Patents

Literature

55results about How to "High degree of factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

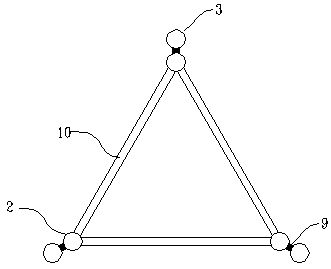

Combined light steel structure house and mounting method thereof

InactiveCN101418592AHigh degree of factoryReduce the ratio of output value to energy consumptionBuilding constructionsFloor slabSandwich panel

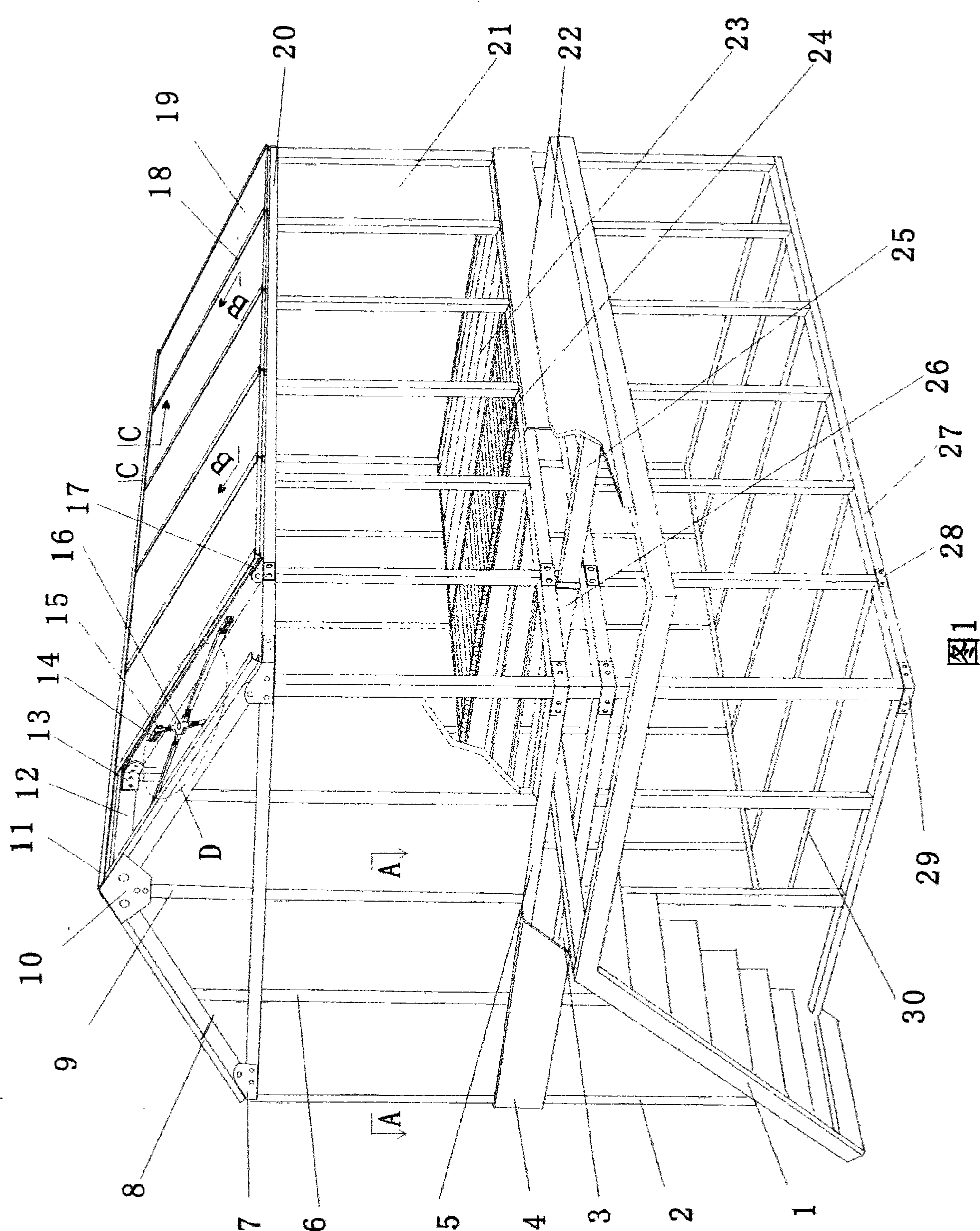

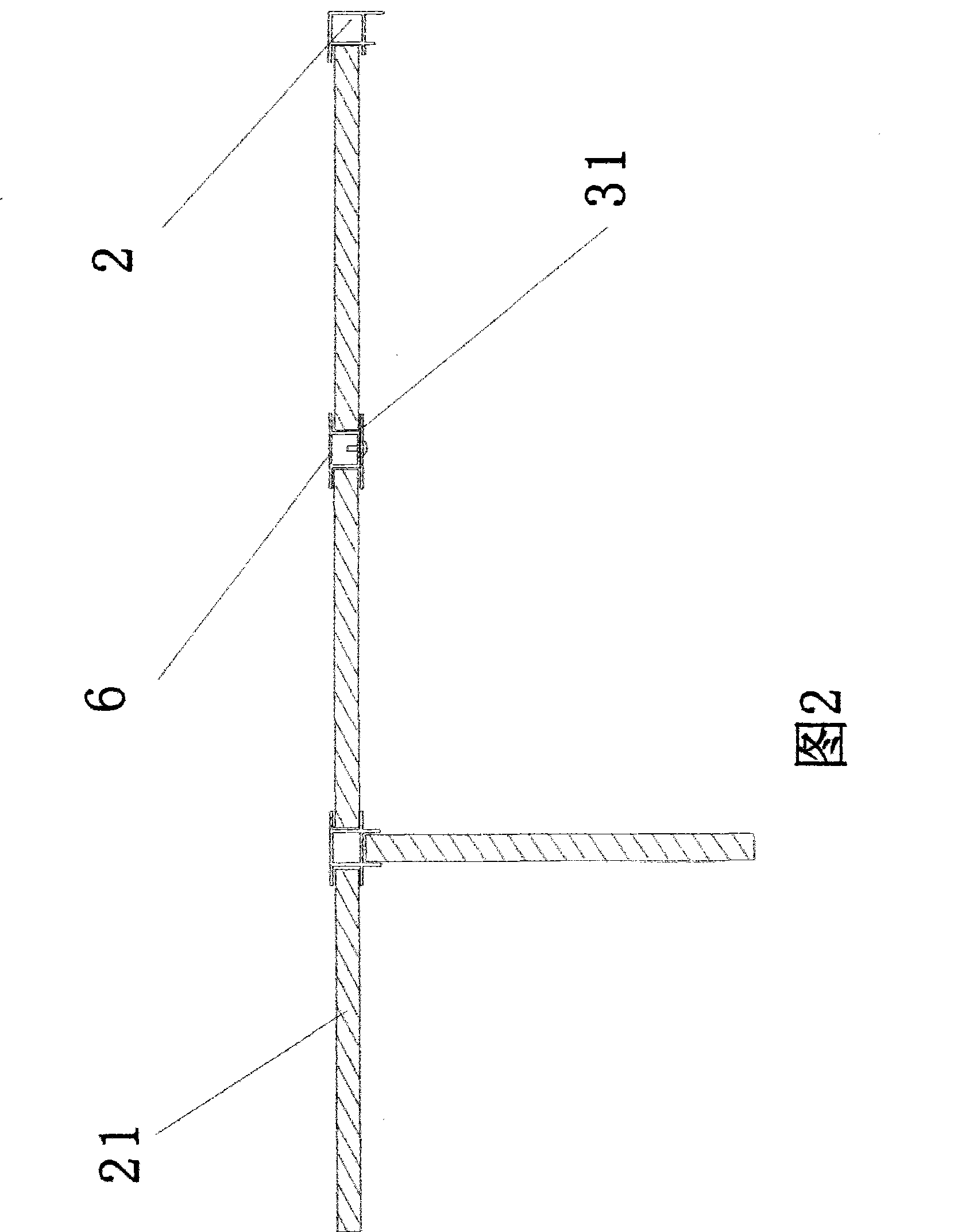

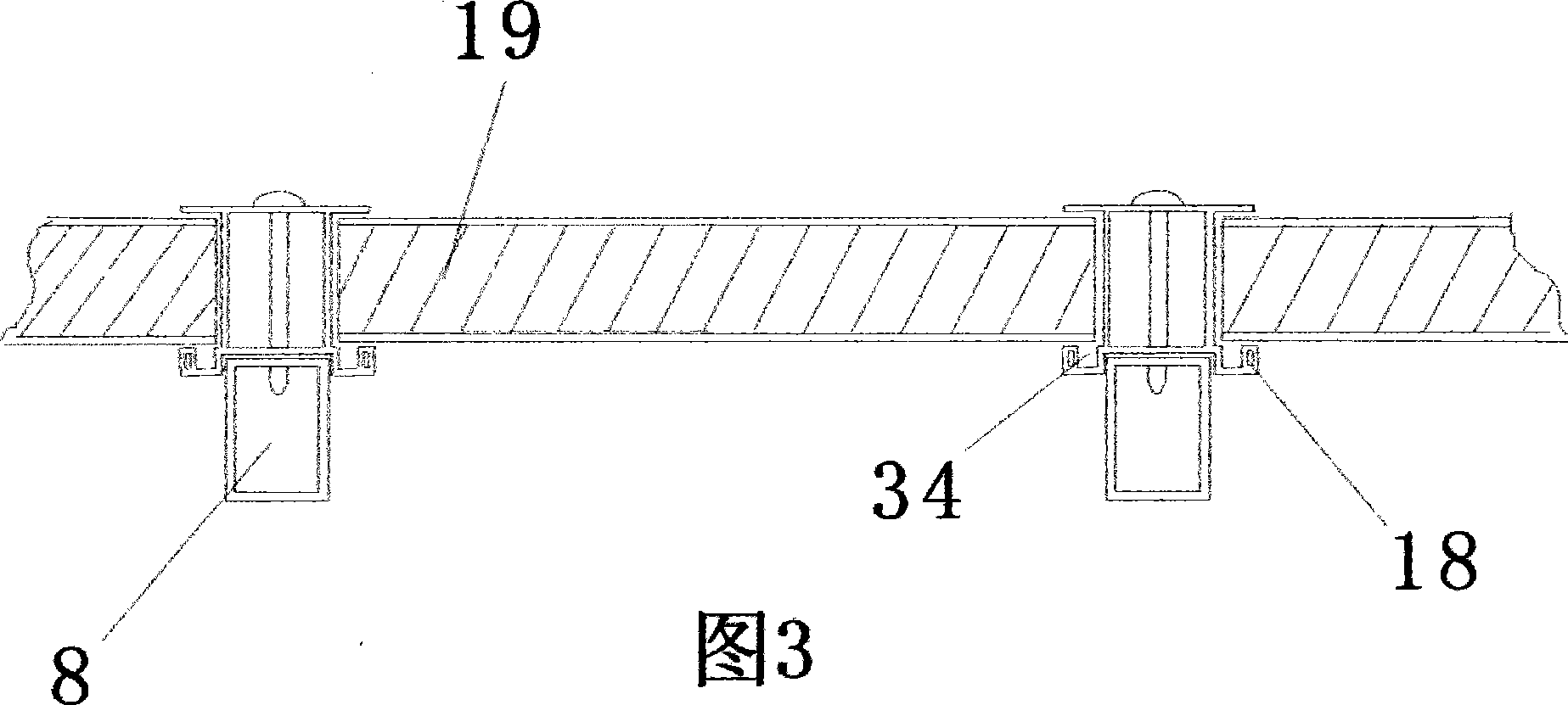

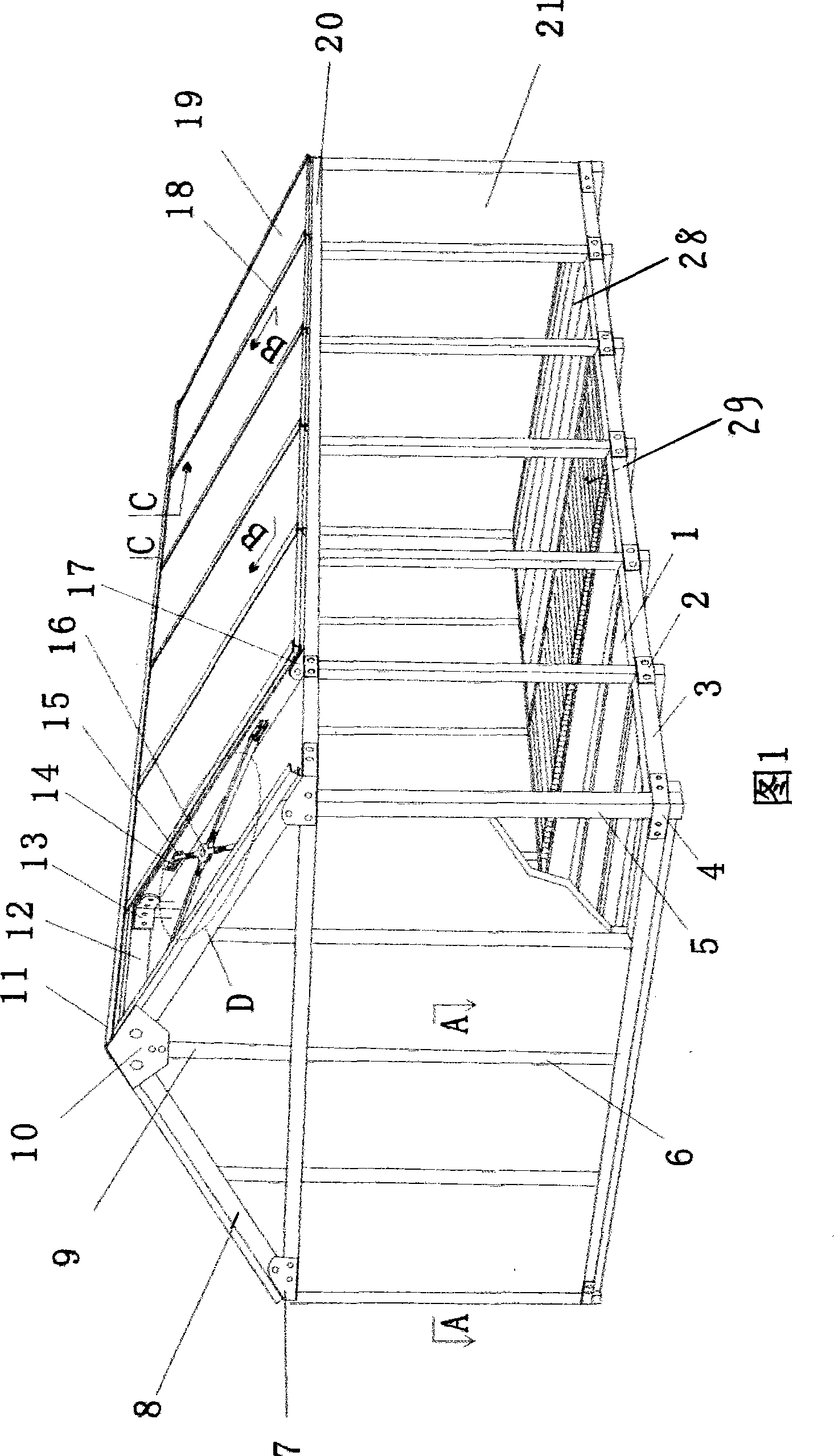

The invention relates to a combined lightweight steel structure building and an assembling method thereof. The combined lightweight steel structure building comprises ground beams, angular upright posts, upright posts, ring beams, sandwich panels, a roof, staircases, doors and windows. The key technical points of the combined lightweight steel structure building are as follows: a plurality of floor bottom girders in parallel are arranged on the ground; four ground beams are arranged on the circumference of each floor bottom girder in turn; bolt fastening sheets which are connected with the ground beams and the ring beams are arranged on joints of upper ends and lower ends of each angular upright post and each upright post respectively; limit baffle plates of wall panels are arranged on angular upright posts and upright posts near the outside of the building; bolt fastening limit treadle bars of the wall panels are arranged on upright posts near the inside of the building; the wall panels comprise wall panels provided with door bodies or wall panels provided with window bodies; metal section supporting layers which are suitable to be connected with balcony bottom girders or / and corridor bottom girders are uniformly distributed between two adjacent floors; metal floor slabs are laid on the metal section supporting layers; and the roof is as follows: a waterproof ridge section is arranged on the upper part of a ridge main girder; the edge of a roof slab is embedded into the ridge section; and a roof slab slot section provided with a drainage channel is arranged on the upper part of a ramp beam of the roof.

Owner:官木喜

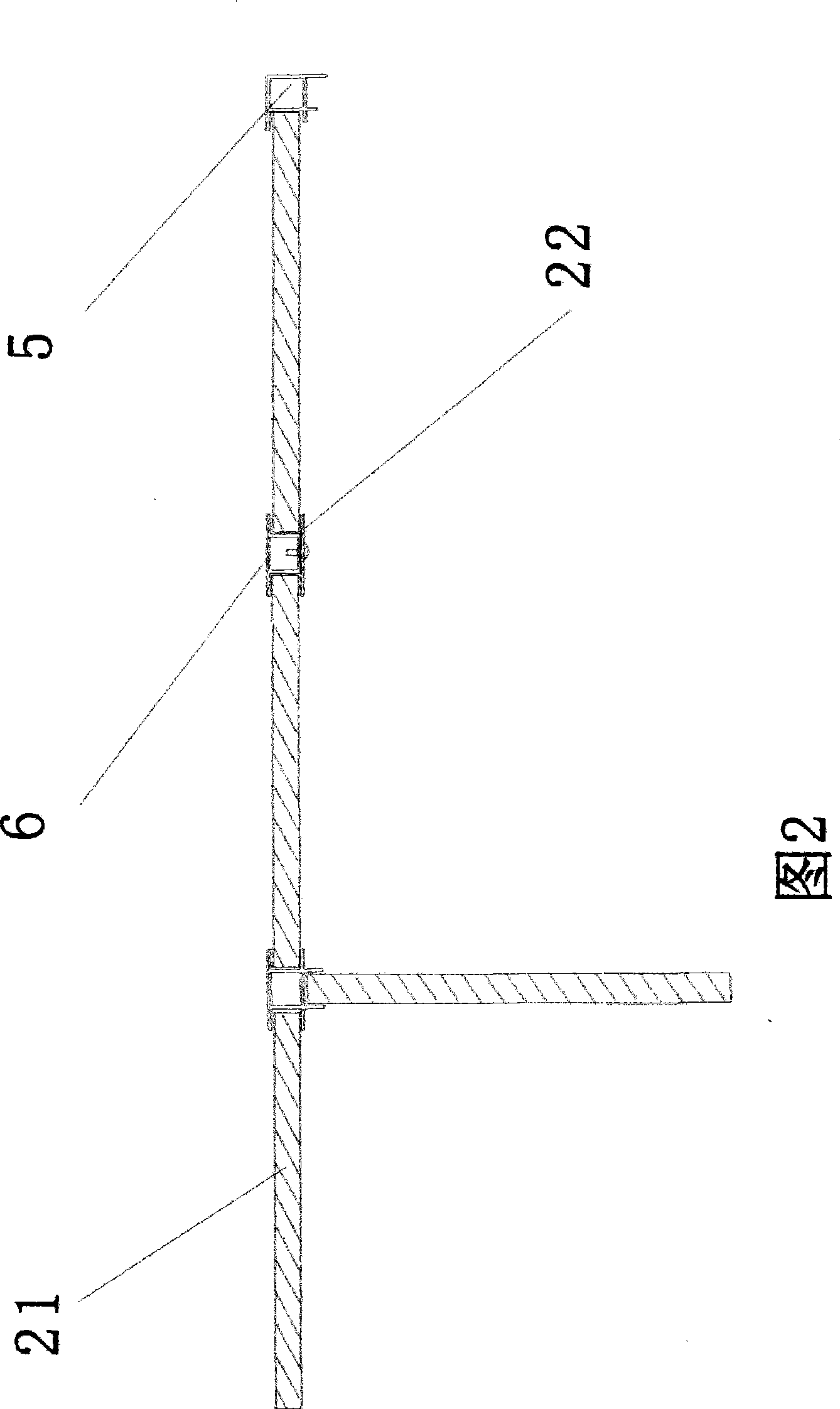

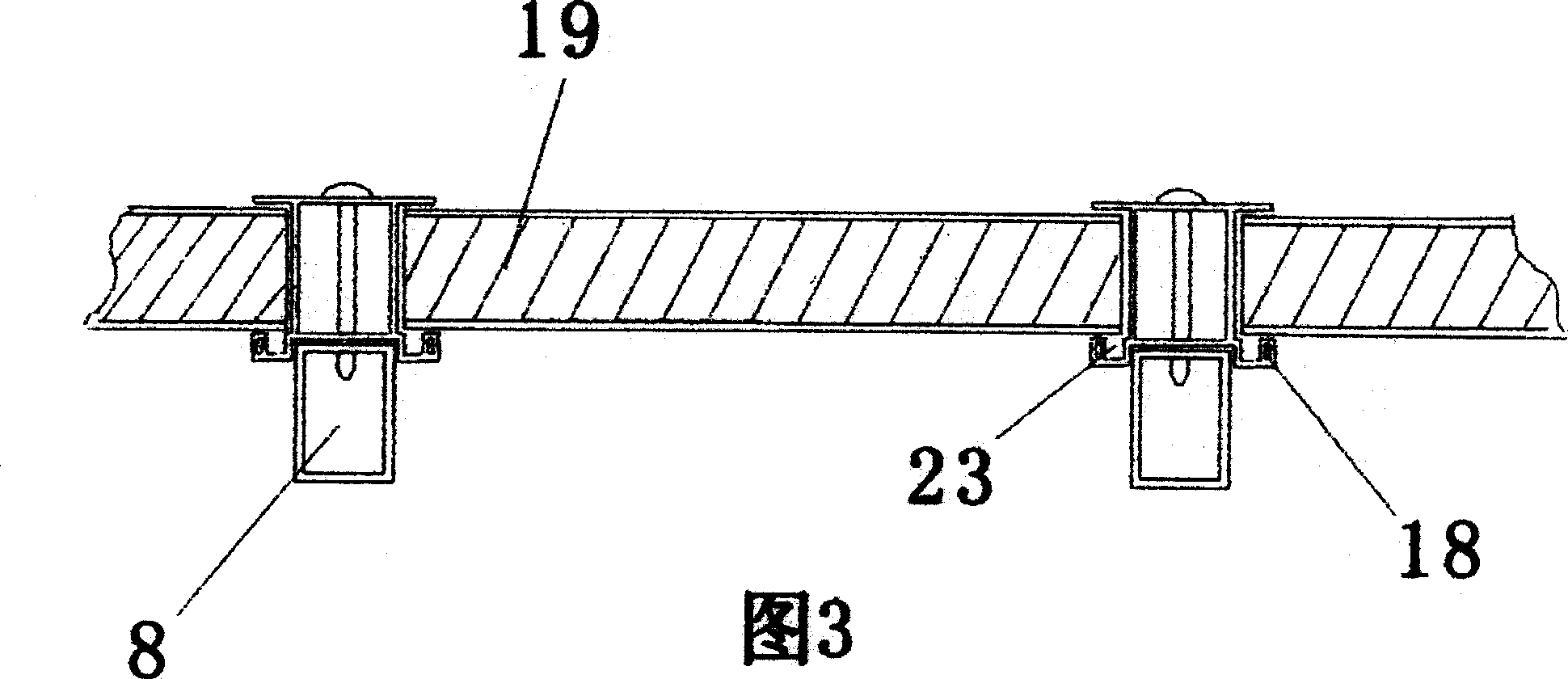

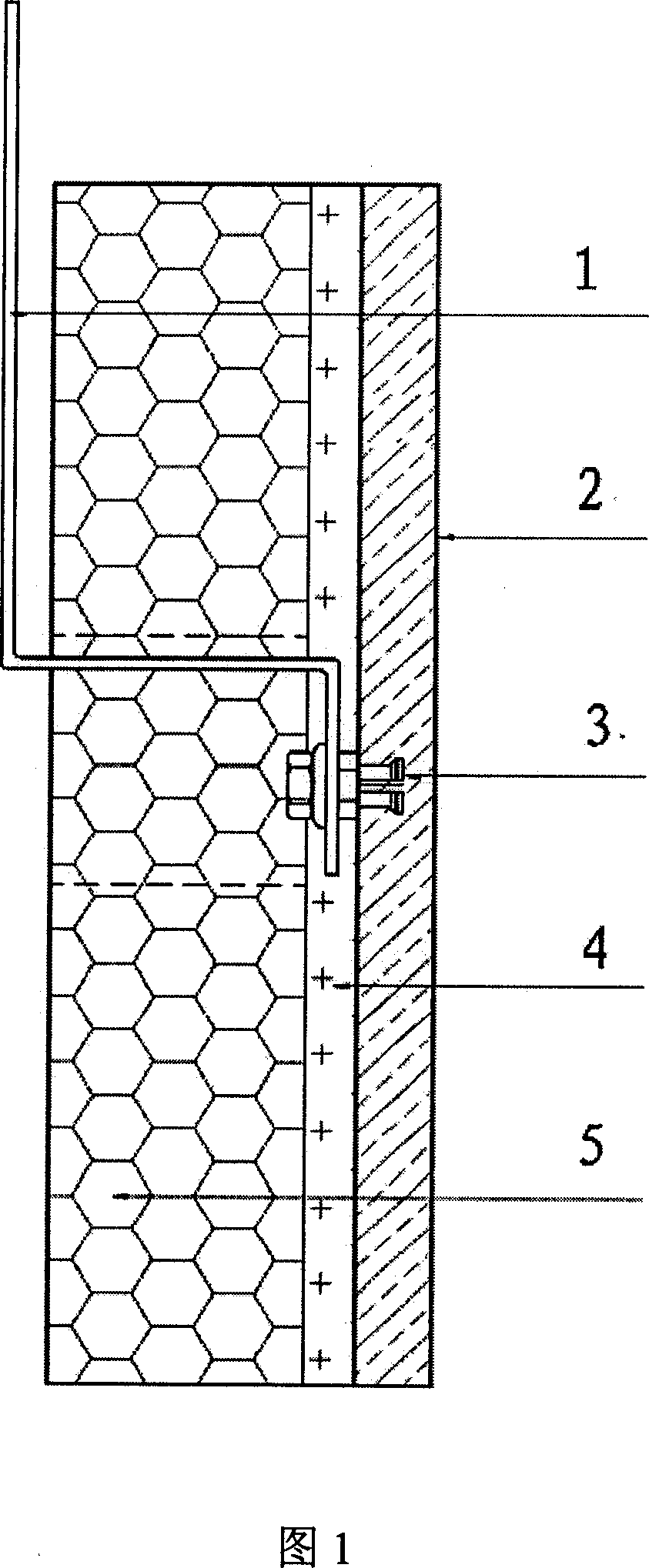

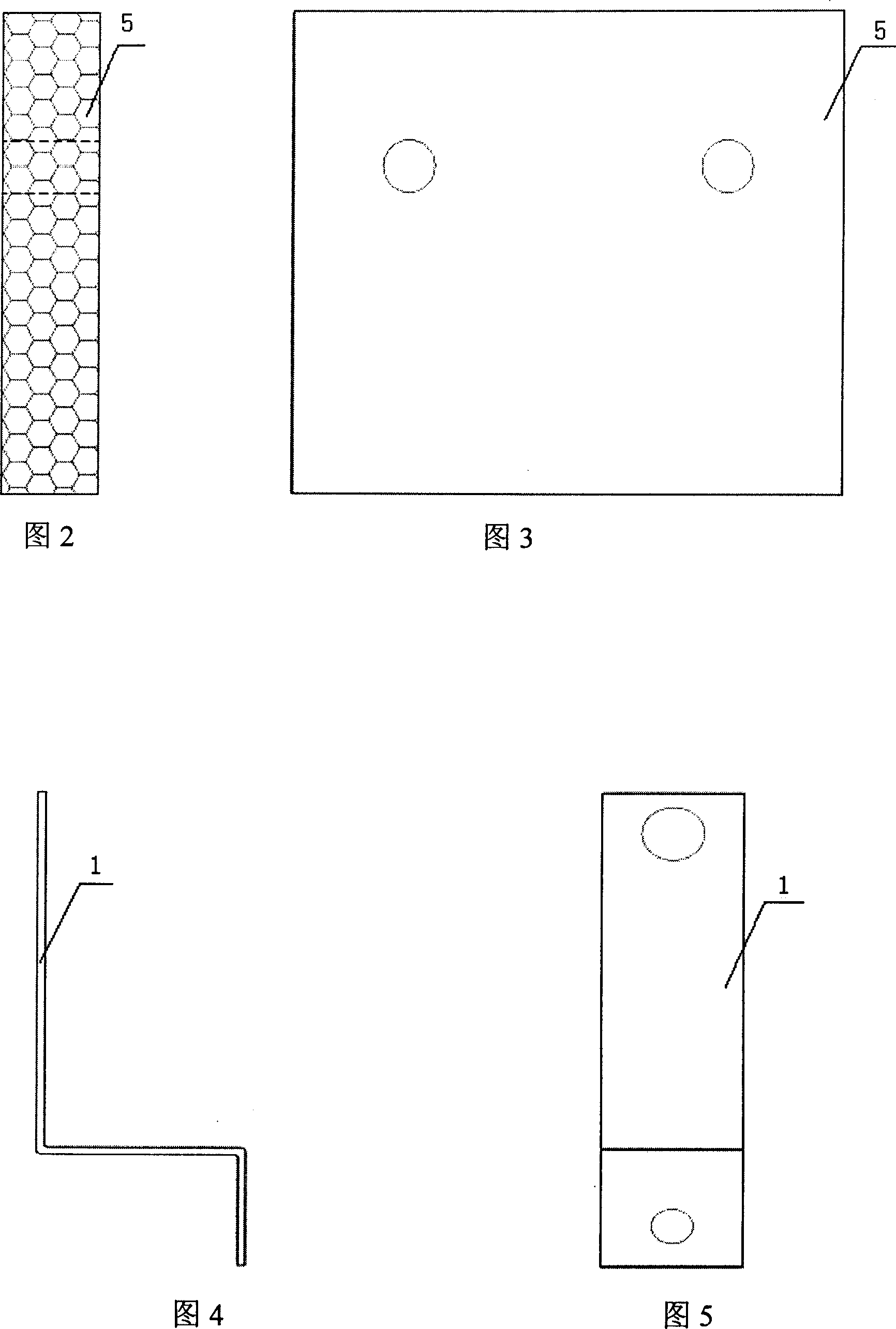

One layer combined type light steel structure house and installation method thereof

