Patents

Literature

153results about How to "Improve support capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

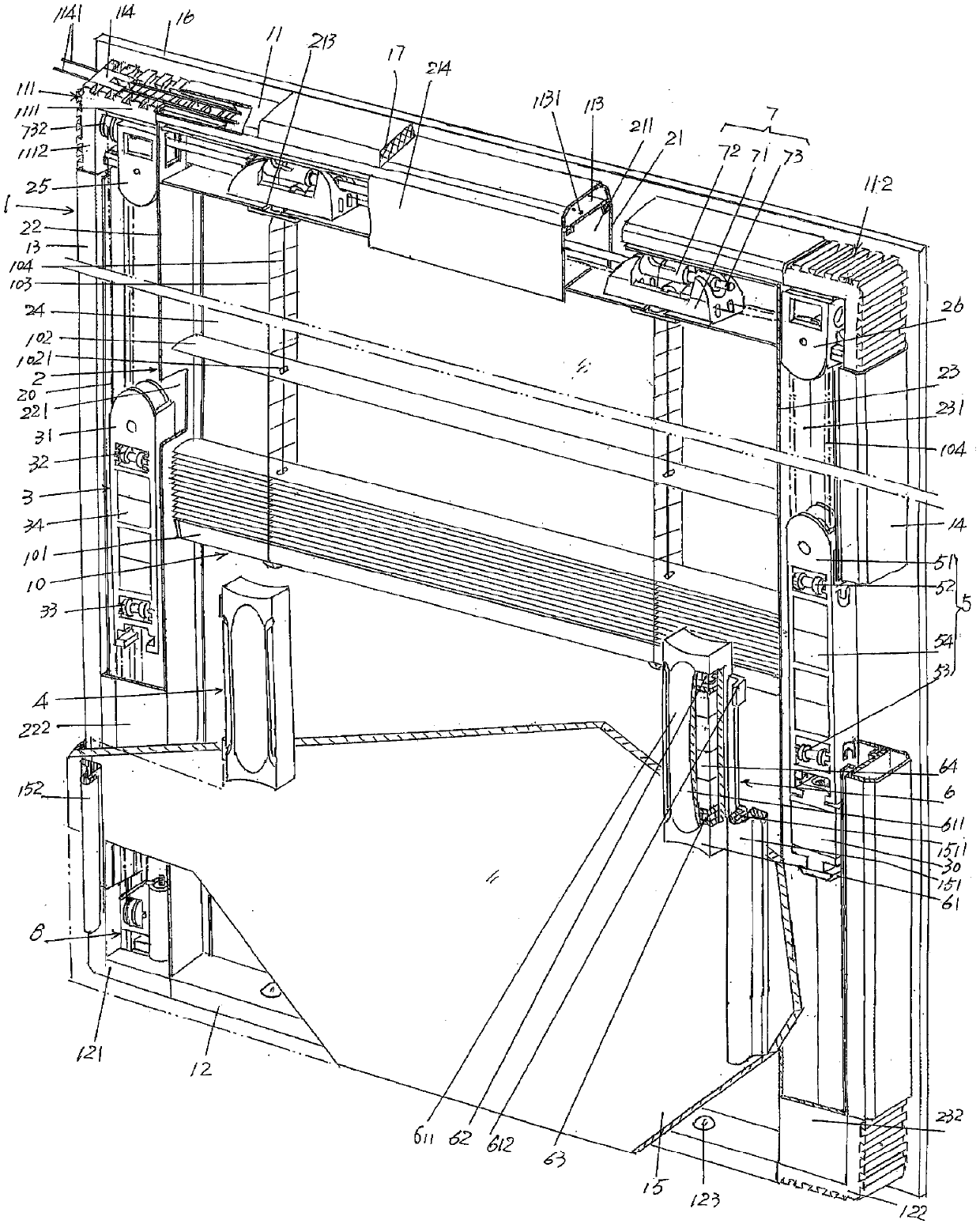

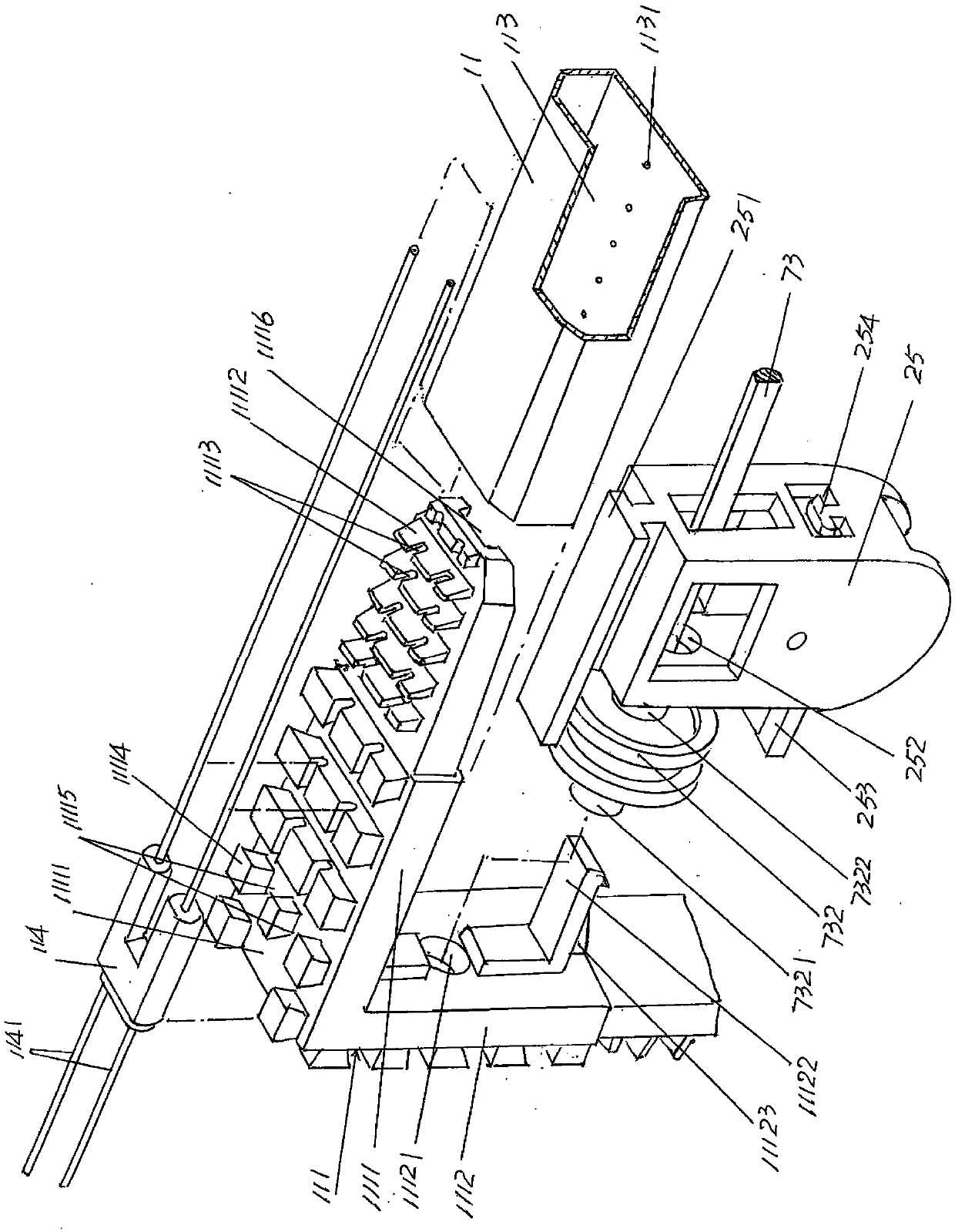

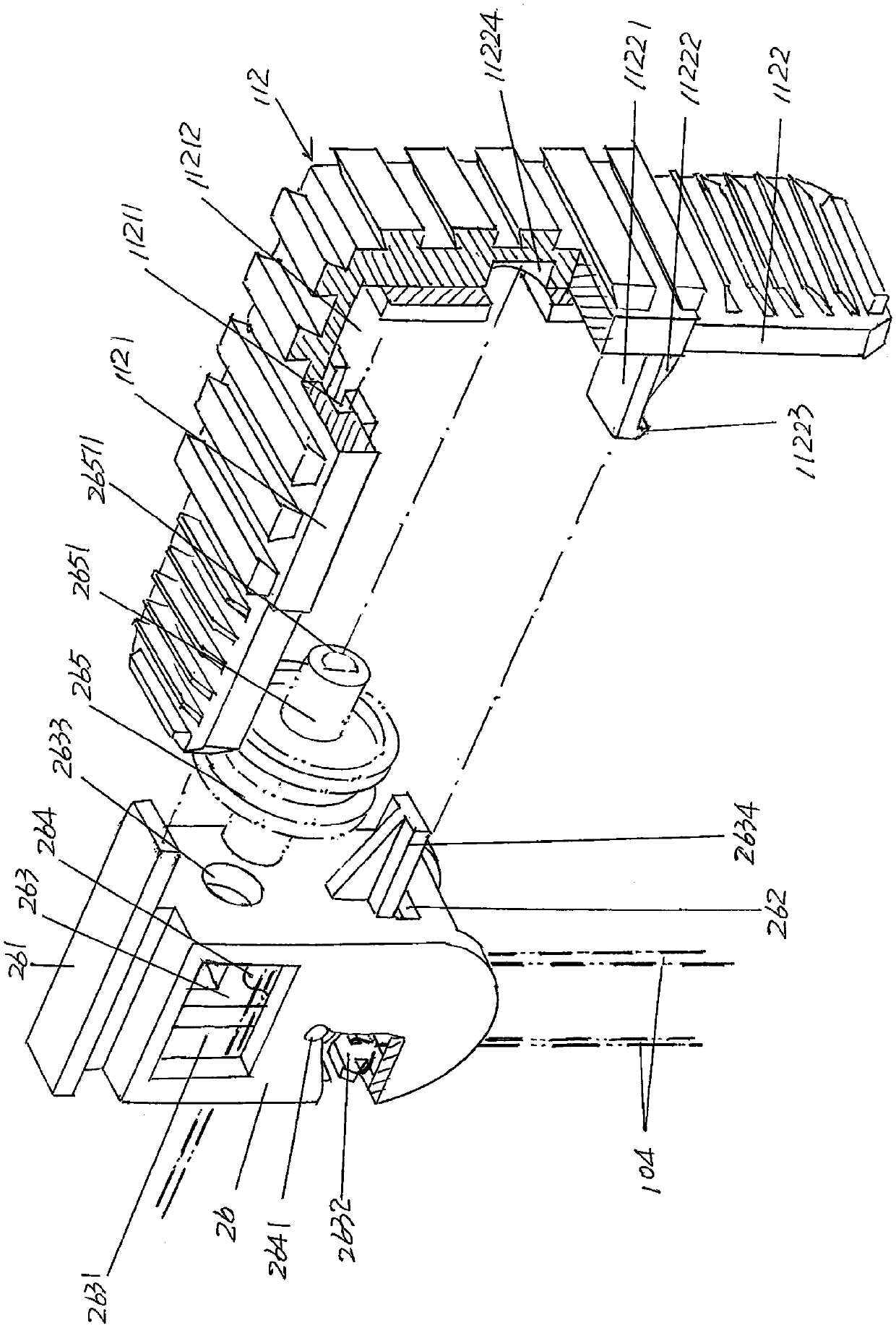

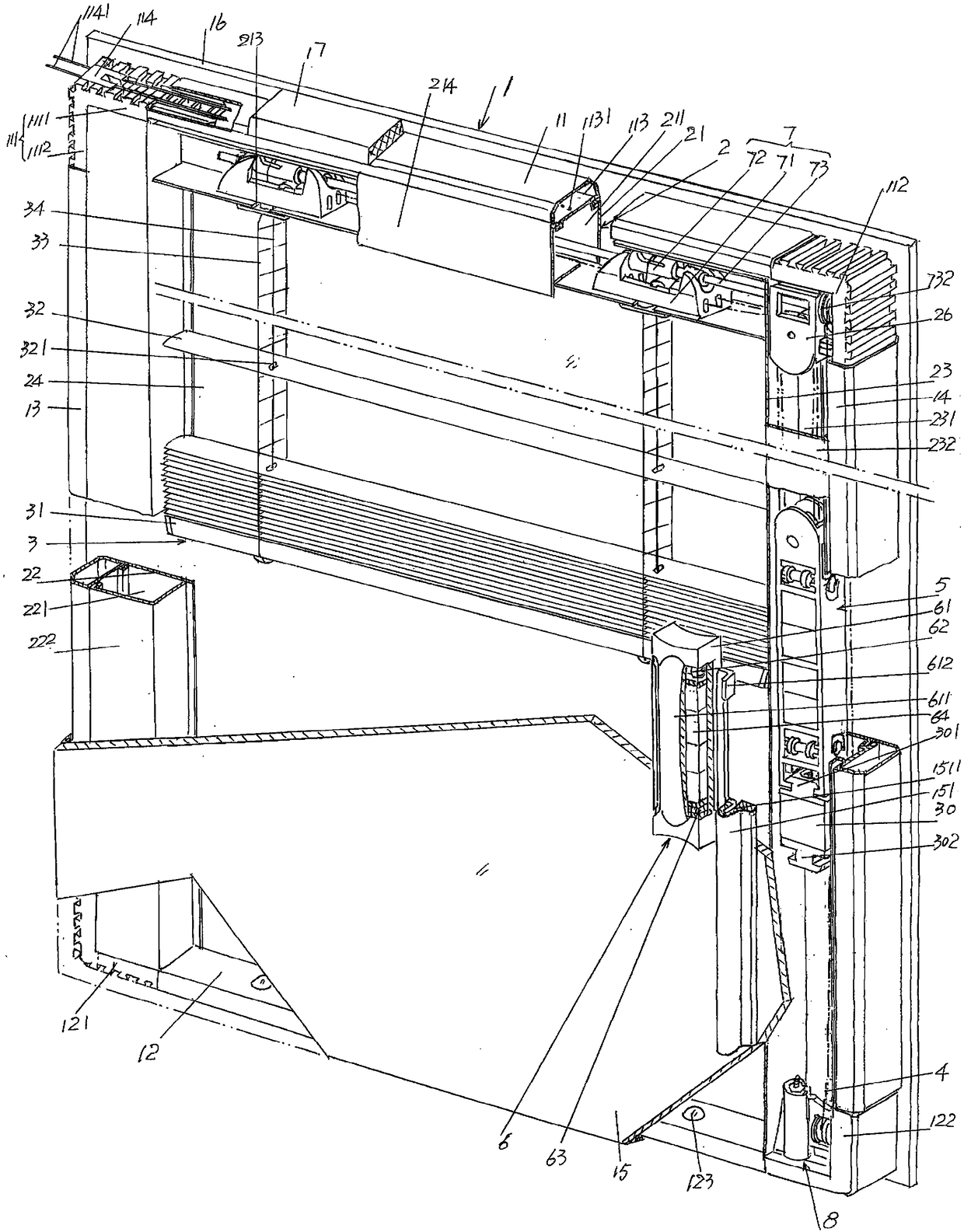

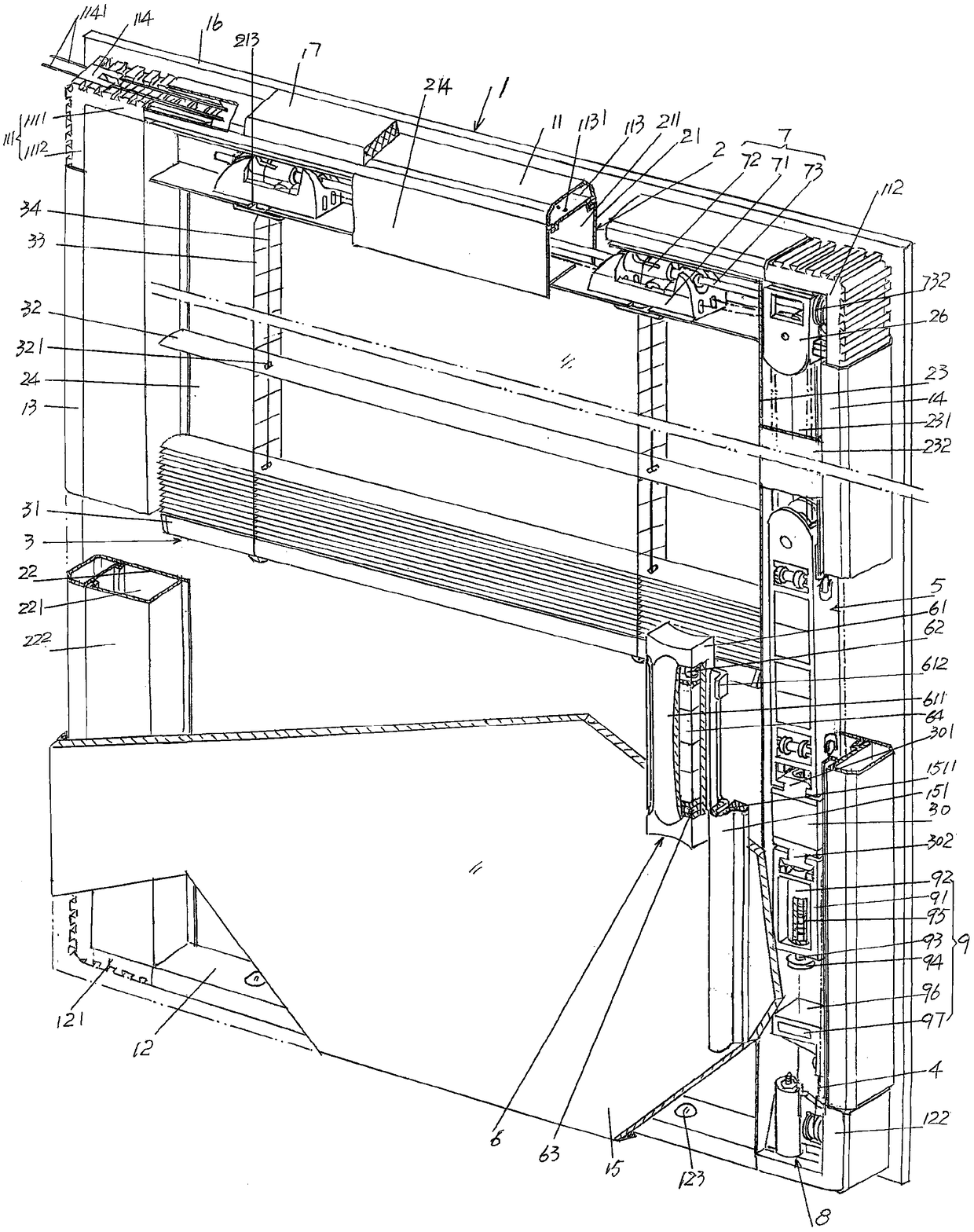

Shutter-blind-cavity-and-external-pressure-balanced dual-control hollow-glass built-in shutter

PendingCN109538096AGuaranteed levelAvoid deformationLight protection screensWindow shutterEngineering

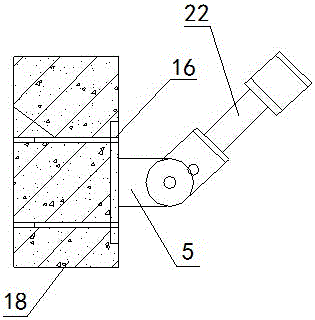

The invention discloses a shutter-blind-cavity-and-external-pressure-balanced dual-control hollow-glass built-in shutter. The shutter-blind-cavity-and-external-pressure-balanced dual-control hollow-glass built-in shutter comprises a shutter body, an inner frame, a curtain-sheet-overturning-pulling-rope inner control mechanism, a curtain-sheet-overturning-pulling-rope outer control mechanism, a shutter-blind-lifting-pulling-rope inner control mechanism, a shutter-blind-lifting-pulling-rope outer control mechanism, a curtain-sheet-overturning executing mechanism, a shutter blind and a curtain-sheet overturning pulling rope, wherein the shutter body comprises an upper transverse frame pipe, a lower transverse frame pipe, a left longitudinal frame pipe, a right longitudinal frame pipe, inner glass and outer glass; the inner frame comprises an upper transverse frame strip, a left longitudinal frame strip and a right longitudinal frame strip. The shutter-blind-cavity-and-external-pressure-balanced dual-control hollow-glass built-in shutter is characterized in that upper-transverse-frame-pipe-cavity ventilating holes are formed in the upper-transverse-frame-pipe bottom wall, towards one side of a shutter blind cavity, of the upper transverse frame pipe, a balance-pipe-fixing-base embedded cavity is formed in the upward side of the left end of an upper-left-rotating-corner-inserting-block transverse inserting arm, a balance-pipe fixing base is arranged at the portion corresponding to the balance-pipe-fixing-base embedded cavity, a pair of balance pipes are fixedly inserted onto thebalance-pipe fixing base, the left ends of the pair of balance pipes extend out of the left end face of the upper-left-rotating-corner-inserting-block transverse inserting arm and penetrates througha sealing rubber strip to be communicated with the outside, and the right ends of the pair of balance pipes extend into an upper transverse frame pipe cavity and are communicated with the upper transverse frame pipe cavity. Air pressure in a shutter blind cavity is same as air pressure of the outside.

Owner:JIANGSU SDL ENERGY CONSERVATION TECH CO LTD

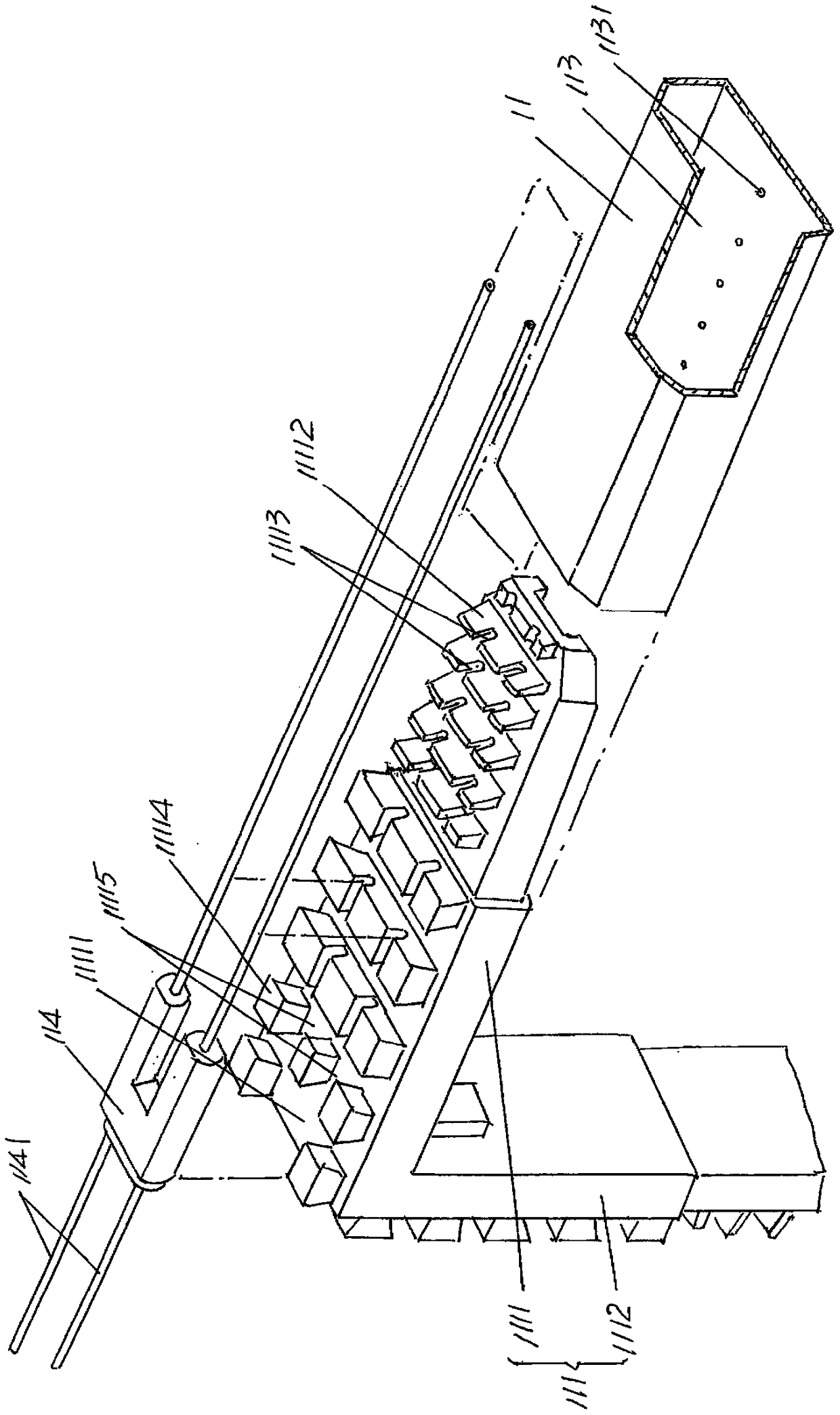

Inward suction prevented single control hollow glass embedded shutter

PendingCN109488189AGuaranteed levelAvoid deformationDoor/window protective devicesSpecial door/window arrangementsWindow shutterEngineering

Disclosed is an inward suction prevented single control hollow glass embedded shutter. The inward suction prevented single control hollow glass embedded shutter comprises a shutter body, an inner frame, inner and outer operating mechanisms, a blind rotating execution mechanism, blinds, a blind rotating traction rope tensioning mechanism and a blind rotating traction rope, wherein the shutter bodyis composed of upper and lower horizontal frame tubes, left and right vertical frame tubes and inner and outer glass; the blind rotating traction rope tensioning mechanism is arranged onto a right bottom corner plug. The inward suction prevented single control hollow glass embedded shutter is characterized in that the bottom wall of one side of the upper horizontal frame tube, which faces towardsto a blind cavity, is provided with upper horizontal frame tube cavity air holes; the upward side of the left end of the horizontal plugging arm of the left upper corner plug is provided with a pressure balancing pipe fixing seat embedding cavity, a pressure balancing pipe fixing seat is arranged corresponding to the pressure balancing pipe fixing seat embedding cavity and provided with a pair ofpressure balancing pipes, the left ends of the pair of pressure balancing pipes extend out the left end surface of the horizontal plugging arm of the left upper corner plug and penetrates through sealing rubber strips to communicated with the outside, and the right ends of the pair of pressure balancing pipes extend into and are communicated with an upper horizontal frame pipe cavity. The can avoids inward suction of the inner and outer glass which is caused by thermal expansion and contraction.

Owner:JIANGSU SDL ENERGY CONSERVATION TECH CO LTD

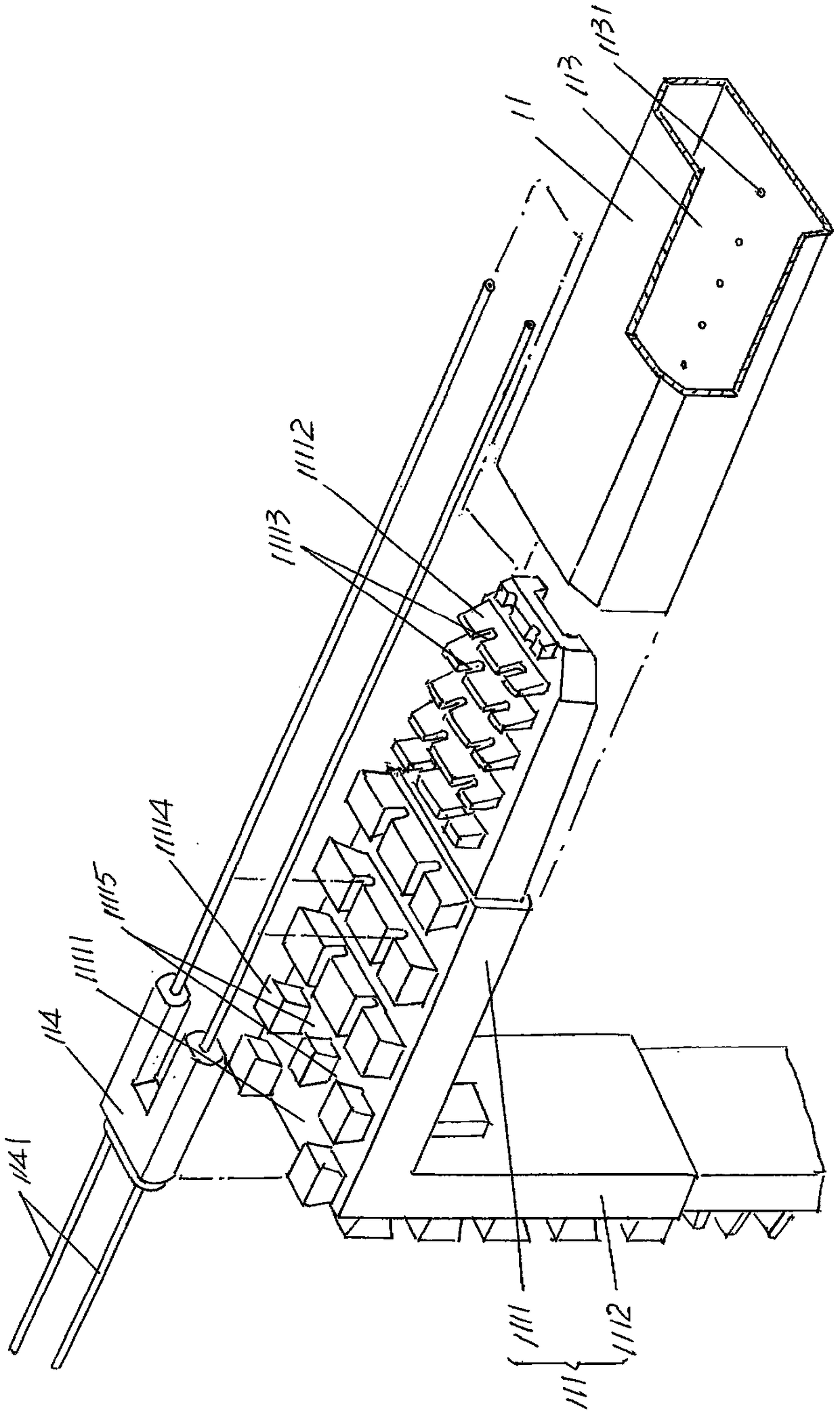

Unilateral controlled hollow glass built-in window-shades capable of preventing venetian blinds from sliding down

PendingCN109441323AGuaranteed levelAvoid deformationDoor/window protective devicesEngineeringVenetian blinds

The invention discloses unilateral controlled hollow glass built-in window-shades capable of preventing venetian blinds from sliding down. The window-shades comprise a window body, an inner frame body, inner and outer control mechanisms, blind piece overturning performing mechanisms, the venetian blinds, a blind piece overturning pulling rope tensioning mechanism and blind piece overturning pulling ropes. The window body comprises upper and lower transverse frame tubes, left and right longitudinal frame tubes and inner and outer glass; the inner frame body comprises an upper transverse frame strip and left and right longitudinal frame strips; the blind piece overturning pulling rope tensioning mechanism is arranged on a lower right corner inserting block; and one ends of the blind piece overturning pulling ropes are fixed to the inner control mechanism, the middle parts of the blind piece overturning pulling ropes are connected with the blind piece overturning performing mechanisms andthe blind piece overturning pulling rope tensioning mechanism, and the other ends of the blind piece overturning pulling ropes are fixed to the inner control mechanism. The unilateral controlled hollow glass built-in window-shades are characterized by further comprising an opposite absorbing mechanism used for keeping the inner control mechanism at the position which enables the venetian blinds to be under an upward lifting condition, and the opposite absorbing mechanism is arranged between the lower part of the right longitudinal frame tube and the inner control mechanism. When the venetianblinds are under an upward lifting condition, the opposite absorbing mechanism keeps the inner control mechanism at the descending position, and the condition that the venetian blinds abnormally slidedownward due to the fact that the inner control mechanism abnormally moves upward cannot occur.

