Patents

Literature

59 results about "Initial fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

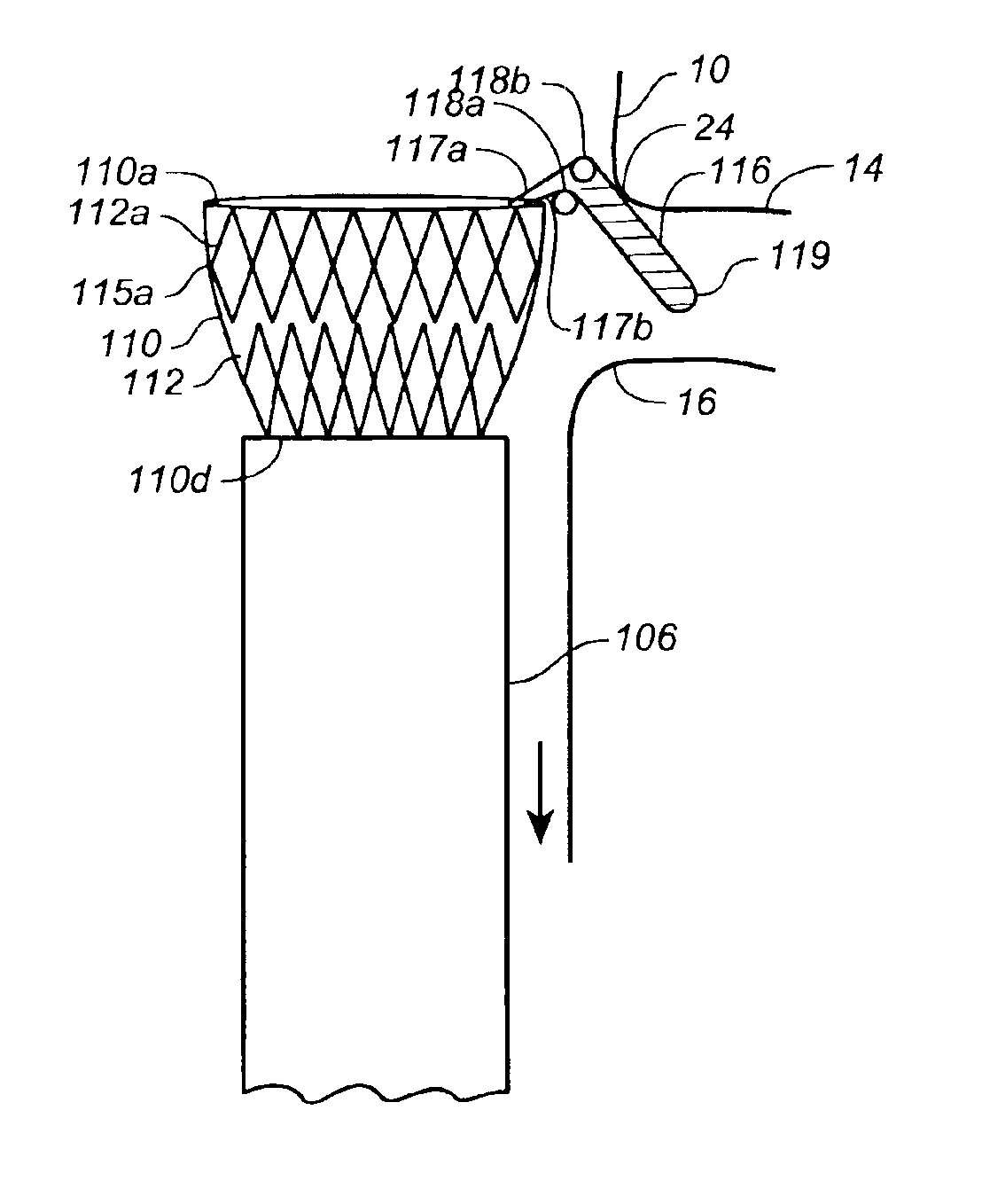

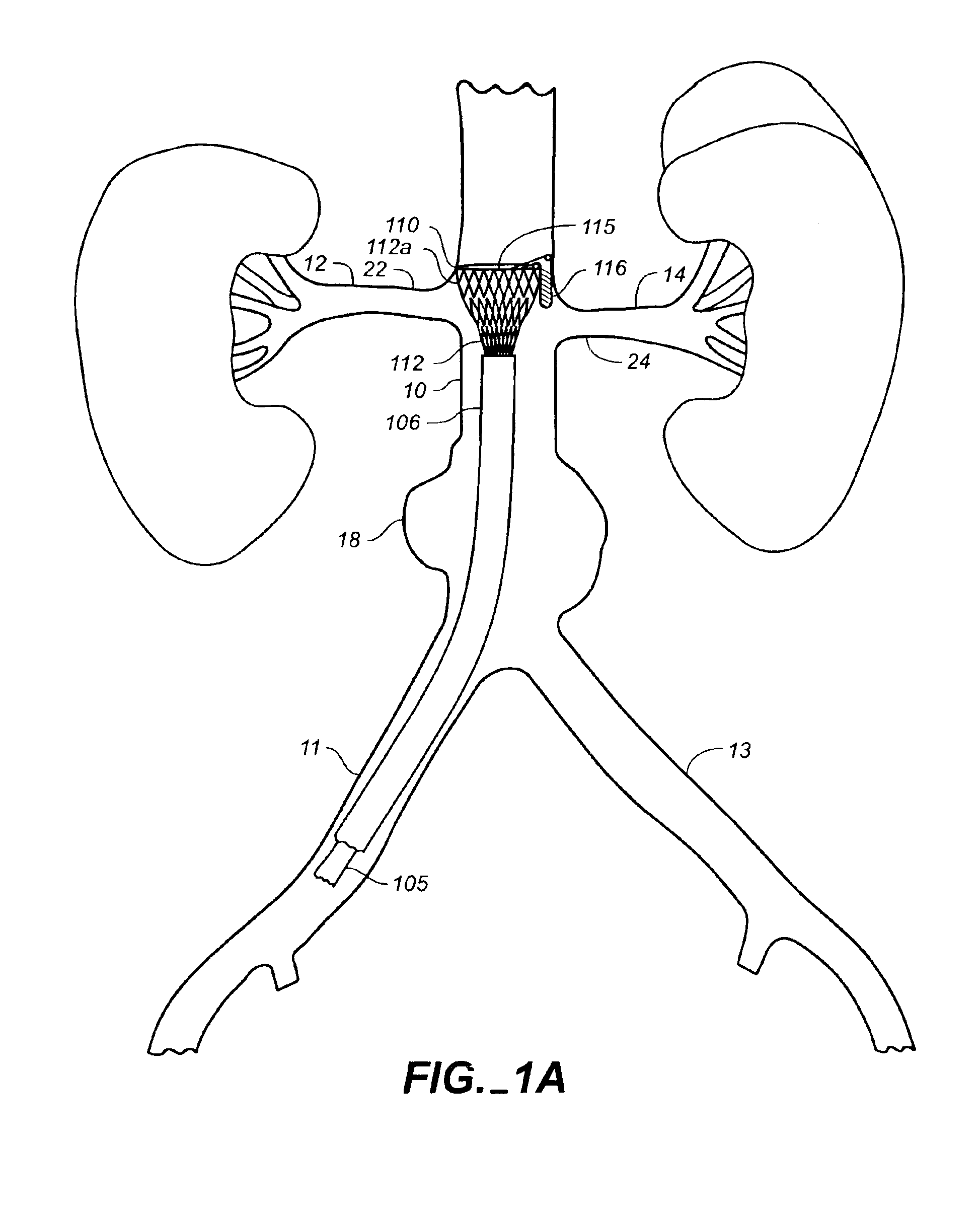

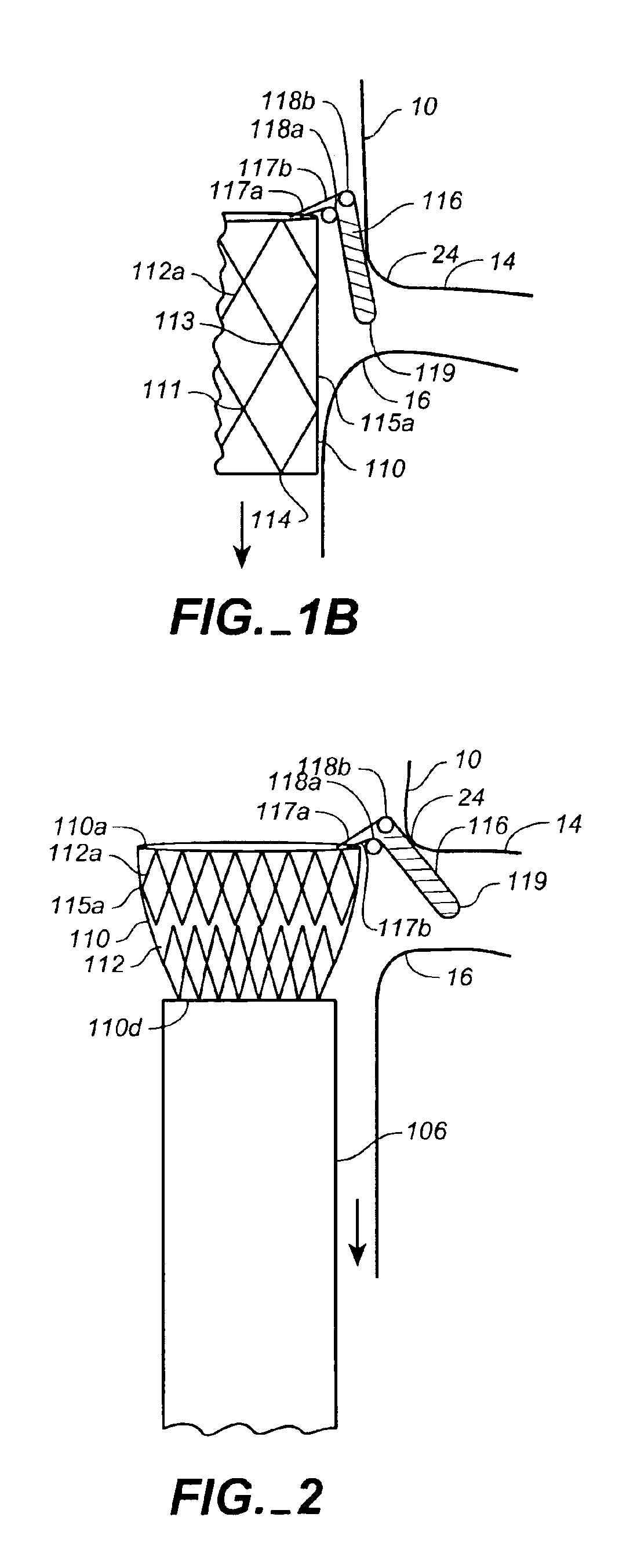

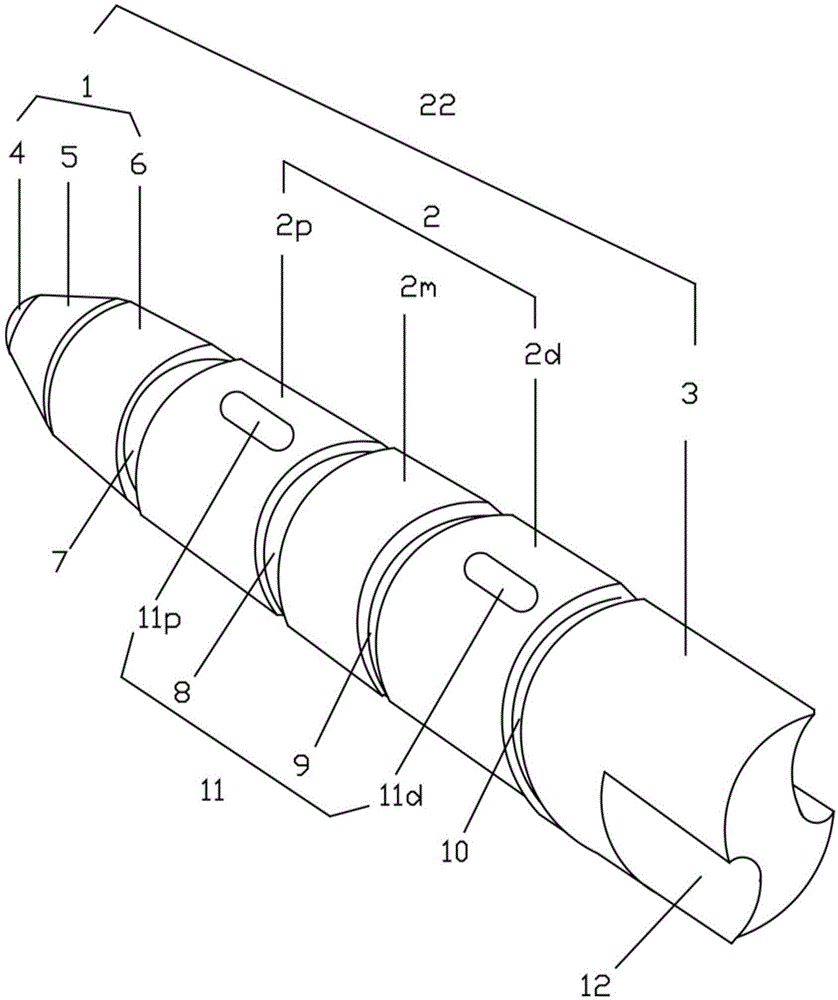

System for transrenal/intraostial fixation of endovascular prosthesis

InactiveUS6918926B2Promote migrationEasy to fixStentsBlood vesselsEndovascular prosthesisBlood vessel

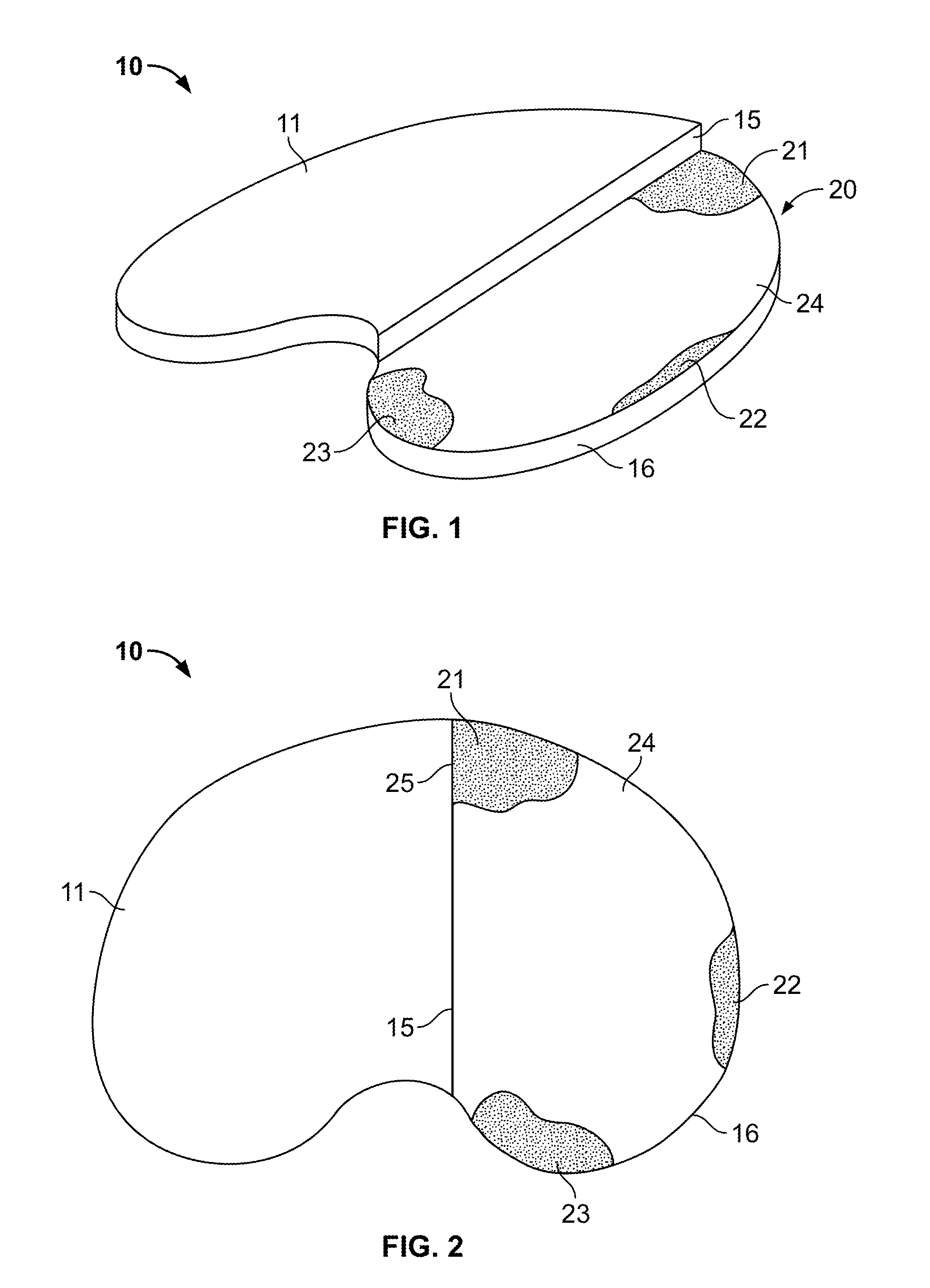

An endoluminal prosthesis is provided with an improved fixation system for coupling the endoluminal prosthesis to an inner wall of a lumen and to reduce distal migration. According to an embodiment of the present invention, a laterally protruding member atraumatically engages the ostium of a side or branch vessel. The protruding member may be fixed to a portion of a prosthesis. In one embodiment the protruding member is provided on a modular fixation device for initial fixation within the body lumen with the finger member within the side or branch vessel. A primary endoluminal prosthesis is then fixed to the modular fixation device to bypass a diseased portion of the anatomy.

