Patents

Literature

69results about How to "Easy to position and adjust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

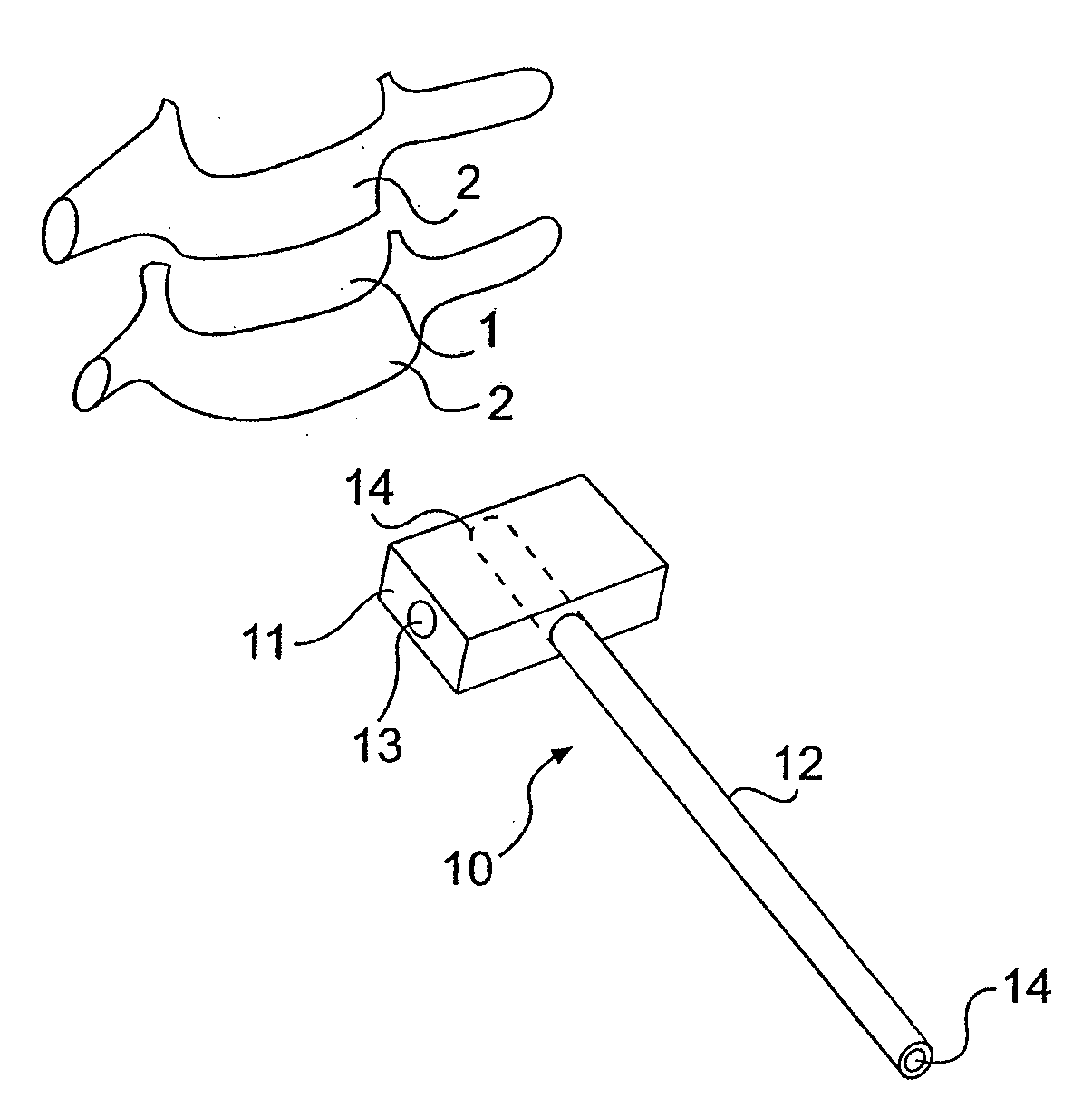

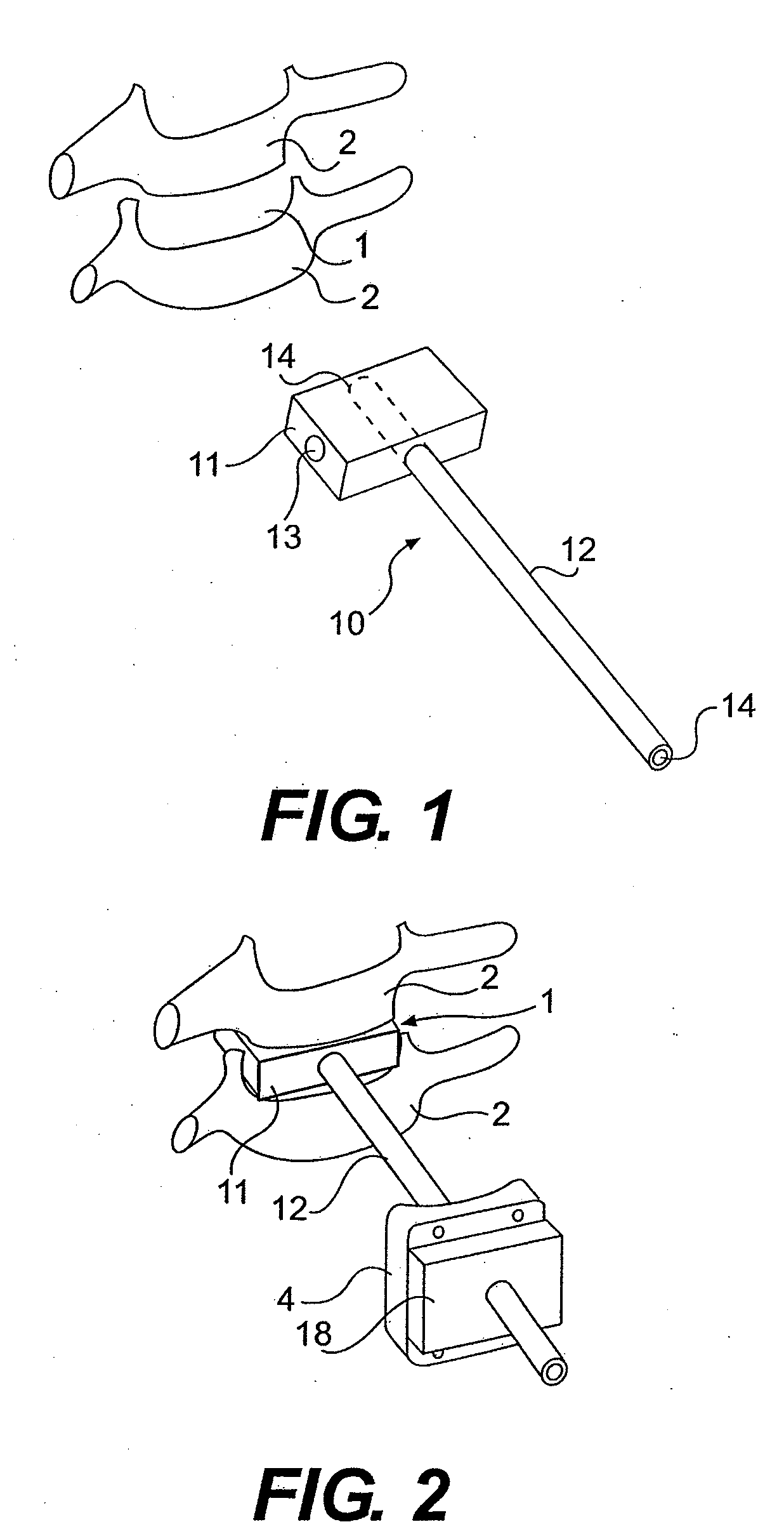

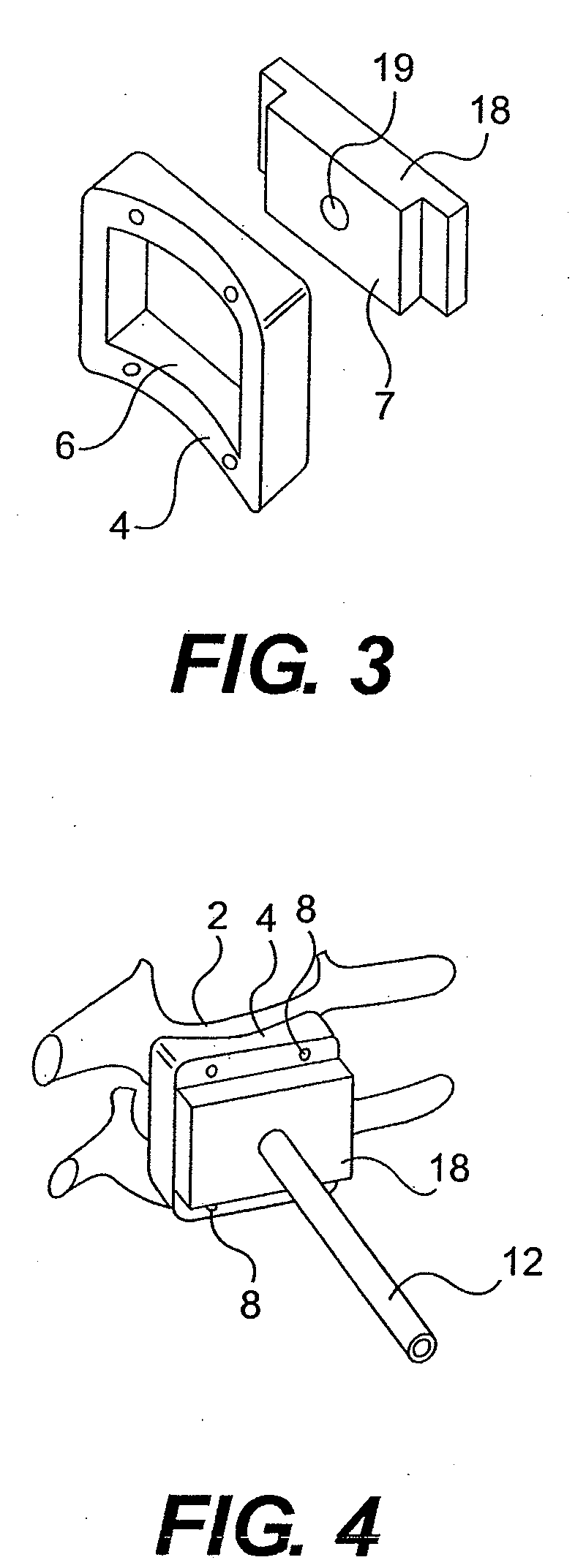

Instrument set for fitting an intervertebral jont prosthesis

InactiveUS20090182341A1High precisionBest possible visual controlInternal osteosythesisJoint implantsIntervertebral spaceIntervertebral disk

An instrument set for fitting an intervertebral prosthesis includes a guide device for an instrument or a prosthesis part, which guide device is to be secured on at least one vertebral body. In order to attach the guide device precisely on the vertebral bodies despite difficult operating conditions, an adjustment instrument is provided which positions the guide device when this is being arranged on the vertebral body. This adjustment instrument may include an intervertebral plate which is fitted into the intervertebral space so as to be positioned exactly in relation to the vertebral bodies.

Owner:CERVITECH INC

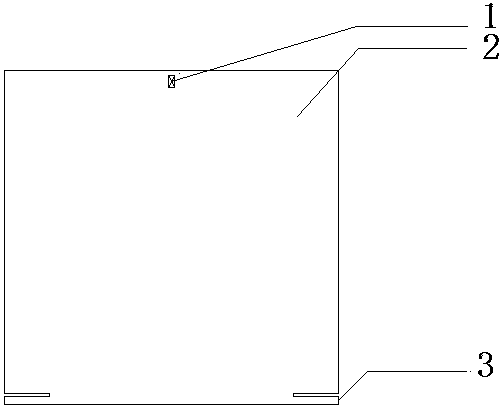

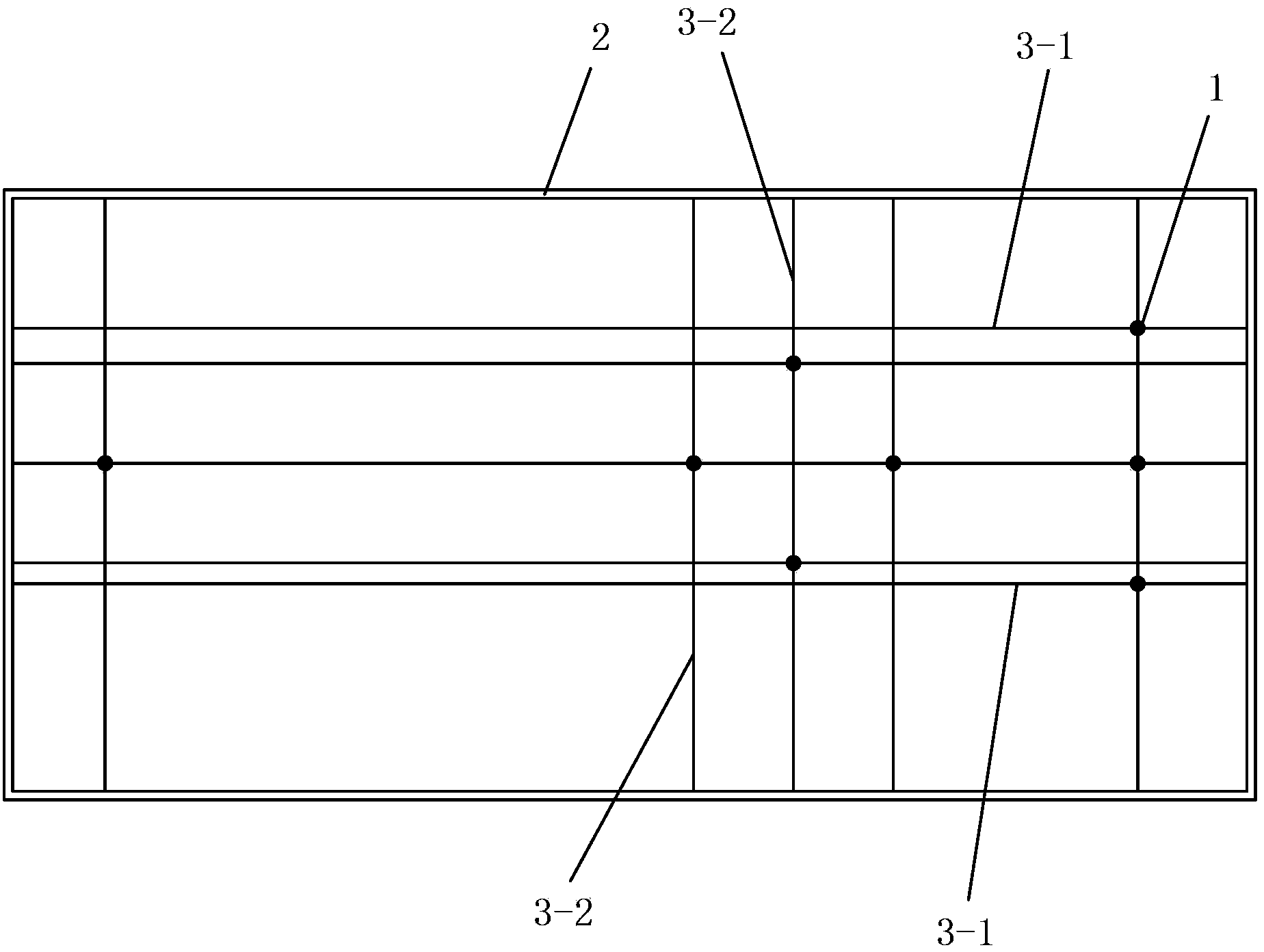

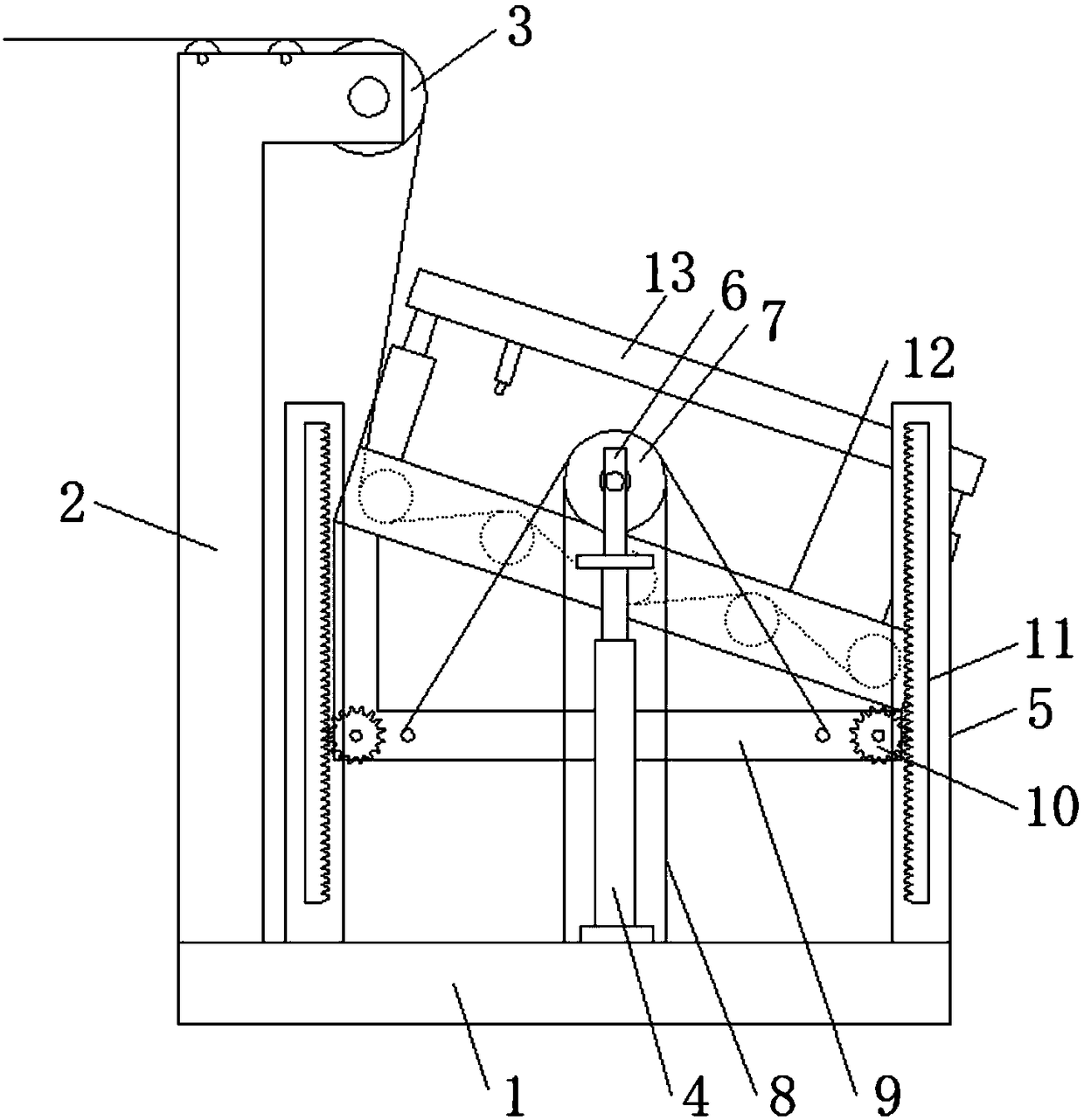

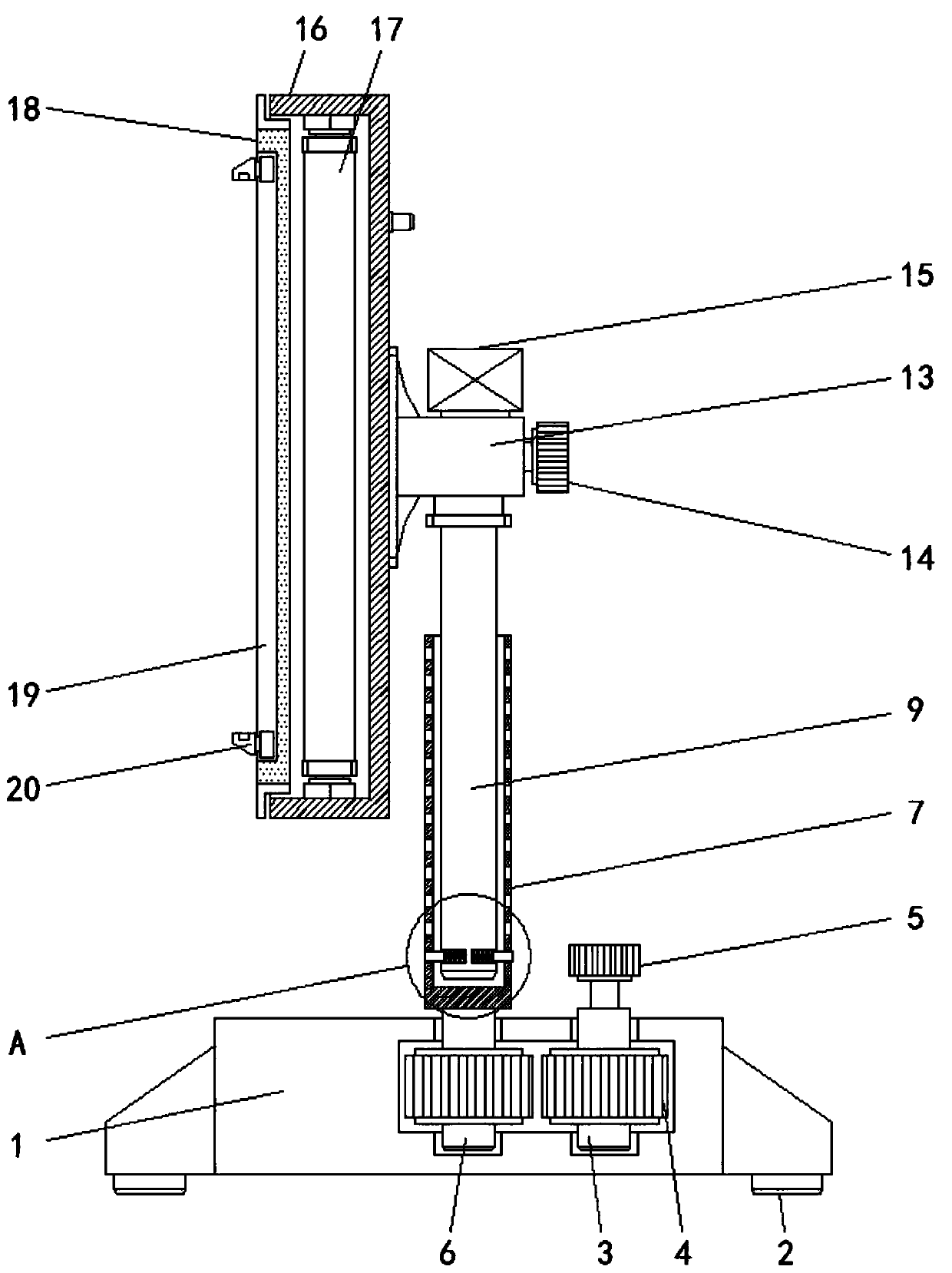

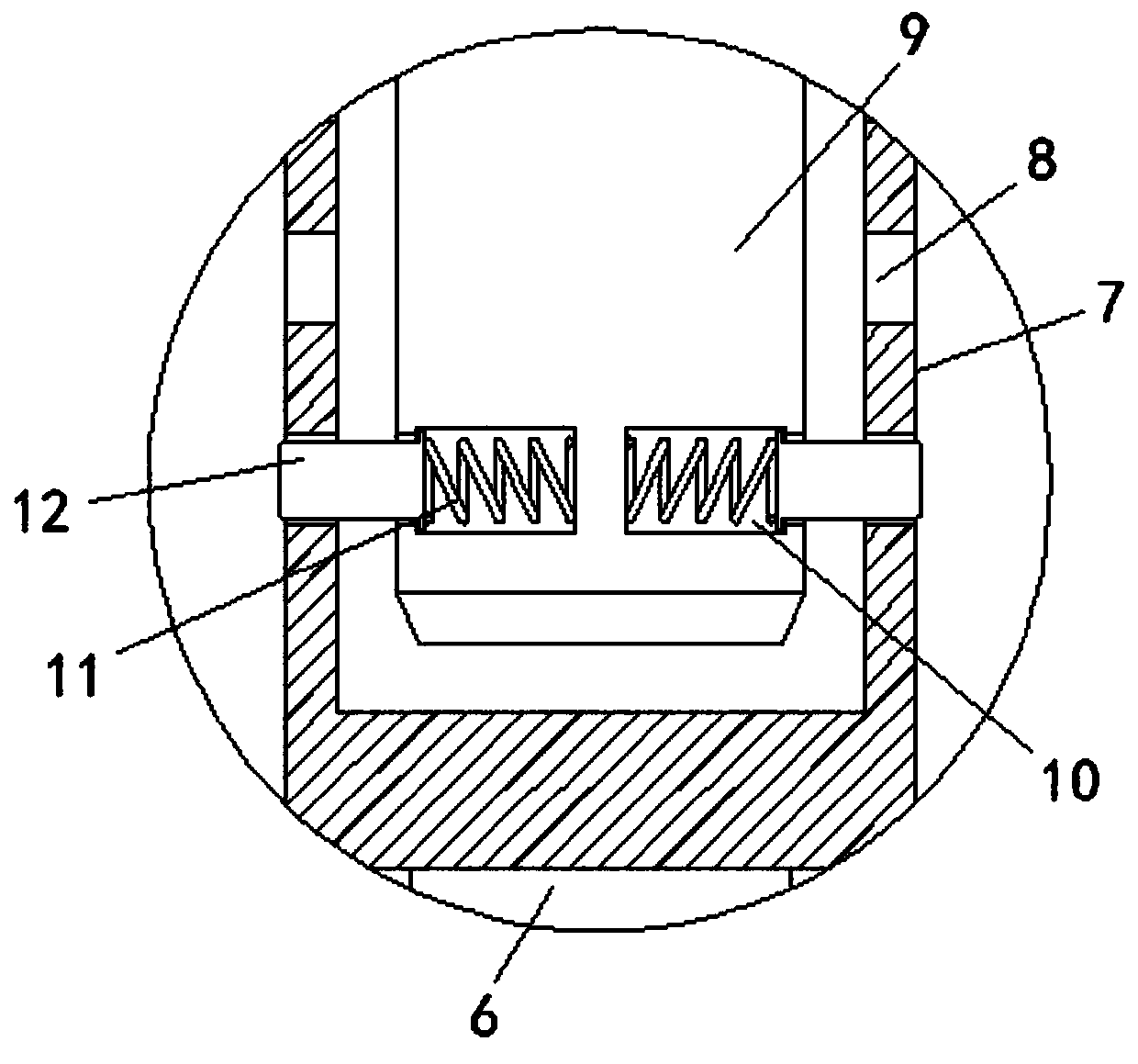

High-rise building measurement control point projection positioning auxiliary device and using method thereof