Owner:JIANGSU SDL ENERGY CONSERVATION TECH CO LTD

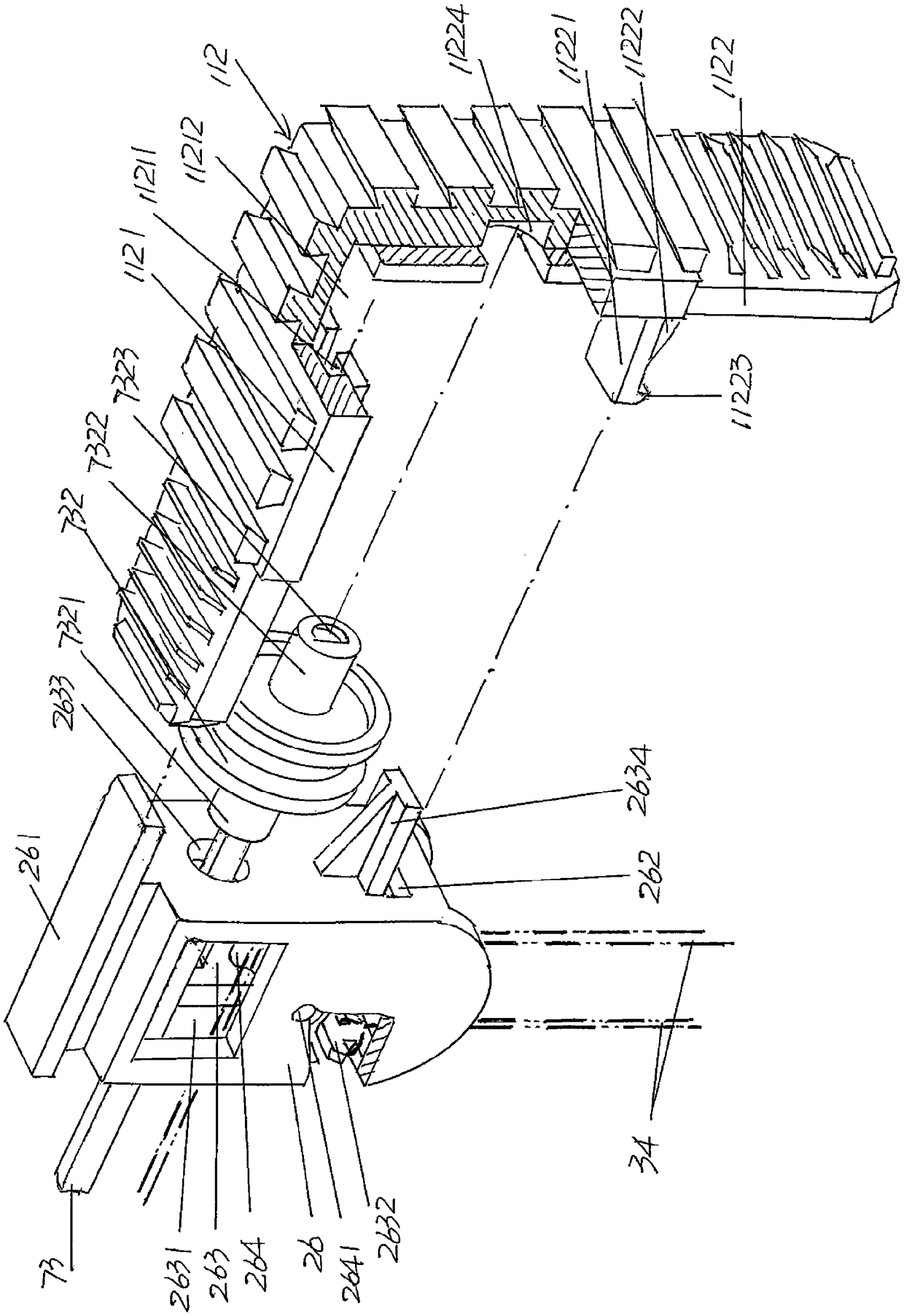

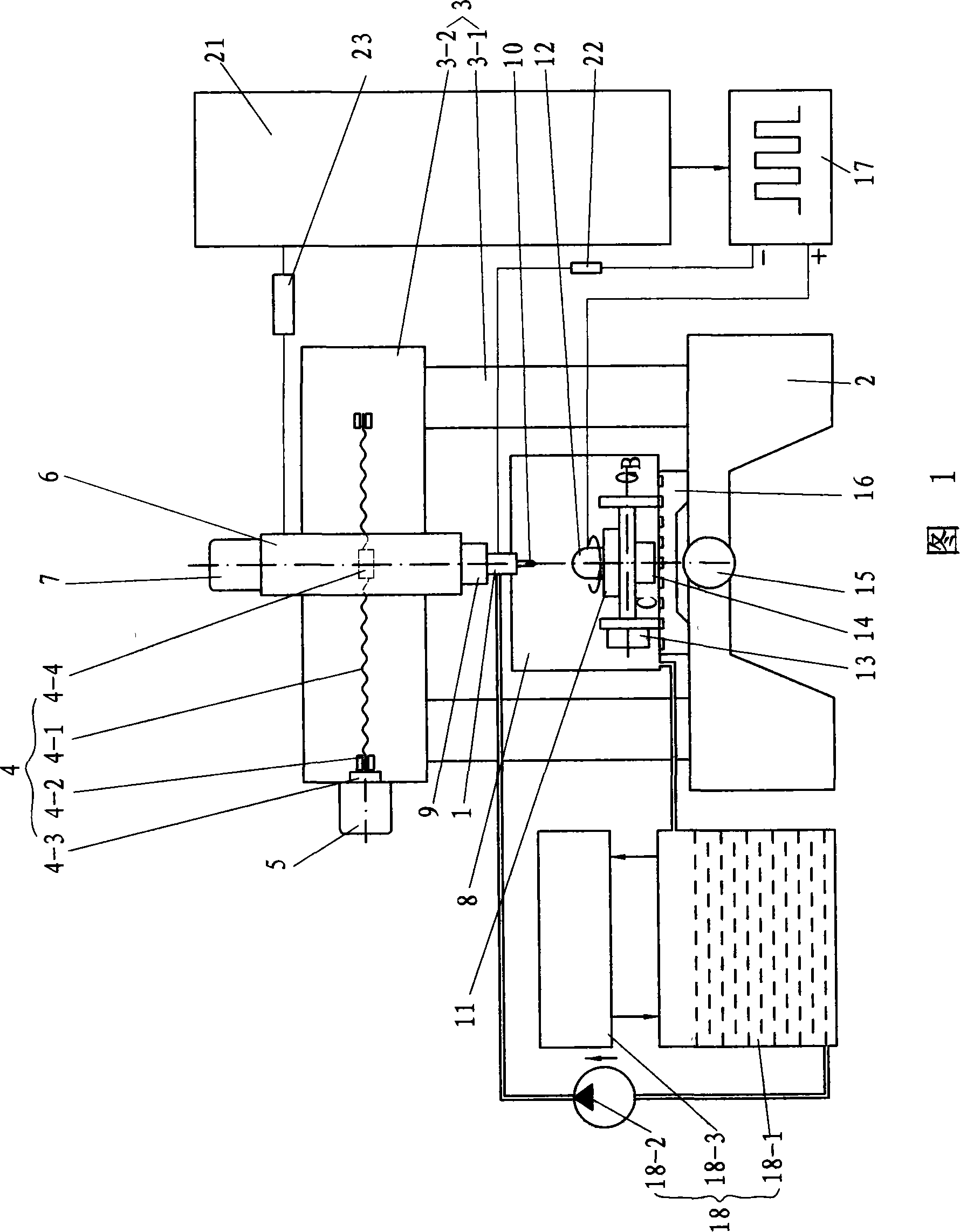

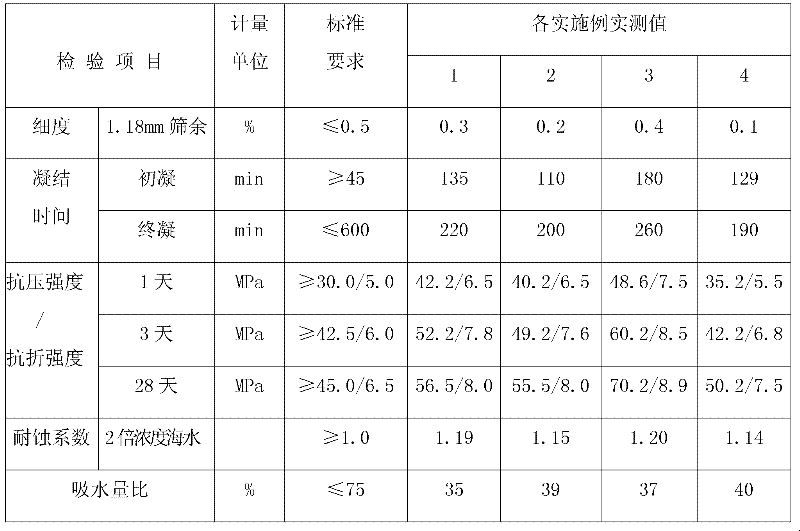

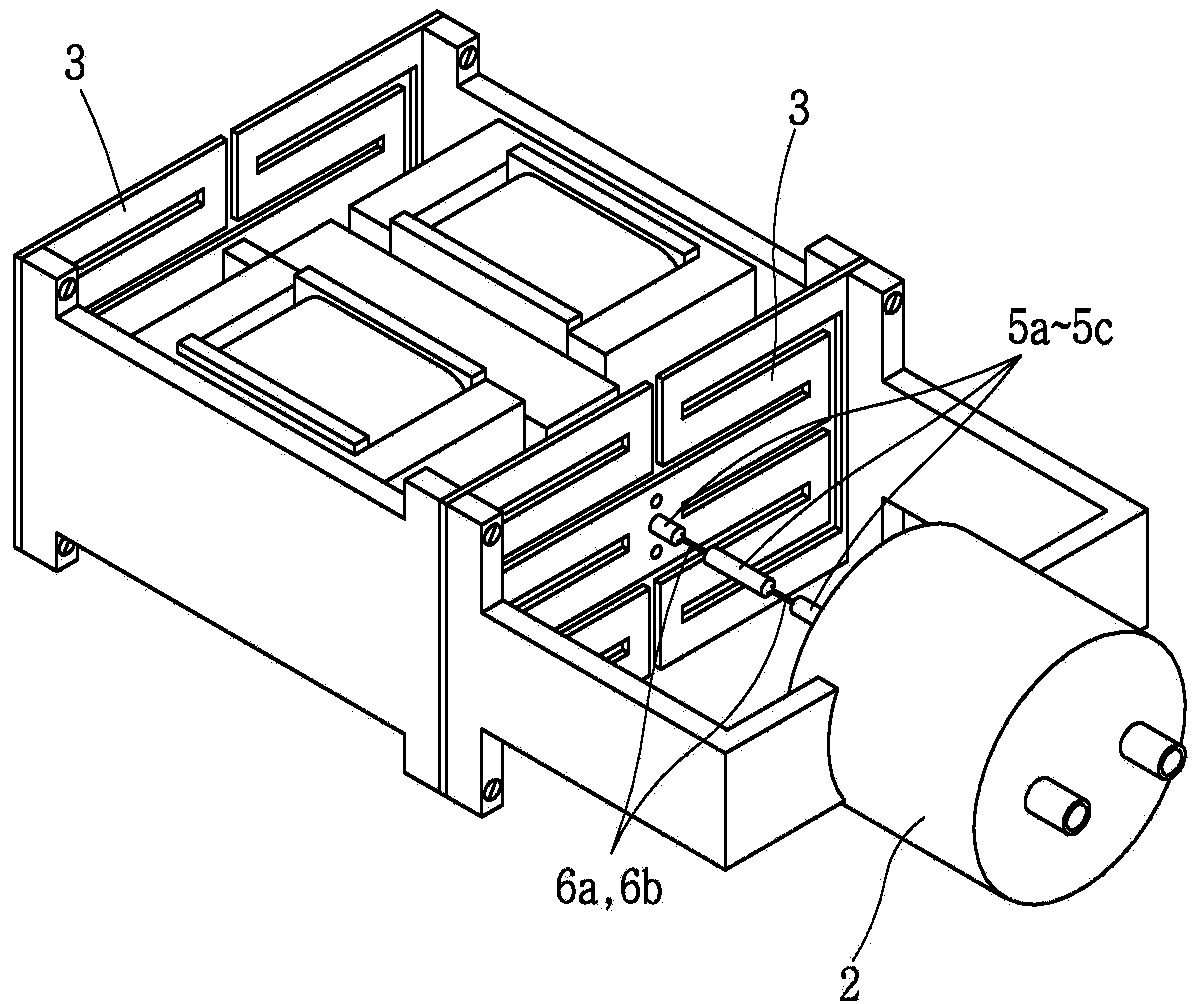

Numerical control electrolyze mechanical compound processing machine tool

InactiveCN101249578AEliminate installation errorsImprove machining accuracyFeeding apparatusElectric circuitsElectric machineryComposite cathode

A numerical control electrolytic-mechanical composite machine tool comprises a machine body, a frame, a horizontal work bench, a numerical control double-revolving work bench, a protection box, a spindle head, an electrical spindle, a numerical control system, a pulse power supply, an electrolyte circulating device, and an X-direction transmission mechanism, a Z-direction transmission mechanism as well as a Y-direction transmission mechanism, wherein the electrical spindle, the pulse power supply, an electrolyte pump of the electrolyte circulating device, an X-direction servo motor, a Z-direction servo motor, a Y-direction servo motor, and a B revolving motor and a C revolving motor of the numerical control double-revolving motor are all controlled by the numerical control system. By controlling the relative movement of a composite cathode and an anode workpiece, the machine tool can process mold cavities and mold surfaces for complex workpieces, thus processing workpieces of different shapes. By changing different composite cathodes and adjusting different processing parameters, rough processing, finish processing and surface smoothing of one part can be achieved by one machine tool in different processing manners such as drilling, milling, cutting, grinding and polishing, thus eliminating installation error caused by repeated installation of workpieces.

Owner:CHANGZHOU INST OF TECH

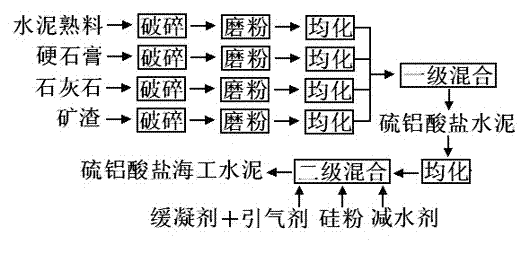

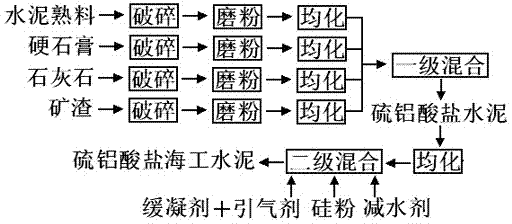

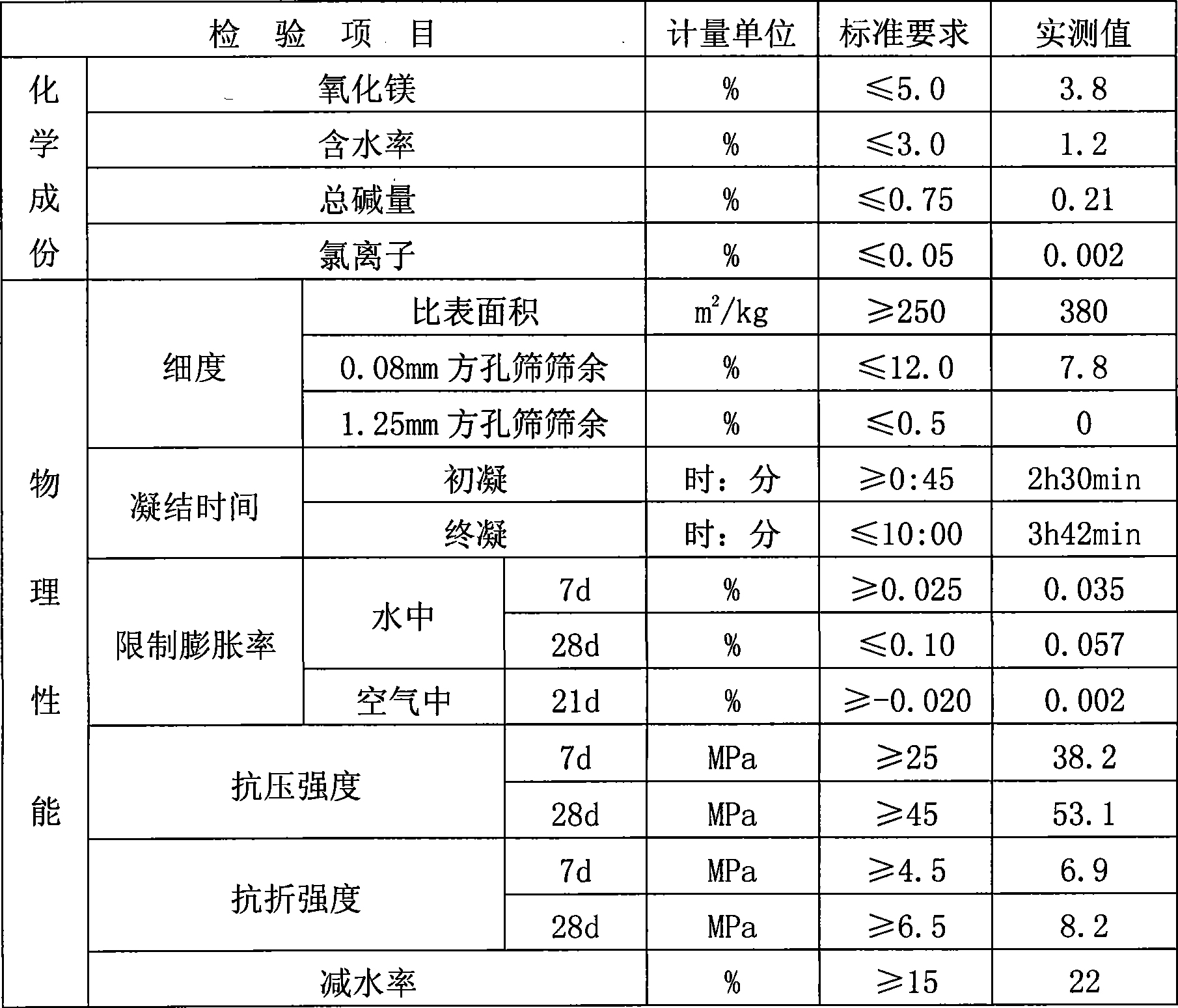

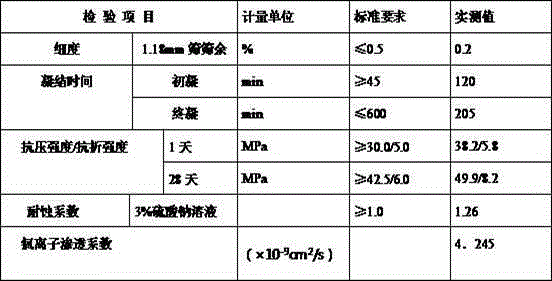

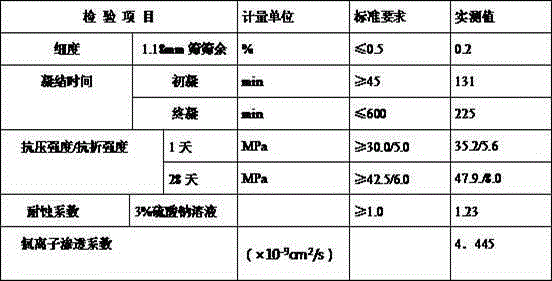

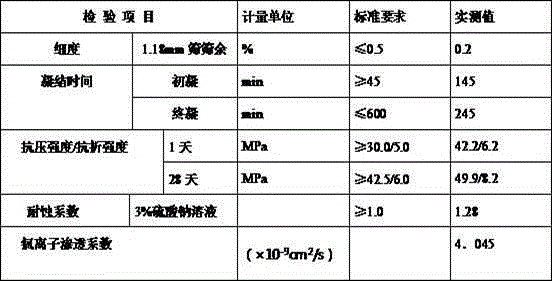

Sulphoaluminate maritime work cement and preparation method thereof

The invention discloses sulphoaluminate maritime work cement and a preparation method thereof. The sulphoaluminate maritime work cement comprises the following main raw materials in parts by weight: 50-80 parts of cement clinker, 8.0-20 parts of anhydrite, 0-30 parts of limestone, 0-30 parts of slag, 0.1-0.5 part of water reducing agent, 0.001-0.005 part of air entraining agent, 0.1-0.5 part of retarder and 2-5 parts of silicon powder. The preparation method comprises the following steps of: respectively smashing, grinding and homogenizing the sulphoaluminate cement clinker, the anhydrite, the limestone and the slag; then, burdening at a ratio, and evenly mixing; adding the water reducing agent, the air entraining agent, the retarder and the silicon powder; and mixing and homogenizing to obtain the product. The concrete mixed by the sulphoaluminate maritime work cement has the advantages of small bleeding rate and high slurry viscidity. The slurry has strong covering and supporting action on aggregate. The concrete keeps good homogeneity and has the advantages of hard and quick early strength, continuously-increased later strength, good slurry structure compactness and high volume stability and is convenient to use and operate for constructing.

Owner:广西云燕特种水泥建材有限公司

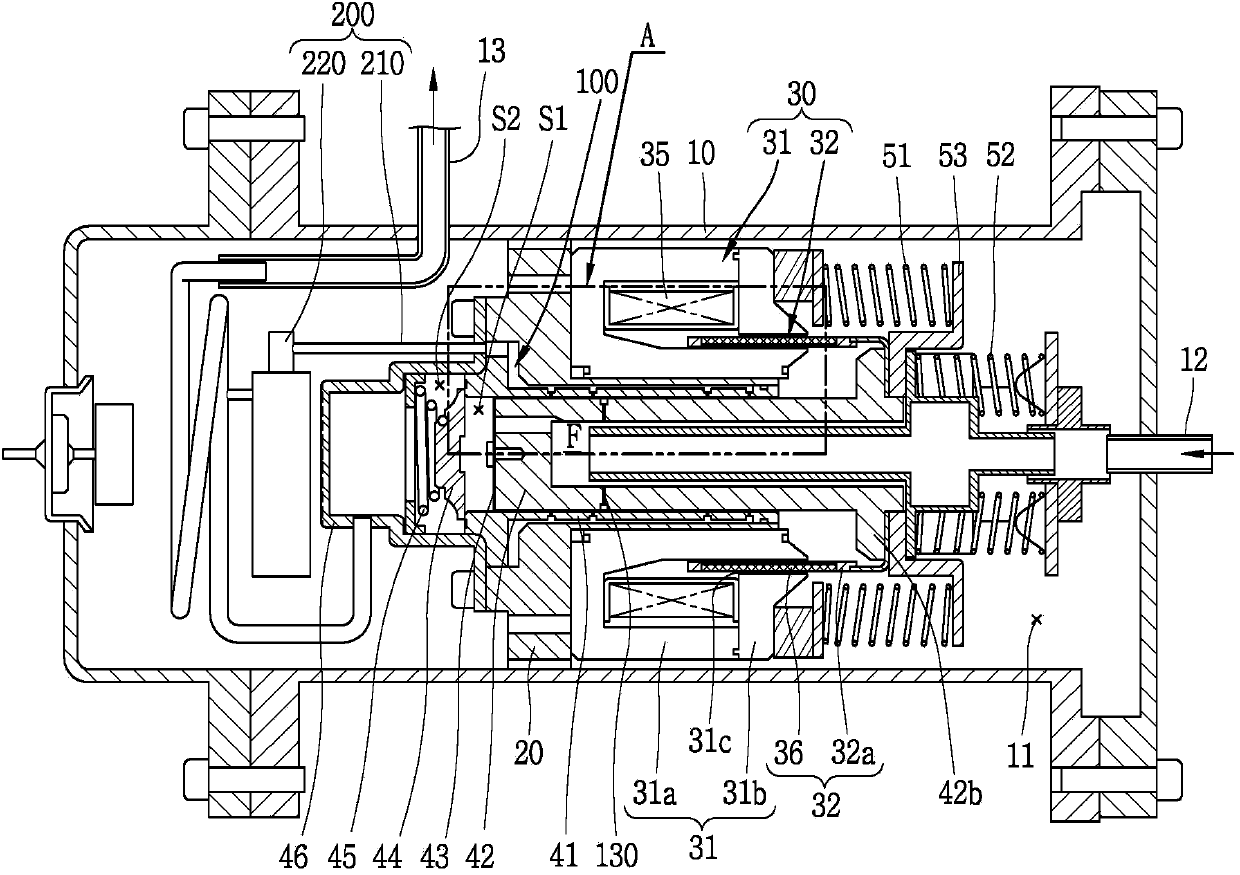

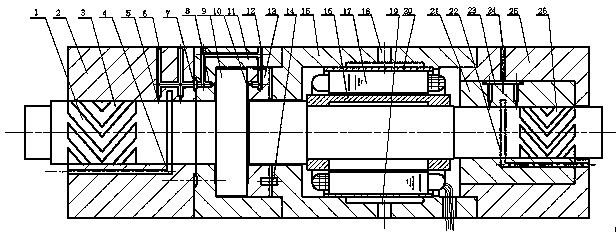

Reciprocating compressor

InactiveCN103629082AImprove support capacityReduce vibrationPositive displacement pump componentsPiston pumpsRefrigerantEngineering

Disclosed is a reciprocating compressor. As bearing holes which constitute a fluid bearing are formed to correspond to an entire region of a piston, a frictional loss or abrasion between a cylinder and the piston can be prevented. As the bearing holes are formed at a lower part of the cylinder in a concentrated manner, the piston can be stably supported. As compression coil springs are configured as resonant springs, the cylinder and the piston can be easily aligned with each other in a concentric manner, and performance of the reciprocating compressor can be enhanced. As gas through holes are formed at the piston in a radial direction, a pressure of a bearing space can be lowered and thus a refrigerant can be smoothly introduced into the bearing space through a gas pocket. As a shell has a double structure of an outer shell and an inner shell, vibrations generated from the reciprocating compressor can be attenuated by friction occurring between the outer shell and the inner shell. As a casing has a double structure of an outer shell and an inner shell, vibration noise generated from the reciprocating compressor can be attenuated.

