Patents

Literature

851results about How to "Easy to control automatically" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater

InactiveCN101665311AReduce processing loadEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationElectrolysis

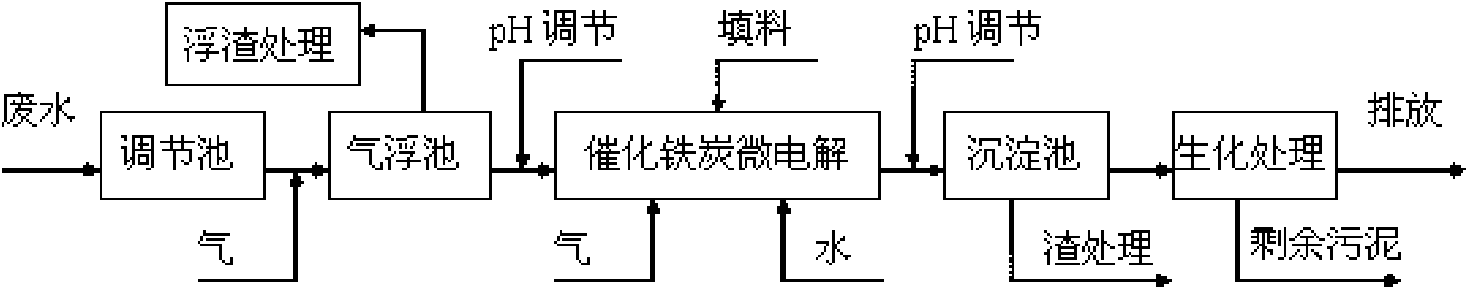

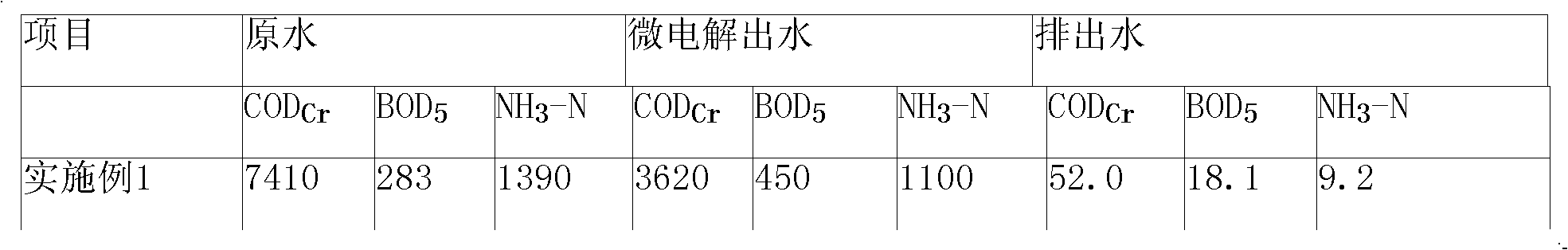

The invention relates to a catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater; the organic wastewater is collected to an adjusting tank and enters an air floatation tank for air floatation treatment to remove part of the organic matters after the adjustment of water volume and water quality; the scruff is collected or recovered; the wastewatergoes through Ph adjustment and then enters a catalytic iron-carbon and micro-electrolysis unit to improve the biochemical quality; the effluent goes through Ph adjustment and then enters a sedimentation tank; the effluent of the sedimentation tank adopts anoxic-aerobic biochemistry treatment to remove the organic matters and ammonia nitrogen and then is emitted after reaching the standard; and the filler of the catalytic iron-carbon and micro-electrolysis unit comprises iron, carbon and a catalyst, wherein the mass ratio of the iron, carbon and catalyst is 1: (0.3-1.5): (0.01-0.5). The invention can effectively improve the micro-electrolysis electrochemical reaction efficiency and the degrading capability to the organic matters, and reduce the wastewater treatment cost with convenient technological operation.

Owner:CENT SOUTH UNIV

Fast laser depositing process of preparing antinwear heat resistant composite coating on surface of crystallizer

InactiveCN1932082ANo pollution in the processRadiation-freeMolten spray coatingArc welding apparatusAutomatic controlHigh power lasers

The fast laser depositing process of preparing antiwear heat resistant composite coating on the surface of crystallizer features that high power laser is first utilized in fast scanning to form transition layer in excellent metallurgical binding with the substrate of crystallizer copper plate on the surface of the plate and then utilized in wide band deposition to form Co base alloy with excellent heat resistance and high wear resistance on the surface of the transition layer. Compared with convenient technological process, the present invention has the advantages of precise control in laser power, position, shape and other parameters, easy automatic control of the whole process, no environmental pollution, high production efficiency, low power consumption, etc. and may be used widely.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

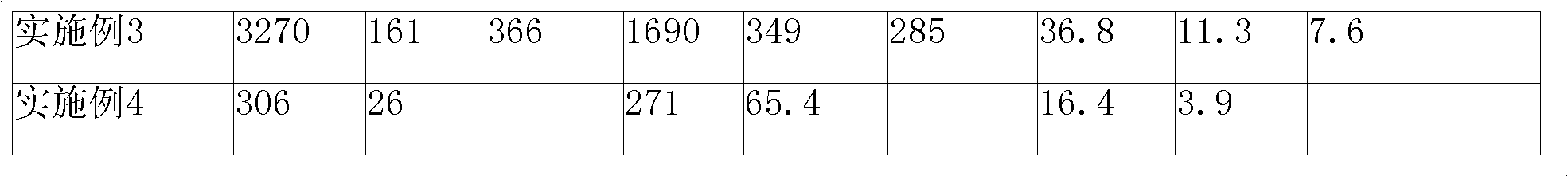

Sulfur-resistant catalytic deoxidization process for methane-rich gas

InactiveCN101139239ALow priceSulfur resistanceMetal/metal-oxides/metal-hydroxide catalystsChemical modification purification/separationReaction temperatureManganese

The present invention discloses a sulfur wearable and catalyzing and oxidizing method for gas abundant of firedamp; the raw material gas abundant of firedamp such as coal bed gas firstly passes through a preheater for preheating, and then enters a oxidizing reaction device; under the condition of 0-0.5MPa of pressure, 500-750 DEG C of reaction temperature, 1000-3000h-1of reaction air speed, the firedamp in the air is reacted with oxygen to produce carbon dioxide and water in manganese base sulfur wearable and catalyzing and oxidizing bed; at the same time, a small quantity of firedamp is decomposed to produce carbon and hydrogen gas; the carbon and the hydrogen after being decomposed are also reacted with oxygen so as to reach the purpose of getting rid of oxygen in the airs abundant of firedamp effectively. The present invention adopts much newer and more economical new catalyzer, which does not need to desulfurize firstly for the air; the air can directly enter the oxidization reaction device for oxidization. So the present invention can decrease the cost and simplify the technics process.

Owner:HAO HUA CHENGDU TECH

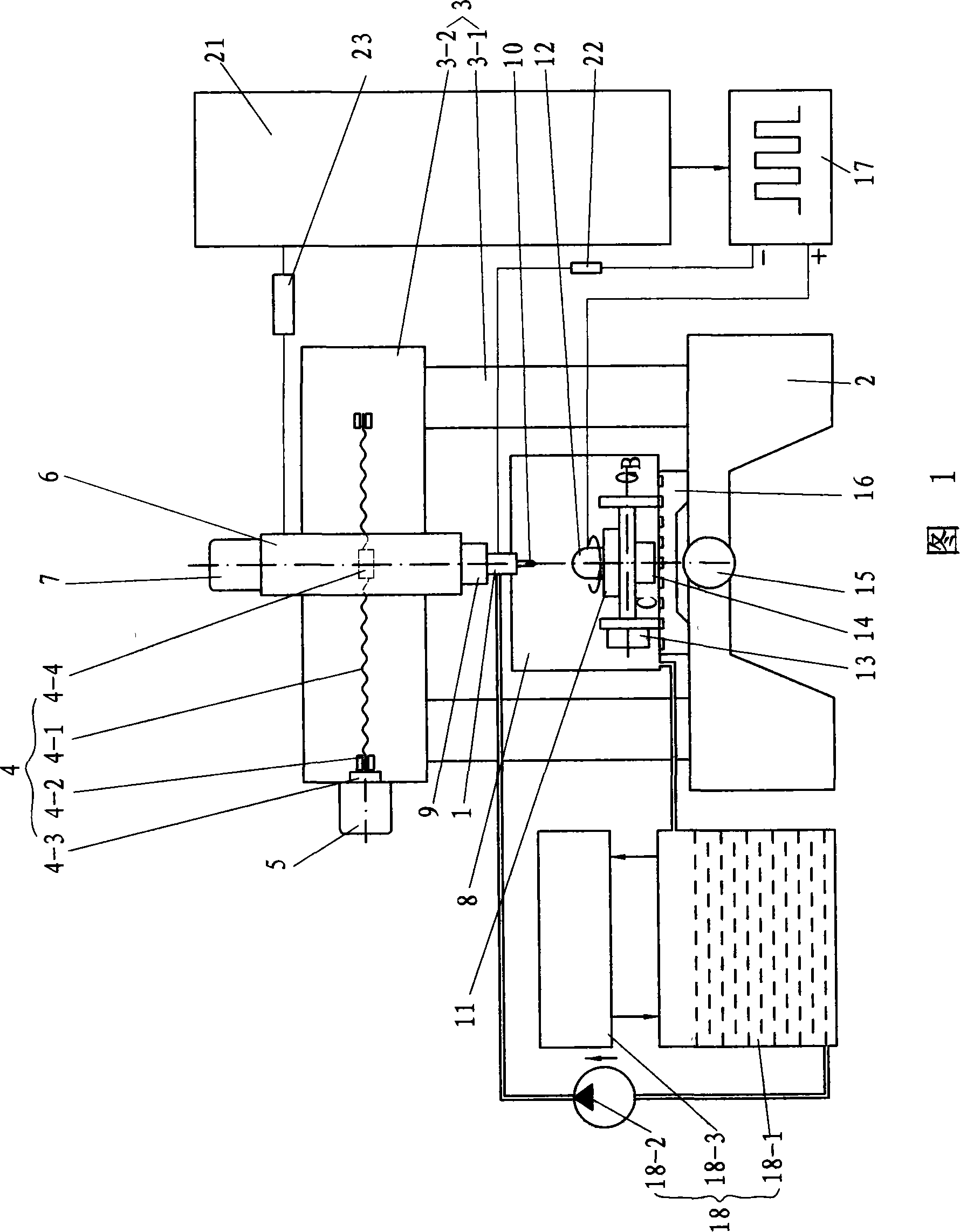

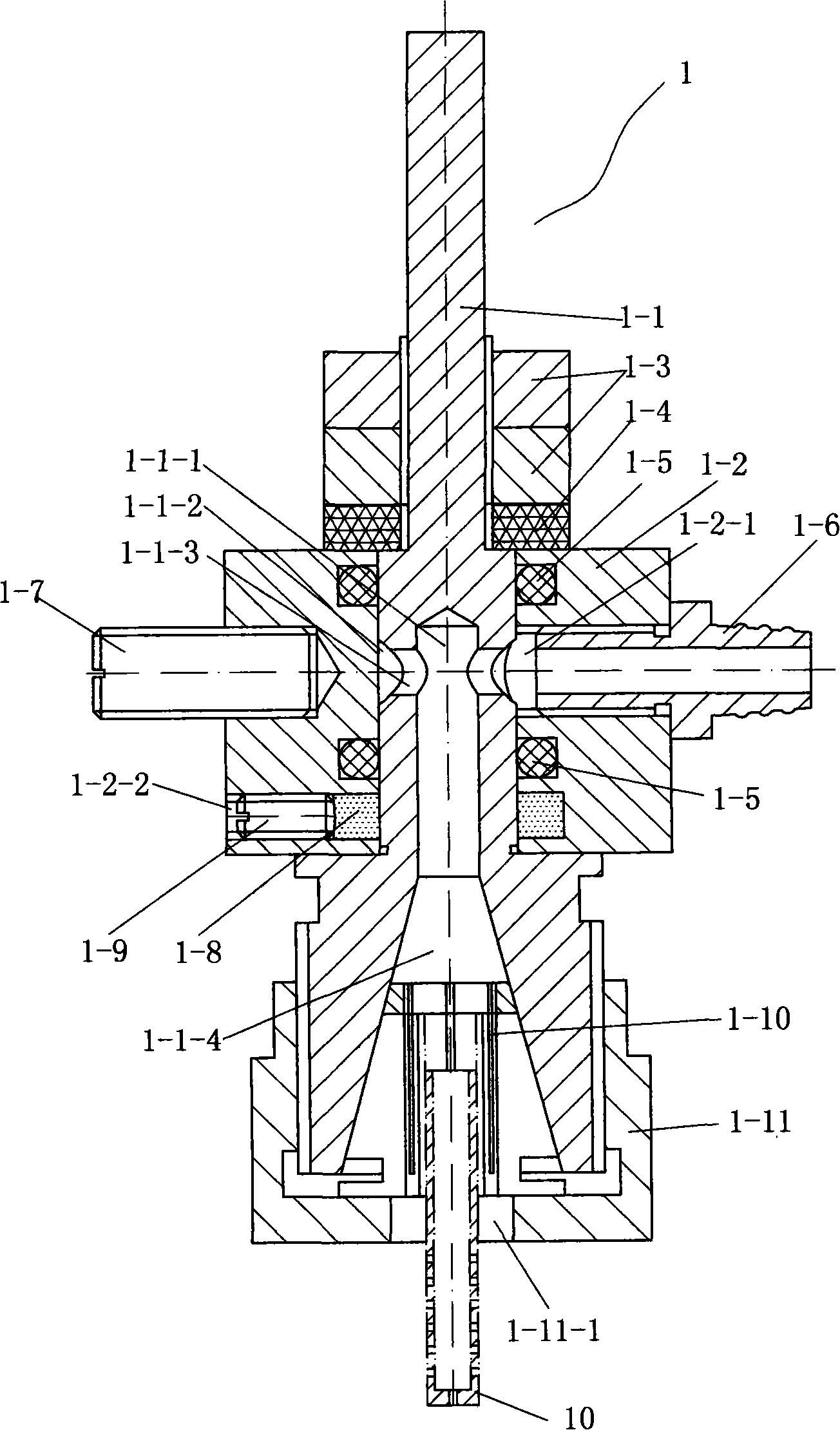

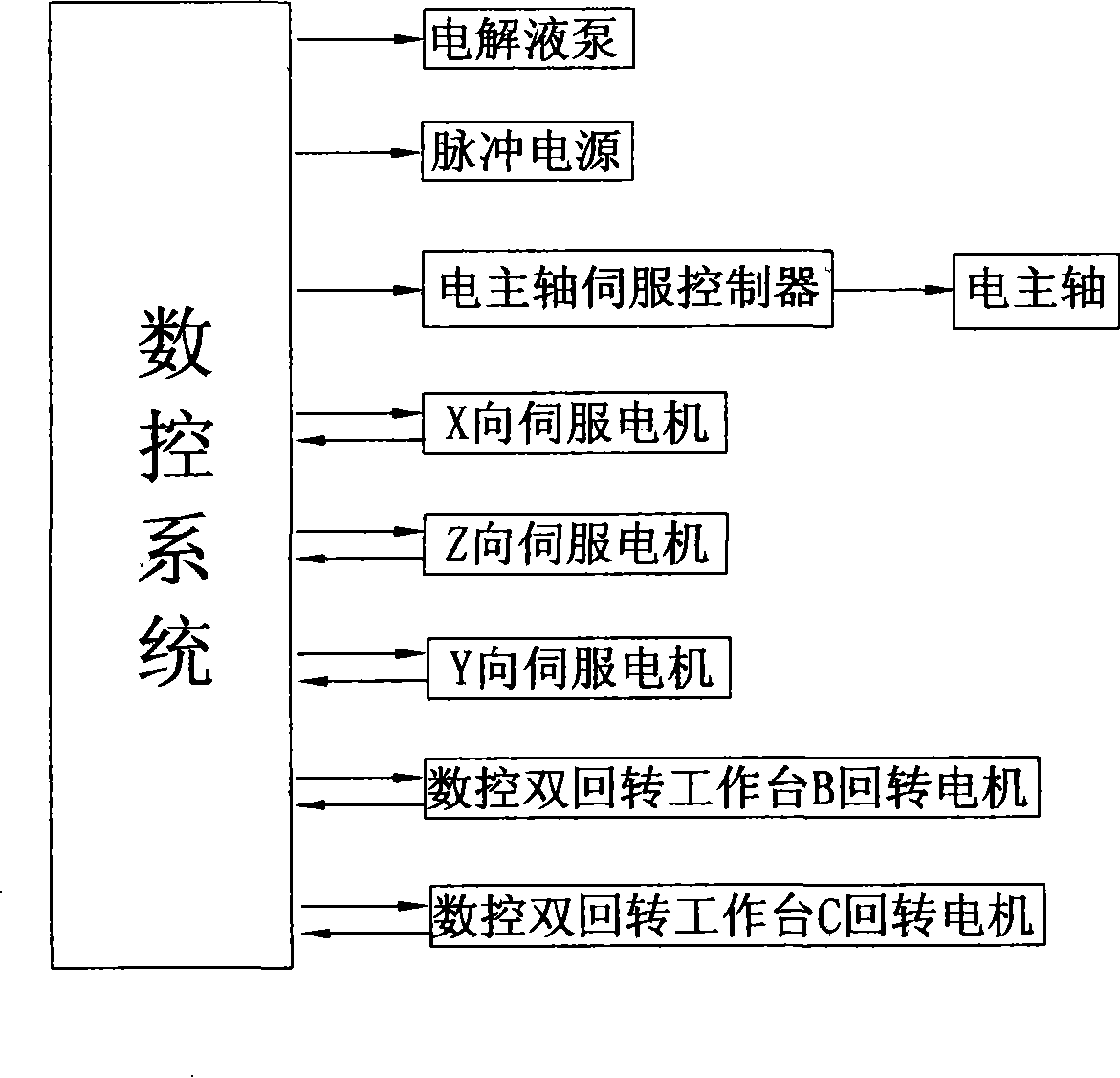

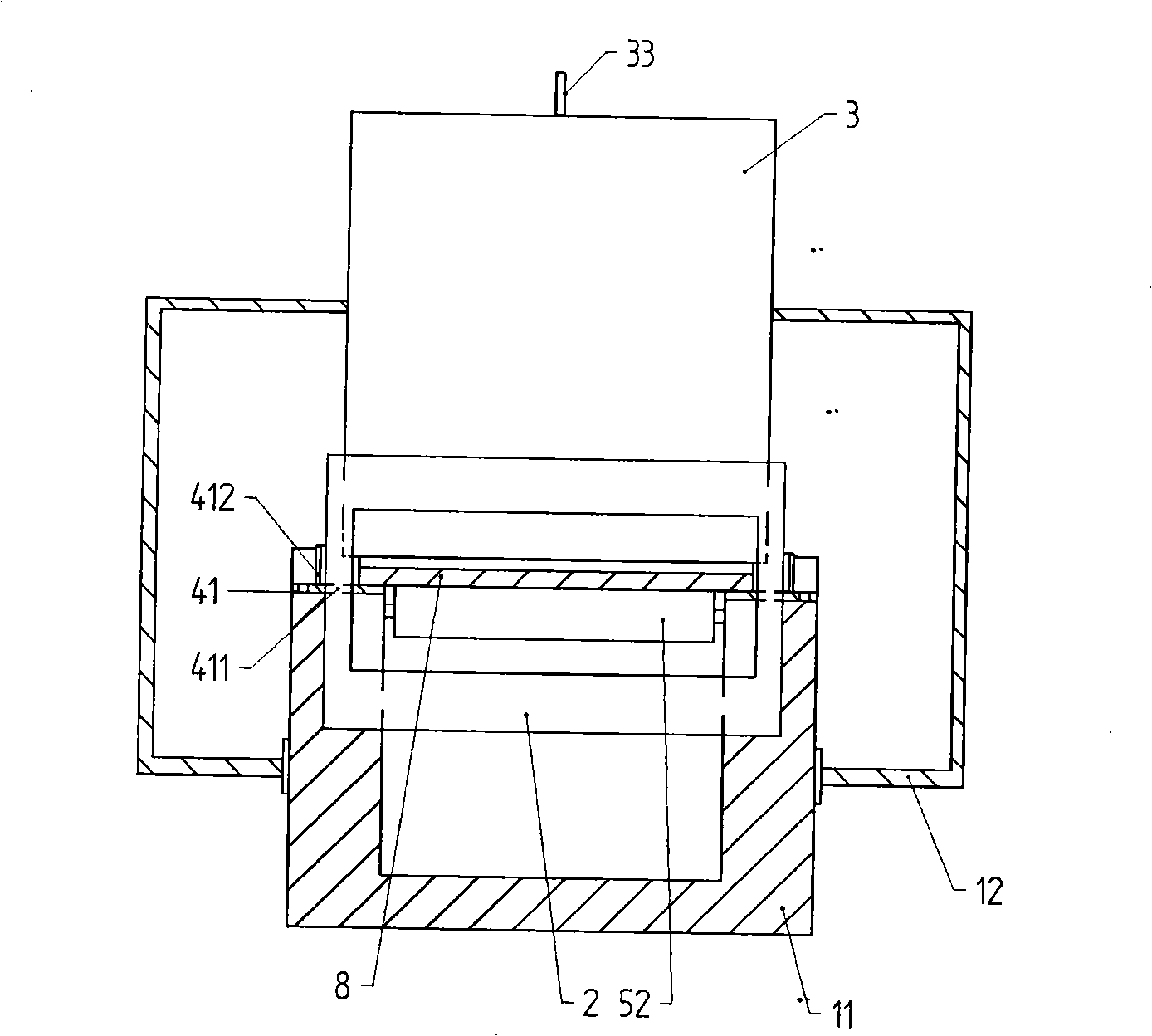

Numerical control electrolyze mechanical compound processing machine tool

InactiveCN101249578AEliminate installation errorsImprove machining accuracyFeeding apparatusElectric circuitsElectric machineryComposite cathode

A numerical control electrolytic-mechanical composite machine tool comprises a machine body, a frame, a horizontal work bench, a numerical control double-revolving work bench, a protection box, a spindle head, an electrical spindle, a numerical control system, a pulse power supply, an electrolyte circulating device, and an X-direction transmission mechanism, a Z-direction transmission mechanism as well as a Y-direction transmission mechanism, wherein the electrical spindle, the pulse power supply, an electrolyte pump of the electrolyte circulating device, an X-direction servo motor, a Z-direction servo motor, a Y-direction servo motor, and a B revolving motor and a C revolving motor of the numerical control double-revolving motor are all controlled by the numerical control system. By controlling the relative movement of a composite cathode and an anode workpiece, the machine tool can process mold cavities and mold surfaces for complex workpieces, thus processing workpieces of different shapes. By changing different composite cathodes and adjusting different processing parameters, rough processing, finish processing and surface smoothing of one part can be achieved by one machine tool in different processing manners such as drilling, milling, cutting, grinding and polishing, thus eliminating installation error caused by repeated installation of workpieces.