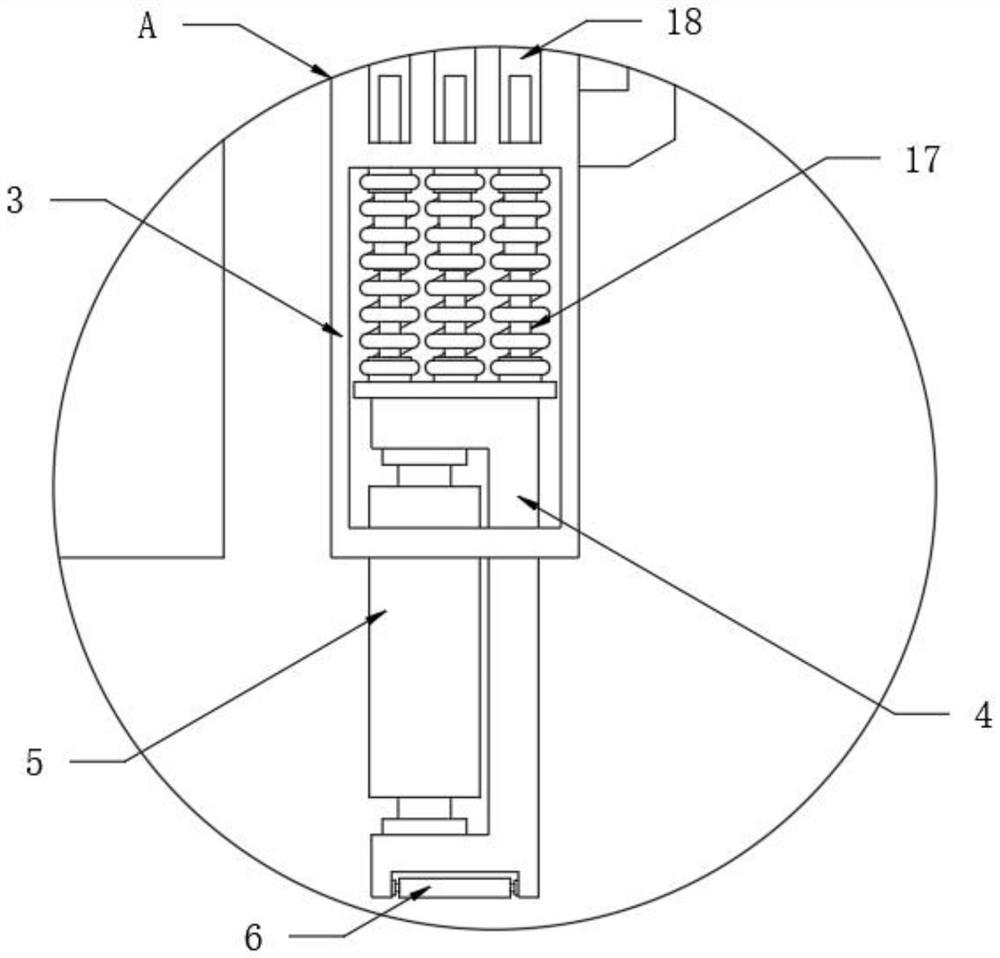

InactiveCN104034319ASolve the accuracy problemFix stability issuesMeasuring points markingEngineeringHigh rise

The invention relates to a high-rise building measurement control point projection positioning auxiliary device and a using method thereof. The device consists of an upper cover plate, a lower cover plate and a laser receiving target, wherein the upper cover plate is connected with the lower cover plate through a connecting shaft; the lower cover plate is covered with the upper cover plate; an upper cover lock of the upper cover plate is aligned to a lock hole of a lower bottom plate; the lower cover plate is internally provided with four rectangular holes; positioning adjusting screw rods are arranged on four sides of the rectangular holes; the positioning adjusting screw rods are provided with bolts; the laser receiving target is arranged into a groove in match with the laser receiving target, in the lower cover plate; elevation points are formed on the plate frame of the lower cover plate. In high-rise building construction measurement, when an internal control method is used, the device is used for receiving laser when a laser plummet is adopted to transmit a bottom layer control point to an upper-layer construction floor, positioning lines are moved by moving the bolts on the positioning adjusting screw rods, and the point location is confirmed through cross points of positioning lines. The device is capable of permanently preserving the control point location, protecting projection holes and improving the construction security; meanwhile as the device is provided with elevation control points, the problems that in the construction process, the elevation control points are not high in precision and the control point location is not stable are solved.

Owner:TONGJI UNIV

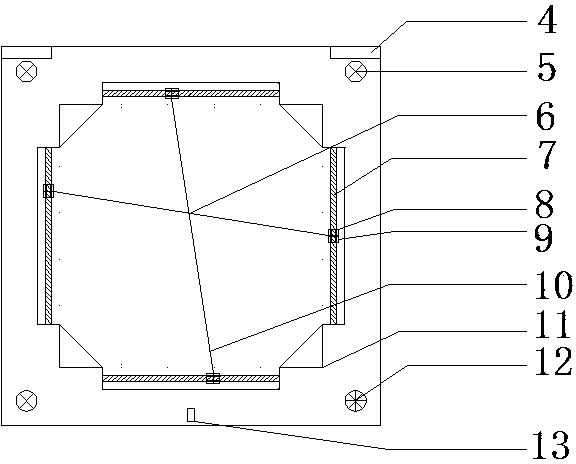

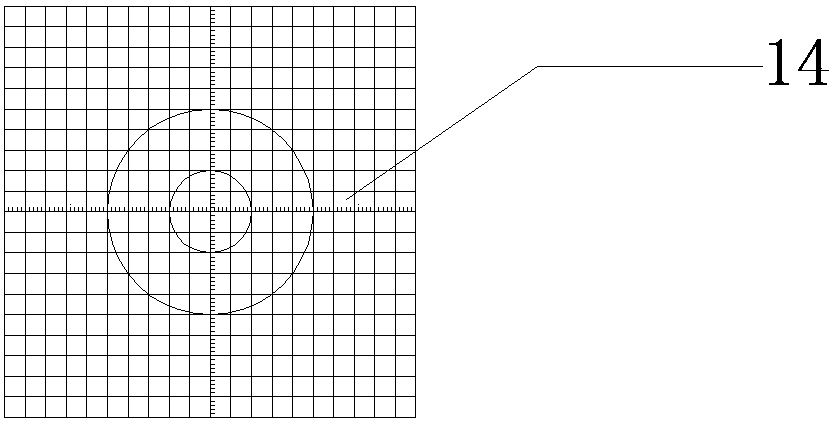

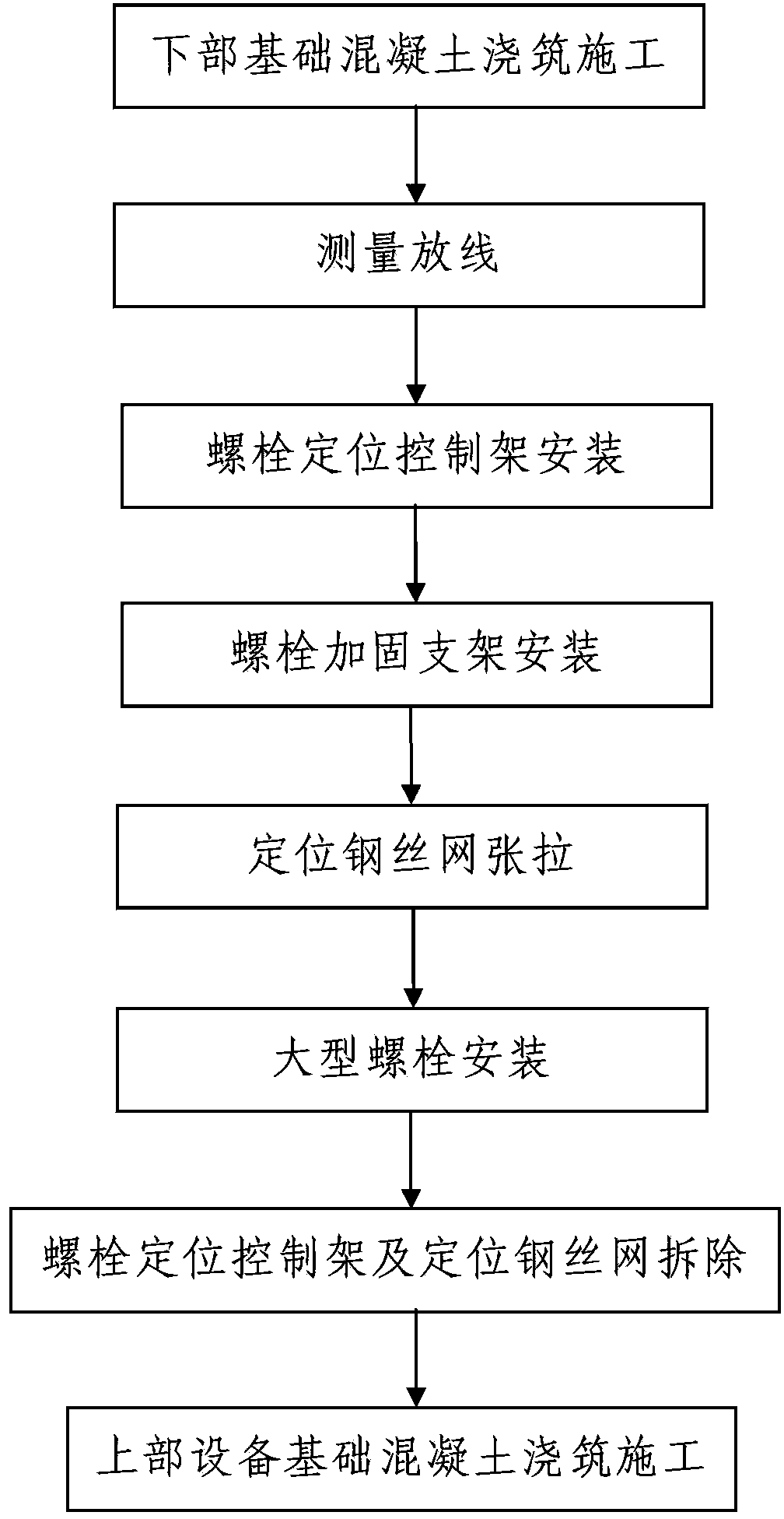

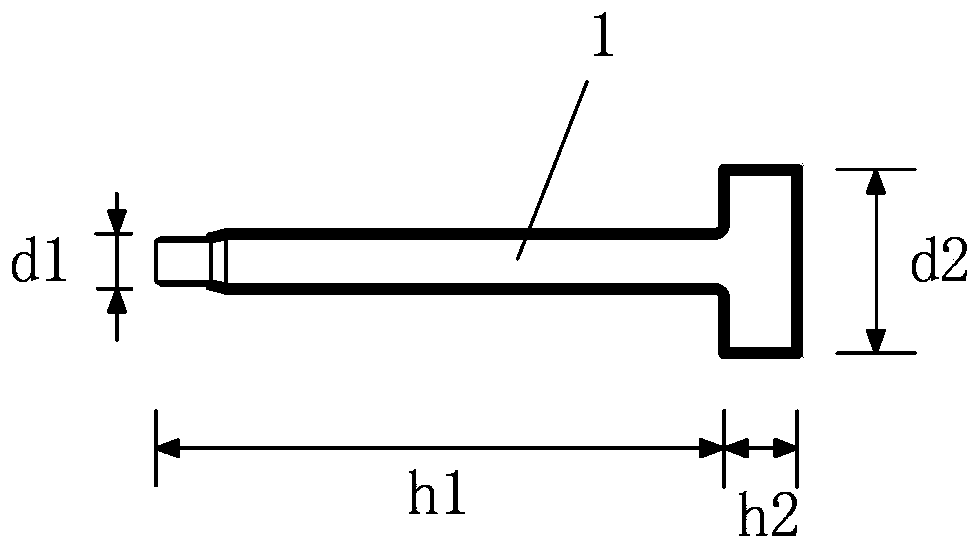

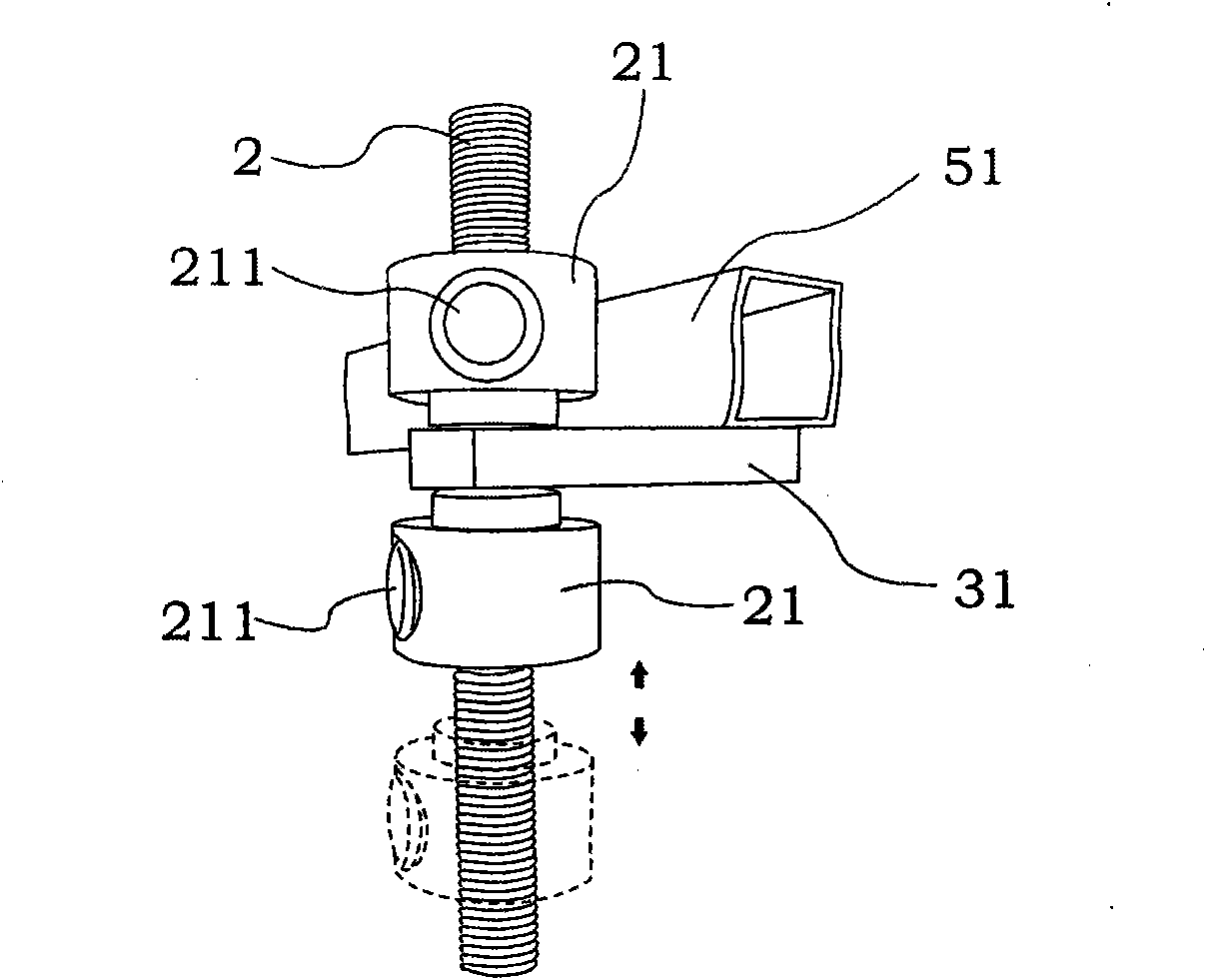

Large-scale bolt high-precision pre-burying construction method

ActiveCN103352476ASimple structureReasonable designFoundation engineeringCushionBuilding construction

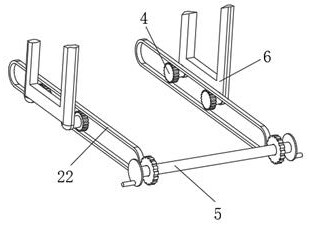

The invention discloses a large-scale bolt high-precision pre-burying construction method. The number of pre-buried large-scale bolts is N, all the large-scale bolts are pre-buried in a construction device foundation, the large-scale bolts comprise screw rods and bases, external threads are arranged at the top ends of the screw rods, the bases are arranged on the bottom portions of the screw rods, and the device foundation is divided into a lower foundation cushion layer and an upper device foundation with the plane where the bottom portions of the bases of the large-scale bolts are located as a boundary. The method comprises a first step of carrying out concrete pouring construction on the lower foundation cushion layer, a second step of carrying out measurement and paying off, a third step of mounting a bolt locating control rack, a fourth step of mounting a bolt reinforcing support, a fifth step of tensioning a locating steel wire net, a sixth step of mounting the large-scale bolts, a seventh step of removing the bolt locating control rack and the locating steel wire net, and an eighth step of carrying out concrete pouring construction on the upper device foundation. The method is simple in process, reasonable in design, convenient to achieve, good in using effect, and capable of simply, conveniently and fast achieving the high-precision pre-burying process of the large-scale bolts in the device foundation in high quality.