Owner:LG ELECTRONICS INC

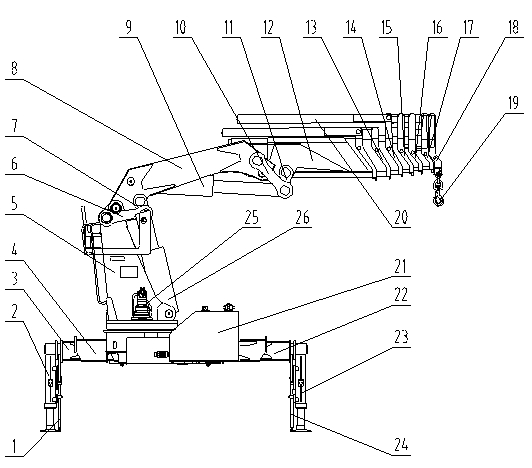

Large-tonnage lorry-mounted crane

The invention relates to a large-tonnage lorry-mounted crane which comprises a base, a lifting hook, an oil tank, a hydraulic control system, a support leg assembly, a swing mechanism, a first amplitude transformation mechanism, a second amplitude transformation mechanism and a telescopic arm assembly, wherein the support leg assembly comprises two horizontal telescopic support legs, two vertical telescopic support legs and two turnover sliding plates; the swing mechanism comprises a swing hydraulic motor, a planet gear reducer, and a swing support with an inner ring fixed on the base; the first amplitude transformation mechanism comprises a main arm, a connecting rod I, a connecting rod II and a first amplitude transformation cylinder; the second amplitude transformation mechanism comprises a second amplitude transformation cylinder connected to the main arm, a connecting rod III and a connecting rod IV; the telescopic arm assembly comprises a fixed telescopic arm; multiple telescopic arms mutually sheathed together are sheathed on the fixed telescopic arm; and telescopic cylinders on each telescopic arm are arranged in a mutually staggered mode. The invention can realize the two-stage telescopic operation by adopting the horizontal support legs, enlarges the span distance among the support legs, enhances the bearing capability and strengthens the stability of the crane. The large-tonnage lorry-mounted crane provided by the invention has the advantages of simple structure, strong adaptability and lighter weight of the finished crane.

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE +1

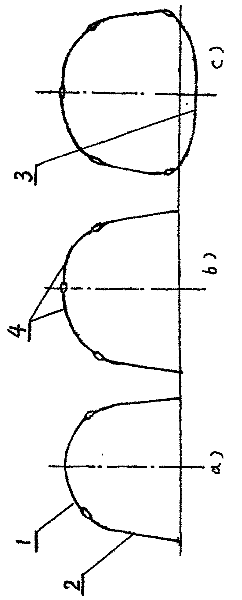

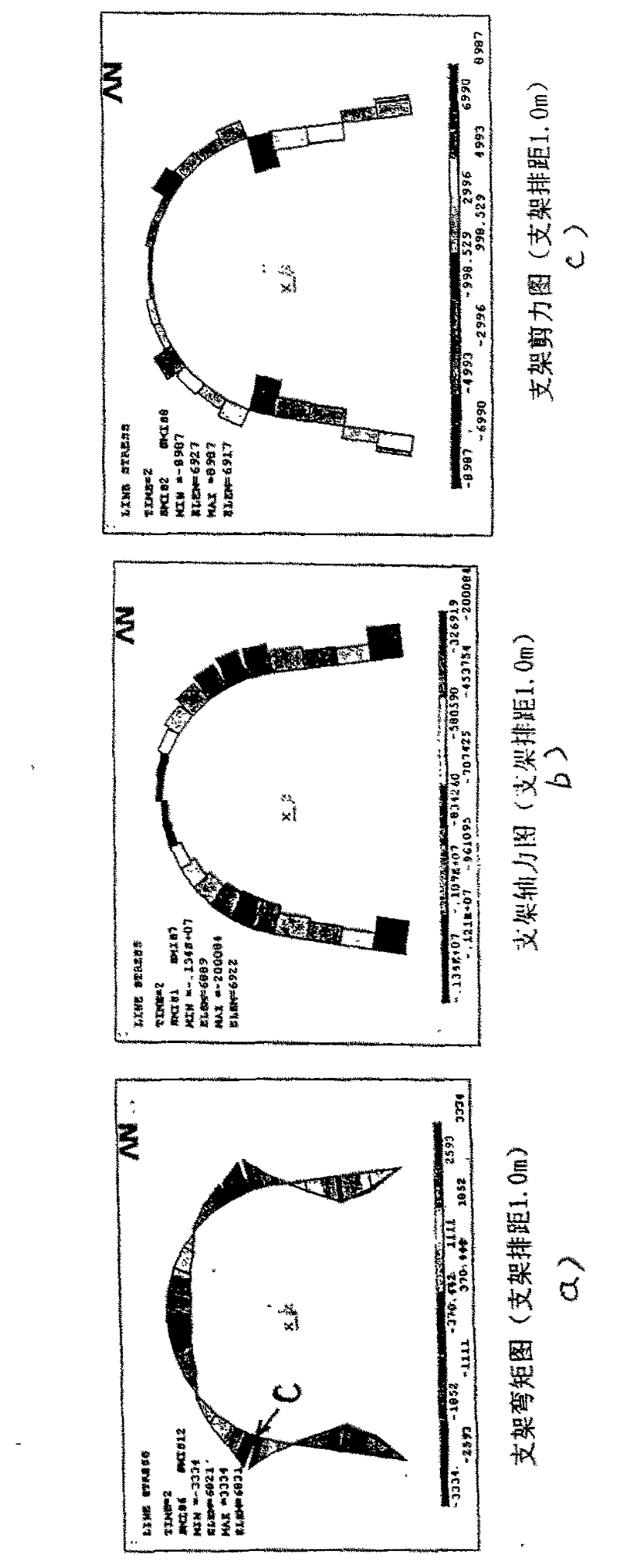

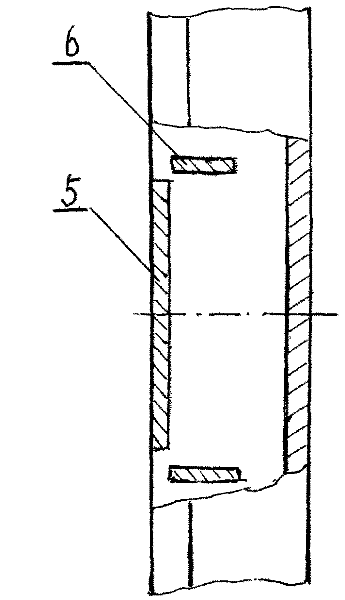

A method for improving the stability of U-shaped steel arch support and connecting components

InactiveCN102268999AIncrease spacingNo wasteUnderground chambersTunnel liningGreenhouseCritical load

A method for improving the stability of U-shaped steel arch support and a connecting component, which are used in the field of roadway excavation support. The retractable support must rely on the friction of the overlapping section to conduct the support, and the failure of the card to loosen accounts for 50% of the accident rate. According to the principle of mechanics, any roadway section, regardless of whether the shape of the arch frame is closed or not, when the steel section is determined, the longer the connection with the card, the more complete, the lower the critical load, and even the overall strength of the material fails due to local weakness. Steady and crumbling. The new method enhances the critical load and support through comprehensive measures such as local reinforcement with moderately variable cross-section to increase the moment of inertia of the weakest part, effective fractured top-to-top connection at the part with large curvature, and mutual pulling between the supports. overall stability. Based on this method, technology and the internal force characteristics of the arch under pressure, several sets of special connecting components are designed. The new method can reduce support accidents, increase shed spacing, reduce support strength and greatly reduce steel consumption.

Owner:颜曙光

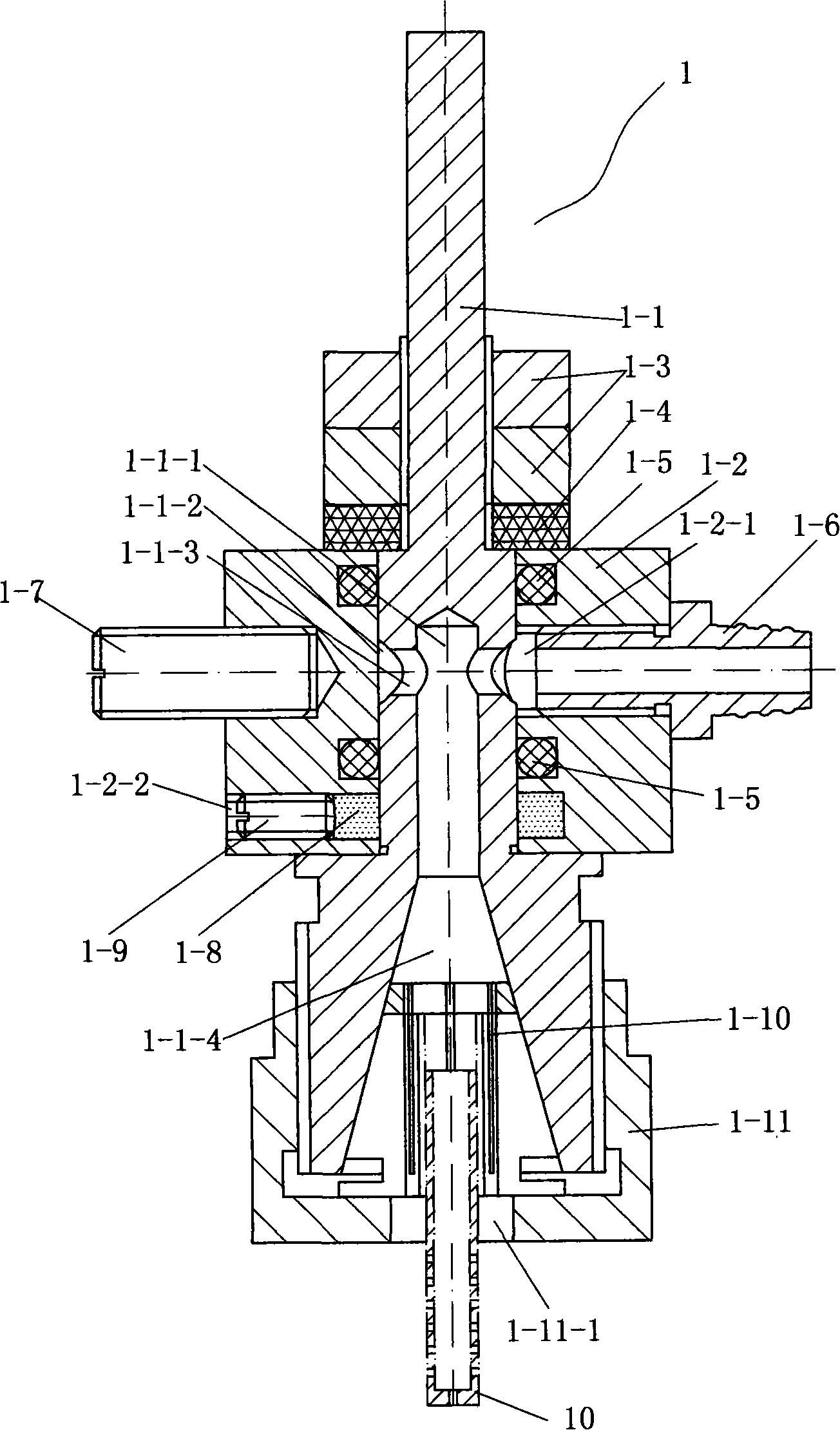

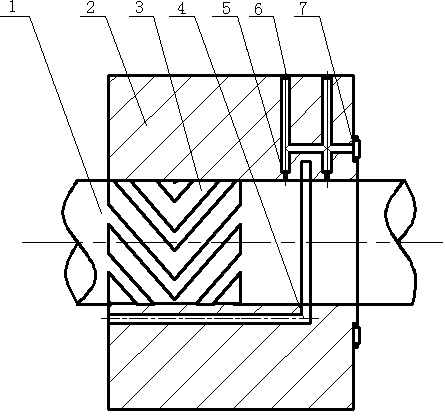

Electric main shaft supported by hydrostatic integrated gas bearing

InactiveCN103846459AHighlight substantiveReduce supplyLarge fixed membersMaintainance and safety accessoriesElectric machineEngineering

The invention discloses an electric main shaft supported by a hydrostatic integrated gas bearing. The electric main shaft comprises a revolving shaft, a front radial hydrostatic integrated gas bearing, a front thrust gas bearing, a thrust color, a back thrust gas bearing, a fastening bolt, a shell, a motor rotor, a motor stator, a back radial hydrostatic integrated gas bearing and a back end cover. The electric main shaft is supported by the hydrostatic integrated gas bearing, the hydrostatic gas bearing of the bearing is supplied with air for a certain period of time till the rotor can float, the hydrodynamic effect of a dynamic pressure gas bearing is utilized by increasing the rotating speed to support a load, so that the air supply time of a static pressure gas is shortened on the basis of not changing the bearing structure, the cost is lowered, the hydrodynamic effect of the hydrodynamic gas bearing is used fully for supporting the load, the carrying force and the stability are improved, and the electric main shaft can keep working normally.

Owner:SHANGHAI UNIV

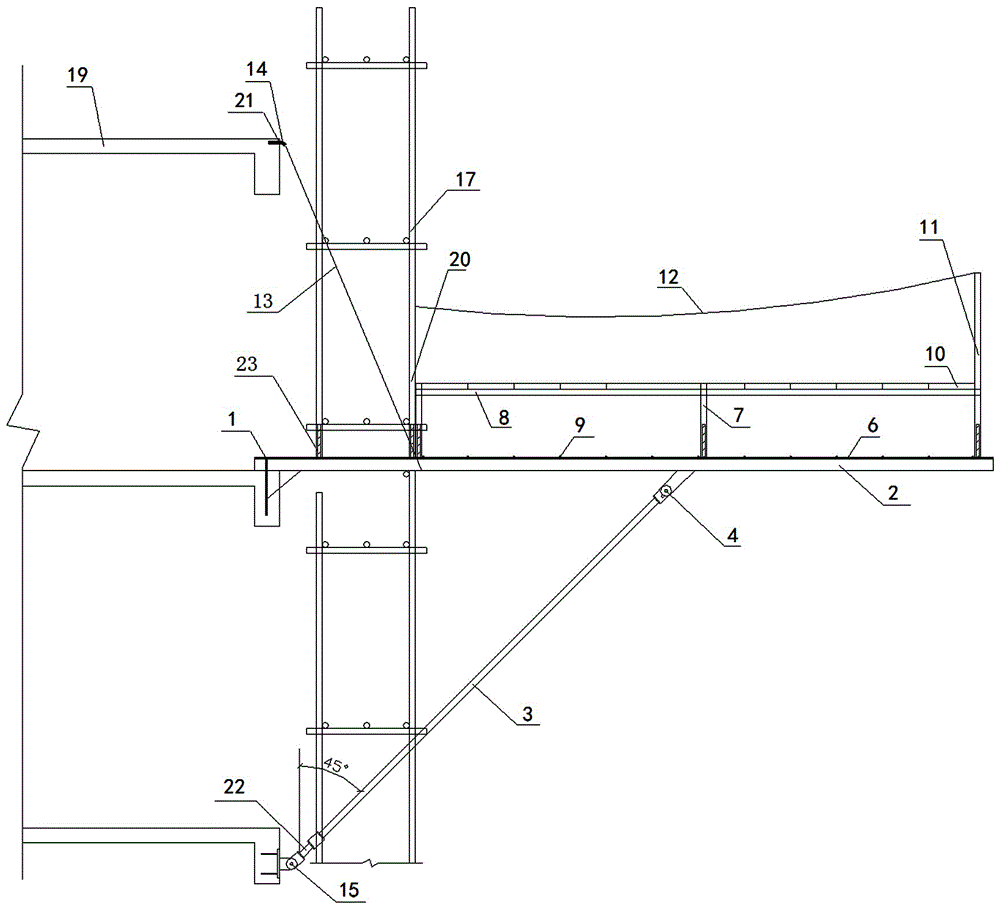

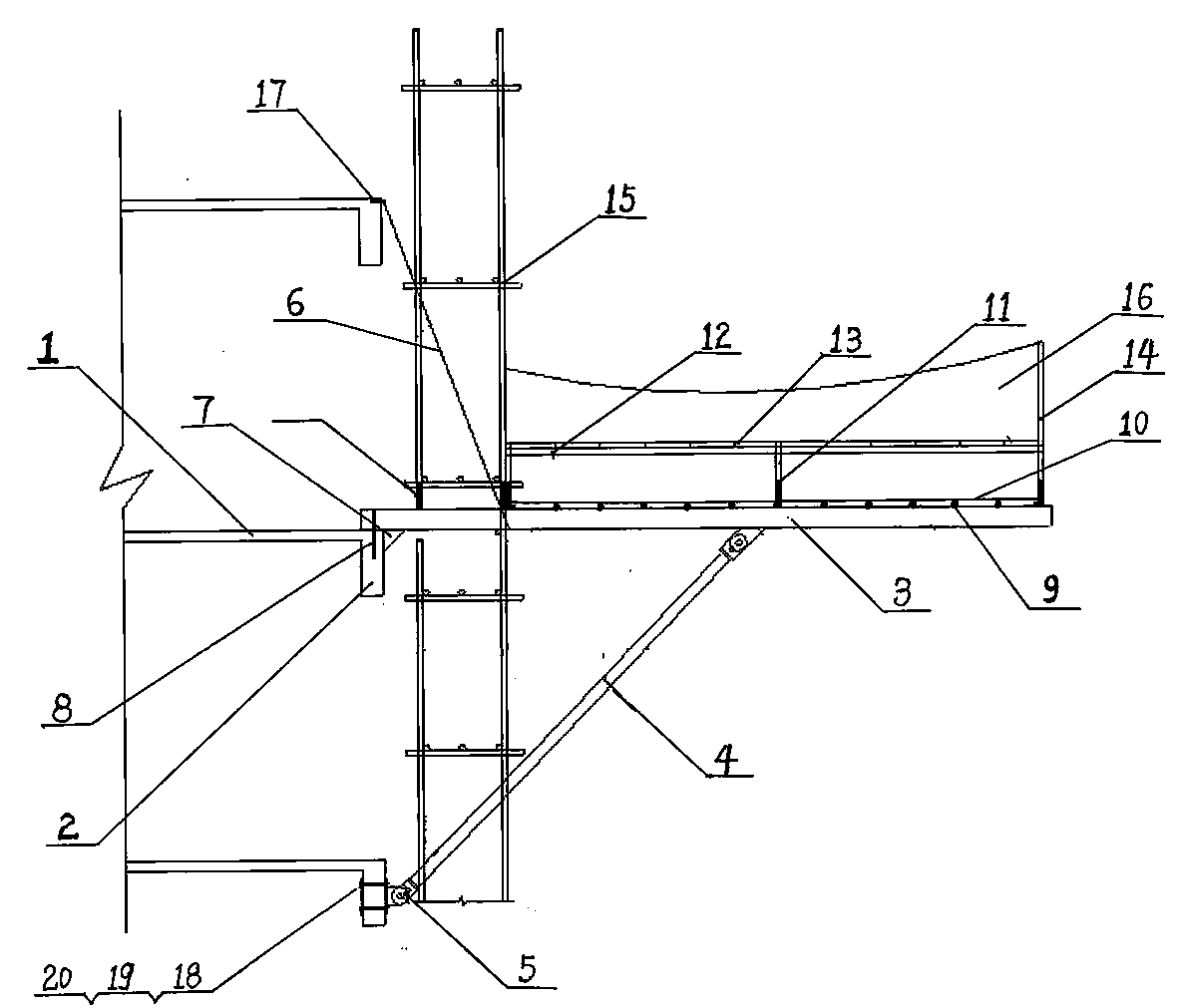

Method for mounting overall steel protective shed cantilever frame

InactiveCN105672678AImprove bearing capacityHigh impact strengthBuilding material handlingRebarSteel plates

The invention discloses a method for installing a pick frame for an integral steel protective shed, which comprises the following steps: using a steel bar ring pre-buried on the outer beam of the main structure floor, and then using a temporary pick frame outside the lower floor to install and fix the I-beam, The beam is fixed to the edge of the cantilevered steel through a reinforcement ring, and then the channel steel is welded with a hydraulic adjustable support rod as a diagonal brace, and the assembled hinge components at both ends of the diagonal brace are connected and fixed; the I-beam on the ground is welded with a short The steel bar head is laid with steel plates on the adjacent I-beams. The surface of the steel plates is welded with multiple steel bars to form reinforcing ribs. The outer scaffolding poles are inserted on the short steel bar heads to form the outer protective frame of the building. Horizontal long steel pipes and vertical short steel pipes are erected to form For the protective shed, the vertical short steel pipes are inserted on the short steel bars, the horizontal long steel pipes are covered with bamboo scaffolding boards, and the protective railings are set outside the protective shed. It is safe, economical and fast to use the tower crane to hoist the prepared double-layer protective shed into place. It does not need the ground and solid foundation as support. The supporting capacity of the cantilevered steel beam is greatly improved by the secondary cable-stayed unloading of the high-strength steel wire rope.

