Patents

Literature

130 results about "Critical stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Critical incident stress. One's emotional reaction to a catastrophic event such as a mass casualty incident or the death of a patient or coworker. Often such events negatively affect the well-being of health care providers.

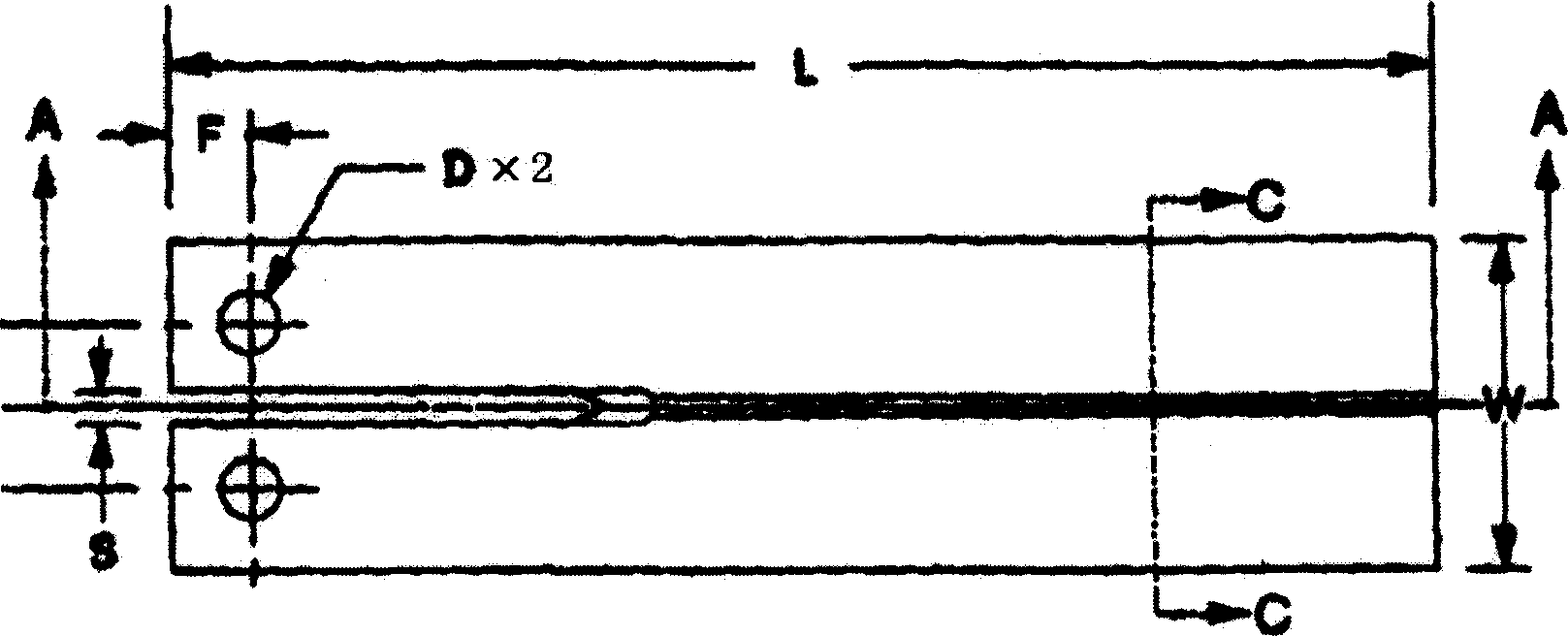

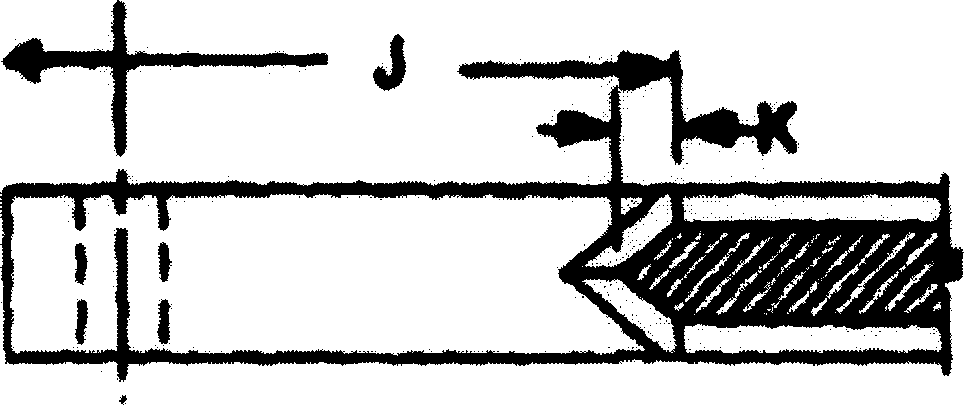

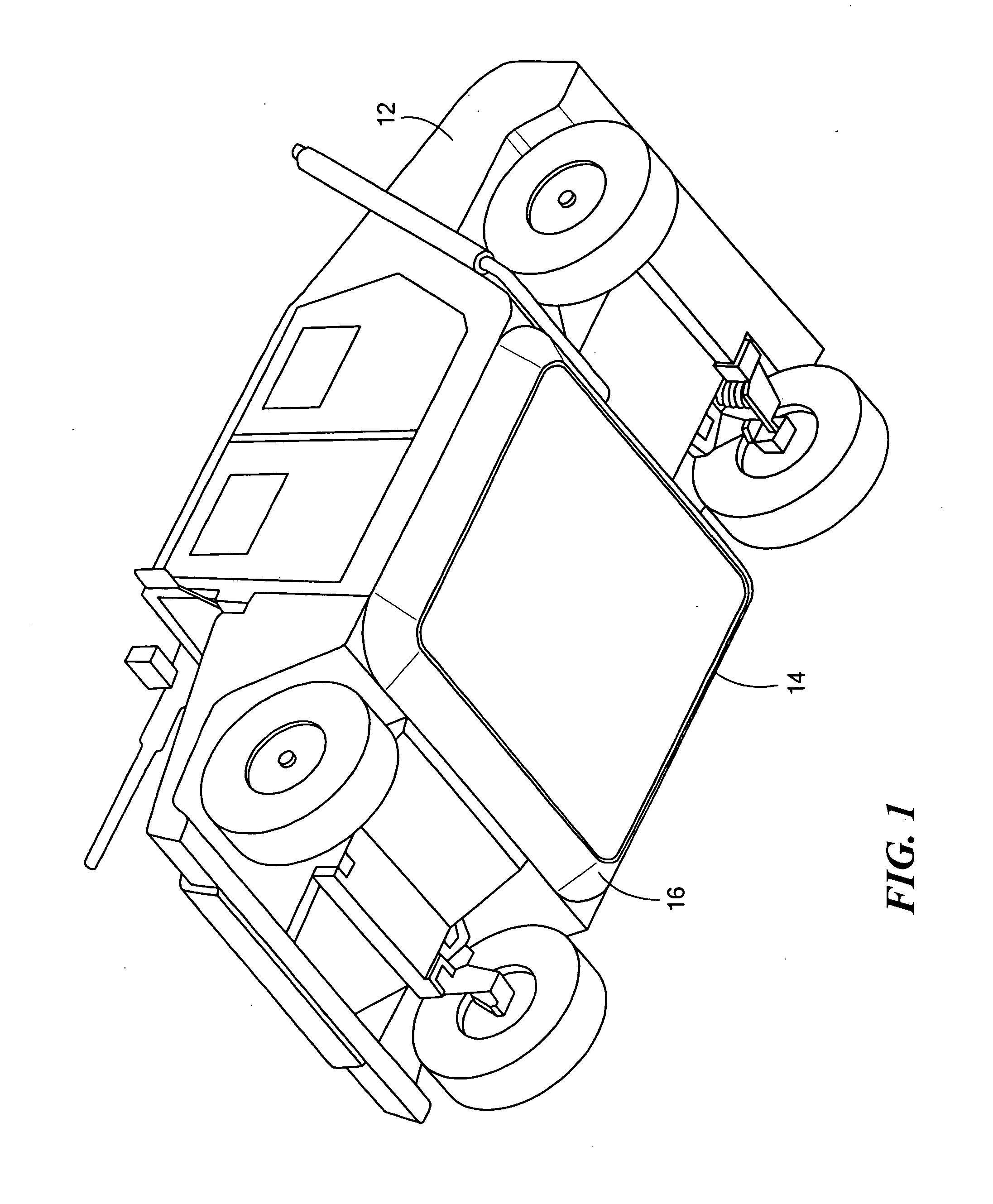

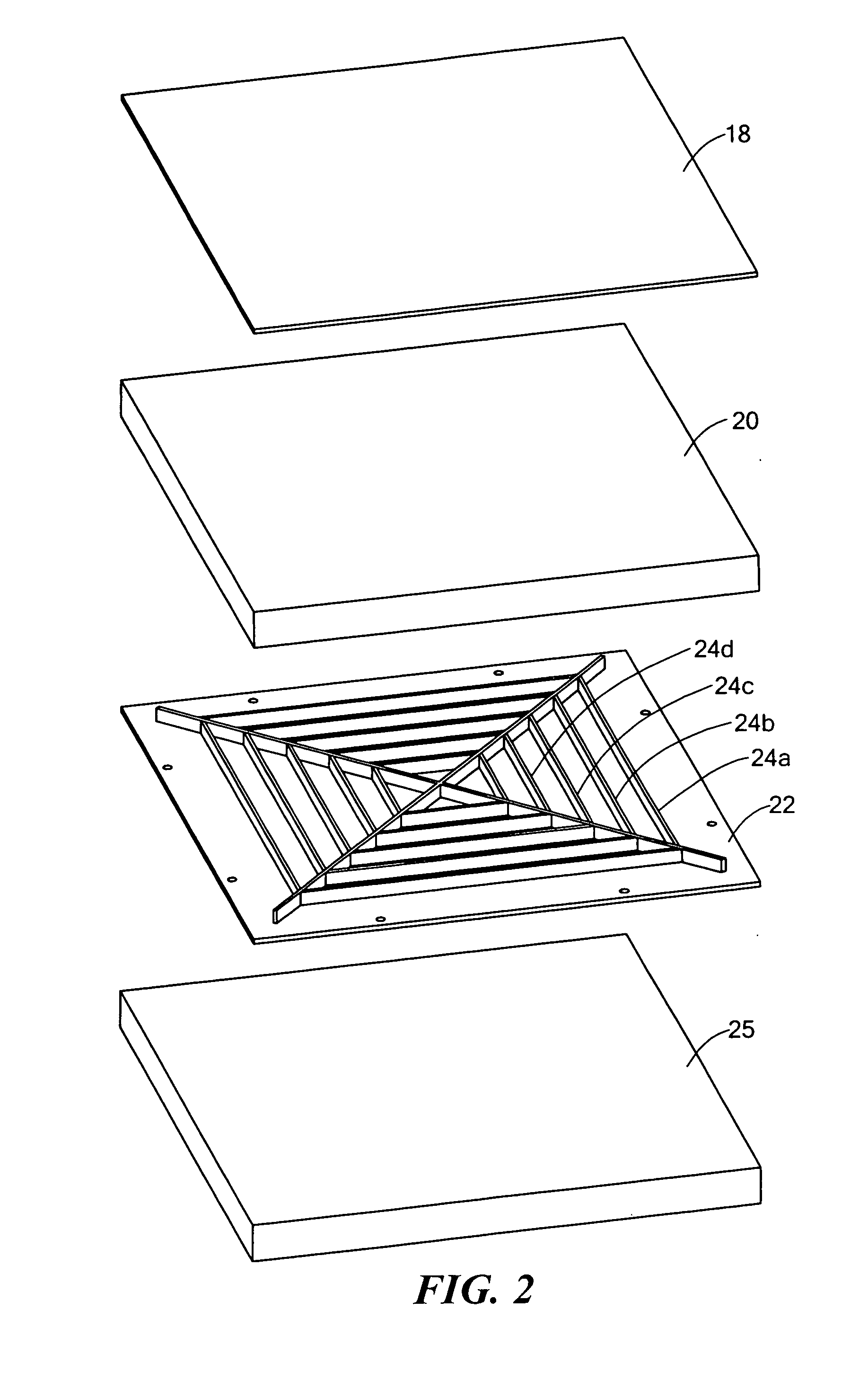

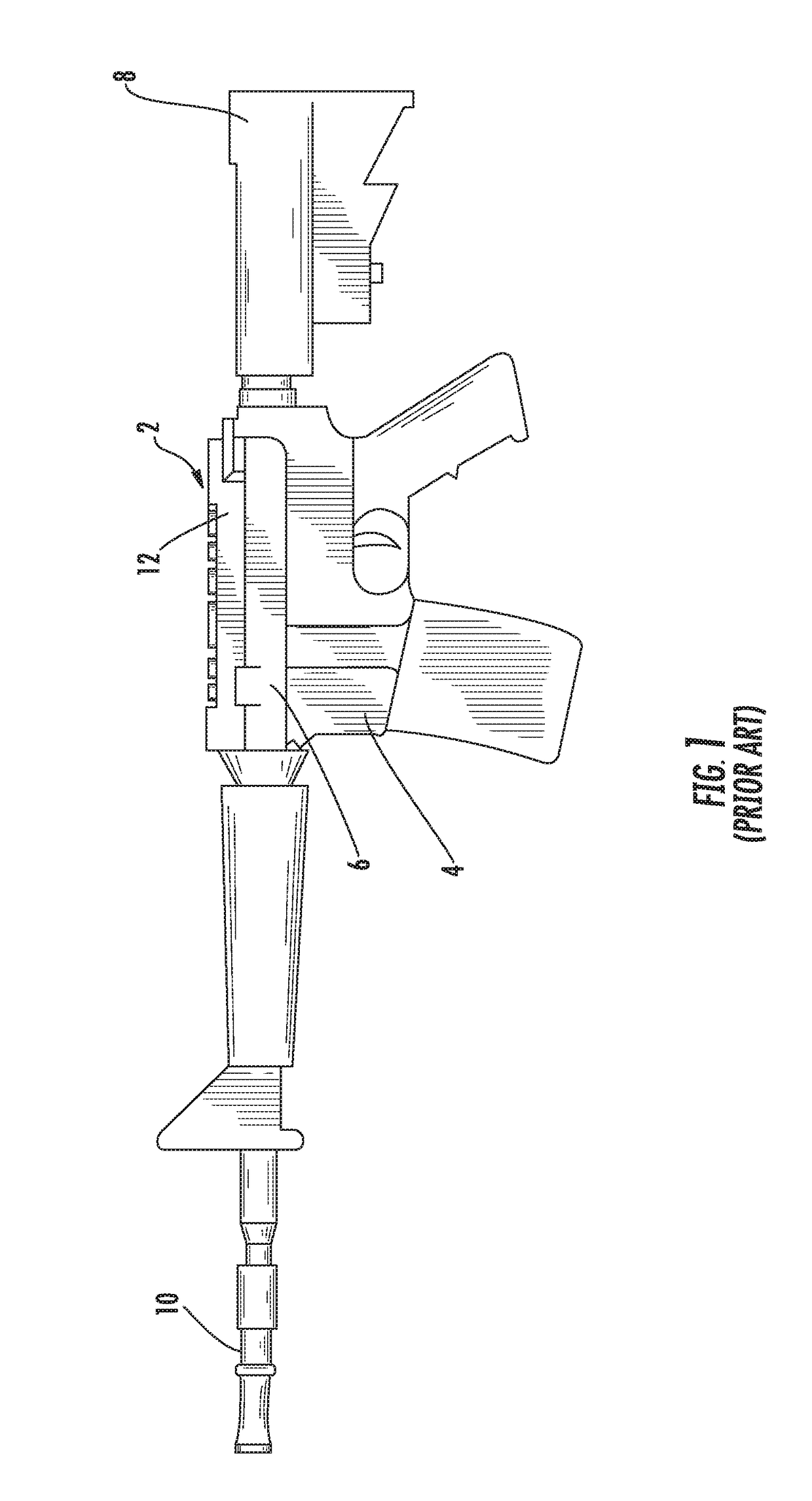

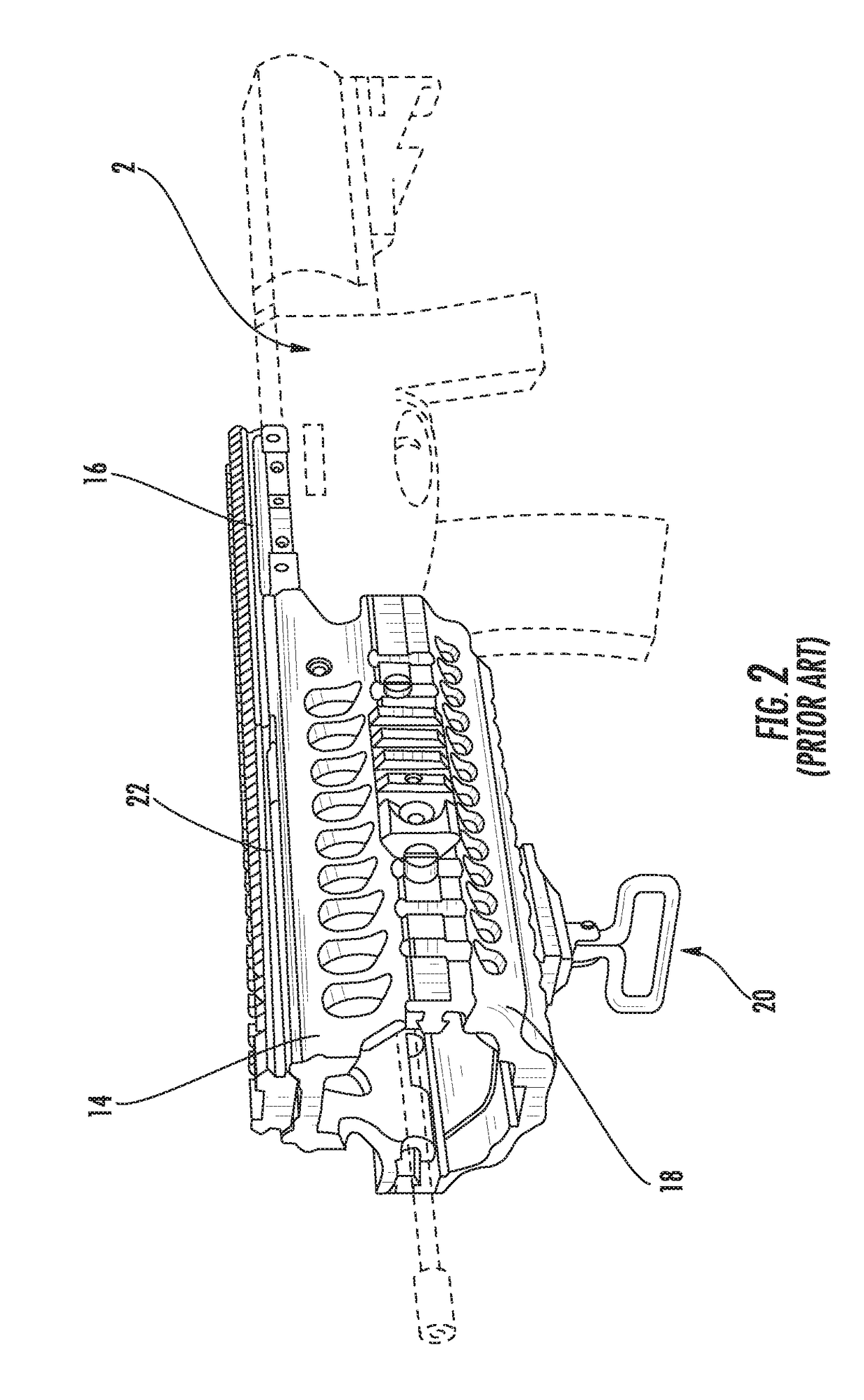

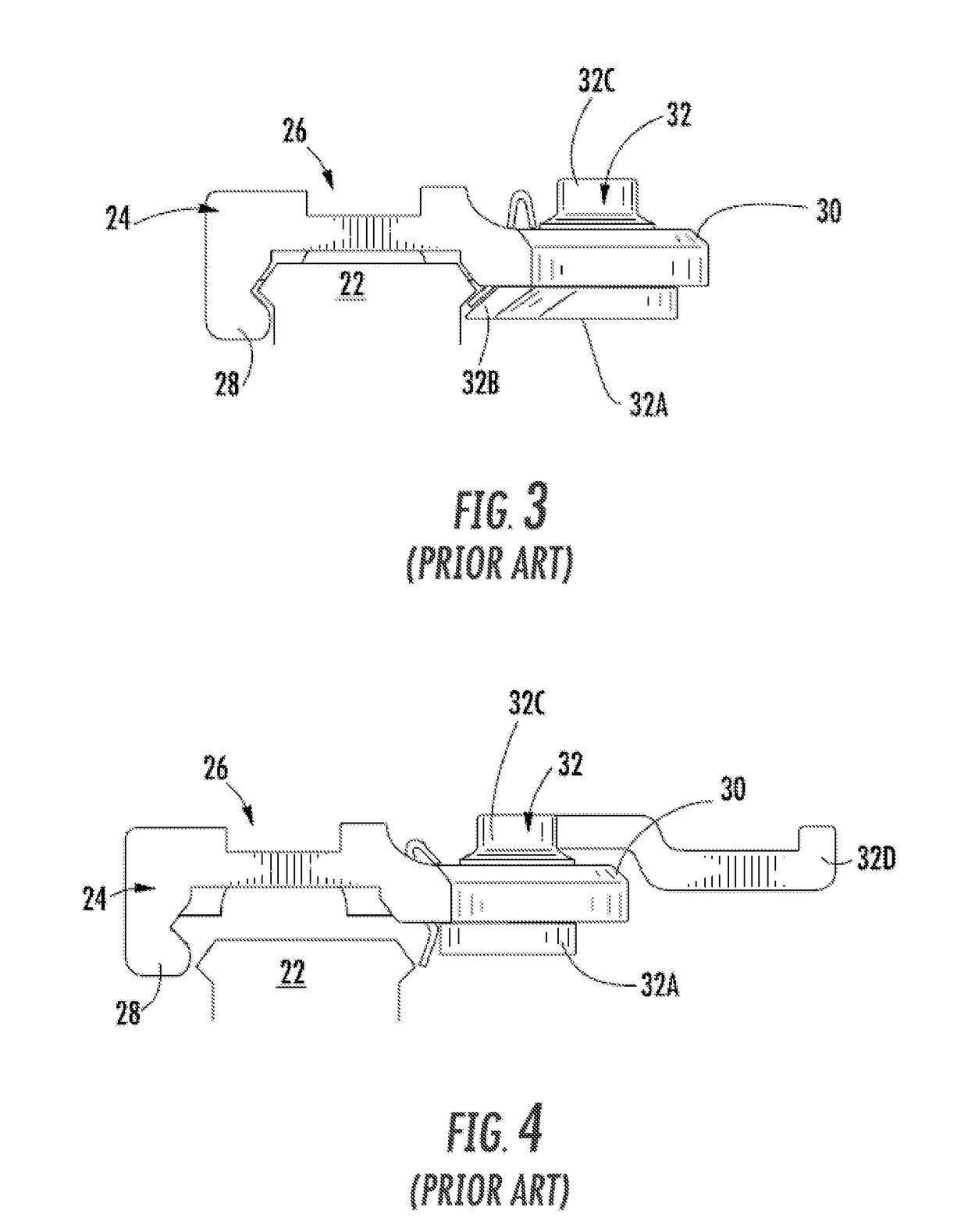

Moment-resistant structure, sustainer and method of resisting episodic loads

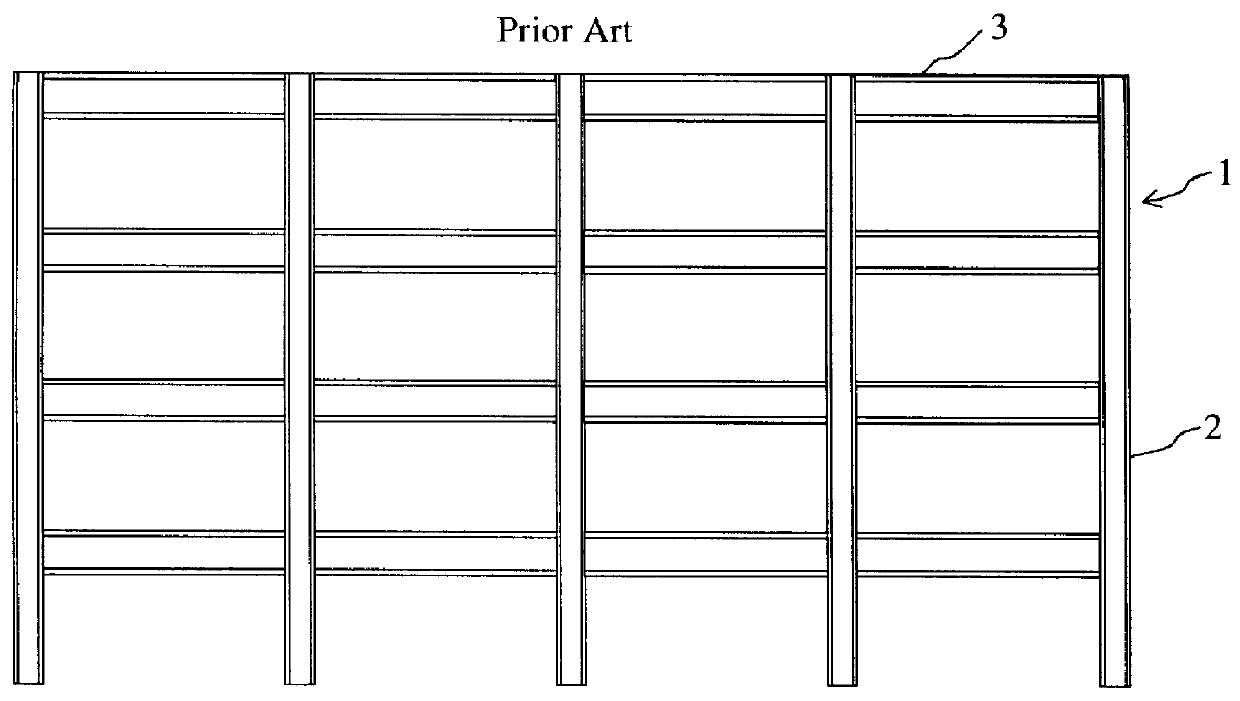

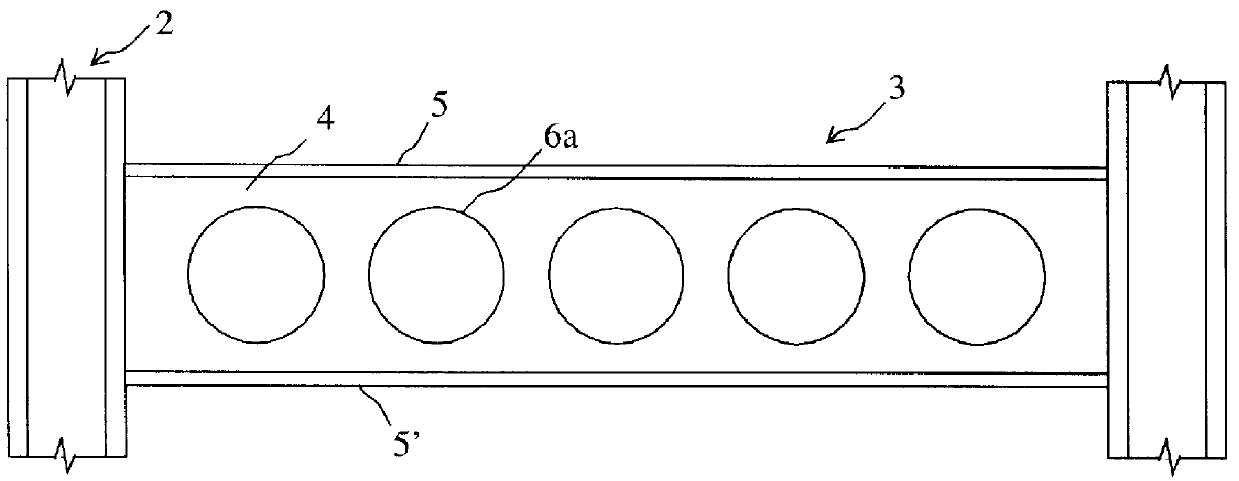

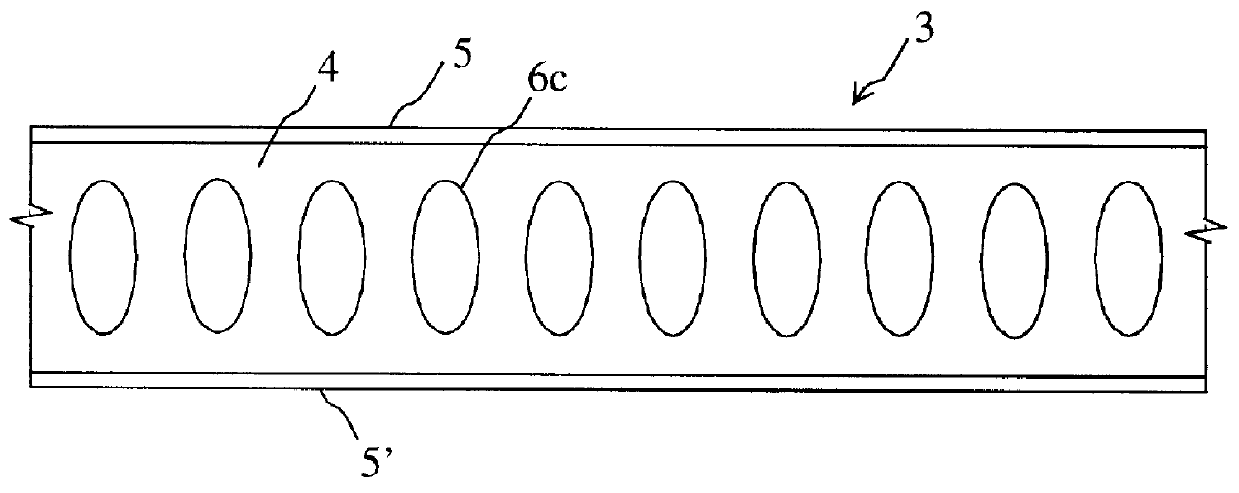

The present invention relates to a moment-resistant structure, sustainer, and method of construction for deformably resisting episodic loads, particularly those of high intensity. The episodic loads may be due to earthquake, impact, or other intense episodic sources. The structure and sustainer may be in buildings, bridges, or other civil works, land vehicles, watercraft, aircraft, spacecraft, machinery, or other structural systems or apparati. Deformation capacity is enhanced by the use of multiple dissipative zones. Dissipative zones that function in a manner similar to plastic hinges are determined by one or more voids that are located in the web of a sustainer. The one or more voids are of a size, shape, and configuration to assure that the dissipative zones deform inelastically when a critical stress, i.e., a maximum allowable demand, is reached, thereby developing the action of a structural fuse, preventing the occurrence of stress and strain demands sufficient to cause fracture of the connection welds or adjacent heat-affected zones, i.e., preventing the stress and strain demands from exceeding the strength capacity of the connection welds or adjacent heat-affected zones. The sustainers may be removably connected to the remainder of the structure, facilitating their replacement after inelastic deformation. The structure, sustainer, and method of construction may be utilized in new construction and in the rehabilitation of existing construction. Mechanical equipment and utilities may pass through the voids.

