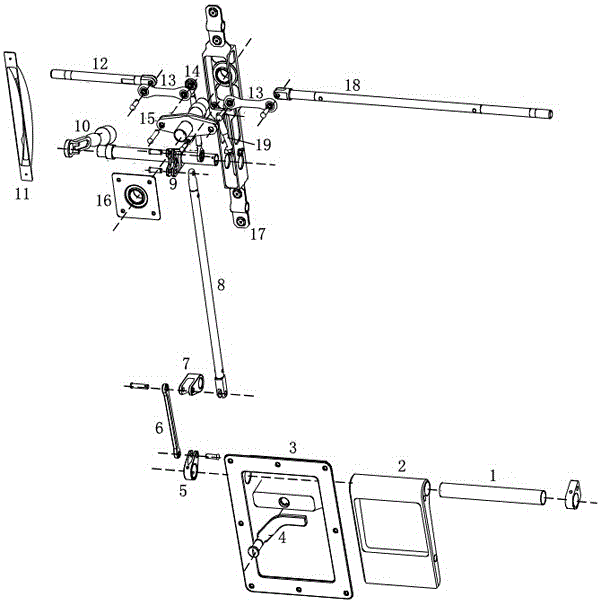

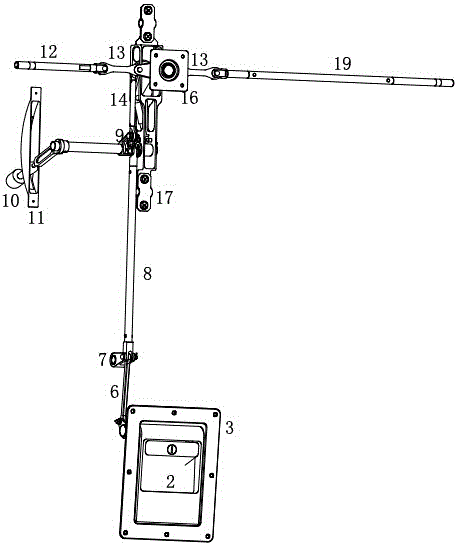

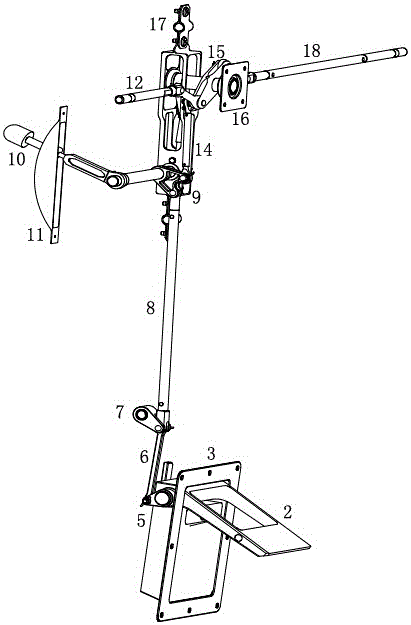

Intra-cabin and extra-cabin linkage type cabin door lock mechanism

The invention discloses an intra-cabin and extra-cabin linkage type cabin door lock mechanism. The intra-cabin and extra-cabin linkage type cabin door lock mechanism comprises an extra-cabin handle support and a lock swing arm base, wherein the extra-cabin handle support and the lock swing arm base are fixed to a cabin door. An extra-cabin handle is connected to the extra-cabin handle support and limited by an extra-cabin lock. A rotary shaft is hinged to the lower end of a connecting rod I through a rotary shaft swing arm. The connecting rod I is hinged to the lower end of a connecting rod II through a swing arm. The connecting rod II is fixedly hinged to an intra-cabin handle through an intra-cabin handle swing arm. The lower ends of connecting rods III are also hinged to the hinge point of the upper end of the connecting rod II and the intra-cabin handle swing arm. A left lock pin and a right lock pin are hinged to the two sides of the lock swing arm support through the two connecting rods III correspondingly. One end of a horizontal central shaft of the lock swing arm support is hinged to the lock swing arm base, and the other end of the horizontal central shaft of the lock swing arm support is hinged to a lock mechanism support and can rotate around the central shaft. According to the intra-cabin and extra-cabin linkage operation type cabin door lock mechanism, the cabin door lock mechanism is compact in structure, small in size and low in weight; the mechanism is ingenious and reasonable in design and high in transmission efficiency, and labor is saved in operation; and the dual-insurance design is adopted for the cabin door lock mechanism, operation is easy, and the reliability of the lock mechanism is guaranteed.

Owner:CHENGDU FULI WEIHANG TECH CO LTD

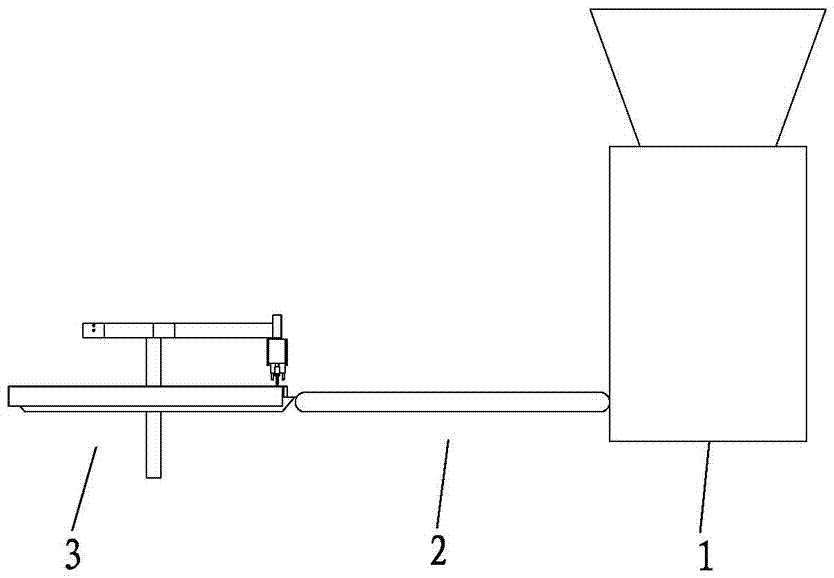

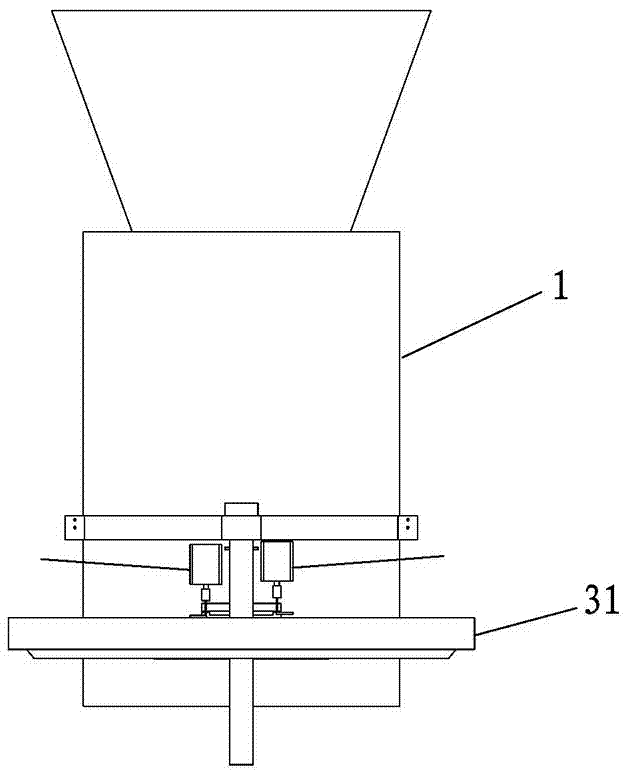

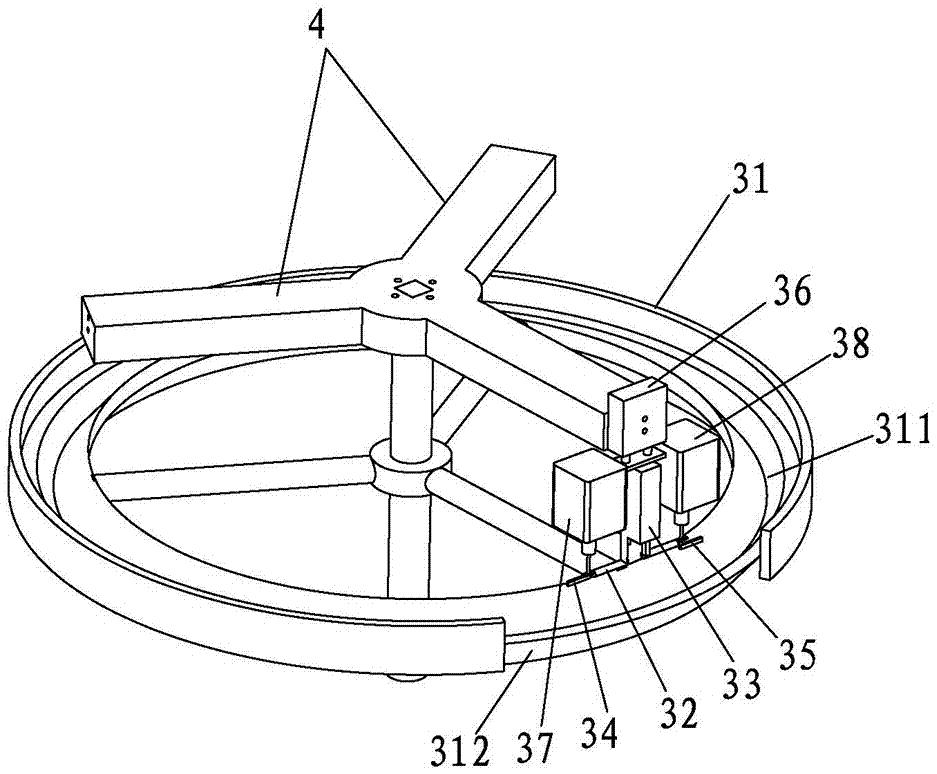

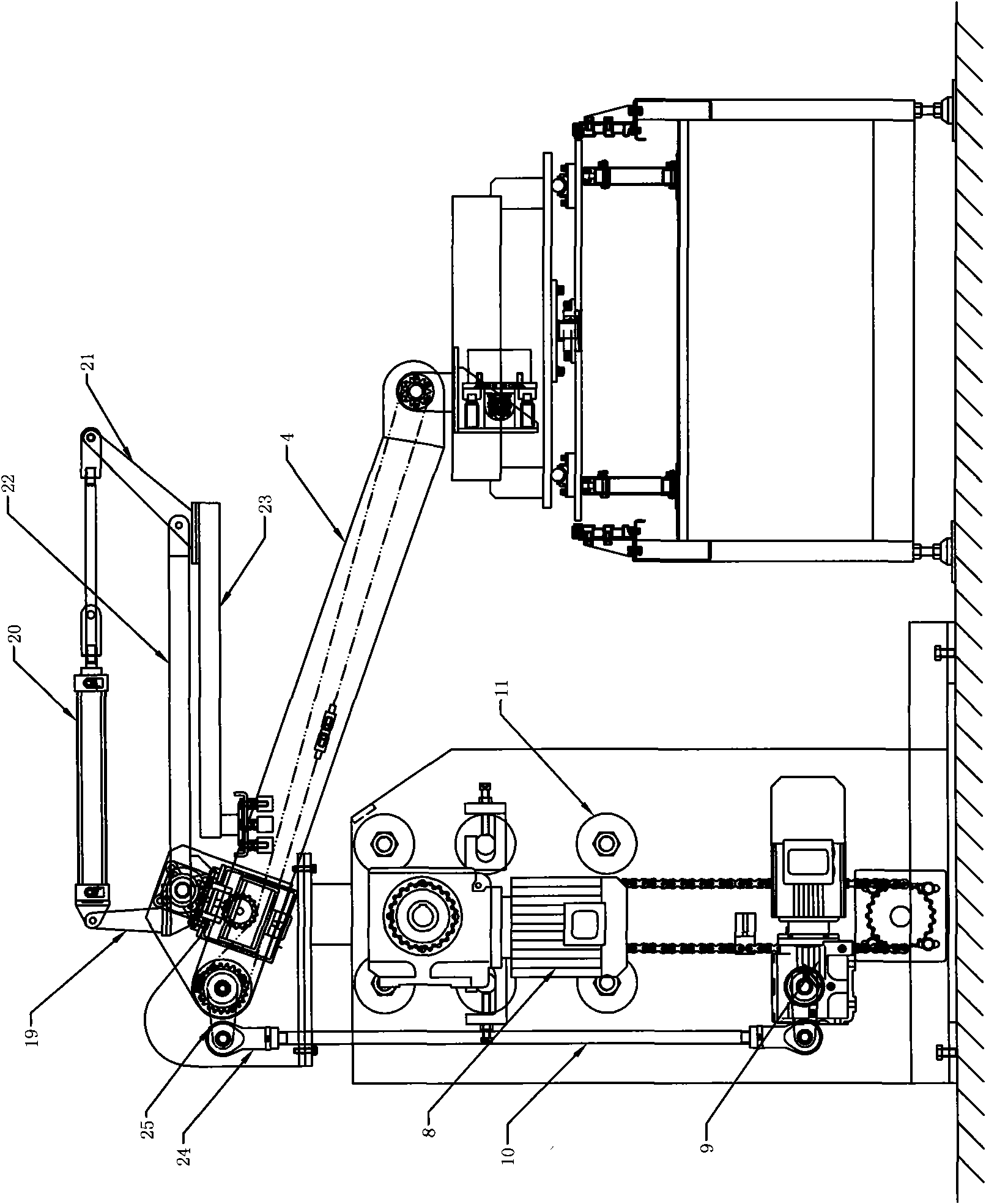

Full automation gold ingot shape Ravioli forming device and all-in-one machine

ActiveCN107047679ASimple structureIngenious and reasonable designDough processingMoulding deviceManufacturing line

The invention discloses a full automation gold ingot shape Ravioli forming device and all-in-one machine. The all-in-one machine comprises a raw material process unit, a transmission unit and a forming unit connected in sequence, the forming unit comprises a turntable and a forming mechanism; sunk grooves of middle sinking are arranged in the turntable; the forming mechanism is arranged above the sunk grooves, the forming mechanism comprises a mandrill, gas claws, a left swing rod and a right swing rod, the mandrill and the gas claws are located between the left swing rod and the right swing rod, the mandrill is connected with an elevating drive unit for driving the lifting of the drive unit, the left swing rod and the right swing rod are in horizontal extension and high-and-low arrangement, and are in connection with a rotating drive unit for leading the two to reverse swing towards the middle. The Ravioli forming device is simple in forming structure, wise and ingenious in design, the full automation molding of gold ingot shape Ravioli is achieved, the all-in-one machine adopts the line production mode, makes the gold ingot shape Ravioli to be produced fast and in batch, increases the production efficiency of ingot shape Ravioli, and significant saves labor and production cost.

Owner:XIAMEN UNIV OF TECH

Solar energy comprehensive utilizing system

InactiveCN1987288ASimple structureIngenious and reasonable designBatteries circuit arrangementsSolar heat devicesElectric energyHeating system

A comprehensive solar energy utilizing system is composed of thermoelectric cells, solar heat collecting tube, thermoelectric relay, heat accumulator set, safety valve, mixer, room heating regulator, auxiliary heater, electric accumulator set, bidirectional pump, switch, diode, power supply system, room heating system, and water supply system.