Owner:陕西建工第十一建设集团有限公司

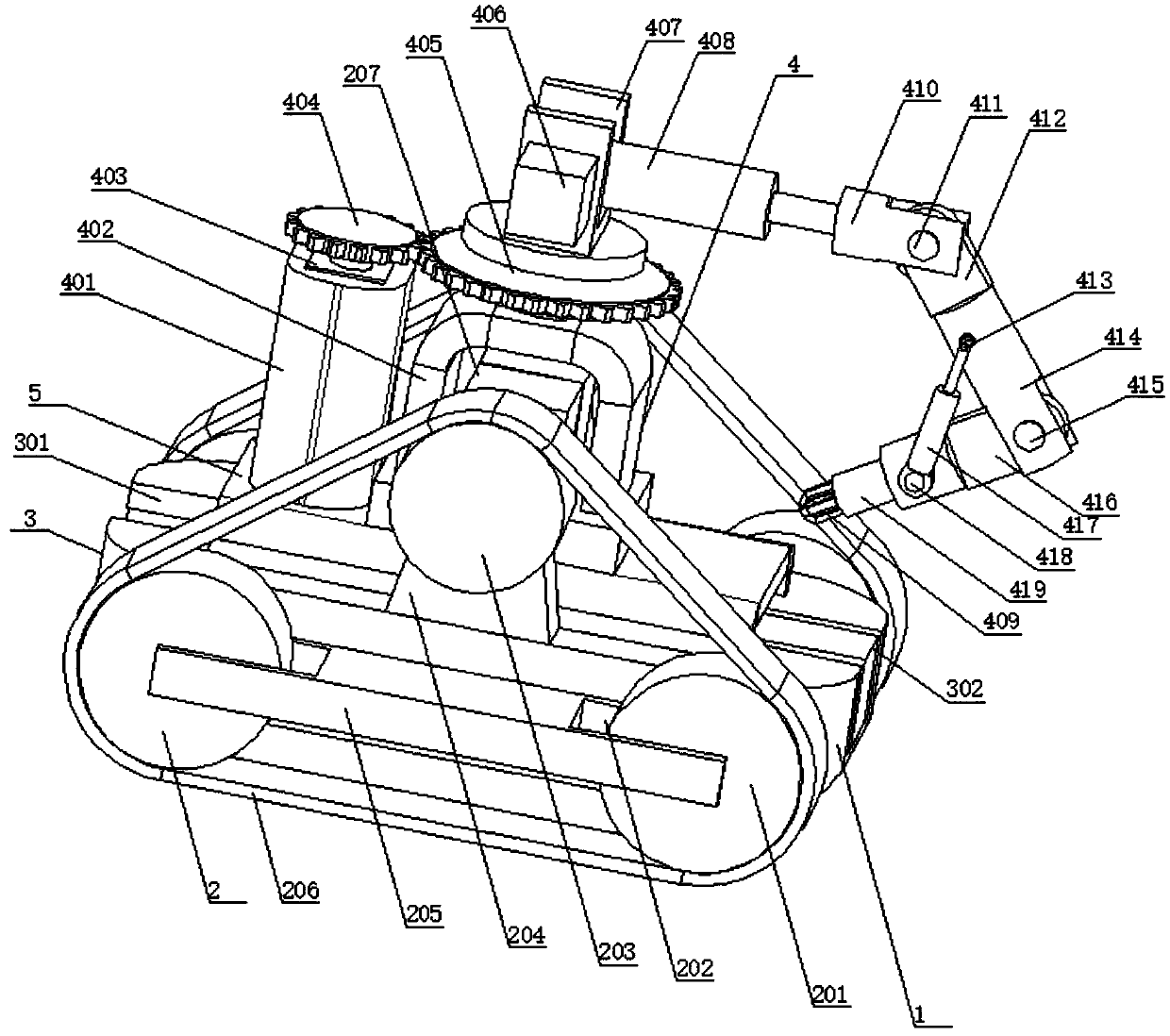

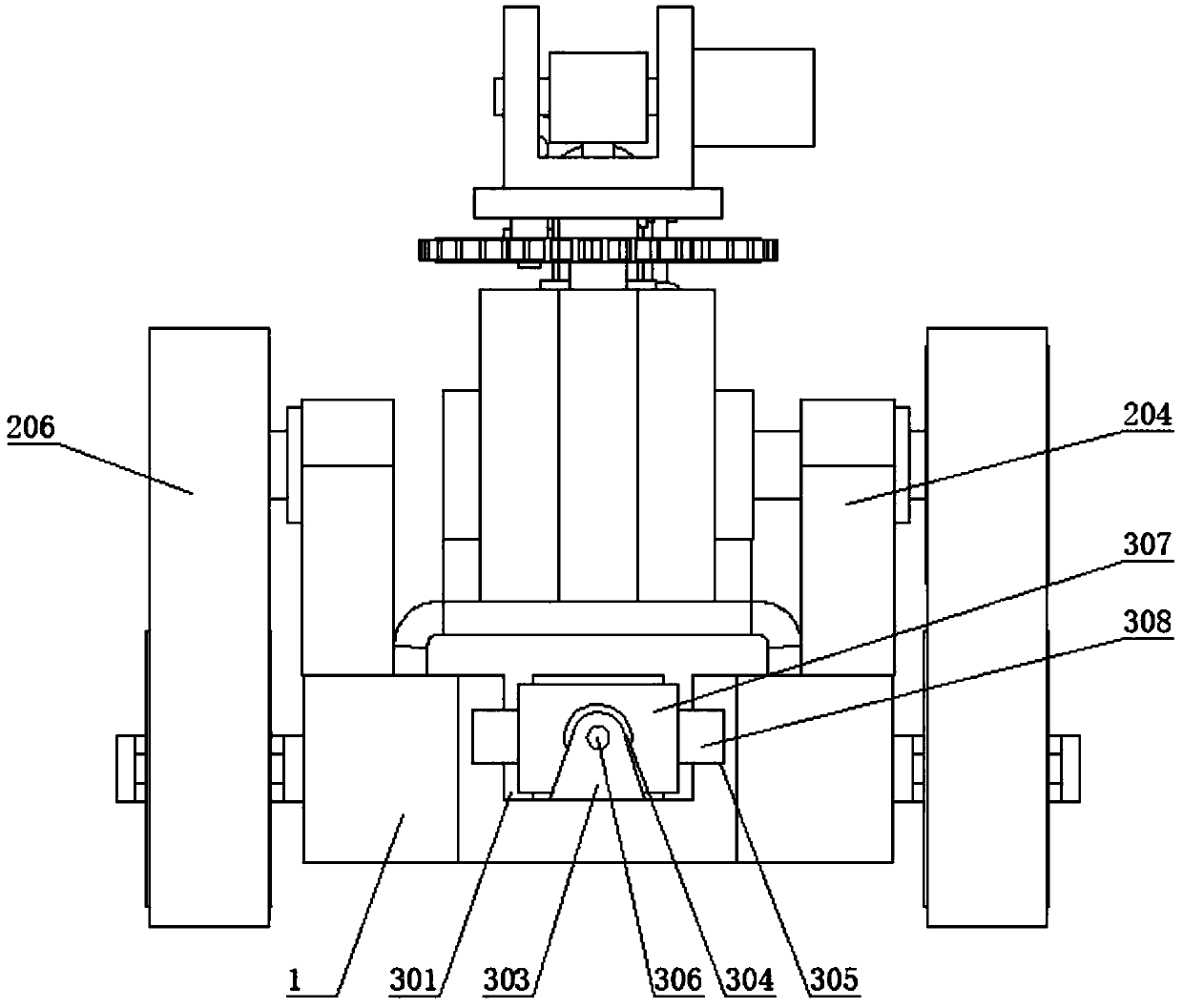

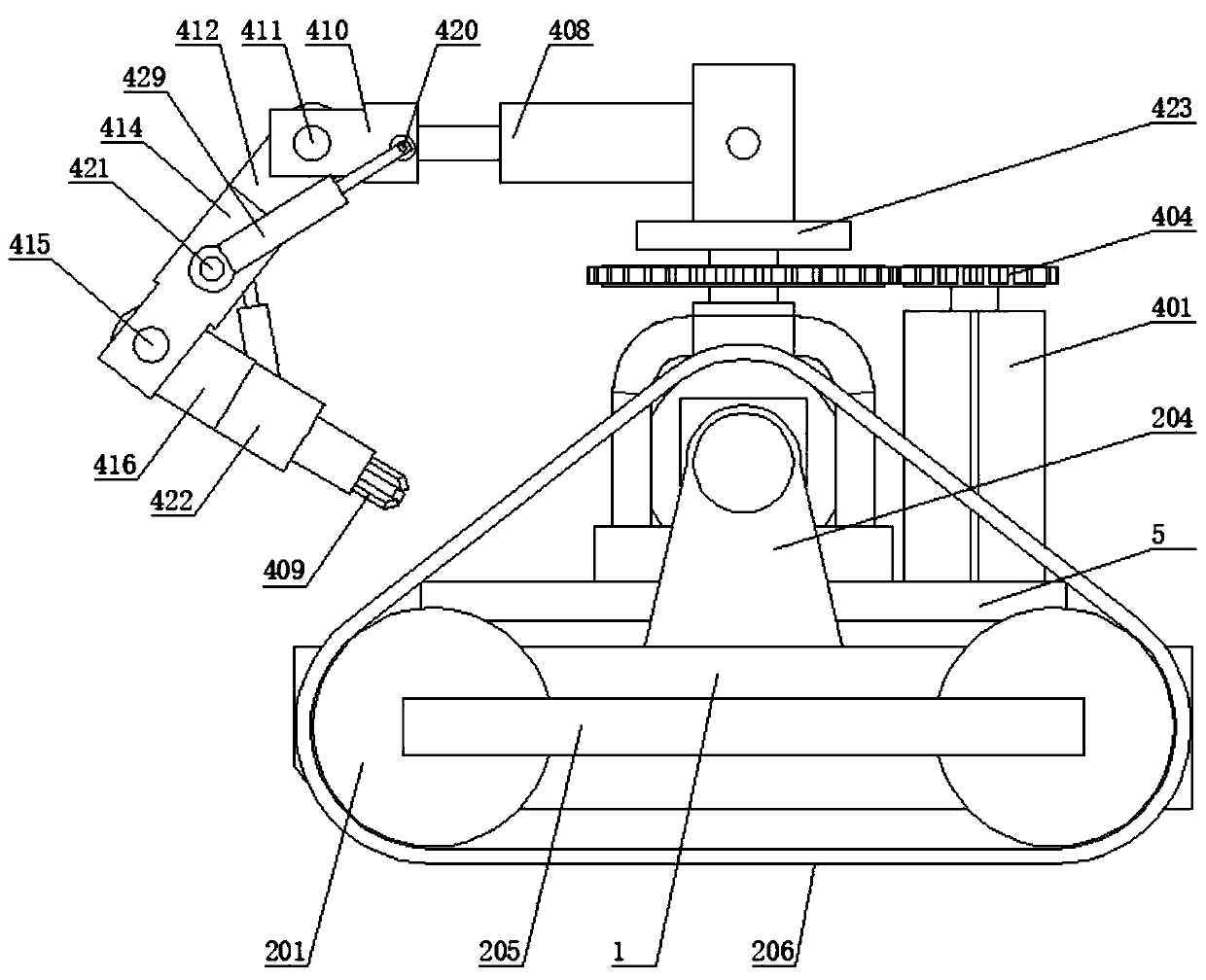

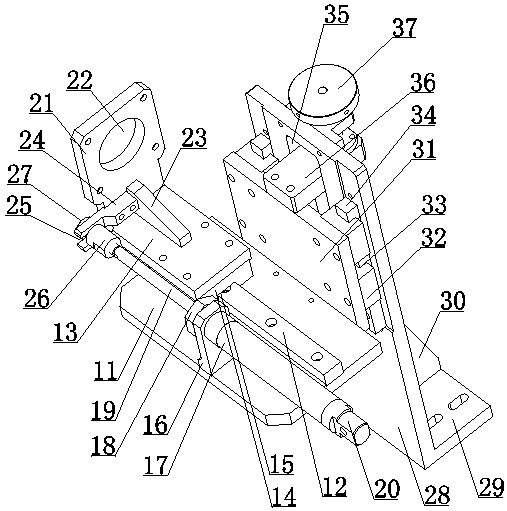

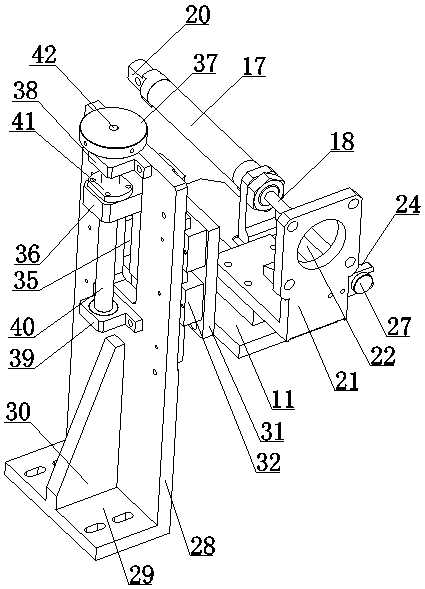

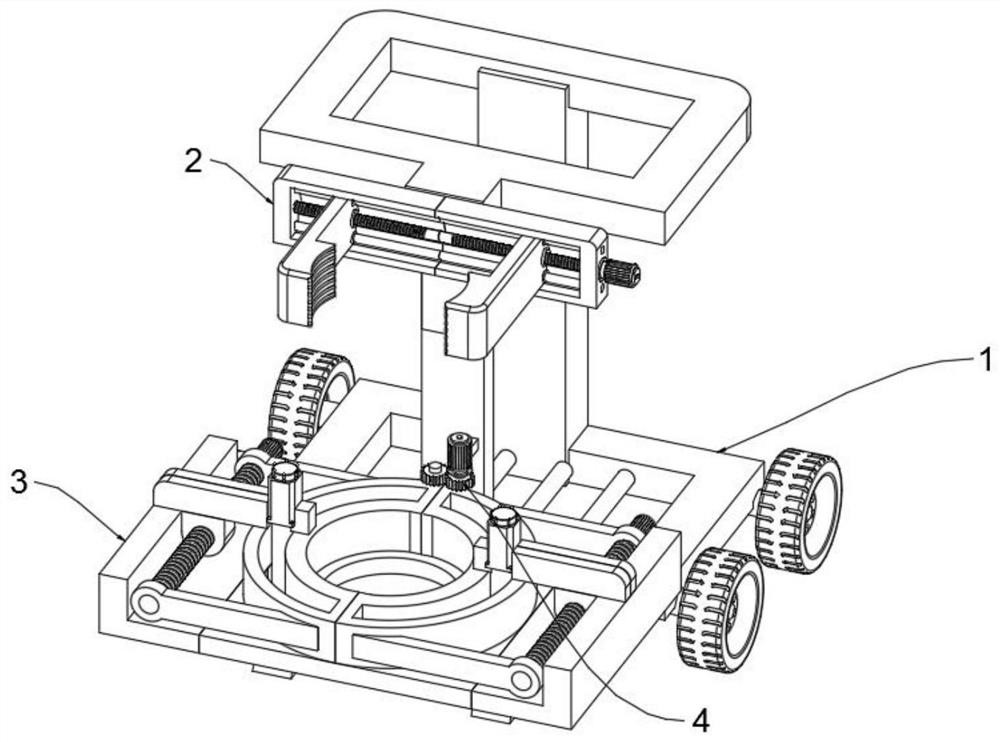

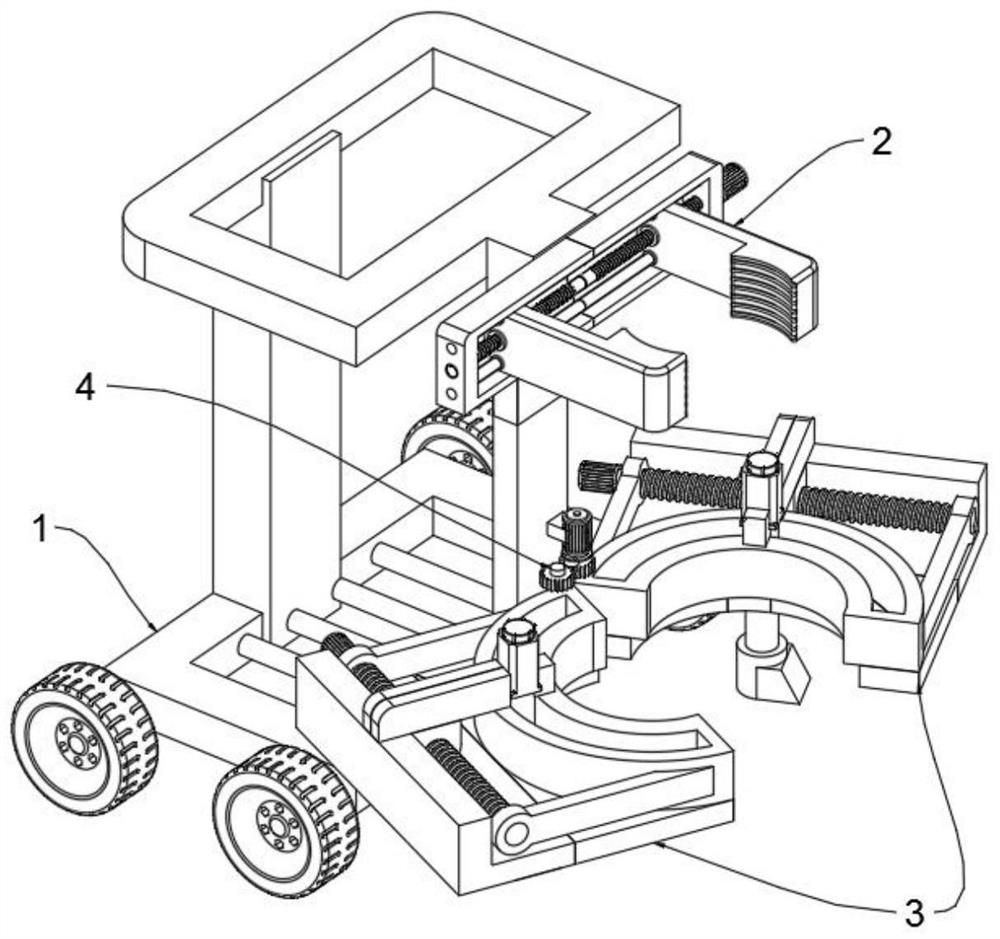

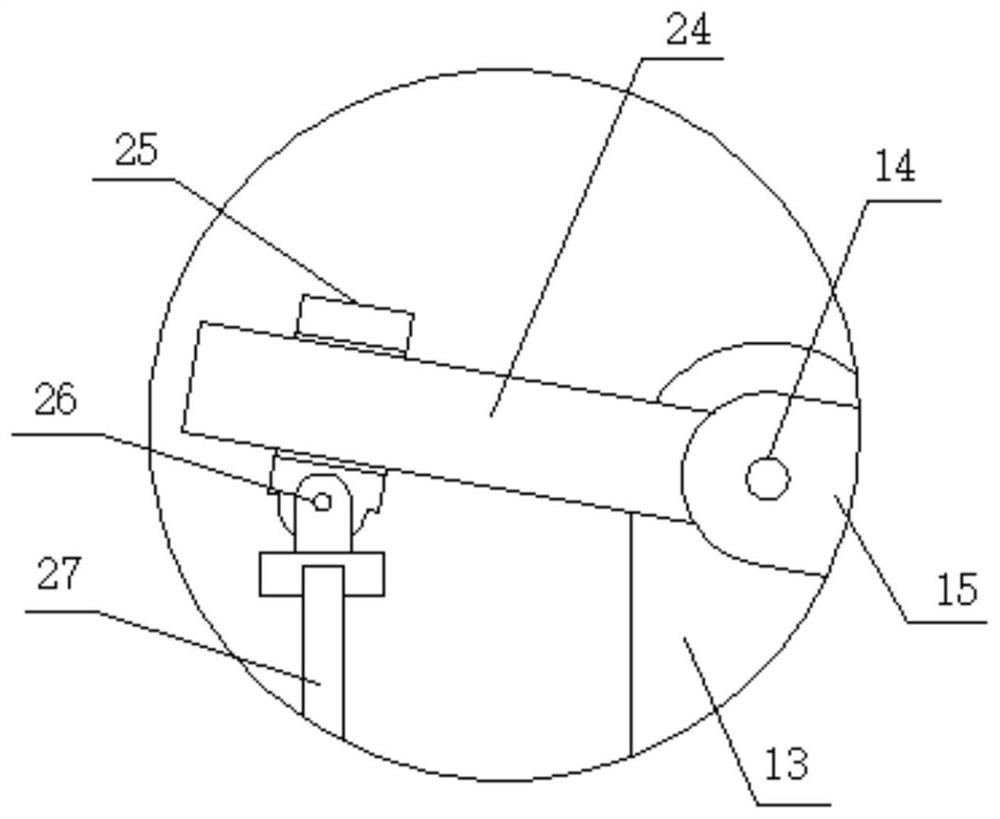

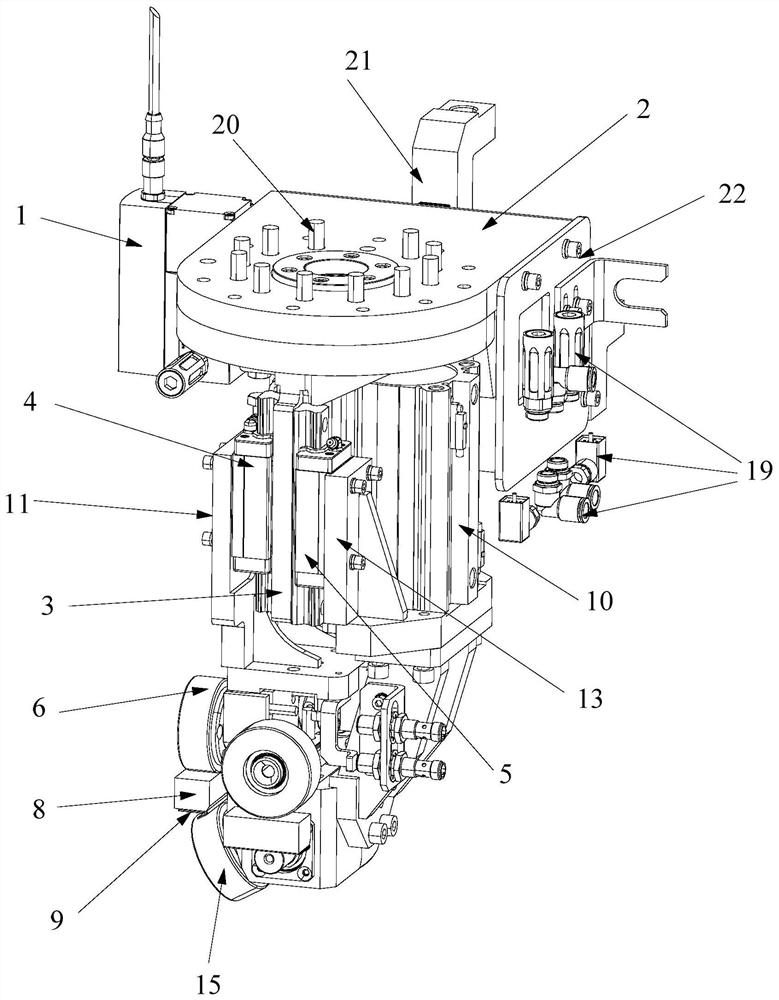

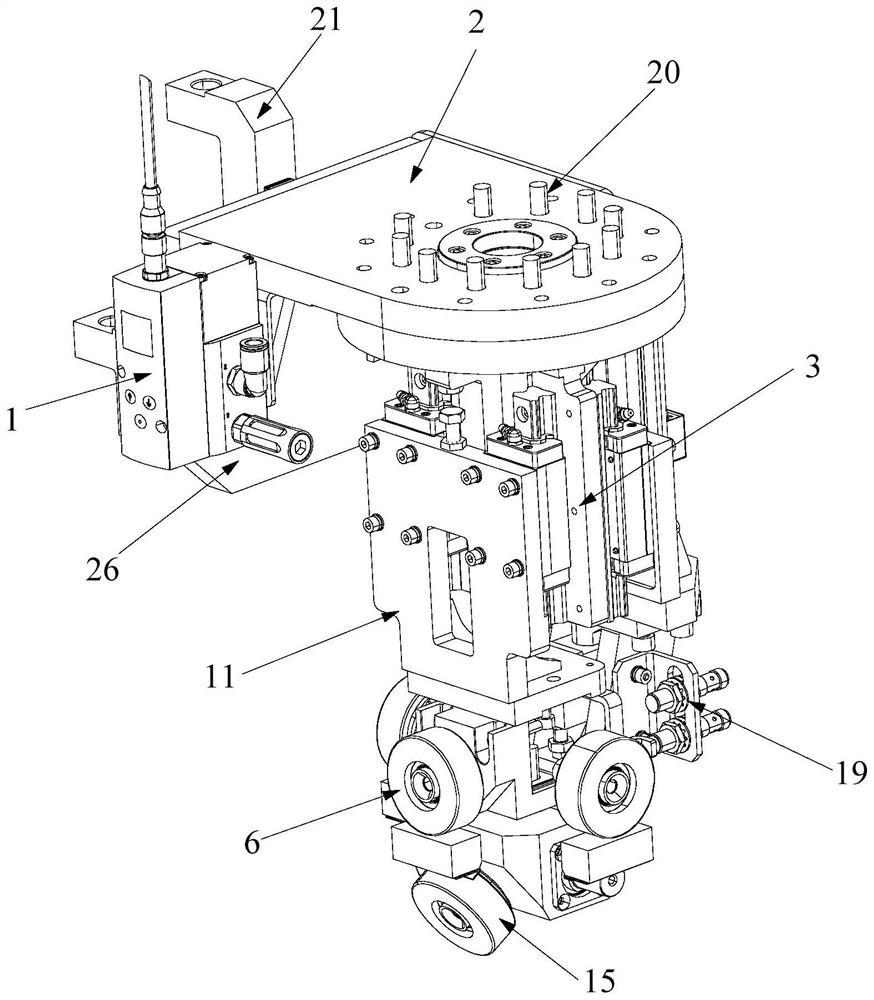

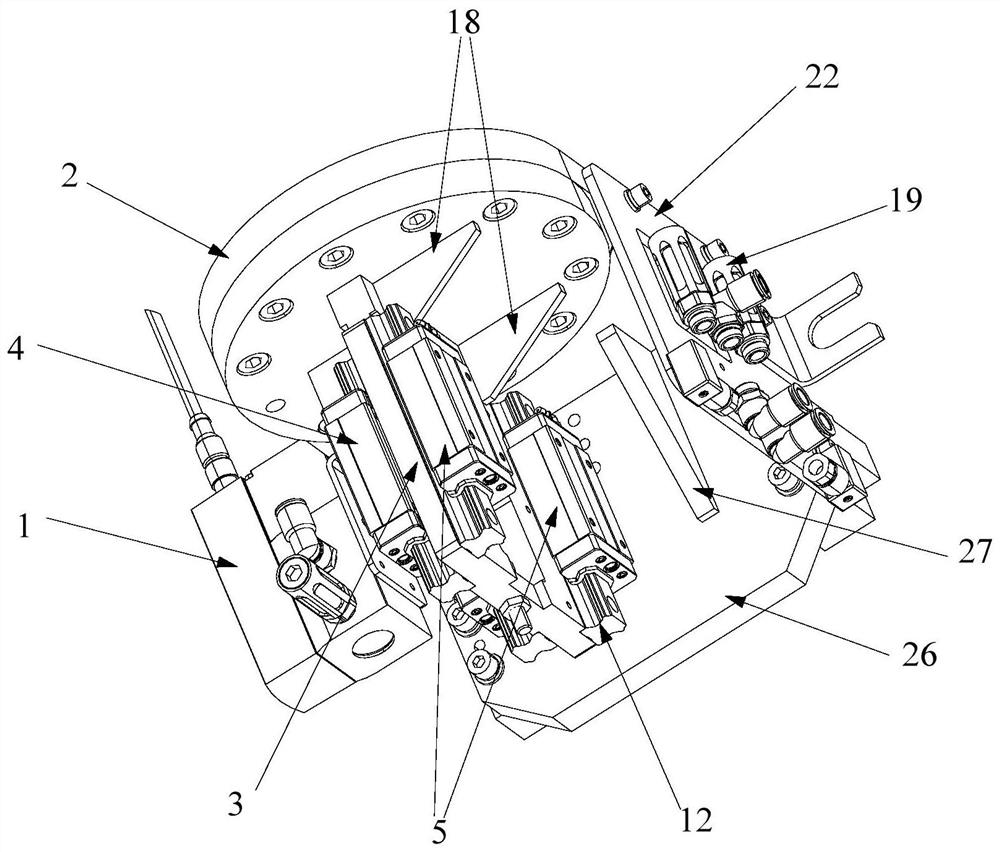

Carrying robot and mechanical arm

ActiveCN109571455AEasy to turnWeight increaseProgramme-controlled manipulatorGripping headsDrive wheelThreaded pipe

The invention discloses a carrying robot and a mechanical arm, and relates to the technical field of robots. The carrying robot comprises a base, driving mechanisms are mounted on the two sides of thebase, a stabilizing mechanism is mounted in the base, and a swing arm mechanism is mounted on the base. According to the carrying robot and the mechanical arm, first servo motors operate to drive driving wheels to rotate, crawler belts are driven to rotate, and therefore the carrying robot is driven to move for transferring; turning operation can be carried out well through the two independent first servo motors, a main control panel of the robot controls a fourth servo motor to operate in the forward direction, therefore, the fourth servo motor operates to drive a threaded rod to rotate in athreaded pipe, the threaded pipe drives a balance weight to move towards the left side, the weight at the left end of the carrying robot is increased, and the weight of an object grabbed by the rightend can be offset; the object grabbing stability of the carrying robot is improved, and the problem of falling down caused during grabbing or conveying is avoided.