Owner:ASCHHEIM MARK AMOS

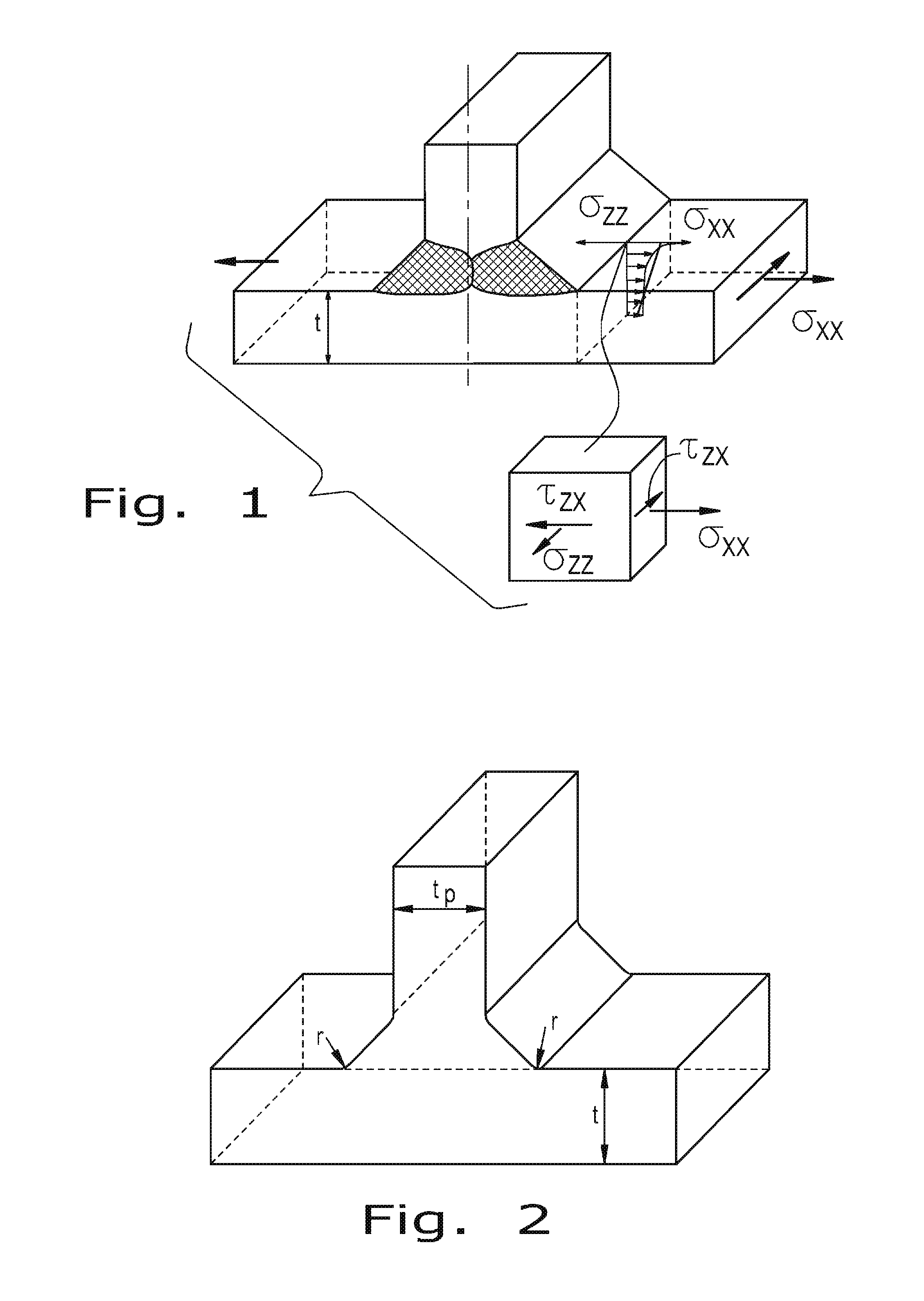

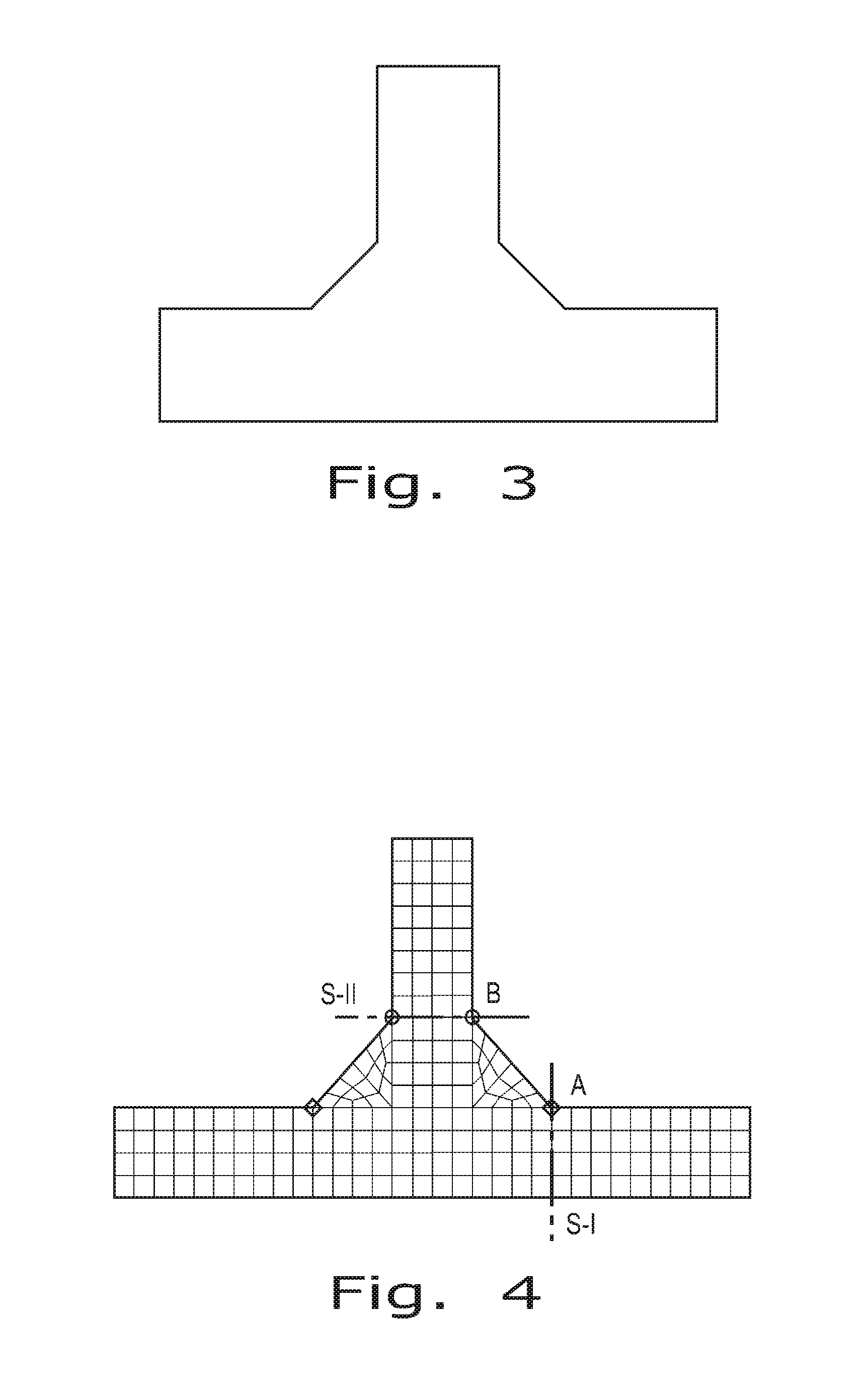

Method for the prediction of fatigue life for welded structures

InactiveUS20120259593A1Design optimisation/simulationComplex mathematical operationsStress distributionCoarse mesh

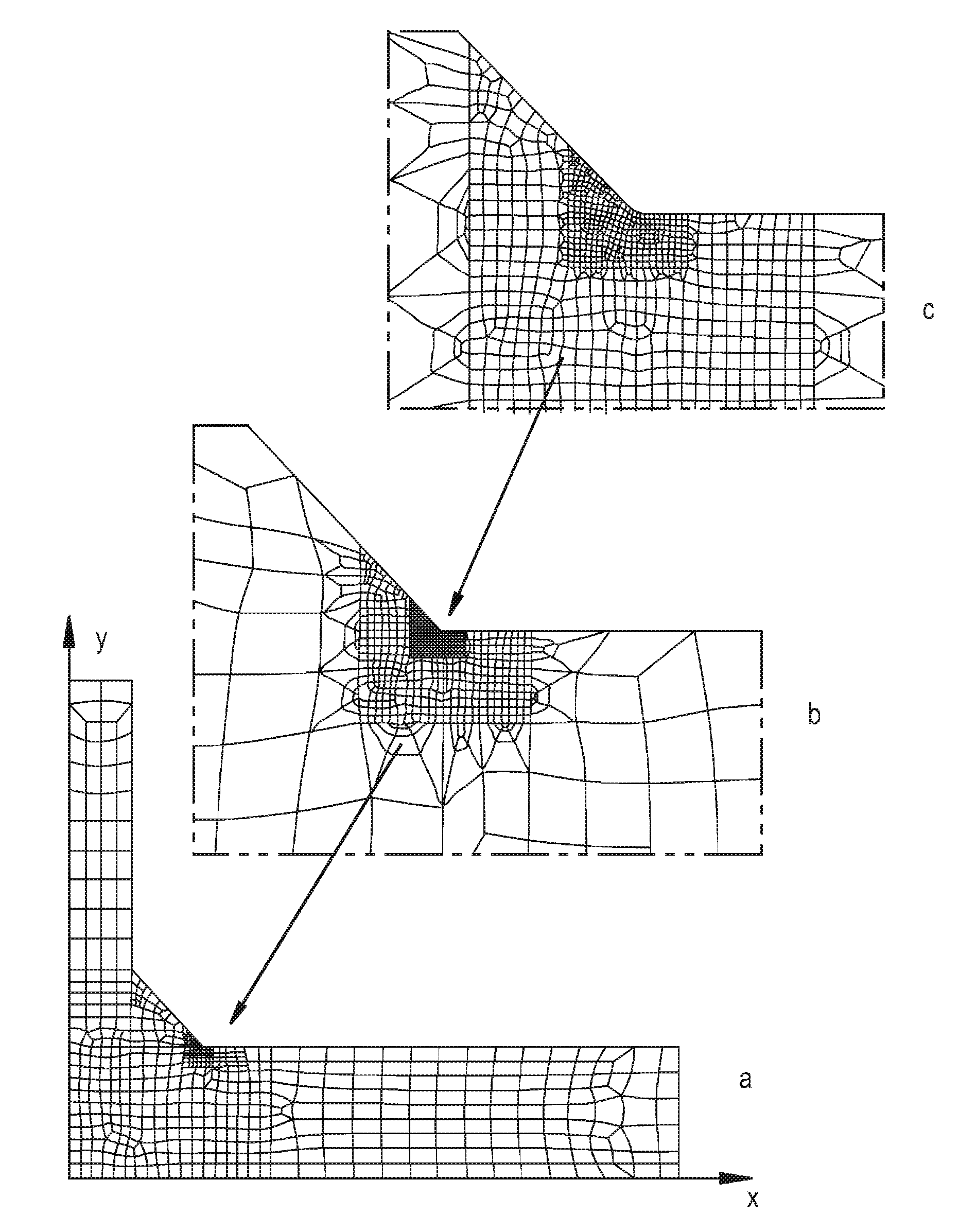

A method of determining the fatigue life of a welded structure, including the steps of: creating a 3D coarse mesh model of the welded structure to be analyzed; analyzing the coarse mesh model using an FEA model to generate FEA data; identifying a critical stress location on the coarse mesh model having a through thickness stress distribution, based on the FEA data; post processing the FEA data in the middle portion of the through thickness stress distribution while excluding the through thickness stress distribution near the edges of the identified critical stress location to determine a peak stress; and determining a fatigue life of the welded structure at the identified critical stress location, dependent on the determined peak stress.

