A method for improving the stability of U-shaped steel arch support and connecting components

A technology for connecting components and stability, which is applied in the field of improving the stability of U-shaped steel arch support and connecting components, which can solve the problems of support failure, insufficient stability, steel consumption and sharp increase in support costs, etc., and achieve the expansion of supports distance, considerable economic benefits, and remarkable effect of saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

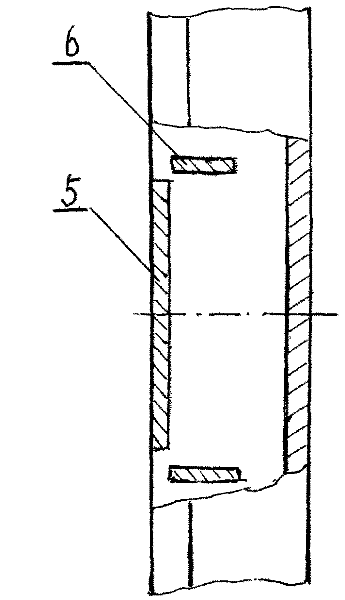

[0022] The present invention only makes changes in the connection and moderately variable cross-section reinforcement methods, and is easy to implement. Reinforcement is welding, and its meaning is obvious, so it will not be described again. For the mutual pulling between the brackets, the ear pieces 9 with holes must be welded to the corresponding parts of the brackets before going into the well, so as to fix the pulling connecting plate 8; the U notch can also be reinforced in advance Boreholes are reserved on the plate 6, so that earpieces can be omitted and the pulling steel plates between the hole fixing brackets can be utilized; coal mines have many scrapped wire ropes, which can be reused to replace steel plates for pulling.

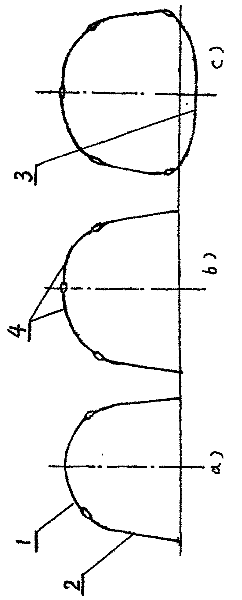

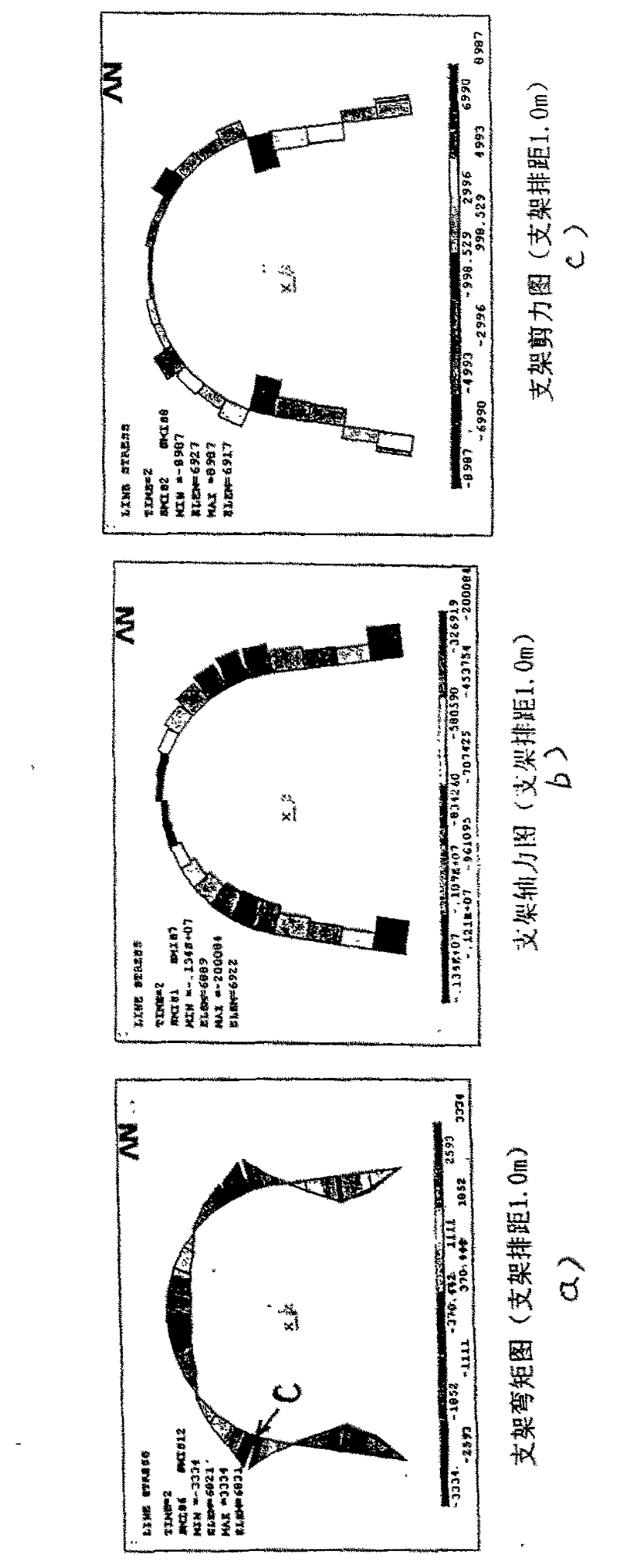

[0023] It should be emphasized that the connection must be based on the cross-sectional shape of the arch roadway and the corresponding internal force distribution characteristics of the arch frame, and the fracture location and docking components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com