InactiveCN101440635ASatisfy the needs of clientsHigh degree of factoryBuilding constructionsSandwich panelBolt connection

The invention relates to a one-story combined type lightweight steel structure house and a mounting method thereof. The house comprises ground beams, corner upright posts, upright posts, ring beams, a sandwich panel, a roof, a door and windows. The house comprises the following technical points: a plurality of parallel floor mudsills are arranged on the ground; the periphery of the floor mudsills are sequentially provided with four ground beams; the connecting parts between the upper ends and the lower ends of each corner upright post and each upright post are provided with a bolt connecting sheet connected with the ground beam and the ring beam respectively; the positions of the corner upright post and the upright post close to the outer side of the house are provided with a limiting baffle plate of a wallboard; the position of the upright post close to the inner side of the house is provided with a bolt connecting and limiting treadle bar of the wallboard; the wallboard comprises the wallboard with a door body or window bodies; and the roof comprises: the upper part of a main girder of a roof ridge is provided with a water retaining roof ridge section; a roof board is embedded into the roof ridge section; and the upper part of an oblique beam of the roof is provided with a roof board slot section with a drainage channel. The method standardizes and generalizes members of the building structure, totally adopts bolt connection without needing welding in mounting and is suitable for the requirement of a routine lightweight structure house.

Owner:官木喜

Cell-type hollow joint stone curtain wall

ActiveCN101956439AAvoid causing inconvenience to constructionHigh degree of factoryCovering/liningsWallsEngineeringRelationship - Father

The invention provides a cell-type hollow joint stone curtain wall which comprises a stone unit, connecting members and a support system, wherein the stone unit is formed by splicing a father material, a mother material, a bottom material, a top material and stone together; the connecting members are respectively arranged on the father material and the mother material; the stone unit is hanged onthe support system through the connecting members; an adjusting screw rod is arranged on each connecting member; a long hole is arranged on the support system; and the stone unit can be horizontally and longitudinally adjusted through the adjusting screw rod and the long hole. The stone curtain wall has the advantages of good security, convenient replacement, high industrial degree as well as time-saving and labor-saving installation.

Owner:SUZHOU KELIDA BUILDING & DECORATION CO LTD

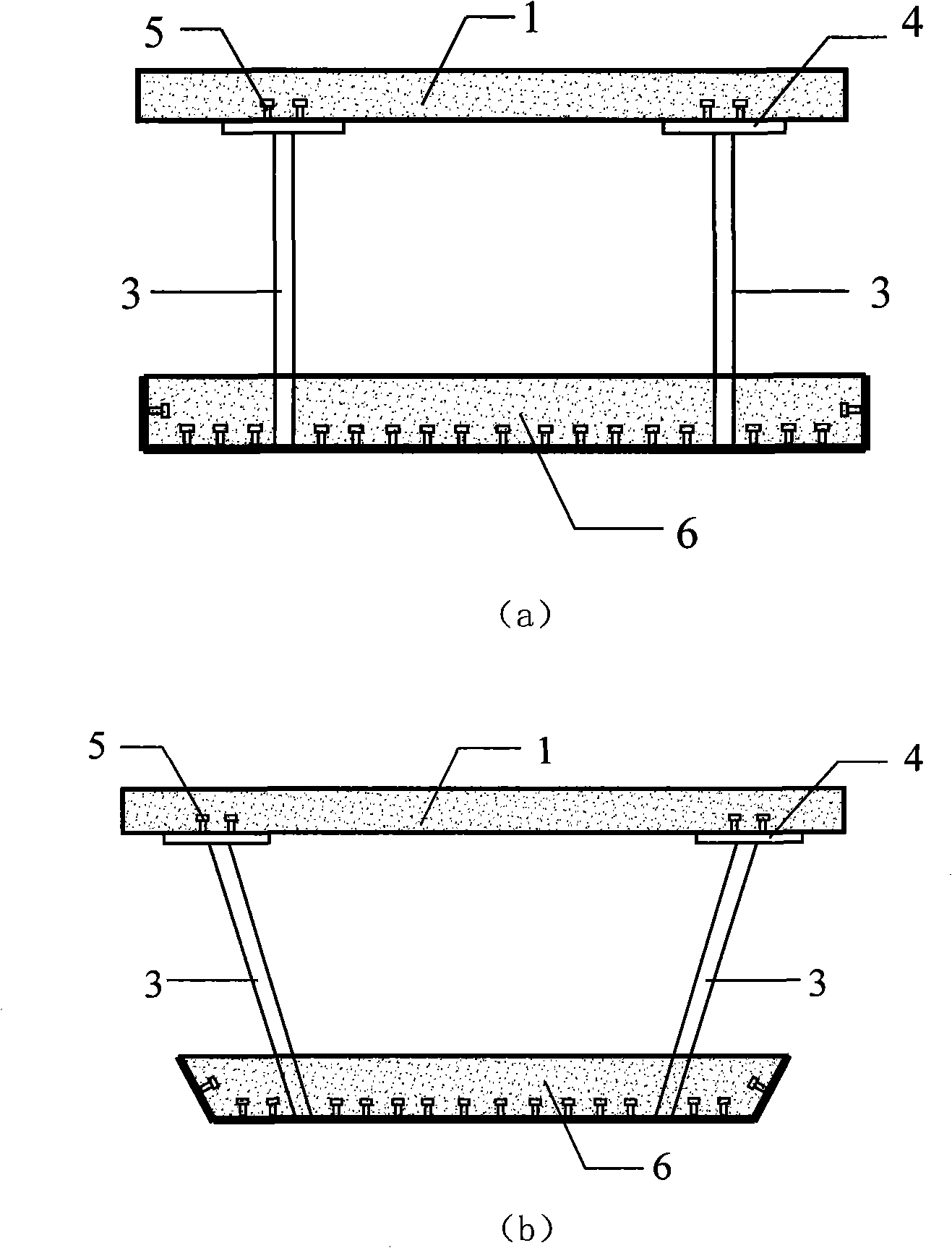

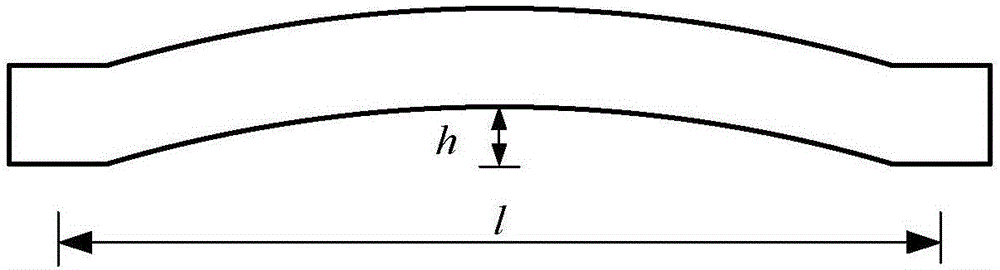

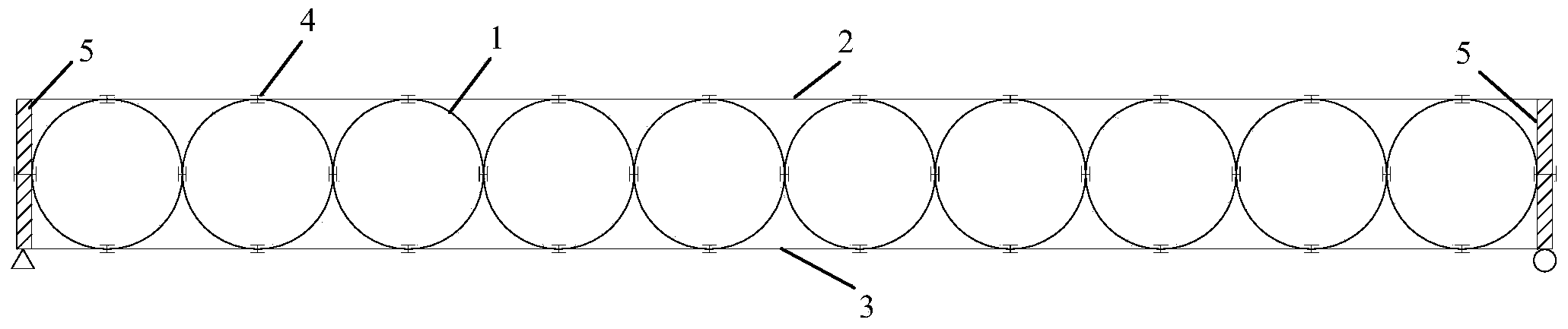

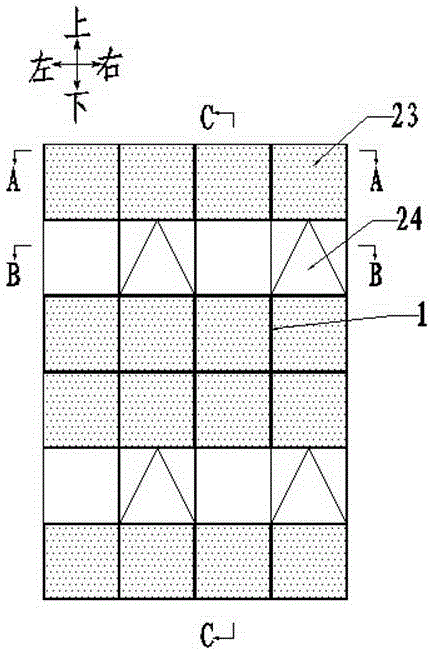

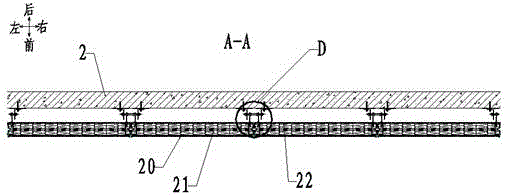

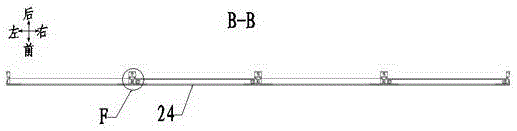

Steel-concrete combined continuous beam bridge deck as well as manufacturing method and application thereof

InactiveCN105926440AAvoid early crackingIncreased durabilityBridge structural detailsBridge erection/assemblyCrack resistancePre stress

The invention discloses an assembly type steel-concrete combined continuous beam bridge deck formed by exerting prestress to a concrete bridge deck in a hogging moment region. The deck comprises a hogging moment region concrete segmental plate, a hogging moment region concrete end plate and a sagging moment region segmental plate. The manufacturing method comprises the following steps of erecting of shuttering, pouring and curing; the deck is applied to the construction of a steel-concrete combined continuous beam bridge. Prestress is exerted to the inner part of the concrete bridge deck of the hogging moment region, but a tendon beam is not used, so that material consumption is reduced, the crack resistance and the bending resistance bearing capacity in the hogging moment region are effectively improved, and the condition that prestress beams rust is avoided; during construction of the steel-concrete combined continuous beam bridge, an assembled type prefabricated prestressed concrete deck is adopted, so that the factory degree is high, the quality of structural members is guaranteed, and the durability of a concrete bridge deck is improved. The assembly type steel-concrete combined continuous beam bridge deck disclosed by the invention is simple in method, convenient to construct, and high in quality, the construction period is greatly shortened, and the comprehensive economic benefits are improved.

Owner:HUNAN CITY UNIV

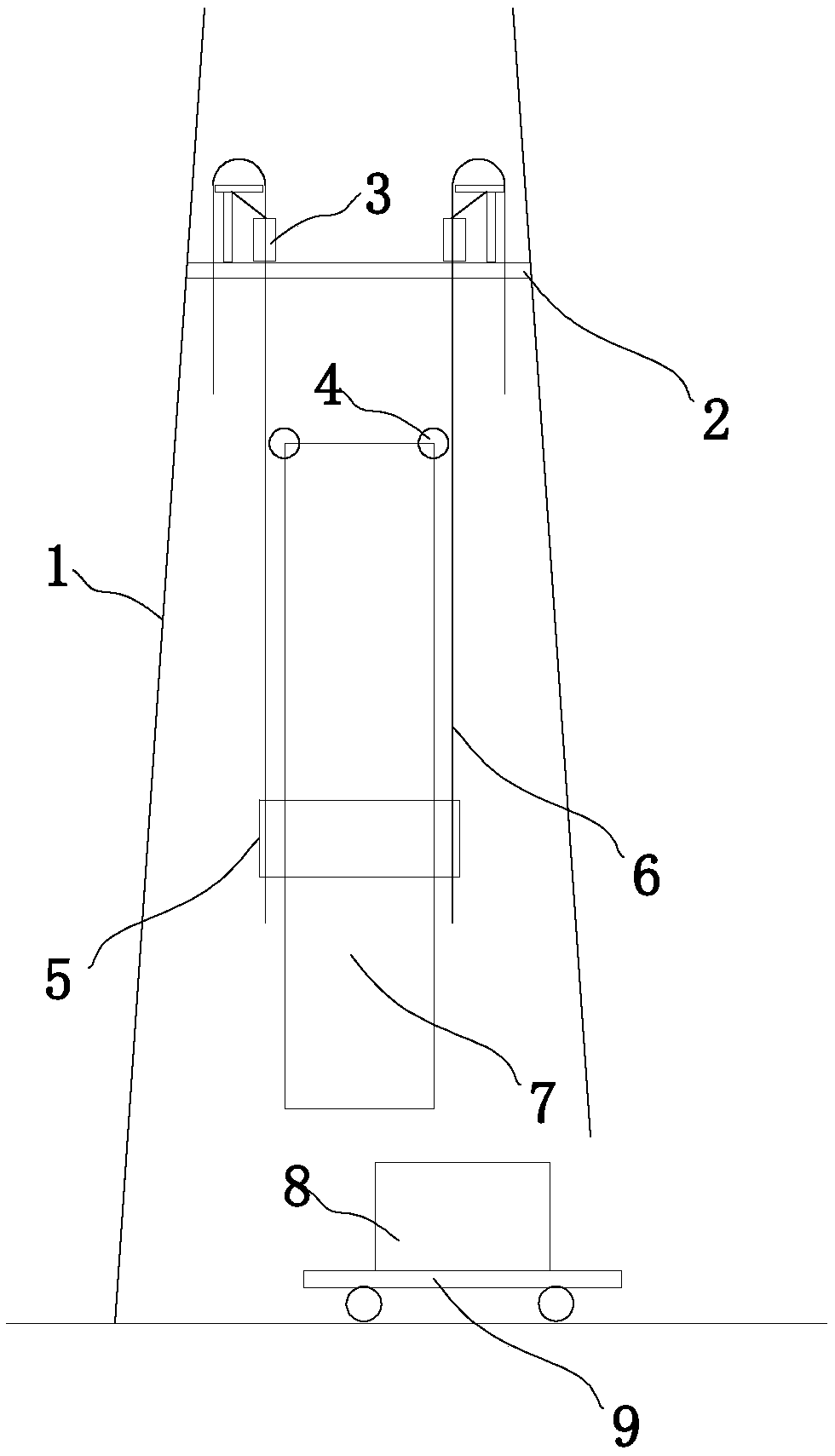

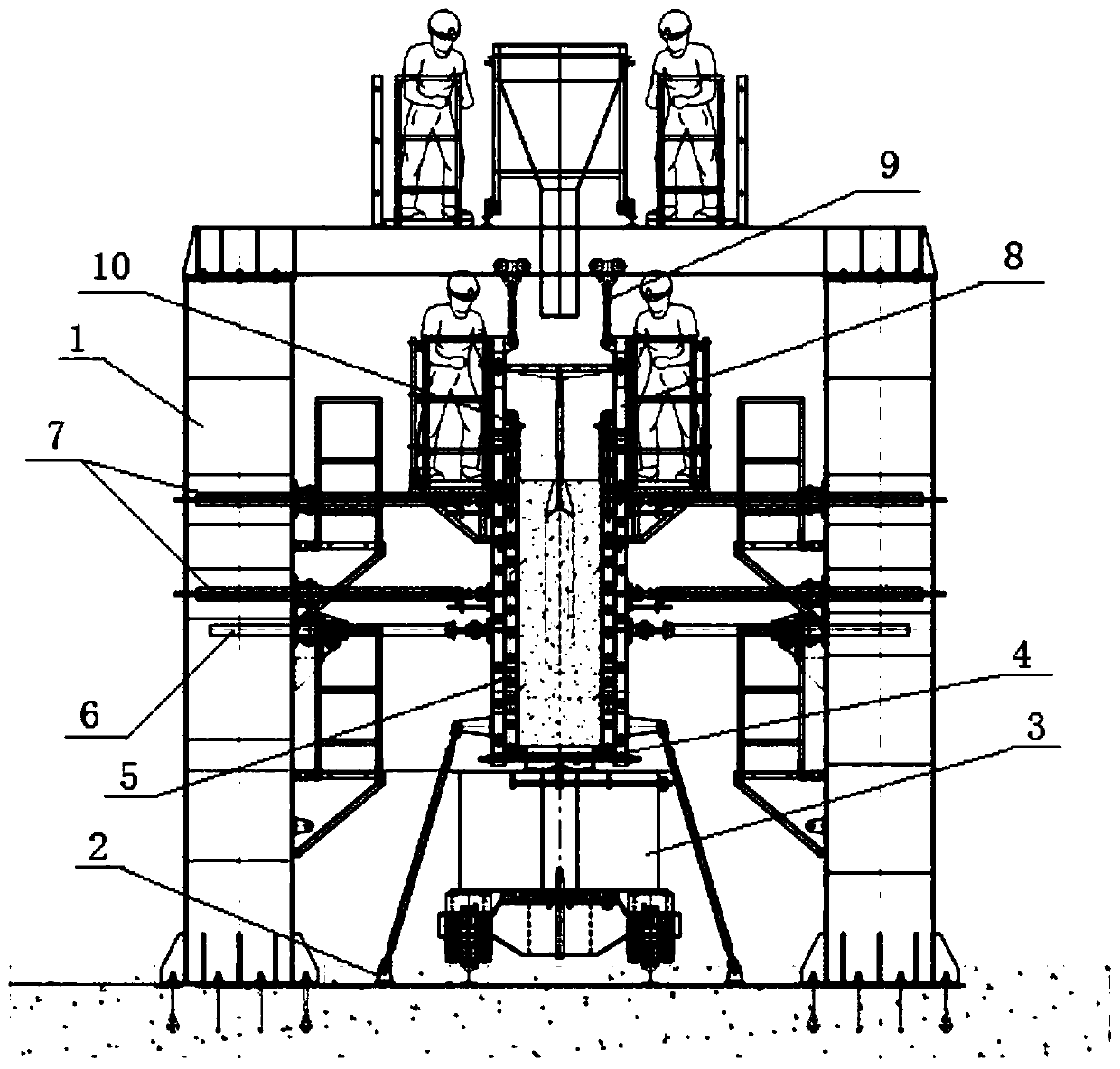

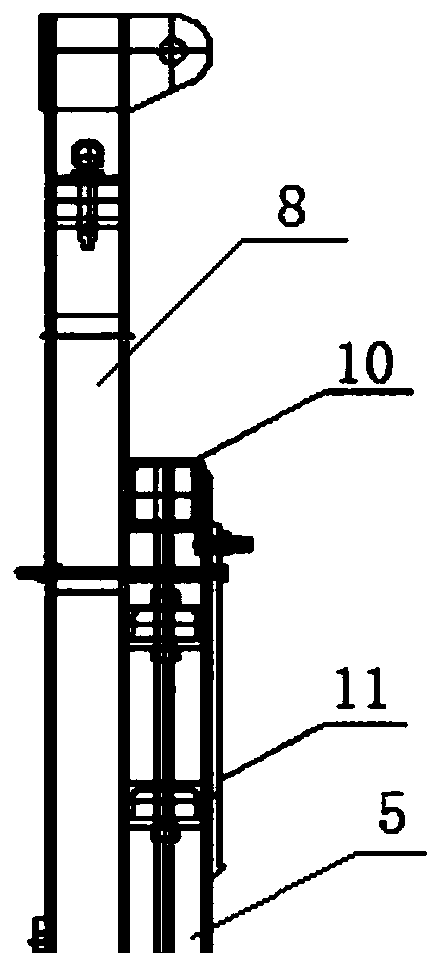

Hydraulic lifting and upside-down construction method for internal steel tube of chimney

The invention provides a hydraulic lifting and upside-down construction method for an internal steel tube of a chimney. The hydraulic lifting and upside-down construction method includes the steps of S1, installing a computer control cabinet, hydraulic pump stations and hydraulic jacks on a steel platform; S2, manufacturing standard sections of the internal steel tube; S3, laying two rails on site and installing a transport trolley on the rails; S4, welding first lifting points and installing anchorage devices and steel stranded wires at the top of the first standard section; S5, lifting a first standard section to a proper height, and transporting a second standard section to an assembly position for assembly and welding; S6, sequentially installing subsequent standard sections, enabling the internal steel tube to descend to the ground when the internal steel tube is lifted to a specific height, and switching to a second lifting point; S7, sequentially installing subsequent standard sections till lifting the internal steel tube is completed. The hydraulic lifting and upside-down construction method has the advantages of high precision, safety, reliability and lower construction cost.