Owner:DEERE & CO

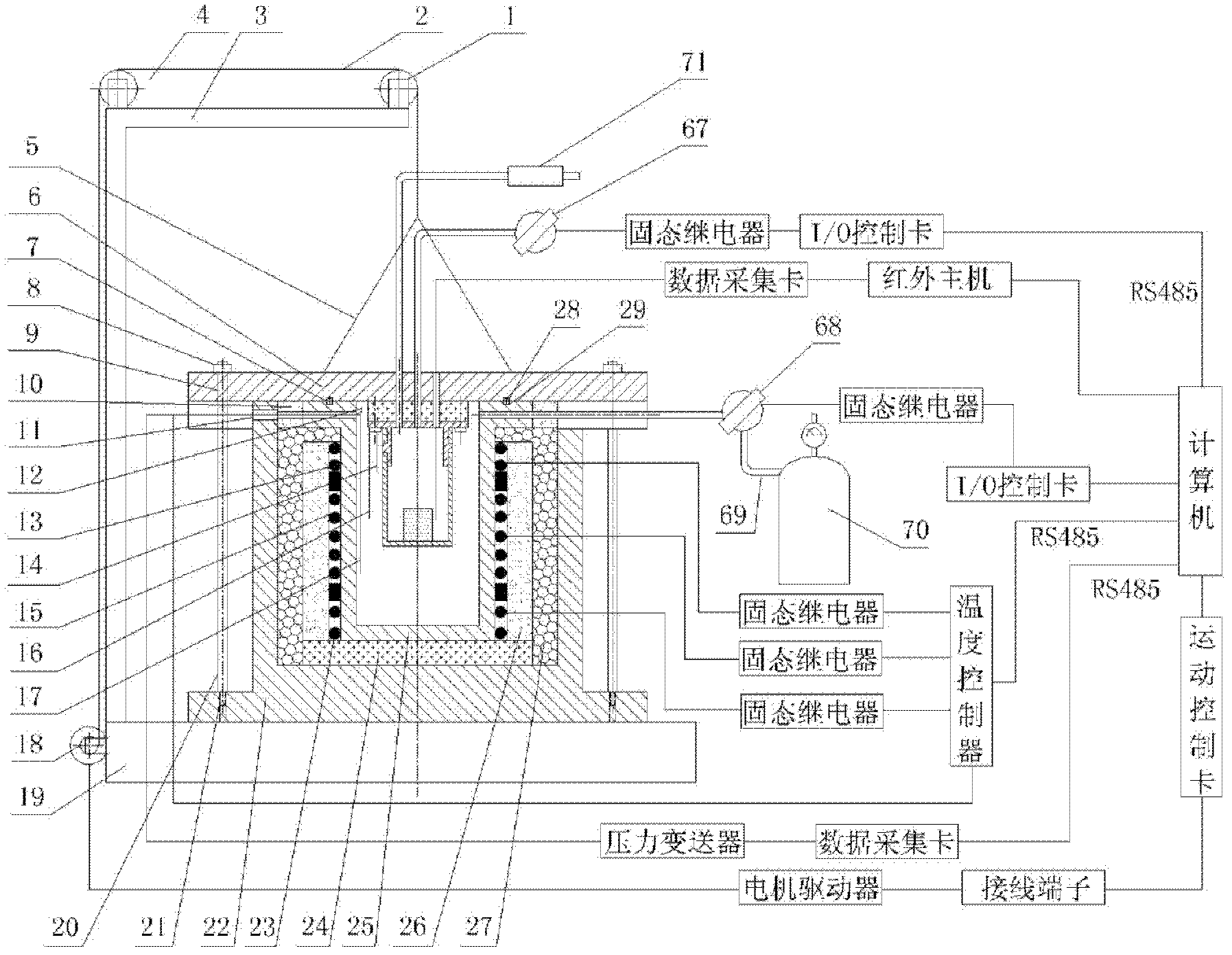

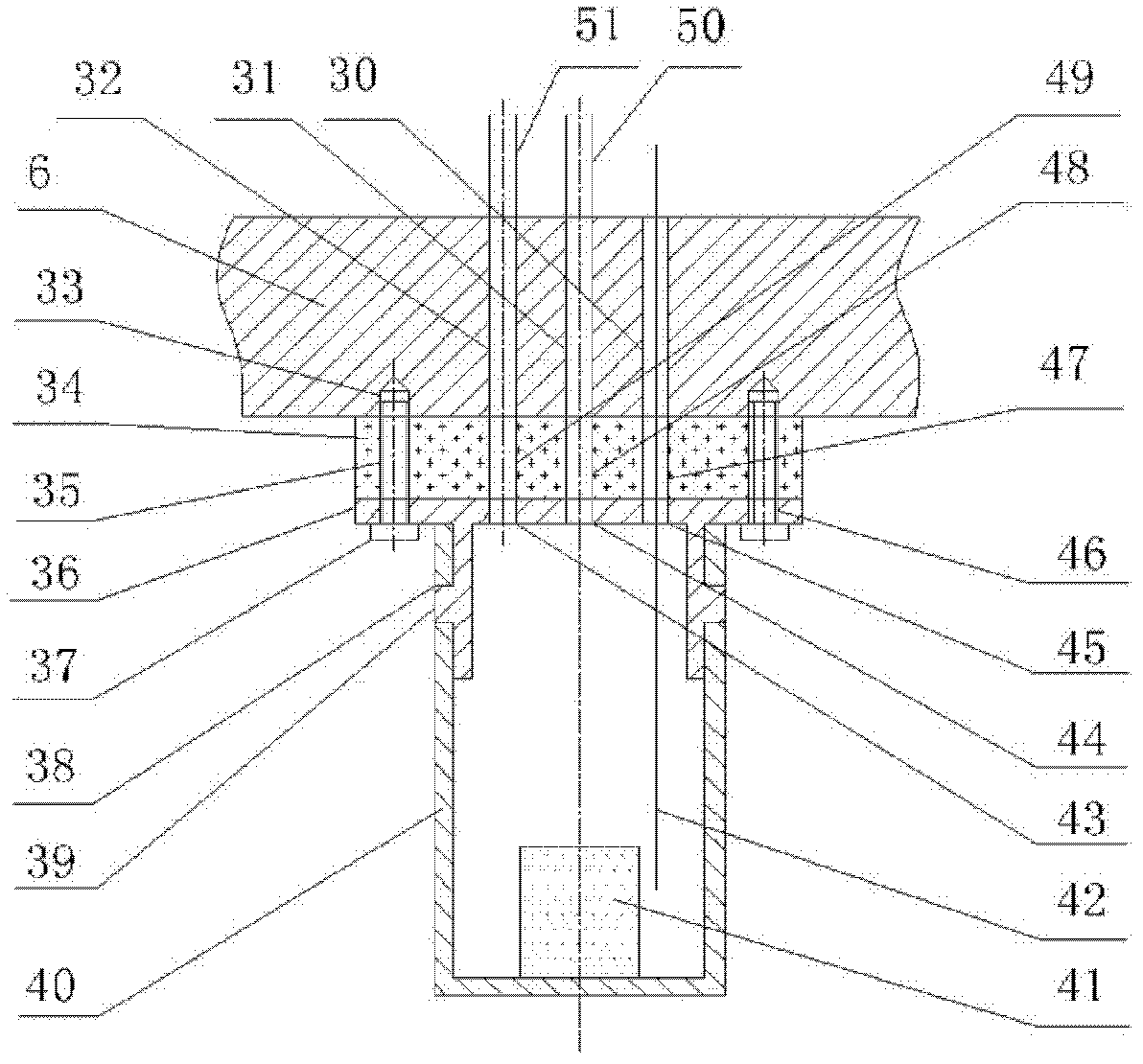

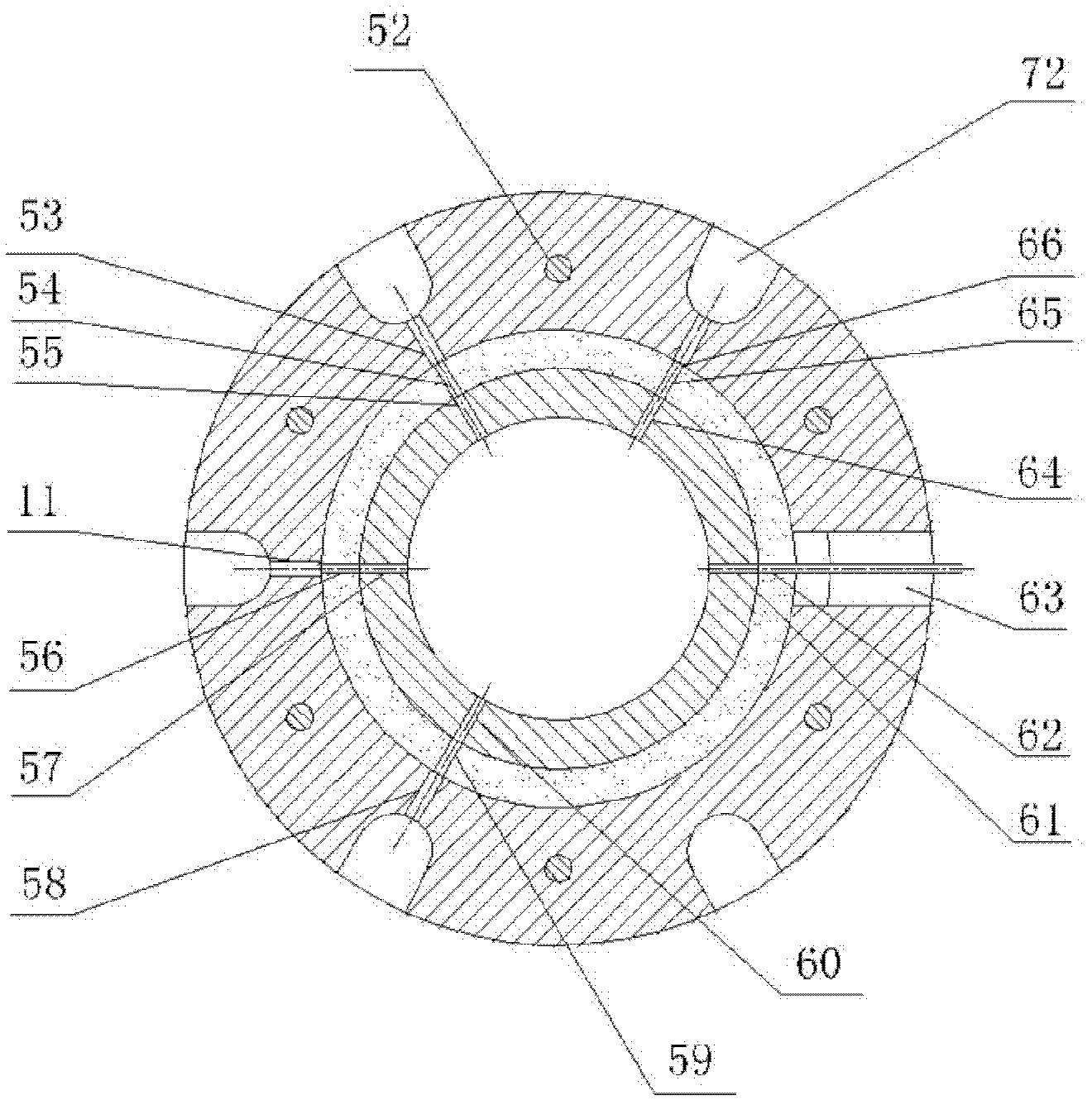

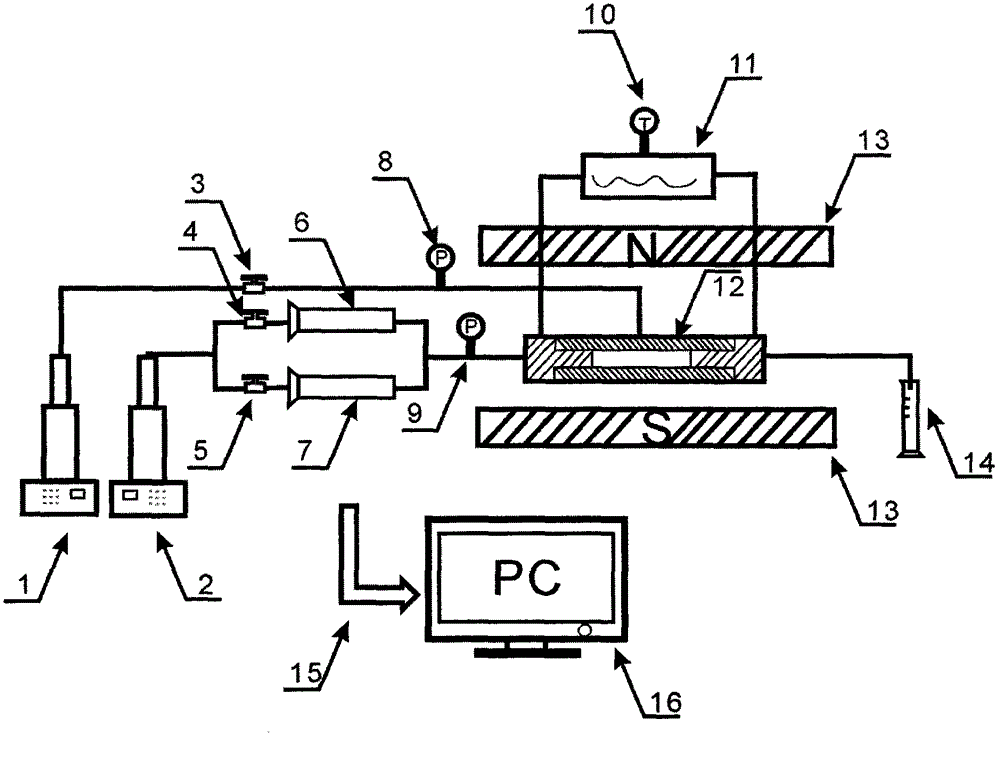

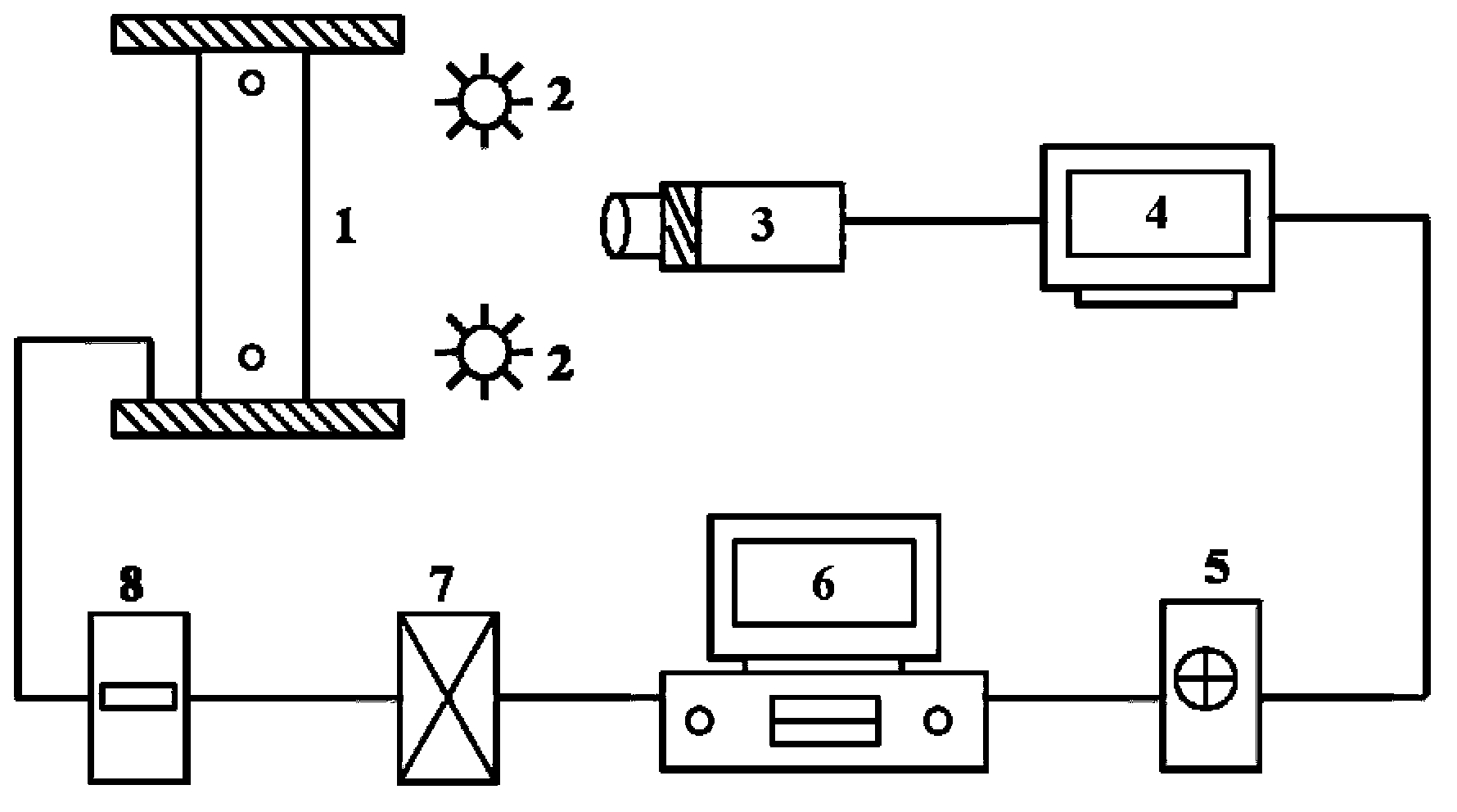

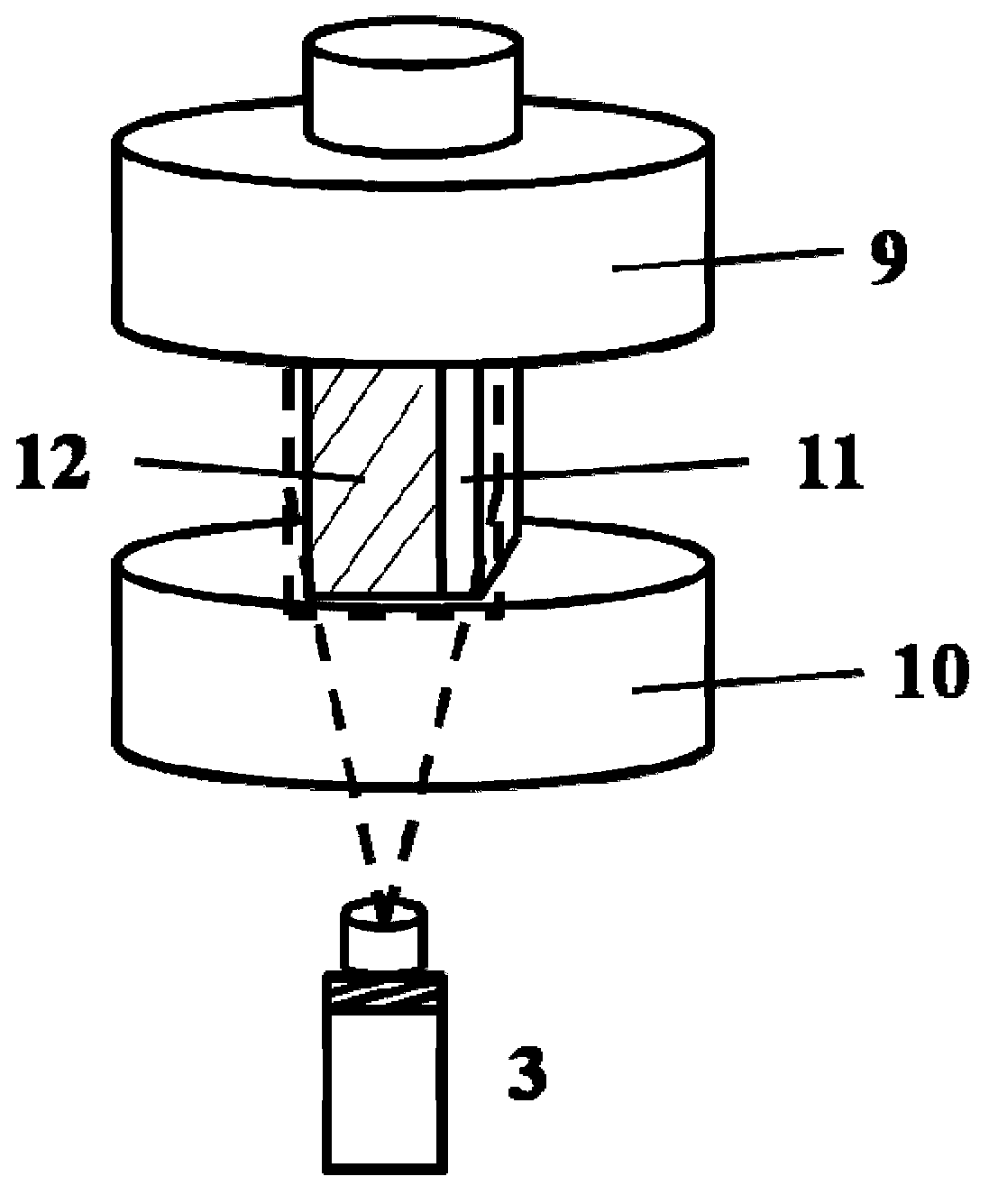

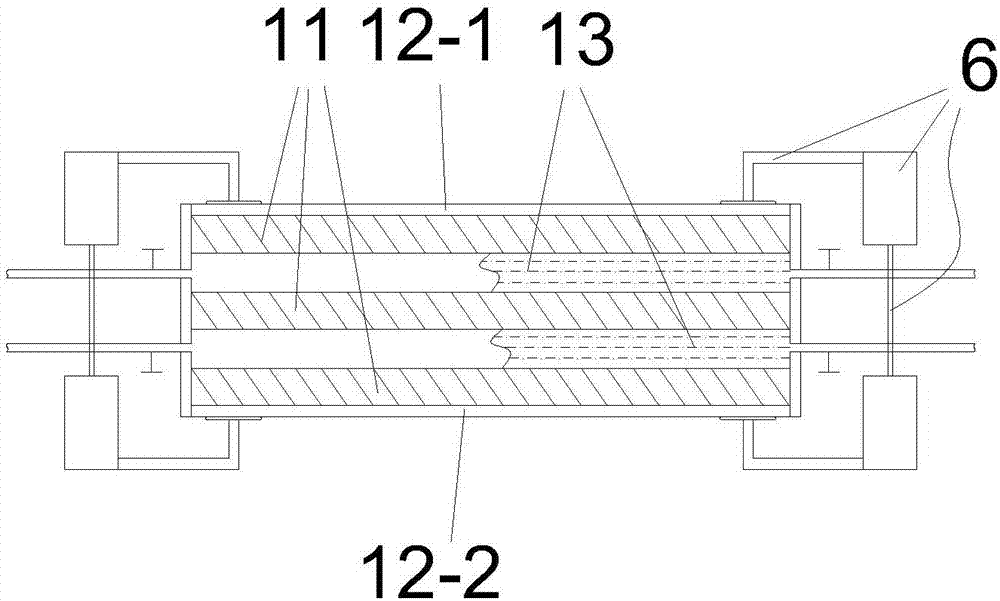

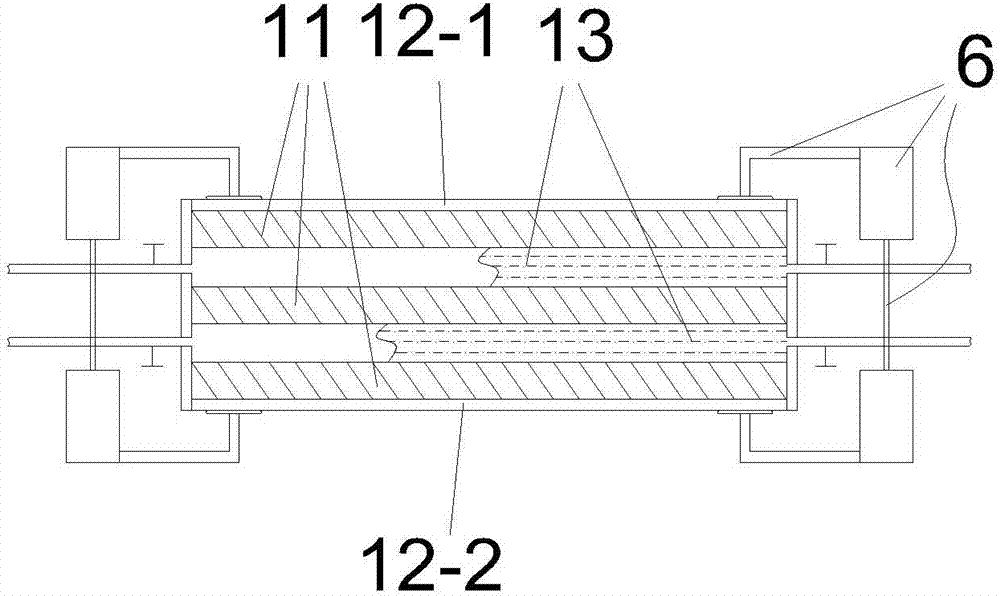

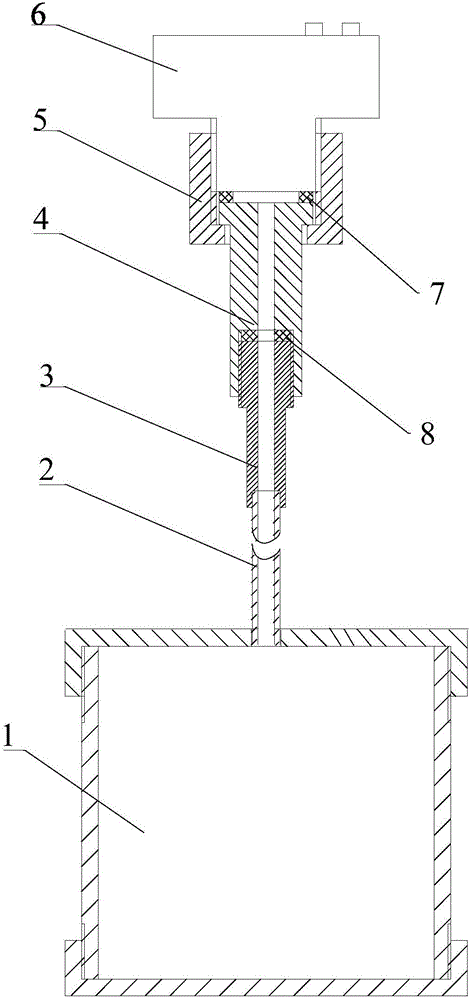

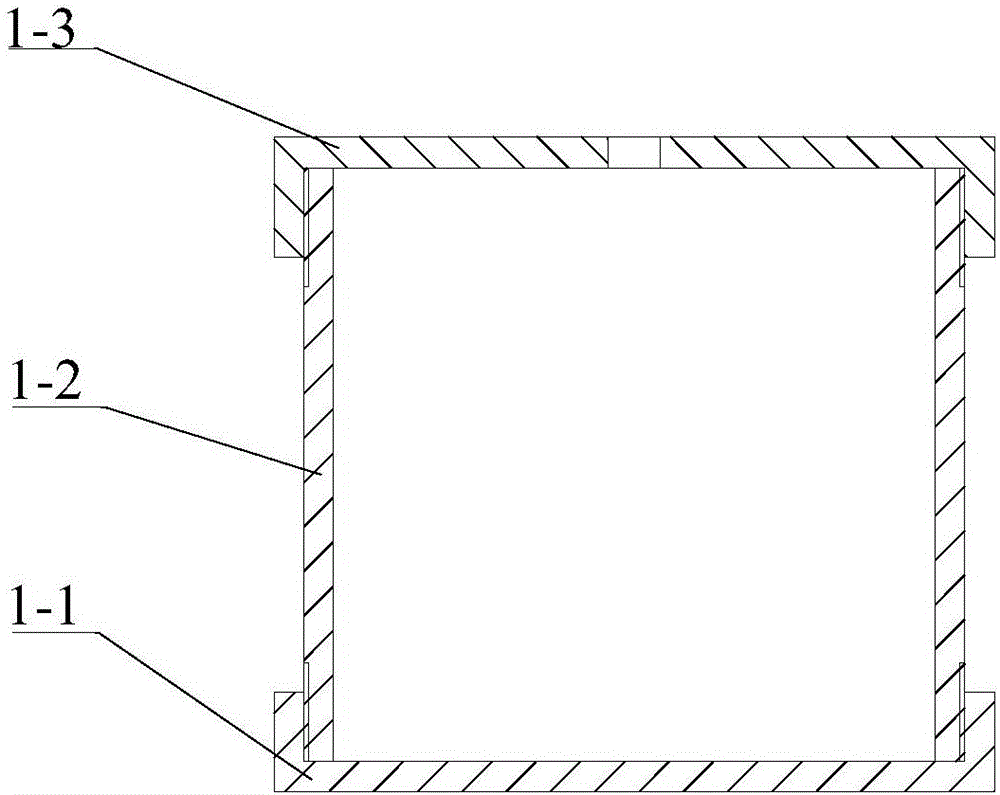

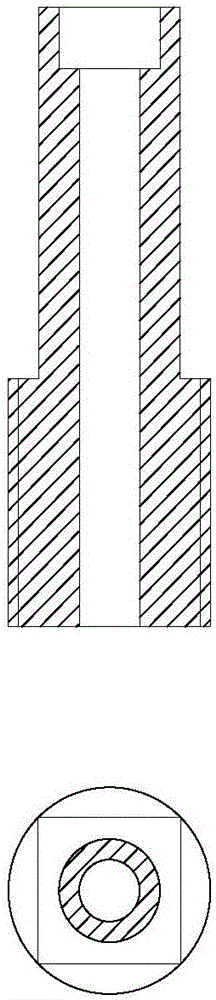

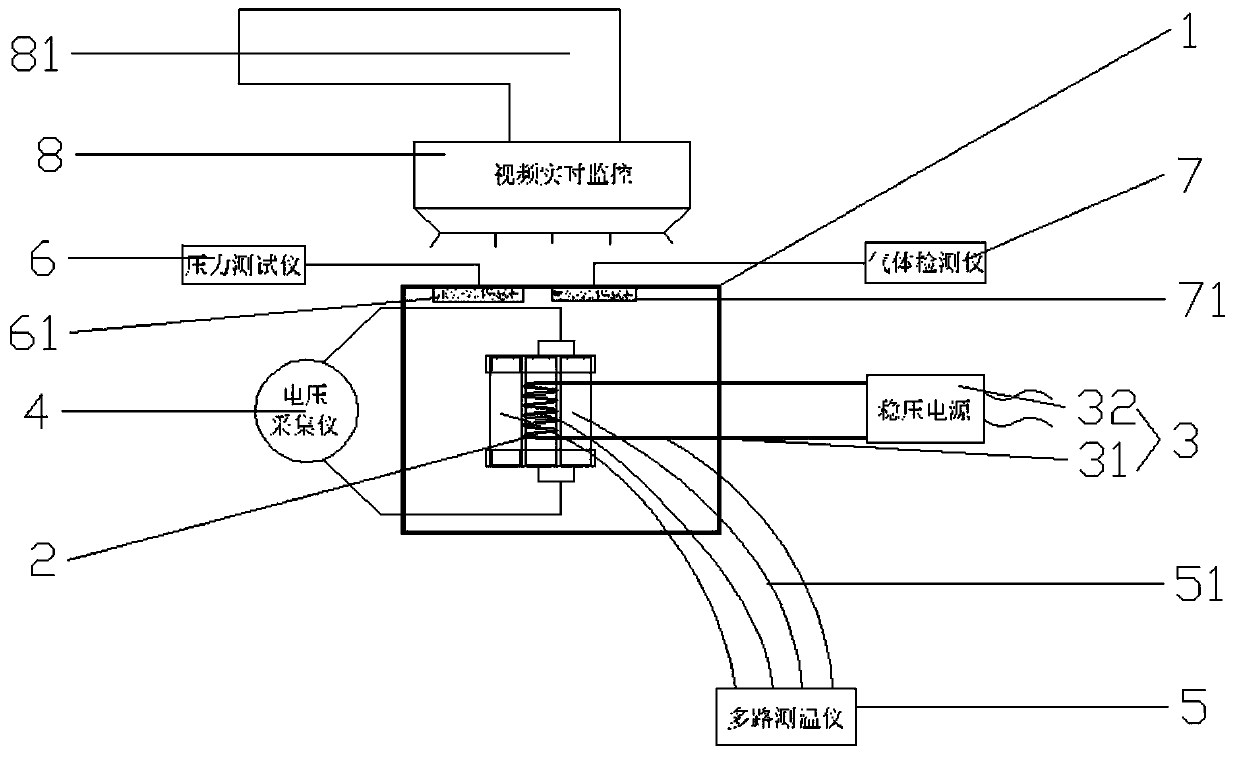

Testing system for critical pressure during thermal explosion of explosives

InactiveCN102608160ARealize multi-point temperature controlImprove uniformityMaterial exposibilityData acquisitionData treatment

The invention discloses a testing system for critical pressure during thermal explosion of explosives. The testing system comprises a pressure-resistance heating unit, a pressure control unit, a sample loader unit, a decomposed product detection unit and a computer; the pressure-resistance heating unit comprises a single-cavity heating furnace body, wherein a temperature sensor which is connected with the computer is arranged in a furnace cavity, and temperature, temperature rise speed and pressure of the single-cavity heating furnace body are controlled by the computer; the pressure control unit comprises a high-pressure gas cylinder, a pressurizing gas channel pipe, a pressurizing electromagnetic valve, a heat conduction layer extension edge pressurizing pipe, a pressure-releasing gas channel pipe, a pressure-releasing electromagnetic valve, a safety valve gas channel pipe, a safety valve and a pressure sensor; the sample loader unit comprises an L-shaped bracket, a stepping motor, two fixed pulleys, a steel wire rope, a furnace cover, a sample reservoir bracket and a sample reservoir; the decomposed product detection unit comprises an infrared sensor which is arranged in the sample reservoir; and the computer is provided with a data acquisition card, a graphic display control and a data processing unit and can be used for identifying the critical state of thermal decomposition to combustion or explosion and acquiring a critical pressure parameter.

Owner:XIAN MODERN CHEM RES INST

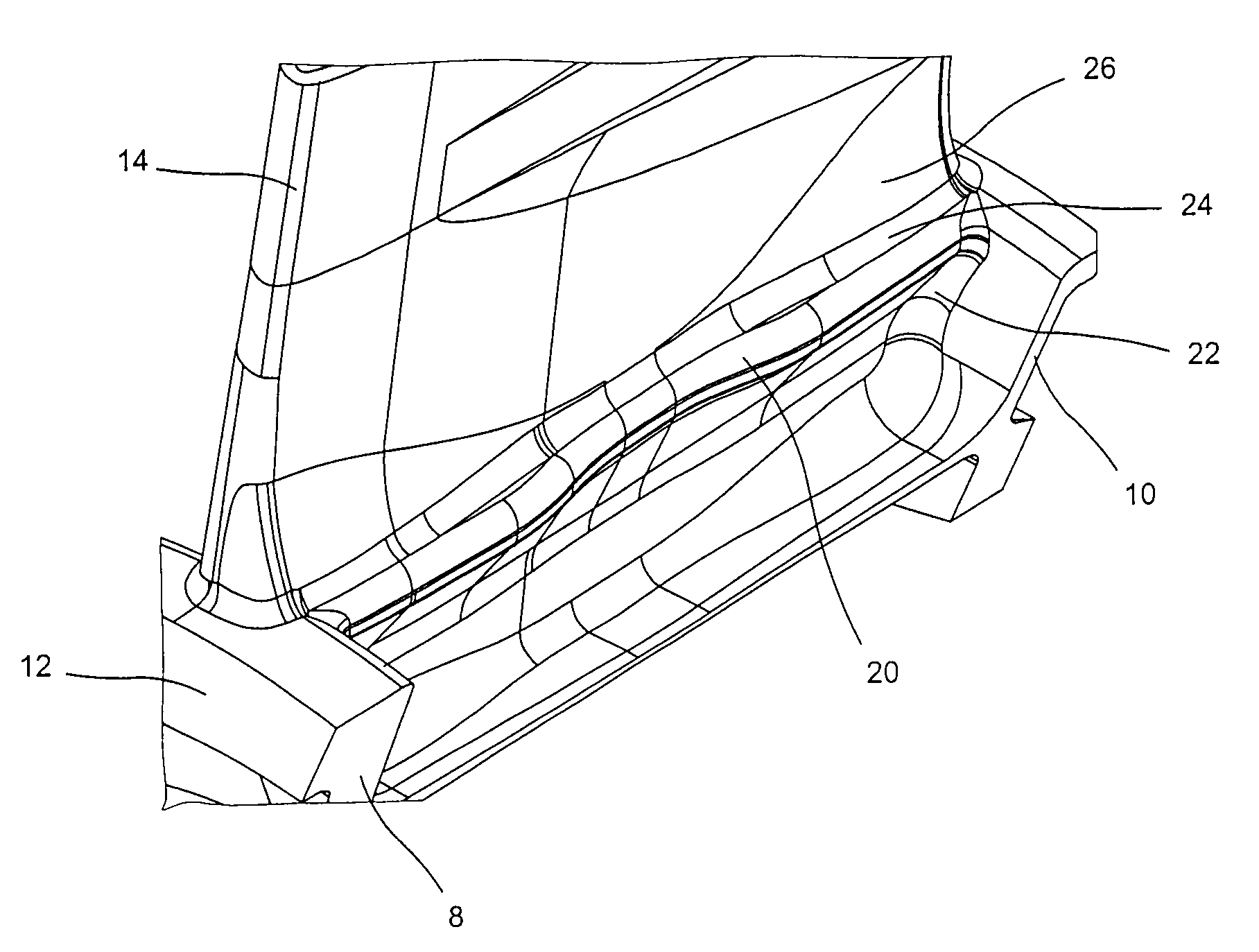

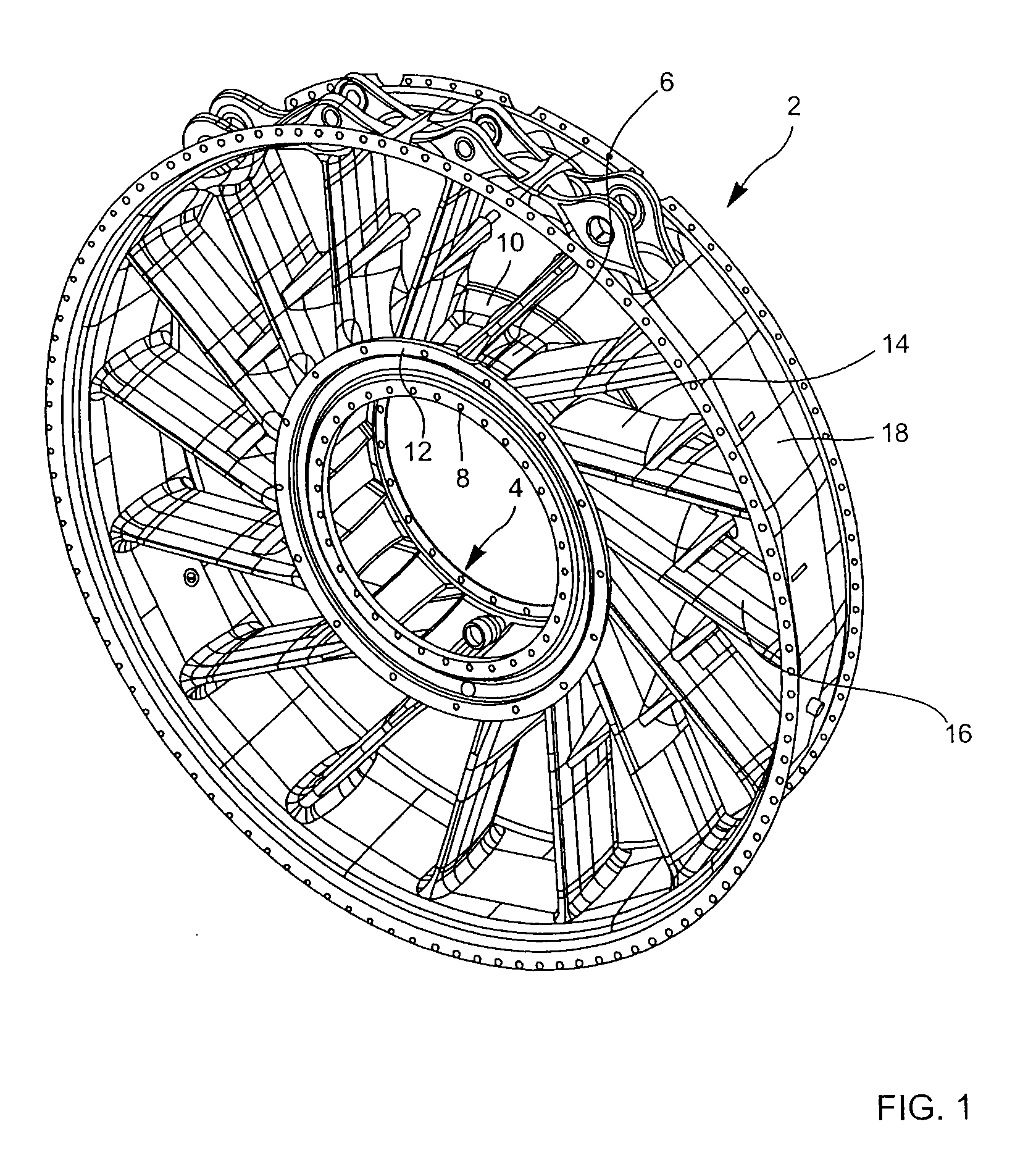

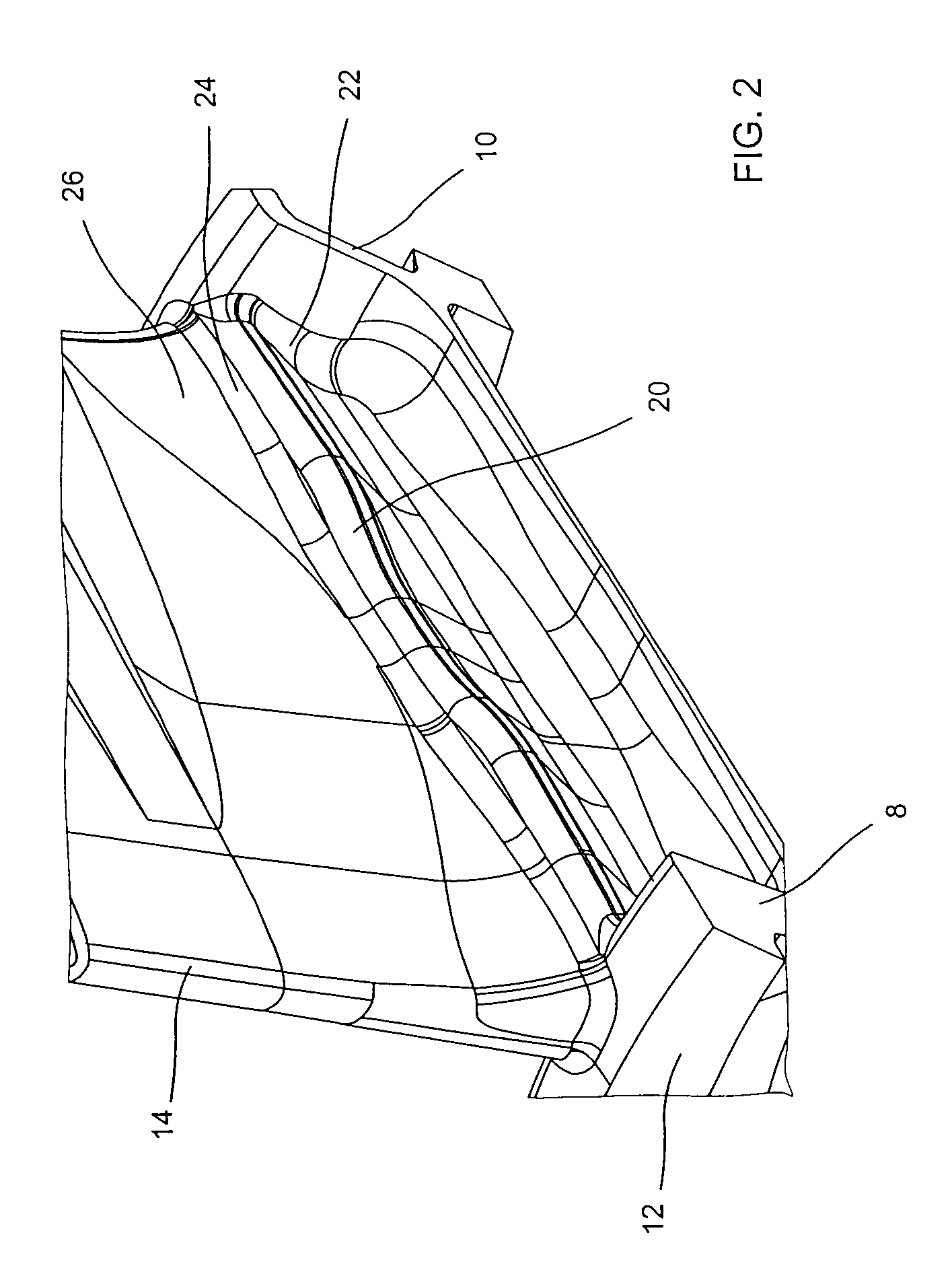

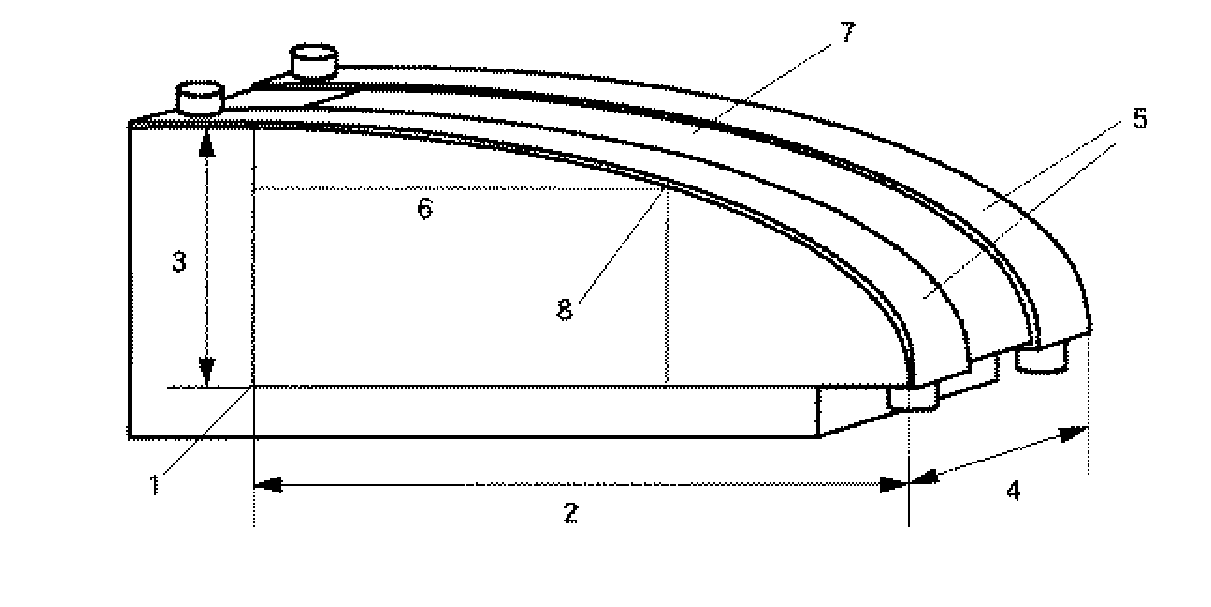

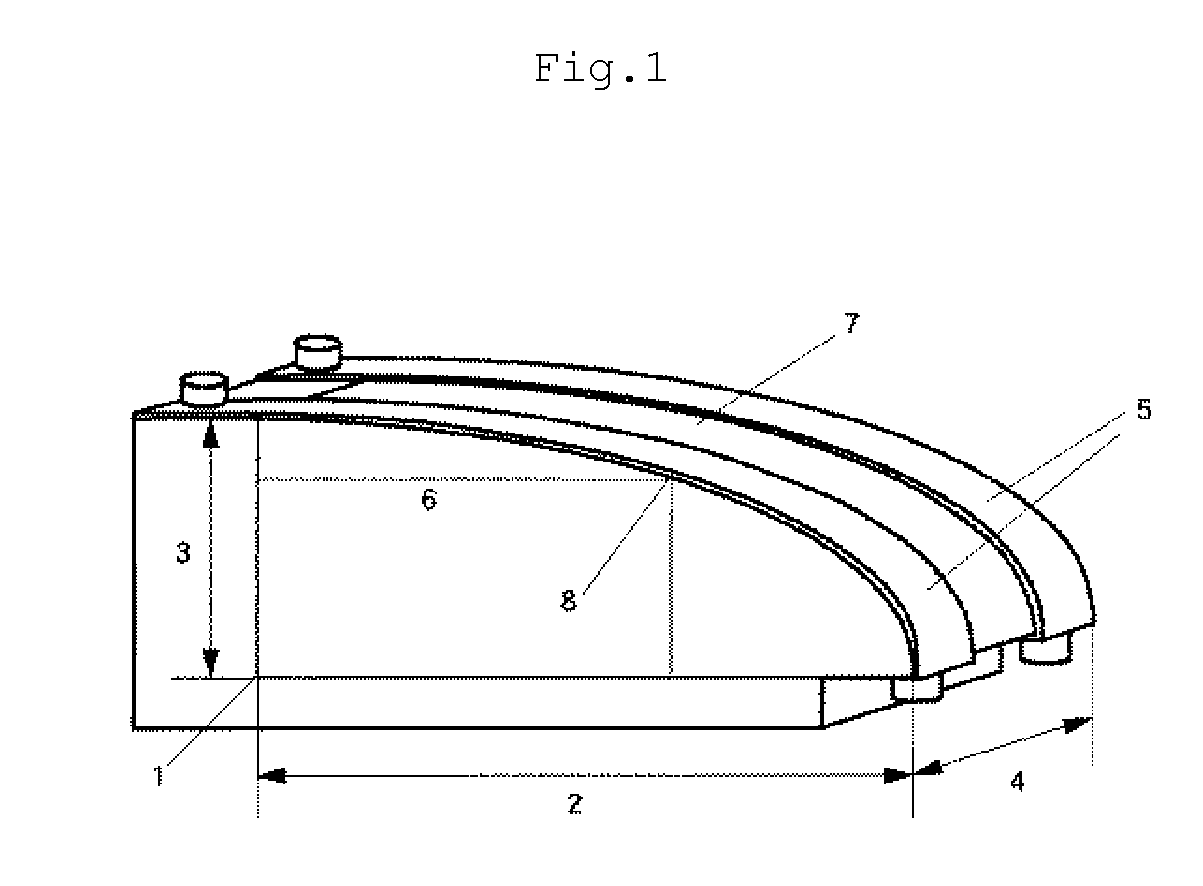

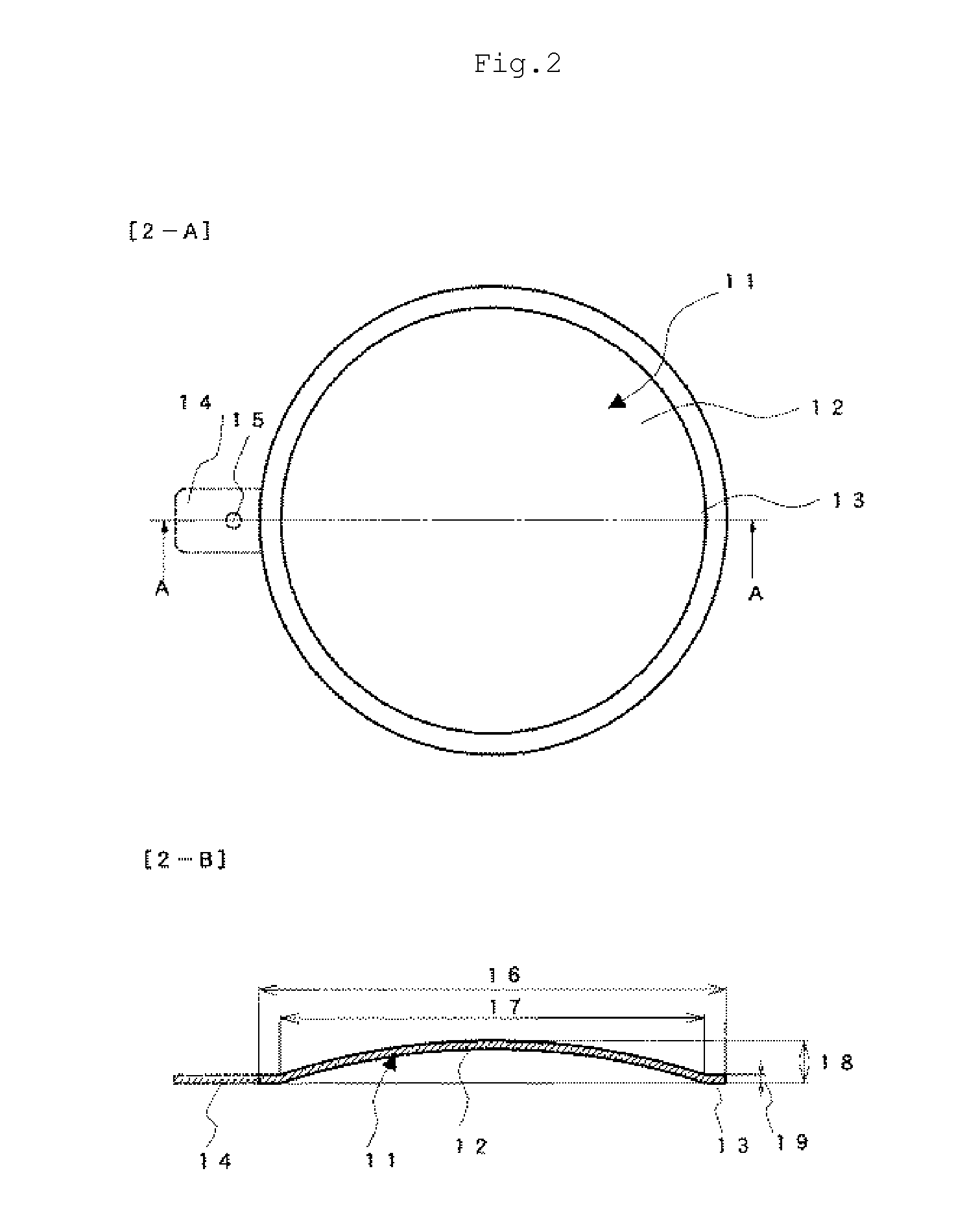

Exhaust casing hub comprising stress-distributing ribs

ActiveUS7891165B2Prolong lifeOvercome disadvantagesEngine manufacturePower plant arrangements/mountingEngineeringCritical stress