Owner:MEDTRONIC VASCULAR INC

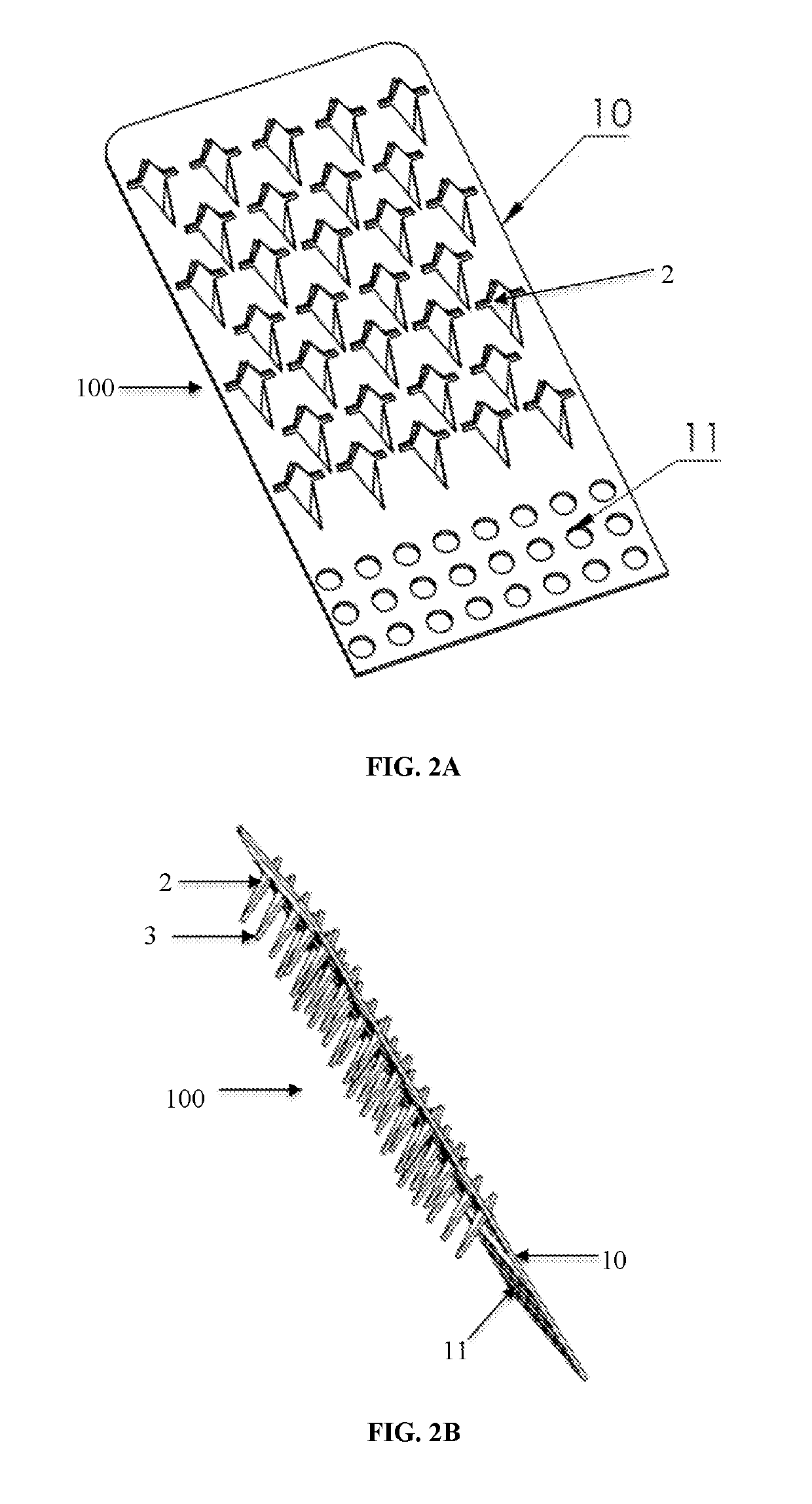

Bone pads

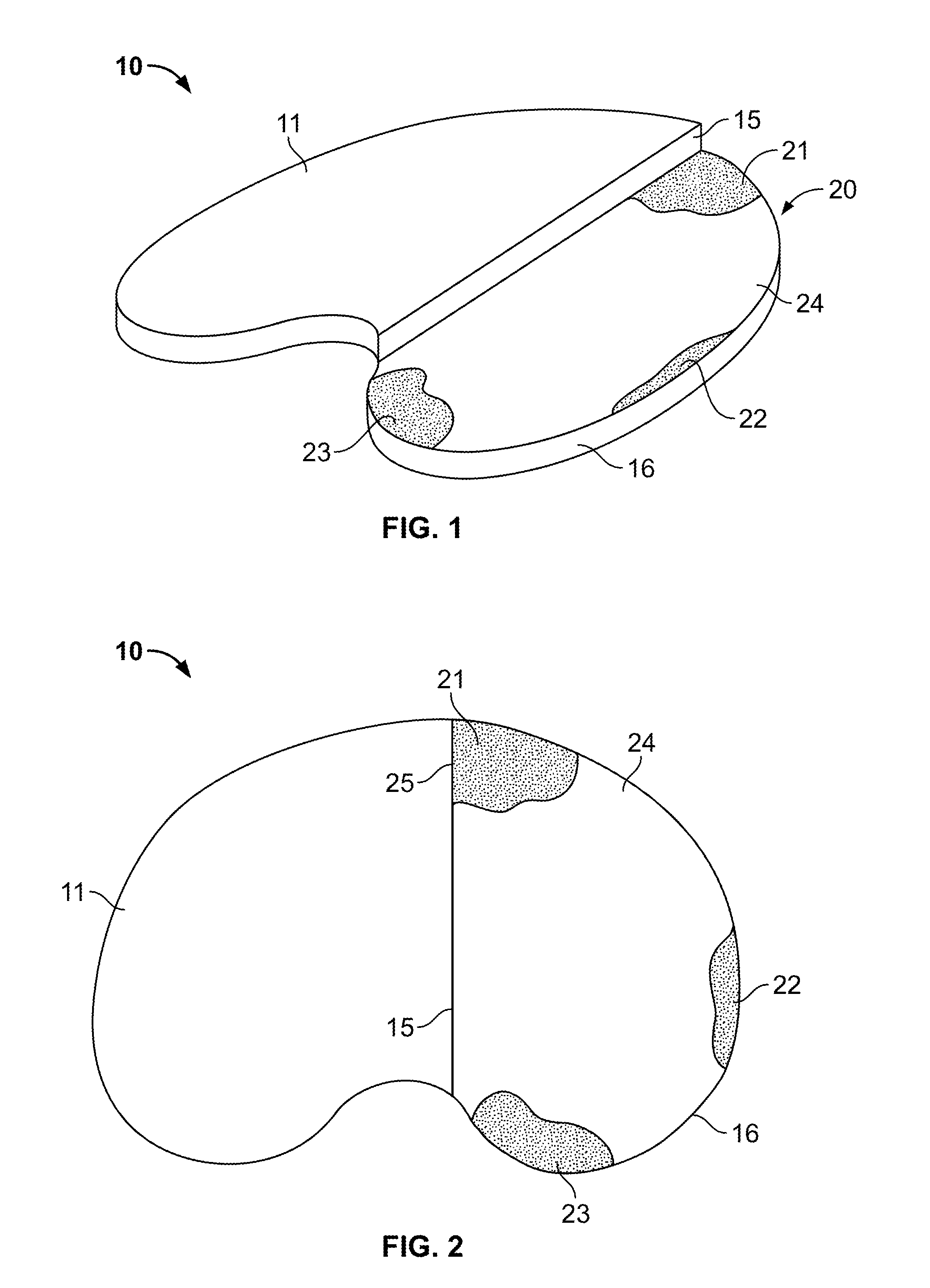

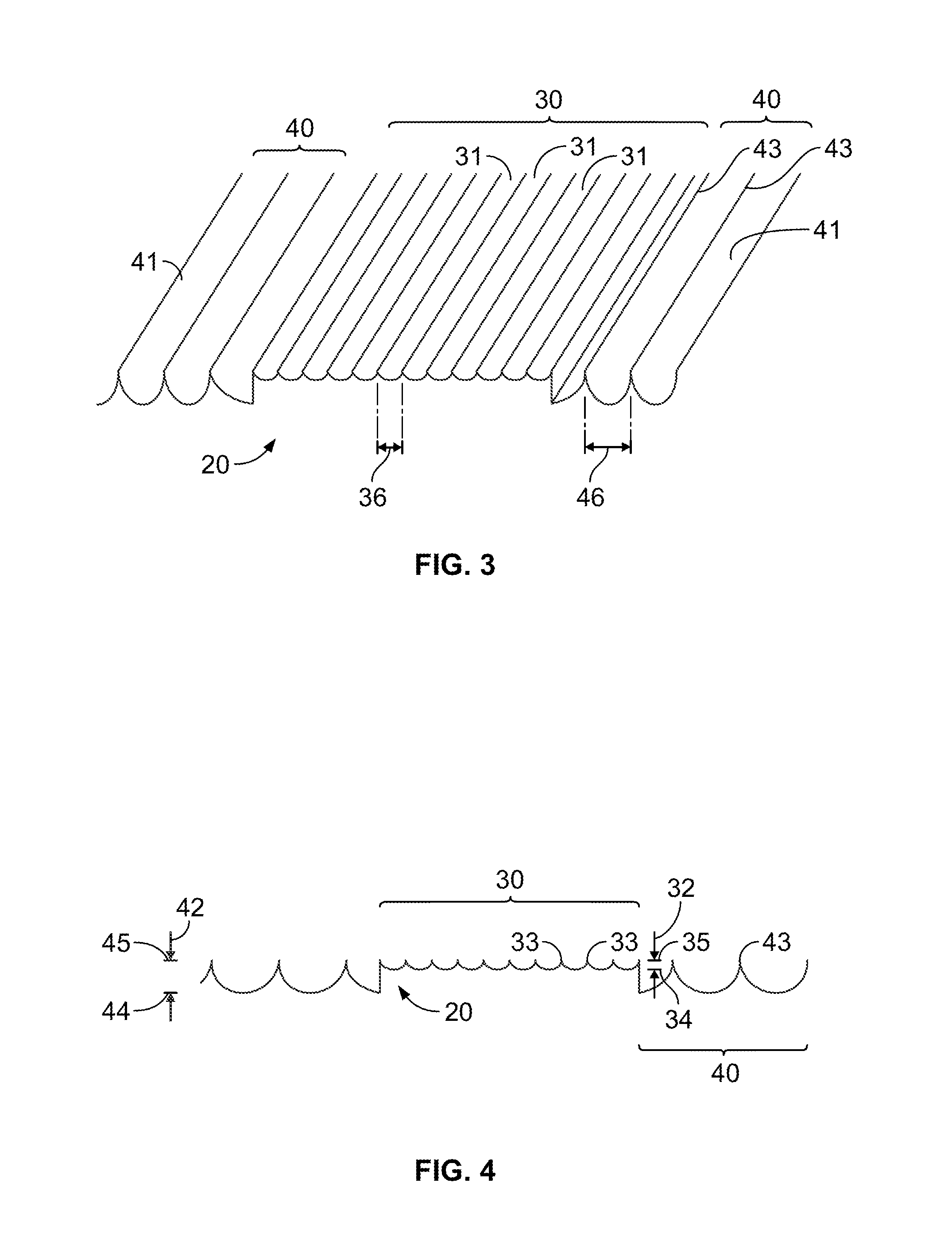

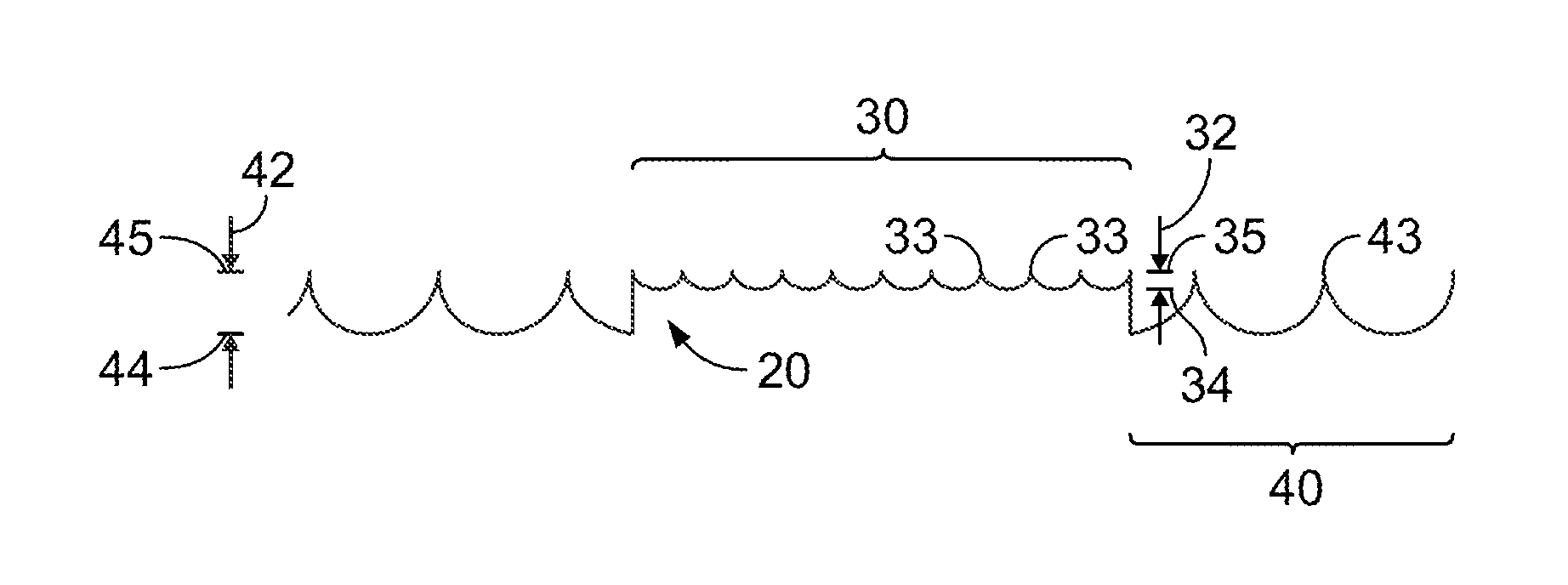

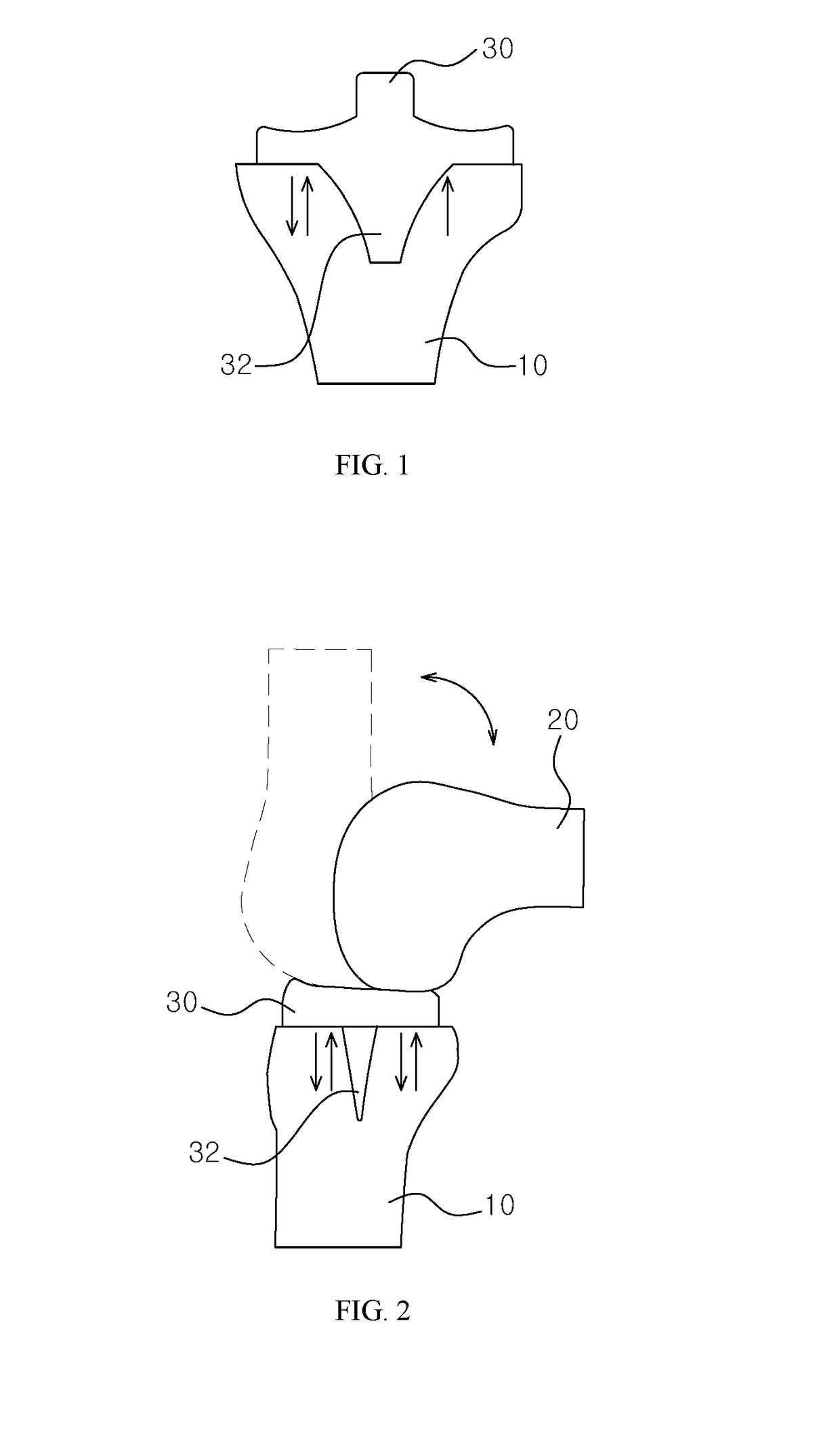

ActiveUS20140257293A1Accurate tolerance profileEasy to fixSurgeryJoint implantsArticular surfacesArticular surface

Disclosed herein are systems and methods for bone preparation with designed areas having accurate tolerance profiles to enable improved initial fixation and stability for cementless implants and to improve long-term bone ingrowth / ongrowth to an implant. A method of preparing a bone surface to receive a prosthetic implant thereon having an articular surface and a bone contacting surface includes resecting the bone surface at a first location to create a first resected region having a first tolerance profile with a first cross-section, resecting the bone surface at a second location to create a second resected region having a second tolerance profile with a second cross-section less dense than the first cross-section, and contacting the bone contacting surface of the prosthetic implant with the first resected region.

Owner:STRYKER CORP

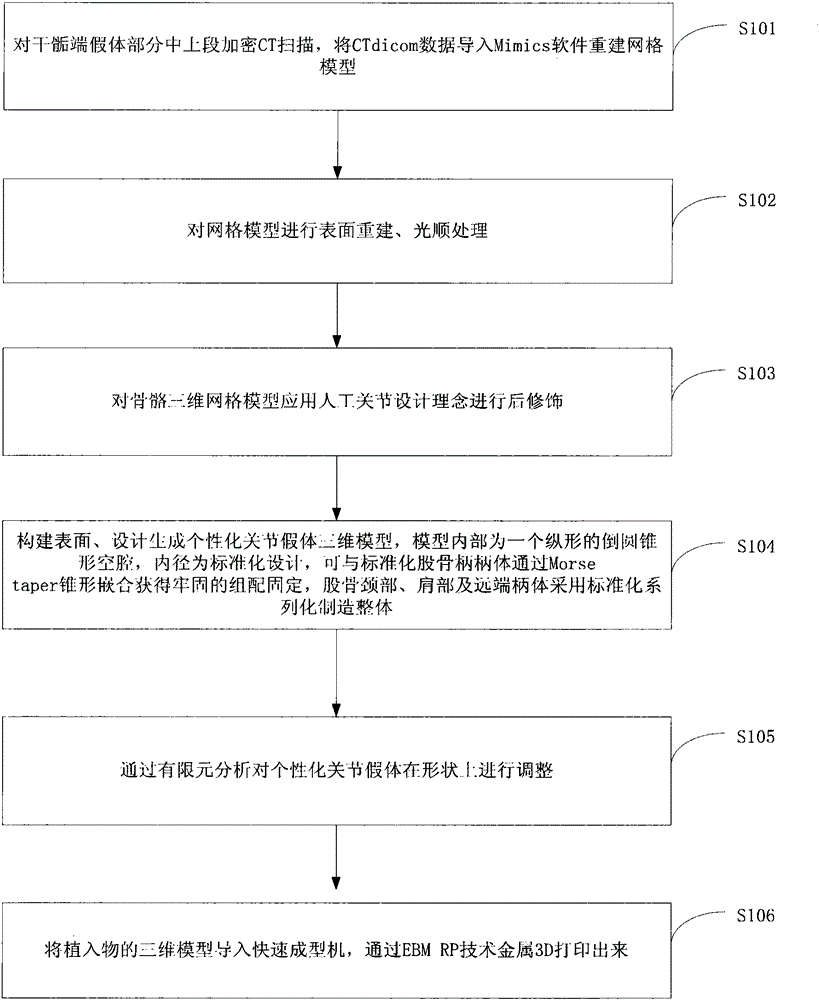

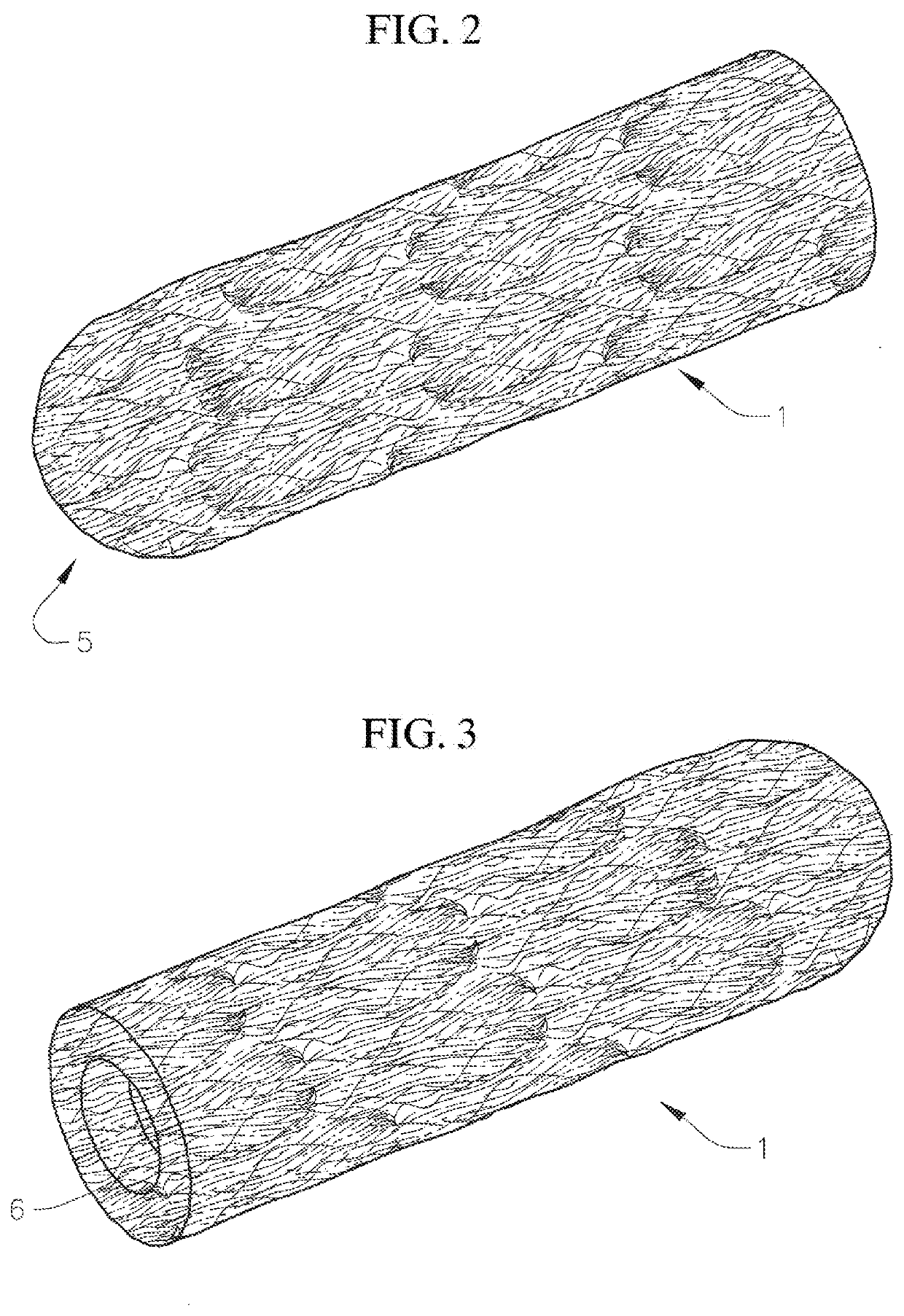

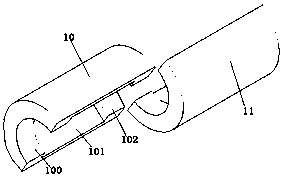

Method for performing EBM metal 3D printing on personalized human body thighbone prosthesis sleeve

InactiveCN105193527AGood initial fixationLong-term biological fixationProsthesisElement analysisBone marrow cavity

The invention discloses a method for performing EBM metal 3D printing on a personalized human body thighbone prosthesis sleeve. The method includes the steps that encrypted CT scanning is performed on the upper middle section of a metaphysis prosthesis part, and CTdicom data are input into Mimics software to reconstruct a grid model; surface reconstruction and smoothing processing are performed on the grid model; post-modification is performed on the bone three-dimensional grid model based on the joint prosthesis design concept; a personalized joint prosthesis three-dimensional model is generated through surface reconstruction and designing; the shape of a personalized joint prosthesis is adjusted through finite element analysis; the three-dimensional model of the implant is input into a rapid prototyping machine and printed through EBM RP technology metal 3D printing. The shape of the printed and manufactured finished product can be completely matched with that of the medullary cavity of the distal femoral metaphysic of every patient, the personalized thighbone prosthesis can be knocked to be implanted just through a few intra-operative medullary cavity files, and good initial fixation and long-time biological fixation can be achieved.

Owner:刘宏伟 +2

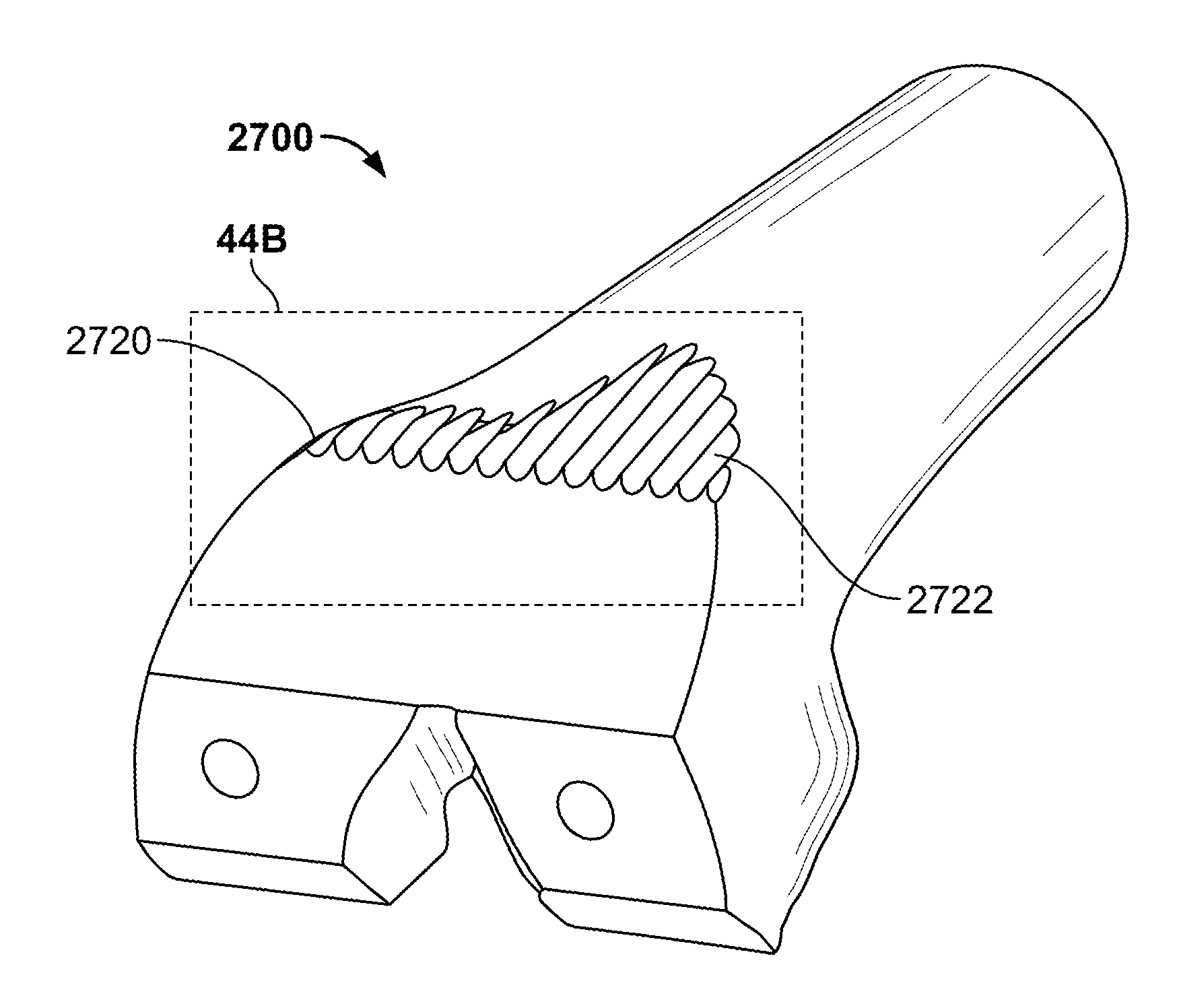

Bone pads

ActiveUS9427334B2Easy to fixImprove stabilitySurgeryJoint implantsArticular surfacesArticular surface

Disclosed herein are systems and methods for bone preparation with designed areas having accurate tolerance profiles to enable improved initial fixation and stability for cementless implants and to improve long-term bone ingrowth / ongrowth to an implant. A method of preparing a bone surface to receive a prosthetic implant thereon having an articular surface and a bone contacting surface includes resecting the bone surface at a first location to create a first resected region having a first tolerance profile with a first cross-section, resecting the bone surface at a second location to create a second resected region having a second tolerance profile with a second cross-section less dense than the first cross-section, and contacting the bone contacting surface of the prosthetic implant with the first resected region.

