Foamed concrete thermal insulation composite wall

A composite technology of foamed concrete and thermal insulation, applied in walls, building components, buildings, etc., can solve the problems of restricting the practical application of cast-in-place foamed concrete composite walls, complex on-site assembly, limited thermal insulation performance, etc., and achieve good thermal insulation , high degree of industrialization, and the effect of ensuring thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

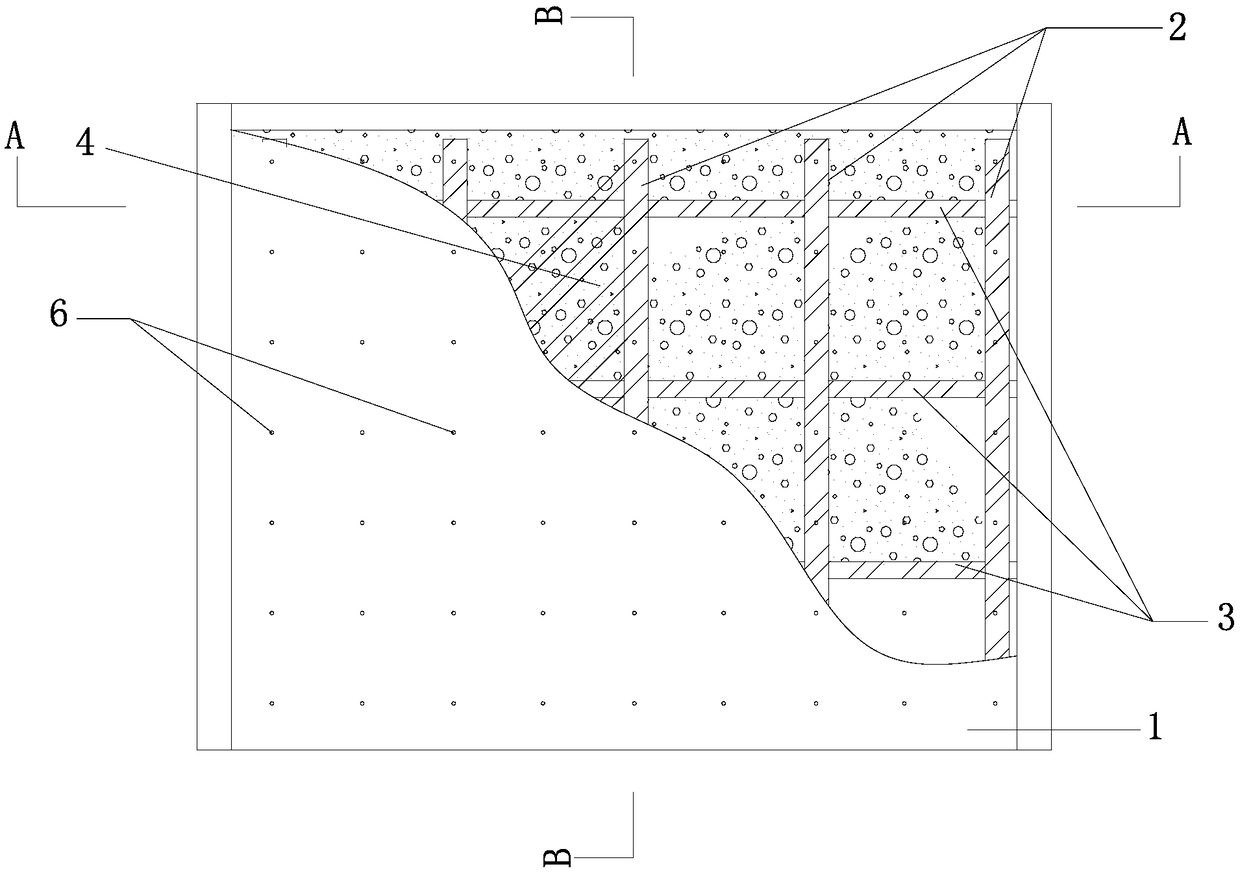

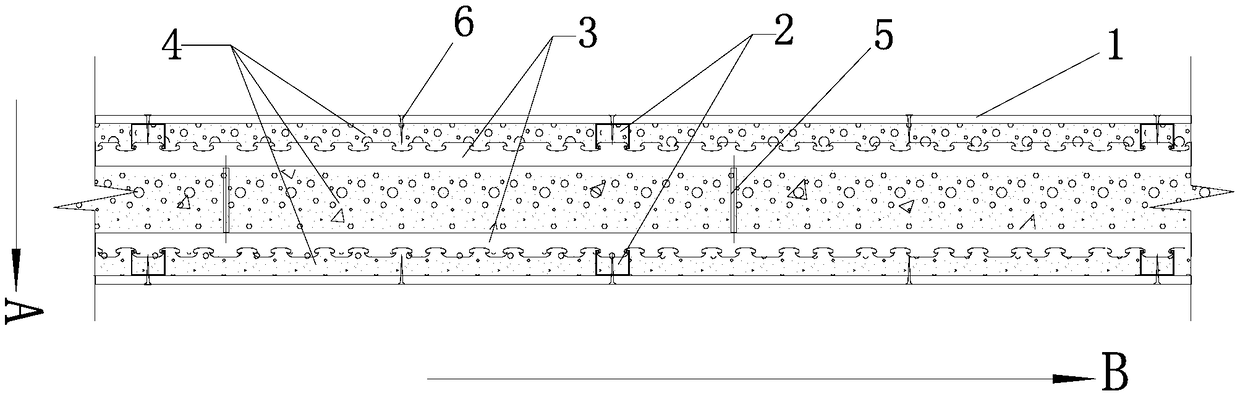

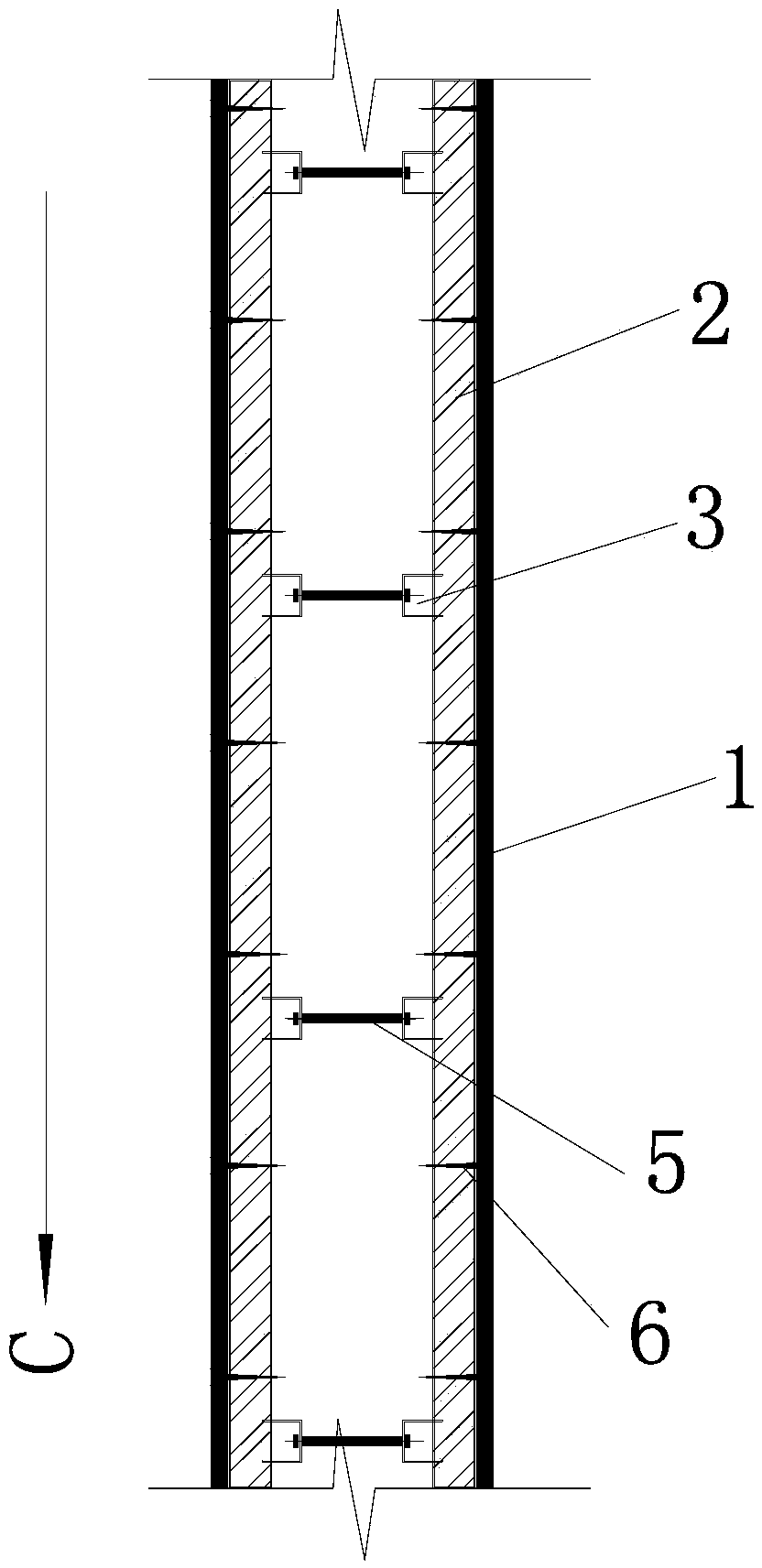

[0046] Such as Figure 1 ~ Figure 3 As shown, the foamed concrete thermal insulation composite wall of the present embodiment includes along the thickness direction of the wall (such as figure 2 direction A) two wall skeletons are arranged at intervals, and the two wall skeletons are fixed on the main structure of the building;

[0047] The wall skeleton includes a panel 1 and a keel assembly, and a pouring space is formed between the inner surface of the two panels 1 and the outer surface of the main structure of the building; the keel assembly is placed in the pouring space; the keel assembly includes multiple vertical keels 2 and multiple horizontal keels 3 ;

[0048] The vertical keel 2 is fixed on the main structure of the building, and a plurality of vertical keels 2 are along the length direction of the wall (such as figure 2 B direction) are arranged at intervals in turn, and the panel 1 is fixed on the vertical keel 2;

[0049] Each horizontal keel 3 is verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com