Owner:JIANGSU UNIV

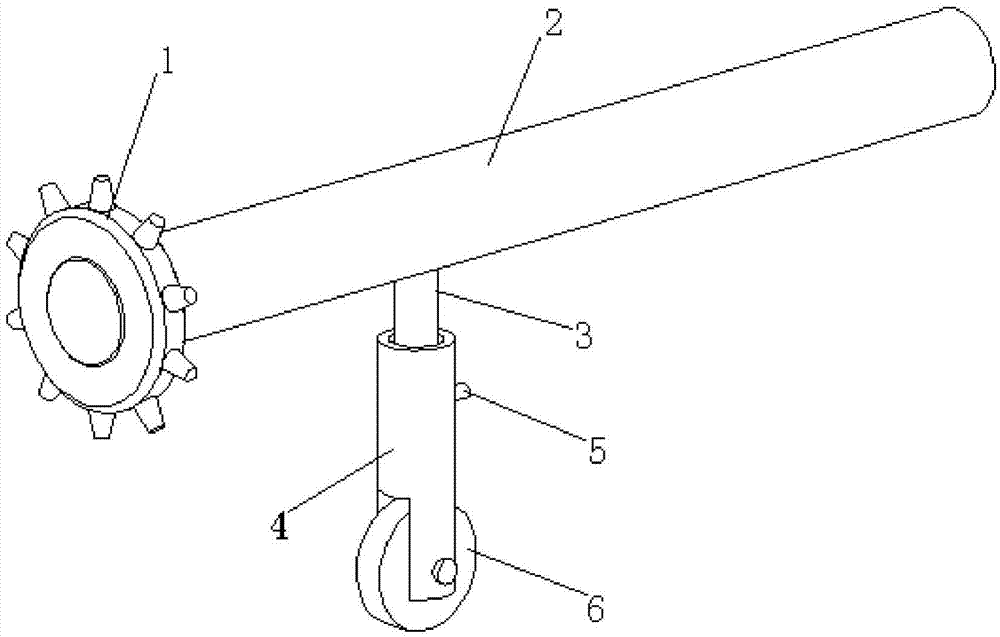

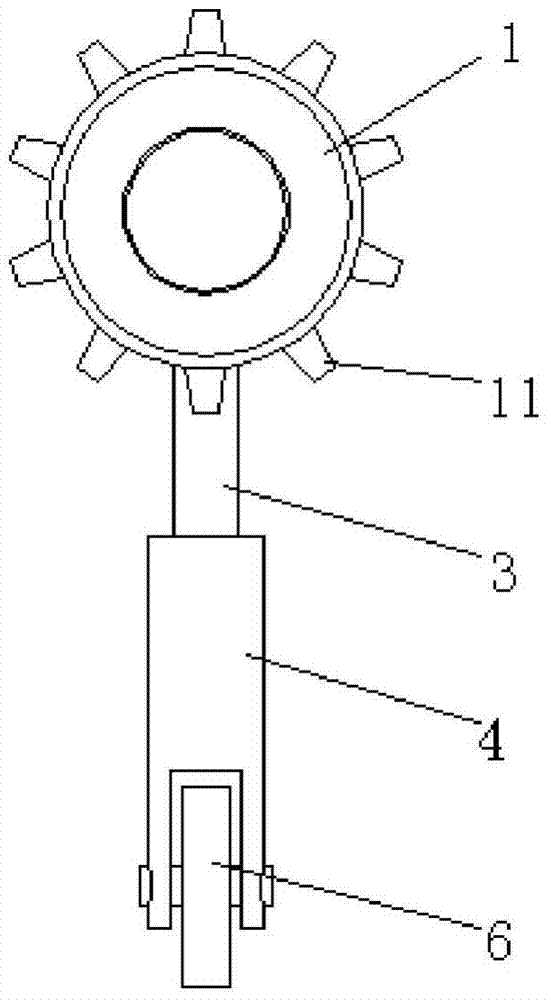

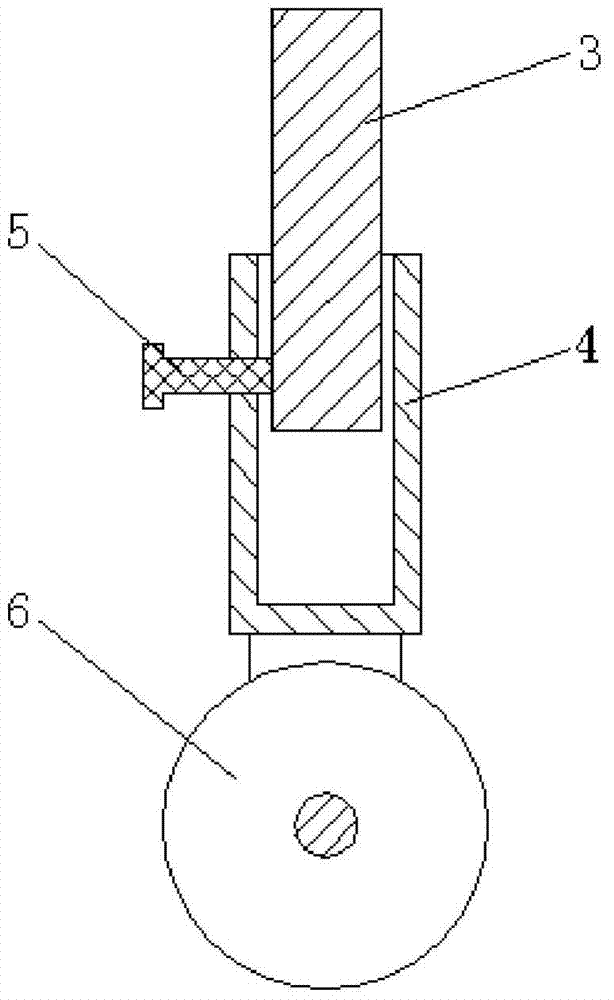

Height-adjustable pipe inner wall spraying equipment

InactiveCN104209214AImprove surface qualitySpray evenlySpraying apparatusEngineeringMechanical engineering

The invention discloses height-adjustable pipe inner wall spraying equipment and belongs to the field of spraying equipment. The height-adjustable pipe inner wall spraying equipment comprises a spraying head, a spraying pipe, a height adjusting device and a walking device, wherein the spraying head is mounted at one end of the spraying pipe and is communicated with the spraying pipe; the height adjusting device comprises a support rod, a connecting bushing and an adjusting screw; the connecting bushing is hollow inside and the side wall of the connecting bushing is provided with a thread hole; one end of the support rod extends into the connecting bushing; the adjusting screw extends into the connecting bushing via the thread hole for propping the support rod on the inner wall of the connecting bushing, and the other end of the support rod is fixedly connected to the part, near the spraying head, of the spraying pipe, and is perpendicular to the spraying pipe; the walking device is mounted at the bottom of the height adjusting device and can drive the spraying pipe to move in the axial direction of a pipe. The spraying equipment has the advantages of stable and reliable operation, good spraying effect, high efficiency and low cost and is suitable for inner walls of various small-diameter pipes, in particular for the inner walls of ultralong small-diameter pipes.

Owner:常州冯士节能环保科技有限公司

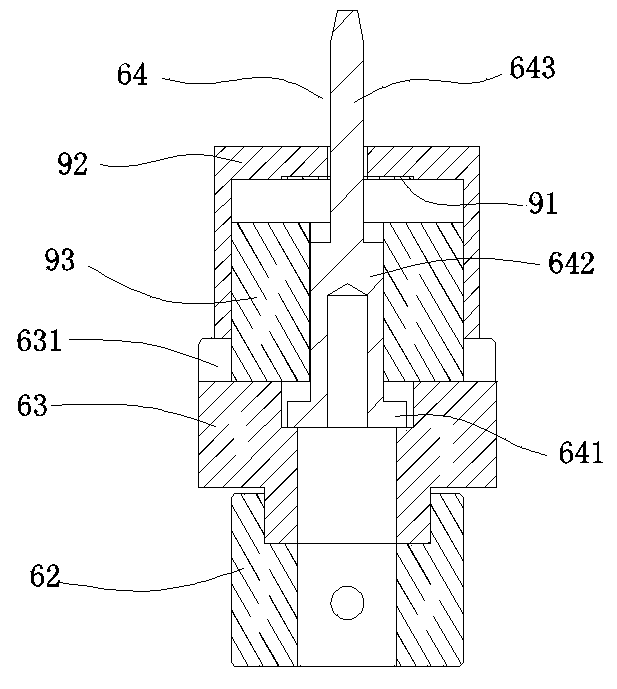

Explosion isolation type low-voltage explosion-proof power generator

ActiveCN101309036ACompact structureReduce axial sizeSynchronous generatorsMagnetic circuit rotating partsElectricityWave shape

The invention relates to an explosion-isolated low voltage explosion-proof generator which is characterized in that an AC exciter and a permanent magnet auxiliary exciter are arranged in the cavity of a generator base. The main generator is provide with a stator which is separately nested and connected with the generator base, and a rotator shaft which is connected with the generator base support through an end cover bearing. An inner cooling fan, a main generator rotator, an excitation generator, a rotating rectification component and the permanent magnet auxiliary exciter are respectively nested on the rotator main shaft of the main generator sequentially through a connection shaft sleeve, and rotate along with the rotator main shaft. Heat dissipation pipes are welded on the outer surface of the generator base and communicated with the inner cavity of the generator base. The generator not only has fine explosion isolating performance, good voltage wave of the generated electricity, but also has compact structure of the parts and smart design of the cooling system. The generator also has the ideal effect of small vibration, good heat dissipation, reasonable temperature rising, and safe and reliable electricity generating.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

Fixed-length cutting device for stainless steel tube

ActiveCN109719570ACompact and reasonable structure designEasy to useMeasurement/indication equipmentsFeeding apparatusEngineeringLength measurement

The invention discloses a fixed-length cutting device for a stainless steel tube. The fixed-length cutting device for a stainless steel tube comprises a cutting platform and a cutting head group, andfurther comprises a length determining assembly and a clamping assembly; the left side end of the cutting platform is provided with an opening groove, a cutting panel is arranged in the opening groove, and a material collecting box is arranged under the cutting panel; and the length determining assembly comprises a fixed side plate, positioning screws and a positioning pressing plate, the fixed side plate is located over the left end of the opening groove and fixedly connected with the top face of the cutting platform, the positioning screws are symmetrically arranged on the front side and theback side of the fixed side plate, and the two ends of the positioning pressing plates are arranged on the two positioning screws in a sleeving mode separately. According to the fixed-length cuttingdevice for the stainless steel tube, the structure is simple, the practicability is high, operation is easy, use is convenient, not only can the cutting rate and the cutting precision of the stainlesssteel tube be improved, but also the cutting length standard can be guaranteed every time only through one time of cutting length measurement, the manual labor intensity is effectively reduced, the error rate brought by each time of manual measurement is decreased, and resources and the cost are saved.

Owner:ANHUI KINGWE PIPE IND

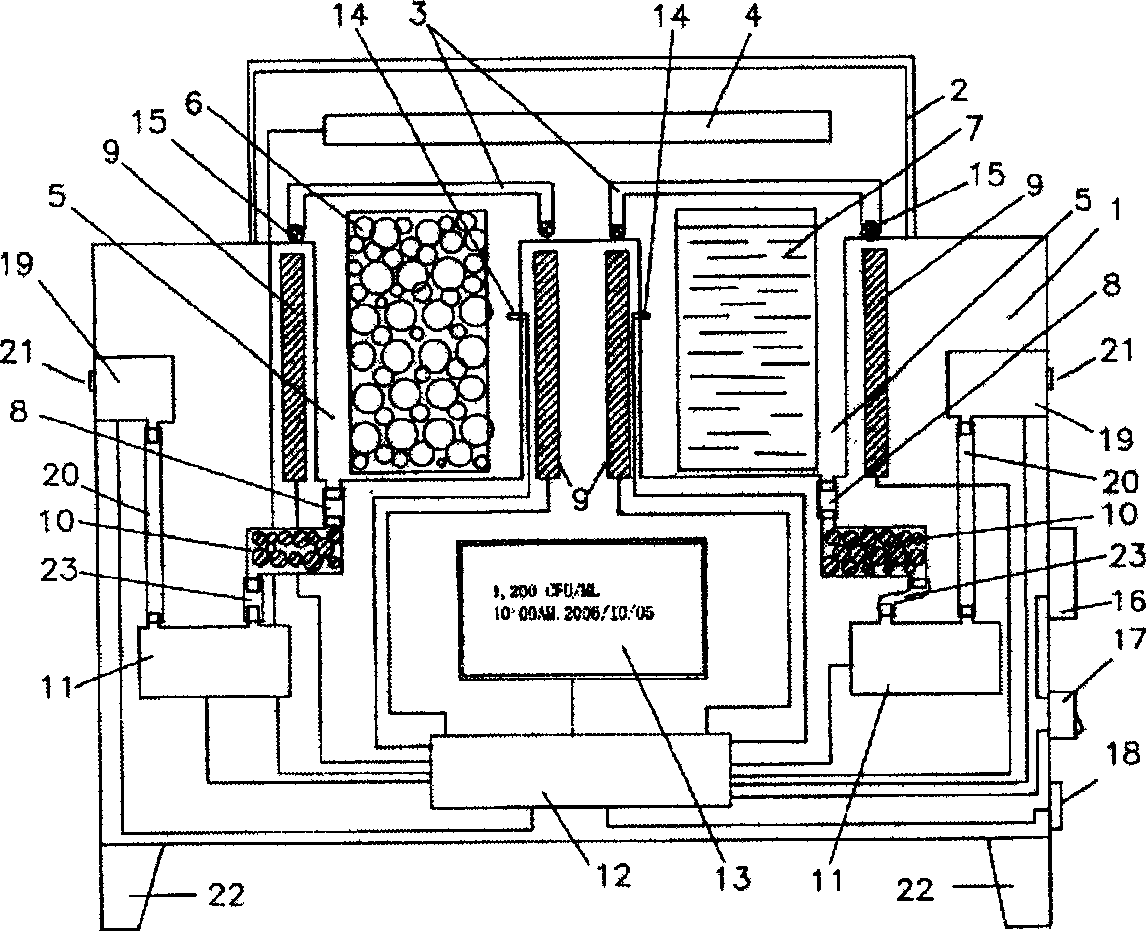

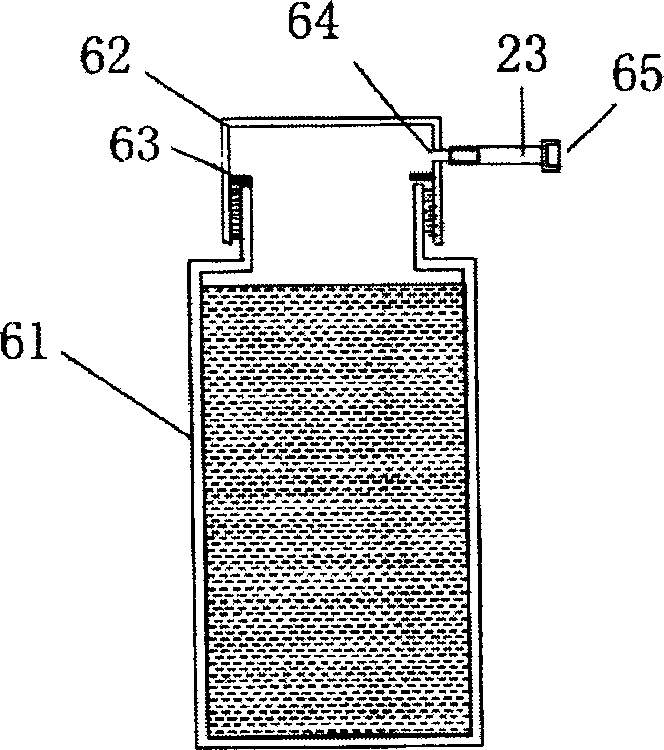

Fast detection method and instrument for microbe content in food

InactiveCN1847405AShort detection timeChange concentrationMicrobiological testing/measurementTesting foodCarbon dioxideFood sample

The fast detection method and instrument for microbe content in food has two parallel sample detecting systems adopted, including one for food sample detection and the other for detecting contrast. These two systems are in the same environment conditions and heated with the same heating element, the CO2 these two systems generate is detected separately in two identical CO2 detecting devices, and the detected data are analyzed and processed to obtain the detection result. The present invention has short detection period, simple structure, low cost and other advantages, and is suitable for fast site detection.

Owner:何宗彦

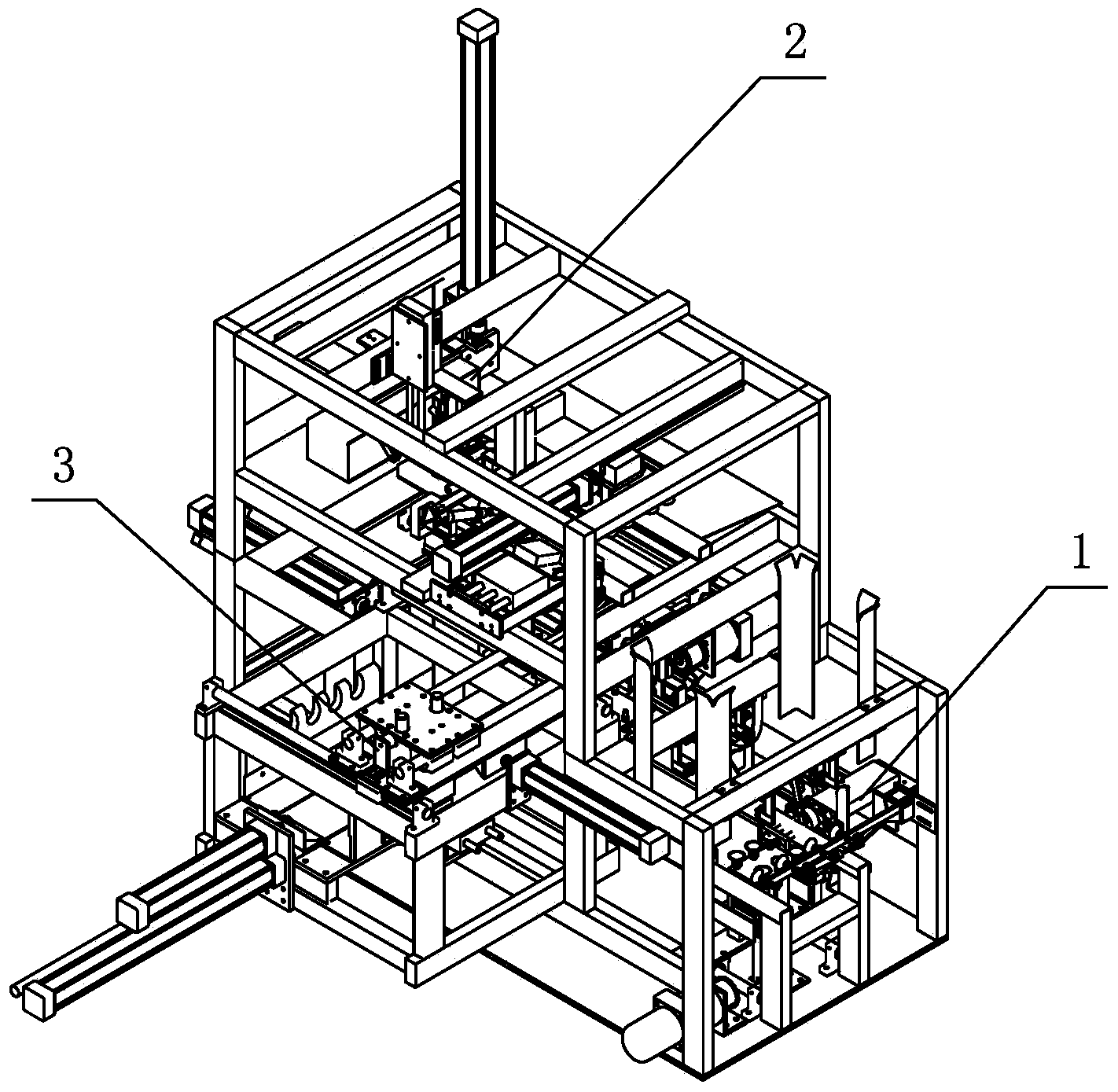

Automatic boxing machine

ActiveCN103448933AReasonable and ingenious combinationEasy to fillIndividual articlesEngineeringMechanical engineering

The invention relates to an automatic boxing machine, belongs to the field of automatic packaging equipment and mainly aims at cylindrical folding boxes of mouth-locking-type, mortise-lock-type and the like. The automatic boxing machine comprises a lower-layer box buckling device, an upper-layer box buckling device, a conveying device and an automatic boxing device, the automatic boxing device is arranged on one side of the tail of the lower-layer box buckling device, the upper-layer box buckling device is arranged above the lower-layer box buckling device, and the conveying device is connected with the lower-layer box buckling device and the upper-layer box buckling device respectively. By the automatic boxing machine, automatic box sealing of the cylindrical folding boxes of mouth-locking-type can be realized, and full automatization of boxing and box sealing can be realized; the automatic boxing machine is reliable in working process and high in working efficiency.