Owner:STRYKER CORP

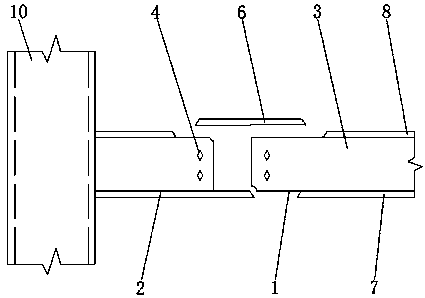

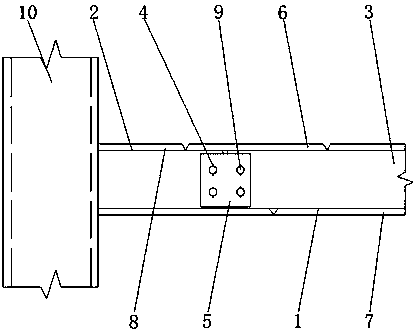

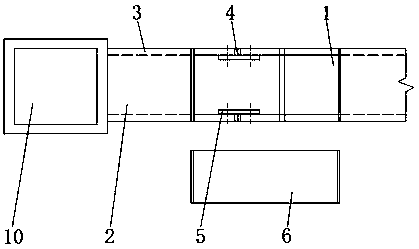

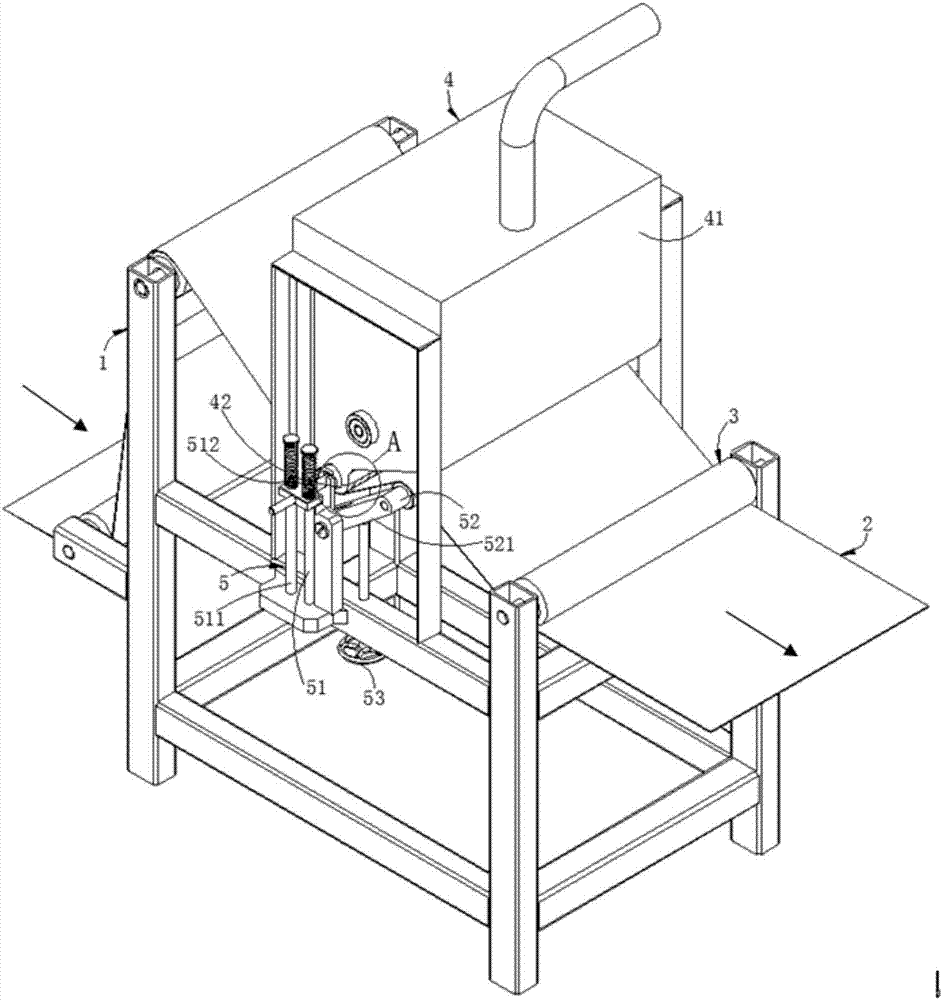

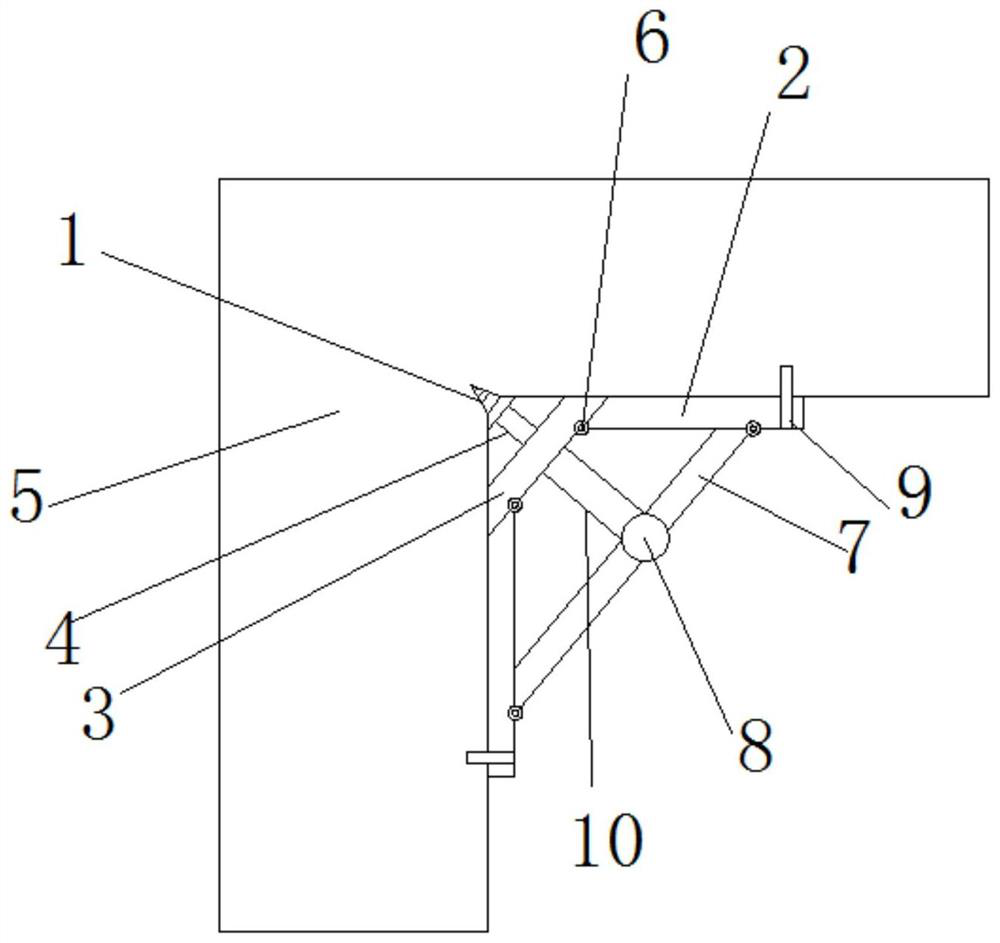

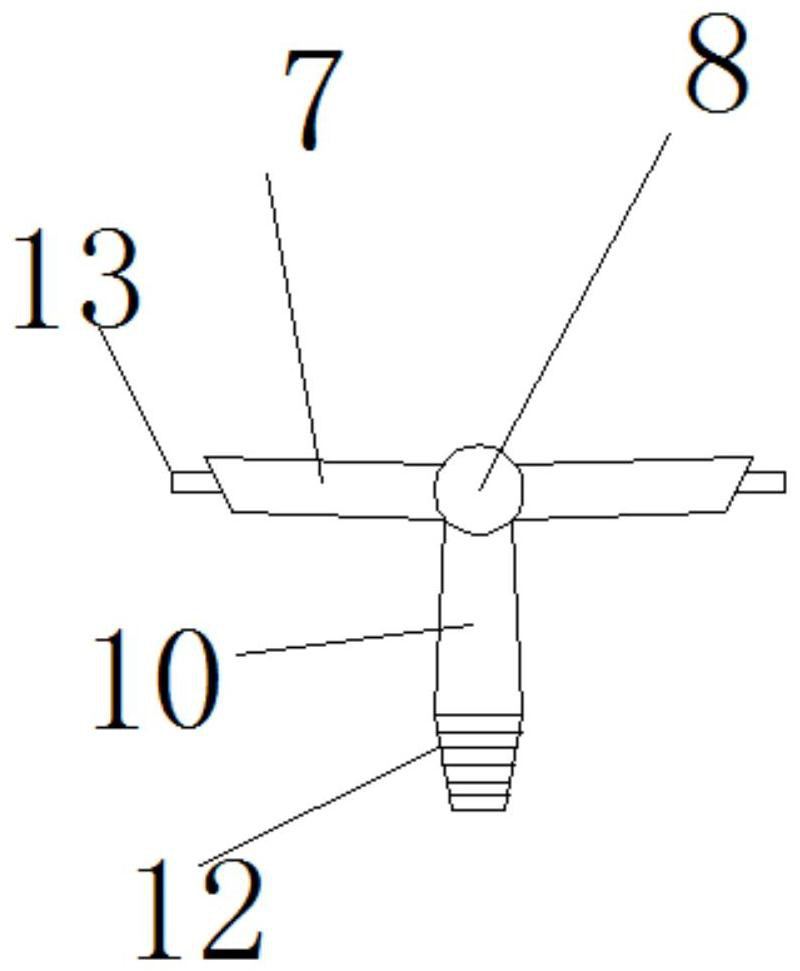

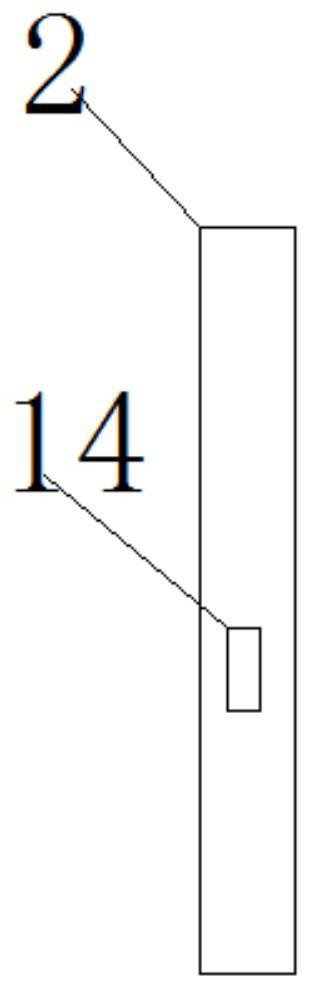

Steel structure box beam connection joint assembling device and an assembling method thereof

InactiveCN109024222AGuaranteed connection qualityReduce labor intensityBridge erection/assemblyShaped beamSpot welding

The invention discloses a steel structure box girder connection node assembling device, Including box girder, box corbel, Webs, connecting plates and mounting bolts, The box girder and the web of thebox corbel are provided with mounting bolt holes adapted to the connecting plate and the mounting bolts, and the connecting plate is arranged on the inner side of the web, and the top and bottom of the box girder and the top and bottom of the box corbel are respectively welded with an upper flange plate and a lower flange plate, which relate to the technical field of construction. A method for assemble that connecting joint of the steel structure box gird it avoids that the positioning of the connection between the corbel and the box girder depends on the skill level and experience of the operator, After temporary positioning, local adjustment is carried out by means of crowbars and other tools, and initial fixation is carried out by spot welding, so as to ensure the connecting quality ofthe box-shaped corbel and the box-shaped beam, thereby preventing the groove assembly size of the connecting joint and the integral welding quality from being affected, and facilitating the weld formation of the lower flange plate at the same time.

Owner:湖南金海集团有限公司

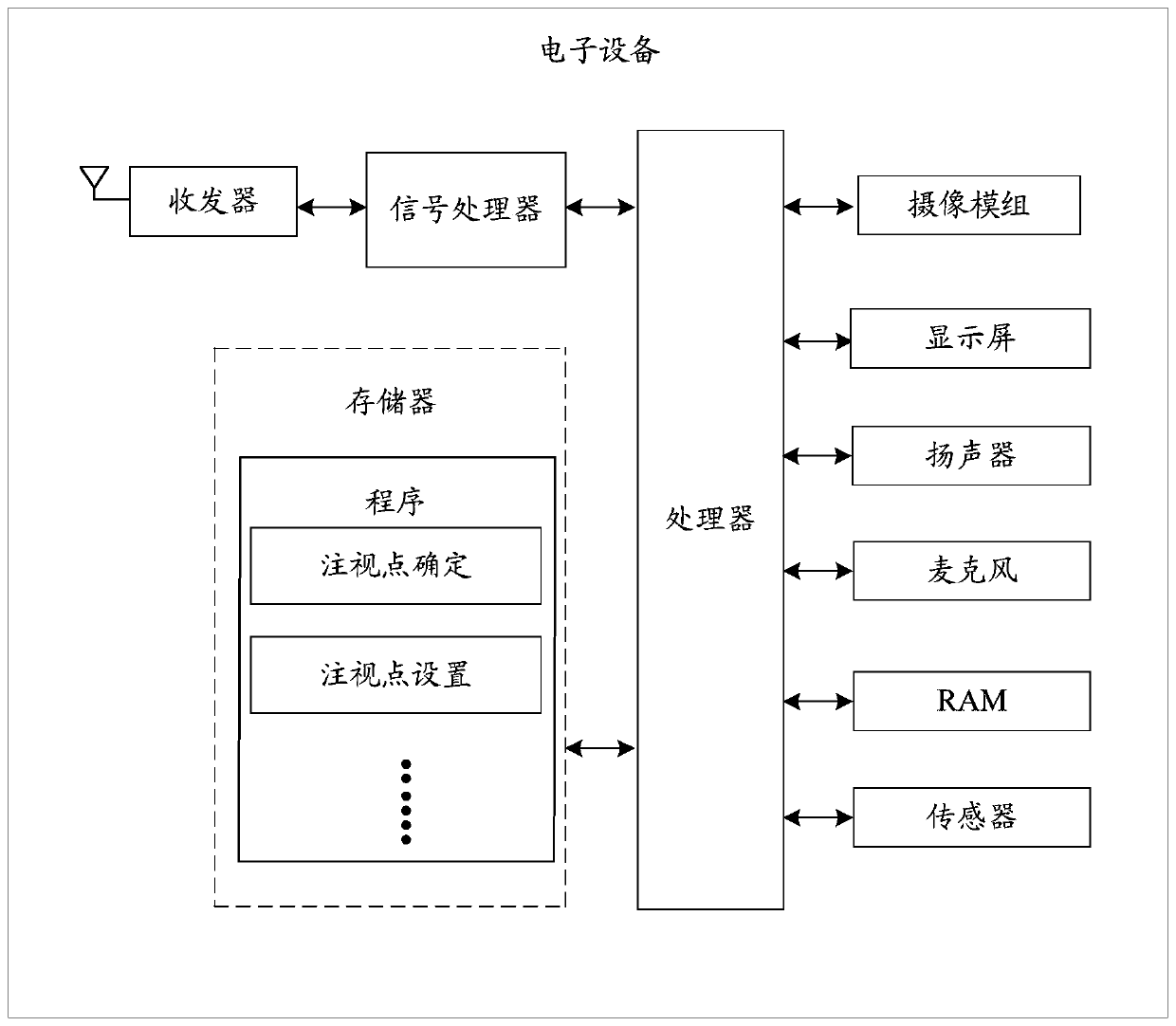

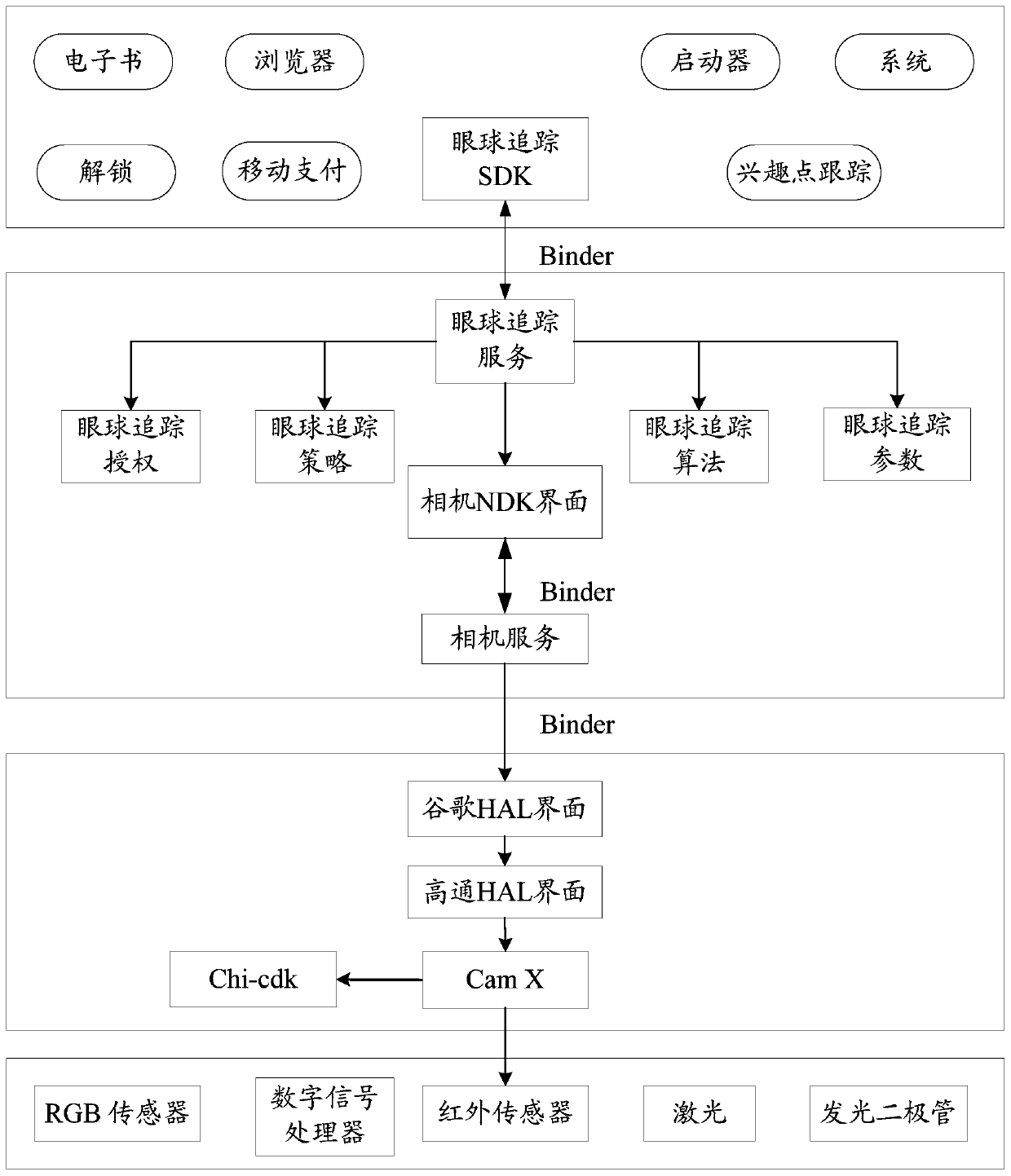

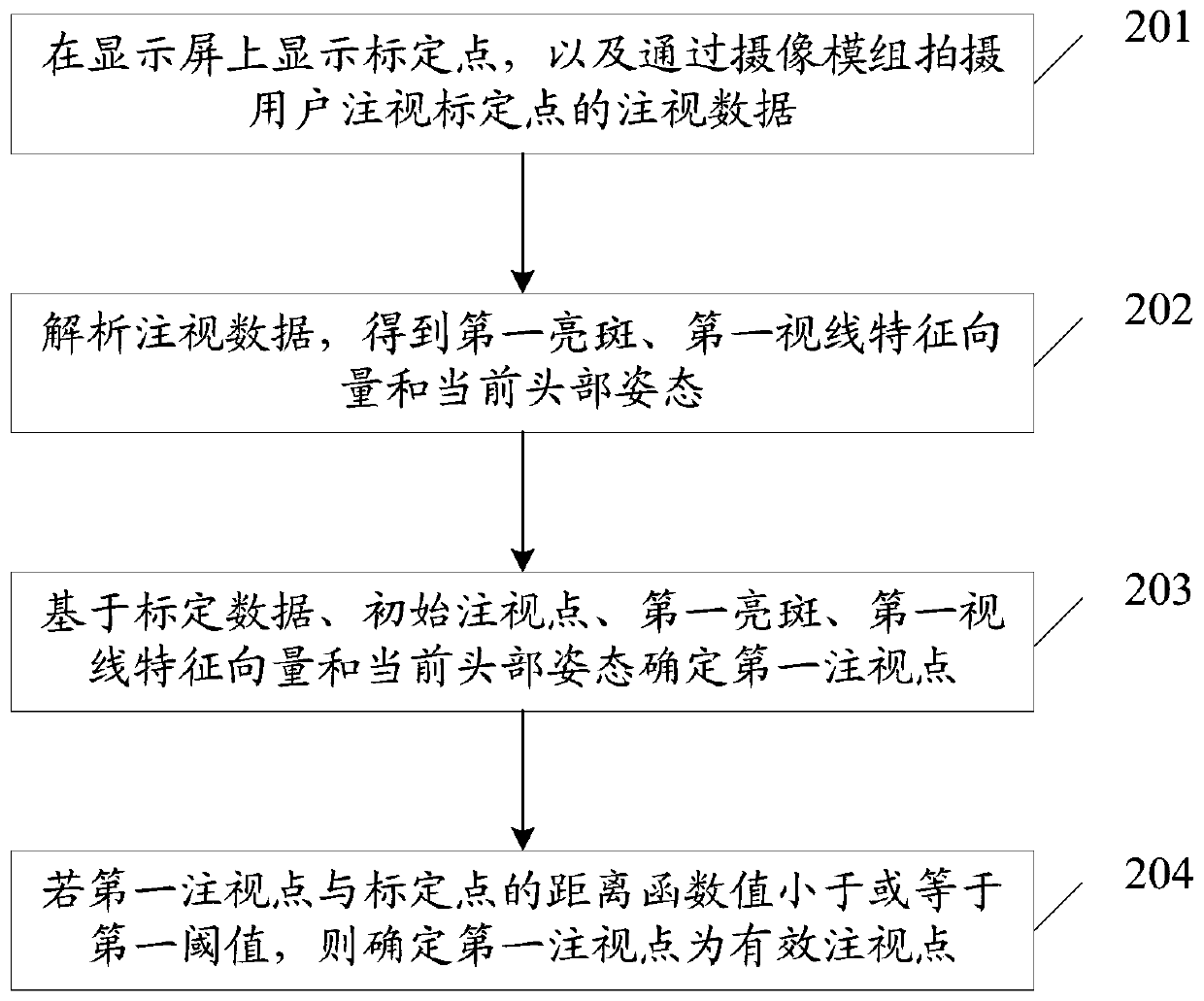

Fixation point calibration method and related equipment

ActiveCN110568930AImprove accuracyInput/output for user-computer interactionGraph readingFeature vectorFixation point

The invention discloses a fixation point calibration method and related equipment, applied to an electronic device. The electronic device comprises a display screen and a camera module, and the methodcomprises the following steps: displaying a calibration point on the display screen, and shooting fixation data of a user for fixation at the calibration point through the camera module; analyzing the fixation data to obtain a first bright spot, a first sight line feature vector and a current head posture; determining a first fixation point based on calibration data, an initial fixation point, the first bright spot, the first sight line feature vector and the current head posture; and if the function value of the distance between the first fixation point and the calibration point is smaller than or equal to a first threshold value, determining the first fixation point as an effective fixation point. By adoption of the embodiment of the invention, the accuracy of the fixation point function can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

