Patents

Literature

204results about How to "Good engineering quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

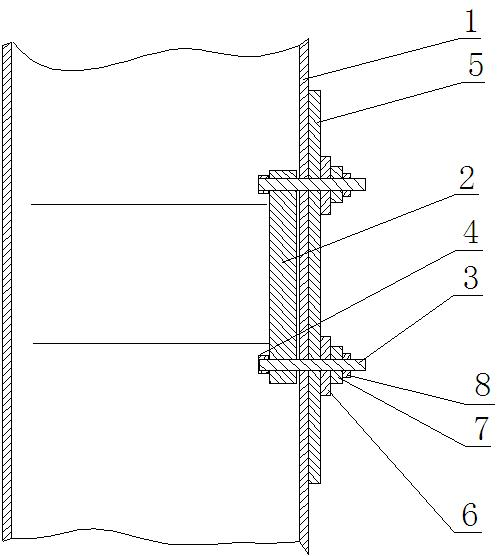

Non-digging tube-pulling construction method

InactiveCN101457853AReduce excavationReduce backfill workloadPipe laying and repairSocial benefitsGeomorphology

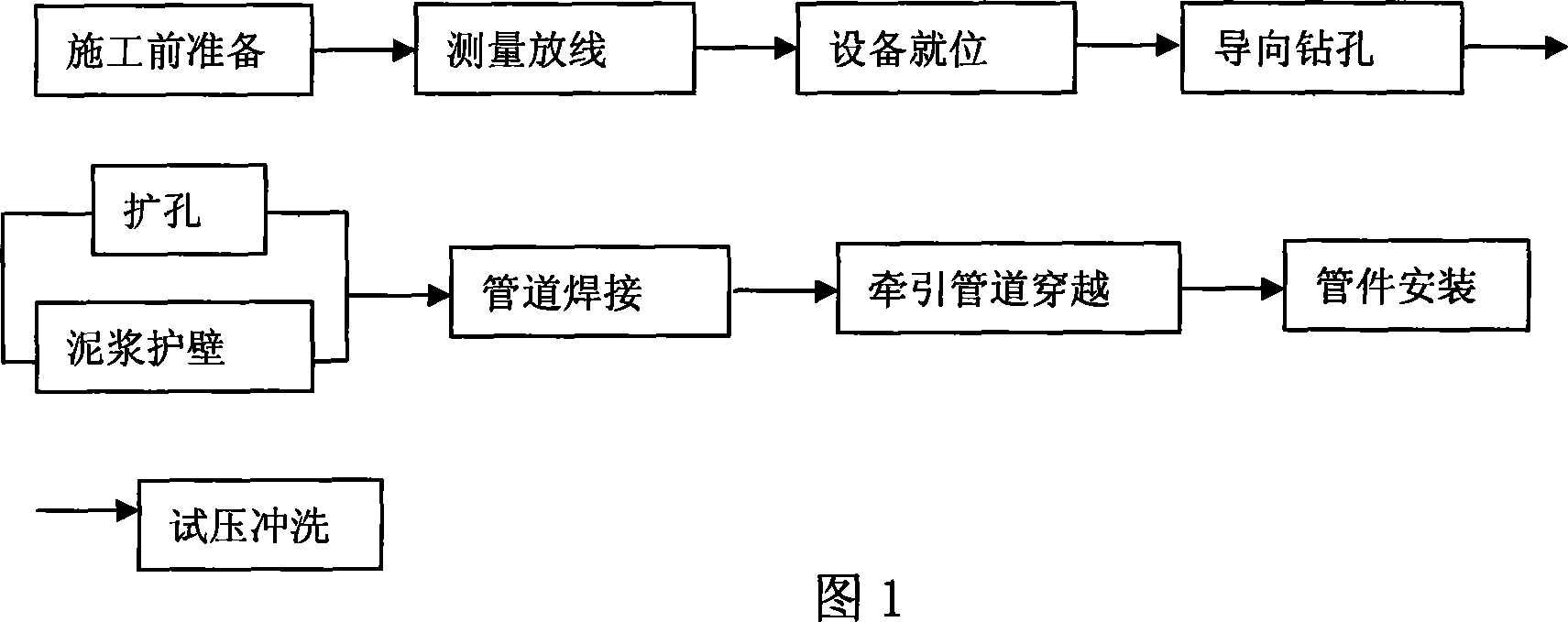

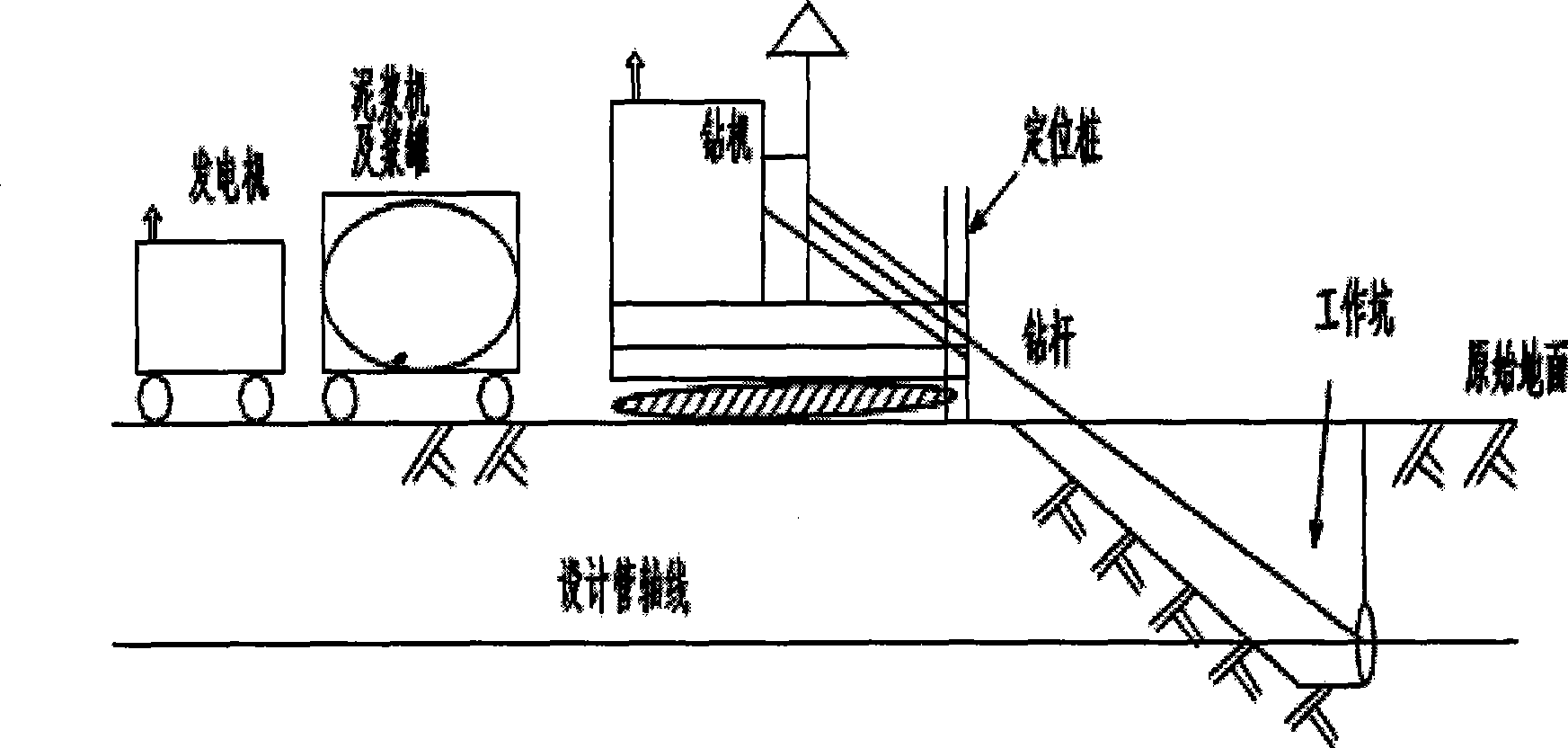

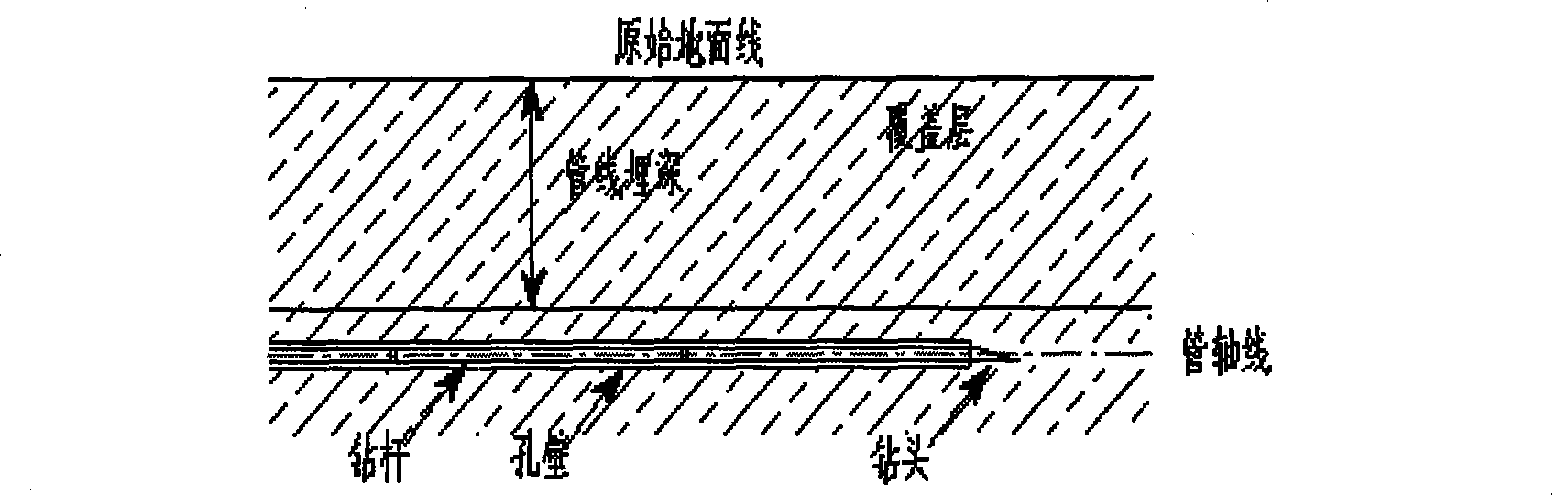

The invention relates to a non-excavation tube pulling construction method which comprises the following steps: (1) preparation work: understanding stratum and underground condition, calculating the number of chambering and the size of a return compandor, and formulating the control data of a pipeline midline and elevation and correction measures; (2) measuring plane surface, controlling payingoff, and measuring the elevation of each pile; (3) setting an active well, and receiving and setting a drilling machine; (4) preparing drilling fluid; (5) drilling pilot holes,; (6) adopting the compandor to chambering, cleaning the hole at the same time, and protecting walls with slurry; (7) welding the pipeline; (8) pulling the tube, and simultaneously pulling a steel tube with the same length as that of the tube; (9) casting slip and fixing; (10) mounting tubes; (11) testing pressure and flushing. The invention can effectively increases economical benefit and social benefit, and has the advantages of environmental protection and energy saving.

Owner:江苏广宇建设集团有限公司

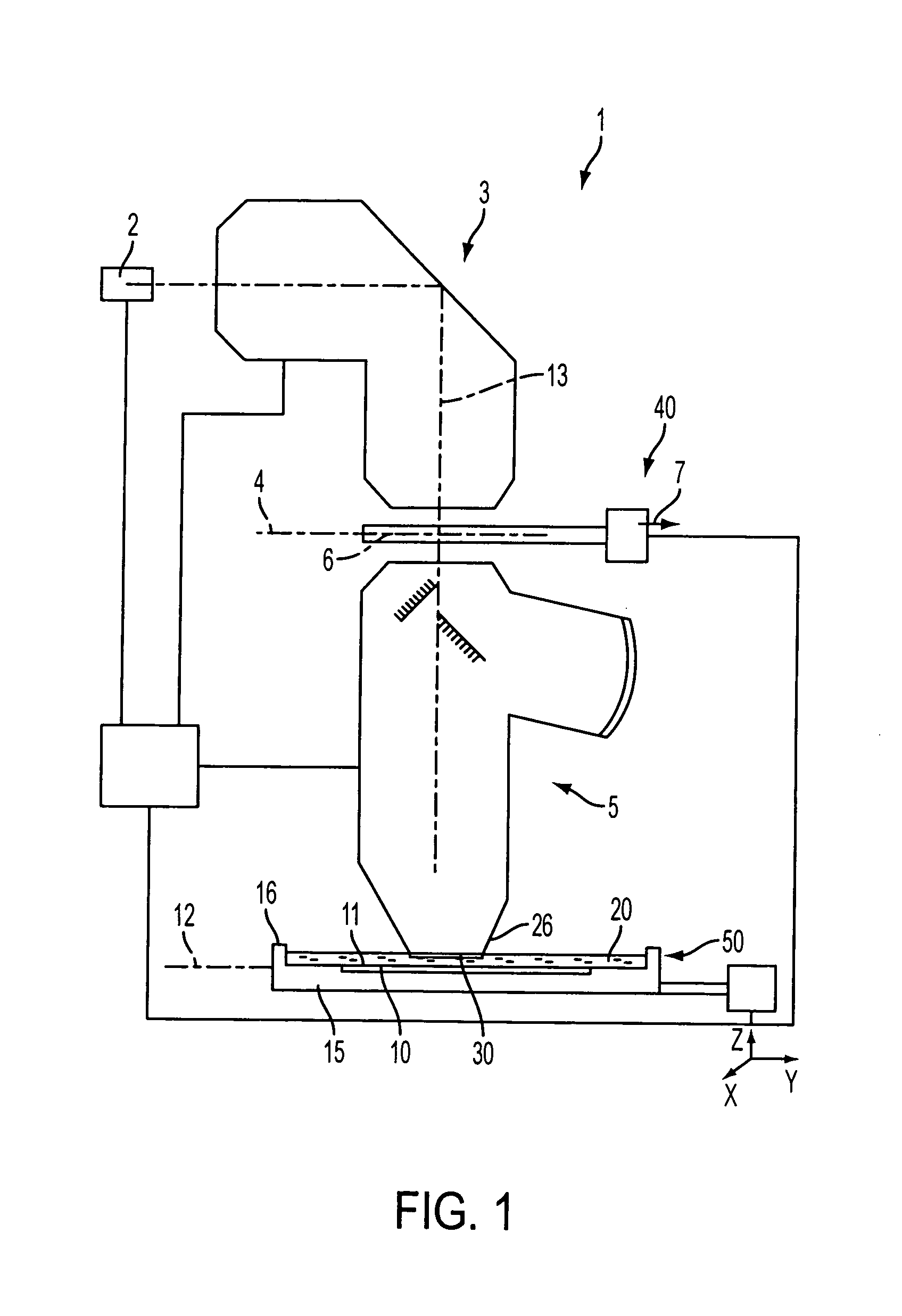

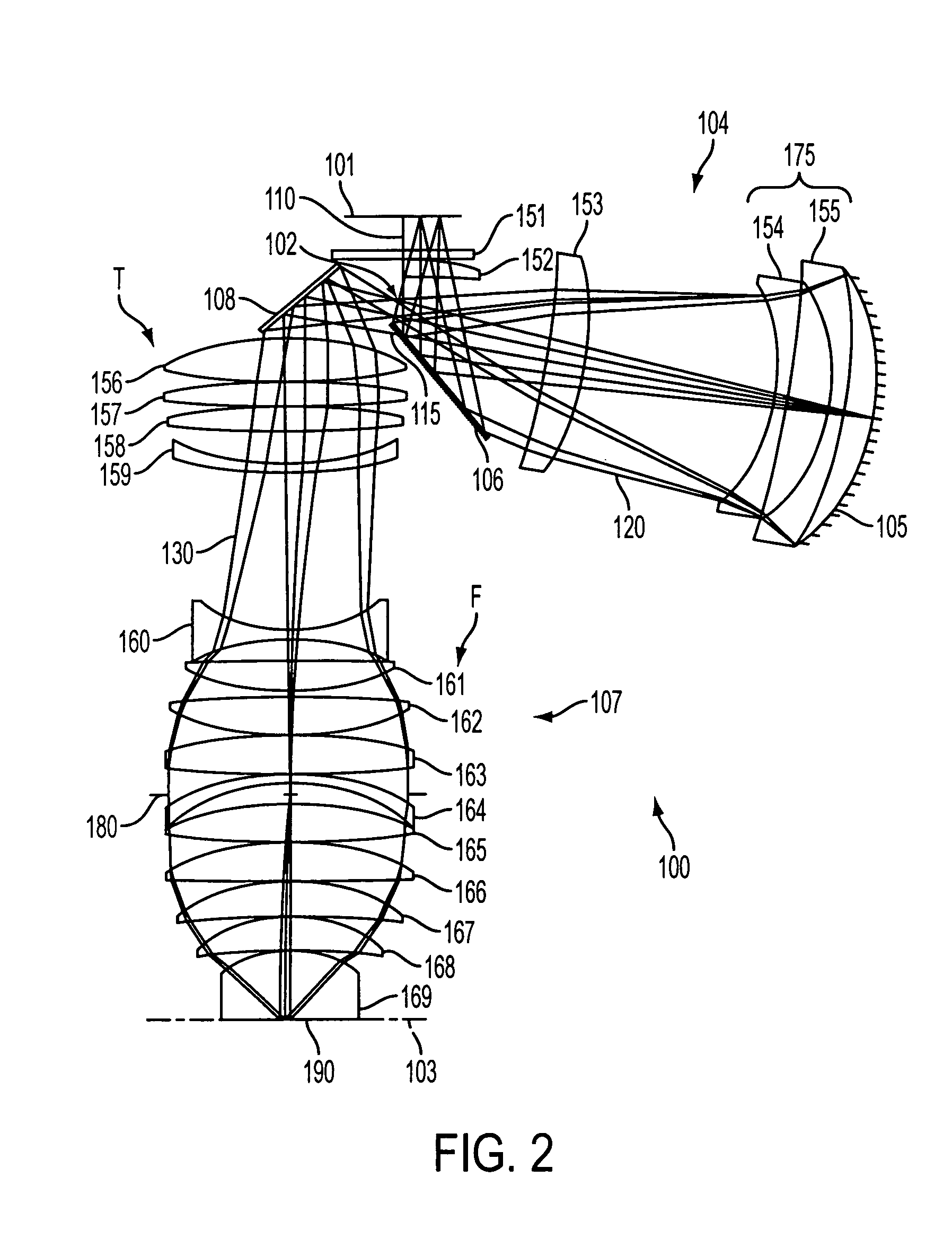

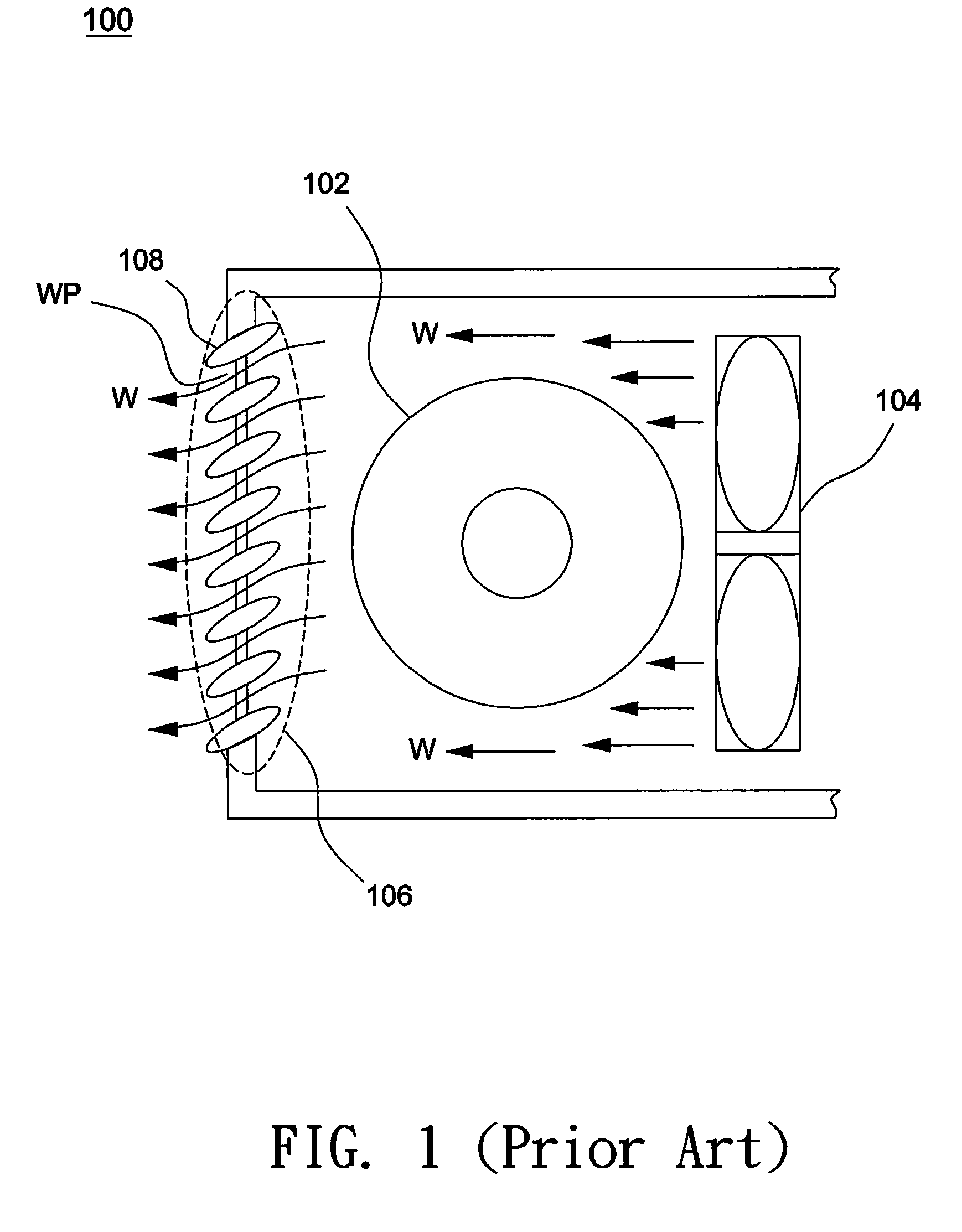

Catadioptric projection objective with geometric beam splitting

InactiveUS6995930B2Easy to installGood engineering qualityMicroscopesPhotomechanical exposure apparatusBeam splittingLight beam

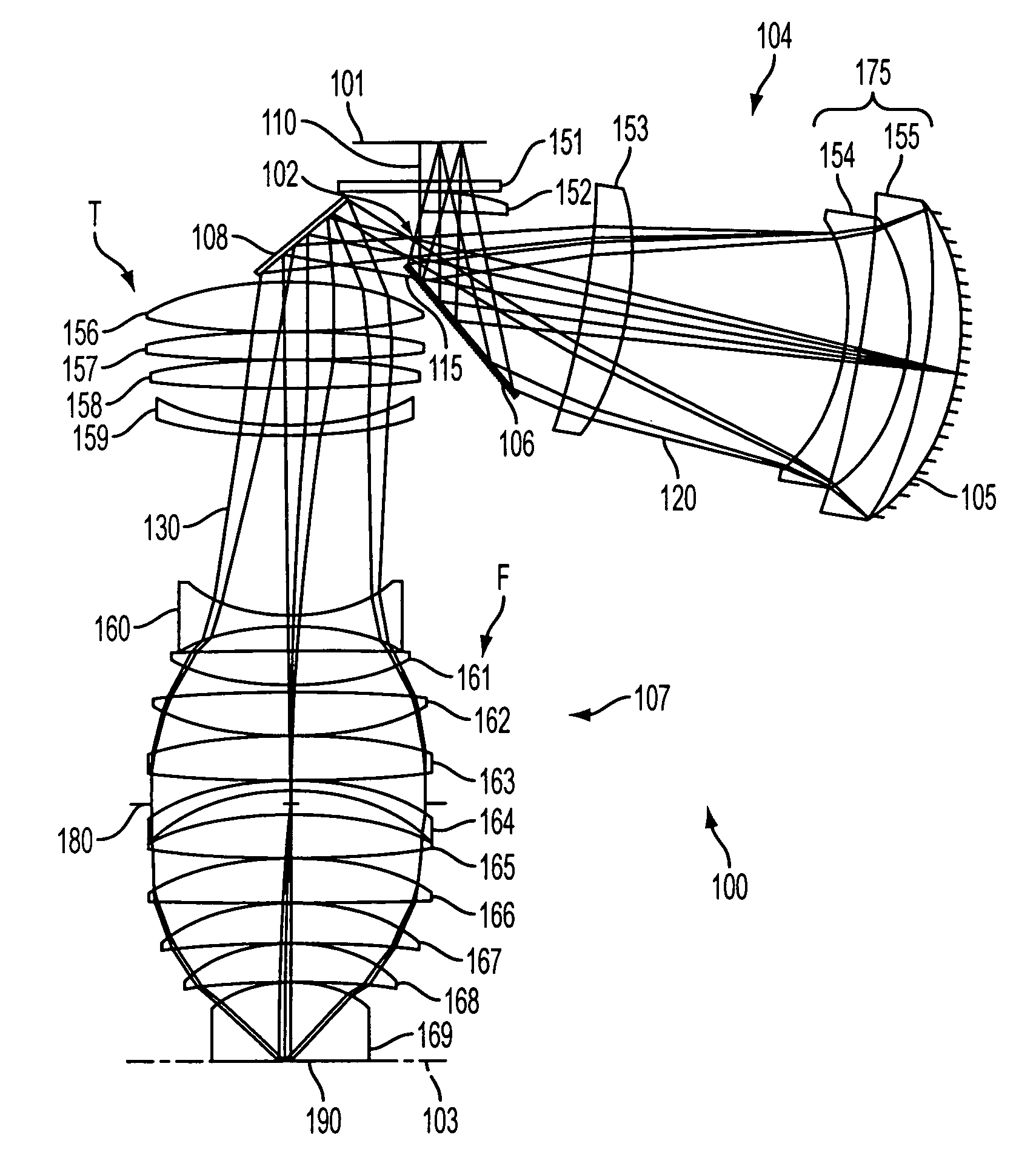

A projection exposure lens has an object plane, optical elements for separating beams, a concave mirror, an image plane, a first lens system arranged between the object plane and the optical elements for separating beams, a second double pass lens system arranged between the optical elements for separating beams and the concave mirror, a third lens system arranged between the optical elements for separating beams and the image plane. The second lens system has a maximum of five lenses.