Owner:MCC TIANGONG GROUP

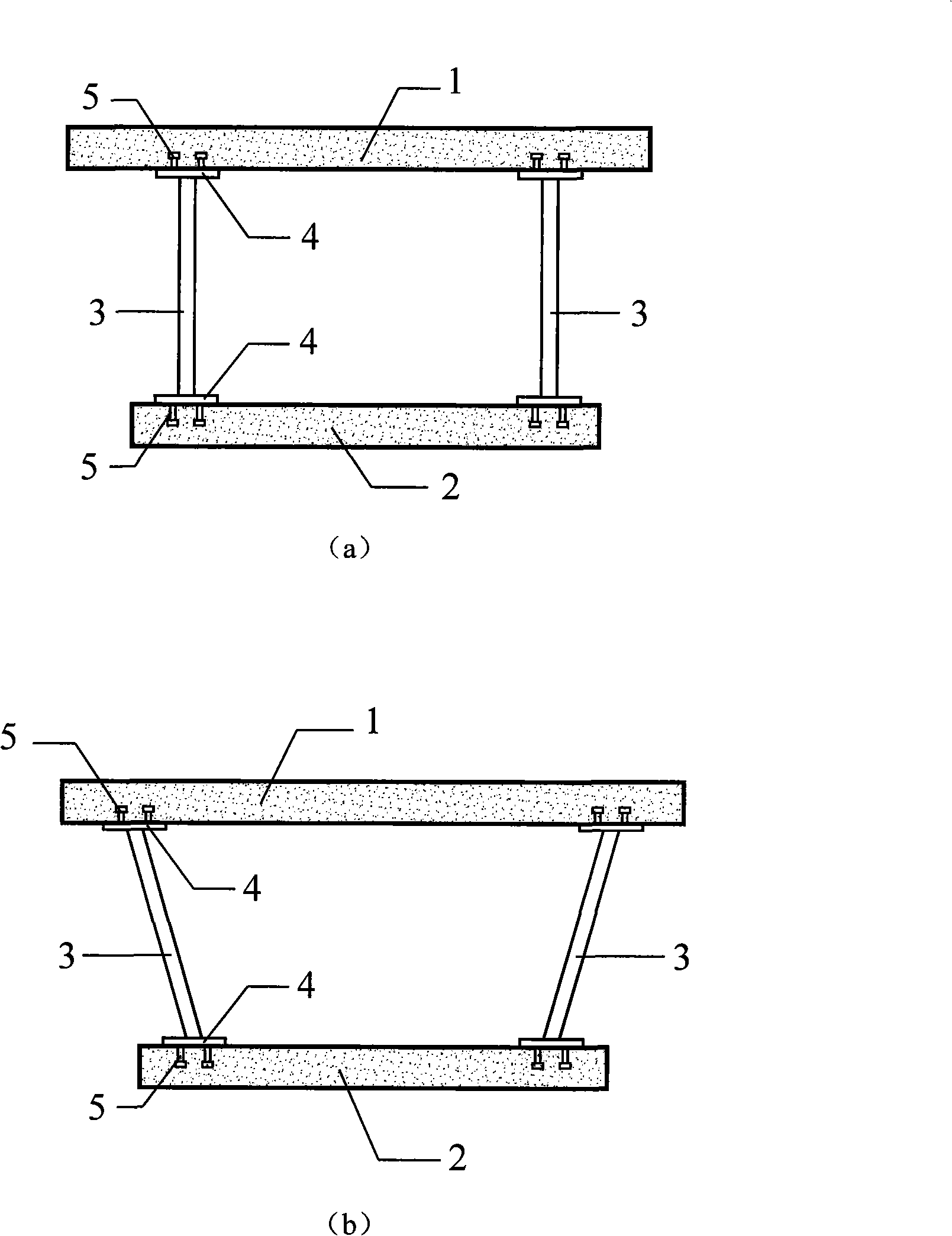

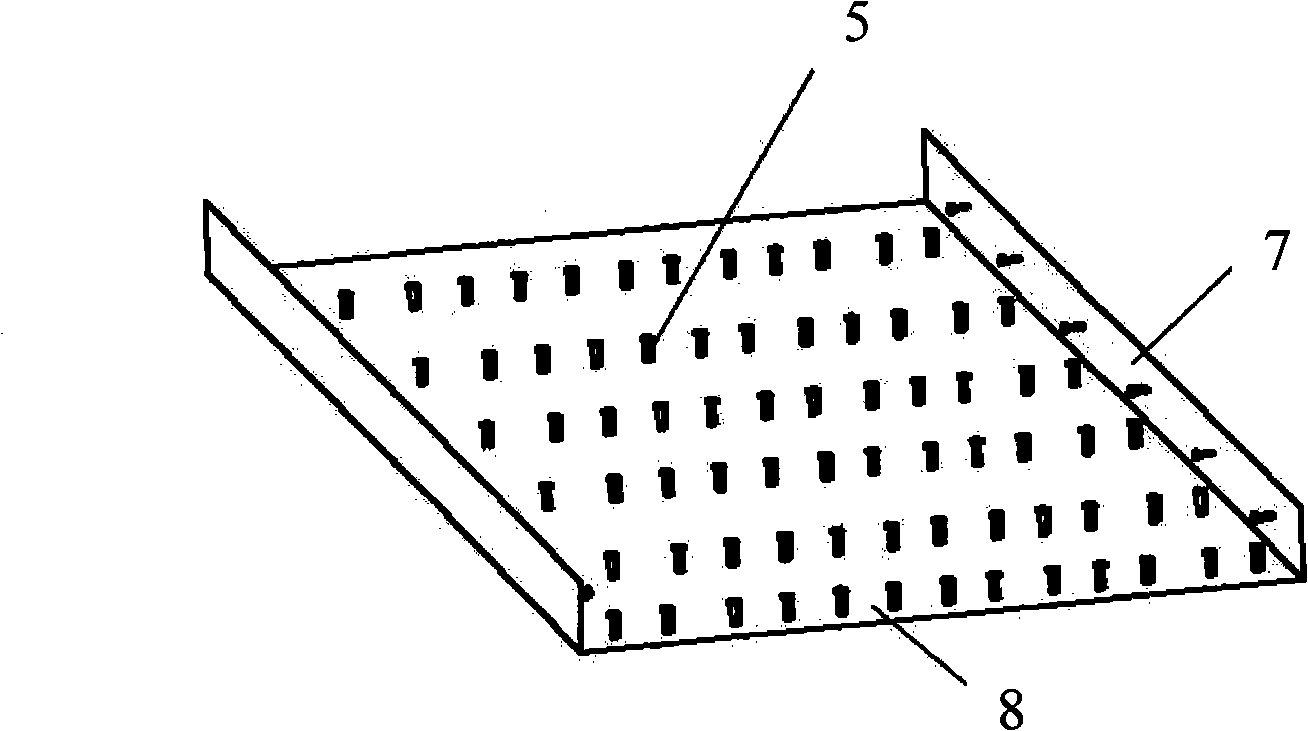

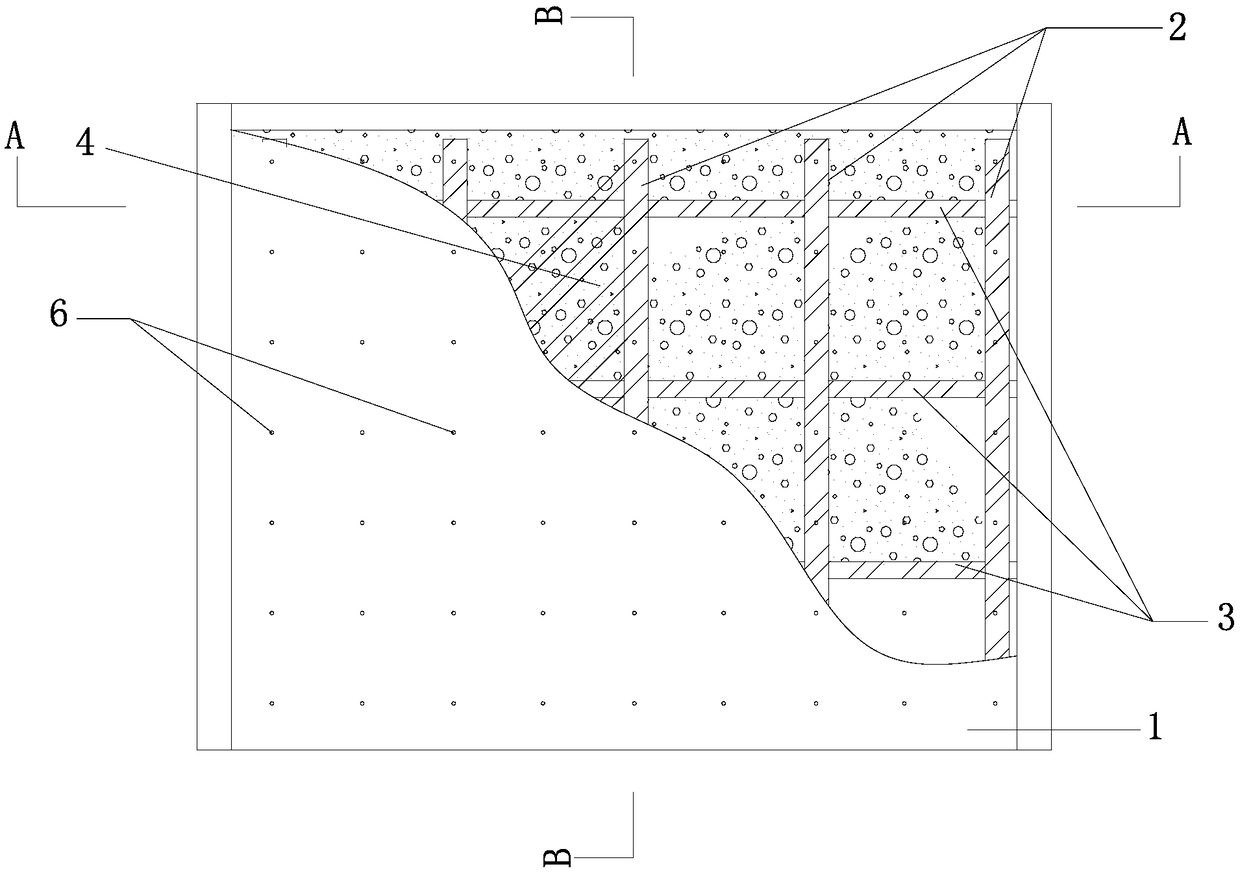

Corrugated steel web box girder with steel-concrete combined board lower wing edges

InactiveCN101280547AOvercoming Construction ComplexityReasonable structureLoad-supporting elementsBridge materialsCrack resistanceSheet steel

The invention relates to a corrugated steel web box beam with steel-concrete composite plate bottom flange, in particular to a corrugated steel web box beam that is applied in railway and bridges. The corrugated steel web box beam is composed of a top flange concrete slab, a corrugated steel web and a steel-concrete composite plate bottom flange, wherein steel-concrete composite plate is composed of a slotted steel plate formed by side plates and bottom plates, and a concrete, the steel plate is welded with bolts and reinforced meshes are arranged at middle position of the concrete. The structure can overcome the problem that the traditional corrugated steel web box beam has complicated construction for steel structure positioning on the spot, and also can exert tensile strength of the steel plate so as to improve crack resistance of structure effectively and avoid crack from being exposed, so that structural endurance is improved obviously, therefore the work load and difficulty of the construction of concrete in-field casting of box beam bottom flange is reduced greatly. The corrugated steel web box beam with steel-concrete composite plate bottom flange has simple structure, rapid and convenient construction and is easy to meet the requirement of planar shape of bridge, and also has good technical economic benefit.

Owner:TSINGHUA UNIV

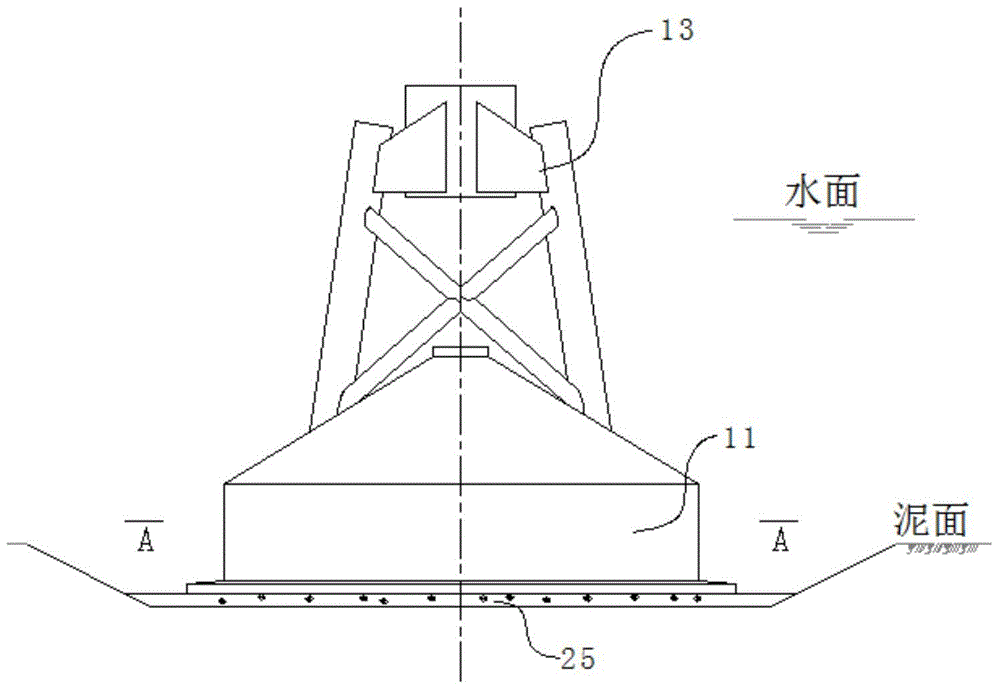

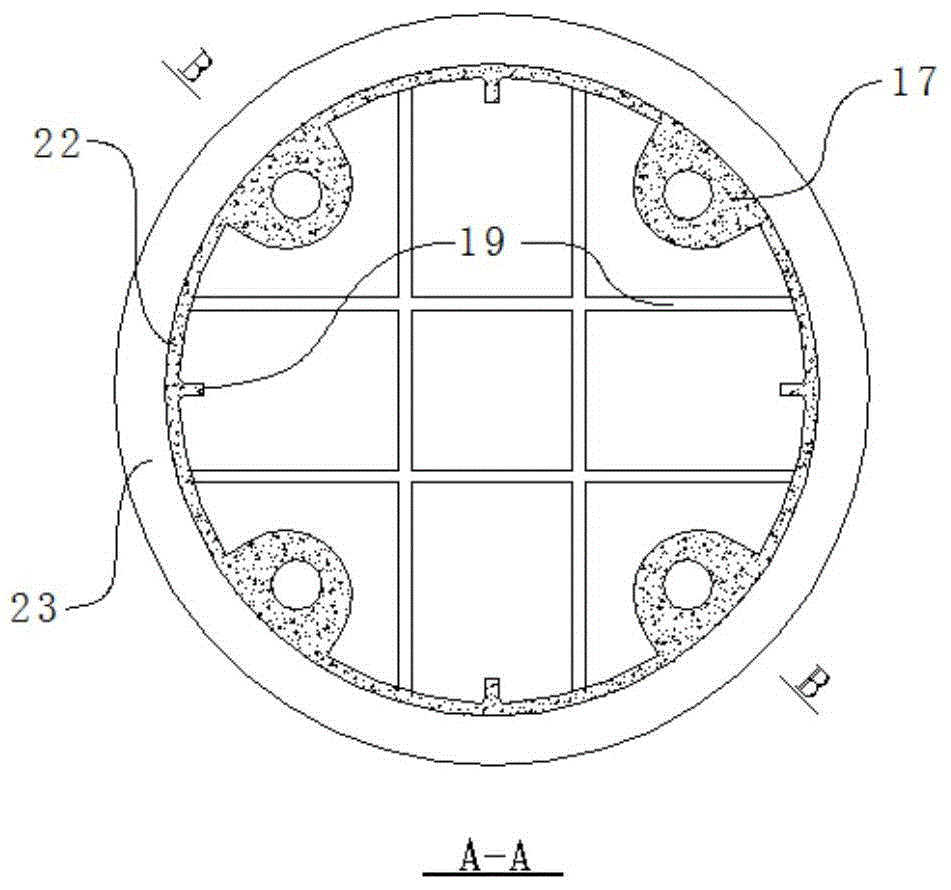

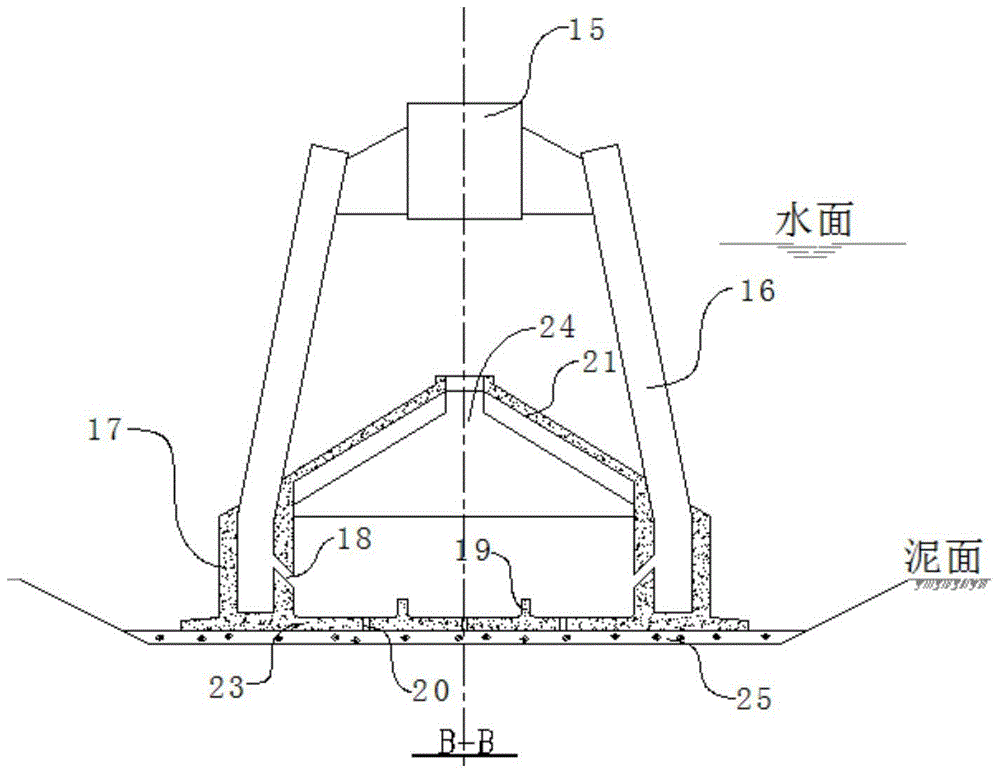

Reinforced concrete-steel structure hybrid gravity foundation for offshore wind power and construction method thereof

ActiveCN104389318ASimple and fast constructionHigh degree of factoryFoundation engineeringHybrid typeElectricity

The invention discloses a reinforced concrete-steel structure hybrid gravity foundation for offshore wind power. The reinforced concrete-steel structure hybrid gravity foundation comprises a caisson base and an upper steel support structure, wherein the caisson base has a gravity type reinforced concrete cavity structure; the steel support structure is fixed on the caisson base; the top end of the steel support structure is provided with a foundation ring which is connected with a fan tower; the caisson base and / or the steel support structure is provided with an irrigation channel which is communicated to the cavity of the caisson base. The invention further discloses a construction method of the reinforced concrete-steel structure hybrid type gravity foundation for offshore wind power. Compared with an ordinary jacket and single pile foundation, the reinforced concrete-steel structure hybrid gravity foundation has the advantages that the advantages of a reinforced concrete structure and a steel structure are combined organically; the reinforced concrete cavity structure is taken as a foundation base, and the steel structure is taken as an upper support structure; a pile foundation is not required; the foundation is made on the land, is assembled integrally, and can be transported by means of semi-submersible barge or the own buoyance. The reinforced concrete-steel structure hybrid gravity foundation is easy and convenient for construction, is shorter in the construction period, is economical, and has a wide application prospect in an offshore wind power project.

Owner:广州华申建设工程管理有限公司

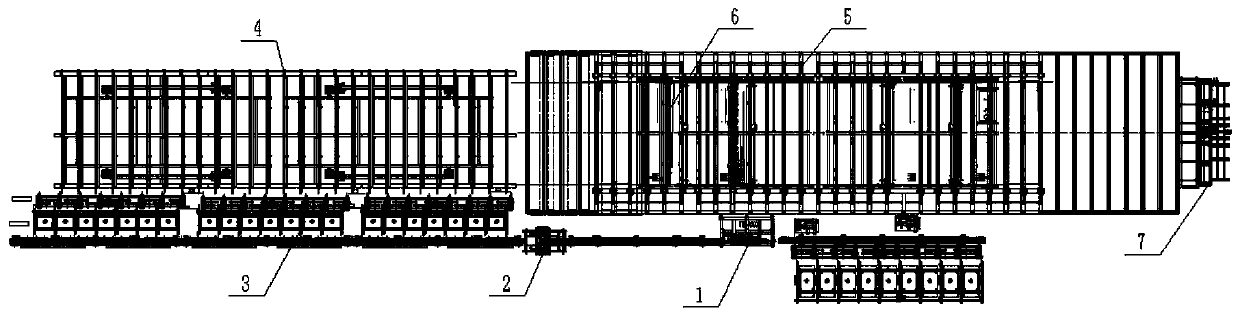

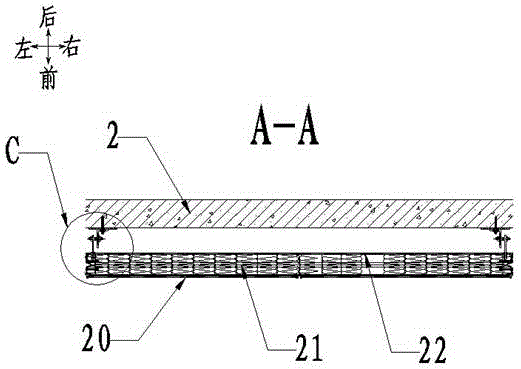

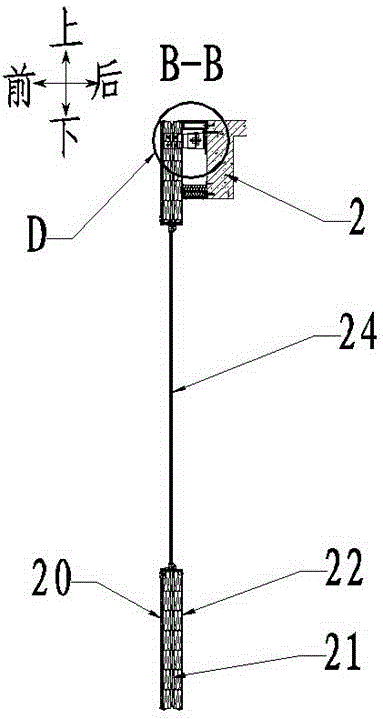

Flexible production line and process for spatial three-dimensional reinforcing mes

PendingCN110918838ALow plane bending accuracyHigh precision of plane bendingMetal-working apparatusWire networkMesh reinforcementStirrup

The invention discloses a flexible production line for a spatial three-dimensional reinforcing mesh, which comprises a stirrup cloth production line, a bending production line, a main reinforcement cloth production line, and a gantry production line. The present invention also discloses a flexible production process for the spatial three-dimensional reinforcing mesh, which includes the following steps: S1, preparing stirrups and completing plane distribution; S2, pulling the stirrups onto a bending platform; S3, horizontally moving a guide beam in the same longitudinal direction so that the stirrups are planarly bent according to a set bending angle; S4, sequentially distributing main reinforcement; S5: welding and binding to form a mesh; S6, successively performing operations from an outside three-dimensional bending mechanisms to bend the mesh twice from the two sides of the production line to its centerline to achieve three-dimensional bending forming of the mesh; and S7, after themesh is formed, lifting the mesh out of the production line. The production line and the production process of the invention can improve the industrialization, mechanization, automation, and assemblylevel of the bridge tower spatial three-dimensional reinforcing mesh construction .

Owner:CCCC SECOND HARBOR ENG

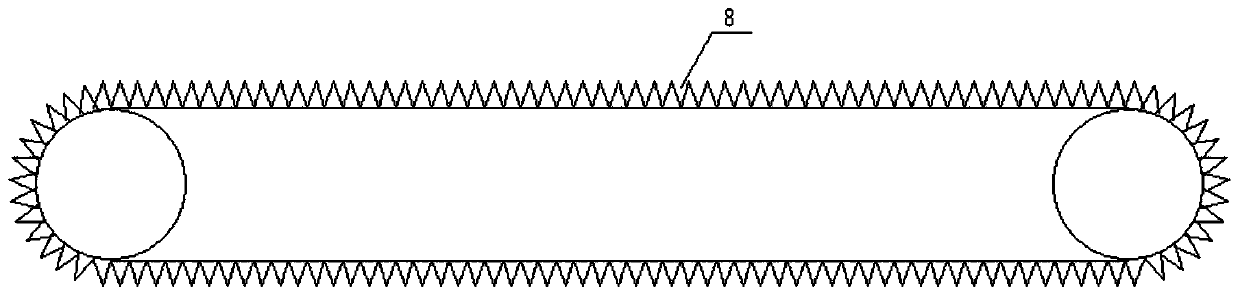

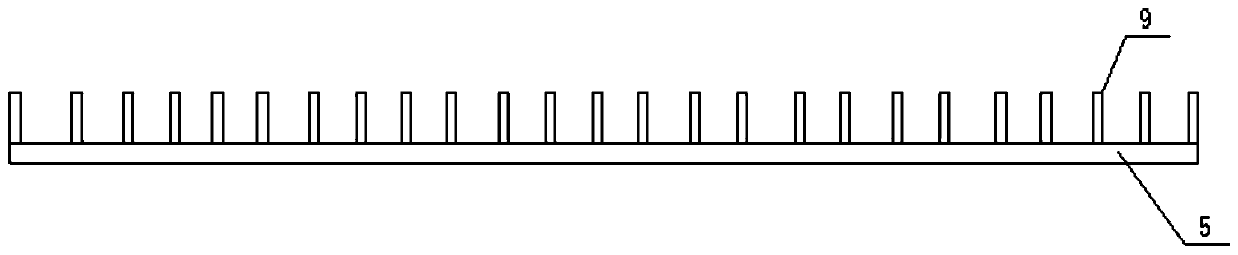

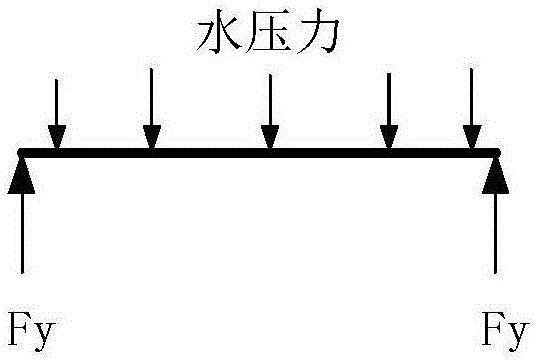

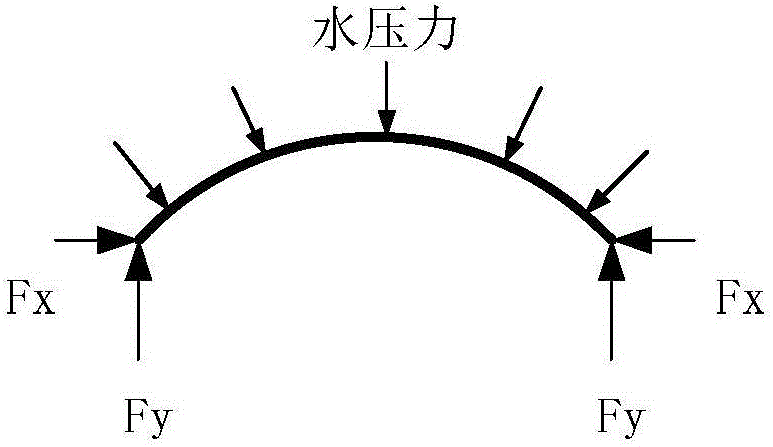

Arch type aluminum alloy flood prevention plate

The invention provides an arch type aluminum alloy flood prevention plate. The arch type aluminum alloy flood prevention plate comprises a foundation, an upright, water blocking plates and a water stopping device. The upright is fixed to the foundation. The two sides of the upright are provided with vertical insertion slots used for clamping and fixing the arch type aluminum alloy water blocking plates. The water stopping device comprises seal rubber mats which are arranged in the insertion slots, between the arch type aluminum alloy water blocking plates and in the positions where the arch type aluminum alloy water blocking plates making contact with the foundation. The water blocking plates are arch water blocking plates protruding towards the water blocking direction. The bending moment and deformation of the arch type water blocking plates provided by the invention are both much smaller than those of a traditional structure, and stress, sealing water stopping and material saving are facilitated. Multiple arch arrangement is adopted, thus horizontal thrust of adjacent arches to the uprights can be balanced mutually, a multiple arch effect is achieved, additional loads of the uprights are not increased, the stress advantage of the arches is used, and the adverse influence of arch thrust is also overcome.

Owner:HOHAI UNIV

Curve PC track beam prefabrication construction method

InactiveCN109808050ATight seamsImprove construction efficiencyDischarging arrangementCeramic shaping plantsSteel barPrefabrication

The invention discloses a curve PC track beam prefabrication construction method. The curve PC track beam prefabrication construction method comprises the operations of steel bar cage binding, template adjusting, steel bar cage placing, concrete pouring and demolding. According to the curve PC track beam prefabrication construction method, a steel cage prefabrication and suspension line positioning device is adopted to assist side template measurement positioning and side template automatic adjustment, the disadvantage of low manual template adjustment efficiency in traditional track beam prefabrication is broken, the automation degree of a template system is improved, and the quantity of operators is reduced.

