Steel cap installation method

An installation method and technology of steel caps, which are applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as difficulty in ensuring flatness of steel caps and difficulty in installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

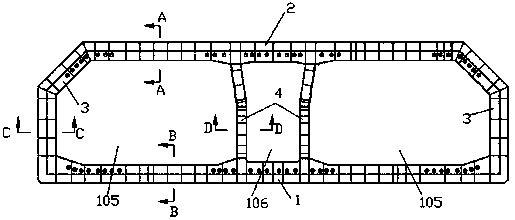

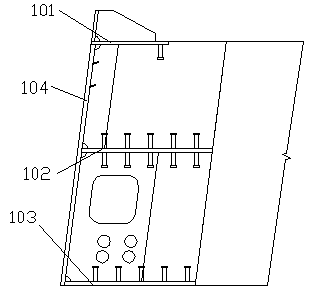

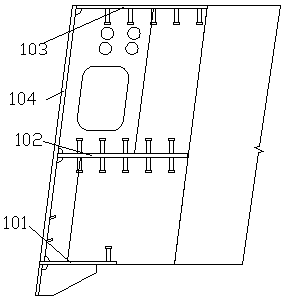

[0122] Such as Figure 7 As shown in the installation method of the steel cap, the steel cap is divided into several segments, and each segment is hoisted in a bottom-up and left-right symmetrical manner, and the segmented steel caps hoisted in place are positioned and welded.

[0123] When the steel cap is segmented, the center line of the steel cap is used as the center of symmetry, and the two symmetrical parts of the steel cap are divided into approximately the same segments, that is, the lengths and positions of the two symmetrical segments are approximately the same.

[0124] The bottom-up hoisting method is as follows: first hoist the bottom plate, then hoist the side walls and middle walls, and finally hoist the top plate.

[0125] The left-right symmetrical hoisting method is as follows: after the steel cap is segmented, after hoisting a certain section of the left or right steel cap, immediately correspondingly hoist the symmetrical right or left steel cap, the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com