Modular construction system of underground building and construction method thereof

An underground building and modular technology, which is applied in earth drilling, mining equipment, tunnels, etc., can solve problems such as constraints on the development and utilization of underground space, and achieve the effects of flexible and changeable section forms, high social benefits, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

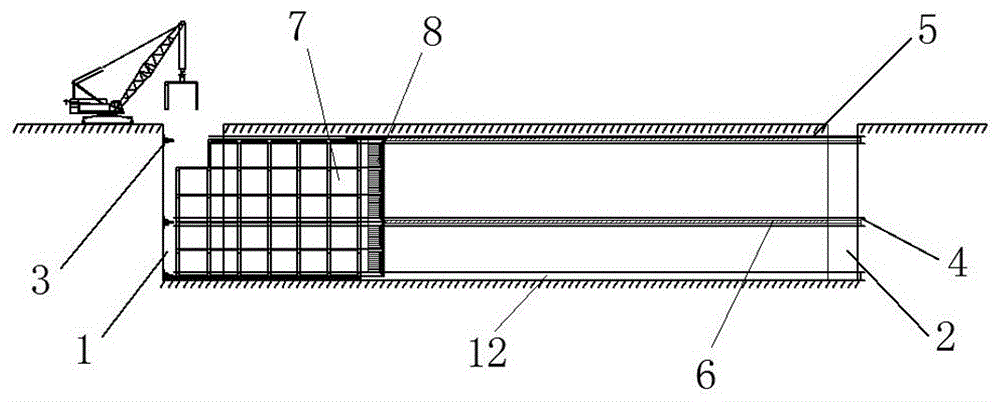

[0058] Embodiment 1: In this embodiment, the detailed construction process will be described in detail for the underground excavation structure project in combination with the structure and construction method.

[0059] For example: a five-storey underground parking lot is proposed, with a column grid size of 4mx6m, a floor height of 3.6m, a total building length of 92m, a width of 30m, a main structure jacking of 80m, and a building area of 14,000 square meters. The main process is as follows:

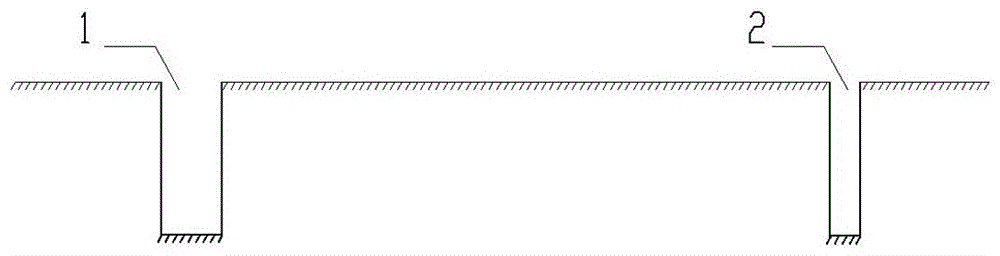

[0060] Process one: if image 3 As shown; the originating shaft 1 and the receiving shaft 2 are completed by the open cut method; the dimension of the originating shaft is 8mX34m, and the size of the receiving shaft is 4mX31m. machine.

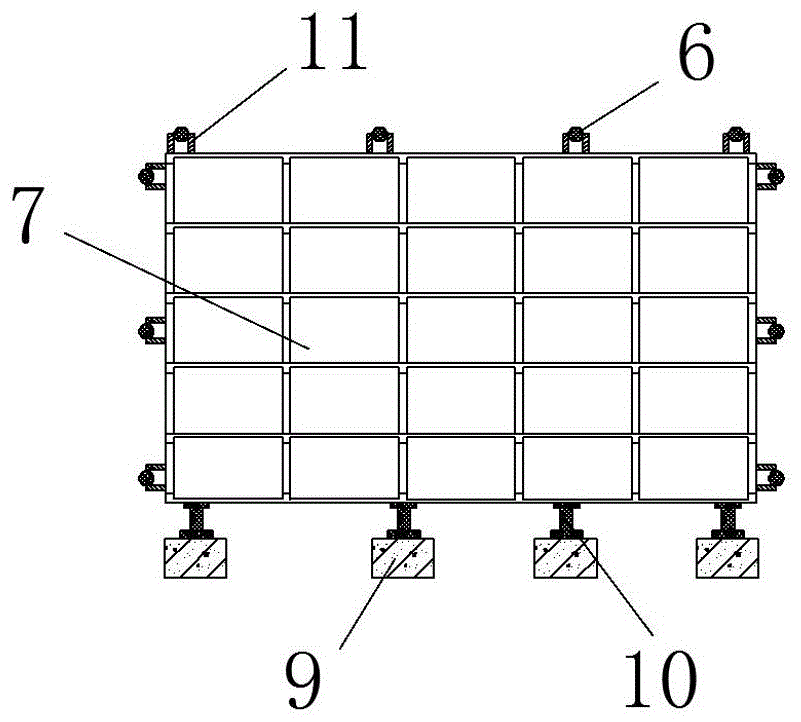

[0061] Process two: if Figure 4 As shown in the figure; set the leading guide hole 8 with a diameter of 20cm, which is completed by using a pipe curtain machine or a small pipe jacking machine or a horizontal drilling rig; the small guide hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com