Owner:CARL ZEISS SMT GMBH

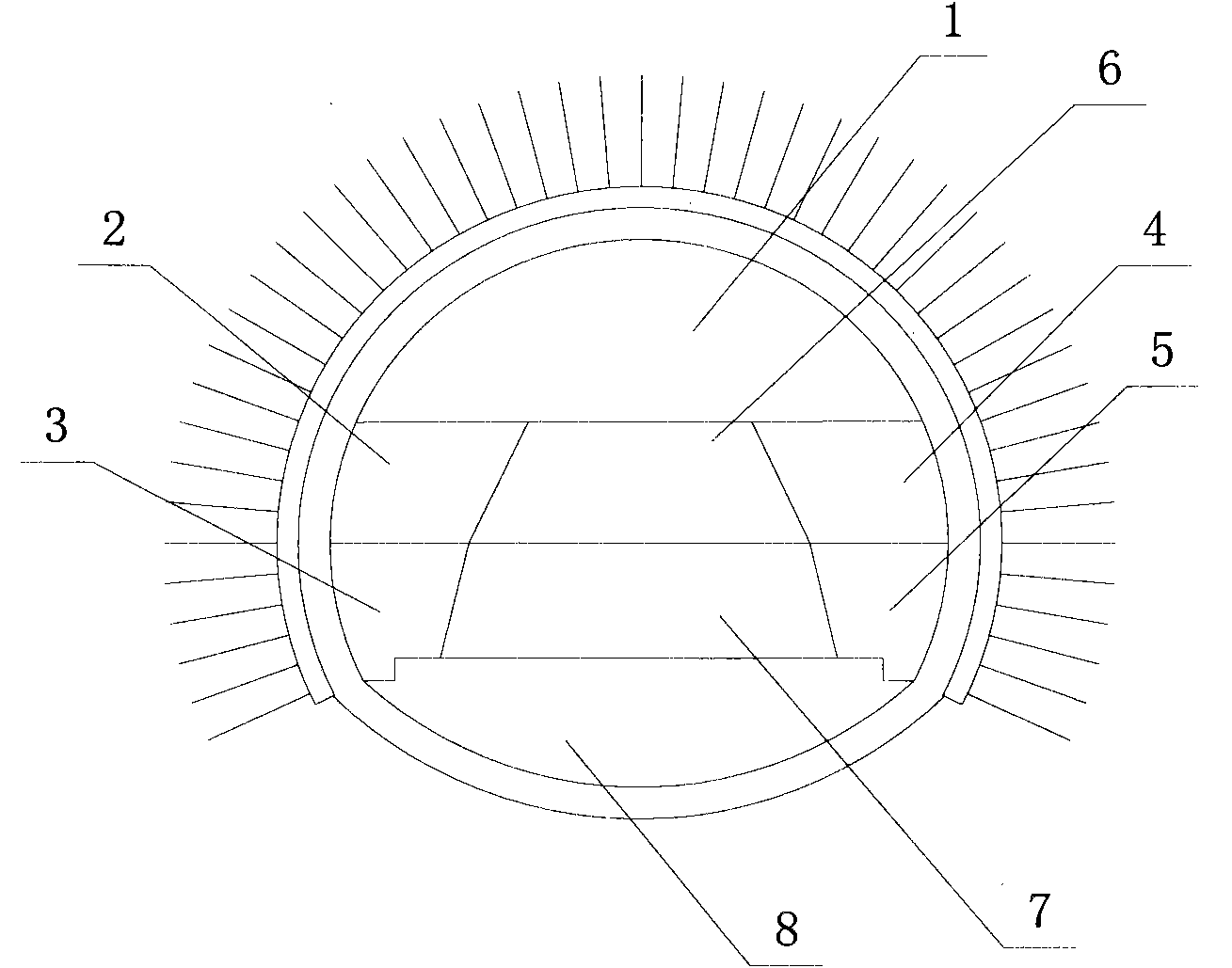

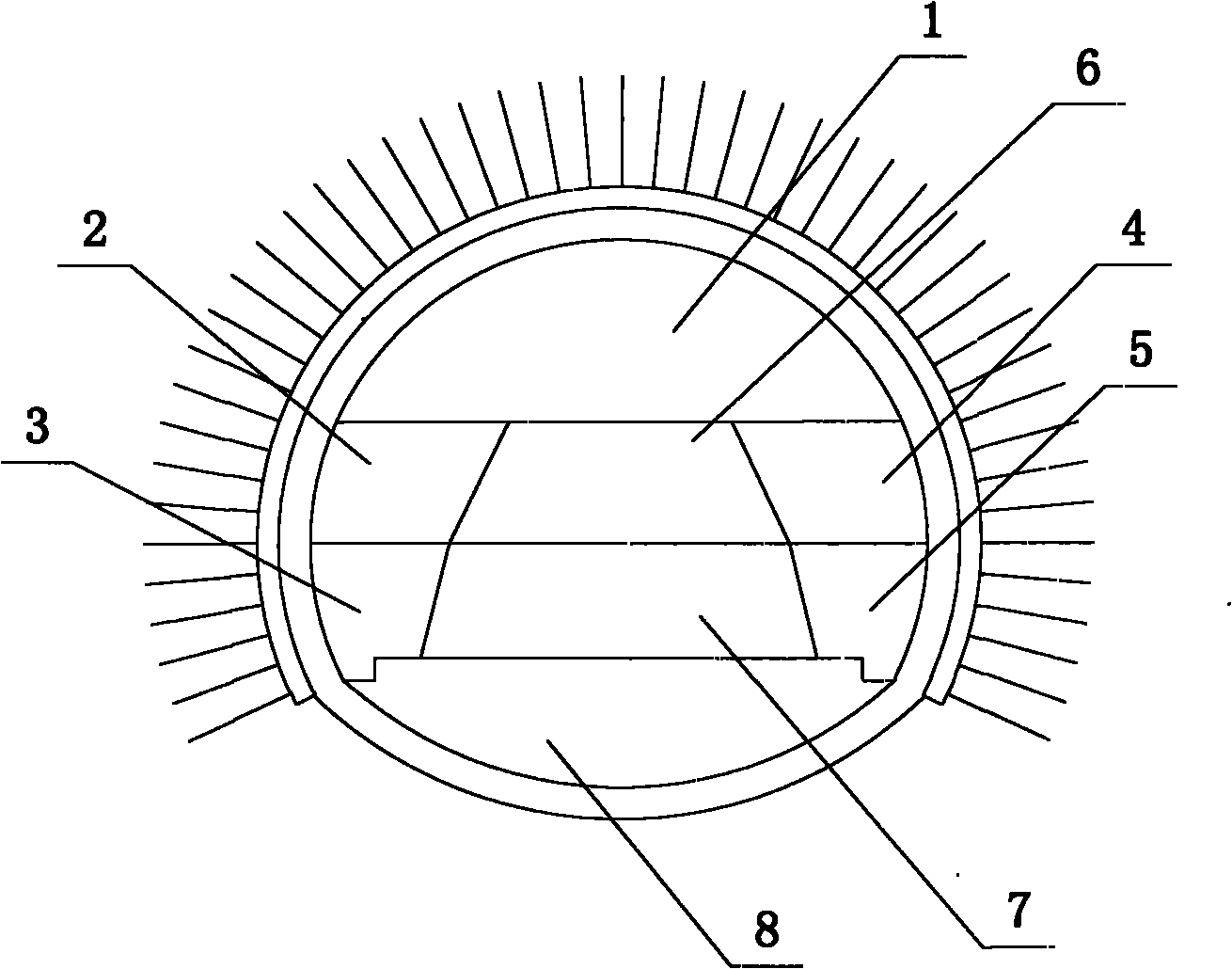

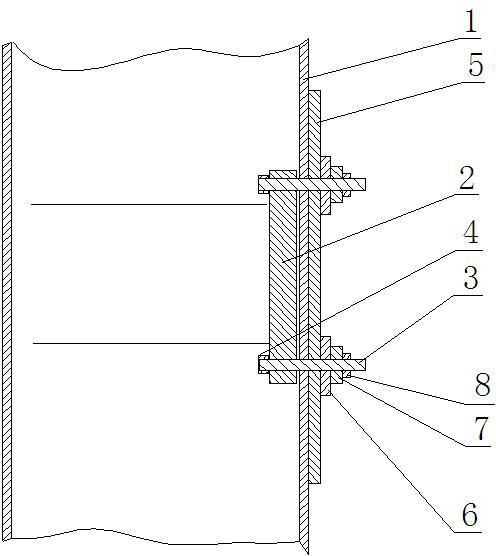

Large-section loess tunnel construction method

The invention discloses a large-section loess tunnel construction method, which comprises the following steps that: the whole section is divided into an upper part, a middle part, a lower part and a bottom part, wherein the middle part is divided into a middle left area, a middle right area and a middle intermediate area, the lower part is divided into a lower left area, a lower right area and a lower intermediate area, the four parts are excavated in a benching tunneling method with altitude differences, the upper part is 3-5m in front of the front middle part, the middle part is 3-5m in front of the front lower part, the lower part is 10m in front of the front bottom part, and the step-by-step tunneling excavation is carried out. The invention is suitable for collapsed loess areas, realizes the safe and reliable construction and saves a large number of temporary supporting steel frames. Due to the arc-shaped pilot tunnel method, the loop can be formed rapidly during excavation, the disturbance to the surrounding rock is low, the primary support is stable, the traditional construction method is further improved to be the 'two-step and four-part excavation method', and the construction cycle period is short. Moreover, the invention can speed up the progress of the project, shorten the construction period, and reduce the cost of the project.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

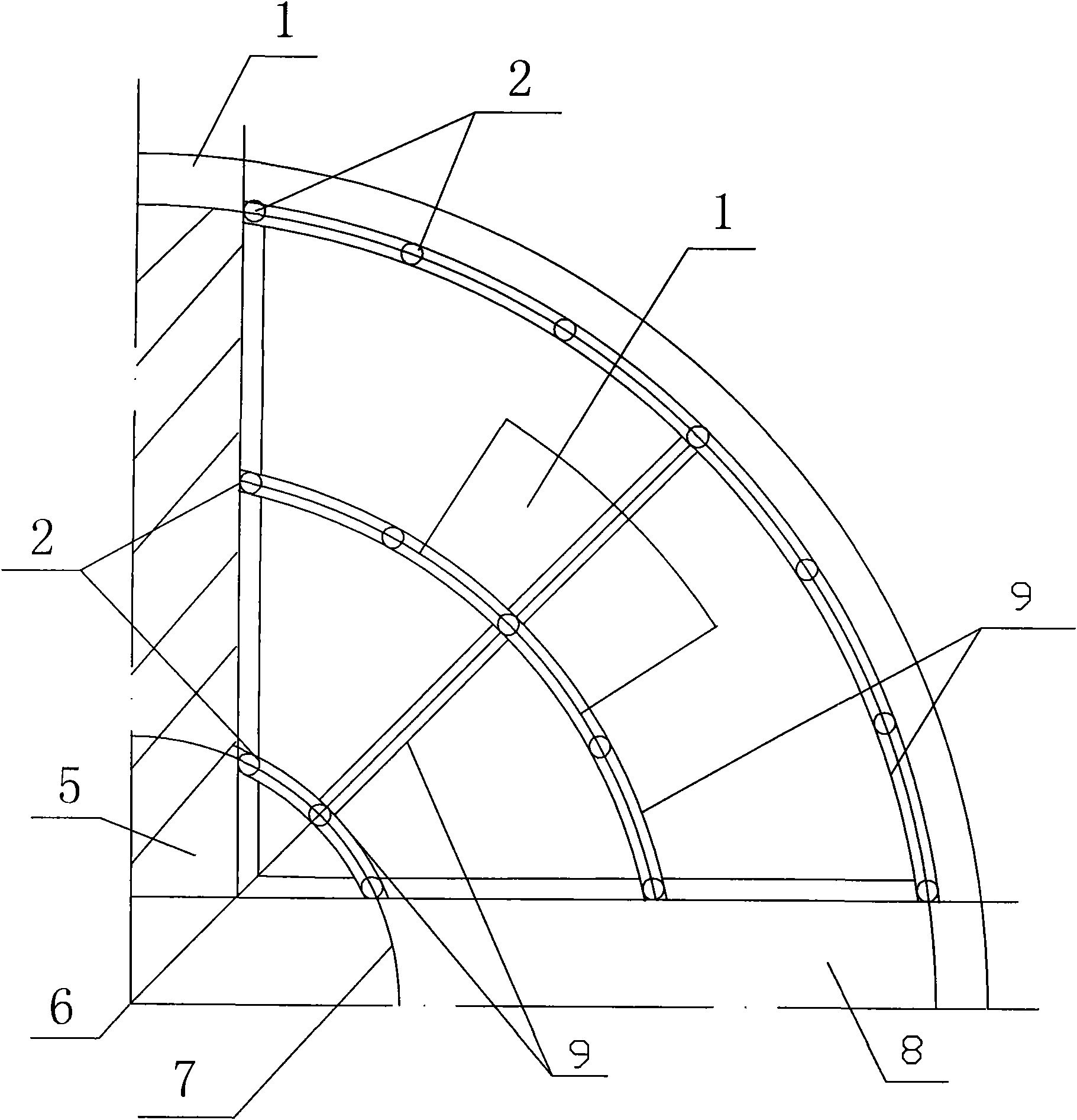

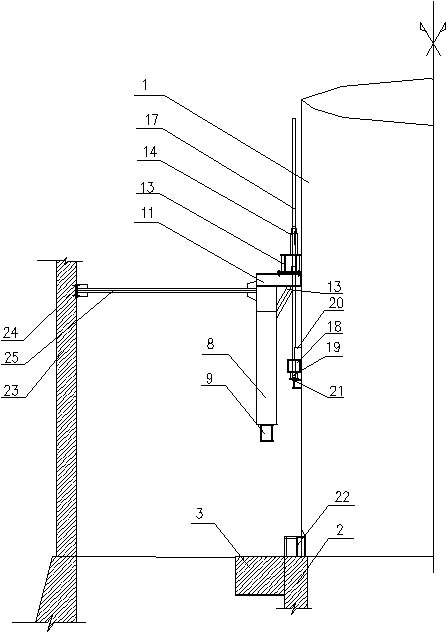

Hydraulic lifting inverted construction method for steel inner cylinder of chimney in thermal power plant

InactiveCN102108737AReduce investmentReduce construction costsBuilding constructionsTowersAnnular beamHydraulic pressure

The invention discloses a hydraulic lifting inverted construction method for a steel inner cylinder of a chimney in a thermal power plant, which comprises the following steps: (1) dividing the steel inner cylinder into a plurality of cylinder sections, and dividing each cylinder section into a plurality of cylinder sheets; (2) manufacturing a jack stand base in the steel inner cylinder, and mounting a hydraulic lifting device and a construction platform on the jack stand base; (3) beginning to assemble the first cylinder section of the steel inner cylinder, welding a plurality of sets of door-shaped clips on the inner wall of the first cylinder section along a circumferential direction, and clipping the horizontal annular beam by the door-shaped clips; (4) lifting the assembled cylinder section to the height of the first cylinder section by using the hydraulic lifting device, assembling a next cylinder section and welding the next cylinder section with the previous cylinder section; (5) cutting off the door-shaped clips and transferring and mounting the door-shaped clips and the horizontal annular beam to the corresponding position of the next cylinder section; and (6) repeatedly circulating the steps (4) and (5), and mounting the subsequent cylinder sections in turn. The method has the advantages that: the construction cost is low; the stress is definite, the operation is simple and convenient, and the safety factor is high; and the construction period is short and the project quality is high.

Owner:DONGDIAN YANTA ENG

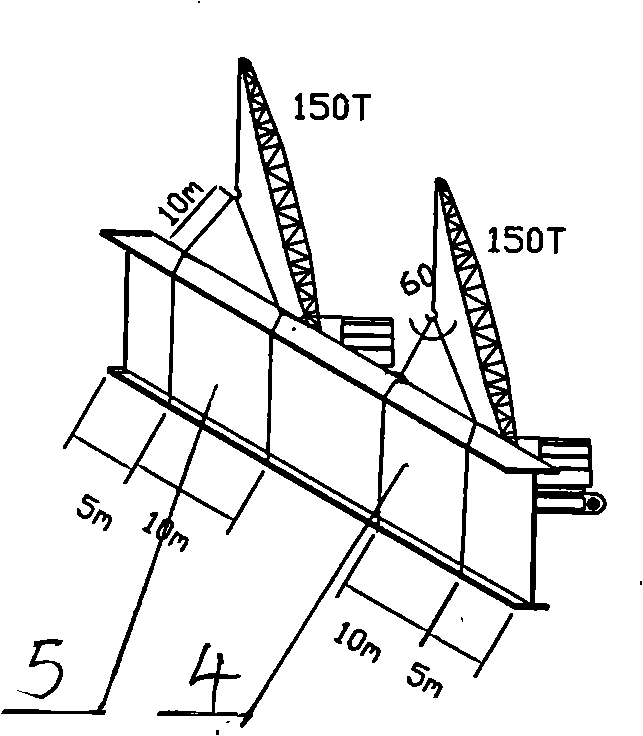

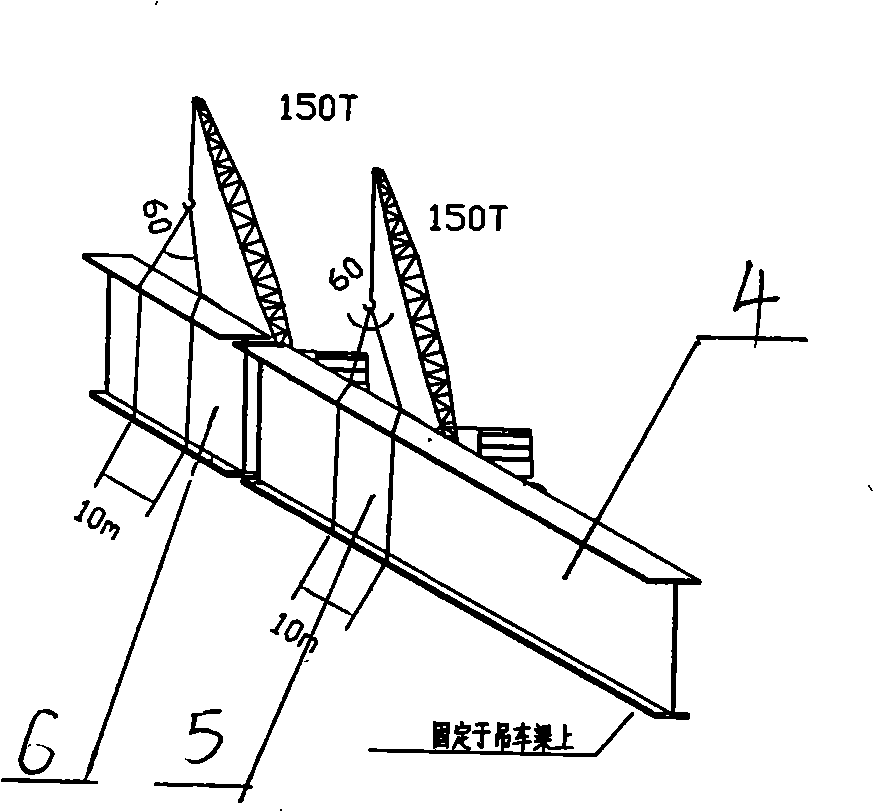

Giant crane beam mounting method

The invention relates to a construction method, in particular to a method for installing super-large crane beams, solving the technical problems of the prior art in the installation of large-span and large-mass crane beams. The method for installing the super-large crane beams comprises the following steps: a temporary bracket is first put up on the ground at one third of the span of a crane beam installation position; a crane beam is assembled on site; a left-segment crane beam component and a middle-segment crane beam component which are welded together are integrally lifted in place by use of two cranes; the left-segment crane beam component is partially fixed with a steel column connecting part; the other end of the middle-segment crane beam component falls on the bracket; a right-segment crane beam component is lifted to the height in accordance with the middle-segment crane beam component by use of another crane; and the right-segment crane beam component and the middle-segment crane beam component are paired and welded in the air. The method is applicable to the installation of the crane beam of which the length is over 60 meters and the mass is over 220 tons. The method has the advantages of high safety performance, short construction period, convenient construction operation and good engineering quality.

