Pneumatic and hydraulic liquid power retarder controller

A technology of hydraulic retarder and control device, which is applied to hydraulic brakes, brake types, hydraulic resistance brakes, etc., achieves the effects of low cost, simple structure and automatic computer control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

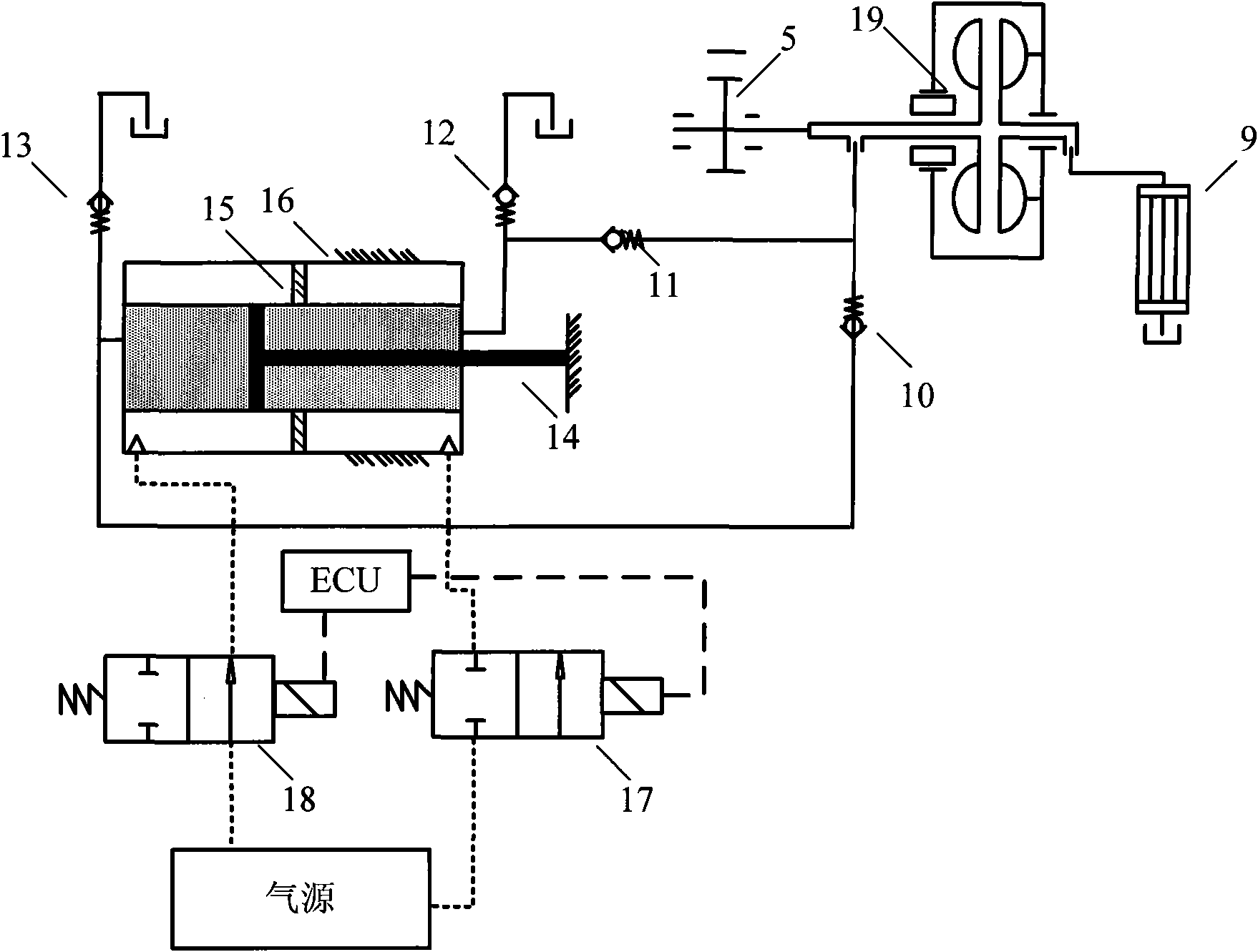

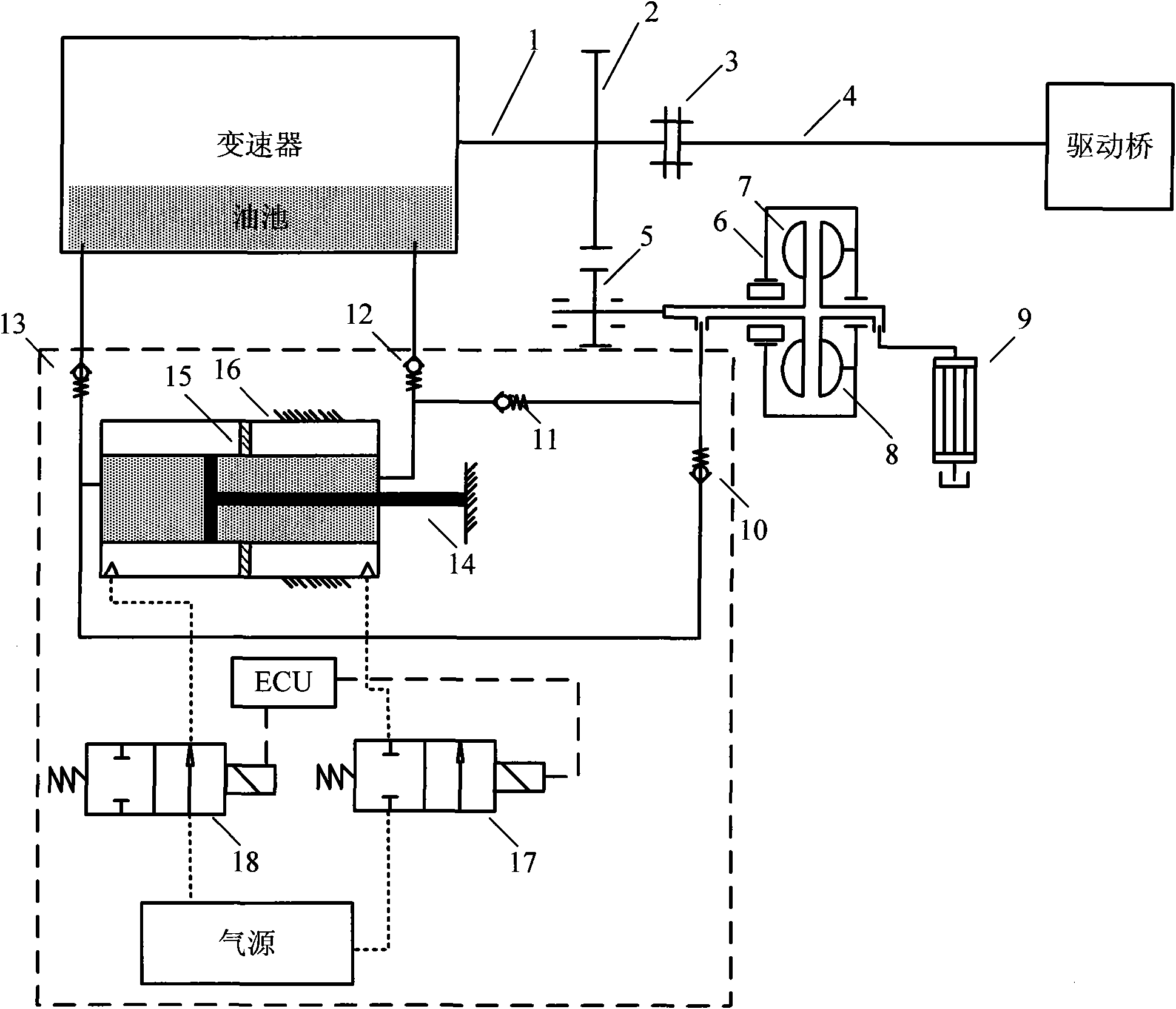

[0010] like figure 1 As shown, a pneumatic-hydraulic hydraulic retarder control device includes a pneumatic-hydraulic converter, and the pneumatic-hydraulic converter is composed of three parts: converter pneumatic cylinder 16, converter pneumatic piston 15 and Converter hydraulic piston 14, the left air chamber of the air pressure-hydraulic converter is connected with the left electromagnetic switch valve 18, and the inlet of the left electromagnetic switch valve 18 is connected with the air source; the right air chamber of the air pressure-hydraulic converter is connected with the right electromagnetic switch valve 17, and the right The inlet of the electromagnetic switch valve 17 is connected to the air source, and the ECU is connected between the working position of the left electromagnetic switch valve 18 and the working position of the right electromagnetic switch valve 17; The oil tank of the transmission is connected with the working oil chamber of the hydraulic retard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com