Owner:淄博荣琦自动化科技有限公司

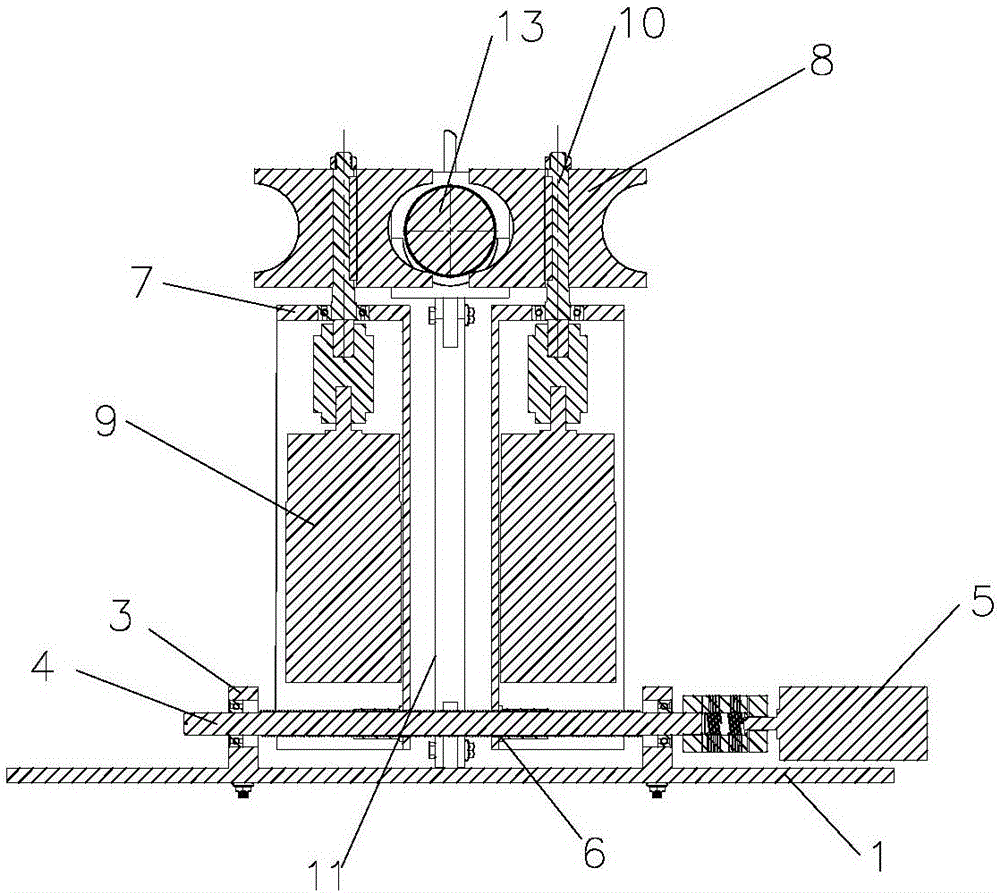

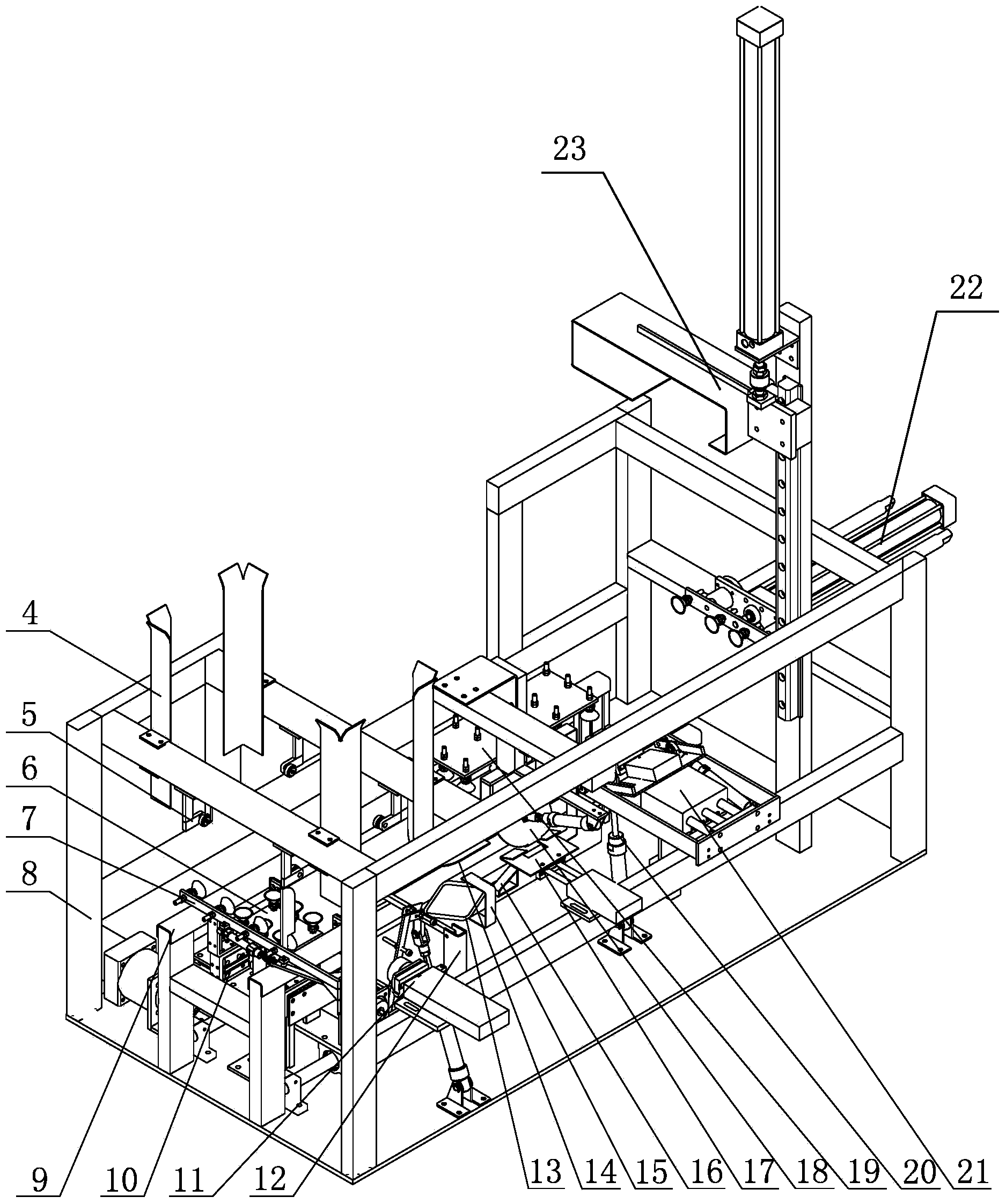

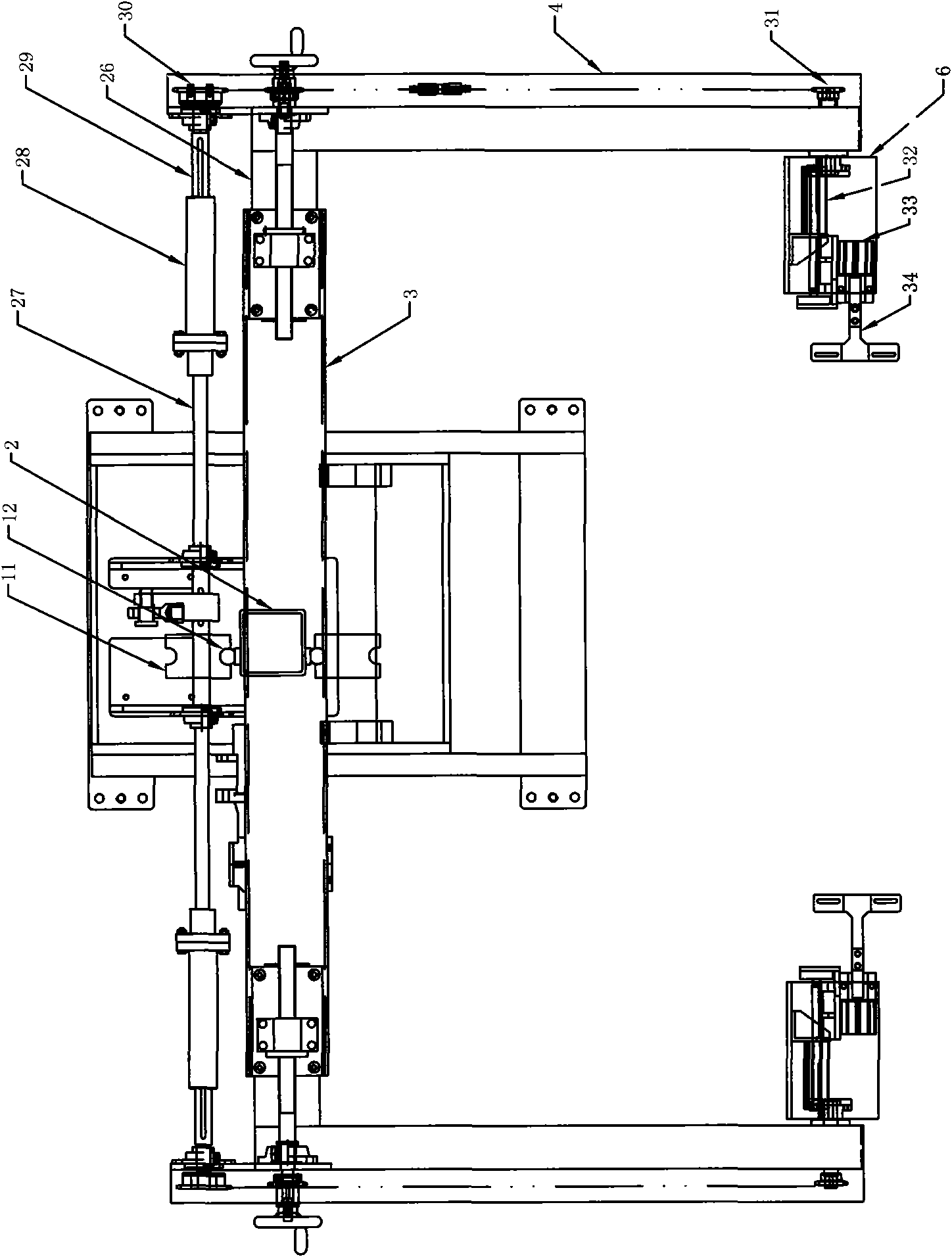

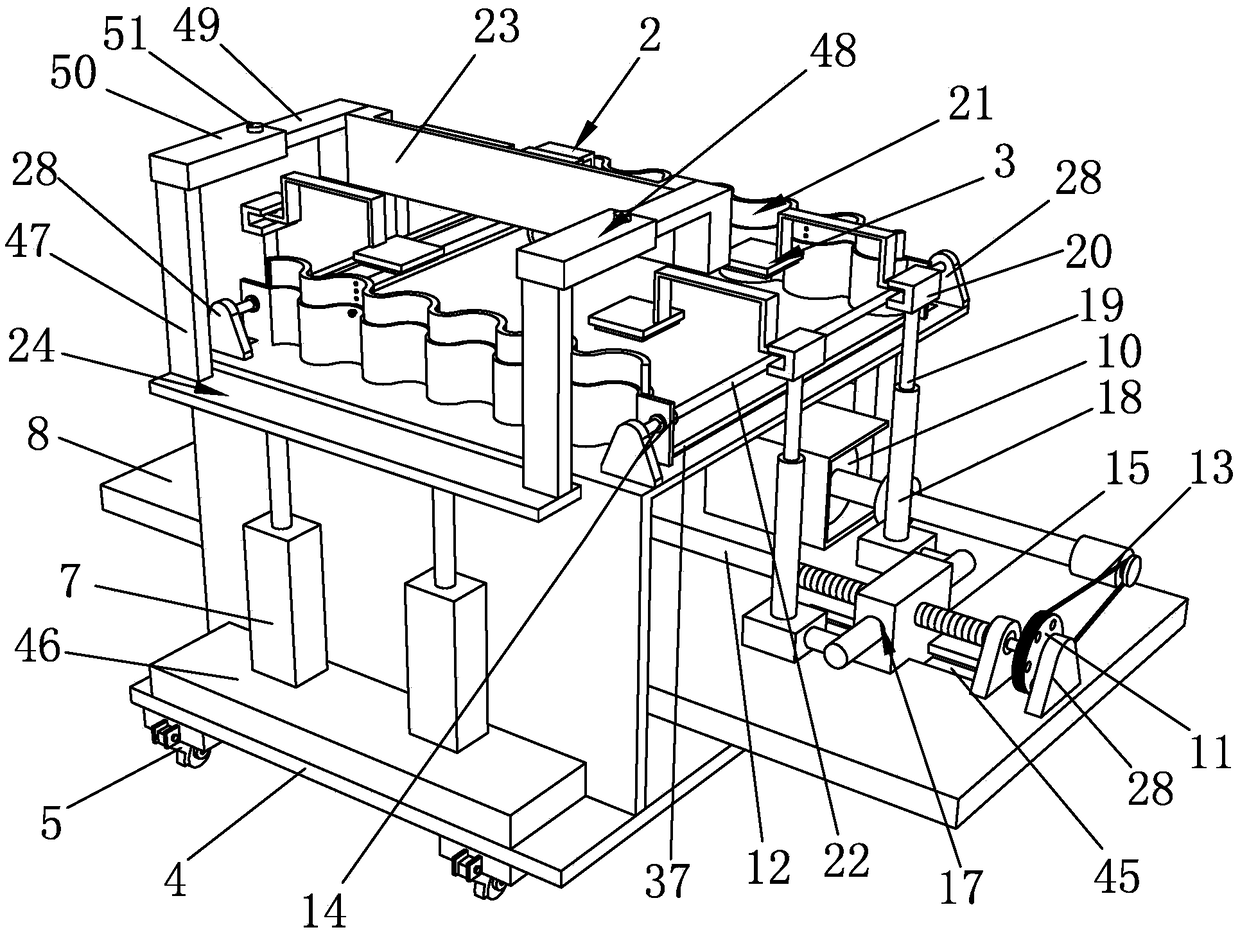

Double-cutter head assembly mechanical hand of four-wheeled grass cutter

ActiveCN101890709APneumatic implementationFully automatedGripping headsAssembly machinesElectric controlManipulator

The invention relates to a double-cutter head assembly mechanical hand of a four-wheeled grass cutter, which comprises a base, lifting columns, a movable arm and a driving device, wherein the movable arm comprises a beam, mechanical arms, clamping and turning mechanisms and a pressing device; the pressing device is arranged at the top ends of the lifting columns; the mechanical arms are arranged at the two ends of the beam; the beam is arranged at the top ends of the lifting columns and is positioned below the pressing device; the driving device comprises a lifting driving device and a rotation driving device; the lifting driving device is arranged at the bottoms of the lifting columns; the rotation driving device is arranged in a base frame and is connected with the pressing device and the beam through a pull rod; and the clamping and turning mechanisms which clamp parts to be assembled are arranged at the front ends of the mechanical arms. In the scheme, the taking and putting of cutter heads from a conveyor line, and the turning of the cutter heads are completely automatically controlled by the mechanical hand, the actions of clamping, lifting, turning, backing-pressure and the like are realized by the combination of pneumatic driving and motor driving, and the complete automation is realized by the effective combination of mechanical control, pneumatic control and electric control.