Owner:MCC TIANGONG GROUP

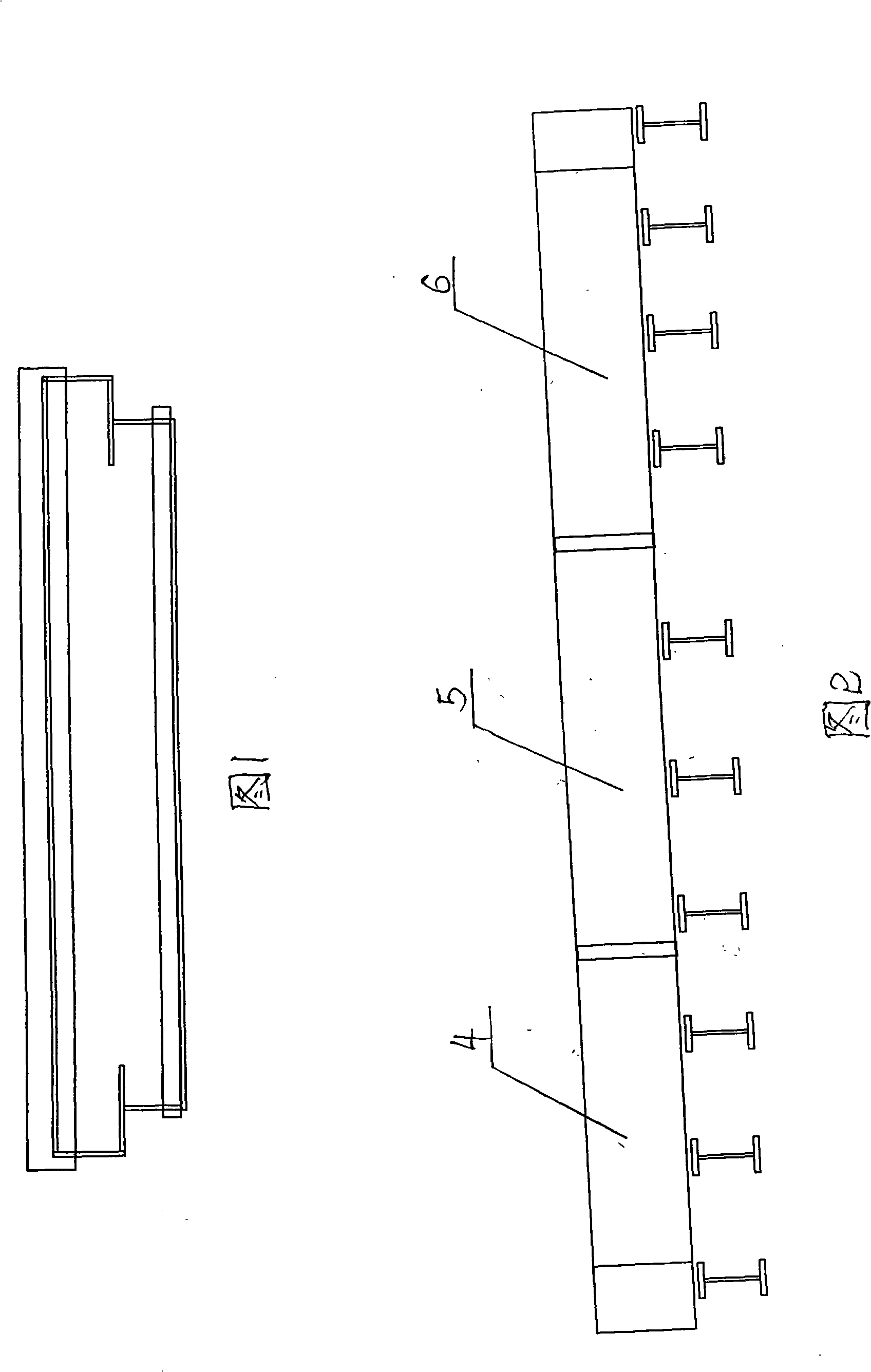

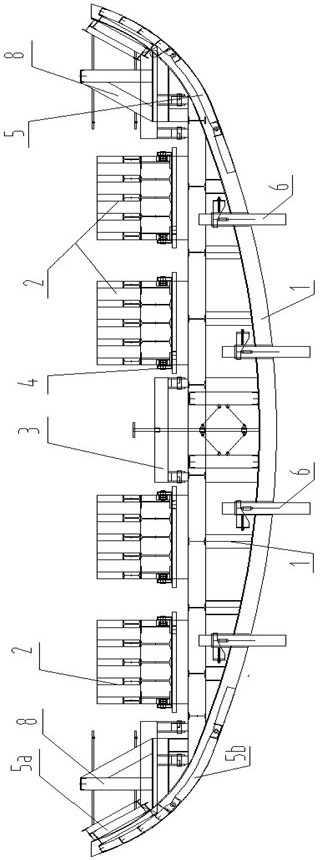

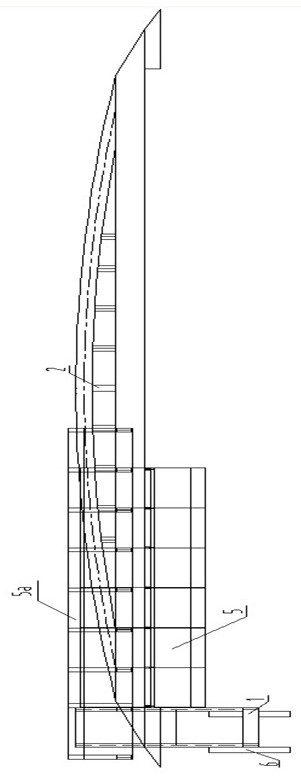

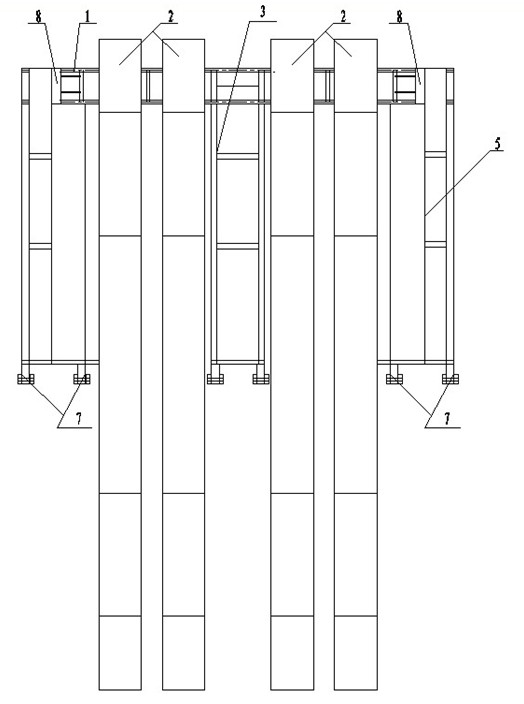

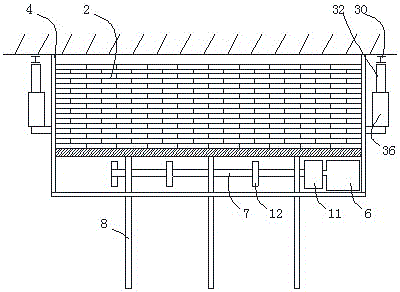

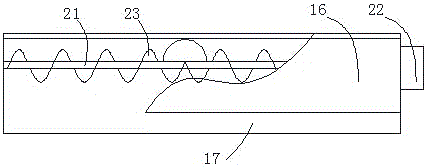

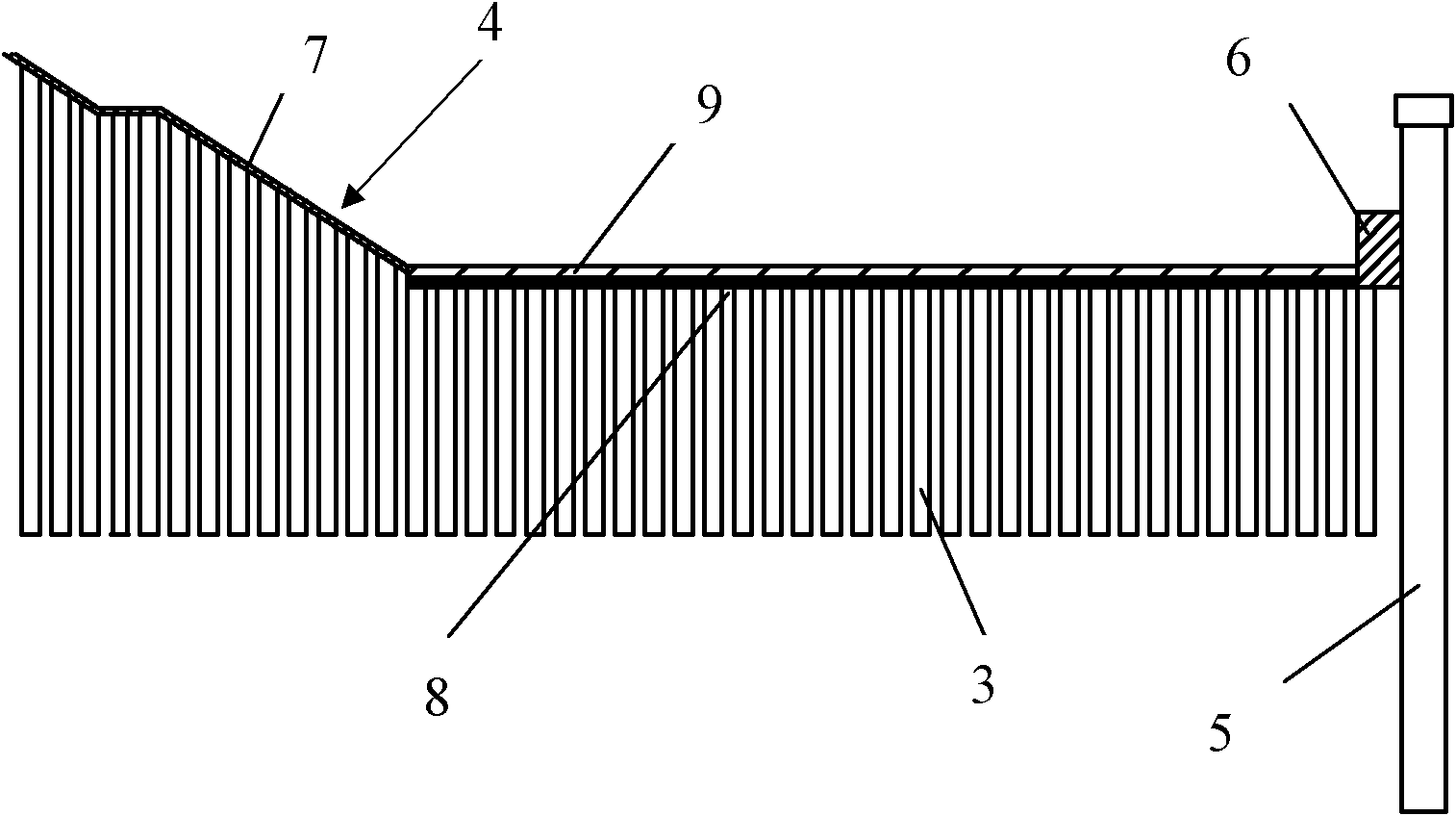

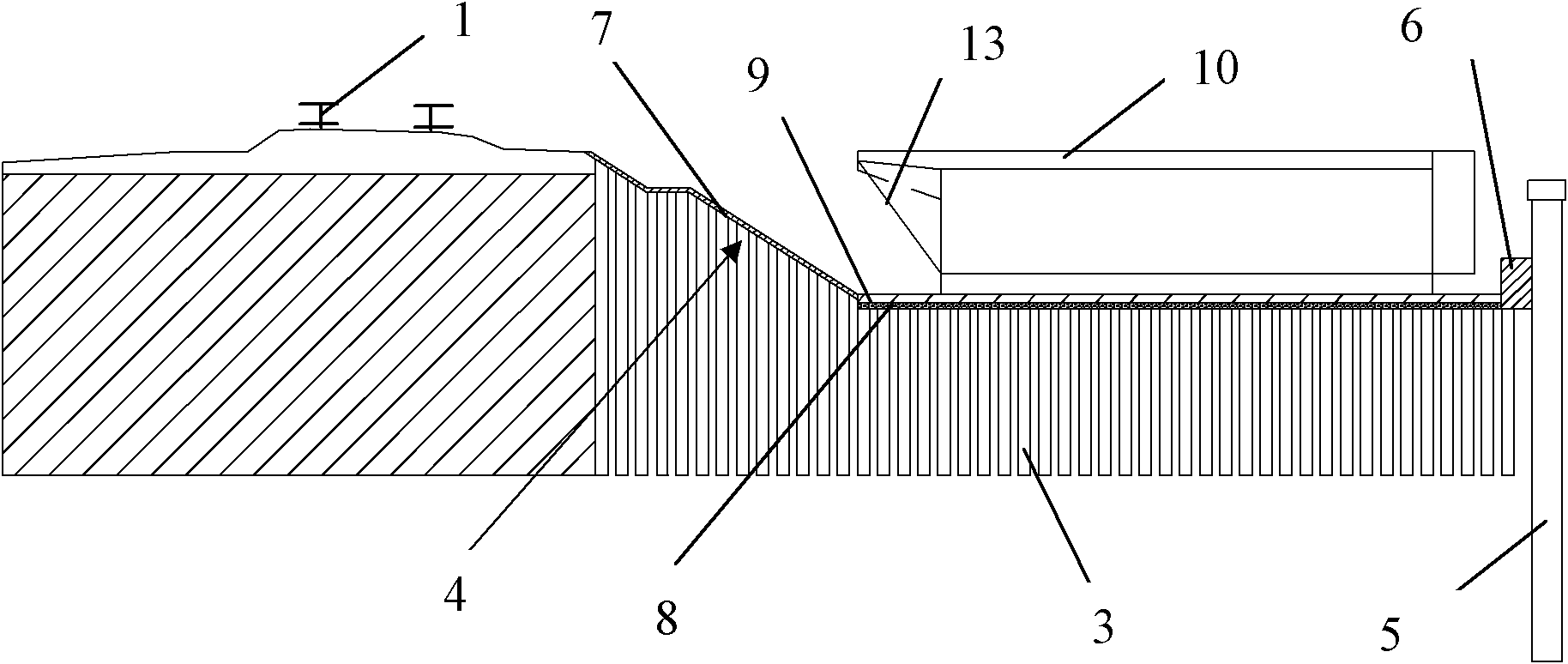

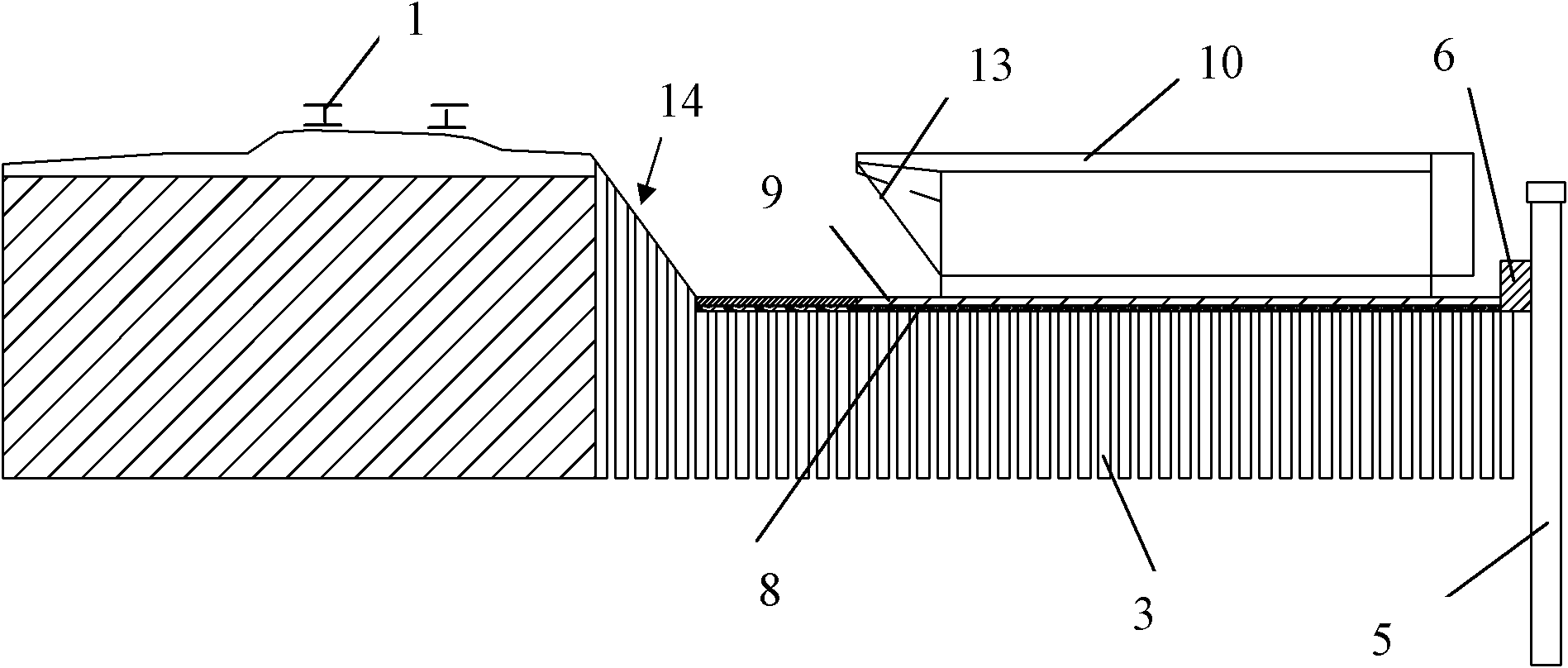

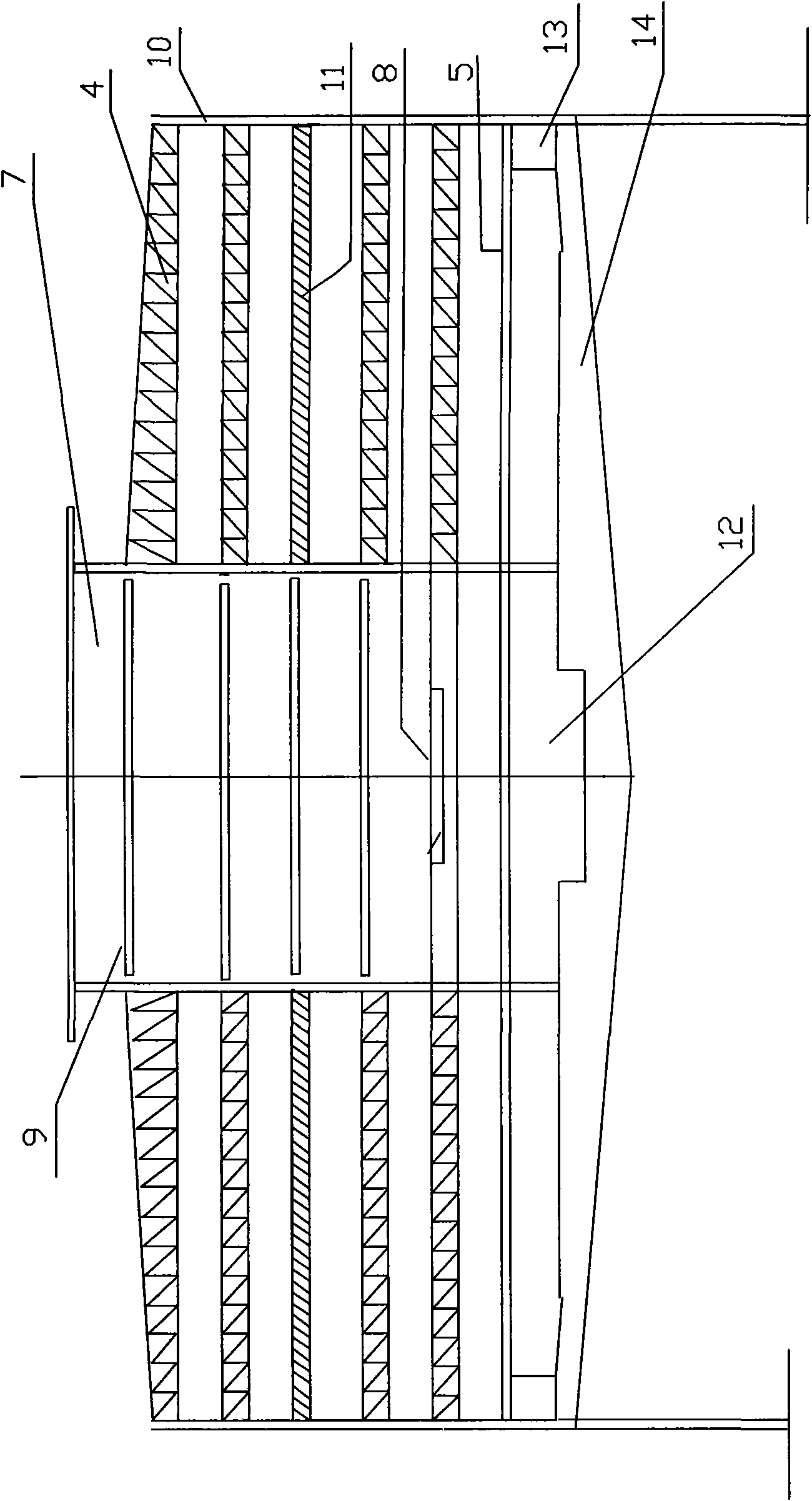

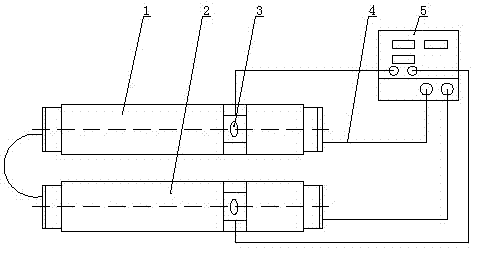

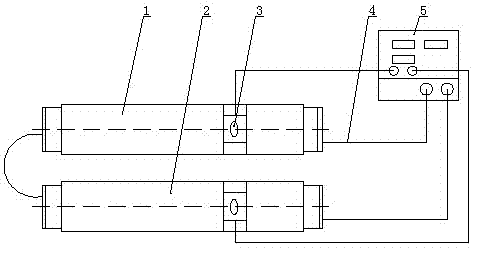

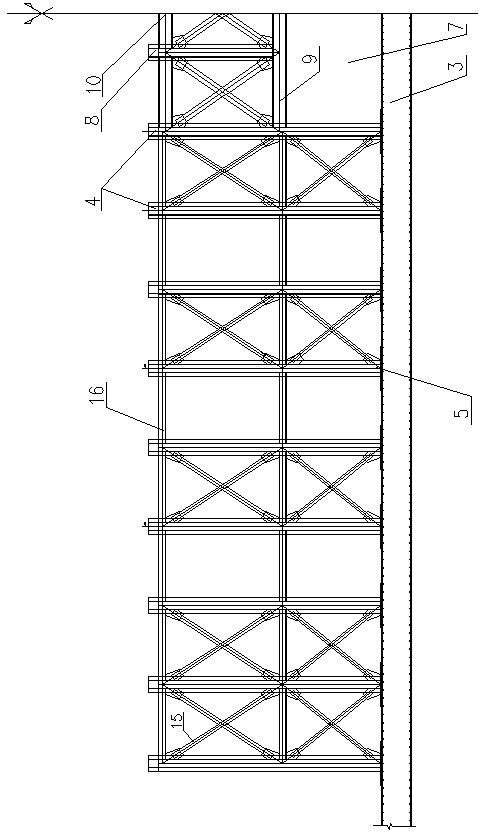

Construction equipment for inverted arch of two-track tunnel of high-speed railway

ActiveCN102146799AIncrease the level of mechanizationPrecise positioningUnderground chambersTunnel liningUltimate tensile strengthMechanization

The invention relates to construction equipment for the inverted arch of a two-track tunnel of a high-speed railway, belonging to the technical field of tunnel construction equipment. In the invention, the construction equipment for the inverted arch of the two-track tunnel of the high-speed railway comprises a trestle, an inverted arch mould frame and a terminal beam, wherein the terminal beam is connected with the inverted arch mould frame to form into a whole; the terminal beam and / or the inverted arch mould frame are / is connected to the trestle; and the terminal beam and the inverted archmould frame autonomously move on the trestle. In the invention, the construction equipment for the inverted arch of the two-track tunnel of the high-speed railway can position accurately, move in place fast and convenient, and has the advantages of high mechanization level, low article labor intensity and low construction cost; the construction equipment can complete the inverted arch through one-time monolithic casting with high construction efficiency and high construction quality, and can provide guarantee for quick tunneling; construction organization and work procedure partition in the tunnel are optimized, thereby being beneficial to standardized operation and safe and civil construction; and the construction operation is convenient and fast, breaks through the traditional inverted arch construction technology and ensures the continuous construction quality of the inverted arch, thus being in favor of popularization and application.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

