Double-outputting torque speed reducing electric machine

A deceleration motor and dual output technology, applied in the direction of electrical components, electromechanical devices, mechanical equipment, etc., can solve the problems of unfavorable automatic control, waste of power configuration, complex structure, etc., and achieve the advantages of automatic control, simple structure, and simple switching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

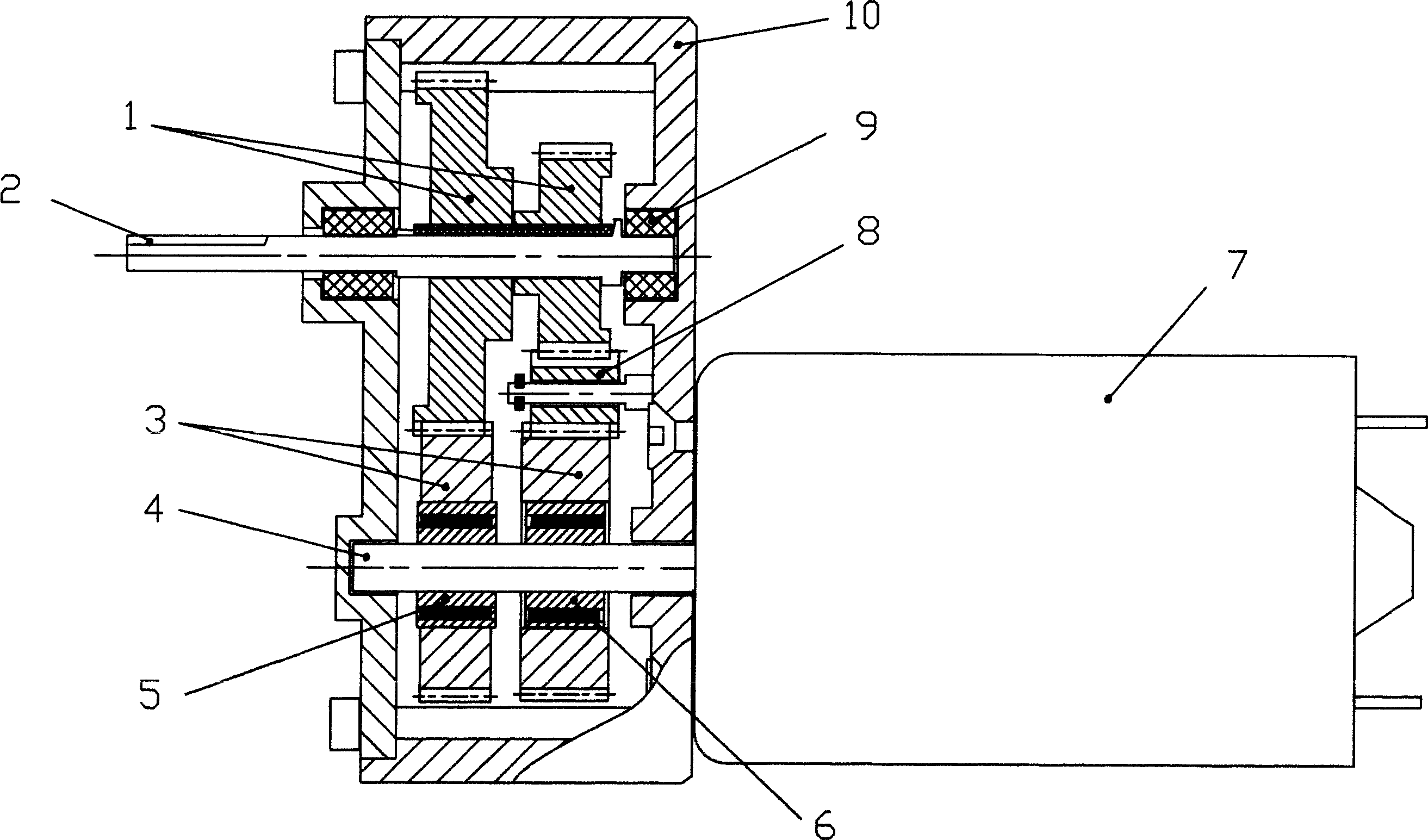

[0009] As shown in the figure, the geared motor with double output torque of the embodiment includes a motor 7 and a gear reduction mechanism, and two one-way bearings are arranged on the motor shaft 4, which are forward rotation one-way bearing 5 and reverse rotation one-way bearing 6 respectively. , there are two sets of gear sets in the gear reduction mechanism. Among the two sets of gear sets, the number of gears in one set is one more than the other set. Therefore, for the comparison of the steering of the output shaft 2 and the motor shaft 4, one set is It is the same as the steering transmission reduction gear set, and the other set is the reverse steering transmission reduction gear set. The two input teeth 3 of the two reduction gear sets are respectively sleeved on the two one-way bearings, and the two output teeth 1 are fixedly sleeved together. on output shaft 2.

[0010] When the rotating shaft 4 of the motor 7 rotates forward, the reverse one-way bearing 6 sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com