Owner:JIANGSU NANTONG SANJIAN CONSTRUCTION GROUP CO LTD

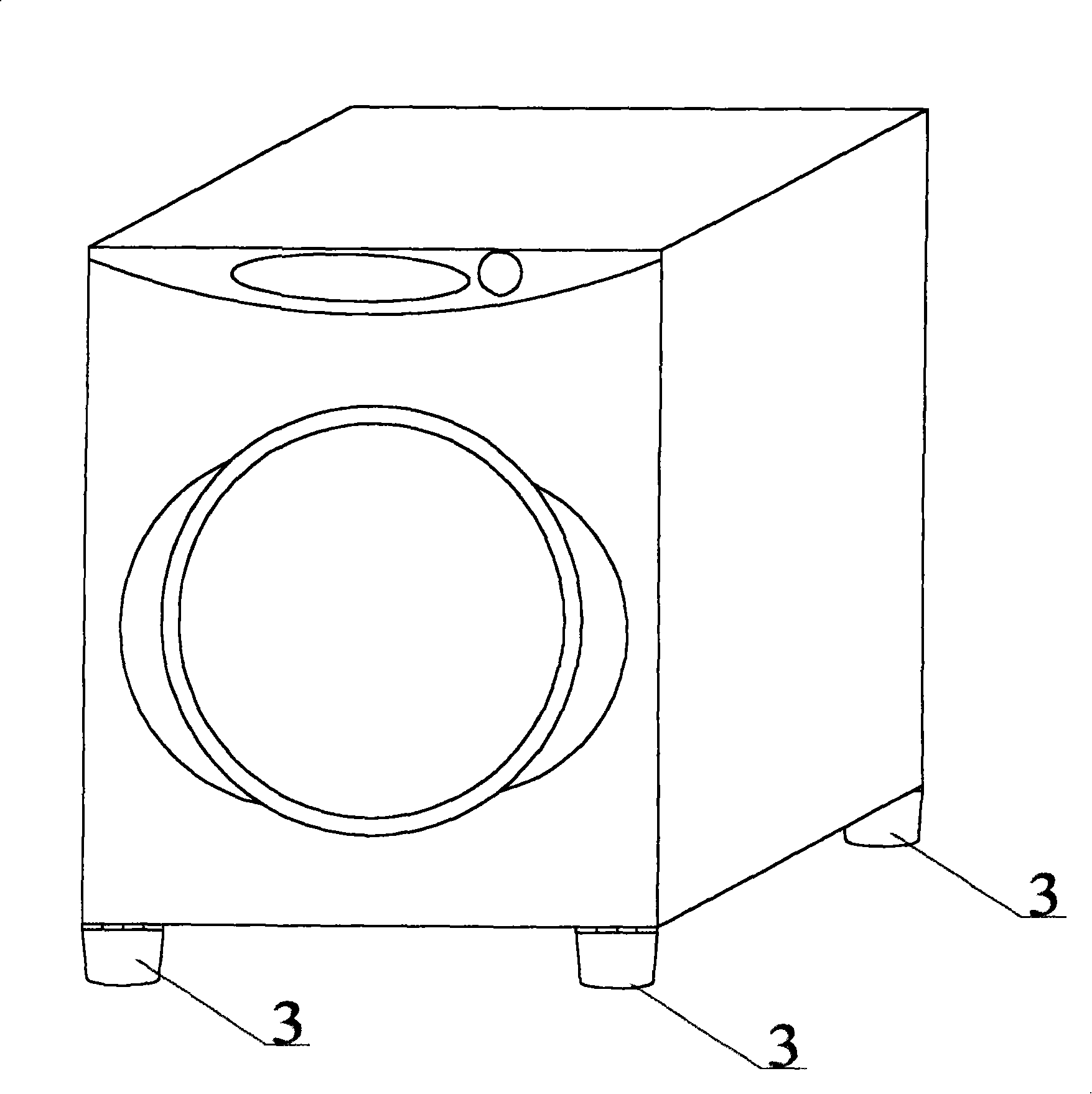

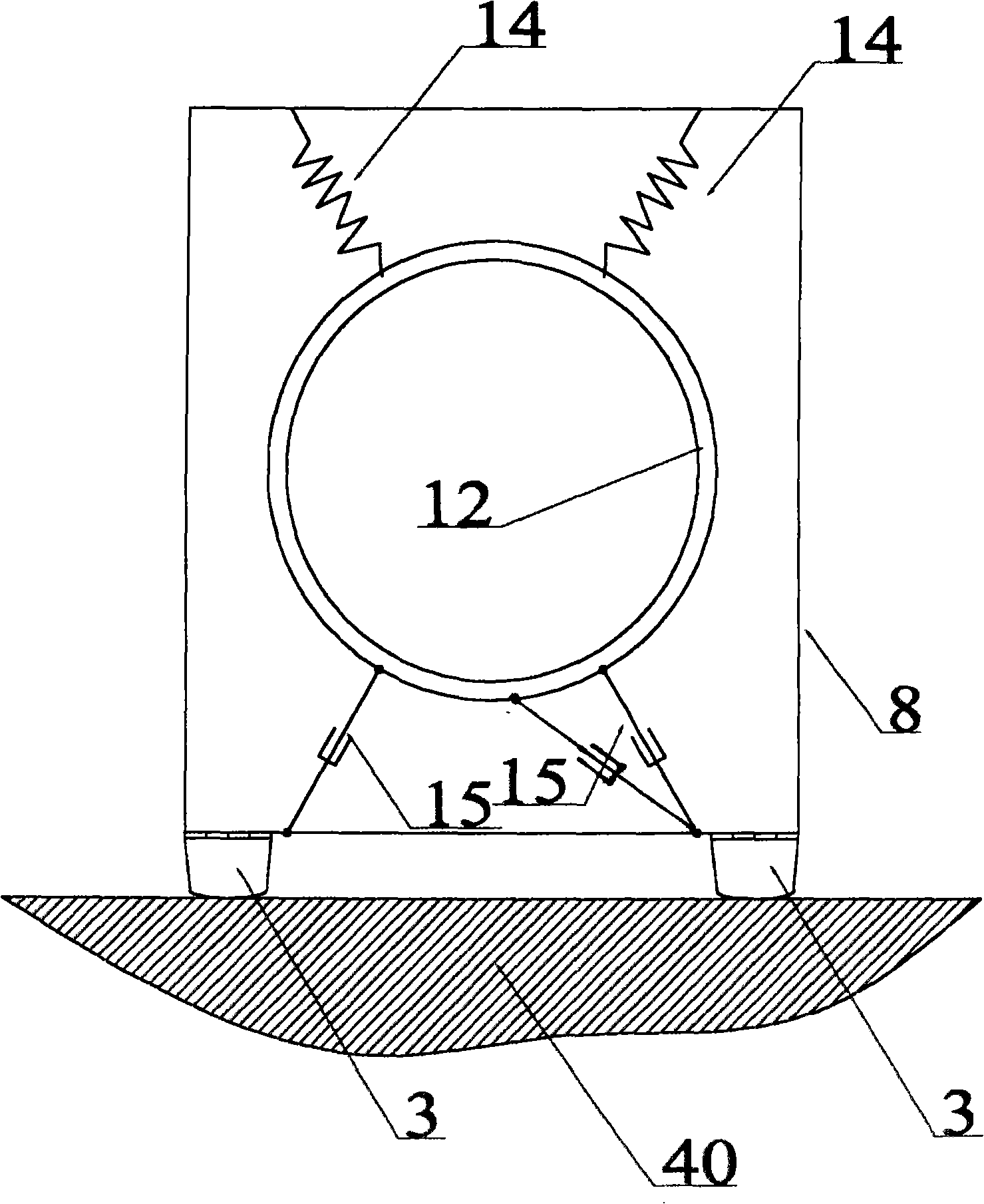

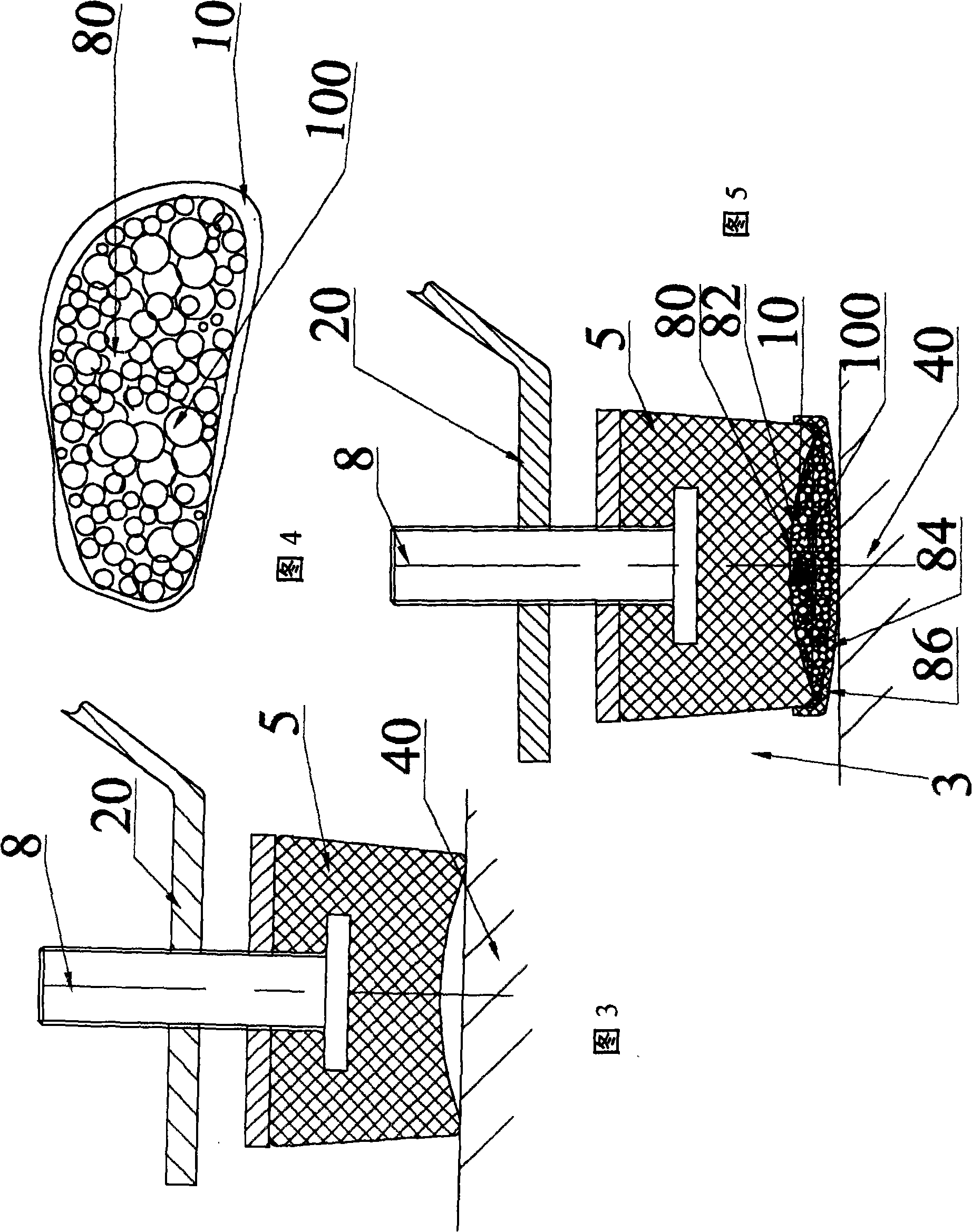

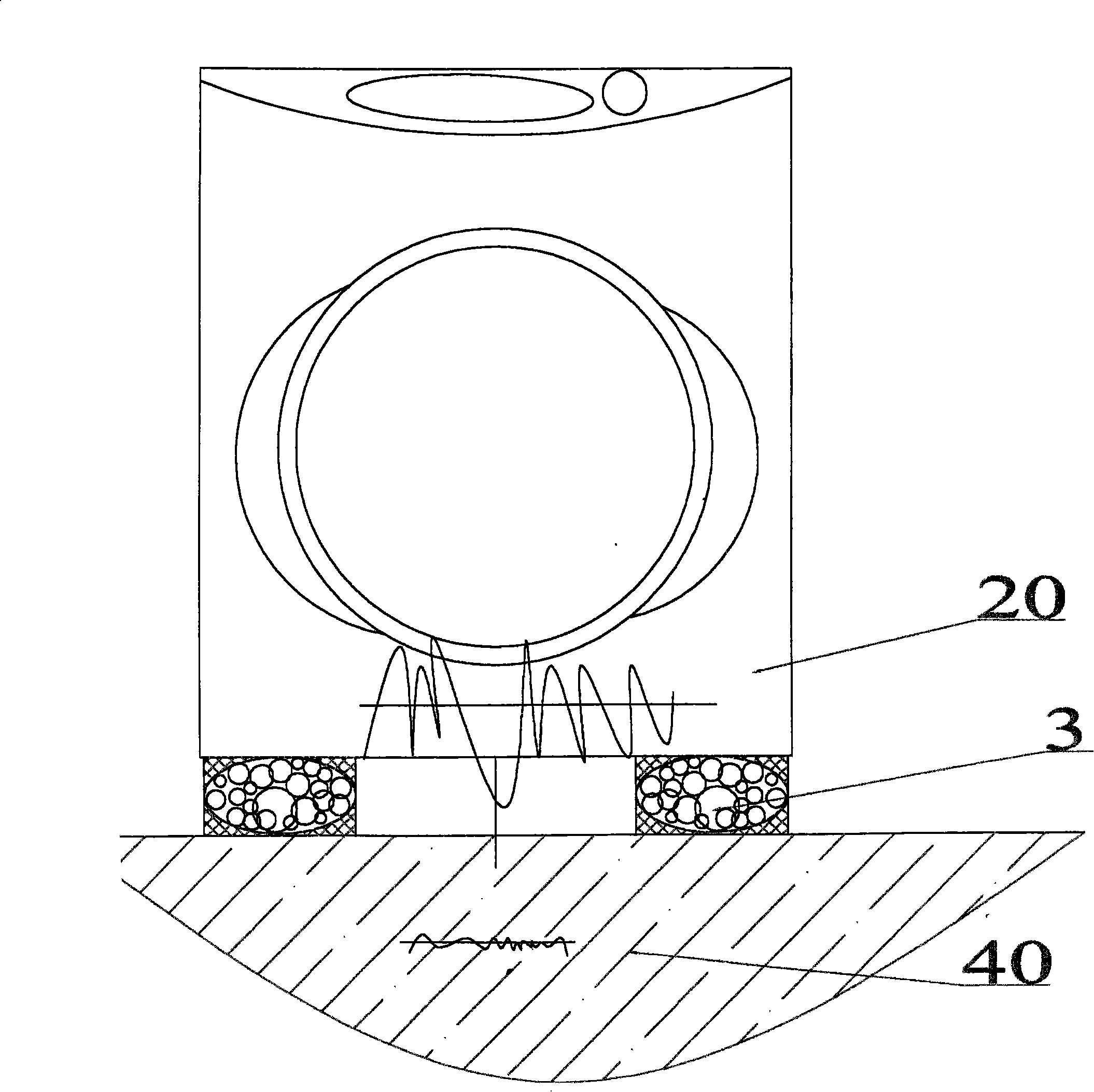

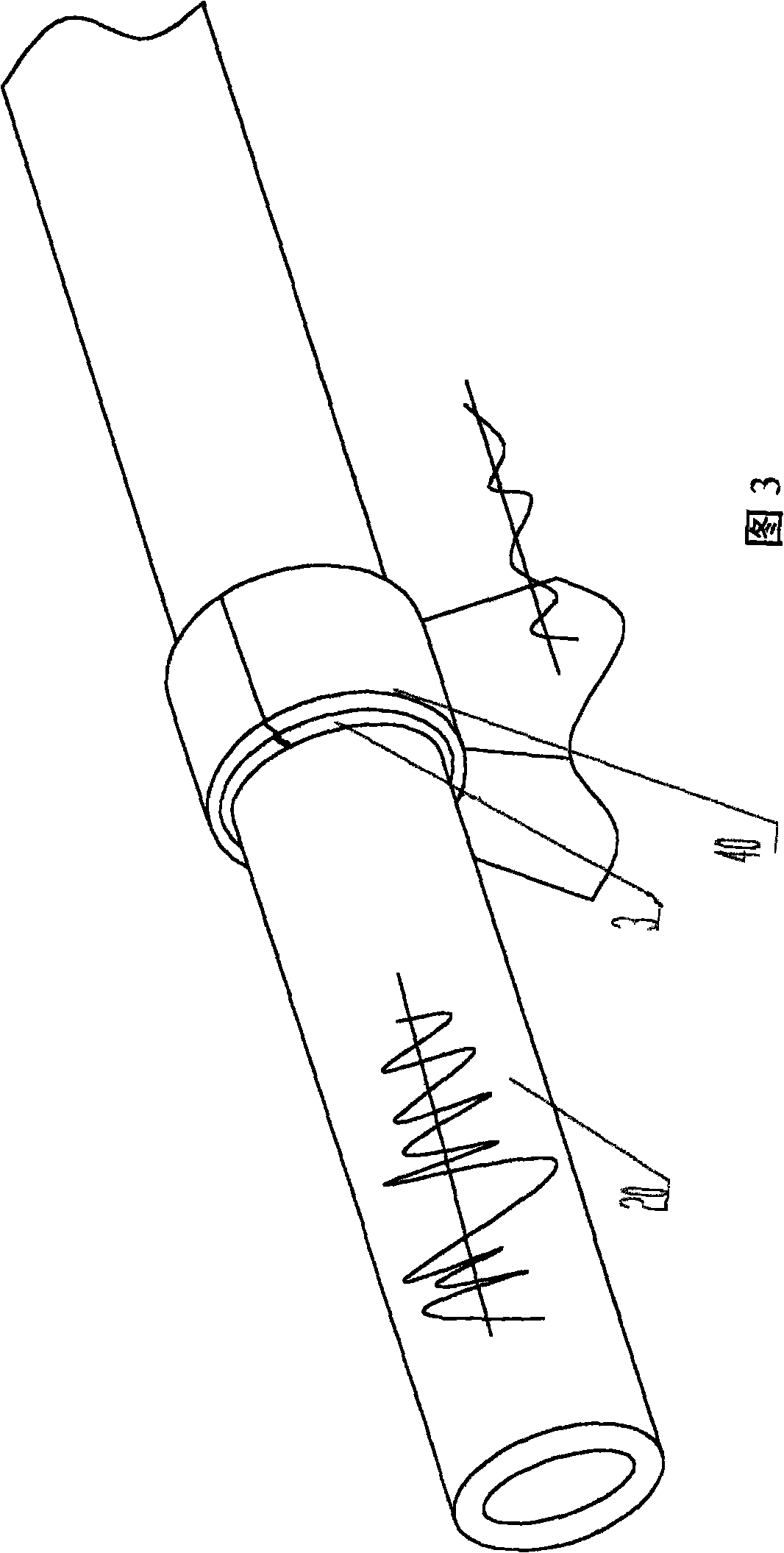

Barrel roll laundry machine wide band elastic granule damper

InactiveCN101302703AReduce jumpingReduce wanderingOther washing machinesTextiles and paperElastic vibrationBroadband

The invention relates to a broadband elastic particle damper of a rolling laundry machine, the elastic particle damper 3 is formed by combining an elastic vibration isolator 5 with a particle damper 10; the elastic particle damper 3 can be positioned between a case 8 of the rolling laundry machine and a supporting ground 40, or between an oscillating damper 15 and the case 8 of the rolling laundry machine or a tumbling cylinder 12, or can be simultaneously positioned between the case 8 of the rolling laundry machine and the supporting ground 40 as well as between the oscillating damper 15 and the case 8 of the rolling laundry machine or the tumbling cylinder 12; the particle damper 10 comprises a sealed cavity 80 and particles 100 that are padded in the cavity, and is mainly used for providing frictional damping for a vibrating system in a broadband range and inhibiting formants by utilizing the mutual frictional action between the particles.

Owner:吕崇耀

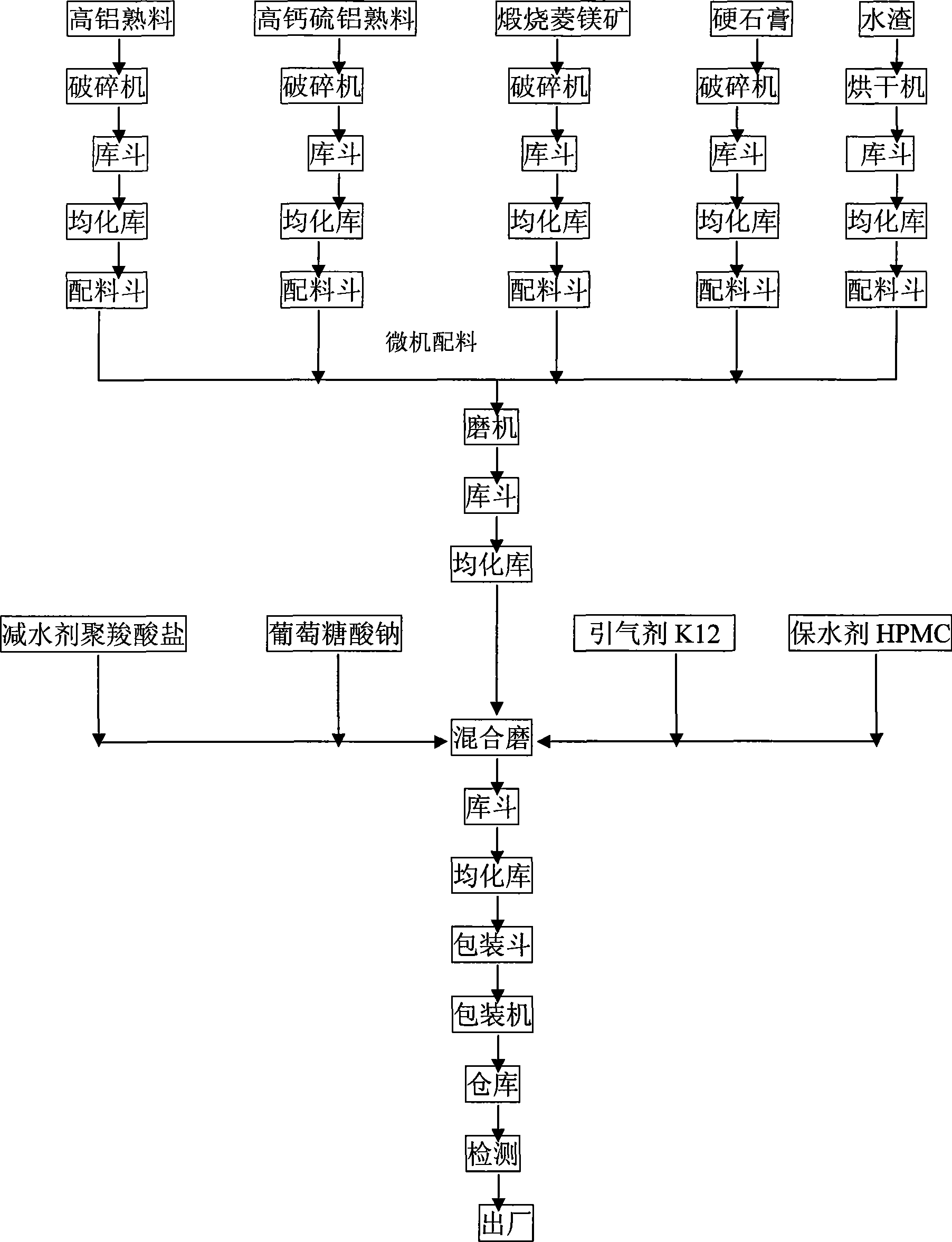

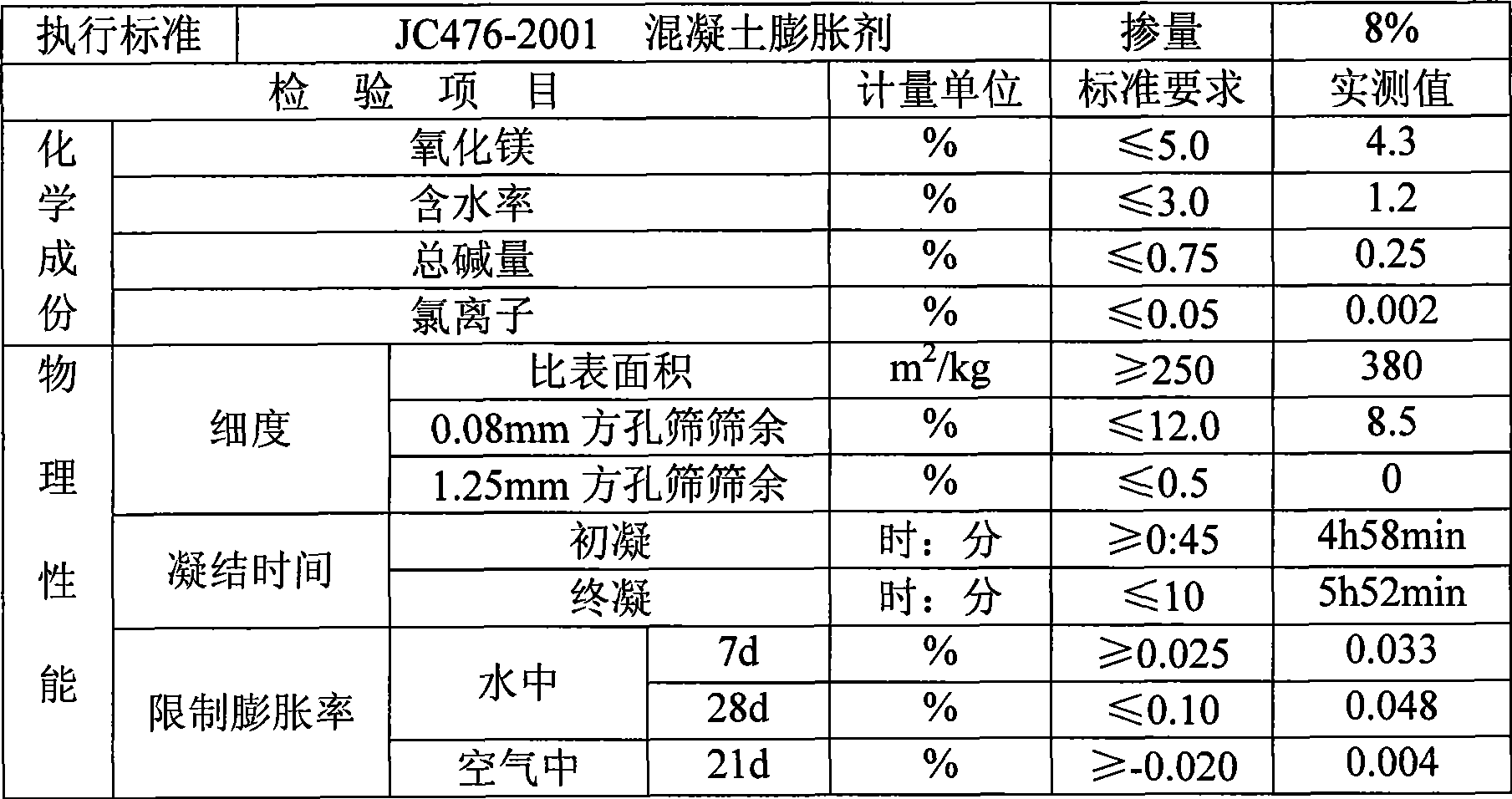

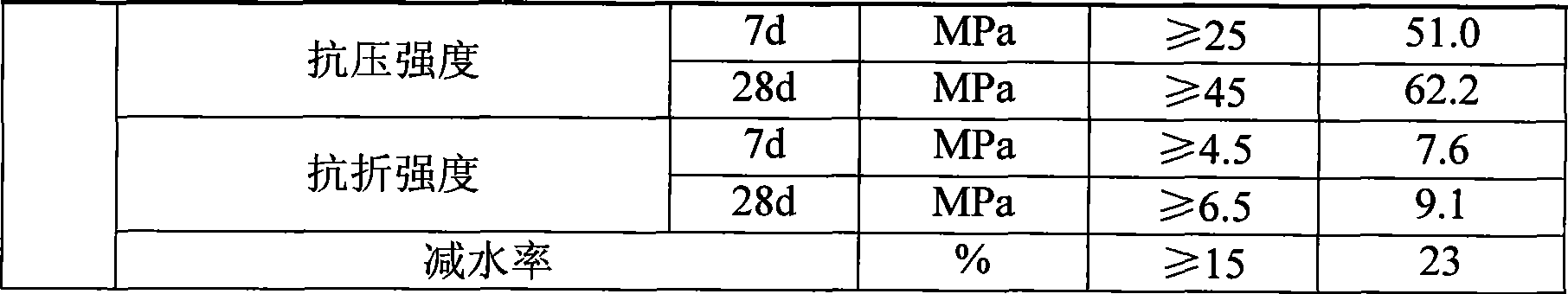

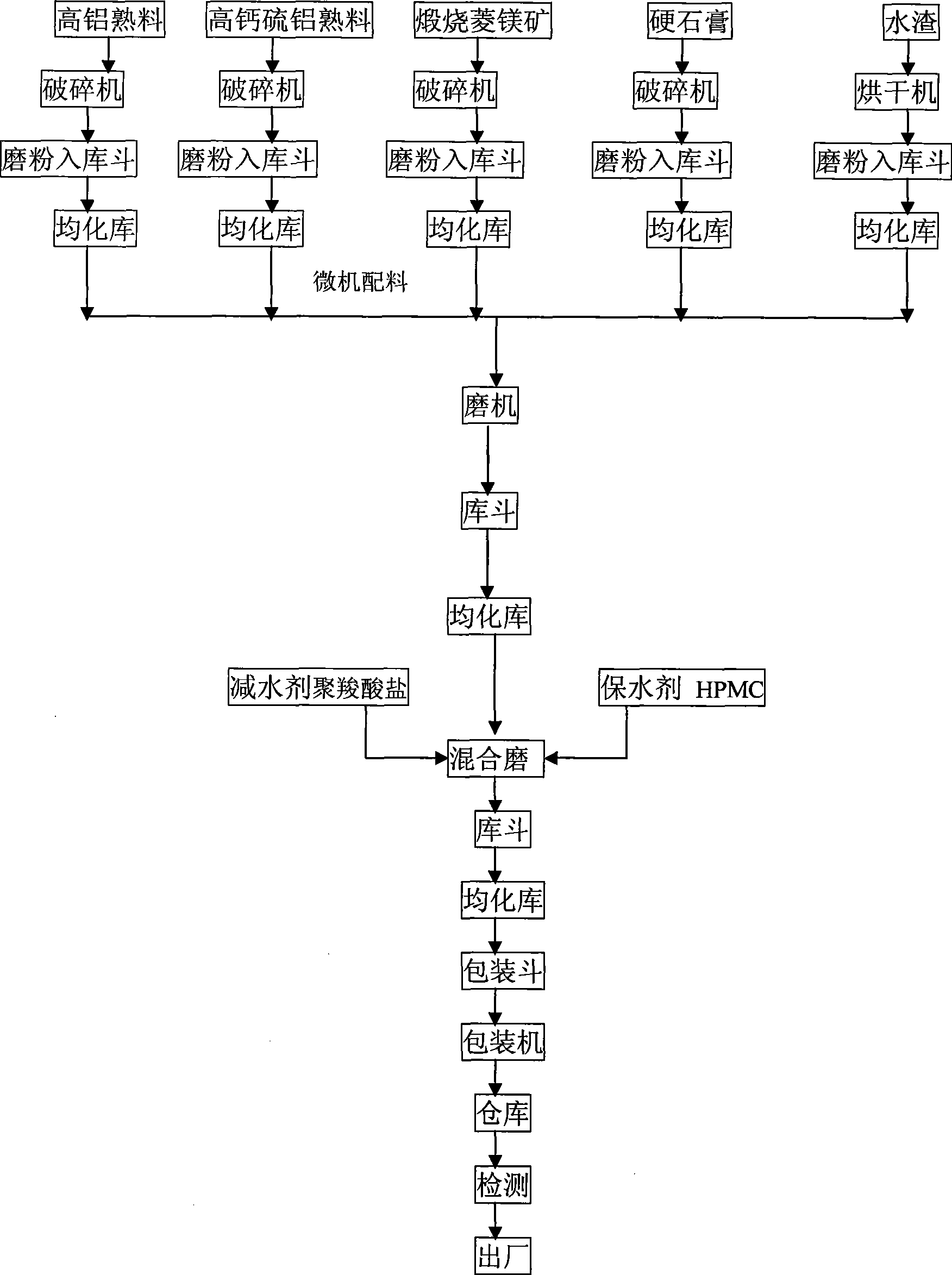

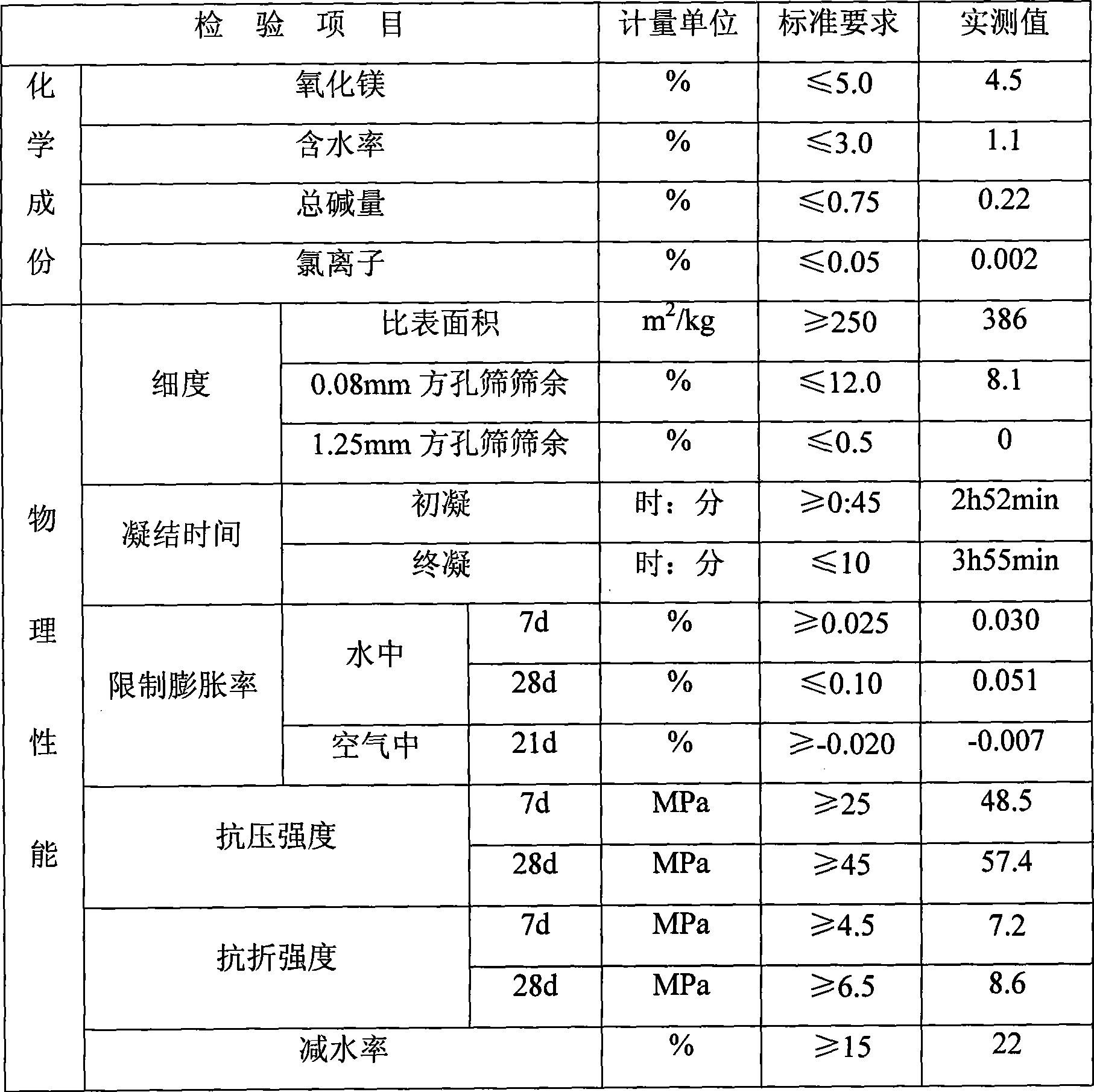

Retardation pumping type three-expansion source cement expansive material

The invention discloses a slow hardening pump deliver type three expansion source concrete expansion agent, which is characterized by comprising preparation of raw materials such as anhydrite, high alumina chamotte, high-calcium sulphoaluminate chamotte, calcined magnesite and so on by weight portion and externally doped slushing agent, water retention agent, air entraining agent and retardant. The preparation method of the expansion agent comprises steps of crushing, common mixture, mixing and grinding and external doping mixture and finish product forming. The product has low alkali content, excellent expansion performance, strong suitability with concrete, balanced mechanical property after hardening, and small gradual slump loss of concrete shrinkage compensation, contributes to improving safety and durability of reinforced concrete, obviously improves the cracking resistance, volume stability, impermeability and frost resistance, and is simple and convenient to use and easy to control quality in construction. The slow hardening pump deliver type three expansion source concrete expansion agent can meet construction use requirements of commercial concrete, long distance pump-delivering concrete and mass concrete.