Owner:江苏博金斯汽车部件科技有限公司

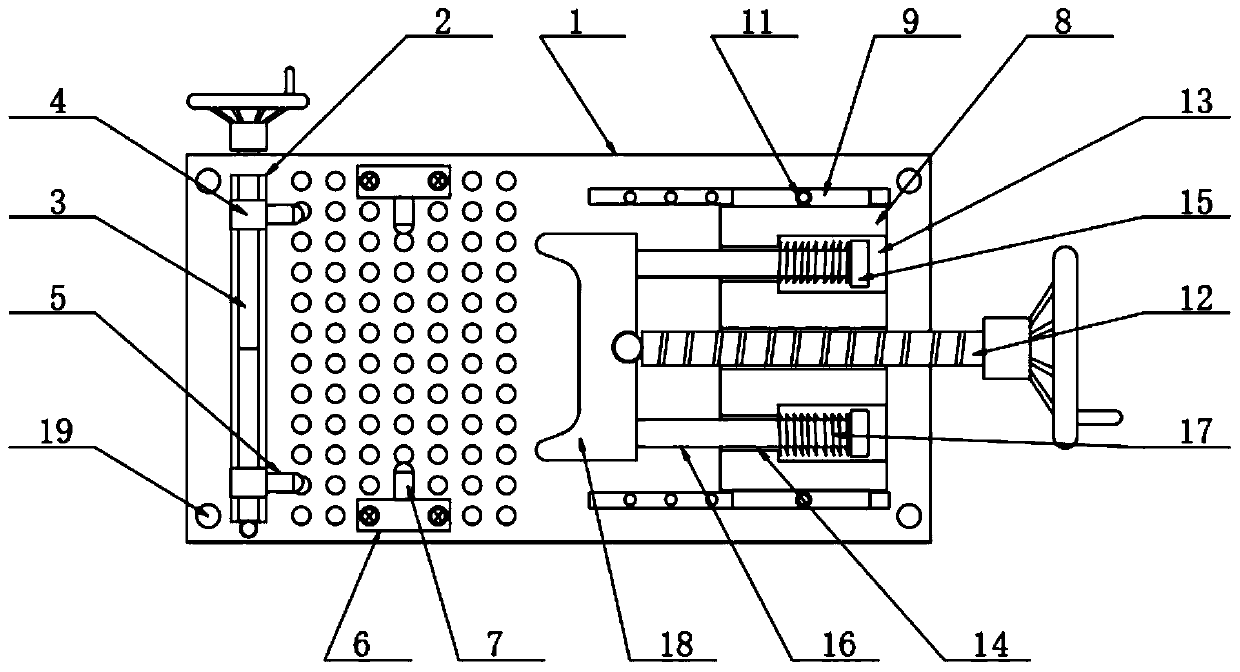

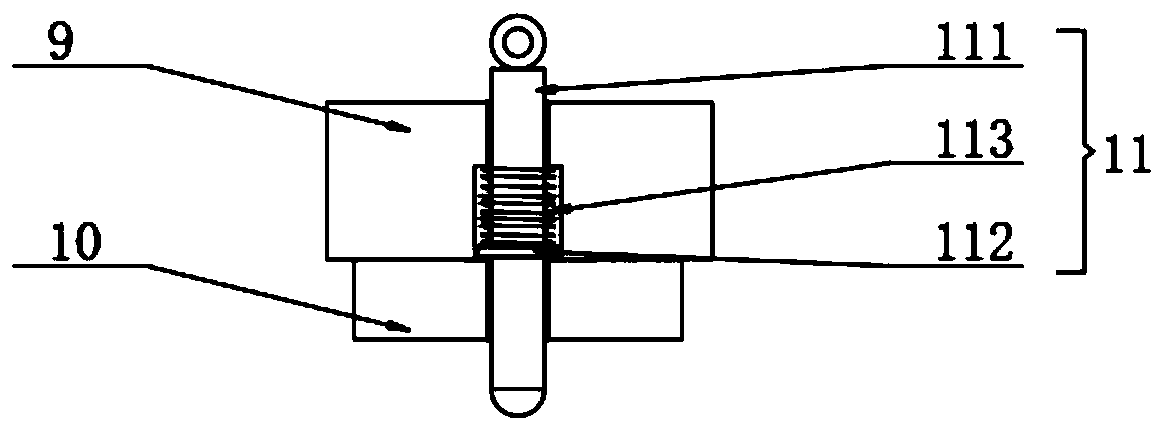

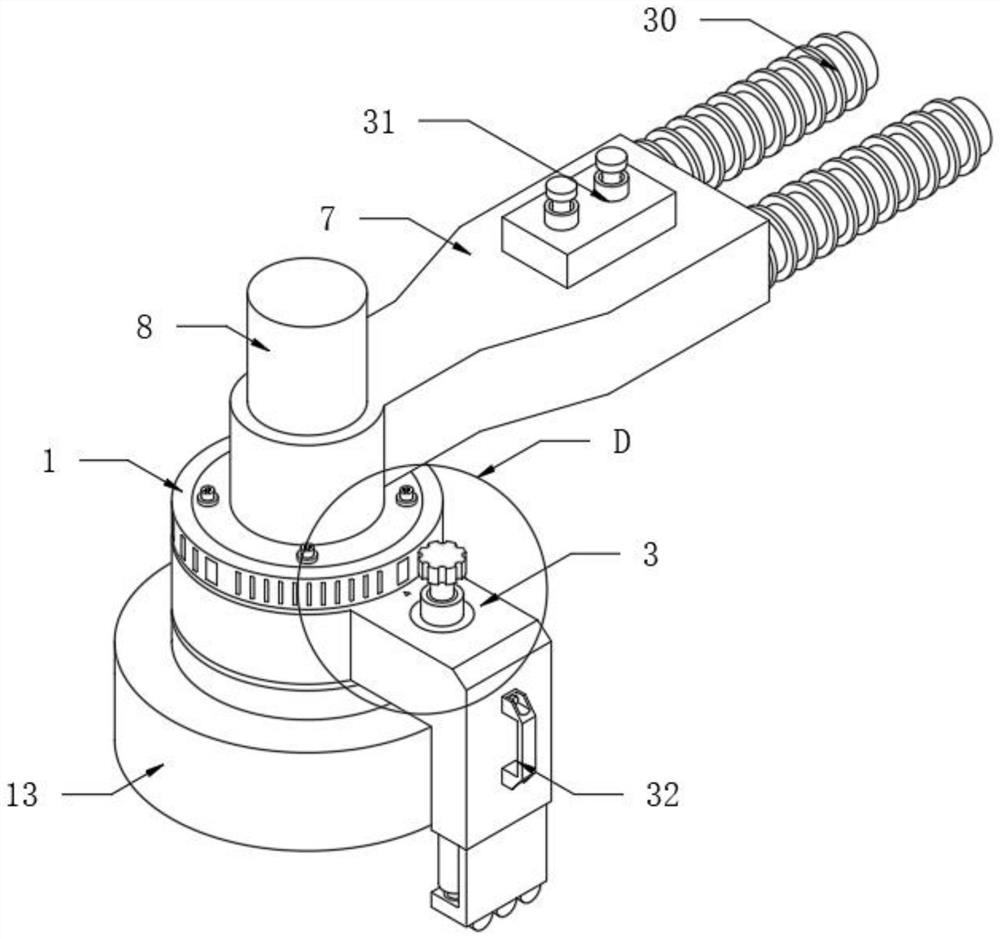

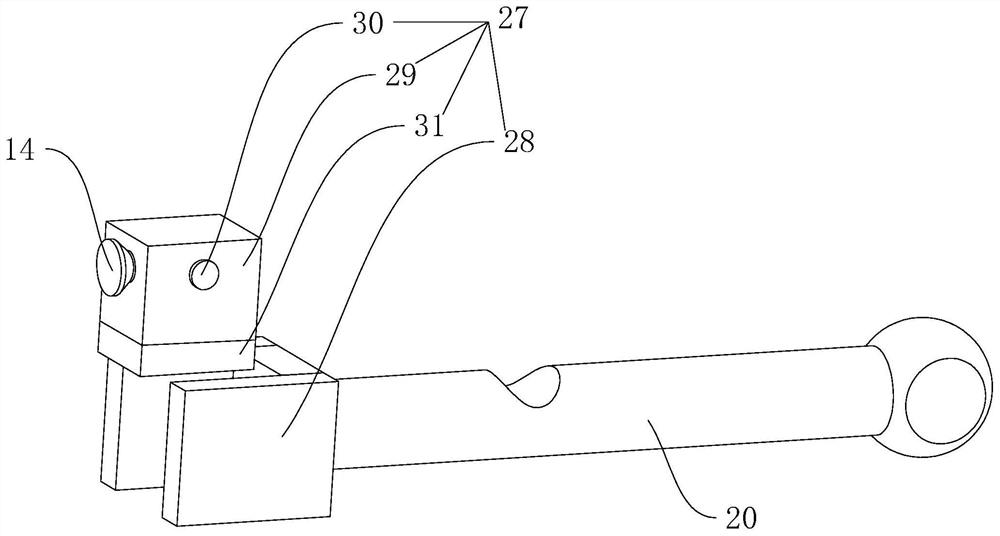

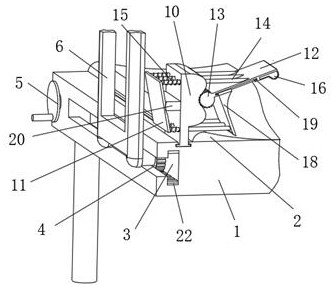

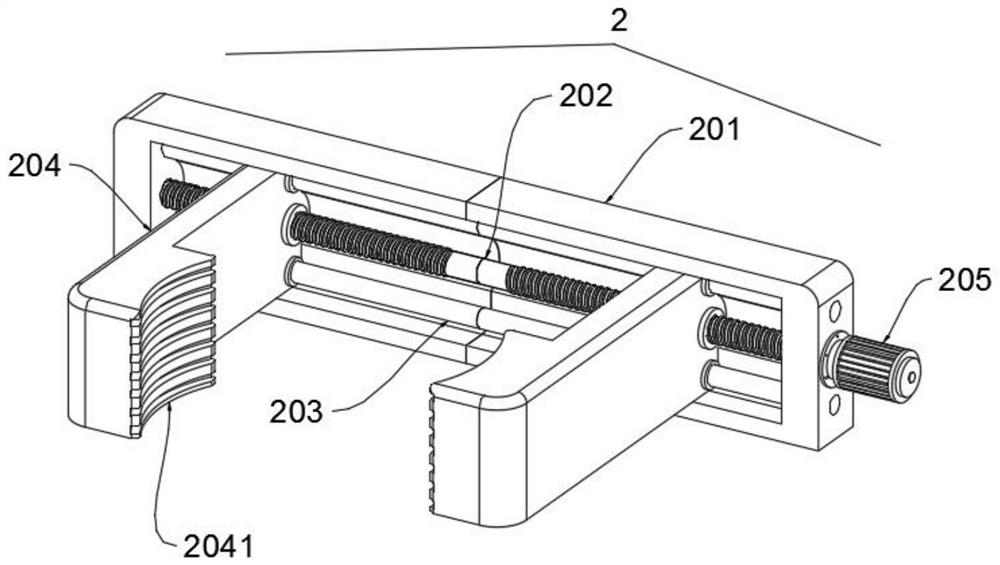

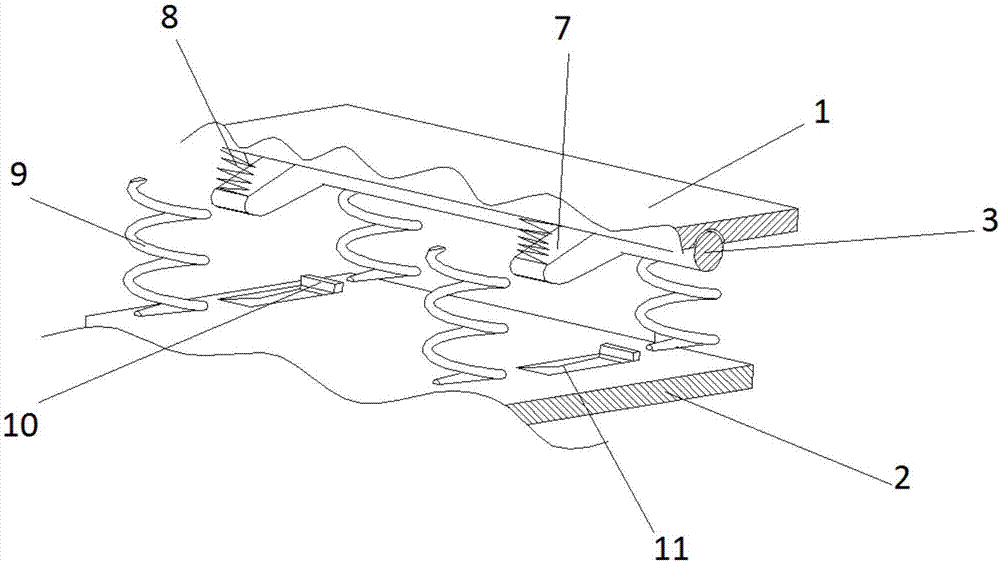

Electromechanical machining clamp for different workpieces

InactiveCN109732378AEasy to position and adjustGuaranteed stabilityPositioning apparatusMetal-working holdersElectromechanicsEngineering

The invention discloses an electromechanical machining clamp for different workpieces in the technical field of electromechanics. The clamp comprises a clamp plate with screw connecting holes evenly formed in the top. The front end and the rear end of the outer wall of a two-way lead screw are symmetrically sleeved with movable blocks matching with a longitudinal sliding groove. The right sides ofthe two movable blocks are each provided with a first cuphead positioning pin. A screw rod is inserted in the middle of the right side of a mounting block. The left end of the screw rod penetrates through the mounting block and is movably connected with a clamping block through a rotating ball. The front end and the rear end of the right outer wall of the clamping block are each provided with a support rod. The left end of each support rod penetrates through the mounting block and is connected with a limit ring. The clamping block moves towards a workpiece by rotating the screw rod; as the diameter of a small hole is greater than the diameter of the support rods, when one end of the clamping block makes contact with the workpiece firstly, the clamping block tilts to the end making contactwith the workpieces firstly till the end not making contact with the workpiece makes contact with the workpiece, and the clamping operation is completed; thus, irregular planes of the workpiece can be clamped conveniently, and clamping is balanced and stable.

Owner:SHANGHAI AIDENGBAO ELEVATOR JIANGSU

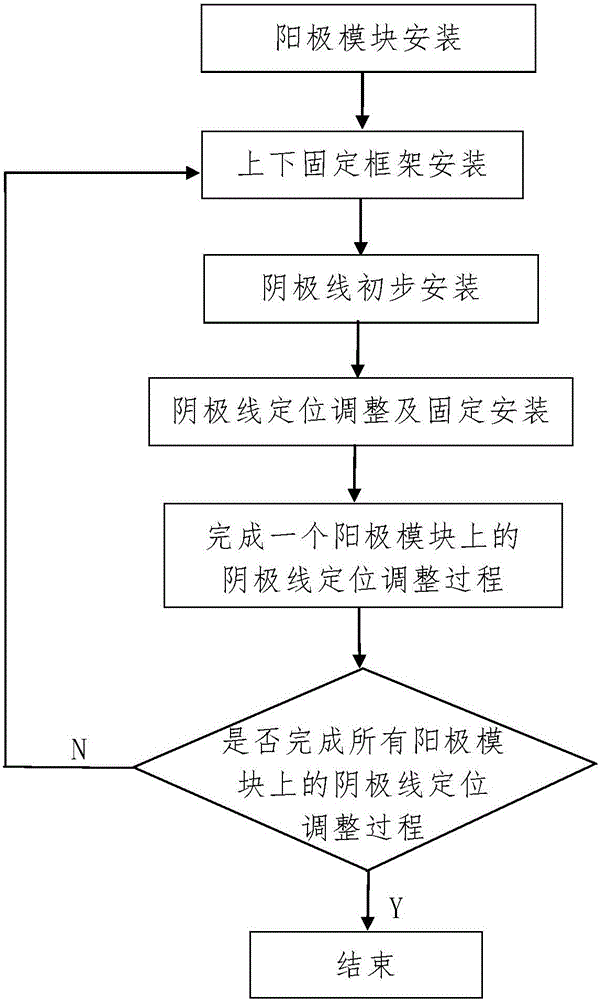

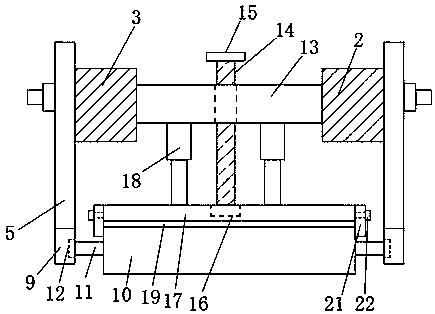

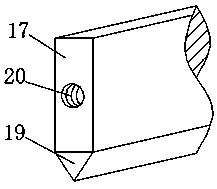

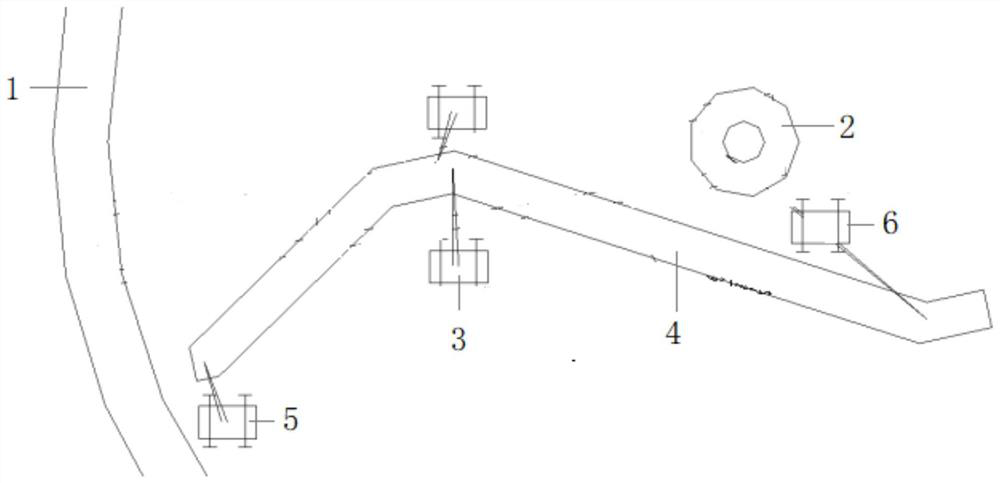

Cathode line positioning die and cathode lien positioning and adjustment construction method

ActiveCN106238212ASimple structureEasy to processElectrostatic separation detailsArchitectural engineeringAnode

The invention discloses a cathode line positioning die and a cathode lien positioning and adjustment construction method. The positioning die comprises a rear measuring rod, a front measuring rod arranged on the front side of the middle of the rear measuring rod and a vertical rod fixed behind the rear portion of the front measuring rod, wherein the front measuring rod and the vertical rod are located in front of the rear measuring rod, the rear measuring rod, the front measuring rod and the vertical rod are straight rods, the rear measuring rod and the front measuring rod are arranged in a perpendicular mode, the rear measuring rod and the front measuring rod form a horizontal positioning rack, and a clamping groove for positioning an adjusted cathode line is formed in the rear side of the middle of the rear measuring rod. The constriction method comprises the steps that 1, anode module installation is performed; 2, cathode line installation construction is performed: when the cathode line is installed on any group of anode modules, the process is that 201, upper and lower fixing frames are installed; 202, preliminary cathode line installation is performed; 203, cathode line positioning, adjustment and fixing installation are performed. The cathode line positioning die is reasonable in design, simple and convenient to use and operate, good in using effect and capable of simply, conveniently and rapidly perform accurate cathode line positioning and ensuring cathode line installing precision.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

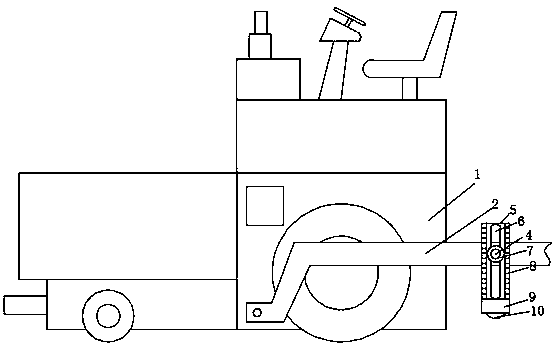

Bituminous concrete paver

PendingCN108532417AEasy height adjustmentEasy to cleanRoads maintainenceArchitectural engineeringBituminous concrete

The invention discloses a bituminous concrete paver. The bituminous concrete paver comprises a machine body, wherein a first traction arm and a second traction arm are arranged at two sides of the machine body. By fixedly arranging a screw rod on the first traction arm and the second traction arm and forming sliding grooves in lifting plates, the lifting plates can be conveniently fixed to the screw rod through locating nuts, so that a locating function can be achieved; by connecting the middle part of a supporting rod with a lifting rod in a threaded way, a locating plate can be convenientlydriven to regulate the height by the lifting rod, two sides of the supporting rod and the locating plate are connected through telescopic rods, and the telescopic rods have guiding and limiting functions on the locating plate; by fixedly arranging a scraper on the lower surface of the locating plate, bituminous concrete attached to the surface of a paving roller can be conveniently cleaned; two sides of the locating plate are in threaded connection with baffle plates through screws, so that two sides of the paving roller can be conveniently baffled, and the bituminous concrete on the surface of the paving roller is not easy to leak towards two sides.

Owner:CHINA CONSTR EIGHTH ENG DIV

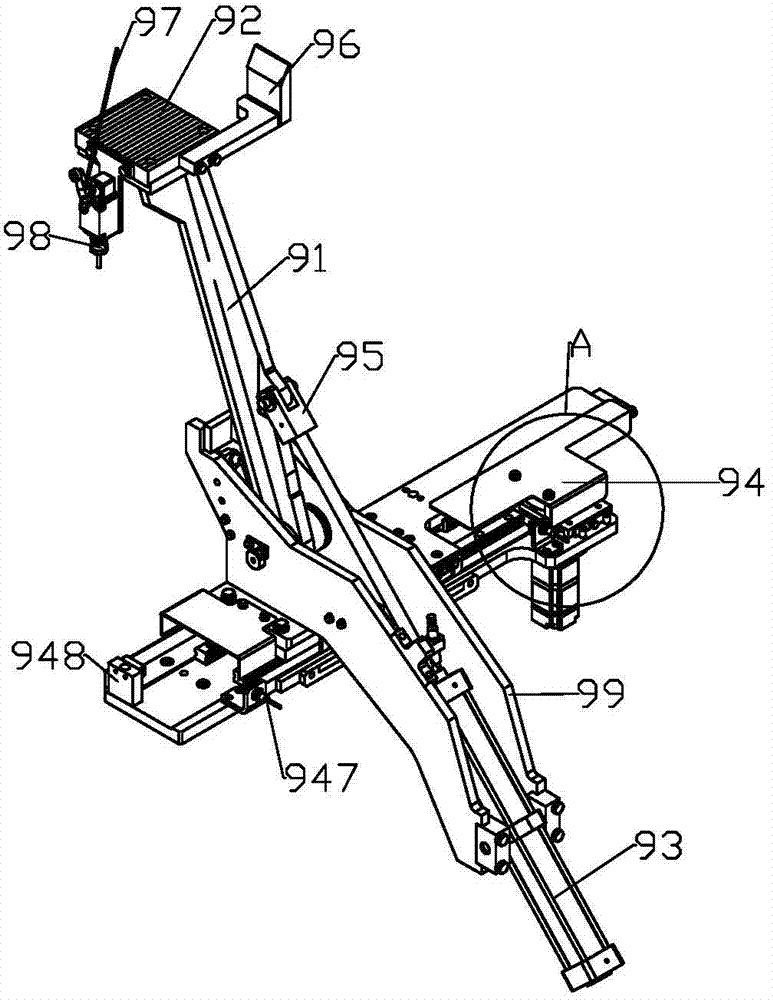

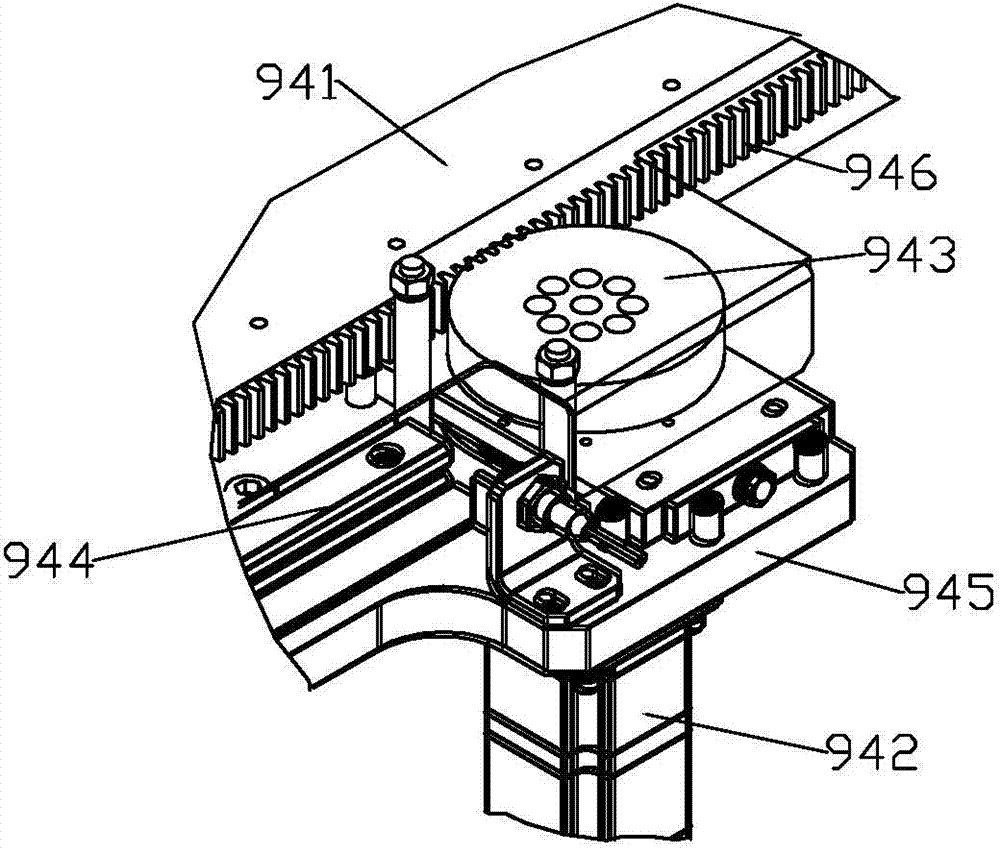

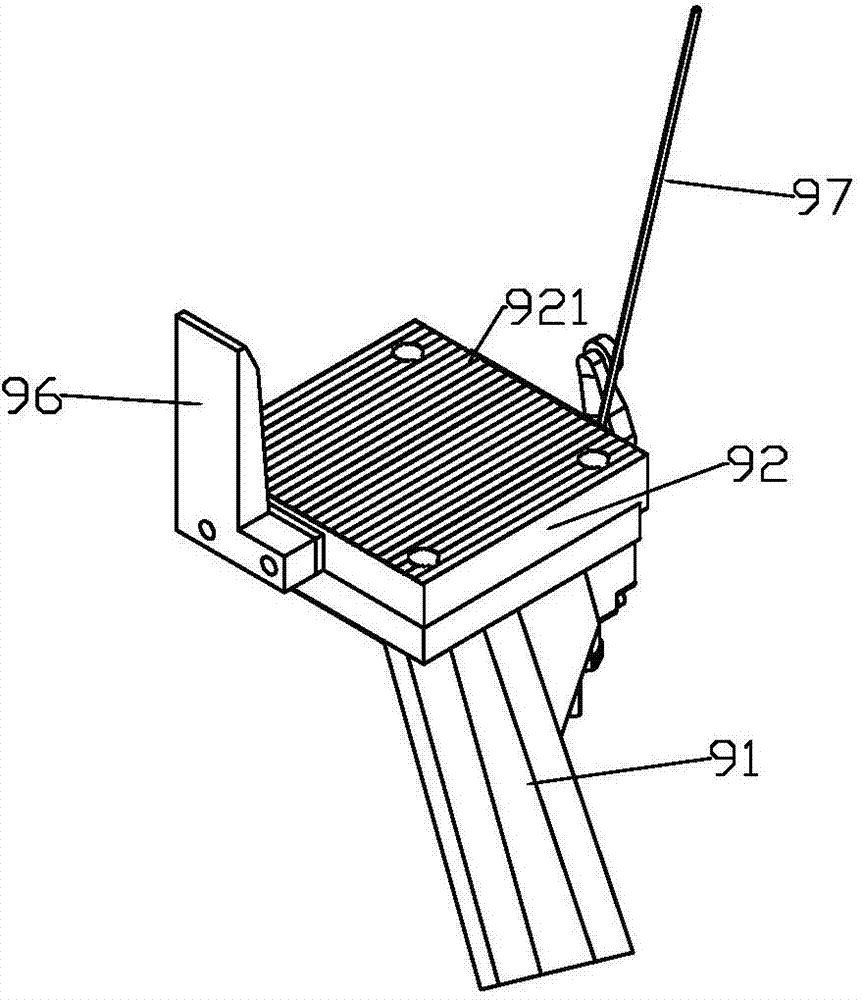

Welding feeding device of car threshold assembly

InactiveCN104476023AEasy transfer carConvenient transfer car positioningWelding/cutting auxillary devicesAuxillary welding devicesProduction lineIndustrial engineering

The invention relates to the car body manufacture field and provides a welding feeding device of a car threshold assembly. The welding feeding device of the car threshold assembly comprises a base, a workpiece transfer car, a material shelf, a guiding component used for locating the workpiece transfer car and the material shelf, a locating component used for locating the material shelf and workpiece transfer car, and a feeding robot. The welding feeding device of the car threshold assembly is controlled by a controller; the material shelf having the threshold assembly is transported to the workpiece transfer car and located by the locating component; the workpiece transfer car having the threshold assembly and the material shelf is transported to the base and located by the guiding component; the controller controls the feeding industrial robot for gradually locating the threshold assembly on the car main body on the lower car body welding production line to be welded by the welding robot. The welding feeding device of the car threshold assembly is convenient to adjust and locate before welding operation and the adjusting efficiency is high, and the welding quality is stable.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

