Composite heatretaining porcelain plate

A composite thermal insulation and porcelain board technology, applied in covering/lining, construction, building structure, etc., can solve the problems of difficult quality control, complex construction process of surface pasting and decorative materials, low structural safety, etc., and prolong the service life. , Excellent resistance to acid and alkali corrosion and aging resistance, the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

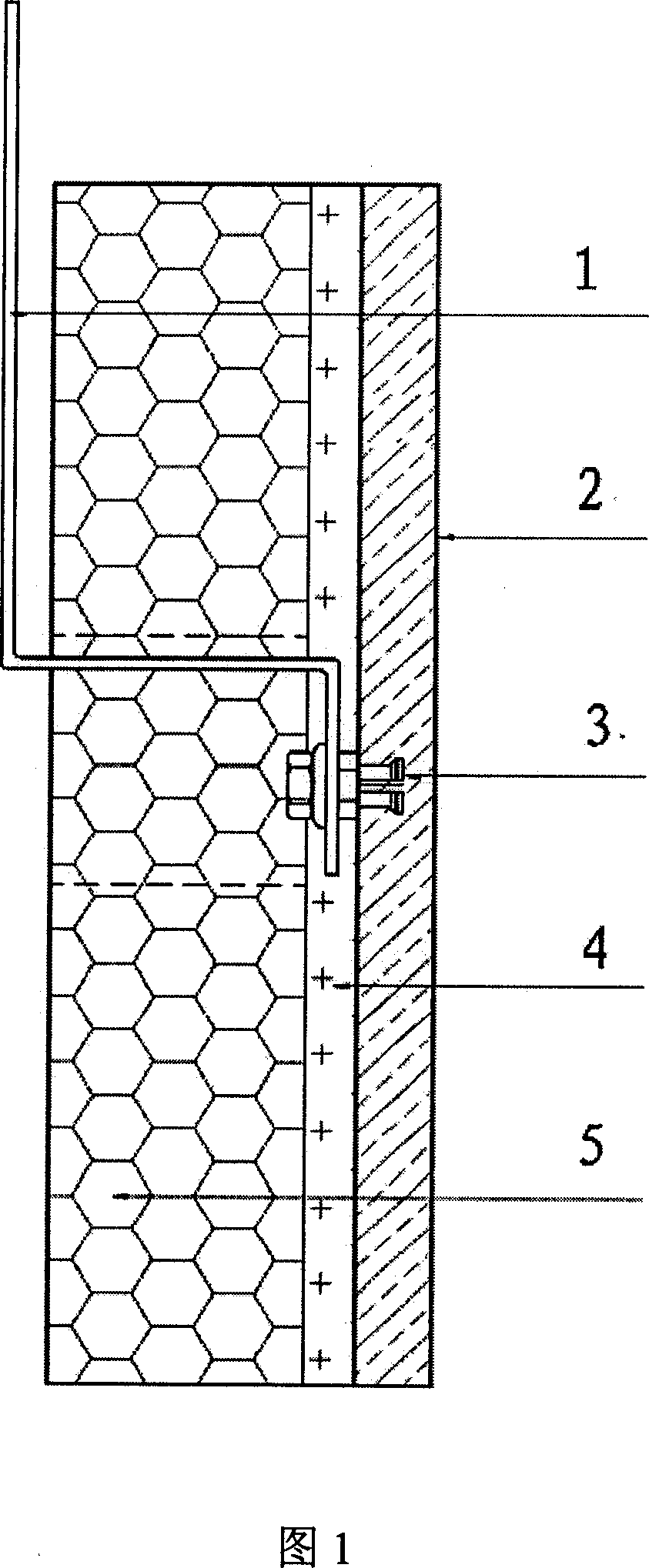

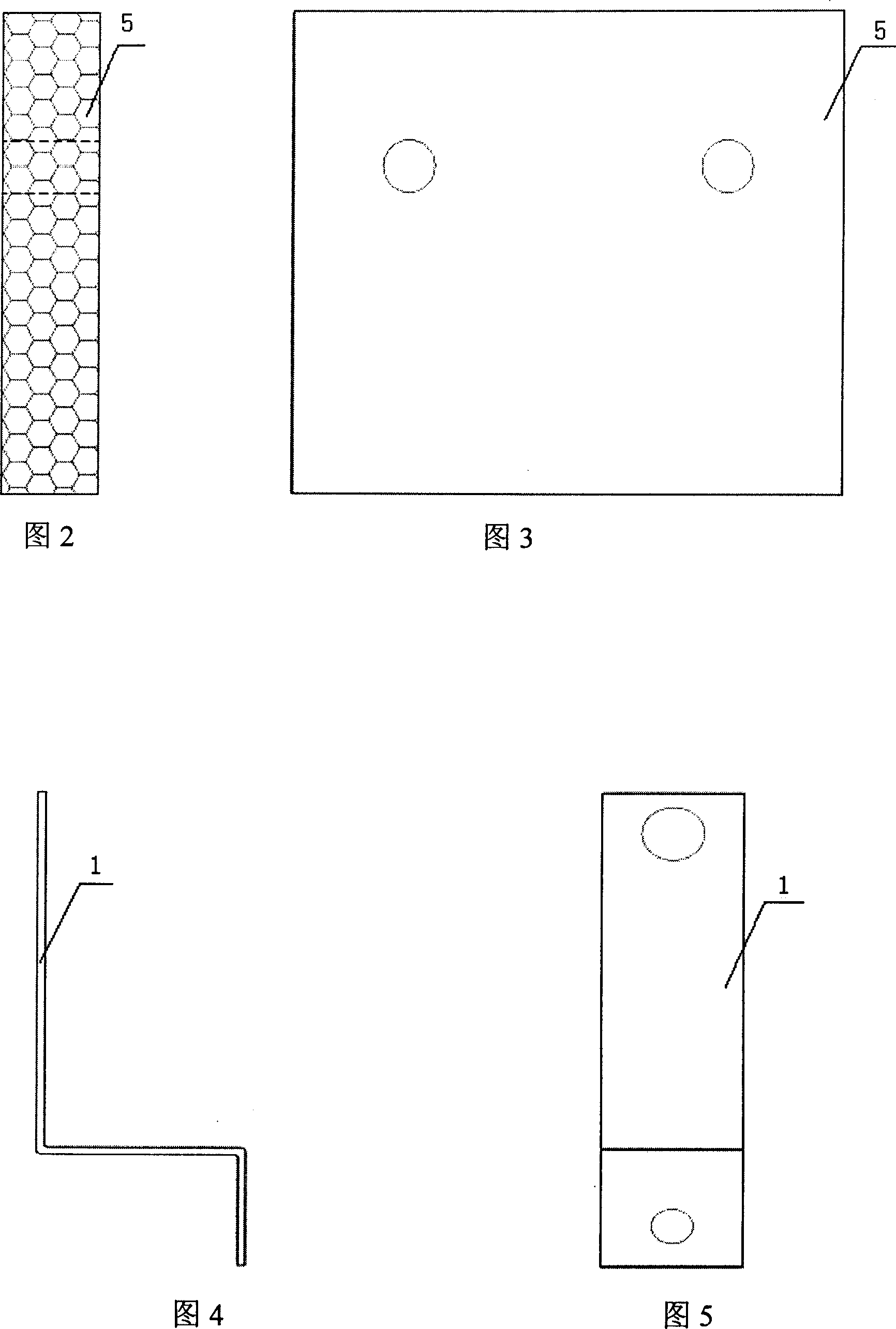

[0020] As shown in Figures 1 to 5, a composite thermal insulation porcelain plate of the present invention mainly includes: "" type stainless steel bar 1, porcelain plate 2, stainless steel anchor bolt 3, adhesive 4, polystyrene foam plastic plate for heat insulation 5. Brush the special interface agent on both sides of the polystyrene foam plastic plate 5 for heat insulation in advance, and drill several rectangular, polygonal or circular holes on the polystyrene foam plastic plate 5 for heat insulation with a drilling tool, and then use a drill bit (patent No.: ZL02 2 18058.3) Drill several inverted tapered blind holes on the back of the porcelain plate 2, implant stainless steel anchor bolts 3 in the blind holes, and use the adhesive 4 to glue the above-mentioned processed polystyrene foam board and porcelain plate Paste and press, and finally fix the "" type stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com