Owner:THE SECOND CONSTR OF CTCE GROUP +2

Foamed concrete thermal insulation composite wall

The invention discloses a foamed concrete thermal insulation composite wall. The foamed concrete thermal insulation composite wall comprises two wall skeletons arranged in the direction of the thickness of the wall at intervals, wherein the two wall skeletons are both fixed to a building main structure. The wall skeletons comprise panels and keel assemblies, a pouring space is formed between the inner surfaces of the two panels and the outer surface of the building main structure, and the keel assemblies are arranged in the pouring space. The keel assemblies include a plurality of vertical keels and a plurality of transverse keels, the vertical keels are fixedly erected on the building main structure, the vertical keels are sequentially arranged at intervals in the length direction of thewall, and the panels are fixed to the corresponding vertical keels. The transverse keels are vertically connected with the corresponding vertical keels and arranged parallel to the corresponding panels, and the transverse keels are sequentially arranged at intervals in the height direction of the wall. Foamed concrete is poured into the pouring space so that the foamed concrete, the two panels andthe keel assemblies form the integrated foamed concrete thermal insulation composite wall. The composite wall has the advantages of good thermal insulation performance, high degree of industrialization, high universality, easy assembly and the like.

Owner:湖南睿盾新材料科技有限公司

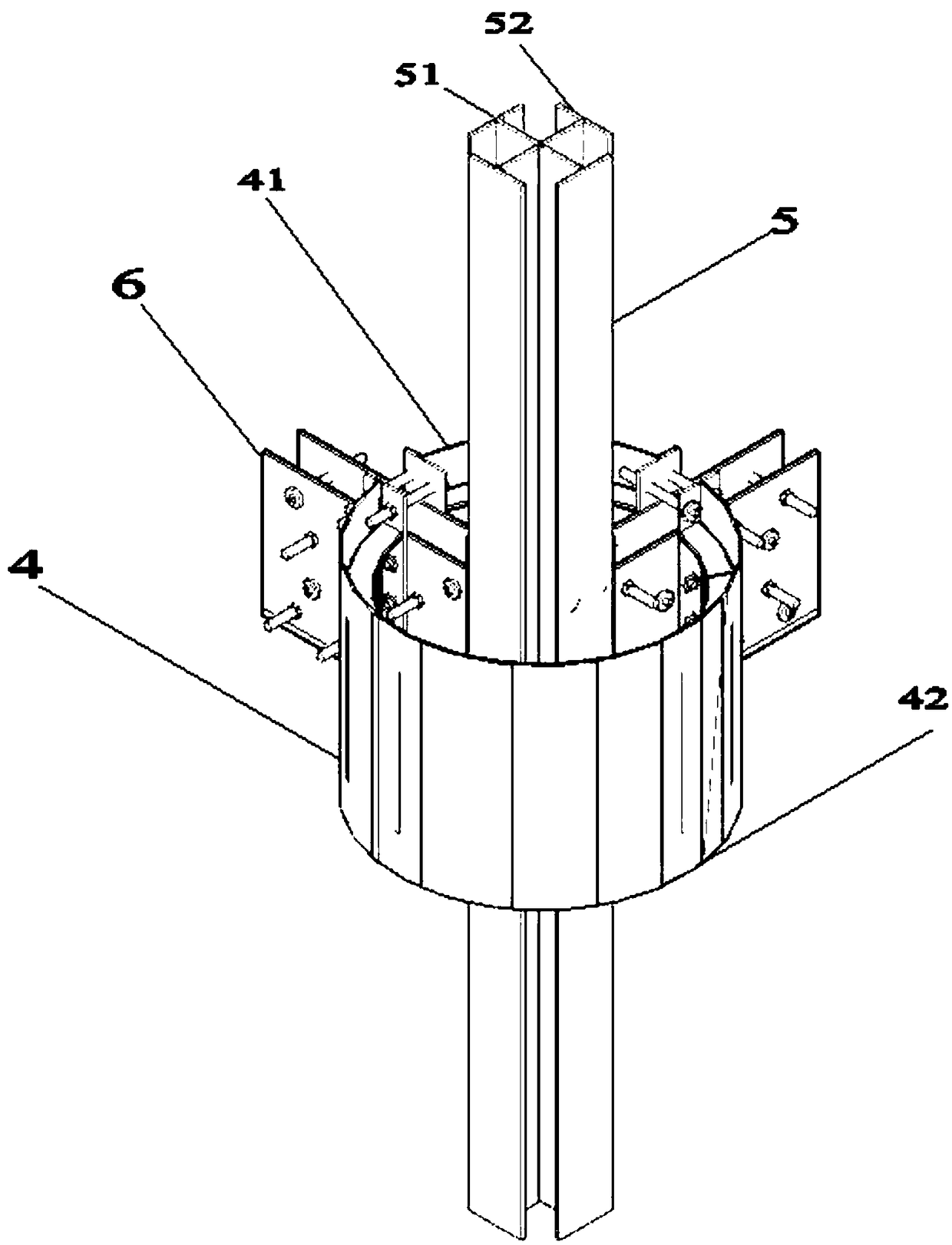

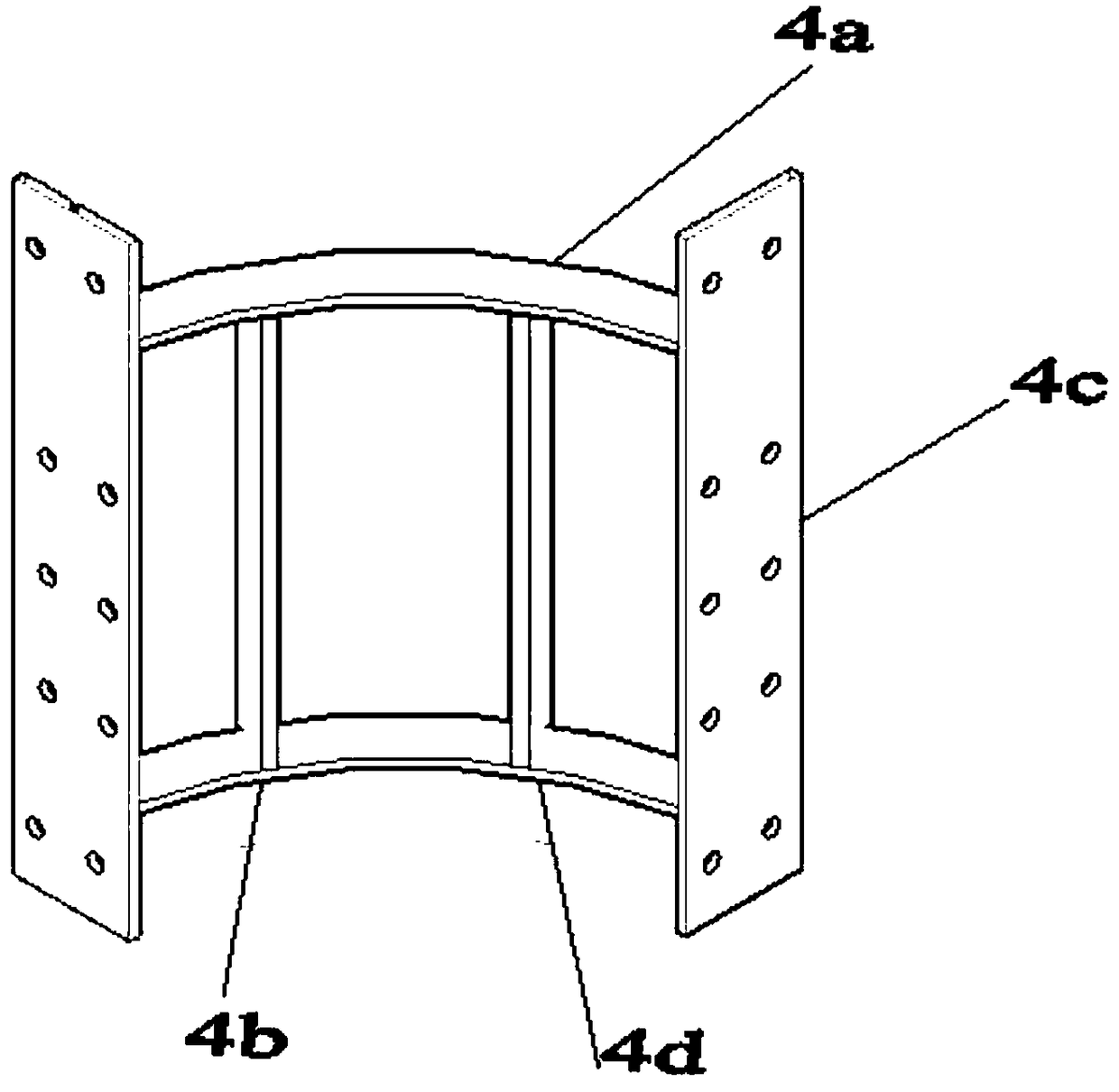

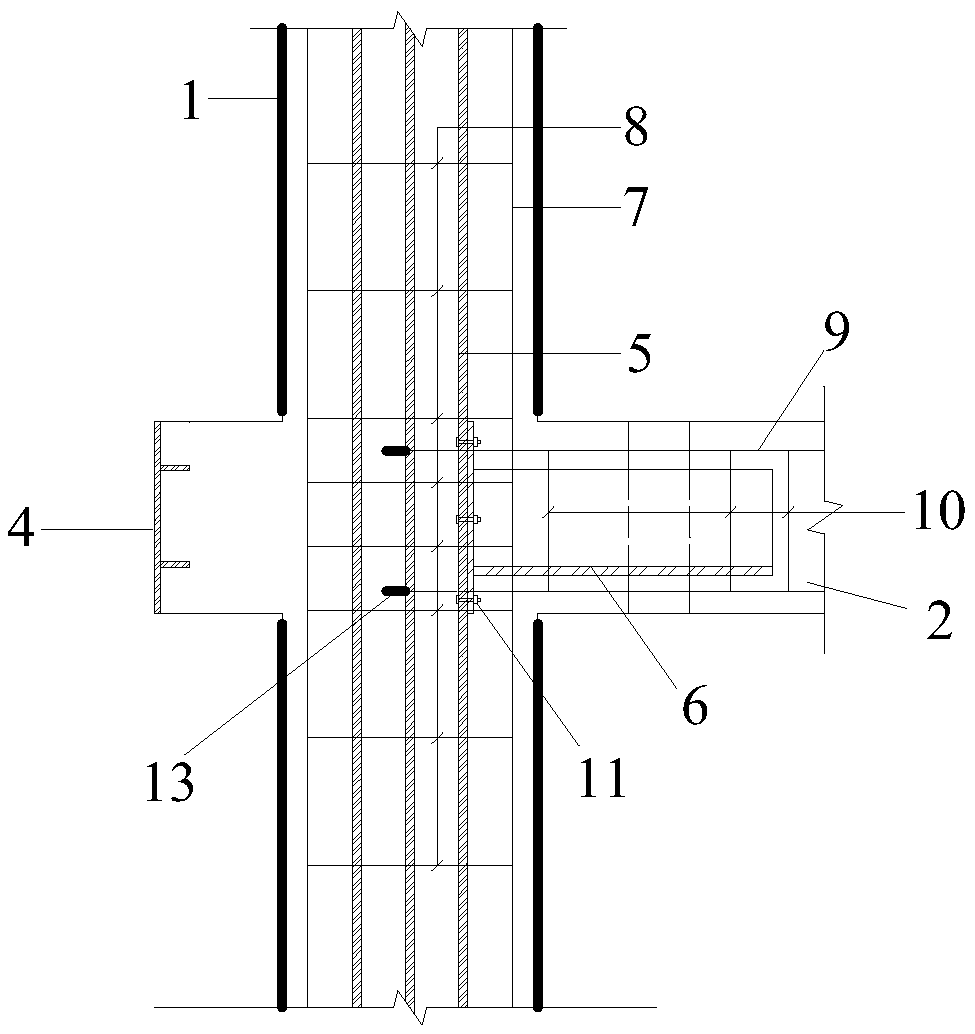

PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam L-shaped node

ActiveCN109024915ASimple structureRealize the purpose of "strong node"StrutsGirdersReinforced concreteHigh intensity

The invention discloses a PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam L-shaped node which comprises the components of two sets of circular steel pipe fasteners, a PVC-FRP pipe, core section steel, two sets of U-shaped hidden brackets, a column longitudinal rib, a column tie-rib, a beam longitudinal rib, a beam tie-rib, high-strength bolts, core-crossing anchor bolts and a stiffening rib plate. The core section steel penetrates through the center of the circular steel pipe fastener. The PVC-FRP pipe sleeves the core section steel. The two sets of U-shaped hidden brackets are fixedly connected with the two sets of circular steel pipe fasteners through high-strength bolts. The two sets of U-shaped hidden brackets are arranged in an L-shape. Core passing anchor bolt pass through the U-shaped hidden bracket. The directions of the core-passing anchor bolts in the same layer are same. The directions of the core-passing anchor bolts are opposite. The circularsteel pipe fasteners are connected through the core-crossing anchor bolt. The PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam L-shaped node can realize quick splicing of steel components in the node and further has advantages of high bearing force, high integrity, convenient construction, high industrialization degree, etc.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Indoor cement pit artificial propagation method for scatophagus arguses

ActiveCN107549064ASolve the technical problems of stable water qualityHigh degree of factoryClimate change adaptationPisciculture and aquariaArtificial inseminationScatophagus argus

An indoor cement pit artificial propagation method for scatophagus arguses includes the steps of scatophagus argus parent strengthening rearing, parent gonad synchronization control, expectant parentselection, artificial insemination and fertilized ovum sectional hatching. The method is characterized in that 3-month old scatophagus arguses are placed into an indoor cement pit and subjected to over-wintering strengthening rearing from the last ten-day period of November in a last year to February in a current year, scatophagus argus reserve male and female parents are separately stocked in different tanks in middle ten days of March, temperature and salt are increased step by step from the last ten-day period of November in the last year to April in the current year until water temperaturereaches 28-29 DEG C and salinity reaches 24-28, the scatophagus arguses are kept under water environment conditions for one month, the selected parents are subjected to artificial insemination to obtain fertilized ova, and the fertilized ova are hatched in a hatching cylinder in a sectional manner and then transferred into a fry rearing tank for hatching to obtain newly-hatched fries.