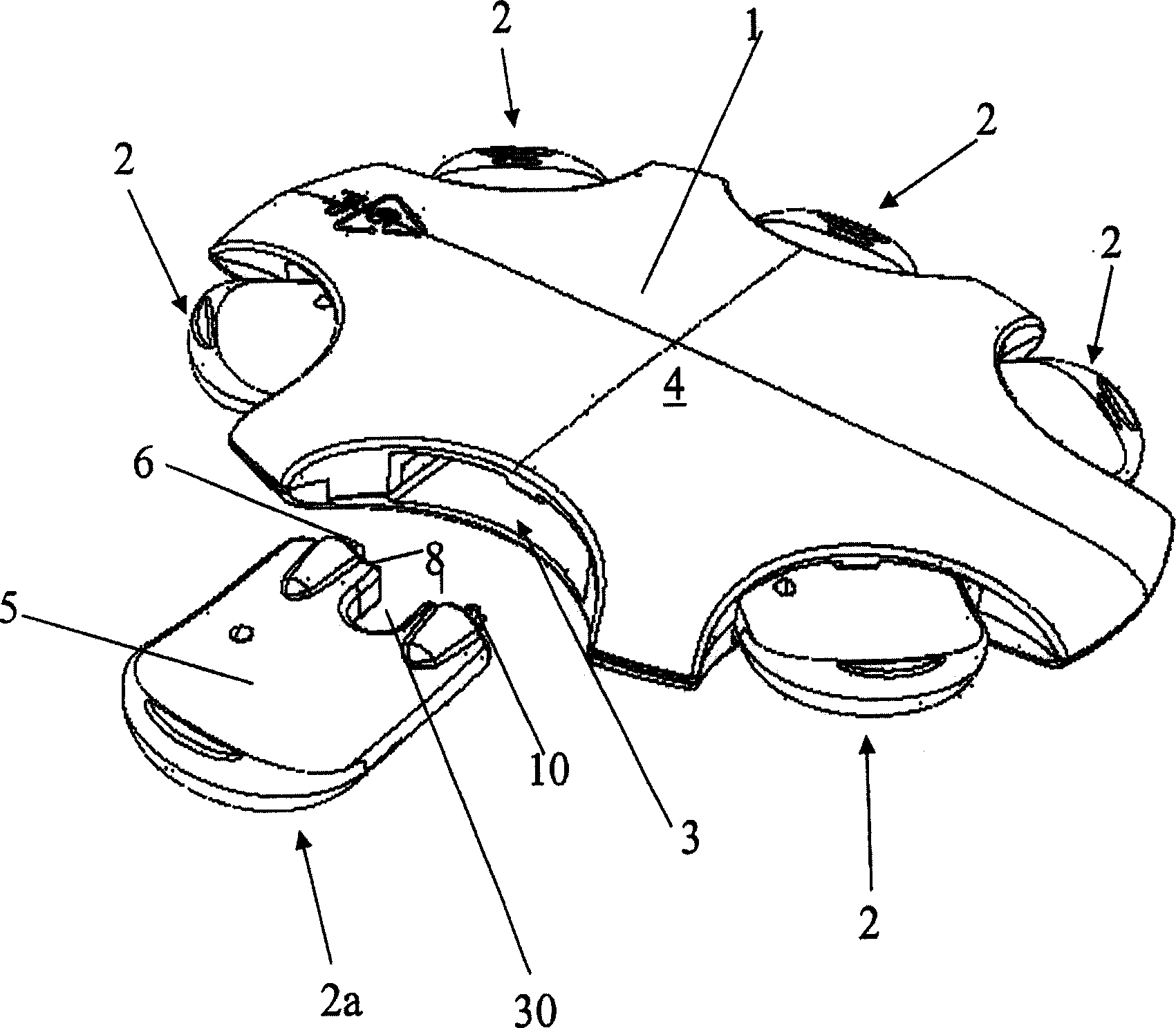

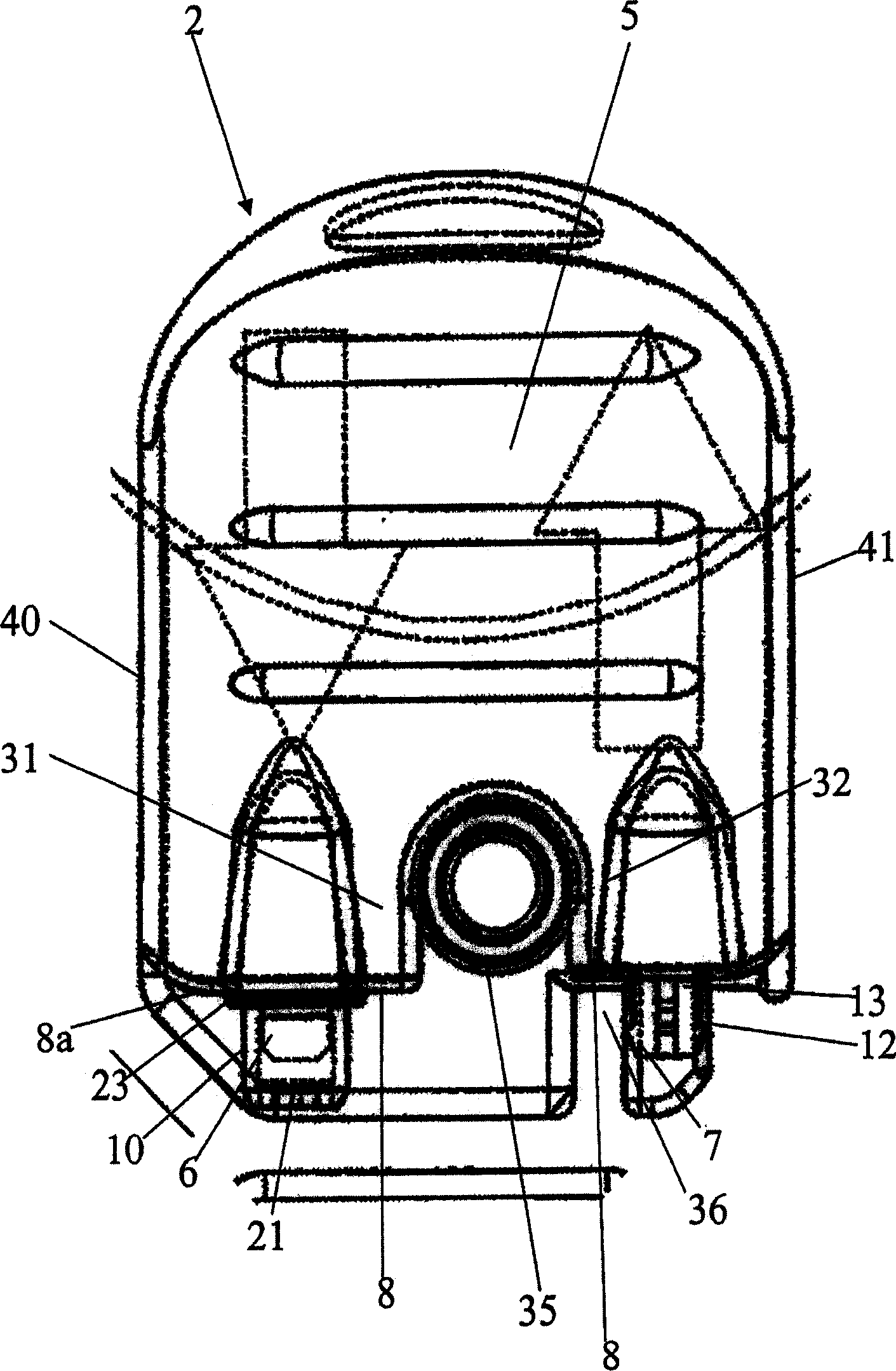

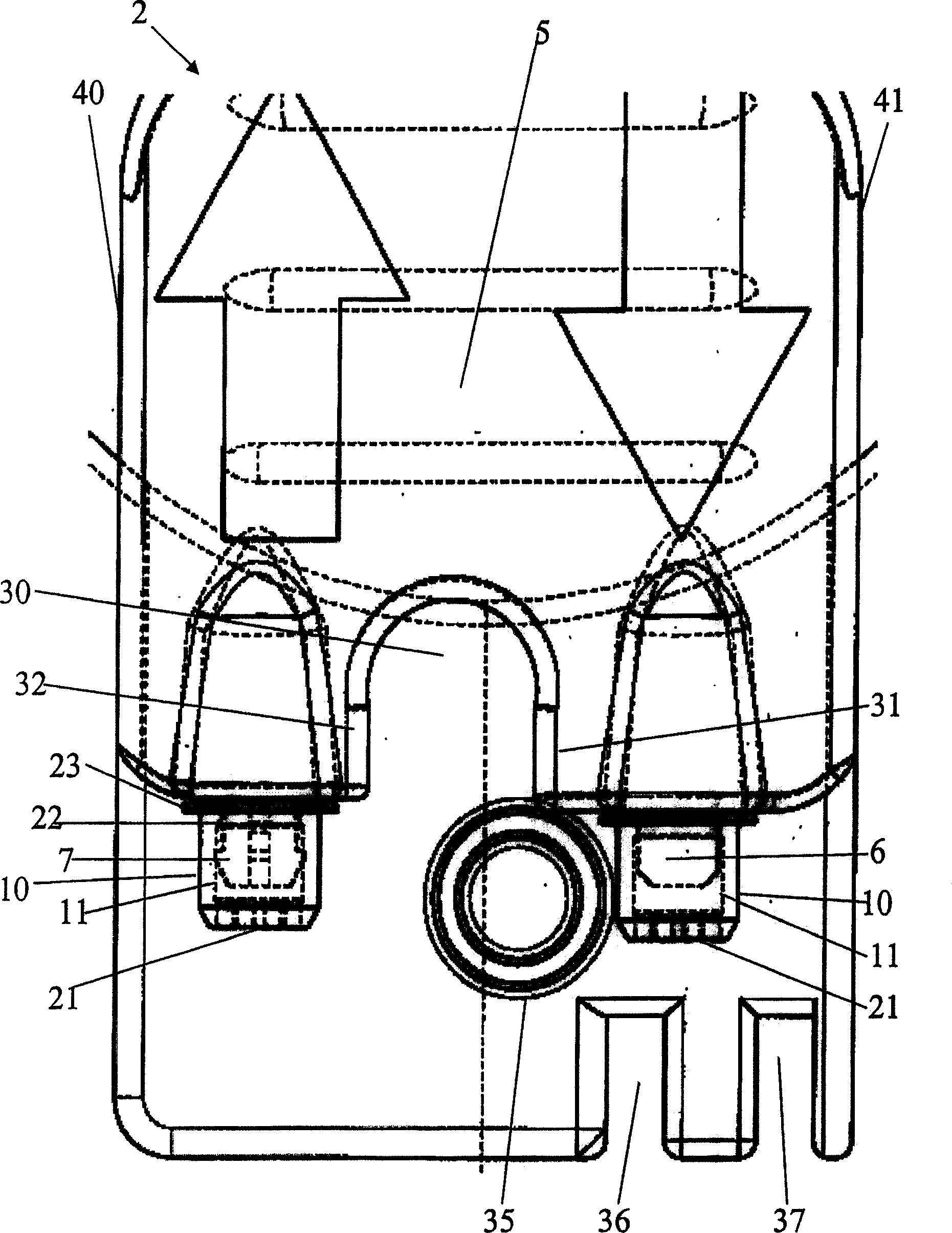

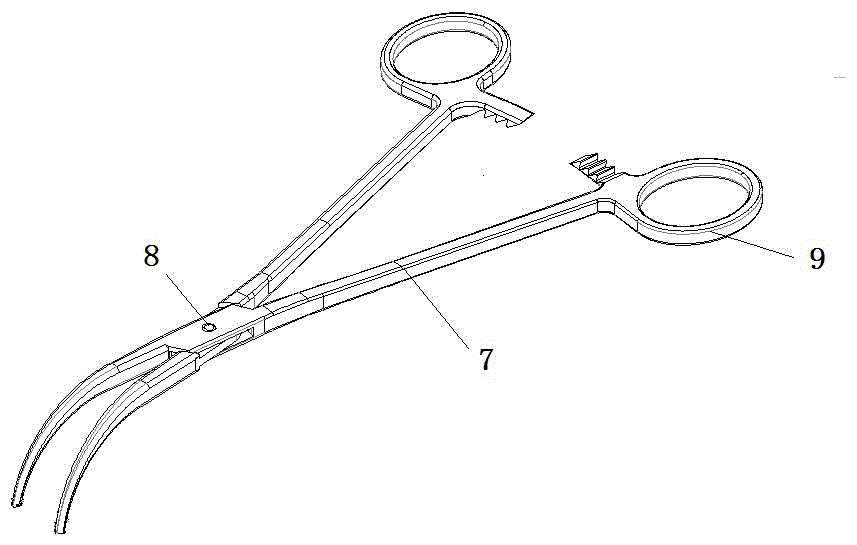

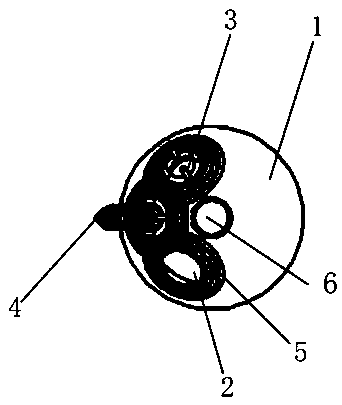

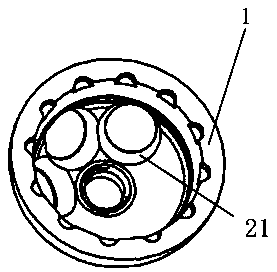

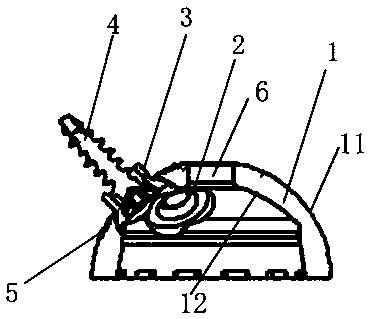

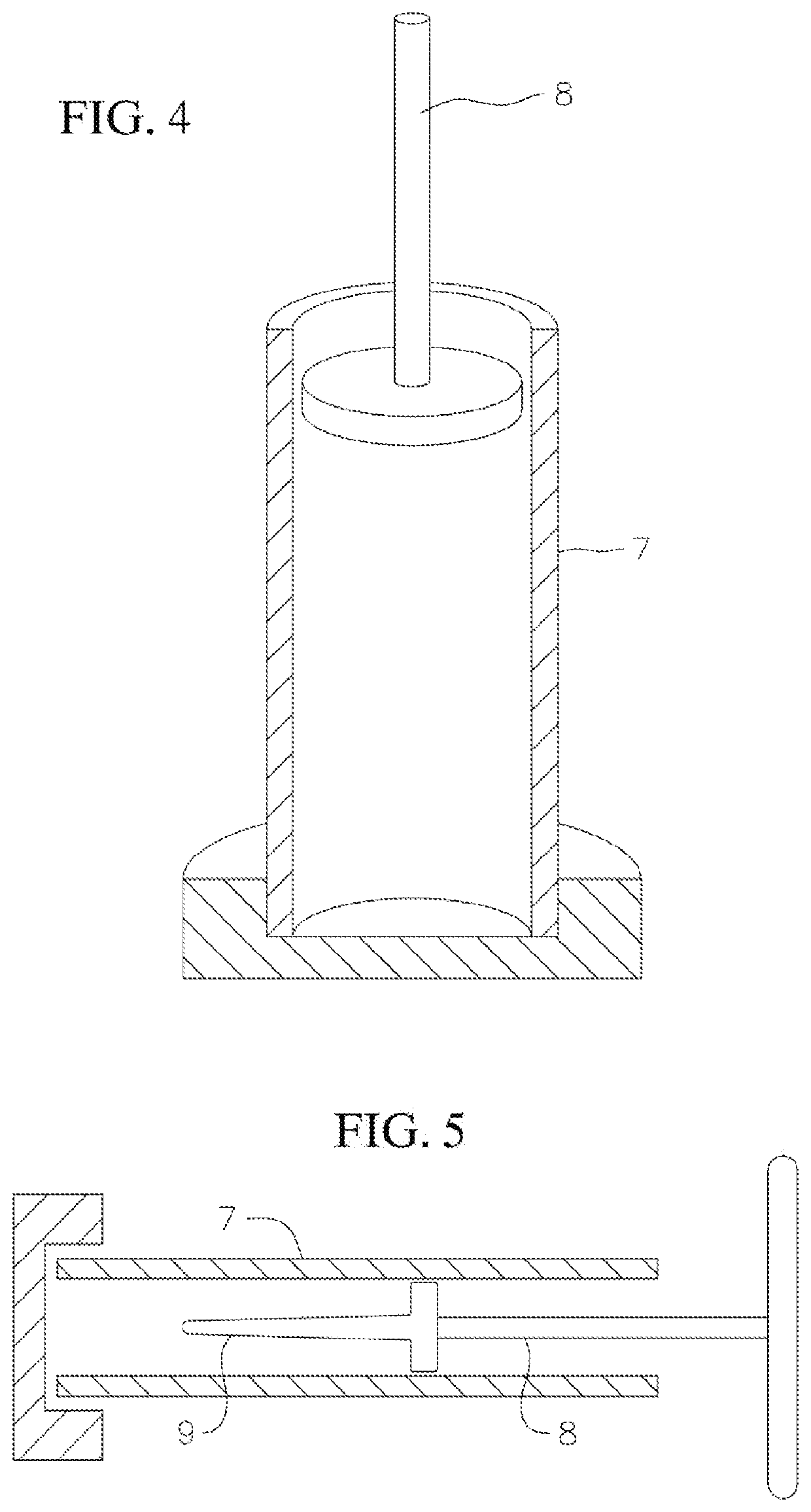

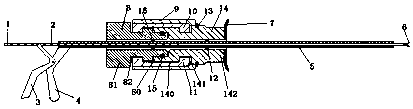

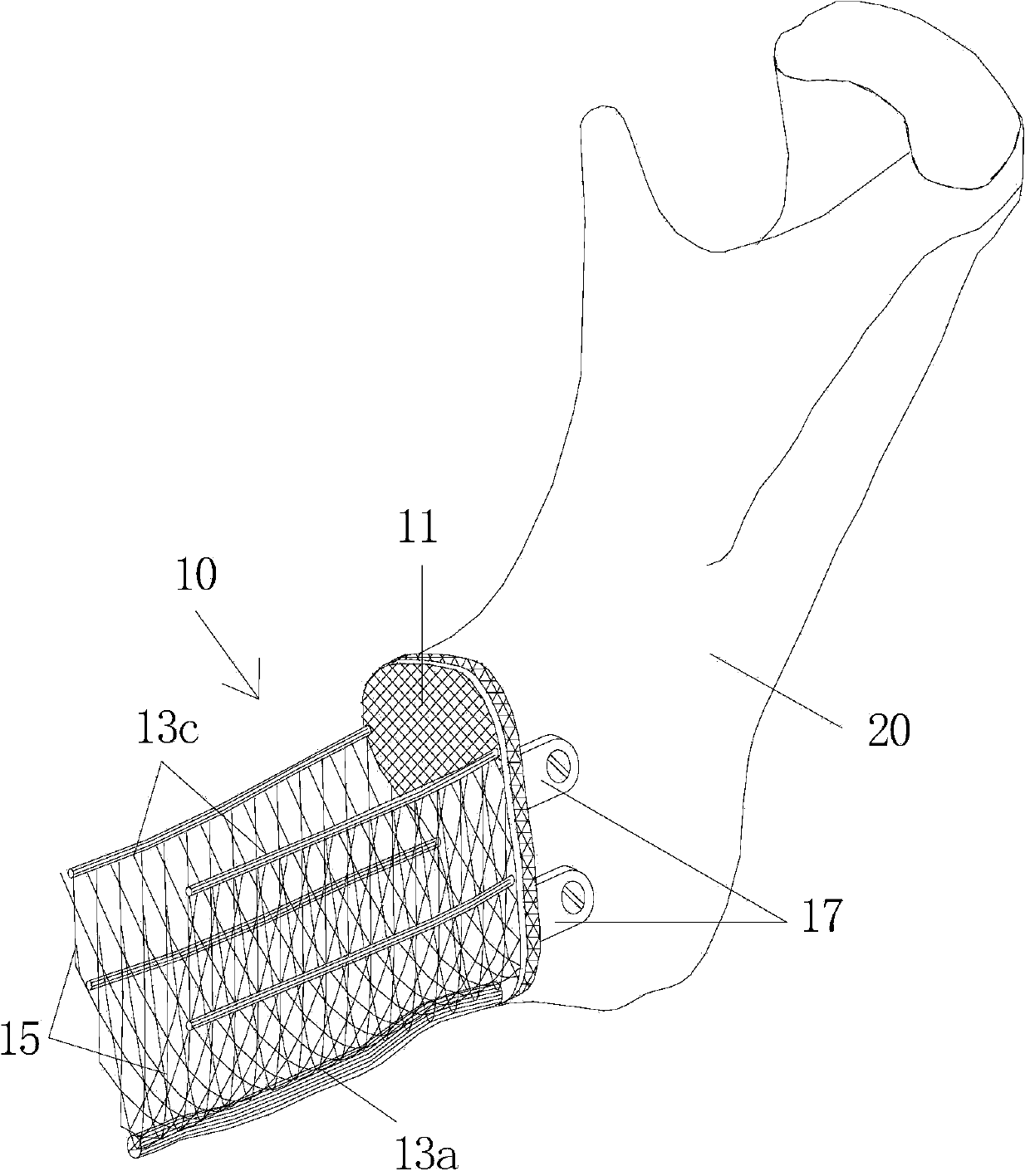

Filter manipulator, filter, holder for a number of filter manipulators, and system comprising a filter manipulator and a holder for a filter manipulator

The present invention includes filter manipulation devices, filters, holders for a plurality of filter manipulation devices, and systems comprising a filter manipulation device and its holder. The system comprises a filter handling device and a holder for the filter handling device, wherein the handling device has a first tool part for initially securing and subsequently releasing a filter in the sound outlet tube or vent outlet of the hearing aid. new filter, the operating device also includes a second tool part adapted to receive and fix the used filter, the operating device also includes a clamping part that can be grasped by the user, and wherein the first and second tool parts are installed side by side and Protruding from an edge portion of the clamping portion in substantially the same direction, wherein the support for the handling device comprises at least one recess for receiving at least the edge portion of the handling device, which secures the two tool parts.