An exhaust casing hub includes a hub center, and an upstream flange and a downstream flange arranged on either side of the hub center. Each flange is terminated by a rim. A plurality of cuffs are arranged on the hub center so as to form an angle from the tangent toward the radial direction of 10° to 80° , preferably 15° to 75°. At least one rib is formed at the base of each cuff below a critical stress region in the cuff. The rib is joined to the downstream flange by a downstream end and to the upstream flange by an upstream end.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

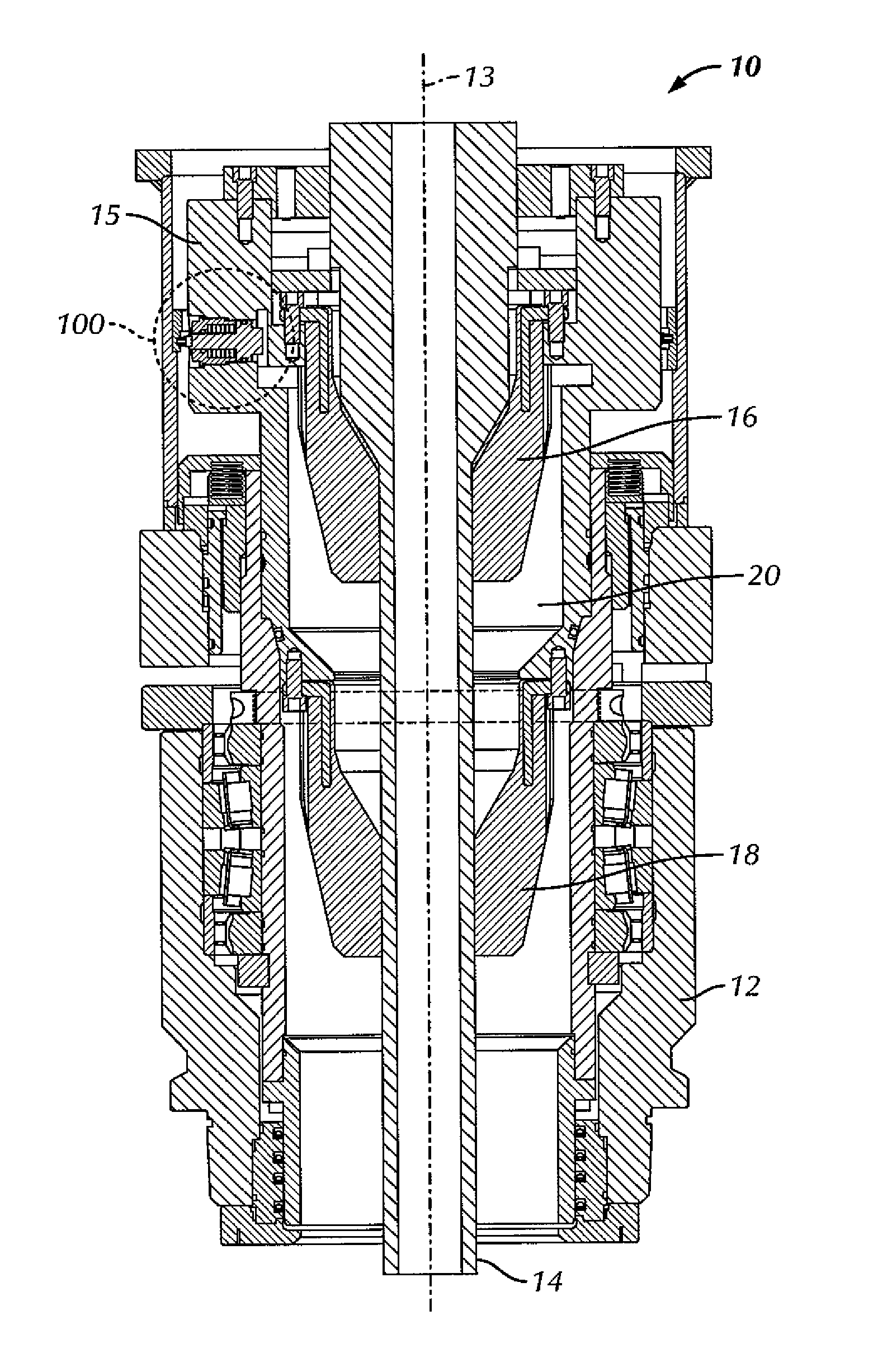

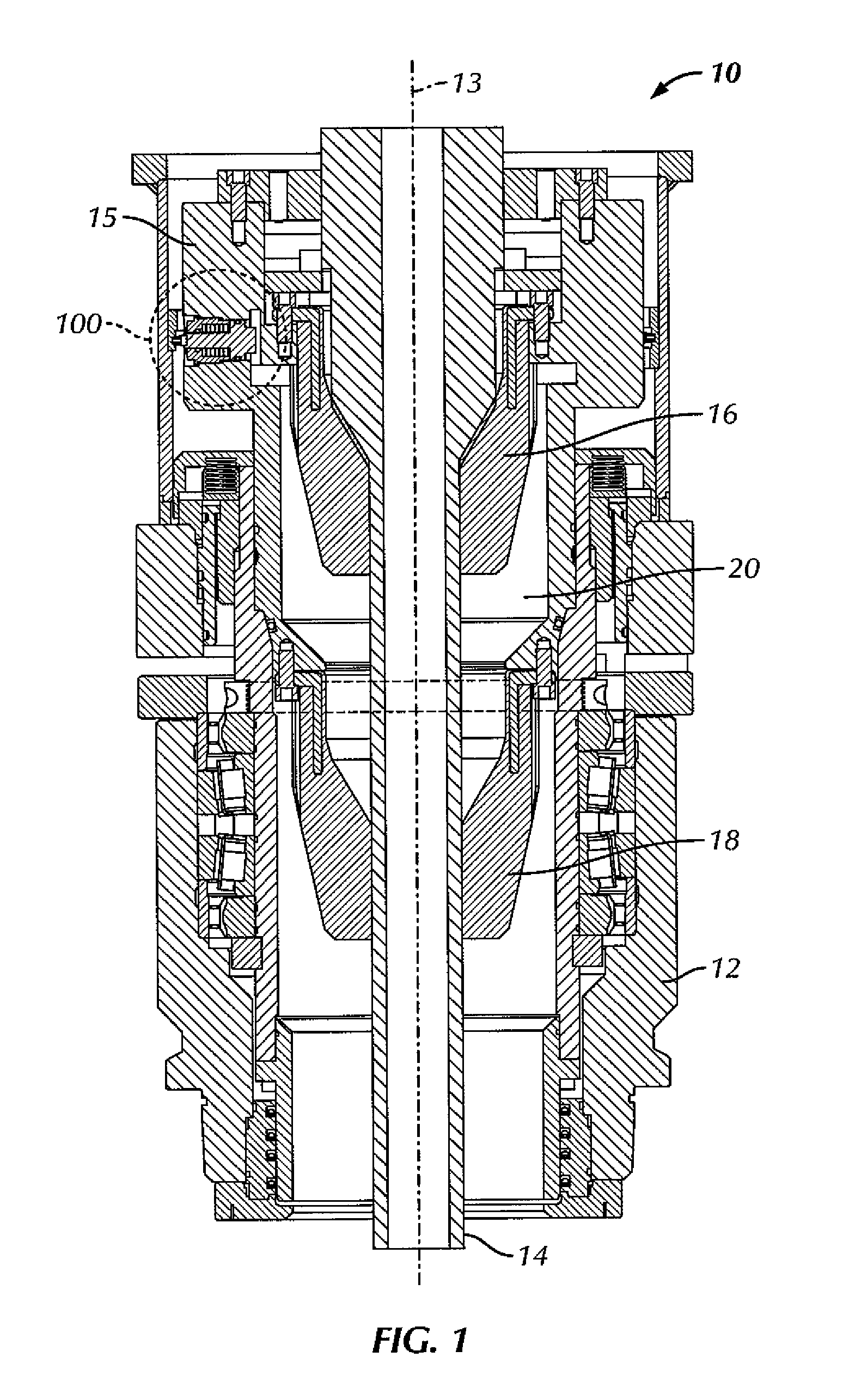

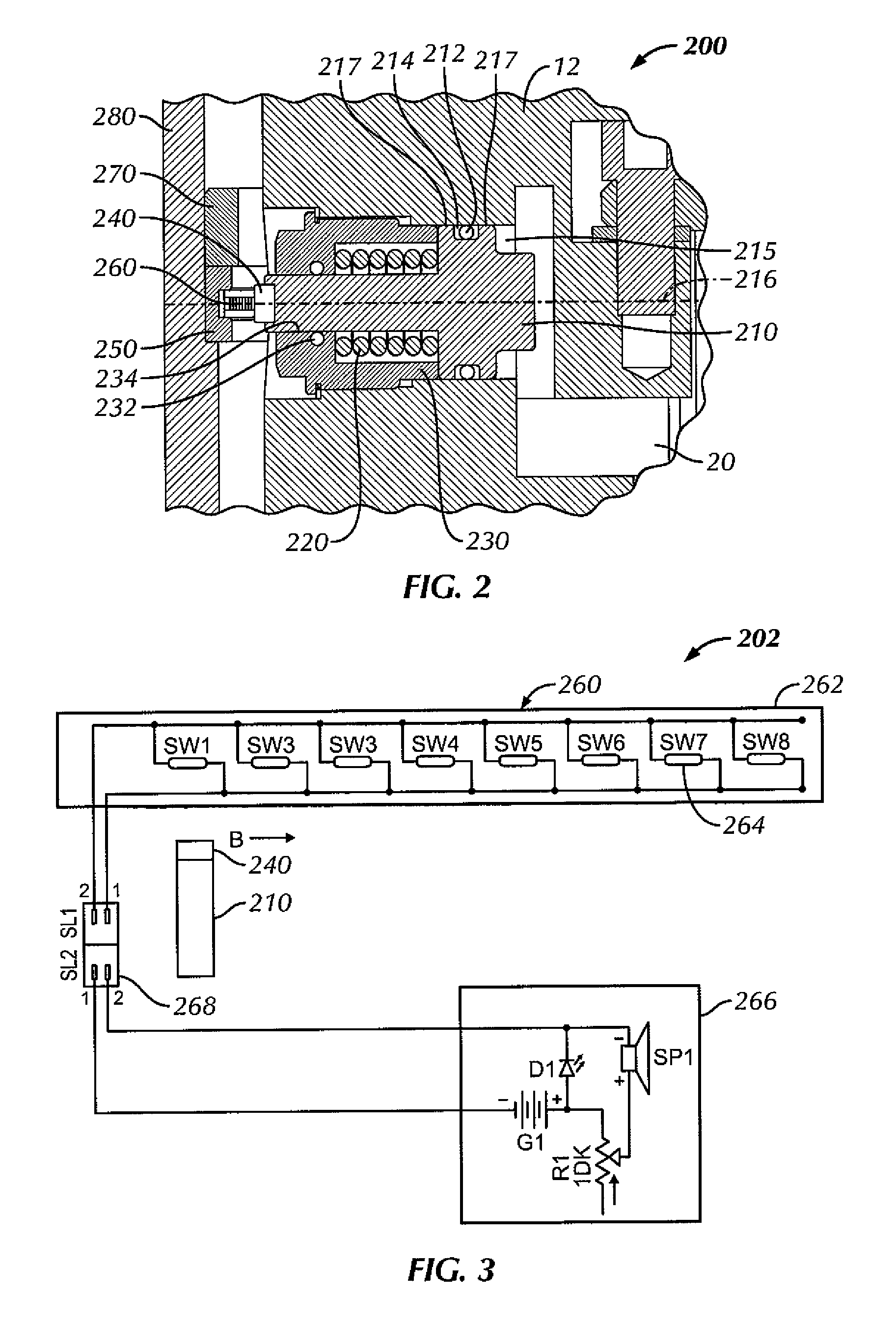

Dual stripper rubber cartridge with leak detection

A rotating control drilling device includes an upper sealing element and a lower sealing element positioned around a drillstring and forming a chamber therebetween and a leak detection device. The leak detection device includes a piston in communication with the chamber, a magnet disc disposed on an end of the piston, and a plurality of magnetic sensors arranged in a magnetic sensing ring around the rotating control drilling device. Upon reaching a selected critical pressure in the chamber, a spring is configured to compress as the magnet disc is positioned proximate to the plurality of magnetic sensors. Furthermore, a method to detect leaks in a rotating control device includes positioning a leak detection device in communication with a chamber located between upper and lower sealing elements and signaling with the leak detection device when a pressure of the chamber exceeds a selected critical pressure.

Owner:SMITH INT INC

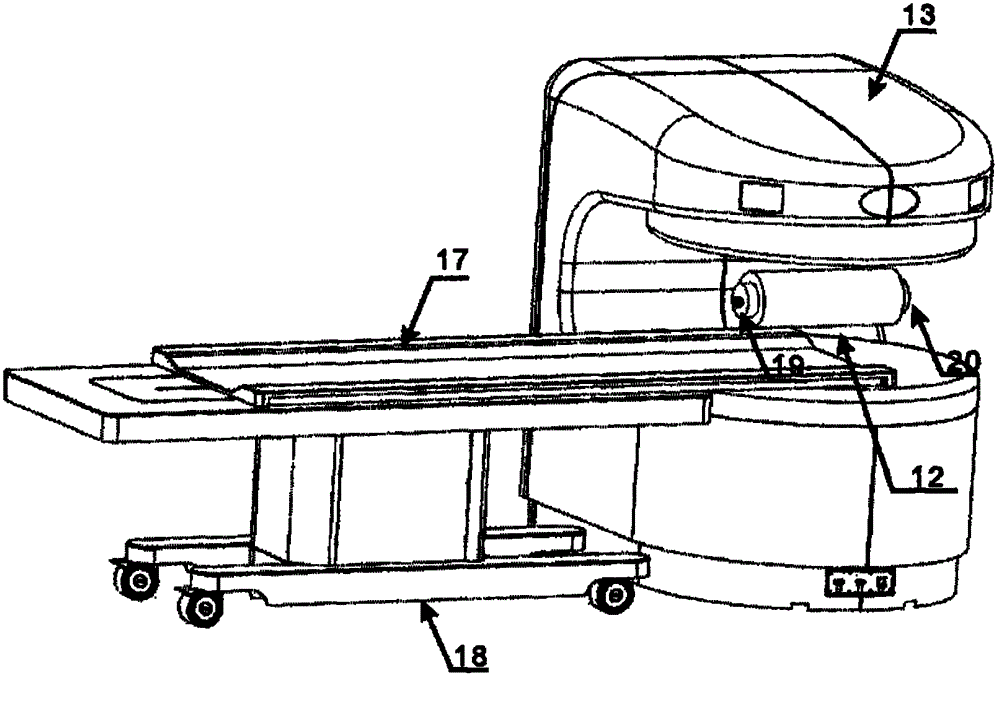

On-line testing device for high temperature and high pressure rock physical property and percolation mechanism nuclear magnetic resonance

The invention relates to an on-line testing device for high temperature and high pressure rock physical property and percolation mechanism nuclear magnetic resonance. The on-line testing device comprises a nuclear magnetic resonance on-line testing module, a rock fluid displacement module (comprising core holder compatible with nuclear magnetic resonance tests) and a computer control and data processing module, a nuclear magnetic resonance testing system and a rock fluid displacement system are combined into a whole through computer control, formation temperature and pressure are simulated, rock displacement tests are carried out under high temperature and high pressure conditions, and real-time nuclear magnetic resonance signals are measured on line to obtain rich rock parameters (porosity, permeability, reservoir forming critical pressure, wettability and the like). The on-line testing device serves as a device for oil gas reservoir forming geological research and oil gas target assessment, and the purposes of analyzing core physical properties and percolation mechanism from micro perspective are achieved.

Owner:PEKING UNIV

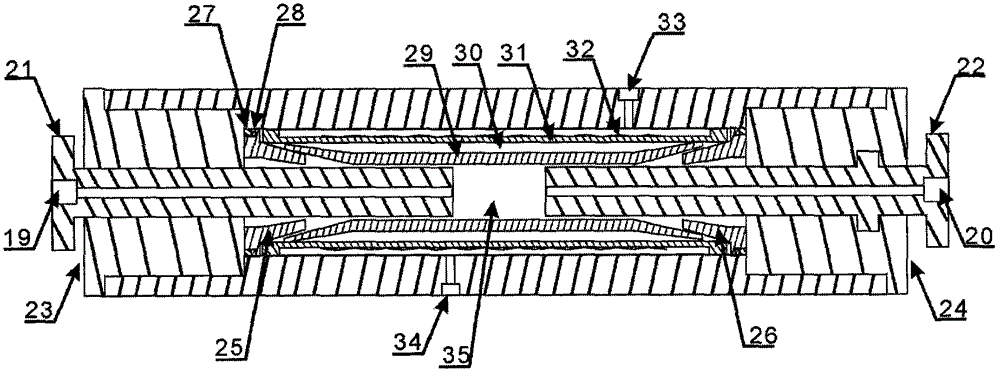

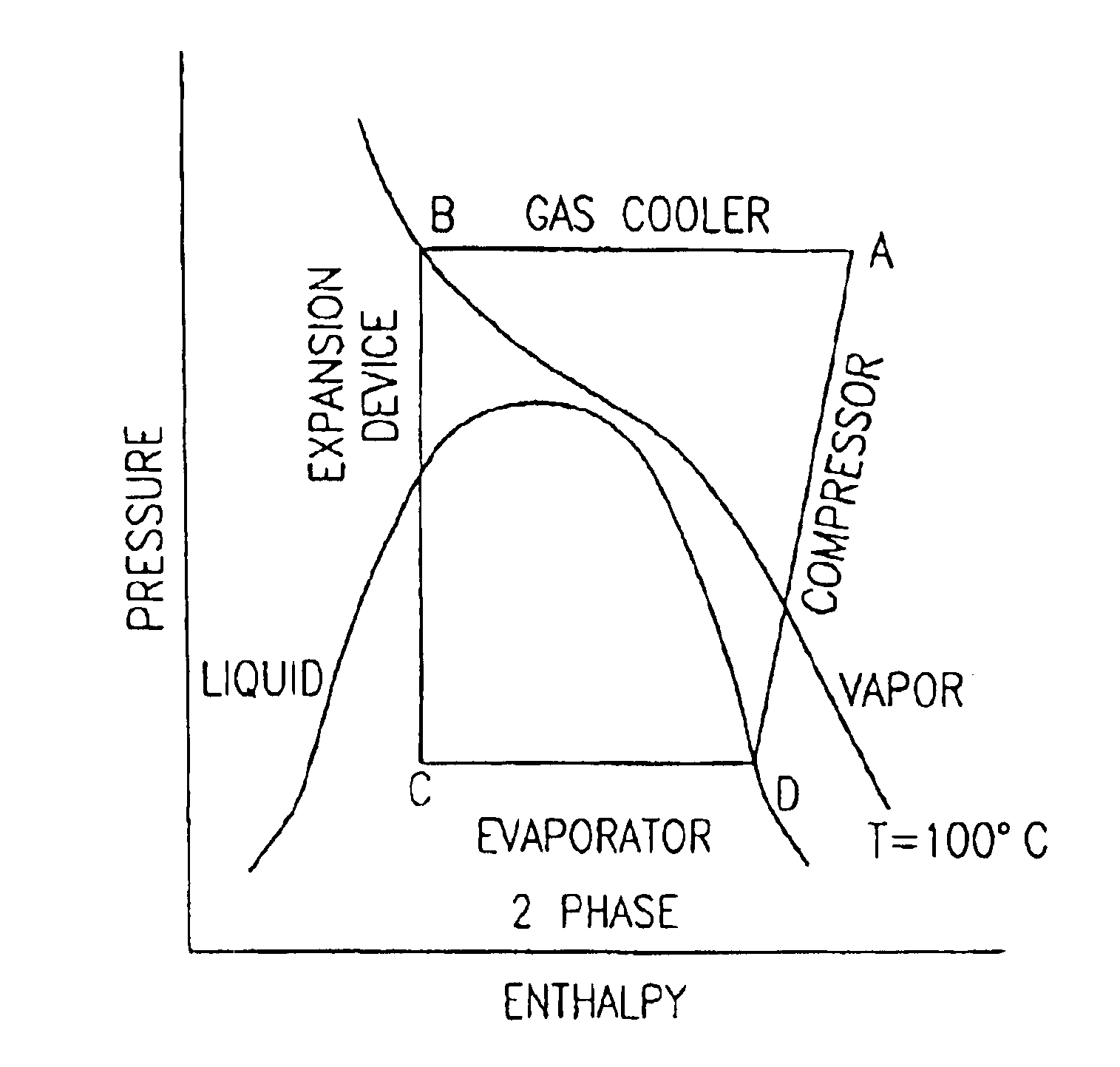

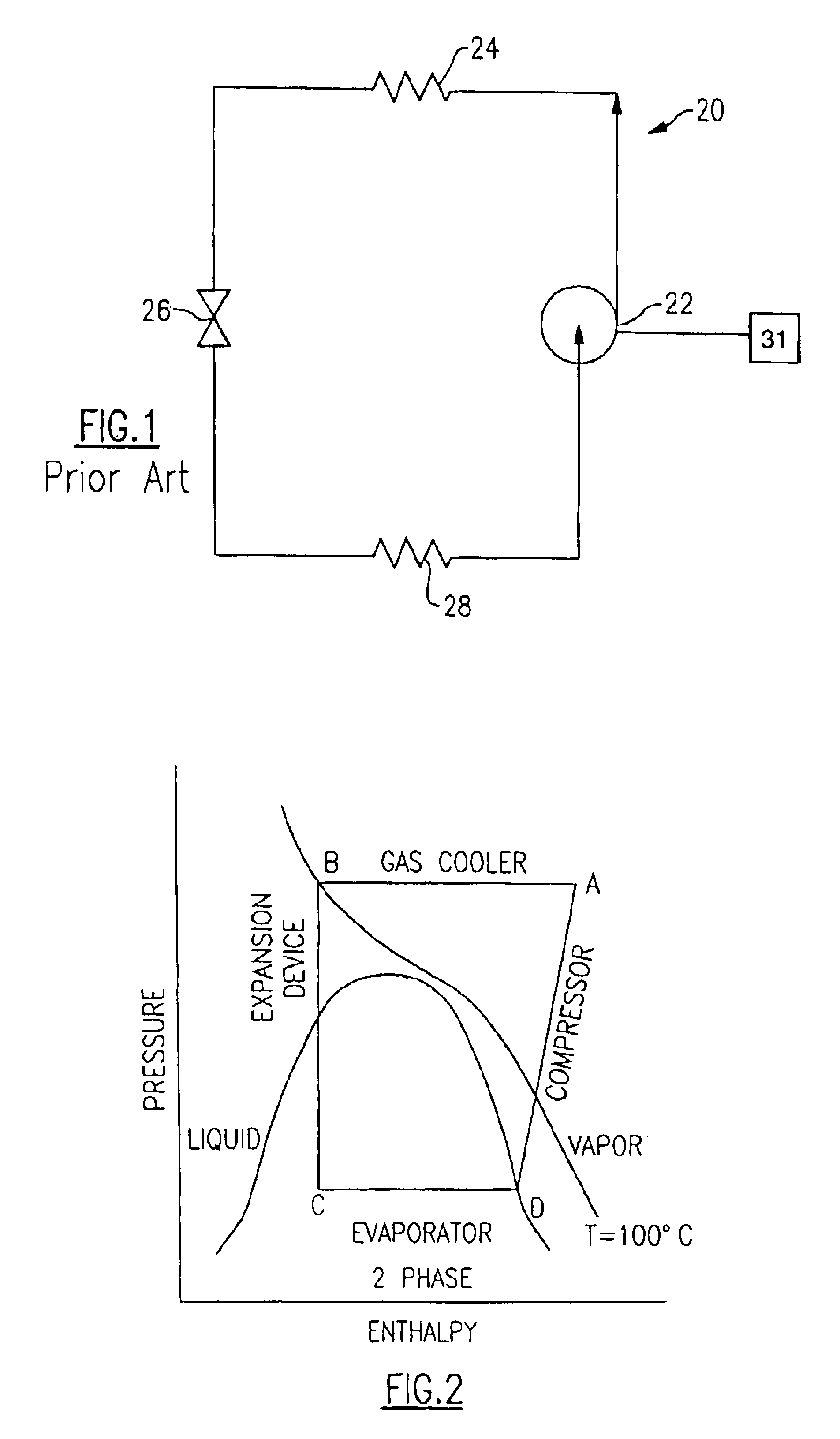

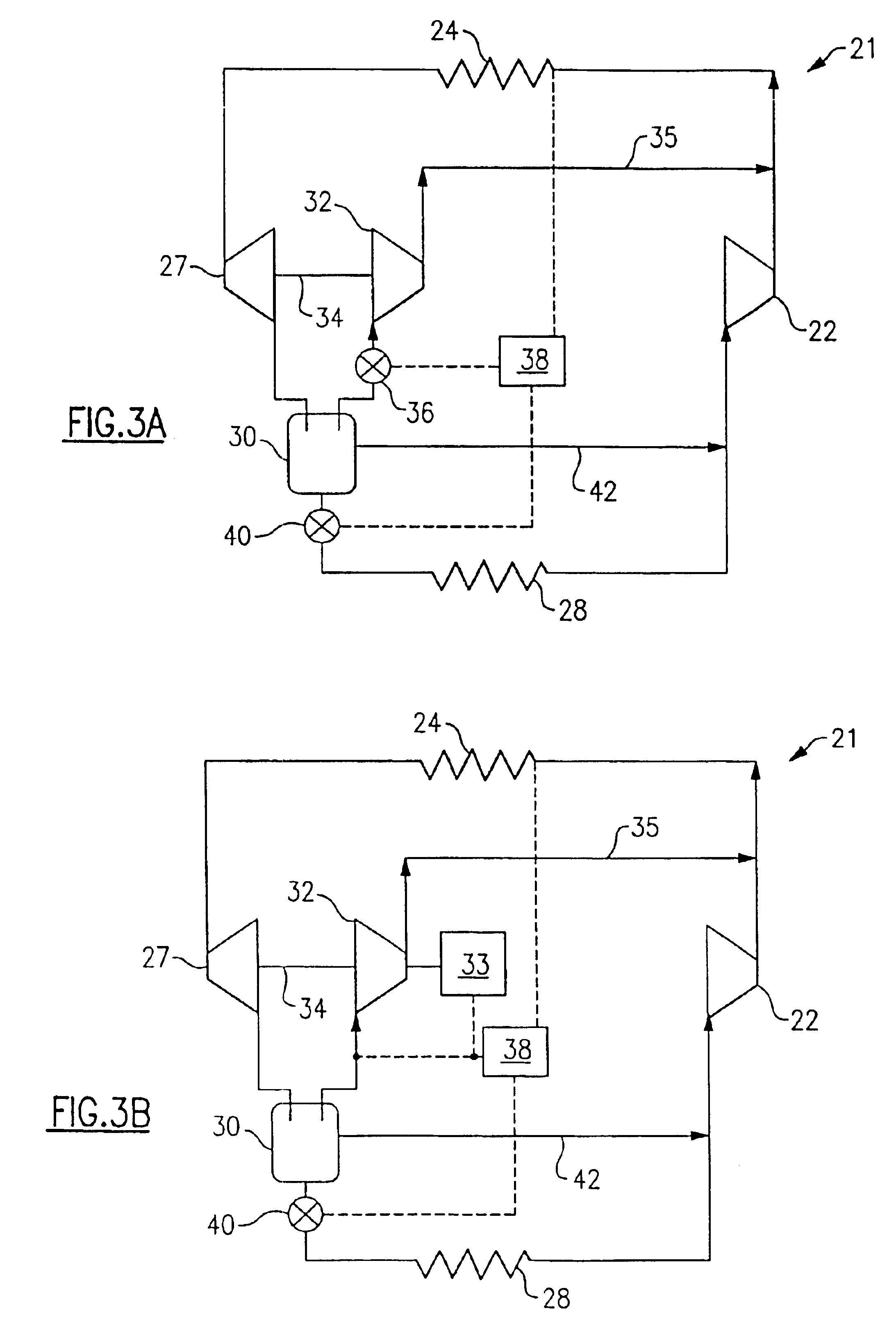

Supercritical pressure regulation of vapor compression system by regulation of expansion machine flowrate

InactiveUS6898941B2Increase capacityImprove efficiencyCompression machines with non-reversible cycleSteam/vapor condensersControl systemHigh pressure

The expansion machine flowrate of a vapor compression system is regulated to directly control the supercritical pressure in the high pressure component of the transcritical system. The expansion machine is directly linked to a recompressor which recompresses the vapor phase of the expanded flow. By controlling the flowrate of the recompressor with a first valve, the flowrate of the expansion machine can be controlled to control the massflow rate through the expansion machine and therefore the high pressure of the system.

