Numerical control electrolyze mechanical compound processing machine tool

A technology of composite processing and electrolytic machinery, which is applied in the direction of electric processing equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of low processing efficiency, poor processing accuracy, and can only process flat and cylindrical surfaces, etc., to achieve processing accuracy High, eliminate installation errors, low roughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

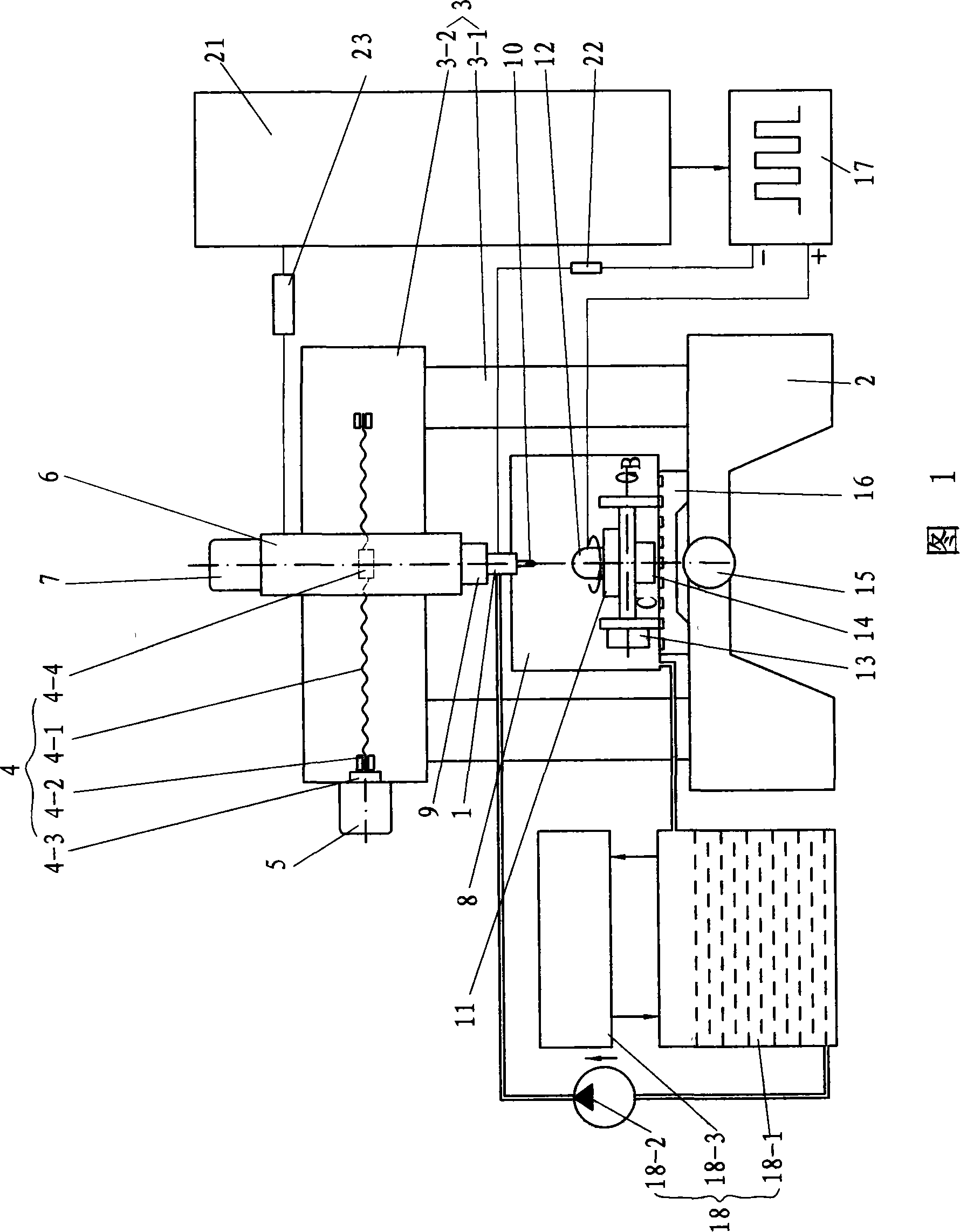

