Assembled type concrete block pressing rod beam and using method, production die and production method thereof

An assembly method and concrete technology, which are applied in the directions of molds, earthwork drilling, roof beams for supporting mine roofs, etc., can solve the problems of excessive labor, long construction period, unfavorable environment, etc. The effect of short and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

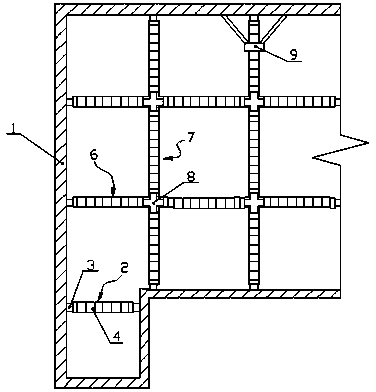

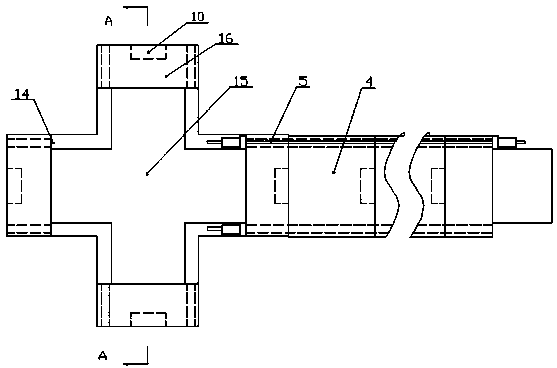

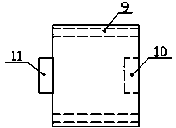

[0031] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0032] like figure 1 and 2 As shown, an assembled concrete block compression bar beam assembled with prestressed steel bars includes a single beam 2 and a well-shaped beam, and the single beam includes two end blocks 3, several middle blocks 4 and at least four prestressed steel bars 5. The blocks at both ends and several middle blocks are connected into a whole through prestressed steel bars; One end of the bar beam 6 is connected to the node block 8, and the other end is supported on the supporting body 1; Supporting columns are provided, and the end-span compression bar beam includes an end block 3, several intermediate blocks 4 and at least four prestressed steel bars 5 for connecting these intermediate blocks 4 in series, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com