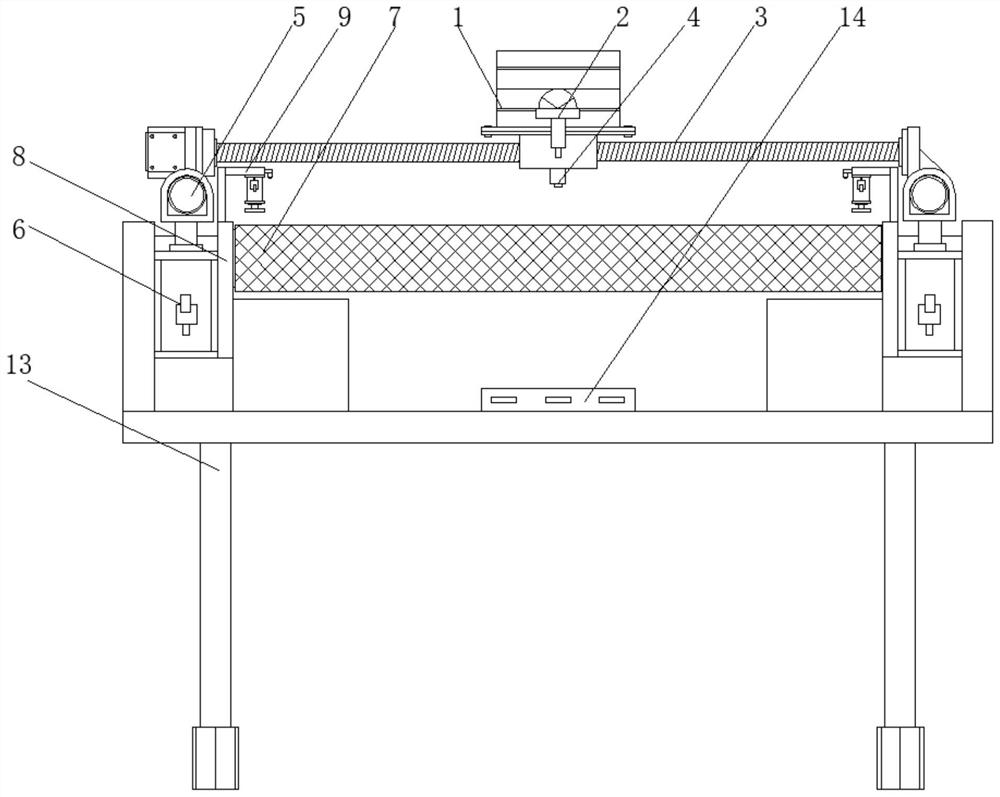

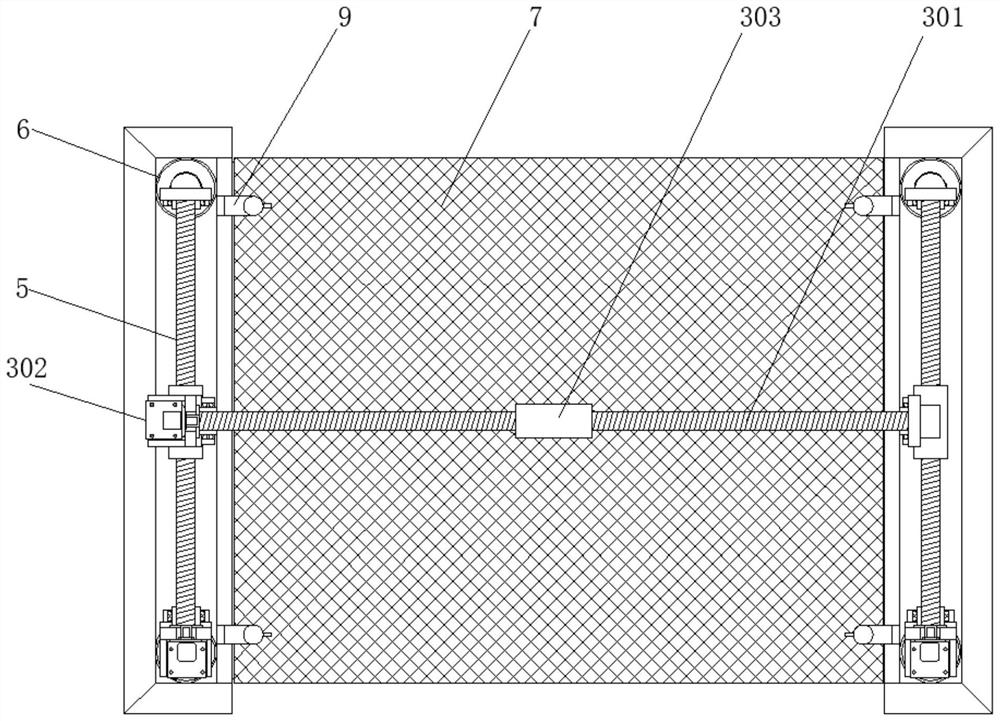

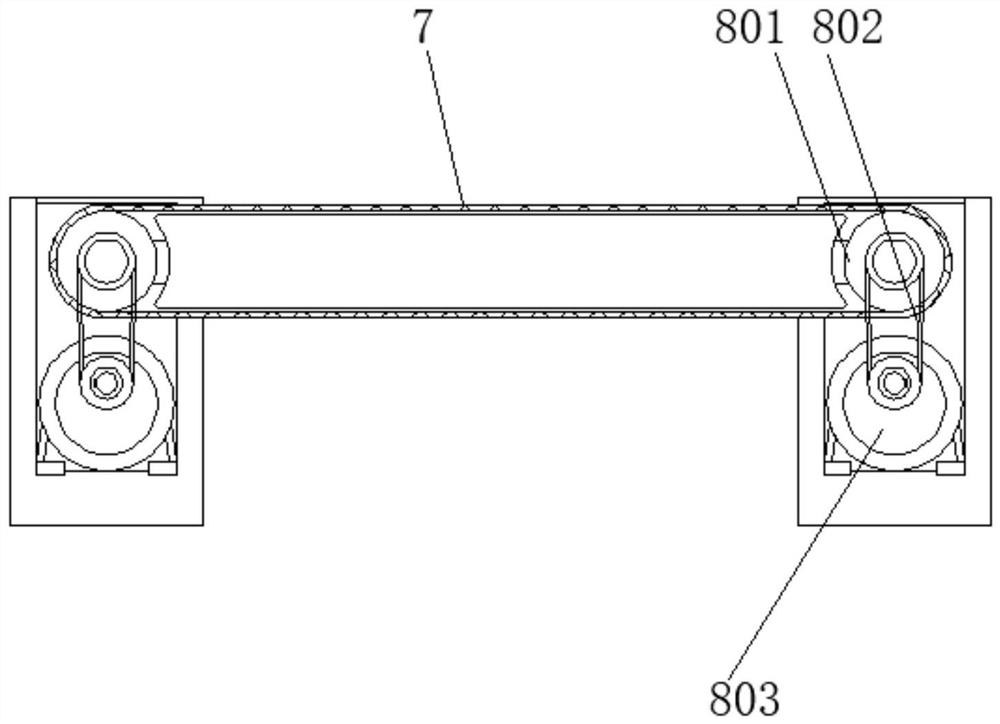

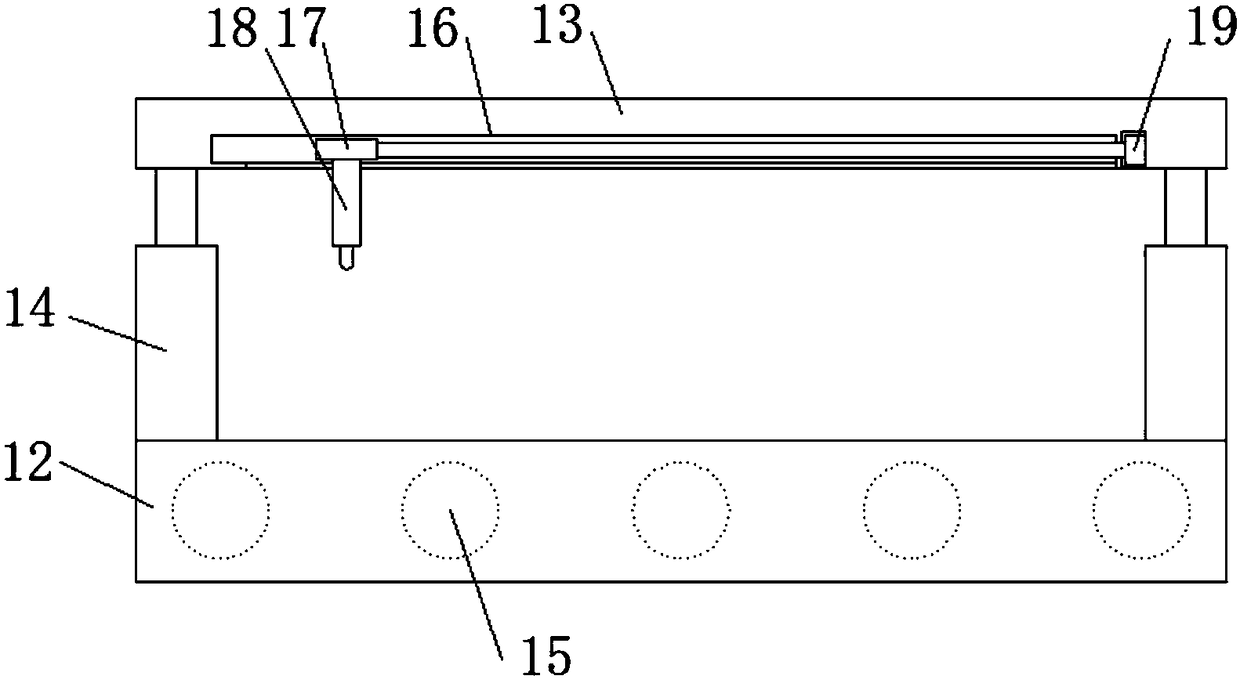

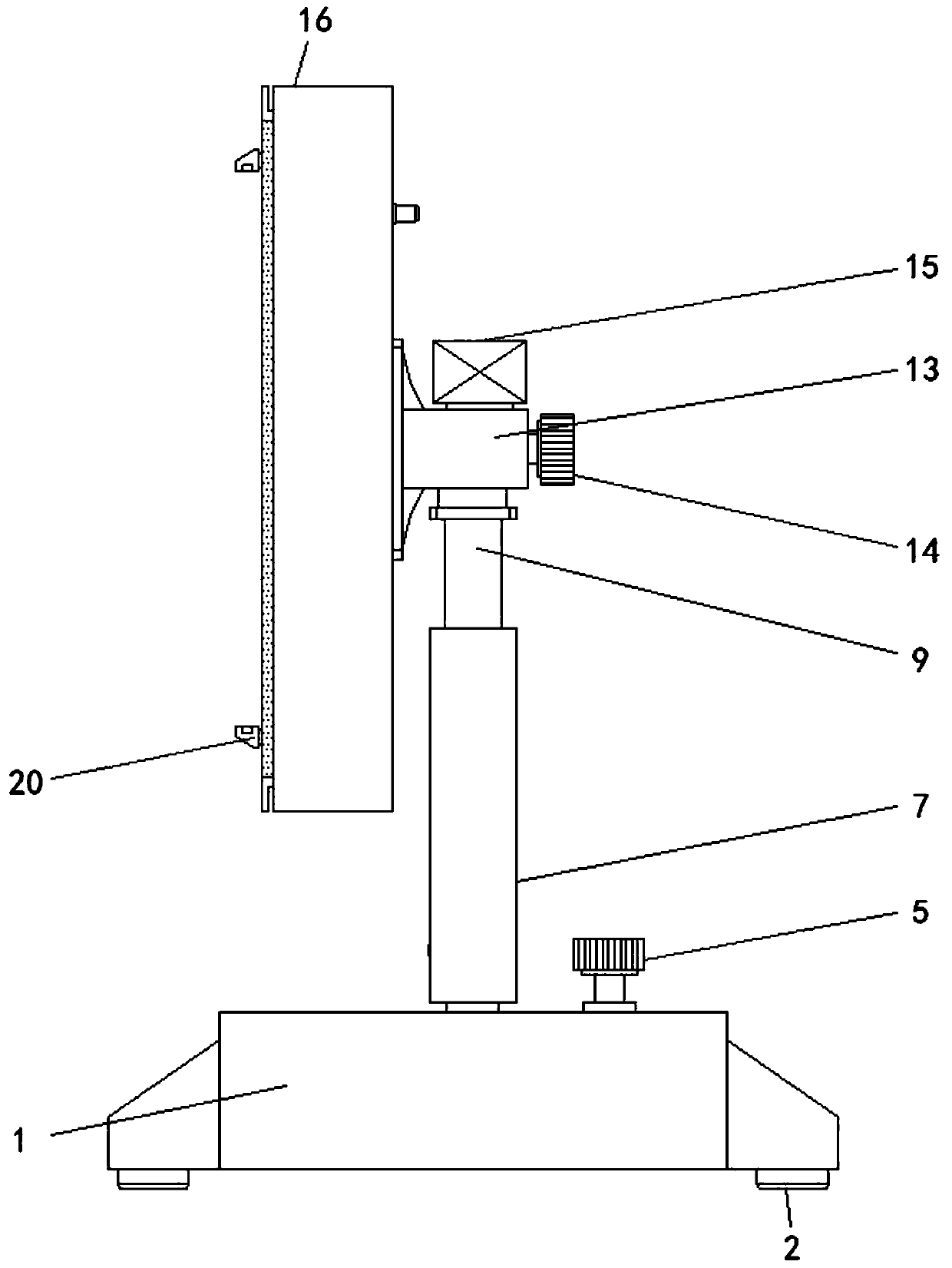

Numerical control laser cutting machine

InactiveCN112975151ASimple structureElectric adjustment is easy to operateLaser beam welding apparatusNumerical controlLaser cutting

The invention discloses a numerical control laser cutting machine which comprises a numerical control laser cutting machine body, a cutting guide table and a fixing mechanism. A laser cutting head is installed on the front side face of the numerical control laser cutting machine body, and an X-axis moving mechanism is installed below the numerical control laser cutting machine body. A distance measuring sensor is installed below the middle position of the X-axis moving mechanism, Y-axis moving mechanisms are arranged below the left end and the right end of the X-axis moving mechanism, first lifting mechanisms are installed below the front end and the rear end of each Y-axis moving mechanism, and driving mechanisms are arranged on the inner sides of the first lifting mechanisms. The cutting guide table is installed between the adjacent inner sides of the driving mechanisms, supports are installed on the upper edges of the driving mechanisms, and fixing mechanisms are installed at the lower ends of second lifting mechanisms. According to the numerical control laser cutting machine, a cut object is automatically fed and discharged through the rotation effect of the cutting guide table, operation is more convenient and faster, the burden of workers can be better relieved, and the automation degree is higher.

Owner:广州市景让信息科技有限公司

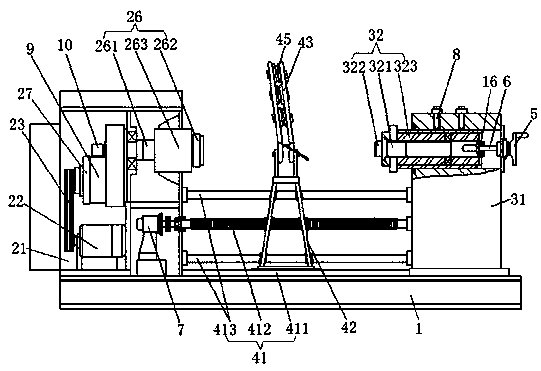

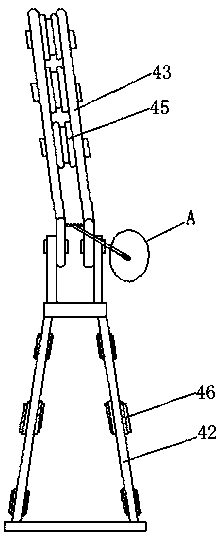

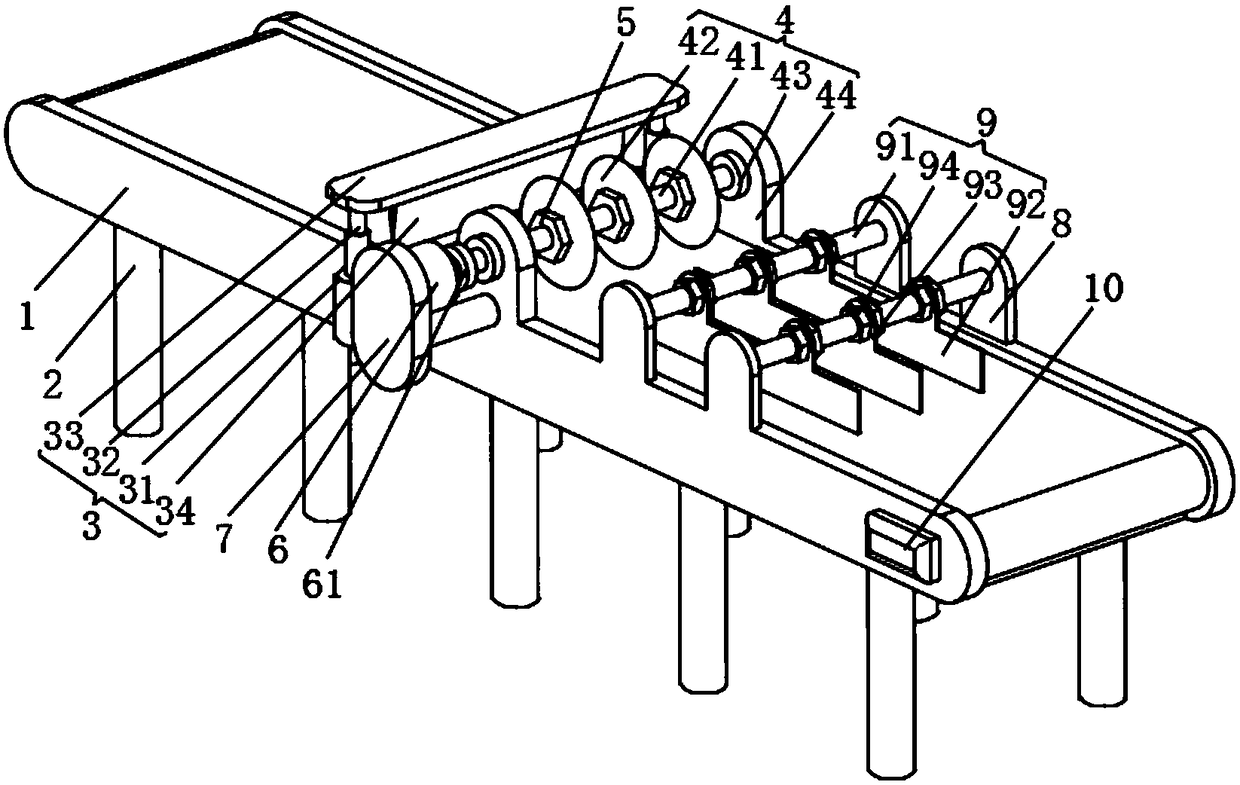

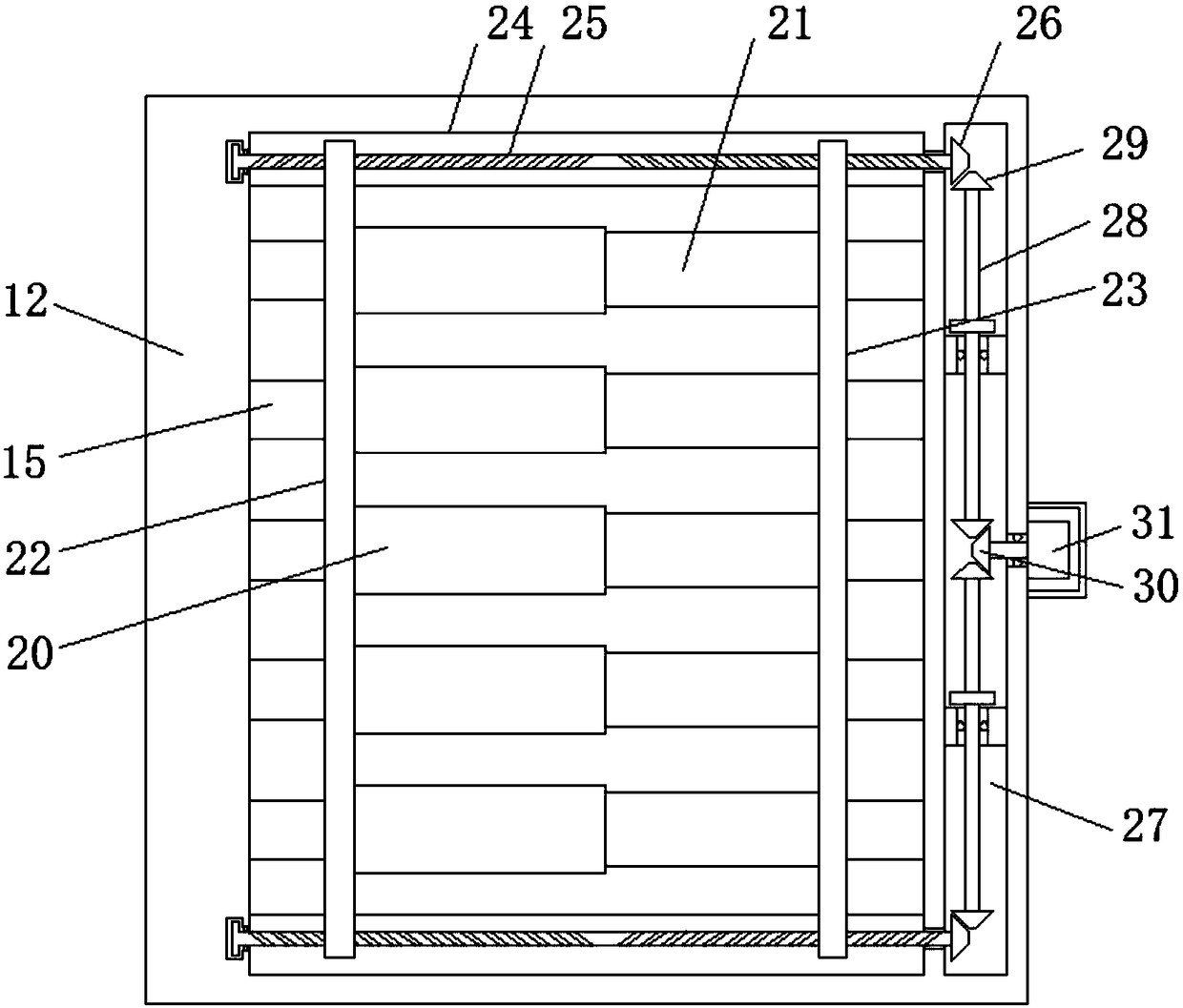

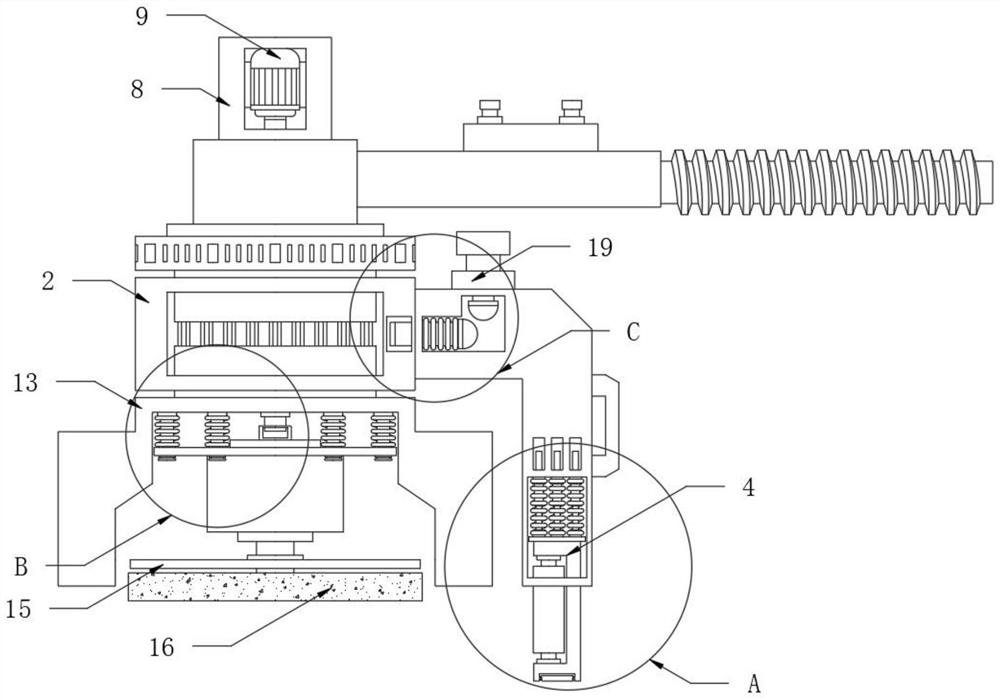

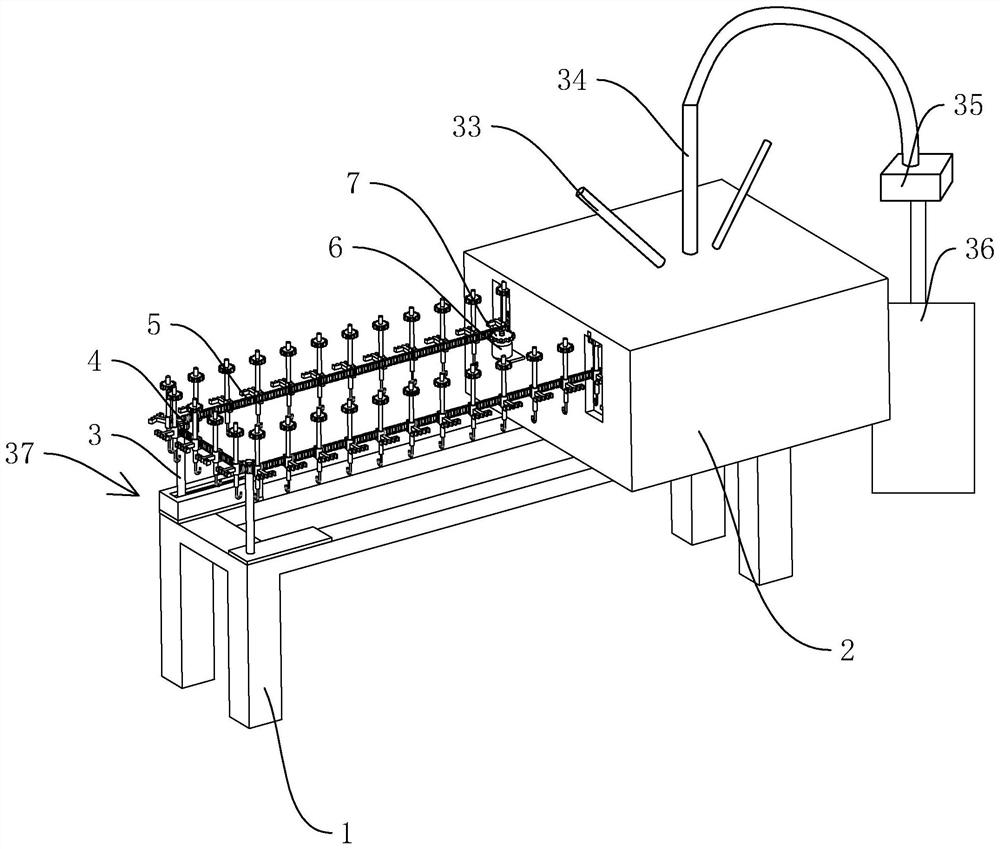

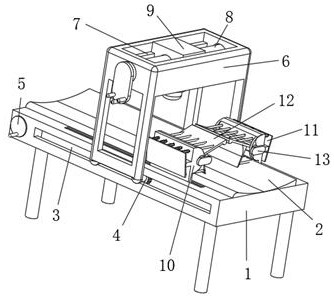

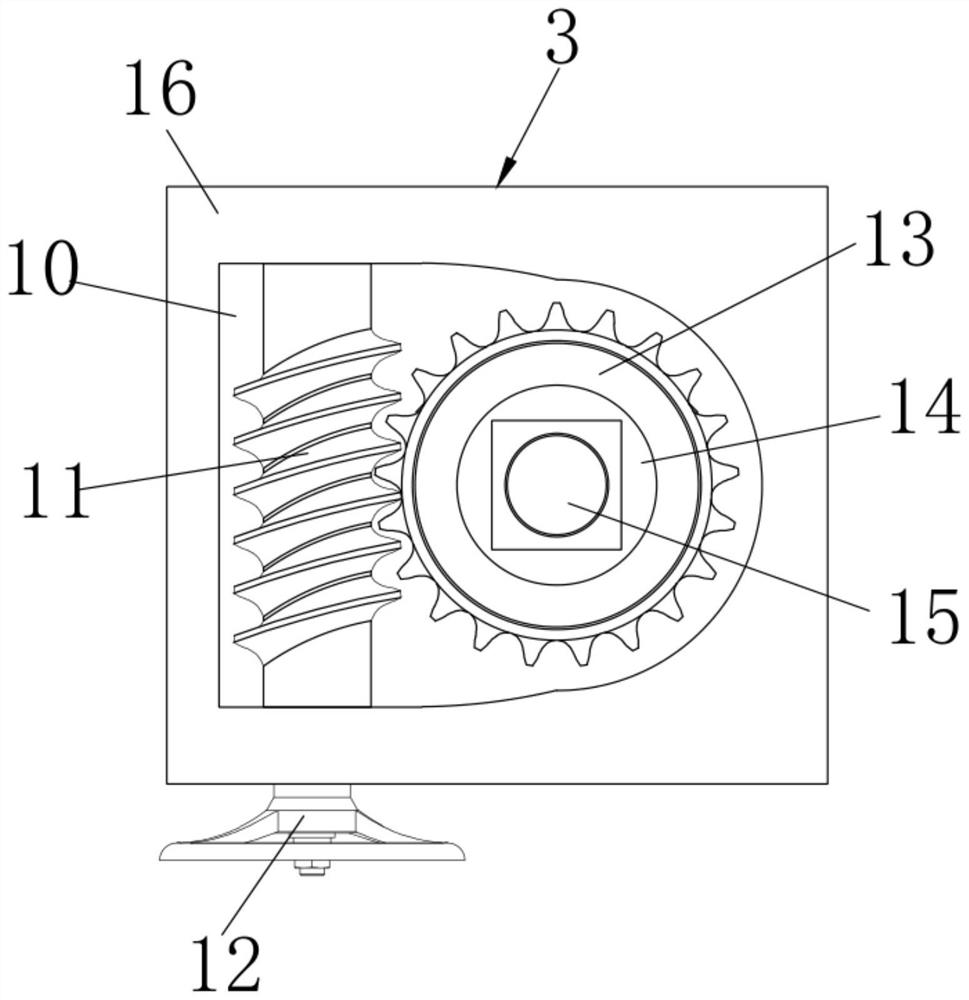

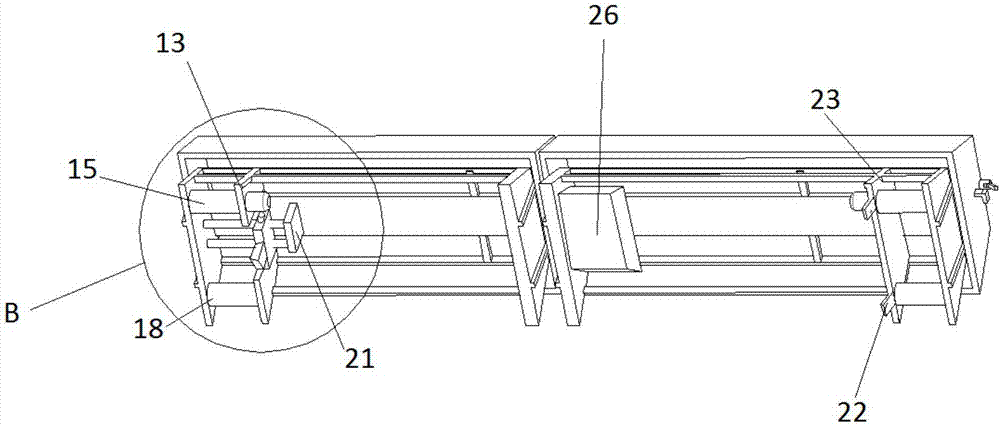

Automatic horizontal winding machine

The invention discloses an automatic horizontal winding machine which comprises a worktable, a main base and a tail base symmetrically arranged on two sides of the worktable and a wire guiding mechanism movably arranged between the main base and the tail base; the main base comprises a main case, a reducing motor fixed in the main case, a transmission shaft in transmission connection to the reducing motor through a belt and a driving supporting part in transmission connection to the transmission shaft through a transmission gear bank; the tail base comprises a tail base box and an auxiliary supporting part which is movably mounted on the upper part of the tail base box and is arranged aligned with the driving supporting part; the wire guiding mechanism comprises a guide rail assembly arranged between the main base and the tail base, a guide seat movably mounted on the guide rail assembly and a wire guiding rack fixed above the guide seat. The automatic horizontal winding machine disclosed by the invention can be suitable for clamping and positioning workpieces of different lengths, and the guide seat is more stable to move, so that the winding precision is improved.