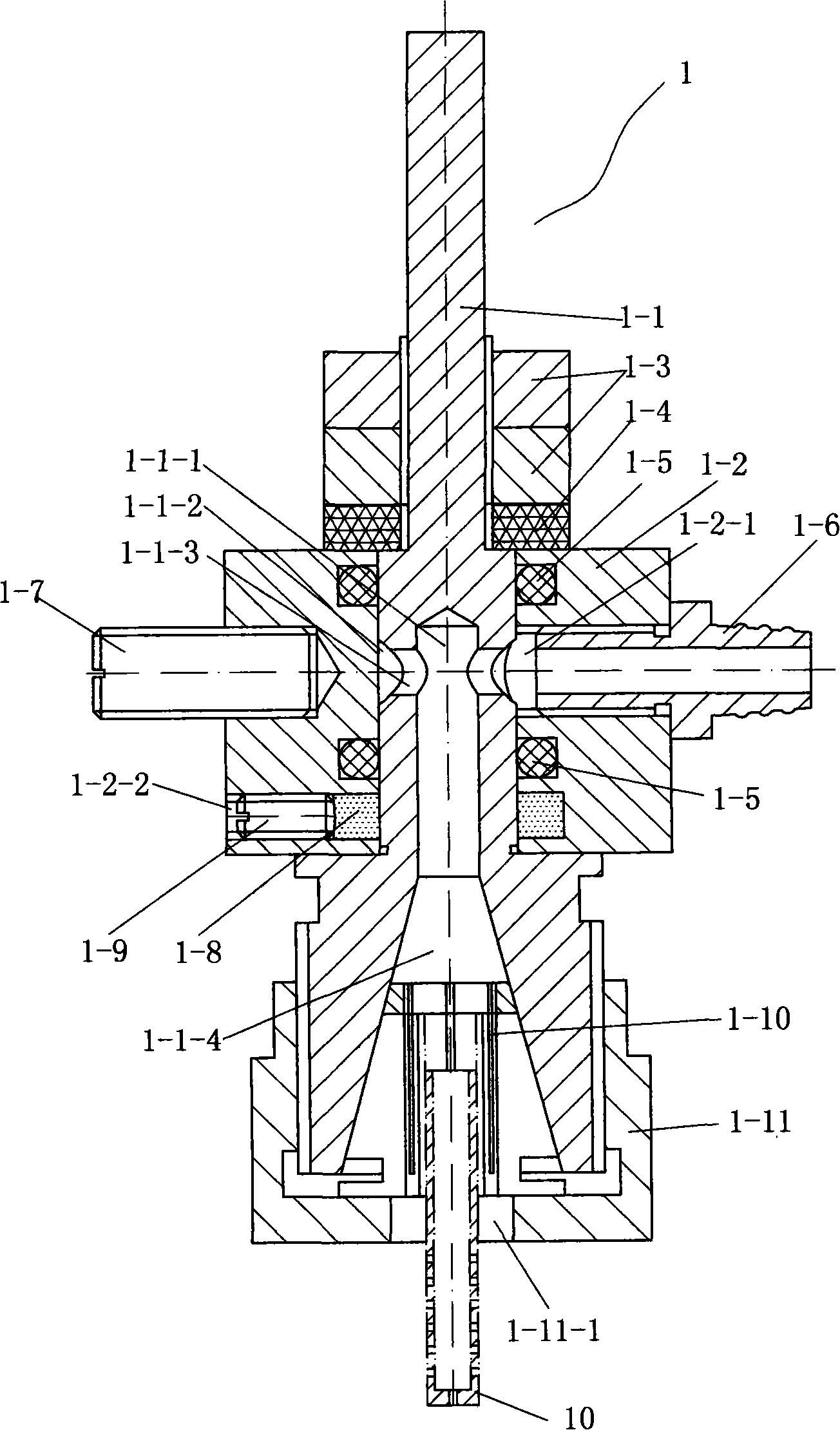

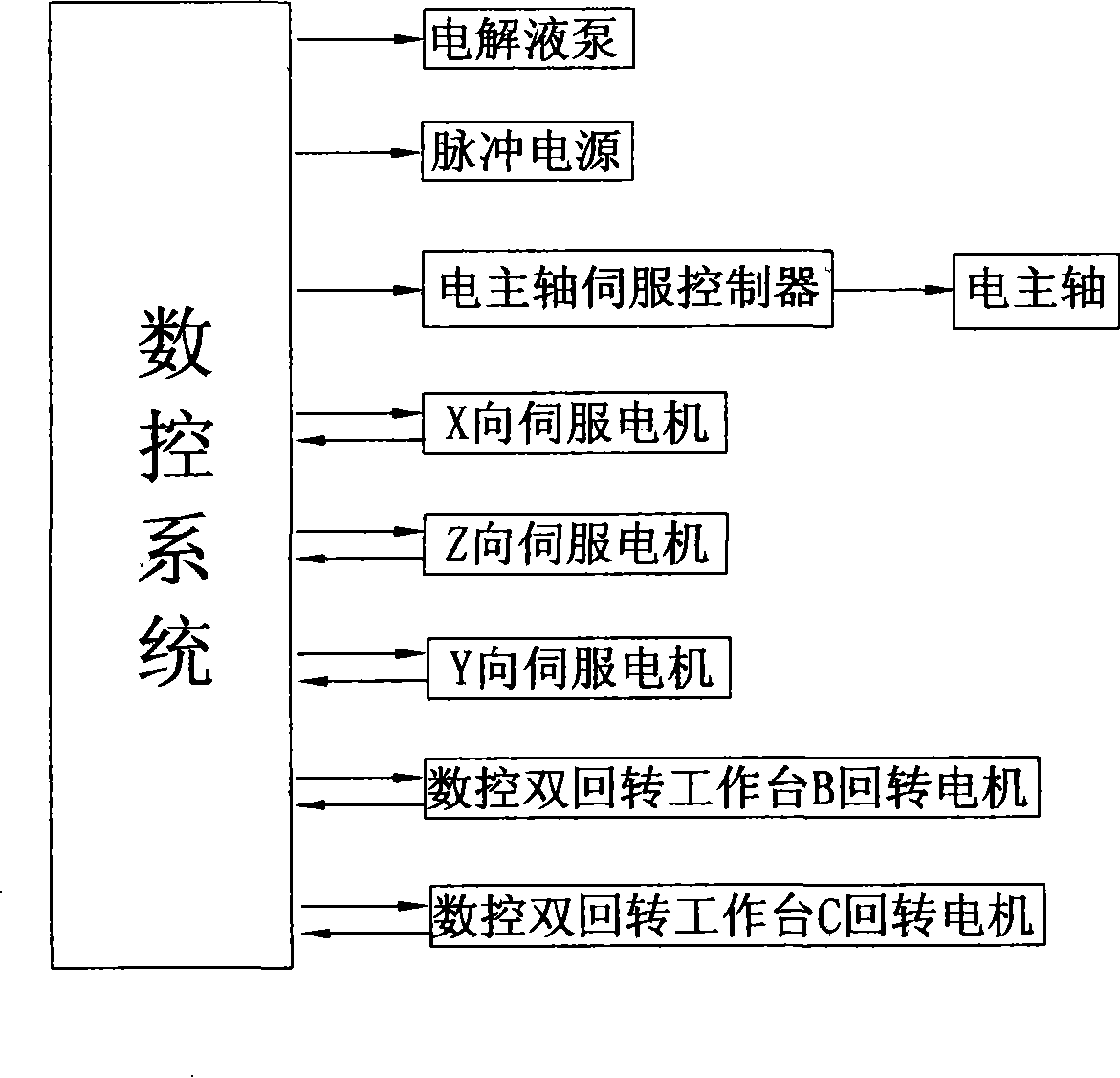

[0026] The embodiment shown in the drawings includes a bed 2, a frame 3, a horizontal workbench 16, a CNC double-rotary workbench 11, a protective box 8, a spindle head 6, an electric spindle 9, a numerical control system 21, a pulse power supply 17, and an electrolyte Circulator 18.

[0027] The frame 3 is a gantry structure, and the frame 3 includes a column 3-1 and a beam 3-2.

[0028] The beam 3 - 2 of the frame 3 is provided with an X-direction transmission mechanism 4 and an X-direction servo motor 5 , and the spindle head 6 is connected to the X-direction transmission mechanism 4 . The X-direction transmission mechanism 4 has an X-direction ball screw transmission pair. The ball screw 4-1 in the X-direction ball screw transmission pair is supported by a pair of bearings 4-2 fixed on the beam 3-2. The ball screw 4 One end of -1 is connected to the X-direction servo motor 5 by a coupling 4-3, and the spindle head 6 is connected to the nut 4-4 in the X-direction ball scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com