Owner:怡锋工业设备(深圳)有限公司

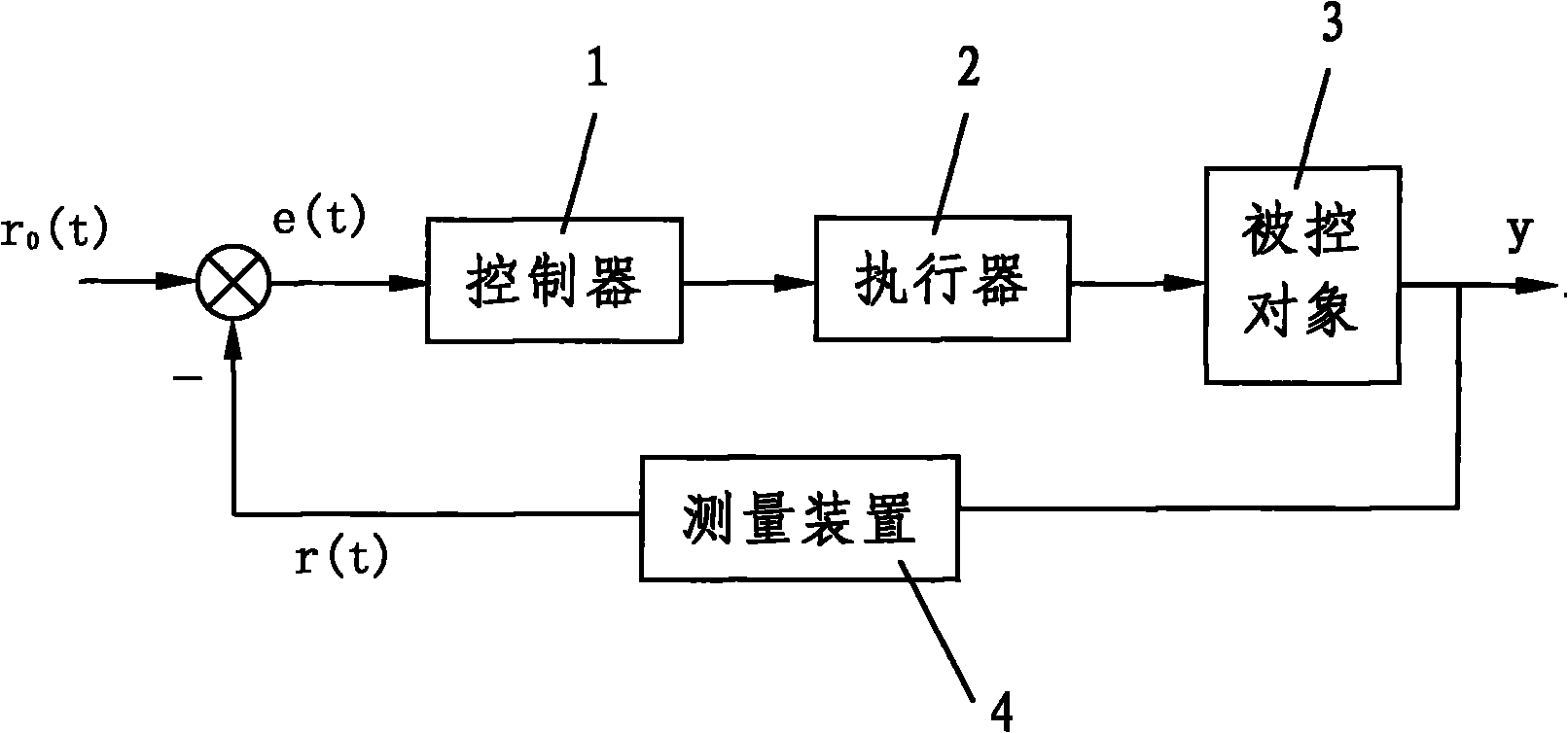

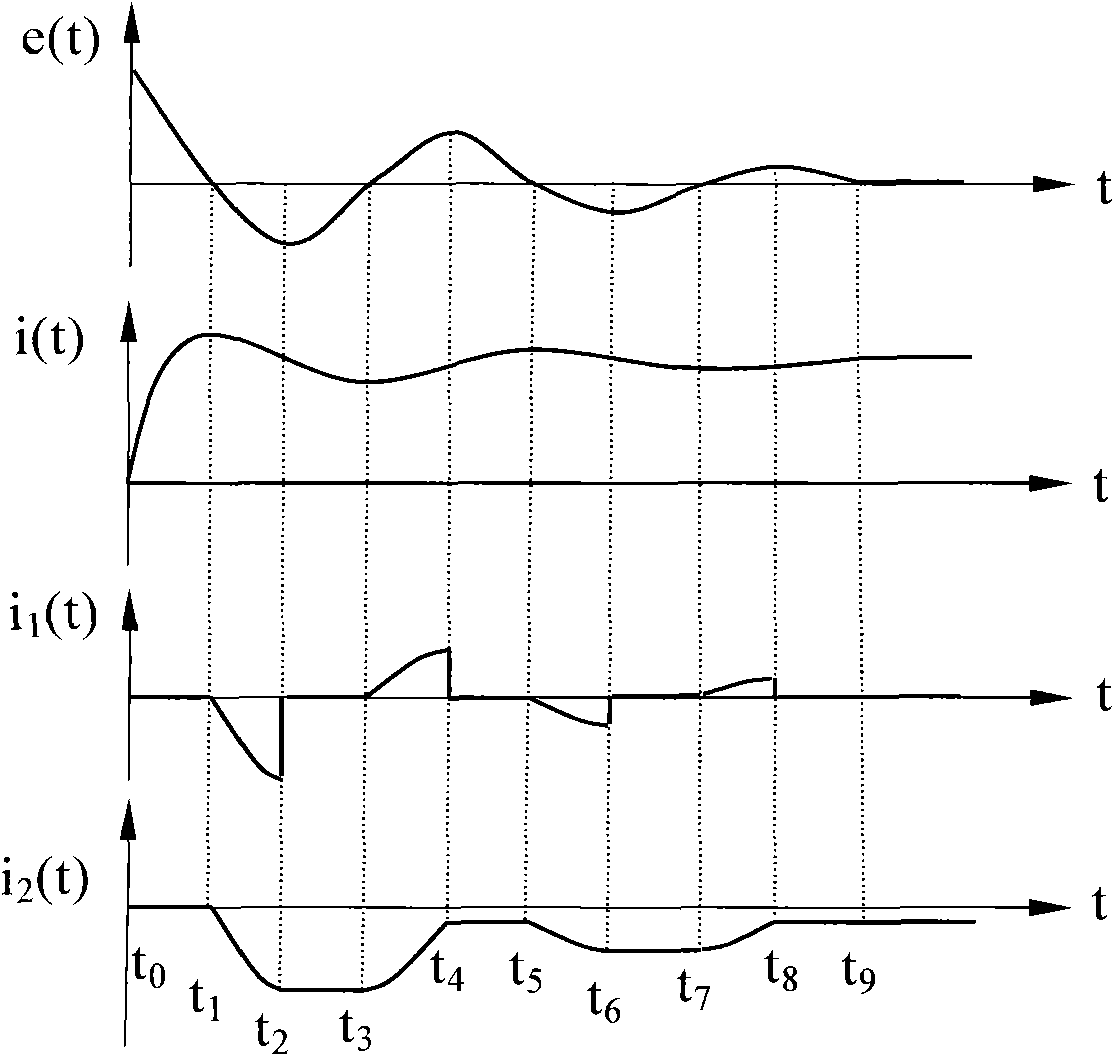

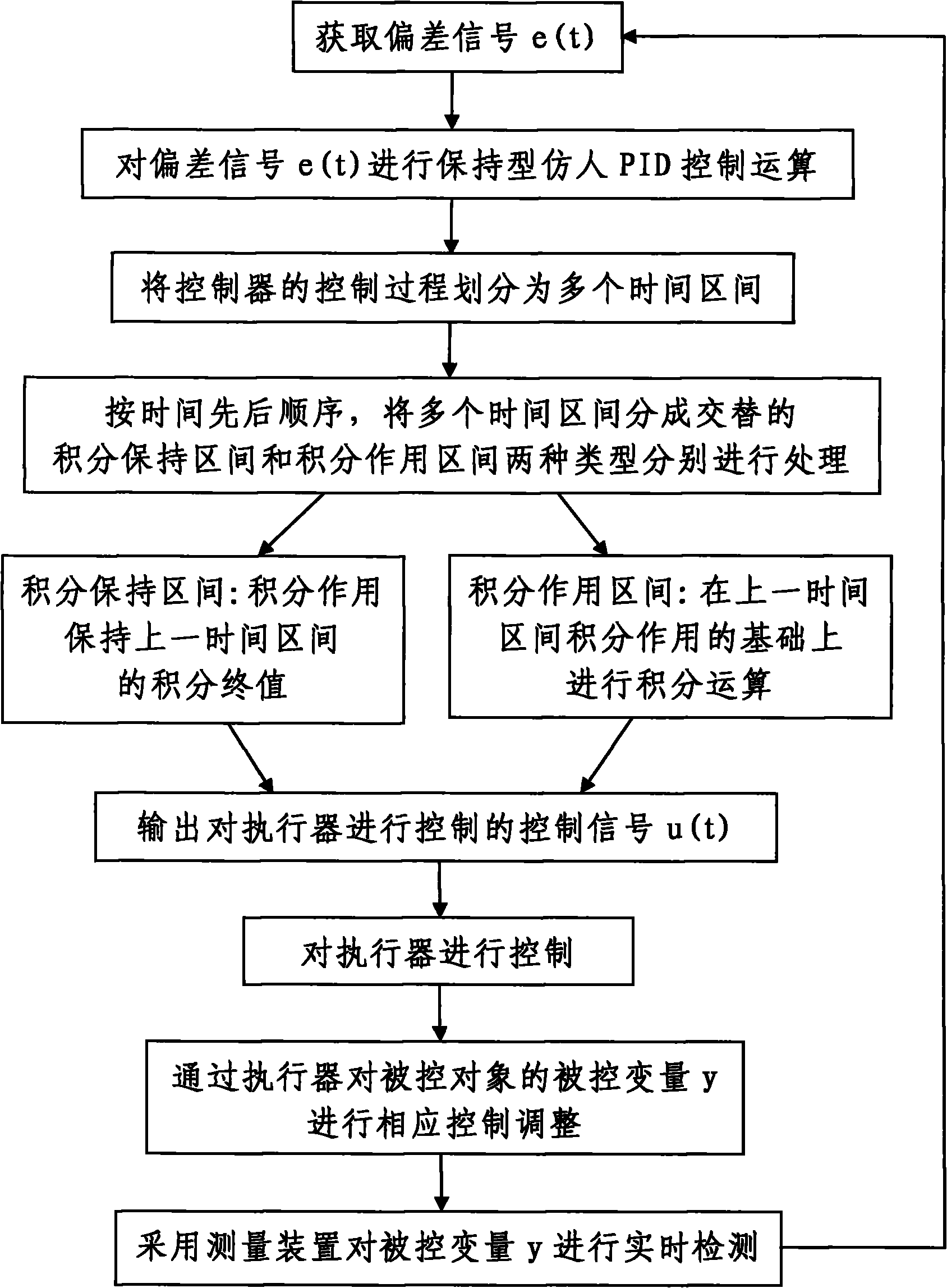

System control method based on maintenance type human-simulating PID

InactiveCN101859097AIngenious and reasonable designSimple and efficient operationControllers with particular characteristicsControl variableMeasurement device

The invention discloses a system control method based on a maintenance type human-simulating PID, which comprises the following steps: 1, acquiring an error signal; 2, carrying out maintenance type human-simulating PID control calculation for the error signal: dividing the control process of a controller into a plurality of time intervals, classifying the time intervals into integral maintenance intervals and integral action intervals for processing according to a chronological sequence, wherein the integral action maintains the final integral value of a previous time interval in the integral maintenance intervals, and the integral operation is carried out based on the integral action of the previous time interval in the integral action intervals; and outputting a control signal to control an actuator; and 3, controlling the actuator, making adjustment through the actuator according to the controlled variable of a controlled object, and promptly detecting the controlled variable with a measuring device. The invention has the advantages of reasonable design, delicate concept, convenient realization, wide scope of application and good control effect, and the control system adopting the maintenance type human-simulating PID control method has the advantages of short control period, small overshoot and high anti-interference capability.

Owner:XIAN UNIV OF SCI & TECH

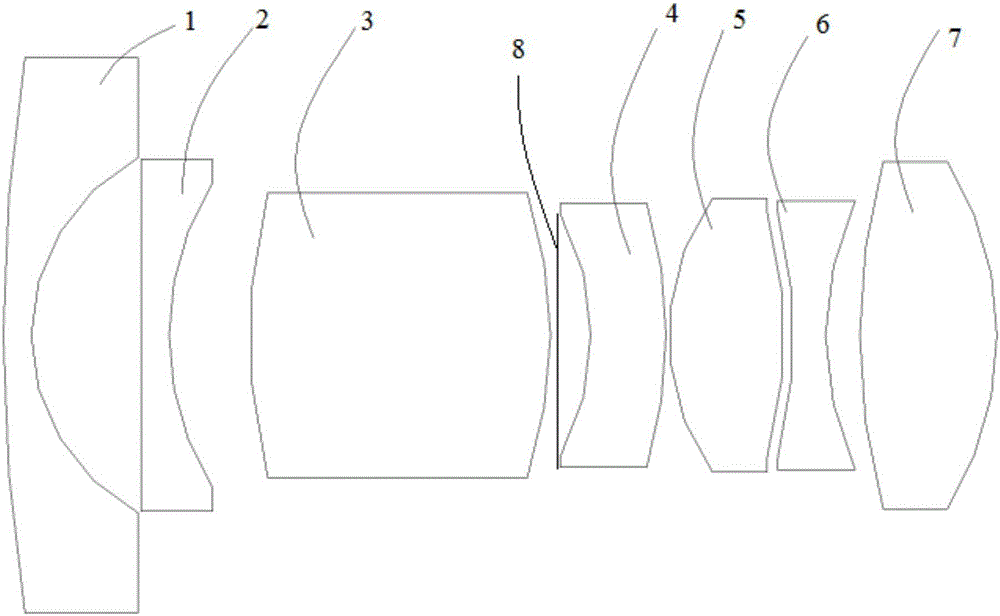

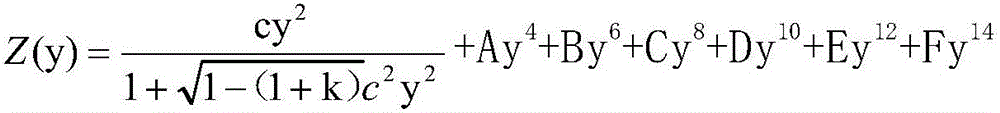

2.8 mm small wide-angle lens with high light flux

InactiveCN106772941AImprove image qualityRealize day and night confocal functionOptical elementsOphthalmologyLight flux

The invention discloses a 2.8 mm small wide-angle lens with high light flux. The 2.8 mm small wide-angle lens comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens and a seventh lens sequentially from object space to image space, wherein the first lens is a convex-concave lens with negative focal power; the second lens is a biconcave lens with negative focal power; the third lens is a biconvex lens with positive focal power; the fourth lens is a concave-convex lens with negative focal power; the fifth lens is a biconvex lens with positive focal power; the sixth lens is a biconcave lens with positive focal power; the seventh lens is a biconvex lens with positive focal power. Compared with the prior art, the 2.8 mm small wide-angle lens has the clear aperture as large as F1.4, has high light flux and is small in size, the total length is 22.2 mm, the optical distortion is about 20%, the lens can realize 3-mega pixels under visible light and infrared conditions without refocusing by cooperating with a chip which is 1 / 2.7 inch in size, suppositional focus is avoided at the temperature ranging from subzero 30 DEG C to 80 DEG C, and the lens has a temperature compensation function.