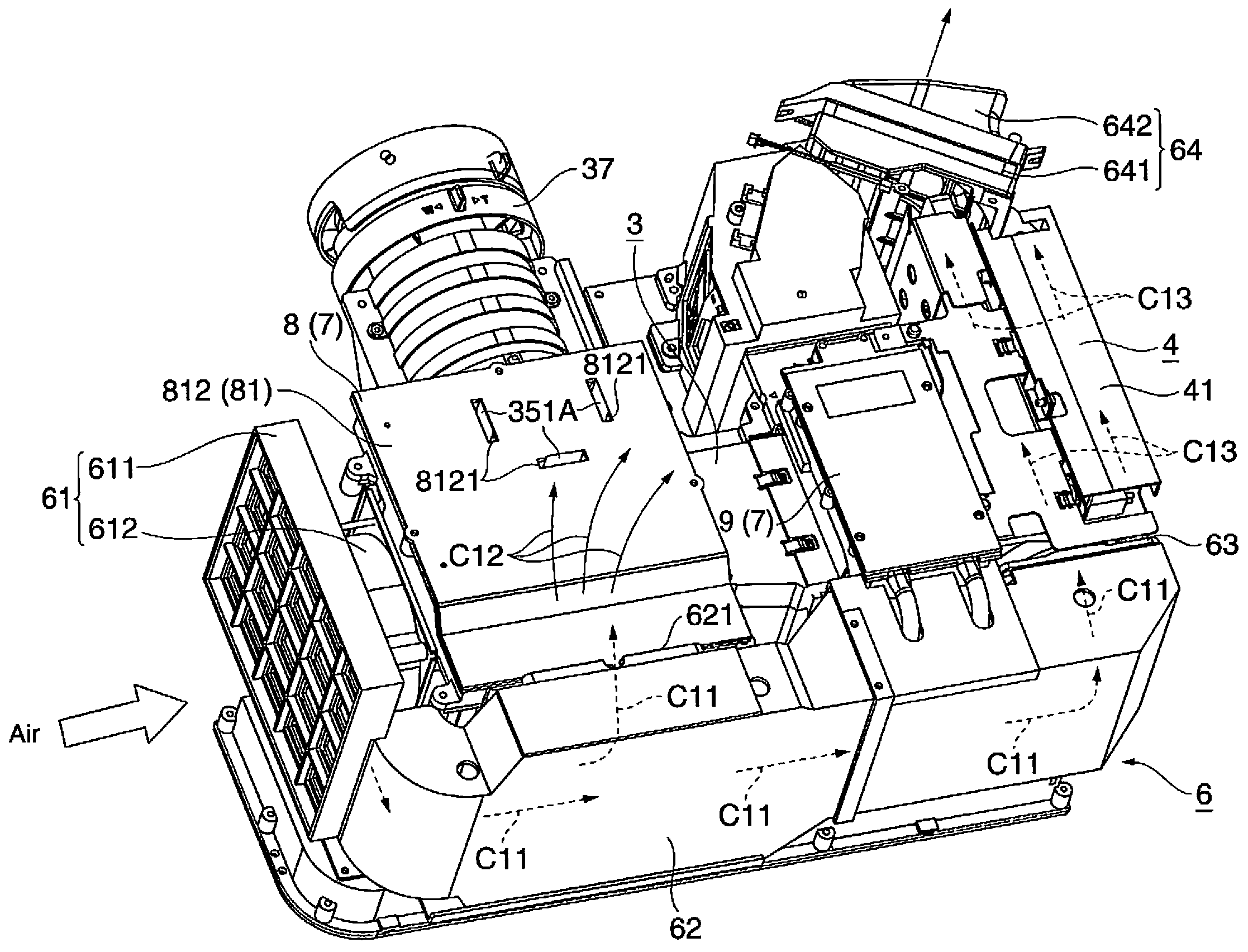

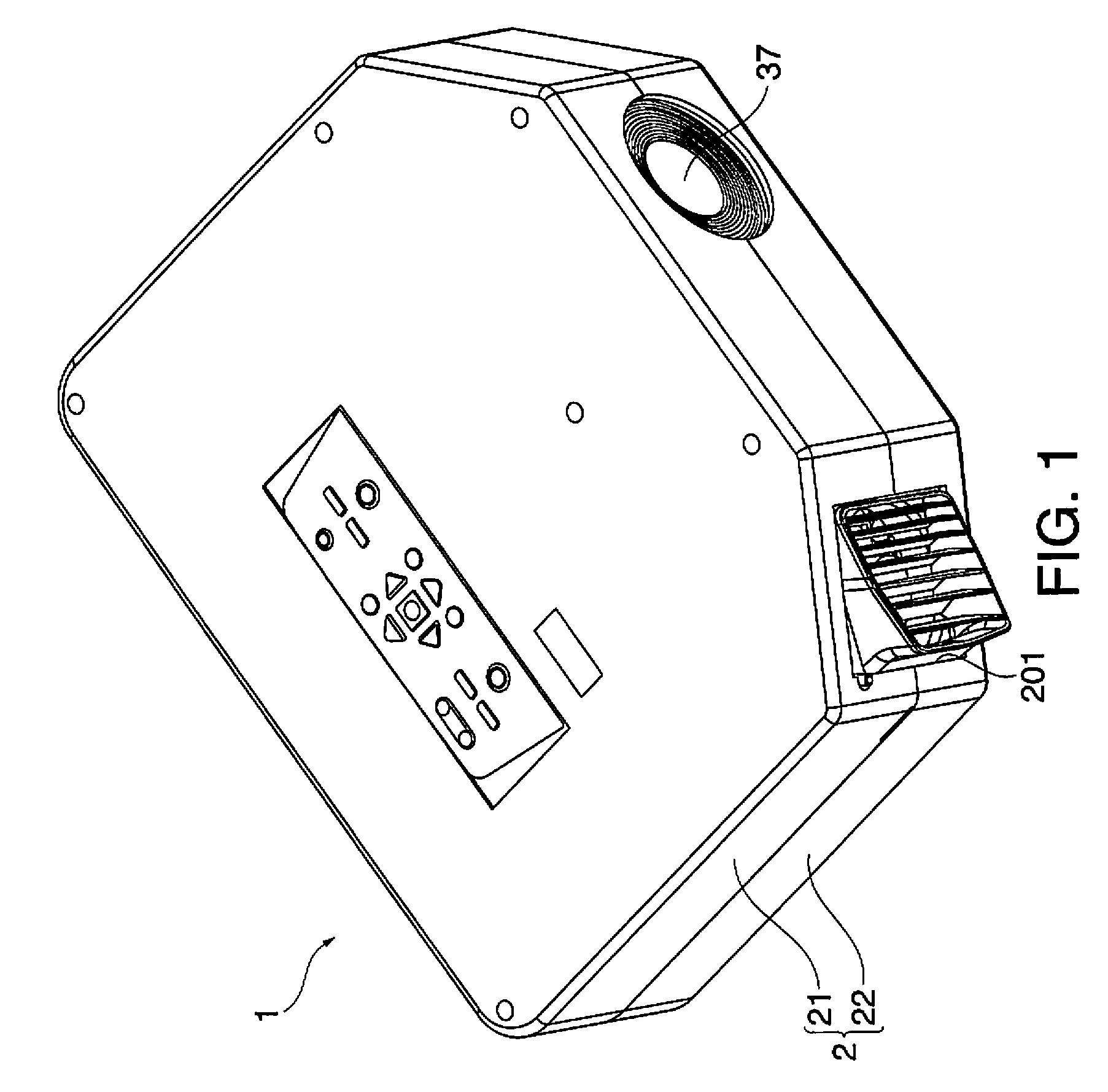

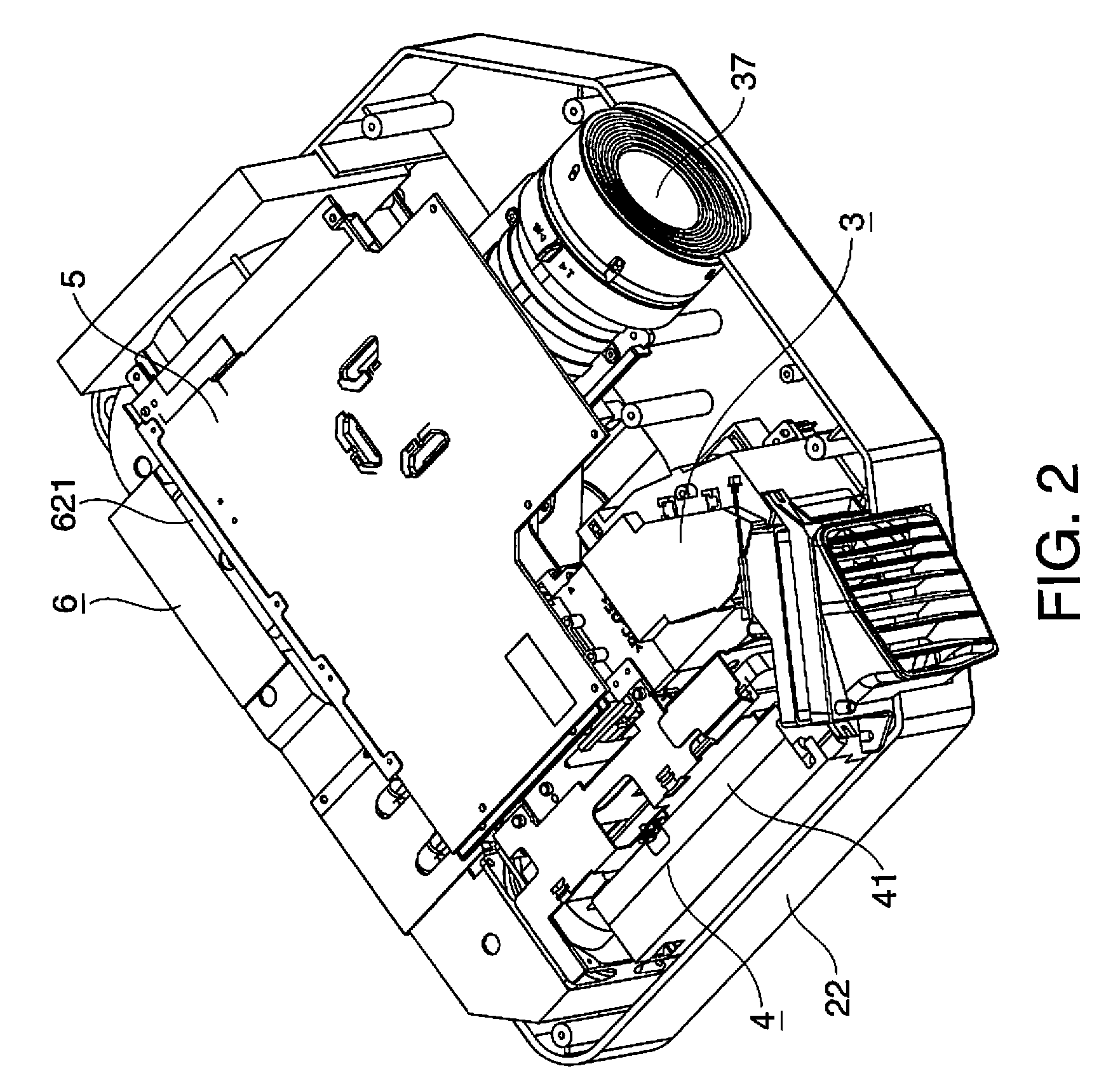

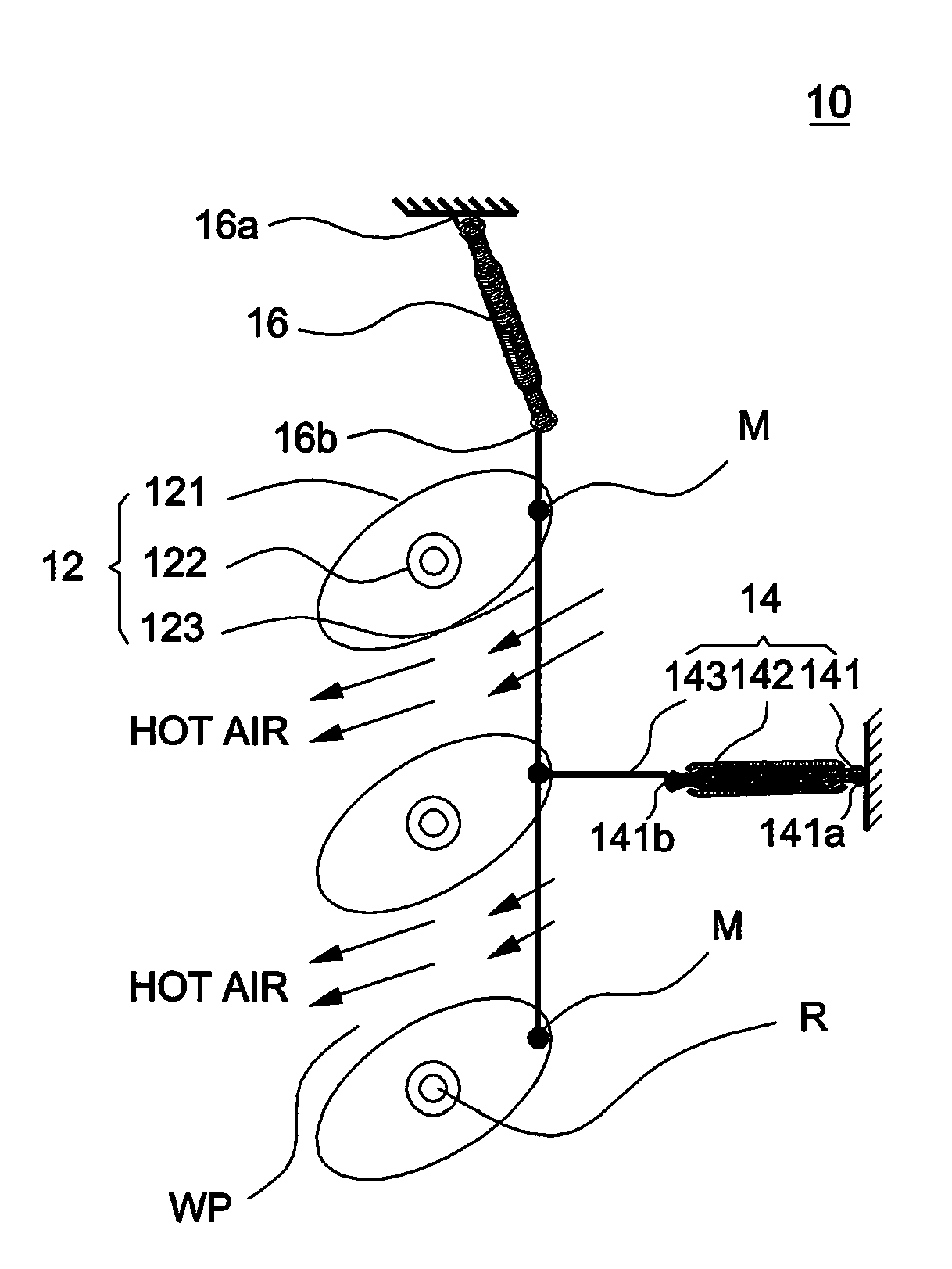

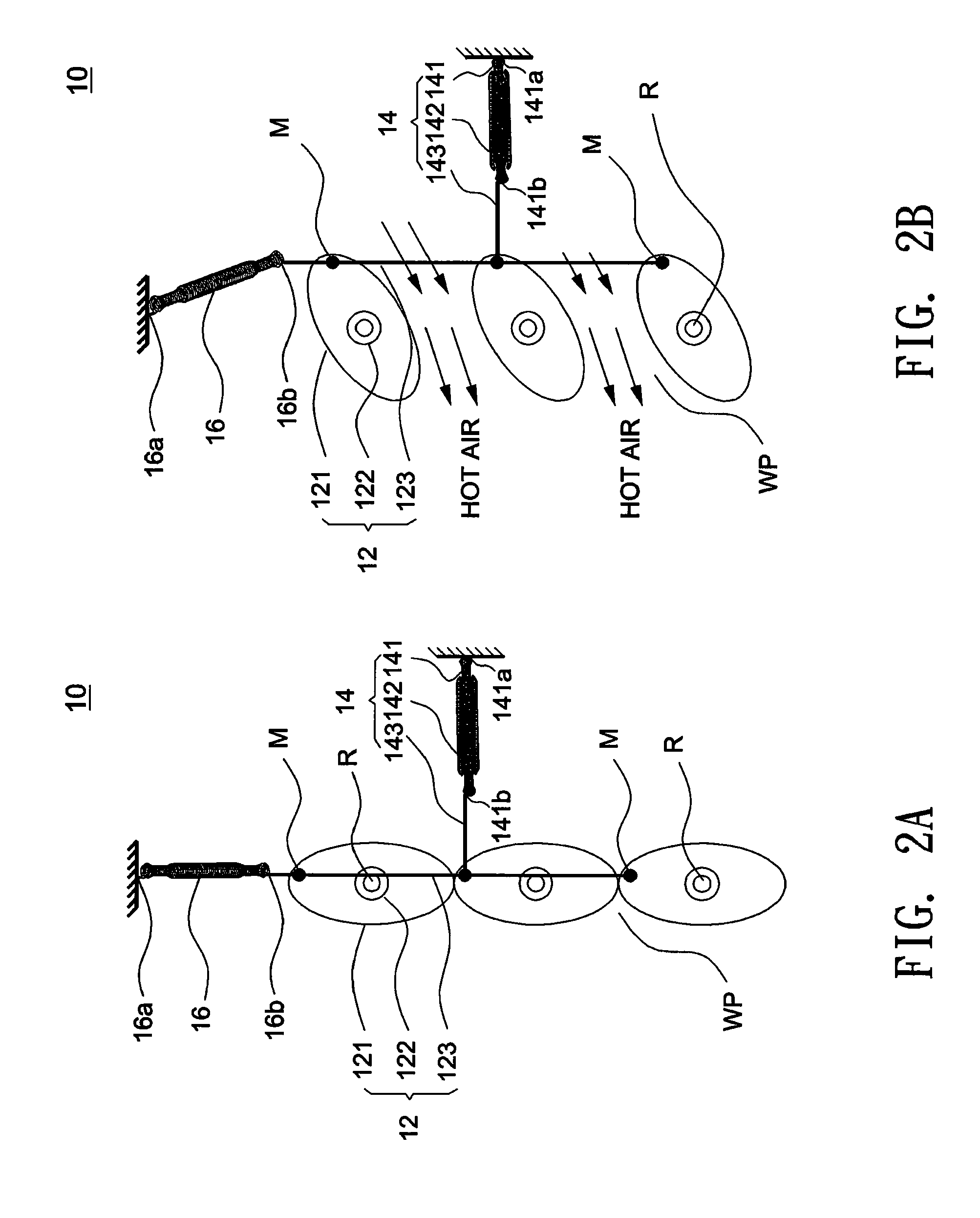

Projector

InactiveUS20090141249A1Improve cooling effectEffective absorptionProjectorsEngineeringHeat exchanger

A projector includes: an optical component disposed inside a closed structure having air flow path through which air flows; and a circulating fan which circulates air. The closed structure includes: an optical component housing which accommodates the optical component; a duct which introduces air into the optical component housing, and introduces the air having flowed to the outside from the inside of the optical component housing again toward the inside of the optical component housing; and a plurality of heat exchangers each of which has a heat receiving side heat transfer member which faces the inside of the closed structure, and a heat releasing side heat transfer member which faces the outside of the closed structure. The plural heat exchangers are disposed in the air flow direction along the air flow path through which air flows to the outside from the inside of the optical component housing.

Owner:SEIKO EPSON CORP

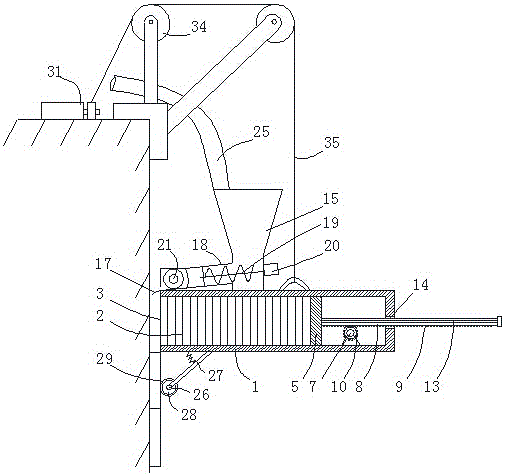

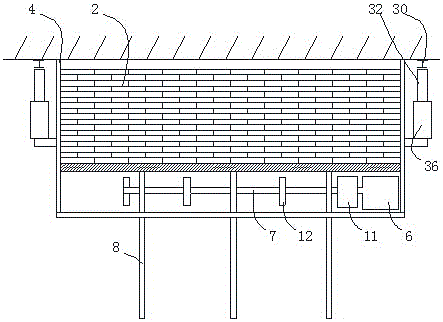

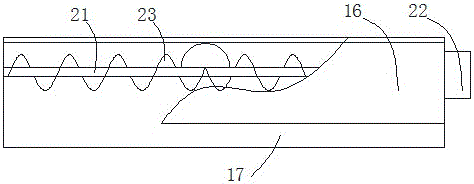

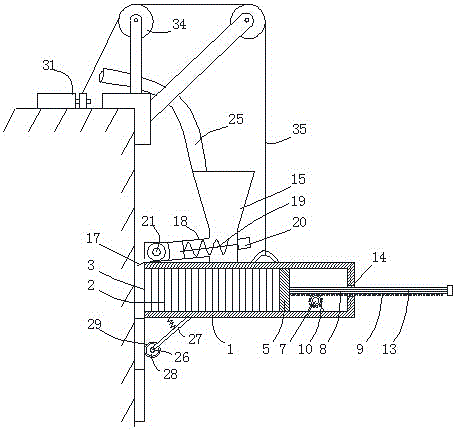

Building external wall surface brick paving machine

InactiveCN105863229AReduce the labor intensity of layingImprove work efficiencyBuilding constructionsBrickArchitectural engineering

The invention discloses a building external wall surface brick paving machine. The building external wall surface brick paving machine is characterized in that the machine comprises a wall brick containing box used for being horizontally installed on the external wall surface of a building. Vertical wall bricks can be arranged and stacked in an inner cavity of the wall brick containing box, one end of the wall brick containing box is the open end and forms an outlet, and the other end of the wall brick containing box is provided with a wall brick push device. The wall brick push device can be used for pushing the wall bricks vertically arranged and stacked in the inner cavity of the wall brick containing box out of the outlet. A plastering grouting device used for performing grouting and plastering on a wall in front of the pushed-out wall bricks is disposed on the upper side of the open end of the wall brick containing box. A supporting lifting device is also included, used for making the outlet end of the wall brick containing box directly face the wall and be supported on the wall and capable of lifting the wall brick containing box upwards. By means of the building external wall surface brick paving machine, automatic flow paving of the building external wall surface bricks can be achieved, and the labor intensity of wall brick paving is relieved. The building external wall surface brick paving machine has the advantages that the working efficiency is high, the project quality is good, and the project quality consistency can be guaranteed.

Owner:YANGTZE NORMAL UNIVERSITY

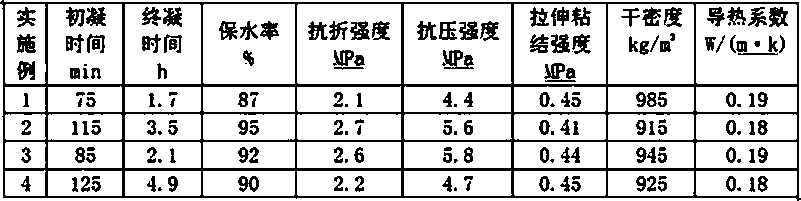

Desulfurized-gypsum-base lightweight spraying gypsum mortar

Disclosed desulfurized-gypsum-base lightweight spraying gypsum mortar is composed of the following compositions in parts by weight: 50-65 parts of desulfurized gypsum, 20-30 parts of building sand, 3-5 parts of vitrified microsphere, 10-20 parts of stone powder, 0.1-0.5 part of a retarder, 0.1-0.3 part of cellulose ether, 0.02-0.04 part of an air-entraining agent, and 0.05-0.1 part of starch ether. The desulfurized-gypsum-base lightweight spraying gypsum mortar employs mechanical spraying for construction, possesses the dry density less than 1000 Kg / m<3>, the heat-conduction coefficient of 0.20 W / (m*K) and the compressive strength lager than 4.0 MPa, and possesses the characteristics of being light in weight, low in heat-conduction coefficient, high in strength and suitable for mechanical spraying construction, and the like.

Owner:JIANGSU NIGAO SCI & TECH +1

Exterior wall thermal insulation brick and manufacturing method thereof

InactiveCN101105062AHigh bonding strengthGood engineering qualityConstruction materialDomestic articlesBrickEngineering

A heat-insulating brick for outer wall comprises a heat-insulating member and a wall member, wherein the wall member is block-shaped and has an inner cavity; the heat-insulating member is filled in the inner cavity and made of foaming materials; and a plurality of barbs are arranged on the side wall of the inner cavity and any one of the barbs is embedded inside the heat-insulating member. A method for manufacturing the heat-insulating brick for outer wall is also provided, which comprises the step of combining the heat-insulating member with the wall member, wherein a die is firstly fabricated, sequentially the wall member is embedded in the die and then the foaming material is filled in the die cavity, heated steam is introduced into the die cavity to allow the expansion of foaming material, and finally the product is cooled and demoulded. The invention integrates the heat-insulating member with the wall member in the manufacturing process, and the connection with the building is realized by mechanical manner using fasteners such as expansion screws. The invention has the advantages of easy construction, no seasonal influence, less working hour, high bonding strength between the heat-insulating member and the wall member, and good construction quality.

Owner:顺旺现代包装材料(上海)有限公司

External wall brick paving method

InactiveCN105863228AReduce the labor intensity of layingImprove work efficiencyBuilding constructionsBrickStructural engineering

The invention discloses an external wall brick paving method. The external wall brick paving method is characterized in that wall bricks are vertically arranged in rows; the wall bricks of all rows are gathered and arranged from front to back according to the actual paving sequence from bottom to top and put in a wall brick containing box of which one end is an outlet and the wall brick paving surfaces directly face the outlet; the outlet of the wall brick containing box directly faces a to-be-paved wall surface, and the wall brick containing box is controlled to be lift gradually; and in the lifting process, plaster is applied to the wall surface in front of the outlet of the wall brick containing box to achieve plastering, then the wall bricks are controlled to be pushed out in rows and attached to the already applied plaster, and paving is finished. Accordingly, the effect of paving the wall bricks in rows can be achieved, and the wall brick paving efficiency is greatly improved. By means of the external wall brick paving method, automatic flow paving of the building external wall surface bricks can be achieved, and the labor intensity of wall brick paving is relieved. The external wall brick paving method has the advantages that the working efficiency is high, the project quality is good, and the project quality consistency can be guaranteed.

Owner:YANGTZE NORMAL UNIVERSITY

A large-scale box jacking control construction method that can improve precision

ActiveCN102277880AHigh precisionImprove bearing capacityArtificial islandsExcavationsSlurryBearing capacity

The invention discloses a large-sized box jacking control construction method capable of enhancing accuracy. The construction method comprises the following steps of: arranging a plurality of cement stirring piles into a foundation pit on one side of a railway on which a frame bridge is required to be paved; reinforcing a subgrade soil body below the railway with cement water glass slurry to enhance the bearing force of a foundation; jacking a large-sized box towards the lower side of the railway by using jacking equipment; and preventing the large-sized box from being subjected to phenomena such as deviation, head tying or head raising and the like by different measures. By adopting the method, the positioning accuracy of the large-sized box can be ensured, good engineering quality and high safety are achieved, and normal operation of the existing railway is not obstructed.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Thermal insulation material and its preparing process and usage

The invention discloses a thermal insulating material which is prepared from the following raw materials: construction gypsum 75-79 parts, thickening agent 1.9-2.3 parts, rubber powder 1.7-2.0 parts, water-loss reducer 0.4-0.5 part, gypsum retarder 0.3-0.5 part, reinforcing agent 0.5-0.7 part, filler 16-19.5 parts, vitreous beads 49-51 parts through a step of blending.

Owner:SHANGHAI KENAI NEW MATERIAL TECH CO LTD

Heat-dissipating device and projection display apparatus having the same

InactiveUS20100007859A1Easy to operateImprove cooling effectLighting heating/cooling arrangementsProjectorsShape-memory alloyEngineering

A heat-dissipating device used in a projection display apparatus with an air outlet includes a fence module, at least one resilient member, and a shape memory alloy module. The fence module is disposed at the air outlet and includes at least one guiding plate with a pivot. The resilient member exerts a first force on the guiding plate to enable the guiding plate to rotate on the pivot, and the shape memory alloy module deforms when heated to exert a second force on the guiding plate to enable the guiding plate to rotate on the pivot.