Owner:SHANGHAI FISHERIES RES INST

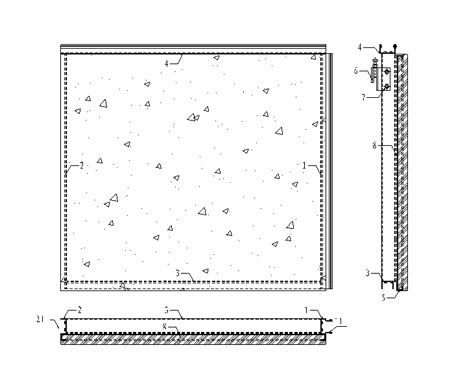

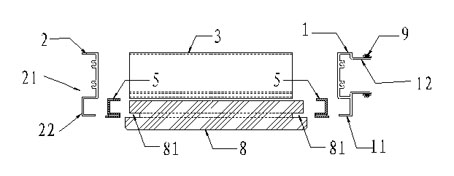

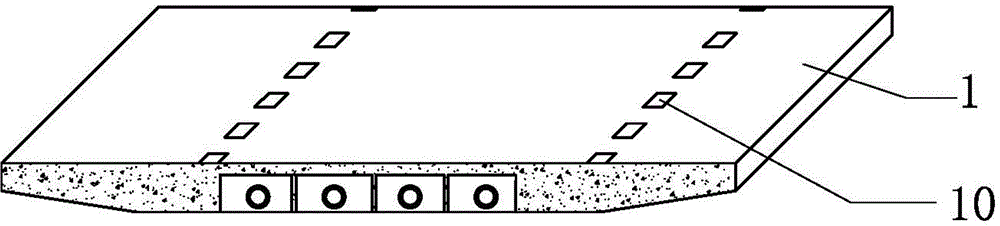

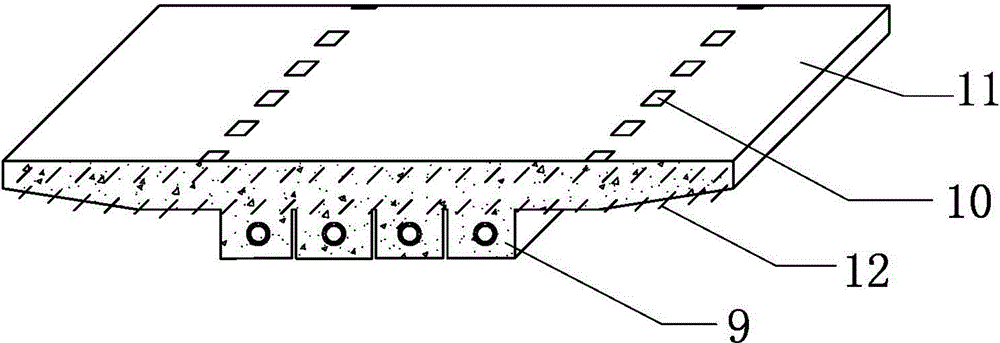

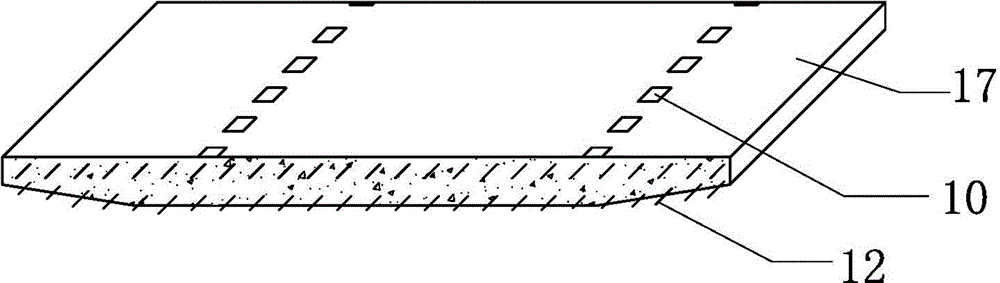

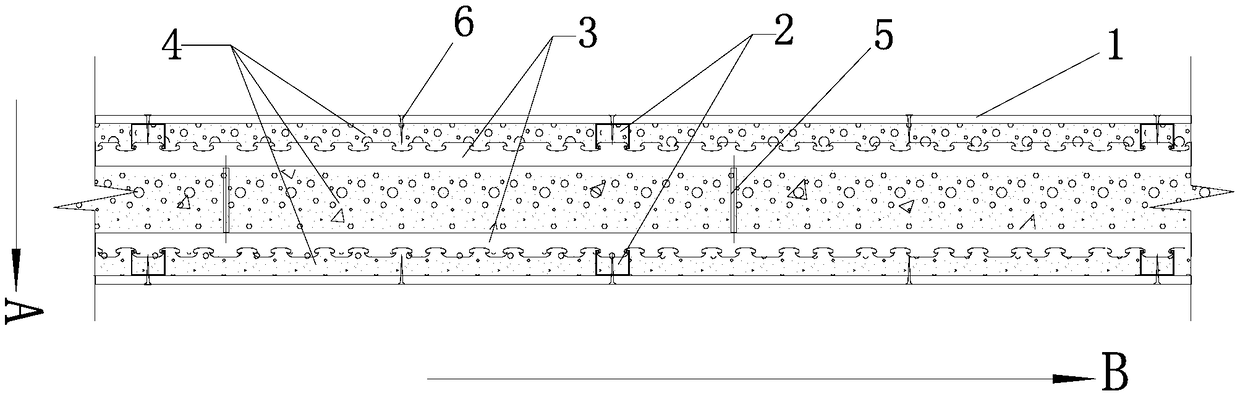

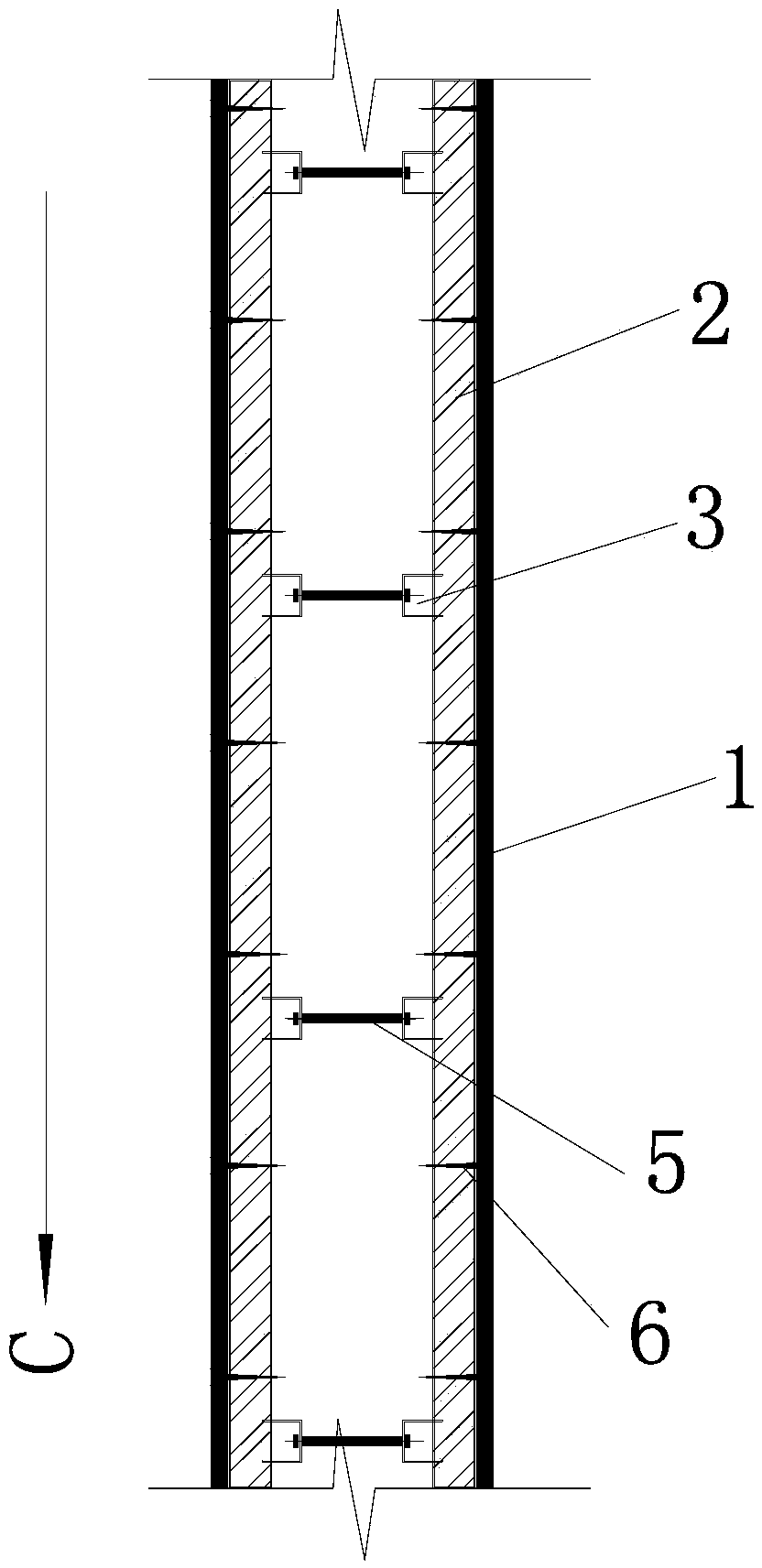

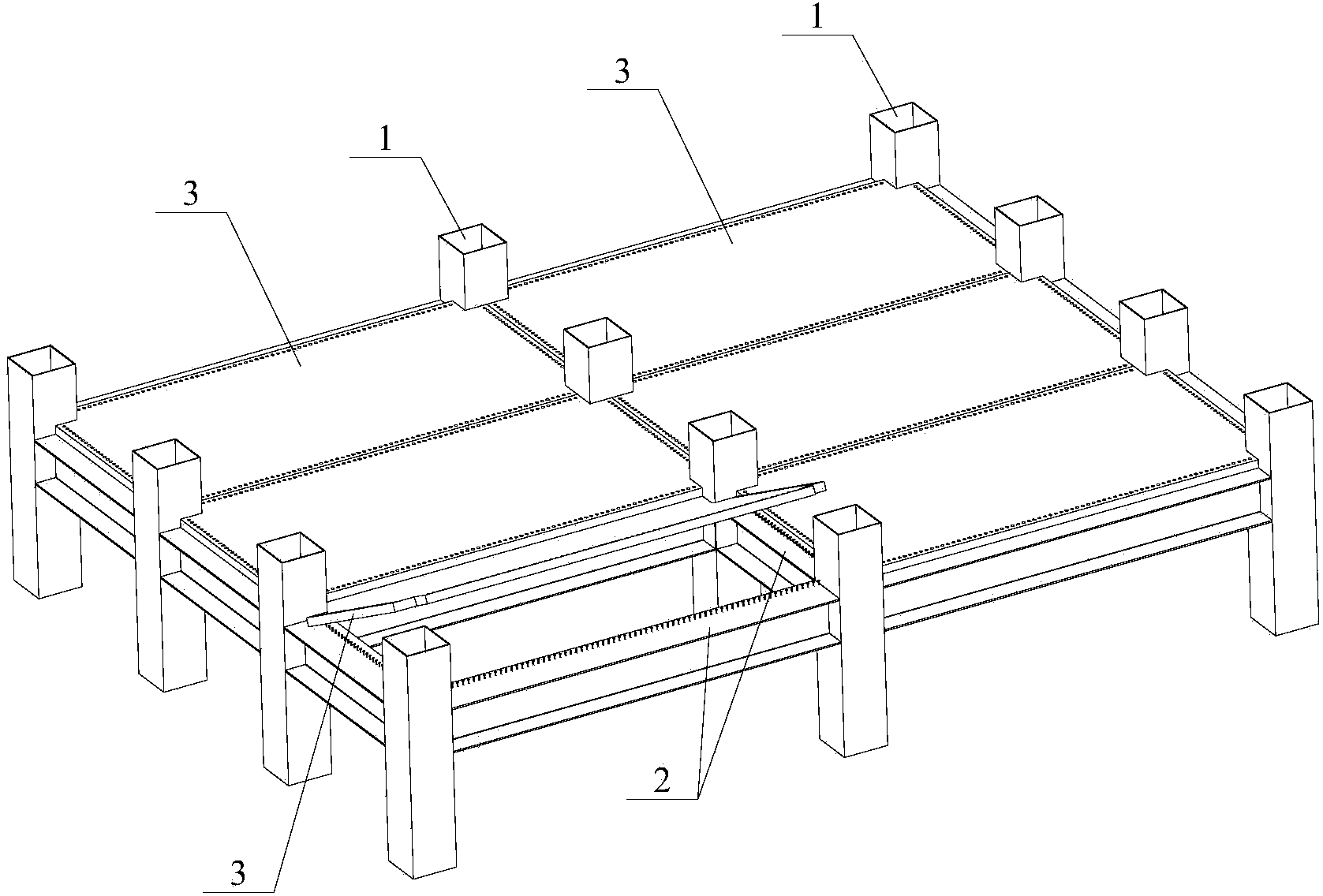

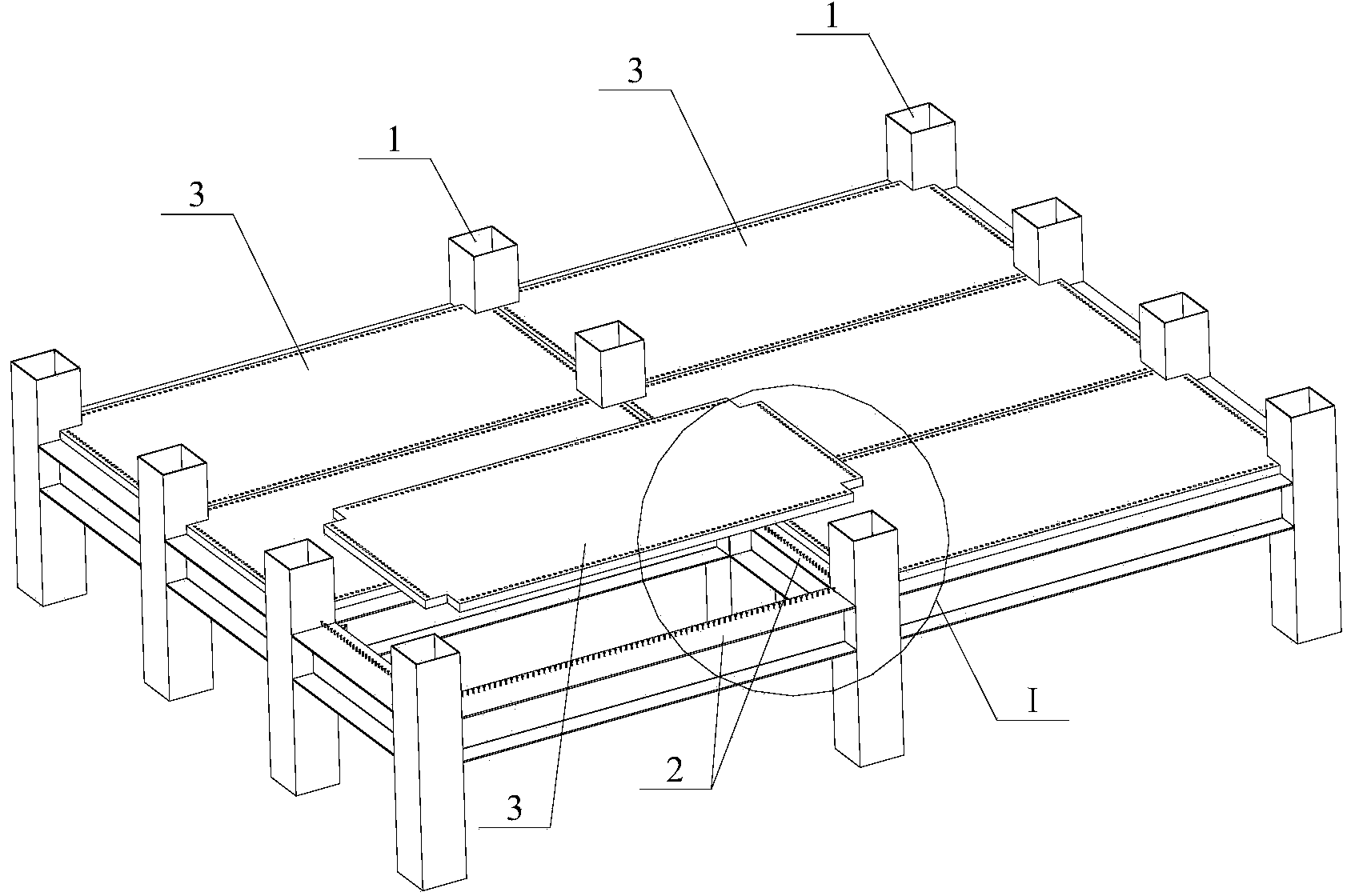

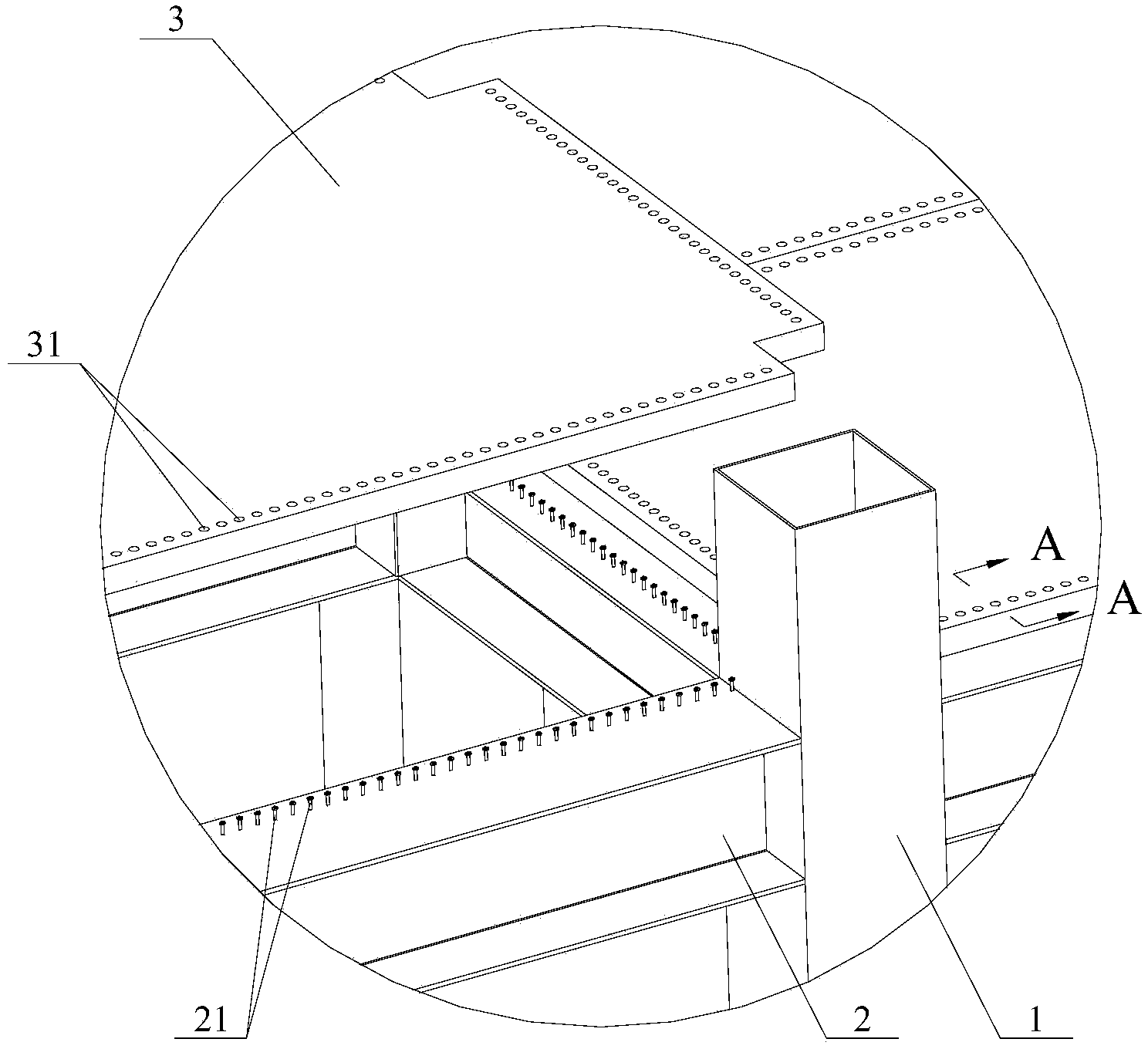

Module floor slab assembling structure for building and process method

ActiveCN104032868AImprove construction progressReduce work intensityFloorsFloor slabUltimate tensile strength

The invention relates to the technical field of modular buildings, and provides a floor slab assembling structure for a building and a process method. Steel building posts of the assembling structure form installing units of module floor slabs; steel beams in arrangement corresponding to the installing units are respectively fixed between the two adjacent steel building posts of the installing units; in addition, the upper surface of each steel beam is respectively and fixedly provided with vertically extending position limiting bulges; through holes are correspondingly formed in the edges of the module floor slabs; the edges of the module floor slabs are lapped and butted against the upper surfaces of the steel beams, and in addition, the through holes are sheathed on the position limiting bulges; grouting materials are filled in seams between the position limiting bulges and the through holes and between the module floor slabs; and an integral floor slab is formed after the grouting materials are solidified. Compared with the prior art, the floor slab assembling structure and the process method have the advantages that the factorization degree of main body components in the technical scheme are higher, the assembly can be fast completed in the whole construction technical process, and the conformance to the development trends of the housing industrialization is achieved; and the pre-positioning of the module floor slab installing positions can be realized, the operation intensity of construction personnel can be effectively reduced, and meanwhile, higher integral assembling precision is obtained.

Owner:山东鲁帆集团有限公司

Guide pipe leg post forficate guide pipe rack foundation and construction method thereof

PendingCN109518711AReduce construction difficultySolve the problem of eccentric forceFoundation engineeringWater levelGuide tube

The invention discloses a guide pipe leg post forficate guide pipe rack foundation. The guide pipe leg post forficate guide pipe rack foundation comprises a truss body connected by multiple connectionrods and multiple guide pipe rack leg posts; a foundation ring structure is arranged on the top end of the truss body; each guide pipe leg post comprises a post body and at least two bending branch posts which are fixedly connected to the lower end of the post body; a stressed pile sleeve is fixedly arranged between every two adjacent branch posts; an auxiliary pile sleeve is fixedly arranged ata high-water-level part of each guide pipe rack leg post; and the stressed pile sleeves and the auxiliary pile sleeves are arranged in a staggered manner. During construction, the integral structure can be prefabricated in a factory, and then is hoisted to the seabed and leveled primarily; the guide pipe rack foundation is fixed temporarily by driving temporary piles; and then stressed piles are driven in, and are connected to pile sleeves through annular high-strength grouting, so that the stable foundation is formed. By adopting the self-supporting and piling guide pipe rack, construction difficulty in positioning, leveling, stabilizing and the like of the sea guide pipe rack is greatly lowered; a guiding rack is not needed; water construction procedures are simplified; construction is safe, and the construction cycle is shortened; economy is good; and the application range is wide.

Owner:熊翱

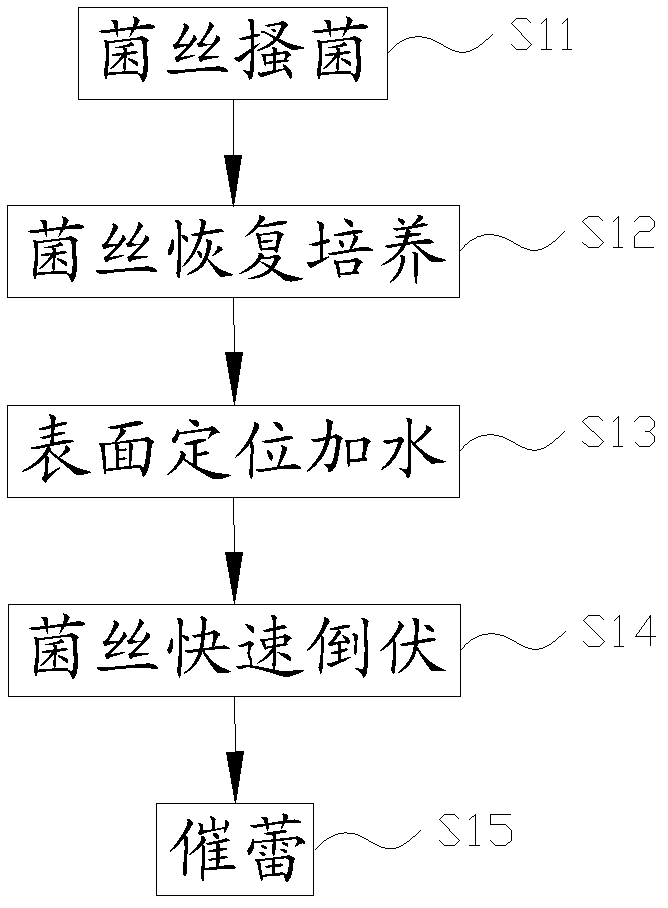

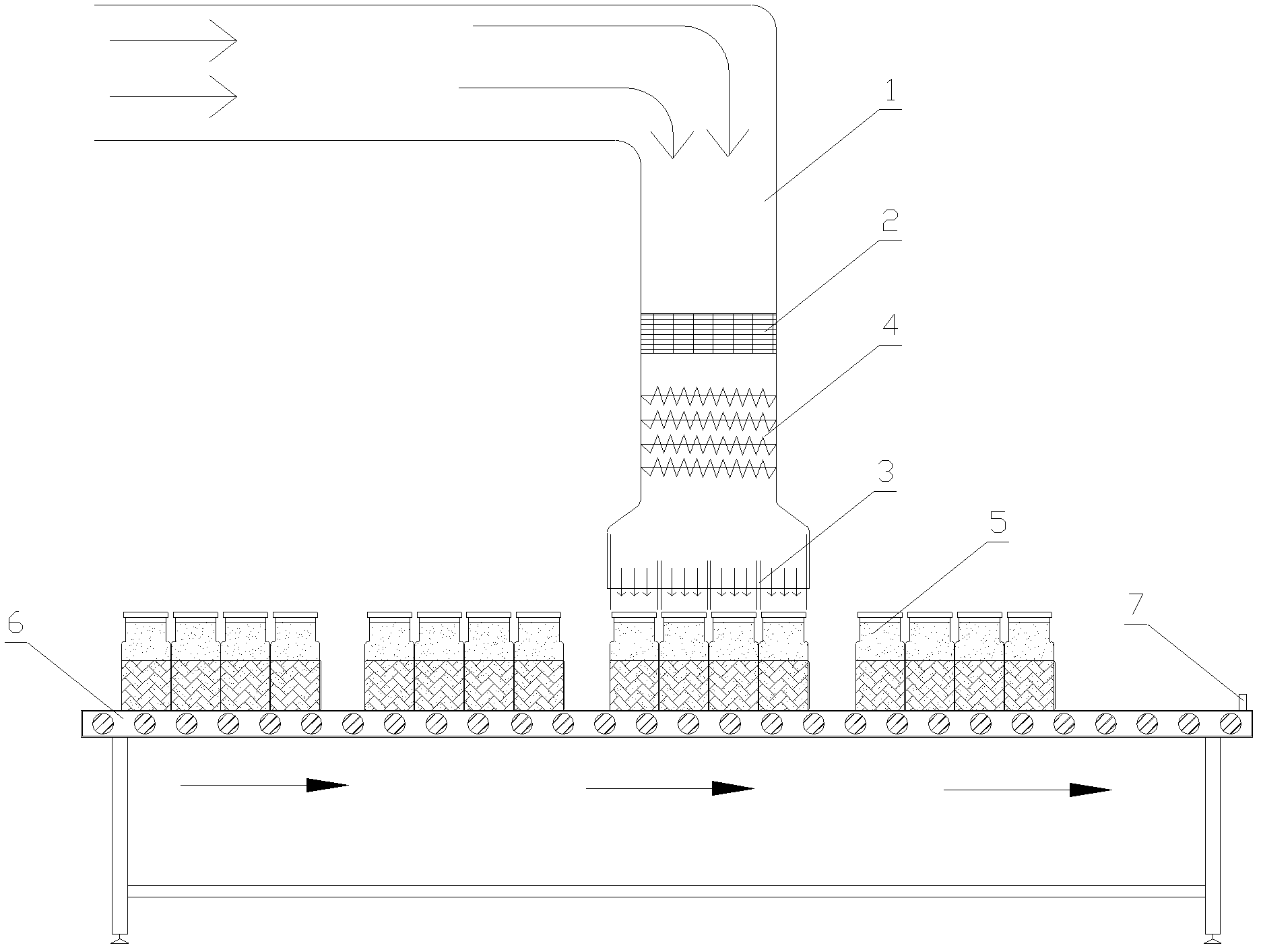

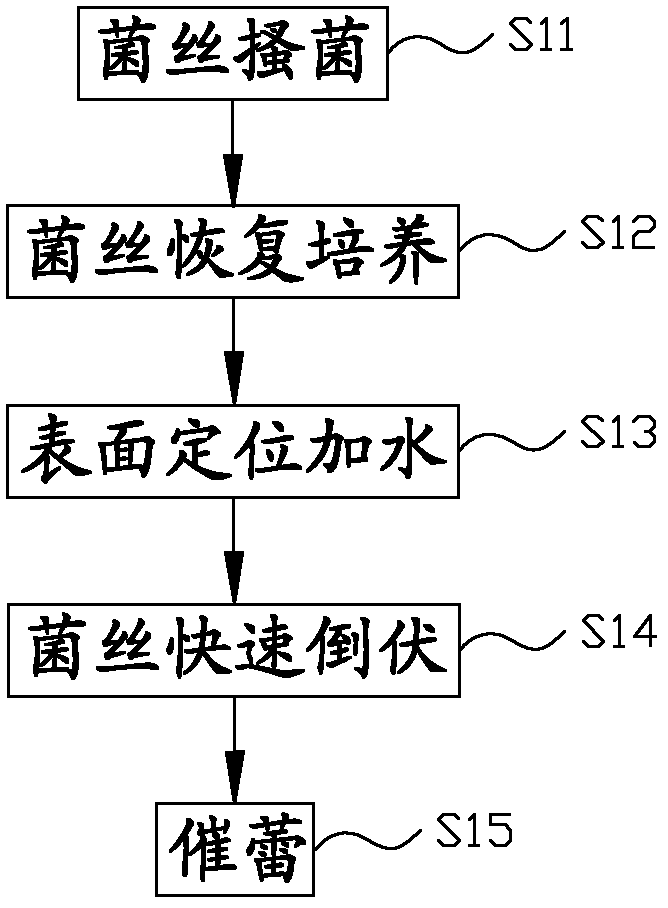

Edible mushroom cultivation method and edible mushroom cultivation system

InactiveCN102612997ARealize the purpose of positioning fruitingSimple structureHorticultureBudBottle

The invention discloses an edible mushroom cultivation method and an edible mushroom cultivation system. The cultivation method includes the steps: scratching mycelia; restoring and cultivating the mycelia; adding water to fixed positions on the surface of the mycelia; and blowing air to the surface of a mushroom bottle at preset speed and preset temperature to lodge aerial mycelia, and keeping the surface of the mycelia dry; conveying the mushroom bottle to a bud pressing room for bud pressing. By adding water and blowing air, the problem of bud redundancy in bud pressing process of edible mushrooms can be solved effectively, and accordingly labor in bud thinning is reduced, labor cost in bottled production is reduced, and yield of the edible mushrooms is increased. In addition, automation level of industrial production of the edible mushrooms is also increased, and finally overall economic benefit in factory bottle cultivation of the edible mushrooms is increased. The cultivation method is especially suitable for cultivation of Pleurotus eryngii.

Owner:郑雪平

Round tube web girder and manufacturing method thereof

The invention provides a round tube web girder and a manufacturing method thereof and belongs to a main girder structural style applied to bridge construction. According to the structure, a traditional girder type thin-wall web structure is replaced with a hollow round tube (steel tube or reinforced concrete tube), and an upper frange plate and a lower frange plate are connected with the hollow round tube into a whole through connecting pieces. The structure is suitable for an upper structure of a simply supported girder bridge with a small span, and can also be used as a girder of a cable system bridge or a girder type component, both aesthetic and capable of bearing force, in a building structure. The structure can be constructed in a factory prefabricating and on-site assembling mode. The working period can be effectively shortened. Due to the fact that light can pass through the hollow part of the round tube, the structure has a unique aesthetic effect. Due to the adoption of the horizontally through structural style, the windward area of the structure is effectively reduced, and the negative influence of wind power on the structure is reduced. The round tube can be made to be a single-layer style or a multi-layer style according to aesthetic or force-bearing requirements, so that the diversified appearance effect and mechanical property are achieved.

Owner:SOUTHEAST UNIV

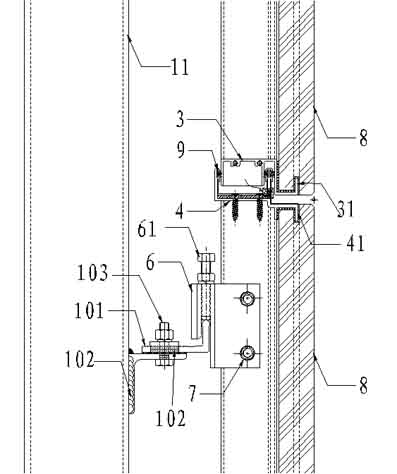

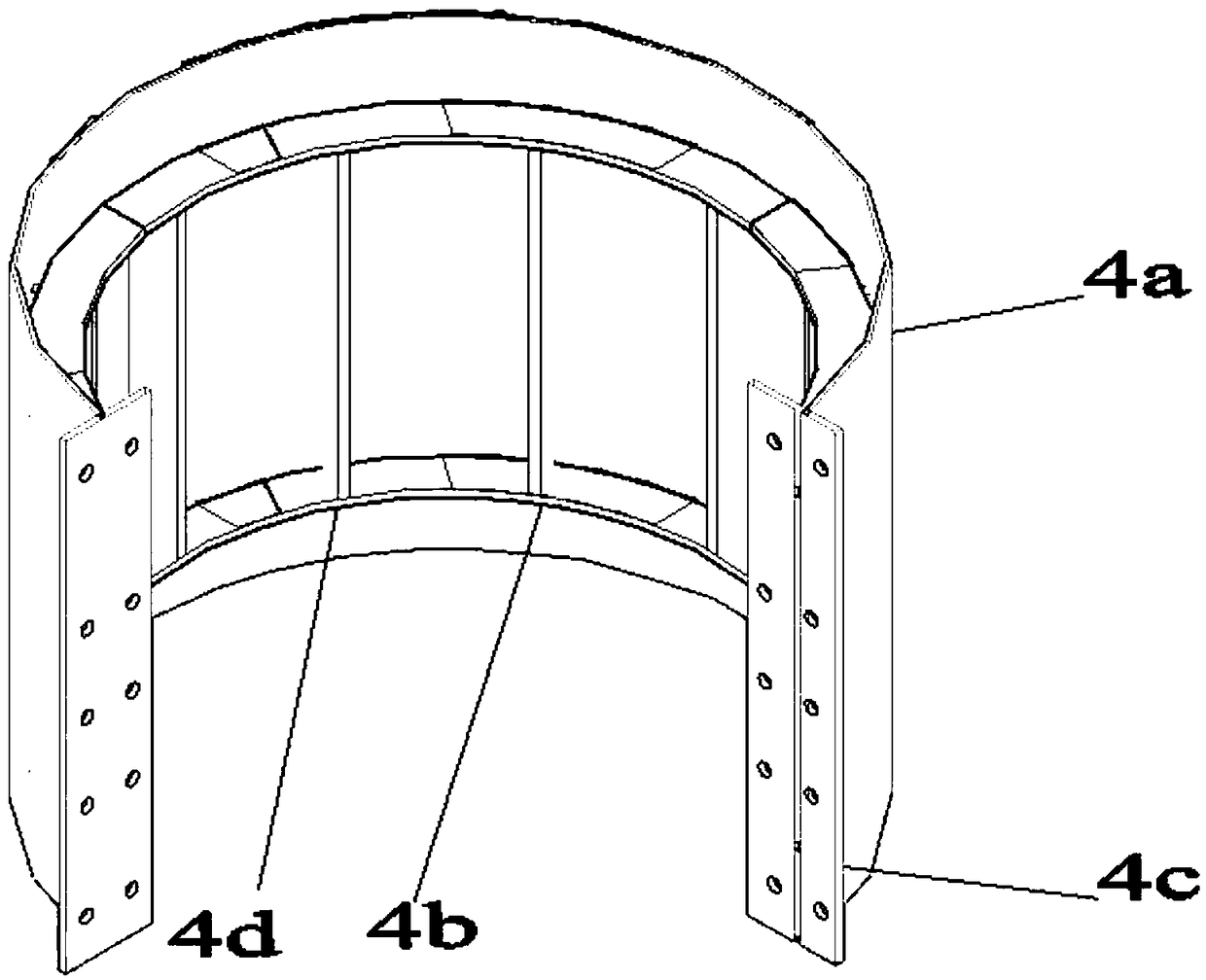

Unit prefabricated type building outer envelope system provided with strip window and construction method of unit prefabricated type building outer envelope system

ActiveCN105113683AHigh strengthHigh surface flatnessCovering/liningsWallsEngineeringElectrical and Electronics engineering

The invention relates to the field of building decoration, in particular to a unit prefabricated type building outer envelope system provided with a strip window. The unit prefabricated type building outer envelope system comprises a plurality of face plate units. Strip window units are arranged on the face plate units. Frames are arranged around the face plate units. The face plate units are arranged on building structural beams through adjustable connection pieces fixedly connected with the frames. Insertion grooves are formed in the frames. Sealing rubber strips are arranged on the frames. Insertion cores matched with the insertion grooves are inserted and connected into the insertion grooves of the adjacent face plate units. The sealing rubber strips of the adjacent face plate units make contact. The strip window is formed by the strip window units. The unit prefabricated type building outer envelope system has the advantages of being easy to prefabricate, high in prefabricating accuracy, high in factorization degree, excellent in seismic performance and windproof performance, convenient to transport and hoist and good in heat preservation effect.