Owner:CARRIER CORP

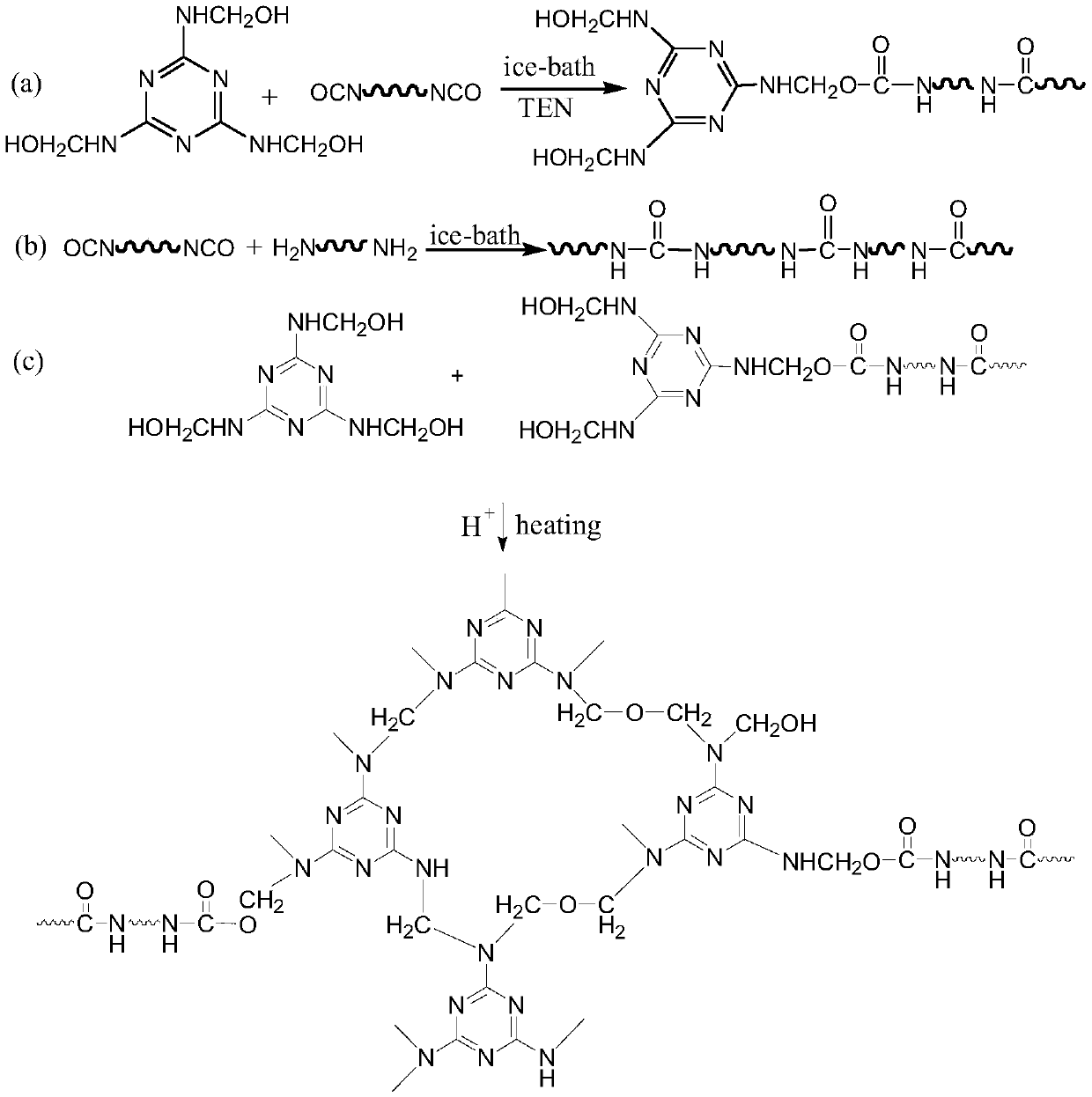

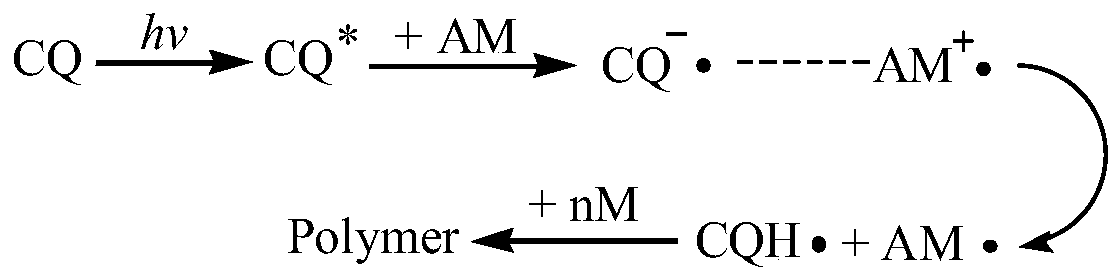

Melamine resin and polyurea resin double-shell microcapsule and preparing method and application thereof

ActiveCN105498652AGood encapsulation effectGood mechanical propertiesMicroballoon preparationMicrocapsule preparationWater bathsLow speed

The invention discloses a melamine resin and polyurea resin double-shell microcapsule and a preparing method and application thereof. The preparing method includes the steps that a melamine prepolymer, a chain extender and an emulsifying agent are added into a reactor by the mass ratio of 100:5:20-100:10:30, and stirred at a low speed at the room temperature until the melamine prepolymer, the chain extender and the emulsifying agent are completely dissolved, the pH value is adjusted to be one to six, a curing agent and core material homogeneous phase mixture is added, an emulsifying machine is used for emulsifying and stirring under the ice-bath condition, and emulsification is conducted continuously; the temperature of a water bath is raised to be 40 DEG C or above, a turbulent stirring paddle is used for stirring, a reaction continues to be conducted, the pH value is adjusted to be larger than or equal to six, and the reaction is stopped to obtain the double-shell microcapsule with the particle size of 0.1-300 micrometers, wherein an outer shell is made of melamine resin, and an inner shell is made of polyurea resin. A core material is protected by two shell materials, storage stability of the microcapsule can be improved, and the water mass content of the double-shell microcapsule is smaller than or equal to 5%; the critical stress is 0-900 mN, and the mechanical property is good.

Owner:SOUTH CHINA UNIV OF TECH

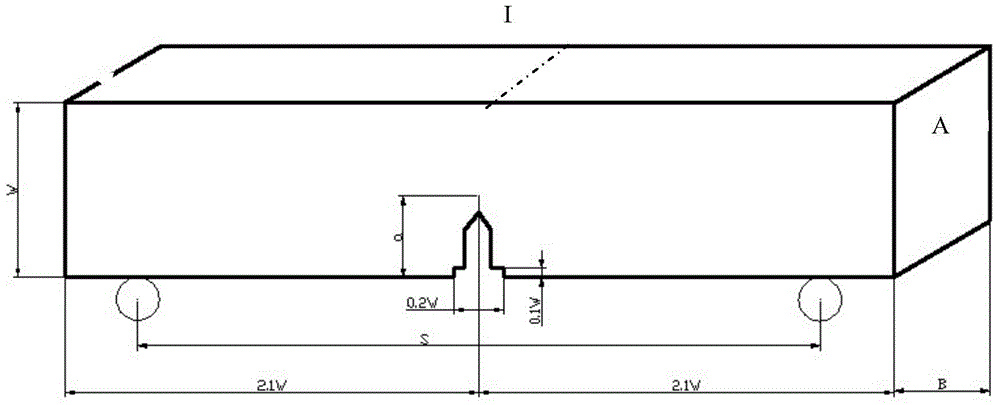

Method for testing fracture toughness of rattan canes based on three-point bending mode

InactiveCN104568605AImprove test accuracyImprove accuracyMaterial strength using steady bending forcesCritical loadStress strength

The invention provides a method for testing the fracture toughness of rattan canes based on a three-point bending mode. The method comprises the following steps: preparing a sample, and regulating a water content rate so as to obtain a sample of which the water content rate is 10-12%; recording a load-crack opening displacement (PV) curve, measuring actual crack depths, and calculating critical loads PQ and critical stress intensity factors KQ. According to the method provided by the invention, the crack opening displacement is measured by a C.O.D Gauge, and the test precision is improved. Aiming at the characteristics of the rattan materials, the sampling method for testing the fracture toughness of rattan canes is ensured, and the measured results having high accuracy and good reproducibility are obtained. The calculation method for testing the fracture toughness of rattan cane, provided by the invention, provides qualitative and quantitative bases for the utilization of the rattan canes.

Owner:INT CENT FOR BAMBOO & RATTAN

Method for evaluating critical stress intensity and sensitive factor of stress corrosion cracking for oil well pipe

ActiveCN1766550APracticalUsing mechanical meansInvestigating material hardnessStress strengthCritical stress

The invention discloses a method for measuring the oil well pipe corrosion cracking critical stress intensity and sensitive factor. It adopts U-type loading hook to do static loading-unloading closed loop movement to the pin-and-hole of the twin cantilever (DCB) sample before and after the sulfide stress corrosion cracking test, makes the firmer chisel, loads the DCB perpetuity shift sample and obtains the loading and the relate curve of the shift at the same time; it quantity measures the DCB sample firmer chisel initial level loading, firmer chisel loading DCB actual cantilever shift and the critical level loading value after the test.

Owner:BAOSHAN IRON & STEEL CO LTD

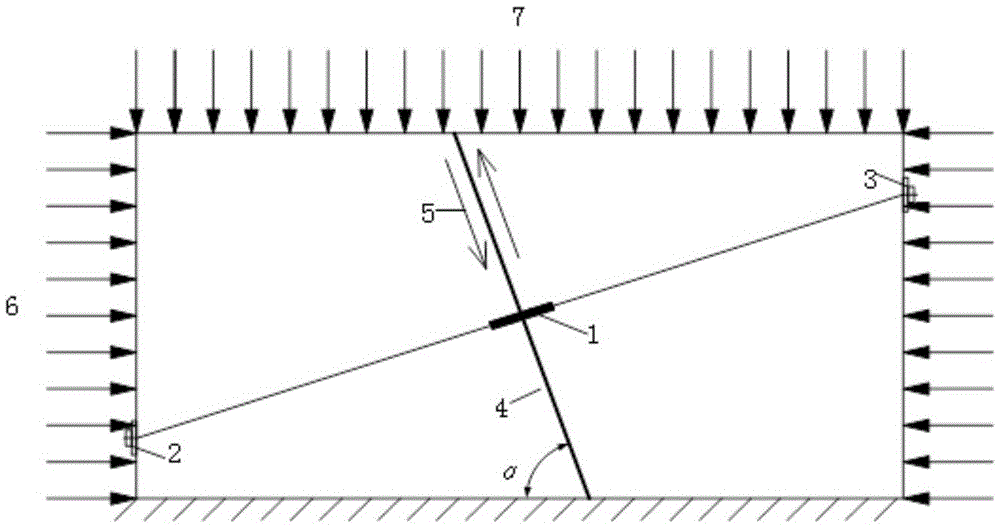

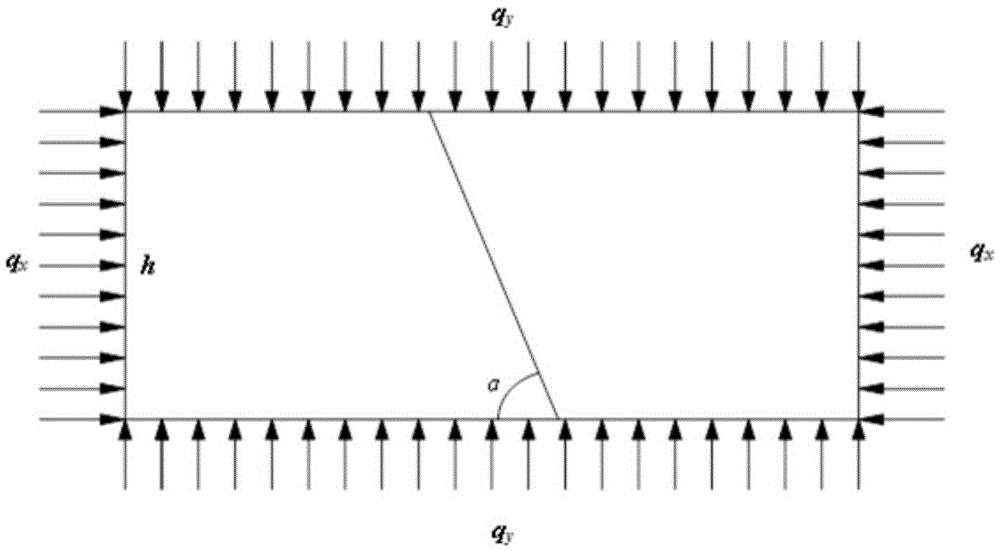

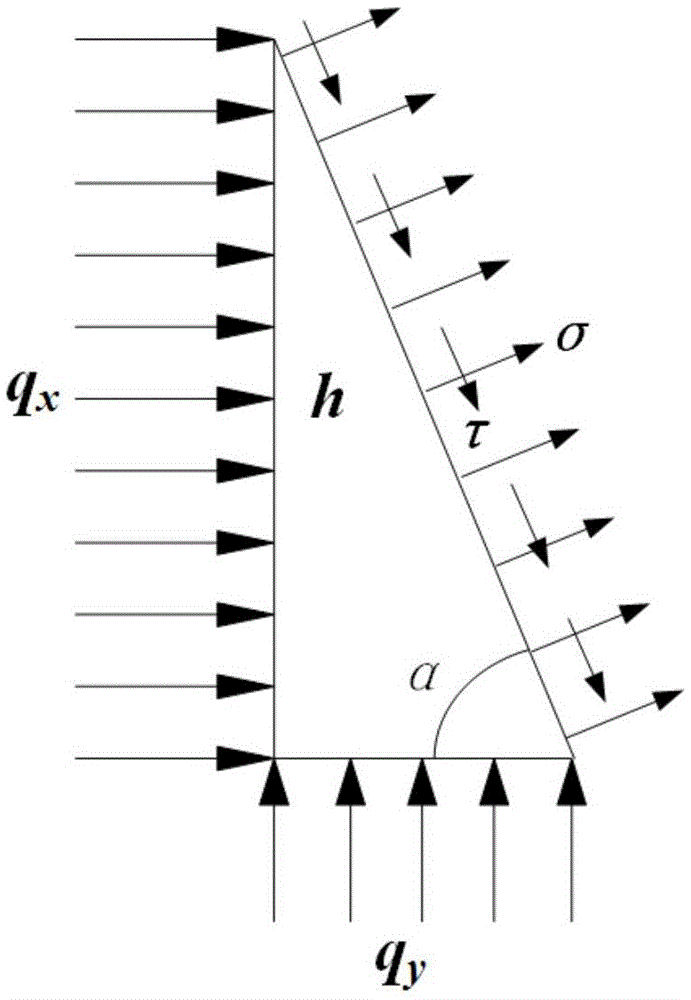

Slope progressive failure latent slide surface calculating method

ActiveCN105335607AStructural/machines measurementMaterial strength using steady shearing forcesFailure ratePrincipal stress

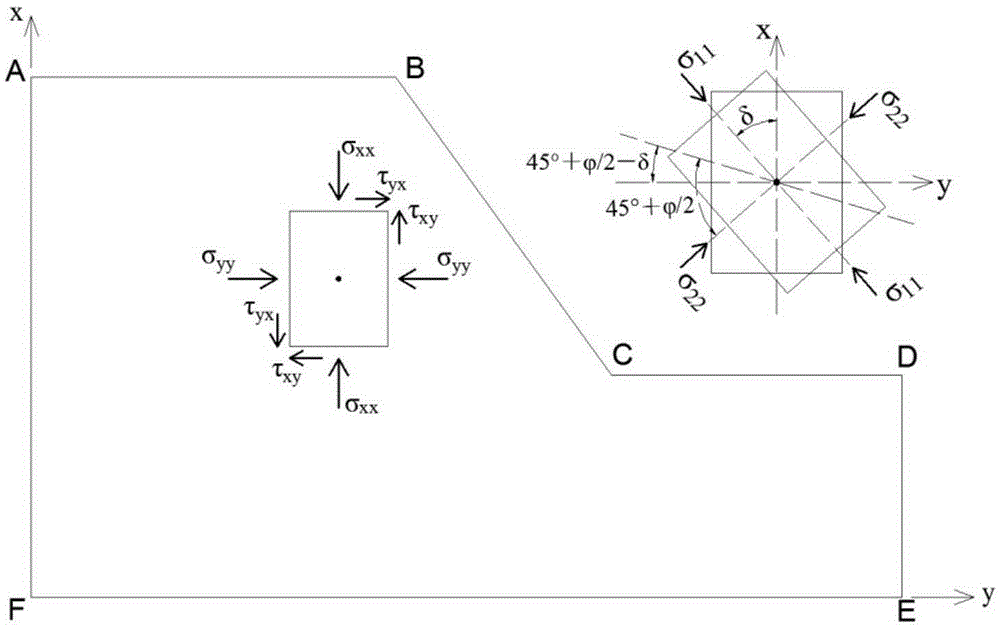

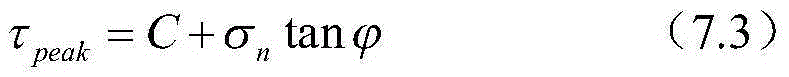

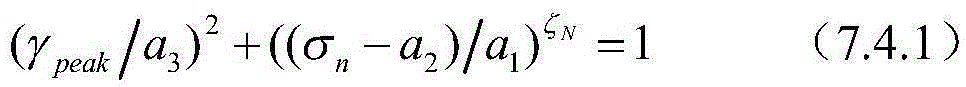

The invention provides a slope progressive failure latent slide surface calculating method-simplified as failure angle rotating method; aiming at the existing disadvantages, assuming geology material failure to satisfy a condition in which an angle between the maximum shear stress surface and the minimum principal stress axis is matched with a critical stress state; because the principal stress direction rotates in different positions when different external load and gravity load are applied on the slope, searching calculation of the slope latent slide surface is carried out, thus determining the latent slide surface, and defining failure rate and failure ratio concepts. The failure angle rotating method ensures that the fail point stress state is at the critical stress state in the slope failure process; in the failure process, the fail path changes along the stress changes; the failure rate and failure ratio concepts are employed, and a failure path constitutive relation considers softening characteristics under different normal stress effects, so the slope latent slide surface can be resolved on the value calculating base.