Owner:CORETRONIC

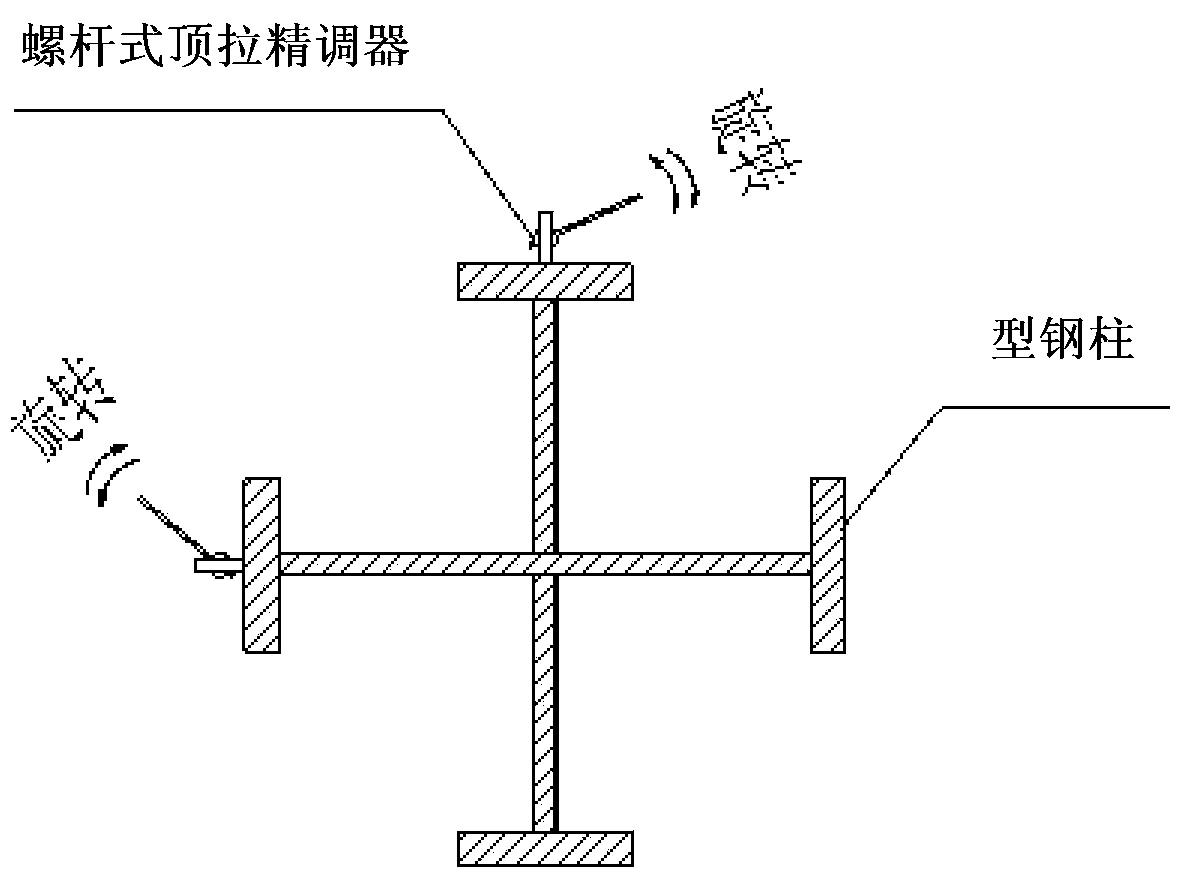

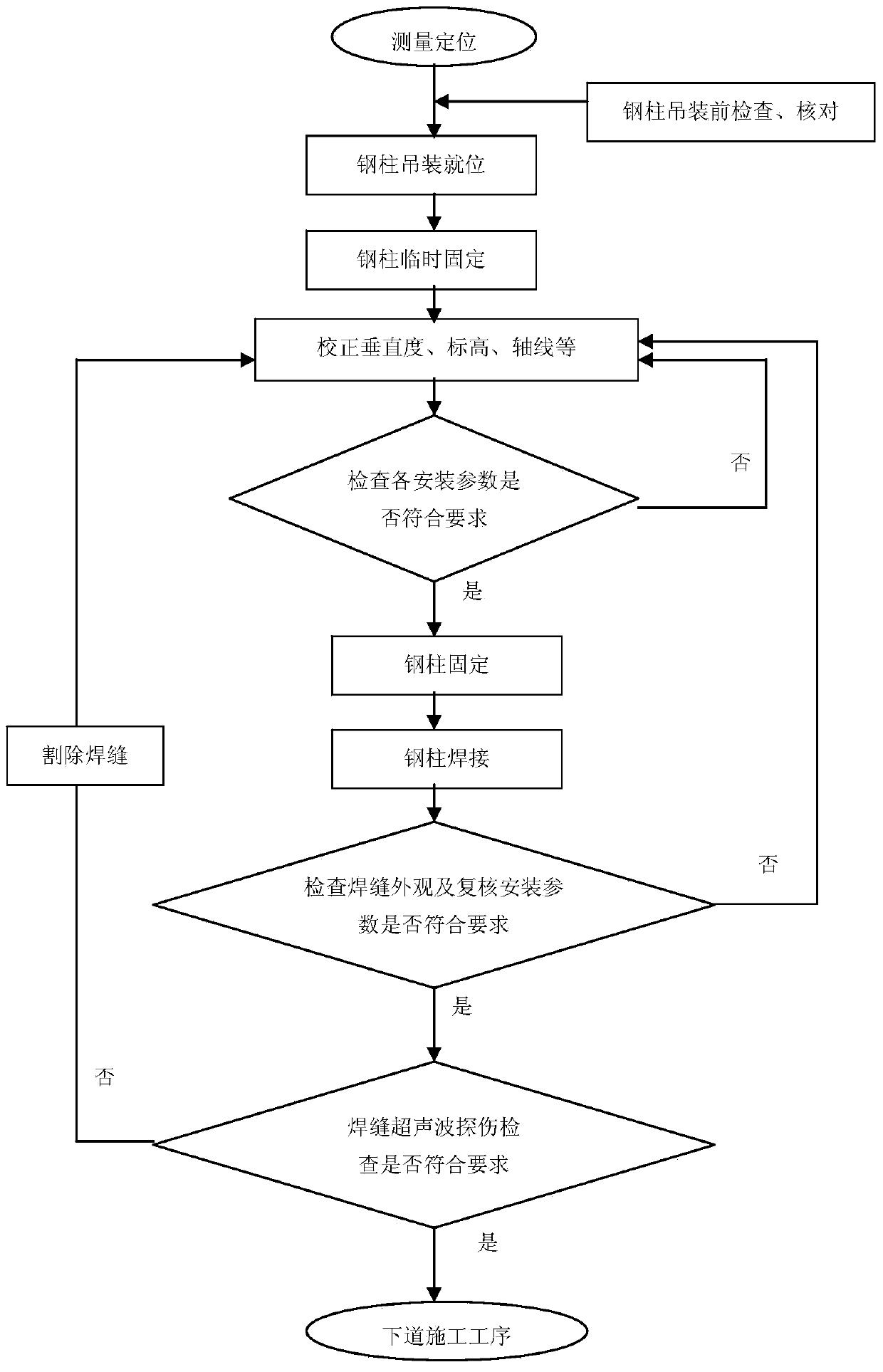

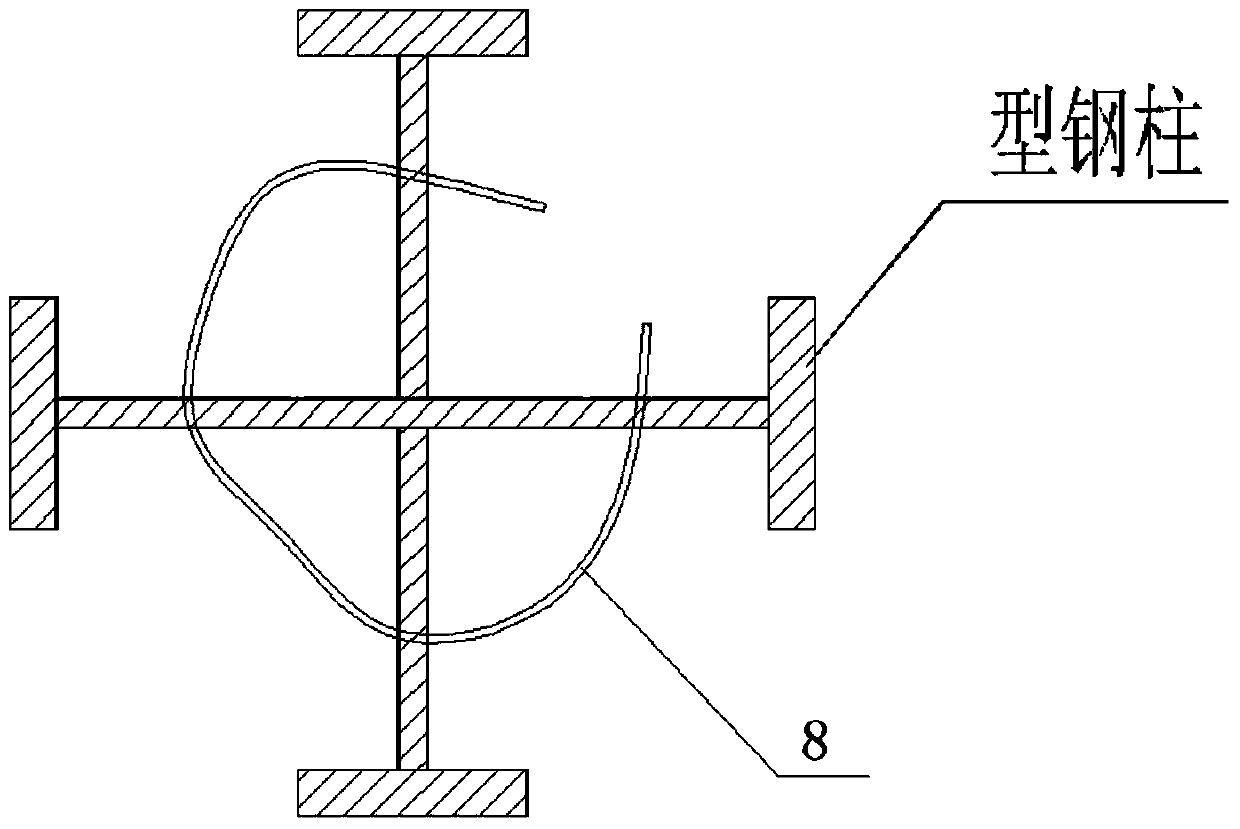

Construction method for H-type steel stiff column with cross fracture surface

InactiveCN103806669AAccurate axis controlAccurate control of verticalityBuilding material handlingSteel columnsHigh rise

The invention discloses a construction method for an H-type steel stiff column with a cross fracture surface. The construction method includes the steps of measuring and positioning, inspecting and checking before hoisting the H-type steel stiff column, hoisting the H-type steel stiff column in place, fixing the H-type steel stiff column temporarily, correcting the H-type steel stiff column, fixing the H-type steel stiff column, welding H-type steel stiff column and the like. The axis and perpendicularity of section steel column installation can be controlled accurately, structural construction is high in precision, construction quality is reliable, and the construction method is suitable for installation and construction of the H-type steel stiff columns with the cross fracture surfaces in a high-rise building, a super high-rise building, a long-span structure and a common structure.

Owner:DALI CONSTR GRP +2

PHC pile and water flush gas lift static pressure pile-sinking method

The present invention is new type of PHC pile and its water flushing-air lifting hydrostatic pile sinking process. The water flushing-air lifting hydrostatic pile sinking process includes the following steps: hydrostatic pile sinking in the surface soft soil layer; water flushing and air lifting hydrostatic pile sinking in the sand and pebble layer; and hydrostatic pile sinking in the soft soil layer or sandstone layer below sand and pebble layer until reaching the designed level. Compared with available perforating and pile grouting process, the present invention has 40-50 % lower cost and is superior in engineering quality, construction period and environment protection. The pile can penetrate any covering layer and its end can be reach ideal bearing course fast.

Owner:李小云

Concrete pouring construction method for steel plate embedded part

InactiveCN102367704ASave positioningShorten the timeBuilding material handlingSheet steelMaterials science

The invention discloses a concrete pouring construction method for a steel plate embedded part, which relates to the technical field of construction engineering, in particular to an installation engineering technology of a steel plate embedded part. The method comprises the following steps of: fixing the steel plate embedded part on the inner side face of a template through a bolt; positioning the template; pouring concrete mortar; and detaching the template after concrete is molded. In the method, the steel plate embedded part is fixed with the template, and the template is taken as a support part of the steel plate embedded part, so that the steel plate embedded part is prevented from displacing in the pouring process of the concrete mortar at a later stage, and the molding quality is ensured. The method is convenient for constructing, the engineering quality is good, and the labor force and time for positioning the steel plate embedded part are saved.

Owner:JIANGSU JIANGDU CONSTR GRP

Method for constructing multi-functional metro interchange station complex

InactiveCN101586346ALess investmentShort construction periodArtificial islandsUnderwater structuresReinforced concreteFiber type

The invention discloses a method for constructing a multi-functional metro interchange station complex, which comprises the steps of: performing high-pressure cement grouting on a foundation within design scope; construction of an underground reinforced concrete diaphragm wall; construction of a steel reinforced concrete underground grouting pile group; construction of well spacing pattern double prestressed steel fiber type ground structure floors; dryness of moisture in a soil body by stages; construction of a first underground floor; construction of a second underground floor; construction of an overhead platform metro shield tunnel, a bridge and an overhead platform; construction of a third underground floor; construction of a bottom platform metro shield tunnel, a bridge and a bottom platform; earthwork excavation under the bottom bridge and construction of column facing of the steel reinforced concrete grouting pile group; construction of steel reinforced concrete of a buttress type annular ground beam and steel reinforced concrete of a bottom inverted arch bottom slab; construction of bottom platform and overhead platform rails and the platforms; construction of a steel reinforced concrete light shaft and a steel reinforced concrete elevator shaft; construction of a ground floor; construction of a first floor; and construction of various pipelines, and installation and debugging of various equipment. The method has the advantages of less investment on the construction of metro interchange stations, short construction period, small construction quantity, high construction efficiency, and social resource economization.

Owner:ZHENGZHOU MUNICIPAL ENG CORP +1

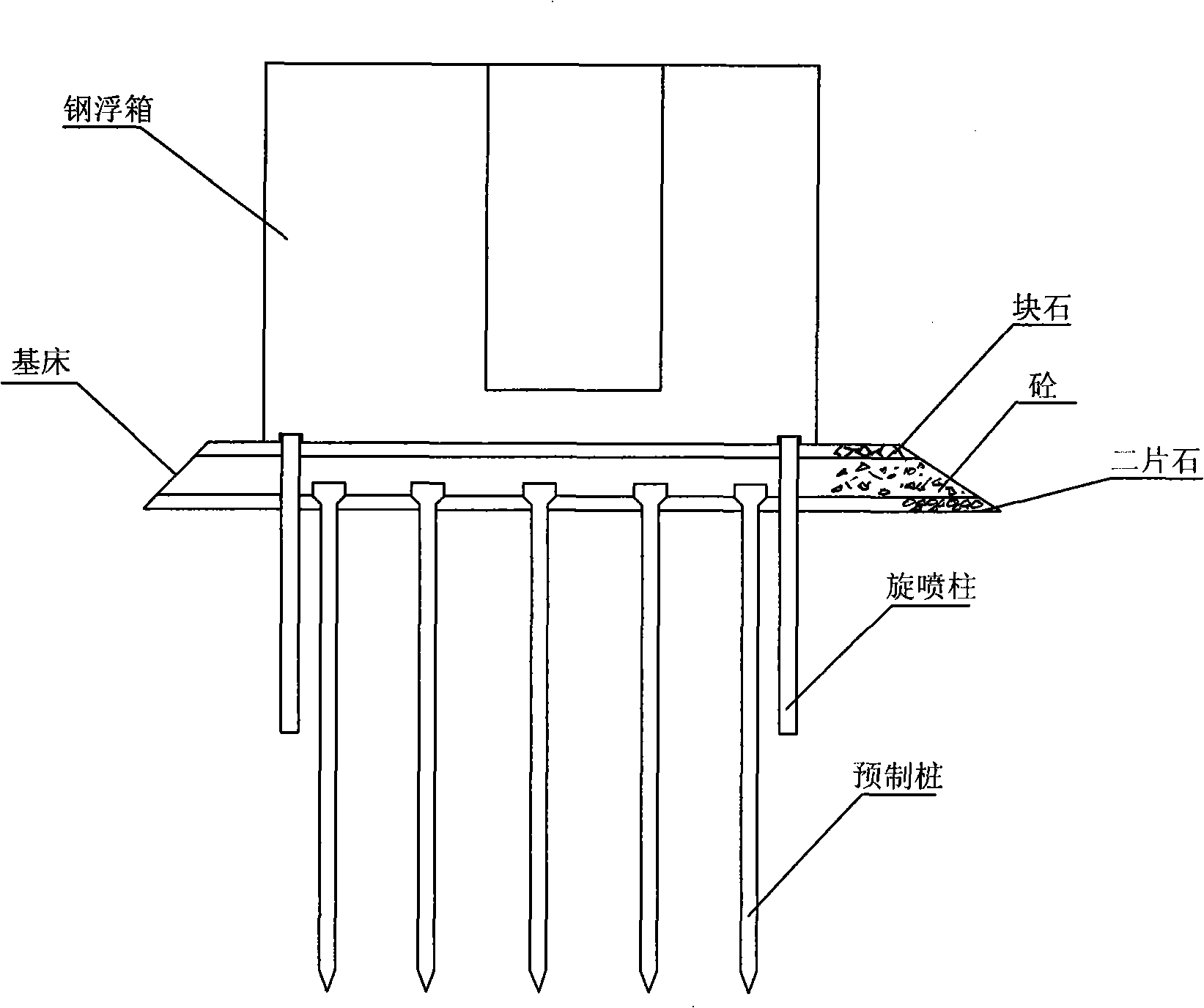

Soft soil foundation large scale steel float lock head construction method

InactiveCN101260664AAdaptableSave construction materialsDry-docksClimate change adaptationCushionWater depth

The invention discloses a soft soil base large-scale steel floating box lock head construction method, which is characterized in that the specific construction steps comprise that: a foundation trench is excavated and silt is removed; a precast pile is beaten; a foundation bed is ripraped and a concrete cushion coat is poured and tamped; a steel floating box is precast and submerged; a waterproof purdah is jet grouted. Compared with the prior art, the invention has the characteristics of strong applicability, mass construction material saving, low construction cost and reliable construction quality; a lock head steel floating box can be also used as construction cofferdam; the soft soil base large-scale steel floating box lock head construction method is in particular suitable for building the lock head in an area with a soft soil base and deep water and can achieve good waterproof effect no matter how depth the foundation bed is.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

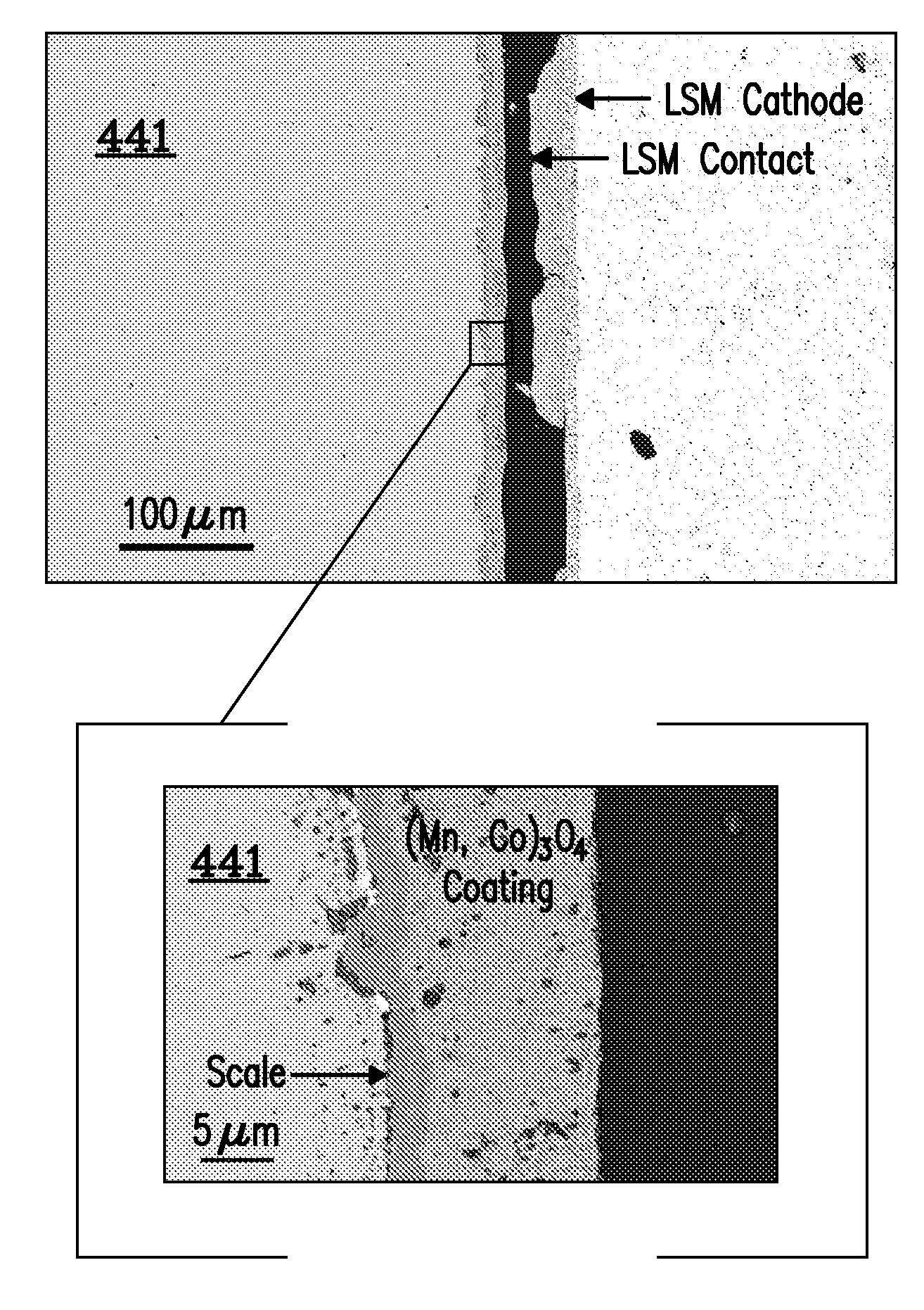

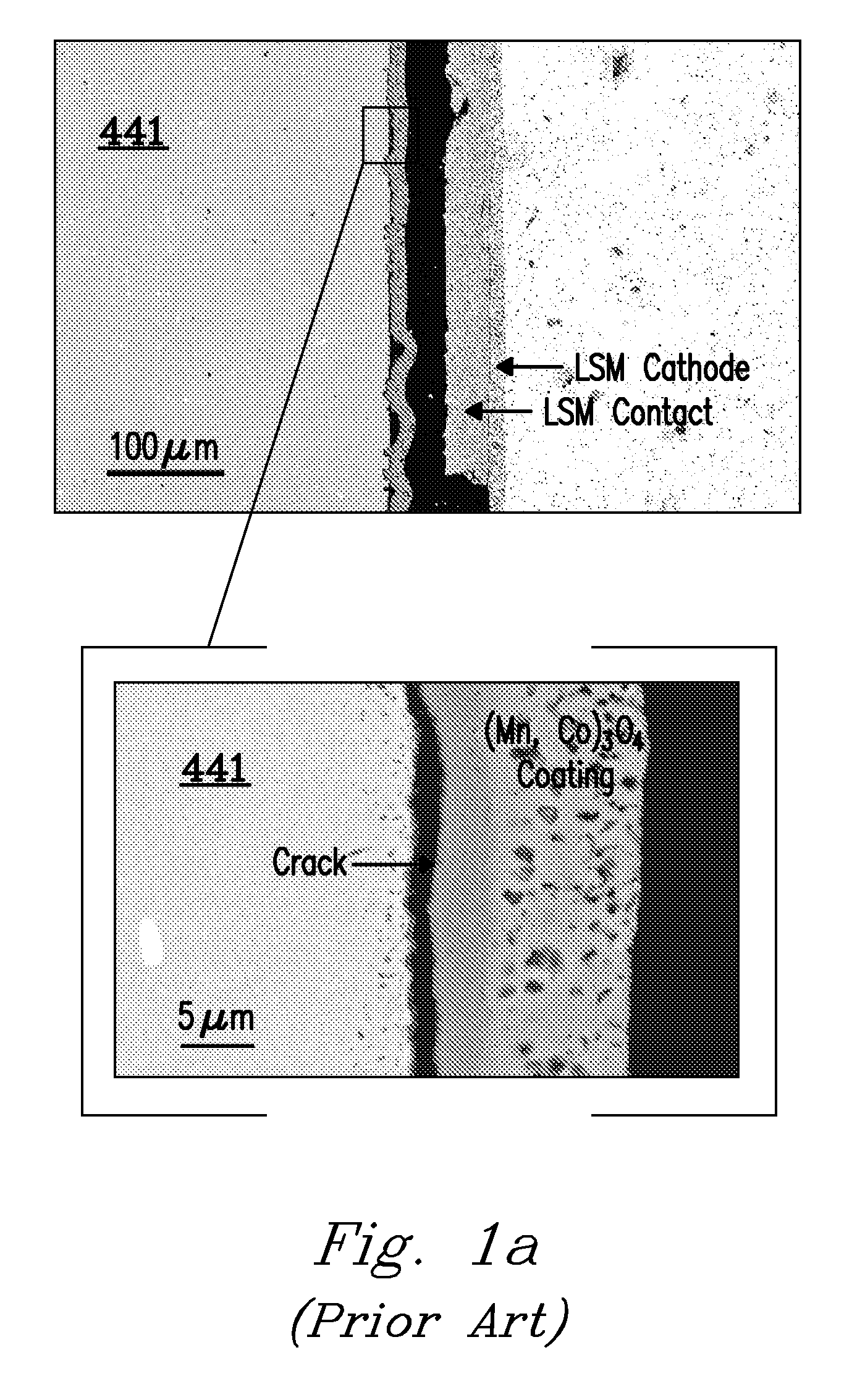

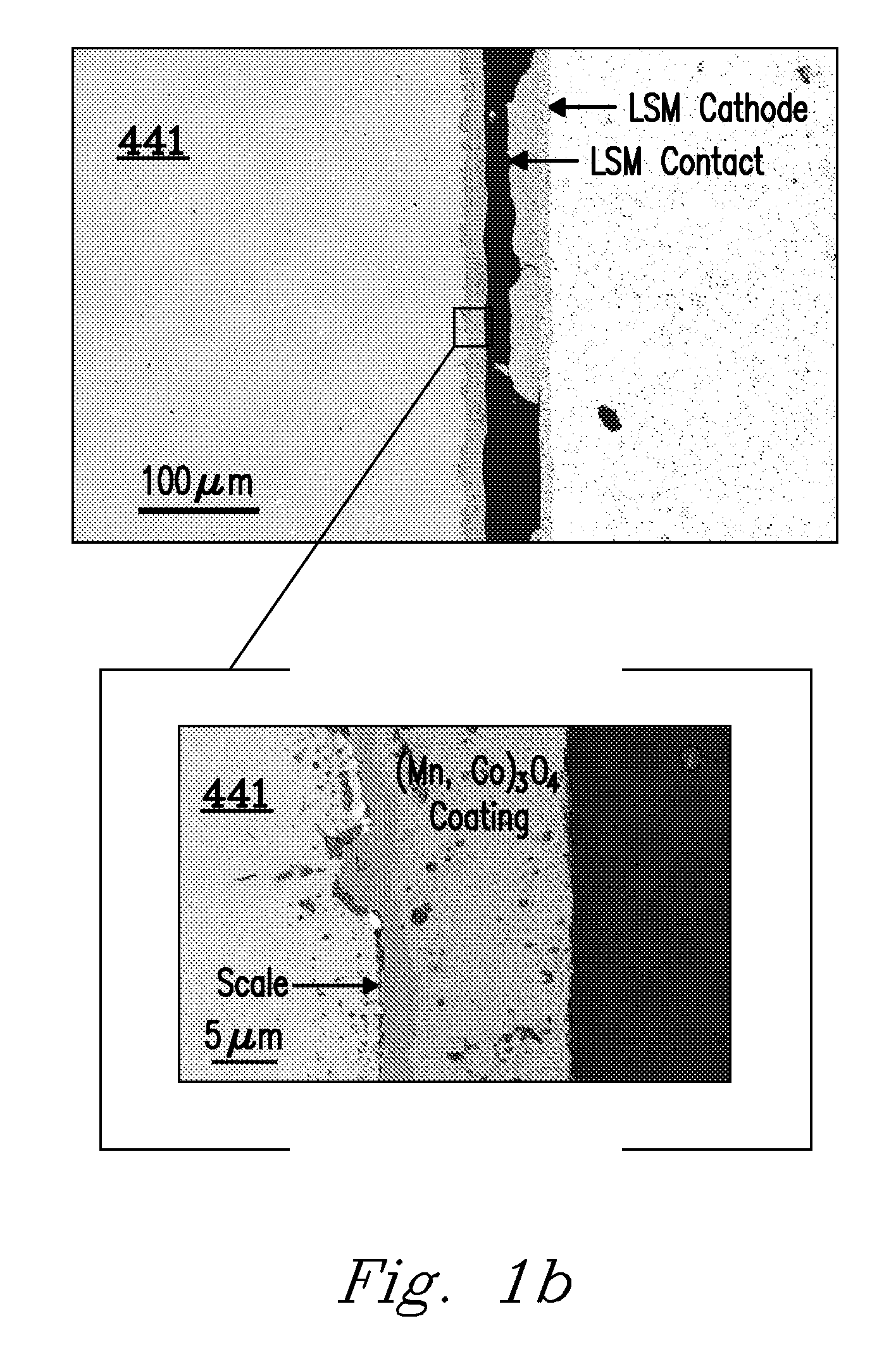

Novel Approach for Improved Stability and Performance of SOFC Metallic Interconnects

ActiveUS20100178586A1Improves scale adherenceLow costElectrode carriers/collectorsSolid electrolyte fuel cellsRare-earth elementOxide coating

The present invention provides a material and a method for its creation and use wherein a reactive element, preferably a rare earth element, is included in an oxide coating material. The inclusion of this material modifies the growth and structure of the scale beneath the coating on metal substrate and improves the scale adherence to the metal substrate.

