Truss unit, truss system and method for enhancing bearing capacity and integrity of building prefabricated slab

A technology of prefabricated slabs and trusses, applied in truss structures, truss beams, building maintenance, etc., can solve the problems of increased load of prefabricated slabs of buildings, and failure of the bearing capacity, integrity and deformation of prefabricated slabs of buildings to meet the requirements, etc. Achieve high bearing capacity, good anti-seismic performance, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

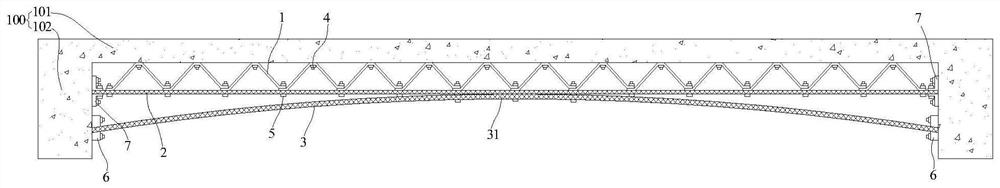

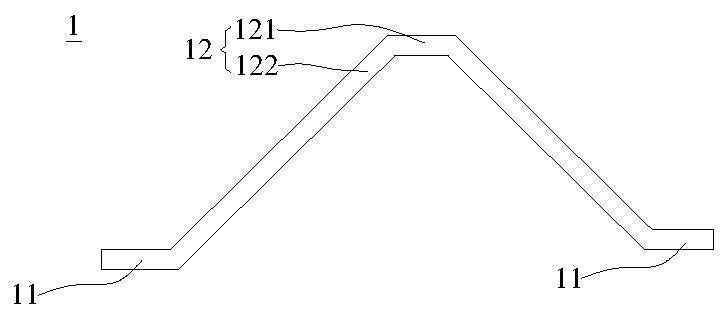

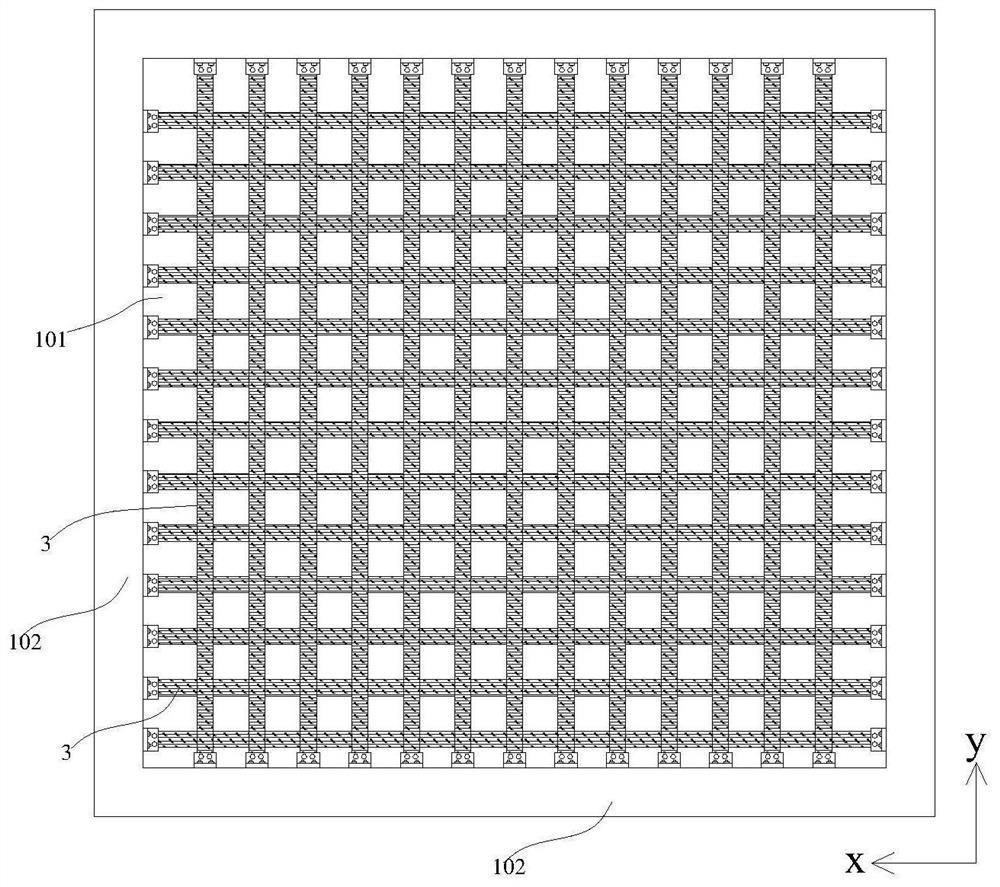

[0033] The invention discloses a truss unit, a system and a method for enhancing the bearing capacity and integrity of a prefabricated slab of a building, wherein the truss unit includes a plurality of steel web components fixedly installed with each other and at the same time with the prefabricated slab of the building and connected with the prefabricated slab of the building. The bamboo chord is fixedly installed by the steel web component. The bamboo chord is located below the steel web component and both ends of the bamboo chord are fixedly installed with the building prefabricated board at the same time.

[0034] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com