Owner:HUBEI UNIV OF TECH

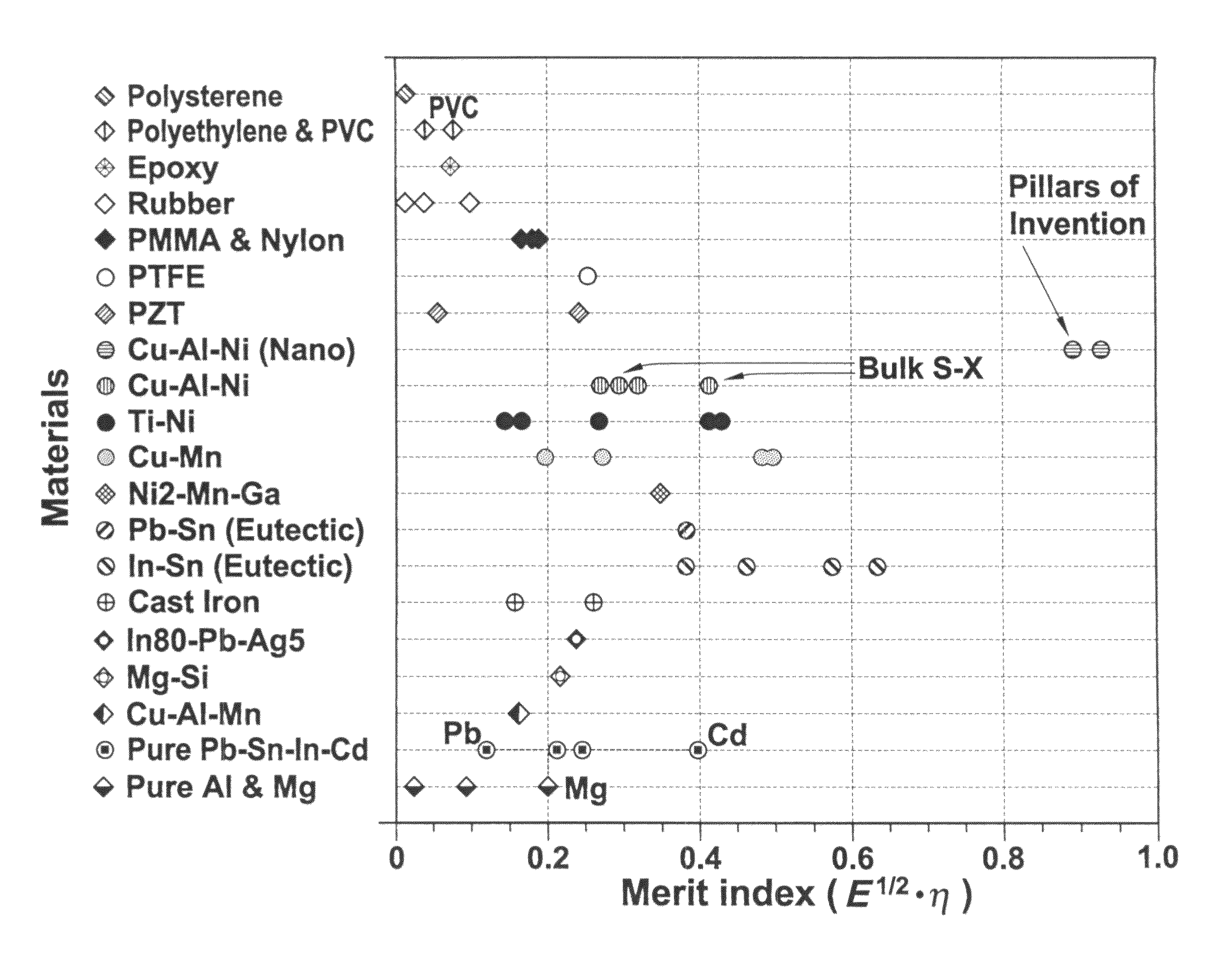

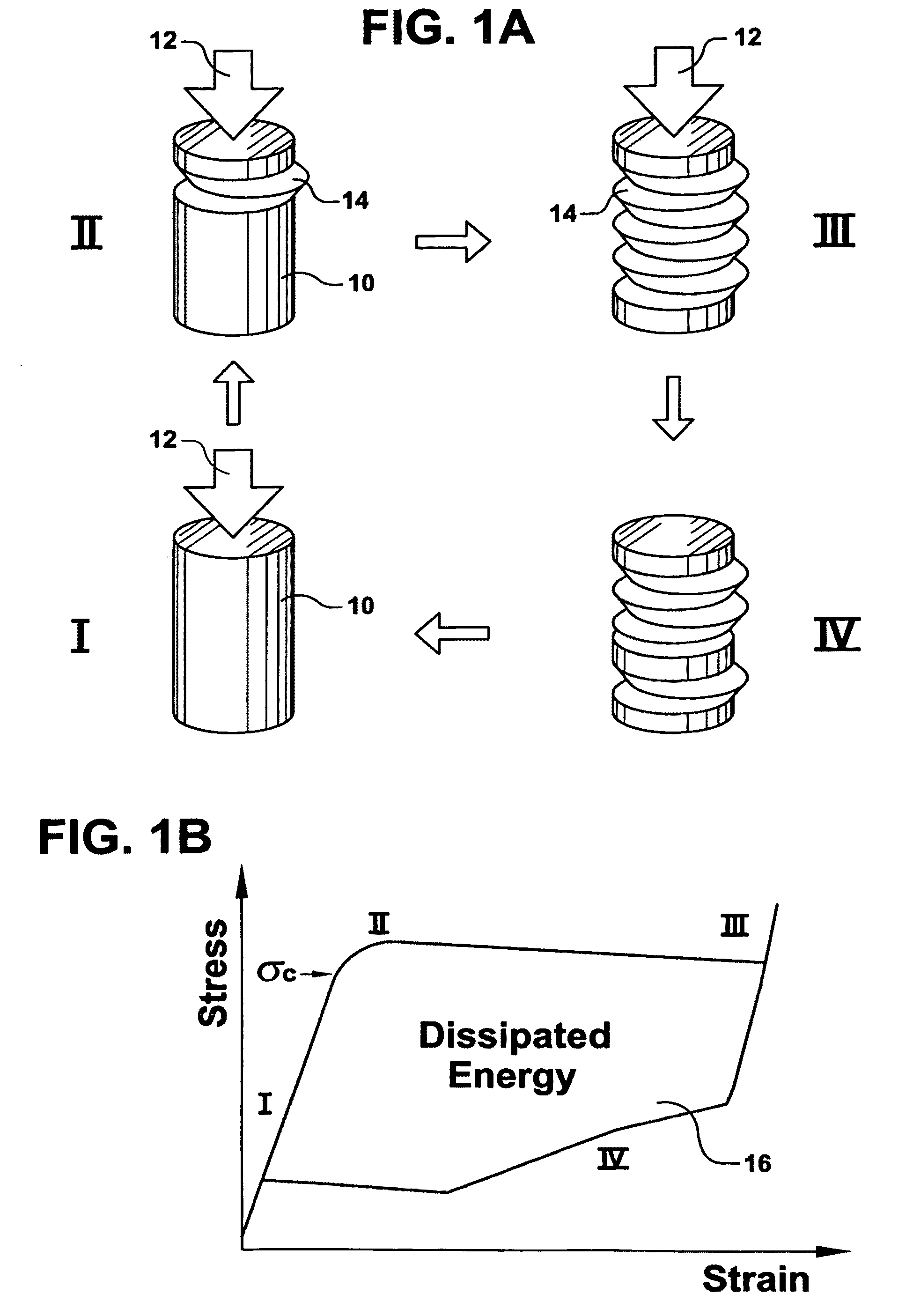

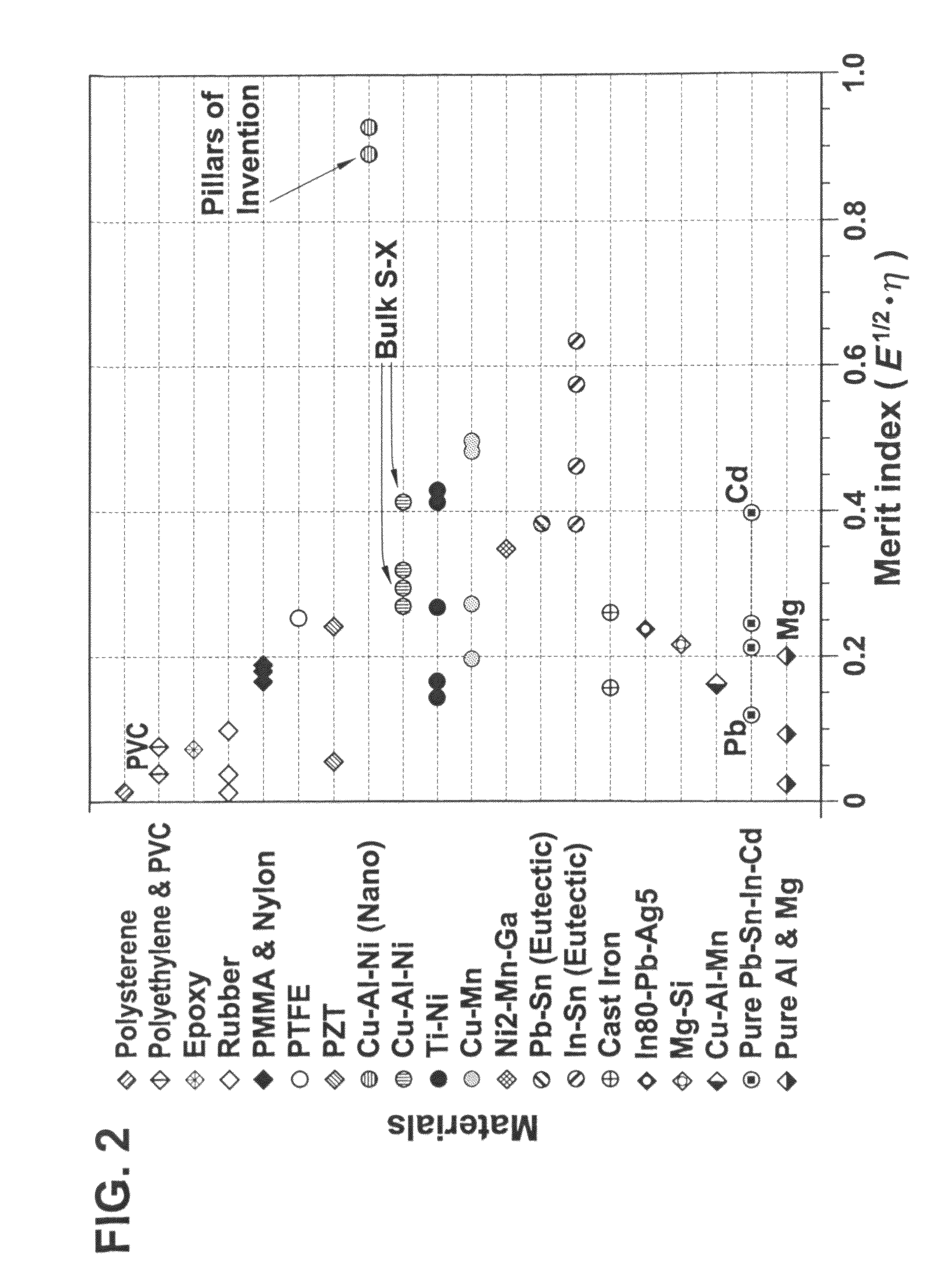

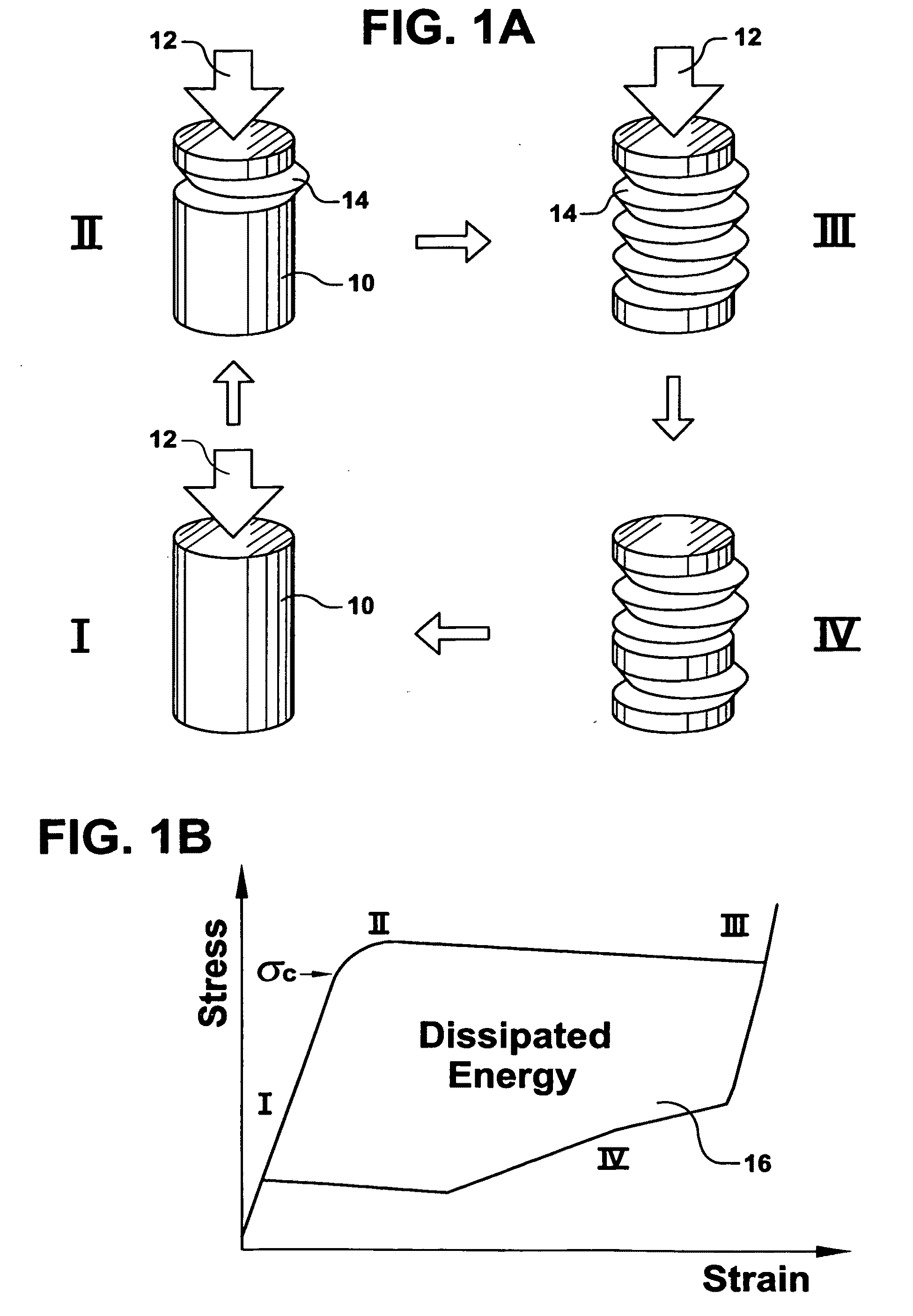

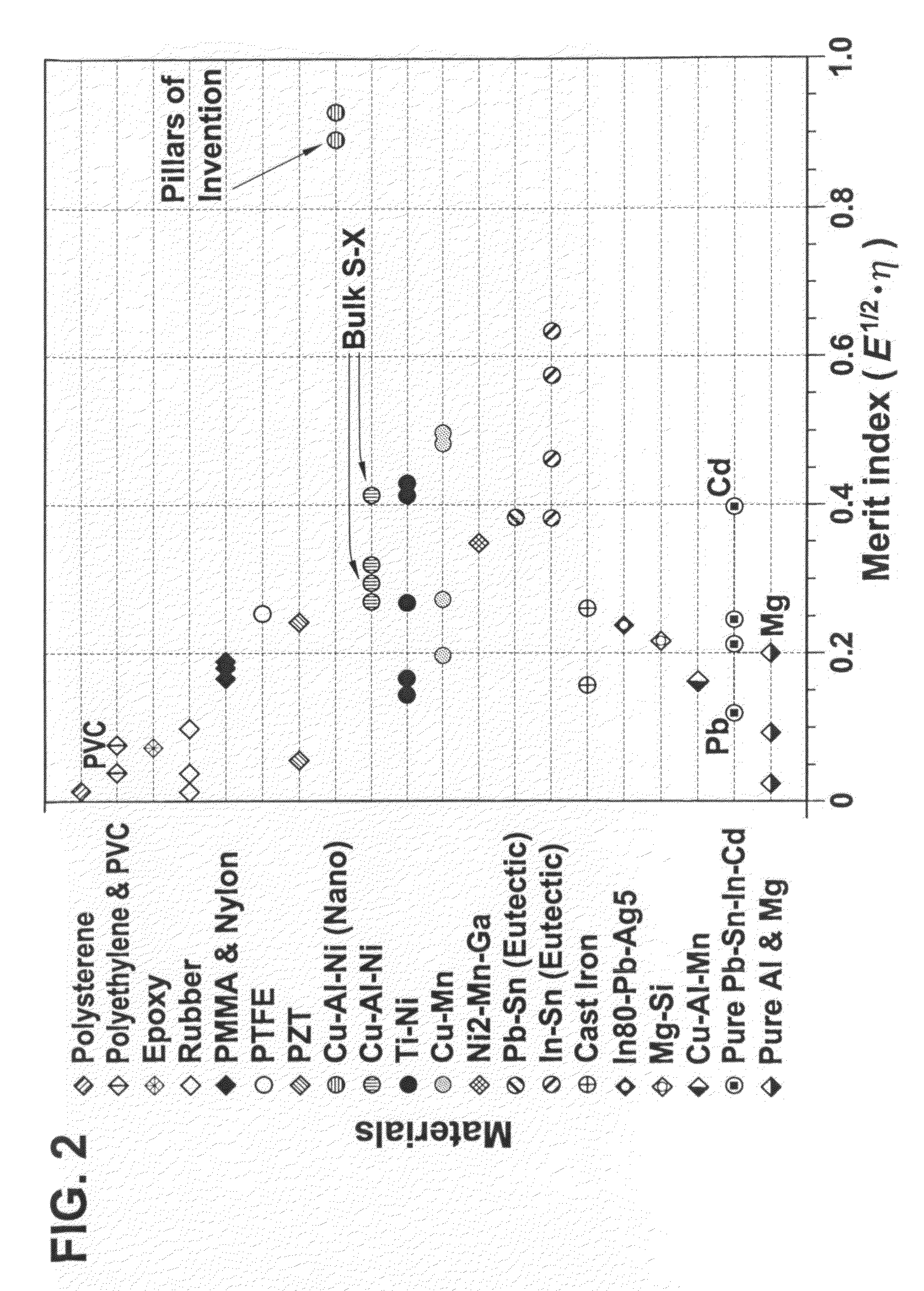

Superelastic alloy structural geometry for ultrahigh mechanical damping

ActiveUS8282746B2Ultra-high-damping performance characteristicsAccurate and reliable processSpringsStands/trestlesMartensite transformationMicrometer

A mechanical structure is provided with a crystalline superelastic alloy that is characterized by an average grain size and that is characterized by a martensitic phase transformation resulting from a mechanical stress input greater than a characteristic first critical stress. A configuration of the superelastic alloy is provided with a geometric structural feature of the alloy that has an extent that is no greater than about 200 micrometers and that is no larger than the average grain size of the alloy. This geometric feature is configured to accept a mechanical stress input.

Owner:MASSACHUSETTS INST OF TECH

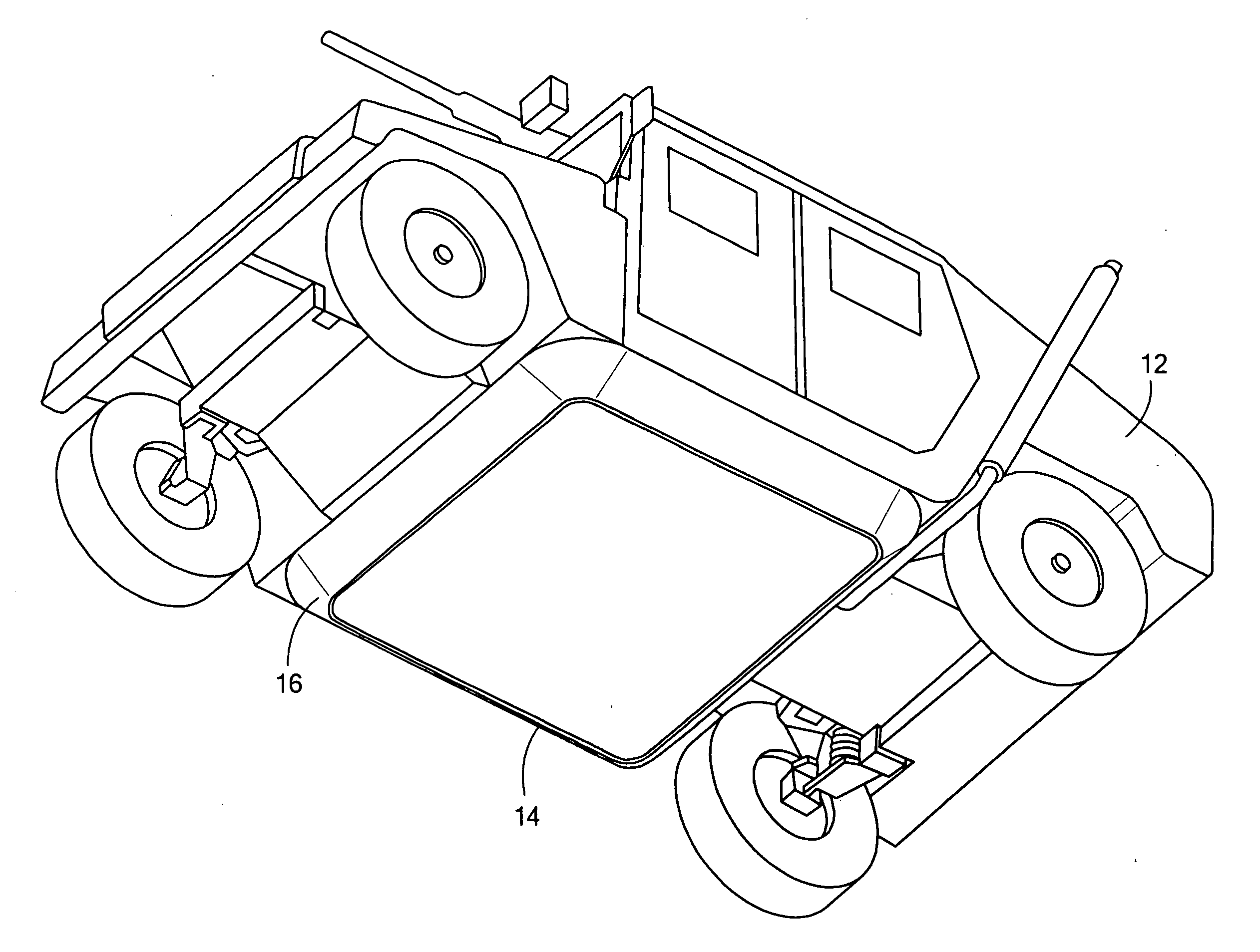

Blast/impact mitigation shield

A blast / impact mitigation shield includes, in one example, a first body including a damping material in a solid state and which transitions to a viscous fluid state when stressed beyond a critical stress and a second body including damping material in a solid state and which transitions to a viscous fluid state when stressed. A plunger plate has blades extending outwardly therefrom and is located between the first and second bodies.

Owner:FOSTER-MILLER

Flexure testing method and flexure testing device for quantitatively characterizing interface binding property of thin-film material

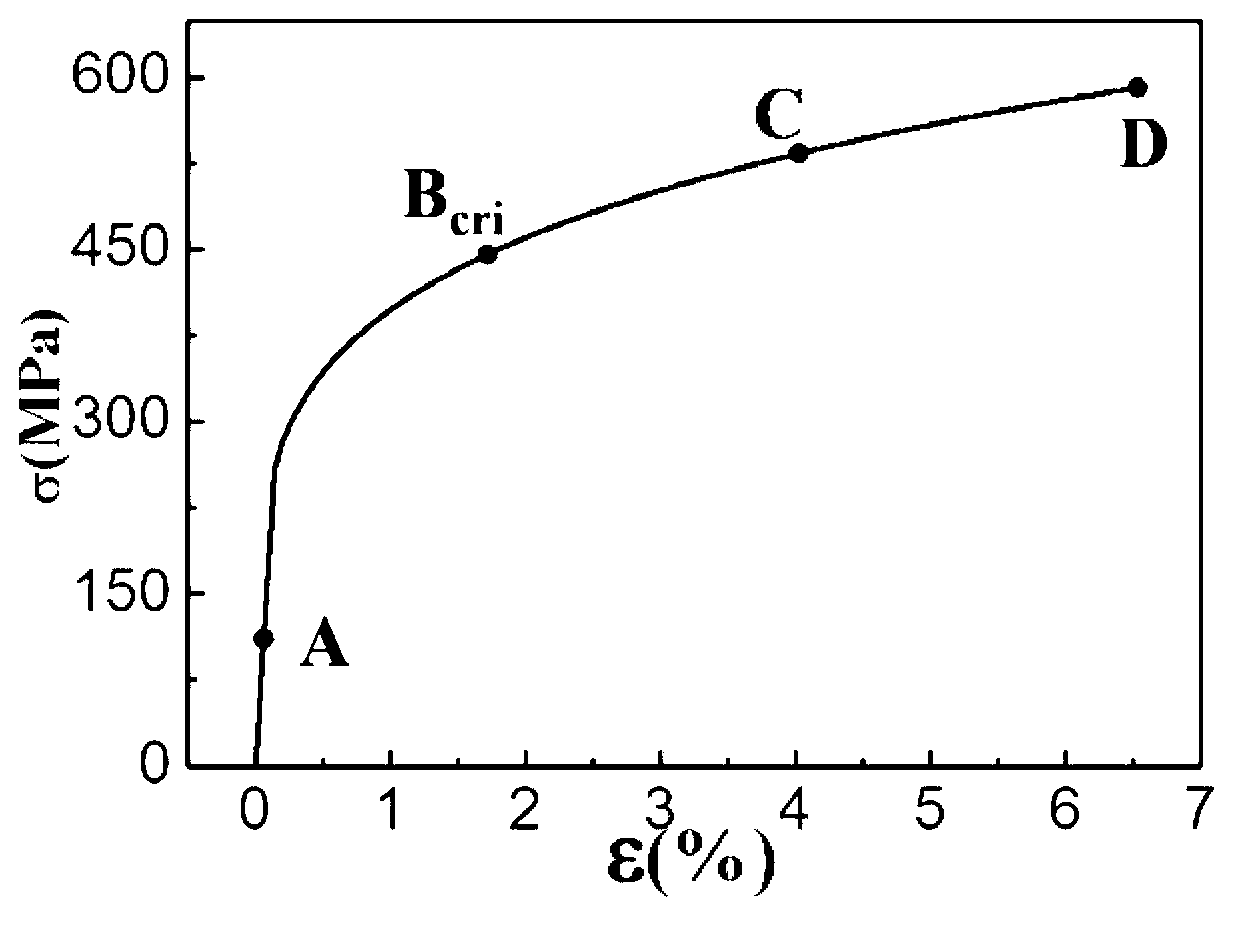

ActiveCN103018160AEasy to makeThe principle is simpleUsing mechanical meansMaterial analysisUniaxial compressionImaging processing

The invention relates to a flexure testing method and a flexure testing device for quantitatively characterizing the interface binding property of thin-film material and belongs to the technical field of property characterization of experimental mechanics and material mechanics. The method is characterized in that uniaxial compression is performed to a sample in the axial direction through a universal material testing machine, and the stress strain values of the sample are recorded; meanwhile, the cross section of the sample is observed synchronously in real time through a CCD camera during the loading process, and stripping characteristics such as critical stress, deflexion and crack length can be recorded in real time during the flexure process; and a relation between the coating and plating-substrate stress strain history and the stripping characteristics is established to characterizing the interface binding property of the coating and plating-substrate. According to the device, the CCD camera, a monitor, an image processing card, a computer, a data processing card, a load sensor and the universal material testing machine are connected in sequence. The invention has the advantages of simple principle, simplicity in sample preparation, clear model, easiness in operation, and the like.

Owner:XIANGTAN UNIV

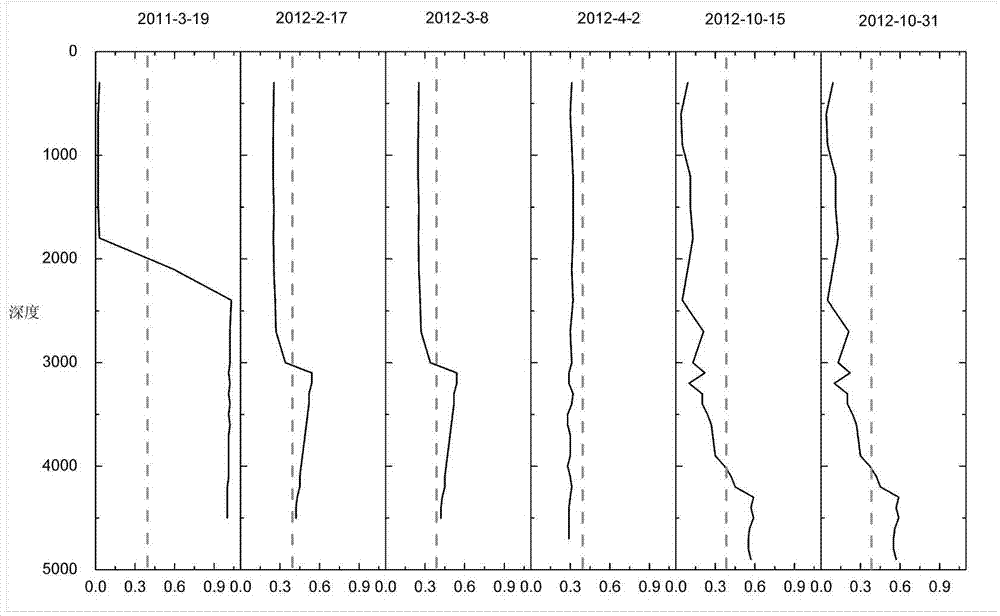

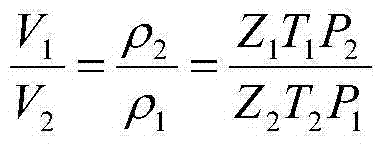

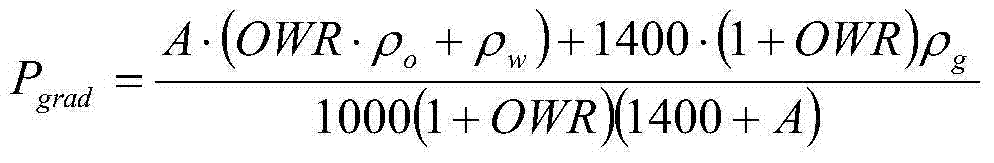

Method for qualifying liquid loading of gas well

InactiveCN104504604AAccurate calculation of critical pressure gradientAvoid misjudgmentData processing applicationsMaterial balanceOil water

The invention discloses a method for qualifying liquid loading of a gas well for use in the development process of gas reservoirs and condensate gas reservoirs. Corresponding oil-water ratios at different time are calculated with daily production data of the gas well in order to obtain corresponding critical pressure gradients, and the critical pressure gradients are compared with a pressure gradient test curve for analysis. If the maximum value of the test pressure gradient curve surpasses the critical pressure gradient value, liquid loading in a shaft occurs; on the contrary, if the maximum pressure gradient value is lower than critical pressure gradient values, liquid loading does not exist in the shaft even the pressure gradient curve fluctuates. Critical pressure gradients under different oil-water ratio conditions are calculated through a substance balance state equation model and a critical pressure gradient model by using daily test data of the gas reservoirs and condensate gas reservoirs, and the critical pressure gradients are compared with the pressure gradient curve to judge whether liquid loading occurs in the shaft or not, so that various errors caused by direct manual qualitative analysis are avoided, and the accuracy of liquid loading judgment is increased.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

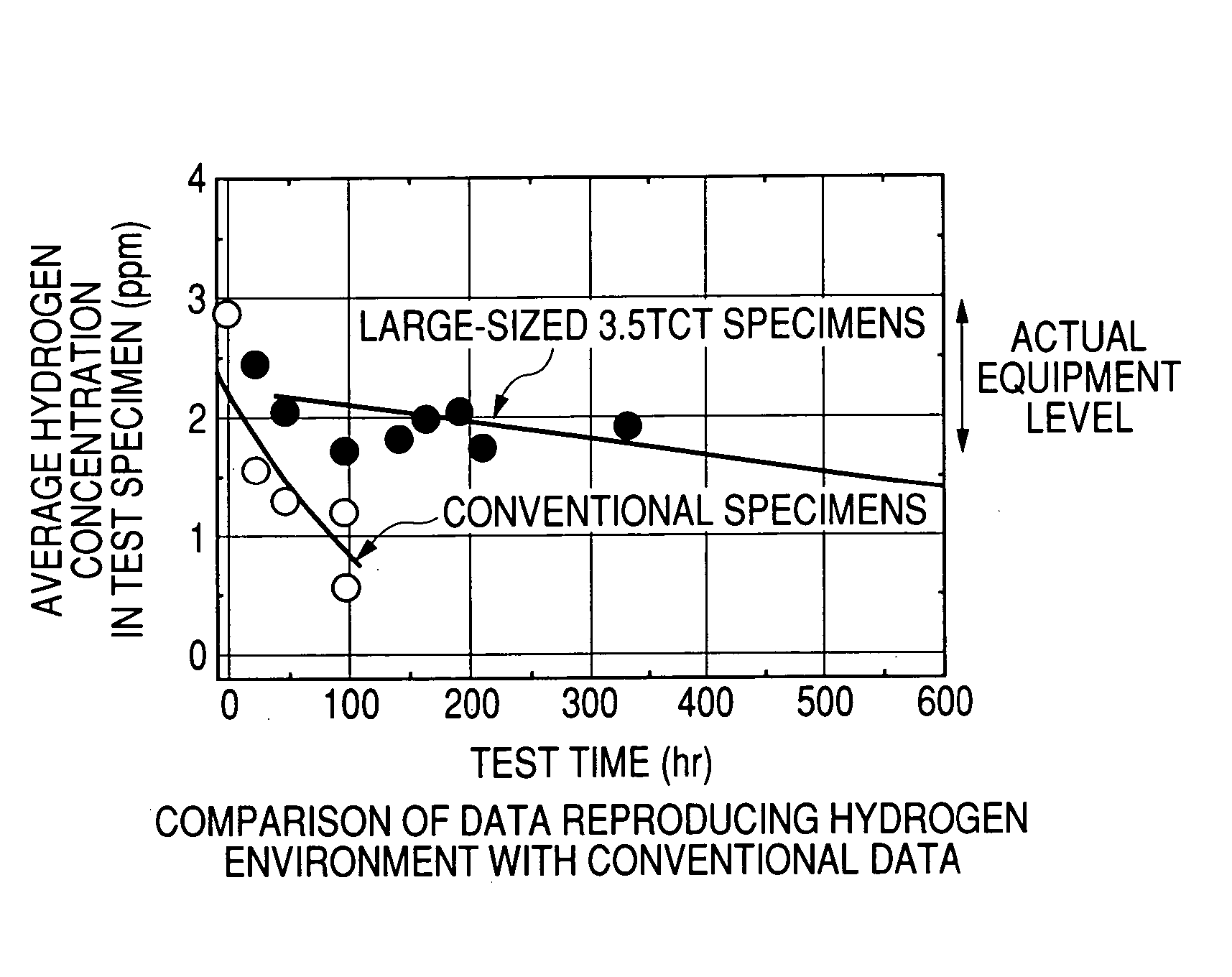

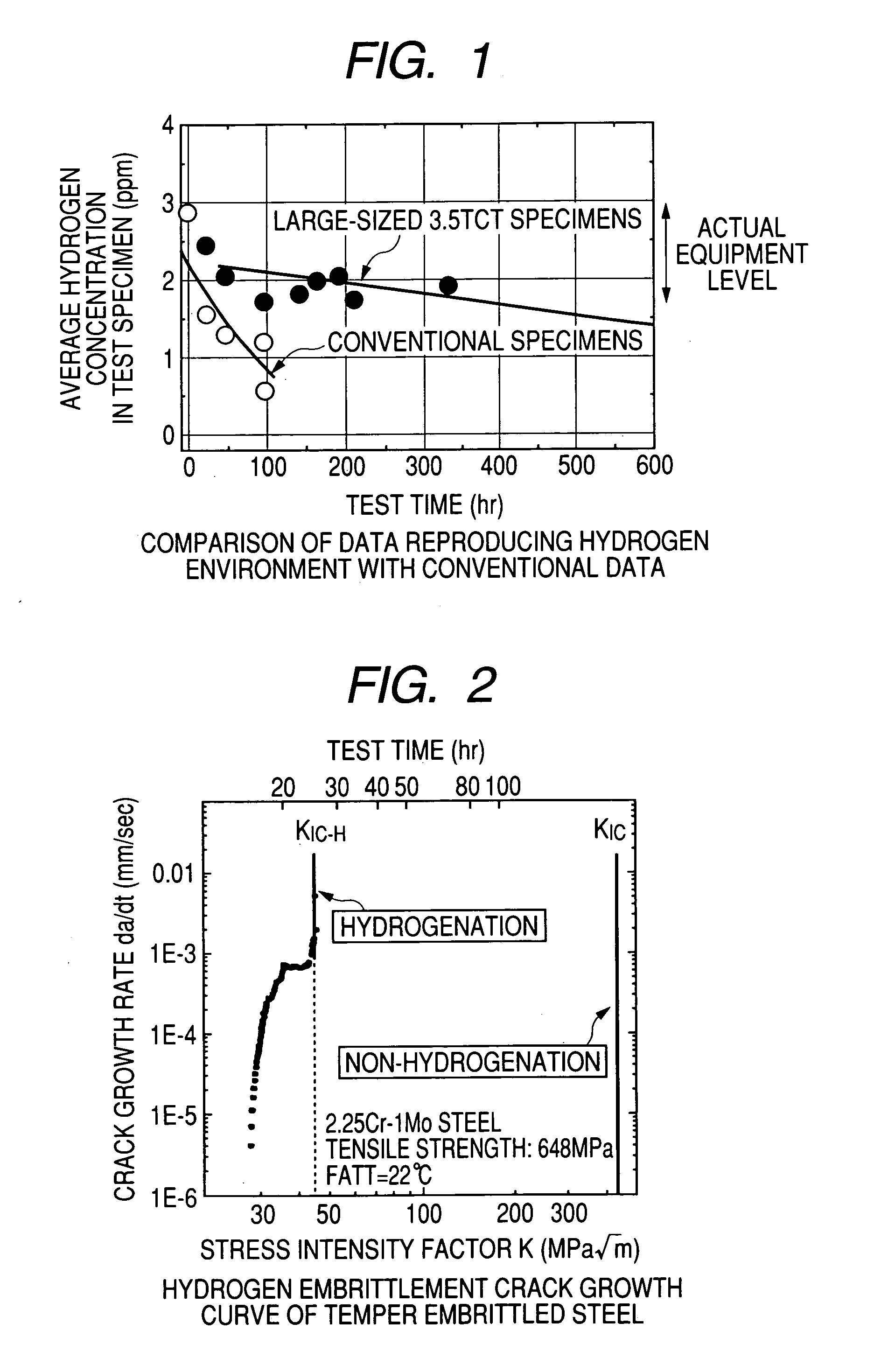

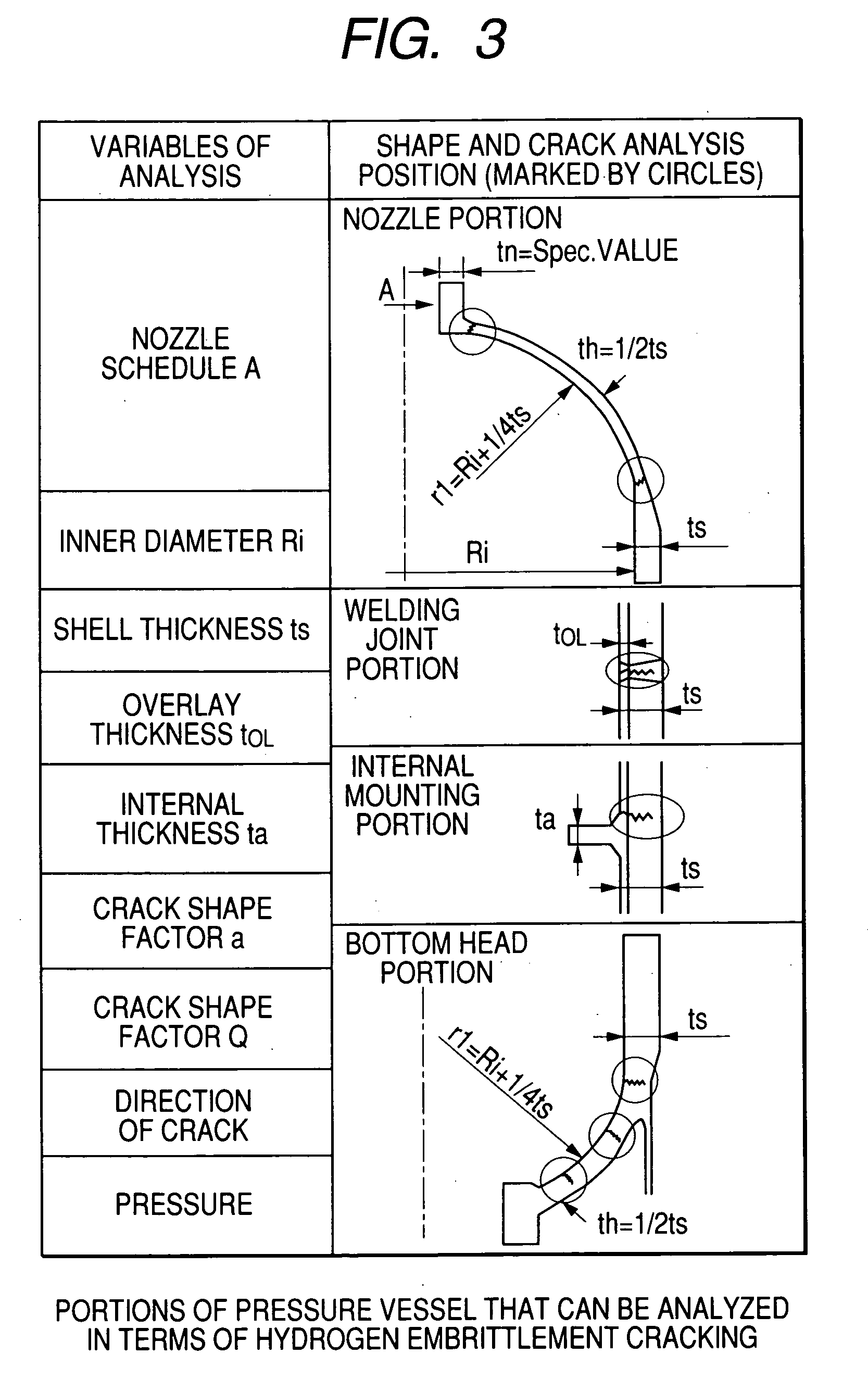

Method of judging hydrogen embrittlement cracking of material used in high-temperature, high-pressure hydrogen environment

ActiveUS20050028882A1Easy and accurate evaluationEvaluating the cracking susceptibility of a vesselWeather/light/corrosion resistanceTesting metalsCrazingHigh pressure hydrogen

Using information about the position, orientation, and shape of a crack appeared in a judged material and information about the structure of the judged material as parameters, the stress intensity factor KI of the crack is found. Based on the stress intensity factor KI, hydrogen embrittlement cracking of the judged material is judged. The crack growth rate and possibility of brittle fracture can be judged by comparing the stress intensity factor KI with the critical stress intensity factor KIH for crack initiation or the critical stress intensity factor KIC-H for brittle fracture about the temper embrittled steel which absorbs approximately 2.0 ppm hydrogen.

Owner:JAPAN STEEL WORKS LTD

Superelastic Alloy Structural Geometry for Ultrahigh Mechanical Damping

ActiveUS20100140439A1Ultra-high-damping performance characteristicsAccurate and reliable processSpringsStands/trestlesMartensite transformationStructural geometry

A mechanical structure is provided with a crystalline superelastic alloy that is characterized by an average grain size and that is characterized by a martensitic phase transformation resulting from a mechanical stress input greater than a characteristic first critical stress. A configuration of the superelastic alloy is provided with a geometric structural feature of the alloy that has an extent that is no greater than about 200 micrometers and that is no larger than the average grain size of the alloy. This geometric feature is configured to accept a mechanical stress input.

