Method for assembling flat-bulb steel on steel slab in ship building

An assembly method and technology of bulb flat steel, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of complex bracing welding process, prone to misoperation, complicated and slow construction, etc., to improve safety and efficiency. The assembly efficiency of bulb flat steel, easy to move the position and adjust the angle, the effect of saving the production cost and the use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below we will further describe in detail the anti-dumping device for assembling flat bulb steel of the present invention in conjunction with the accompanying drawings and specific embodiments, in order to understand its structural composition and working mode more clearly, but it cannot be used to limit this invention. protection scope of the invention.

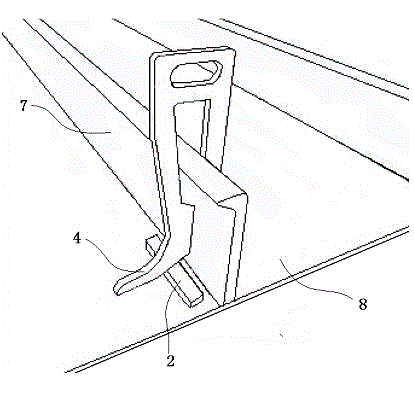

[0030] Such as figure 2 As shown, the essence of the present invention tells about a new assembly method used when a flat bulb steel is assembled on a steel plate. The assembly method includes the following steps:

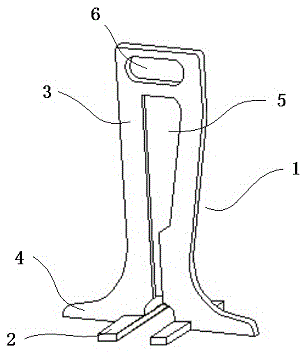

[0031] In the first step, the steel plate 8 is first placed in the construction area, and the fixed position of the ball flat steel is determined by drawing a line on the steel plate 8, and a special anti-dumping device is prepared. The anti-dumping device is composed of the main support body 1 and the longitudinal support Composed of feet 2, the main support body 1 is vertically welded and fixed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com