Method and device for preparing semi-solid state slurry through intensive cooling stirring

A technology of semi-solid slurry and stirring shaft, which is applied in the field of compound stirring semi-solid slurry continuous preparation equipment, can solve the problems of reducing the strong stirring effect of complex agitators, the melt is easily involved in gas, and the process is unstable, so as to reduce the Potential air entrainment problem, stable process and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

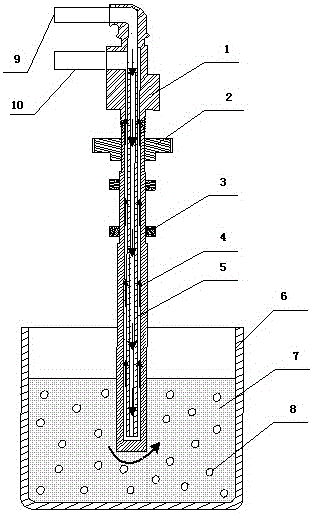

[0019] In this example, the rotary joint (1) adopts a composite inner tube fixed type, and the forced cooling and stirring equipment is combined with a die-casting machine to prepare rheological die-casting moldings. First, adjust the rotating stirring shaft (4) to an appropriate speed, turn on the circulating cooling water, the water enters from the cooling medium inlet pipe (9), passes through the cooling inner pipe (5), and then passes through the cooling inner pipe (5) and the rotating stirring shaft (4 ), and finally flows out from the cooling medium outlet pipe (10); the mechanical arm of the die-casting machine controls the crucible or ladle (6) to take the aluminum alloy melt in the melting furnace (superheat degree 0~100°C), and move it to Fixed position; use the lifting device to control the rotating stirring shaft (4) to drop to a certain depth below the liquid surface of the alloy melt in the ladle and stir the alloy melt; when the stirring time is fixed or the melt...

example 2

[0021] In this example, the rotary joint (1) adopts the composite inner tube rotary type, the cooling inner tube rotates with the rotating stirring shaft (4), and the forced cooling stirring equipment is combined with the die forging machine to prepare semi-solid die forging parts. First, adjust the rotating stirring shaft (4) to an appropriate speed, and then pass in the cooling gas. The cooling gas enters from the cooling medium inlet pipe (9), passes through the cooling inner pipe (5), and then passes through the cooling inner pipe (5) and the rotating stirring shaft ( 4) and finally discharged from the cooling medium outlet pipe (10); use the mechanical arm to control the crucible or ladle (6) to hold the light alloy melt in the melting furnace (superheat degree 0~100°C), and move to Fixed position; use the lifting device to control the rotating stirring shaft (4) to drop to a certain depth below the liquid surface of the alloy melt in the ladle and stir the alloy melt; whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com