Owner:JINAN KO YO ELECTRICAL TECH

Processing production line with seasoner flour products

InactiveCN109122754AEasy to handleEasy to position and adjustDough shaping and cutting apparatusDough dividingProduction lineCoupling

The invention discloses a processing production line with seasoner flour products. The processing production line comprises a conveying belt conveyer, wherein braces which are distributed uniformly are arranged on the lower surface of the conveying belt conveyer; a cutting-off device is arranged in the middle of the upper surface of the conveying belt conveyer; a slitting device is arranged on theright side of the cutting-off device; the side surface of a first screw of the slitting device is in threaded connection with a positioning nut; the side surface of the positioning nut is in contactwith the side surface of an annular cutter; the front end of the first screw is fixedly connected with an output shaft of a servo motor through a coupler; the servo motor is fixedly connected with themiddle of the side surface of the conveying belt conveyer through a motor seat; and a mounting seat is arranged at the right end of the upper surface of the conveying belt conveyer. The processing production line with the seasoner flour products is simple in structure, the flour products can be cut off and slit, the widths and lengths of flour product slits can be adjusted, the working efficiencycan be improved effectively, time is saved, labor is also saved, and the processing production line is convenient to use.

Owner:阜阳市雪伟食品有限公司

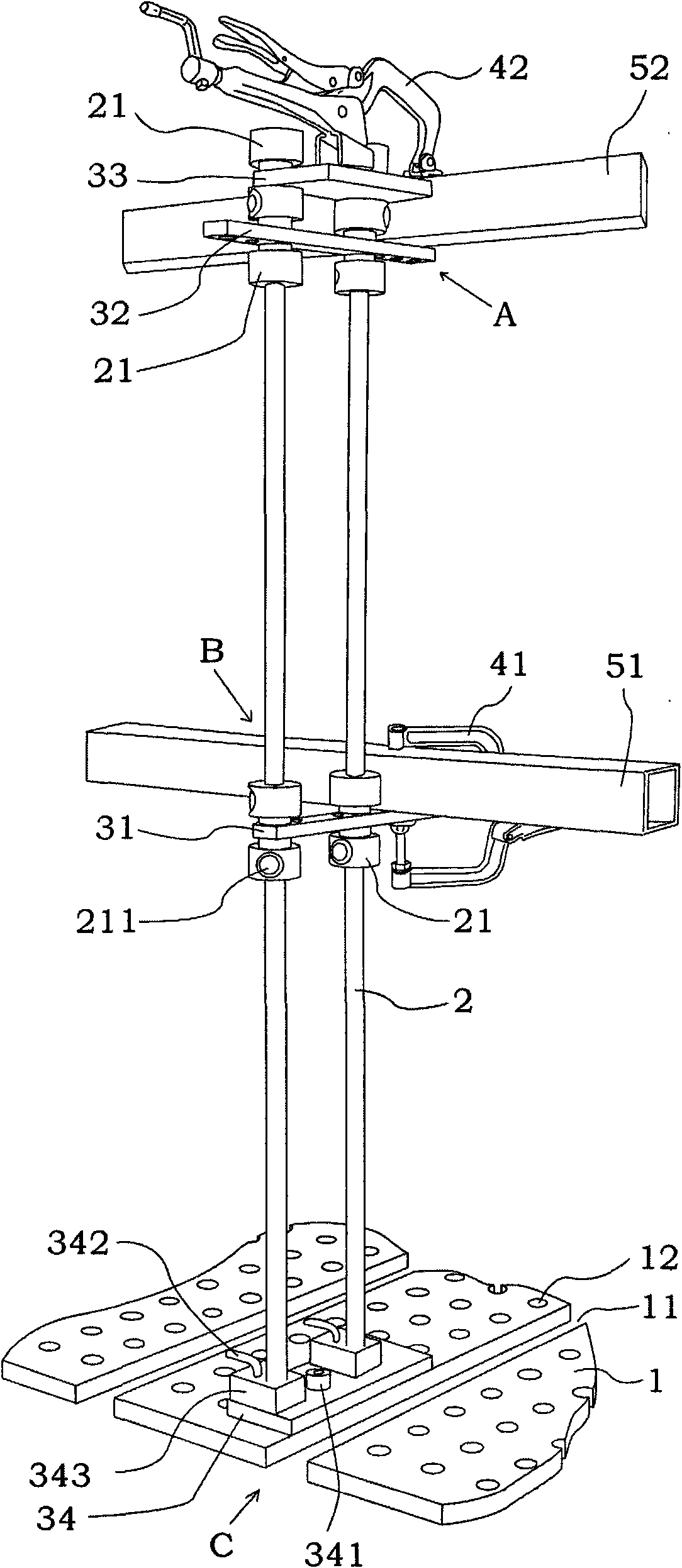

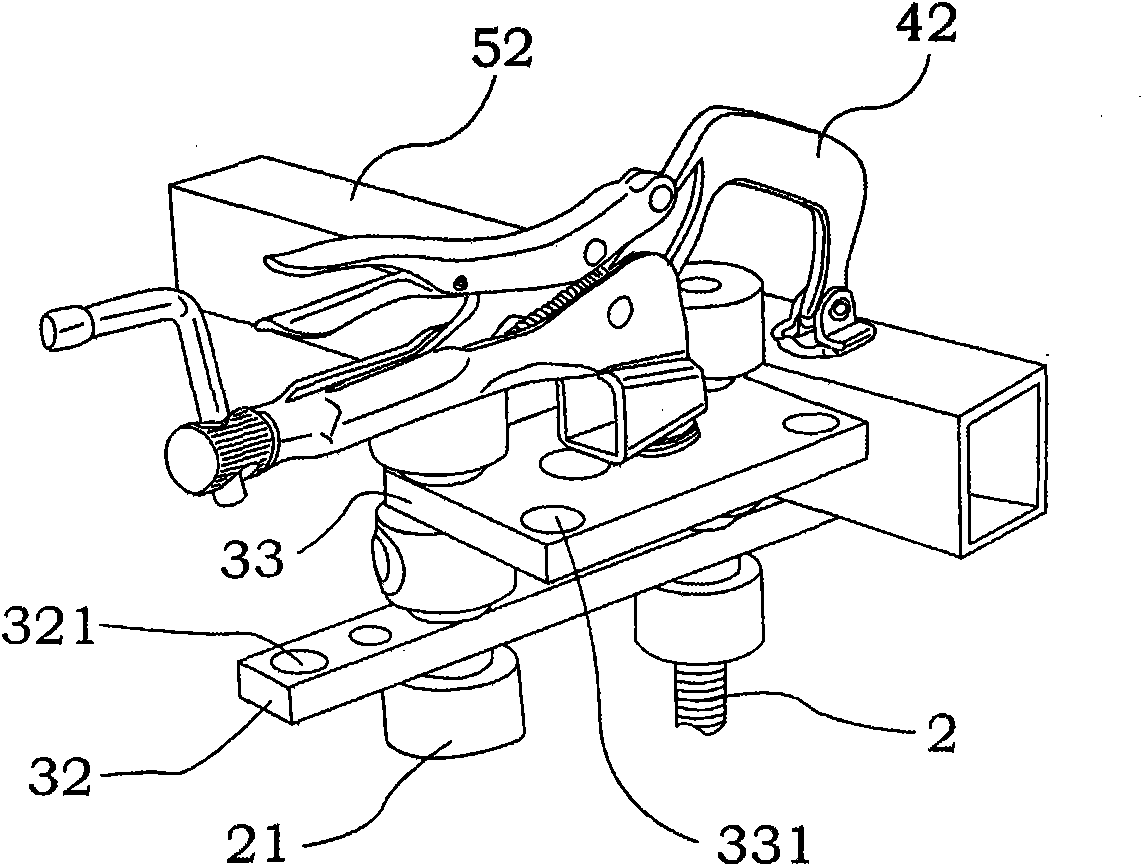

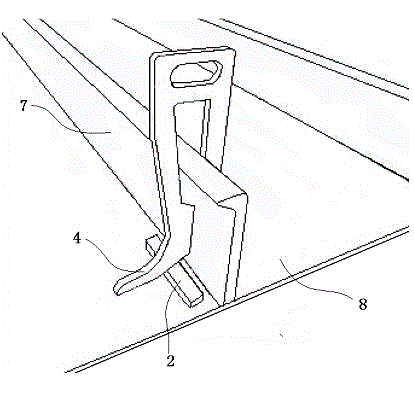

Positioning jig of hole system welding platform

InactiveCN101676062ASmall footprintEasy to position and adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSupport surface

The present invention relates to a positioning jig of a hole system welding platform, which comprises more than one positioning support rod, the positioning support rod is suitable for passing througha positioning hole of the hole system welding platform and extending positioning along two sides of the positioning hole, more than one of the positioning support rod is used as support for forming at least one positioning support surface or clamping surface. The positioning support surface or support platform formed by building the support bar can replace a square-box function in prior art. Thesupport rod can extend along two sides of the positioning hole, thereby, a height of the formed support surface or support platform can be adjusted. Compared with the clamping by utilizing an insert type clamp in prior art, the formed support surface is more stable and accurate by selecting more than one positioning support bar, which realizes the support function no existed in the insert type clamp.

Owner:VALTRA (SHANGHAI) MASCH CO LTD

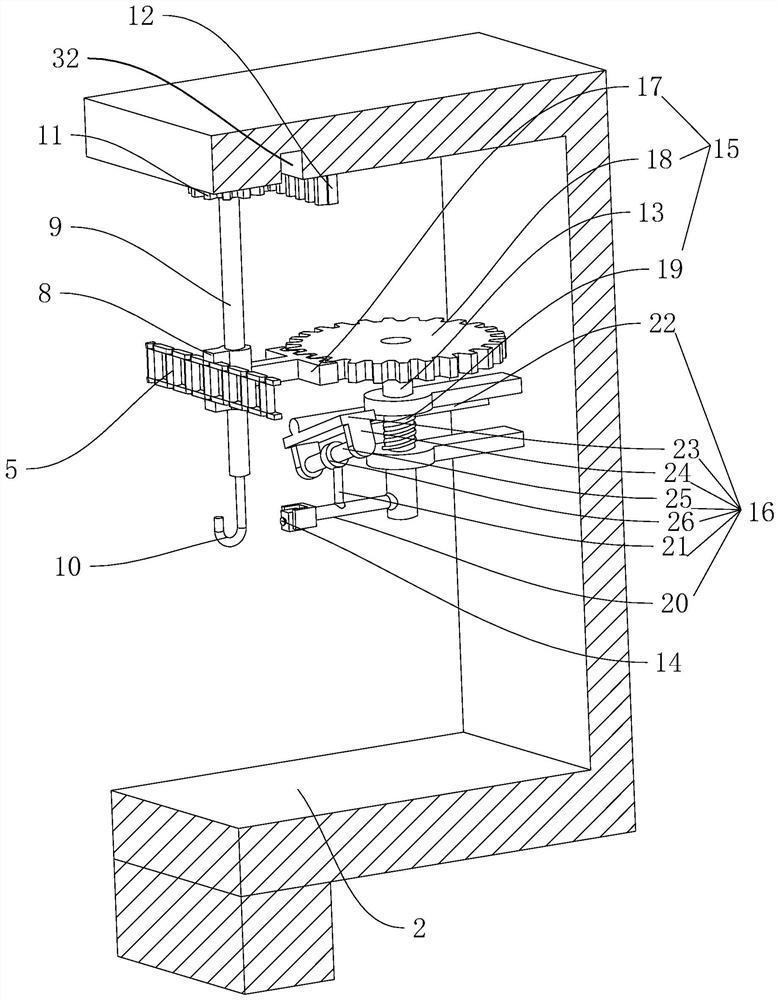

Anti-knotting textile equipment

InactiveCN108178026AAvoid skewAvoid easy knot problemsFilament handlingFunction indicatorsGear wheelEngineering

The invention discloses anti-knotting textile equipment which comprises a fixed base. The anti-knotting textile equipment further comprises an orienting mechanism, a tensioning mechanism and a windingmechanism which are arranged at the top of the fixed base. The tensioning mechanism comprises a first driving device and guide plates which are vertically installed at the two sides of the top of thefixed base. The guide plates are located at the two sides of the first driving device. A fixing rack capable of moving up and down is installed at the top of the first driving device. A pulley is installed inside the fixing rack in a rotating mode. Two sets of steel wires arranged side by side are wound onto the pulley. One ends of the steel wires are connected to the top of the fixed base. A balanced lifting plate is horizontally arranged among the four guide plates. Two sets of gears are further installed at the two sides of the balanced lifting plate. The sides, close to the balanced lifting plate, of the four guide plates are all provided with vertical racks. The anti-knotting textile equipment is reasonable in design, the tensioning degree of processed textile products can be accurately controlled, different numbers of the textile products can be positioned and adjusted, the guide effect is good, knotting of the textile products can be prevented and the textile quality and efficiency are improved.

Owner:苏州朦井纺织科技有限公司

Encoder positioning adjusting device for roller conveyor

InactiveCN107598827AEasy to position and adjustFlexible positioning adjustmentMetal-working hand toolsHydraulic cylinderEngineering

The invention discloses an encoder positioning adjusting device for a roller conveyor. The encoder positioning adjusting device for the roller conveyor comprises a lifting base which is provided witha first guide rail; a movable base is arranged on the first guide rail; a first sliding base is arranged at the bottom of the movable base, and is installed on the first guide rail; a side base is arranged on the lifting base; a hydraulic cylinder is arranged on the end portion of the side base; a piston rod is arranged on the front portion of the hydraulic cylinder; a positioning base is arrangedon the front portion of the movable base; a positioning groove is formed in the middle portion of the positioning base; a fixing block is arranged between the positioning base and the front portion of the movable base; a lock block is arranged on the side portion position of the fixing block; a lock groove is formed in the side portion positioning of the lock block; and the end portion of the piston rod is connected to the position of the lock groove in a locked manner. According to the encoder positioning adjusting device for the roller conveyor, the positioning base can be horizontally moved to be adjusted, an encoder can be firmly positioned and installed conveniently through the positioning base, and flexible movement and fine adjustment can be conveniently performed on the encoder.

Owner:SUZHOU HONGYE LAMP EQUIP CO LTD

Deburring device for desk and chair machining

PendingCN114055281AEasy to polishEasy to position and adjustEdge grinding machinesGrinding machine componentsElectric machineryPolishing

The invention discloses a deburring device for desk and chair machining, and the device comprises a fixing cylinder, a fixing ring is movably installed at the middle of the fixing cylinder, a connecting piece is fixedly installed on the side, away from the fixing cylinder, of the fixing ring, and a support is arranged at the bottom end of the connecting piece. A supporting plate is arranged, a second motor is started, then a grip is held by two hands to attach a polishing wheel to the desk edge, at the moment, a guide roller on one side of a support is attached to the surface of the desk, the polishing wheel and the connecting piece are kept perpendicular, in this way, when burrs are polished, the equipment can be pushed by the two hands, and the equipment cannot move under supporting of the connecting piece; and the equipment can be rapidly pushed to perform polishing at the desk edge, when the desktop needs to be polished, the polishing wheel is attached to the surface of the desk and is pressed downwards, at the moment, after being subjected to the pressure of the top, the support can contract into the connecting piece through a damping spring till a carrier roller is attached to the desktop, the carrier roller and the polishing wheel are kept horizontal, and therefore the purpose of facilitating polishing is achieved.

Owner:JIANGSU ZICHEN EDUCATION EQUIP

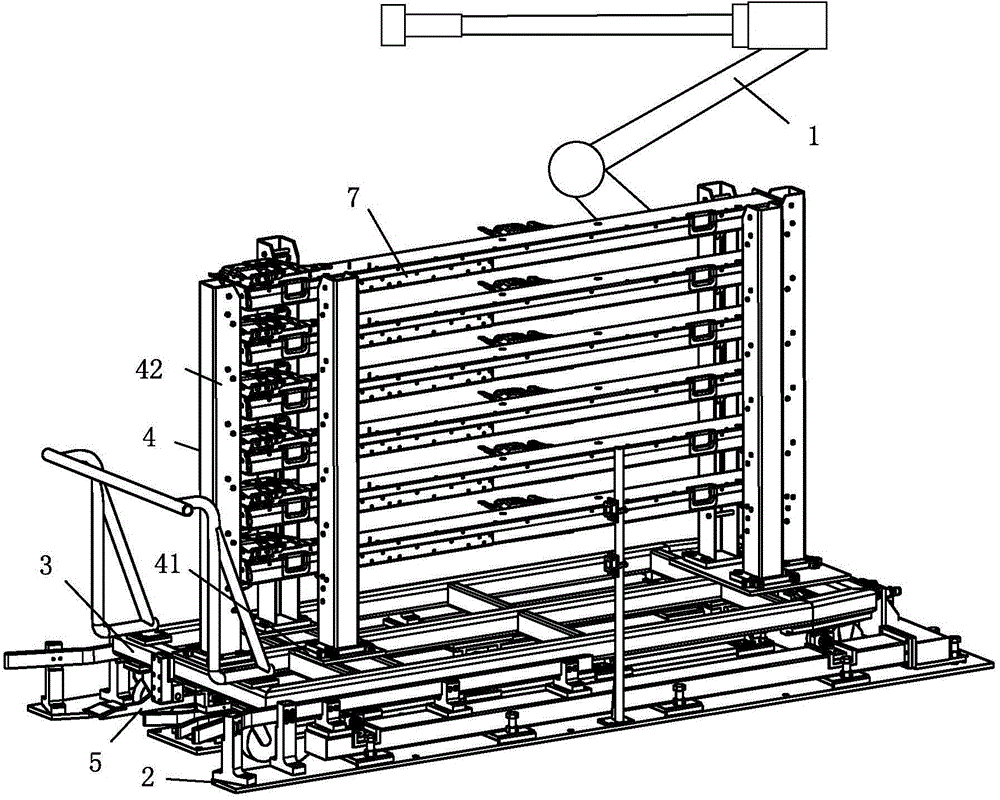

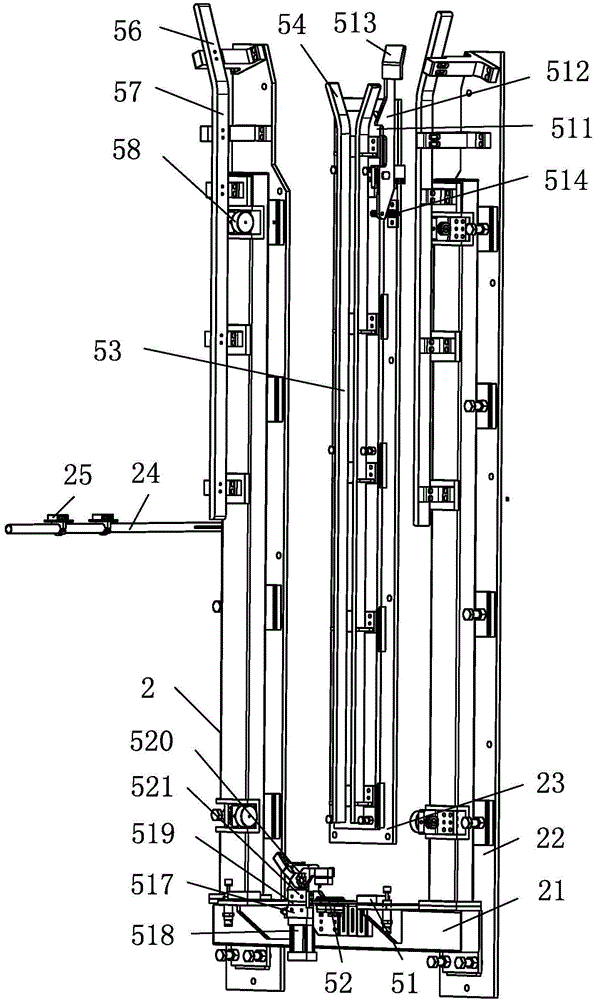

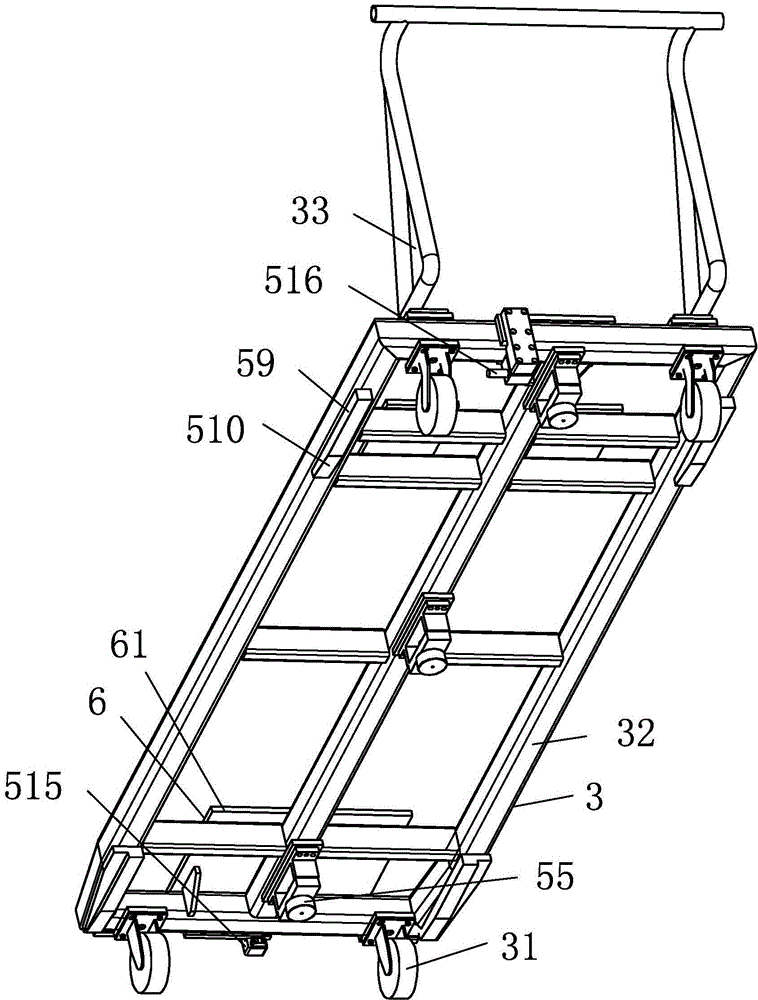

Transportation equipment based on multiple vehicle types

ActiveCN104843446AEasy to position and adjustEasy to operateMechanical conveyorsIndustrial engineeringSupport surface

The invention discloses transportation equipment based on multiple vehicle types. The equipment comprises a rail support provided with a first rail and a second rail, lifting support mechanisms, a rail motor and a rail gear; the first rail is provided a the lifting support mechanism, the second rail is provided with a lifting support mechanism, and a rail rack is engaged with the rail gear; the rail motor is connected to the rail gear, is installed on the lifting support mechanisms and drives the rail gear to rotate to drive the lifting support mechanisms to move; the lifting support mechanisms include lifting mechanisms, workpiece front support mechanisms and workpiece rear support mechanisms; the workpiece rear support mechanisms comprise clamping arms, supporting blocks, swing cylinders and walking mechanisms; the workpiece front support mechanisms comprise clamping arms, supporting blocks and swing cylinders; positioning grooves adaptive to workpieces with different widths are arrayed on the supporting surfaces of the supporting blocks at intervals. The equipment is adaptive to workpiece transportation of different vehicle types, positioning and adjustment are facilitated, the adjusting efficiency is high, and the welding quality is stable.

Owner:GUANGZHOU RISONG HOKUTO AUTOMOTIVE EQUIP CO LTD +1

Paint spraying system for monitoring equipment

The invention relates to a paint spraying system for monitoring equipment. The paint spraying system comprises a support and a paint spraying room; supporting rods are fixedly connected to the supportand the paint spraying room, driving gears are fixedly connected to the supporting rods, a driving chain is wound between the driving gears, a driving motor and a driving gear are fixedly connected to the paint spraying room, a U-shaped block is fixedly connected to the driving chain, a mounting rod is rotationally connected to the U-shaped block, a lifting hook is fixedly connected to the mounting rod, a rotating gear is fixedly connected to the mounting rod, a driving rack is fixedly connected to the paint spraying room, a connecting rod is rotationally connected to the paint spraying room,a spray head is arranged on the connecting rod, a driving mechanism is arranged between the mounting rod and the connecting rod, and a driving part is arranged between the spray head and the inner wall of the paint spraying room. The driving motor conveys a workpiece into the paint spraying room, the workpiece rotates under the action of the rotating gear and the driving rack, the driving mechanism drives the spray head to rotate along with the workpiece, the spray head is driven by the driving part to move up and down, paint spraying on the workpiece is facilitated, and the workpiece paint spraying efficiency is improved.