Owner:BATTELLE MEMORIAL INST

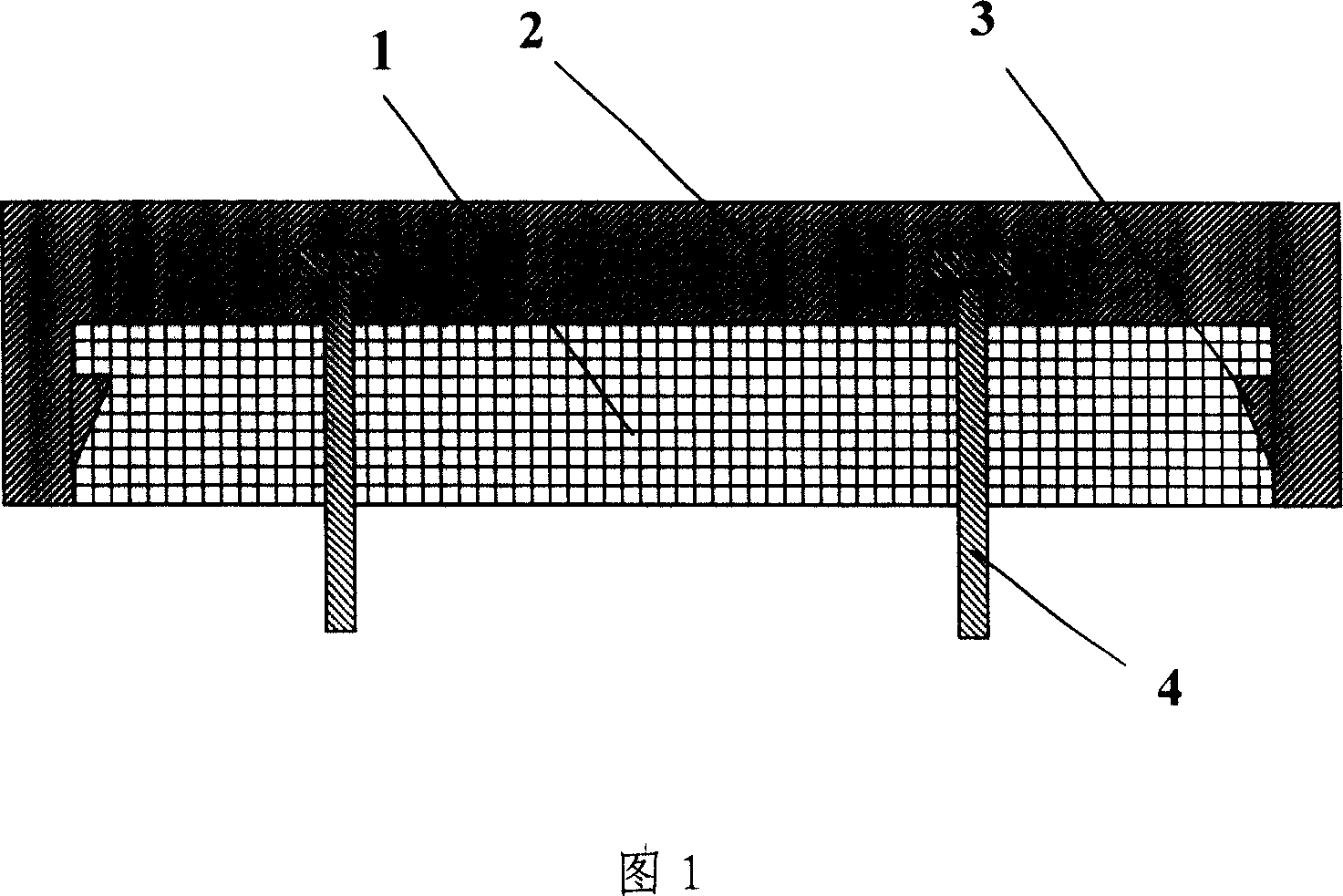

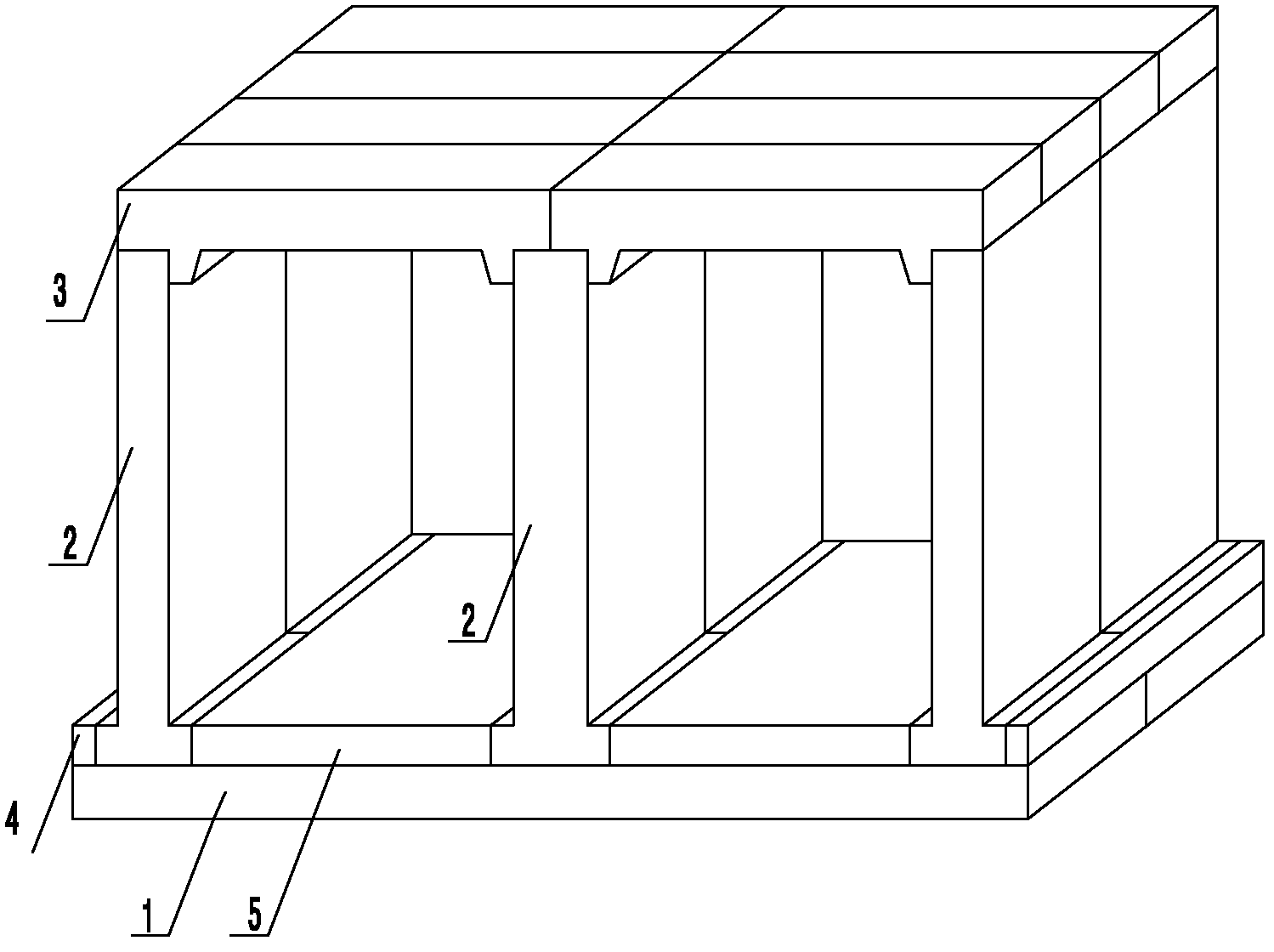

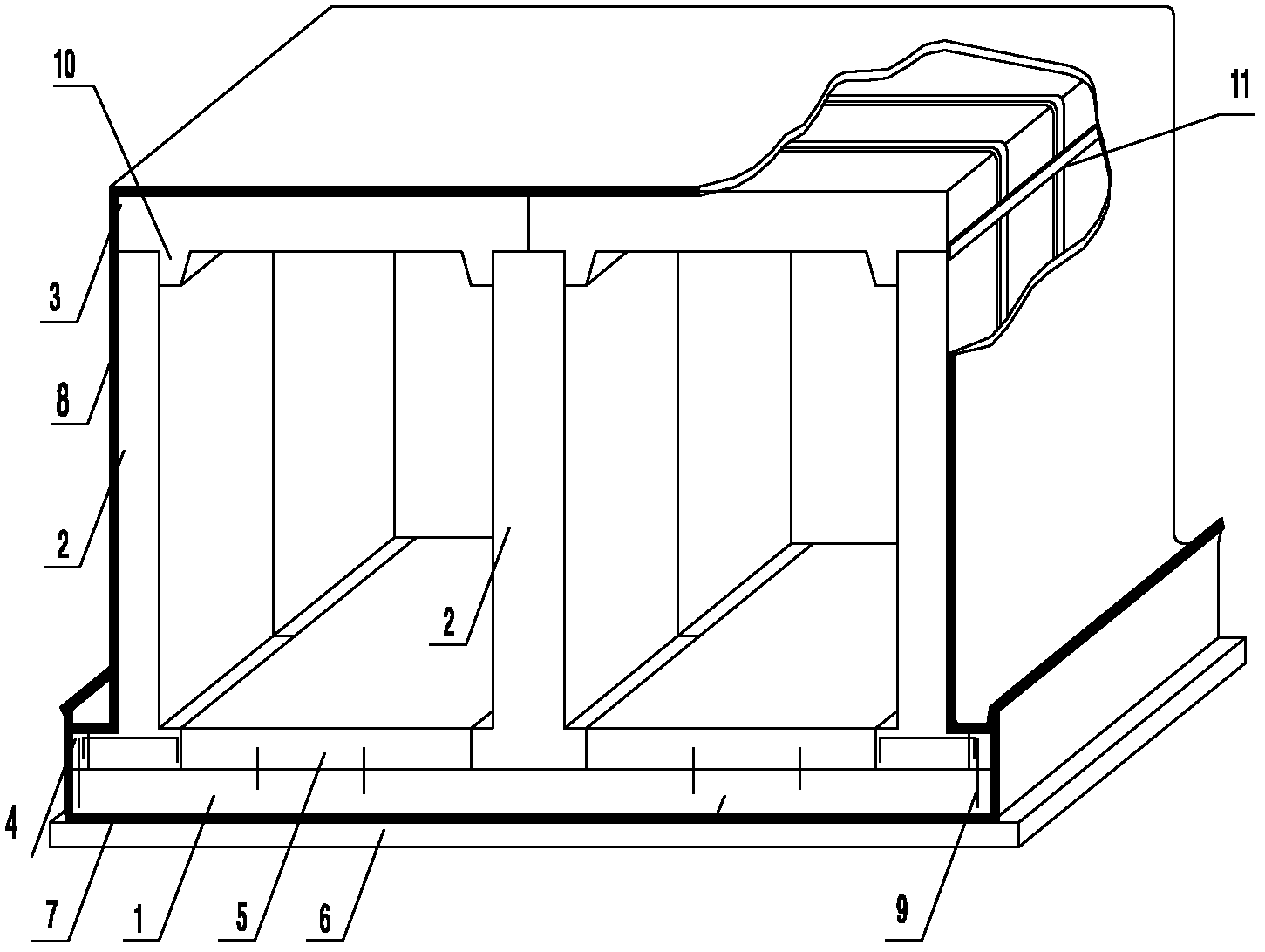

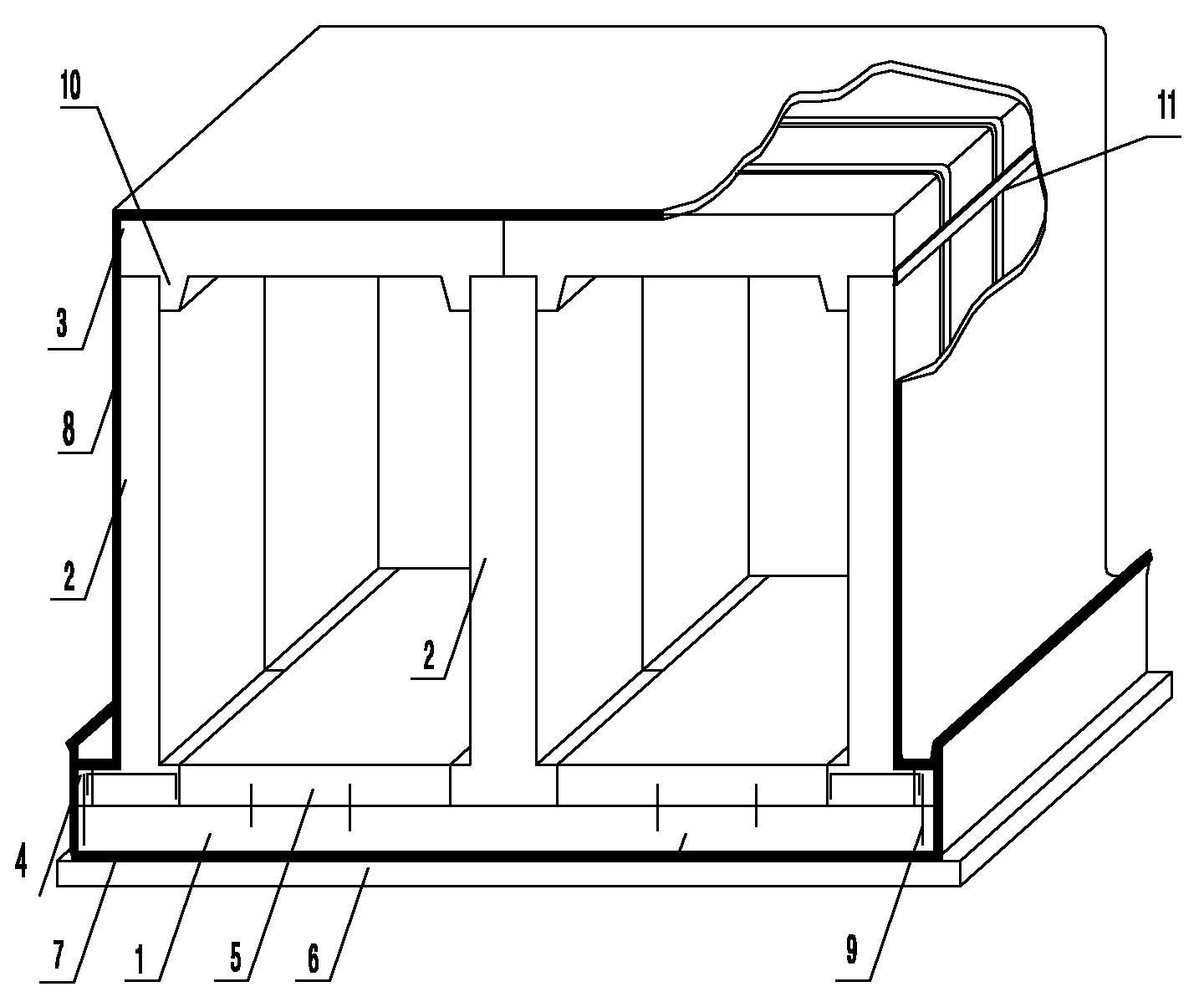

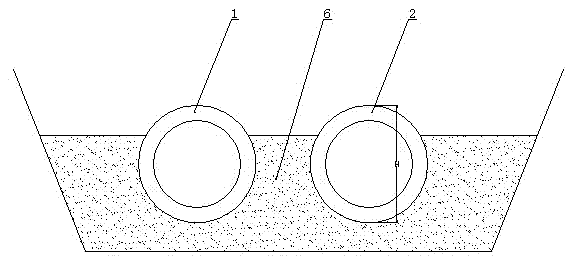

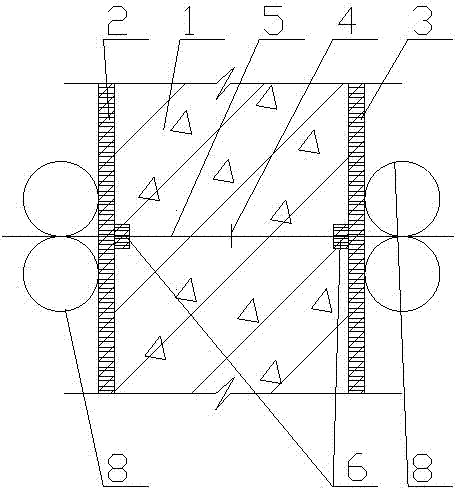

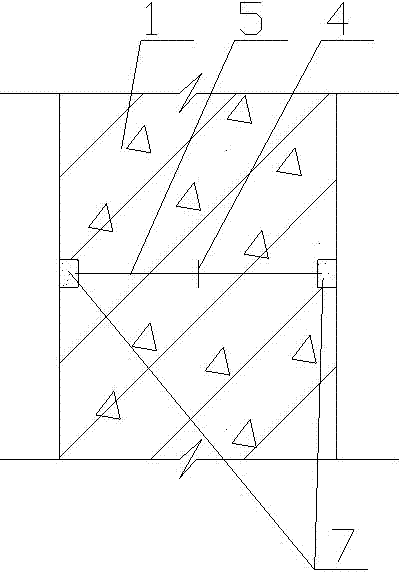

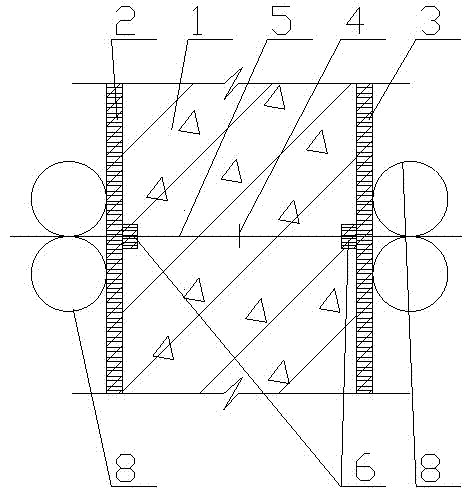

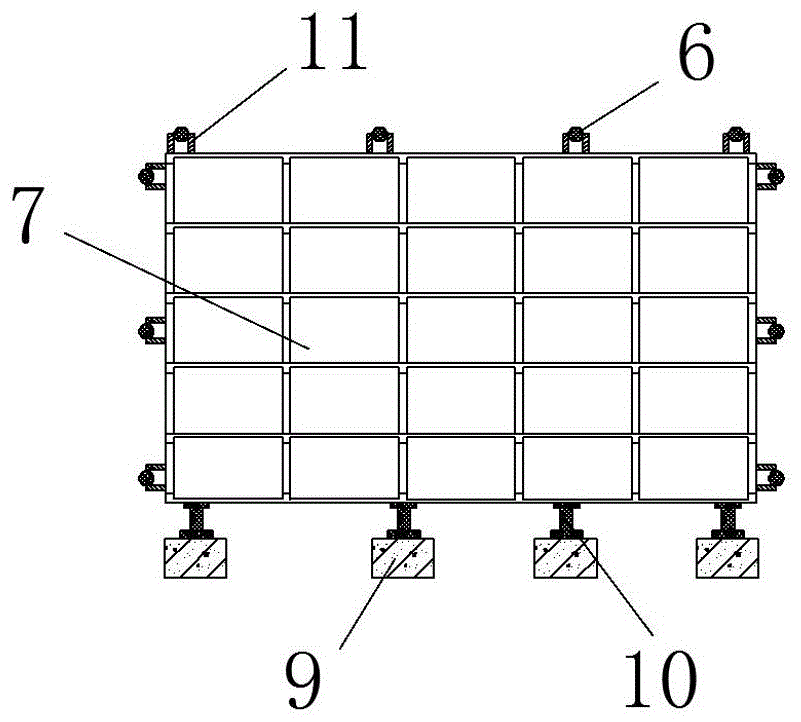

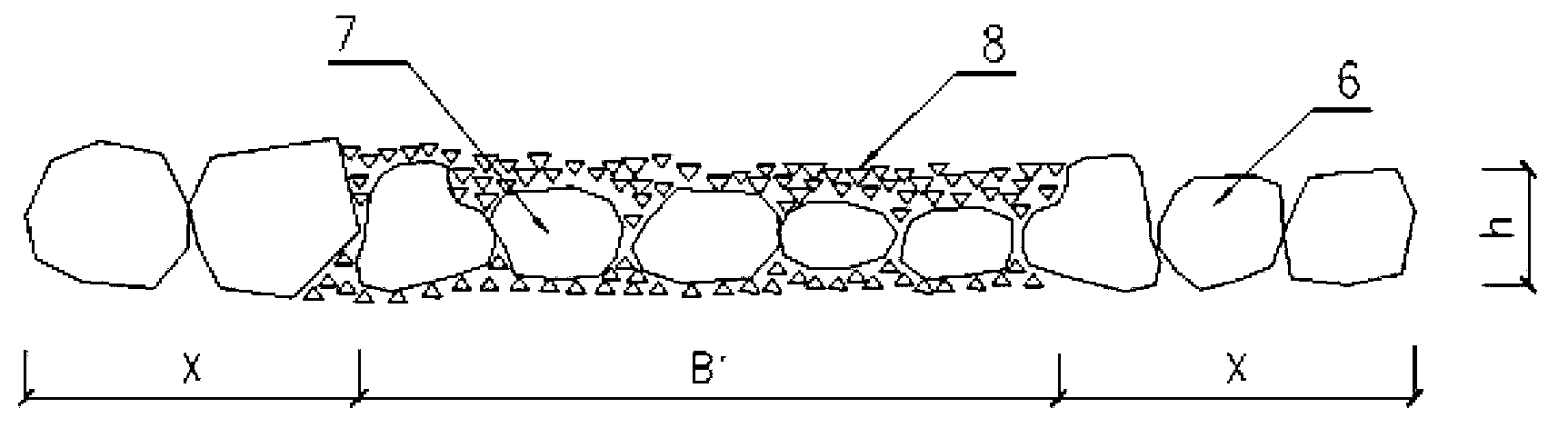

Prefabricated laminated steel concrete two-hole culvert

The invention discloses a prefabricated laminated steel concrete two-hole culvert. The prefabricated laminated steel concrete two-hole culvert comprises a bottom plate 1, wall boards 2, cover plates 3, edge strips 4, an inner bottom plate 5, a cushion layer 6, a bottom waterproof plate 7, upper covering waterproof plates 8 and waterproof strips 11, wherein the cushion layer 6 is paved on an excavated foundation; the bottom waterproof plate 7 is spread on the cushion layer 6; the bottom plate 1 is cast on the waterproof plate 7 in situ; lines are placed on the bottom plate 1; the wall boards 2 at two sides and in the middle part are suspended on the bottom plate 1 and are finely adjusted, aligned and leveled; the two cover plates 3 are respectively placed at the top parts of the wall boards 2; the bottom plate 1 is connected with connecting ribs of the wall boards 2, and concretes are filled to form the edge strips 4 and the inner bottom plate 5; and construction gaps among the wall boards 2 and the cover plates 3 are subjected to waterproof gap blockage treatment, the waterproof strips 11 and the covering waterproof plates 8 are paved, the waterproof plates 7 and 8 are welded to form a seal, and soil is filled. The prefabricated laminated steel concrete two-hole culvert is convenient and fast in construction, good in quality, long in durability, waterproof, reliable and the like, and can be used as a culvert, a channel and a municipal integrated pipe ditch below urban roads and high-speed roads.

Owner:刘山健

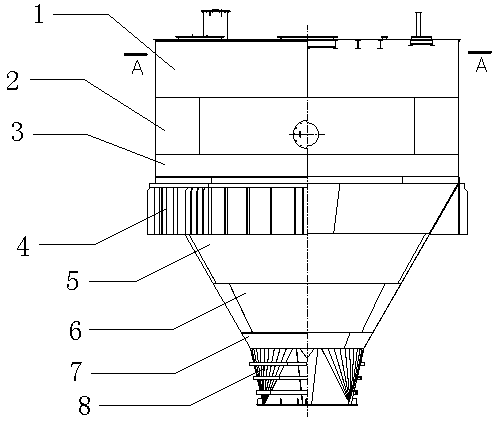

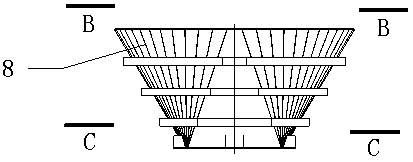

Large hopper manufacturing method

The invention discloses a large hopper manufacturing method, wherein the upper part of a hopper is equipped with a cylindrical barrel body, and the lower part of the hopper is equipped with a taperedhopper which is round and square. The large hopper manufacturing method is characterized by comprising the following steps of: a, unloading; b, drilling; c, bending and forming a wall plate of the hopper; d, assembling; e, welding; f, pre-assembling; and g, coating. The large hopper manufacturing method has the advantages that hopper manufacturing steps are reasonable in design, operability is strong, manufacturing is convenient, construction is simple and convenient, a construction period is short, project quality is guaranteed to be excellent, hopper manufacturing engineering cost is reduced, and the good result of saving 0.1035 million RMB is achieved.