Owner:OTICON

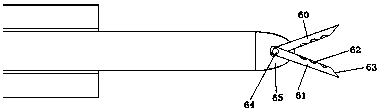

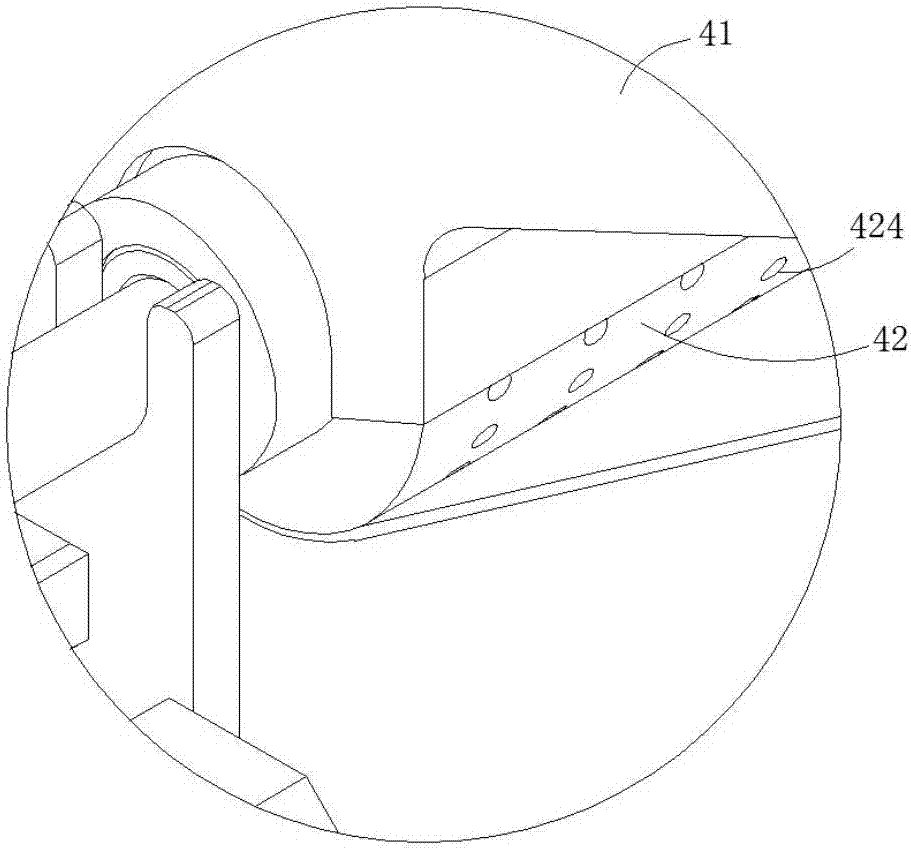

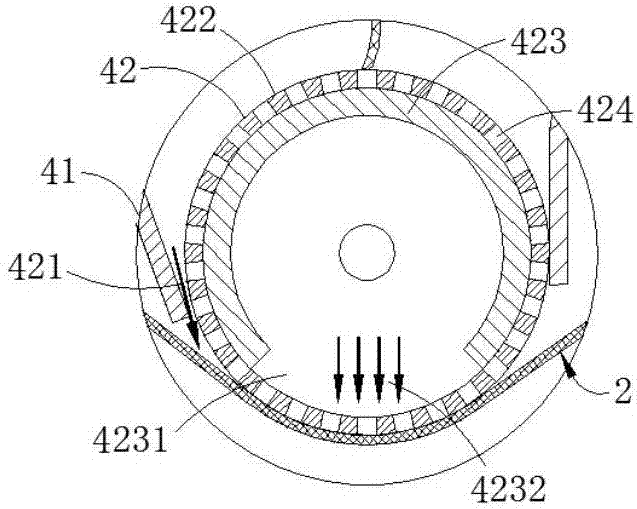

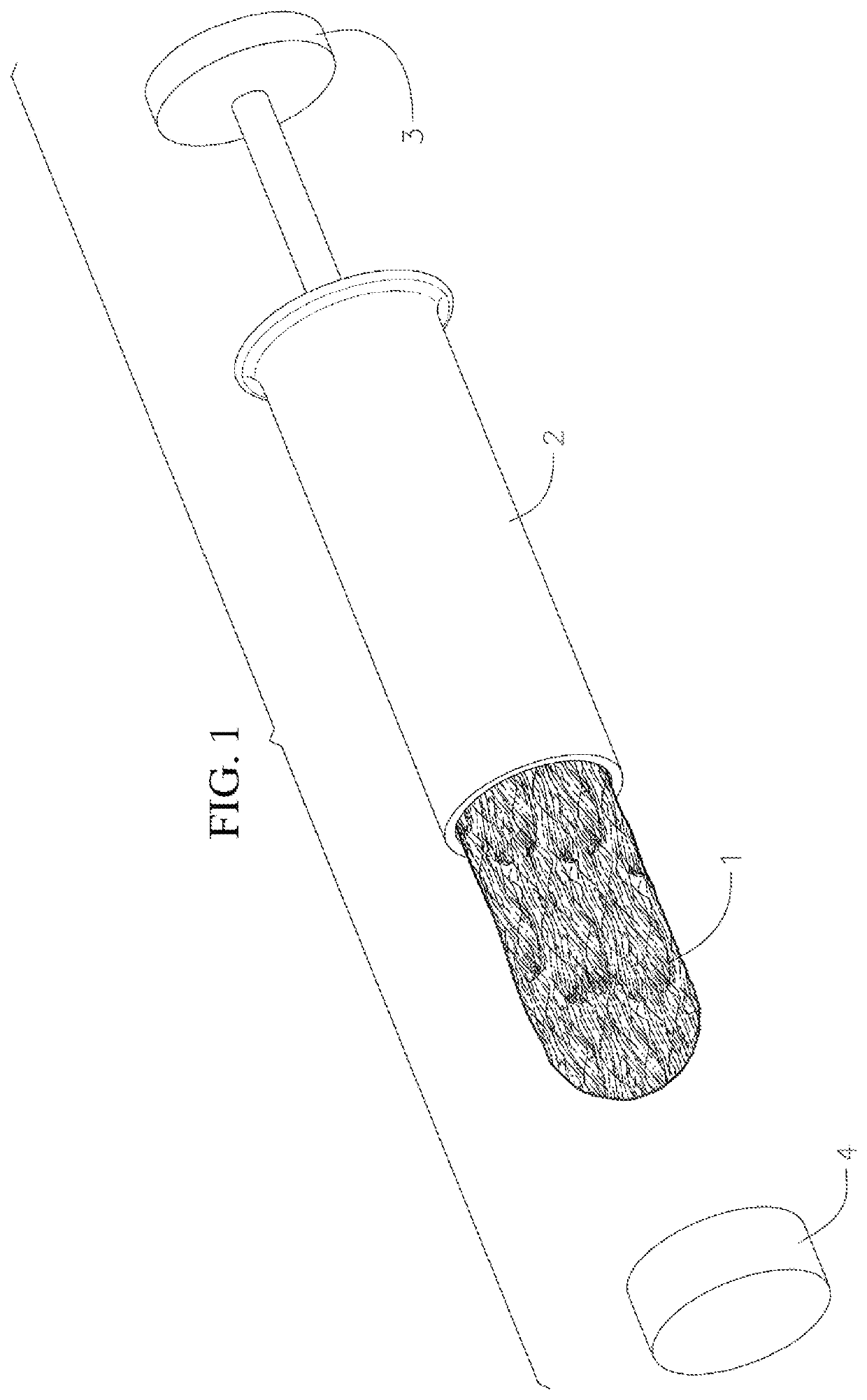

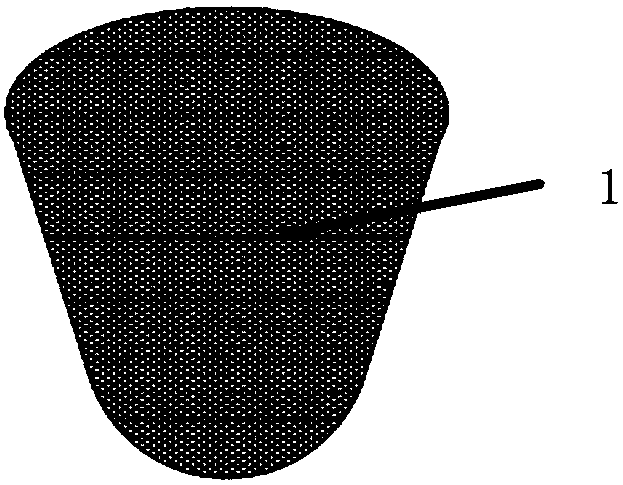

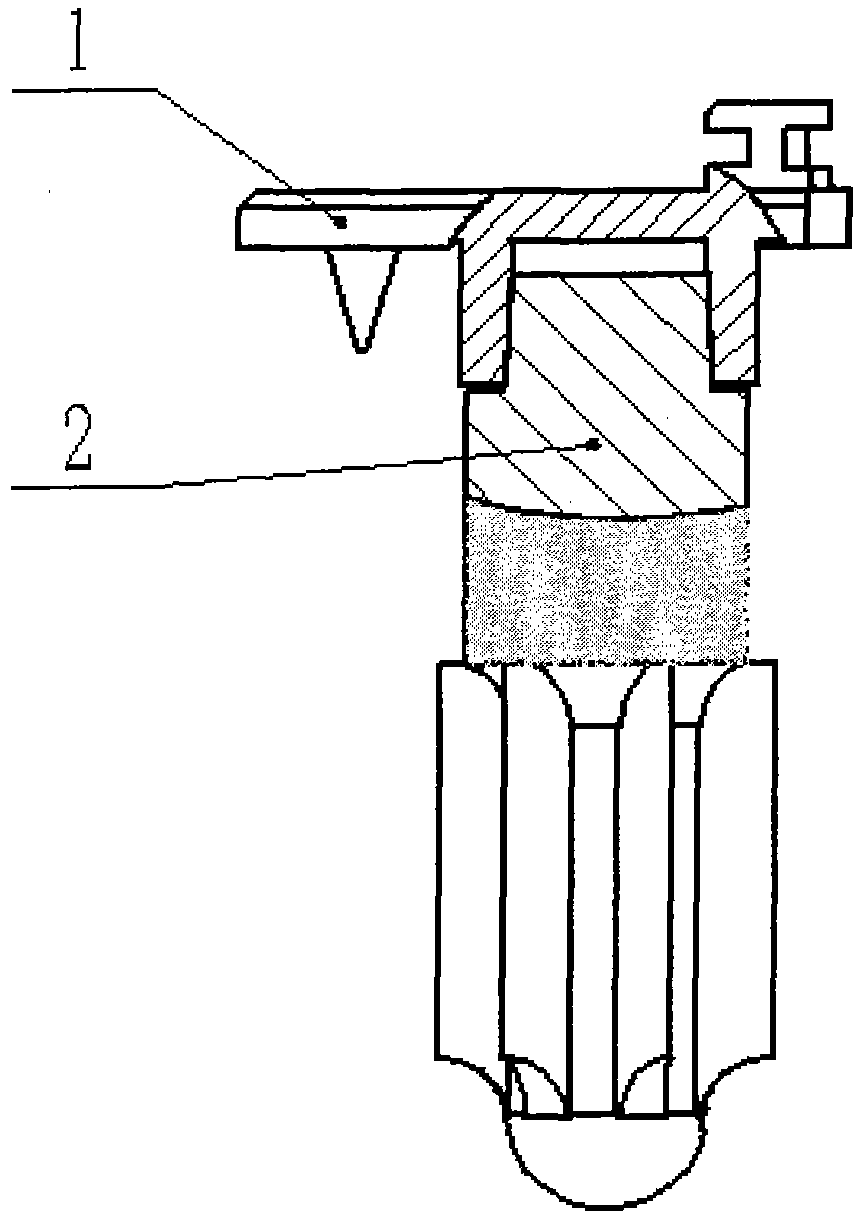

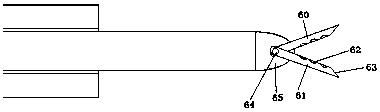

Pathological sampling device

ActiveCN107796650AEasy to sampleAccurate samplingWithdrawing sample devicesComputer scienceInitial fixation

The invention discloses a pathological sampling device. A sampling body component is an easily-releasable structure, a sampling needle is coaxially nested in a sampling barrel, an end of the samplingneedle is provided with a sampling blade component, and an operating component controls the sampling needle to slidably extend into and out of the sampling barrel along the axis of the sampling barrel. The pathological sampling device allows sampling to be conveniently performed on an affected part; screwing the sampling barrel in proper position according to the affected part is required only forsampling; after initial fixation, the sampling needle is used to sample the affected part; the position of the sampling needle is adjustable so that the pathological sampling device is more applicable; in addition, the sampling body component herein is of easily-releasable structure and is convenient to disassemble and assemble so as to replace the sampling needle; in pathological sampling, replacing the sampling needle is only required; the sampling body component is reusable, replacing efficiency is high, positioning accuracy is good, sampling cost can be greatly reduced, and sampling convenience and accuracy are improved.

Owner:YICHANG CENT PEOPLES HOSPITAL

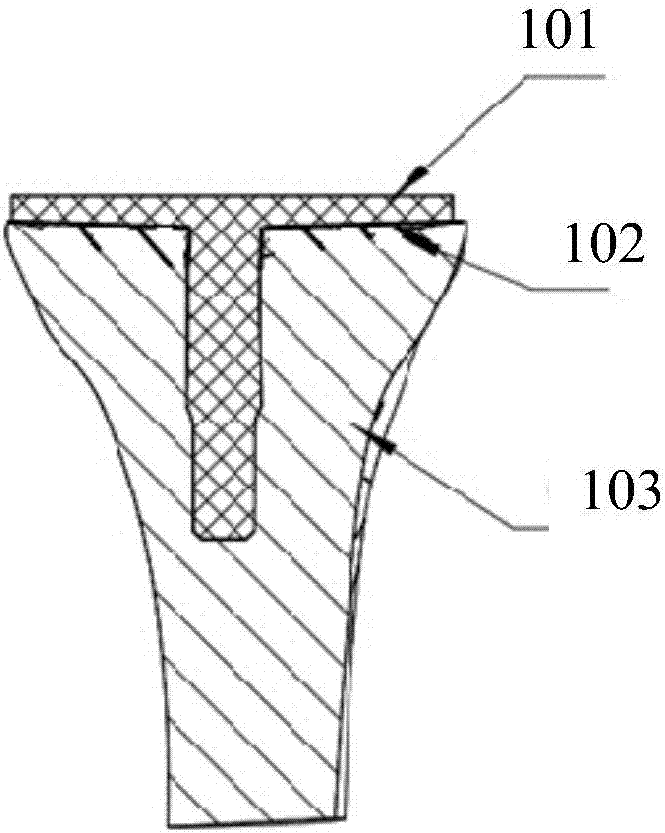

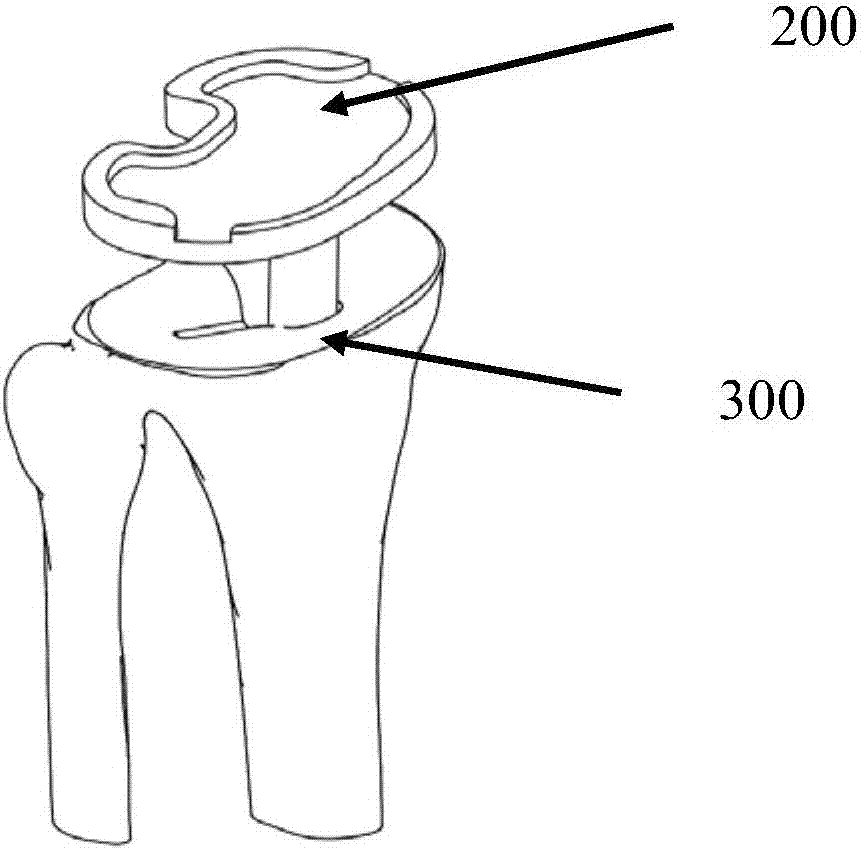

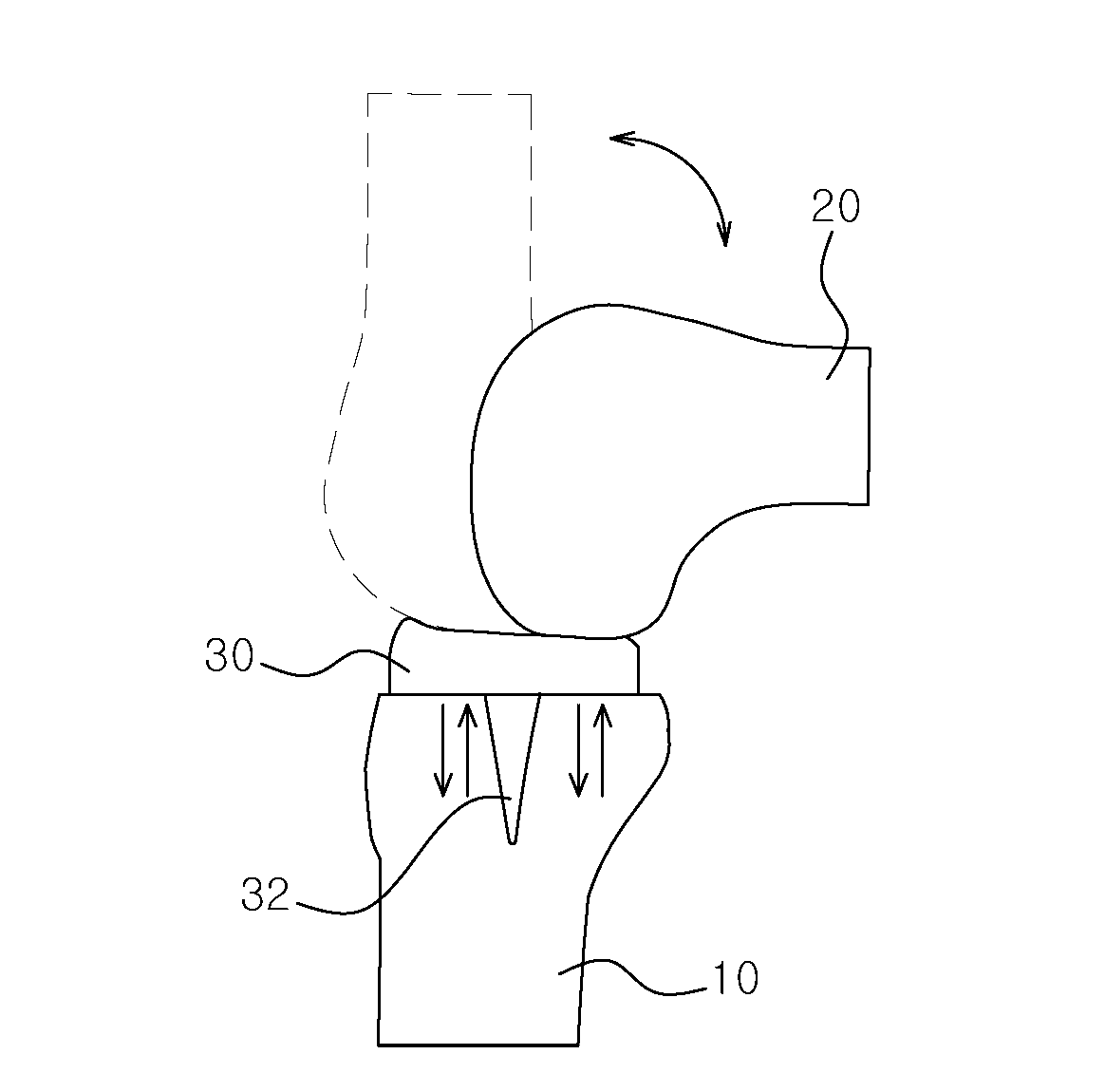

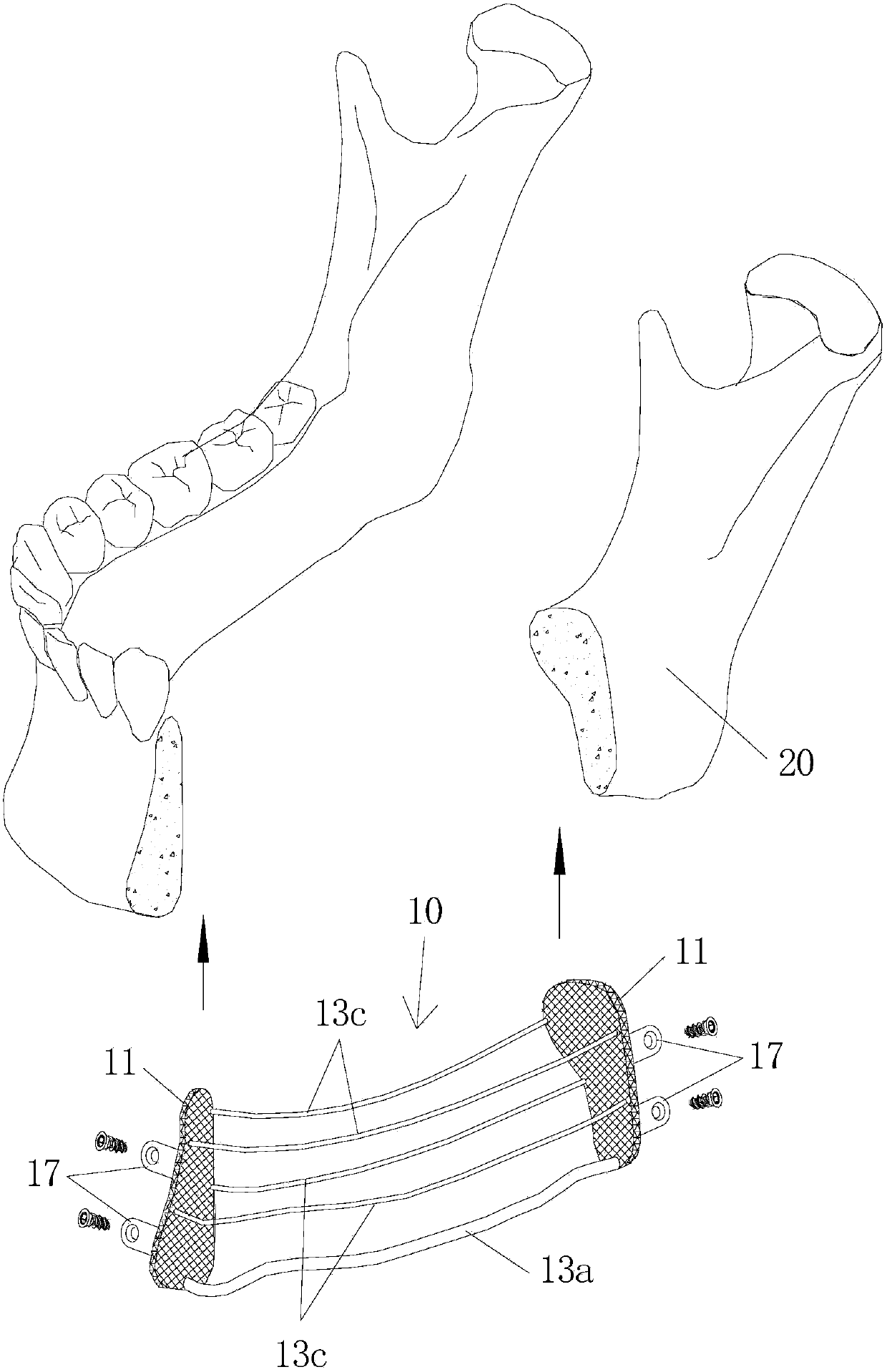

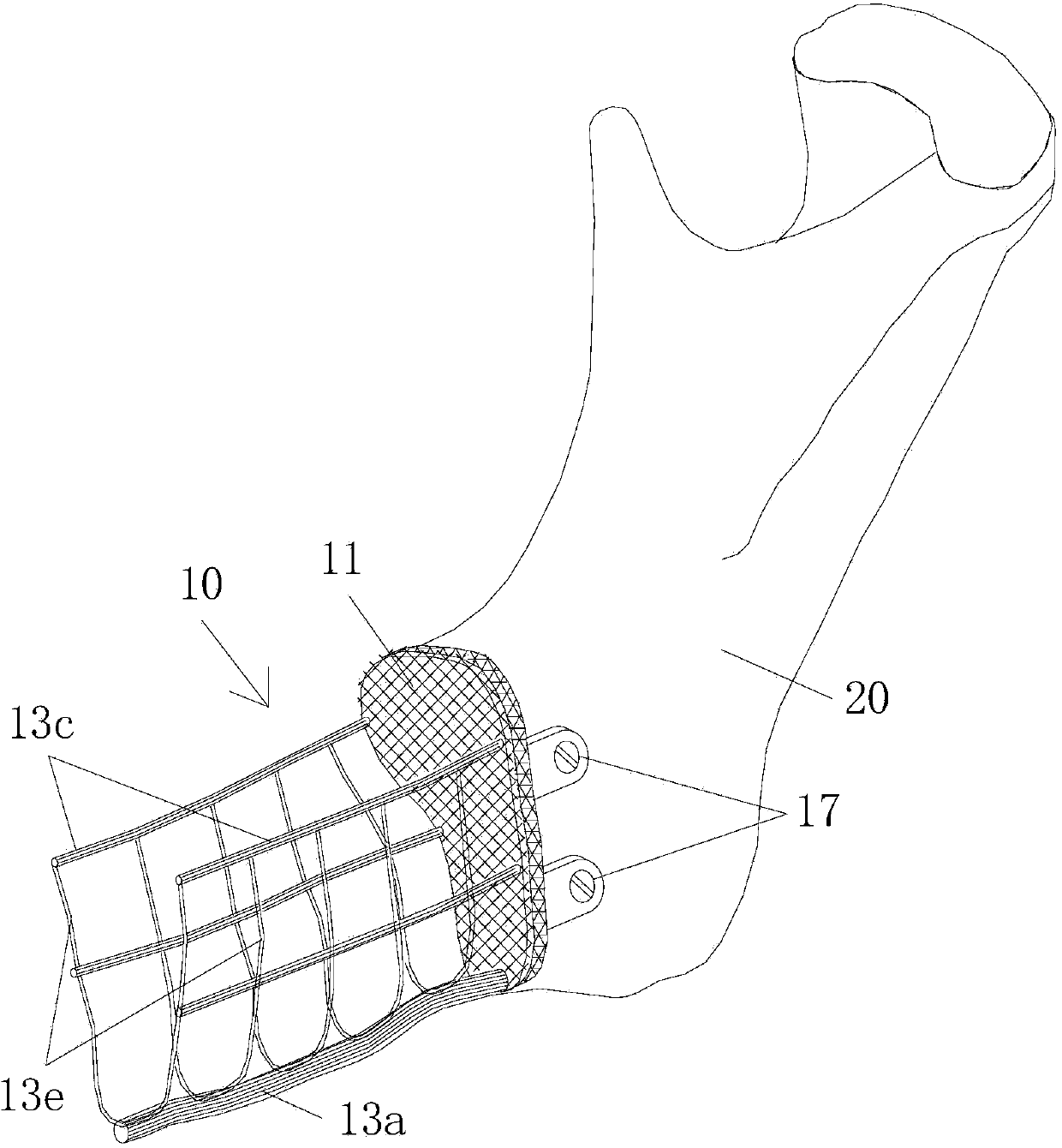

Knee joint tibial component

The invention provides a knee joint tibial component. The knee joint tibial component comprises a contact surface in contact with a tibial resected surface, wherein the contact surface comprises a surface protruded towards the tibial resected surface. The knee joint tibial component provided by the embodiment of the invention is provided with the surface protruded towards the tibial resected surface, therefore, the surface protruded towards the tibial resected surface, of the knee joint tibial component, is in press fit combination with a tibial resected concave surface, the aims of gradually tightening along with pressure increase is achieved, further initial fixation of a product is facilitated, and a better press fit environment is provided; bone ingrowth on a biological fixation coating or a trabecular structure of the knee joint tibial component is realized under the pressure action of endoskeleton and the knee joint tibial component, bone growth is promoted, and finally a biological fixing effect of the bone ingrowth is realized.

