Curtain wall beam column sliding pin connection system

A connection system and column technology, applied in the field of architectural decoration curtain wall, can solve the problems of high precision requirement of column pin hole milling, spring easy to fail over time, and difficult to accurately judge spring, etc., to achieve high construction efficiency, easy on-site installation, factory high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

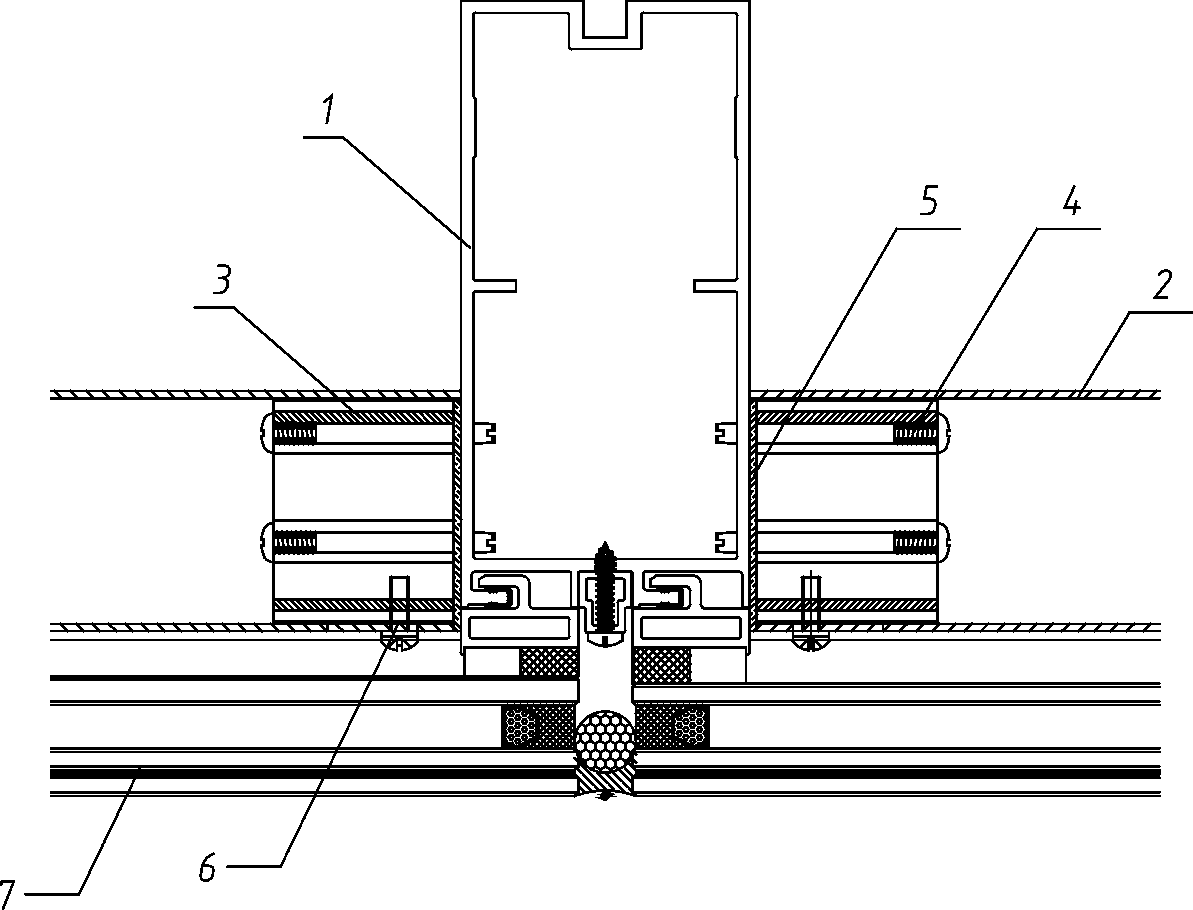

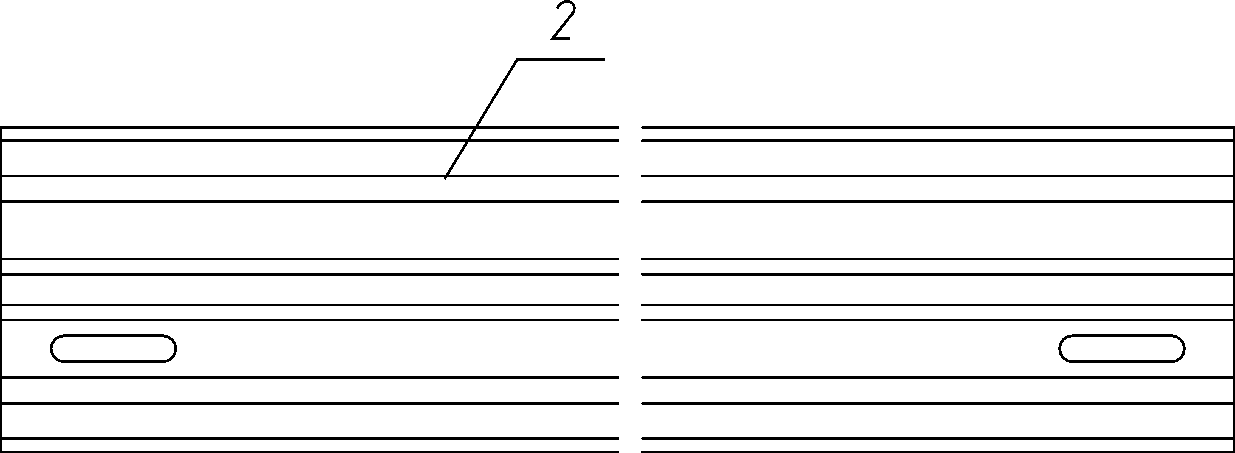

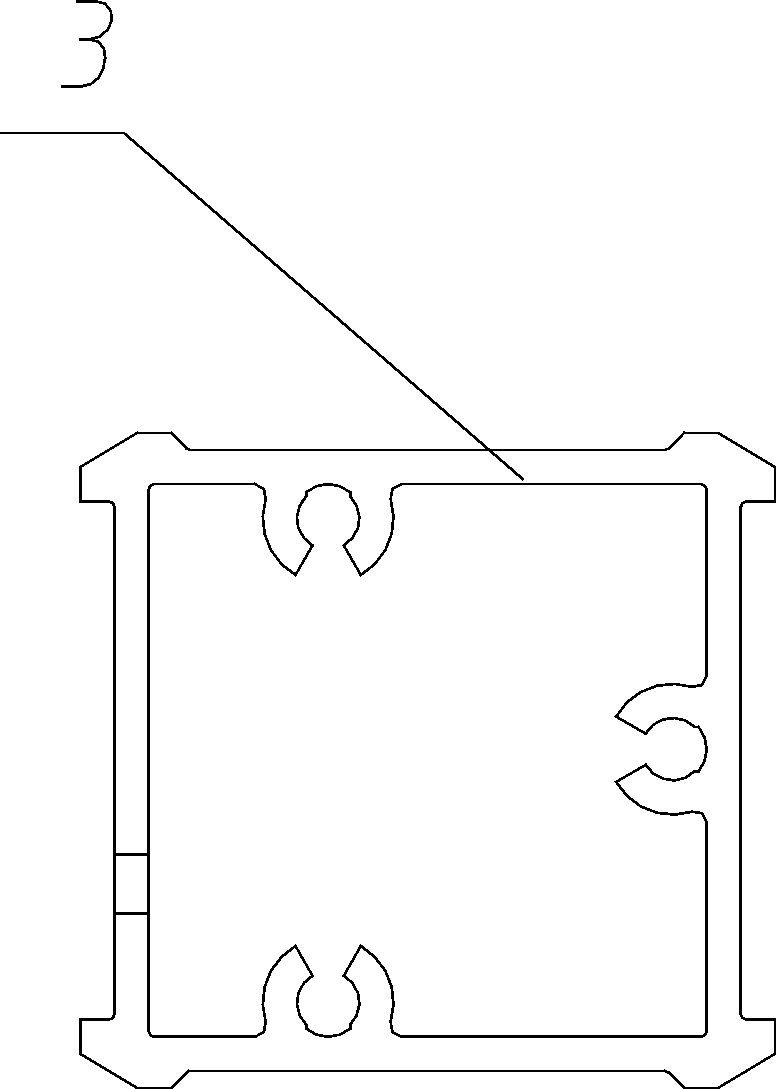

[0018] The curtain wall beam column sliding pin connection system includes an aluminum alloy vertical keel 1, and the aluminum alloy vertical keel 1 is vertically inserted into the aluminum alloy horizontal keel 2, and is characterized in that the aluminum alloy horizontal keel 2 is provided with a waist Holes, the aluminum alloy horizontal keel 2 is set with a keel core sleeve 3, the keel core sleeve 3 is provided with a round hole, the waist-shaped hole is aligned with the round hole, and the bolt 6 is inserted to fix it initially. The above-mentioned keel core sleeve 3 is aligned with one side of the aluminum alloy vertical keel 1 to set a plurality of stainless steel special pins 4, and the two sides of the aluminum alloy vertical keel 1 are provided with post holes, and the above-mentioned post holes are connected with the stainless steel special pins. 4 On the same horizontal line, a decorative panel 7 is arranged under the aluminum alloy vertical keel 1 and the aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com