Owner:广西云燕特种水泥建材有限公司

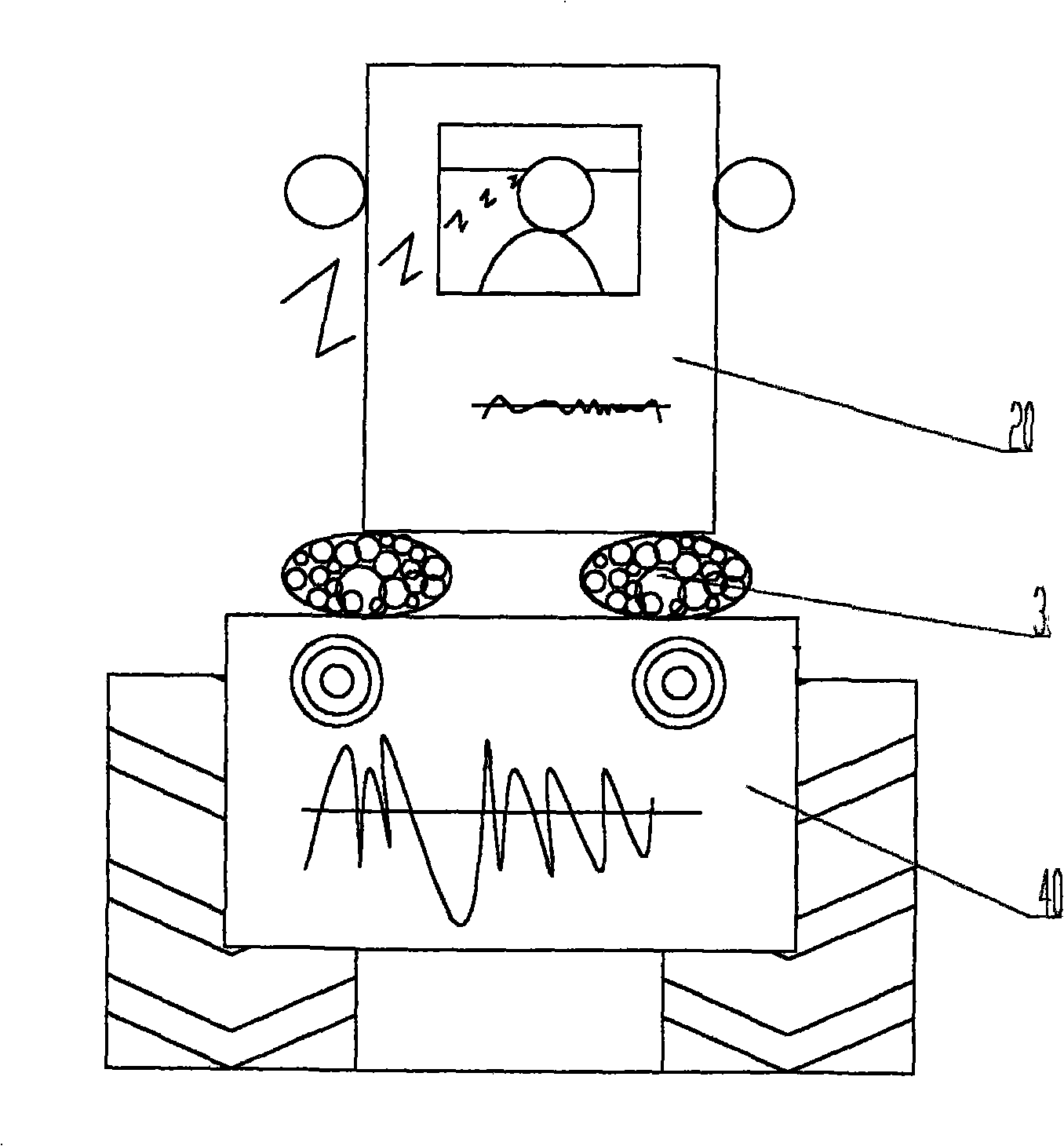

Broad band damp type vibrating isolation system

InactiveCN101303058ASmall sizeIncrease dampingNon-rotating vibration suppressionElastic vibrationEngineering

The invention relates to a broadband damping type vibration isolation system which is formed by connection and composition of an elastic vibration isolator and a particle damper; the particle damper can either be positioned inside the elastic vibration isolator or be positioned between supports or between controlled objects. The broadband damping type vibration isolation system is arranged between the supports and the controlled objects; in the particles, the contact compressive stress caused by the gravity of the controlled objects or imposing pretightening force between the support and the controlled objects, or in this foundation, imposing an electric field or a magnetic field on the particles inside the particle dampers of the broadband damping type vibration isolation system, can cause relative friction movements that occur between the particles at a close contact state in the particle dampers of the broadband damping type vibration isolation system when the controlled objects vibrate corresponding to the support, thereby consuming the vibration energy of the controlled objects within 0.1 to 5000Hz broadband scope and at least at a freedom direction, and resulting in that the controlled objects do not slide or move for vibration.

Owner:吕崇耀

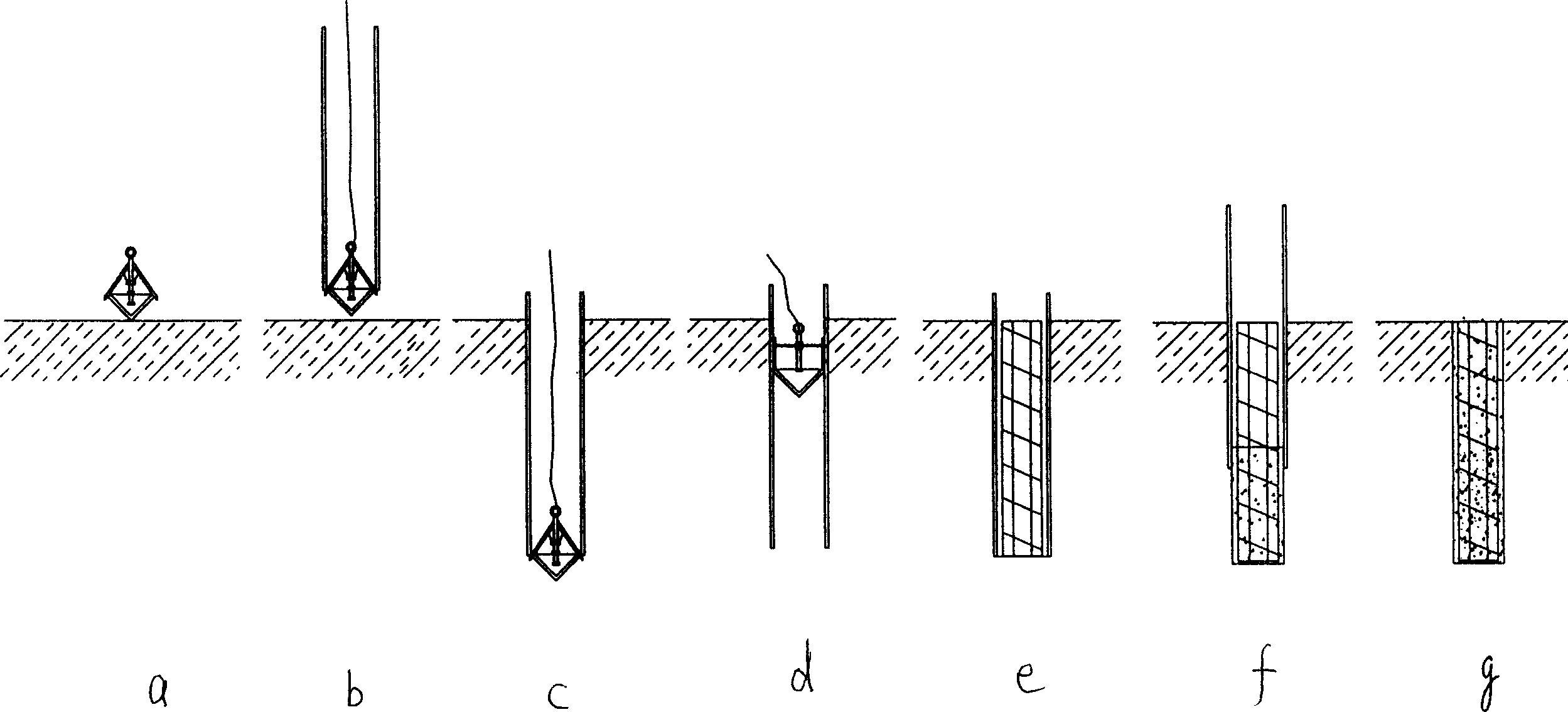

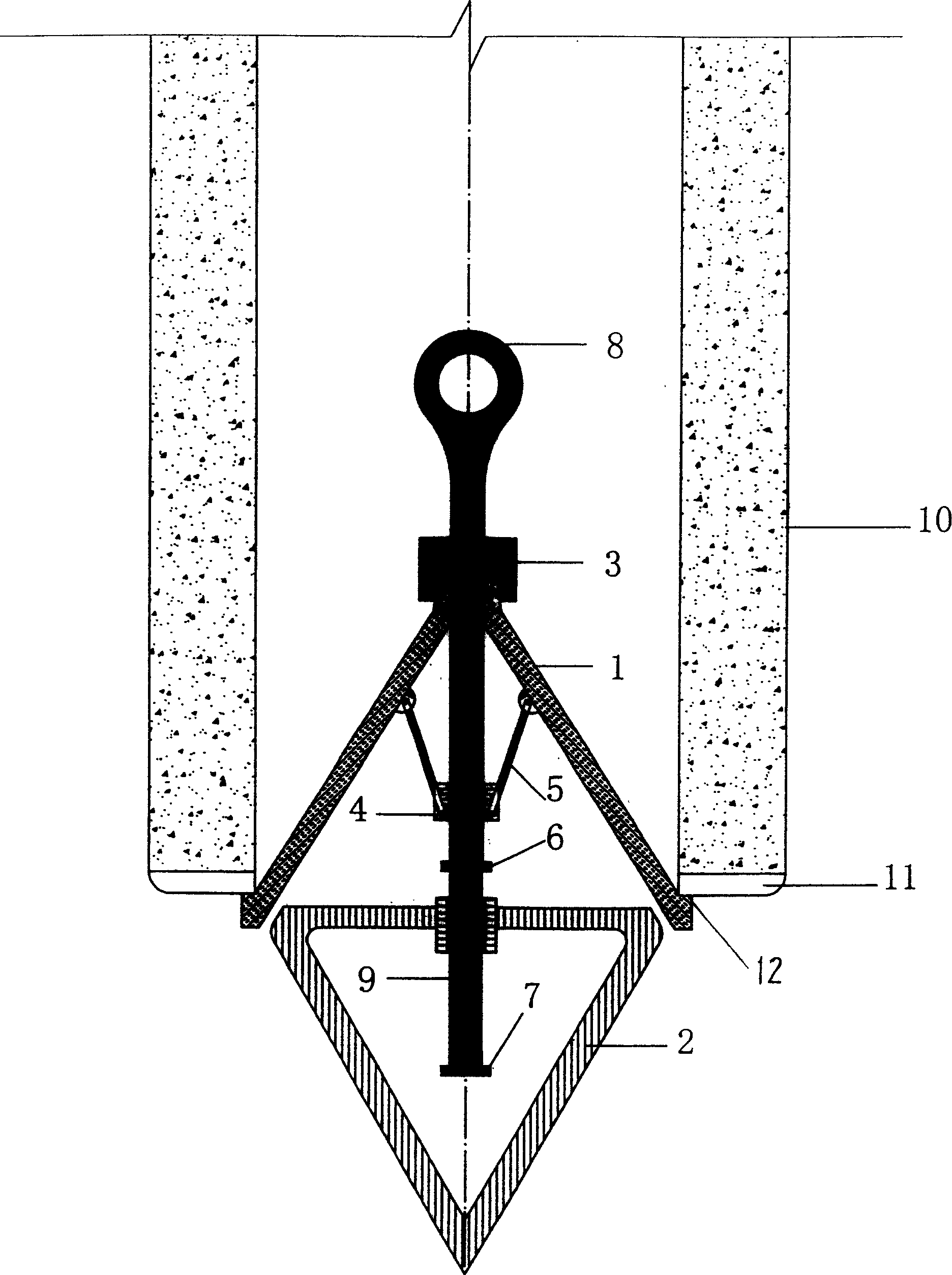

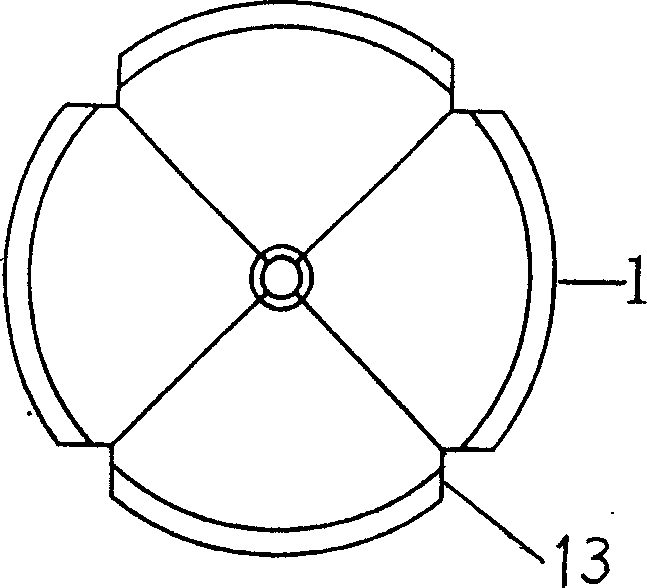

Immersed tube grout pile construction process and pile tip bearing capacity reinforcement equipment

The invention is a sinking tube pouring picket constructing technique and picket-end bearing capacity enhancer, placing the enhancer at positioning point of the picket base; the picket machine takes its place to align the end of the steel sleeve with the enhancer; starting sinking the tube to the calculated position; pulling the rope linked with the enhancer to drive axial umbrella rod, so that the top cap relieves the inclined support from restriction, the fixed stop block drives the annular slide block to make the supporting link rod push and spread the inclined support around so as to shrink into the steel sleeve, and the active stop block drives the picket boot to take out the enhancer. Placing bar reinforcement cage in the steel sleeve; vibrantly pulling the tube while pouring the concrete, and forming a picket. It can enhance the penetrating property of the steel sleeve, extrude picket end soil body closely, heighten picket-end bearing capacity, reduce deposition quantity, heighten picket forming quality and constructing efficiency, etc.

Owner:北京中技天昊工程技术有限公司

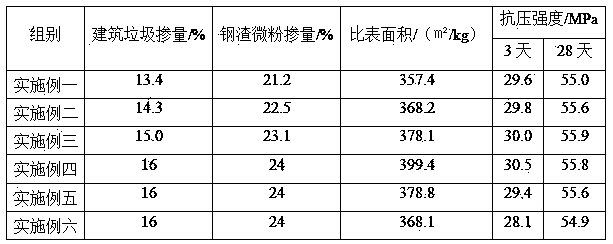

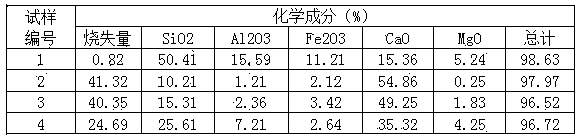

Method for producing green ecological cement resistant to seawater corrosion by using construction wastes

The invention discloses a method for producing green ecological cement resistant to seawater corrosion by using construction wastes. The cement comprises the following raw materials in parts by weight: 40-50 parts of sulphoaluminate cement clinkers, 5-20 parts of construction wastes, 20-25 parts of steel slag powder, 0.06-0.08 part of compound activating agent, 2-5 parts of early strength agent, 0.3-0.5 part of water reducing agent, 0.005-0.007 part of air entraining agent and 0.3-0.5 part of retarder. The production method is characterized by breaking, grinding and homogenizing the construction wastes, the sulphoaluminate cement clinkers, the compound activating agent and the early strength agent respectively, preparing the materials in proportion, mixing the materials, homogenizing the mixture, then adding the water reducing agent, the air entraining agent and the retarder, mixing the materials and homogenizing the mixture, thus preparing the product. The green ecological cement resistant to seawater corrosion has the excellent characteristics of high strength, resistance to seawater corrosion and seawater scouring, and the like besides the properties of ordinary cement, and is especially suitable for underground engineering, ports, wharfs and other engineering suffering corrosion of erosion media.

Owner:广西云燕特种水泥建材有限公司

Method for producing seawater corrosion-resistant green ecological cement from stone waste

ActiveCN104291717AReduce stone dust pollutionWide variety of sourcesCement productionScrapCorrosion resistant

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from stone waste. The seawater corrosion-resistant green ecological cement comprises the following raw materials in parts by weight: 30-40 parts of stone waste, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of a complex activator, 2-4 parts of an early-strength agent, 0.3-0.5 part of a water-reducing agent, 0.005-0.007 part of an air entraining agent, and 0.3-0.5 part of a retarder; and the production method comprises the following steps: respectively crushing the stone waste, sulphate aluminum cement clinker, complex activator and early-strength agent, grinding, homogenizing, then mixing and homogenizing according to a proportion, then adding the water-reducing agent, air entraining agent and the retarder, mixing and homogenizing to obtain the seawater corrosion-resistant green ecological cement. The seawater corrosion-resistant green ecological cement has the excellent properties of being high-strength, seawater corrosion-resistant, seawater scouring-resistant and the like besides the performances of common cement, and is especially applicable to underground engineering, ports, wharfs and other engineering corroded by erosion media.

Owner:广西云燕特种水泥建材有限公司

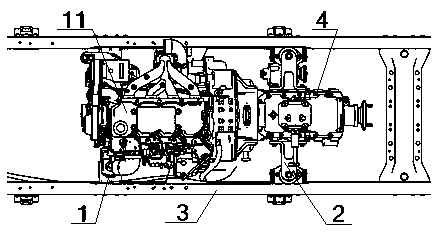

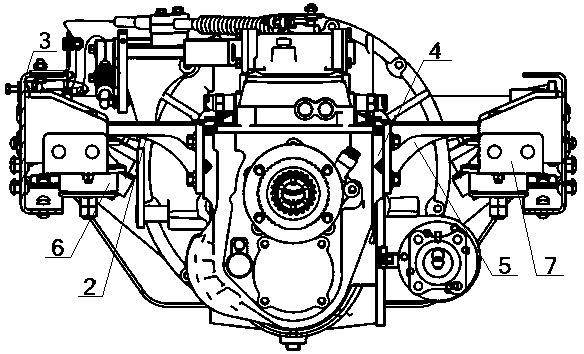

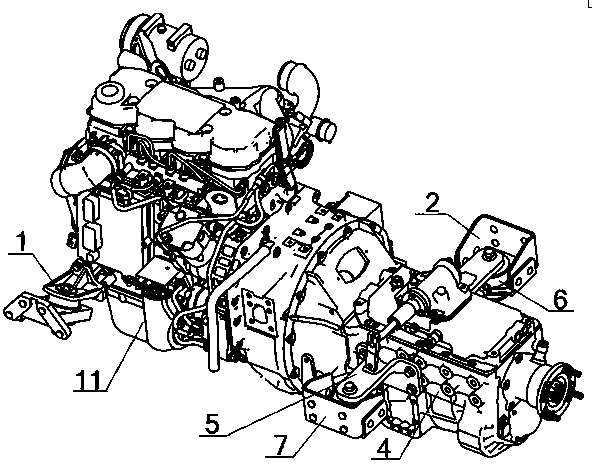

Four-point distribution power assembly suspension device

InactiveCN103802648AExtended service lifeImprove comfortJet propulsion mountingInternal combustion mountingVehicle frameVibration isolation

A four-point distribution power assembly suspension device comprises a front suspension device and a rear suspension device, wherein one end of the front suspension device is fixedly connected with an engine shell, the other end of the front suspension device is fixedly connected with a vehicle frame longitudinal beam, one end of the rear suspension device is fixedly connected with a side board of a gearbox shell, and the other end of the rear suspension device is fixedly connected with the vehicle frame longitudinal beam; one end of the rear suspension device is fixedly connected with the middle portion of the side board of the gearbox shell, and the other end of the rear suspension device is fixedly connected with the vehicle frame longitudinal beam; the rear suspension device comprises a suspension bracket, a suspension soft cushion assembly and a suspension bracket, the top of the suspension soft cushion assembly is fixedly connected with the middle portion of the side board of the gearbox shell through the suspension support, and the middle portion of the suspension soft cushion assembly is fixedly connected with the vehicle frame longitudinal beam through the suspension bracket. According to the design, the span distance between the front suspension device and the rear suspension device is increased, vibration isolation performance of a power suspension system is enhanced, whole-vehicle comfort is enhanced, the rear suspension device is not provided with a transverse beam, original assembly space of a vehicle model is not changed, and a suitable range is wide.

Owner:DONGFENG COMML VEHICLE CO LTD

Assembly-type section steel cantilever protective shed

ActiveCN103993728AImprove bearing capacityHigh impact strengthBuilding material handlingScaffold accessoriesSheet steelArchitectural engineering

The invention relates to an assembly-type section steel cantilever protective shed which comprises a base and a shed body. The base and a building floor are arranged in parallel, one end of the base is supported on a main structure beam of any building floor, the other end of the base stretches out of the building floor, the base comprises two or more I-shaped steel main beams, a plurality of reinforcing steel bar cross beams are perpendicularly connected between the two I-shaped steel main beams, and a steel plate is laid on the reinforcing steel bar cross beams. A plurality of supporting steel pipes are perpendicularly welded onto the I-shaped steel main beams at intervals, a main steel pipe is welded onto the supporting steel pipes in a supported mode, and a scaffold board is laid on two main steel pipes which are supported on the two I-shaped steel main beams respectively. The shed body comprises a shed body framework and a protective net. The shed body framework comprises a scaffold and framework steel pipes, wherein the scaffold is supported at the near ends of the I-shaped steel main beams and the near end of the building floor, and the framework steel pipes are perpendicularly welded to the far end of the building floor. The protective net is arranged between the scaffold and the framework steel pipes and arranged between every two framework steel pipes in an expanded mode.