Owner:SUZHOU SINOMED BIOMATERIALS CO LTD

Bench vice long in service life

Owner:方敏

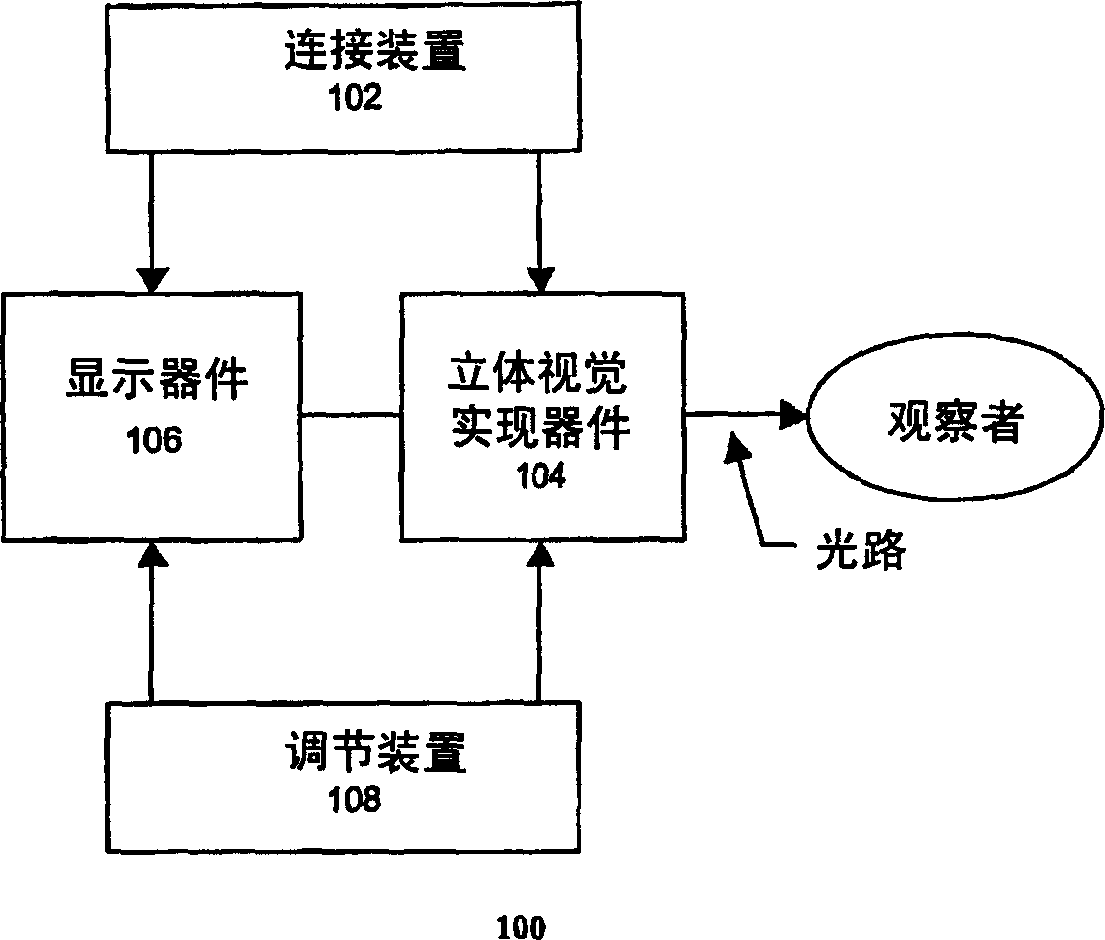

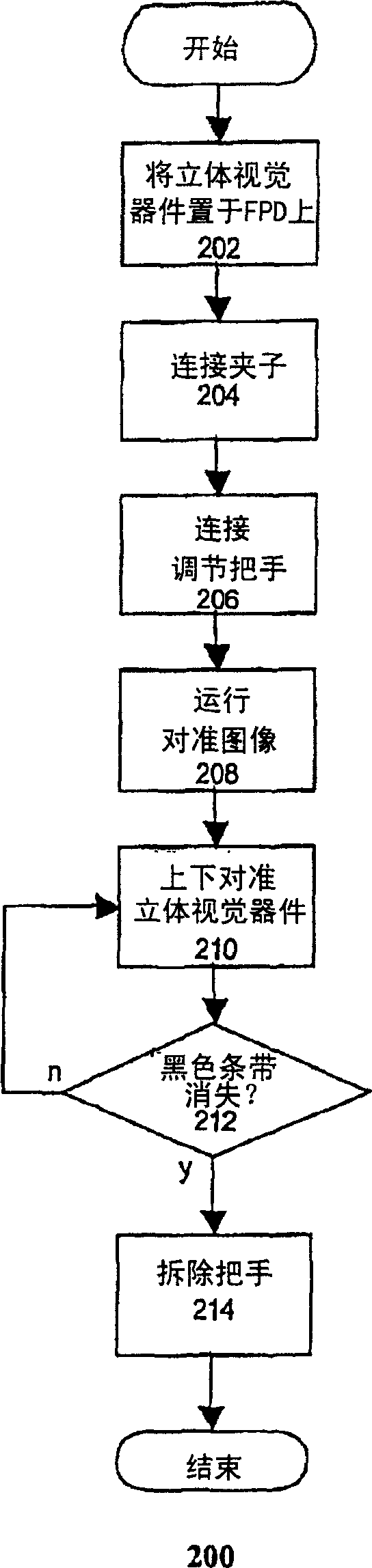

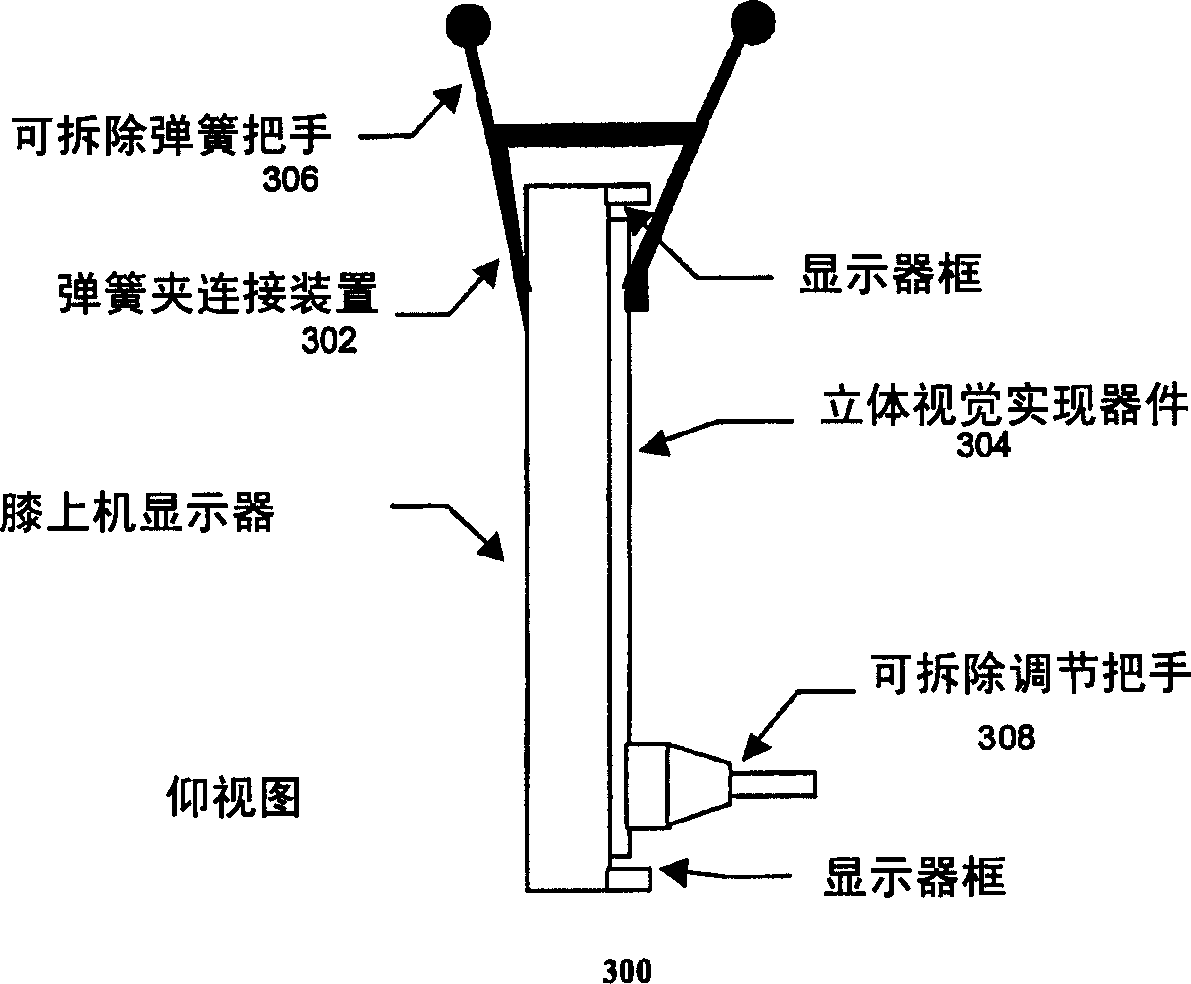

Method and apparatus for easy attachment and alignment of stereoscopic vision enabling devices

This disclosure addresses the problem of connecting and adjusting 3D stereoscopic vision enabling devices by providing a method and apparatus for connecting and aligning SEDs in a simple and straightforward manner. Several mounting options are available in two categories, including spring clip and screw clip mounting systems. Any major stereoscopic vision enabling device can be fixed to a flat panel display (using a variety of display technologies including LCD, plasma, OLED, etc.) Devices include, but are not limited to, micropolarizers, lenticular lens arrays, microlens arrays, parallax barriers, and holographic arrays manufactured by Vrex. Once the initial fixation of the stereoscopic enabling device has been completed, a method of correct alignment for optimal 3D stereoscopic viewing is provided by using appropriate test images depending on the stereoscopic enabling device used.

Owner:VREX

Adjustable cloth drying and sizing device

InactiveCN107012611AImprove dyeing uniformityPlay a role in fixing the colorTextile treatment machine arrangementsTextile treatment carriersState of artEngineering

The invention relates to an adjustable cloth dyeing and setting device, which includes a frame, a cloth guide roller group and a dyeing mechanism. The dyeing mechanism includes: a dye bin fixedly installed on the frame and a dyeing roller assembly installed inside the dye bin. The dye liquid flow path is formed between the dyeing roller assembly and the dye chamber; the dyeing roller assembly includes a rotating dyeing roller installed on the frame, a sealing baffle arranged inside the rotating dyeing roller and adapted to its inner ring, and A number of gas injection holes are arranged on the outer circumferential surface of the rotating dyeing roller, and the sealing baffle is provided with a gas channel connected to the inside of the rotating dyeing roller, and the gas passes through the gas channel to form an air curtain acting on the gray cloth; the rotating dyeing roller While the dye is rolled on the surface of the gray cloth, high-pressure infiltration is carried out by high-pressure steam to complete the dyeing, preliminary color fixation and uniform penetration, realizing efficient and uniform dyeing operation on the gray cloth, and solving the dyeing problems existing in the prior art Uneven, easy to fade and other technical problems.

Owner:ZHEJIANG HUANFENG TEXTILE CO LTD

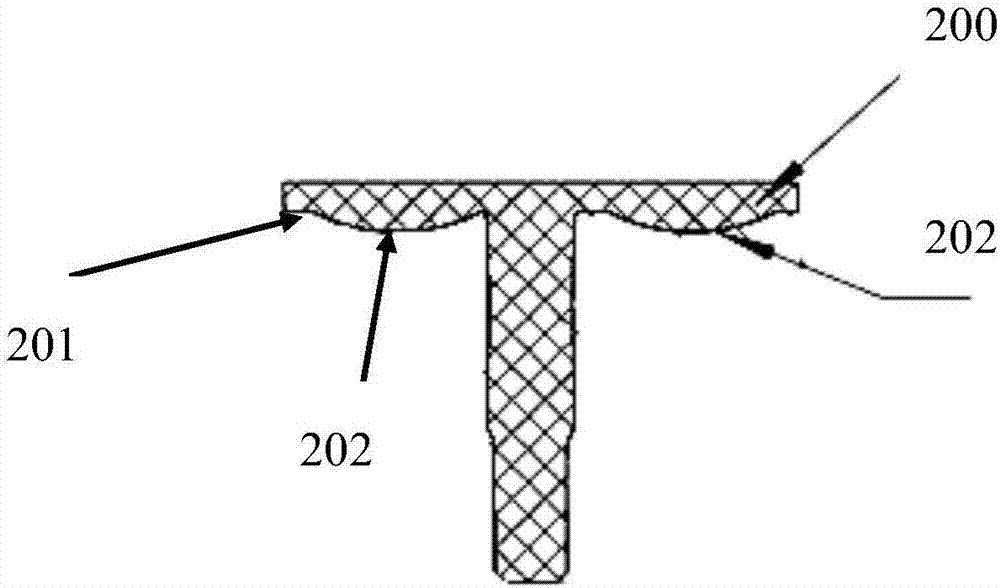

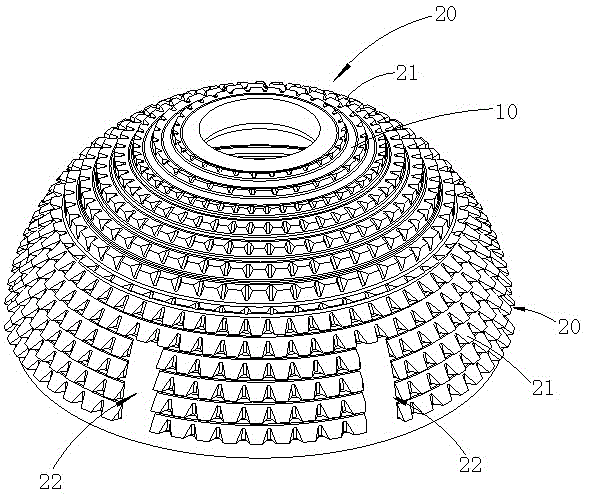

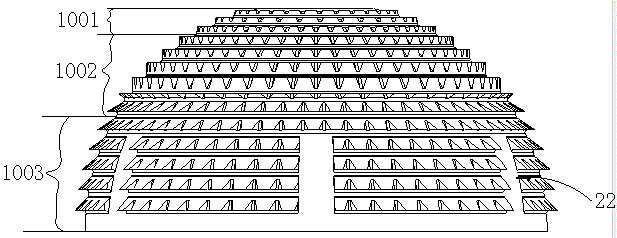

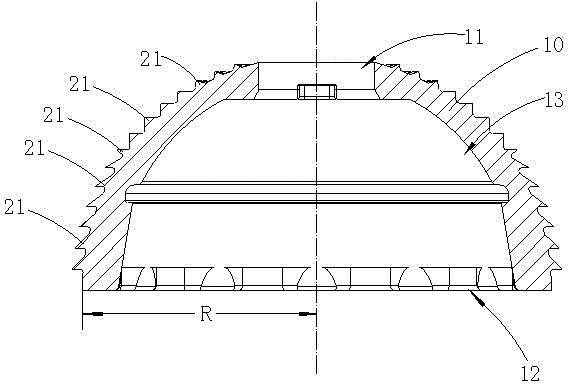

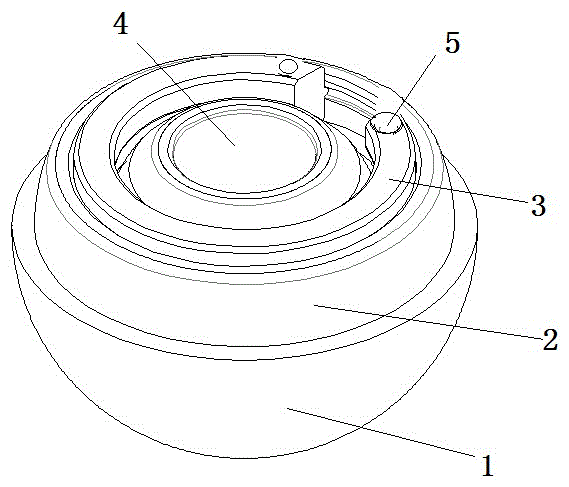

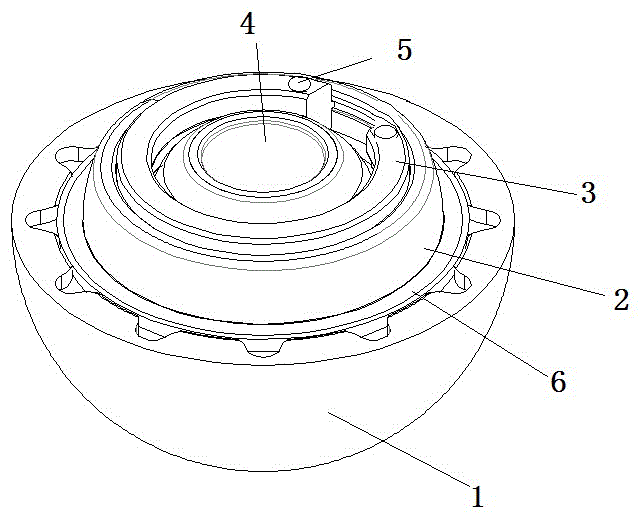

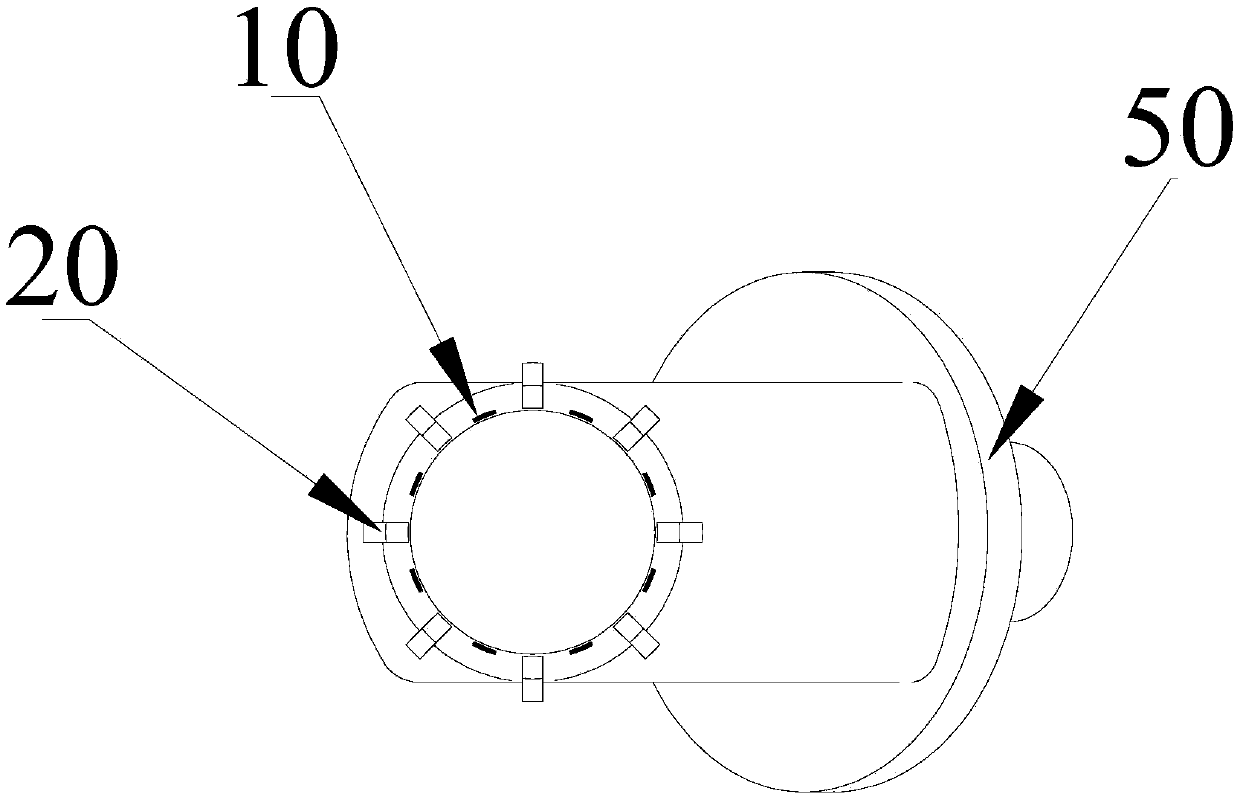

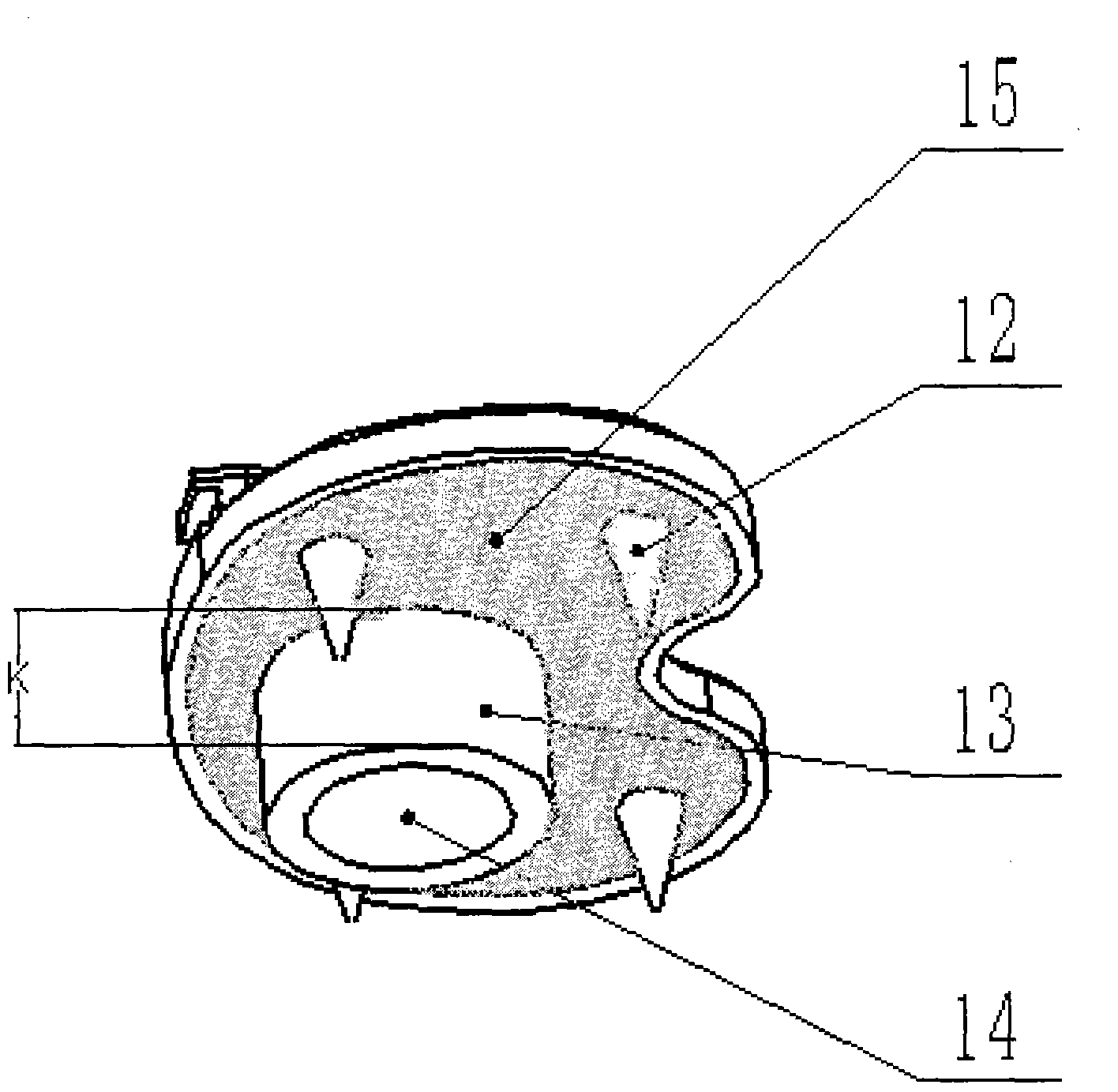

Acetabular cup for artificial hip joint

The invention provides an acetabular cup for an artificial hip joint and relates to the field of artificial joints. The acetabular cup comprises a cup body and multiple fixing tooth rings layered on the surface of the cup body, wherein the cup body is provided with a cup top hole at the top of the cup body and a cup opening at the bottom of the cup body; an accommodating cavity is formed in the cup body; the cup top hole and the cup opening are both communicated with the accommodating cavity; each layer of fixing tooth ring comprises multiple fixing teeth surrounding the center line of the cup body and positioned on the same horizontal plane; and each fixing tooth is arranged on the surface of the cup body. Compared with the prior art, in the acetabular cup for an artificial hip joint provided by the invention, the fixing teeth are arranged on the surface of the cup body, and the dimension and angle of the fixing teeth on the surface of the cup body are gradually increased; and therefore, the acetabular cup is always kept in press fit with the acetabular fossa, and good initial fixation and long-term fixation of the acetabular cup in the acetabular fossa are realized.

Owner:优适医疗科技(苏州)有限公司

Novel double-action hip joint prosthesis

InactiveCN106388979AAddress the risk of dislocationDislocation risk avoidanceJoint implantsFemoral headsRight femoral headCoxal joint

The invention discloses a novel double-action hip joint prosthesis. The novel double-action hip joint prosthesis mainly comprises an acetabular cup, a polythylene liner, a locking ring and a femoral head and is characterized in that a circle of groove is formed at the bottom of the polythylene liner; firstly, the femoral head is put into a ball socket of the polythylene liner, and then the locking ring is put into the groove of the polythylene liner and is arranged at the upper end of the femoral head; and the polythylene liner is externally arranged in the acetabular cup. The novel double-action hip joint prosthesis has the beneficial effects of being capable of solving the risk problem of dislocation of the femoral head in polythylene liner, not only being convenient to implant during operation, but also avoiding the dislocation risk of the femoral head after operation; and due to adoption of the novel double-action hip joint prosthesis, relatively good initial fixation and good long-term fixation of the femoral head in the polythylene liner are achieved, and the femoral head is convenient to install.

Owner:优适医疗科技(苏州)有限公司

Method for baking tobacco leaves with mucor disease

InactiveCN105686049ADisease controlEffective disease phenomenonTobacco preparationDiseaseMucor species

The invention discloses a method for baking tobacco leaves with the mucor disease.A baking room and tobacco rods contaminated by mucor are fumigated for 22-24 hours with sulphur powder; meanwhile, when the tobacco leaves with the mucor disease are baked, a high-temperature low-humidity baking method or a staged moisture discharge baking method is adopted from the middle yellowing period to the initial fixation period for baking, and the tobacco leaf mucor disease is effectively controlled; according to the high-temperature low-humidity baking method, the baking time when the low temperature at the yellowing stage is below 38 DEG C is shortened; according to the staged moisture discharge baking method, a high-temperature moisture discharge method is adopted for regulating and controlling the baking temperature at the yellowing stage.The method is characterized in that firstly, the flue-cured tobacco mucor disease is found, especially the temperature and humidity point and time of the baking stage are controlled, the mucor disease can be effectively restrained in a good dispersion environment, the tobacco leaf mucor disease phenomenon is effectively controlled, and economic losses brought to tobacco growers are reduced.

Owner:GUIYANG OFFICE OF GUIZHOU TOBACCO CORP

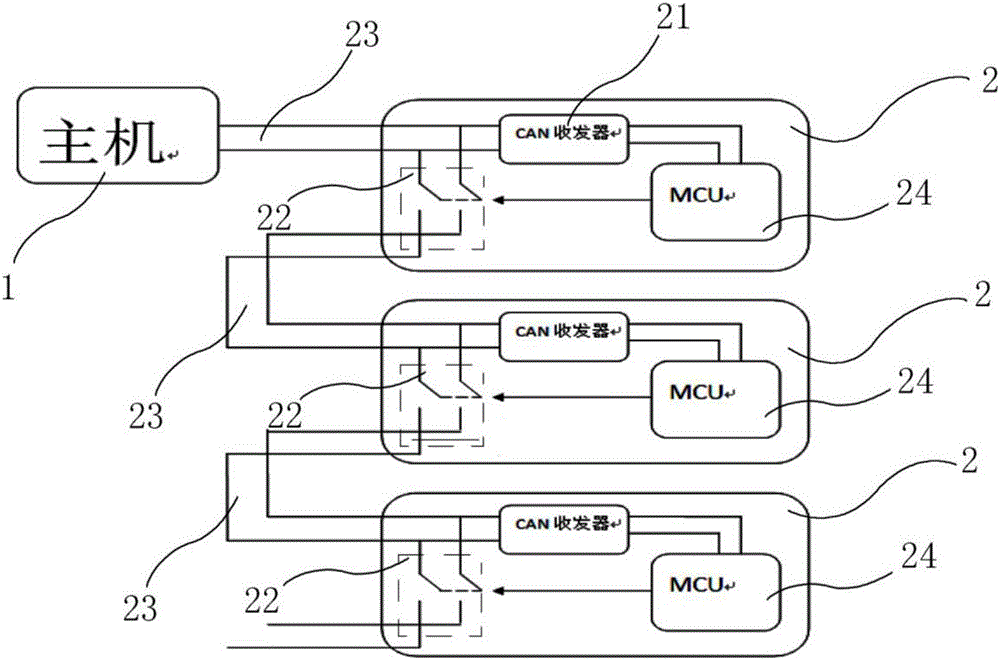

CAN bus automatic coding circuit and method

PendingCN106647393ALow costAuto-encoding is efficientProgramme control in sequence/logic controllersBus networksTransceiverComputer module

The present invention belongs to the CAN bus circuit, and especially relates to a CAN bus automatic coding circuit. The circuit comprises a host module and a slave computer module. There are at least two slave computer modules, the slave computer modules are in cascade connection with the host module, the host module can send detection frames and an encoding command to the slave computer module, and the detection frame can detect whether the slave computer module ID is an initial fixation ID or not; the slave computer module comprises a CAN transceiver and a communication cascade switch, the CAN transceiver is provided with an external outgoing line, the CAN transceiver of the first-grade slave computer module is connected with the host through the external outgoing line, one end of the communication cascade switch is connected with the external outgoing line of the CAN transceiver of this grade slave computer module, the other end of the communication cascade switch is connected with the external outgoing line of the CAN transceiver of the next-grade slave computer module, and the slave computer module completes the automatic switching of the communication cascade switch after the encoding is completed. The CAN bus automatic coding circuit employs the communication cascade switch to realize automatic encoding to simplify the circuit and improve the encoding efficiency and has high stability. The present invention further provides a CAN bus automatic coding method.