Owner:DONGGUAN YUTONG OPTICAL TECH

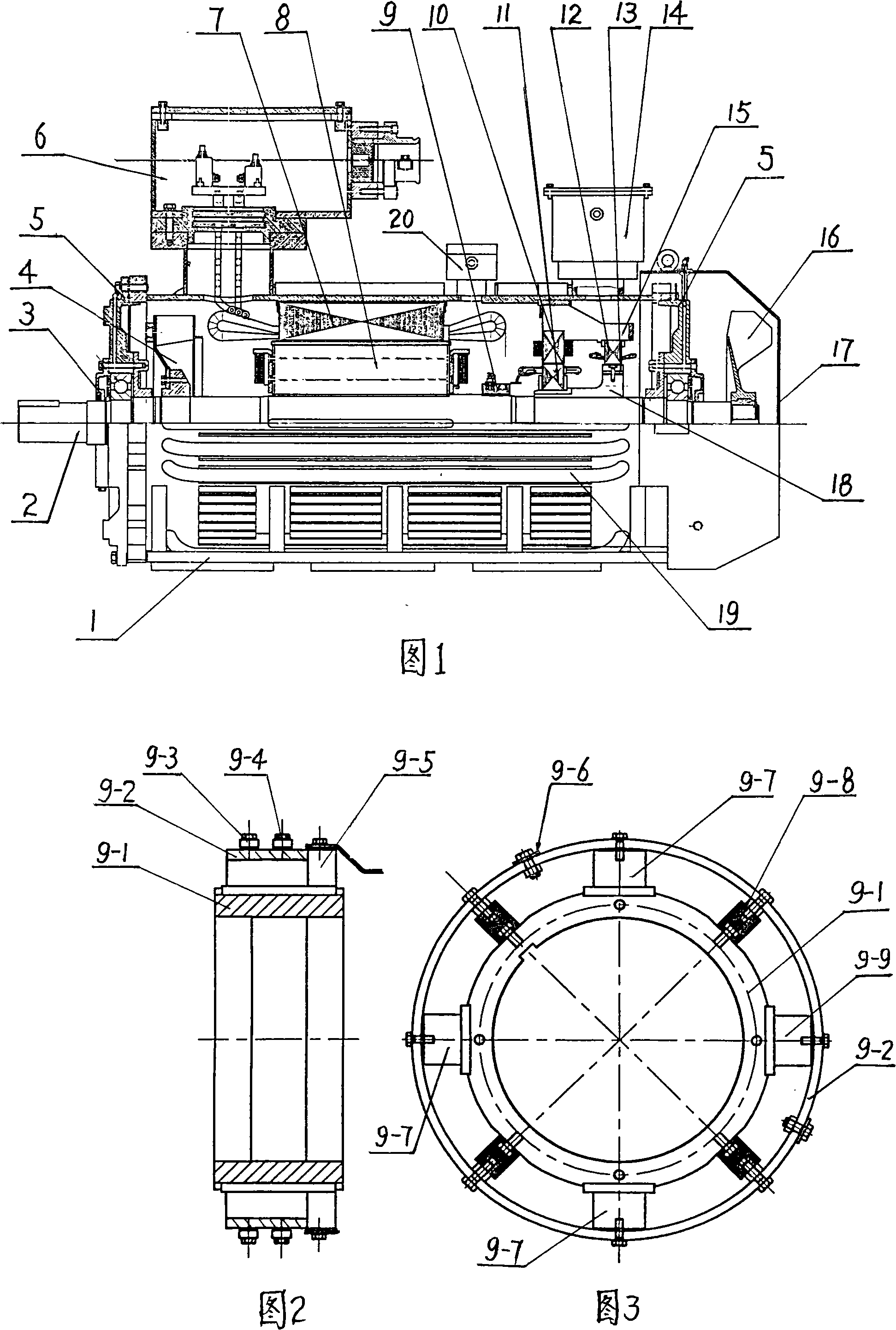

Numerical control vane wheel intelligent forming machine and using method thereof

InactiveCN103846826ASimple structureIngenious and reasonable designFlexible-parts wheelsGrinding devicesEngineeringMechanical engineering

The invention discloses a numerical control vane wheel intelligent forming machine, which comprises an intelligent forming machine main body and an abrasive cloth bearing rotary table, wherein the intelligent forming machine main body comprises a servo feeding mechanism, an abrasive cloth positioning groove, an abrasive cloth blanking mechanism and an abrasive cloth vane wheel indexing automatic composing assembly which are arranged in the feeding direction of abrasive cloth in sequence; the abrasive cloth vane wheel indexing automatic composing assembly comprises a turnplate which is fixed to a turnplate servo motor; at least two abrasive cloth vane wheel indexing automatic composing devices are arranged on the turnplate according to spacing distance; when the turnplate servo motor is in an initial position, a slot position, used for placing the abrasive cloth, of one of the abrasive cloth vane wheel indexing automatic composing devices corresponds to the abrasive cloth positioning groove. The numerical control vane wheel intelligent forming machine has the advantages that the product structure is simple, the design is ingenious and reasonable, working procedures such as the conveyance of the abrasive cloth, cutting, automatic indexing composing, external diameter shaping, circular brand placement, and the fixation of an external diameter positioning ring are automatically completed in high speed and high efficiency, the production efficiency of a vane wheel is effectively improved, and the product quality is stable and reliable.

Owner:方晓斌

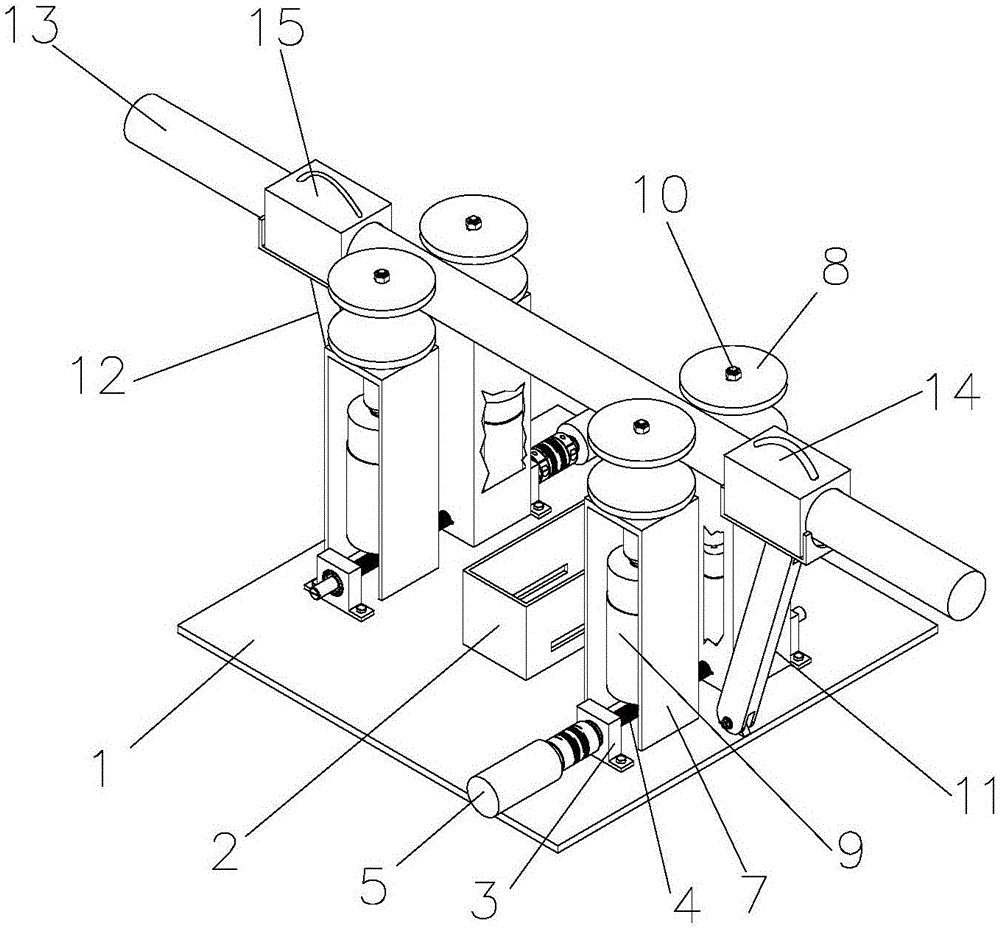

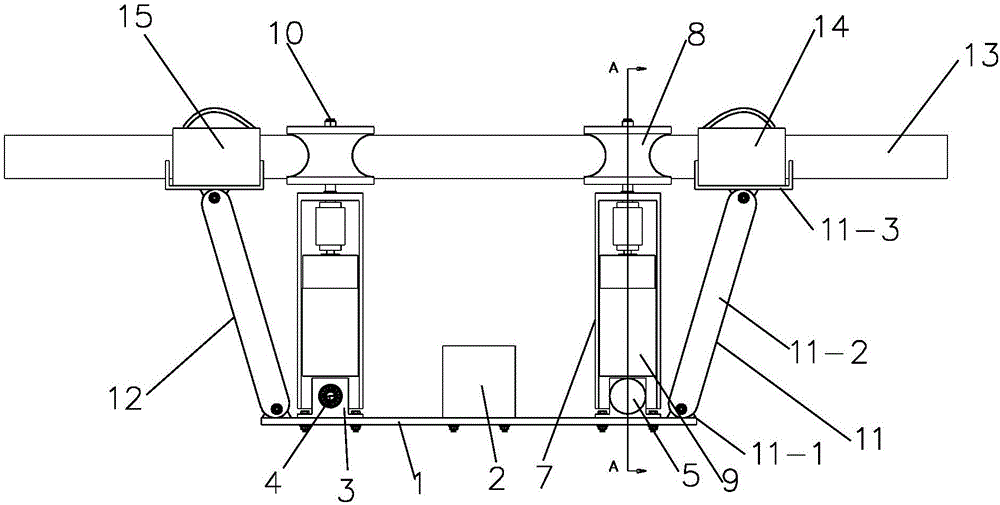

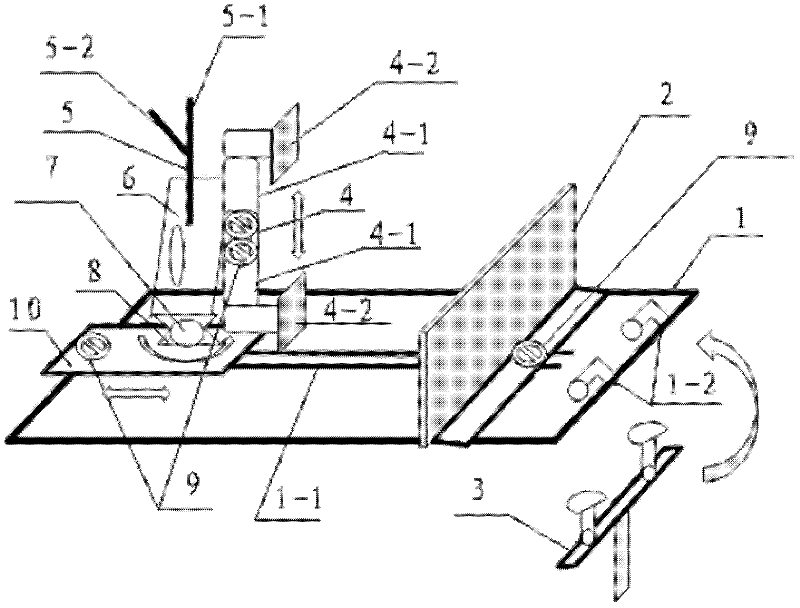

External fixing device of pelvis at lateral position in artificial hip-joint replacement and working method thereof

InactiveCN102309392AAccurate implantation angleAccurate locationDiagnosticsOperating tablesHuman bodyArtificial hip joints

The invention relates to an external fixing device of the pelvis at the lateral position in artificial hip-joint replacement, comprising a flat plate, a sliding plate, an operating arm, a sacrum fixing plate, an operating bed connecting and fixing piece, an anterior superior iliac spine fixing piece, a guide needle, a universal rotating shaft, a universal shaft seat and a fixed piece. A working method of the external fixing device of the pelvis at the lateral position in the artificial hip-joint replacement comprises the following detailed steps: (1) the device is fixed with the operating bed to lead a human body to be in the lateral position; (2) the sliding plate is adjusted to drive the anterior superior iliac spine fixing piece; (3) the anterior superior iliac spine fixing piece is adjusted; (4) a vertical needle body is parallel to the connecting line of the anterior superior iliac spines at the two sides, an inclined needle body expands outwards by 45 degrees, and inclines forwards by 15-20 degrees; and (5) an acetabulum placer is parallel to the inclined needle body. The external fixing device has the advantages that (1) the angle design of the inclined needle body in the two-in-one guide needle ensures the accuracy of the operation; (2) the accuracy, the firmness and the reliability of the pelvis fixing are ensured; (3) the operation is convenient; and (4) the wound is avoided.

Owner:朴哲 +1

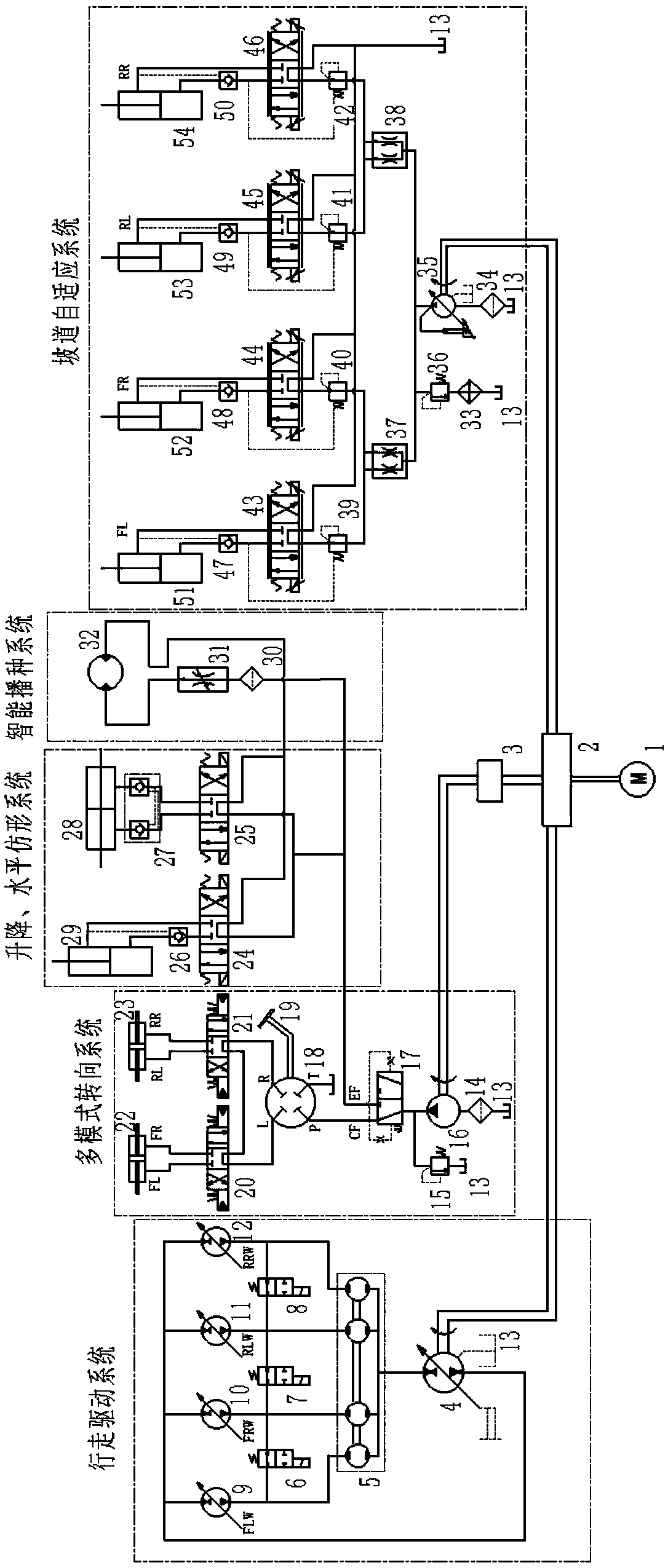

Hydraulic transmission system of tractor in hilly mountain area

PendingCN108799223AExpand the high-efficiency rangeFlexible layoutServomotorsVehicle frameTransfer case

The invention relates to a hydraulic transmission system of a tractor in a hilly mountain area. According to the technical scheme, an engine is connected with a transfer case, the transfer case divides the power into three paths of power, wherein one paths of the power is distributed to a two-way variable plunger pump of a walking driving system, the second path of the power is distributed to a constant-voltage variable pump of a ramp self-adaptation system, and the third path of the power is distributed to a gear pump of a multi-mode steering system through a speed increasing mechanism; the walking driving system uses a single-pump four-motor configuration mode; the multi-mode steering system realizes switching among four modes, namely, a front wheel steering mode, a rear wheel steering mode, a four-wheel concentric steering mode and a four-wheel crab-shaped steering mode; the ramp self-adaptation system can adjust a tractor frame to be in a horizontal state in the uphill and downhillprocess of the tractor; a lifting profiling system ensures working parts to automatically keep the same distance as the ground, and also serves as an active lifting power part of the working parts; ahorizontal profiling system can enable the working parts to be changed and adjusted according to the fluctuation of the terrain; and an intelligent seeding system can adapt to the seeding requirements of different driving speeds and different crops, and the seeding consistency is high.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