Owner:TAIXING FIRST CONSTR INSTALLATION

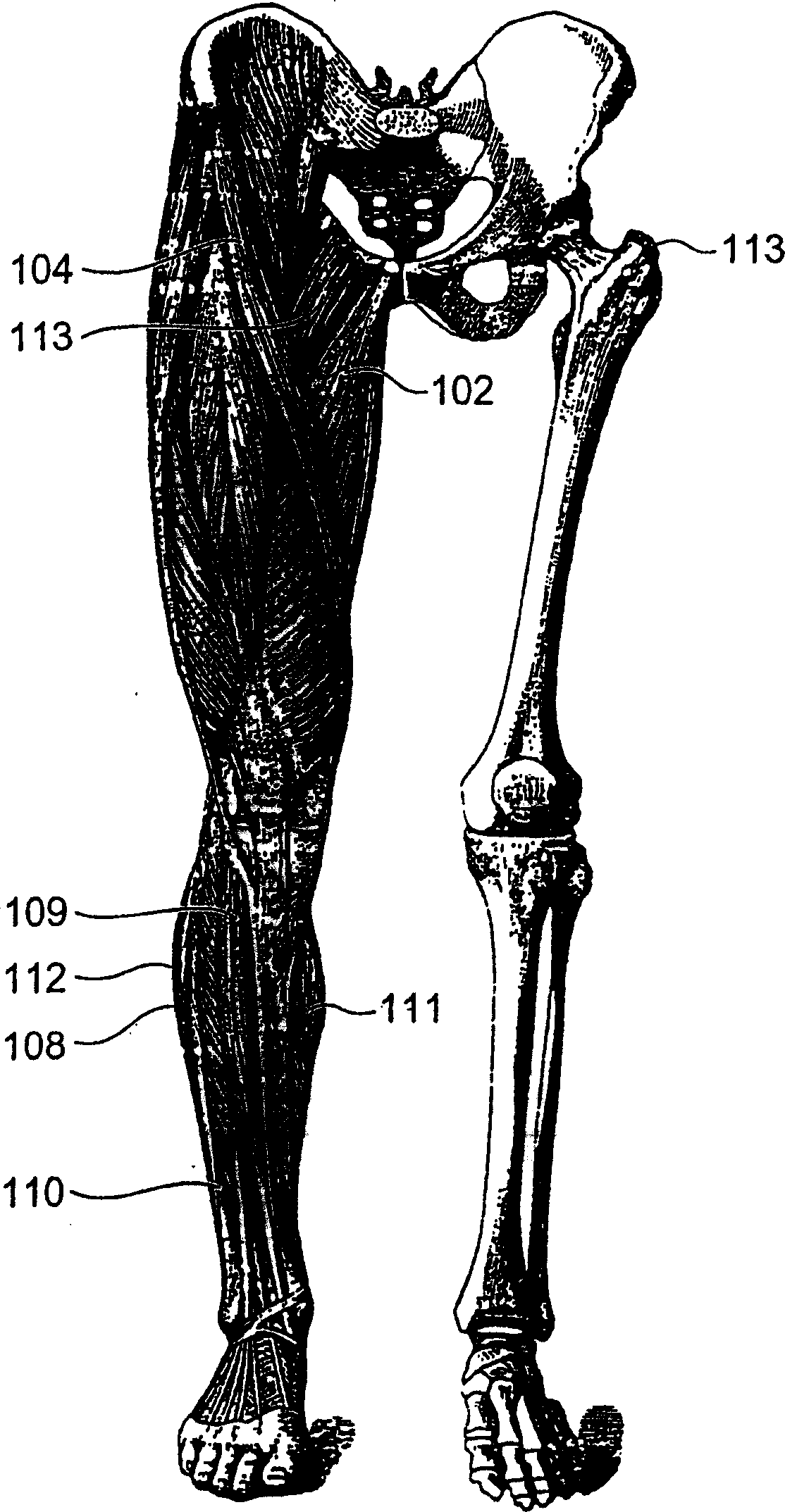

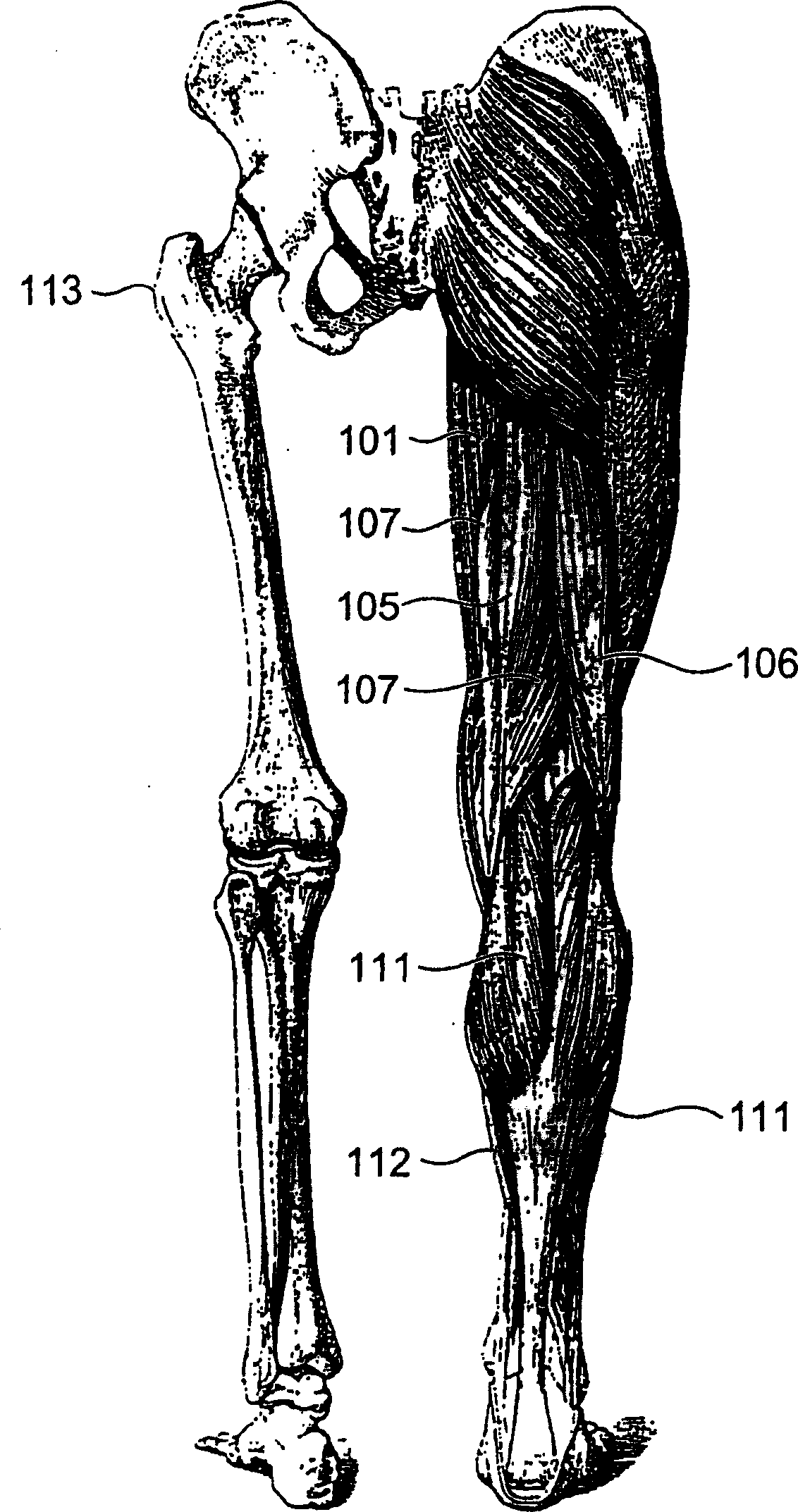

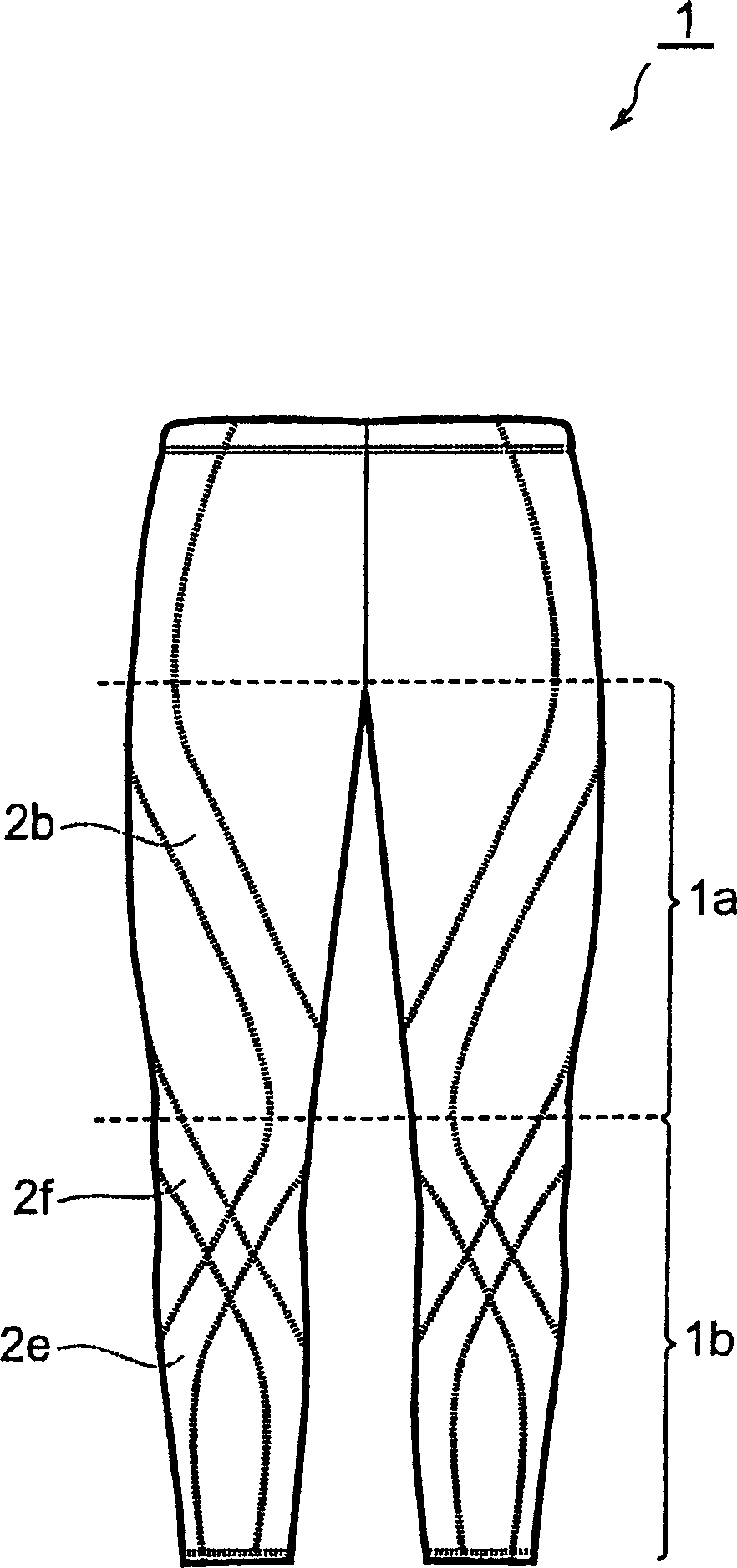

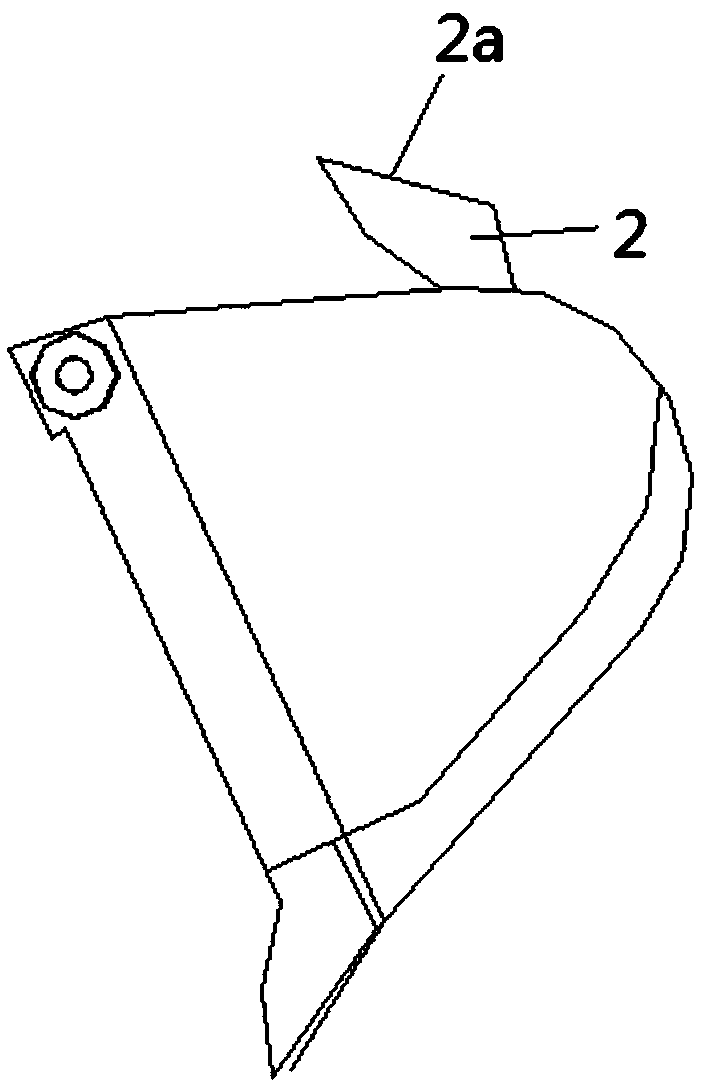

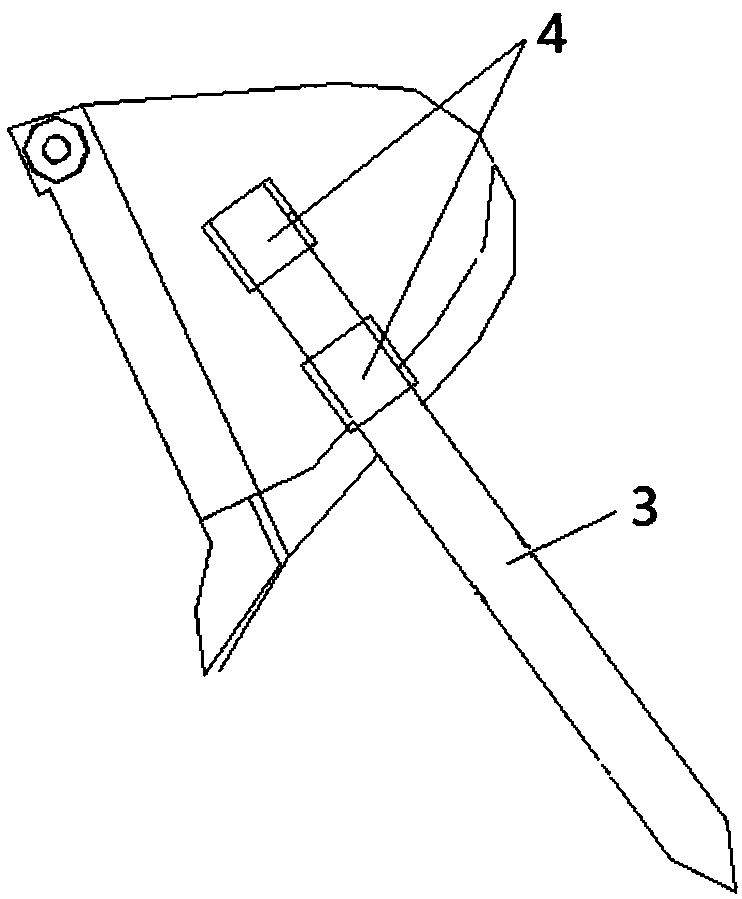

Wearing article with crotch

The tightening part formed in a belt shape has: a thigh front tightening part (2b), which is in the front part (1a) corresponding to the front side of the thigh, from the front part (1a) formed obliquely from above to below; the thigh rear side tightening portion is formed obliquely from above to below the rear side portion in a rear side portion corresponding to the rear side of the thigh; and the calf The front side tightening parts (2e, 2f) are formed obliquely from above to below in the front part (1b) corresponding to the front side of the lower leg. Thereby, the thigh is supported from front to back by the thigh front tightening part (2b) and the thigh rear tightening part.

Owner:WACOAL

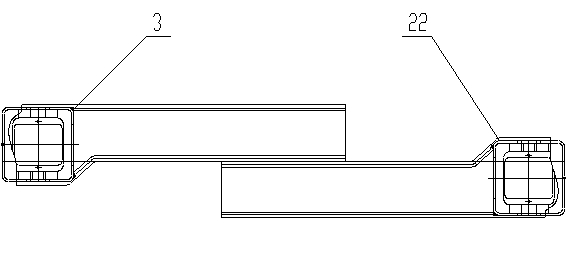

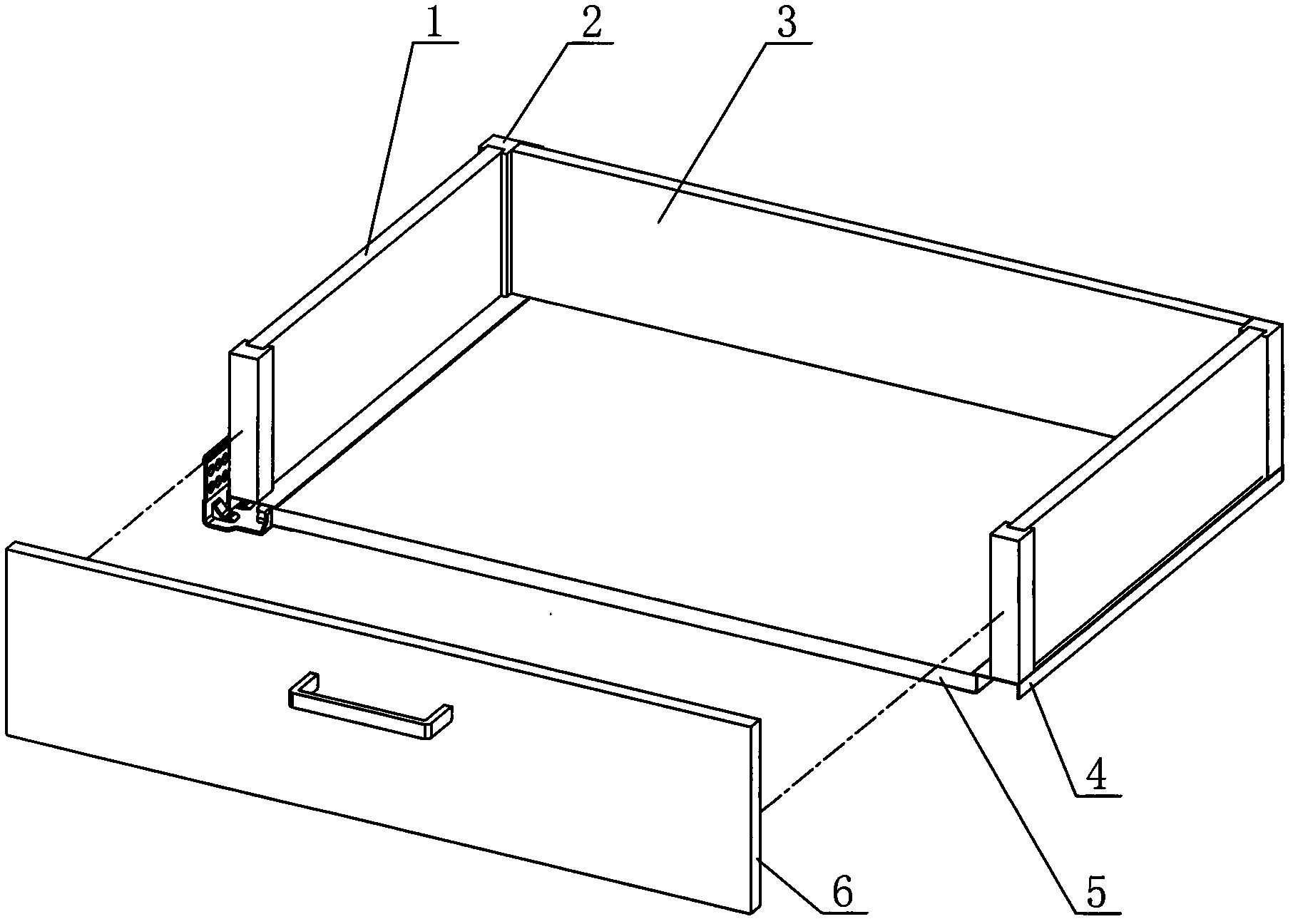

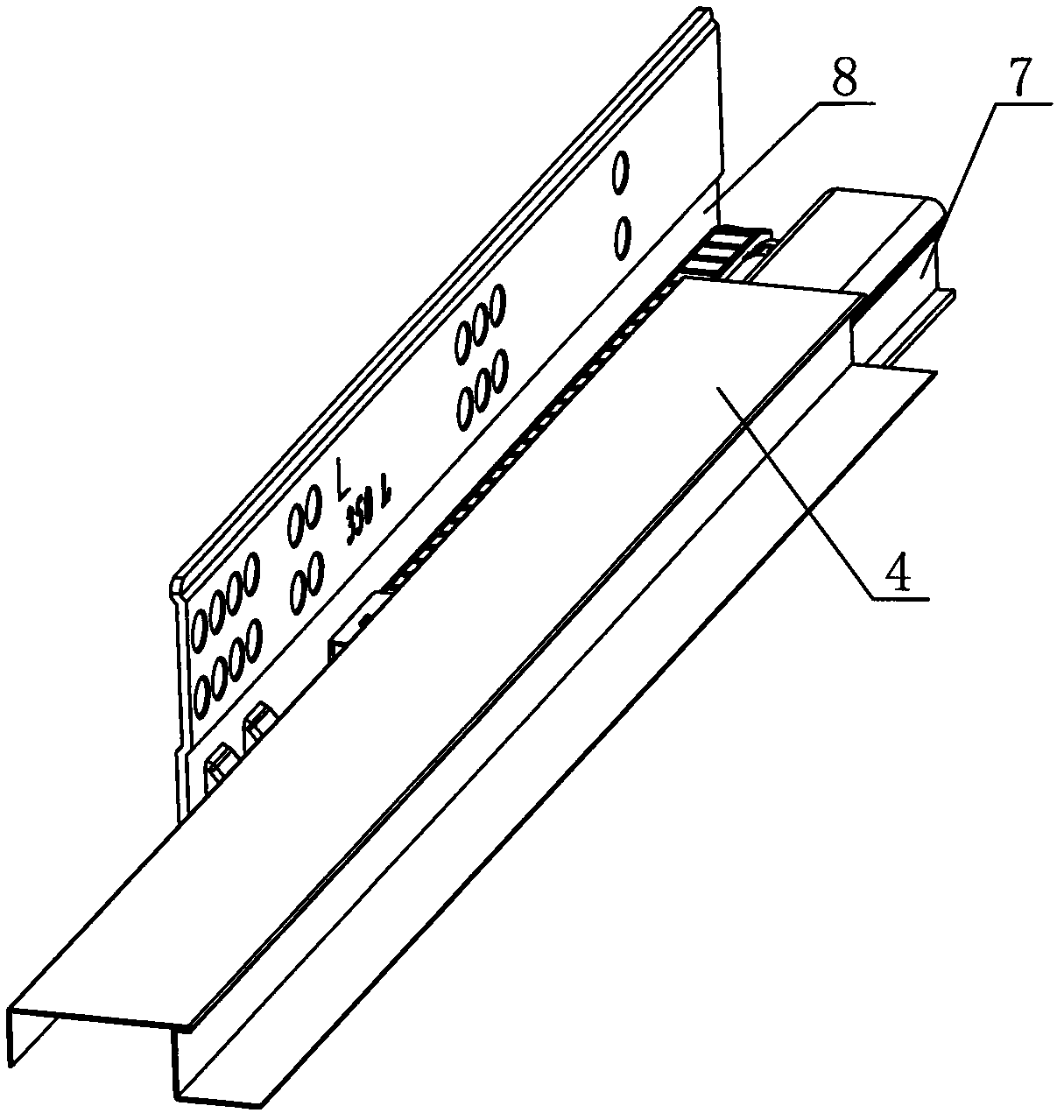

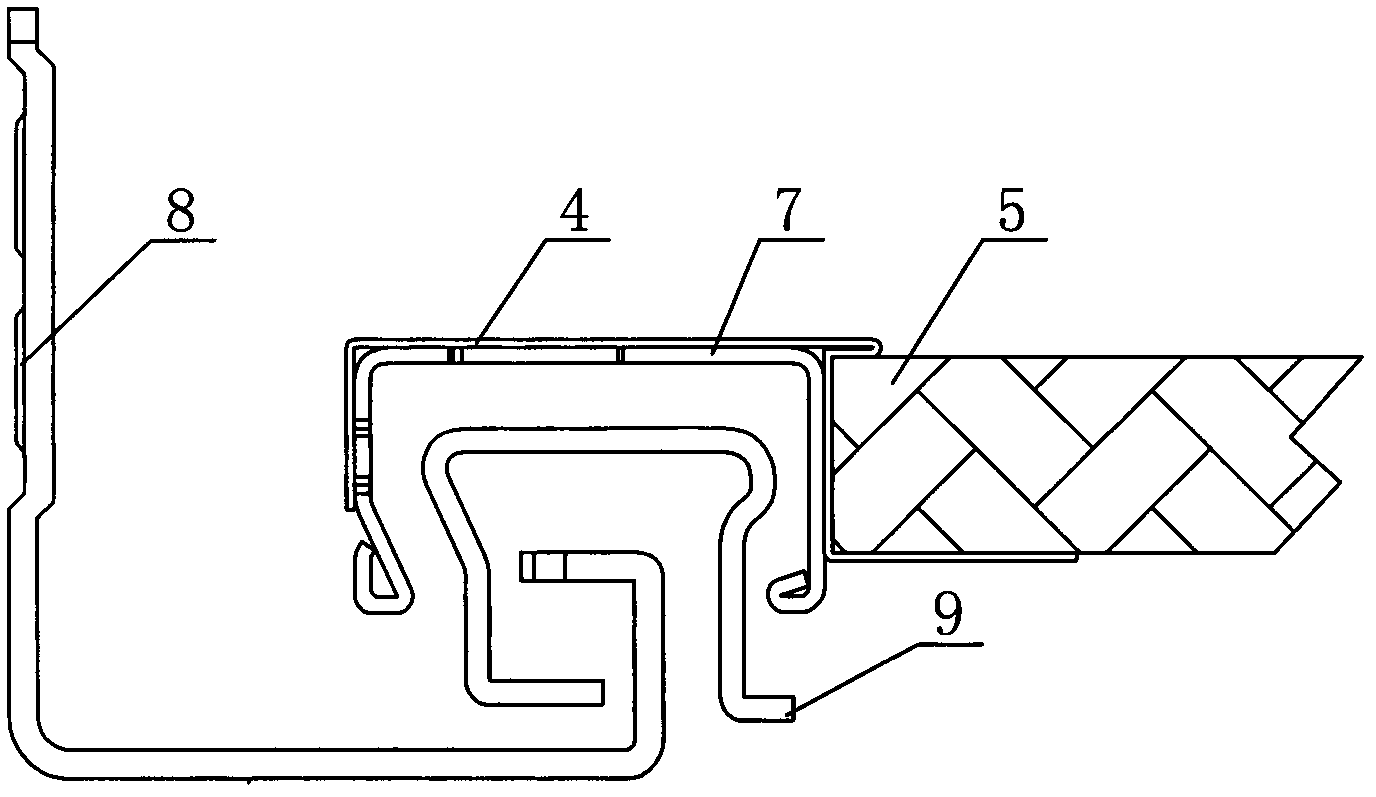

Drawer slide rail for furniture

The invention discloses a drawer slide rail for furniture. The drawer slide rail for the furniture comprises a slide rail component which is arranged on a drawer main body and is formed by assembling at least one movable slide rail and a fixed slide rail, wherein the fixed slide rail is fixedly matched with the inner wall of a cabinet body; the movable slide rail is provided with a detachable supporting rail; one end of the supporting rail is connected with side plates of the drawer main body through a connecting piece, and the other end of the supporting rail is provided with a fixation part corresponding to the bottom plate; and the fixation part and the supporting rail are integrally arranged. The supporting rail in the drawer slide rail is detachably connected with the movable slide rail, is fixed on the movable slide rail in a clamping or buckling way, and is provided with the fixation part and a bearing strip which form a trench for accommodating the bottom plate together; and the bottom plate is fixed on one side of the movable slide rail, so that close connection between the left side plate and the right side plate as well as the bottom plate is guaranteed, and the bearing capacity of the drawer main body is improved; the drawer slide rail for the furniture has the characteristics of simple and rational structure, low cost, capability of saving processing time and assembly time and convenience in processing production; and the attractive appearance and the practicability of a product are improved.

Owner:伍志勇

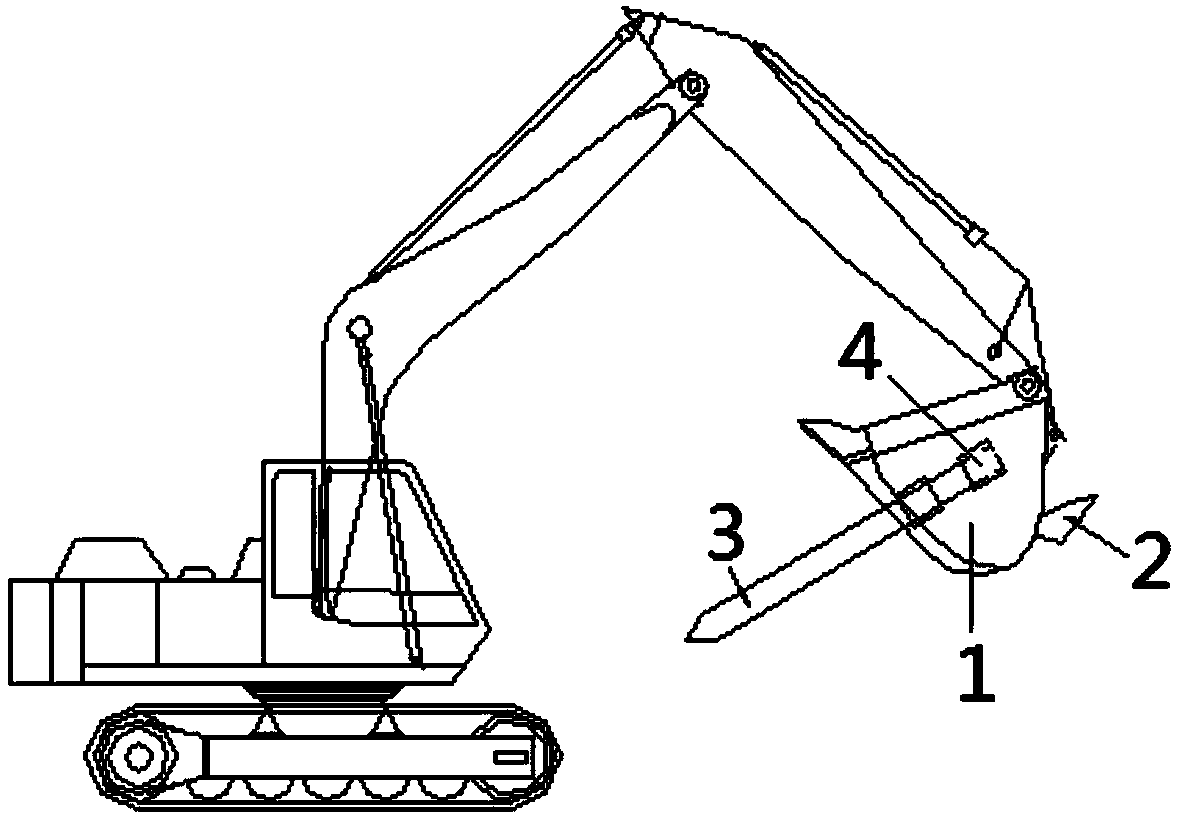

Construction method of shallow tunnel in Xigeda special stratum

ActiveCN108756901AHigh degree of mechanizationImprove ergonomicsUnderground chambersDrainageEngineeringExcavator

The invention discloses a construction method of a shallow tunnel in a Xigeda special stratum. The construction method of the shallow tunnel in the Xigeda special stratum comprises the following stepsthat 1, advance geological forecast is carried out; 2, an improved small-and-medium-sized excavator is used for bench cut method excavation assisted by manual operation; 3, a small guide pipe and a large pipe shed with built-in bundled bars are adopted to carry out advanced support; 4, the initial support stiffness is increased, water guiding and drainage treatment is carried out, and then concrete wet spraying is carried out; 5, the deformation stability is analyzed through monitoring and measurement, and if disqualification exists, rectifying is carried out until the deformation stability is qualified; and 6, secondary lining is carried out, the safe step distance is strictly controlled, and timely closing is carried out to form a ring. The construction method of the shallow tunnel in the Xigeda special stratum starts from various links such as excavation, initial support, water guiding and drainage, safe, fast, efficient and low-cost tunnel construction is realized, and the construction method of the shallow tunnel in the Xigeda special stratum is especially for construction of the shallow tunnel in the Xigeda special stratum.

Owner:中铁十一局集团第五工程有限公司 +1

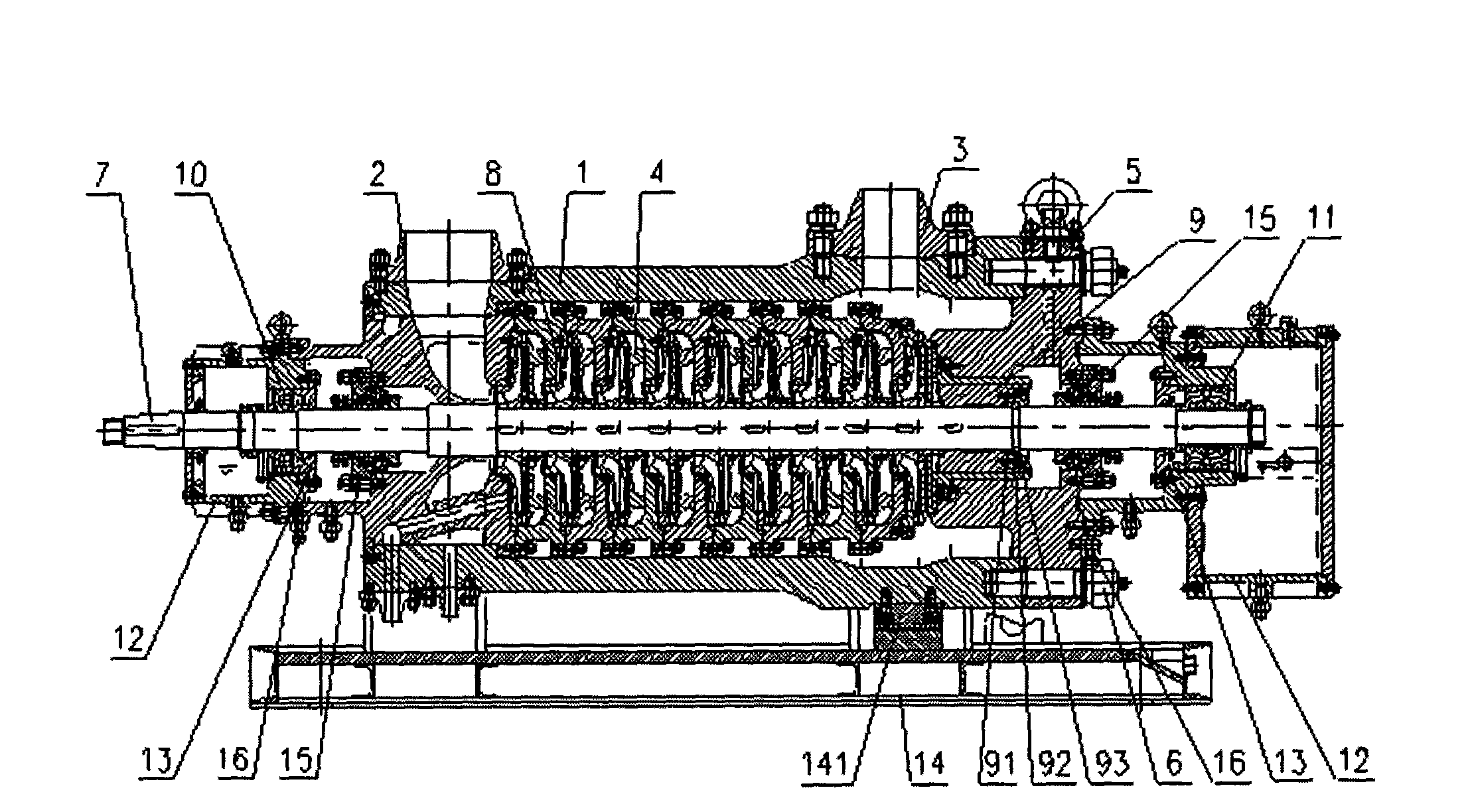

Auxiliary water supply electric pump in nuclear power plant

ActiveCN101666316AImprove sealingSolution to short lifePump componentsRadial flow pumpsBall bearingNuclear power

The invention relates to an auxiliary water supply electric pump in a nuclear power plant, which comprises a horizontal-structure multi-stage centrifugal pump provided with a pump body in a double shell type, wherein the inside of the pump body is provided with a multi-stage segmental inner shell. The inside of the multi-stage centrifugal pump is provided with a stator component, a rotor component, a balance mechanism component, a bearing component and a shaft seal component, wherein the lower part of the pump body is provided with a pump foot; the stator component is fixed on the pump body; the rotor component comprises a pump shaft, impellers and a balance drum; the balance mechanism component is fixed on the shaft and a pump cover; the bearing component comprises a radial roller bearingand a double-direction thrust ball bearing; and the bearing component is arranged on both ends of the pump body and on the periphery of the radial roller bearing and the double-direction thrust ballbearing respectively by adopting fast-loading mechanical seal. The auxiliary water supply electric pump adopts the double-cylinder structured pump body and the self-lubricating bearing; the balance drum is arranged on the shaft reasonably, and the radial roller bearing and the thrust ball bearing are arranged on both ends of the pump shaft respectively, so the auxiliary water supply electric pumphas no structural welding, has convenient maintenance, can effectively prevent a medium from leaking and polluting the environment, and the shock resistance and the maintainability of the pump are improved.