Owner:山东津单幕墙有限公司

Composite heatretaining porcelain plate

ActiveCN101092842AHigh degree of factoryProcess quality control throughoutCovering/liningsAdhesivePolystyrene

This invention relates to a compound heat preservation porcelain plate including a porcelain plate, polystyrene foam plate for isolating heat, stainless steel strips, stainless steel anchoring bolts and an adhesive, in which said compound heat-preservation porcelain plate is prepared by sticking and pressing the polystyrene foam plates and several holes are drilled on the foam plate, several reverse taper blind holes are drilled on the back of the porcelain plate, and stainless steel anchoring bolts are placed in the blind holes for fixing the steel strips with nuts.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

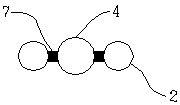

PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam T-shaped node

ActiveCN109024917ASimple structureRealize the purpose of "strong node"StrutsGirdersReinforced concreteSteel bar

The invention discloses a PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam T-shaped node which comprises the components of a PVC-FRP pipe, circular steel tube fasteners,core section steel, U-shaped hidden brackets, a column longitudinal rib, a column tie-rib, a beam longitudinal rib, a beam tie-rib, high-strength bolts, core-passing anchor bolts and a stiffening ribplate. The PVC-FRP pipe sleeves the core section steel. Three sets of U-shaped hidden brackets are distributed in a T-shape. The flange of the section steel is connected with the U-shaped hidden brackets through the high-strength bolts. The circular steel tube fastener is connected with the U-shaped hidden brackets through the high-strength bolts. The beam longitudinal rib is welded and anchored with a section steel web plate through the stiffening rib plate. The column tie-rib passes through the U-shaped hidden bracket and is bond with the column longitudinal rib. The PVC-FRP pipe restrainedsection steel concrete column-reinforced concrete beam T-shaped node has advantages of reasonable structure design and simple node structure. Steel components in the node can be directly assembled andfixed by the high-strength bolts. Placement of an annular steel par which restrains the core region of the node is not required in the node area is not required. A purpose of strong node can be realized through a restraining action of the peripheral circular steel pipe fasteners to the node concrete.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

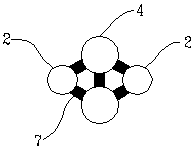

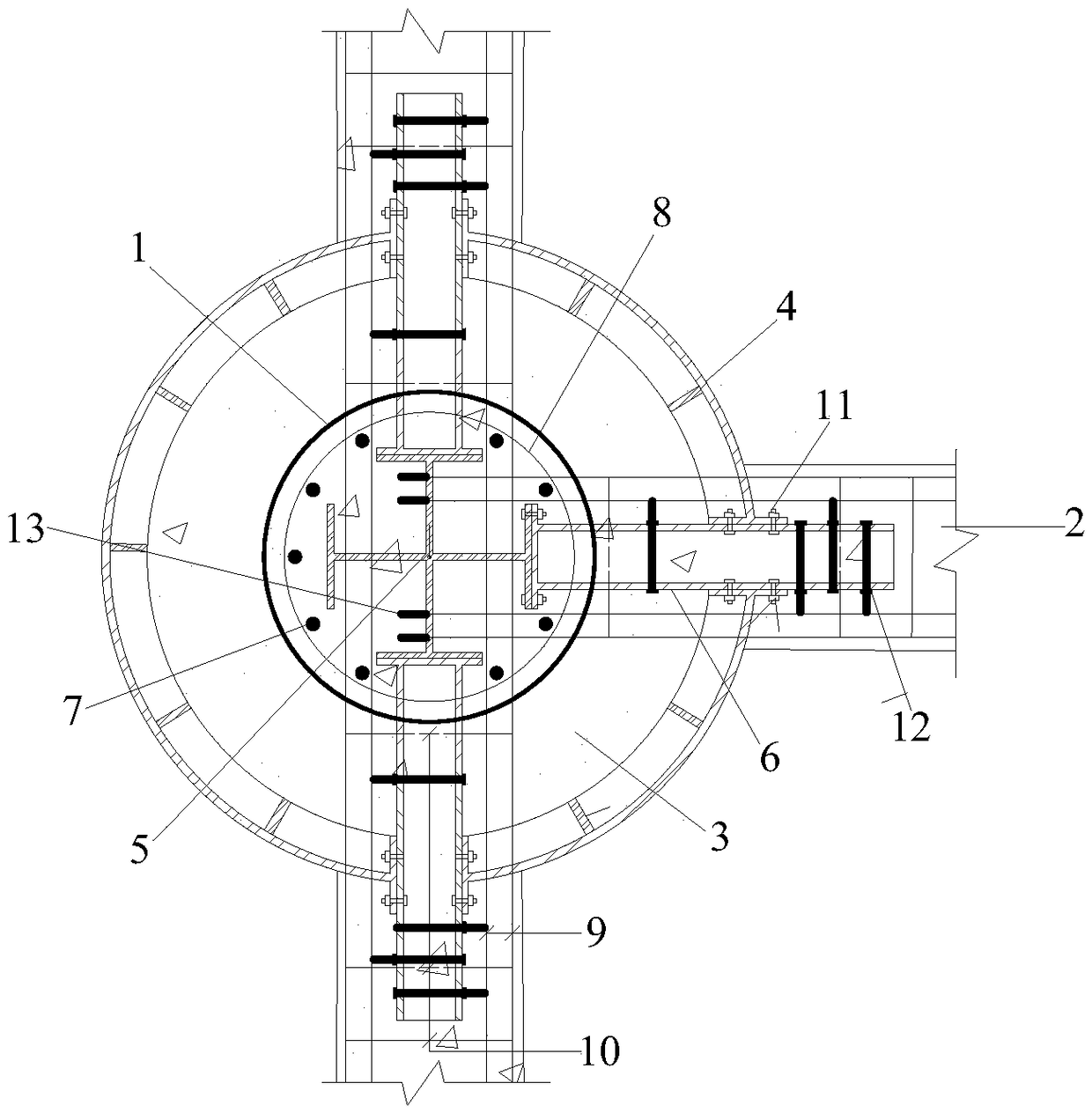

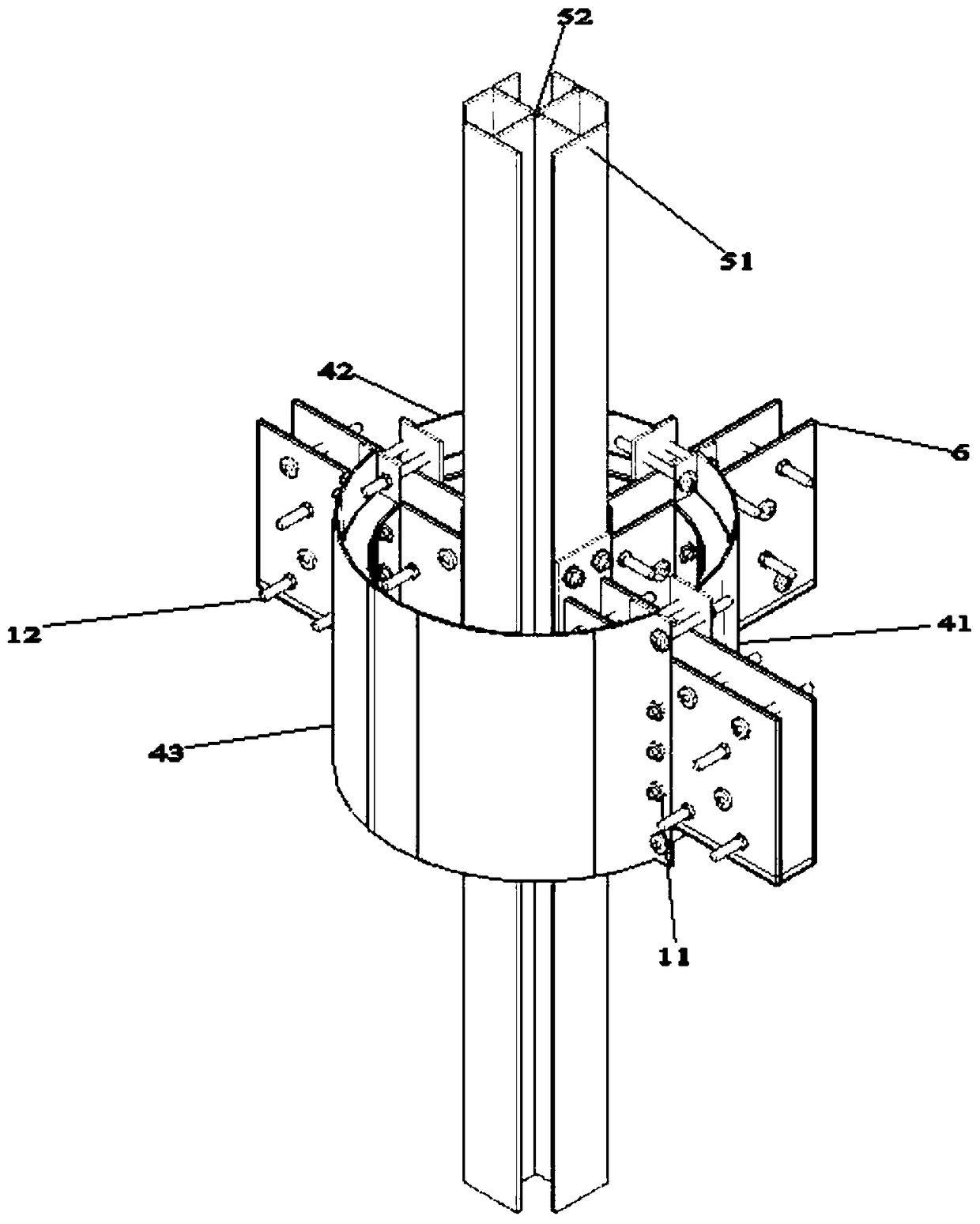

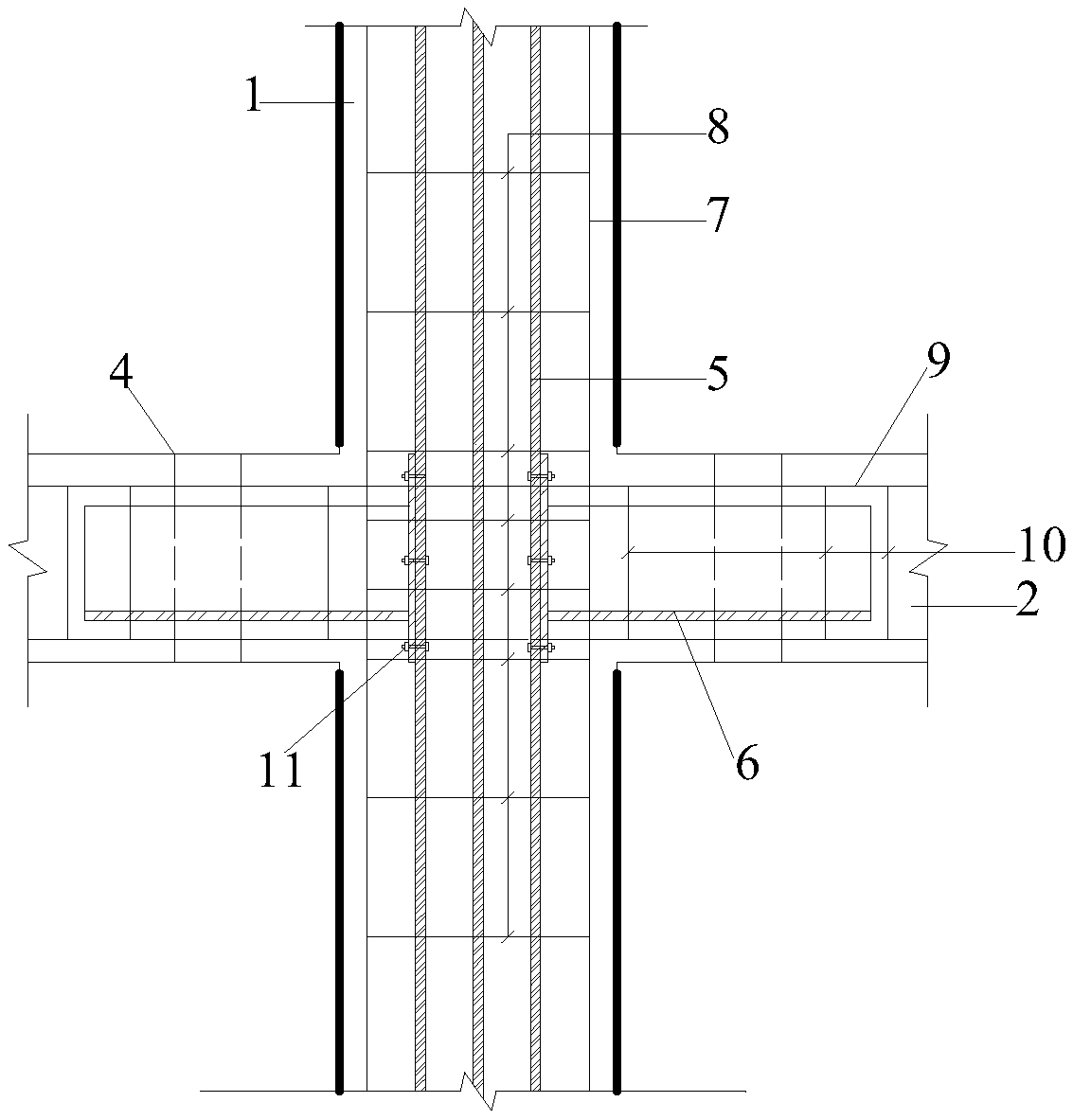

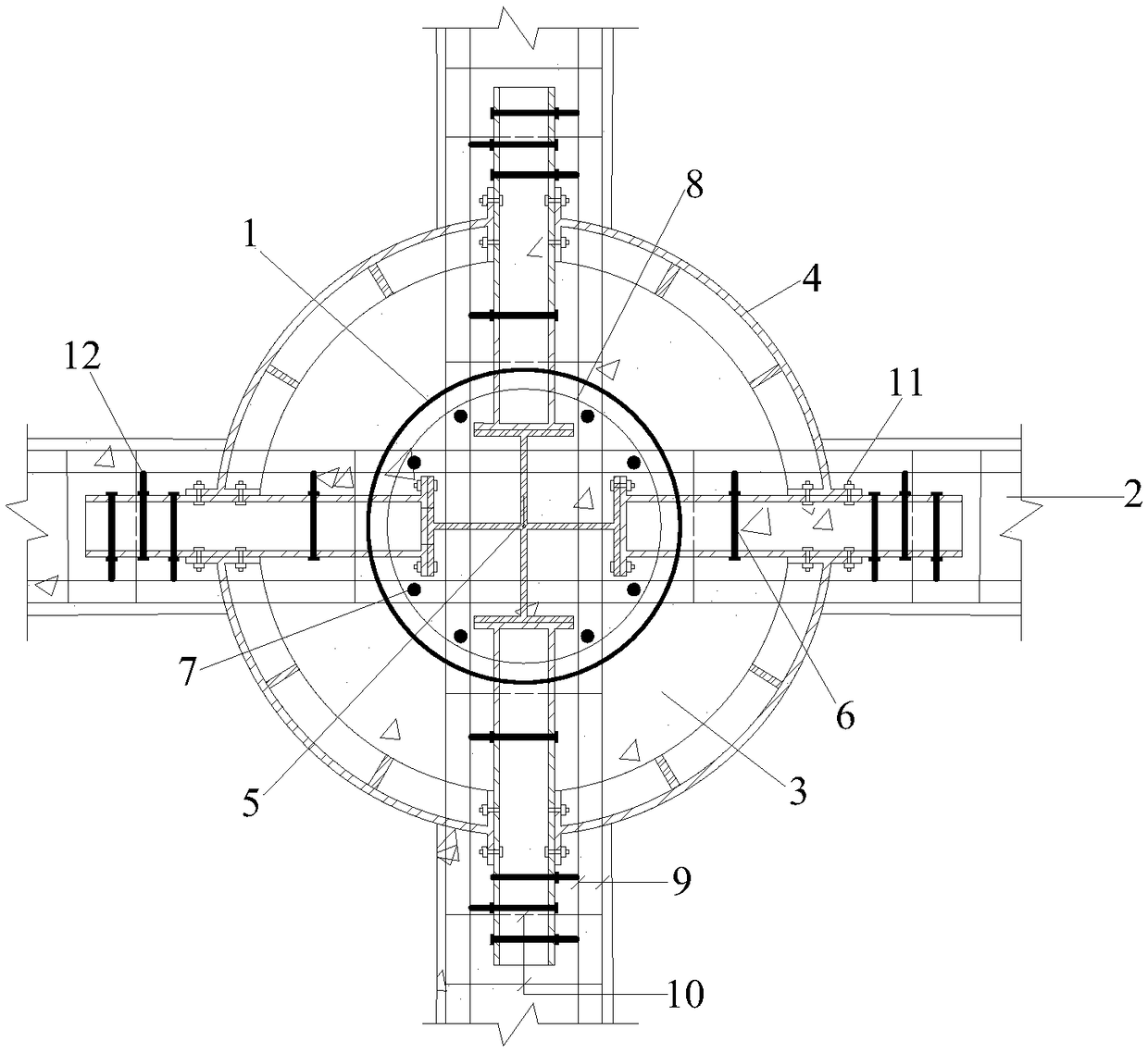

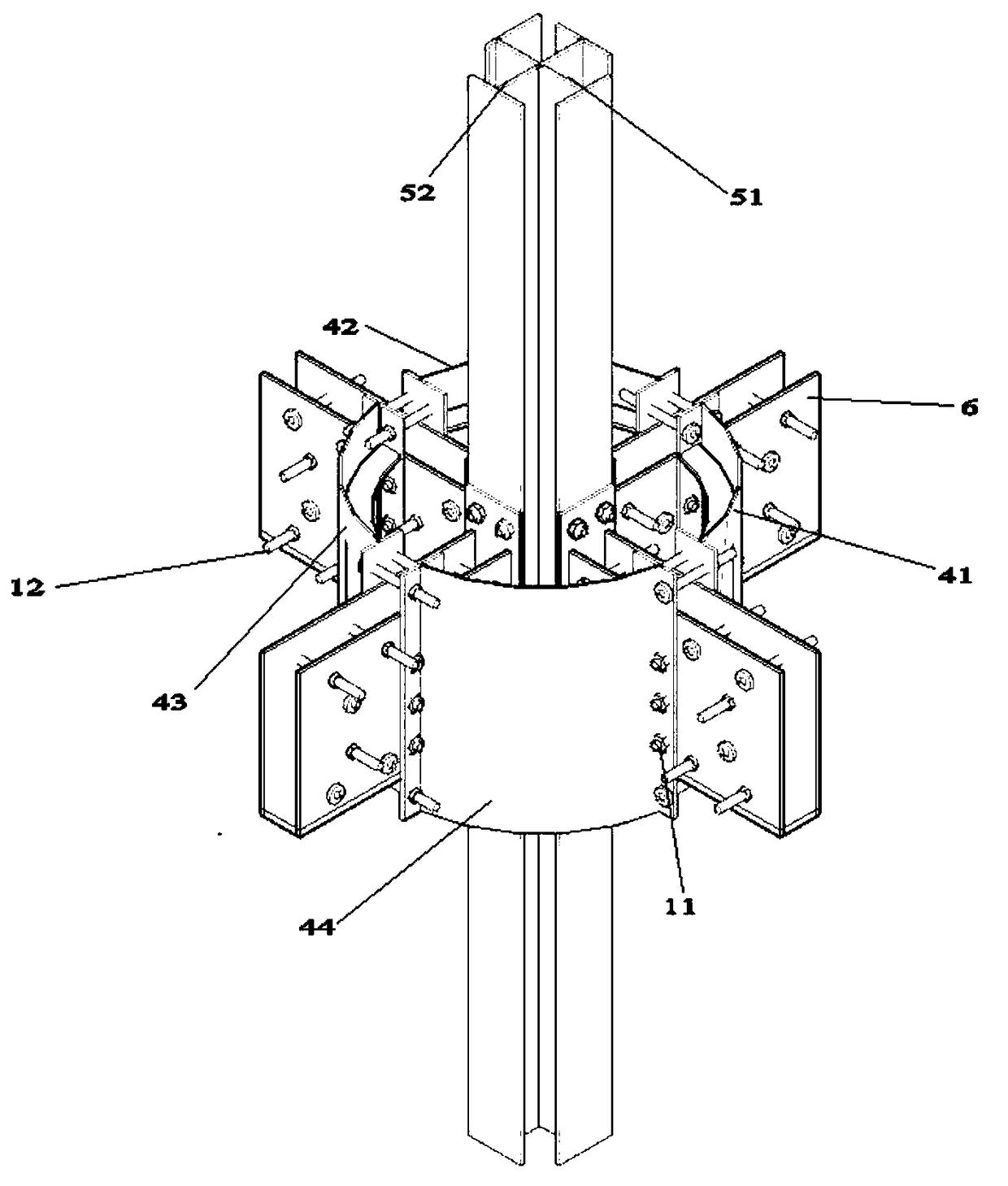

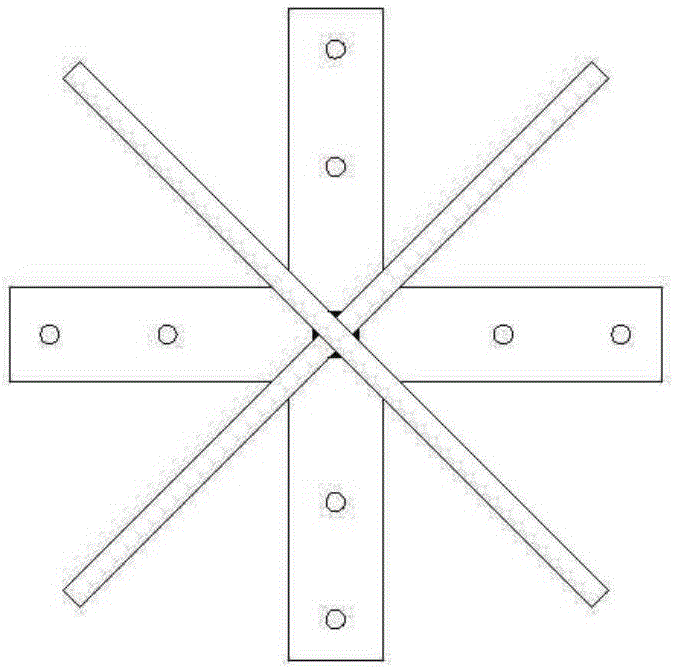

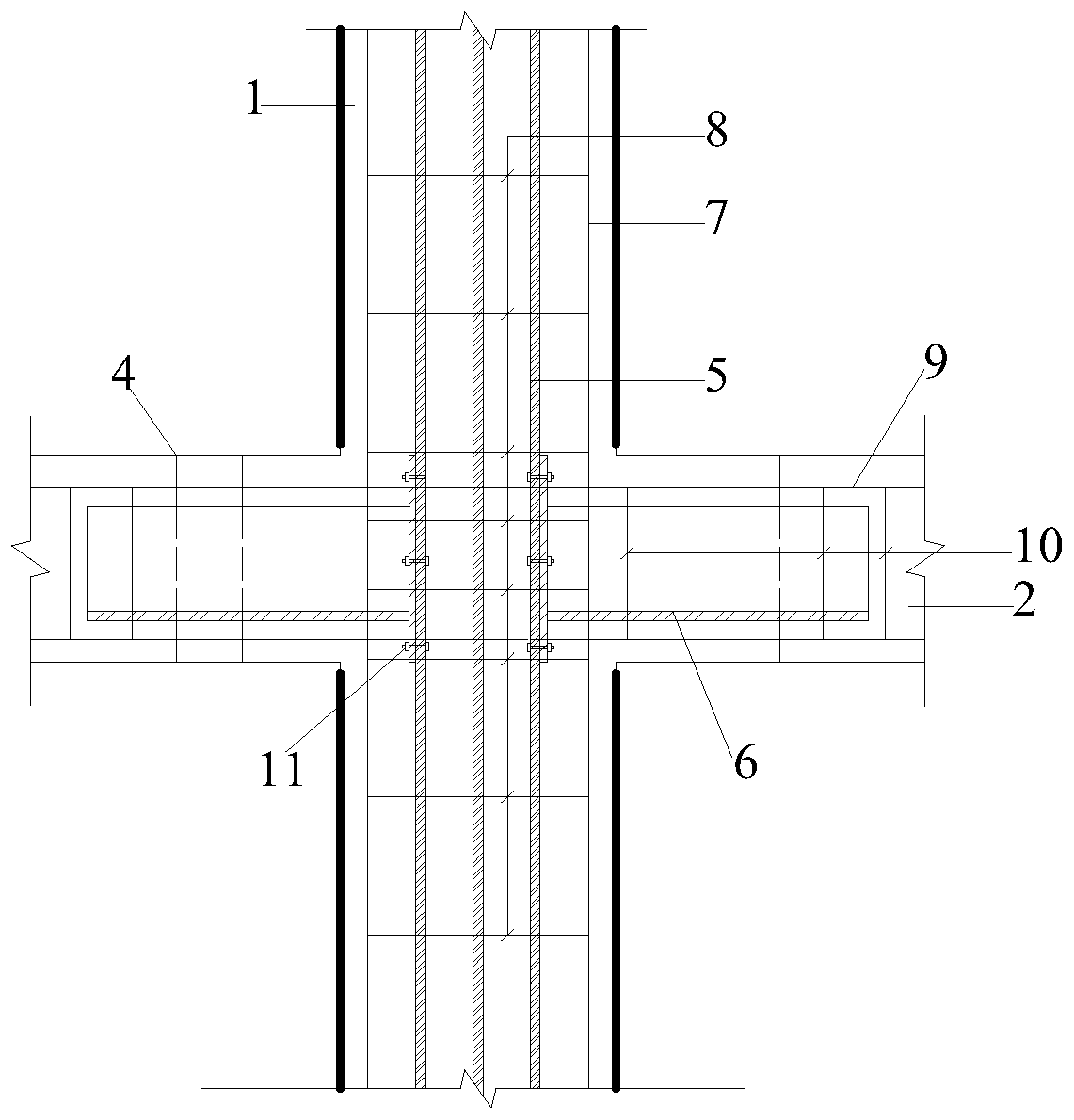

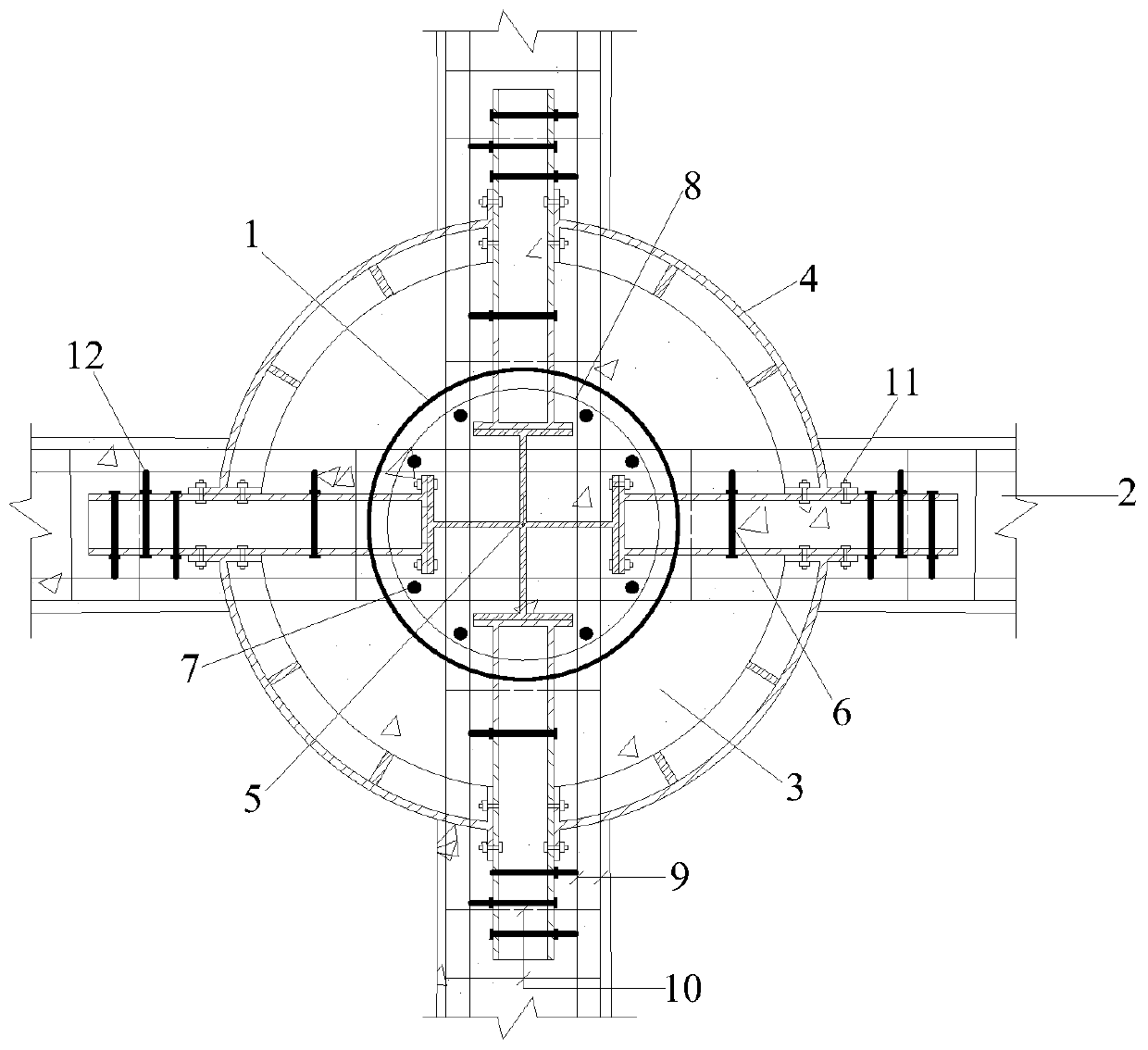

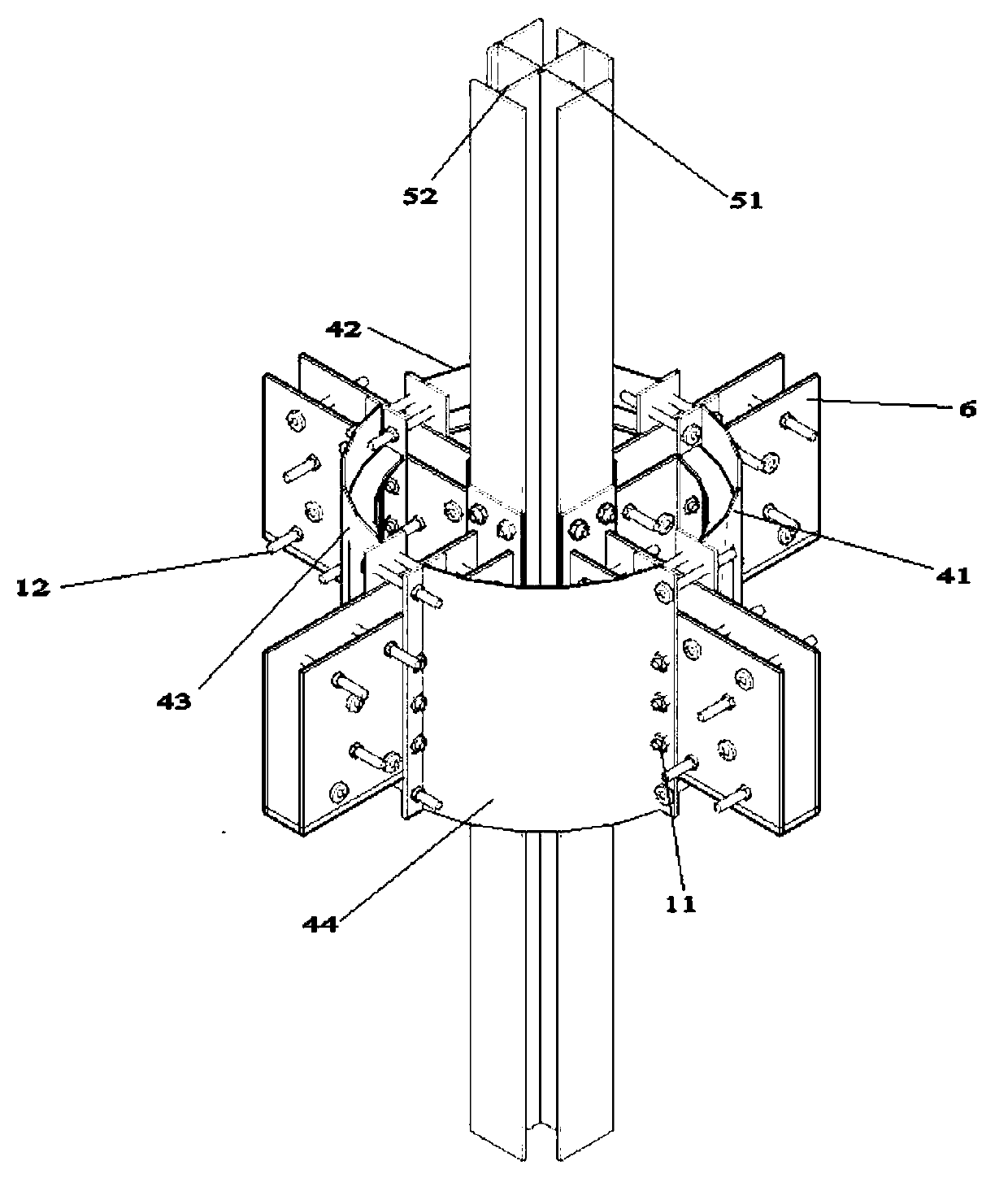

PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam cross-shaped node

ActiveCN109024916ASimple structureRealize the purpose of "strong node"StrutsGirdersReinforced concreteHigh integrity