Owner:MASSACHUSETTS INST OF TECH

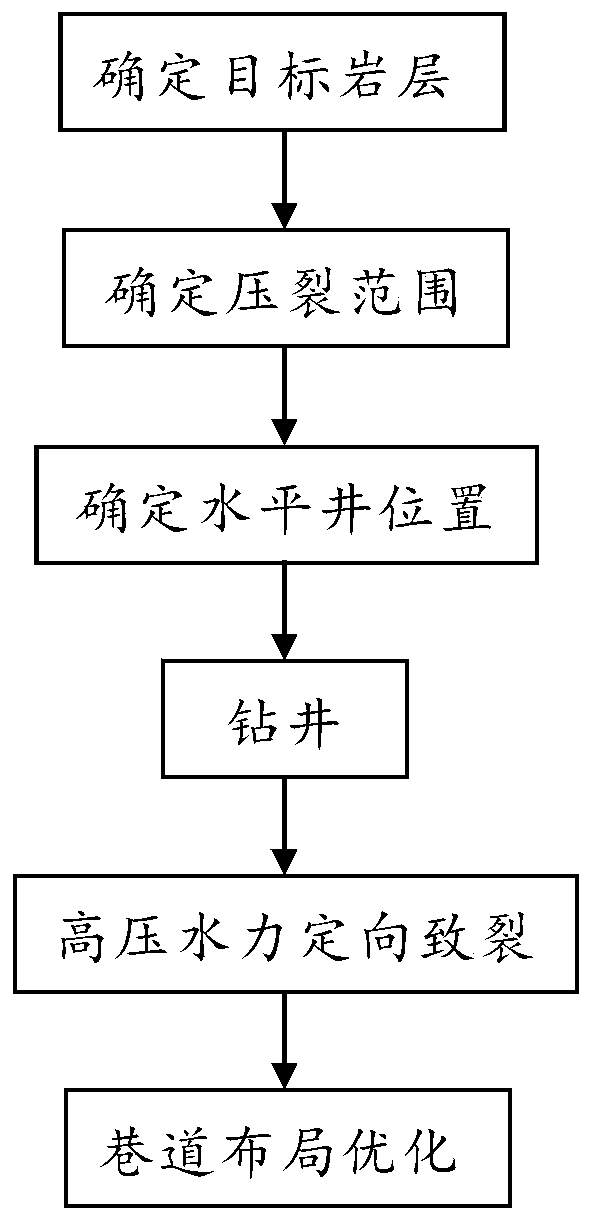

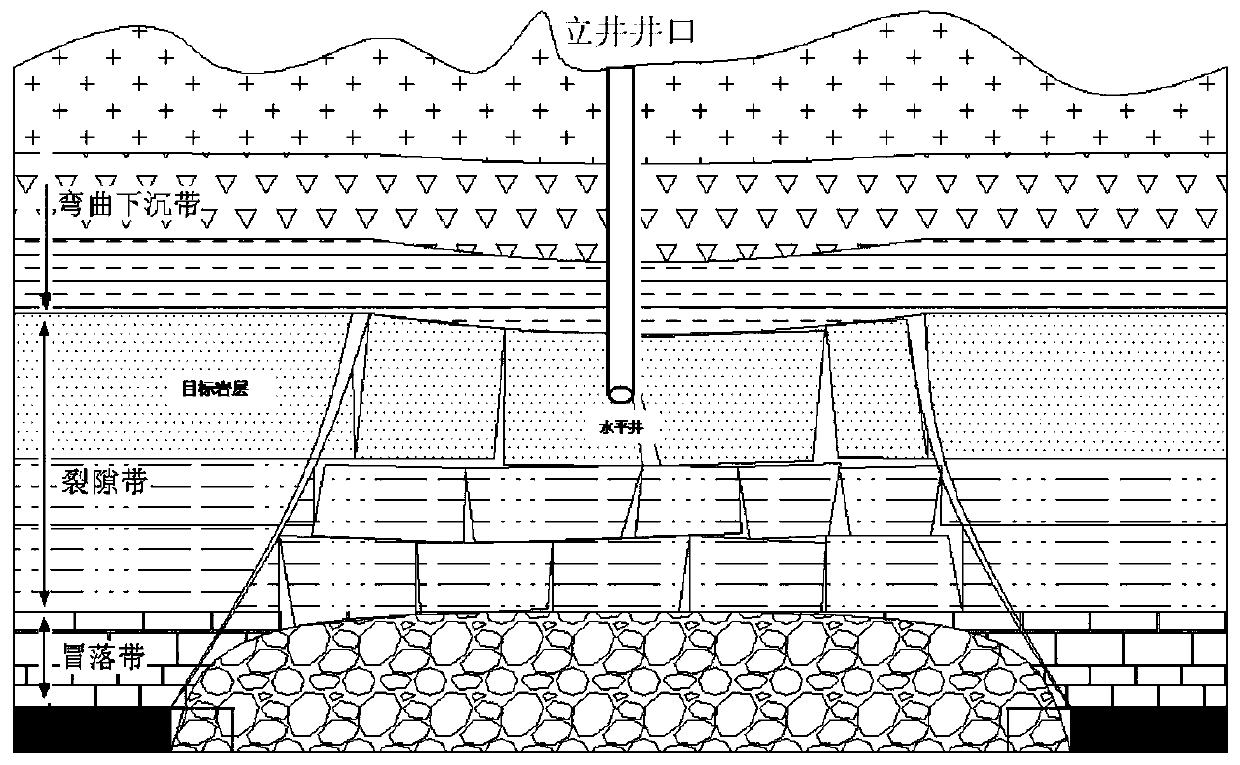

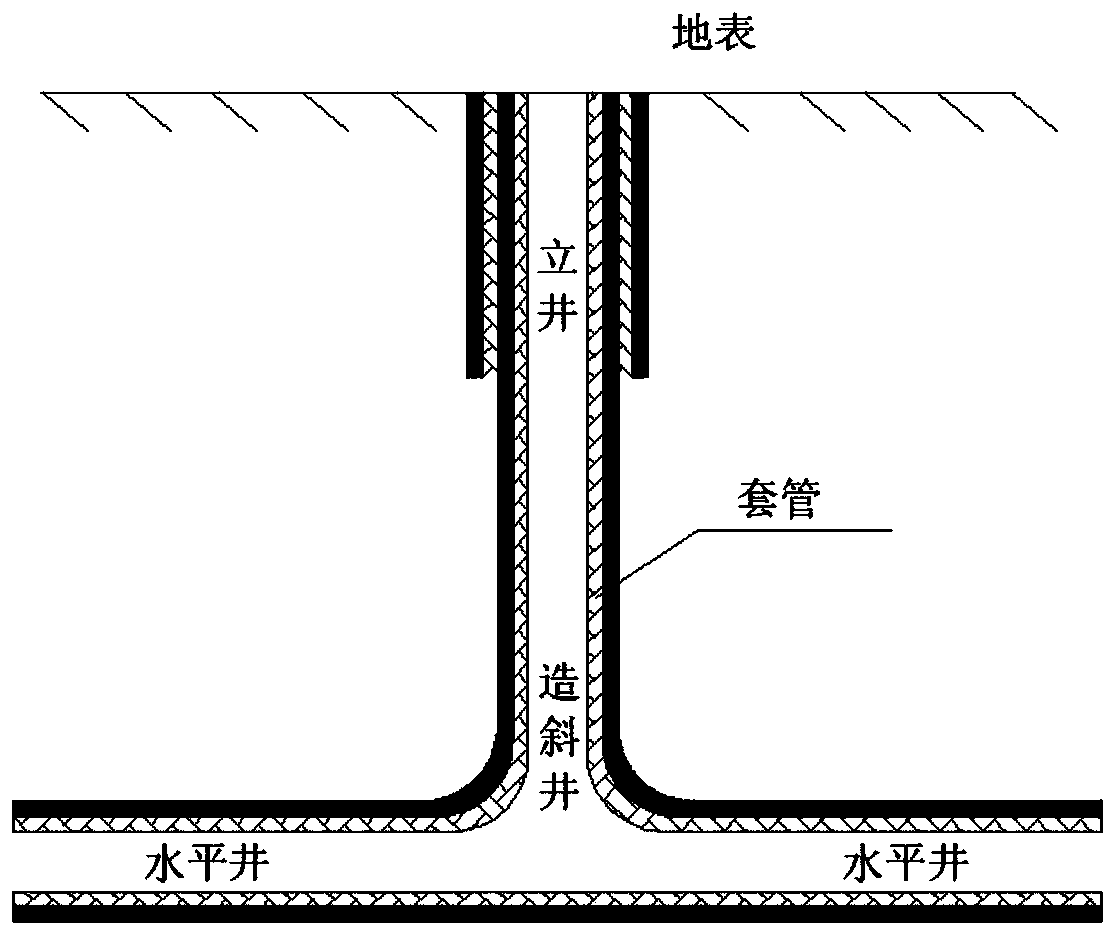

Method for treating rock burst through thick-layer hard roof modified pressure relief source

InactiveCN109736805AImprove mining stress environmentReduced impact riskUnderground miningSurface miningStress concentrationWell drilling

The invention provides a method for treating rock burst through a thick-layer hard roof modified pressure relief source. The method comprises the steps of target rock stratum determination, fracturingrange determination, horizontal well position determination, well drilling, high-pressure hydraulic directional fracturing, and roadway layout optimization. According to the method for treating the rock burst through the thick-layer hard roof modified pressure relief source, a stress concentration degree in a coal mining period can be remarkably reduced, the coal stress is made to be always underthe critical stress for generation of rock burst, and the serious rock burst hidden danger caused by sudden breakage of a large-area roof is fundamentally eliminated.

Owner:TIANDI SCI & TECH CO LTD

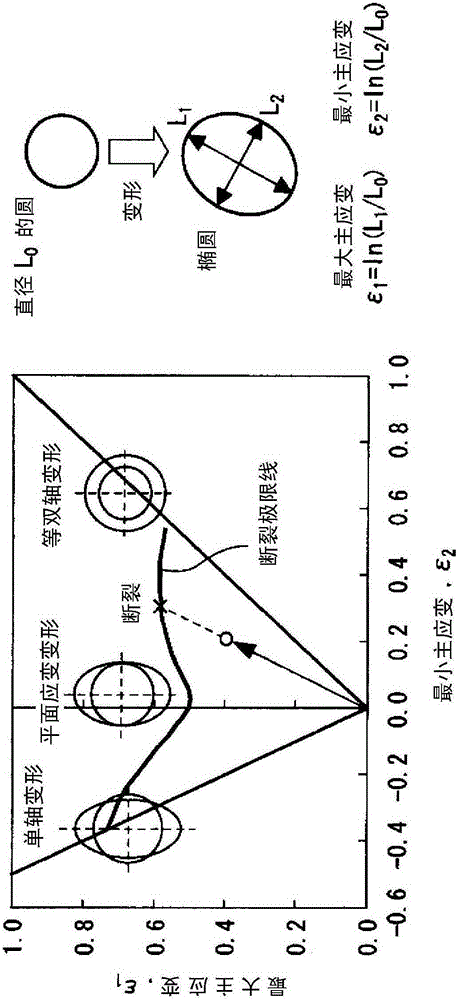

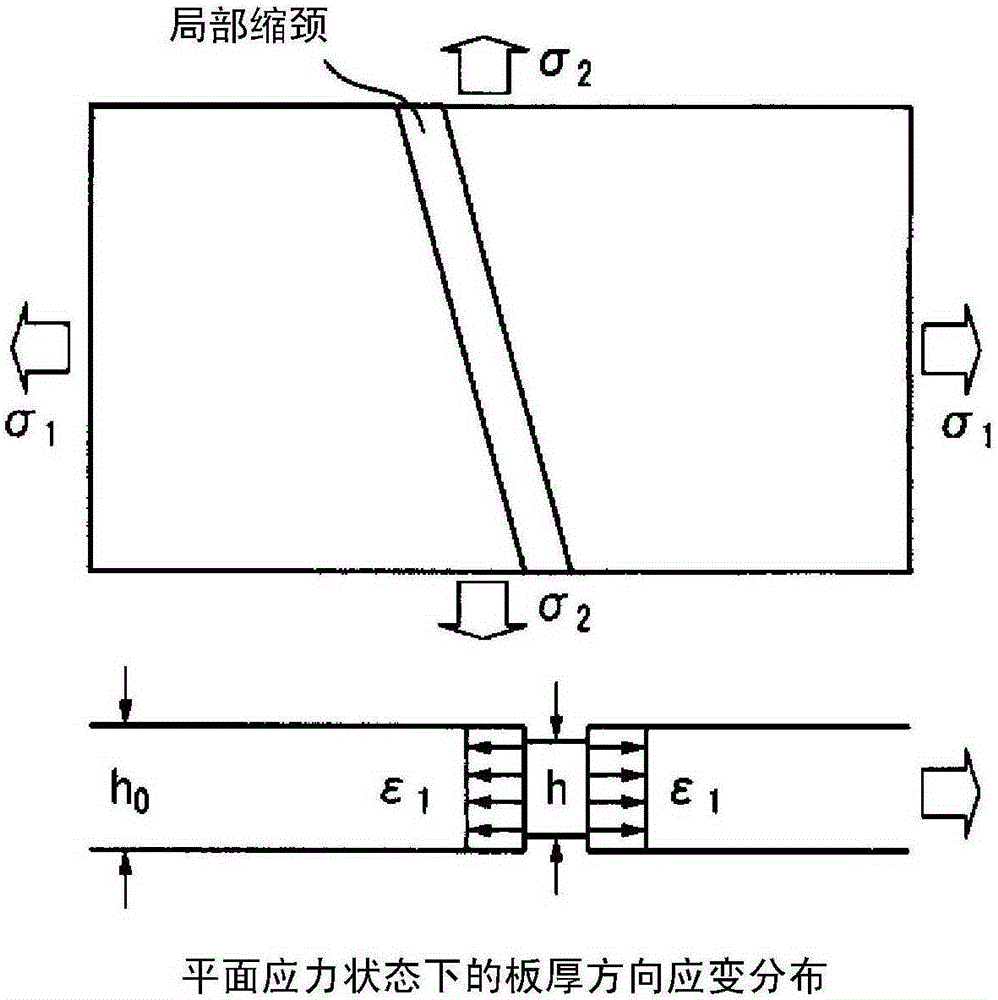

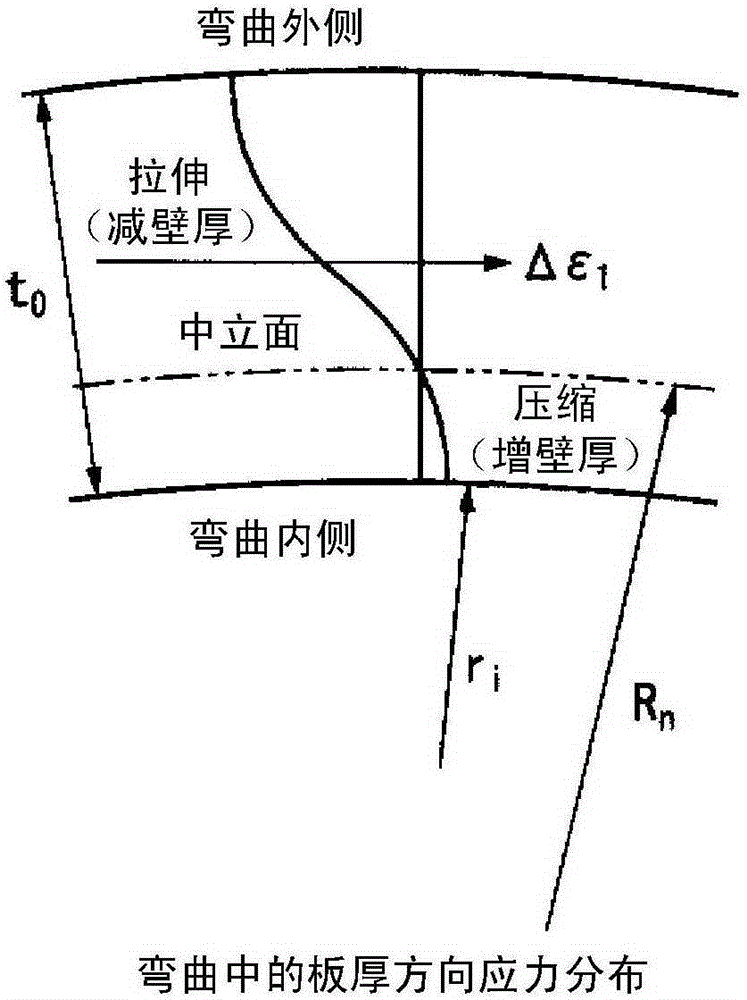

Method for determining bending fracture in metal plate, program, and storage medium

ActiveCN105283874AQuantitatively determine the risk of bending fractureMaterial strength using steady bending forcesDesign optimisation/simulationPrincipal stressTensile testing

A bending fracture limit stress [sigma]cr is calculated for each bending radius R at plate thickness center / initial plate thickness t0 of a metal plate. A fracture limit stress [sigma]1_pl under plane strain deformation is calculated, as is a fracture limit line L1 in a uniform deformation state in a stress space for which a static strain rate is assumed from work hardening characteristics obtained from uniaxial tensile testing of the material constituting the metal plate. A determination is made of the ratio [gamma] between the bending fracture critical stress [sigma]cr and the plane strain fracture limit stress [sigma]1_pl in a uniform deformation state that corresponds to the R / t0 of a determination subject element in the metal plate. The ratio [gamma] is multiplied by the stress component of the fracture limit line L1, whereby a fracture limit line L2 corresponding to R / t0 is calculated. The maximum principal stress [sigma]OBcr of the determination subject element is calculated from the maximum principal stress [sigma]OR of the determination subject element and the fracture limit line L2 corresponding to R / t0 in a stress mode. A risk ratio [sigma]OR / [sigma]OBcr, which is the risk ratio for tensile bending fracture, is calculated from the sizes of the stress [sigma]OR and the fracture limit stress [sigma]OBcr. Fracture is determined for the determination subject element on the basis of the risk ratio [sigma]OR / [sigma]OBcr.

Owner:NIPPON STEEL CORP

Method for preparing silica aerogel by supercritical drying with high-pressure liquid medium

InactiveCN101863479ASolve the phenomenon of prone to shrinkage and crackingRaw materials are easy to getSilicaSupercritical dryingLiquid medium

The invention relates to a method for preparing silica aerogel by supercritical drying with a high-pressure liquid medium, which comprises the following steps of: (1) adding silicon tetrachloride and water to perform reaction with stirring under the acidic condition that the pH is between 3 and 5, adjusting the pH to be between 8 and 10 by using ammonia water, adding the water and ethanol to perform hydrolysis and polycondensation reaction to form alcogel; (2) loading the alcogel into a high-pressure reaction kettle, filling the high-pressure liquid medium into the reaction kettle, and slowly raising the temperature to reach supercritical pressure after the reaction kettle is filled with the high-pressure liquid medium; and (3) slowly releasing gas medium while slowly raising the temperature until the pressure in the kettle and external atmosphere are balanced, opening the reaction kettle, taking the sample out and drying the sample. The method has the advantages of readily available raw materials, simple process and low cost, solves the problem of easy shrinkage cracking of the SiO2 aerogel when dry, and can stably improve the reaction speed at the same time.

Owner:应城市东诚有机硅有限公司

Polycarbonate resin composition and molded article thereof

ActiveUS20120095141A1Good effectExcellent in releasabilityGroup 5/15 element organic compoundsUltravioletCarboxylic acid

This invention seeks to provide a resin composition and a molded article which are excellent in transparency, weatherability, resistance to boiling water and resistance to molding heat, which have an internal strain reduced and which are excellent in breaking durability.This invention is a resin composition comprising(A) 100 parts by weight of a polycarbonate resin (component A),(B) 0.005 to 1 part by weight of an ester (component B) of pentaerythritol and an aliphatic carboxylic acid,(C) 0.003 to 0.2 part by weight of an epoxy compound (component C),(D) 0.01 to 1 part by weight of an ultraviolet absorbent (component D), and(E) 0.001 to 0.5 part by weight of a phosphorus stabilizer (component E),wherein the components B and the component C have a critical stress of 12 MPa or more each when they are treated at a temperature of 120° C. for 24 hours in a one / fourth ellipse test method using a bisphenol A type polycarbonate resin sheet that is produced by a melt-extrusion method and has a viscosity average molecular weight of 24,500, and a molded article thereof.

Owner:TEIJIN KASEK KK

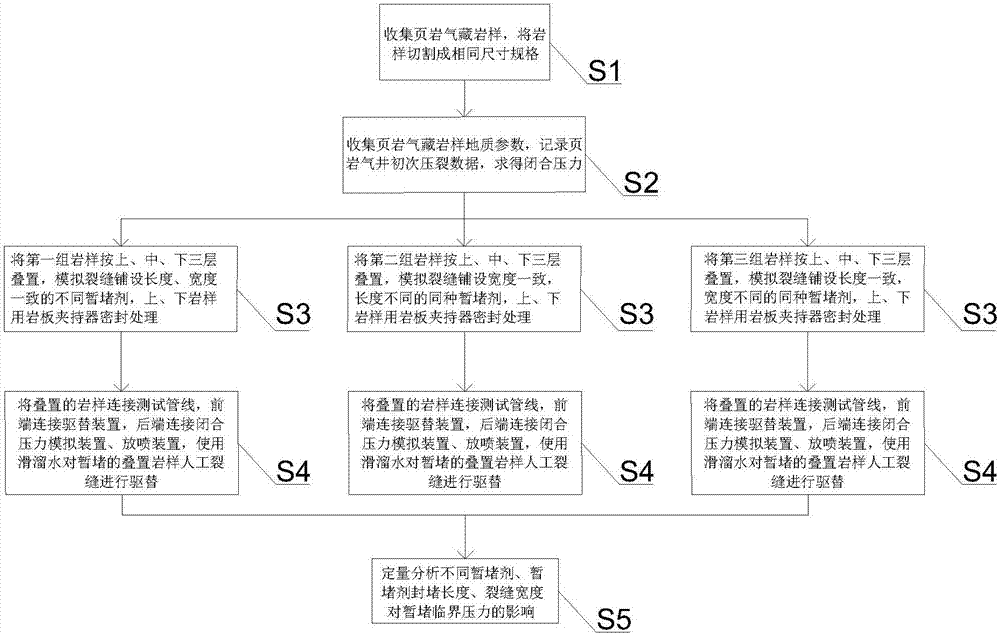

Shale gas horizontal-well refracturing temporary-plugging critical pressure testing method

The invention belongs to the technical field of unconventional oil and gas innovation for increasing output, and discloses a shale gas horizontal-well refracturing temporary-plugging critical pressure test method. The shale gas horizontal-well refracturing temporary-plugging critical pressure test method comprises the following steps that shale gas reservoir rock samples are collected, and the rock samples are cut into the same size specifications; geological parameters of the shale gas reservoir rock samples are collected, a pressure curve of initial fracturing construction of a shale gas well is analyzed, and closure pressure of a reservoir stratum is obtained; the rock samples are divided into three groups, each group of shale gas reservoir rock samples are overlaid according to upper, middle and lower layers, and quantitative temporary plugging additives are evenly laid between every two adjacent rock samples; the overlaid rock samples are connected with test pipelines, and displacement is conducted on temporary plugging overlaid rock sample created fractures by using slickwater; and effects of the different temporary plugging additives, the temporary plugging additive sealing and plugging lengths and the fracture widths on temporary plugging critical pressure are analyzed quantitatively. According to the shale gas horizontal well refracturing temporary plugging critical pressure test method, under the condition of formation effective closure stress, the temporary plugging critical pressure of different types and amounts of the temporary plugging additives on a hydraulic fracture can be tested conveniently, and reference standards for optimization selection and optimization design of the temporary plugging additives are provided.