Owner:SHANGHAI APOLLO MACHINERY

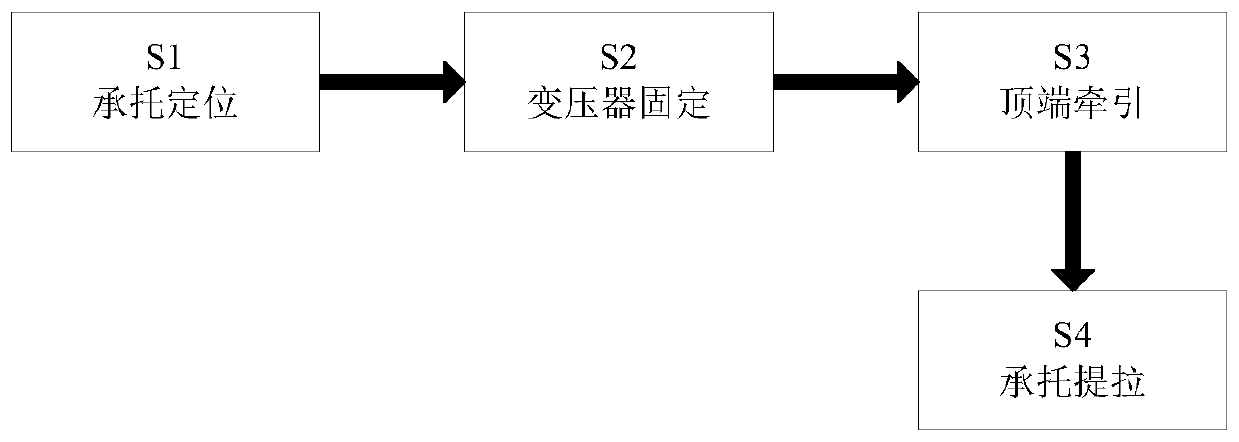

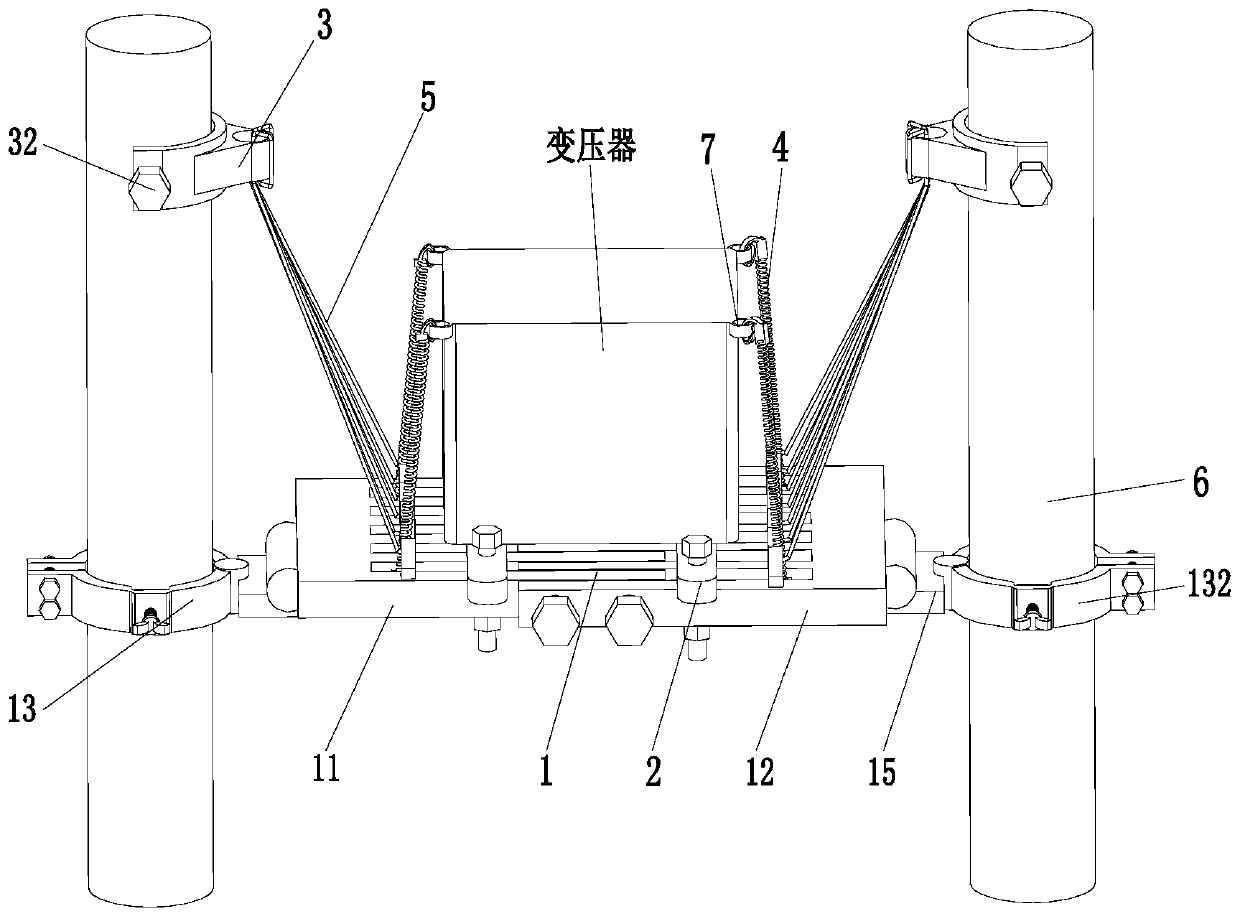

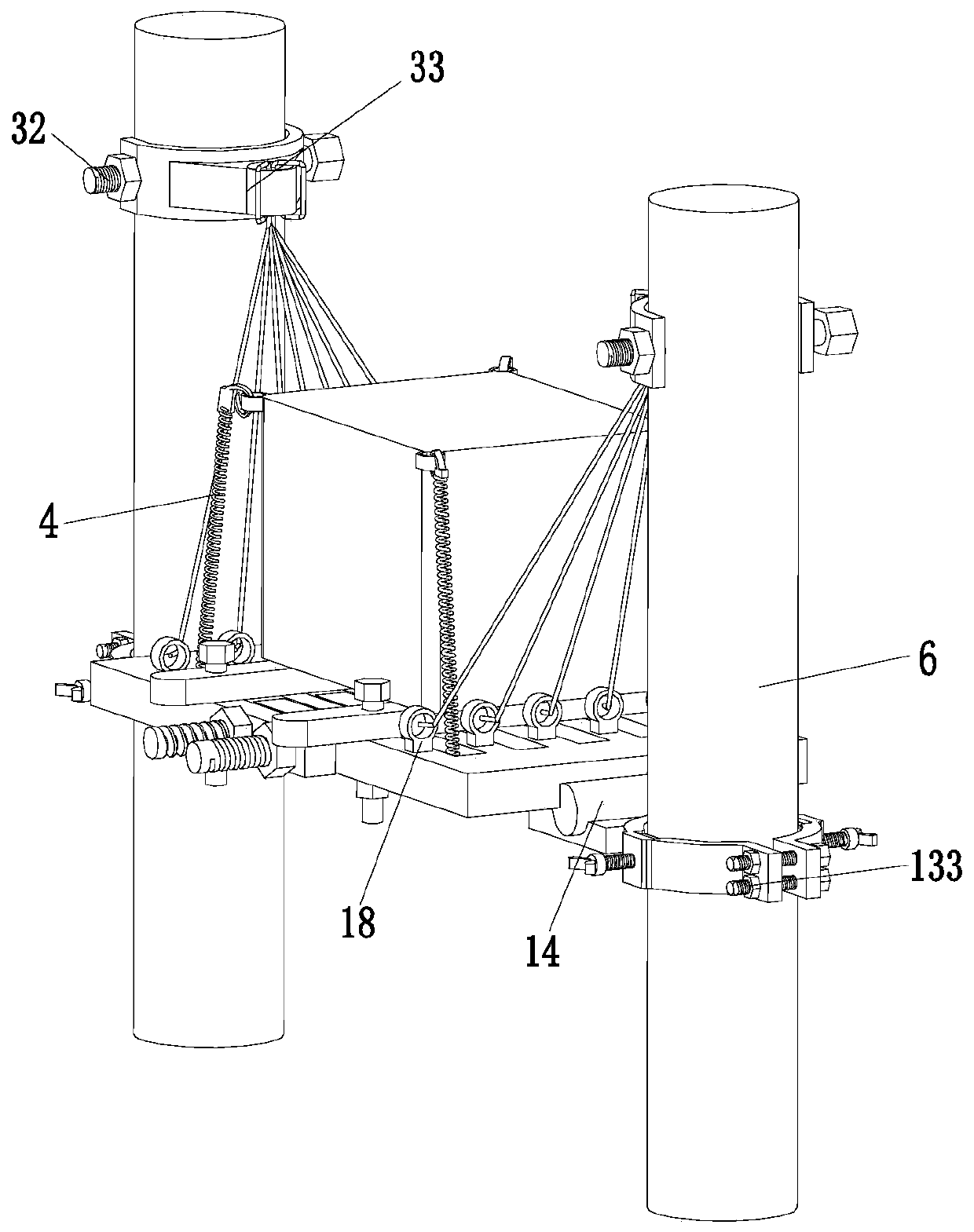

Hoisting construction method for oil-immersed high-voltage transformer

InactiveCN111081456AEffectively disperse the supporting forceDistributed supporting forceTransformers/reacts mounting/support/suspensionSubstation mounted on poleControl engineeringStructural engineering

The invention relates to a hoisting construction method for an oil-immersed high-voltage transformer. According to the transformer hoisting construction method, a transformer hoisting structure is adopted; the transformer hoisting structure comprises a bearing device, a mounting strip, a fixing element, a locking spring, a traction steel wire, an electric pole stand column and a locking circular ring. The supporting device comprises a left supporting plate, a right supporting plate, an embracing mechanism, an overturning pin shaft, a fixing plate and a locking bolt, the embracing mechanism comprises an embracing pin shaft, an embracing hoop and an embracing bolt, and the transformer hoisting construction method adopting the transformer hoisting structure comprises the following steps: S1,supporting and positioning; S2, transformer fixation; S3, top end traction; S4, supporting and lifting. The method can solve the problems that an existing transformer mounting structure is poor in mounting stability, safety and practicability and large in improvement space when an oil-immersed high-voltage transformer is erected and mounted.

Owner:王乐炯

Water reduction type three-expansion source cement expansive material

The invention discloses a slushing type three expansion source concrete expansion agent, which is characterized by comprising preparation of raw materials such as anhydrite, high alumina chamotte, high-calcium sulphoaluminate chamotte, calcined magnesite and so on by weight portion and externally doped slushing agent and water retention agent. The preparation method of the expansion agent comprises steps of crushing, common mixture, mixing and grinding and external doping mixture and finish product forming. The product has low alkali content, excellent expansion performance, synchronous shrinkage-compensating effect and strong suitability with concrete; and newly mixed concrete has small bleeding rate and high vicidity of slurry, and the slurry has strong function of coating and supporting aggregate to greatly reduce the phenomenon of sinking of coarse aggregate, so that the newly mixed concrete keeps good homogenization in the construction process and balanced mechanical property after hardening, and is simple and convenient to use and easy to control quality in construction. The slushing type three expansion source concrete expansion agent is suitable for multiple kinds of concrete for construction.

Owner:广西云燕特种水泥建材有限公司

Method for producing high-salinity maritime work cement through mineral waste residue waste materials

The invention discloses a method for producing high-salinity maritime work cement through mineral waste residue waste materials. The high-salinity maritime work cement is prepared from, by weight, 30-40 parts of mineral waste residues, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of composite activating agents, 2-4 parts of early strength agents, 0.3-0.5 part of water reducing agents, 0.005-0.007 part of air entraining agents and 0.3-0.5 part of retarder. The method for producing the high-salinity maritime work cement comprises the steps that the mineral waste residue waste materials, the sulphate aluminum clinker, the composite activating agents and the early strength agents are smashed, ground into powder and homogenized respectively and then dosed, mixed and homogenized according to proportions, then the water reducing agents, the air entraining agents and the retarder are added, mixed and homogenized, and the product is obtained. The high-salinity maritime work cement has the performance of common cement, further has the excellent characters of early-stage hardness resisting, long-term corrosion resistance, retardation progressive increasing and the like, and is especially suitable for ports, wharfs and other engineering which are corroded by corrosive media.

Owner:广西云燕特种水泥建材有限公司

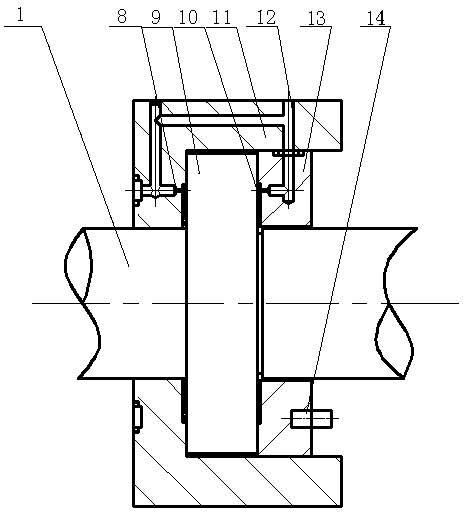

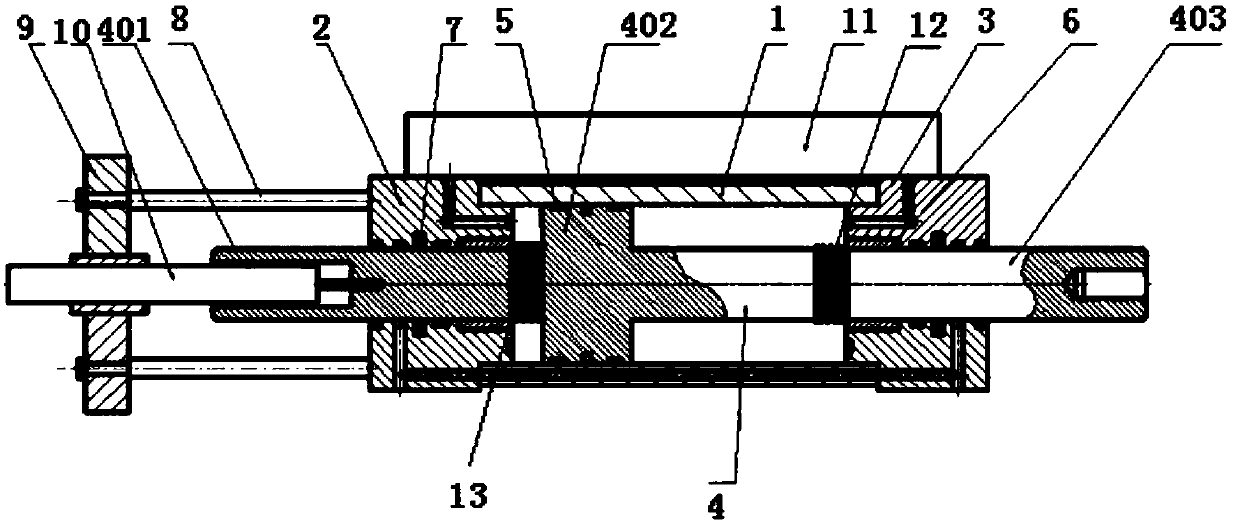

High-frequency-vibration servo hydraulic cylinder

PendingCN107816469AQuick responseImprove dynamic characteristicsFluid-pressure actuatorsHydraulic cylinderPulp and paper industry

The invention discloses a high-frequency-vibration servo hydraulic cylinder. The servo hydraulic cylinder comprises a cylinder barrel; a left cylinder cover and a right cylinder cover which are identical are fixed on the left end surface and the right end surface of the cylinder barrel in a sealed manner; a piston rod is sleeved with the cylinder barrel; two ends of the piston rod penetrate through the left cylinder cover and the right cylinder cover and are fixed in the left cylinder cover and the right cylinder cover in a sealed manner; through holes are formed in the surface of the left cylinder cover and the surface of the right cylinder cover; the piston rod comprises a left piston rod, a piston and a right piston rod which are connected and fixed sequentially and are molded integrally; a piston seal is fixed on the outer surface of the side wall of the piston in a sleeving manner; the piston is in sealed connection with the inner surface of the side wall of the cylinder barrel bythe aid of the piston seal; and the outer surface of the side wall of the left piston rod and the outer surface of the side wall of the right piston rod are sleeved with metal supporting rings and piston rod seals. The hydraulic cylinder is quick in system response, good in dynamic characteristic and high in motion precision, low-amplitude and high-frequency vibration can be realized through cooperation of a servo valve group and a high-precision displacement sensor, and meanwhile, the amplitude can be adjusted as required.