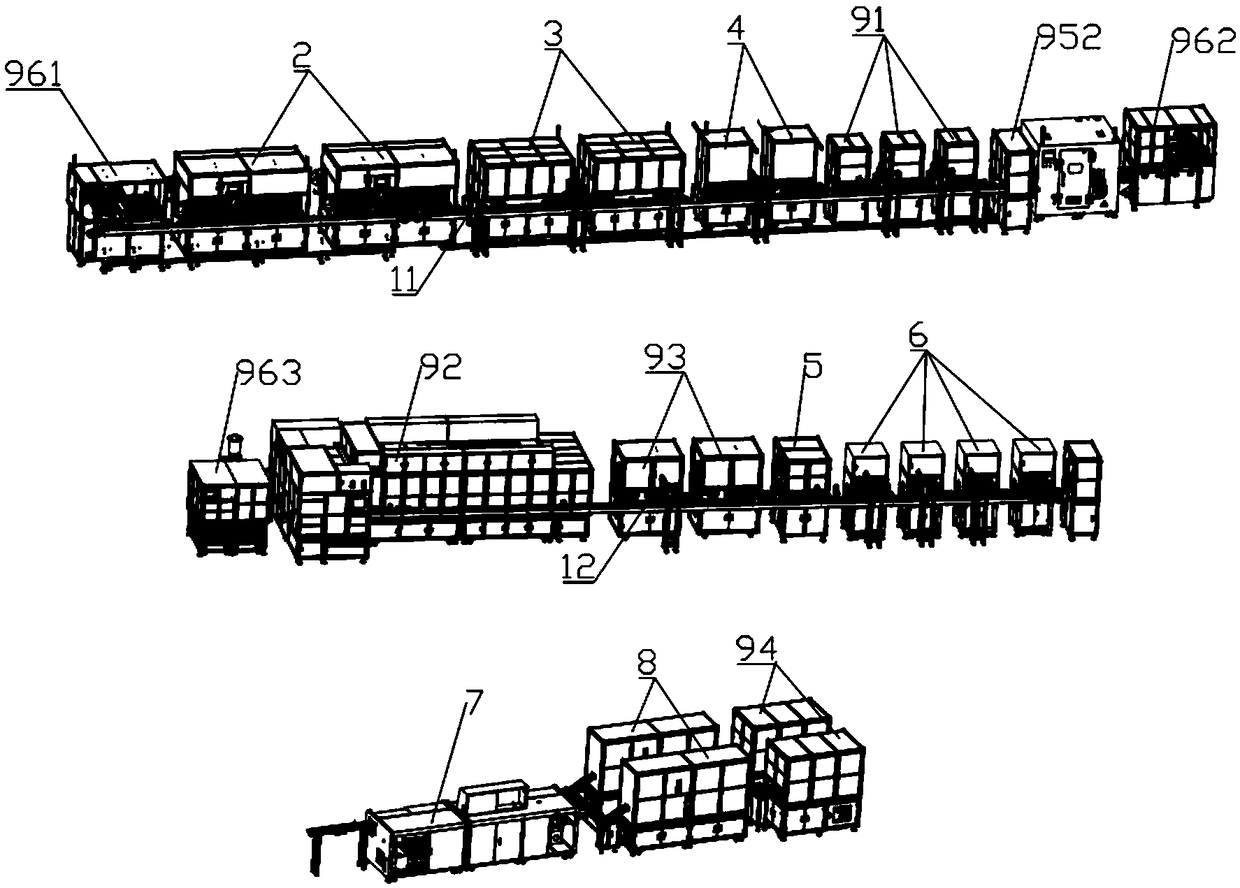

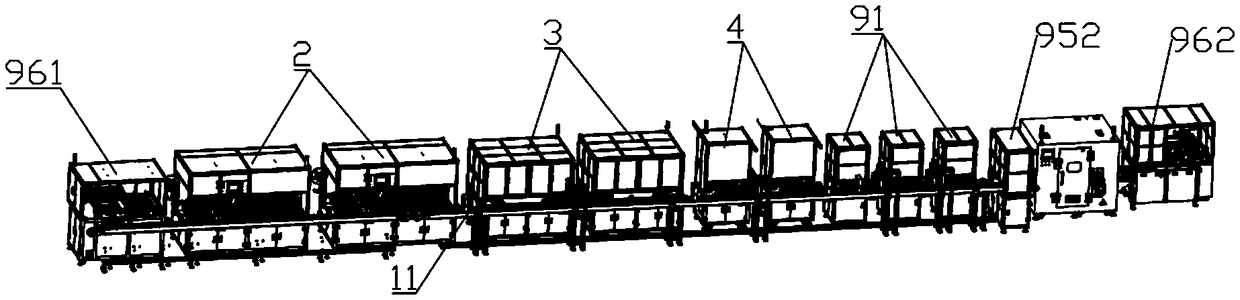

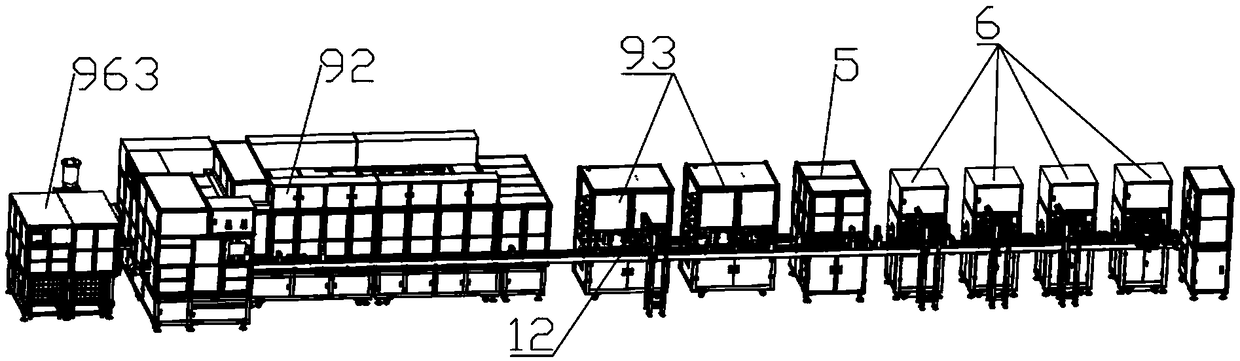

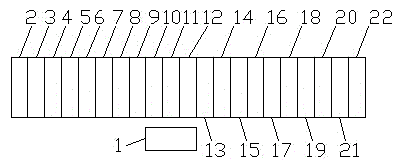

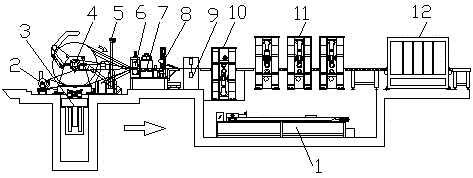

Automatic production line for lithium battery

PendingCN108878952AContinue to work efficientlyFully automatedAssembling battery machinesFinal product manufactureLogistics managementFully automatic

The invention discloses an automatic production line for lithium batteries. The automatic production line comprises a first production line for assembling battery cells, a second production line for assembling batteries, and a third production line for packaging batteries, which are sequentially arranged; the first production line comprises a first logistics line horizontally arranged on the ground and a shelling machine, a point bottom welding machine, a positive electrode face pad machine and a groove rolling machine which are sequentially arranged on one side of the first logistics line along the conveying direction of the first logistics line, the second production line comprises a second logistics line horizontally arranged on the ground and a liquid injection machine, a cap welding machine, a pre-sealing machine and a sealing machine which are sequentially arranged on one side of the second logistics line along the conveying direction of the second logistics line. The automatic production line for lithium battery is reasonable and ingenious in design, stable in performance, convenient to operate and maintain, and arranged with a safety protection alarm device, low in labor cost, high in production efficiency and product quality, and guaranteed to operate continuously and efficiently, the line is never stopped, the production is constantly produced, and a fully automatic intelligent factory is realized.

Owner:广东彩扬能源装备有限公司

Cutting device for glass table board of integrated cooker and cutting method by adopting cutting device

ActiveCN108943446AAvoid harmAvoid hard frictionWorking accessoriesStone-like material working toolsDrive wheelMotor drive

The invention discloses a cutting device for a glass table board of an integrated cooker. The cutting device comprises a workbench, a cutting mechanism and clamping devices, a movable seat is arrangedbelow the workbench, a mounting plate is arranged between the workbench and the movable seat, a rotating motor, a driven wheel and a rotating screw rod are arranged on the mounting plate, the rotating motor drives the driven wheel to rotate through a belt wheel, the driven wheel drives the rotating screw rod to rotate, the cutting mechanism is located above the workbench, and the clamping devicescomprise supporting rods and clamping pressing plates. A cutting method comprises the following steps that (1) a to-be-cut raw material is fed; (2) positioning and clamping are carried out on the glass plate raw material; (3) the position of the cutting mechanism is adjusted; and (4) cutting machining is carried out. According to the cutting device, the overall structural design is ingenious andreasonable, omni-directional adjustment of the position of the cutting mechanism can be realized, and accurate positioning between the cutting mechanism and the to-be-cut position is ensured; and meanwhile, the clamping devices are designed so that the to-be-cut raw material can be clamped and fixed, and the application range is wide.

Owner:浙江欧帝智能厨电有限公司

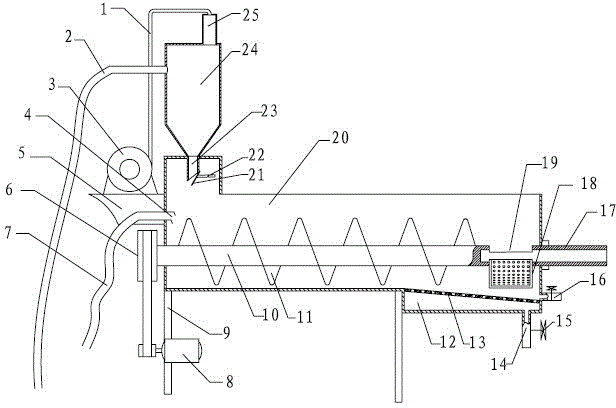

Impurity removal cleaning machine for sesame

InactiveCN104643270AIngenious and reasonable designSimple processGas current separationFood treatmentSedimentSesamum orientale

The present invention relates to equipment for removing impurities in sesame and cleaning the sesame, in particular to an impurity removal cleaning machine for the sesame. The impurity removal cleaning machine is provided with a cleaning groove, a sesame storage bin is installed above the front end of the cleaning groove, an impurity removal bucket is installed at the top of the sesame storage bin, the lower portion of the sesame storage bin is in an inverted-cone shape, a discharging tube is arranged at the bottom of the sesame storage bin, and a movable cover plate is installed on a discharging port of the discharging tube. A rotary shaft is arranged in the cleaning groove, an auger is arranged on the rotary shaft, a filter net I is installed at the bottom of the rear end of the cleaning groove, and a mud sediment groove is formed below the filter net I. A mud discharging tube is arranged at the bottom of the mud sediment groove, the tail end of the rotary shaft is a hollow blind tube with an outer open end, an opening is formed in the side wall of the hollow blind tube, a sesame scooping hopper is installed on the opening and provided with a circular-arc-shaped filter net II, baffles are arranged at the two ends of the filter net II, and a sand discharging tube is installed on the lower portion of the rear end of the cleaning groove. Cleaning and impurity removing of the sesame are finished in the same equipment in a one-off mode and performed at the same time, the multiple operation processes of cleaning, sand and stone removing, impurity removing and the like are omitted, working efficiency is high, and cleaning and impurity removing effects are good.

Owner:山东省十里香芝麻制品股份有限公司

Combined machining center for stainless steel coiled materials

InactiveCN106271665ASolve troublesome problemsSimple structureOther manufacturing equipments/toolsEngineeringSpot welding

The invention discloses a combined machining center for stainless steel coiled materials. The combined machining center comprises a paper tape filtering machine and a paper collecting machine. A feeding trolley, an uncoiler, a centering device, a front pinch conveyor, a leveling machine, a hydraulic shear, a gantry spot welding machine, a back grinder, three front grinders, a five-axis straight-grain machine, a non-woven cloth polisher, a cleaning and drying machine, a film pasting machine, a rear pinch conveyor, a hydraulic shear, guide rollers, an edge aligning device, a discharging trolley, a coiler and a paper releasing machine are sequentially mounted behind the paper collecting machine. The combined machining center for stainless steel coiled materials is simple in structure, ingenious and reasonable in design, stable and reliable in quality, and high in machining speed and precision.

Owner:佛山市吉力佳机械有限公司

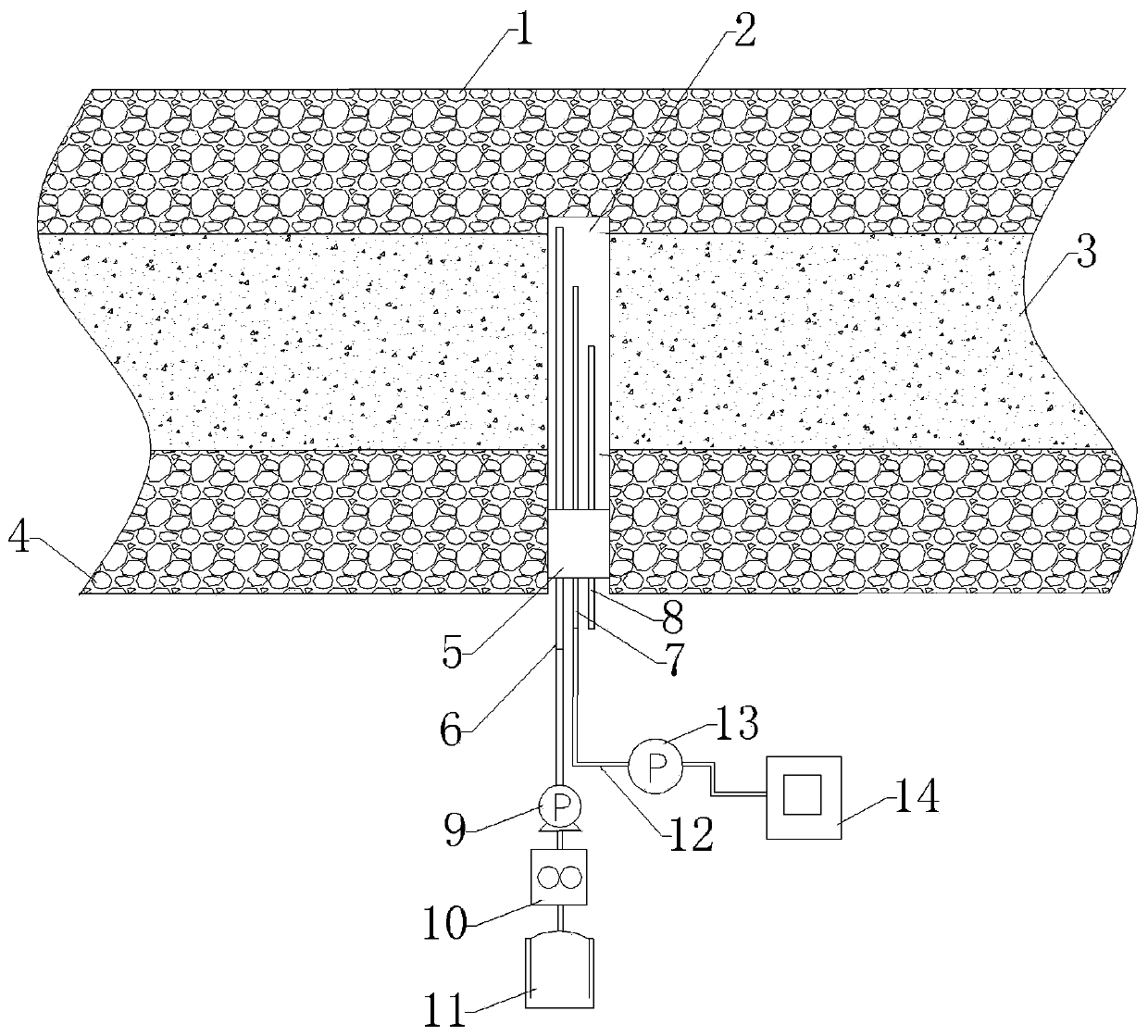

Gas extraction method using phase change material to assist liquid nitrogen to crack and extraction system

InactiveCN109723488AFacilitate dissociationSmooth and efficient dischargeFluid removalGas removalLiquid nitrogen coolingPhase-change material

The invention discloses a gas extraction method using a phase change material to assist liquid nitrogen to crack and an extraction system, wherein the method comprises the following steps of: 1) drilling a hole; 2) establishing the gas extraction system; 3) cracking a coal seam; 4) heating the coal seam; 5) extracting gas. The extraction system comprises a coal bed, wherein an extraction hole is formed in the coal bed; a hole sealing device is arranged in the extraction hole; a steel pipe, a liquid nitrogen pipe and a gas extraction pipe, which penetrate through the hole sealing device, are additionally arranged and extend into the extraction hole; the outer end of the steel pipe is communicated with a storage bin; and the outer end of the liquid nitrogen pipe is communicated with a liquidnitrogen tank. The device has novel conception and ingenious and reasonable design; according to the technical scheme, after the coal bed is cracked through cooling with liquid nitrogen, the coal bedcan be further cracked by heating with a phase change material under the condition of alternate temperature treatment of cold and heat, and the dissociation of the gas can be accelerated, so that thegas is discharged from the coal seam more smoothly and efficiently, and the whole pumping work is safer and more reliable, convenient to operate, smooth and high in efficiency.