Owner:CHANGZHOU INST OF TECH

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

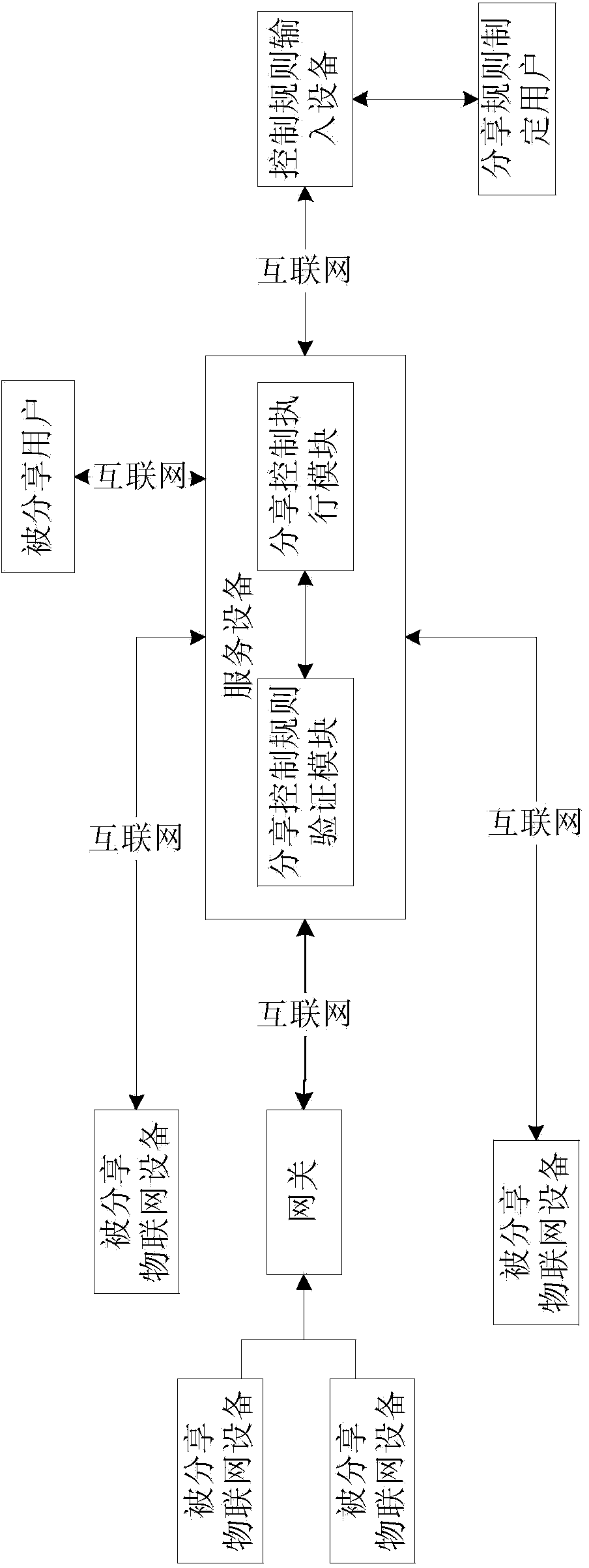

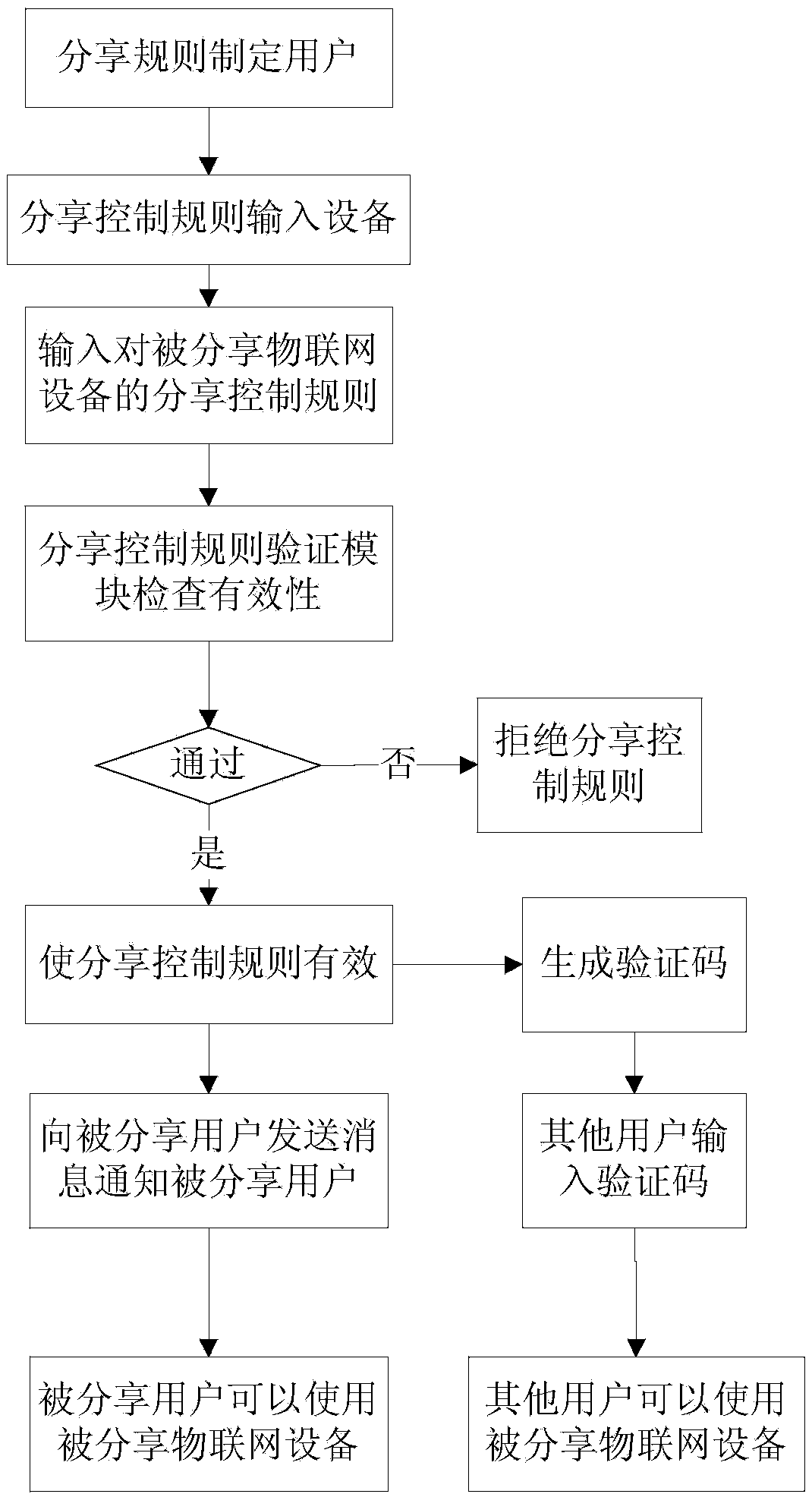

Sharing system and sharing method for internet-of-things device

ActiveCN104219328AReflect the characteristics of open sharingSave resourcesTransmissionThe InternetDistributed computing

The invention relates to a sharing system and a sharing method for an internet-of-things device. The sharing system comprises a shared internet-of-things device, a service device, a sharing rule designing user, a shared user and a sharing control rule input device, wherein the service device comprises a sharing control rule verification module and a sharing control execution module, the sharing control execution module is connected with the sharing control rule verification module, the sharing control execution module sends a message to the shared user to inform the shared user, thereby, the shared user can know that a control rule of the shared internet-of-things device is already shared to the shared user, and when the shared user logs in the service device, the shared user can automatically obtain a corresponding permission to the shared internet-of-things device in accordance with the regulations in the sharing control rule. Compared with sharing systems and sharing methods in the prior art, the sharing system and the sharing method for the internet-of-things device have the advantages that the permission of the internet-of-things device can be shared to other users within the internet for usage, internet open sharing feature can be really reflected, and the idea of making the best use of everything and saving resources is reflected.

Owner:NINGBO HAIBO GRP CO LTD

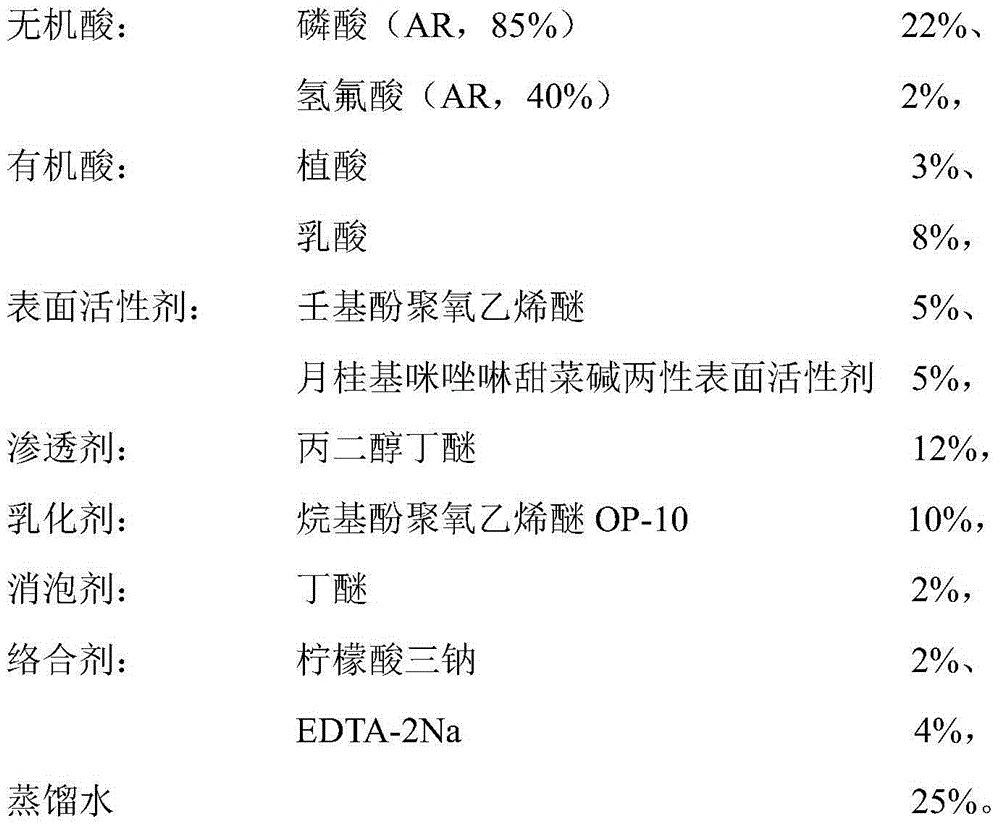

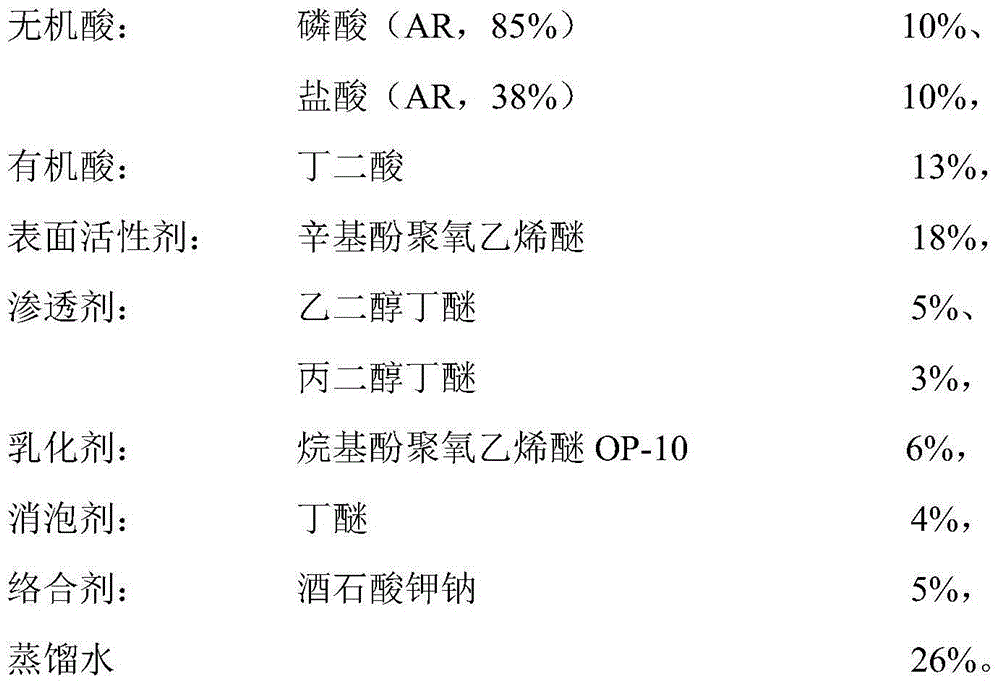

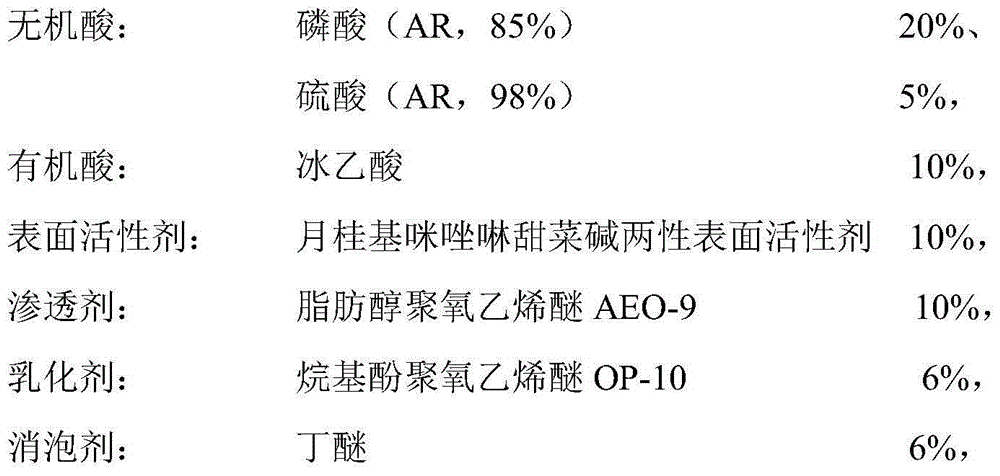

Environment-friendly aluminum cleaning agent and preparation method thereof

The invention discloses an environment-friendly aluminum cleaning agent and a preparation method thereof. The cleaning agent is composed of the following components in percentage by weight: 20% to 25% of inorganic acid, 10% to 20% of organic acid, 10% to 18% of surfactant, 8% to 15% of osmotic agent, 6% to 18% of emulsifier, 2% to 8% of antifoaming agent, 5% to 8% of complexing agent, and 25% to 30% of water. In the provided cleaning agent, the using amount of hydrochloric acid, sulfuric acid, and nitric acid is reduced, the aluminum parts are washed by medium-strong acids and organic acids, and the cleaning agent has a very good oil stain and rust removing ability. The cleaning agent is acidic, the pH value of the cleaning agent is 2.1 to 5.6, and the cleaning agent can well remove the oxide scale on the aluminum surface. Because the acidity of the organic acids is weak, the over-corrosion on work tools and acid volatilization, which can harm the workers' health, are effectively avoided, and the cleaning effect is not influenced at the same time. Moreover the adopted organic acids are easy to decompose, and thus the cleaning agent is environment-friendly.

Owner:PINGGAO GRP +1

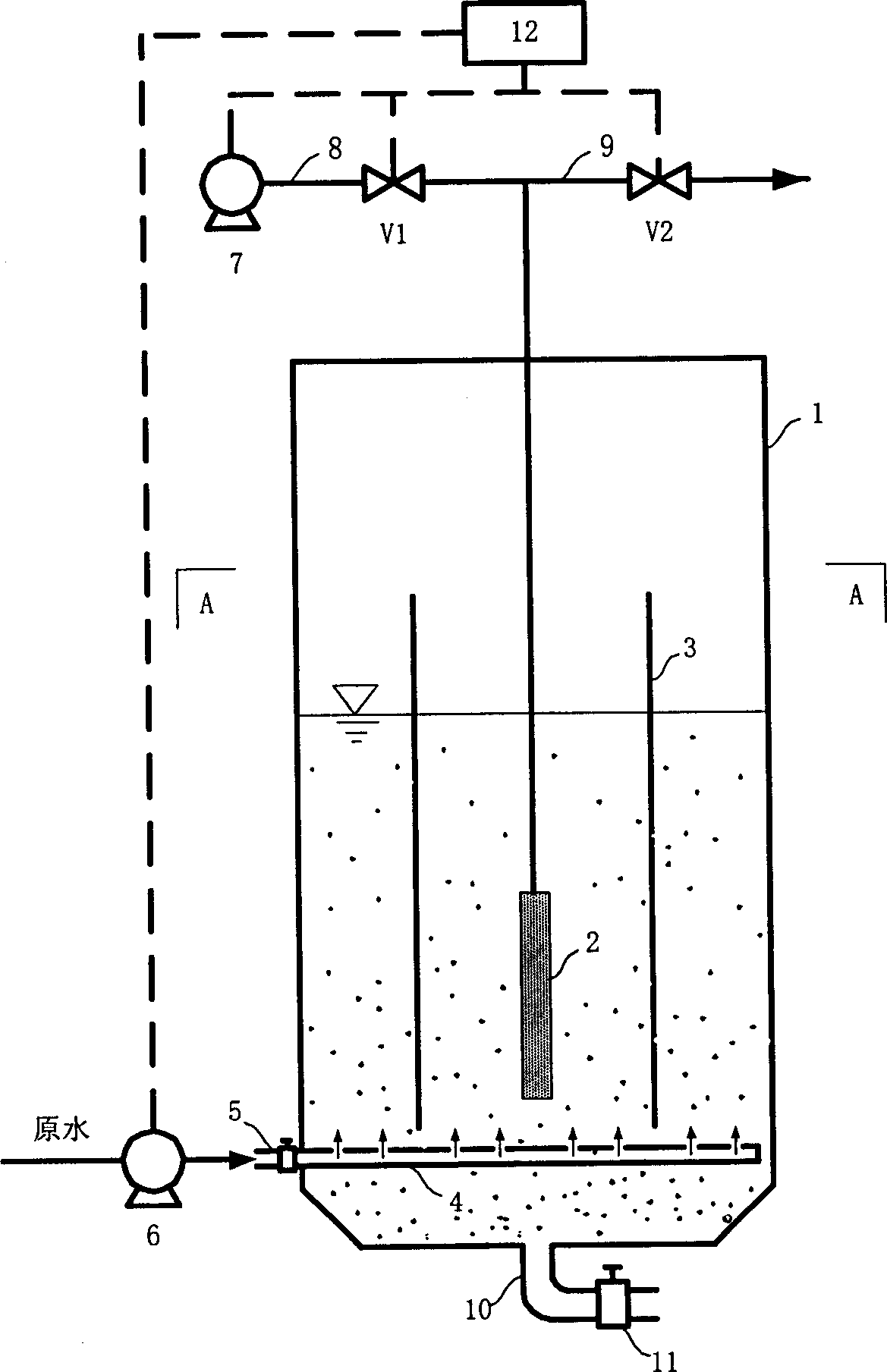

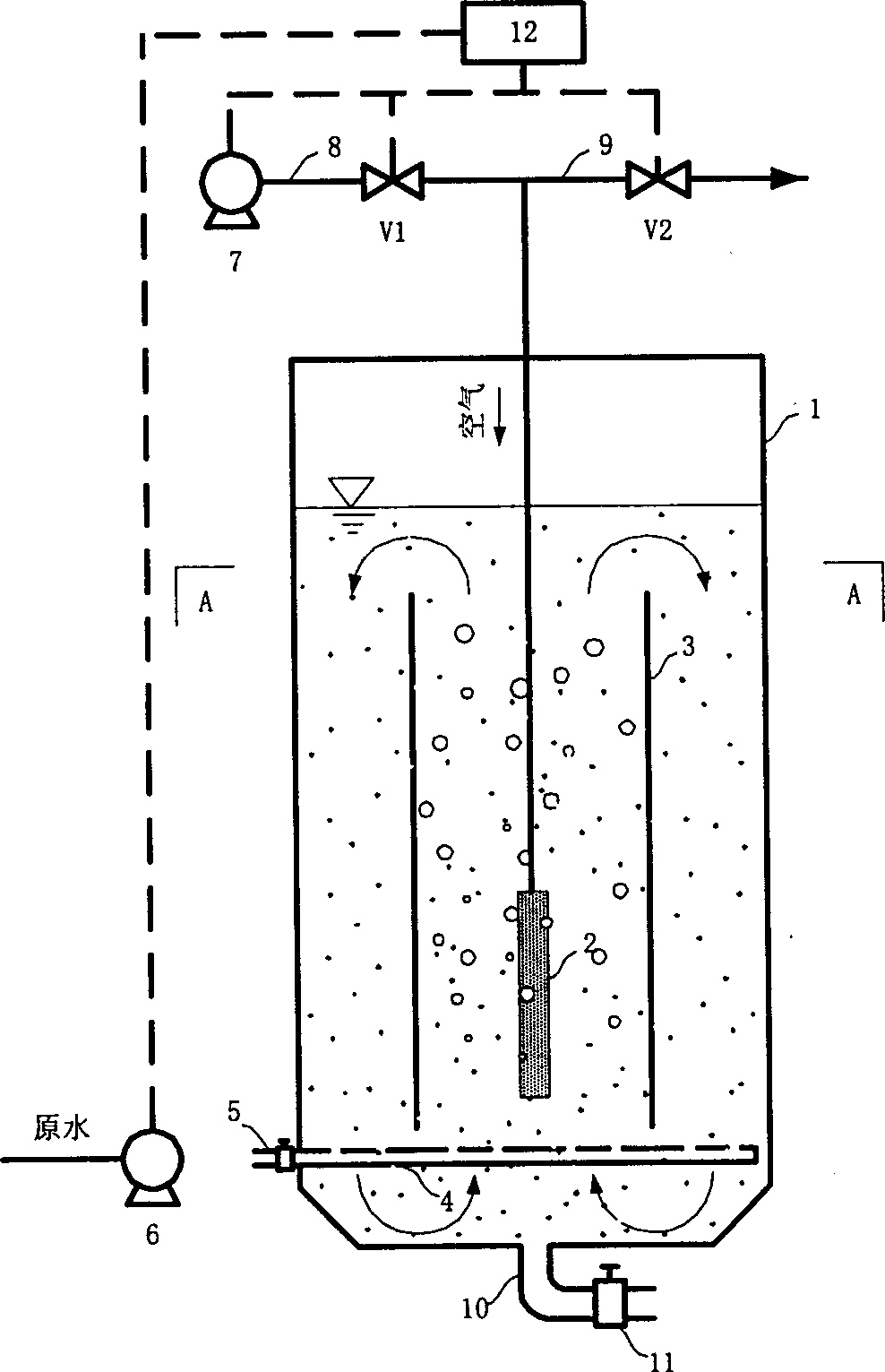

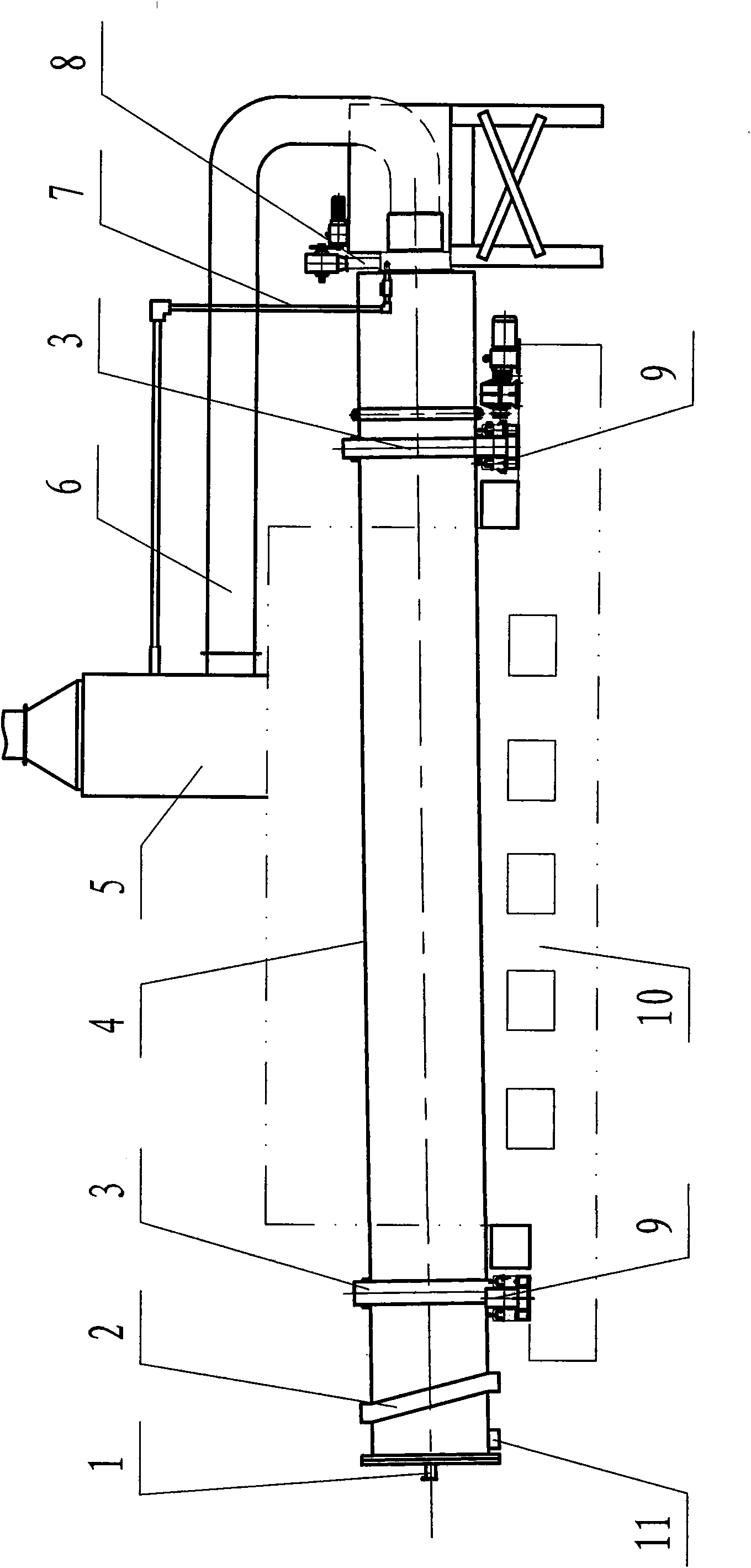

Process and apparatus for wastewater by batched membrane-bioreactor

InactiveCN1424265AGood water qualitySimple device structureWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesAutomatic controlPollutant

A process for treating sewage by integrating sequential active sludge method with membrane-bioreactor features that the membrane assembly is put in bioreacting pool, its outlet is respectively connected to air inlet pipe and water outlet pipe via two control valves, the whole system sequentially passes through flow-in, reaction, discharge and idle steps, that is, anaerobic, aerobic and anoxic states, and said membrane assembly plays the roles of aerating unit in reaction step or separator in discharge step. Its advantages are simple structure and high effect.