Owner:MCC5 GROUP CORP SHANGHAI

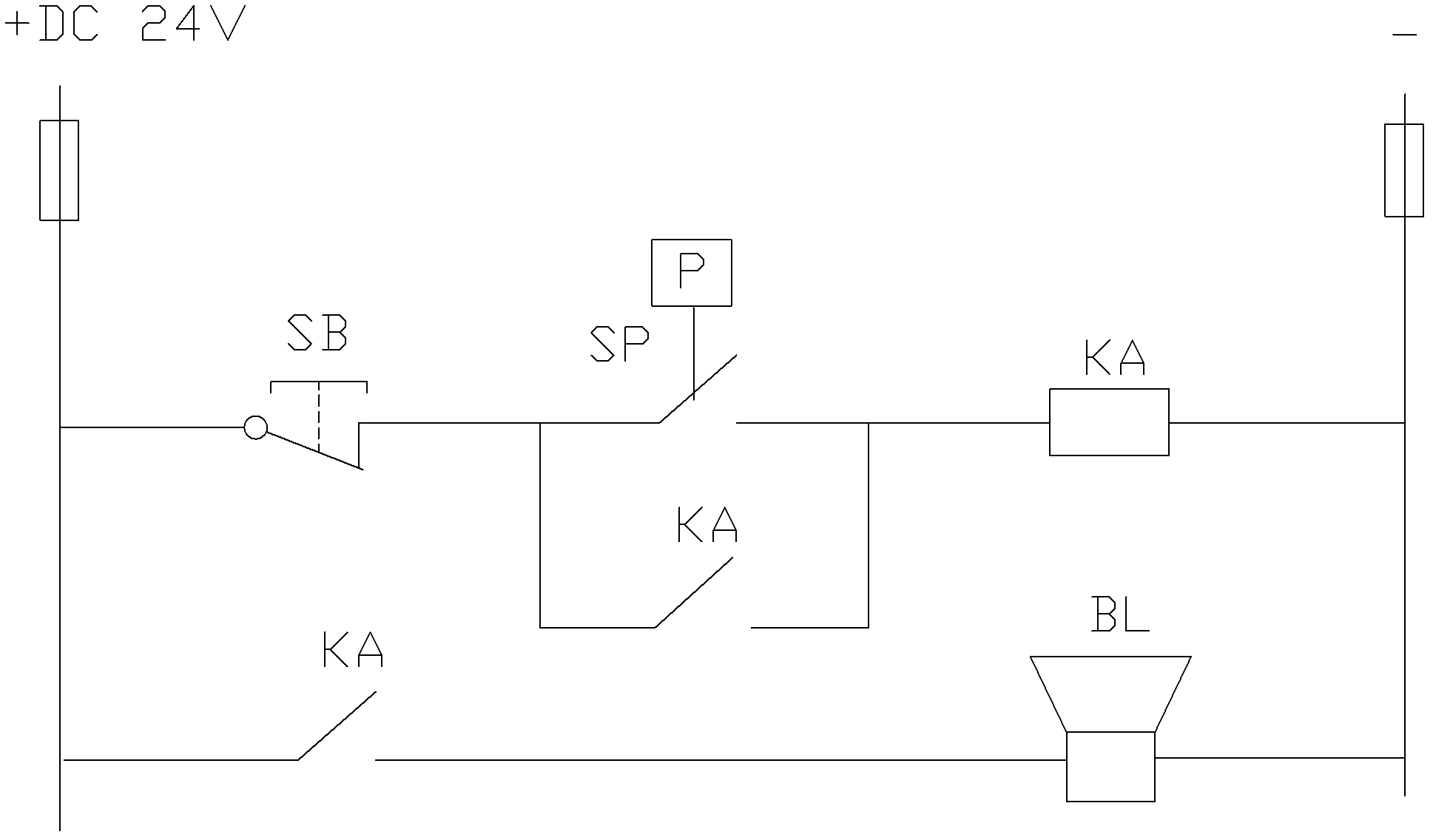

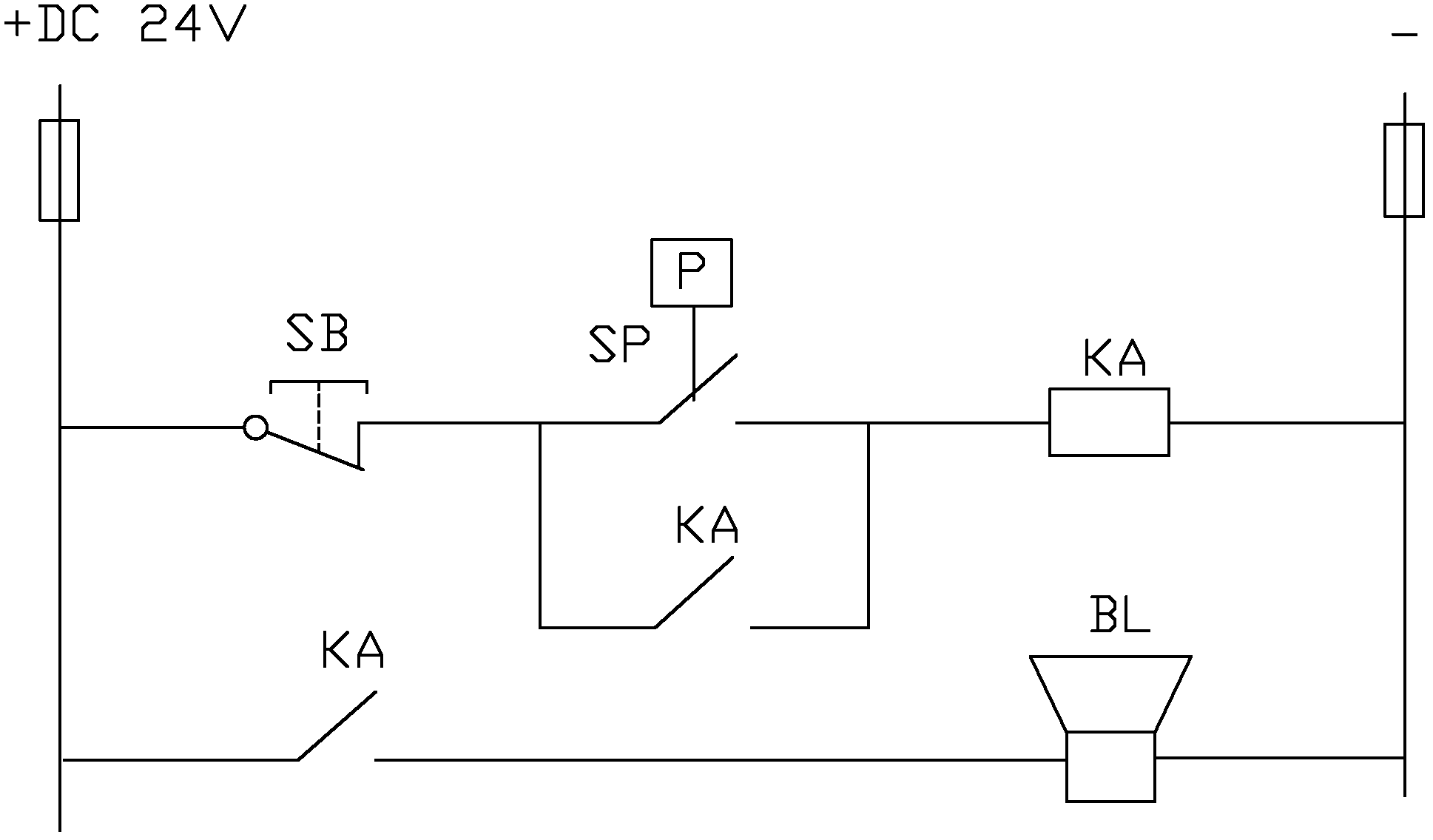

Automatic internal pressure alarm system of sealing film used in vacuum combined surcharge preloading

InactiveCN102323002AShorten the timeReduce construction costsFluid pressure measurement by electric/magnetic elementsVacuum pressureHuman power

The invention discloses an automatic internal pressure alarm system of a sealing film used in vacuum combined surcharge preloading. A pressure gauge of a vacuum preloading device is an electric contact pressure gauge; a normally-open contact of the electric contact pressure gauge is connected in parallel with one auxiliary normally-open contact of an intermediate relay and is then connected in series with a normally-closed contact of a reset button to a coil power supply loop of the intermediate relay; and another auxiliary normally-open contact of the intermediate relay is connected in series to a power supply loop of an audible and visual alarm. According to the automatic internal pressure alarm system, a structure that the electric contact pressure gauge and the audible and visual alarm work cooperatively is adopted, when the vacuum pressure is reduced to a set value, the audible and visual alarm is immediately started, and an operator on duty begin to check gas leak points at the first time, so the project quality is benefited; and meanwhile, the time, the machine fee and the electric charge needed by re-arriving at a design pressure are decreased, and the construction cost is reduced. Furthermore, the automatic alarm system has a simple structure, the mounting is convenient, the labor intensity is reduced to a great degree, the work efficiency is improved, the labor input is little, the cost is low, and the labor power, the material resources and the financial resources are saved.

Owner:TIANJIN 20 CONSTR

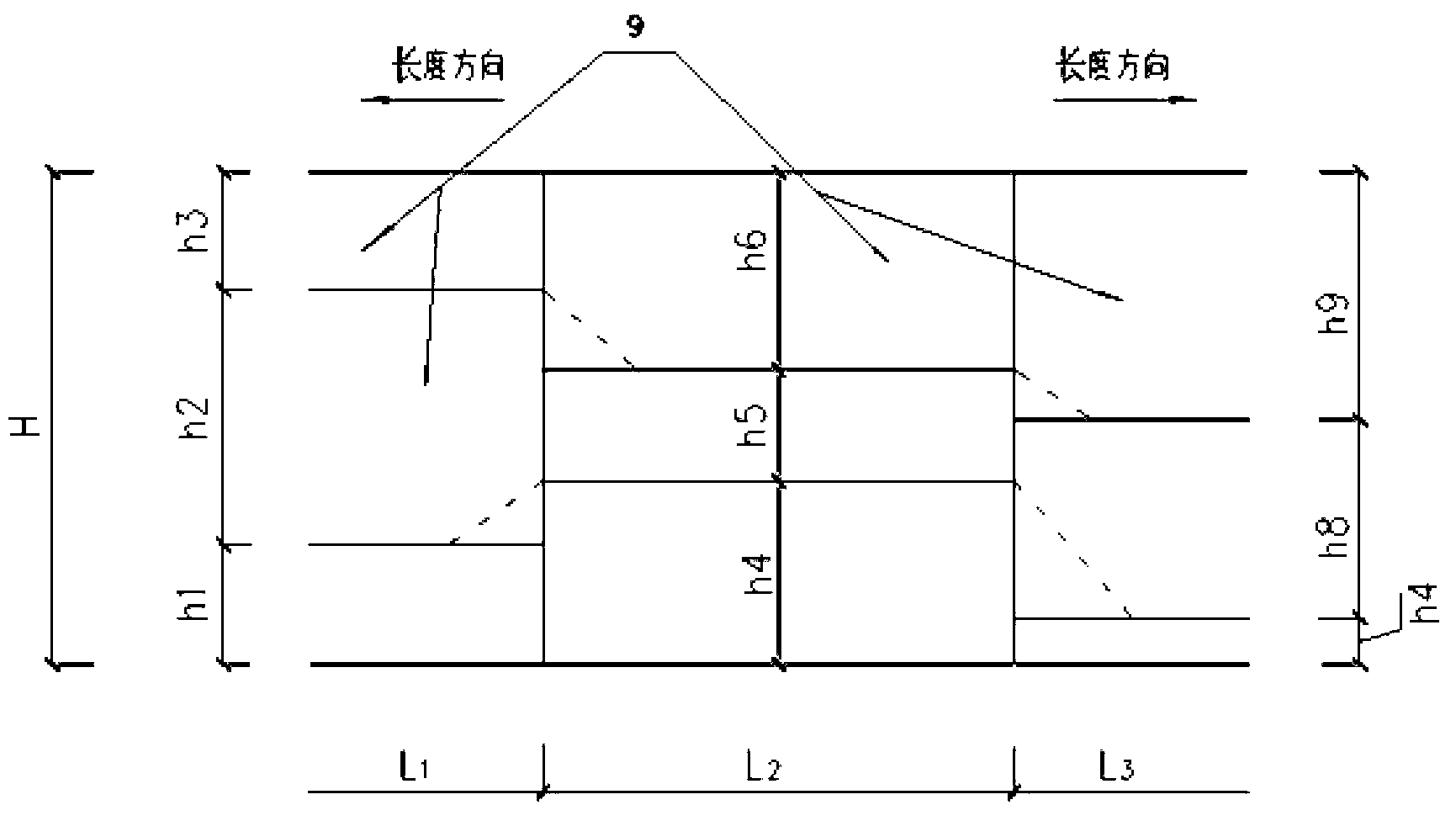

Construction method for prefabricating directly-buried uncompensated centralized heat supply pipeline by electrically preheating

InactiveCN102444750AImprove running stabilityGuaranteed elongationPipe laying and repairElectricityEngineering

The invention relates to a construction method for prefabricating a directly-buried uncompensated centralized heat supply pipeline by electrically preheating. The method comprises the following steps of: (1) grooving, adjusting the coordinate and scale height of the heat supply pipeline, and computing the preheating temperature and the designed elongation of the heat supply pipeline; (2) controlling the sand refilling height at a half to three quarters of the pipeline height H; (3) connecting the same-side end of the heat supply pipeline with preheating equipment through a cable respectively, and short-circuiting the other side of the heat supply pipeline through a cable; (4) arranging temperature sensors on the heat supply pipeline respectively; (5) recording the initial temperature of the heat supply pipeline and the initial position of a measuring point, starting temperature raising, controlling the temperature raising gradient within 1 DEG C per hour, and preserving heat after a preheating temperature is reached; (6) refilling sand into both sides of the heat supply pipeline, tamping, and controlling the preheating temperature within the range of + / -2 DEG C; (7) after the designed elongation is reached, shutting down the preheating equipment; and (8) performing subsequent construction according to the steps (1)-(7). The construction method disclosed by the invention is safe, reliable, easy and practical, is easy for accurately controlling construction equipment, and is consistent with the national policy of energy saving and emission reduction.

Owner:MCC TIANGONG GROUP

Method for manufacturing reinforced concrete basement external wall

InactiveCN102444285AAvoid shakingGuaranteed depthWallsBuilding material handlingSocial benefitsBasement

The invention discloses a method for manufacturing a reinforced concrete basement external wall. The method is characterized by installing a cork at the two ends of a pull screw with a water stop iron plate respectively when the pull screw is connected with an internal formwork and an external formwork, connecting reinforcing steel pipes to the two ends of the pull screw respectively at the external sides of the internal and external formworks, then pouring a reinforced concrete basement external wall in a conventional way, later, prying out the corks manually so that cork holes can be formed on the surface of the reinforced concrete basement external wall at the moment, cutting off the parts exposed out of the cork holes, of the pull screw, filling and leveling up the cork holes with waterproof mortar and then carrying out waterproof construction on the surface of the reinforced concrete basement external wall by the conventional method. The method has the advantages of construction convenience, high construction efficiency, good waterproof effect, low construction cost and good construction quality, and economic and social benefits can be brought to the enterprises by adopting the method.

Owner:CHINA CONSTR FOURTH ENG DIV

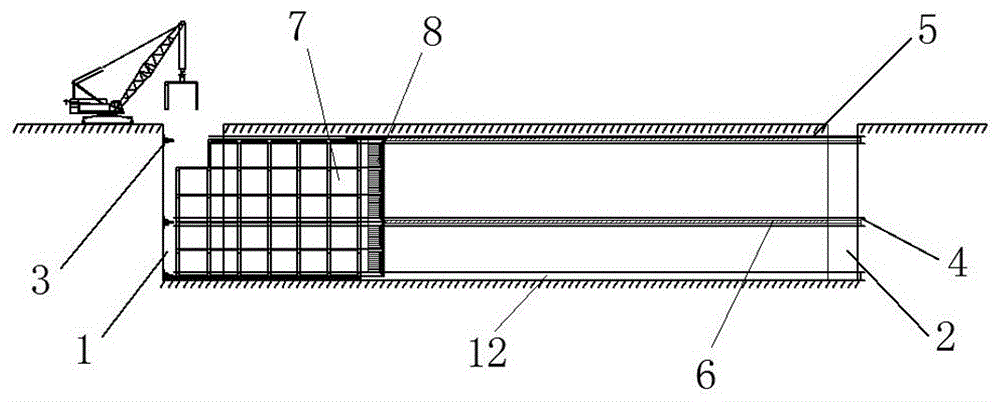

Modular construction system of underground building and construction method thereof

The invention belongs to the technical field of underground excavation engineering and particularly relates to a modular construction system of an underground building and a construction method thereof which effectively solve the technical problem of high construction difficulty of underground space structure engineering and improve the safety and the degree of mechanization of underground engineering by utilizing a modular construction technology of fabricated construction. The modular construction system, provided by the invention, of the underground building comprises an original well and a reception well which are arranged in an underground excavation structure, wherein a pushing device is arranged in the original well, a traction device is arranged in the reception well, an antecedent pilot tunnel is also arranged between the original well and the reception well, a steel cable or a section steel pull rod is arranged in the antecedent pilot tunnel, one end of the steel cable or the section steel pull rod is connected with the traction device in the reception well, and the other end of the steel cable or the section steel pull rod is connected with a connecting piece reserved on the outer side of a main body structure of the building. The structural construction and the method thereof are suitable for development of huge underground spaces, therefore, a large area of open excavation engineering can be effectively avoided, the influence on the ground environment is small, and the social benefit is high.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

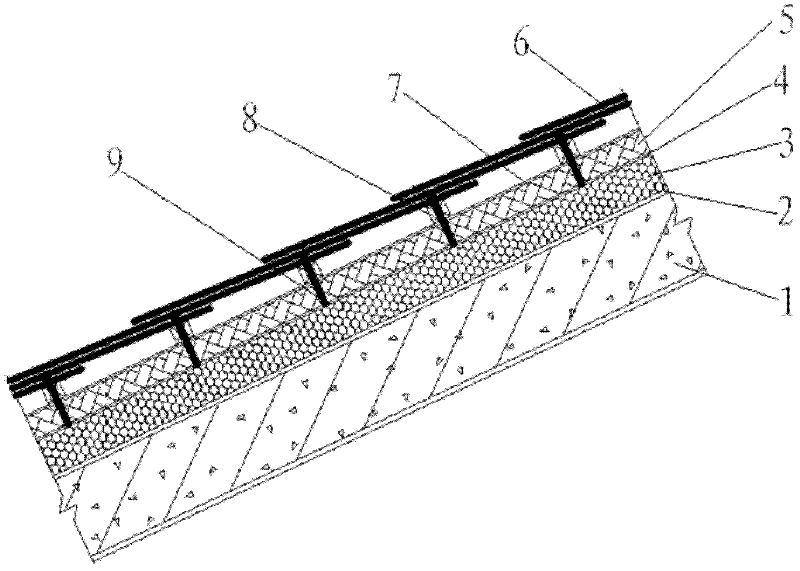

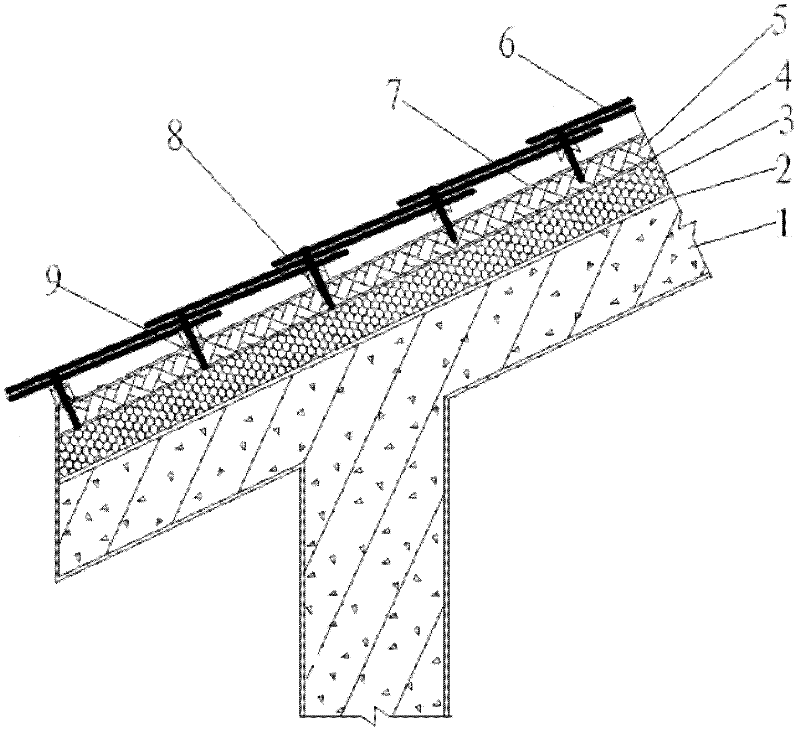

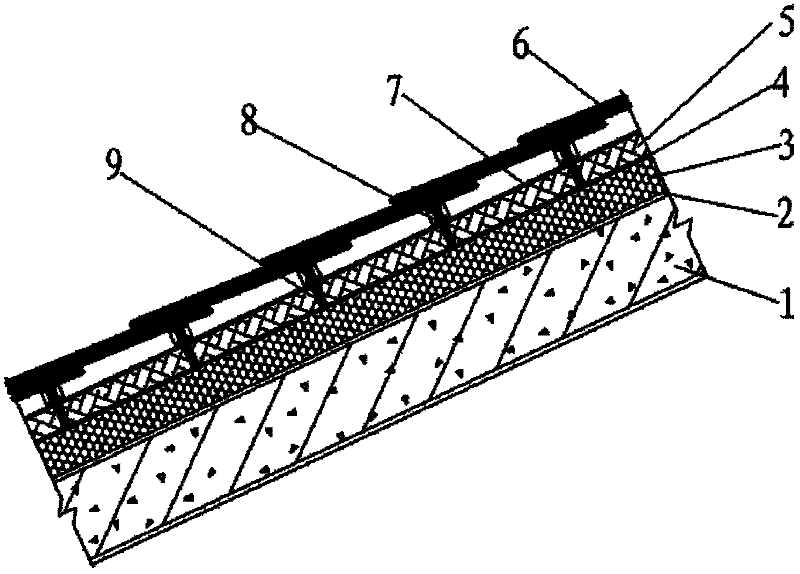

Slate tile roof

InactiveCN102535759AEasy to fixImprove waterproof performanceRoof covering using slabs/sheetsBuild-up roofsAnti freezingEngineering

The invention discloses a slate tile roof which sequentially comprises a concrete roof plate (1), a cement mortar leveling layer (2), a macromolecule coiled material waterproof layer (3), an extruded sheet insulating layer (4), a rigid waterproof layer (5) and a tile layer from inside to outside, wherein the slope of the slate roof is 35-50 degrees; the tile layer is composed of slate tiles (6); the slate tiles (6) are overlapped and hung on the tile-hanging bars (8) alternately and are fixed on the tile-hanging bars (8) by stainless steel nails (9); the slate tiles (6) and the base layer are fixed firmly, so that the slate tile roof has good integrity, waterproof performance, fireproof performance, anti-freezing performance, anti-corrosion performance and durability.