Owner:DONGGUAN LILONG BATTERY TECH CO LTD

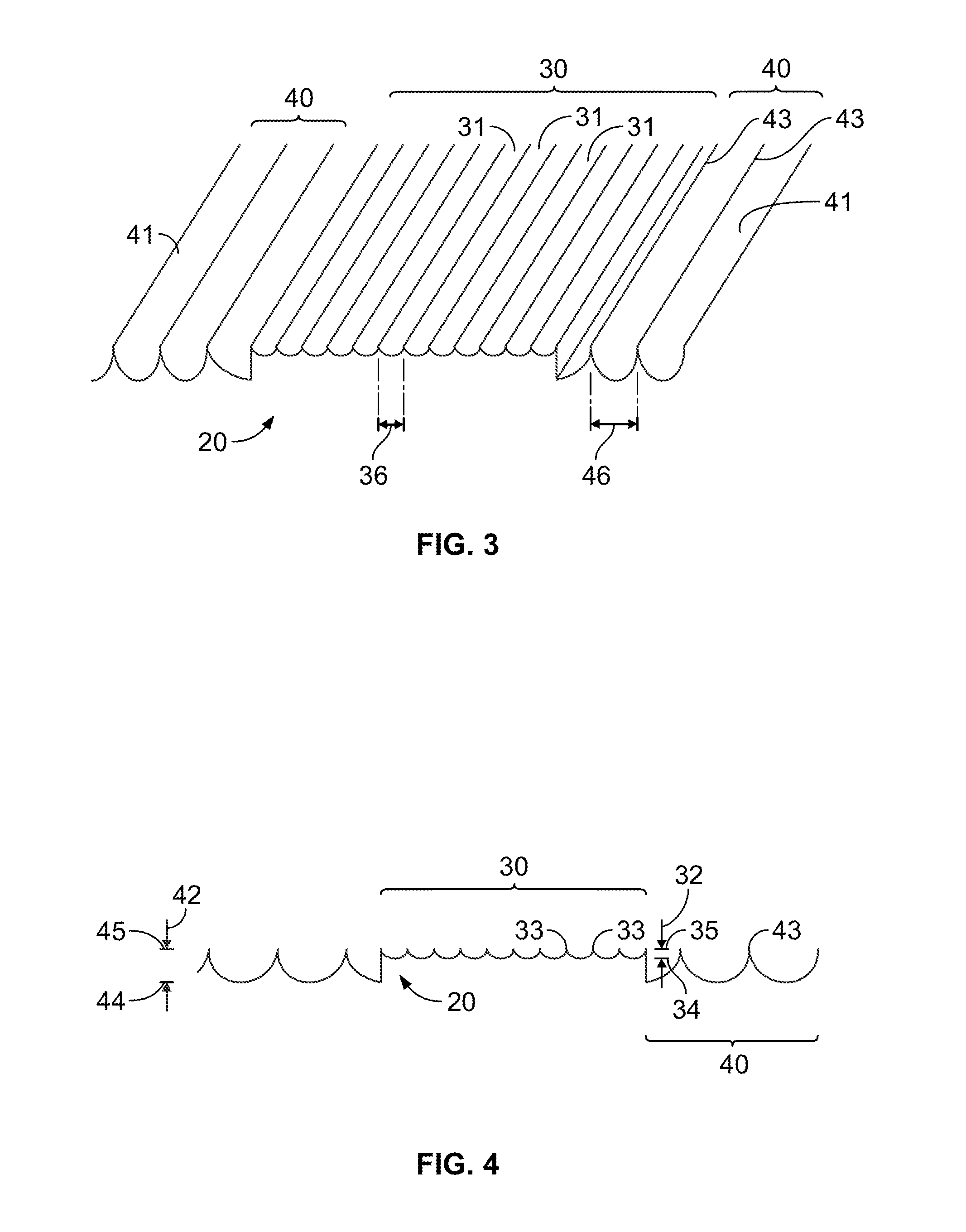

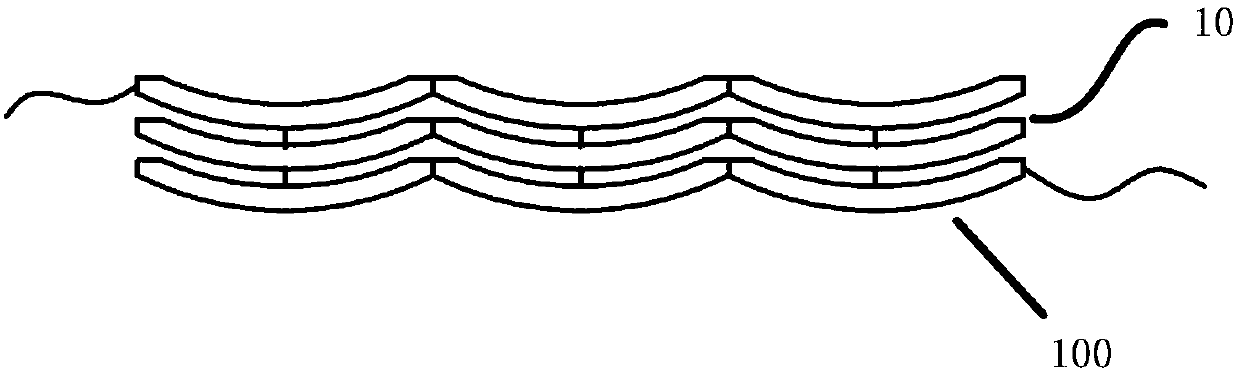

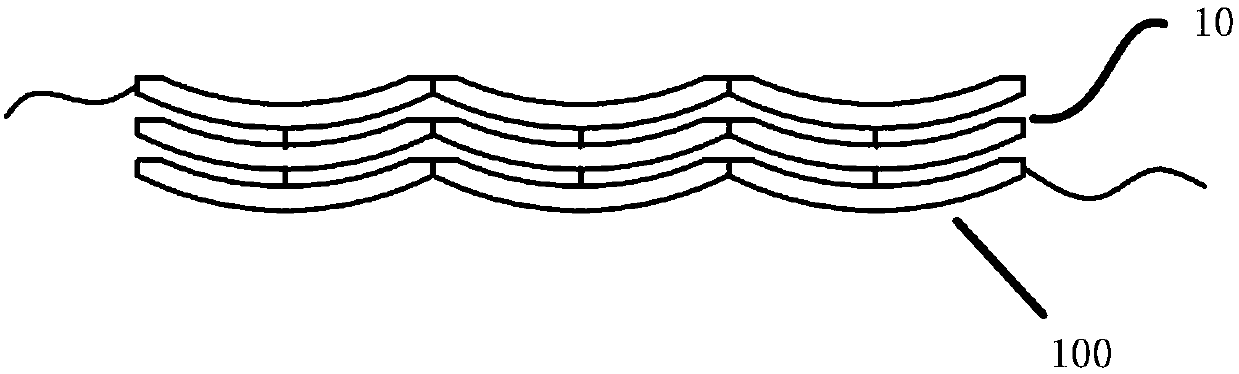

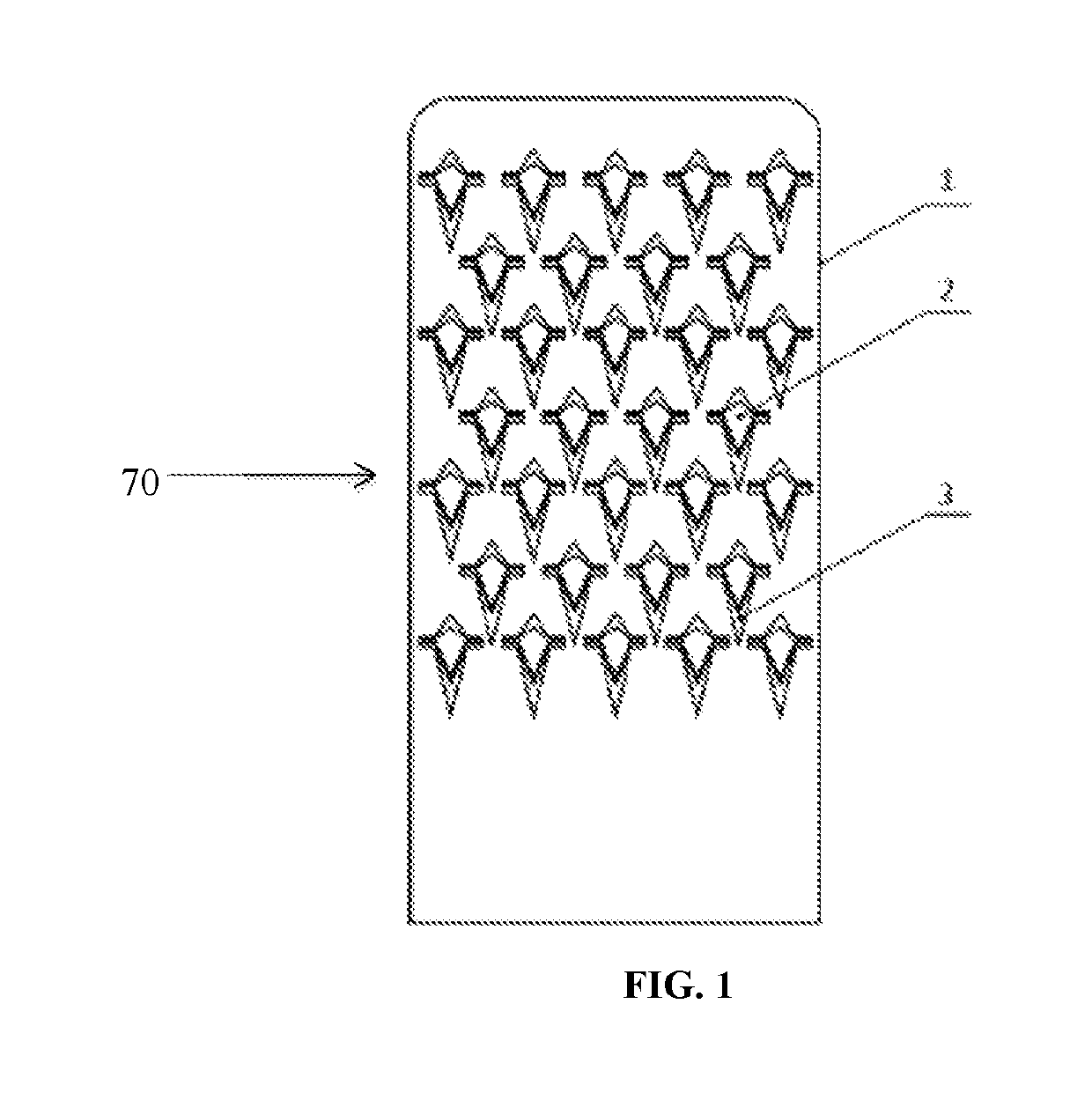

Absorbable composite patch for rotator cuff repair and manufacturing method

PendingCN107854194APromote healingHigh initial fixation strengthProsthesisComposite materialInitial fixation

The invention provides an absorbable composite patch for rotator cuff repair. The absorbable composite patch comprises a woven body, the woven body comprises one or more weaving units, and each weaving unit forms a supporting base layer and an absorbable layer in a thickness extension direction by stacking. Each absorbable layer is disposed on one end surface or both end surface of the two end surfaces of each supporting base layer in the thickness extension direction. Both the supporting base layer and the absorbable layer are made of degradable materials. Correspondingly, the invention alsoprovides a method for manufacturing the absorbable composite patch for rotator cuff repair. The absorbable composite patch has higher initial fixation strength and can simultaneously tightly integratea rotator cuff and a humerus head and reduce the gap; moreover, as collagen is gradually degraded, human body's self connective tissue gradually grows into patch micropores to form an integrated structure and to speed up the healing of the rotator cuff.

Owner:SHANGHAI LIGETAI BIOTECH CO LTD

External acetabulum cup and hip joint prosthesis including the same

PendingCN110420076AExtended service lifeIncrease contact areaJoint implantsAcetabular cupsFossa acetabuliBiomedical engineering

The invention provides an external acetabulum cup and a hip joint prosthesis including the same. The external acetabulum cup includes a cup body, the cup body is provided with an external surface andan internal surface connected with the external surface, the cup body is provided with a central hole and a mounting hole which extend from the external surface to the internal surface, and the external surface of the cup body is provided with a groove around the mounting hole. The contact area of the external acetabulum cup and a fossa acetabuli is obviously increased, initial fixation and compression stability are good, long-term bone in-growth is facilitated, and the service life of the external acetabulum cup is improved.

Owner:TIANJIN ZHENGTIAN MEDICAL INSTR CO LTD

Demineralized bone fiber implant compositions and methods for augmenting fixation in bone repair

ActiveUS20220105242A1Easy to fixReduce chanceSuture equipmentsInternal osteosythesisFiberBone formation

A composition and methods of making or use thereof include a plurality of fibers forming a shape for augmenting fixation of a bone screw, or the plurality of fibers form a shape having a peg portion and a sheet portion to augment tendon to bone repair. The physical presence of the plurality of fibers provides initial fixation, while the use of an osteoinductive material provides long term enhancement of bone formation around the site of the bone screw or the tendon to bone repair.

Owner:THERACELL INC

Partially-absorbable patch applied to rotator cuff repair and manufacturing method of partially-absorbable patch

ActiveCN107928837APromote healingHigh initial fixation strengthTissue regenerationProsthesisHuman bodyConnective tissue fiber

The invention provides a partially-absorbable patch applied to rotator cuff repair. The partially-absorbable patch comprises a braided body and a coating, wherein the braided body comprises a supporting base layer; the supporting base layer comprises one or more braiding units; the coating is arranged on one or two end faces in a thickness extension direction of the supporting base layer; the supporting base layer is made from a non-degradable material; the coating is made from a degradable material; and the coating is sprayed on the supporting base layer. Correspondingly, the invention also provides a manufacturing method of the partially-absorbable patch applied to the rotator cuff repair. The partially-absorbable patch provided by the invention is relatively high in initial fixation strength; meanwhile, close binding between a rotator cuff and a humeral head is guaranteed, and gaps are reduced; and moreover, along with gradual degradation of collagen, connective tissues of a human body gradually grow and enter patch pores, so that an integral structure is formed, and the healing of the rotator cuff is accelerated.

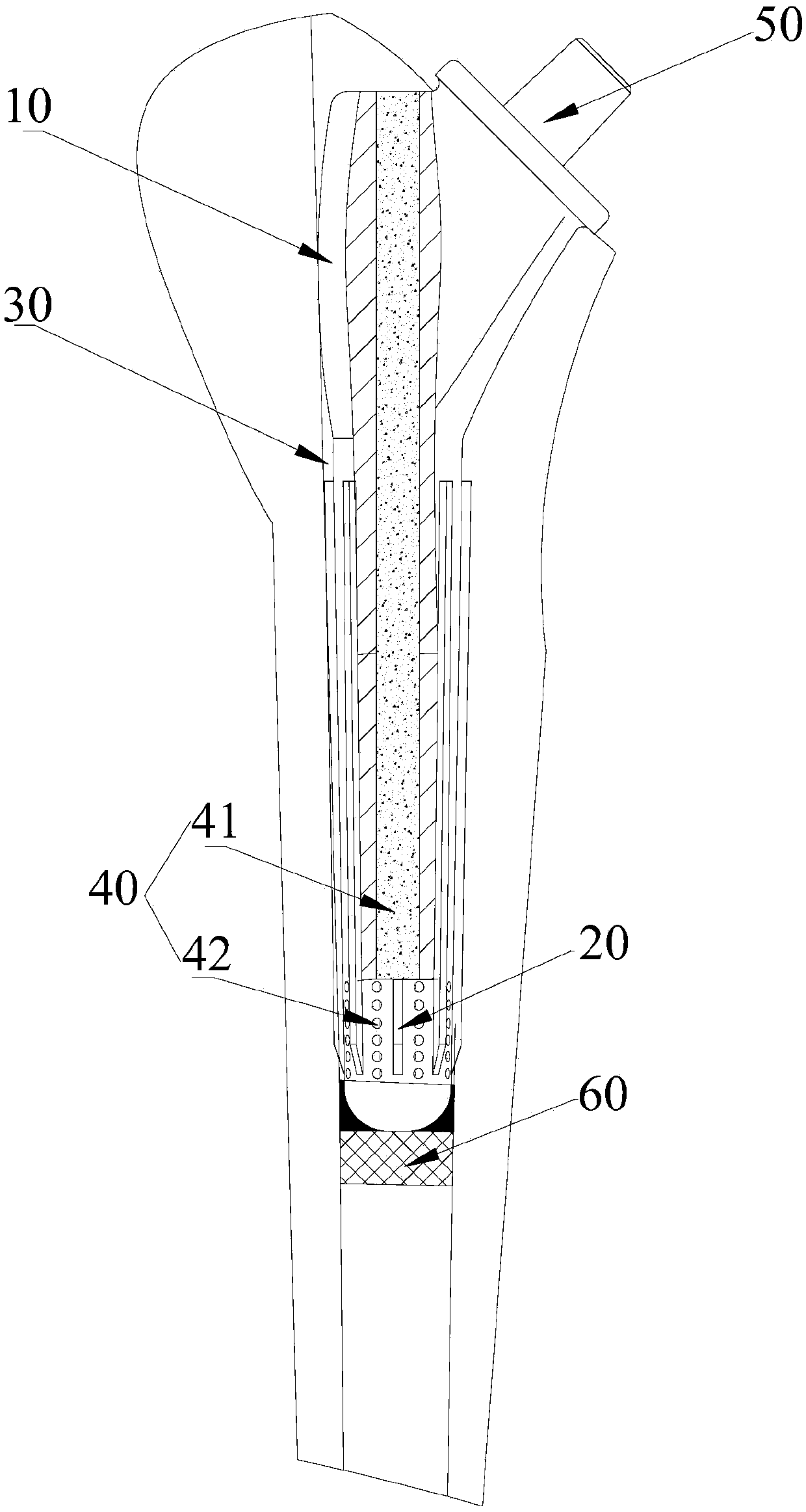

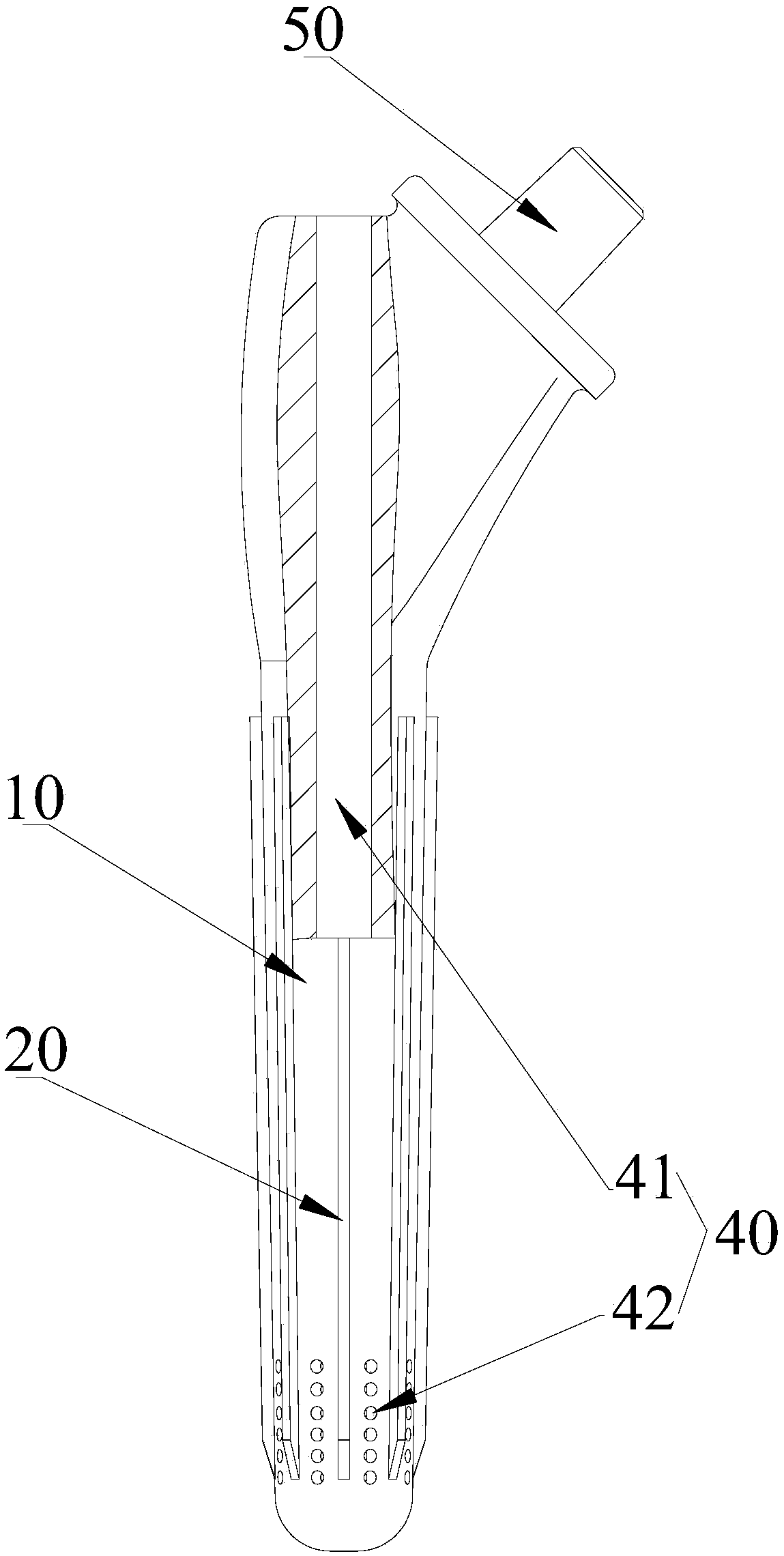

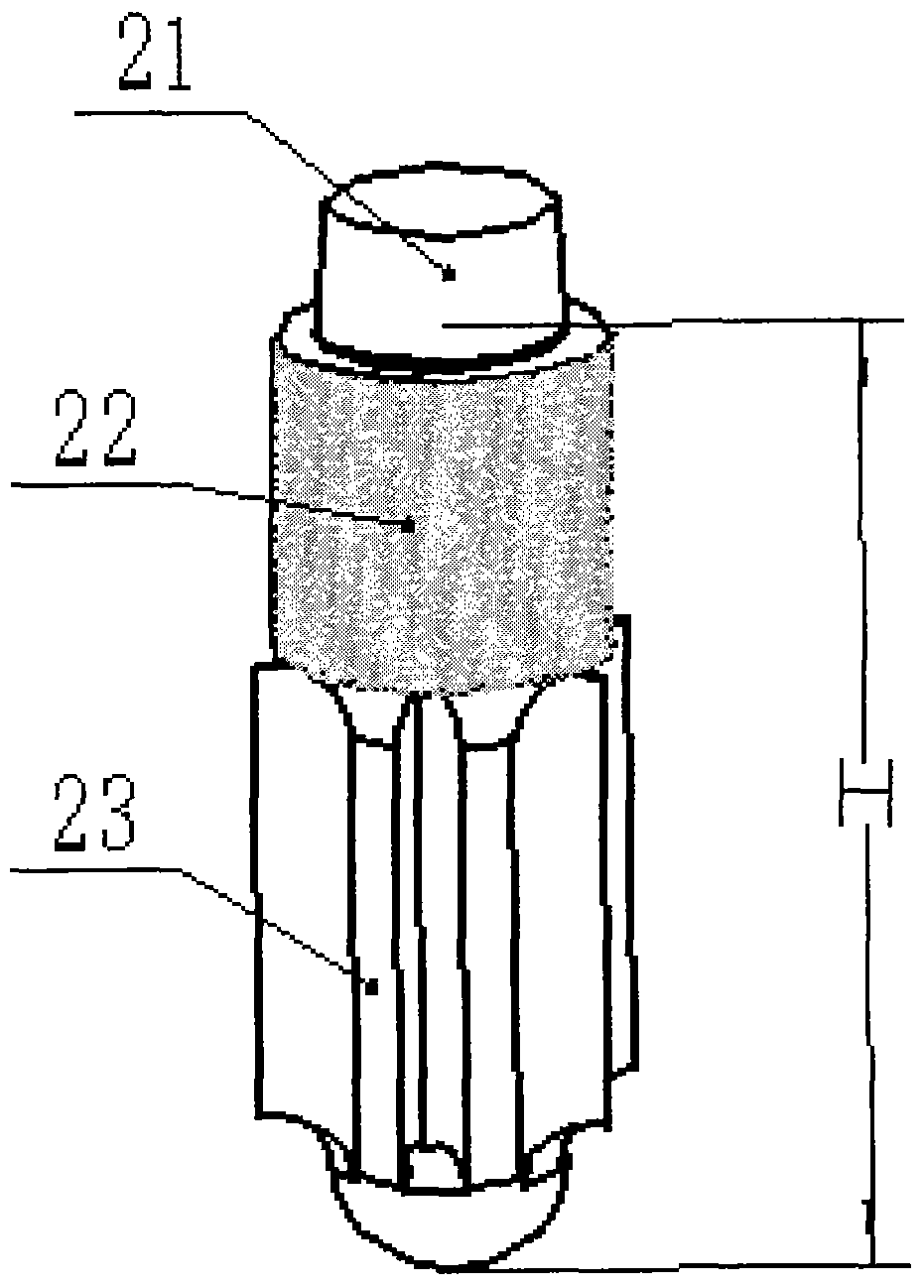

Shoulder-joint humerus handle prosthesis

InactiveCN107582219AAchieve fixationAchieve initial fixationJoint implantsShoulder jointsMedicineProsthesis

The invention provides a shoulder-joint humerus handle prosthesis. The shoulder-joint humerus handle prosthesis includes a main handle body and strip-shaped spines; the strip-shaped spines are arranged on the outer wall of the main handle body, so that when the main handle body is implanted in the humerus marrow cavity, the strip-shaped spines are embedded in the bone cortex of the humerus marrowcavity to fix the main handle body inside the humerus marrow cavity. Therefore, initial fixation of the humerus handle prosthesis in the humerus marrow cavity can be achieved, the situation is prevented that after the humerus handle prosthesis is stressed, the position of the humerus handle prosthesis changes, and the stability of the fixed humerus handle prosthesis is effectively ensured. The problem is solved that the initial stability of a current humerus-handle-prosthesis initial fixation technology is relatively low.