Owner:TSINGHUA UNIV

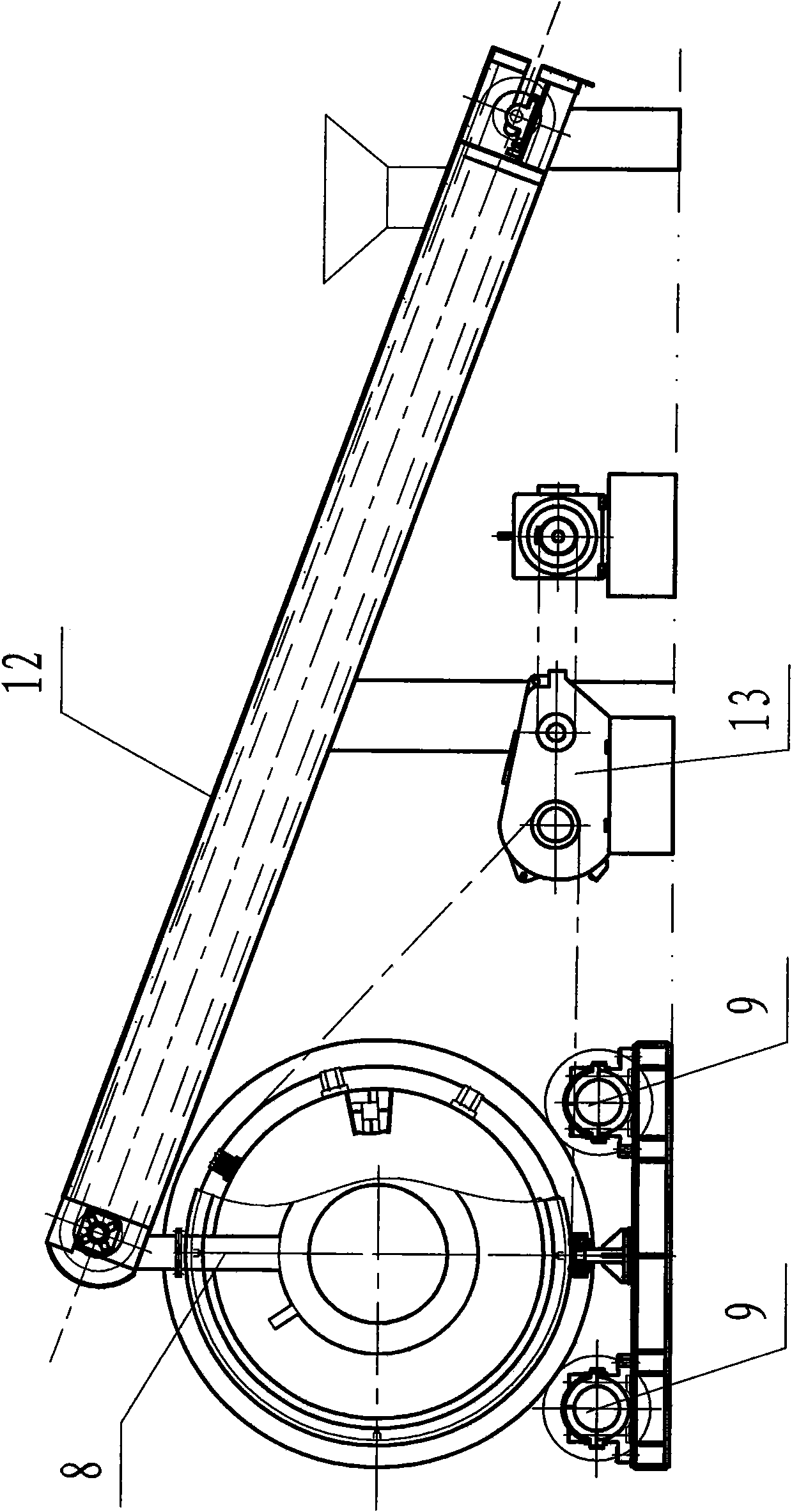

Active carbon horizontal converter

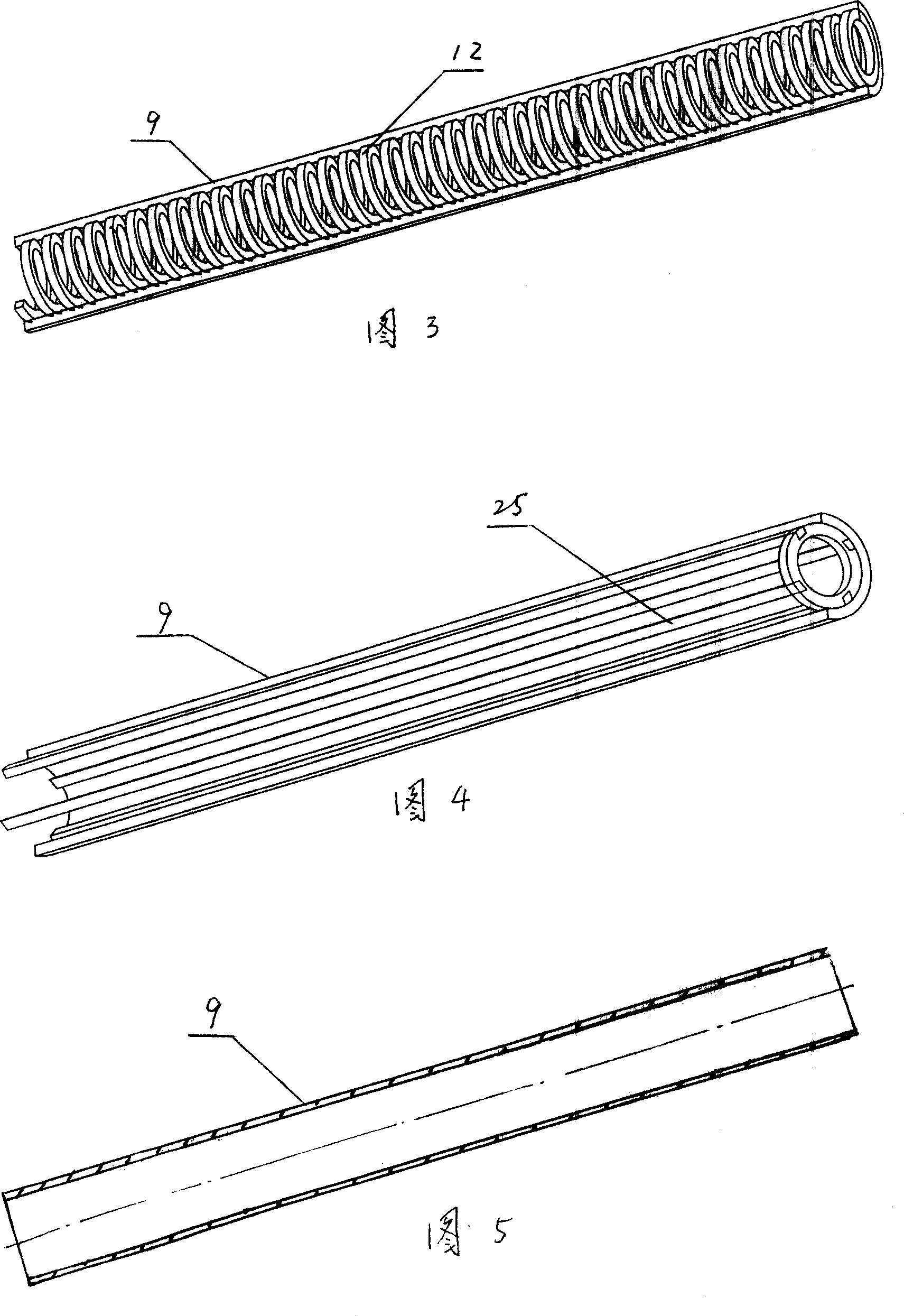

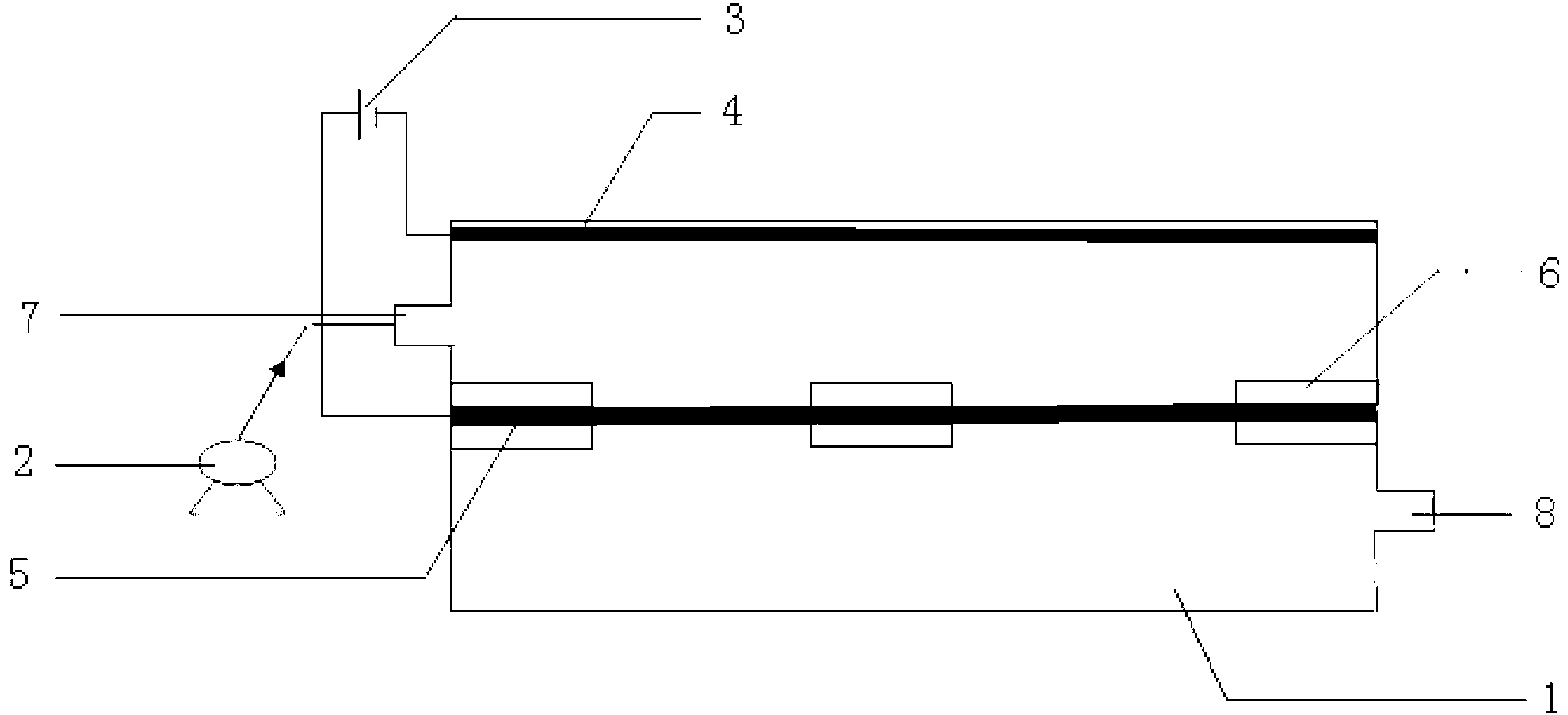

InactiveCN101592439AEvenly heatedImprove the activation effectRotary drum furnacesEngineeringBiological activation

The invention discloses an active carbon horizontal converter in the field of equipment producing active carbon, which comprises a driving mechanism (13), a feed mechanism (12), an outer barrel (4), a gas distributing pipe (1), an exhaust pipe (24), a flue (6), a steam generator (5), and a steam pipe (7), wherein an inner barrel (27) is arranged in the outer barrel (4) and is welded in the outer barrel (4) through a vertical plate (25);at least three independent material channels (18) are formed by the separation of the vertical plate (25) between the outer barrel (4) and the inner barrel (27) ; a shoveling plate is welded in each material channel; and one end of the gas distributing pipe (1) is provided with a gas distributing pipe cover (31), while the other end extends into the inner barrel (27). The active carbon horizontal converter not only can continuously produce the active carbon with a particle size range between 60 meshes and 12 millimeters, but also ensures the bidirectional heating of the inside and outside of materials, thereby having high utilization rate of heat energy and good activation effect, and only needing the activation time for 4 to 5 hours.

Owner:淮北市协力重型机器有限责任公司 +2

Preparation method of cold soluble instant health food of grains, vegetables and fruits

ActiveCN101926463AWide variety of sourcesImprove immunityFood preparationBeta-CaroteneAdditive ingredient

The invention provides to a preparation method of cold soluble instant health food of grains, vegetables and fruits and relates to a novel preparation method of food with complete nutrients and high bioavailability, belonging to the technical field of modern nutritious food preparation. The method comprises the following steps: carrying out nonthermal physical field energy conservation dehydrateddesiccation on fresh plant source food raw materials, namely grains, vegetables and fruits which are unpolluted, green and safe; smashing the raw materials to 80-120 meshes; evenly compounding and mixing micronutrient functional factors with 10%-60% of corn, 10%-50% of vegetables and 10%-40% of fruits in the weight ratio, so as to prepare the all natural nutritious food of grains, vegetables and fruits which can be taken by mixed with cool boiling water. The invention mutually mixes the different grains, vegetables and fruits which are processed, so that the cold soluble instant product contains complete nutrients such as dietary fiber, protein, fat, vitamine, mineral composition, beta-carotene, flavone, natural coloring matter and the like, has high utilization ratio of nutritious components and good taste, and belongs to a novel health food.

Owner:JIANGNAN UNIV +1

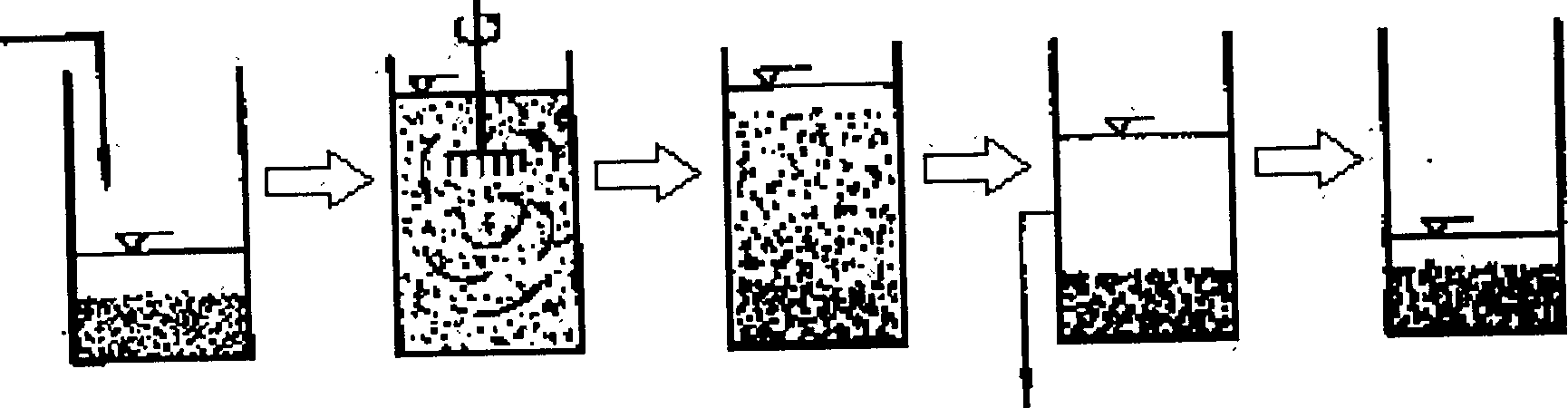

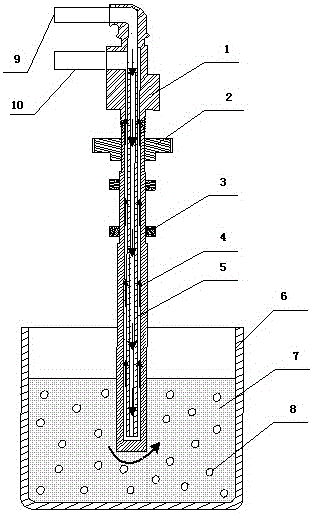

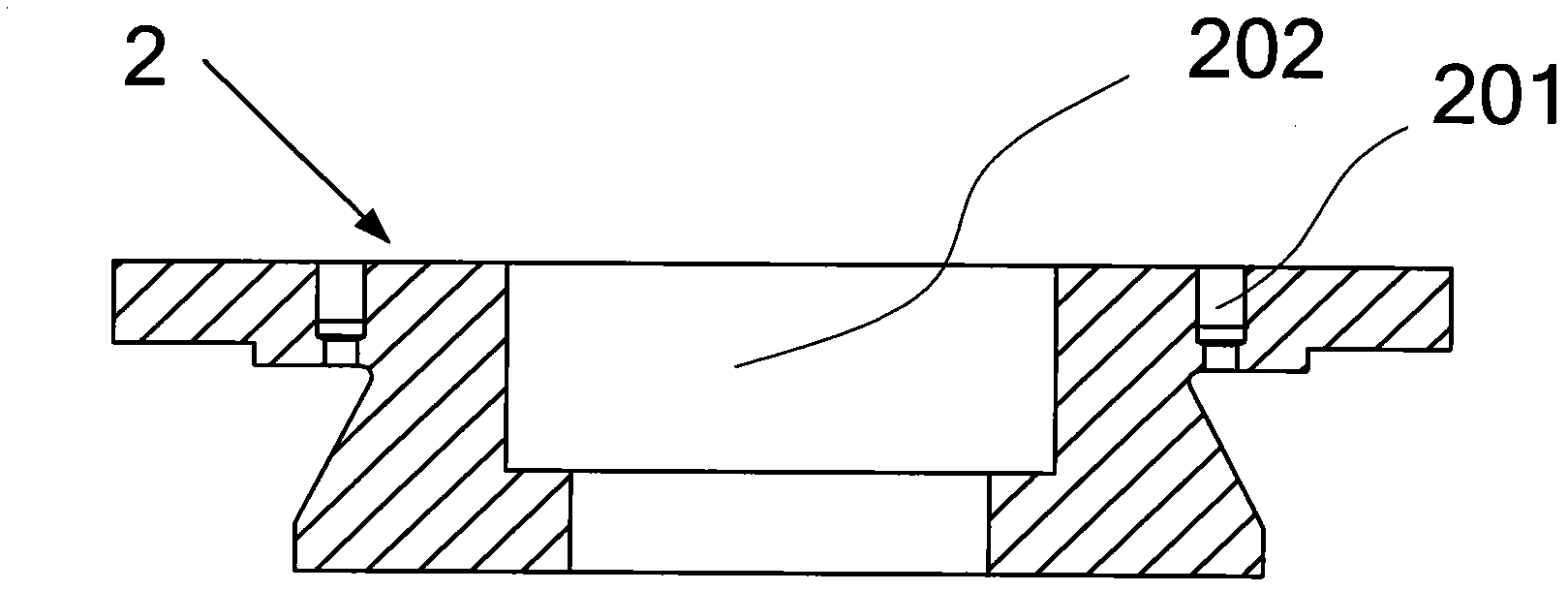

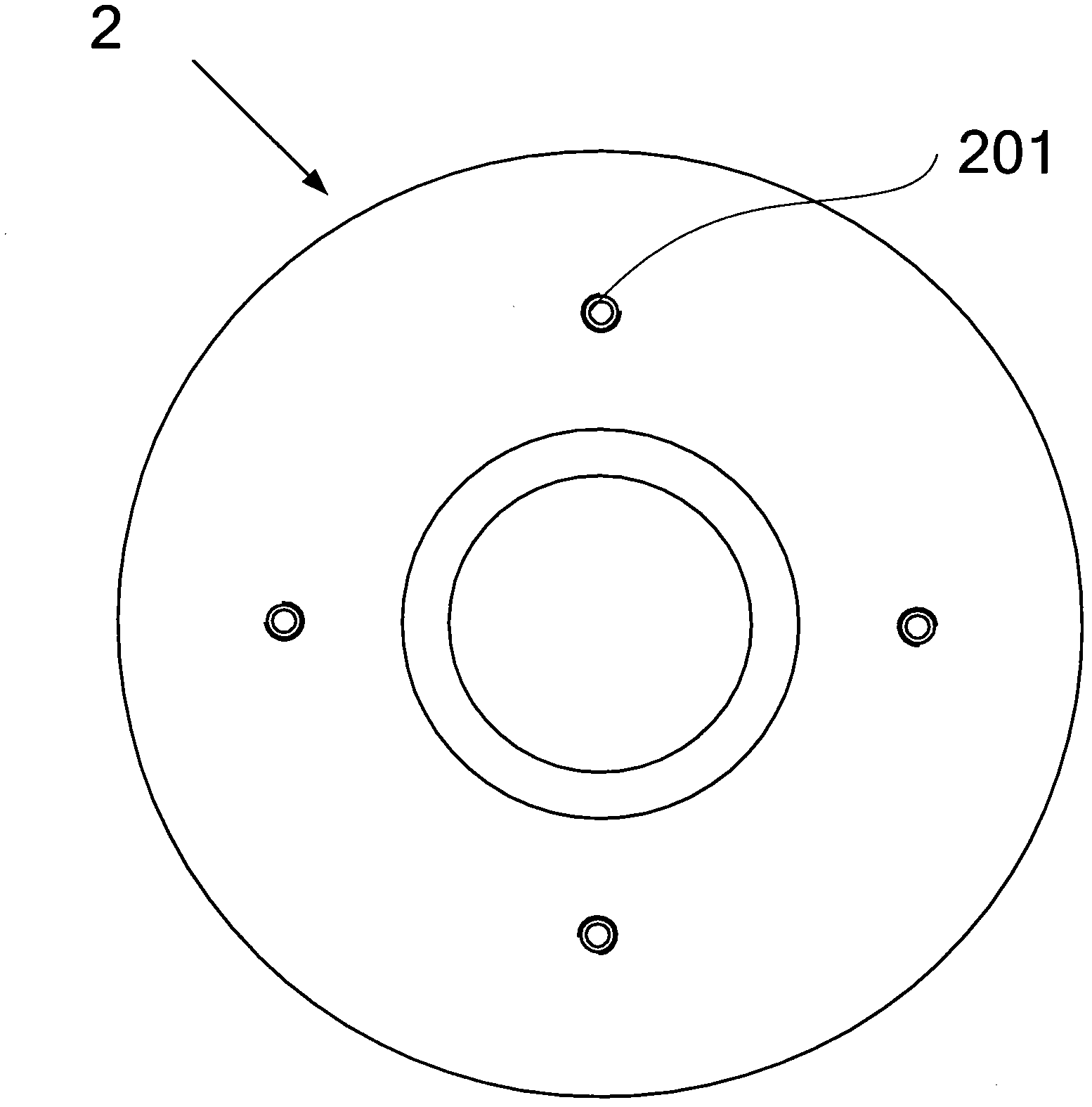

Method and device for preparing semi-solid state slurry through intensive cooling stirring