Owner:HEFEI UNIV OF TECH +2

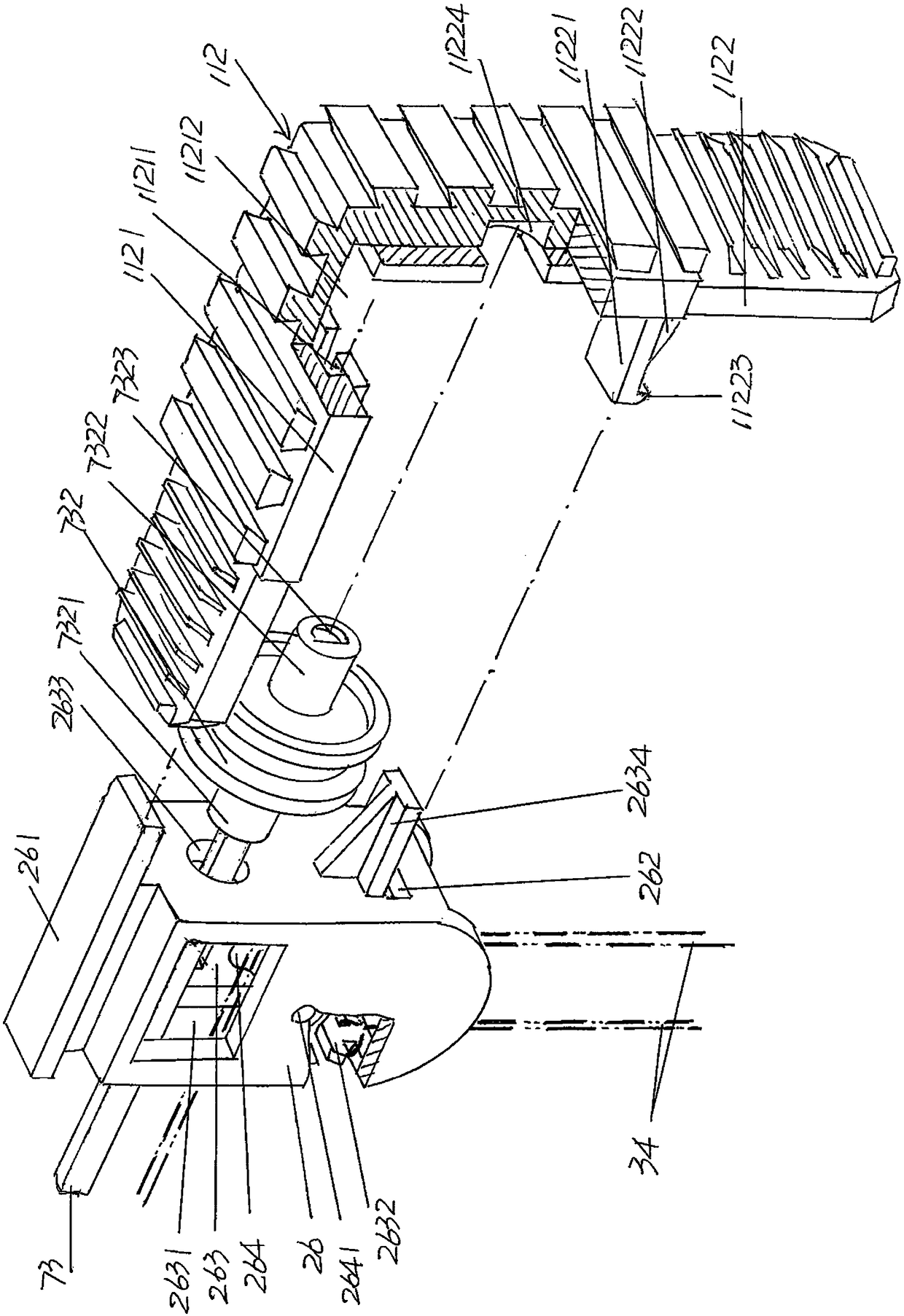

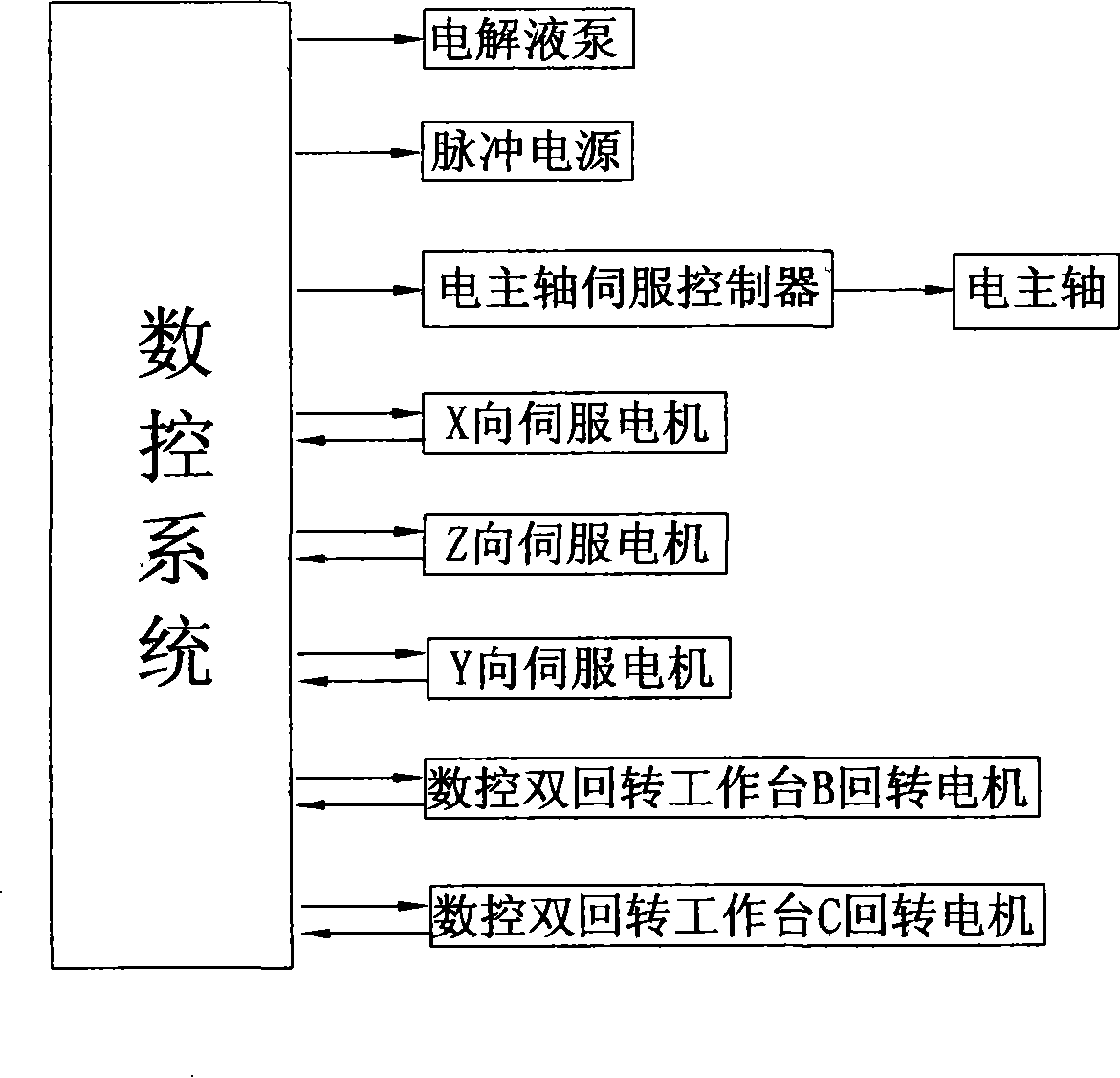

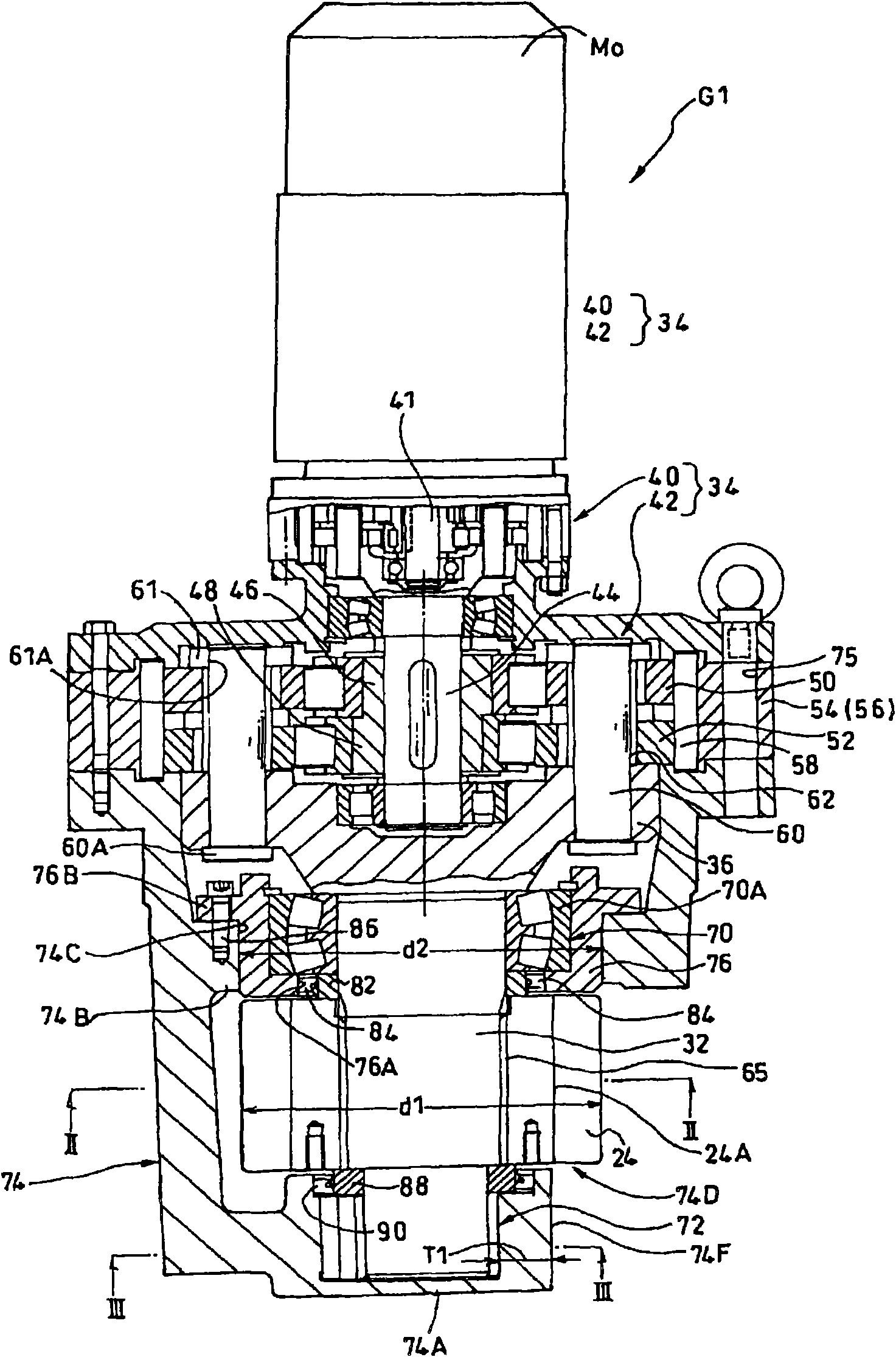

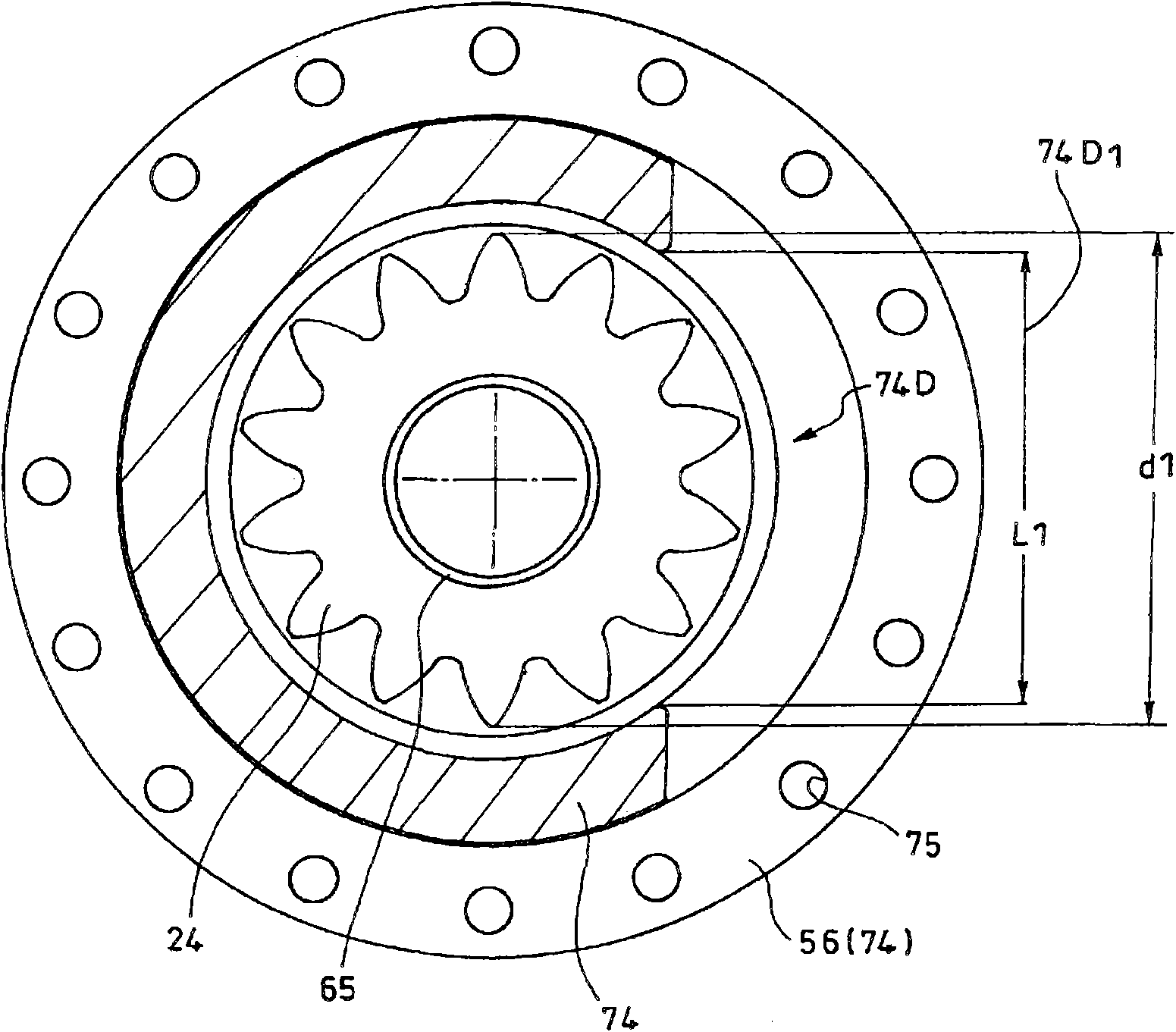

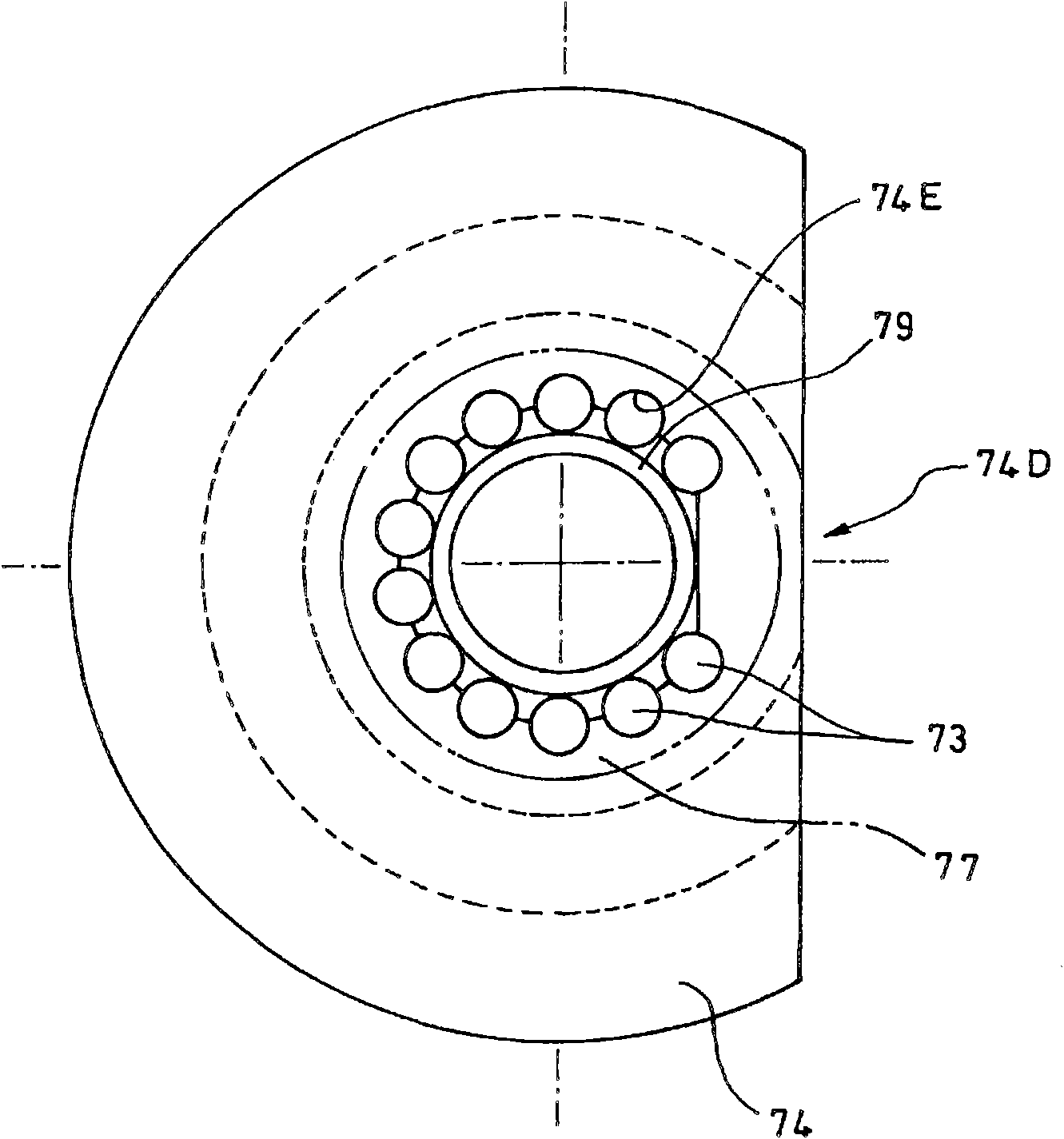

Decelerator with output pinion of wind power generation system

InactiveCN101852187AImprove support capacityWind energy generationWind motor componentsGear wheelEngineering

The invention provides a decelerator with an output pinion of a wind power generation system, which especially improves the bearing capability of the output shaft on one side opposite to the drive source side when dually supporting the output shaft of the decelerator with the output pinion of the wind power generation system. In the decelerator (G1) with the output pinion of the wind power generation system, the output shaft (32) is dually supported by a pair of bearings including an automatic aligning roller bearing (70) and a roller bearing (72); in the pair of bearings (70, 72), the roller (73) on one side opposite to the drive source side is composed of a plurality of rollers not only doing rotation but also doing revolution; and there has no roller (73) on the engaged window (74D) side.

Owner:SUMITOMO HEAVY IND LTD

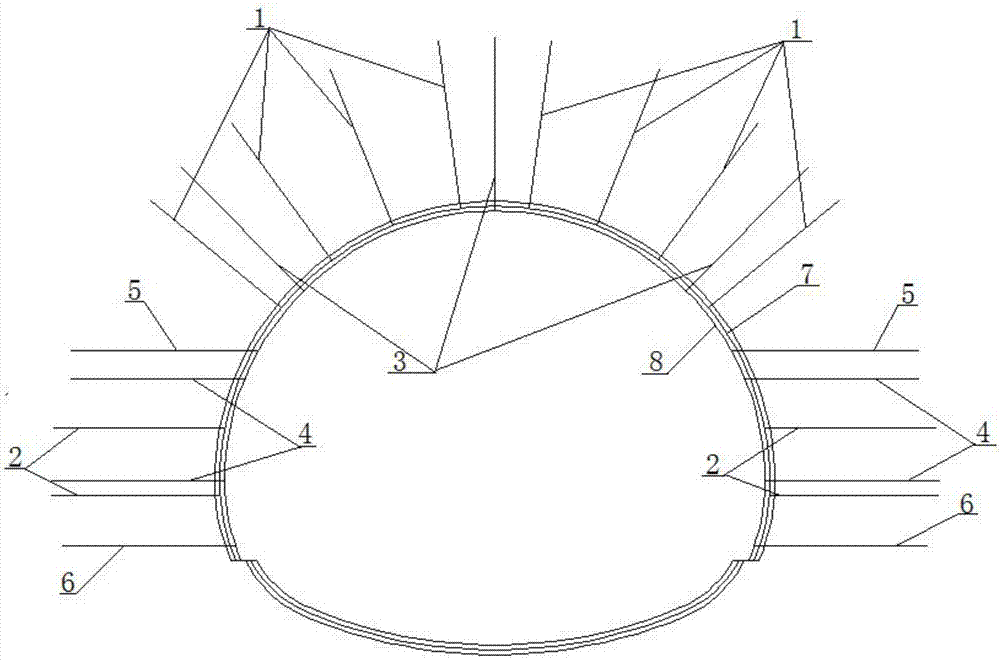

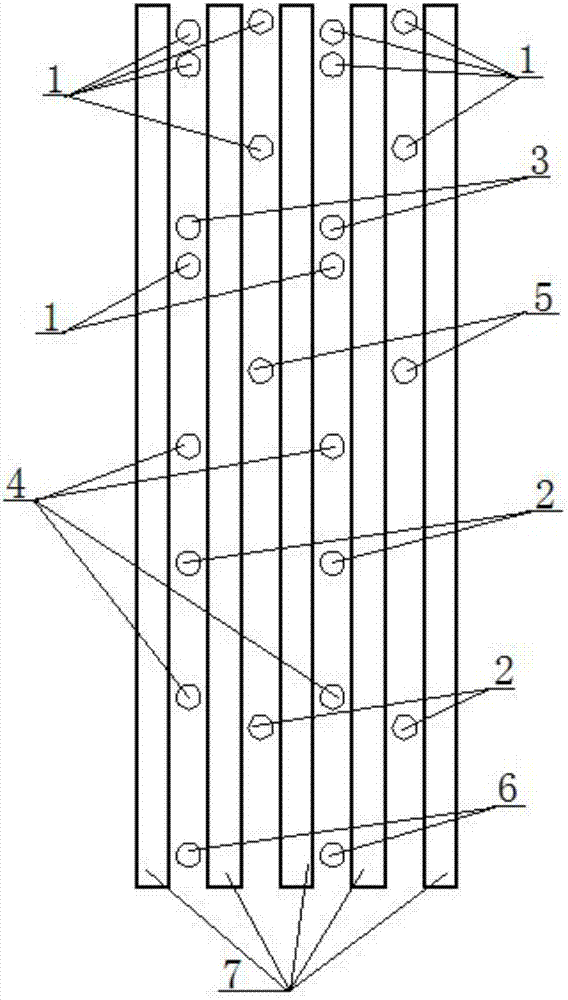

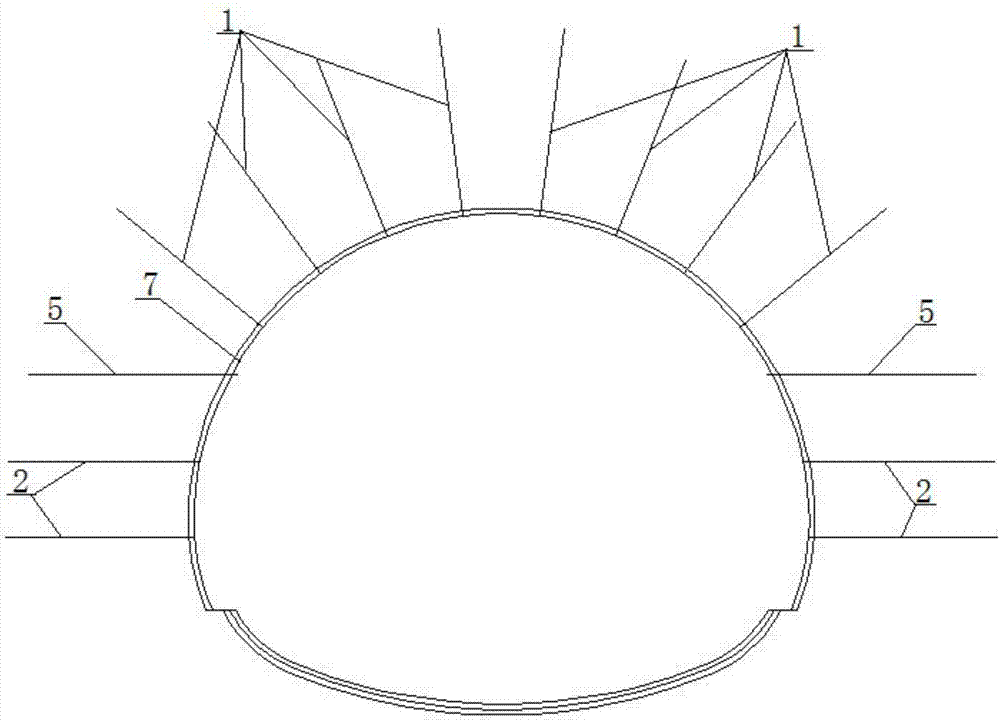

Squeezing weak surrounding rock tunnel prestressed anchor cable group support structure and construction technology

The invention relates to a squeezing weak surrounding rock tunnel prestressed anchor cable group support structure and a construction technology. The support structure comprises arch speed control anchor cables (1), side wall speed control anchor cables (2), arch limiting anchor cables (3), side wall limiting anchor cables (4), arch locking anchor cables (5), side wall locking anchor cables (6), a first layer primary support (7) and a second layer primary support (8); all anchor cables in the construction technology adopt drilling and grouting simultaneously, however, reserved tensioning is conducted according to times, batches and parts. Controlling release on surrounding rock stress is achieved, the surrounding rock deformation growth rate and deformation accumulation amount are lowered, large deformation is effectively controlled, steel arch centering replacement caused by too large deformation is avoided, and the surrounding rock collapse hazard is lowered; in addition, the work efficiency is improved, constructors can conduct drilling conveniently, and it is guaranteed that the anchor cable positions are accurate, and tensioning can be conducted in time.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

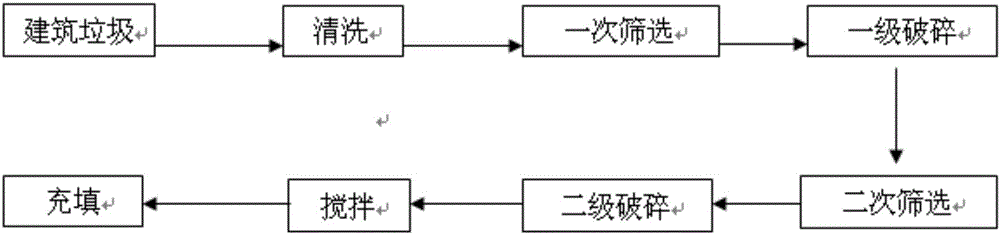

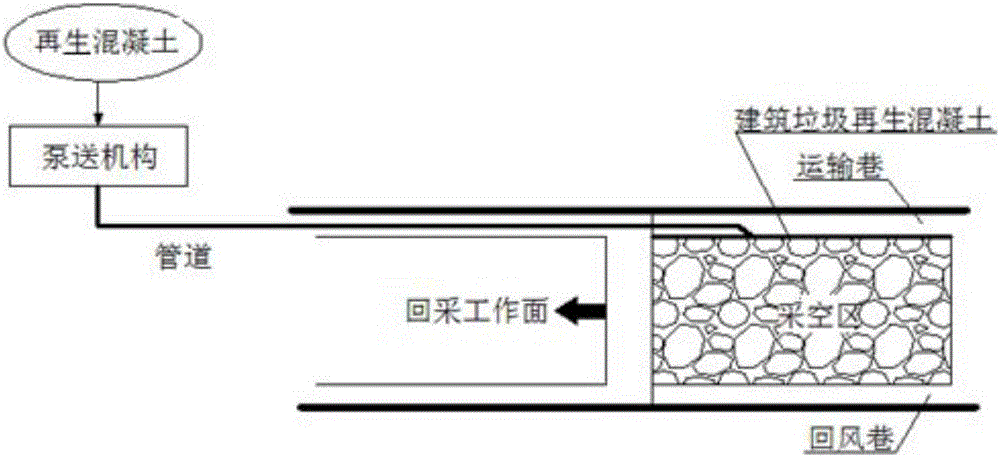

Dynamic concrete roadside filling method based on construction waste regeneration

InactiveCN105863726AEfficient recyclingHigh degree of mechanizationMaterial fill-upMaterials preparationArchitectural engineering

The invention discloses a dynamic concrete roadside filling method based on construction waste regeneration. The method comprises the following steps of material preparation, proportioning, stirring, conveying and filling. The regenerated concrete prepared from construction waste is filled into a roadside filling support frame of a goaf. The dynamic concrete roadside filling method based on construction waste regeneration has the advantages that the efficient recycle and reuse of the construction waste can be realized; the effect of changing waste materials into valuable materials is achieved; the integrally cast roadside filling support resistance increase speed is high; the support capability is high; the sealing performance is good; and the mechanization degree is high.

Owner:HOHAI UNIV

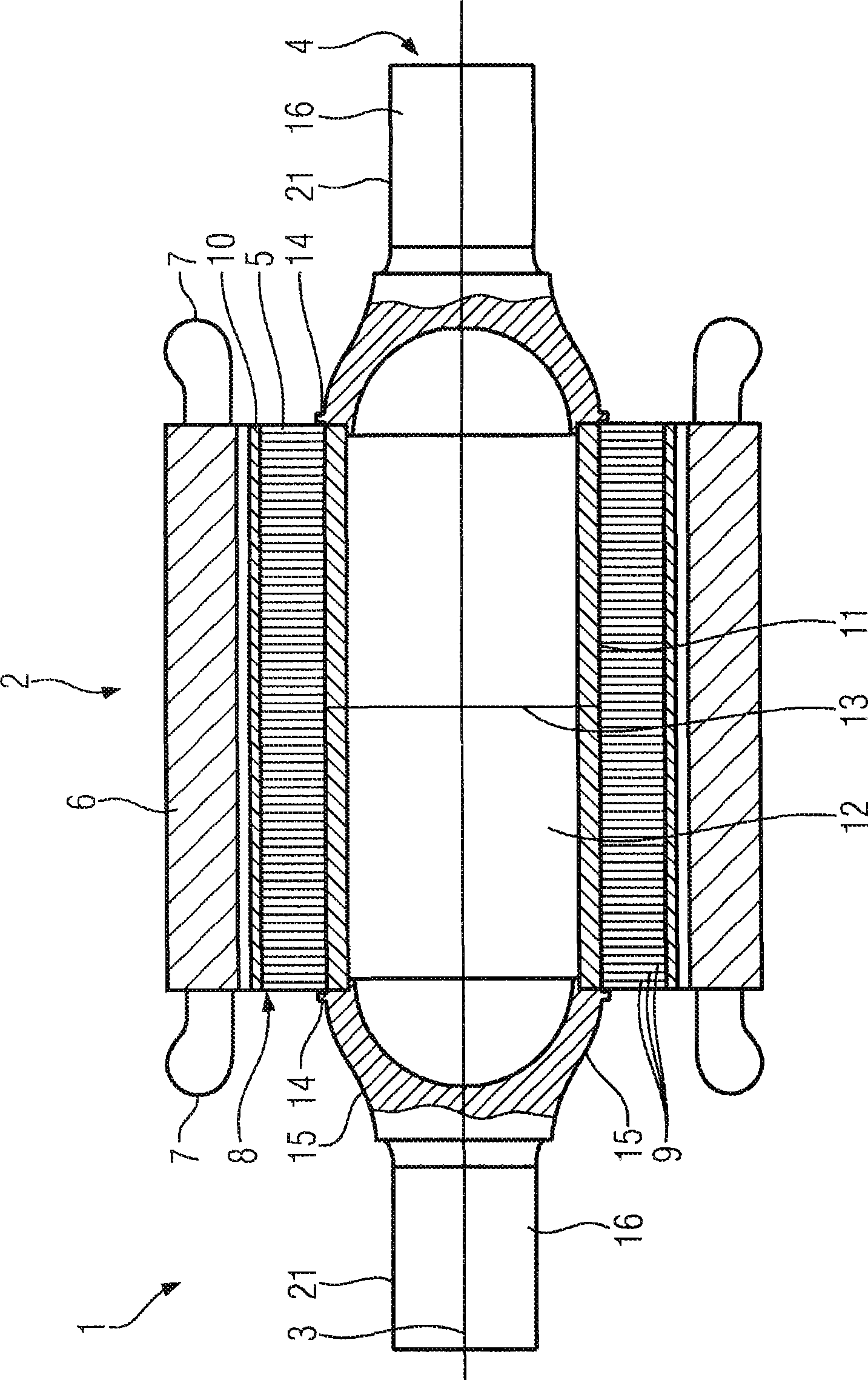

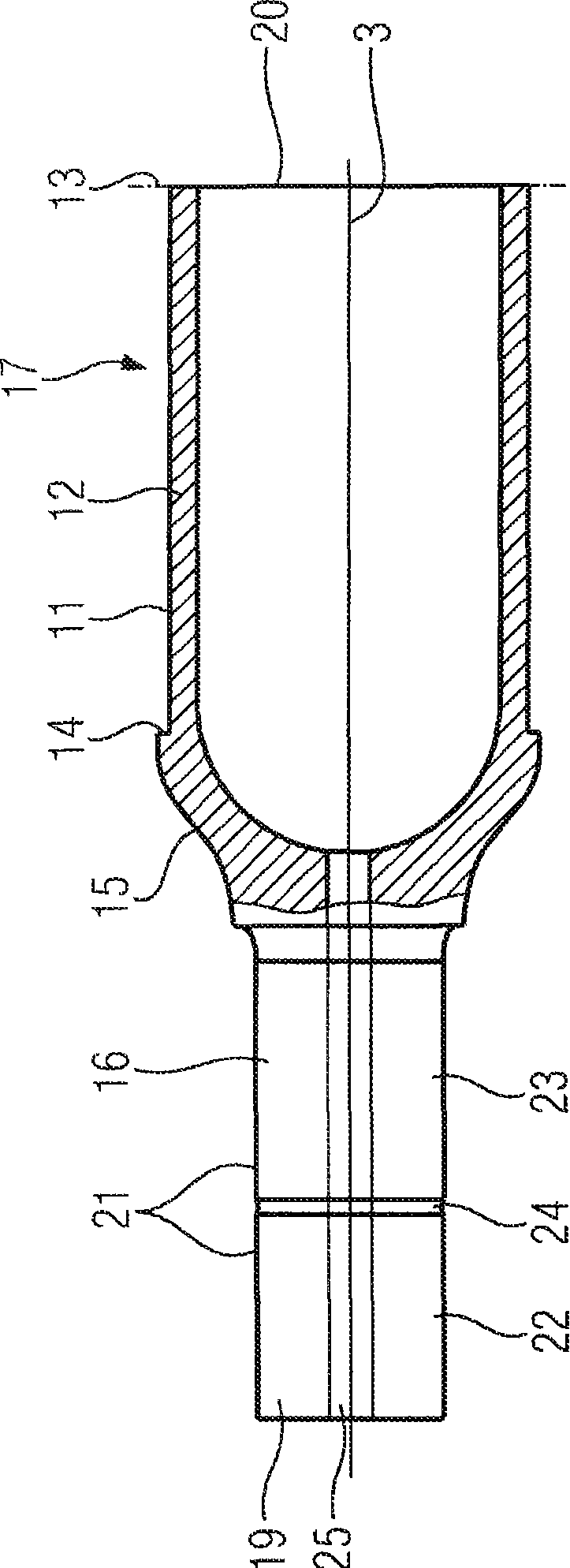

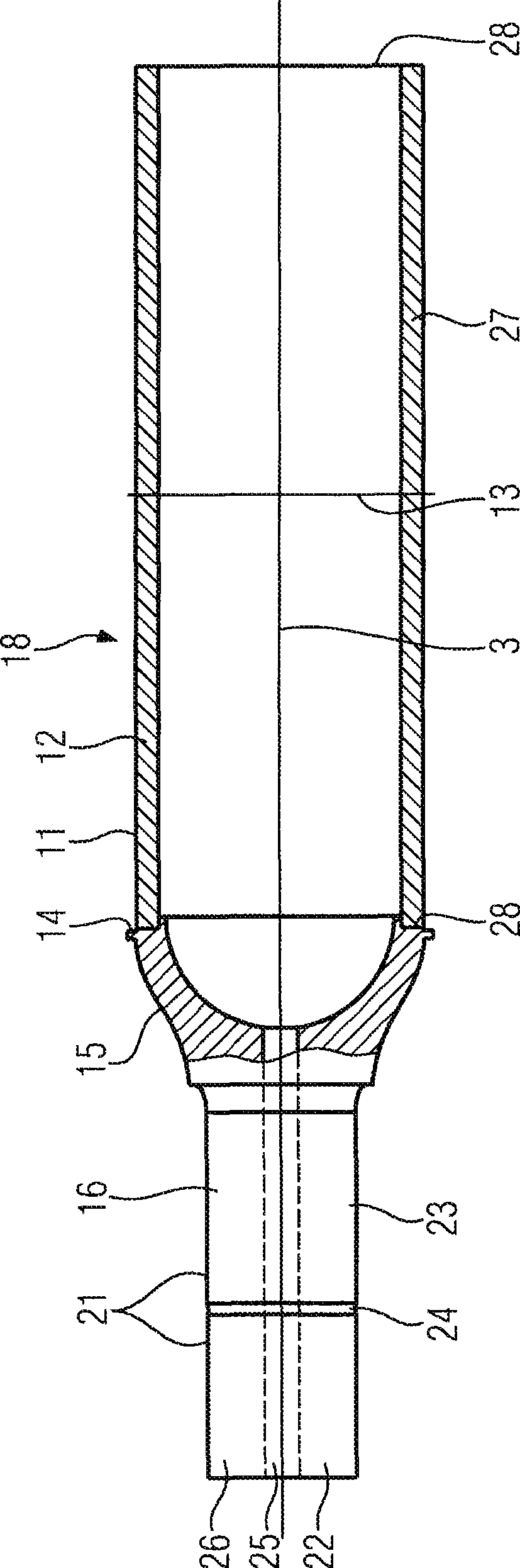

Wheel set shaft for an electric drive unit mounted on the axle and drive unit

InactiveCN101522501ANo fretting corrosionSave materialMagnetic circuit rotating partsElectric propulsion mountingMechanical stabilityElectric drive

The wheel set shaft (4) is intended for an electric drive unit mounted on the axle (2). It comprises two axially lateral edge regions (15, 16) and a center region (12) disposed between the edge regions (15, 16). Each edge region (15, 16) is at least partially designed substantially as a full cylinder having a first outer circumferential surface (21) for mounting a wheel or a bearing. The center region (12) is designed as an empty hollow cylinder having a second outer circumferential surface (11) for the direct mounting of a rotor (5) of the electric drive unit (2) mounted on the axle. Thus, the manufacturing effort and the overall weight are reduced, while at the same time ensuring high mechanical stability.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com