Owner:杭州禹联科技有限公司

Positioning device for CT image

Owner:程磊

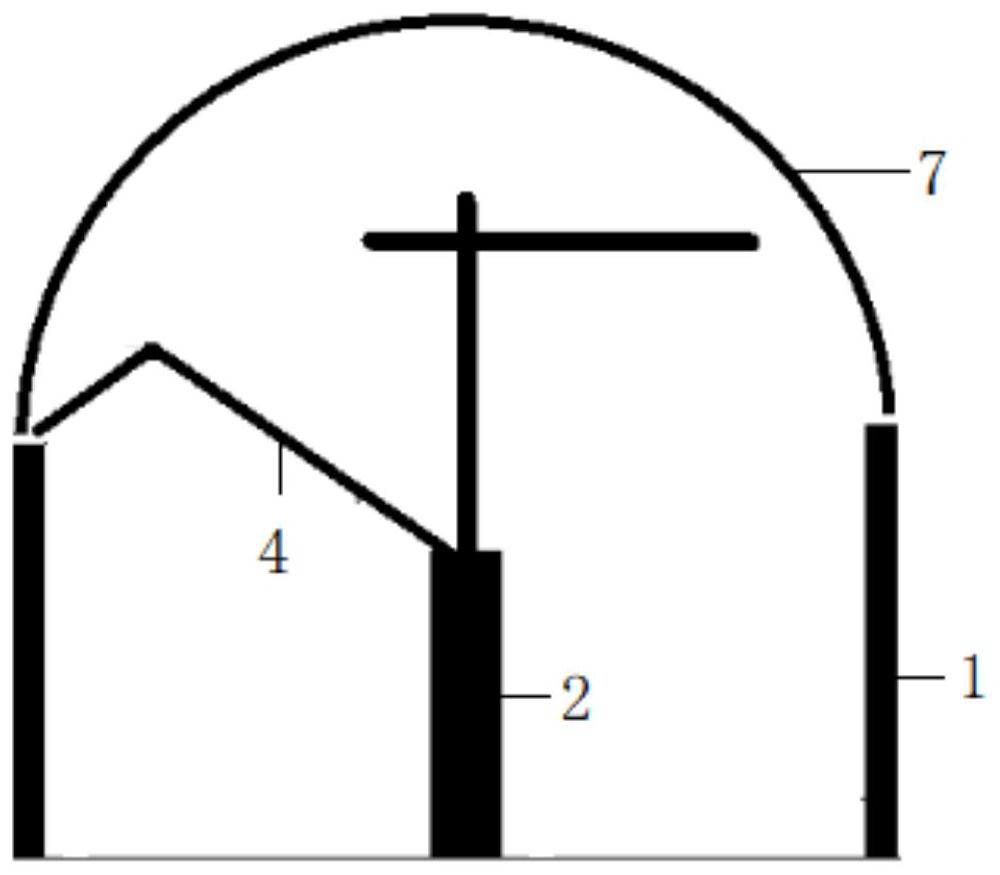

Combined positioning frame device convenient for chest tumor radiotherapy

InactiveCN114010965AImprove clamping effectImprove the fixed effectX-ray/gamma-ray/particle-irradiation therapyPediatricsAbnormal tissue growth

The invention belongs to the technical field of medical instruments, and particularly relates to a combined positioning frame device convenient for chest tumor radiotherapy, which comprises a placing bed and an adjusting frame, the lower end of the placing bed is provided with supporting legs for supporting, the upper end of the placing bed is provided with an arc-shaped pad for improving the comfort of a patient, the arc-shaped pad is in an arc-shaped groove shape, and the adjusting frame is provided with a positioning groove. The side end of the placing bed is provided with a sliding groove used for sliding of the adjusting frame, through arrangement of a first clamping block, one end of the first clamping block is fixed to a P-shaped block, the other end of the first clamping block is connected with a second clamping block through a T-shaped groove, through rotation of a T-shaped rod, the angle of the first clamping block is adjusted, and the first clamping block rotates to drive a connecting rod to move; according to the device, the second clamping block is driven to slide, angle adjustment is facilitated, the clamping effect is improved. Meanwhile, in the adjusting process, the second clamping block slides under stress, the effect of better attaching to a patient is achieved, the fixing effect is improved, and the working precision is ensured.

Owner:杨海林

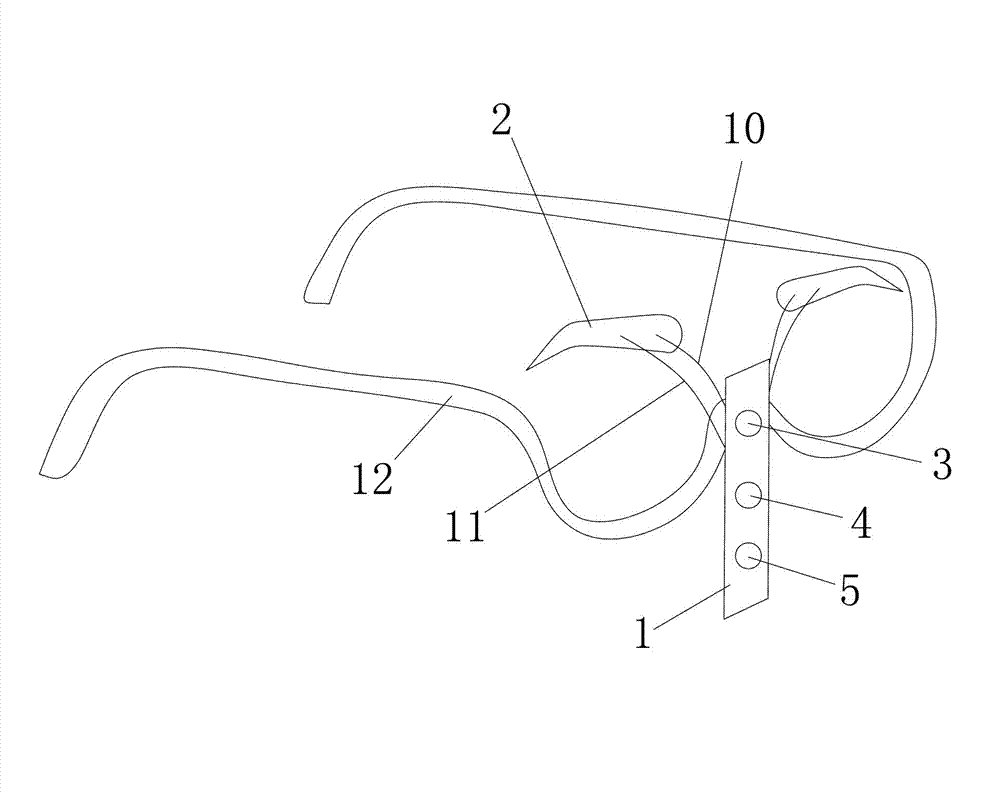

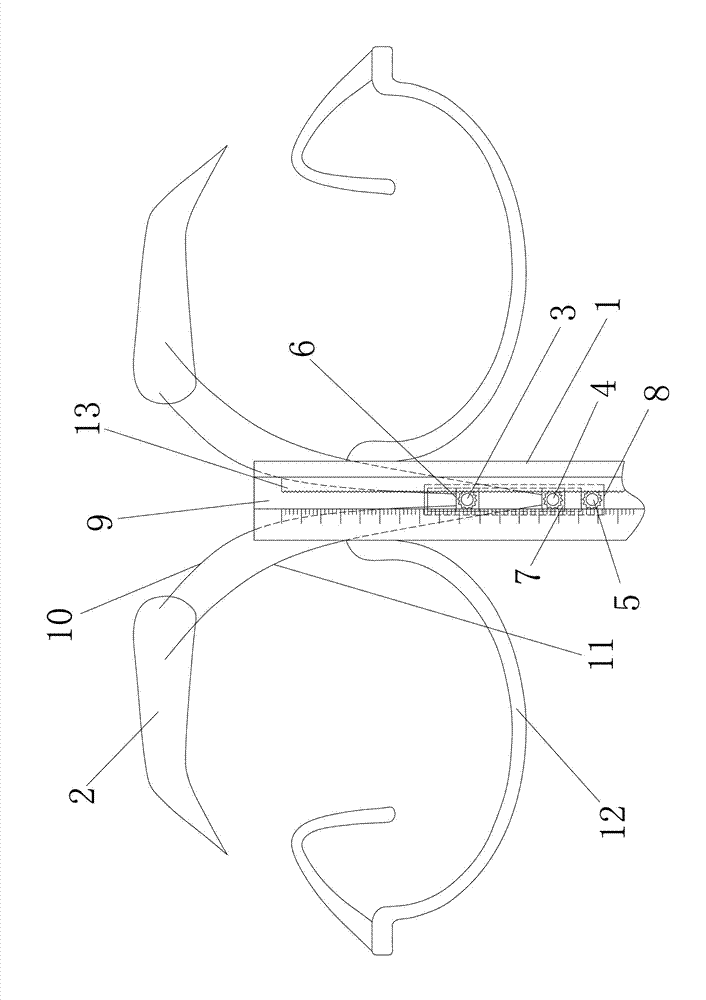

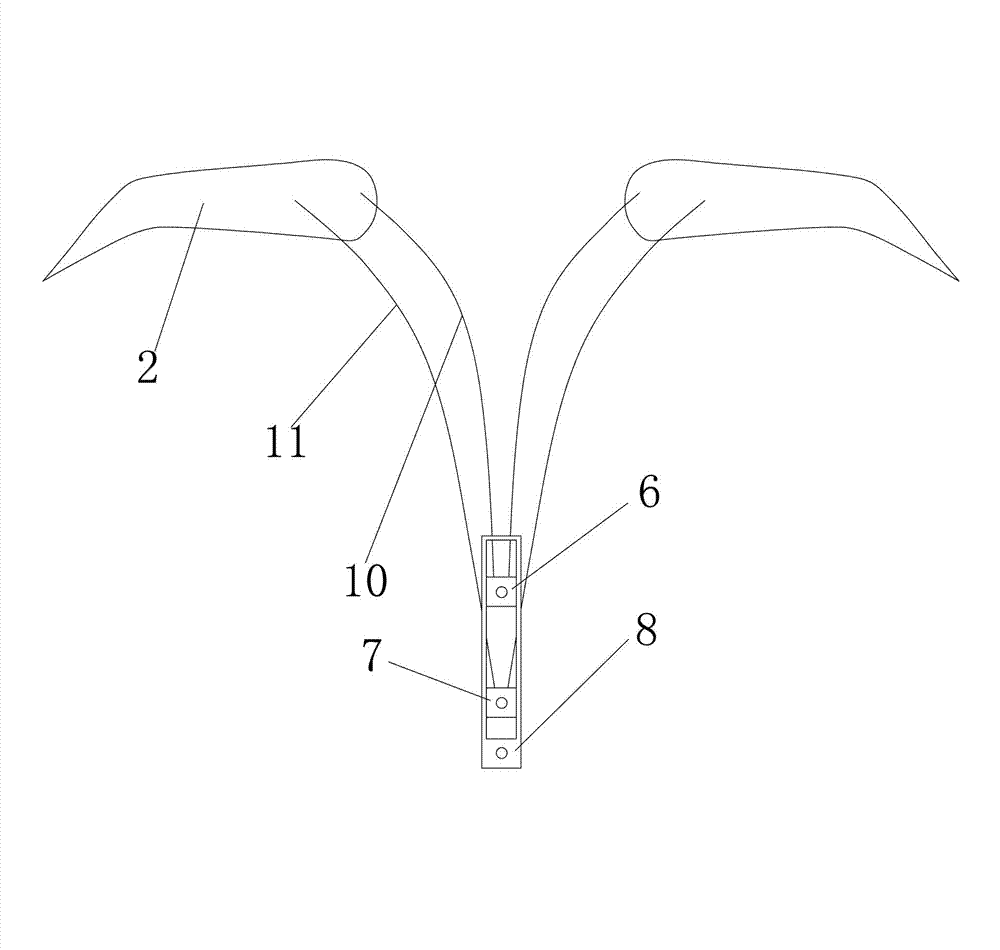

Spiral fine-adjustment spectacle frame type symmetrical eyebrow tattooing positioner

InactiveCN103028190ASafe to useStrong operabilityMedical devicesMechanical engineeringControl theory

The invention relates to a spiral fine-adjustment spectacle frame type symmetrical eyebrow tattooing positioner, which comprises a positioning base, two eyebrow shape plates, an eyebrow shape width regulating knob, an eyebrow tip height regulating knob and an eyebrow shape plate integral moving knob, wherein the positioning base is provided with a spectacle frame, the two eyebrow shape plates are symmetrically positioned at two sides of the positioning base, the positioning base is arranged at the nose pad part of the spectacle frame, a sliding groove is arranged in the positioning base, a straight rack is arranged in the sliding groove, the eyebrow shape width regulating knob, the eyebrow tip height regulating knob and the eyebrow shape plate integral moving knob are sequentially arranged in the sliding groove from top to bottom and are engaged with the straight rack, an eyebrow shape width regulating slide block is camped between the eyebrow shape width regulating knob and the groove bottom of the sliding groove, an eyebrow tip height regulating slide block is clamped between the eyebrow tip height regulating knob and the groove bottom of the sliding groove, an integral moving framework is clamped between the eyebrow shape plate integral moving knob and the groove bottom of the sliding groove, and the eyebrow shape width regulating slide block and the eyebrow tip height regulating slide block are positioned in sliding positions where the integral moving framework upwards extends. The spiral fine-adjustment spectacle frame type symmetrical eyebrow tattooing positioner has the advantages that the use is safe, the operability is high, the positioning and the regulation are convenient, and the like.

Owner:刘伟忠

Steel cap installation method

ActiveCN107620324AEasy to transportEasy to liftArtificial islandsUnderwater structuresMetallurgyImmersed tube

The invention relates to the technical field of immersed tube tunnels, in particular to a steel cap installation method. The installation method comprises the steps that a steel cap is divided into aplurality of sections, and the sections are hoisted from bottom to top in a left-right symmetrical mode; and the hoisted-in-place sectional steel caps are positioned and welded. According to the steelcap installation method, the steel cap is divided into the sections for being installed, so that the steel cap is conveniently transported and hoisted, and the construction difficulty is greatly reduced; the construction efficiency is improved, and the construction risk is also reduced; the sections are hoisted from bottom to top, the firstly-installed steel cap is conveniently positioned and adjusted, it is ensured that the steel cap has the high precision, so that the late-installed steel cap also has the good precision, and it is ensured that design requests are met after the steel cap iswholly hoisted; and meanwhile, the bottom plate section of the firstly-hoisted steel cap supports the sections of the late-hoisted steel cap, and the subsequently-installed sections are conveniently constructed.

Owner:THE SECOND ENG COMPANY OF CCCC FOURTH HARBOR ENG +3

Method for ex-situ rejuvenation of endangered ancient tree

The invention provides a method for ex-situ rejuvenation of an endangered ancient tree. The method for ex-situ rejuvenation of the endangered ancient tree is realized by using equipment for ex-situ rejuvenation of the endangered ancient tree, so that the ex-situ rejuvenation of the endangered ancient trees is completed. The equipment for ex-situ rejuvenation of the endangered ancient tree comprises a rack; a positioning device is mounted at the top end of the front side of the rack, and two side moving frames are mounted at the bottom end of the front side of the rack; a rotating shaft is arranged at the bottom end of the inner side of each side moving frame, and the rotating shafts at the bottom ends of the inner sides of the side moving frames are rotationally mounted at the bottom end of the front side of the rack; and adjusting components are mounted at the top ends of the side moving frames on the two sides. The middle section of the trunk of the ancient tree is clamped and fixed through the positioning device, the operation positions of the side moving frames are adjusted and positioned, cylindrical ex-situ at the root of the ancient tree is excavated and isolated through reciprocating motion of two moldboards, and the arc-shaped motion trail of the moldboards can be adjusted according to the optimal range, obtained through calculation, of the rhizome of the ancient tree.

Owner:肥城市园林绿化中心

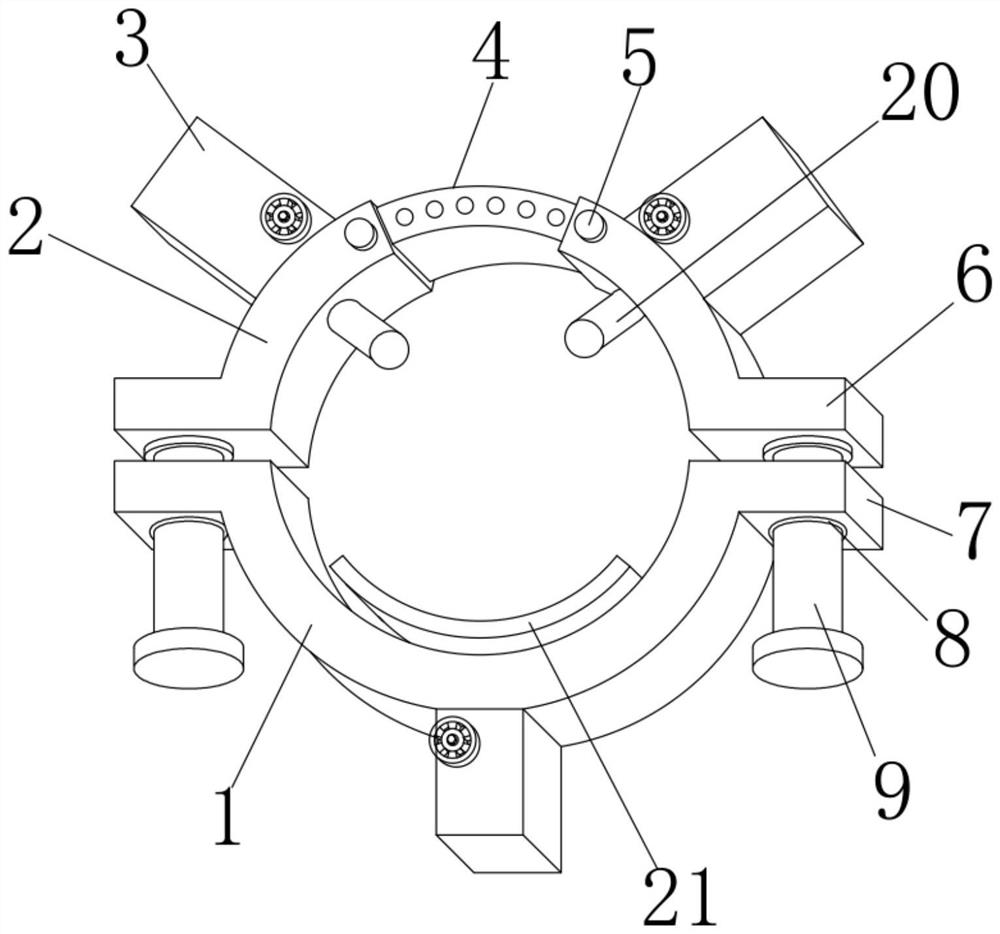

Clamping device for automatic equipment part machining

InactiveCN112045594APrevent clamping instabilityEasy to squeeze and holdWork holdersTurbineWheel drive

The invention discloses a clamping device for automatic equipment part machining. The clamping device comprises a carrier ring and a stringing ring. A clamping carrier ring is arranged on the inner side of the carrier ring. A clamping head is arranged on the inner side of the stringing ring. Pushing mechanisms are arranged on the outer side of the carrier ring and the outer side of the stringing ring correspondingly. Each pushing mechanism comprises a clamping base, wherein a pushing groove is formed in the clamping base, a worm is connected to one end of the inner side of the pushing groove in a rotating manner through a bearing, a pushing nut is connected to the other end of the inner side of the pushing groove through a bearing in a rotating manner, and a turbine is fixedly connected tothe outer side of the pushing nut. According to the clamping device, by designing the pushing mechanisms, the clamping head and the clamping carrier ring, when the device is used, the pushing mechanisms push the clamping head and the clamping carrier ring to position and clamp an automatic equipment part, by means of transmission of the worms and the turbines, after a drive hand wheel drives pushing screw rods to move, self-locking can be achieved, and thus the phenomenon that due to stress self-rotation, clamping is not stable is prevented.

Owner:周洁

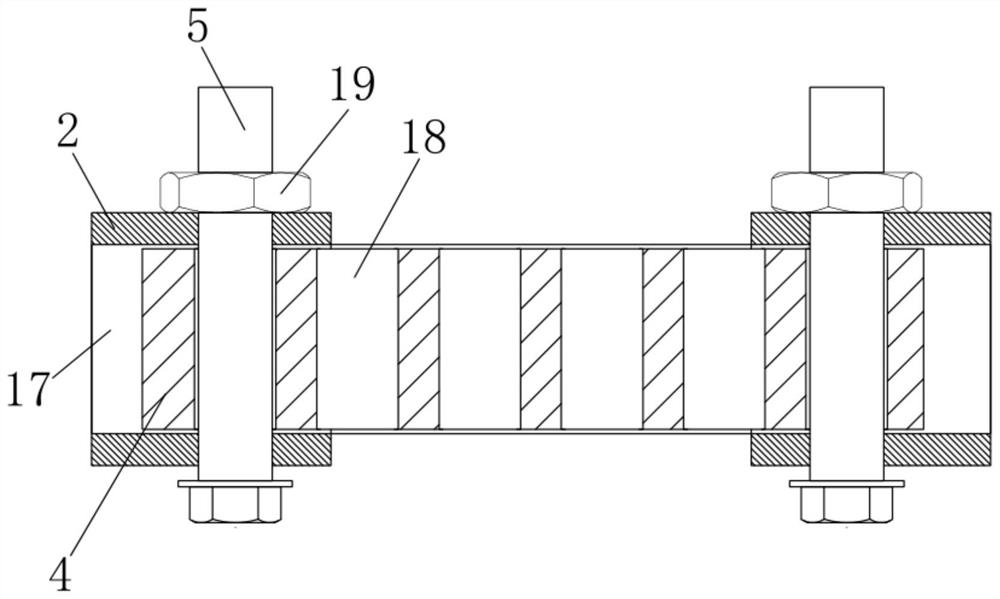

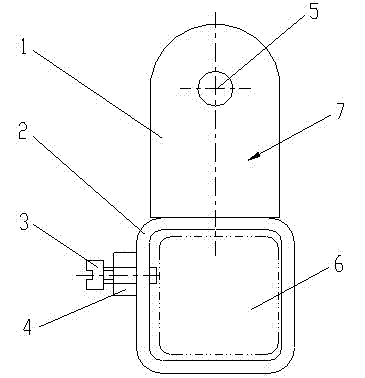

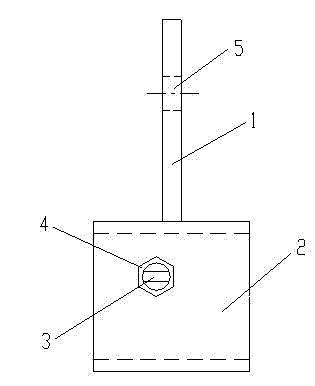

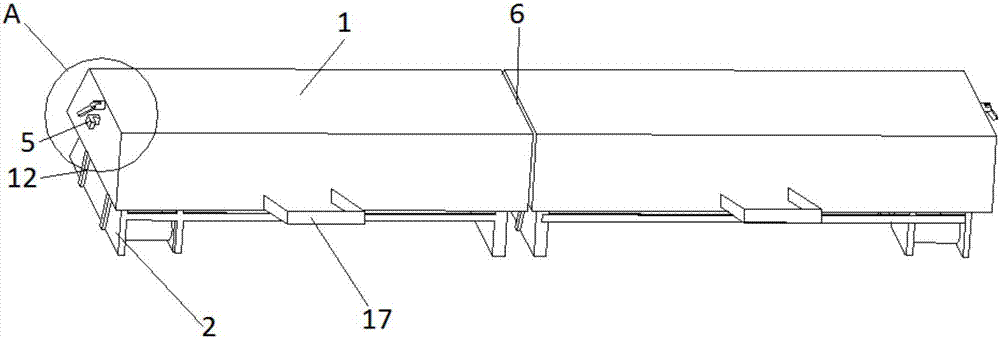

Square pipe mounting bracket

The invention discloses a square pipe mounting bracket. The square pipe mounting bracket comprises a mounting plate, a square pipe, bolts and nuts, wherein the mounting plate is positioned on the external surface of the square pipe and vertical to the square pipe; the mounting plate is provided with a first plane; the first plane is parallel to the end surface of the square pipe; the nut is fixed on the plane of the square pipe adjacent to the plane of the mounting plate; the bolts are respectively fastened into the nuts and penetrate through the wall of the square pipe; and the bolts and the nuts are connected and fixed through matched threads. Through the above mode, the square pipe mounting bracket disclosed by the invention has the advantages of simple structure, firm and stable connections of tubular parts, convenient detachment, accurate positioning of the tubular parts and convenient positioning and adjusting; and external shaft parts can be also mounted.