The invention discloses a method for preparing semi-solid state slurry through intensive cooling stirring. The method comprises the following steps: placing overheated alloy melt in a crucible or a casting ladle, descending a rotary stirring shaft internally introduced with a circular cooling medium in the alloy melt through a lifting device, driving the convection heat exchange of the alloy melt through stirring, continuously cooling the rotary stirring shaft through the circular cooling medium, stirring for a fixed period of time or cooling the melt to a set temperature, raising the rotary stirring shaft to prepare the semi-solid state slurry and form an ingot casting; closing the casting ladle containing the semi-solid state slurry to formation equipment and pouring the semi-solid state slurry into a cavity or material chamber of the formation equipment to take the shape; and taking out a formed part and moving the crucible or the casting ladle back to an original position and filling the overheated alloy melt to perform the next semi-solid state slurry preparation. The invention further provides a device for realizing the above method. Through the adoption of the method and device provided by the invention, large volume of semi-solid state slurry can be prepared once, and the semi-solid state slurry can be continuously produced in batch, and then the rheolytic formed part can be prepared through the combination of pressure casting, rolling, die-forging and other conventional formation equipment.

Owner:SHANGHAI INST OF TECH

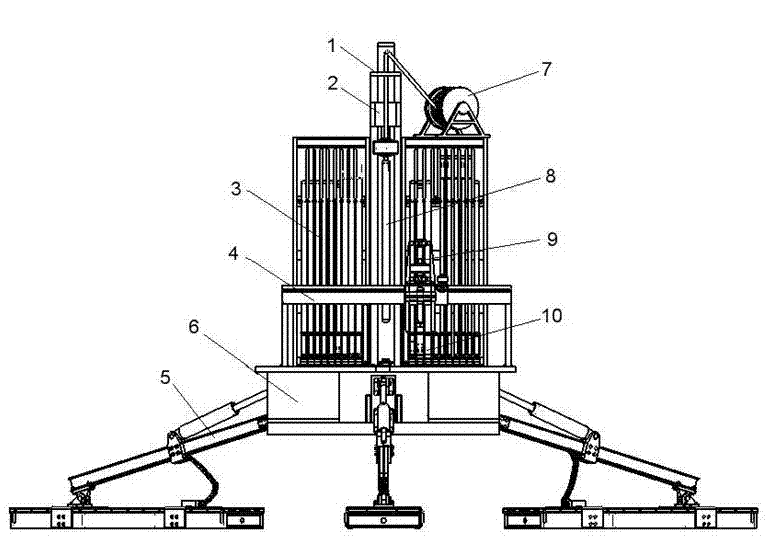

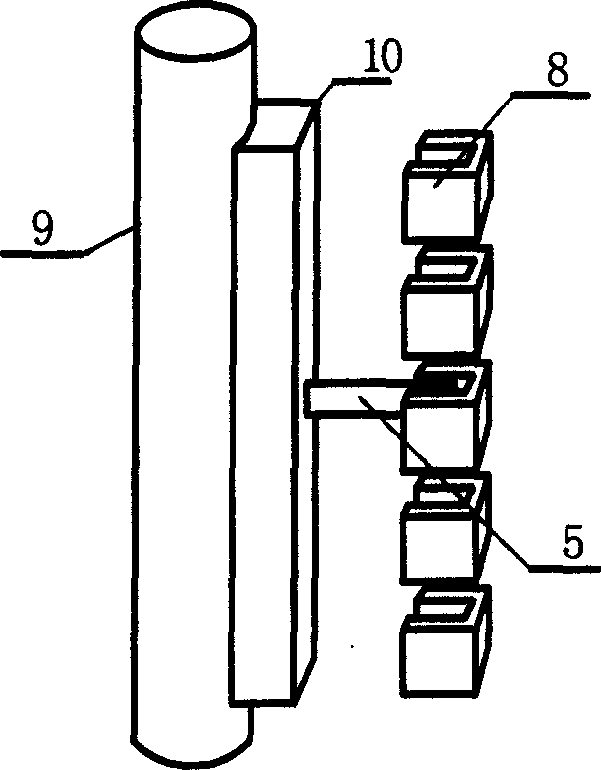

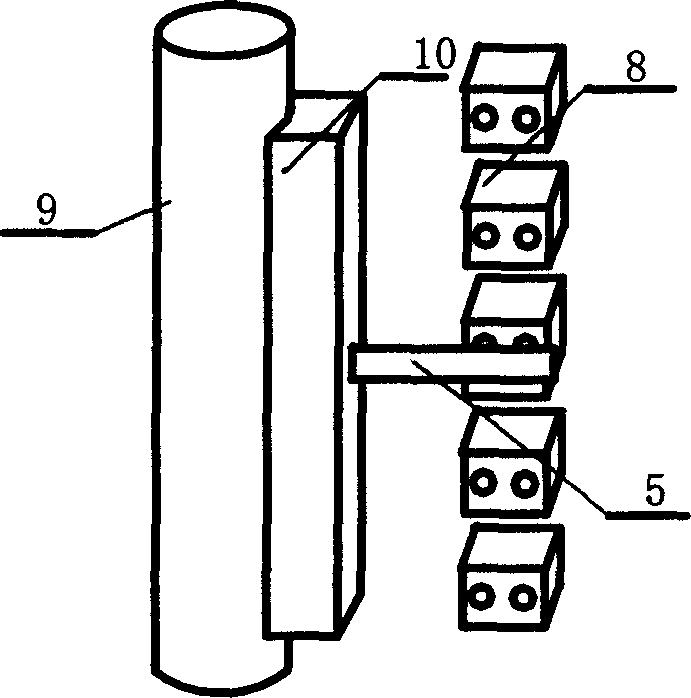

Seabed type conical investigating and drilling integrated machine

InactiveCN102383723AIncrease coefficient of frictionImprove securityDrilling rodsConstructionsManipulatorEngineering

The invention relates to a seabed type conical investigating and drilling integrated machine which comprises a tower, a power head, a drilling tool storeroom, a manipulator mechanism, a leveling mechanism, an instrument box, a winch, a drilling tool, a clamp holder and a hydraulic pump. According to the drilling process of a seabed drilling machine, the power head provides the rotation power and realizes the feeding and recycling of the drilling tool through a tower guide rail on the tower; the drilling tool storeroom is arranged on the two sides of the power head and used for storing variousdrilling tools; the drilling tools are automatically stored and fetched through the manipulator mechanism, and the leveling mechanism keeps the drilling tool vertical to the seafloor when the integrated machine works; a core barrel for wire line coring is released and recycled by the winch; and the drilling tool is clamped and removed by the clamp holder. The integrated machine provided by the invention has a scientific and reasonable structure, is simple and convenient to control and safe and reliable to use and is suitable for the large-depth deep hole core sampling on seabed and also for operation on land.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

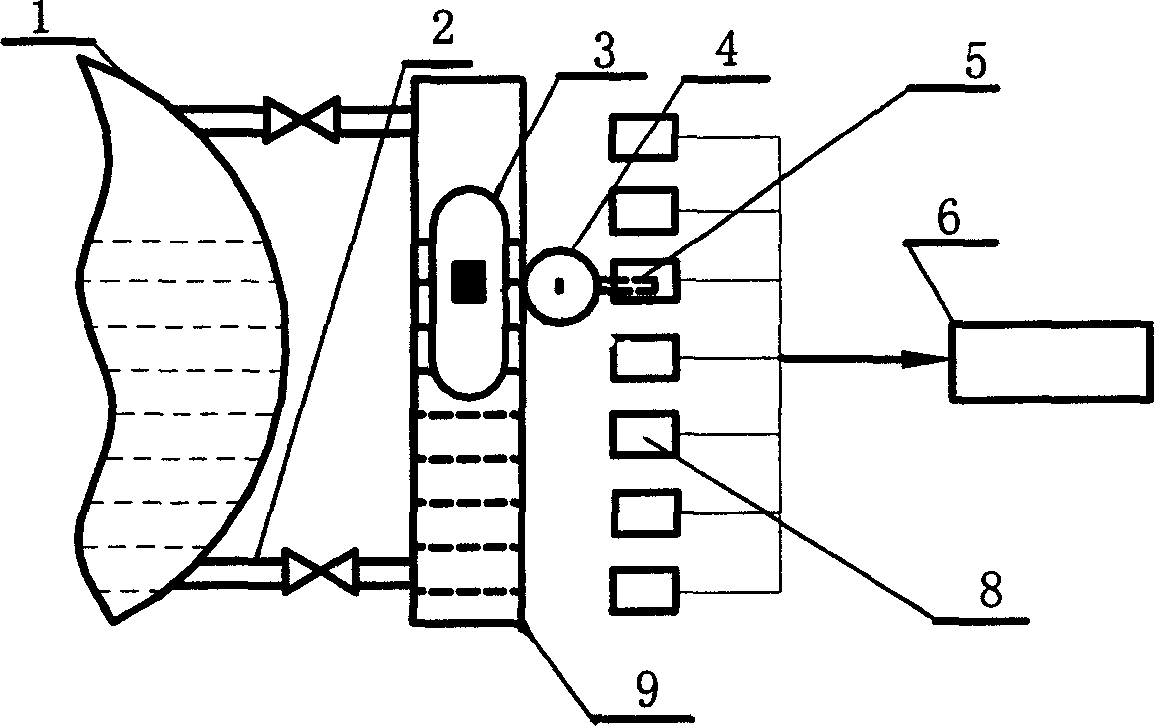

Level meter

InactiveCN1560574ASimple structureReal-time quick responseLevel indicators by floatsLevel sensorEngineering

The invention discloses a fluid level gage applied to high pressure boiler. The fluid level gage includes a connector connected to the measured container, the connector has a magnetic float elevating with the fluid level, the external side of the connector has a vernier coupled with the magnetic float, several photoelectric switches are arranged on the measured container with the fluid height, the vernier corresponds to different photoelectric switch when it is in different height, thus it is shaded and reflected; each photoelectric switch is connected to the control unit, it outputs voltage different to other photoelectric switch according to the voltage of the photoelectric switch, acquires the fluid height of the measured container. The device in the invention can provide fluid level electric signal output.

Owner:JINAN UNIVERSITY

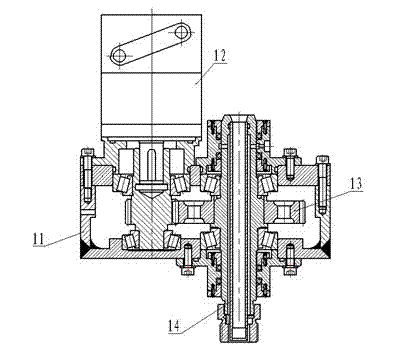

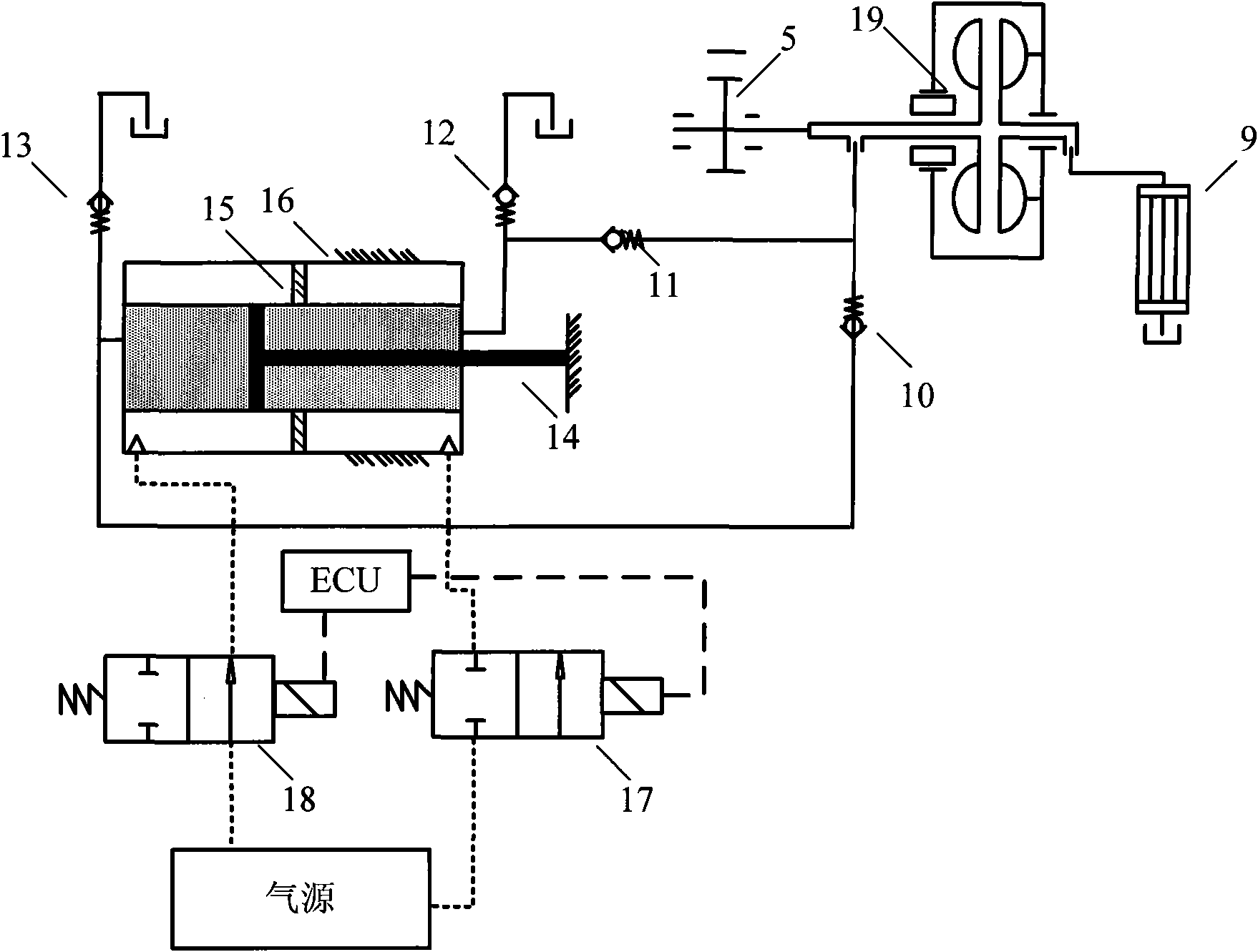

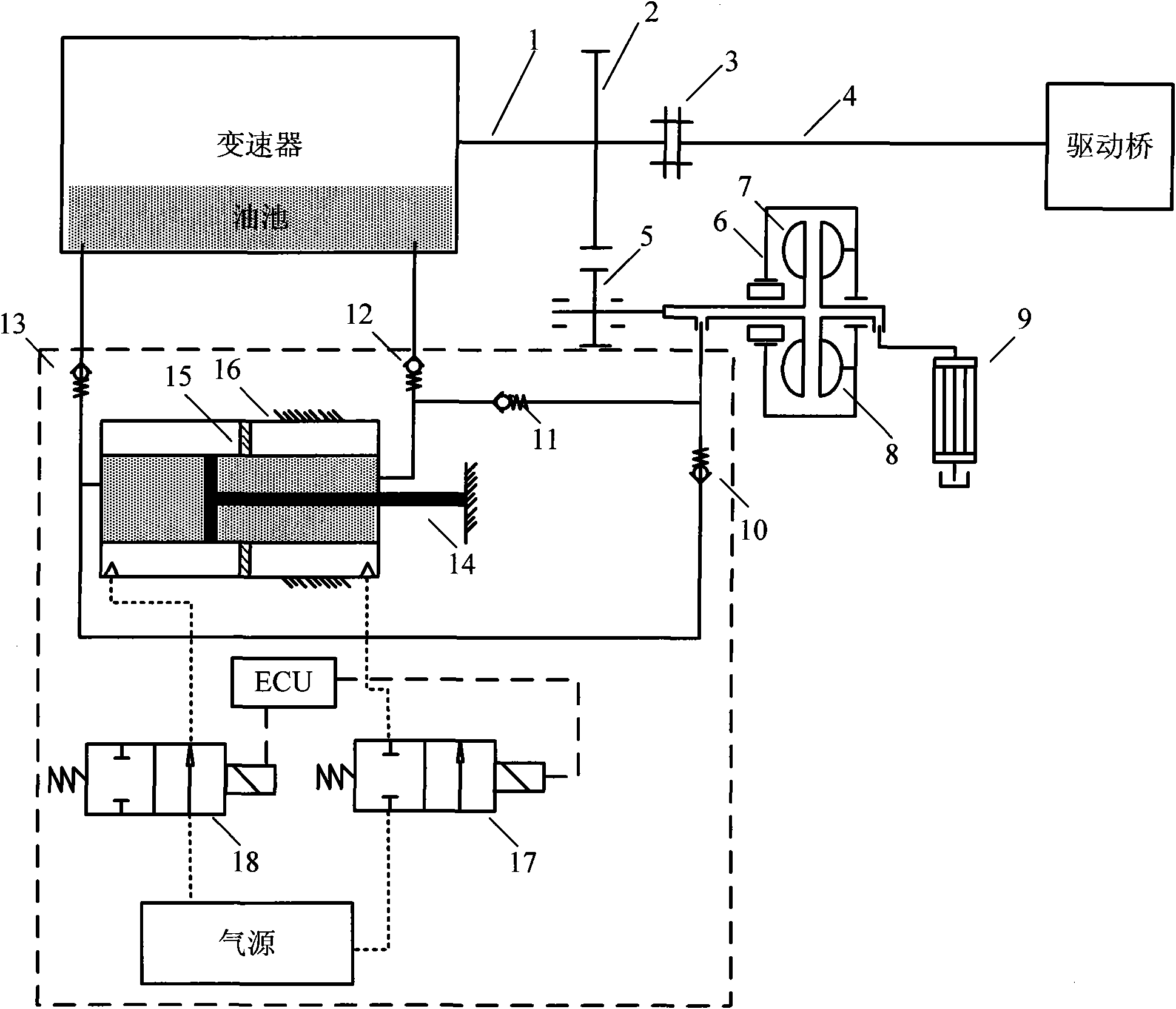

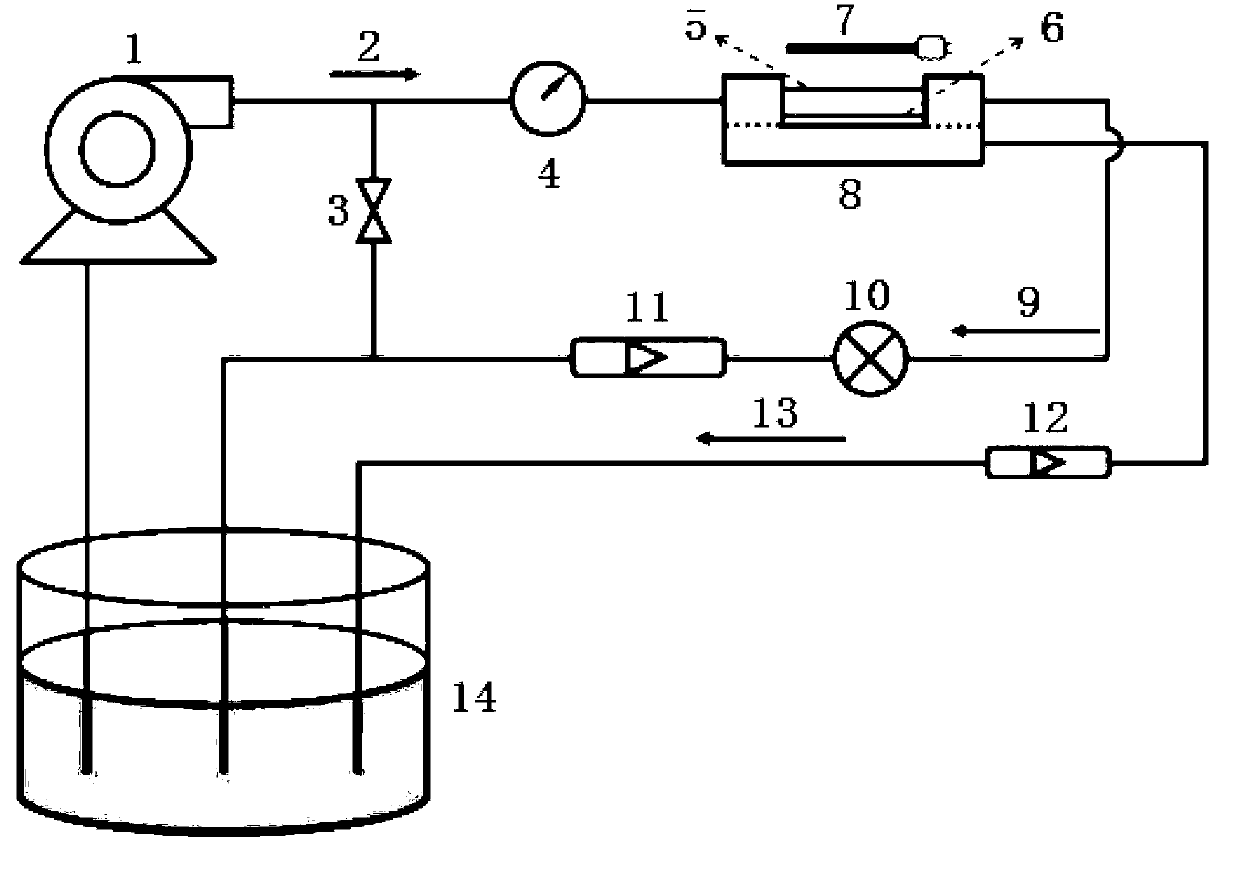

Pneumatic and hydraulic liquid power retarder controller

InactiveCN101566200ARealize computer automatic controlSimple structureLiquid resistance brakesHydrodynamic brakesPneumatic cylinderAutomatic control

The invention discloses a pneumatic and hydraulic liquid power retarder controller, comprising a pneumatic-hydraulic convertor consisting of a converter pneumatic cylinder, a converter pneumatic piston and a converter hydraulic piston, wherein a left air cavity of the pneumatic-hydraulic convertor is connected with a left electromagnetic switching valve, an inlet of which is connected with an air source; a right air cavity of the pneumatic-hydraulic convertor is connected with a right electromagnetic switching valve, an inlet of which is connected with an air source, and an ECU is connected between the working position of the left electromagnetic switching valve and the working position of the right electromagnetic switching valve; a left oil cavity of the pneumatic-hydraulic convertor is connected with a transmission oil pool through a left oil pool one-way valve and connected with a working oil pool of a hydraulic retarder through a right retarder one-way valve; a right oil cavity of the pneumatic-hydraulic convertor is connected with the converter oil pool through a right oil pool one-way valve; a bypass one-way valve is connected between the front end of the right oil pool one-way valve and the rear end of the right retarder one-way valve; and a hydraulic retarder driving gear is arranged on the pump wheel shaft of the hydraulic retarder, a turbine of the hydraulic retarder is fixed on the housing and an oil outlet thereof is connected with a heat exchanger. The invention has the beneficial effects as follows: 1. the existing air sources of the vehicles can accomplish the transportation of medium to save the special intermediate and high pressure hydraulic pumps; 2. the electromagnetic switching valves are used instead of the conventional electro-hydraulic proportional valves to assist the achievement of automatic control of computer; and 3. simple structure and low cost are provided.