Owner:SOUTHWEST PETROLEUM UNIV

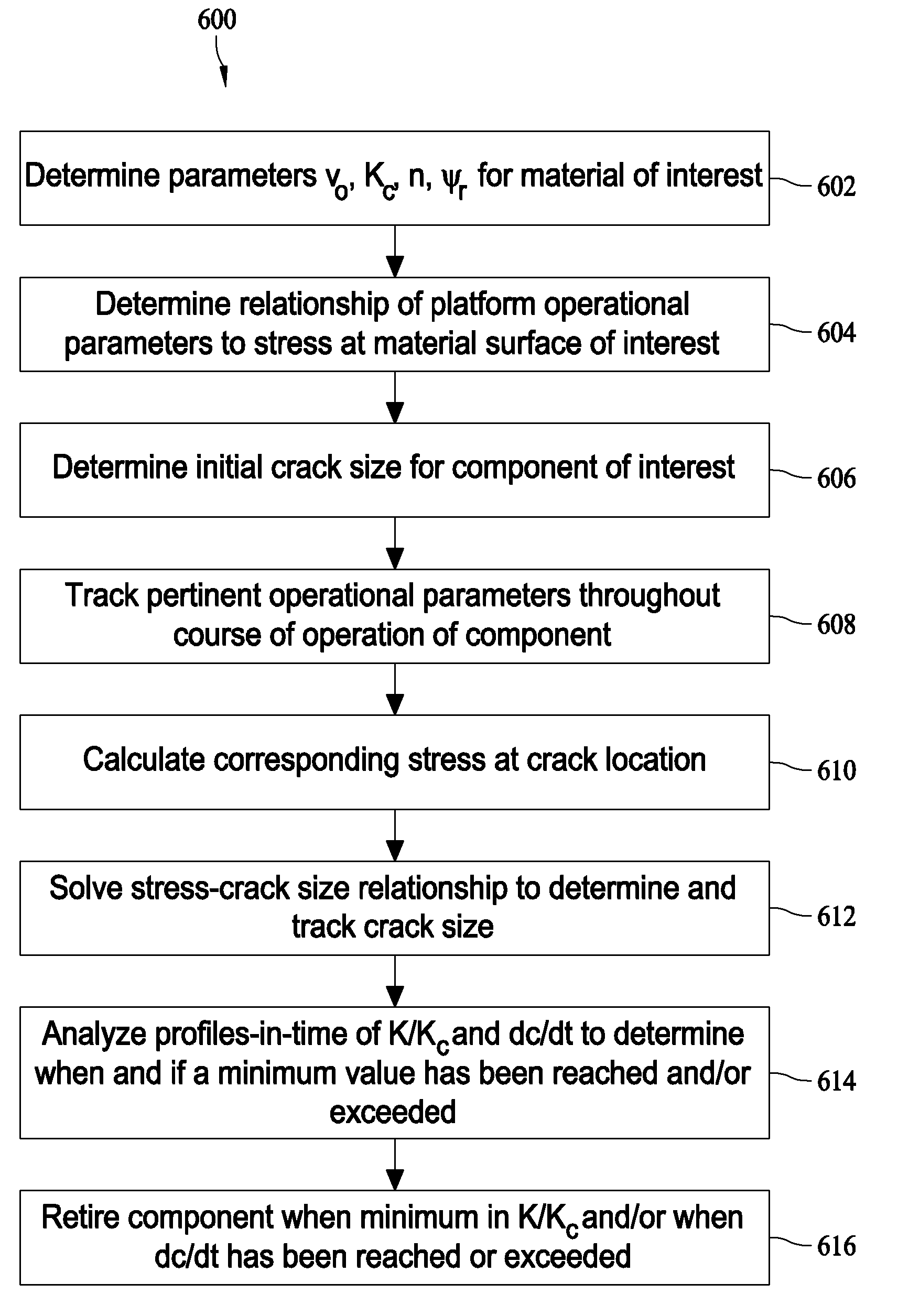

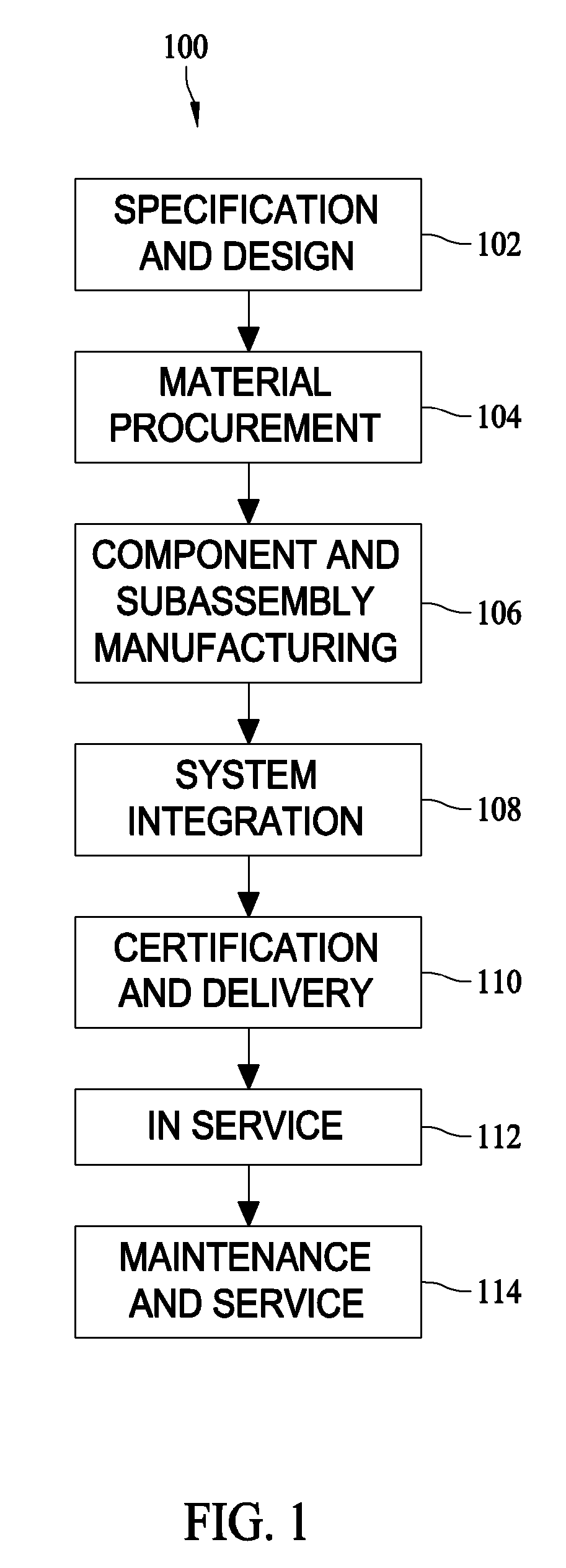

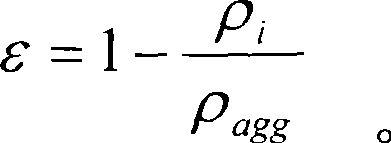

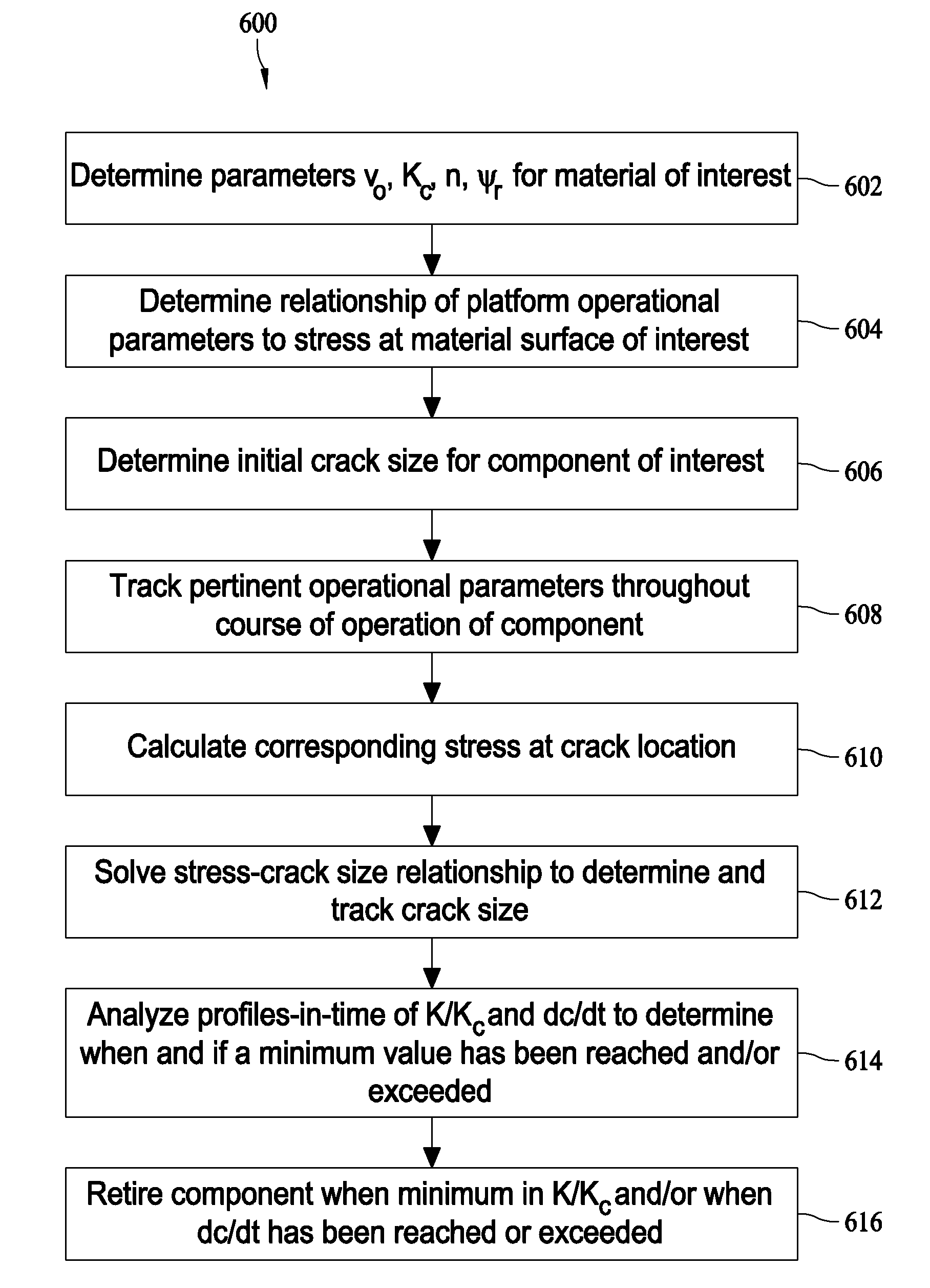

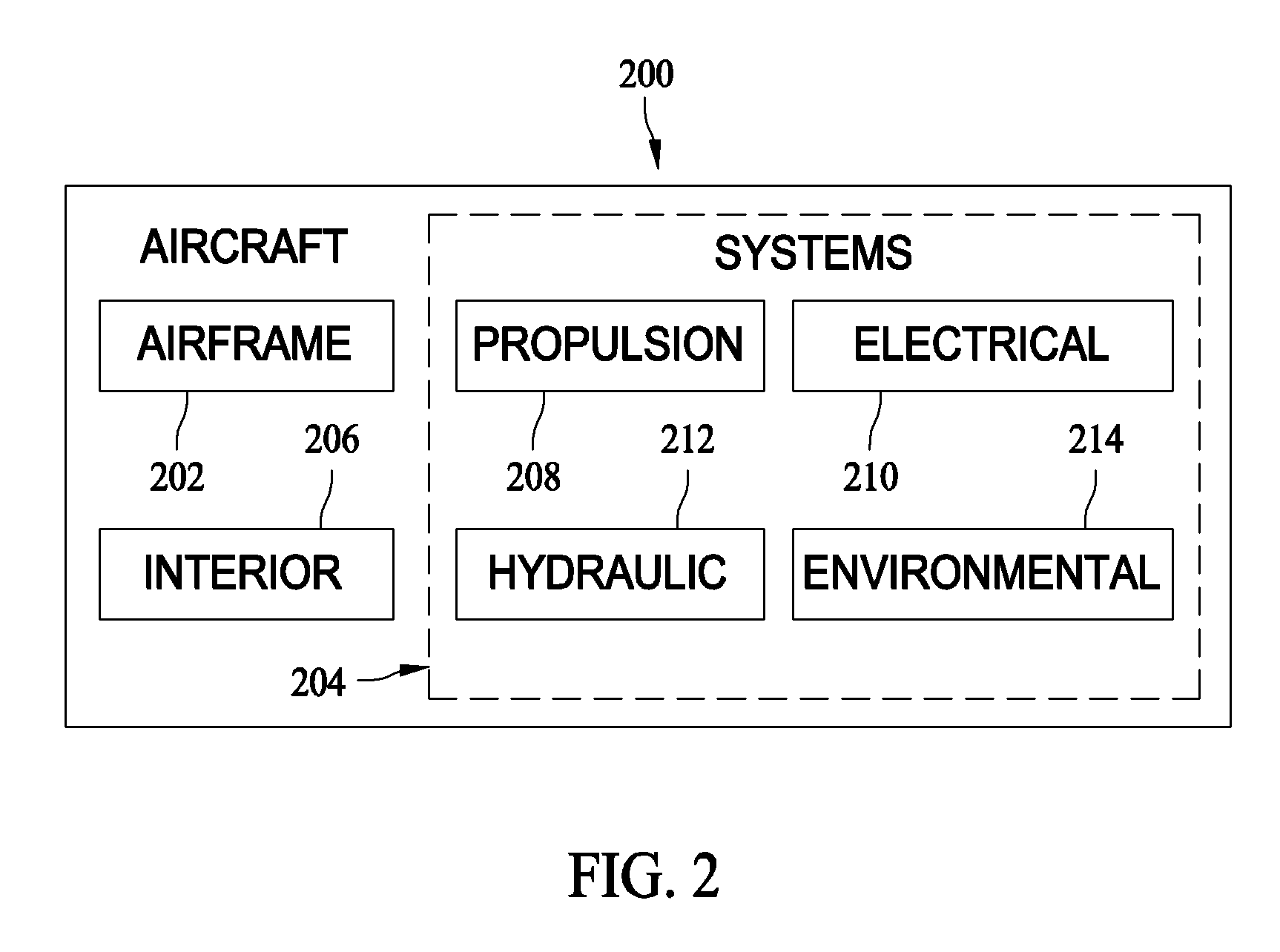

Method and systems for estimating remaining service life of a component subject to stress

A method is described for determining when a ceramic component on a platform should be replaced. The method includes determining the parameters vo, Kc, n, and ψr for the component, where vo and n are empirically determined parameters, Kc is a critical stress intensity factor, ψr is a geometry factor for the material in the form of the component, determining a relationship of between platform operational parameters to the generation of stress at the surface of interest of the component, determining an initial crack size of a crack within the component at installation, tracking operational parameters of the platform throughout a course of usage of the component, calculating the corresponding stress at the crack location due to the tracked operational parameters, and calculating a numerical solution that illustrates a crack growth rate velocity and tracks a size of the crack over time.

Owner:THE BOEING CO

Explosive grain thermal explosion critical pressure measurement apparatus

InactiveCN105043623ASolving High Temperature Pressure Measurement ProblemsAvoid damageMaterial exposibilityApparatus for force/torque/work measurementMeasurement deviceEngineering

The invention discloses an explosive grain thermal explosion critical pressure measurement apparatus, for solving the problem of high-temperature pressure measurement of explosive grains under a thermal stimulus effect and providing a means for critical pressure measurement when the explosive grains explore under the thermal stimulus effect. The apparatus is mainly composed of a simulated cook-off bomb, a guide tube, an air tap, an adapter, a nut, a pressure sensor and sealing rings. The measurement apparatus measures the thermal explosion critical pressure of the explosive grains through the general pressure sensor by use of a guide tube gradient cooling method and can be applied to research on safety of the explosive grains under the thermal stimulus effect.

Owner:XIAN MODERN CHEM RES INST

Mounting assembly with metal injection molded lever and selective threaded governor post

An improved mounting assembly is provided that is configured to be releasably attached to a dovetail rail profile, wherein the clamping tension of the clamping actuator is adjustable. The assembly includes a molded foot portion and a turned steel threaded governor post which provides superior strength and durability to a critical stress point in the assembly. The threaded, removable governor post configuration also provides the ability to change the post material to increase overall component strength and to increase thread strength. The arrangement further simplifies field maintenance and repair in the event of damage and reduces repair costs by not having to replace the entire lever assembly.

Owner:SWAN RICHARD E

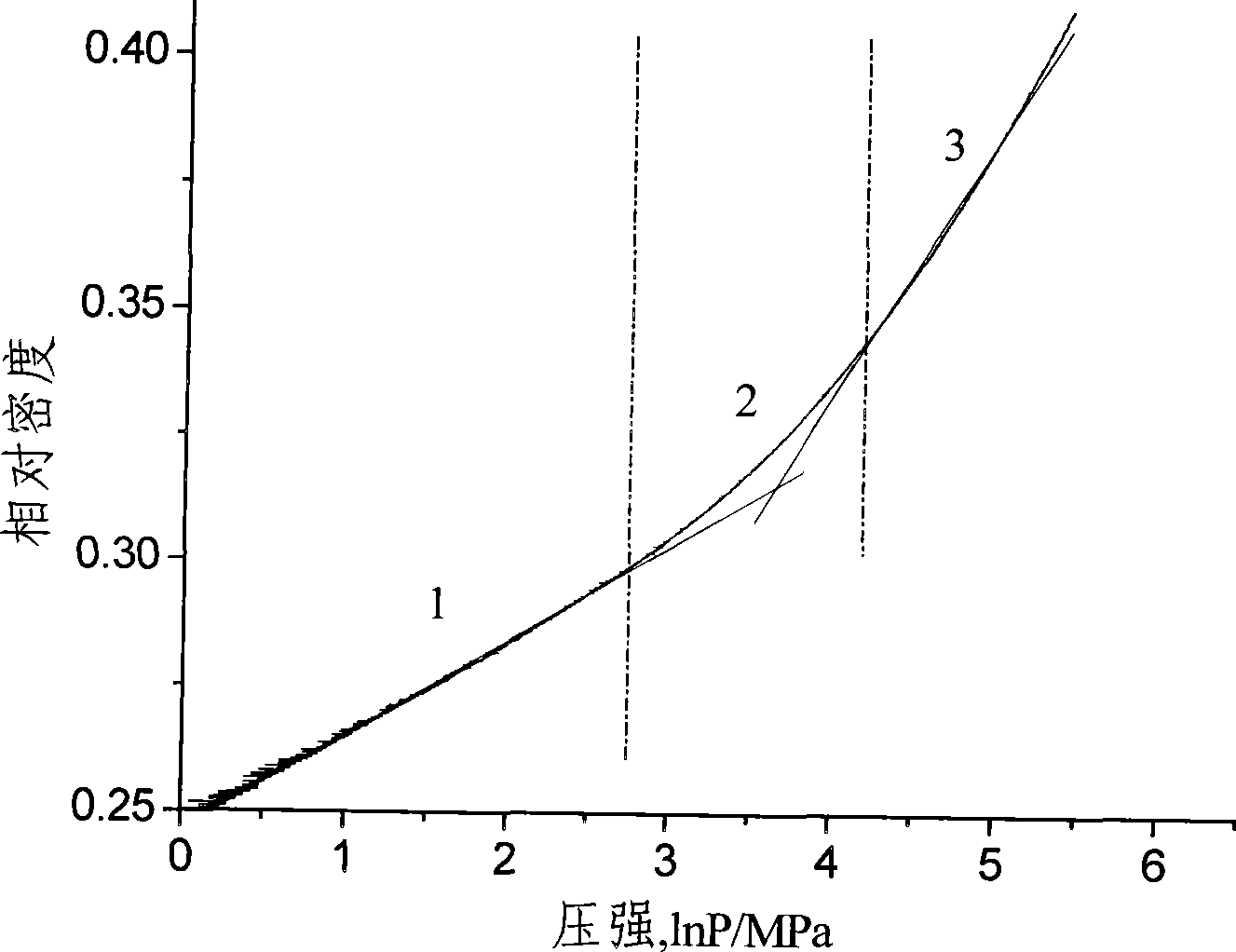

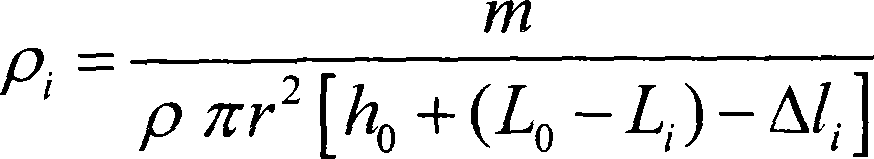

Method for measuring bond strength of aggregate in superfine and nanometer tungsten carbide powder

The invention relates to a method for measuring the primary particle combination strength in an aggregate body in superfine or nanometer tungsten carbide powder. The steps are as follows: (1) on a universal dynamic tester, the superfine or nanometer tungsten carbide powder is added into a single-way or double-way continuous steel or hard alloy compressed mould; (2) according to pressures and displacements during compression process automatically recorded by a computer, the relation curve of a green density and a pressure is drawn, so that a critical pressure presented at a turning point is determined; (3) according to the relative density of the aggregate body and the like, the porosity degree between the aggregate bodies are calculated; (4) the primary particle combination strength of the tungsten carbide or the aggregate body strength of the tungsten carbide are calculated according to the critical pressure. In the method of the invention, general dynamic test equipment is used, and the operation is simple and convenient.

Owner:GRIMAT ENG INST CO LTD

Method and systems for estimating remaining service life of a component subject to stress

ActiveUS8255171B2Plug gaugesMachine gearing/transmission testingUltimate tensile strengthCritical stress

A method for determining when a ceramic component on a platform should be replaced. The method includes determining parameters for the ceramic component, the parameters include empirically determined a critical stress intensity factor, and a geometry factor for the ceramic component. The method also includes determining a relationship between platform operational parameters to the generation of stress at the surface of interest of the ceramic component, determining an initial crack size of a crack within the ceramic component at installation, tracking operational parameters of the platform throughout a course of usage of the ceramic component, calculating the corresponding stress at the crack location due to the tracked operational parameters, and calculating a numerical solution that illustrates a crack growth rate velocity and tracks a size of the crack over time. The ceramic component is replaced based on the crack growth rate velocity and the size of the crack.

Owner:THE BOEING CO

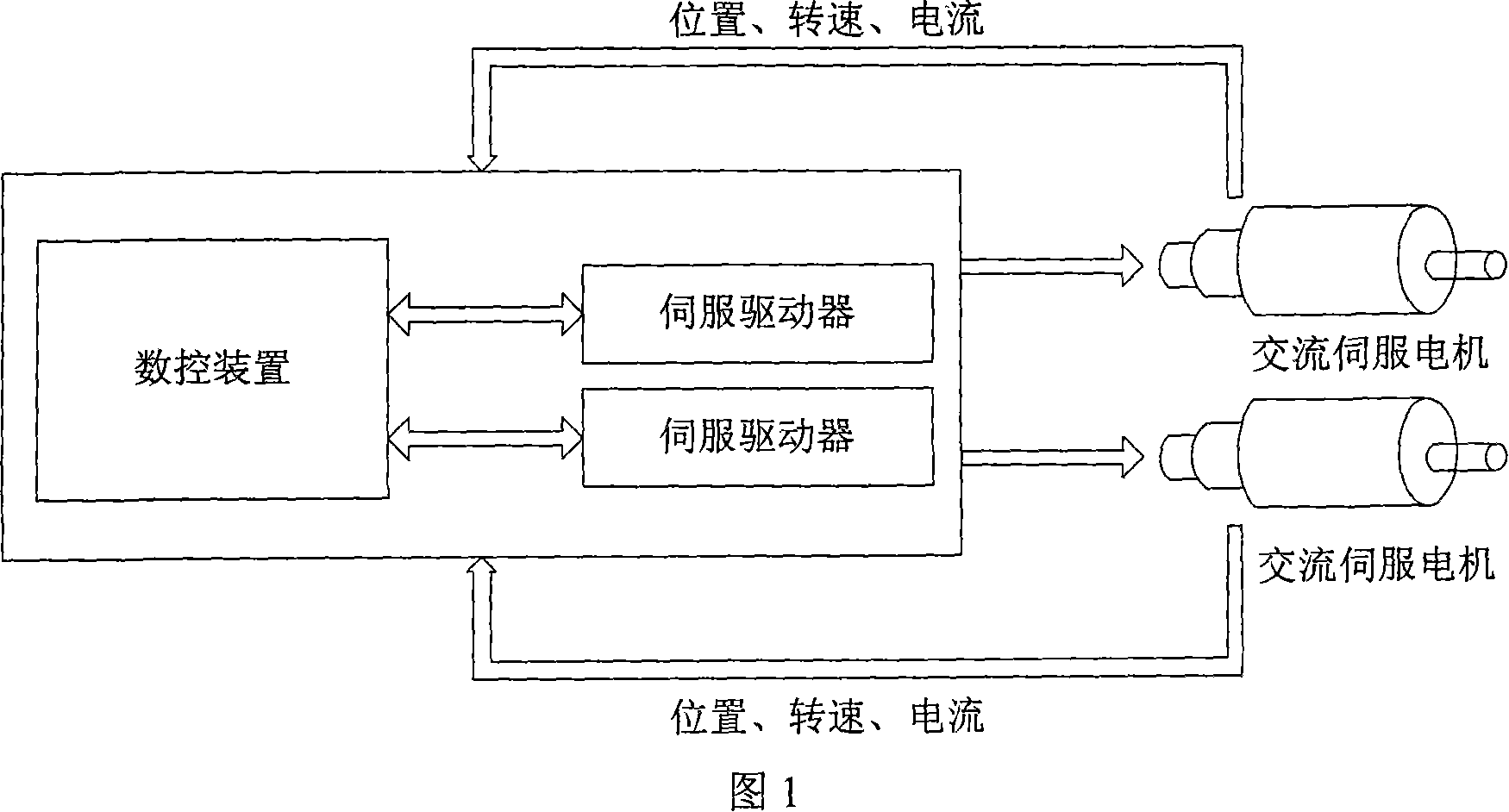

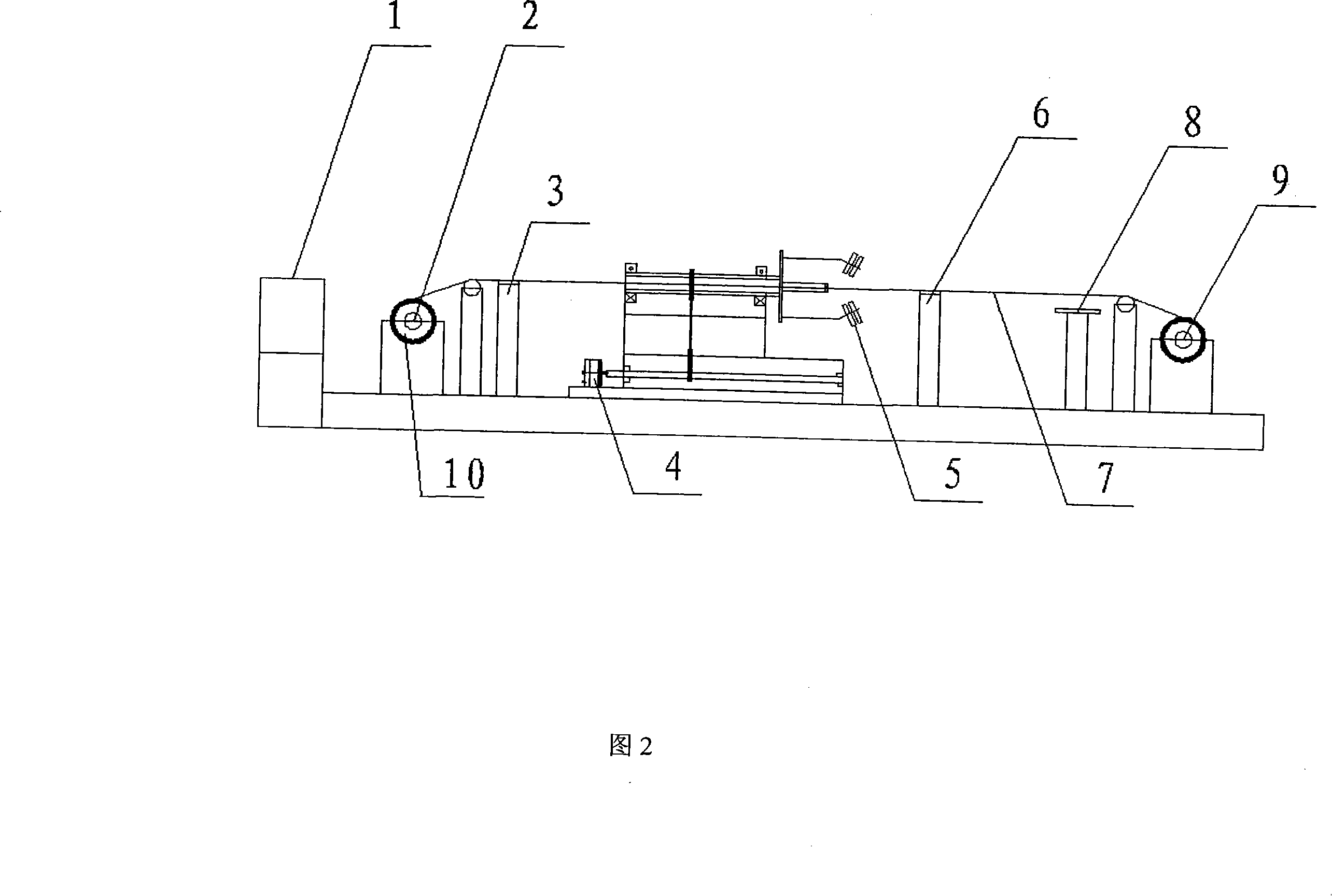

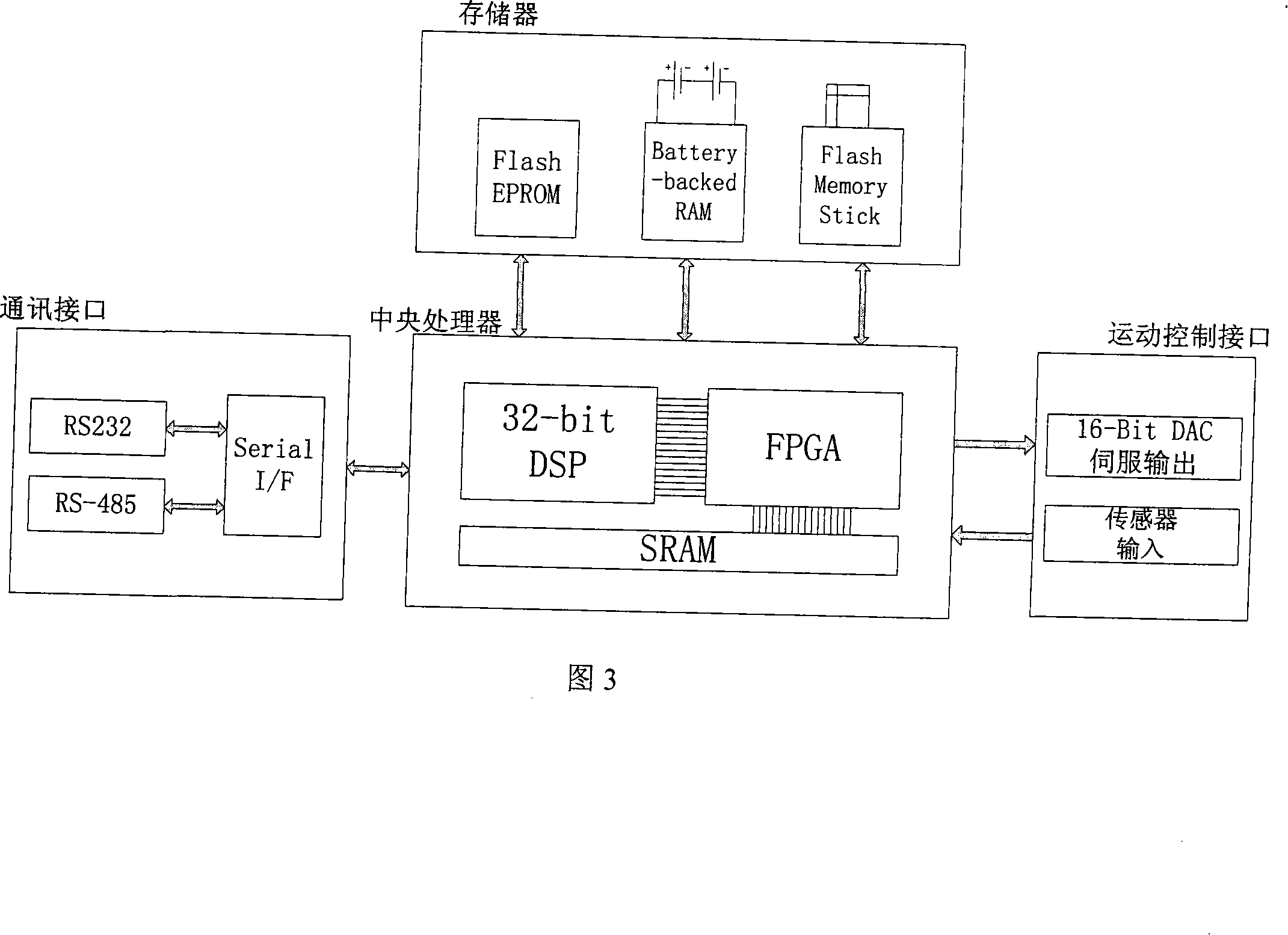

Digital control system of superconducting strip material insulation wrapping device

InactiveCN101169641AInductances/transformers/magnets manufactureNumerical controlThermal insulationEngineering

A NC system for a superconducting material insulation covered device comprises a numerical control device, a servo system and a measurement feedback system, wherein, the numerical control device receives information of requirement for superconducting material insulation covered, compiles and sends the information to the CPU of the numerical control device for memorizing and processing, the instructions of location and speed are sent to the servo system through the output device. The servo system, after power amplification and filtering plastic processing, converts the instructions from the numerical control device into the linear displacement and the angular displacement campaign of executive institutions. The measurement feedback system detects the current operation value of an AC servo motor and feedbacks to the numerical control device; wherein, the numerical control device compares the prior operation value with value of orders, and outputs the order that meets the requirement of the setting value to the servo system. The invention can realize superconducting material with lower irreversible strain (for example, the Bi-2223 high-temperature superconducting material with the critical stress of 230 MPa, MgB on the critical stress of 465 MPa2 superconducting material) to safely and accurately cover an insulation material with lower mechanical strength.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

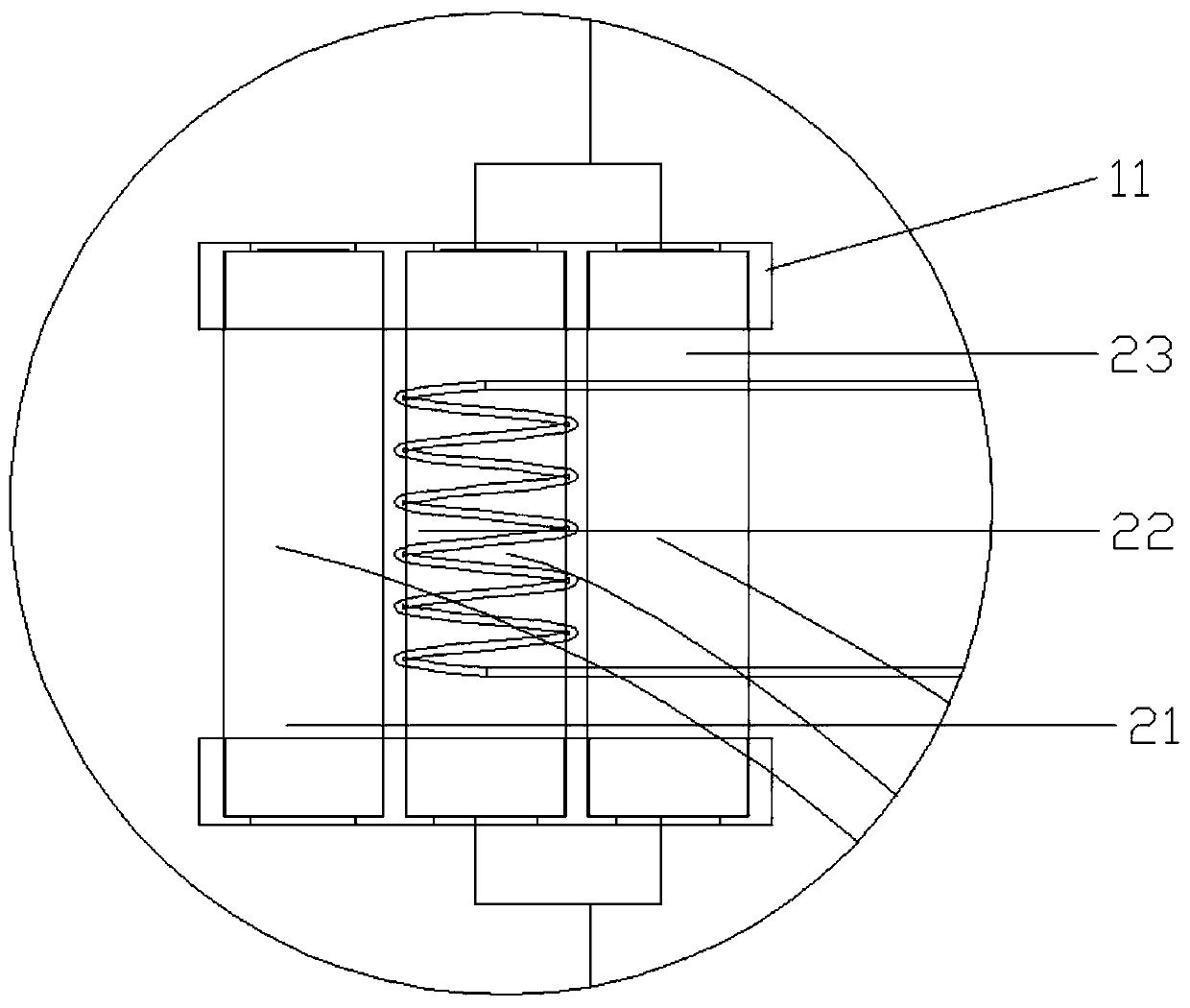

Thermal runaway simulation device for battery system

PendingCN109916454AReduce manufacturing costComprehensive data collectionMeasurement devicesGas detectorElectrical battery

The invention provides a thermal runaway simulation device for a battery system. The device comprises an explosion-proof box, a battery cell group, a heating device, a voltage acquisition instrument,a multi-path temperature measurement instrument, a pressure detector, a gas detector and a video monitor; the battery cell group is mounted on a bracket in the explosion-proof box and includes a battery cell (21), a battery cell (22) and a battery cell (23), wherein the battery core (22) and the battery core (23) are connected in parallel, and the battery core (21) is independently installed; andthe heating device continuously and stably heats the battery core (22). With the thermal runaway simulation device for the battery system of the invention adopted, the critical temperature, critical voltage and critical pressure of the battery cores during thermal runaway can be obtained; change relationships between the voltages, temperatures and pressures of the battery cores during the thermalrunaway can be monitored in real time; basic data can be provided for various battery core anomaly processing devices, and better and more accurate analysis can be performed; the data collect influence relationships between the battery cores, and better data support can be provided for guiding the development and design of the battery cores.

Owner:FUJIAN YIDONGLI ELECTRONICS TECH CO LTD

Device and method for monitoring fault tectonic stress

The invention relates to a method and device for monitoring fault tectonic stress. The method for monitoring fault tectonic stress comprises following steps: stress sensor installation, fault pre-fabrication, load application, critical stress of fault instability determination, theoretical value and experimental value comparison and analysis, and precursory information of fault instability acquisition; the device for monitoring fault stress comprises a fault analogue simulation test platform and a fault stress sensor. According to the device, by use of the stress sensor vertically installed on a fault surface, the normal stress and shearing stress of the fault surface are monitored; through the establishment of a fault dynamic module, the functional relations between the normal stress and shearing stress of the fault surface and horizontal load and vertical load are calculated; the errors between experimental values and theoretical values are analyzed; the critical stress value of fault instability is determined; the device and method provide theoretical basis and experimental data support for researching dynamic disasters such as rock burst and pressure bump caused by fault slip instability in study fields of geotechnical engineering and mining engineering, and provide pre-cursor information for predicting and preventing dynamic disasters.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com