Owner:CHONGQING UNIV

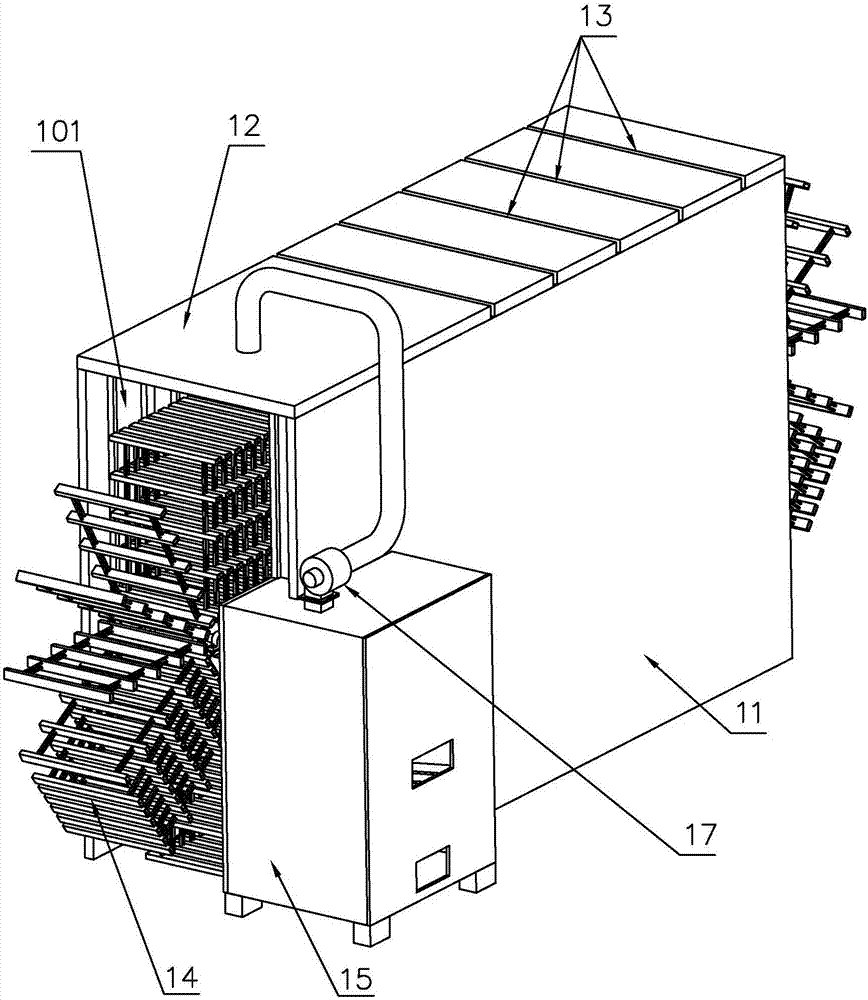

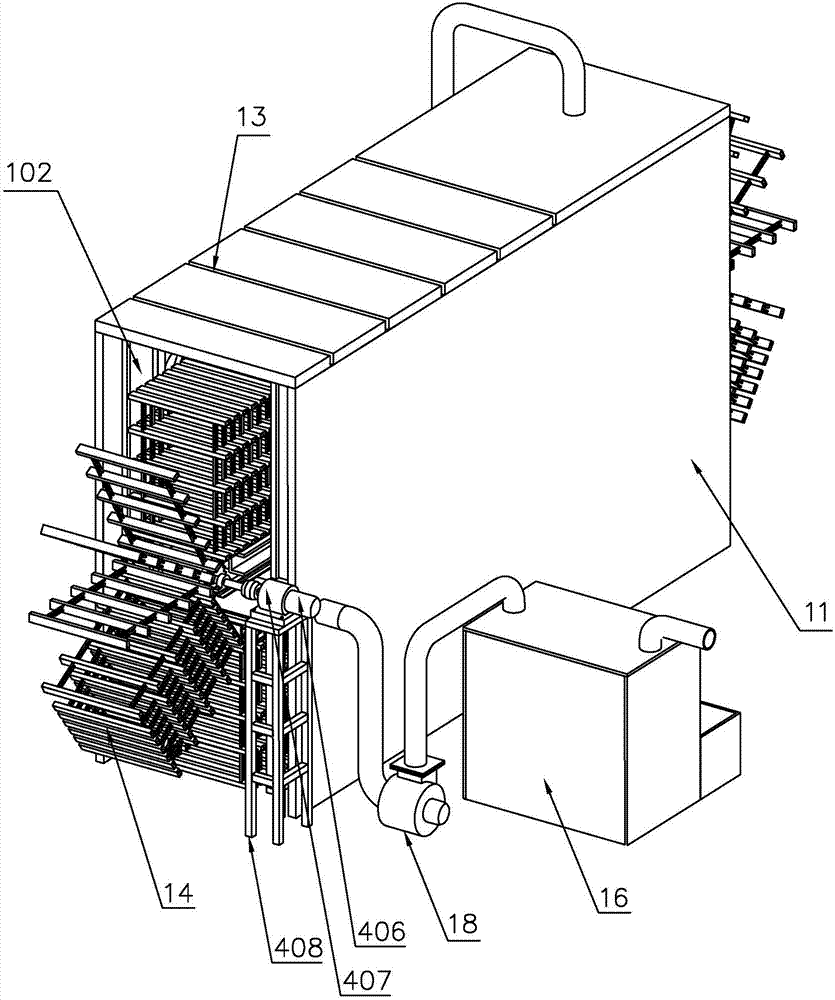

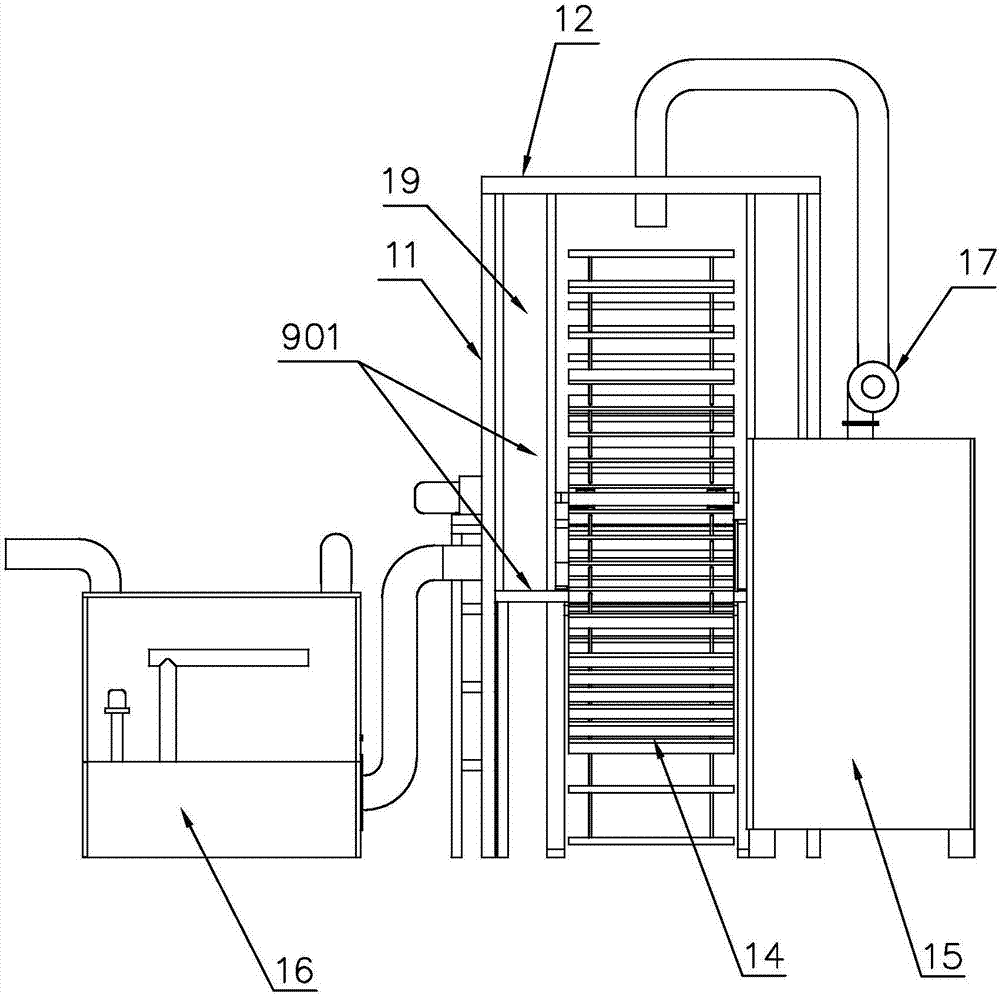

Environment-friendly efficient veneer drying device

ActiveCN107084607AUniform moisture contentImprove flatnessDrying gas arrangementsDrying chambers/containersDrive shaftFixed frame

The invention provides an environment-friendly efficient veneer drying device comprising a veneer inlet, a veneer outlet, a machine frame, a heat preservation box, a top cover, a plurality of moisture outlets, a conveying mechanism, air blowing devices, a flame path, smoke pipelines and a flue. The heat preservation box is arranged on the outer side of the machine frame. The upper portion of the heat preservation box is provided with a top cover. The top cover is provided with the multiple moisture outlets which are close to the veneer outlet. The conveying mechanism comprises a transmission shaft, clamping arms, supporting cushion blocks, a chain, chain wheels, carrier rollers, a motor, a speed reducer and a motor fixing frame. The supporting cushion blocks are arranged on the upper portion of the chain. The clamping arms are arranged on the upper portion of the supporting cushion blocks. The flame path, the smoke pipelines and the flue are fixedly connected to the machine frame. The air blowing devices are arranged on the two sides of an upper circulation position of the conveying mechanism and the two sides of the flame path. Each air blowing device comprises partition plates, air blowing fans and fan supports. The environment-friendly efficient veneer drying device is low in energy consumption, reduces the production cost of a traditional large-sized drying device, is good in veneer drying effect and solves the problem that after being dried, veneer naturally warps.

Owner:李学淑

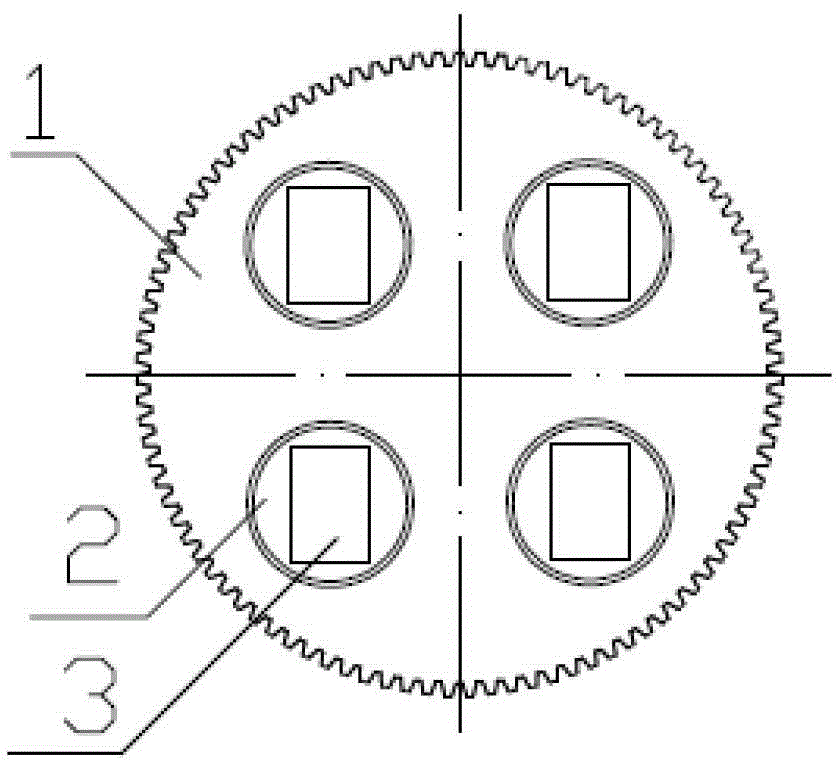

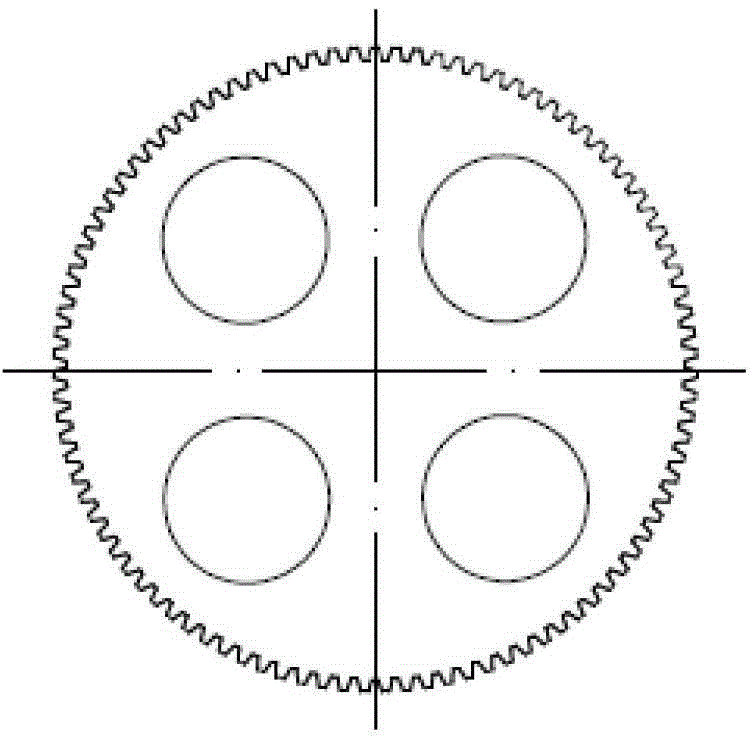

Wandering star wheel

InactiveCN102975114AIngenious and reasonable designFix issues with crafting multiple vehiclesWork carriersEngineeringTotal thickness

The invention discloses a wandering star wheel, belonging to the technical field of sapphire processing. The wandering star wheel consists of a main wheel and sub-wheels, wherein teeth matched with grinding equipment are arranged on the outer circumference of the main wheel; holes matched with the external diameters of the sub-wheels are formed in the main wheel; and other holes for the accommodation of workpieces to be processed are formed in the sub-wheels. In comparison with the prior art, during the grinding of the wandering star wheel, the sub-wheels rotate in the main wheel, so that the processed workpieces are driven to self-rotate; in such a way, the grinding is more uniform; after the grinding, the indexes such as TTV (Total Thickness Variation) and Warp for the surfaces of wafers can reach requirements; the wandering star wheel is skillful and rational in design; and in addition, the problem of manufacturing multiple diecarriers during the grinding ofn various nonstandard pieces is solved, and the grinding cost is decreased greatly.