Owner:XIANGTAN UNIV

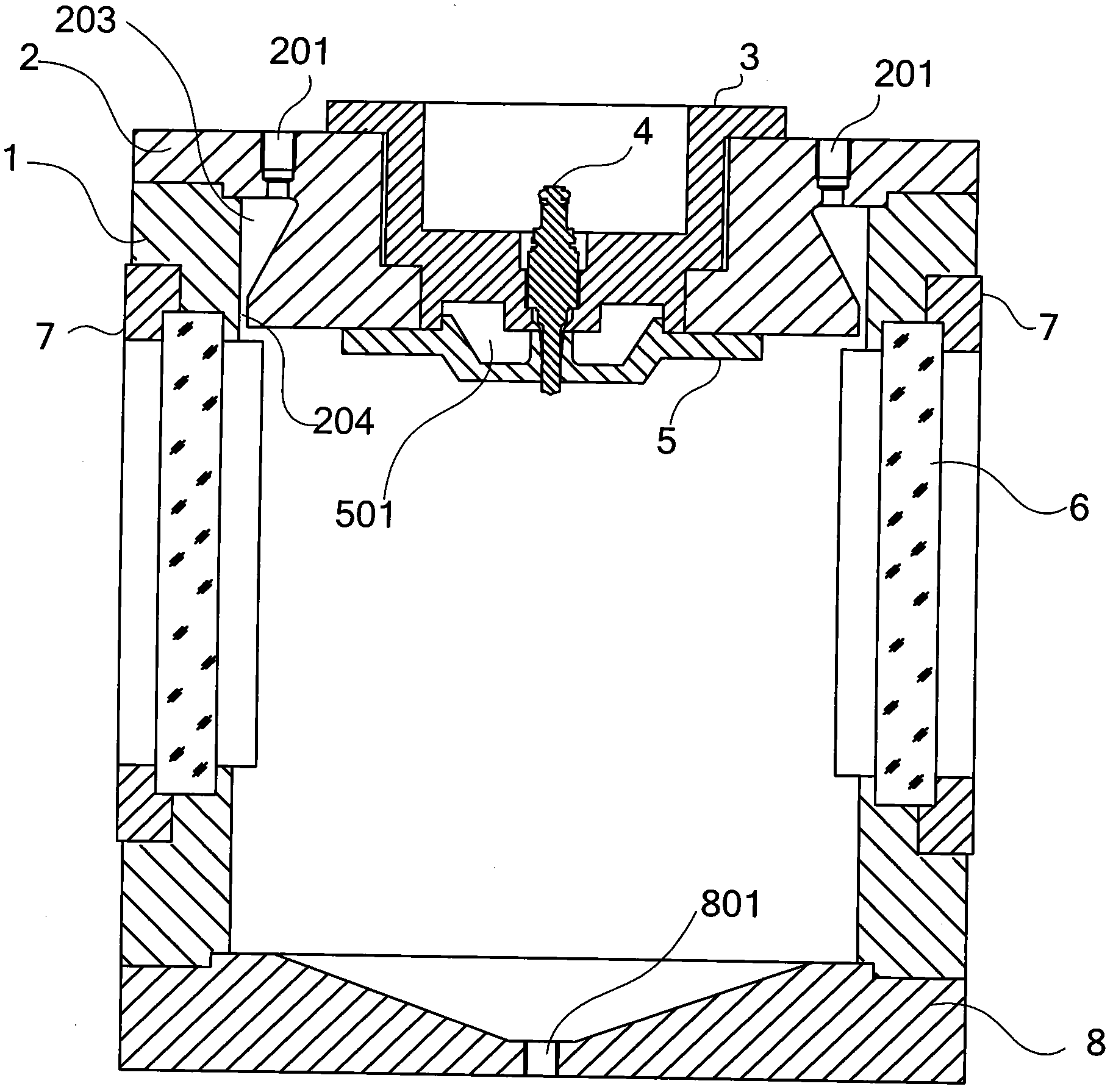

Atomizing test constant-volume elastomer

InactiveCN101943097AReduce preparation work and timeReduce riskEngine testingFuel injection apparatusQuartzFlange

The invention discloses an atomizing test constant-volume elastomer, which comprises an elastomer main body, an elastomer upper cover, an oil atomizer mounting seat, an oil atomizer, an elastomer sealing plate, quartz glass, a quartz glass flange and an elastomer lower cover. The atomizing test constant-volume elastomer can improve the experiment efficiency of an oil atomizer atomizing characteristic experiment considerably, increase the safety of the oil atomizer atomizing characteristic experiment and enhance the image photographing effect of the atomizing experiment, so that the accuracy of experiment analysis and the experiment quality are improved, the influences of the temperature of the atomizing test constant-volume elastomer on the oil atomizer temperature are reduced, the temperature of the oil atomizer is guaranteed to be equal to the atmosphere temperature, the atomizing characteristics of different oil atomizers can be tested and the applicability of the atomizing test constant-volume elastomer is improved.