Owner:BEIJING AKEC MEDICAL

Reinforcing connection device for a building structure

ActiveCN110984617BAchieve secondary fixationRealize integrationBuilding repairsArchitectural engineeringScrew head

The invention relates to a reinforcing connection device for a building structure, which belongs to the technical field of building. During the use of the present invention, firstly, the drill bit is screwed into the right angle to fix the device for the first time, and the screw head on the fixing rod is screwed into the screw port of the support plate to realize the second fixation of the device, and at the same time, the screw on the rod is consolidated. The clamping head snaps into the bayonet on the fixing plate to realize the integration of the device, and fix it again, and finally drive it into the main body of the building structure through expansion screws for final fixing.

Owner:安徽永筑建设工程有限公司

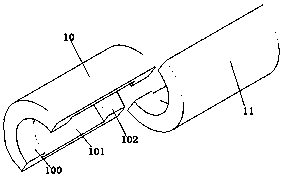

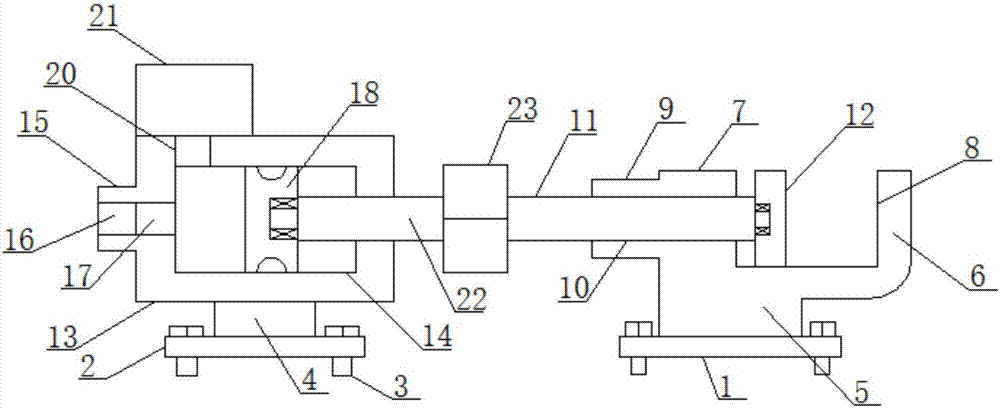

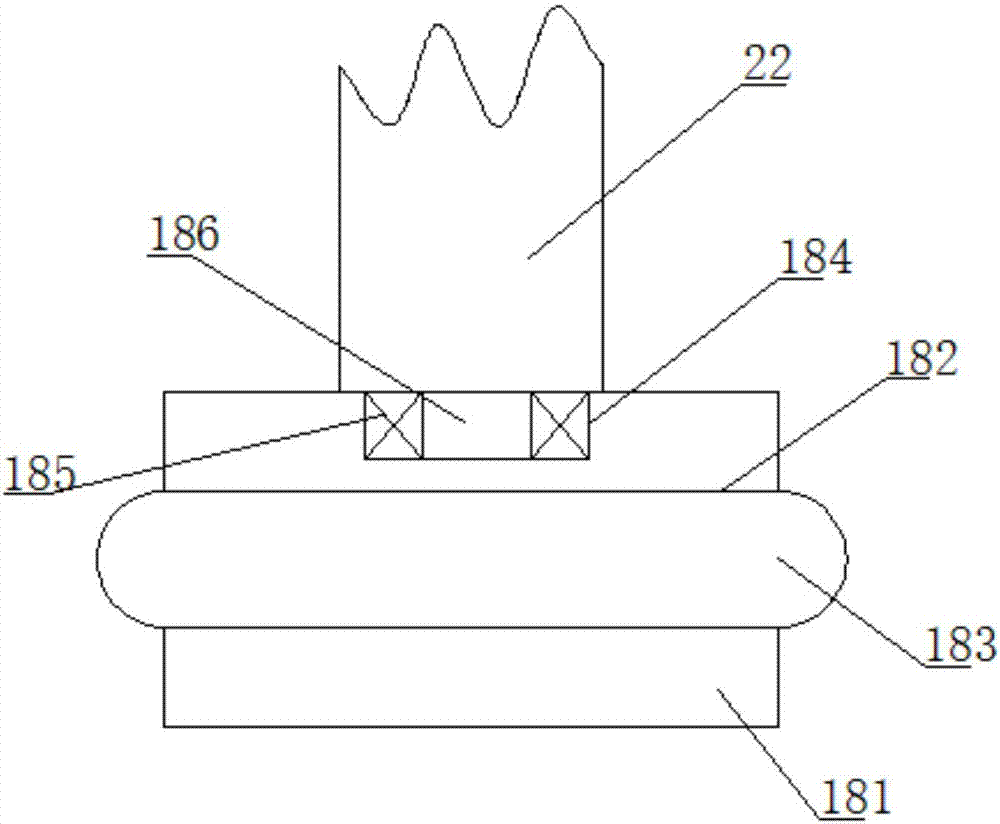

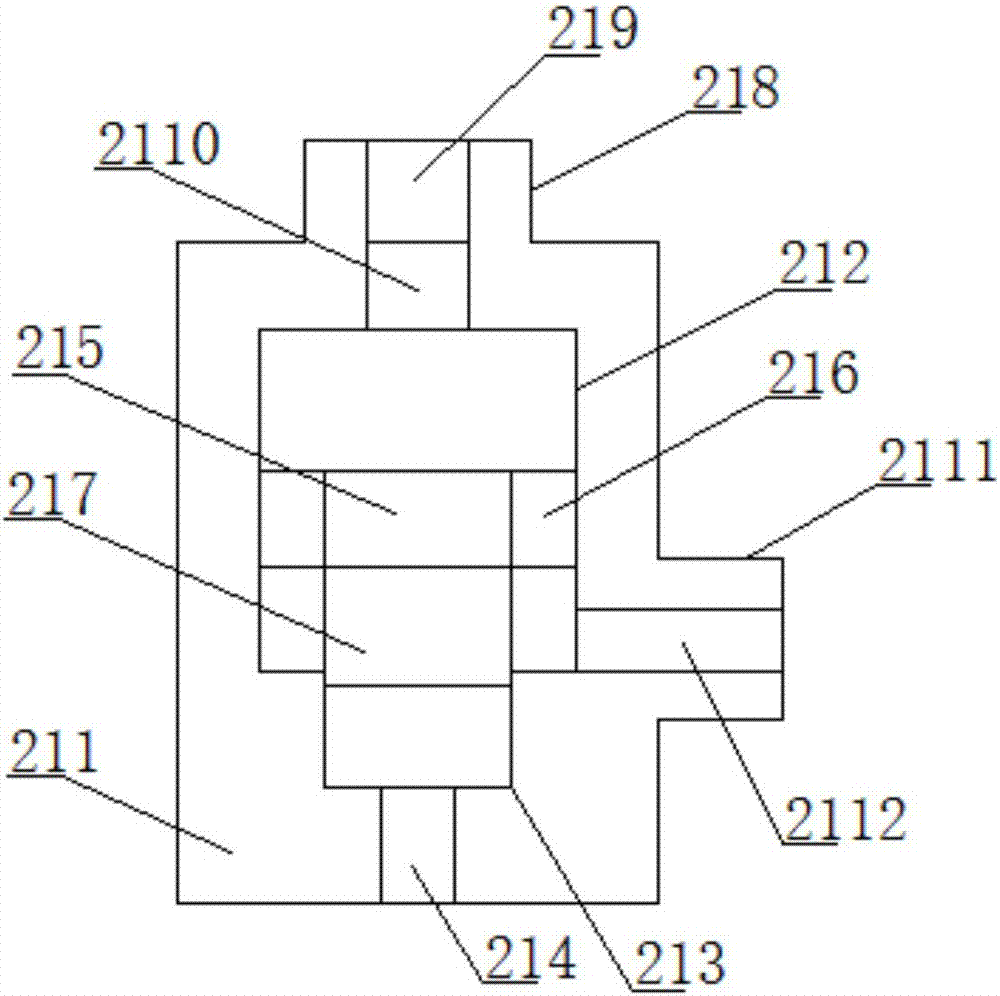

Biological fixation type tibia platform

InactiveCN103705319AGood for initial fixationStable anti-rotation abilityJoint implantsCoatingsTibiaIntramedullary rod

The invention discloses a biological fixation type tibia platform for surgery implants. The biological fixation type tibia platform is composed of a platform body and an intramedullary rod. A biological coating adheres to the lower surface of the platform body, and thorn-shaped protrusions are arranged on the platform body which facilitates initial fixation of the platform. The intramedullary rod is connected with the platform through a conical structure, the biological coating adheres to the upper portion of the intramedullary rod, and spine-shaped structures which are evenly distributed are arranged on the columnar face of the lower portion of the intramedullary rod. A prosthesis can be conveniently inserted into the bone, meanwhile, the anti-rotation function is provided, and the biological fixation type tibia platform can still be firmly fixed under the action of rotation force. The biological fixation type tibia platform can provide immediate fixation after an operation, the good anti-rotation function is achieved, and due to different combination modes, the biological fixation type tibia platform meets the requirements of different patients.

Owner:BEIJING AKEC MEDICAL

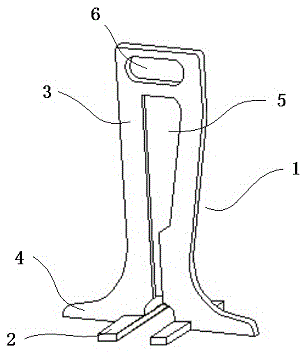

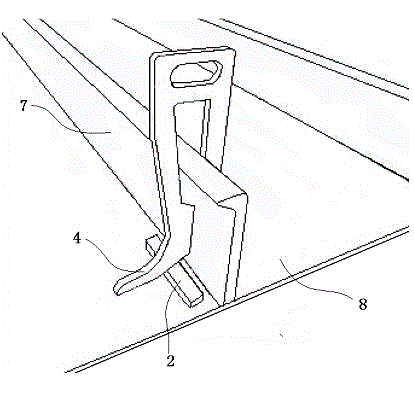

Method for assembling flat-bulb steel on steel slab in ship building

ActiveCN104942456AImprove securityImprove assembly efficiencyWelding apparatusSpot weldingFixed position

The invention relates to a method for assembling flat-bulb steel on a steel slab in ship building. The method is used for fixing the flat-bulb steel to the steel slab in ship building. The method for assembling the flat-bulb steel on the steel slab in ship building includes the steps that firstly, the steel slab is placed in a construction region, the fixing position of the flat-bulb steel is scribed and determined, and anti-toppling devices are prepared, wherein each anti-toppling device is composed of a main supporting body and longitudinal supporting feet; secondly, the flat-bulb steel is hoisted to the construction region through a crane, the two anti-toppling devices are installed on the flat-bulb steel from the two ends respectively, and the flat-bulb steel with the anti-toppling devices is placed on the steel slab; thirdly, the anti-toppling devices are adjusted according to the chalk line of the steel slab so as to change the position and the angle of the flat-bulb steel, and the flat-bulb steel vertically stands on the steel slab; fourthly, spot welding operation is firstly conducted for initial fixation, the anti-toppling devices are detached after detection qualification, and further welding fixation is conducted. The method and a special tool are convenient to install and operate, safe, reliable and high in realistic value.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

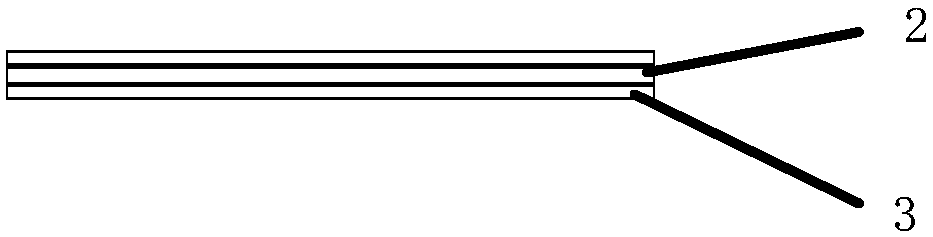

Biological joint-less locking nail

The invention relates to the technical field of medical biological internal fixation instruments, and discloses a biological joint-less locking nail, which comprises a locking nail body (22), wherein the locking nail body (22) comprises a nail head (1), a nail body (2) and a nail tail (3), which are sequentially connected; the nail body (2) is provided with threading holes (11), and is made from cortical bones; so that the biological joint-less locking nail is endowed with high biocompatibility and bone conduction and induction activity, and can be completely degraded and absorbed after complete bone healing. The biological joint-less locking nail is convenient to use, time-saving and efficient in operation and firm in fixation; the biological joint-less locking nail is made from cortical bones, so that initial fixation strength can be achieved, and tendon-bone healing fixation can be facilitated; the raw materials are low in cost, so that the economic burden of a patient is greatly reduced.

Owner:北京科健生物技术有限公司

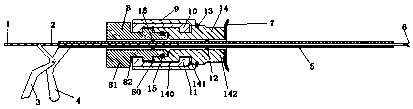

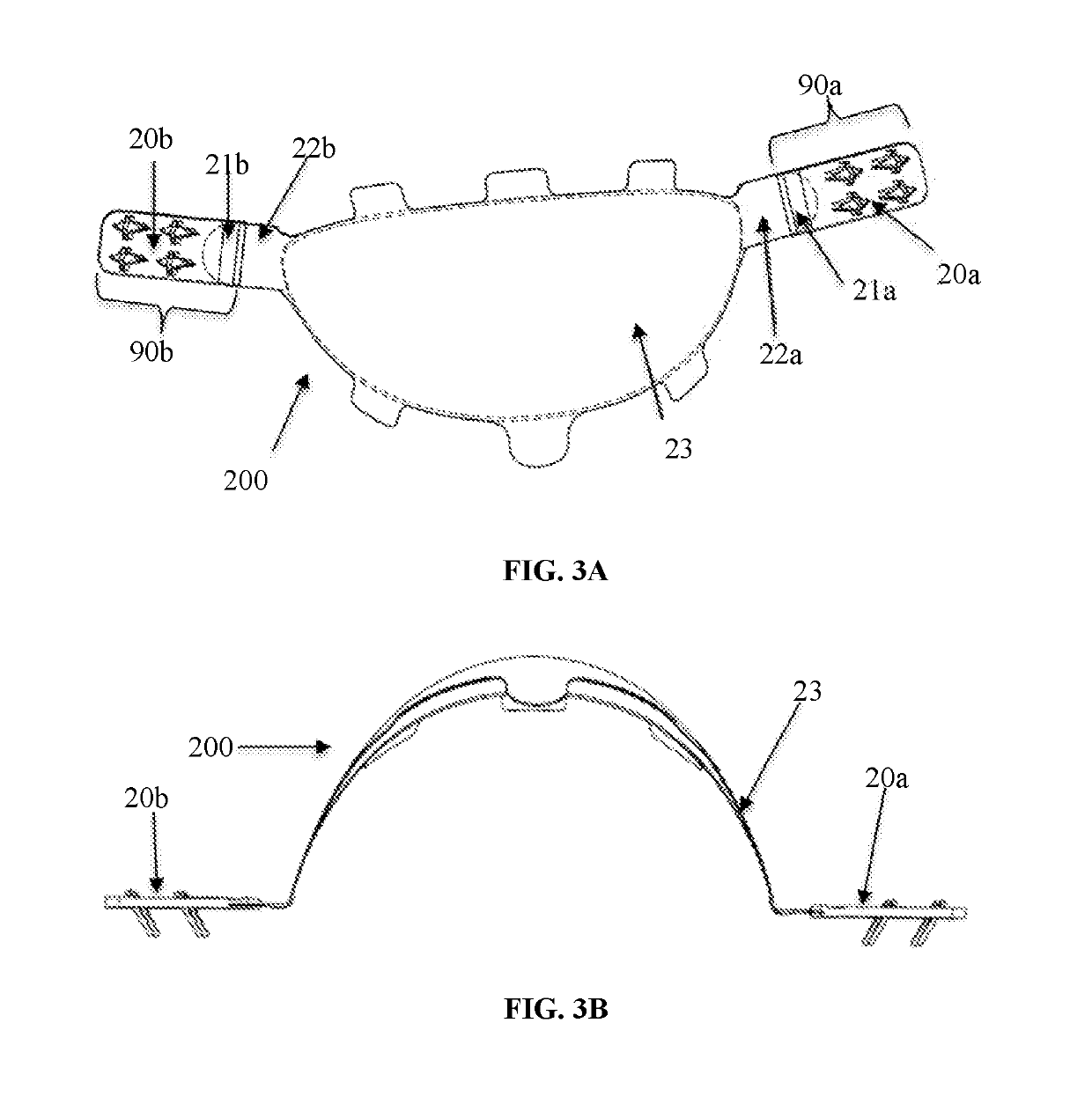

Implantable fastener for attachment of a medical device to tissue

Implantable fasteners that can be repositioned after implantation, and implants including these repositionable implantable fasteners, have been developed. The fasteners are designed to fixate medical devices and other implantable components in the body, and can be adjusted after initial fixation in tissue to reposition the implanted medical device. The fasteners include a plurality of tissue retainers emanating from a supportive backing, wherein the tissue retainers can swivel from the plane of the supportive backing to engage tissue. The fasteners are fixated in tissue by movement in a first direction, and can be removed when pulled in a direction opposite to the first direction. The fasteners may be attached to medical devices before or after implantation. In one embodiment, the implant is a mastopexy device in the form of a mesh and the repositionable fastener.

Owner:TEPHA INC

A sampling device for pathology department

ActiveCN107796650BEasy to sampleAccurate samplingWithdrawing sample devicesComputer scienceInitial fixation

The invention discloses a sampling device for a pathology department. The sampling body component is a detachable detachable structure. A sampling needle is provided on a coaxial sleeve in the sampling cylinder. The sampling blade assembly is provided at the end of the sampling needle. The needle slides in and out in the sampling cylinder along the axial direction of the sampling cylinder. The present invention can not only sample the pathological place conveniently, but only need to screw the sampling cylinder into the proper position according to the sampling location, and after preliminary determination, use sampling to sample the pathological location, the position of the sampling needle can be adjusted, which improves the sampling efficiency. The applicability of the device, in addition, the sampling body assembly of the present invention adopts a detachable structure, which can be easily disassembled and assembled, so as to realize the replacement of the sampling needle. When sampling pathologically, only the sampling needle needs to be replaced. The sampling body components can be reused, the replacement efficiency is high, the positioning is accurate, the sampling cost can be greatly reduced, and the convenience and accuracy of sampling can be improved.

Owner:YICHANG CENT PEOPLES HOSPITAL

Purple ampelopsis grossedentata processing method

The invention relates to a purple ampelopsis grossedentata processing method including the following steps: 1) collection; 2) spreading; 3) de-enzyme in hot water; 4) air drying; and 5) de-enzyme. The processing method employs a high- and low-temperature alternating method to eliminate grass smell and reduce astringent substances. For ensuring no burnt smell existing in the product, initial fixation temperature is low, and at this temperature, the grass smell can be eliminated. The drying step is carried out in a baking manner to prevent yellowing and blackening in the product. The baked product has a unique flavor, In addition, the product, through fragrance enhancement, maintains the flavor better.

Owner:ZHANGJIAJIE MAOYANMEI

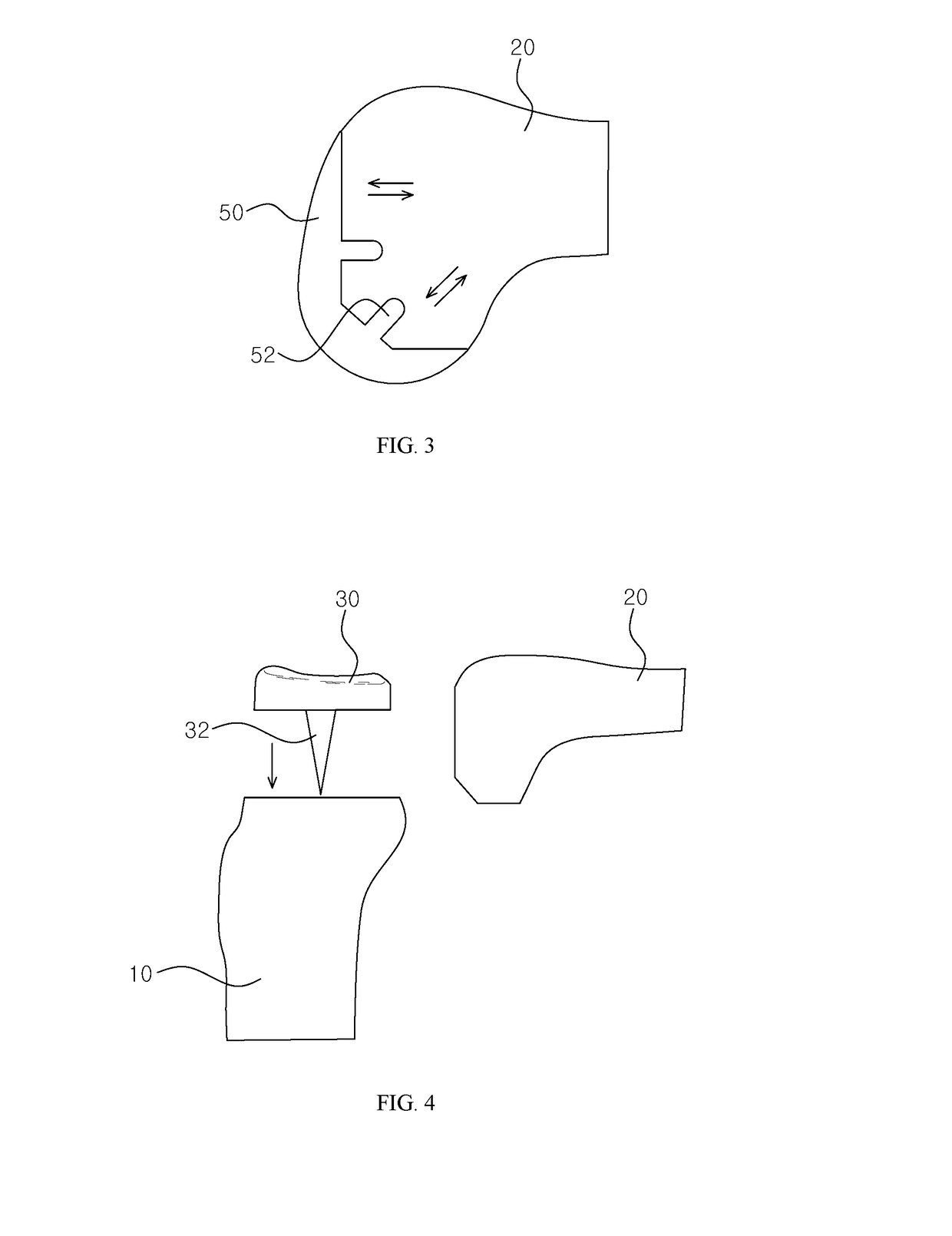

Knee joint implant

ActiveUS20180098857A1Stable fixing forceSimplify surgical proceduresJoint implantsKnee jointsKnee JointCementless implant

A knee joint implant is capable of resolving issues of conventional cementless or uncemented implants. The knee joint implant improves fixing force of the implant in a vertical direction and provides improved initial fixation for the implant.

Owner:CORENTEC

Bone defect repairing device

The invention provides a bone defect repairing device which comprises a bone filling cavity which is hollow and matched with the defected bone in shape. Due to the fact that the bone filling cavity is hollow, autologous, xenogenous or artificial bone blocks, bone particles even bone powder prepared in advance can be filled into the bone filling cavity, the filled bone facilitate later bone cell crawling growing in after initial fixation, normal attachment of soft tissues wrapping outside is achieved, and matching of prosthesis with physiological bones is increased as a whole.

Owner:BEIJING AKEC MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com