Welding feeding device of car threshold assembly

A threshold and assembly technology, applied in the field of automotive threshold assembly welding and feeding devices, can solve the problems of low adjustment efficiency, difficult positioning and adjustment of threshold assembly, unstable welding quality, etc., and achieve high adjustment efficiency, simple and reliable structure , simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

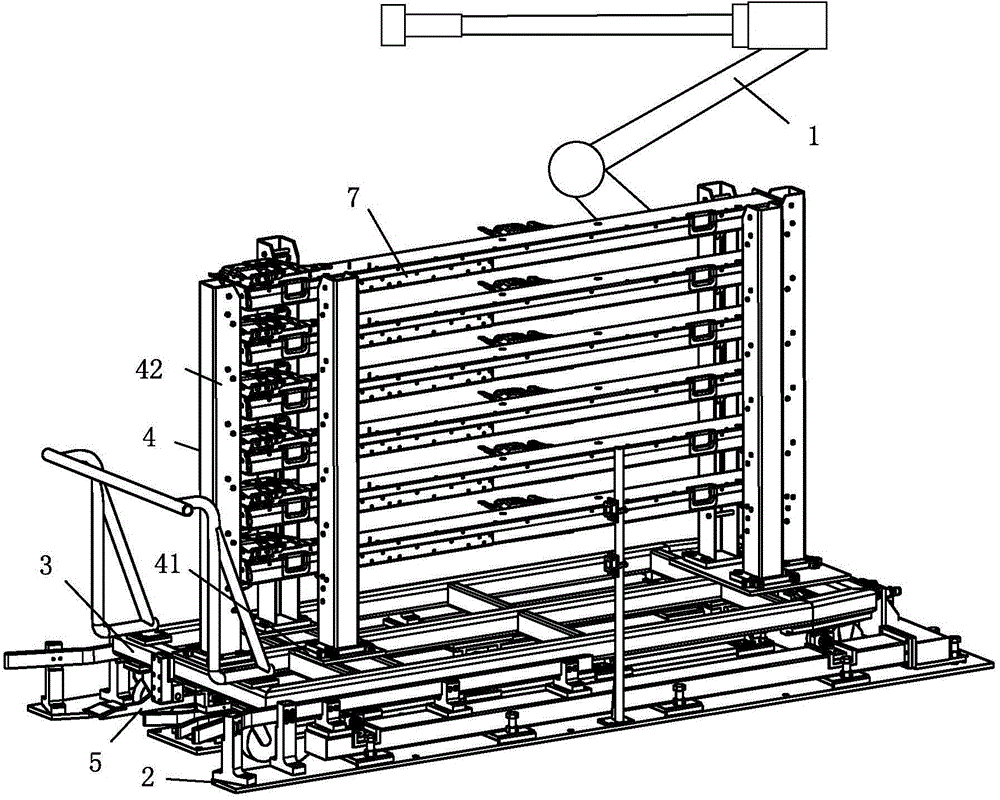

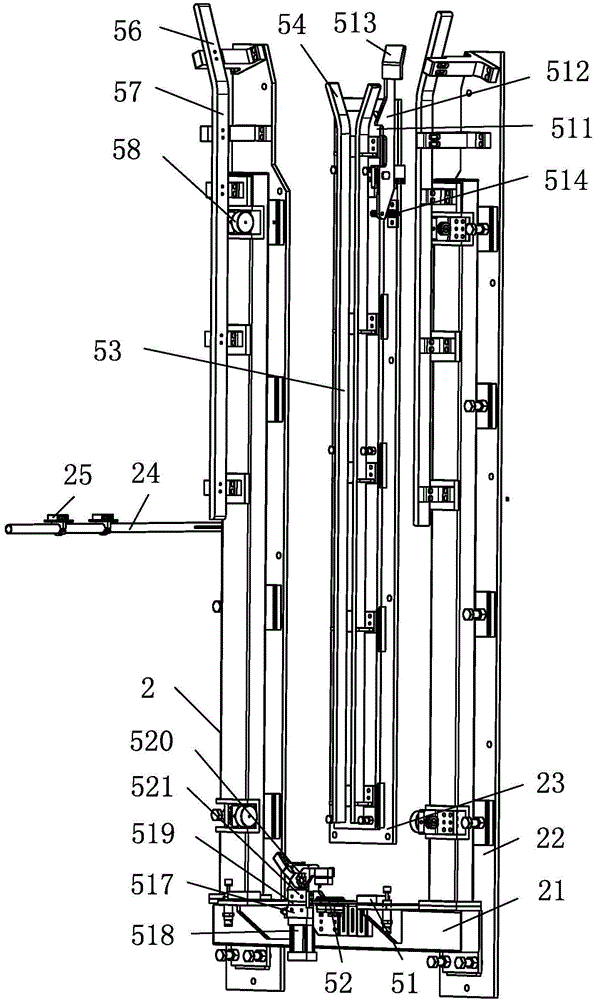

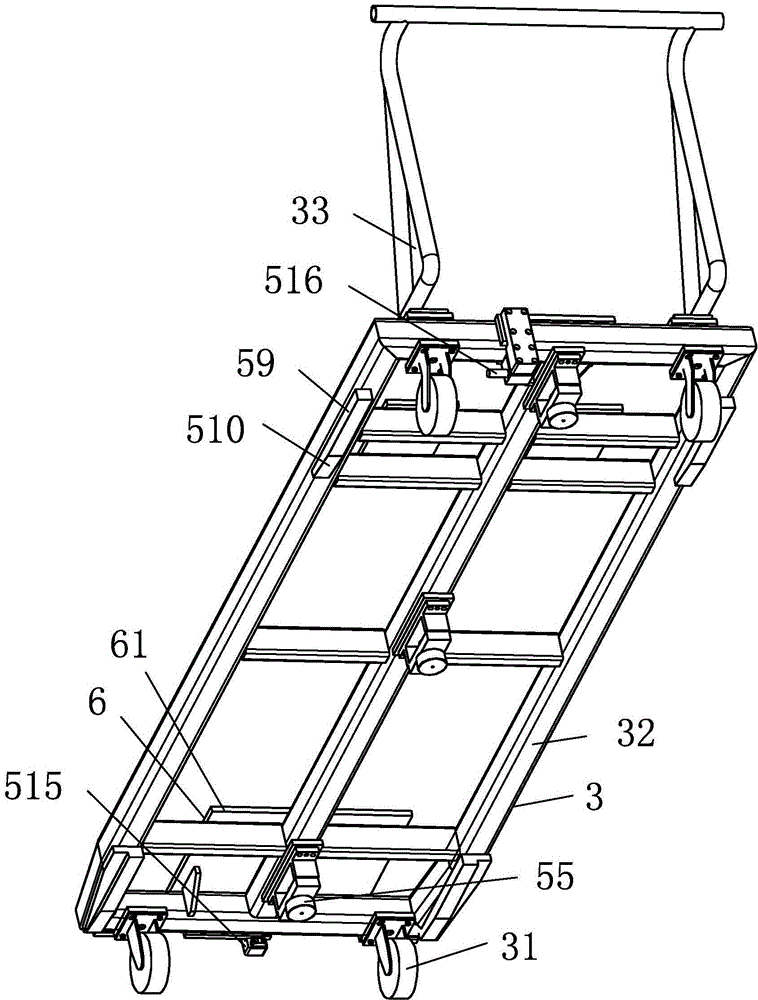

[0019] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Shown: a welding and feeding device for an automobile door sill assembly, including a base 2, a workpiece transfer vehicle 3, a material rack 4, an in-position component 5 for positioning between the workpiece transfer vehicle 3 and the base 2, and a material rack 4. The positioning assembly 6 and the loading industrial robot 1 positioned between the workpiece transfer vehicle 3.

[0020] The base 2 includes an end frame 21, two side frames 22 whose rear ends are welded to the end frame 21 respectively, and a middle frame 23 between the two side frames 22; The bottom frame 32 of the two casters 31, the handle 33 welded with the bottom frame 32 rear ends; the positioning assembly 5 includes a limit stopper 51 and a limit proximity switch 52 connected with the end frame 21 screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com