Owner:BEIHANG UNIV

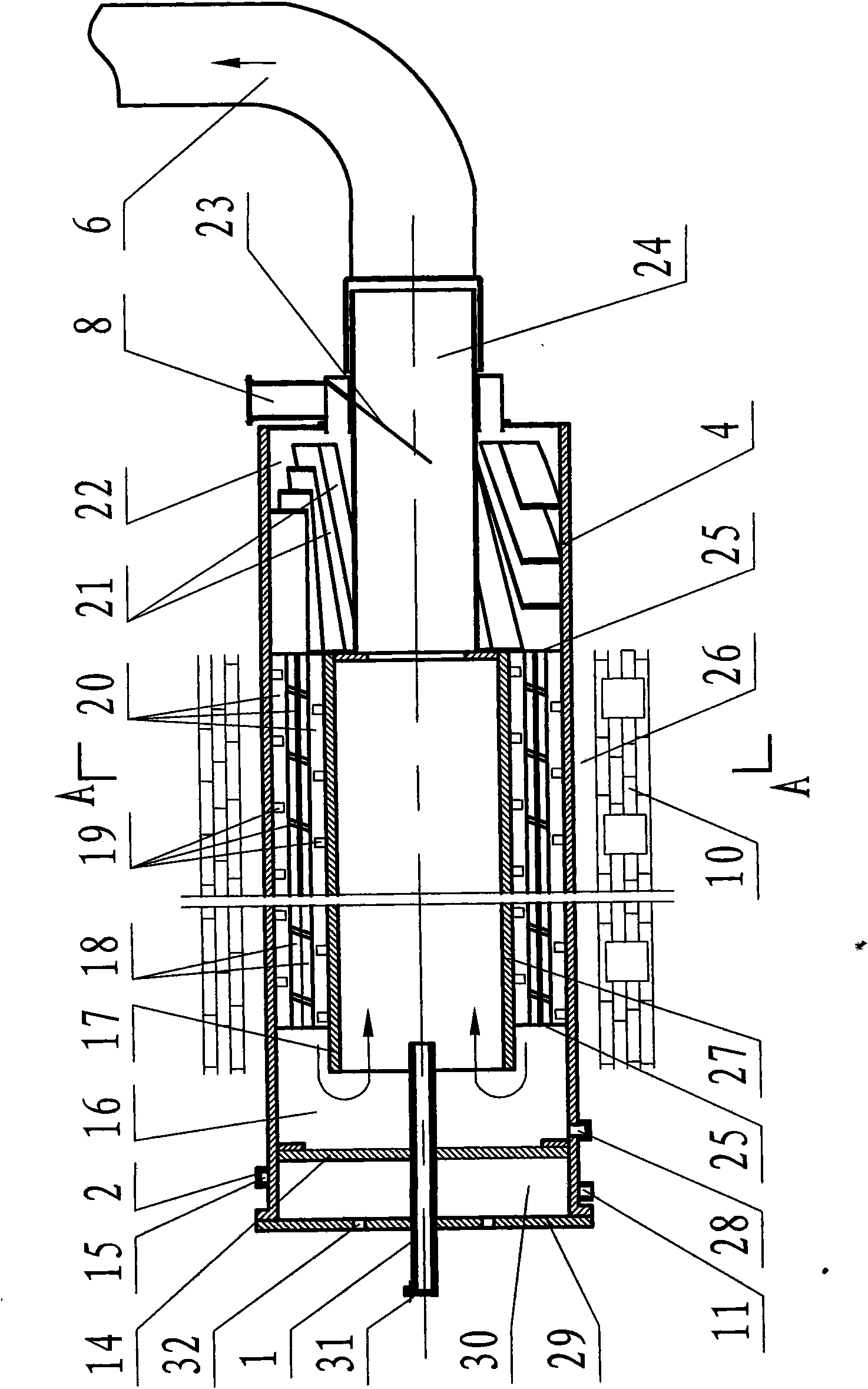

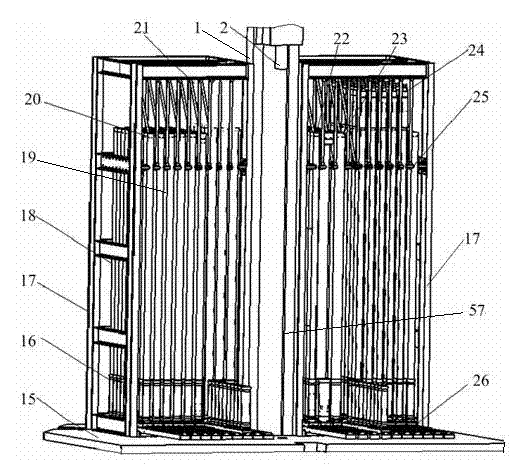

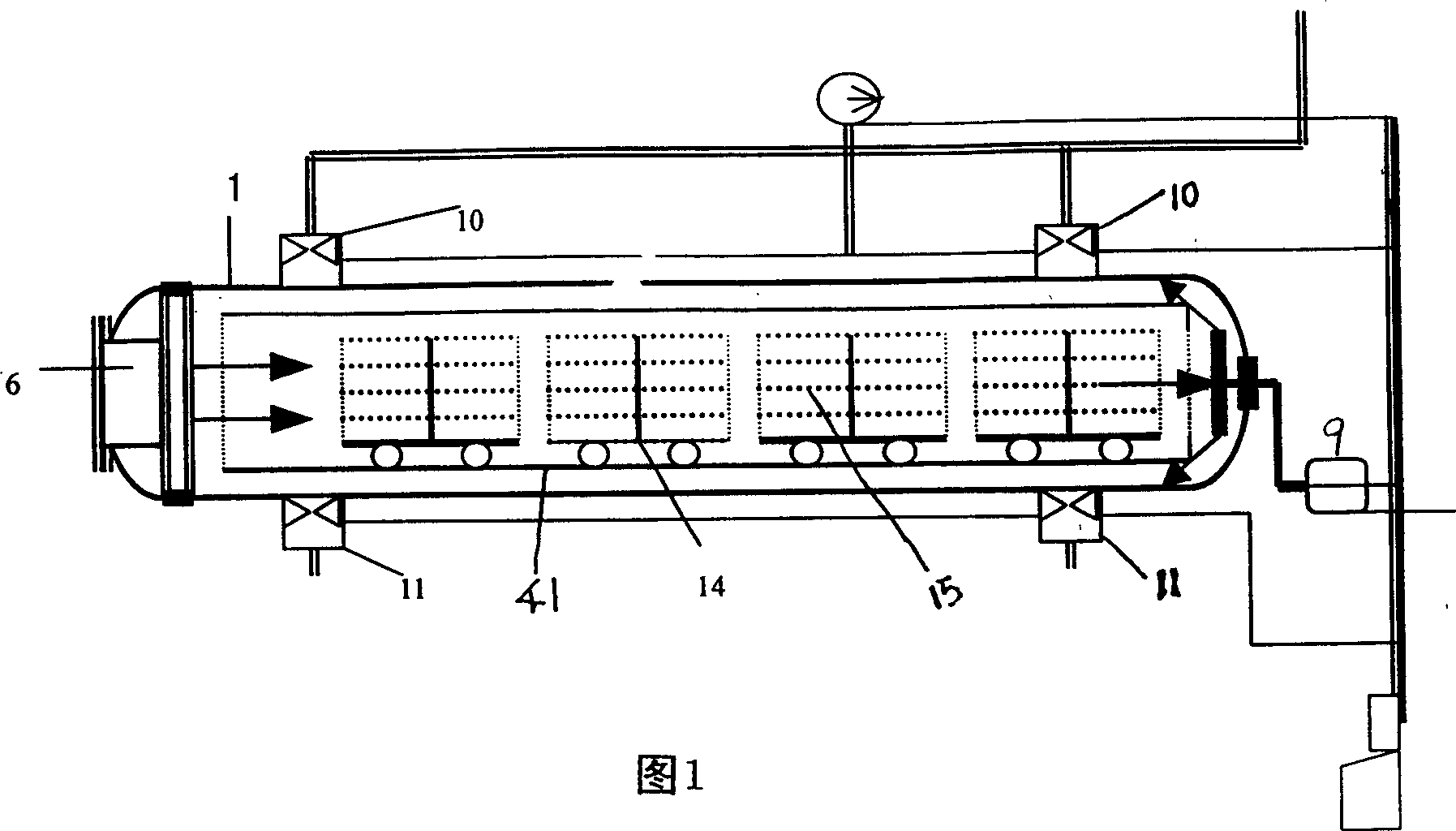

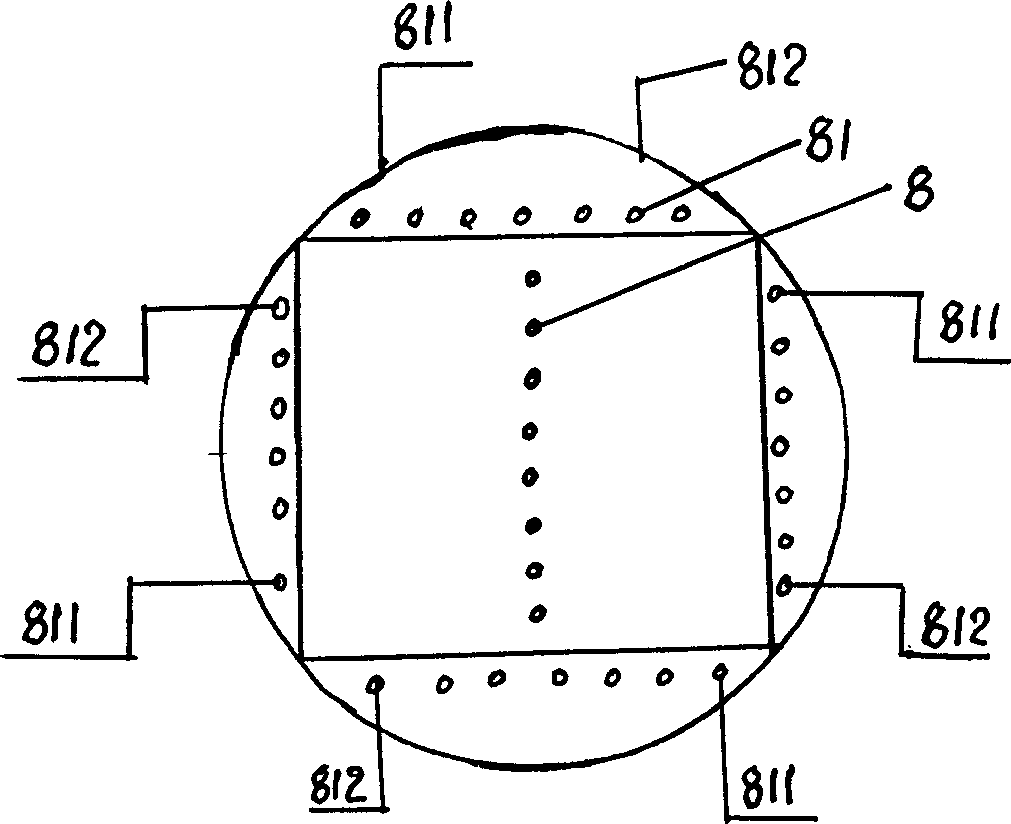

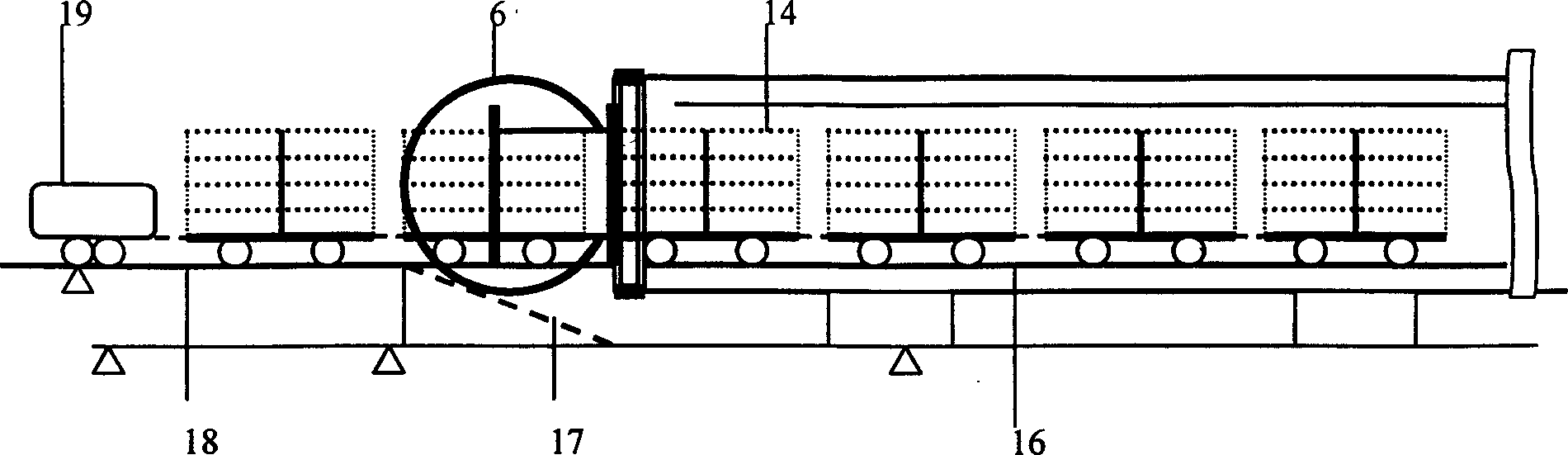

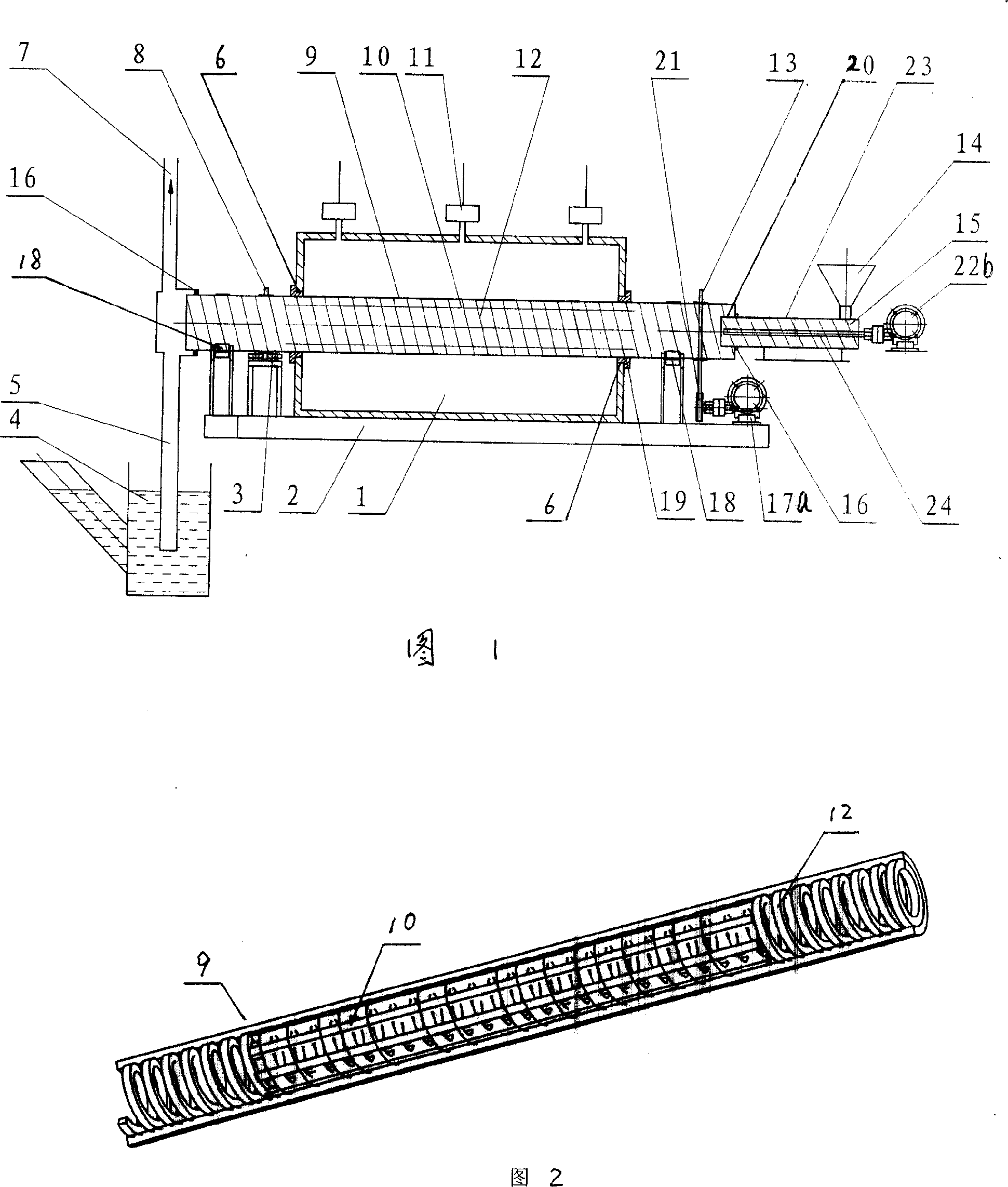

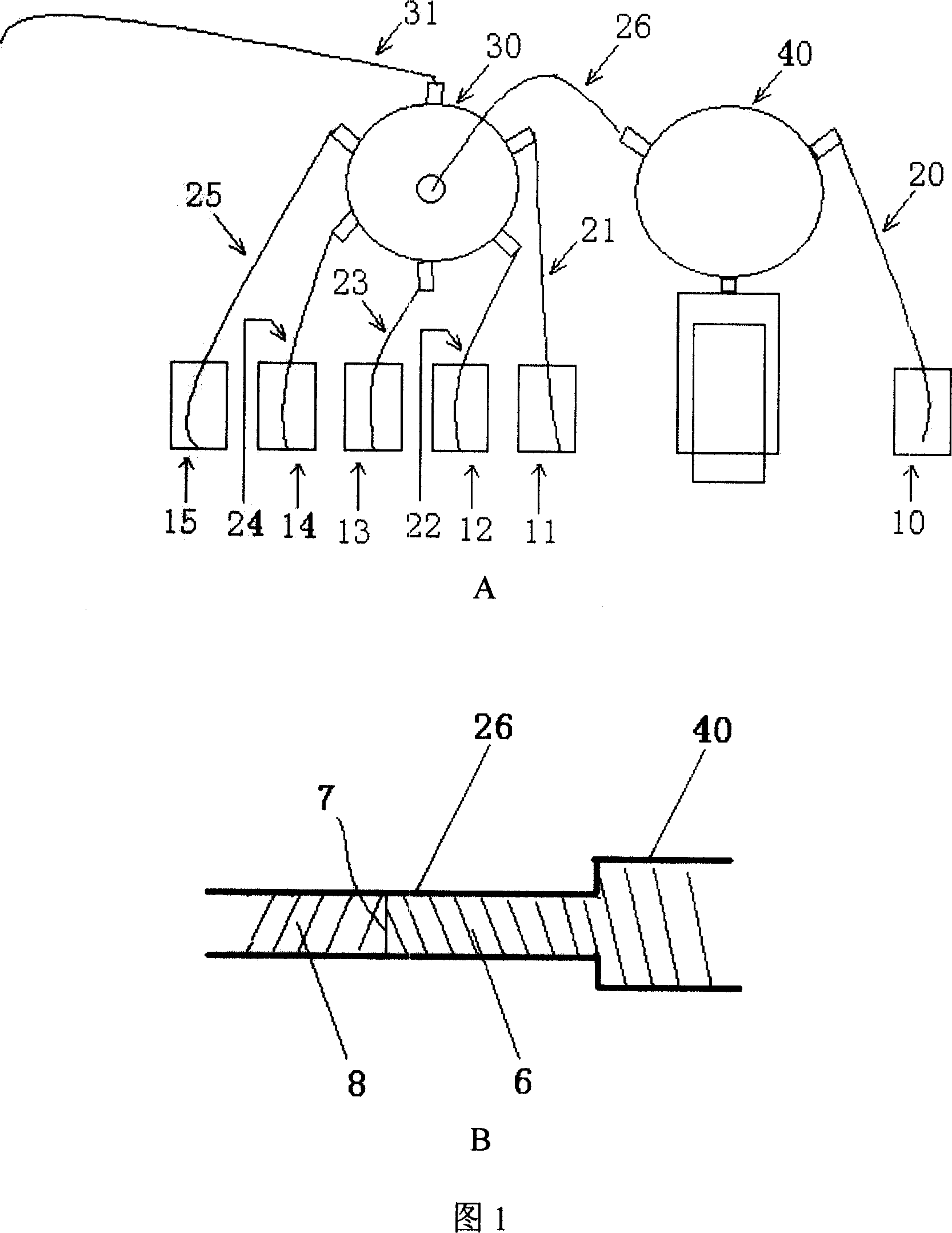

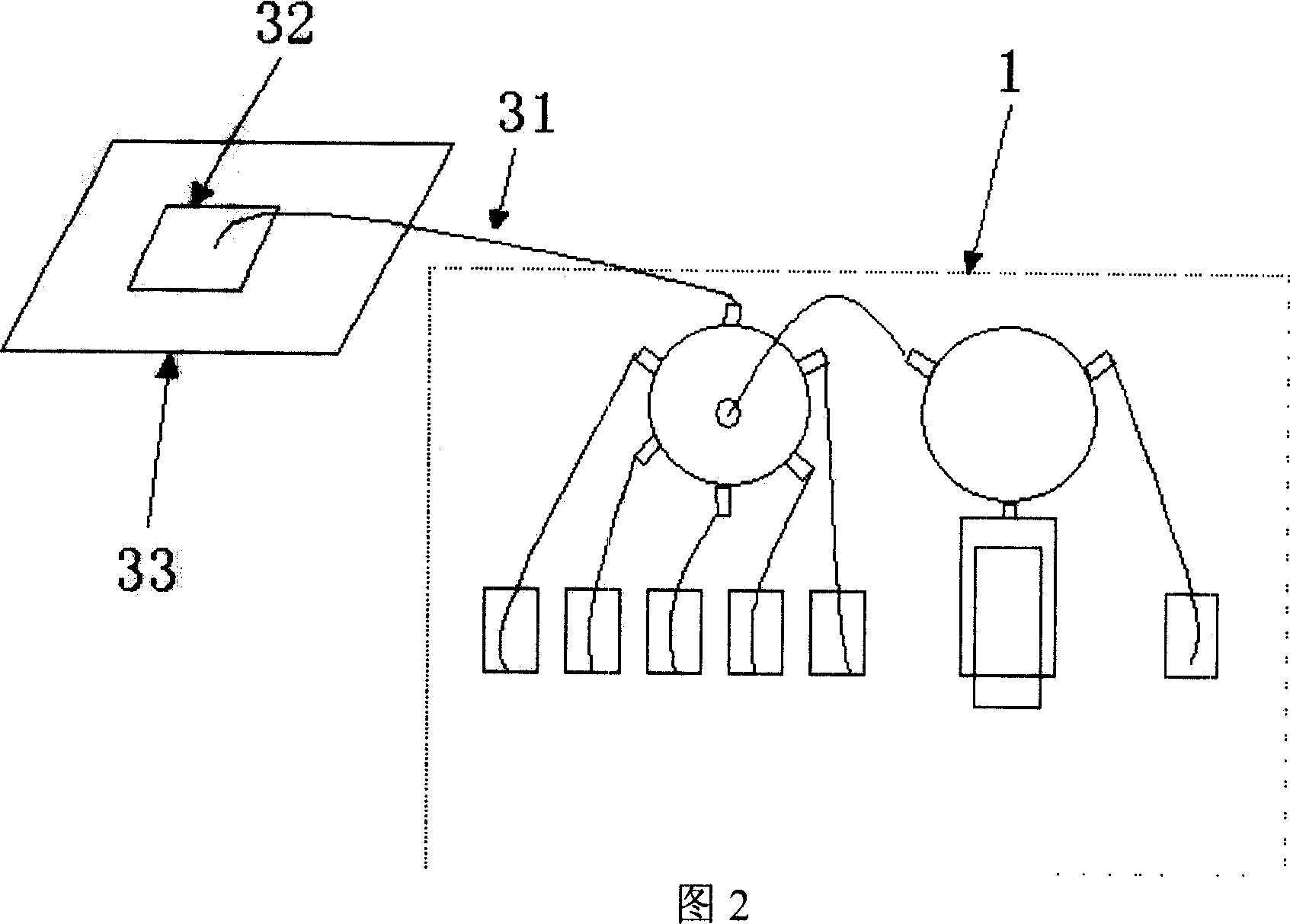

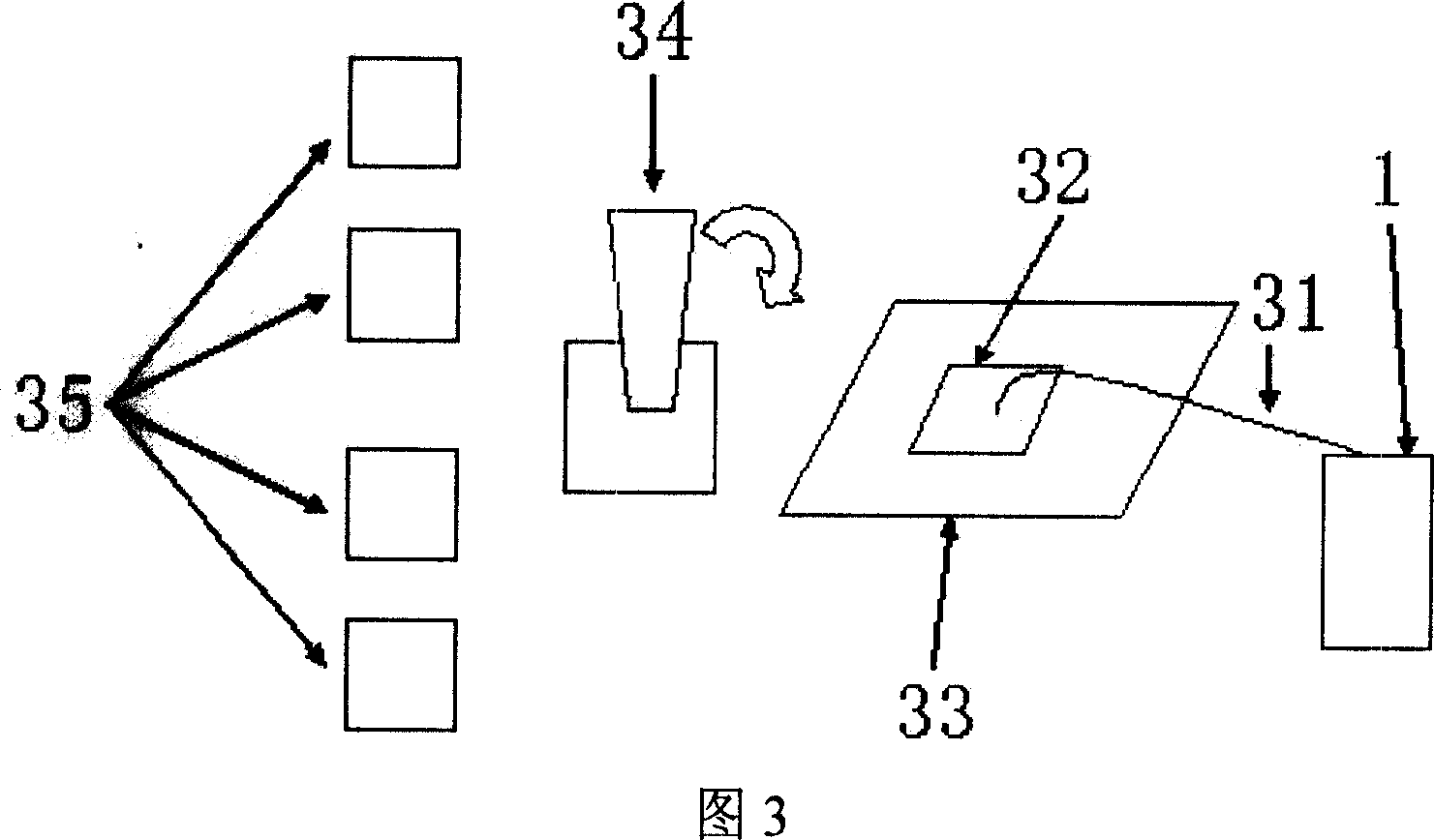

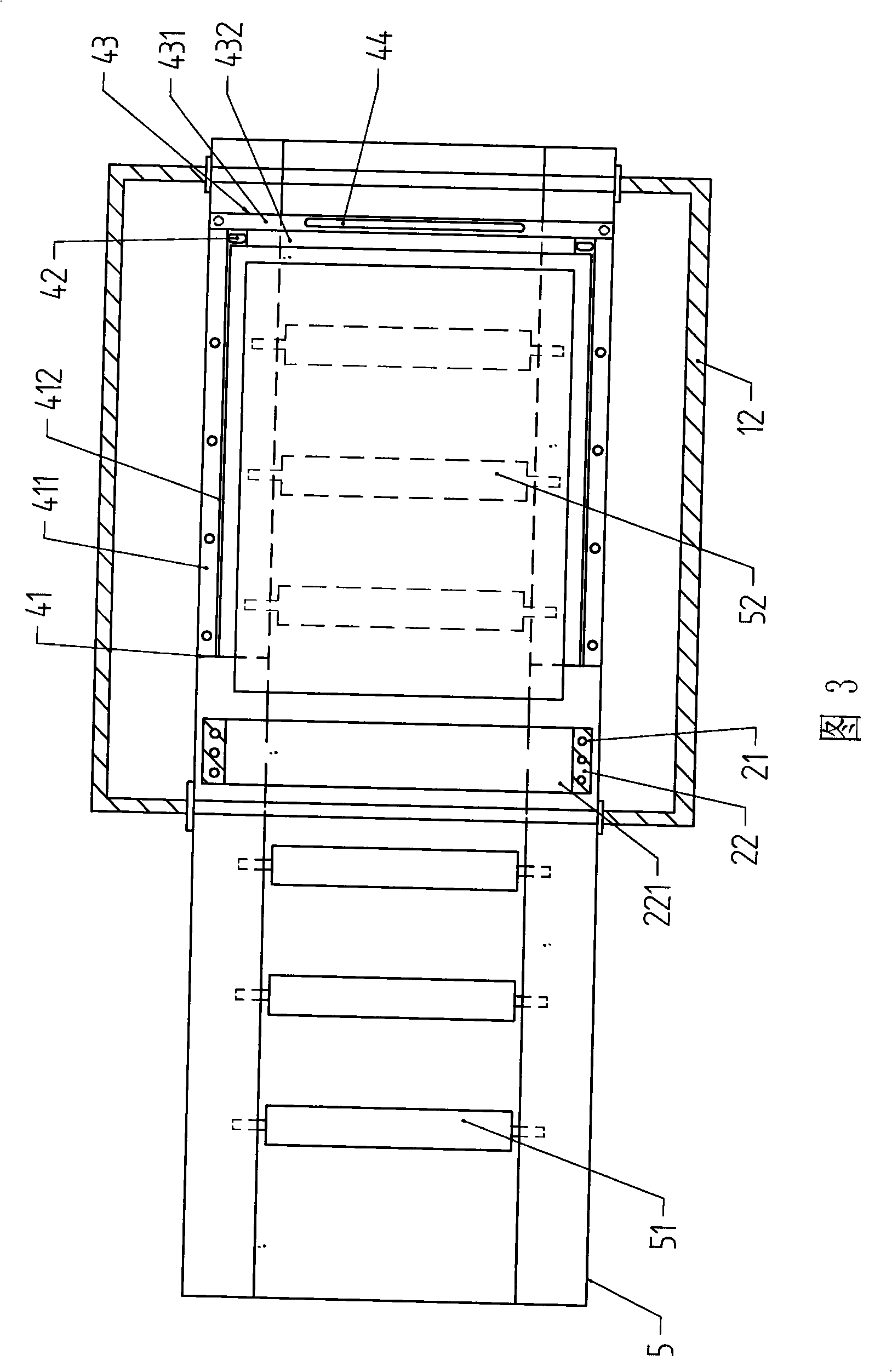

Gas-phase double-dynamic solid fermentation technology and fermentation apparatus

InactiveCN1434113ASimple structureImprove sealingBioreactor/fermenter combinationsBiological substance pretreatmentsGas phaseEngineering

The present invention relates to a gas-phase double-dynamic solid fermentation techinque, and is characterized by that the solid material to be fermented is placed into a double-dynamic environment with pressure pulsatino and circular flowing air to make solid fermentation. Its fermentation equipment includes a horizontal cylindrical tank with a quickly-opening door, in the interior of the tank arectangular spacing cylinder which is formed from four partition boards and whose section is quadratic is axially placed, and in the space of partition board and tank wall a cooling calandria parallel to the partition board is arranged, and the vertical centre of the spacing cylinder is equipped with horizontally-arranged several groups of cooling calandria.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

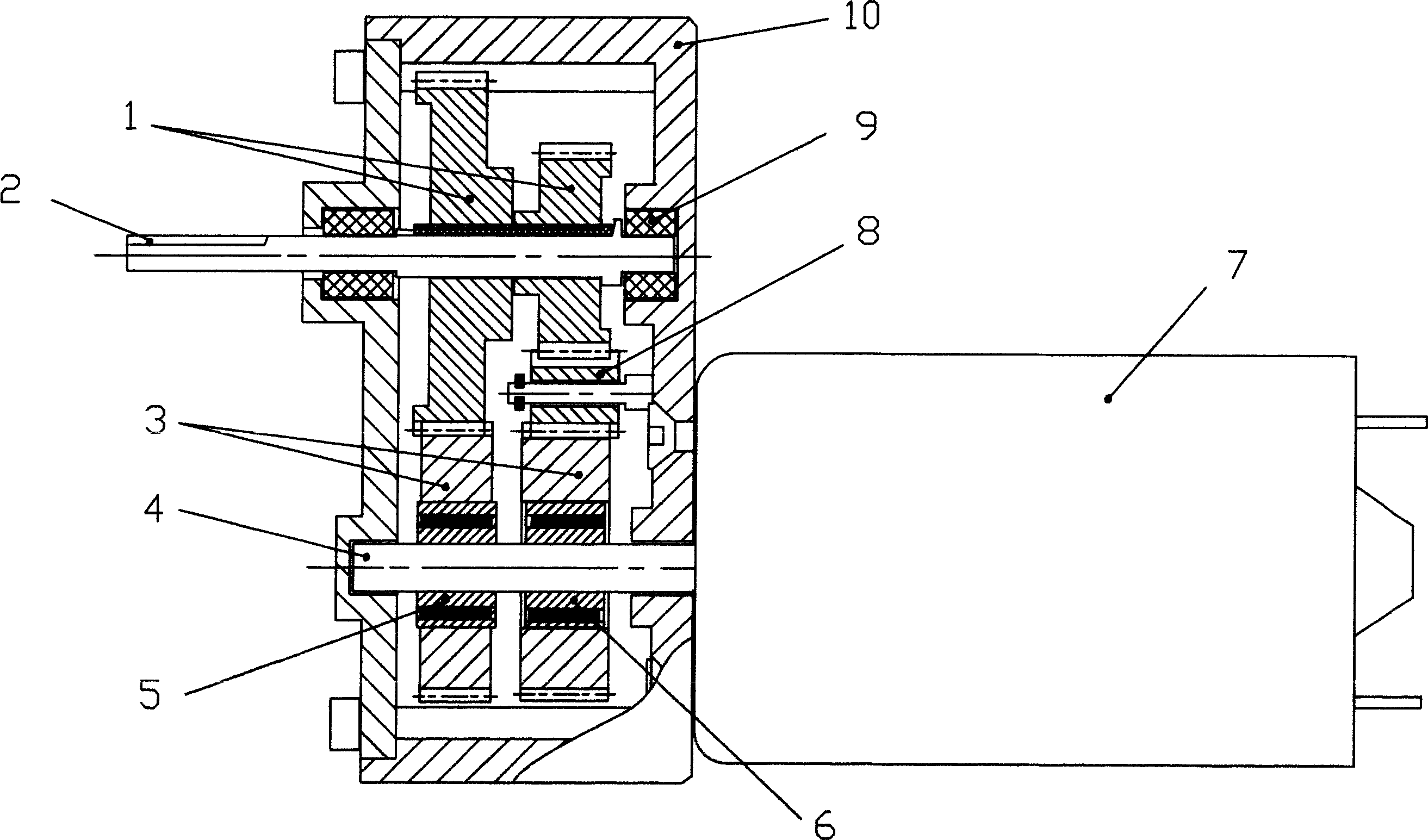

Double-outputting torque speed reducing electric machine

InactiveCN1976173AMake full use of output powerEasy to switchToothed gearingsMechanical energy handlingAutomatic controlElectric machine

A speed reduction motor with double output-torque is prepared as setting two one-way bearings on motor rotary shaft as one being positive rotation bearing and another being negative rotation bearing, setting two sets of gear groups in gear speed reduction mechanism as one being same-direction speed reduction gear group and another being reverse-direction speed reduction gear group, jacketing two input teeth separately on two one-way bearings and firm-jacketing two output teeth commonly on output shaft.

Owner:卢能晓

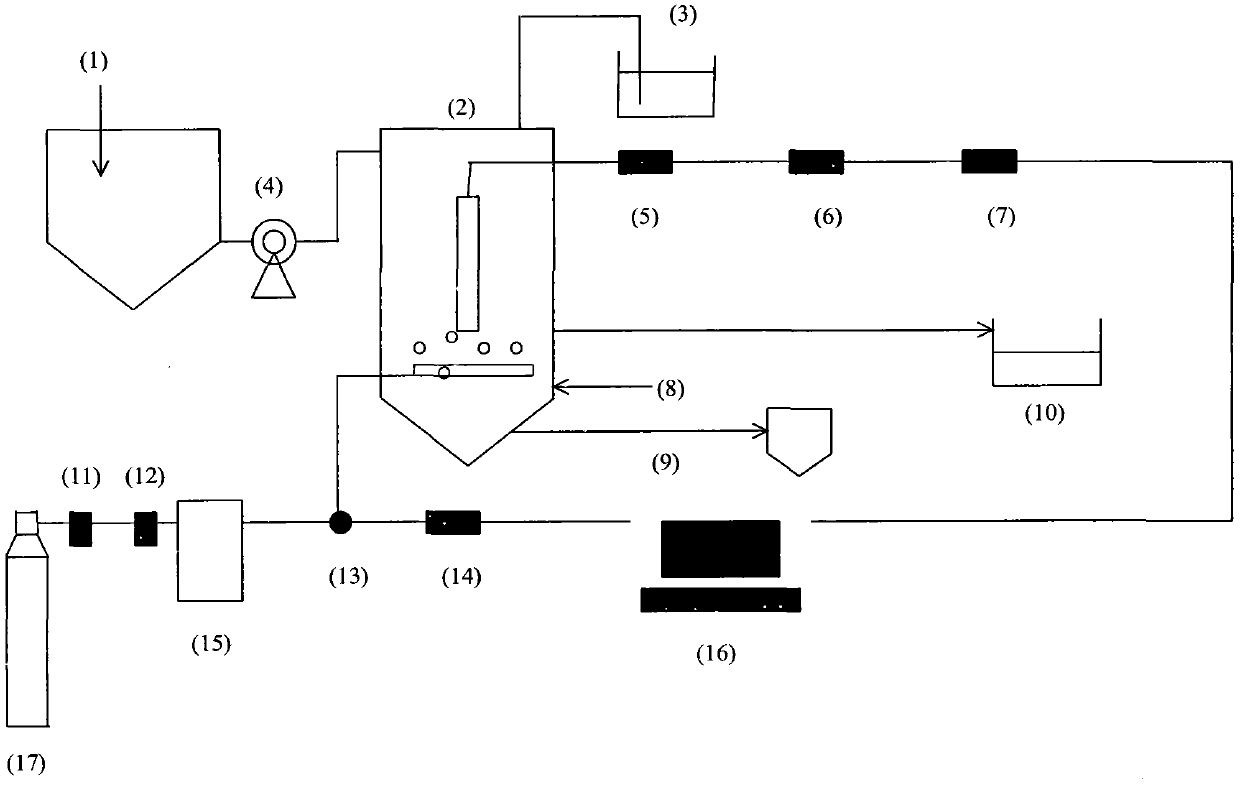

Water treatment method for catalytic ozonation of refractory organics in water by ceramic membrane

InactiveCN103951028AIncrease profitEnhance its oxidative capacityWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by oxidationHazardous substanceData acquisition

The invention relates to water deep treatment technology of heterogeneous catalytic ozonation depollution. With the combination of catalytic ozonation depollution technology with membrane filtration technology, a novel, high-efficient, and economical catalytic ozonation water deep treatment technology is provided, which combines the advantages of the two technologies, overcomes their disadvantages, effectively improves the ozone utilization rate and the ozone oxidation capability, reduces some toxic and harmful substances generated due to incomplete oxidation, alleviates the problem of ceramic membrane contamination, and prolongs the system operation period. An experiment device mainly comprises three parts: an ozone generation device, a ceramic membrane device, and a computer data acquisition and analysis system; an ozone outlet of the ozone generation device is connected with a water inlet valve of the ceramic membrane assembly through a silicone flexible pipe to realize the coupling of the two system. The method of the invention can improve the purifying effect of routine water treatment technology, and provides novel, high-efficient and cheap water deep treatment technology for enhanced removal of low-concentration high-toxicity refractory organic pollutants in water.