The invention discloses an assembled PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam cross-shaped node which comprises core section steel, U-shaped hidden brackets, circular steel pipe fasteners, core-passing anchor bolts, a node area longitudinal rib, a column tie rib and concrete. The core section steel which is formed through welding a section steel flange and a section steel web plate has a cross-shaped structure. The U-shaped hidden brackets are connected with the section steel flange through the high-strength bolts. The U-shaped hidden brackets are distributed in a crossed manner. The core-passing anchor bolts horizontally pass through the U-shaped hidden brackets and are reversely arranged in a staggered manner. Four sets of circular steel pipe fasteners are distributed among the U-shaped hidden brackets along a circumferential direction. The circular steel pipe fasteners are connected with and fixed to the U-shaped through the high-strength bolts.The column tie rib passes through a process hole on the U-shaped hidden bracket rib plate and is bond with a column longitudinal rib which passes through the node, thereby forming a steel reinforcement cage. According to the assembled PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam cross-shaped node, quick splicing of the steel component in the node is realized by means of the high-strength bolts. The assembled PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam cross-shaped node has advantages of high bearing force, high integrity, convenient construction, high industrialization degree, etc.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

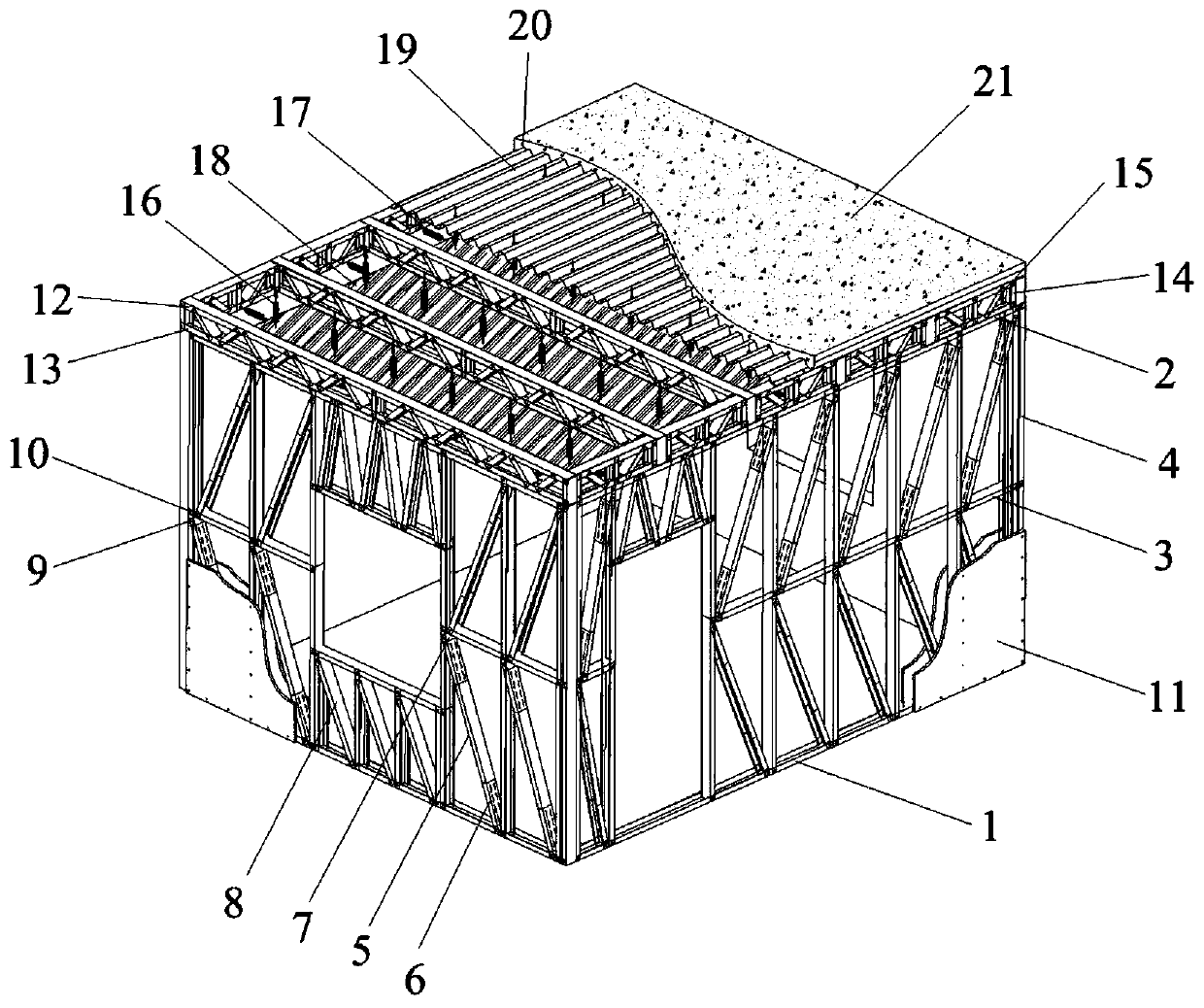

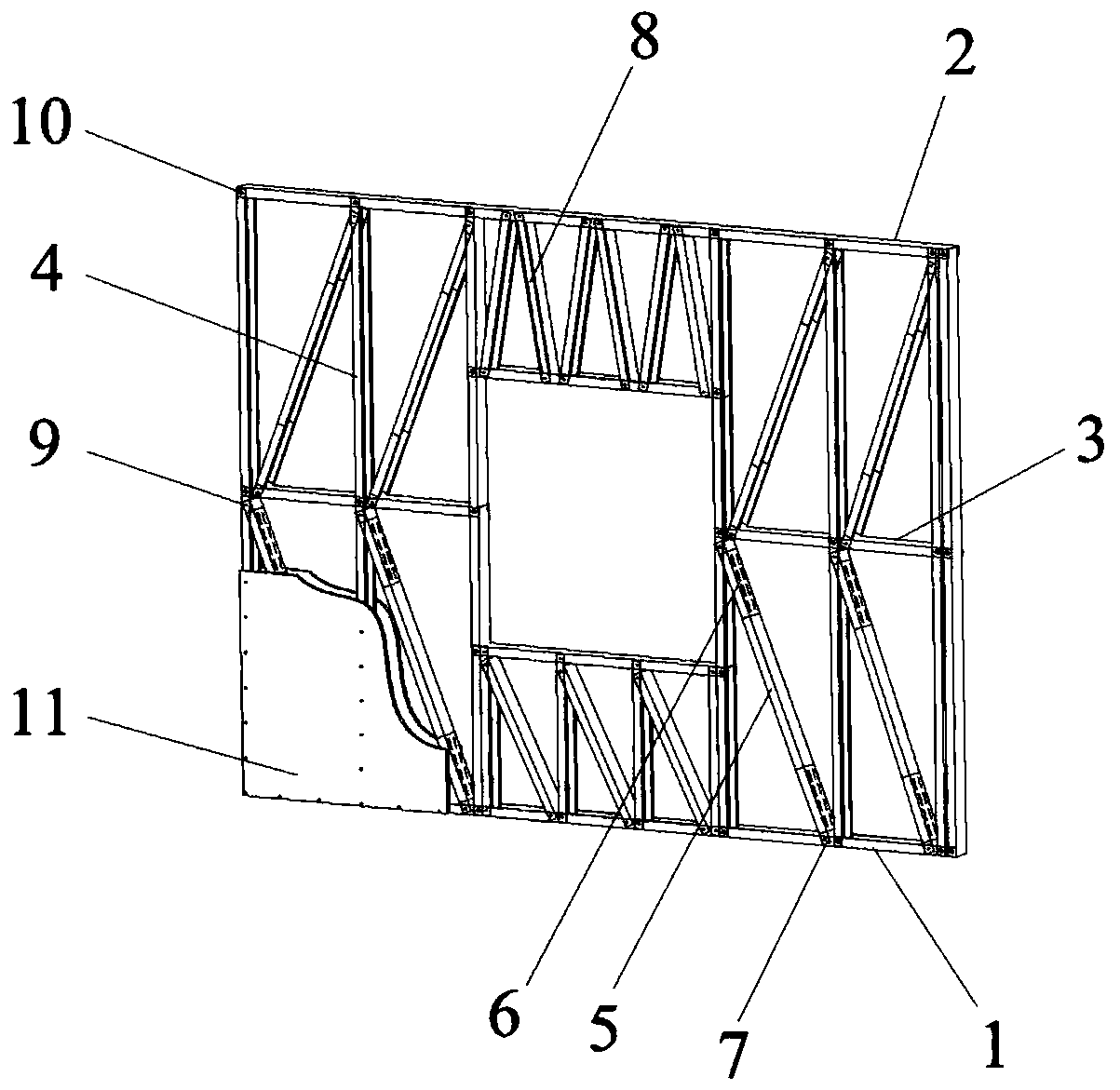

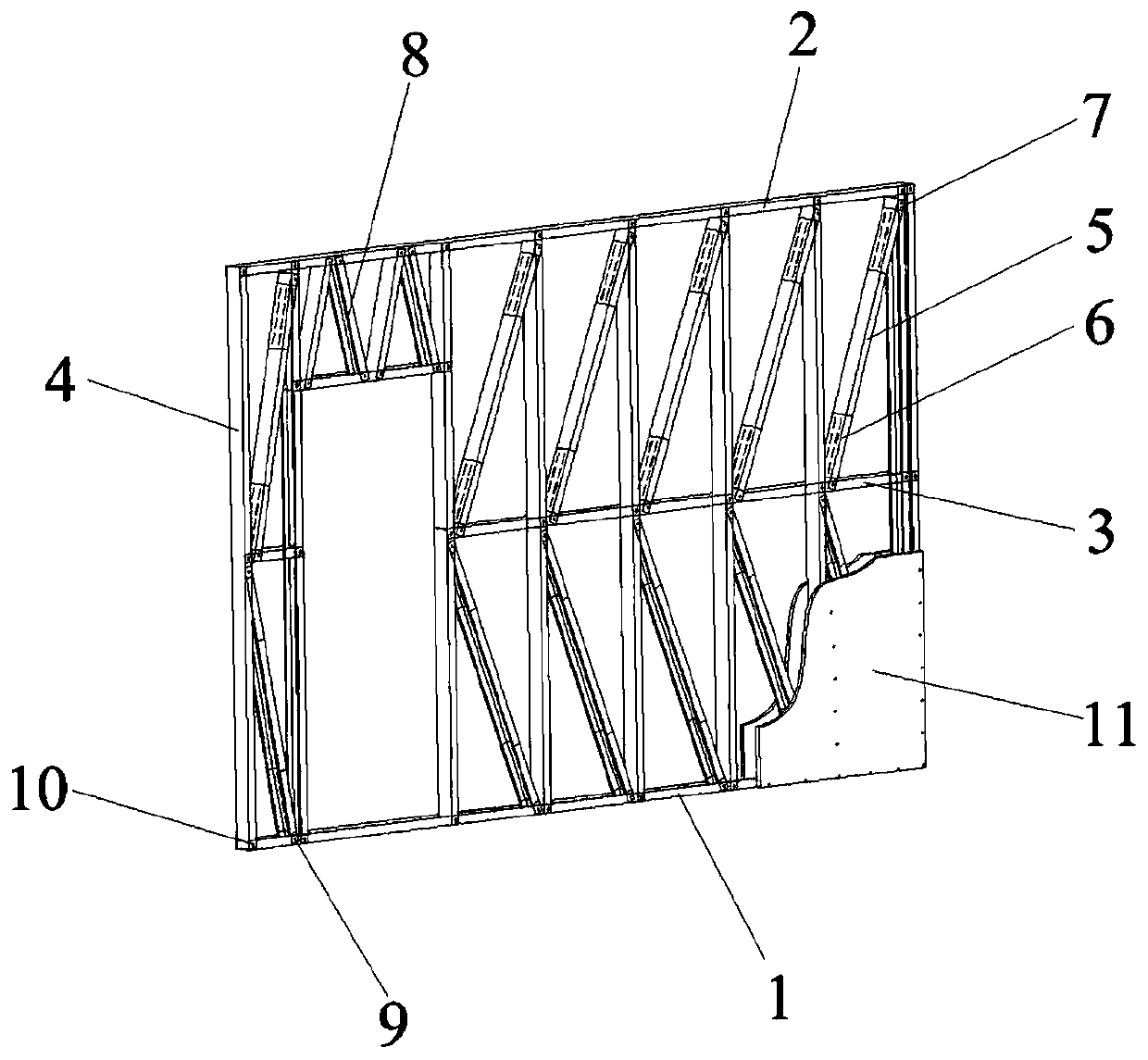

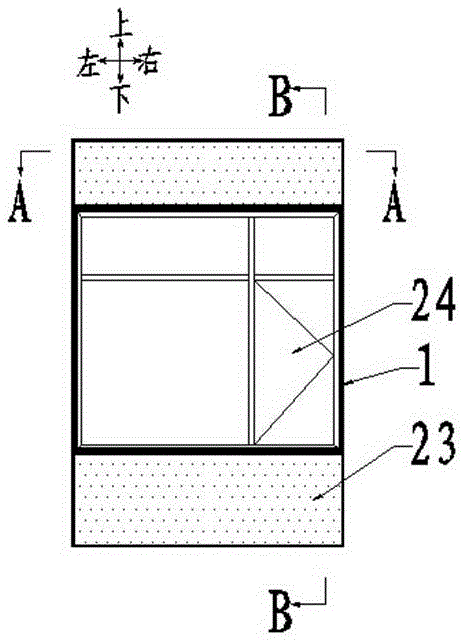

Multi-dimensional energy dissipation and seismic mitigation type cold-formed thin-walled steel structure residential system

ActiveCN110952798ARealization of energy dissipation and shock absorptionImprove plastic deformation abilityProtective buildings/sheltersDwelling buildingArchitectural engineeringRebar

The invention discloses a multi-dimensional energy dissipation and seismic mitigation type cold-formed thin-walled steel structure residential system. The seismic mitigation type cold-formed thin-walled steel structure residential system comprises a bottom guide rail, a top guide rail, a horizontal cross brace, a wall column, an energy dissipation diagonal brace middle part, an energy dissipationdiagonal brace yield section, an energy dissipation diagonal brace end part, a rigid diagonal brace, a self-tapping screw, a friction gasket, a covering plate, a truss upper chord, a truss lower chord, a truss column, a truss diagonal brace, a chemical bolt spring, a mass steel plate, a corrugated steel plate, a reinforcing mesh and a lightweight concrete plate. A corrugated plate-lightweight concrete-chemical bolt spring-bolt spring-mass steel plate jointly forms a tuned mass energy dissipation device, and the energy dissipation and seismic mitigation capacity of the cold-formed thin-walled steel structure residential system floor system is effectively improved. The industrialized and integrated modes of the structural system are outstanding, the construction speed is high, the advantagesof light weight, high strength and energy dissipation and seismic mitigation are integrated, and the application prospect is very wide.

Owner:BEIJING UNIV OF TECH

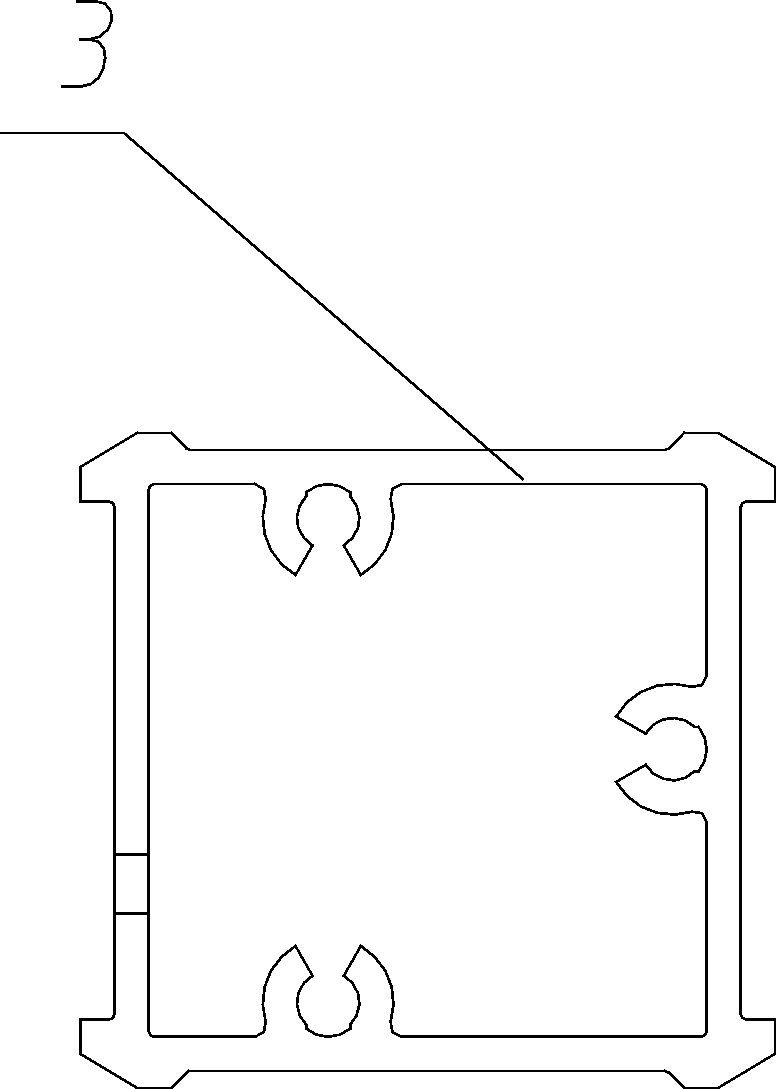

Panel unit of building external bounding system

The invention relates to the field of building decoration, in particular to a panel unit of a building external bounding system. The panel unit comprises a unit body. Frames are arranged on the periphery of the unit body. The unit body is installed on a building structural beam through an adjustable connecting piece fixedly connected with the frames. The frames are provided with slots and sealing rubber strips. The panel unit has the advantages of being easy to assemble, high in assembly precision, high in industrialization degree, good in anti-seismic property and wind-proof performance, convenient to convey and hoist, and good in heat insulation effect.

Owner:山东津单幕墙有限公司

Method for improving primordium inducement uniformity of bottle-cultivated pleurotus eryngii

InactiveCN103999689AImprove the bud-inducing effectIncrease vitalityHorticulture methodsVitalityHypha

The invention discloses a method for improving primordium inducement uniformity of bottle-cultivated pleurotus eryngii, and relates to the technical field of pleurotus eryngii cultivation. The method comprises the steps that mycelium stimulation is carried out on the bottle-cultivated pleurotus eryngii, and then pleurotus eryngii enters a pleurotus eryngii cultivation room; ventilation and light illumination of the pleurotus eryngii cultivation room are closed, the pleurotus eryngii cultivation room is made to be in the closed dark condition, the temperature is adjusted to range from 8 DEG C to 10 DEG C, the relative humidity is improved to 95%, and the pleurotus eryngii is kept in the pleurotus eryngii cultivation room under the cultivation environment for 24 hours; then the temperature is increased to range from 16 DEG C to 18 DEG C; the light illumination is adjusted to be opened for 30 min after being closed for 60 min every time; the ventilation quantity is adjusted so as to maintain the indoor concentration of carbon diode to be 2000 ppm, and primordium inducement is carried out for 5 days to 8 days. According to the method, the growth characteristics of the pleurotus eryngii under the natural environment are met, the primordium inducement effect of the pleurotus eryngii is improved by reasonably controlling the light illumination, ventilation, temperature and humidity of the pleurotus eryngii cultivation room, the step of transition cultivation is set in the primordium inducement process, the vitality of hyphae can be vigorous, the phenomenon that the growing pleurotus eryngii is not uniform is avoided, water is supplemented in the step of transition cultivation, the hyphae can be positioned, and it is further ensured that the growing pleurotus eryngii is uniform.

Owner:安徽金豪生态农业科技有限公司

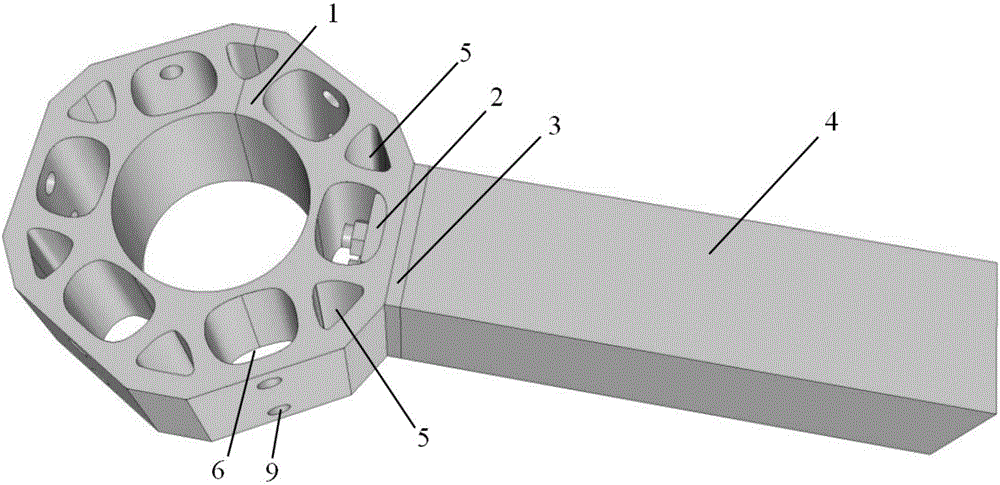

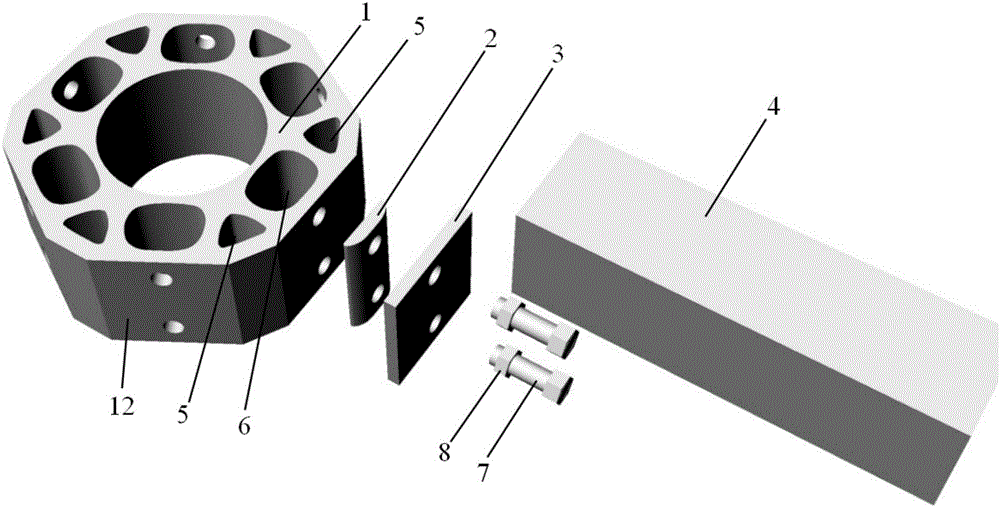

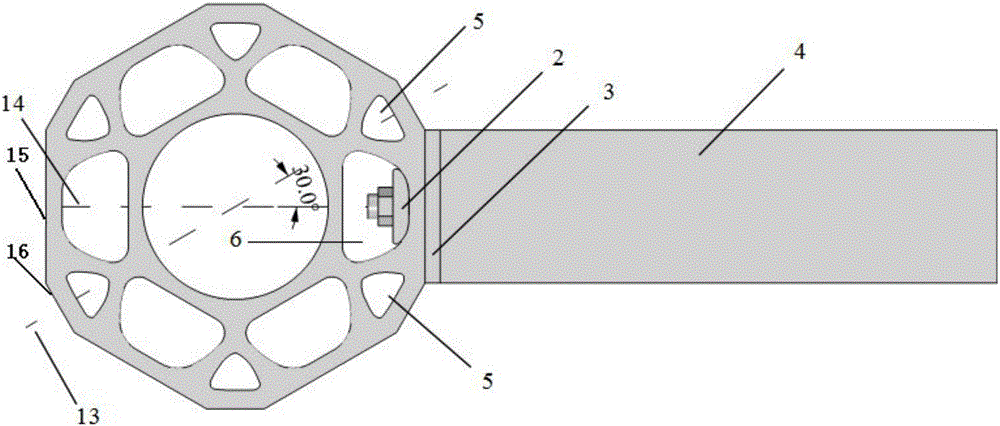

Hollowed-out circular-ring-shaped space grid structure assembly type joint

ActiveCN106592778AAchieve perfect unityBeautiful appearanceBuilding constructionsIsosceles trapezoidMesh grid

The invention discloses a hollowed-out circular-ring-shaped space grid structure assembly type joint. The hollowed-out circular-ring-shaped space grid structure assembly type joint comprises a center hollowed-out circular ring (1), a joint inner gasket (2), a seal plate (3), a connection rod part (4) and a bolt (7). The seal plate is provided with a bolt hole. The section of the center hollowed-out circular ring is provided with a first hollowed-out hole (6). The two sides of the first hollowed-out hole are each provided with a second hollowed-out hole (5). The first hollowed-out hole is in an isosceles trapezoid shape. The four edges of the first hollowed-out hole all have certain radian. The peripheral wall of the first hollowed-out hole is provided with bolt holes. The second hollowed-out holes are in a triangular shape, and the three edges of each second hollowed-out hole have certain radian. The center hollowed-out circular ring, the seal plate and the connection rod part are connected through bolts, and an assembly type rod part is formed. The hollowed-out circular-ring-shaped space grid structure assembly type joint has wide application prospects in single-layer triangular space grid structure lighting roofs.