Owner:CHANGSHU CITY BIXI ELEVATORING & HOISTING EQUIPMNT FACTORY

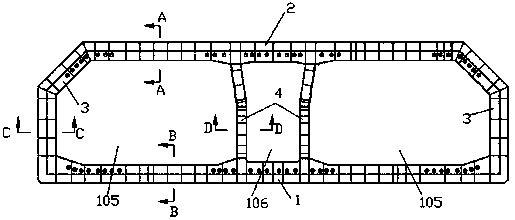

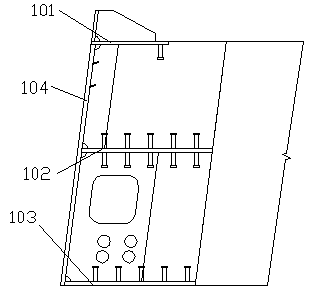

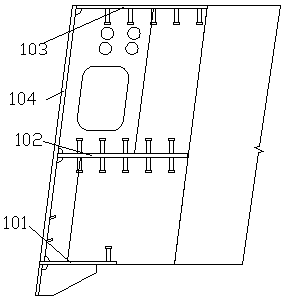

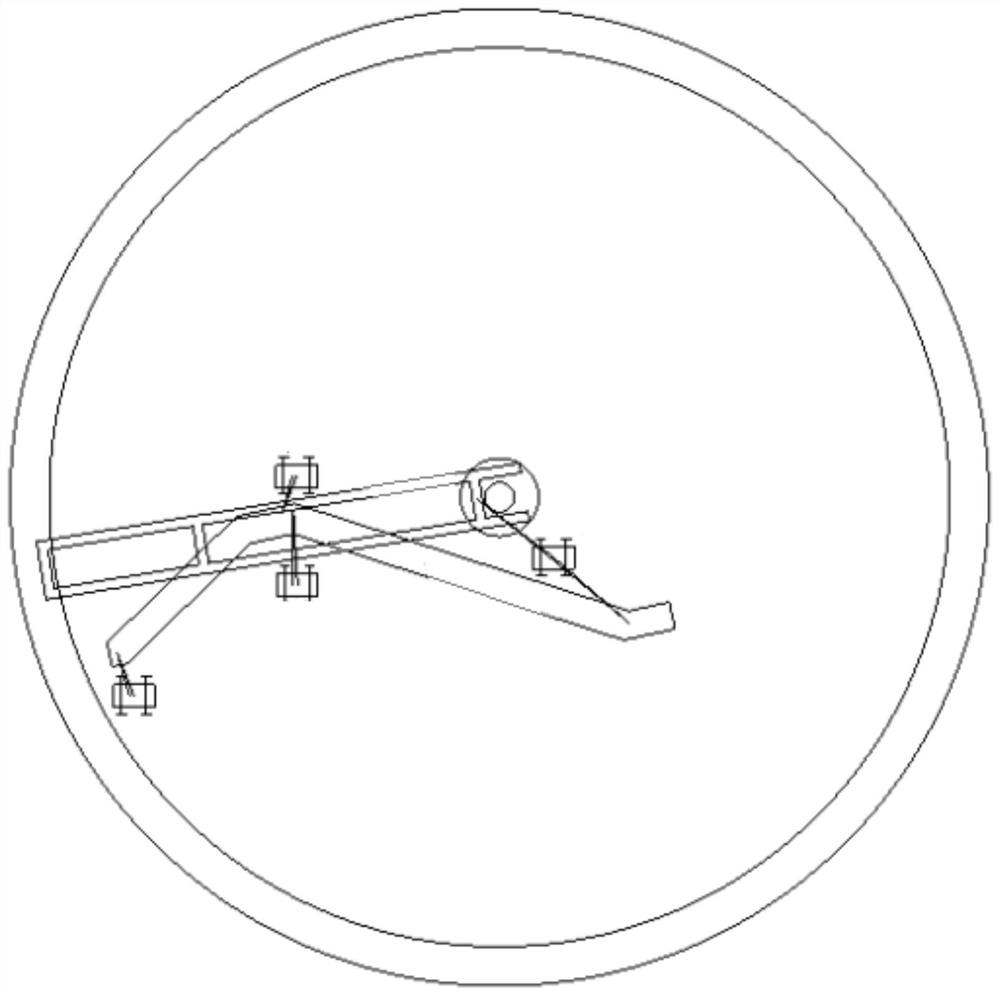

Portable and foldable full-automatic railway detection vehicle

ActiveCN106926853AAvoid displacementEasy to position and adjustRailway inspection trolleysRailway transportVehicle framePrism

The invention discloses a portable and foldable full-automatic railway detection vehicle comprising a detection vehicle body. Detection vehicle covers and detection vehicle frames are arranged on the left and right sides of the detection vehicle body correspondingly. The two detection vehicle covers are movably connected through a hinge; guide rails are arranged at the left and right ends of each detection vehicle frame correspondingly; a supporting shaft is movably connected on the inner wall of each detection vehicle cover; clamping pins are fixed in the position, at the two ends inside the detection vehicle covers, of the supporting shafts correspondingly; and the detection vehicle covers and the detection vehicle frames are movably connected through extension springs. By hiding the detection vehicle frames inside the detection vehicle covers, the detection vehicle is designed to be two trapezoidal prisms, it is convenient to fold the detection vehicle to constitute a hexagonal prism, and the design is ingenious. Movable wheels and fixed wheels which are capable of being shifted can be mounted in the detection vehicle frames. The wheel track between the movable wheels and the fixed wheels are adjusted and changed through adjusting sliding blocks. The detection vehicle can adapt to various specifications of railways, and positioning adjustment of the railway detection vehicle is convenient. The design is ingenious, and carrying is convenient.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Special construction process for mounting stacker-reclaimer gantry

PendingCN112249899AEffective installationReasonable structural designLoading/unloadingSafety gearReclaimerIndustrial engineering

The invention discloses a special construction process for mounting a stacker-reclaimer gantry. The process comprises the following steps that first, the crane position is set, four auto cranes are adopted for hoisting, two 350t auto cranes serve as the main cranes, the hoisting points of the two 350t auto cranes are arranged at the centers of two arms at the top of the gantry up and down, the hoisting point of a 130t auto crane is arranged at the position, close to a central column, of the gantry, and the hoisting point of another 80t auto crane is arranged on the walking mechanism side of the gantry; second, a walking mechanism is hoisted; third, a gantry hoisting test is carried out, two cranes of the gantry are slowly hoisted by 0.5 m under the hoisting command at first, at the moment,the head of the gantry has already lifted, the 130t auto crane at the point B and the 80t auto crane at the point C are slightly lifted up to leave the ground to wait for 10 minutes, and the stressing conditions of all stressing points are checked; fourth, gantry rotating is conducted; and fifth, gantry lifting is made in place. According to the method, the structural design is reasonable, the gantry can be effectively mounted under the condition that a steel ball net rack is mounted, time is saved, and positioning and adjusting are facilitated.

Owner:山西省安装集团股份有限公司

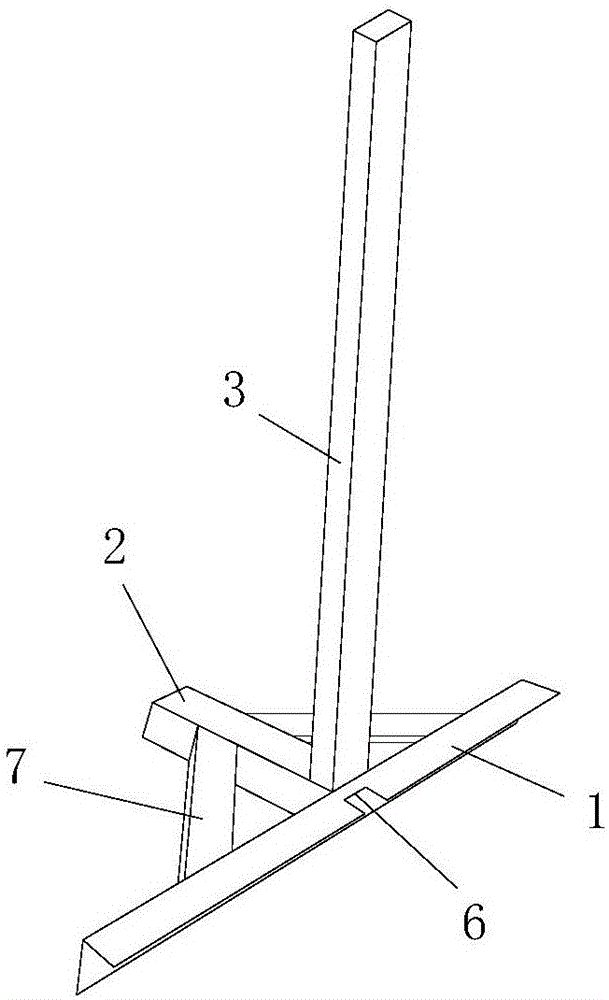

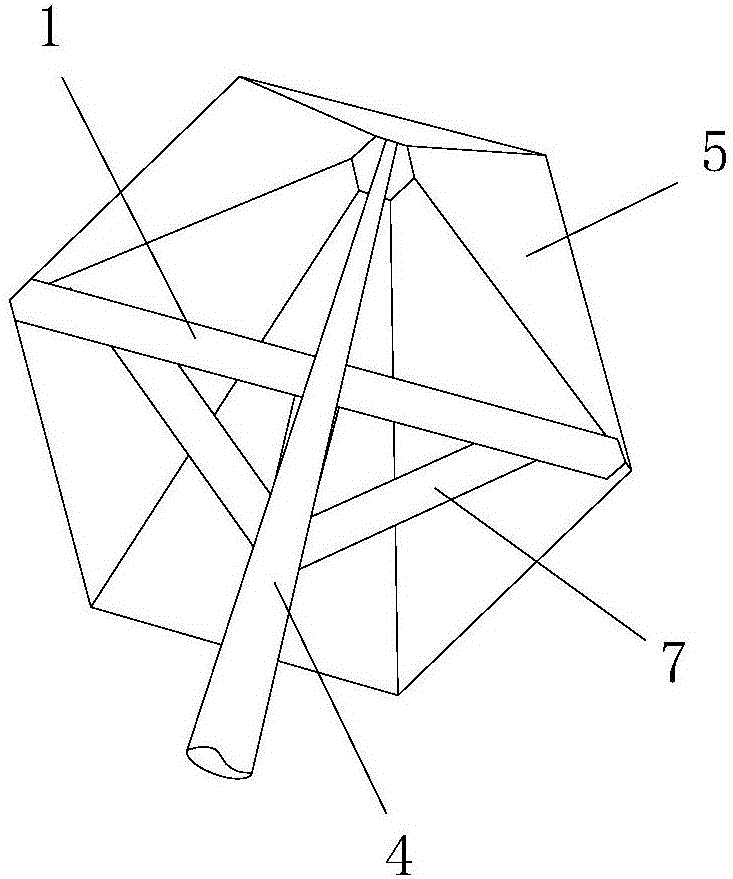

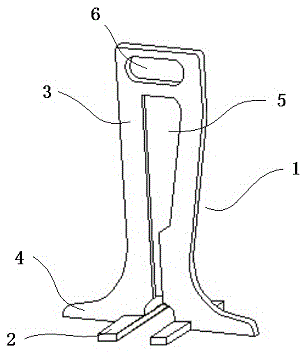

Method for assembling flat-bulb steel on steel slab in ship building

ActiveCN104942456AImprove securityImprove assembly efficiencyWelding apparatusSpot weldingFixed position

The invention relates to a method for assembling flat-bulb steel on a steel slab in ship building. The method is used for fixing the flat-bulb steel to the steel slab in ship building. The method for assembling the flat-bulb steel on the steel slab in ship building includes the steps that firstly, the steel slab is placed in a construction region, the fixing position of the flat-bulb steel is scribed and determined, and anti-toppling devices are prepared, wherein each anti-toppling device is composed of a main supporting body and longitudinal supporting feet; secondly, the flat-bulb steel is hoisted to the construction region through a crane, the two anti-toppling devices are installed on the flat-bulb steel from the two ends respectively, and the flat-bulb steel with the anti-toppling devices is placed on the steel slab; thirdly, the anti-toppling devices are adjusted according to the chalk line of the steel slab so as to change the position and the angle of the flat-bulb steel, and the flat-bulb steel vertically stands on the steel slab; fourthly, spot welding operation is firstly conducted for initial fixation, the anti-toppling devices are detached after detection qualification, and further welding fixation is conducted. The method and a special tool are convenient to install and operate, safe, reliable and high in realistic value.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

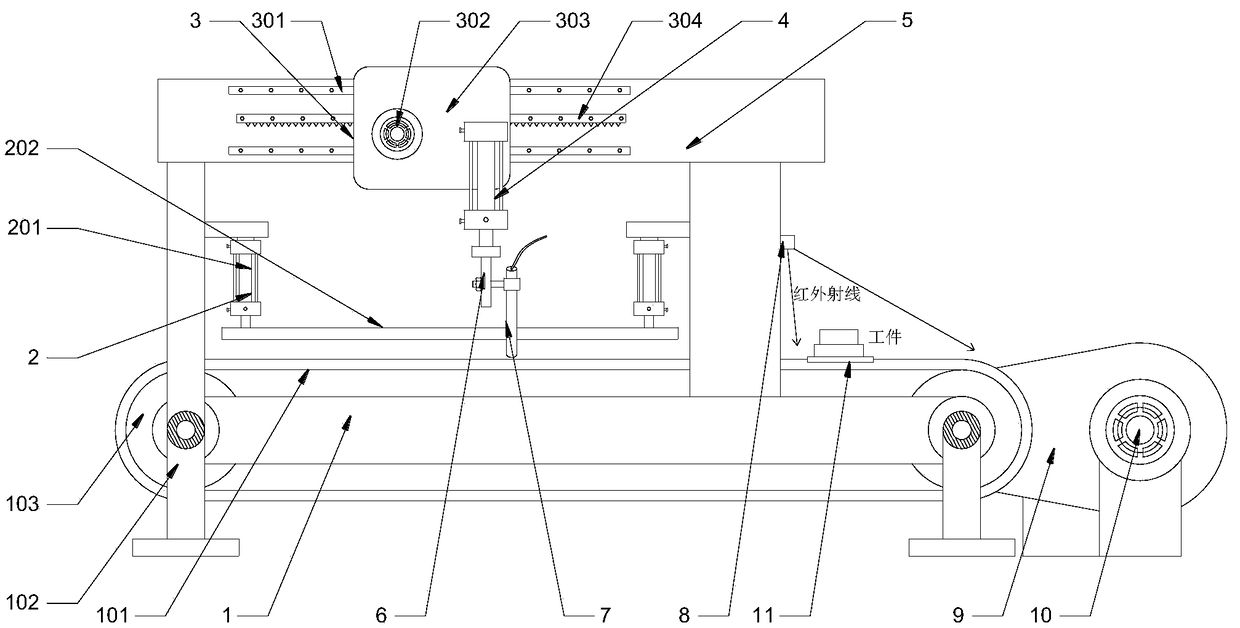

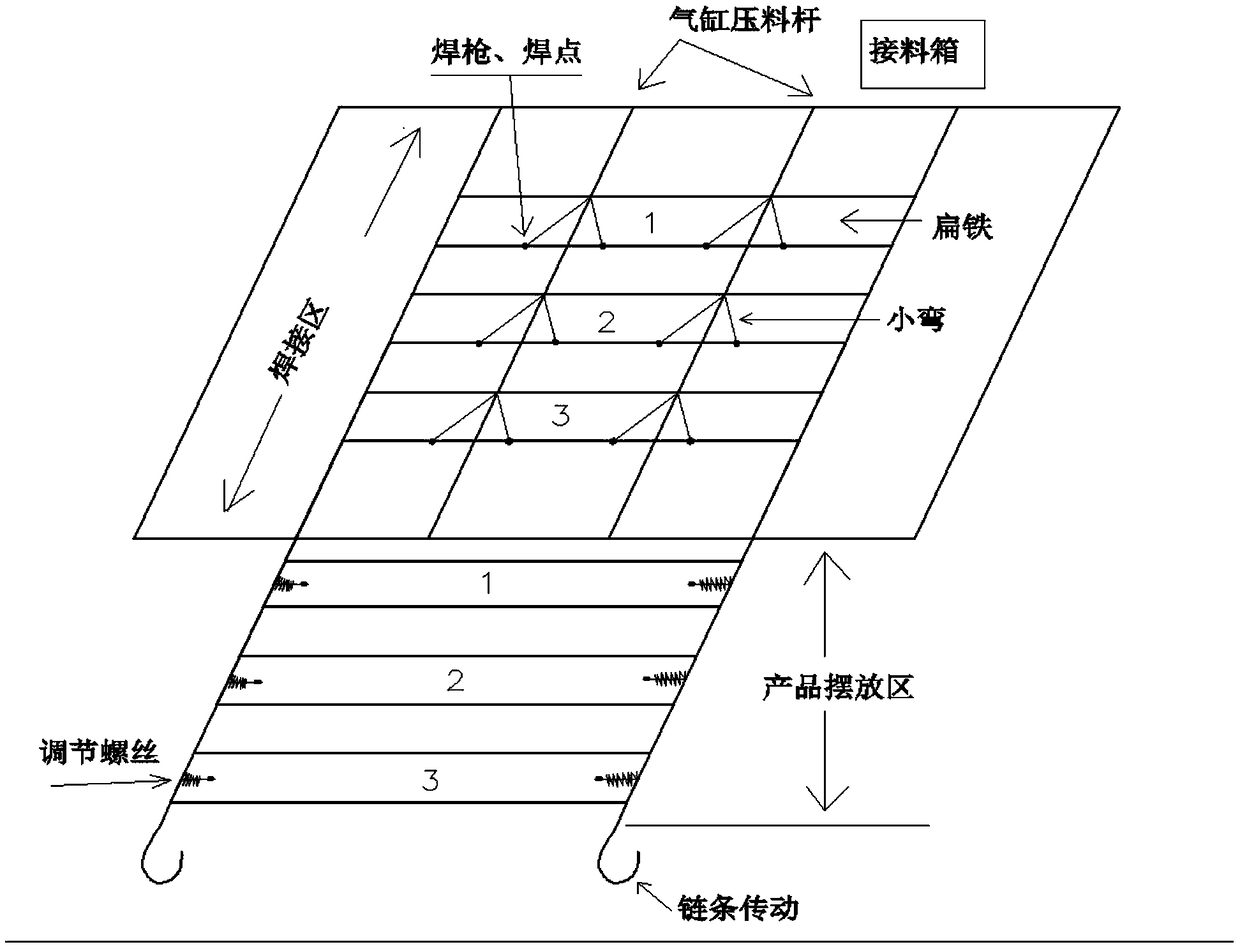

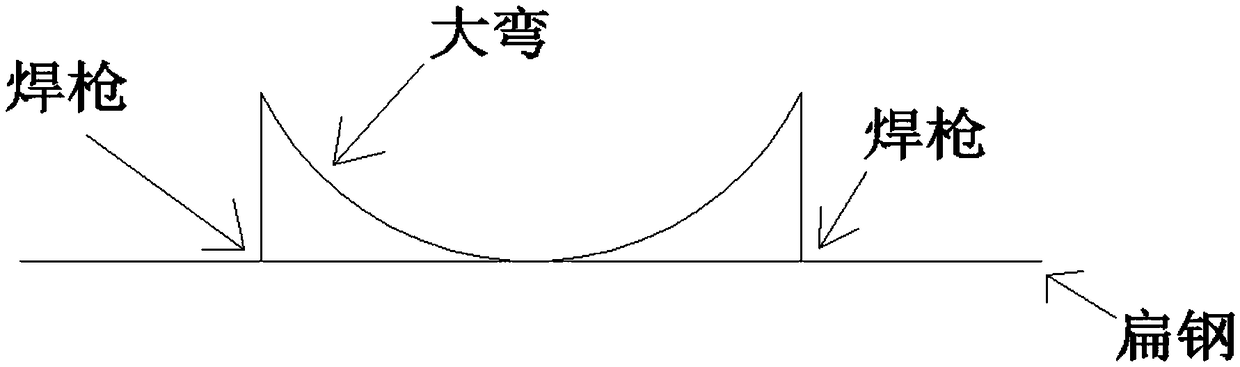

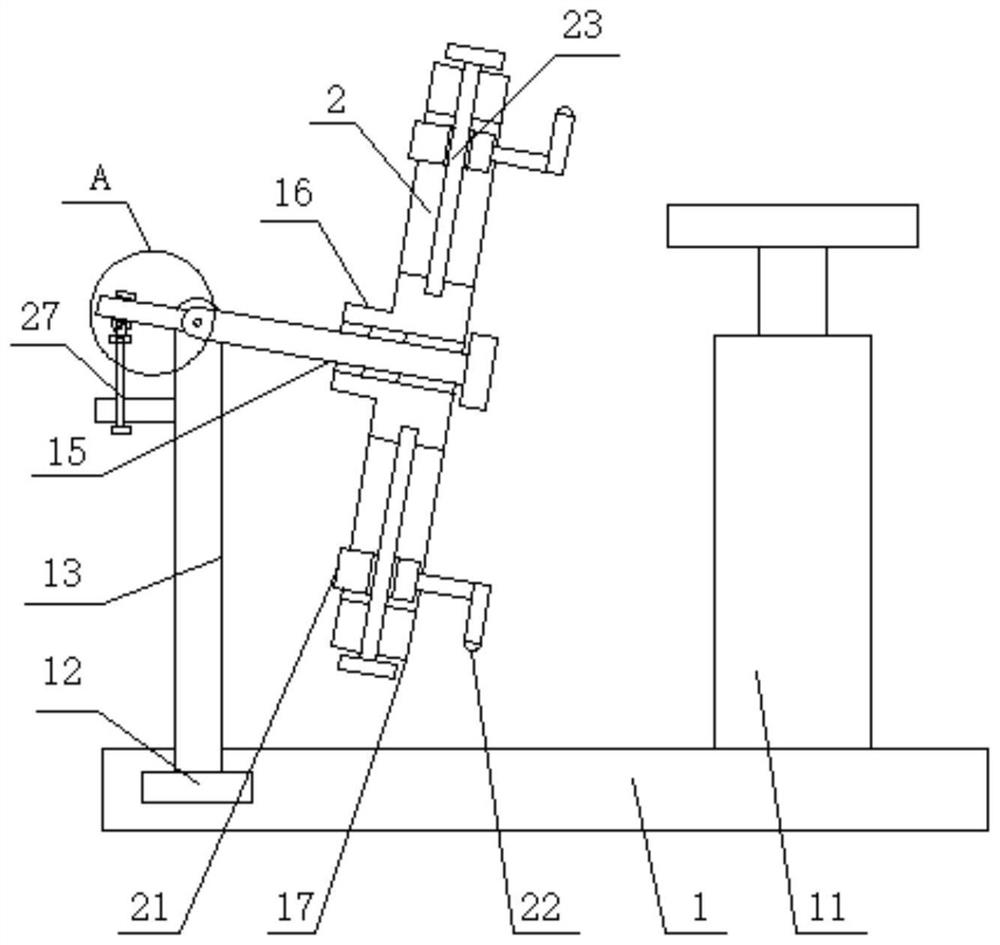

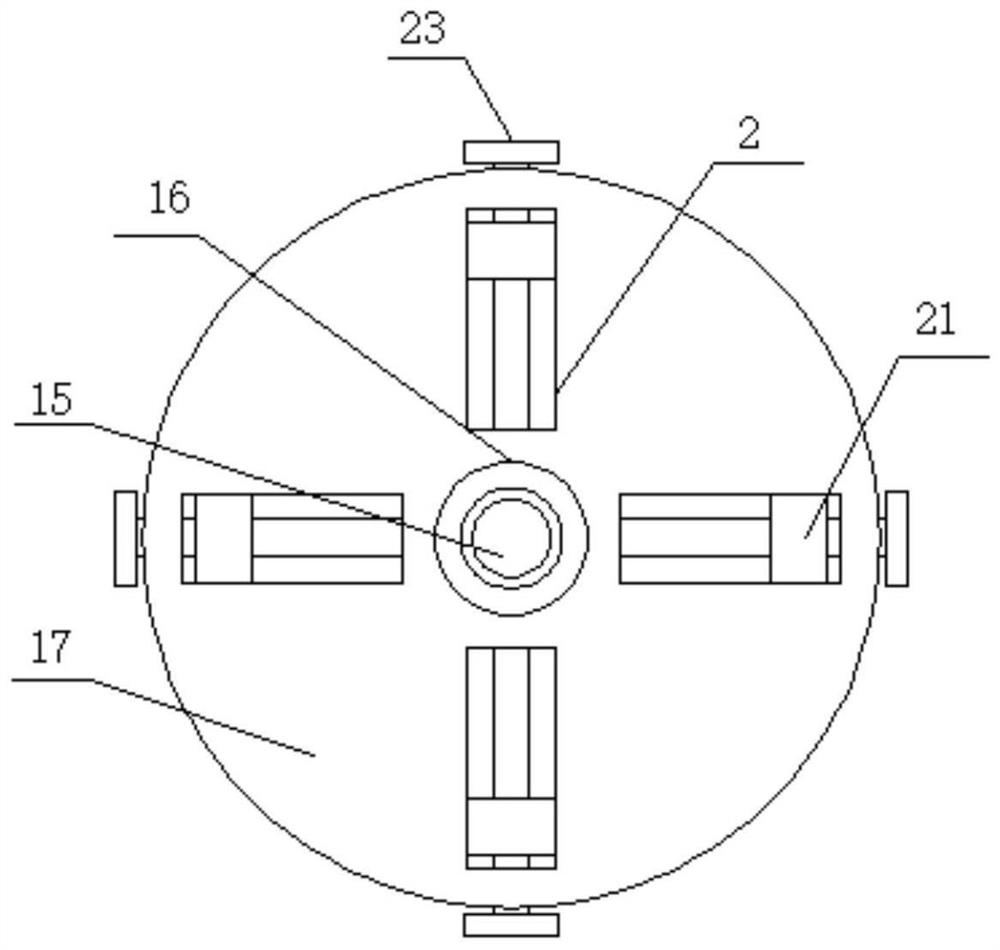

M-shaped sizing block automatic welding equipment

InactiveCN109365953AWide range of automatic weldingImprove ergonomicsElectrode supporting devicesWelding accessoriesMachiningSizing

The invention relates to the field of welding automatic machining equipment. M-shaped sizing block automatic welding equipment comprises a welding gun and further comprises a conveying device for conveying a workpiece and a pressing device for pressing the workpiece; a welding moving device is arranged above the conveying device and provided with a welding lifting pneumatic cylinder facing towardsthe conveying device; the head of a telescopic rod of the welding lifting pneumatic cylinder is connected with a welding gun installation plate; and a plurality of welding guns are installed on the welding gun installation plate. The M-shaped sizing block automatic welding equipment is suitable for linear welding and wide in automatic welding range, the working efficiency is improved by 1.4 timescompared with that of manual welding, professional welding personnel are not needed for operation, common personnel can operate the equipment after being trained, the working efficiency is improved by 0.9 time compared with two-welding-gun welding equipment, the working efficiency is greatly improved, and the cost is reduced.

Owner:富顺县电力金具有限公司

Supporting mechanism for replacing trailer tires

InactiveCN112140806AEasy to position and adjustStable support positioningWheel mounting apparatusTyre repairingJackscrewControl theory

The invention discloses a supporting mechanism for replacing trailer tires. The supporting mechanism comprises a bottom plate, a hydraulic jack is fixedly installed on the surface of one end of the bottom plate, a supporting rod is rotatably installed on the surface of the other end of the bottom plate through a rotating block, a hinge seat is arranged at the other end of the supporting rod, a guide rod is installed on the surface of the hinge seat in a hinged mode, a sliding cylinder is slidably mounted on the surface of the guide rod, a detaching disc is fixedly connected to the surface of the sliding cylinder, a long-strip sliding groove is formed in the surface of the detaching disc, an adjusting sliding block is slidably mounted on the side face of one end of the long-strip sliding groove, a right-angle positioning rod is fixedly connected to the surface of one side of the adjusting sliding block, a threaded rod is rotatably mounted on the side face of the long-strip-shaped sliding groove, and the surface of the threaded rod is in threaded connection with the surface of the adjusting sliding block, so that the use convenience and stability can be greatly improved, and the safety and high efficiency of disassembly and replacement are guaranteed.

Owner:李云

Self-adaptive binding tool

The invention discloses a self-adaptive binding tool. The self-adaptive binding tool comprises a connecting base plate, a group of edge covering cylindrical wheels, a group of auxiliary cylindrical wheels, an auxiliary wheel sliding table and an edge covering wheel sliding table, and the auxiliary wheel sliding table and the edge covering wheel sliding table are arranged at the lower end of the connecting base plate; and the auxiliary cylindrical wheels are connected with a first sliding block on the auxiliary wheel sliding table through a first connecting assembly, and the edge covering cylindrical wheels are connected with a second sliding block on the edge covering wheel sliding table through a second connecting assembly, so that the gaps between the auxiliary cylindrical wheels and the edge covering cylindrical wheels can be adjusted to adapt to forming dies and plates of different thicknesses. According to the self-adaptive binding tool, two groups of roller sets are connected to a connecting disc, the two groups of roller sets can axially move by means of sliding rails and sliding blocks, a gap between the two groups of roller sets can be conveniently changed, edge covering of the forming dies and the plates between the two groups of roller sets can be conveniently completed in three steps after the two groups of roller sets are oppositely clamped, and the edge covering quality is improved; and meanwhile, a proportional valve capable of controlling output pressure of an air cylinder is additionally arranged, the proportional valve is operated, different edge covering forces for pre-edge covering and final edge covering can be provided, and the edge covering effect is improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com