Owner:BEIJING FORESTRY UNIVERSITY

Method for removing smelly substances in water

InactiveCN103121732APollution controlReduce concentrationWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisNano catalystHollow fibre

The invention discloses a method for removing smelly substances in water, which comprises the following steps: 1. preparing an inorganic nano catalyst, an organic high-polymer basal film material, additives, a solvent and the like into a film casting solution at certain temperature, and preparing a flat or hollow-fiber or tubular inorganic-organic hybrid photocatalytic separation film; and 2. putting the inorganic-organic hybrid photocatalytic separation film on a film filter unit, and filtering smelly-substance-containing water to be treated in a dead end filtering or cross-flow filtering mode under the conditions of a proper light source. The photocatalytic unit and the film separation unit which are mutually independent are organically fused into one unit for operation, and thus, the invention can simultaneously have the advantages of both photocatalysis and film separation. The method disclosed by the invention has the advantages of simple technique, no need of reagents, high operation reliability, compact equipment and easy automatic control; and the method can effectively remove smelly substances in water, reduce the film pollution, prolong the service life of the film, and lower the technological cost.

Owner:SHANGHAI JIAO TONG UNIV

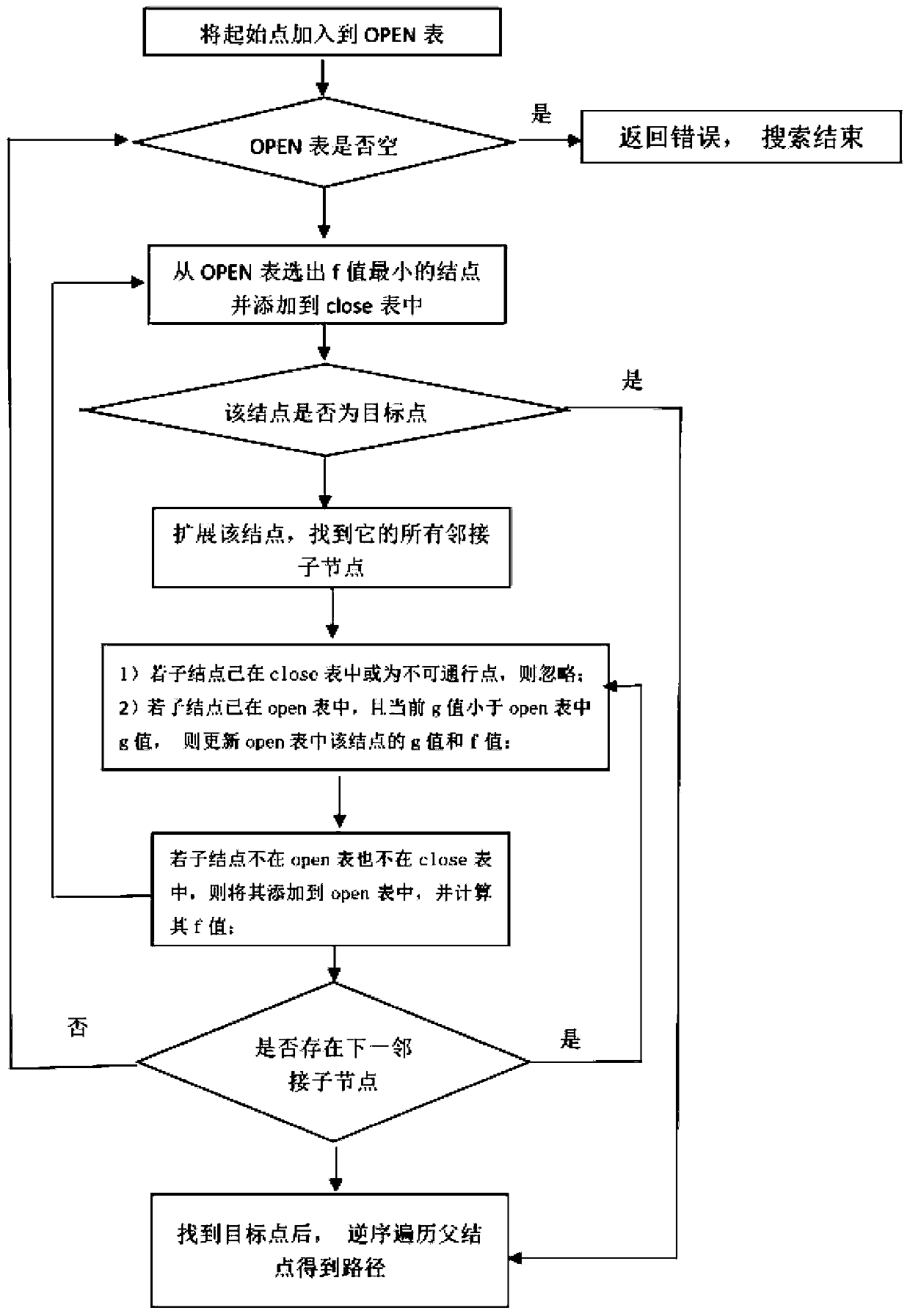

Foot-type robot path planning method

InactiveCN111174798AShorten the timeShort path lengthInstruments for road network navigationForecastingSimulationLocal planning

The invention discloses a path planning method for a foot-type robot. An improved A* algorithm and a self-adaptive DWA algorithm are utilized to plan a reasonable path of robot motion, one characteristic of the improved A * algorithm is as follows, as long as a passable path from a starting point to a target point exists in the environment, the method can always be successfully searched. Comparedwith other local path algorithms, the method has very outstanding advantages, the thought of the fusion algorithm adopted by the method is to perform global path planning by using the characteristic,and then perform real-time local planning in combination with the adaptive DWA, so a final path is close to global optimum and has better dynamic adaptive capacity at the same time.

Owner:CHANGAN UNIV

Microwave drum dry distiller and its application in dry distilling and pyrolyzing oil shale

InactiveCN101020828AFast heatingRapid responseSpecial form destructive distillationMicrowave ovenSlag

The present invention relates to carbon material pyrolyzing and dry distilling technology, and is especially one kind of microwave drum dry distiller and its application in dry distilling and pyrolyzing oil shale. The microwave drum dry distiller includes one microwave oven, and one inner screw drum on supporting rolls. The inner screw drum set on the microwave oven has material inlet, slag discharging barrel, gas exhausting pipe, and discharging port connected to the spiral conveyer. Granular oil shale entering to the microwave oven spirally through the inner screw drum absorbs microwave for dry distilling and pyrolysis so as to produce shale oil, fuel gas and semi-coke. The present invention has simple structure, convenient operation, fast dry distilling, high energy utilizing rate, environment friendship and other advantages.

Owner:NORTHEAST DIANLI UNIVERSITY +1

Novel graphene-Ti electrode printing and dyeing wastewater treatment electrochemical reactor

ActiveCN103058335ASmall external voltageImprove economyWaste water treatment from textile industryWater/sewage treatment by sorptionElectrochemical responseElectrolysis

The invention relates to a novel graphene-Ti electrode printing and dyeing wastewater treatment electrochemical reactor. The reactor comprises a reactor body, a pump, a power supply, a Ti electrode, a graphene membrane electrode and a support; the reactor body is provided with a hollow structure; the support is arranged in the reactor body; the Ti electrode is a Ti plate and is arranged at the top end of the reactor body; the graphene membrane electrode is arranged on the support; a positive electrode of the power supply is electrically connected with the graphene membrane electrode, while a negative electrode of the power supply is connected with the Ti electrode; the reactor body is also provided with a reactor inlet and a reactor outlet; the reactor inlet is formed between the Ti electrode and the graphene membrane electrode; the reactor outlet is formed between the graphene membrane electrode and the bottom end of the reactor body; and the pump is connected with the reactor inlet.According to the novel graphene-Ti electrode printing and dyeing wastewater treatment electrochemical reactor, the printing and dyeing wastewater is treated through the electrode manufactured by the graphene membrane, so that the printing and dyeing wastewater can be treated by absorbing, and the electrolytic treatment can be realized; the removal efficiency of the total organic carbon content ishigh; and the power supply is low in voltage, so that less power is consumed.

Owner:WENDENG HAODUN FAN

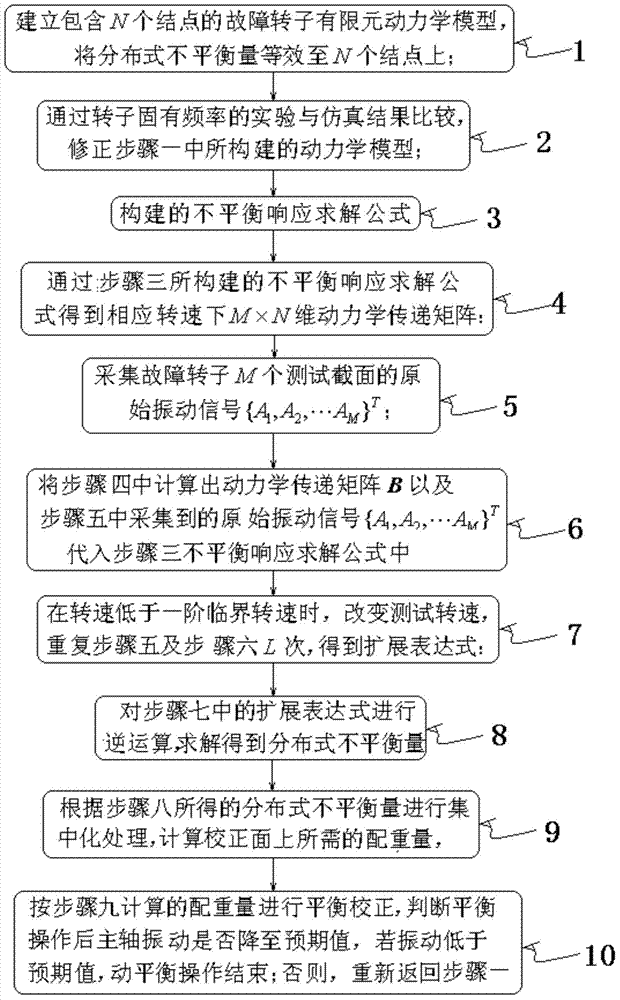

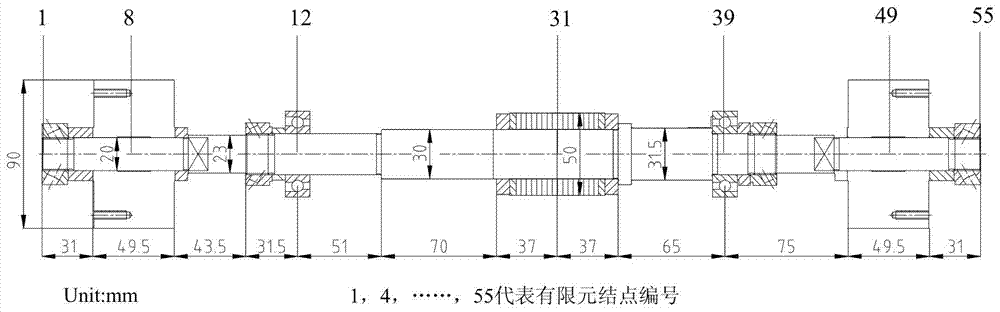

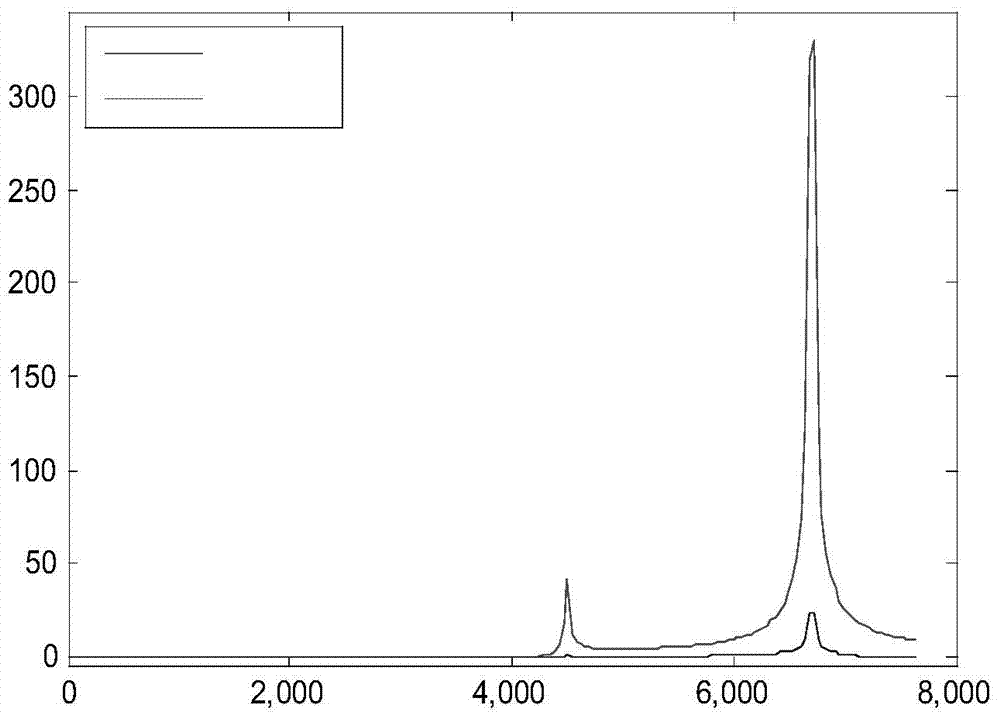

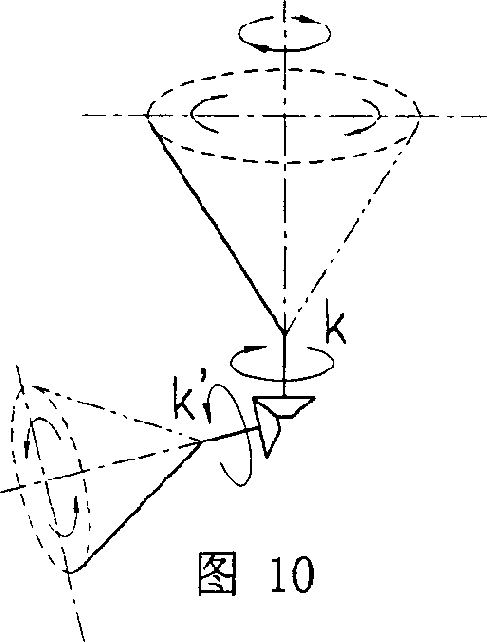

Rotor non-trial-weight dynamic balancing method suitable for distributed unbalance

InactiveCN103592081AImprove efficiencyReduce vibrationStatic/dynamic balance measurementAutomatic controlDynamic models

The invention discloses a rotor non-trial-weight dynamic balancing method suitable for distributed unbalance. The method includes the steps that firstly, on the basis of an established rotor finite element dynamic model, correction of the dynamic model is achieved through experiments and simulation, and then finite element node stress is used for describing the distributed unbalance of a rotor; secondly, dimensions of a dynamic transfer matrix in a describing equation of the distributed unbalance are extended through increase of the test rotating speed, reversibility of the transfer matrix is achieved, and then solution of the distributed unbalance is achieved through matrix inverse operation; finally, precise dynamic balance of the rotor is achieved through a concentrated correction method of the distributed unbalance. According to the rotor non-trial-weight dynamic balancing method suitable for the distributed unbalance, the distributed unbalance can be recognized integrally, and the dynamic balance precision is improved; no test weight is needed in the dynamic balance process, dynamic balance can be completed with the only requirement that the speed is lower than a critical rotating speed, safety of dynamic balance operation is guaranteed, and the requirements of the high-speed rotor are met; the dynamic balance process is concise, and automatic control of computers is achieved conveniently.