Owner:江苏吉星新材料有限公司

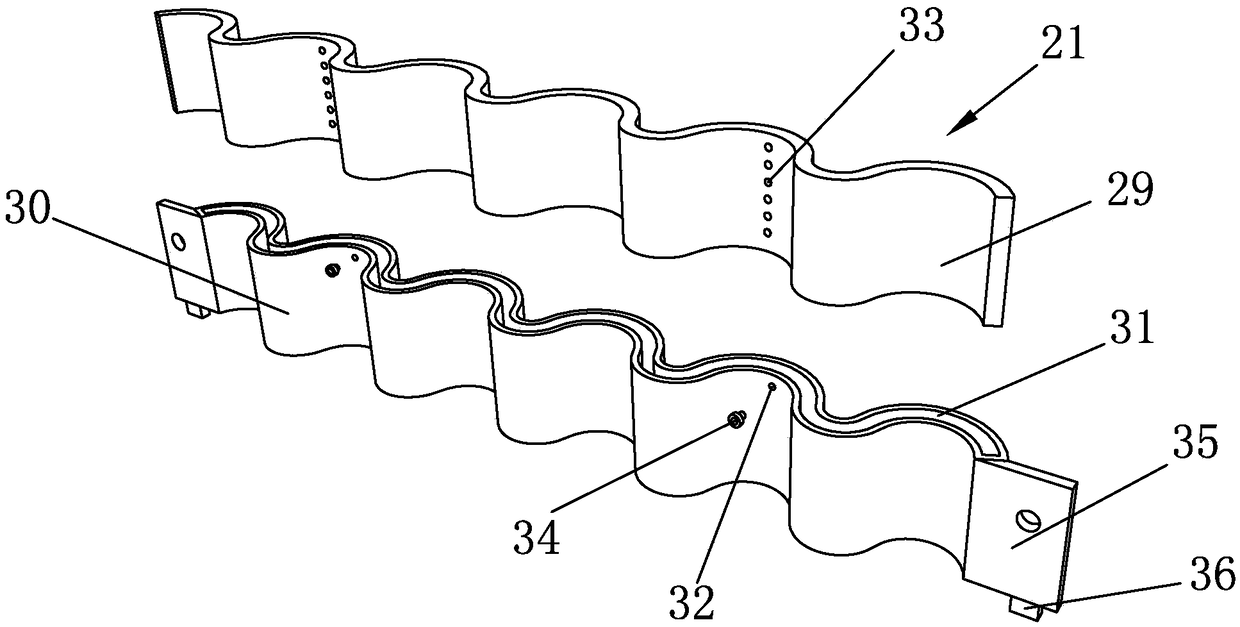

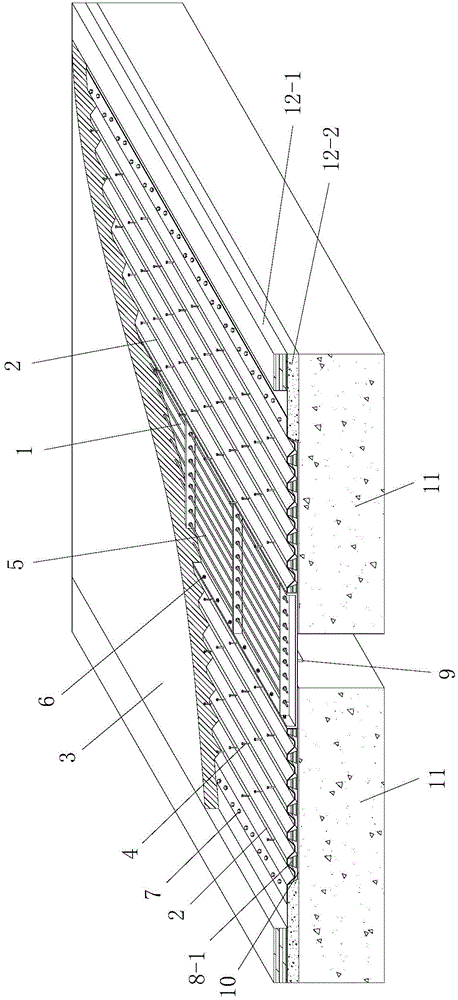

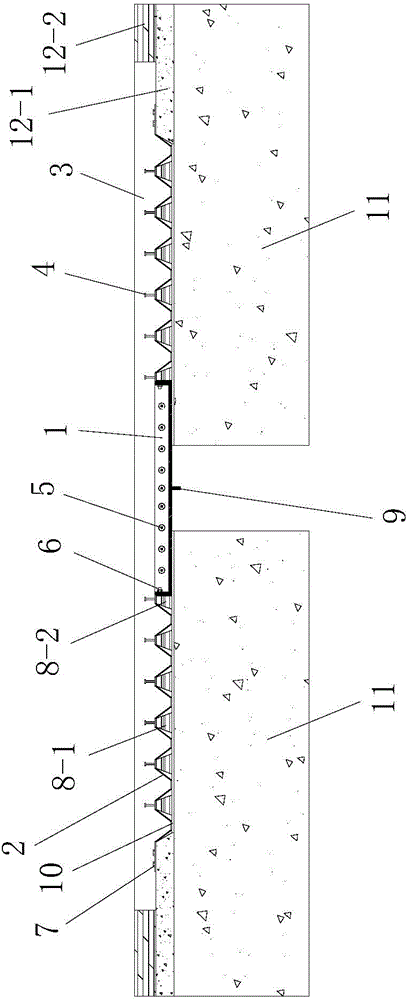

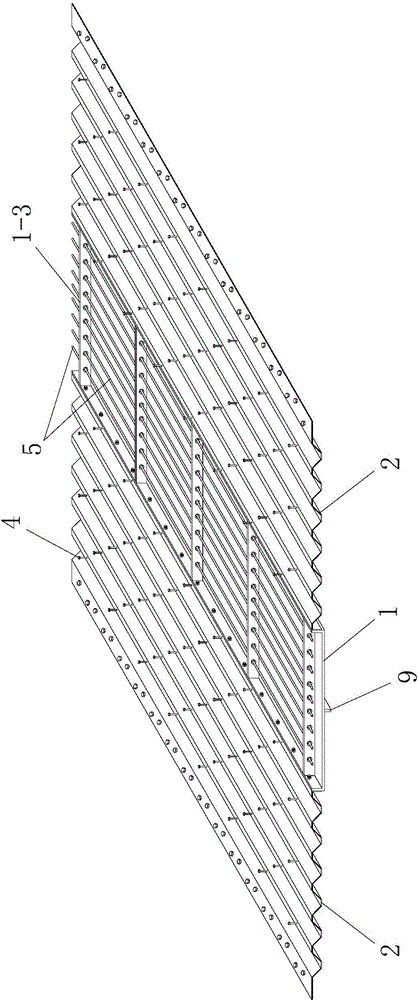

Stiffened joint-crossing plate based bridge deck jointless expansion device and construction method thereof

InactiveCN104674650ASimple structureReasonable designBridge structural detailsBridge erection/assemblyWave shapeExpansion joint

The invention discloses a stiffened joint-crossing plate based bridge deck jointless expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion assembly and an expansion joint filler filled layer filled above the prefabricated expansion assembly, wherein the prefabricated expansion assembly is arranged on an expansion joint reserved between every two adjacent girder segments, and a sliding layer is laid on a girder exposed segment of each girder segment; the prefabricated expansion assembly comprises a stiffened joint-crossing plate and two wave-shaped expansion plates. A construction method for an expansion device to be repaired comprises the steps of cleaning an original bridge expansion device, constructing reserved mounting grooves, constructing the sliding layers, carrying out field assembly and mounting on the prefabricated expansion assembly and constructing the expansion joint filler filled layer. A construction method for an expansion device to be constructed comprises the steps of prefabricating the prefabricated expansion assembly, carrying out field assembly on the prefabricated expansion assembly, constructing the sliding layers, mounting the prefabricated expansion assembly and constructing bridge deck pavement structures and the expansion joint filler filled layer. The stiffened joint-crossing plate based bridge deck jointless expansion device and the construction method thereof have the advantages that the design is reasonable, the construction is convenient, the use effect is good, and multiple problems of the existing expansion devices can be solved.

Owner:XIAN HIGHWAY INST

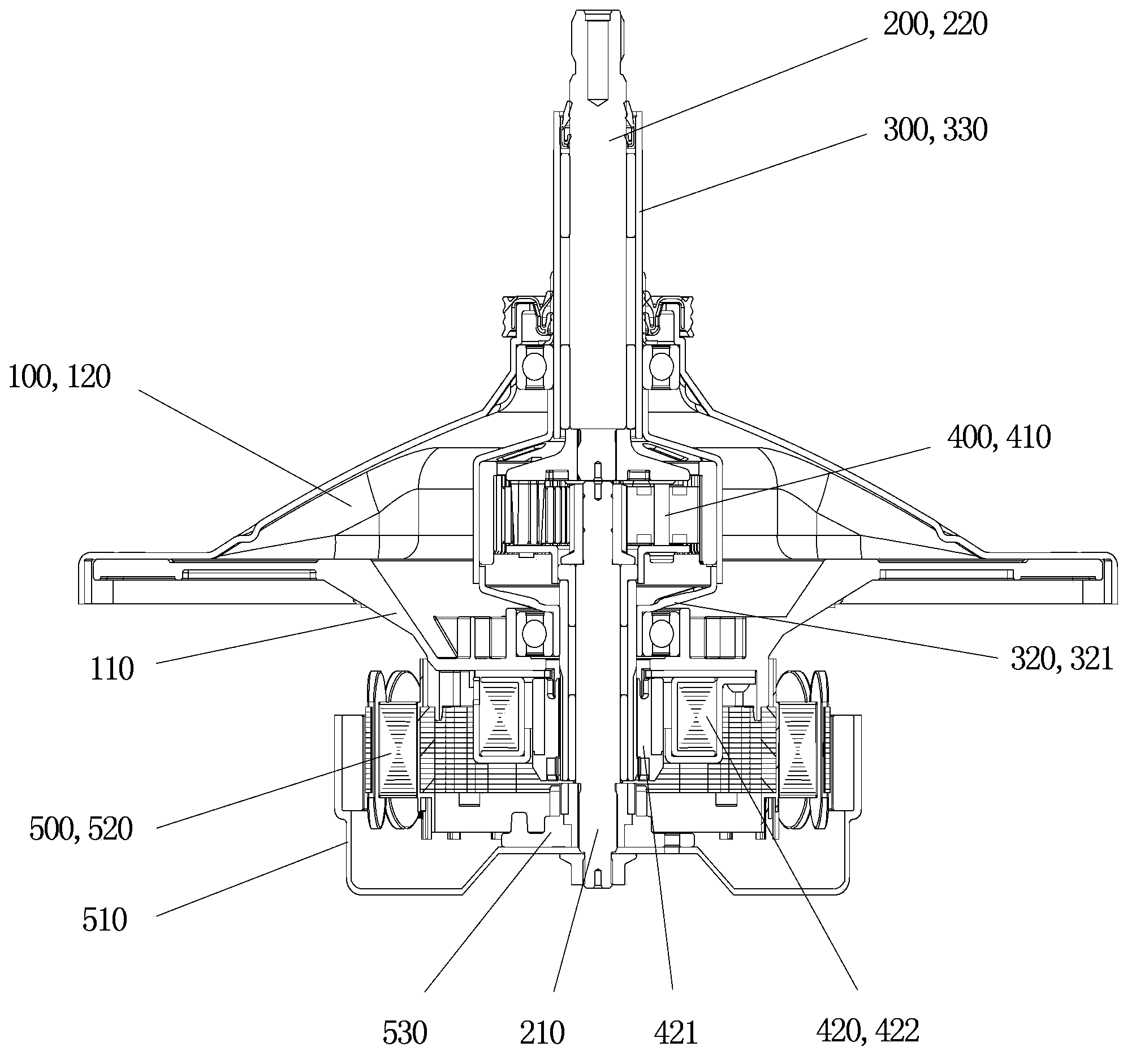

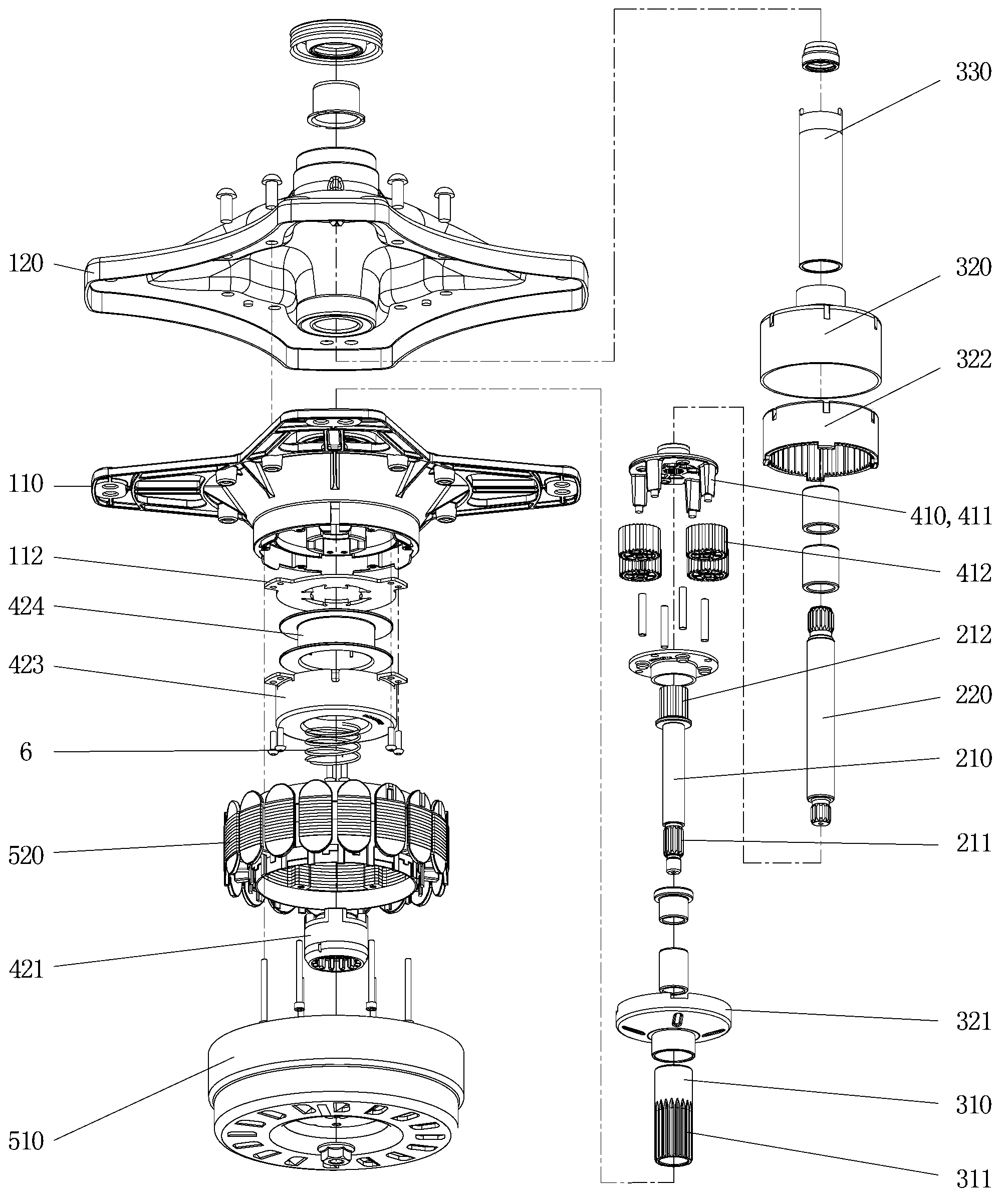

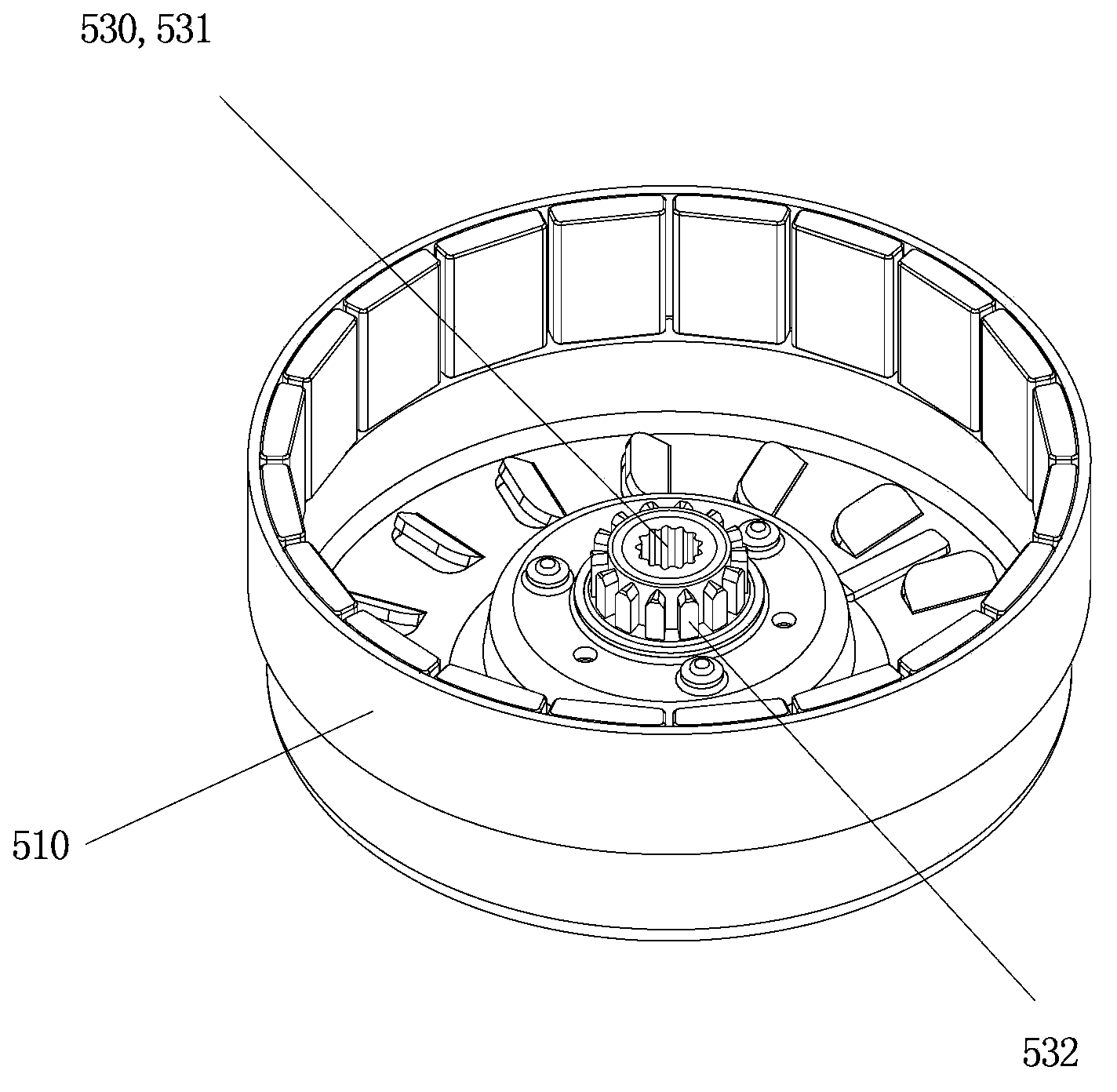

Drive assembly of pulsator washing machine

InactiveCN103422323AImprove transmission efficiencyAccurate clutch controlOther washing machinesTextiles and paperPull in voltageClutch control

The invention relates to a drive assembly of a pulsator washing machine. The drive assembly comprises a mounting tray. A spindle and a shaft sleeve sleeved on the spindle are rotatably disposed on the mounting tray. A reduction electromagnetic clutch mechanism is disposed between the spindle and the shaft sleeve. A drive mechanism is disposed on the lower portion of the spindle. The reduction electromagnetic clutch mechanism is an electromagnetic clutch mechanism having a function of electromagnetic clutch planetary gear reduction. The reduction electromagnetic clutch mechanism is provided with a planetary gear component and an electromagnetic clutch component. The drive mechanism is an external rotor direct-drive motor comprising a rotor and a stator. The stator is fixedly connected to the mounting tray. The rotor is fixedly connected with the spindle. The spindle and the electromagnetic clutch and planetary gear reduction mechanism are directly driven by an external rotor motor, and accordingly defects such as complex ratchet and pawl structure, large size and low control accuracy in the prior art are broken through. Electromagnetic clutching is high in transmission efficiency, accurate in transmission and clutching control and low in noise; the whole drive assembly is light in weight, pull-in voltage and holding voltage are less demanded in electromagnetic clutching, and energy consumption is reduced effectively.

Owner:CHANGZHOU XINYA ELECTROMOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com