Owner:SOUTHEAST UNIV

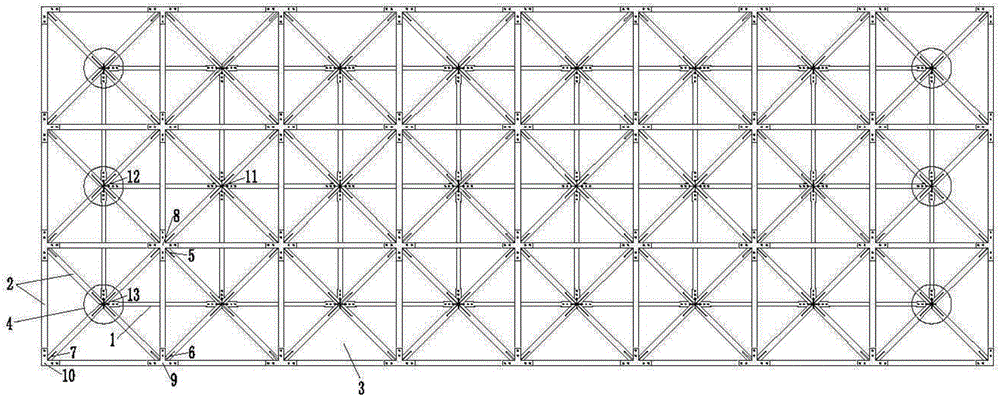

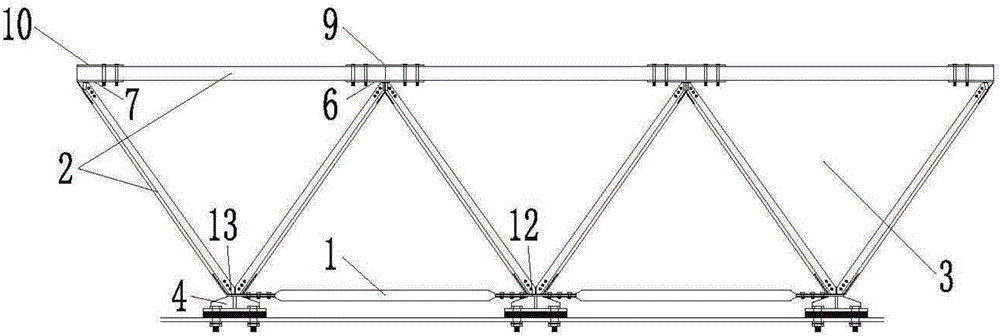

Combined net rack

ActiveCN106088468AFlexible section formImprove carrying capacityGirdersJoistsEngineeringHigh pressure

The invention discloses a combined net rack and belongs to the technical field of building combined structures. The net rack is a quadrangular pyramid spatial net rack formed by combining tubes with high tension resistance with members made from other materials with high pressure resistance. Lower chord members are made from the tubes, upper chord members and web members are formed by the members made from the other materials, and all the members are connected through plate-type joints. Supports are arranged in the proper positions of the lower portions of lower chord joint plates, so that the whole structure is fixed to supporting structures. The net rack is suitable for square or rectangular structures such as roofs and canopies. Compared with net racks of traditional steel structures, the net rack has the advantages of being small in steel consumption, low in self weight, simple in structure, convenient to manufacture and mount, low in cost, good in mechanical performance and the like.

Owner:NANJING UNIV OF TECH

Unit prefabricated type building outer envelope system provided with strip window and construction method of unit prefabricated type building outer envelope system

ActiveCN105113684AHigh degree of factoryShorten construction timeCovering/liningsWallsSurface plateElectrical and Electronics engineering

The invention relates to the field of building decoration, in particular to a unit prefabricated type building outer envelope system provided with a strip window. The unit prefabricated type building outer envelope system comprises a plurality of face plate units and strip window units. Frames are arranged around the face plate units and the strip window units respectively. The face plate units and the strip window units are arranged on building structural beams through adjustable connection pieces fixedly connected with the frames. Insertion grooves are formed in the frames. Sealing rubber strips are arranged on the frames. Insertion cores matched with the insertion grooves are inserted and connected into the insertion grooves of the adjacent face plate units or the insertion grooves of the adjacent strip window units or the insertion grooves of the adjacent face plate units and the adjacent strip window units. The sealing rubber strips of the adjacent face plate units make contact, or the sealing rubber strips of the adjacent strip window units make contact, or the sealing rubber strips of the adjacent face plate units and the adjacent strip window units make contact. The strip window is formed by the strip window units. The unit prefabricated type building outer envelope system has the advantages of being easy to prefabricate, high in prefabricating accuracy, high in factorization degree, excellent in seismic performance and windproof performance, convenient to transport and hoist and good in heat preservation effect.

Owner:山东津单幕墙有限公司

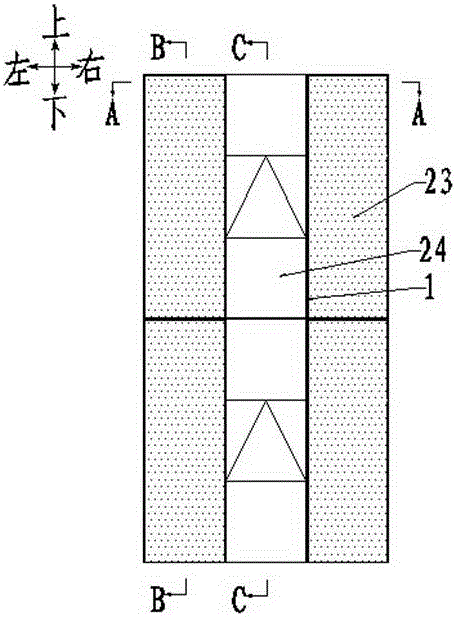

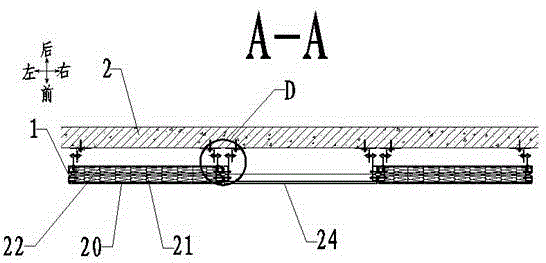

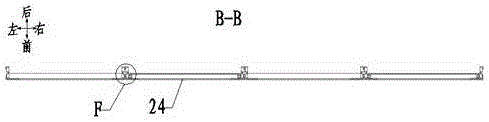

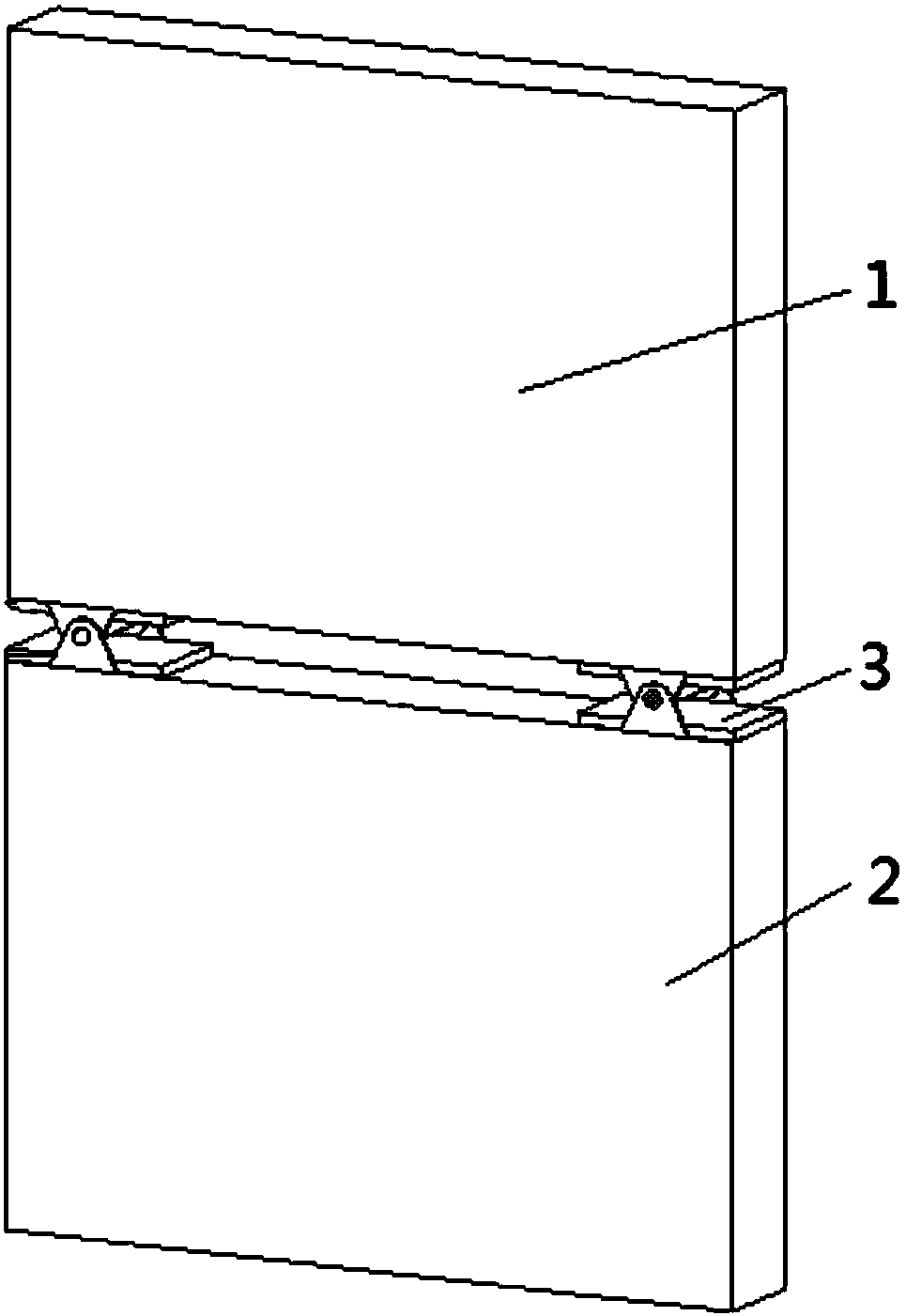

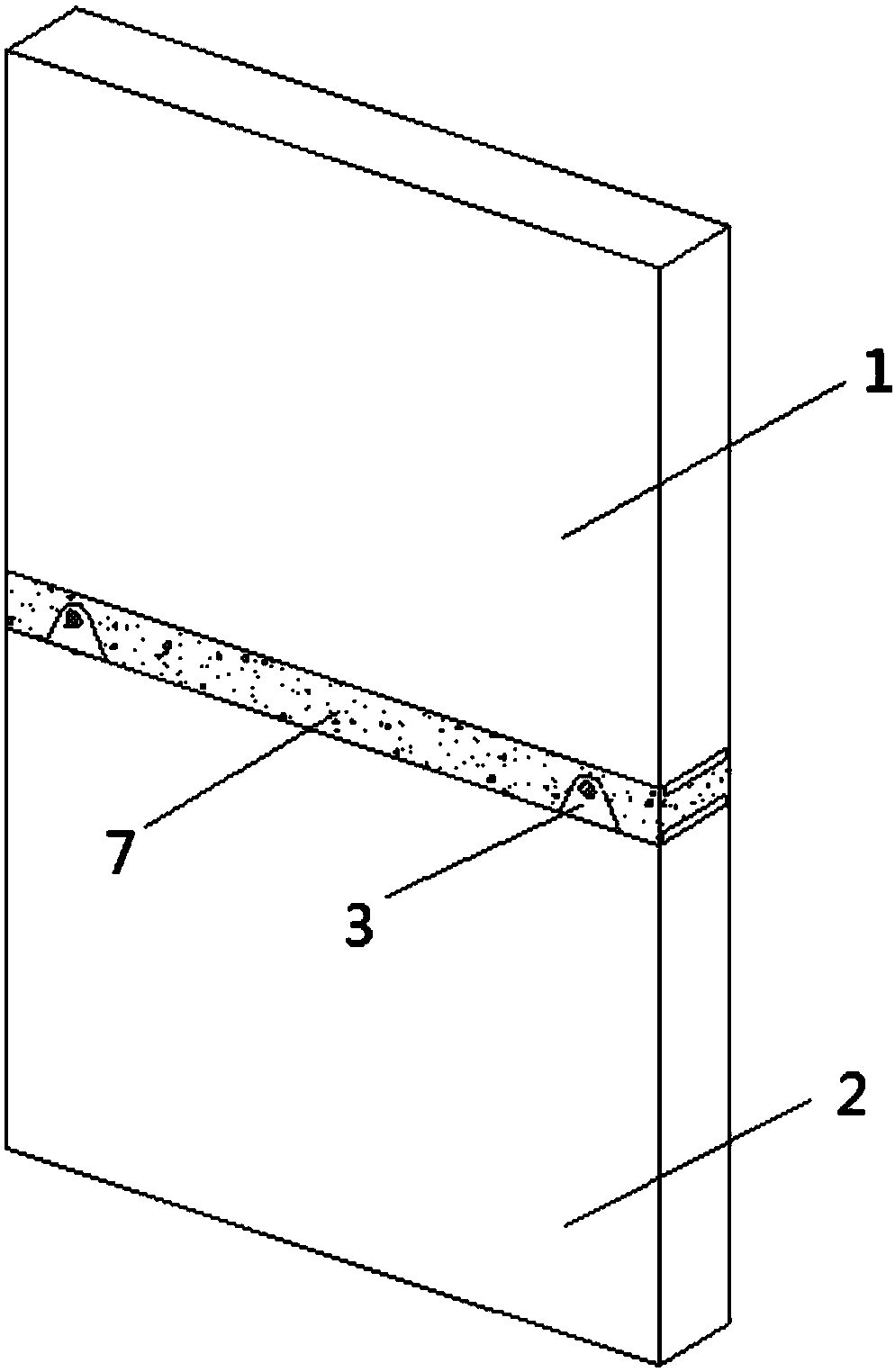

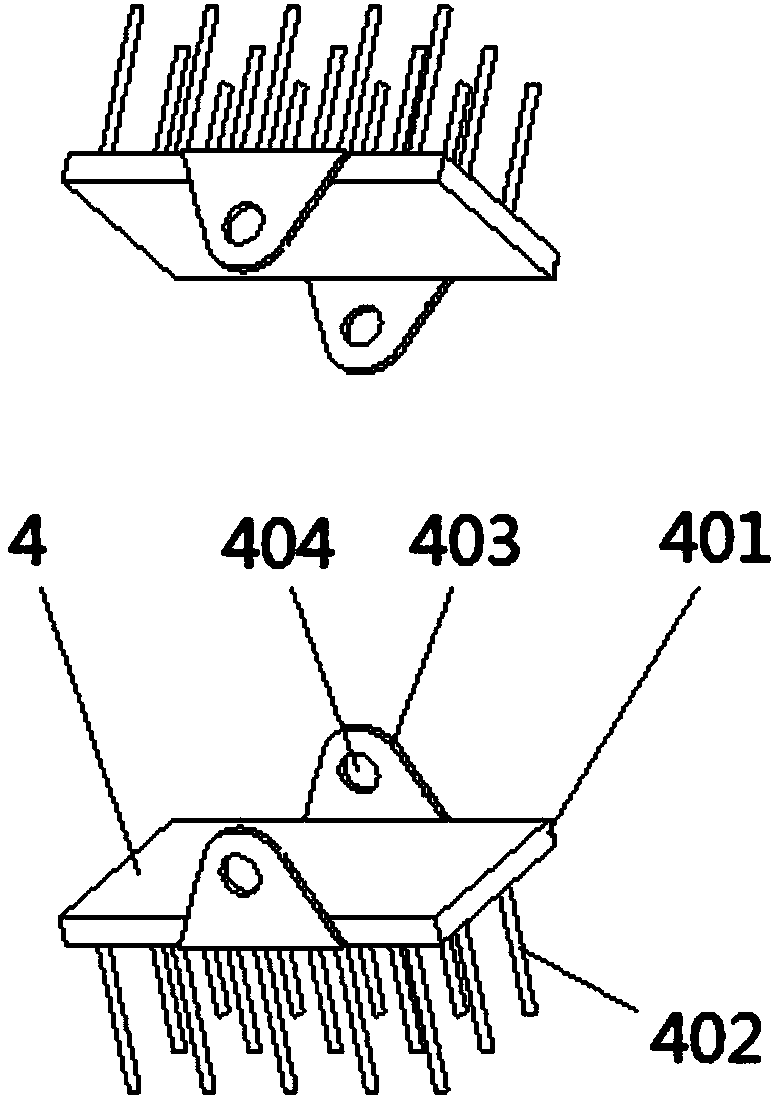

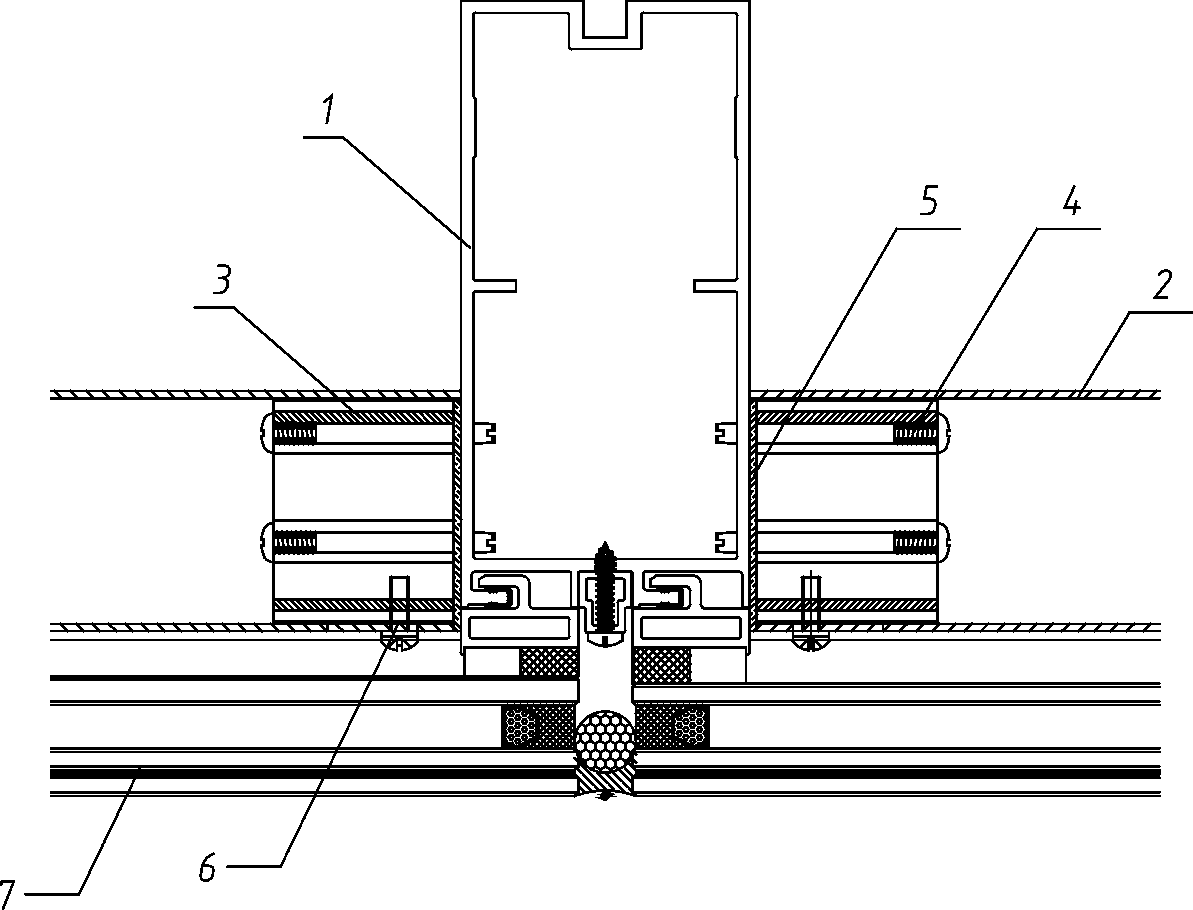

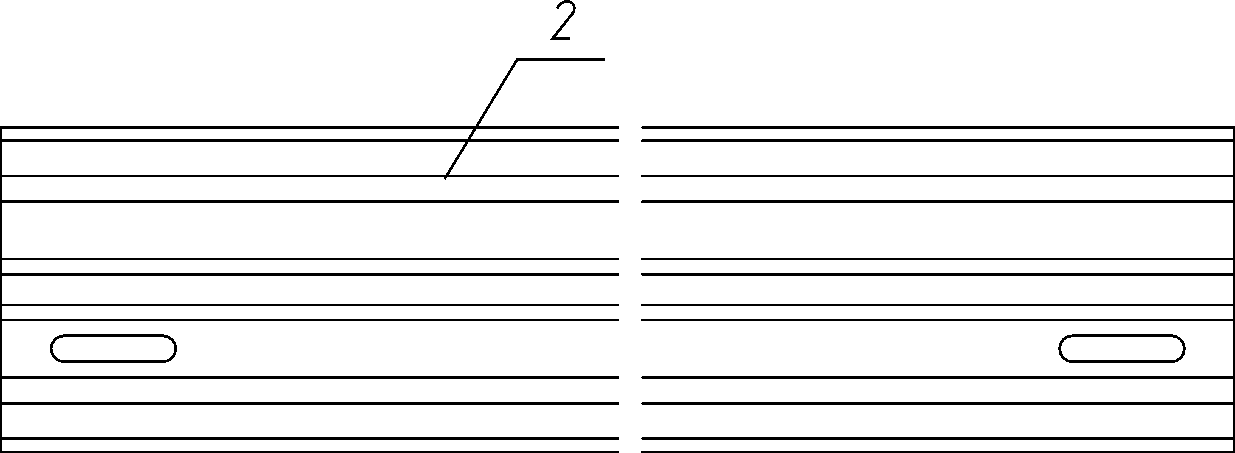

Vertical multi-hinge connection structure between assembled shear walls and construction method

PendingCN107724544AReduce constructionHigh degree of factoryBuilding constructionsRebarUltimate tensile strength

The invention relates to a vertical multi-hinge connection structure between assembled shear walls and a construction method, belongs to the technical field of assembled concrete structures, and in order to solves the problems that alignment connection of steel bars is needed in vertical connection construction of the existing assembled shear walls, the processing and mounting accuracy and the technical requirements for workers are high, and the strength is difficult to reach the standard. The left and right ends of the bottom end surface of a first pre-cast shear wall are connected with the top end surface of a second pre-cast shear wall through pre-buried connecting pieces; two pre-buried connecting pieces are defined as a first pre-buried connecting piece and a second pre-buried connecting piece; each pre-buried connecting piece comprises two lug plate components and a bearing rod; and the two lug plate components of the first pre-buried connecting piece are respectively pre-buriedat the left ends of the lower end surface of the first pre-cast shear wall and the upper end surface of the second pre-cast shear wall. The vertical multi-hinge connection structure between the assembled shear walls and the construction method have the advantages of simple connection construction process, high construction speed, reliable force transfer and high strength.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

Curtain wall beam column sliding pin connection system

PendingCN109162388AAccurately determine whether it is effectiveAvoid safety hazardsWallsKeelEngineering

The invention provides a curtain wall beam column sliding pin connection system which comprises an aluminum alloy vertical keel which is vertically inserted into an aluminum alloy horizontal keel, thealuminum alloy horizontal keel is provided with a waist hole and sleeves a keel core sleeve, the keel core sleeve is provided with a round hole, the waist hole is aligned with the round hole, and a bolt is inserted for initial fixation. One side of the keel core sleeve facing the aluminum alloy vertical keel is provided with multiple stainless steel special pins, two sides of the aluminum alloy vertical keel are provided with column holes which are the same horizontal line as the stainless steel special pins. The curtain wall beam column sliding pin connection system has the advantages that an installation unit is processed and assembled in a factory, the industrialized degree is high, the precision is high, the on-site installation is simple and fast, and the construction efficiency is high. Whether the special pins are effective or not can be accurately judged, safety hazards caused by the long-term failure of stainless steel springs in traditional spring pins are avoided, and the curtain wall beam column sliding pin connection system has all the advantages of a spring pin connection system.

Owner:宁波建工建乐工程有限公司

A pvc-frp tube-confined steel concrete column-reinforced concrete beam cross joint

ActiveCN109024916BSimple structureRealize the purpose of "strong node"StrutsGirdersConcrete beamsArchitectural engineering

The invention discloses an assembled PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam cross-shaped node which comprises core section steel, U-shaped hidden brackets, circular steel pipe fasteners, core-passing anchor bolts, a node area longitudinal rib, a column tie rib and concrete. The core section steel which is formed through welding a section steel flange and a section steel web plate has a cross-shaped structure. The U-shaped hidden brackets are connected with the section steel flange through the high-strength bolts. The U-shaped hidden brackets are distributed in a crossed manner. The core-passing anchor bolts horizontally pass through the U-shaped hidden brackets and are reversely arranged in a staggered manner. Four sets of circular steel pipe fasteners are distributed among the U-shaped hidden brackets along a circumferential direction. The circular steel pipe fasteners are connected with and fixed to the U-shaped through the high-strength bolts.The column tie rib passes through a process hole on the U-shaped hidden bracket rib plate and is bond with a column longitudinal rib which passes through the node, thereby forming a steel reinforcement cage. According to the assembled PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam cross-shaped node, quick splicing of the steel component in the node is realized by means of the high-strength bolts. The assembled PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam cross-shaped node has advantages of high bearing force, high integrity, convenient construction, high industrialization degree, etc.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com