Owner:XIDIAN UNIV

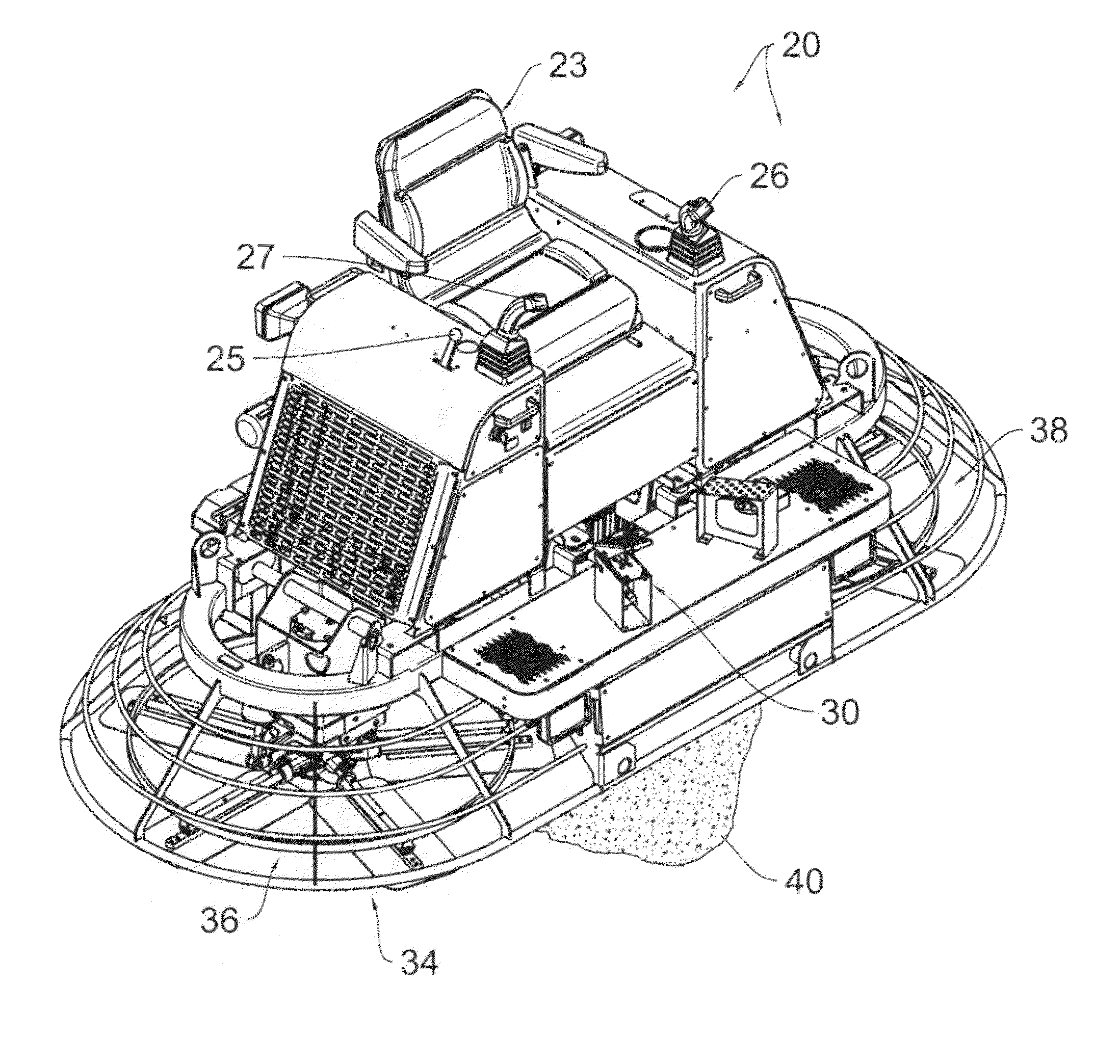

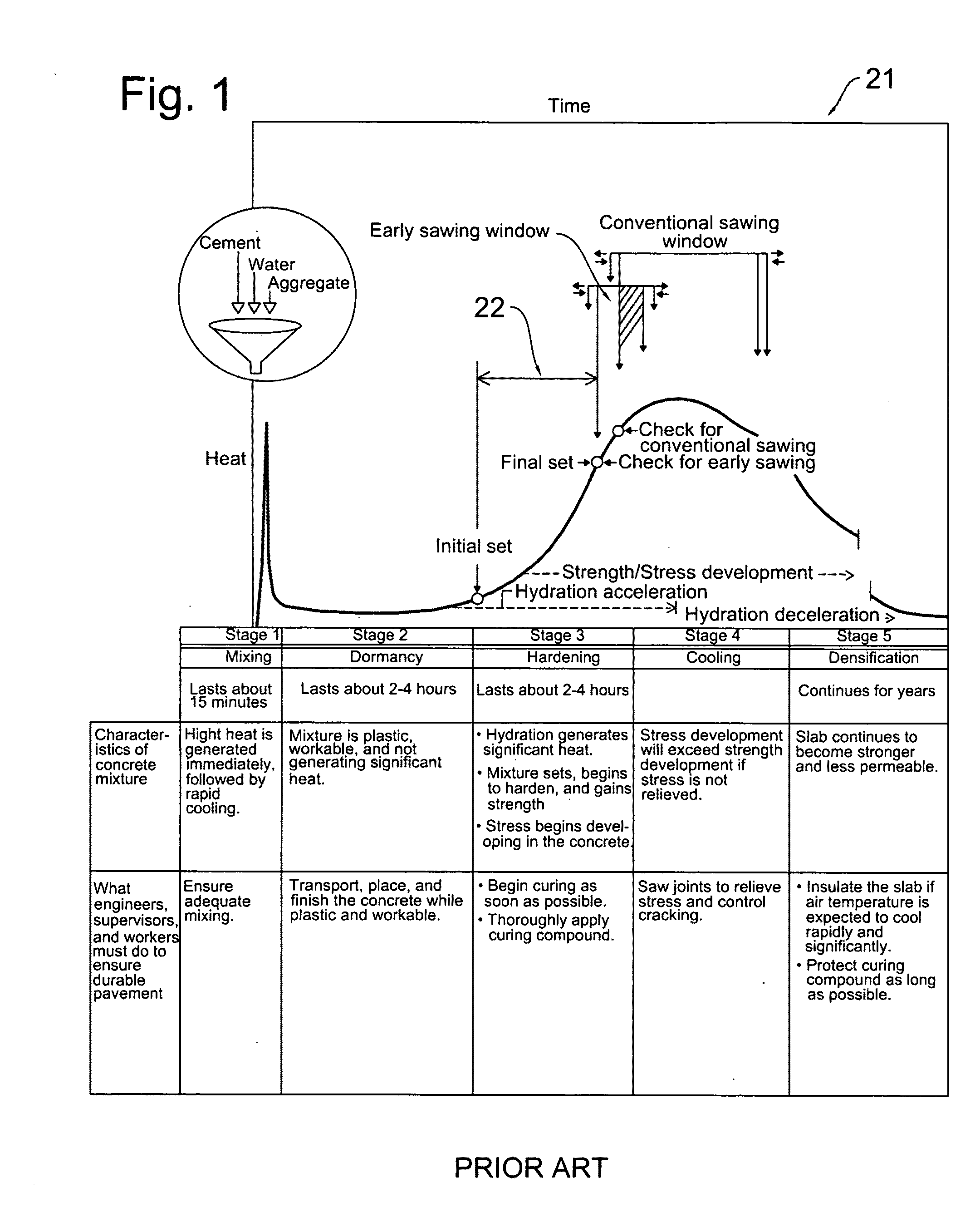

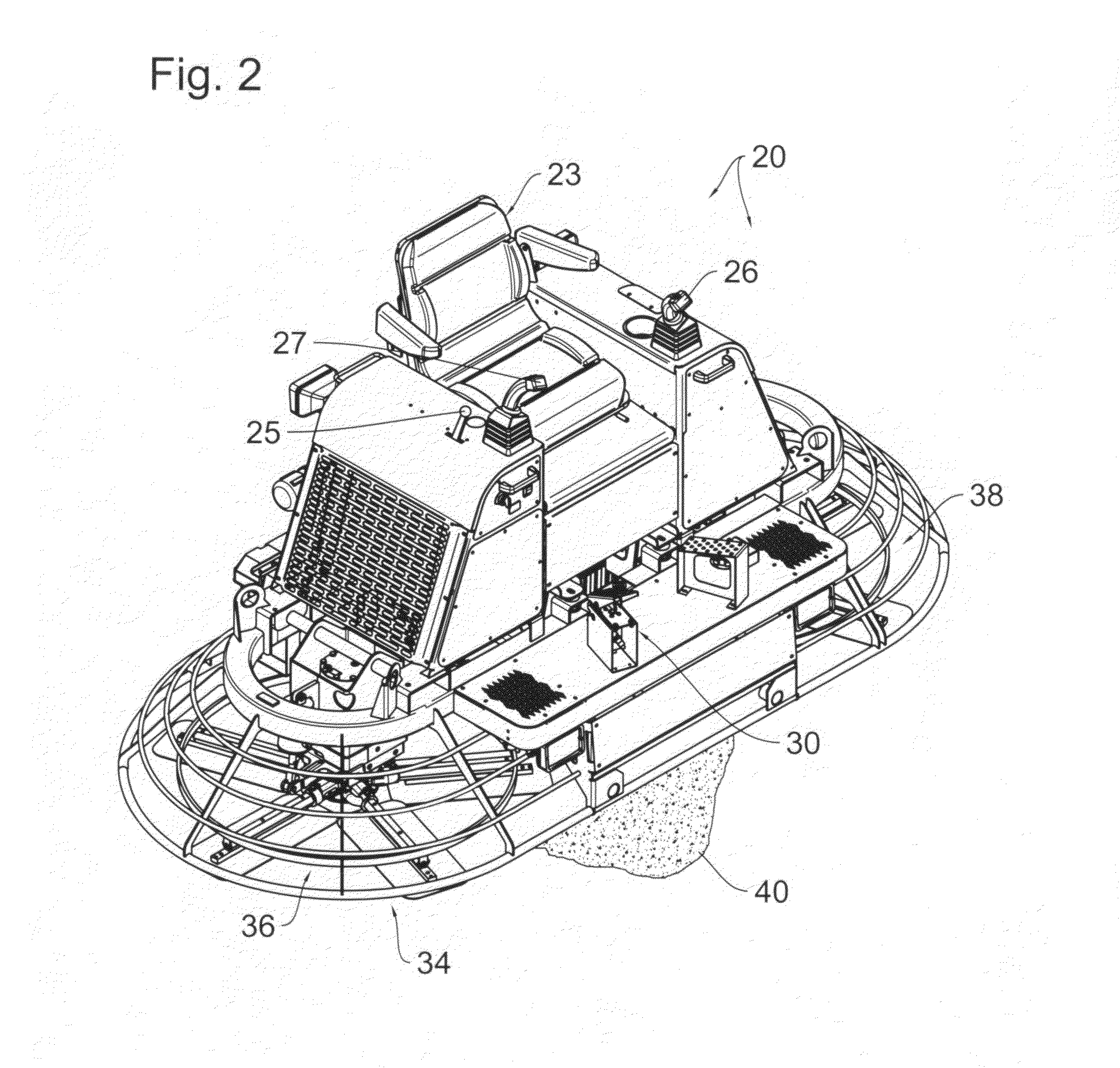

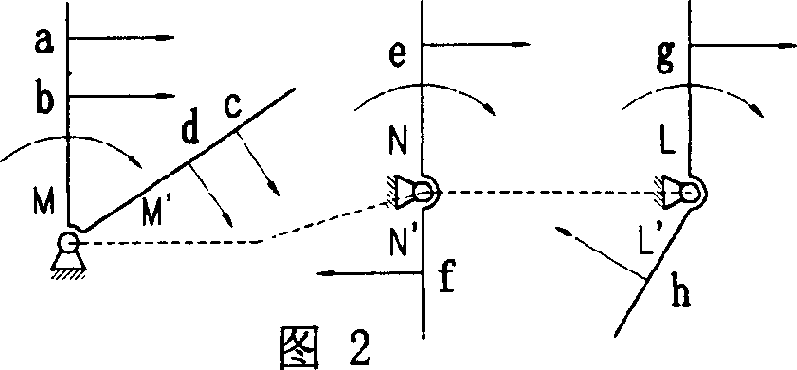

Hydraulic riding trowels with automatic load sensing

ActiveUS20110222966A1Increase powerEasy to control automaticallyBuilding constructionsRoads maintainenceAutomatic controlLoad sensing

High performance, multiple rotor, hydraulically driven riding trowels for finishing concrete have unloader valve circuitry for controlling hydraulic pressure. Each trowel has a rigid frame with two or more downwardly-projecting, bladed rotor assemblies that finish concrete. The rotor assemblies are tilted manually or hydraulically to effectuate steering and control. Blade pitch is controlled manually or hydraulically. The unloader valve system monitors drive pump pressure with a shuttle valve to derive an unloader pilot signal. A sequence valve responds to the unloader pilot signal to control a pressure valve that bypasses the normal foot control valve in an overpressure situation. The pressure control head signal normally applied to the hydraulic drive motor control heads is modified with a feedback signal to automatically control the associated pump swash plates. A gearbox may be disposed between the drive motors and rotors. Piston type and gear and vane type motors may power the rotors.

Owner:ALLEN ENG

Method for processing and preparing resistant starch by Pullulanase cooperated with acid alcohol

The invention discloses a method for processing and preparing resistant starch by Pullulanase cooperated with acid alcohol, comprising the following steps: heating starch milk of which the weight concentration is 10-45% and the pH value is 3.5-6.5 to 40-70 DEG C, adding Pullulanase of which the dosage is 1-40ASPU per gram of starch, and keeping for 8-48hrs; inactivating enzymes, assisting by acid alcohol processing, cooling, filtering, drying, crushing and sieving to obtain the product. The invention takes starch as a raw material, adopts the biological technology and acid alcohol processing means, thus greatly improving the content of the resistant starch, simplifying the process for preparing the resistant starch, effectively enhancing the yield, and lowering energy consumption. The obtained product not only has the function of dietary fiber, but also has the characteristics of fat substitute, and can be widely used as functional food materials and biochemical drug carriers.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing L-omithine through immobilized ectocellular enzyme method

A process for preparing L-ornithin by imobilized cell enzyme method includes coating the fermented microbe cells by different immobilizing carrier, filling in column, making the L-arginine solution to flow through the column, collecting the flowing-out liquid, concentrating and crystallizing or purifying by cationic exchange column.

Owner:NANJING UNIV

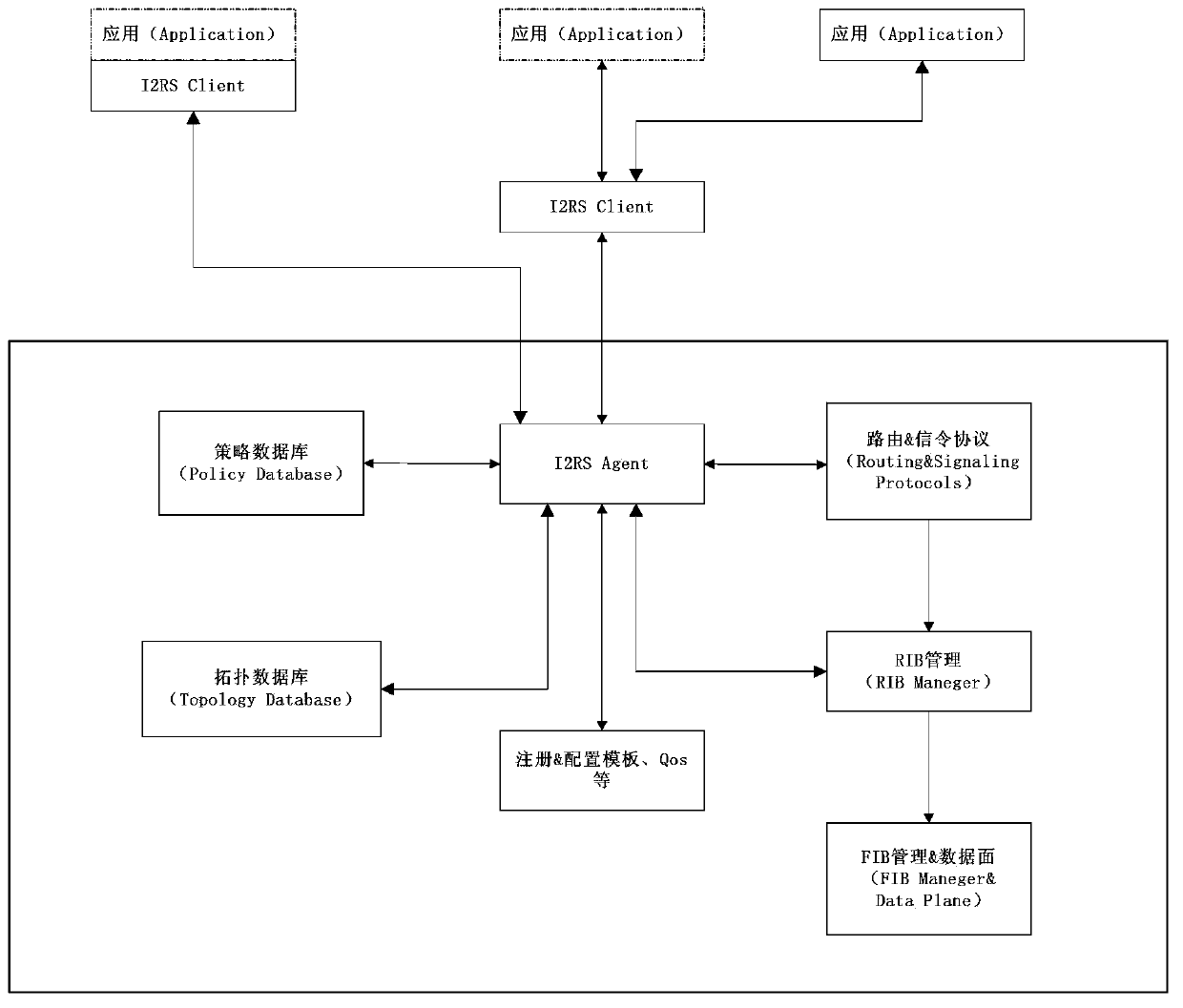

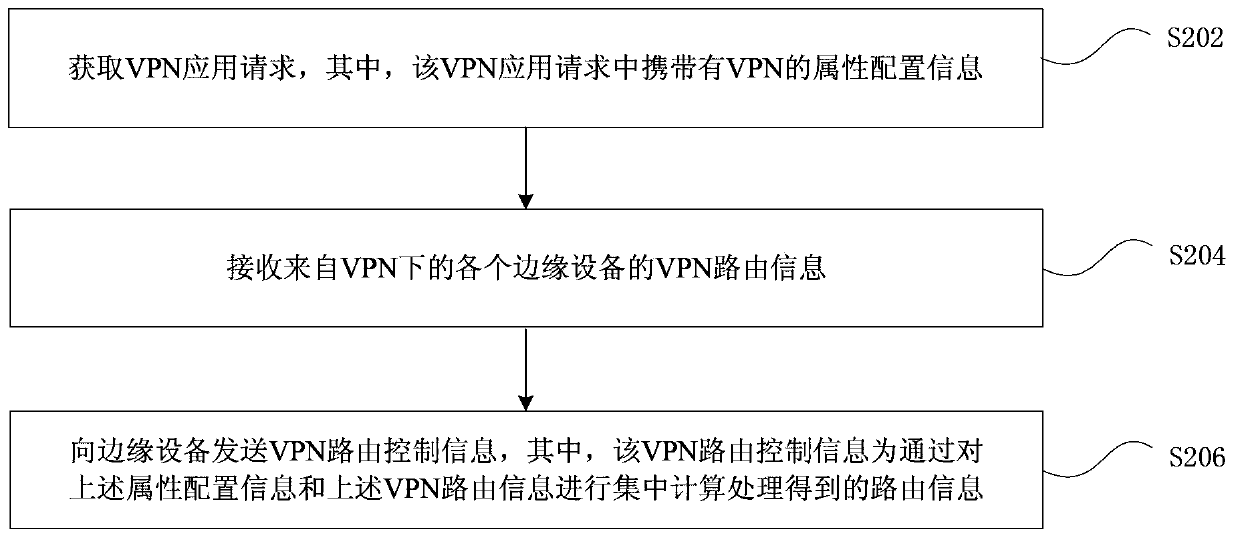

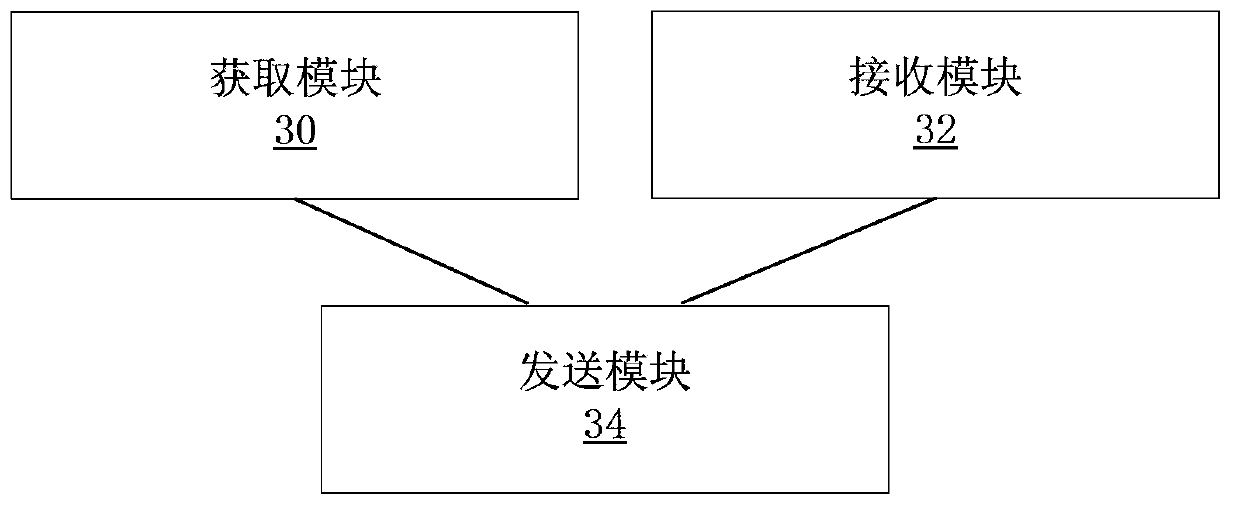

Implementation method and device of VPN (virtual private network) for edge equipment

InactiveCN104219147AReduce configuration and entry capacitySimple configurationHybrid transportNetworks interconnectionAutomatic controlCentralized computing

The invention provides an implementation method and device of a VPN (virtual private network) for edge equipment. The method includes the steps of acquiring a VPN application request which carries VPN attribute configuration messages; receiving VPN routing messages of edge devices in a VPN; transmitting a VPN routing control message to each edge device. The VPN routing control message is a routing message obtained by central calculation of the attribute configuration messages and the VPN routing messages. According to the scheme, the implementation method and device has the advantages that the technical problems such that in related arts, VPN auto-control schemes have complex configurations and table item contents are solved, release of simpler configurations, more concentrated table item management and release of table items can be automatically controlled under a uniform control platform, and the existing equipment needs less configuration and table item capacity.

Owner:ZTE CORP

Transfer pipet and its use

InactiveCN101028607ASimple structureLow costBurettes/pipettesMaterial analysisTest facilityElectrical and Electronics engineering

A liquid transfer device for sucking the experimental liquid and distributing it to analyzing or testing apparatus has a pump unit, a connection unit and the cleaning liquid, which can be filled in said connection unit by pump unit and then be driven to move the experimental liquid in connection unit without mixing with experimental liquid. Its application, its operation method, and the analyzing and testing apparatus containing the liquid transfer device are also disclosed.

Owner:上海浩源生物科技有限公司

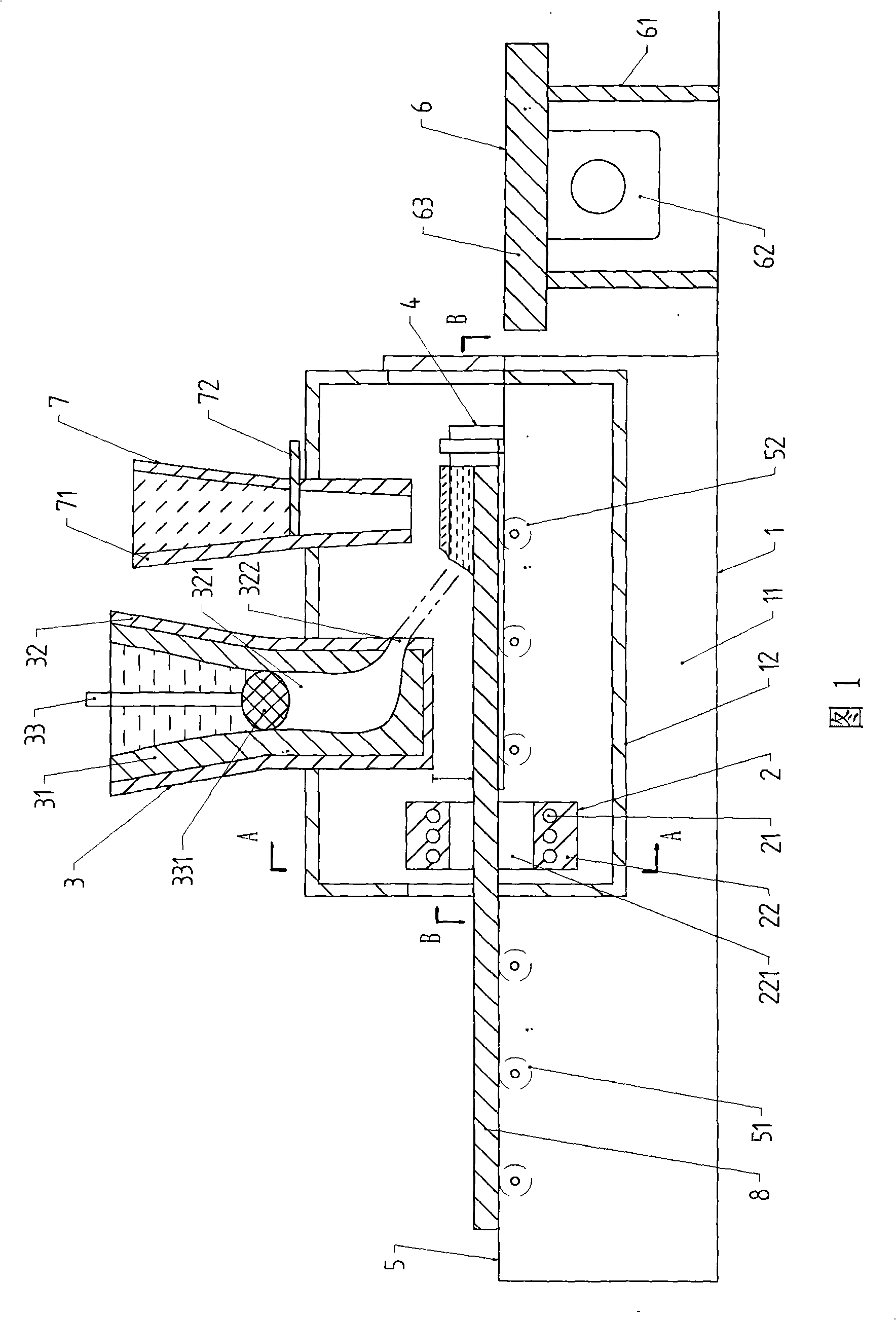

Production method of large-sized duplex metal composite board and device thereof

The invention discloses a method of producing large double metal composite plate and a device thereof. The method and device can continuously produce large-size thick double metal composite plates with high production efficiency, low cost, accurate control of interface layer and good lamination. The device comprises a frame with a sealed chamber, an induction heater arranged inside the sealed chamber, a gap-type heat-insulating caster and a conveying mechanism. The sealed chamber has an oxygen-free protective atmosphere inside. The method includes the following steps: substrate preparation, casting preparation, continuous hot casting, oscillatory crystallization and finishing. The continuous hot casting step includes: continuously heating a continuously forward-moving substrate by the induction heater and the gap-type heat-insulating caster in the oxygen-free protective atmosphere, allowing a molten metal coating for continuous casting to flow towards the substrate through a casting gate in a downward-oblique direction, and completely solidifying the molten metal coating on the substrate by means of oscillatory crystallization.

Owner:BEIJING JIAOTONG UNIV

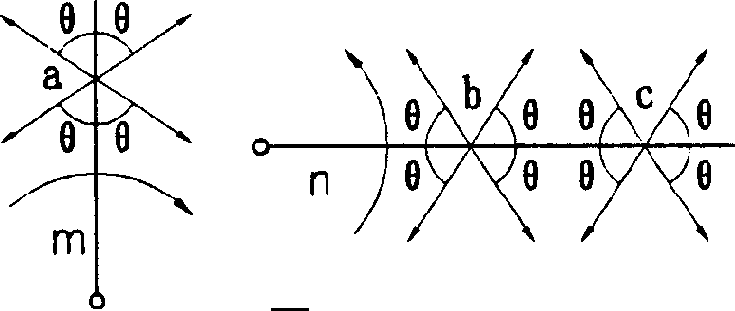

Mechanical stepless speed gear with equal angular speed and shape-position and high gear ratio

A constant angular speed and synchro-positioning mechanical stepless gear with low paired and high gearing ratio is designed as infinitely gear with equally regular characteristics on theories of constant angular speed and synchro-positioning movement and constant angular speed and iso-directional and reversal speed regulation so as to dissolve the vital problem of traditional impulsive stepless gear. No weakness in the whole driving chain has equal bearing capacity and high load and shock resistance. The spatial structural series is flexible and can have driving shaft in all the directions. Its advantages include reasonable structure, easy operation, accurate and stability, and economical efficiency. Its main gearing system works at low-paired transmission, with high loading ability and outputs torque at low speed.

Owner:王国斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com