Owner:江苏金土木建设集团有限公司 +1

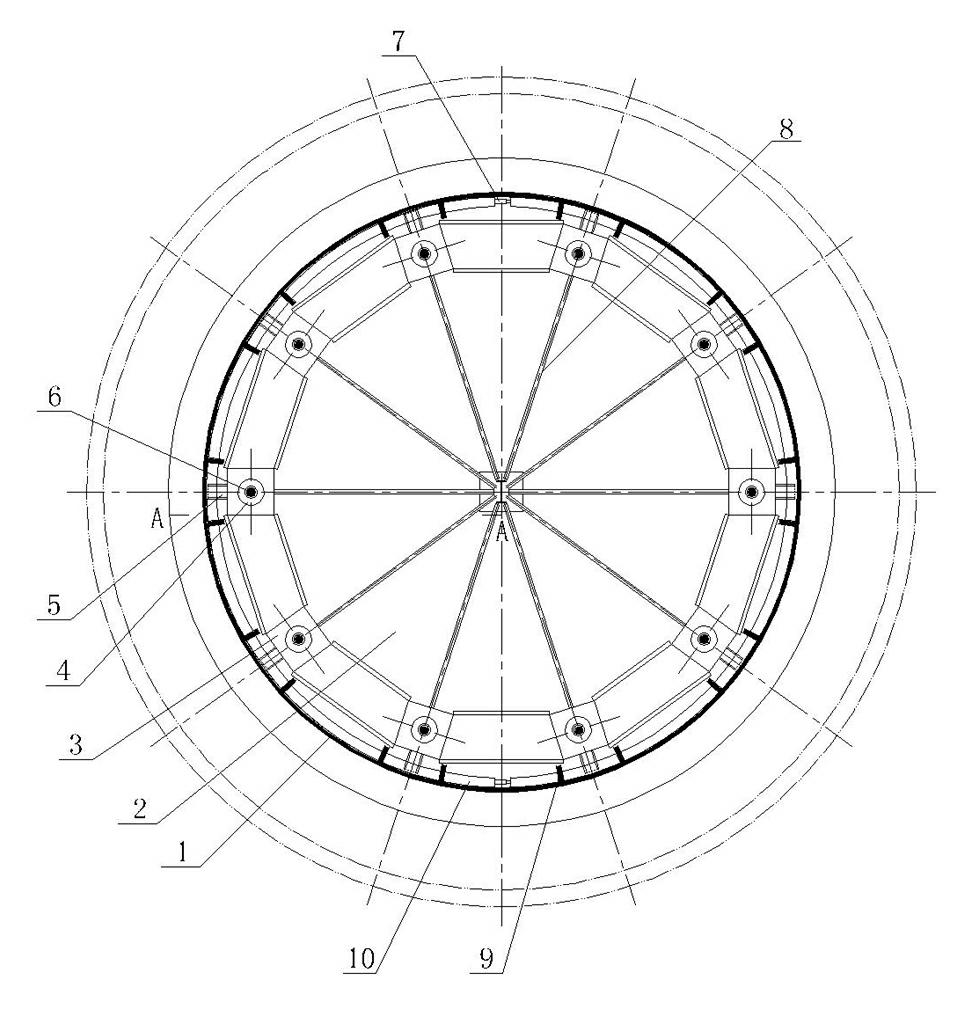

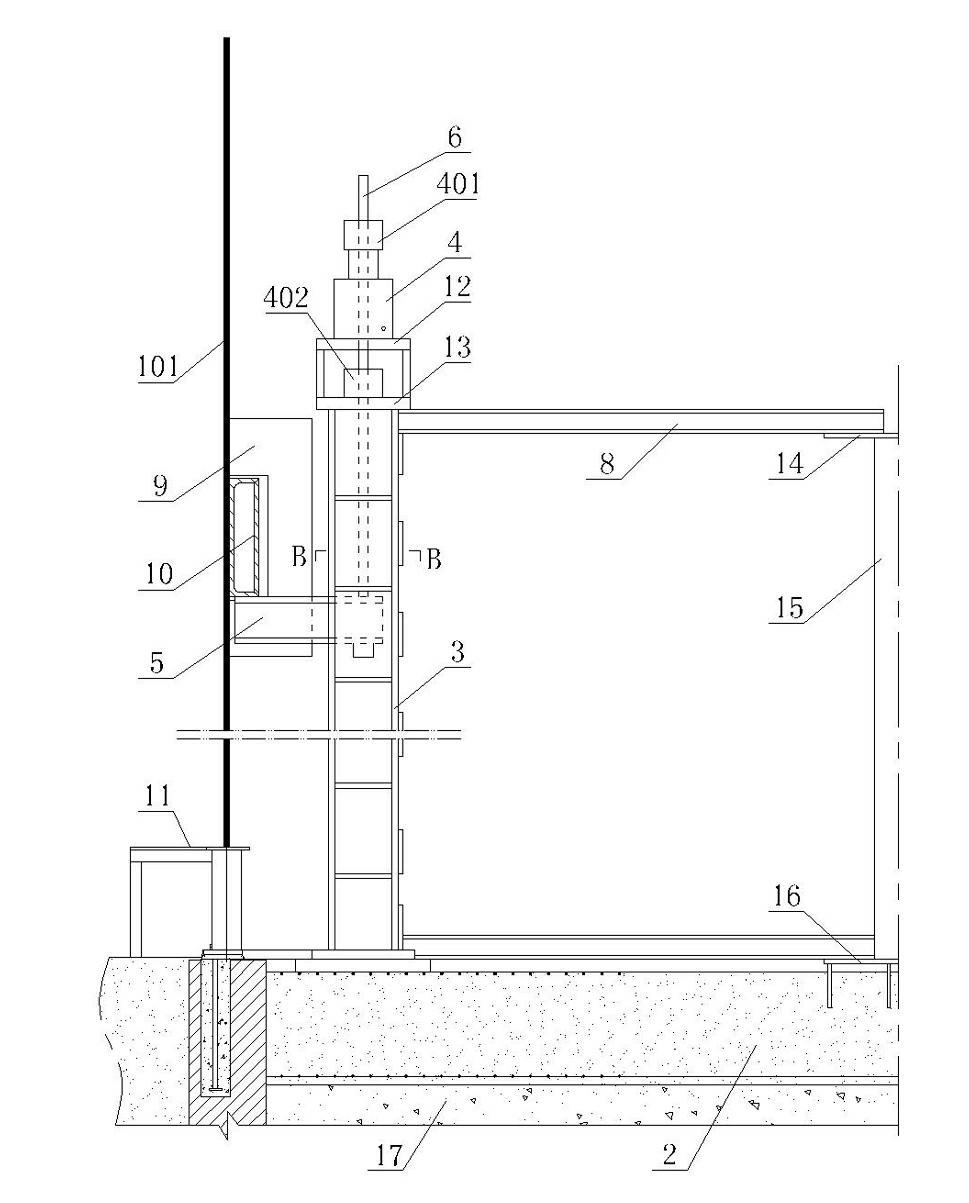

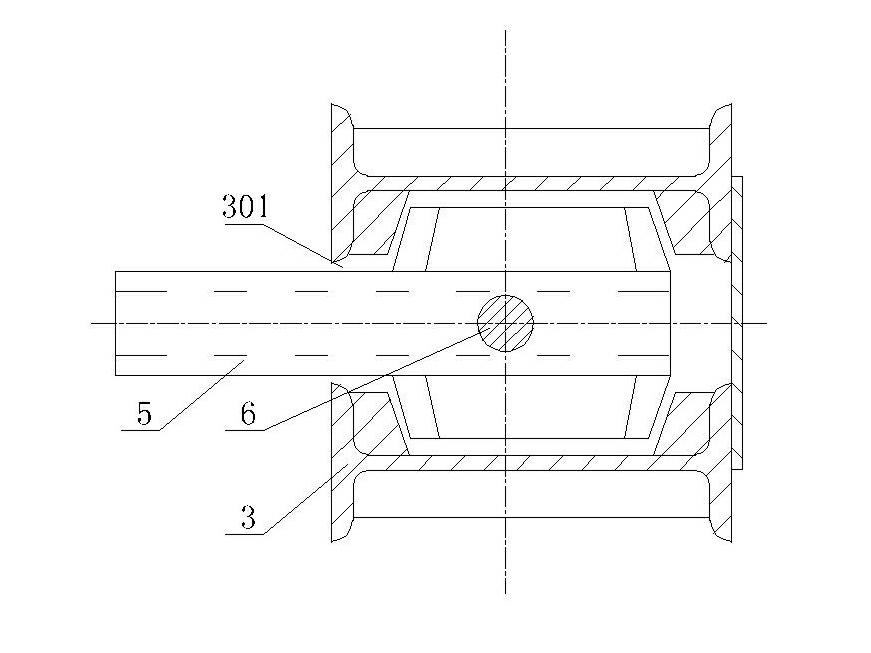

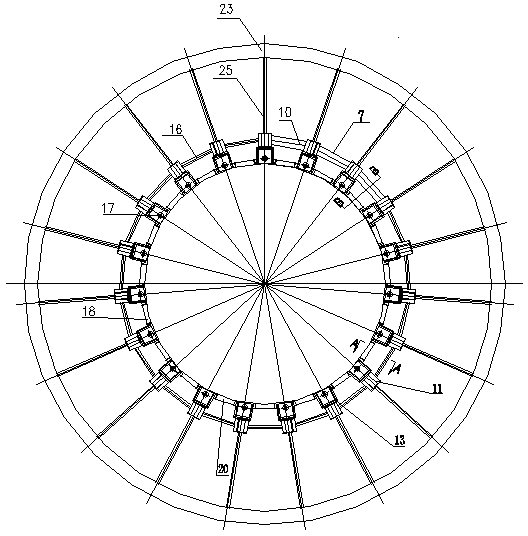

Titanium plate steel inner tank reversed construction device for chimney of thermal power station

The invention relates to a titanium plate steel inner tank reversed construction device for a chimney of a thermal power station. The titanium plate steel inner tank reversed construction device is provided with a hoisting system foundation distributed on the outer side of a steel inner tube foundation in the circumferential direction, wherein an annular steel structure supporting system with a material inlet on the surface is fixed on the hoisting system foundation, the annular steel structure supporting system is arranged on the outer side of a steel inner tank, an outrigger is arranged at the top of the annular steel structure supporting system radially, a hydraulic hoisting system is installed on the outrigger, a box-type horizontal annular beam is arranged at the bottom of the hydraulic hoisting system, a clamping block welded with the steel inner tube is clamped on the box-type horizontal annular beam, and a draw bar is arranged between an outer tube wall of the chimney and the annular steel structure supporting system. The titanium plate steel inner tank reversed construction device has the advantages of being convenient to construct, clear in stress, easy and convenient to operate, high in safety coefficient and good in engineering quality and is particularly suitable for traditional chimney transformation engineering where bearing systems cannot be distributed at the top.

Owner:DONGDIAN YANTA ENG +1

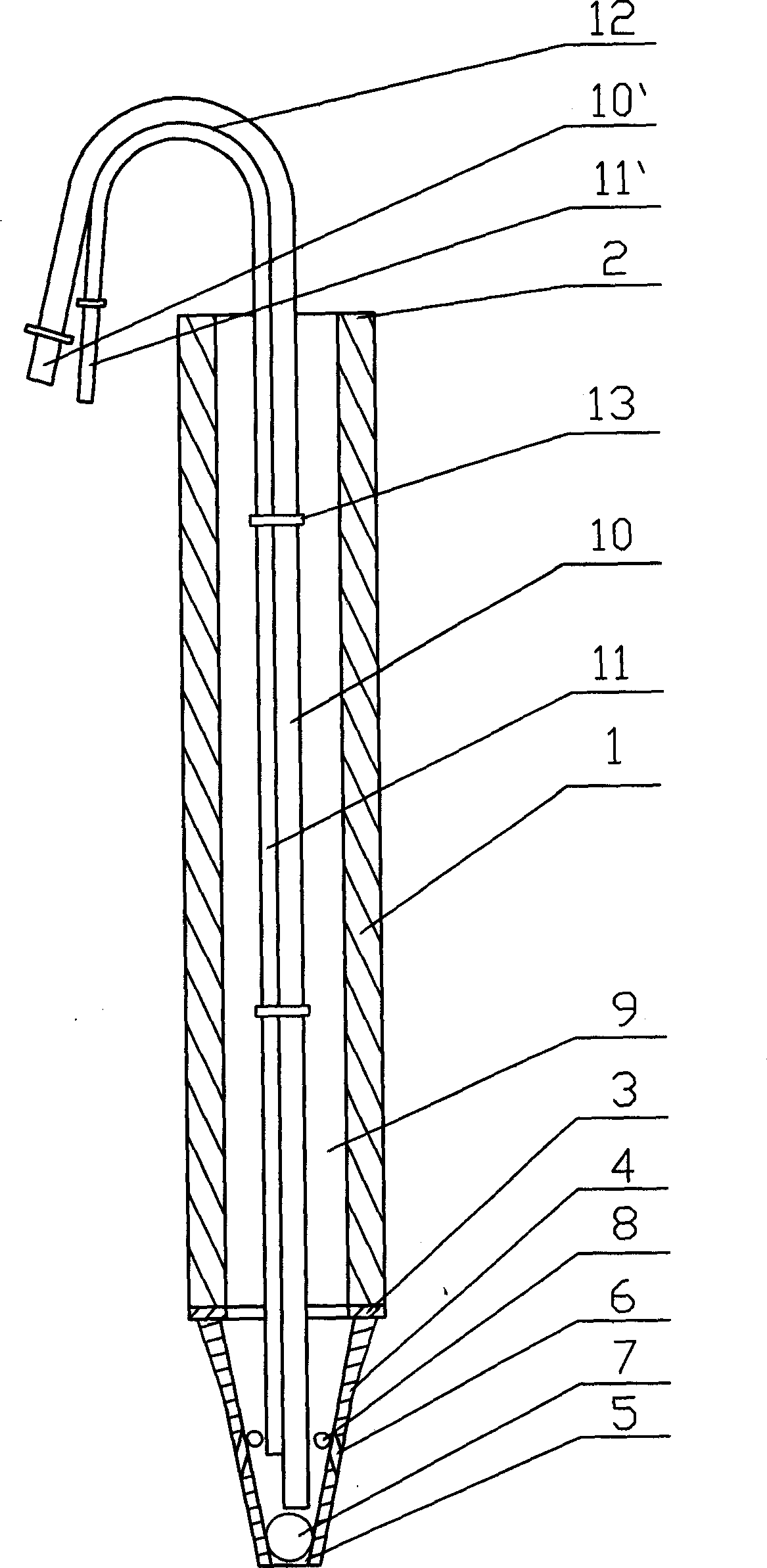

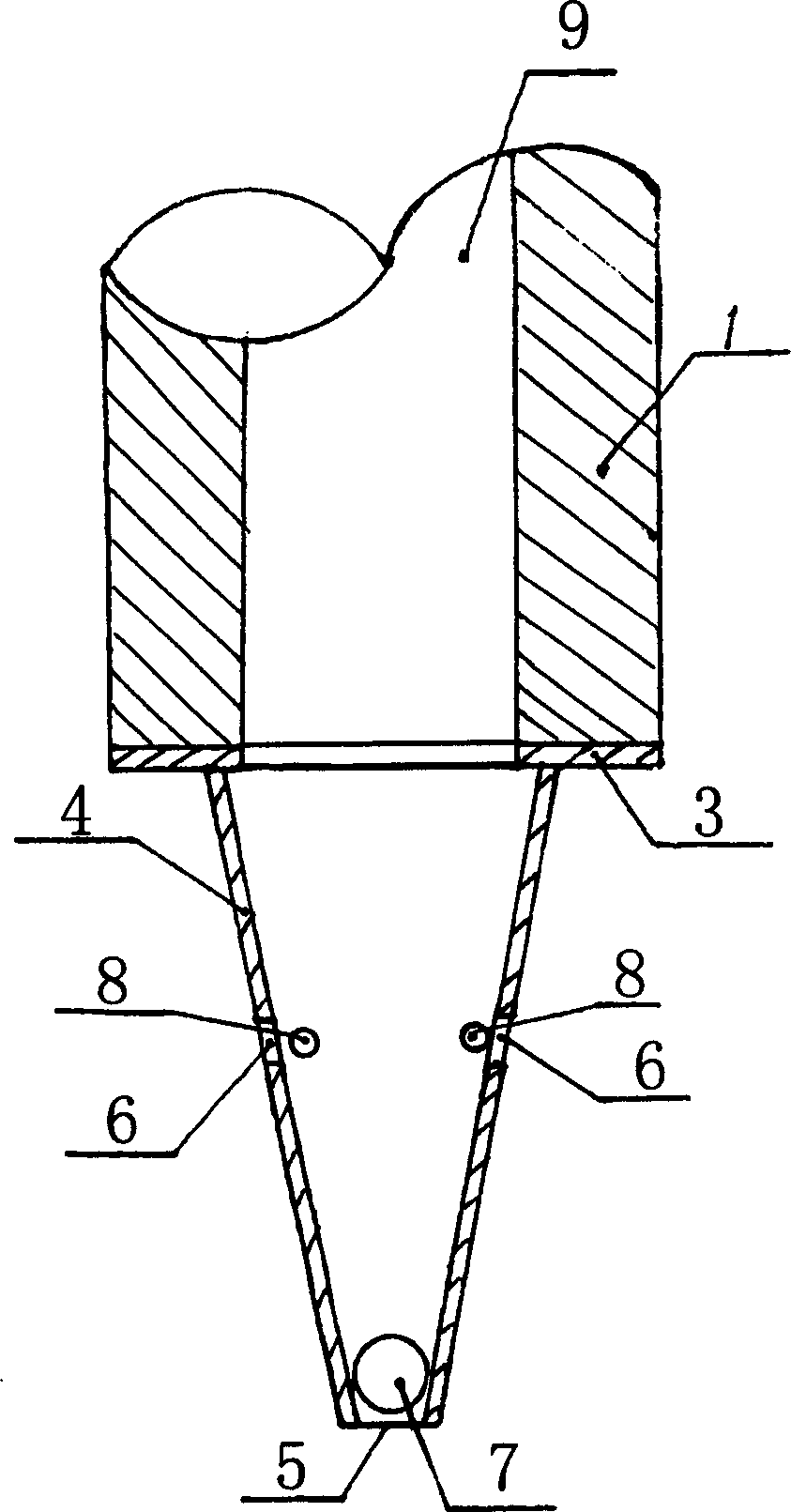

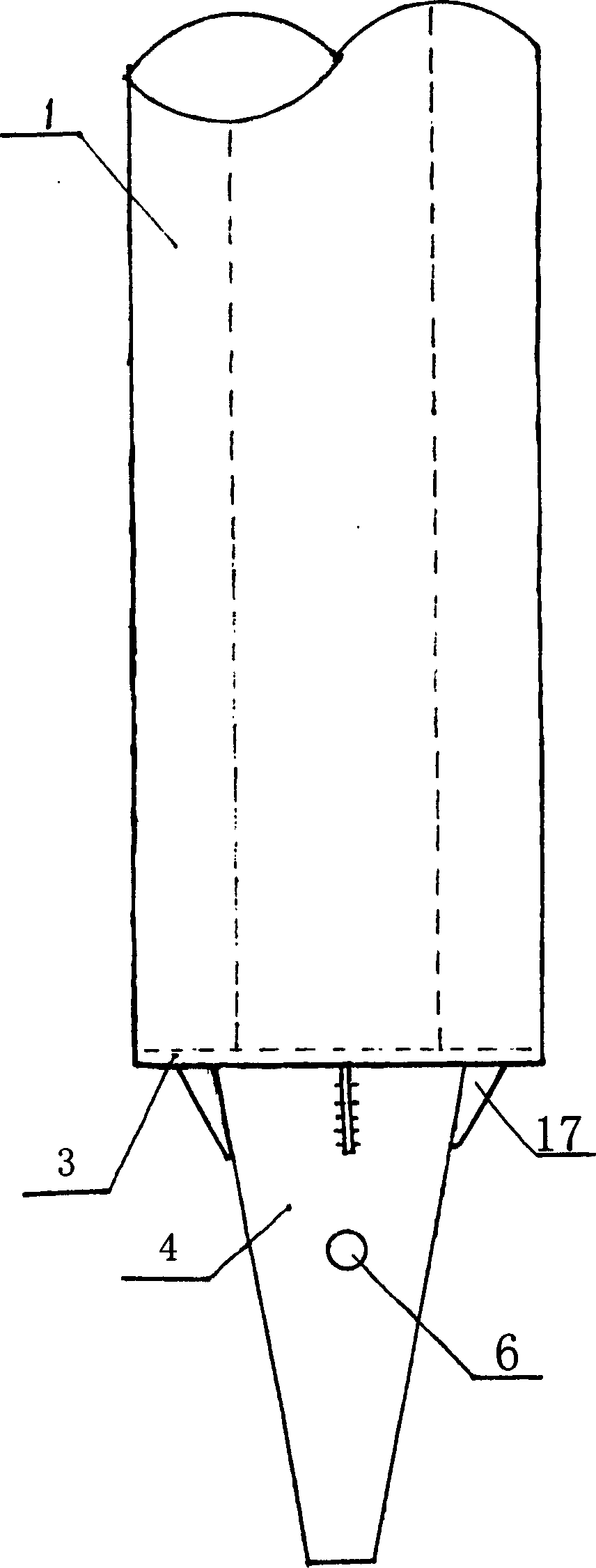

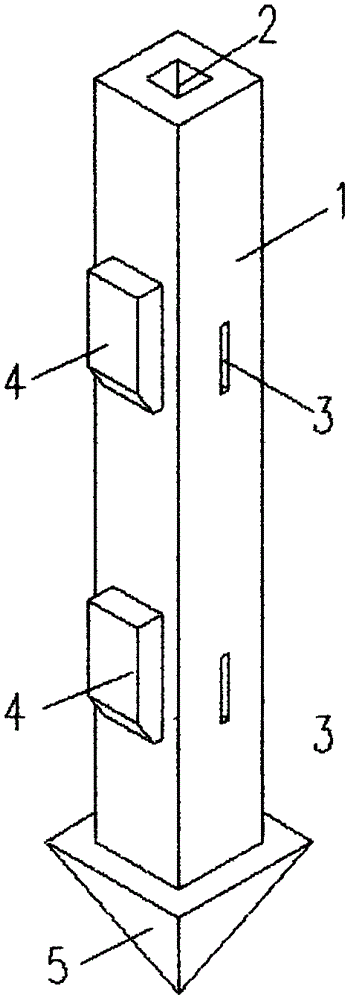

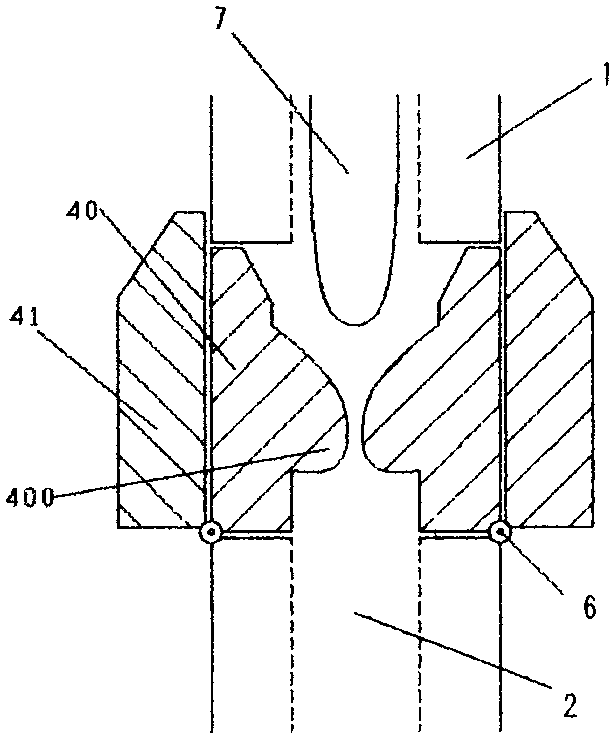

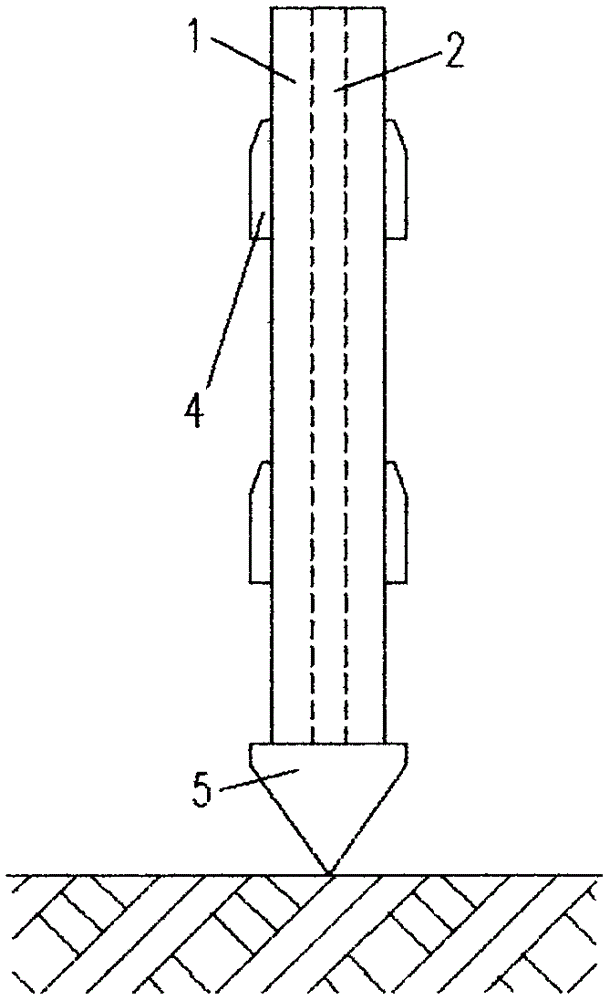

Uplift pile with unfolding barb and construction method thereof

InactiveCN105544525AImprove project qualityImprove securityBulkheads/pilesEngineeringBearing capacity

The invention discloses an uplift pile with an unfolding barb and a construction method thereof. The uplift pile comprises a precast tubular pile. The precast tubular pile comprises a maternal pile and a pile tip, wherein a pile body of the maternal pile extends from a pile tail to a cavity of the pile tip, one or more layers of vane pushing-away holes communicating with the cavity are formed in the pile wall of the maternal pile in the length direction of the pile body, the lower edges of the side, far away from the cavity, of the vane pushing-away holes are provided with vanes through rotary devices, the vanes can rotate away from the cavity around the rotary devices, and the cavity is provided with a force application part used for pushing the vanes away from the vane pushing-away holes. The construction method with the uplift pile with the unfolding barb is shown in the specification. Compared with a traditional precast pile, the unfolding vanes attached to the pile body work together with a soil body, so that the anti-floating design capacity of the uplift pile is greatly improved, the bearing capacity of the pile is improved by several times or even dozens of times, the number of piles and the length of the pile are greatly reduced, and the comprehensive benefits are quite remarkable.

Owner:陈明

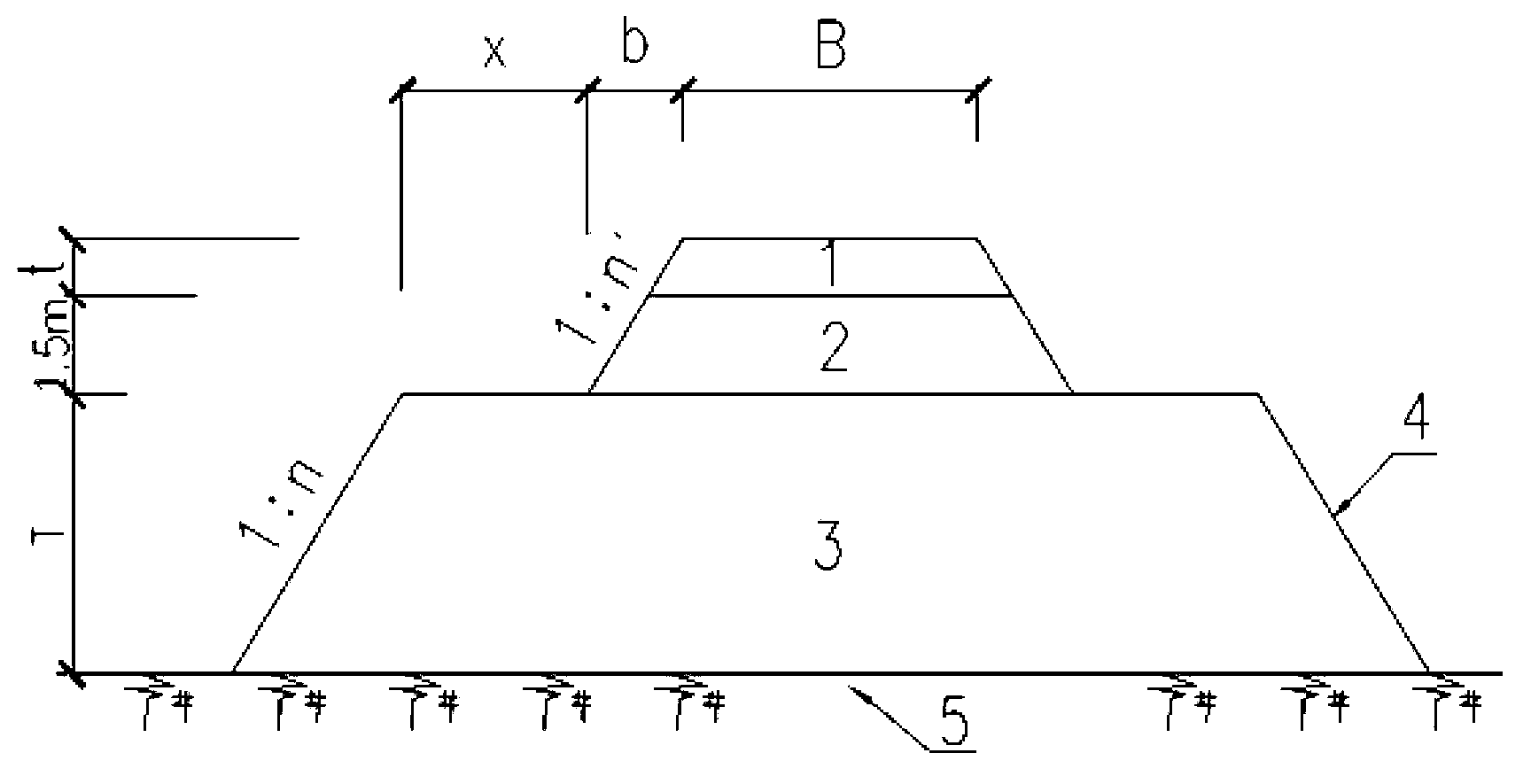

Method for constructing multi-thickness rockfill embankment with lateral confinement and layering functions

The invention discloses a method for constructing a multi-thickness rockfill embankment with lateral confinement and layering functions, belongs to the technical field of road construction, and solves the problems of high possibility of uneven settlement after construction, pavement cracking, high construction cost and the like in the conventional rockfill embankment. The method comprises the following steps: processing a foundation bed; measuring and lofting; carrying out rock excavation and controlling the particle size; and carrying out filling construction, wherein the filling construction process comprises the steps of inserting a rod and hanging a line, building on a side slope, spreading rockfill embankment main aggregates, and laying stone ballasts. In the effective width range of a roadbed, artificial dry building rubbles of 0.8-1.5 m are arranged on each side; filler capable of forming a plate body is filled within the roadbed range of 1.5 m; the layering thickness is 30-80 cm; and the rockfill embankment is divided into a plurality of circulation layers according to the total height of the rockfill embankment. The rockfill embankment has the advantages of attractive appearance, quality guarantee, short filling cycle, low cost and high working efficiency, is suitable for temporary foundation treatment and the like of civil engineering, roads and novel scaffolds, and has high promotional and economic benefits.

Owner:云南交投集团云岭建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com